10 Series Family

Installation Guide

Code: 45006657R

Rev. 16

PUBLICATION ISSUED BY:

OSAI S.p.A.

Via Torino 14, 10010 Barone Canavese (TO) - Italy

Tel. +39-0119899711

Web: www.osai.it

e-mail: sales@osai.it

service@osai.it

Copyright 2001-2008 by OSAI

All right reserved

Edition: April 2008

IMPORTANT USER INFORMATION

OSAI reserves the right to modify and improve the product described by this document at any time

and without prior notice.

This manual has been prepared by OSAI for the sole use of its customers. It describes the latest

release of the product.

Actual application of this product is up to the user. In no event will OSAI be responsible or liable for

indirect or consequential damages that may result from installation or use of the equipment

described in this text.

abc

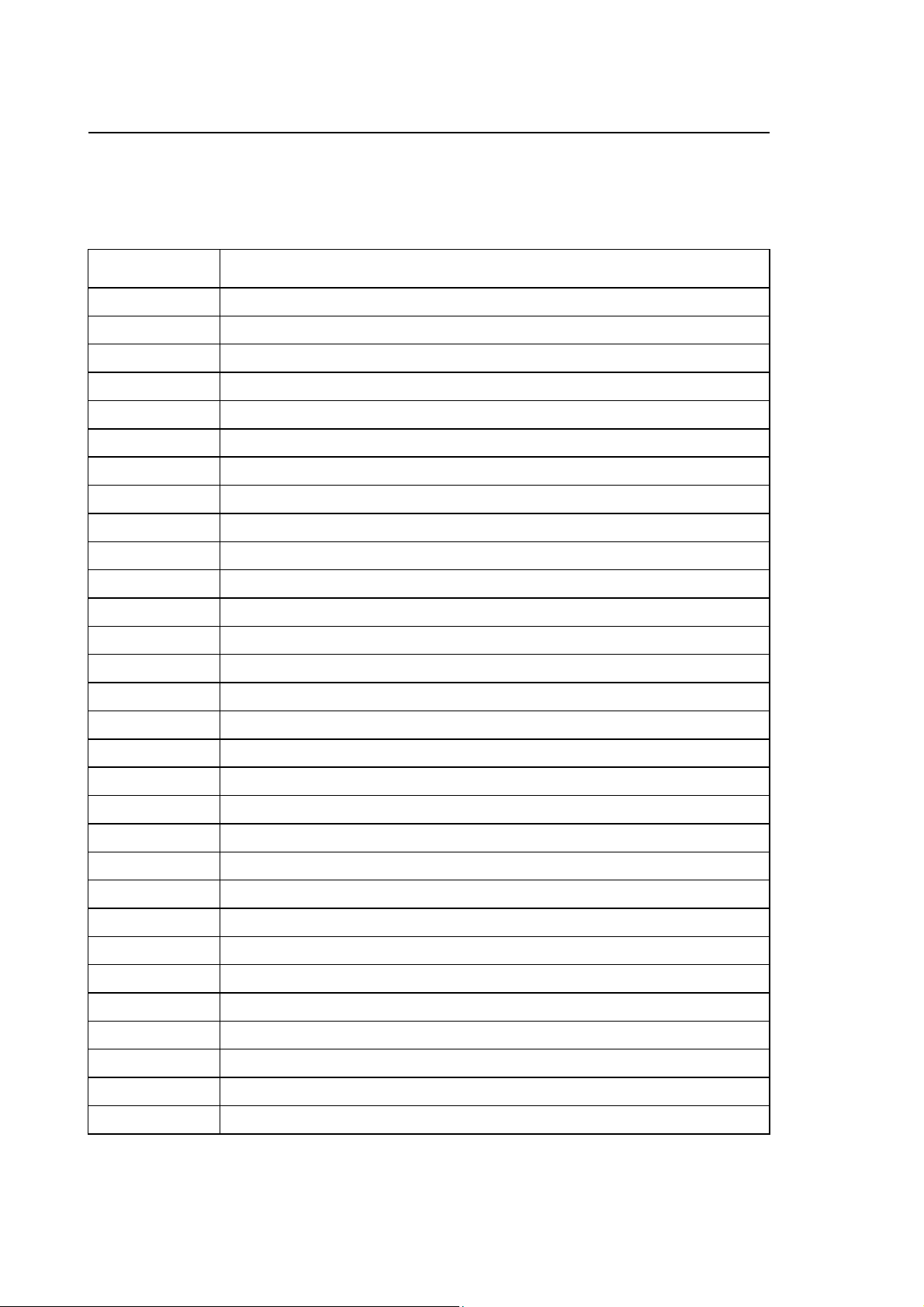

UPDATES IN THE PRESENT EDITION

General

The present edition presents the following changes in the manual:

PAGE TYPE OF UPDATE

UPDATE

10 Series Family - Installation Guide

INDEX

Chap. 4

Chap. 6

Chap. 8

page 2

page 4

page 5

page 12

page 20

page 31

page 35

page 40

page 53

page 57

page 65-69

page 1

page 5

page 10

Updated

Added note in picture of the emergency circuit

Modified description of 10/510S Light Cpu board

Modified description of expansion boards

Modified description of expansion boards

Modified description of expansion boards

Modified table: product code and installed Cpu type

Modified description of expansion boards CN module

Added OS8533/1 board

Modified IMAX value

Added description

Added paragraphs: OS8513 Sercos digital axes board - Layout customer

connector (OS8513-OS8513/1) - Layout encoder connector (OS8513) Layout connector 2 Analog Input - 1 Analog Out 8 bit - 1 Analog Out 15 bit

(OS8513) - Layout connector 2 Analog Input - 1 Analog Out 8 bit

(OS8513/1) - Layout connector Fast I/O (OS8513) - Sercos connectors

(OS8513, OS8513/1) - Can/Profibus connector (OS8513, OS8513/1) Connector shells

Modified description of Cpu board and Cpu board Prox-1260

Modified table: product code and installed Cpu type

Modified IMAX value

Chap. 9

page 1

Chap. 13

page 6

page 8

page 10

page 11

page 12-13

page 14-15

Declaration of

Conformity

10 Series Family - Installation Guide (16)

Modified description

Modified picture

Added PIN 1 in OS8511 board

Added PIN 1 in OS8532 board

Added PIN 1 in OS8533 board

Added PIN 1 in OS8516 board

Added paragraph: OS8513, OS8513/1 Board setting

Updated

Preface

10 Series Family - Installation Guide

PREFACE

This manual contains all information required for a correct installation of the 10 SERIES Family

products.

This manual is intended for engineers who are required to set up the interface between machine

tool and control. It is assumed that these engineers will be fully acquainted with problems relating

to numerical control, even if they are new to 10 SERIES controls.

The Series 10 systems are available in a version with the control unit integrated into the operator

panel (models 10/510 and 10/110) or as a rack module plus operator panel module (model Control

Unit 10/510).

The Operator Panel is available in the versions BLink, OPLink and WinMedia.

SUMMARY:

The manual is organized into the following chapters:

1. Mechanical Characteristics

Details all the mechanical and environmental conditions needed for proper installation and

cooling

2. Electrical Connections

This chapter describes the modules' power connection.

3. Grounding and Noise Suppression

Provides indications on ground connections and noise

4. Emergency Circuit

Explains how to build a functional emergency circuit

5. System Connections

This chapter gives information on the connection of the control unit operator panel, describes

the remote connection adapters, the FDU kit, the network connections and the teach pendant.

10 Series Family - Installation Guide (15) 1

Preface

10 Series Family - Installation Guide

6. Control Unit 10/510

Describes System 10/510i and illustrates its features and connections.

7. WinMedia ETX

This chapter describes the WinMedia System and illustrates their features and connections.

8. 10/110 Control Unit

This chapter describes the 10/110 System and discusses its characteristics and connections.

9. Encoders and Connection Cables

It describes the characteristics of the encoders and their connection cables

10. I/O Ring and Module Management

Provides information on management of I/O Ring environment and modules used.

11. OS-Wire and CanOpen module Management

Supplies information on management of OS-Wire and CanOpen environment.

12. Peripherals Units

Provides indications for Peripheral Units Connection

13. Board location and calibration

It describes how to configure the boards.

2 10 Series Family - Installation Guide (15)

Preface

10 Series Family - Installation Guide

WARNINGS

For correct control operation, it is important to follow the information given in this manual. Take

particular care with topics bearing one of the headings: WARNING, CAUTION or IMPORTANT,

which indicate the following types of information:

draws attention to facts or circumstances that may cause damage to the

WARNING

control, to the machine or to the operators

CAUTION

indicates information to be followed in order to avoid damage to equipment in

general.

indicates information to be followed in order to avoid damage to equipment in

IMPORTANT

general.

TERMINOLOGY

The following terms frequently appear throughout the manual:

Control Refers to the 10 Series CNC numerical control considered as a unit comprising

front panel and control unit

Front Panel The interface module between machine and operator; it has a monitor on which

messages are output and a keyboard to input data. It is connected to the control

unit

Control Unit The hardware-software "unit" handling all the machine functions. It is connected

to the front panel and to the machine tool.

I/O Ring Decentralized handling system for the digital and analogic input/output, based

on modules connected to each other and to the system through an optic fiber

"loop"

10 Series Family - Installation Guide (15) 3

Preface

10 Series Family - Installation Guide

BIBLIOGRAPHY

In order to understand in depth problems relative to the project and design of the interface between

control and machine tool (HW and SW), use the following manuals as a reference guide:

CODE TITLE

45006511 B OSARING DIGITAL I/O DEVICE

45006581 H ADARING ANALOG I/O DEVICE

45006466 Z RITEC

45001237 J 10 Series CNC PRODUCT SPECIFICATIONS

45006667 V 10 Series CNC AMP – Software Characterization Manual

45006672 P 10 Series CNC PLUS LANGUAGE & PLUSEDIT

45006677 Z 10 Series CNC PLUS APPLICATION MANUAL

45006682 C 10 Series CNC PLUS LIBRARY

45004457 K 10 Series CNC PROGRAMMING MANUAL

45004452 H 10 Series CNC USER MANUAL

45006687 N 10 Series CNC SOFTWARE INSTALLATION MANUAL

45004487 Q 10 Series CNC TEACH PENDANT

45006791 F 10 Series CNC SERIAL MINI DNC for WINDOWS - User Guide

45001232 E 10 Series CNC WOOD PRODUCT SPECIFICATIONS

45006697 J 10 Series CNC WOOD SOFTWARE INSTALLATION MANUAL

45004482 E 10 Series CNC WOOD USER MANUAL

45006762 L 10 Series GP SOFTWARE INSTALLATION MANUAL

45006747 N 10 Series GP AT USE AND PROGRAMMING MANUAL

45006752 G 10 Series GP SIPROM - Programming Manual

45006767 W 10 Series GP GP UTILITIES

45006771 N 10 Series GP TEACH PENDANT

45001247 F 10 Series T PRODUCT SPECIFICATIONS

45006807 Z 10 Series T SOFTWARE CHARACTERIZATION MANUAL

45006817 S 10 Series T SOFTWARE INSTALLATION MANUAL

45006812 Q 10 Series T USE AND PROGRAMMING MANUAL

45006822 U 10 Series T SIPROM LANGUAGE

45006862 V CNC Series 10 WINPLUS APPLICATION MANUAL

45006877 B CNC Series 10 WINPLUS Programming Manual

45006872 Z CNC Series 10 WINPLUS System Function

45006867 F CNC Series 10 WINPLUS Library - User Manual

4 10 Series Family - Installation Guide (15)

Preface

10 Series Family - Installation Guide

45006921 T Power GP Series 10 WINPLUS Libreria

45006927 F POWER GP Series 10 WINPLUS APPLICATION MANUAL

45006932 Z POWER GP Series 10 Release Software 7.4 Installation software

EUROPEAN DIRECTIVES COMPLIANCE

EMC Directive 89/336 EEC (Electromagnetic Compatibility)

The modules described in this manual comply with the EMC Directive 89/336 EEC, and conform to

European standards.

EN50082-2 (Immunity, Industrial Environment)

EN55011 (Emissions, ISM apparatus, group 1 class A)

Low Voltage Directive 73/23/EEC (L.V.D)

The modules described in this manual supplied with AC (therefore those supplied in 24 VDC are

excluded), must comply to the L.V.D. obtained by conforming to the European standards.

EN60950 Safety of Information Technology Equipment

EN60204-1 Safety of Machinery - Electrical Equipment of Machines - General

Requirements

NOTE:

The modules cannot withstand the voltage test at 1000 Vac (EN60204-1 - paragraph 20.4), due to

the presence of 600V overvoltage suppressors, included to allow the modules to pass the “Surges

Test” (EN50082-2).

10 Series Family - Installation Guide (15) 5

Preface

10 Series Family - Installation Guide

END OF PREFACE

6 10 Series Family - Installation Guide (15)

10 Series Family - Installation Guide

INDEX

MECHANICAL CHARACTERISTICS

MOUNTING INSTRUCTIONS FOR OPERATOR CONSOLES / CONTROL UNITS AND

ACCESSORIES............................................................................................................... 1-1

PRECAUTIONS FOR THE PROTECTION AND THE CONSERVATION OF THE LCD

DISPLAY.......................................................................................................................... 1-1

OPLINK 10.4” TFT OPERATOR PANEL ....................................................................... 1-2

BLINK 10.4” TFT OPERATOR PANEL.......................................................................... 1-3

Drilling Template for OPLINK, BLINK operator panel ........................................... 1-4

KEYBOARD FOR OPLINK, BLINK OPERATOR PANEL AND THE CONTROL UNIT

10/110 .............................................................................................................................. 1-5

Drilling template for keyboard................................................................................ 1-5

FDU KIT........................................................................................................................... 1-6

Normal FDU Kit...................................................................................................... 1-6

Reduced FDU Kit................................................................................................... 1-7

Drilling template for FDU access and fixing and the corresponding

protection door....................................................................................................... 1-8

Dimensions of the protection door......................................................................... 1-8

10/110 CONTROL UNIT.................................................................................................. 1-9

Drilling Template for 10/110 Control Unit .............................................................. 1-9

10/510S/I LIGHT CONTROL UNIT ................................................................................. 1-10

10/510i BLINK CONTROL UNIT..................................................................................... 1-11

10/510i OPLINK CONTROL UNIT .................................................................................. 1-12

Drilling template for 10/510i Oplink/Blink Control Unit .......................................... 1-13

10/510i CONTROL UNIT................................................................................................. 1-14

Mounting Bracket for unit 10/510i.......................................................................... 1-15

10/510I WINLINK USB CONTROL UNIT ....................................................................... 1-16

Drilling template for 10/510i WINLINK USB Control Unit ...................................... 1-17

INSTRUCTIONS FOR MOUNTING THE CONTROL UNIT TO THE PANEL ................ 1-18

INSTALLATION INFORMATION .................................................................................... 1-18

COOLING ........................................................................................................................ 1-19

Cooling requirements ............................................................................................ 1-19

Environment Specifications ................................................................................... 1-19

Heat exchanger or air-conditioner ......................................................................... 1-20

Heat exchanger ..................................................................................................... 1-21

Air conditioner........................................................................................................ 1-22

FIRE PROTECTION ........................................................................................................ 1-22

Fire enclosures ...................................................................................................... 1-22

VIBRATIONS, SHOCK.................................................................................................... 1-23

Index

10 Series Family - Installation Guide (16) i

Index

10 Series Family - Installation Guide

Vibrations .......................................................................................................... 1-23

Shock ................................................................................................................ 1-23

Shock ................................................................................................................ 1-23

ELECTRICAL CONNECTIONS

UNIT POWER SUPPLY SPECIFICATIONS.................................................................... 2-1

BLink and OPLink Operator Panel......................................................................... 2-1

WINMEDIA ETX..................................................................................................... 2-1

Analog/OS-Wire 10/110 control units .................................................................... 2-1

10/510S/i Light and 10/510i control units............................................................... 2-2

10/510i OpLink-Blink Control Unit.......................................................................... 2-2

10/510i WinLink USB Control Unit ......................................................................... 2-2

UNIT POWER SUPPLY CONNECTION AND PROTECTION GND...............................2-3

Analog/OS-Wire 10/110 control unit ......................................................................2-3

General interconnection diagram........................................................................... 2-12

GROUNDING AND NOISE SUPPRESSION

EARTH GROUNDING...................................................................................................... 3-1

Cabinet earth grounding ........................................................................................ 3-2

ELECTRICAL NOISE ......................................................................................................3-3

General information................................................................................................ 3-3

Noise sources ........................................................................................................3-3

Noise suppression .................................................................................................3-4

Suppressing DC noise in c.c..................................................................................3-5

Suppressing AC noise ........................................................................................... 3-6

Noise suppression in AC motors............................................................................ 3-7

Connections to earth.............................................................................................. 3-8

CROSS-SECTIONAL AREA OF PROTECTION CONDUCTORS................... 3-9

Shielded cables......................................................................................................3-10

Cable routing..........................................................................................................3-11

Cabinets ................................................................................................................. 3-11

EMERGENCY CIRCUIT

EMERGENCY CONNECTIONS FOR MONO-PROCESS SYSTEMS ............................ 4-2

MANAGEMENT OF ANOMALIES ASSOCIATED WITH THE EMERGENCY............... 4-3

SYSTEM CONNECTIONS

OPLINK/BLINK OPERATOR PANEL CONNECTIONS ................................................. 5-1

10/510i Control Unit ...............................................................................................5-1

Connection Cables................................................................................................. 5-2

Layout of Console Cable for 10/510i Control Unit .................................................5-4

Long distance LCD repeater connection ...............................................................5-5

CONNECTING THE FDU KIT TO THE CONTROL UNIT............................................... 5-6

Analog 10/110 Control Unit.................................................................................... 5-6

OS-Wire 10/110 Control Unit ................................................................................. 5-7

10/510i, 10/510i OpLink-BLink Control Units......................................................... 5-8

Connection Cables................................................................................................. 5-9

INSTALLING THE PORTABLE TEACH PENDANT....................................................... 5-10

ii 10 Series Family - Installation Guide (16)

10 Series Family - Installation Guide

Connection............................................................................................................. 5-11

Adapter board ........................................................................................................ 5-12

Power connector J1............................................................................................... 5-14

Connector for emergency and Live-Man buttons, J3 ............................................ 5-14

FEMALE-MALE CONNECTORS OF SERIAL CABLE .................................................. 5-15

Dummy plug ................................................................................................................... 5-16

SERIES 10/510 UNITS

10/510S/i Light UNIT ...................................................................................................... 6-1

General and views of unit 10/510S/i Light ................................................................... 6-1

Note: ...................................................................................................................... 6-3

Led ......................................................................................................................... 6-3

Back Board ............................................................................................................ 6-3

10/510S Light Cpu Board (ProX-1260) ......................................................................... 6-4

10/510i Light Cpu Board (ProX-1635)........................................................................... 6-4

Mass memory ................................................................................................................. 6-4

External connections ............................................................................................. 6-5

Expansion boards .................................................................................................. 6-5

UNIT 10/510i....................................................................................................................6-6

General and views of units .................................................................................... 6-6

Leds ....................................................................................................................... 6-10

Back Board ..................................................................................................................... 6-11

CPU Board 10/510i (PROX-1635) .................................................................................. 6-11

Mass memory ........................................................................................................ 6-11

External connections ............................................................................................. 6-12

Expansion boards .................................................................................................. 6-12

Connections to remote panel................................................................................. 6-12

10/510i OpLink/BLink UNIT ........................................................................................... 6-13

General and views of units .................................................................................... 6-13

LEDs ...................................................................................................................... 6-18

Back Board ..................................................................................................................... 6-19

CPU Board 10/510i OpLink/BLink (PROX-1635) ......................................................... 6-19

Mass memory ........................................................................................................ 6-19

External connections ............................................................................................. 6-20

Expansion boards .................................................................................................. 6-20

OpLink-BLink 10/510i module keyboard connection............................................. 6-21

WinLink USB 10/510i UNIT............................................................................................ 6-22

General .................................................................................................................. 6-22

Cpu board for NC/PC modules (ProX-1635)................................................................ 6-22

Mass memory ........................................................................................................ 6-30

Fdu peripheral in PC module................................................................................. 6-30

Keyboard connection............................................................................................. 6-30

Ethernet connection............................................................................................... 6-30

Ethernet connector ................................................................................................ 6-31

Led’s ...................................................................................................................... 6-32

External connections of PC module ...................................................................... 6-34

External connections of CN module ...................................................................... 6-34

Expansion boards CN module............................................................................... 6-35

UNIT 10/510: EXPANSION BOARDS, CONNECTORS, CABLES................................ 6-36

Interbus board........................................................................................................ 6-36

Profibus board ....................................................................................................... 6-37

Can Open board .................................................................................................... 6-38

OS8532 and OS8533 OS-Wire board ................................................................... 6-40

Index

10 Series Family - Installation Guide (16) iii

Index

10 Series Family - Installation Guide

Layout of line signals / LED connectors (all versions) ........................................... 6-40

Layout of Customer connectors (OS8532 , OS8532/2, OS8533, OS8533/2 ) ...... 6-41

Layout of Encoder connector (OS8532, OS8533) ................................................. 6-41

Layout of analog Inp/Out connectors (OS8532, OS8533)..................................... 6-42

Analog Inp/Out connector layout (OS8532/2, OS8533/2) ..................................... 6-42

Layout of analog Inp/Out connectors (OS8532/3, OS8533/3)............................... 6-43

Layout of Fast I/O connectors (OS8532, OS8533)................................................6-44

Fast Input characteristics ....................................................................................... 6-44

Fast Output characteristics ....................................................................................6-44

“OS Wire OS8528 splitter box” ..............................................................................6-45

Axes board ............................................................................................................. 6-46

Encoder section .....................................................................................................6-46

Input Channel Characteristics........................................................................... 6-47

Encoder signals ................................................................................................6-48

Encoder Characterisation: Marker Detection.................................................... 6-48

Encoder Characterisation: Broken Wire Reading............................................. 6-50

D/A and A/D sections ..................................................................................................... 6-50

Analog output characteristics:................................................................................ 6-50

Analog input characteristics: .................................................................................. 6-50

Six Analog Outputs Connector............................................................................... 6-51

Two Analog Outputs - One Analog Input Connector .............................................6-51

“Customer” Connector ........................................................................................... 6-53

D.S.I. Connectors................................................................................................... 6-54

Connector shells ....................................................................................................6-54

Encoder connector adapter .......................................................................................... 6-55

Cable to the Axes Board ........................................................................................ 6-57

Cable to the Encoders ........................................................................................... 6-58

Encoder Power Supply .......................................................................................... 6-58

Analog input board ........................................................................................................6-59

Analog input characteristics ................................................................................... 6-59

Analog Input Connector .........................................................................................6-59

BOARD OS8516 ............................................................................................................. 6-61

Characteristics .......................................................................................................6-61

Encoder connector layout ...................................................................................... 6-61

14-bit analog output connector ..............................................................................6-62

Characteristics of 14-bit analog output .................................................................. 6-62

Connector for 2 analog inputs – 1 8-bit analog output........................................... 6-62

Voltage input characteristics............................................................................. 6-63

Current input characteristics ............................................................................. 6-63

“Customer” connector ............................................................................................ 6-63

Mechatrolink connector.......................................................................................... 6-64

CANOPEN option................................................................................................... 6-64

OS8513 Sercos digital axes board ........................................................................6-65

Layout customer connector (OS8513, OS8513/1) ............................................... 6-65

Layout encoder connector(OS8513)...................................................................... 6-66

Layout connector 2 Analog Input – 1 Analog Out 8 bit – 1 Analog Out

15 bit (OS8513).....................................................................................................6-66

Layout connector 2 Analog Input – 1 Analog Out 8 bit (OS8513/1) ....................6-67

Layout of Fast I/O connector (OS8513)................................................................. 6-68

Fast Input characteristics ....................................................................................... 6-68

Fast Output characteristics ....................................................................................6-68

Sercos Connectors (OS8513, OS8513/1) .............................................................6-69

Can/Profibus connector (OS8513, OS8513/1) ......................................................6-69

Connector shells ....................................................................................................6-69

CONNECTORS / CABLES.............................................................................................. 6-70

iv 10 Series Family - Installation Guide (16)

10 Series Family - Installation Guide

Module Power Supply Connector .......................................................................... 6-70

Ethernet Connector................................................................................................ 6-70

Keyboard Connector.............................................................................................. 6-72

I/O Ring Connectors .............................................................................................. 6-73

Connector external FDU signals............................................................................ 6-73

Parallel Port Connector ......................................................................................... 6-74

COM2 - Serial Interface Connector ....................................................................... 6-75

COM1 - Serial Interface Connector ....................................................................... 6-76

VGA Connector...................................................................................................... 6-76

Standard Keyboard Connector .............................................................................. 6-77

LD Keyboard connector......................................................................................... 6-77

LD Display connector ............................................................................................ 6-78

WINMEDIA ETX

GENERAL........................................................................................................................ 7-1

Mass memory ................................................................................................... 7-11

CD-ROM peripheral.......................................................................................... 7-11

Keyboard / Touch pad connection.................................................................... 7-11

Mouse connection ............................................................................................ 7-11

Ethernet connection.......................................................................................... 7-11

PCI expansion slot............................................................................................ 7-11

External connections ........................................................................................ 7-11

OS8737 OS-Wire board connections............................................................... 7-17

OS8733 CanOpen board connections ............................................................. 7-18

OS-Wire module address setup ............................................................................ 7-20

OS-Wire module indicator LEDs............................................................................ 7-20

CanOpen address module setup...................................................................... 7-21

Can Open module indicator LEDs.................................................................... 7-22

CANbus line terminations ...................................................................................... 7-23

Setting the Baud Rate of the CANbus network ..................................................... 7-23

Index

10/110 CONTROL UNIT

PPrrooXX--11226600 CCppuu BBooaarrd

CHARACTERISTICS OF OS8353 BOARD (ANALOG 10/110)..................................... 8-2

CHARACTERISTICS OF OS8365 BOARD (OS-WIRE 10/110) .................................... 8-2

CHARACTERISTICS OF OS8361 BOARD (10/110 MECHATROLINK)....................... 8-2

CONNECTORS COMMON TO THE THREE VERSIONS .............................................. 8-5

Ethernet connection............................................................................................... 8-5

Ethernet connector ................................................................................................ 8-5

External Fdu connector ......................................................................................... 8-7

Serial interface connector COM1 .......................................................................... 8-8

Serial interface connector COM2 .......................................................................... 8-8

Keyboard connector .............................................................................................. 8-9

ANALOG 10/110 SPECIFIC CONNECTORS................................................................. 8-10

Analog 10/110 Module power supply connector ................................................... 8-10

Analog 10/110 "Customer" connector ................................................................... 8-10

Analog 10/110 Encoder connectors ...................................................................... 8-11

Input Channel Features ......................................................................................... 8-11

Encoder Signals..................................................................................................... 8-12

Encoder Powering ................................................................................................. 8-13

Encoder Characterisation: Marker Detection ........................................................ 8-13

Encoder Characterisation: Broken Wire Reading ................................................. 8-15

d .................................................................................................... 8-1

10 Series Family - Installation Guide (16) v

Index

10 Series Family - Installation Guide

14-bit D/A ANALOG 10/110 CONNECTOR ...................................................................8-16

Characteristics of the Analog Drive Outputs.......................................................... 8-16

D/A ANALOG 10/110 CONNECTOR .............................................................................. 8-18

CONNECTORS COMMON TO THE ANALOG 10/110 AND 10/110 OS-Wire

VERSIONS ....................................................................................................................... 8-19

24 Output analog 10/110 and 10/110 OS-WIRE connector ..................................8-19

Output characteristics ............................................................................................8-19

24 + 24 INPUT ANALOG 10/110 and 10/110 OS-Wire CONNECTORS....................... 8-20

Input Section Features........................................................................................... 8-20

Input Connector (25-48)......................................................................................... 8-21

SPECIFIC 10/110 OS-WIRE CONNECTORS ................................................................. 8-22

10/110 Os-Wire Module power supply connector.................................................. 8-22

OS-Wire 10/110 "Customer" connector ................................................................. 8-22

OS-Wire CONNECTOR................................................................................................... 8-23

10/110 OS-Wire A/D – D/A CONNECTOR .....................................................................8-24

Characteristics of voltage input......................................................................... 8-24

Characteristics of current input ......................................................................... 8-24

SPECIFIC 10/110 MECHATROLINK CONNECTORS.................................................... 8-25

10/110 Mechatrolink power supply connector .......................................................8-25

10/110 Mechatrolink "Customer" connector .......................................................... 8-25

MECHATROLINK 10/110 A/D – D/A CONNECTOR ...................................................... 8-27

Characteristics of voltage input......................................................................... 8-27

Characteristics of current input ......................................................................... 8-27

Analog 10/110 AND Os-Wire 10/110 T-Probe characteristics ............................. 8-28

Connecting the Inputs/Outputs and Powering the Module .................................... 8-29

(Analog 10/110 and OS-Wire 10/110) ................................................................... 8-29

OS8371 expansion board ...................................................................................... 8-30

Encoder Connector (OS8375/5 – OS8375/6) ........................................................ 8-30

Analog Output Connector (OS8375/6)................................................................... 8-30

ENCODERS AND CONNECTION CABLES

ENCODERS ..................................................................................................................... 9-1

ENCODER CONNECTION CABLES .............................................................................. 9-2

ELECTRONIC HANDWHEEL ......................................................................................... 9-3

I/O RING AND MODULE MANAGEMENT

I/O RING...........................................................................................................................10-1

INSTALLING CONNECTORS ......................................................................................... 10-2

Installing your Fibre Optic Cable............................................................................ 10-5

Fibre Optic Cable Specifications............................................................................ 10-5

CONFIGURING THE I/O RING........................................................................................ 10-6

I/O Ring physical configuration .............................................................................. 10-7

I/O Ring software configuration.............................................................................. 10-8

HIGH DENSITY I/O UNIT................................................................................................. 10-9

Electrical specifications .......................................................................................... 10-9

Input specifications................................................................................................. 10-10

Output specifications..............................................................................................10-11

Connections ........................................................................................................... 10-12

Connections for CE Compliance............................................................................10-18

Setting node addresses .........................................................................................10-19

Dimensions of the High Density I/O Module .......................................................... 10-20

OSARING MODULE ........................................................................................................ 10-21

vi 10 Series Family - Installation Guide (16)

10 Series Family - Installation Guide

Characteristics and dimensions ............................................................................ 10-21

ANALOGUE I/O MODULE (ADARING) ......................................................................... 10-23

Input specifications ................................................................................................ 10-23

Output specifications ............................................................................................. 10-23

Power supply specifications .................................................................................. 10-23

Dimensions ............................................................................................................ 10-24

PILOT PANEL ................................................................................................................. 10-25

Specifications......................................................................................................... 10-25

Connections........................................................................................................... 10-25

Electrical Specifications......................................................................................... 10-25

Calibrating node addresses................................................................................... 10-26

Dimensions ............................................................................................................ 10-27

Power supply, earth and GND connections .......................................................... 10-28

OS-WIRE AND CANOPEN MODULE MANAGEMENT

OS-Wire ........................................................................................................................... 11-1

Connection between OS-Wire modules ...................................................................... 11-2

............................................................................................................................... 11-3

OS8720 Compact I/O OS-Wire ............................................................................. 11-4

Dimensions and installation................................................................................... 11-5

Board technical data and resources...................................................................... 11-5

Configurable 24V I/O (connector J7)................................................................ 11-7

Module Address Selection..................................................................................... 11-10

Status LEDs........................................................................................................... 11-10

Connections........................................................................................................... 11-11

Wire size ................................................................................................................ 11-11

BRIDGE OS8751 BOARD .............................................................................................. 11-12

Dimensions and installation................................................................................... 11-12

Board Technical Data and Resources................................................................... 11-12

Encoders (connectors J3, J5, J6).......................................................................... 11-13

Analog outputs (connector J9)............................................................................... 11-13

I/O 24V – Touch-Probe (connector J7) ................................................................. 11-14

OS-Wire BUS connectors (J2, J4, HD 15-pin FE shell) ........................................ 11-15

Module Address Setting ........................................................................................ 11-15

“ENCODER broken wire” SETTING...................................................................... 11-16

Status LEDs........................................................................................................... 11-16

CONNECTIONS .................................................................................................... 11-17

Wire size ................................................................................................................ 11-17

OS8730/2 I/O CANOPEN MODULE ............................................................................... 11-19

Dimensions and assembly instructions ................................................................. 11-19

Board characteristics and resources ..................................................................... 11-19

Output specifications ............................................................................................. 11-19

Input specifications ................................................................................................ 11-19

Connector pinout ................................................................................................... 11-21

Connector J4 – Digital input .................................................................................. 11-21

Connector J1 – Two-way digital input/output ........................................................ 11-22

Connector J2 – CANbus/CANopen and network side power supply connector ... 11-22

Connector J5 – I/O power supply .......................................................................... 11-22

CANbus line terminations ...................................................................................... 11-23

Setting the Baud Rate of the CANbus network ..................................................... 11-23

Error codes displayed by the Led's ....................................................................... 11-23

Index

10 Series Family - Installation Guide (16) vii

Index

10 Series Family - Installation Guide

PERIPHERAL UNITS

SERIAL INTERFACES .................................................................................................... 12-1

Protections .............................................................................................................12-1

Peripheral connections .......................................................................................... 12-2

RS232 extension cable .......................................................................................... 12-2

Female-male RS232 cable ....................................................................................12-4

Female/male RS232 cable with crossover signals ................................................ 12-6

RS232 female/female cable with crossover signals ..............................................12-8

PARALLEL INTERFACE................................................................................................. 12-10

BOARD LOCATION AND CALIBRATION

10/110 UNITS................................................................................................................... 13-1

Special functions board OS8353 for analog 10/110 Control Unit.......................... 13-2

Special functions board OS8365 for OS-Wire 10/110 Control Unit....................... 13-3

Back-Board OS8502 for control units 10/510i .......................................................13-6

OS8505 board for 10/510i Light and 10/510S Light ..............................................13-7

OS8511 boards in various versions....................................................................... 13-8

OS8521/1 Board ....................................................................................................13-9

OS8532 board in its various versions .................................................................... 13-10

Board OS8533 in various versions ........................................................................13-11

OS8516 board in various versions.........................................................................13-12

OS8513, OS8513/1 Board setting ........................................................................13-14

INTERBUS ISA Board............................................................................................ 13-17

CAN OPEN Board..................................................................................................13-18

PROFIBUS board................................................................................................... 13-19

DECLARATION OF CONFORMITY

END OF INDEX

viii 10 Series Family - Installation Guide (16)

Chapter 1

MECHANICAL CHARACTERISTICS

This chapter lists the dimensions of the control hardware components. In addition it provides the

necessary information for designing the electrical cabinet and describes the environmental

requirements for best system operation.

MOUNTING INSTRUCTIONS FOR OPERATOR CONSOLES / CONTROL UNITS AND ACCESSORIES

The Operator Panels described in this manual provide IP54 protection level on the frontal panel

and do not require further protection against environmental factors.

However, it is recommended to mount a gasket around the edge of the slot to protect the module

from dust. In some cases it is advisable to use a dust cover.

Numerical control units and Operator Panels must be able to receive air from the ventilation holes;

for this reason, the walls surrounding the module must always be at a distance of at least 10 cm

from the module.

PRECAUTIONS FOR THE PROTECTION AND THE CONSERVATION OF THE LCD DISPLAY

The following precautions should be observed when handling or

cleaning the Flat Panel Displays:

CAUTION

Avoid hitting or abrading the display surface.

To avoid deterioration of the display due to chemical action do not

touch the display with dirty hands.

To clean the display use a soft dry cloth or cotton wool. DO NOT USE

any chemical detergents or solvents.

10 Series Family - Installation Guide (14) 1-1

Chapter 1

Mechanical Characteristics

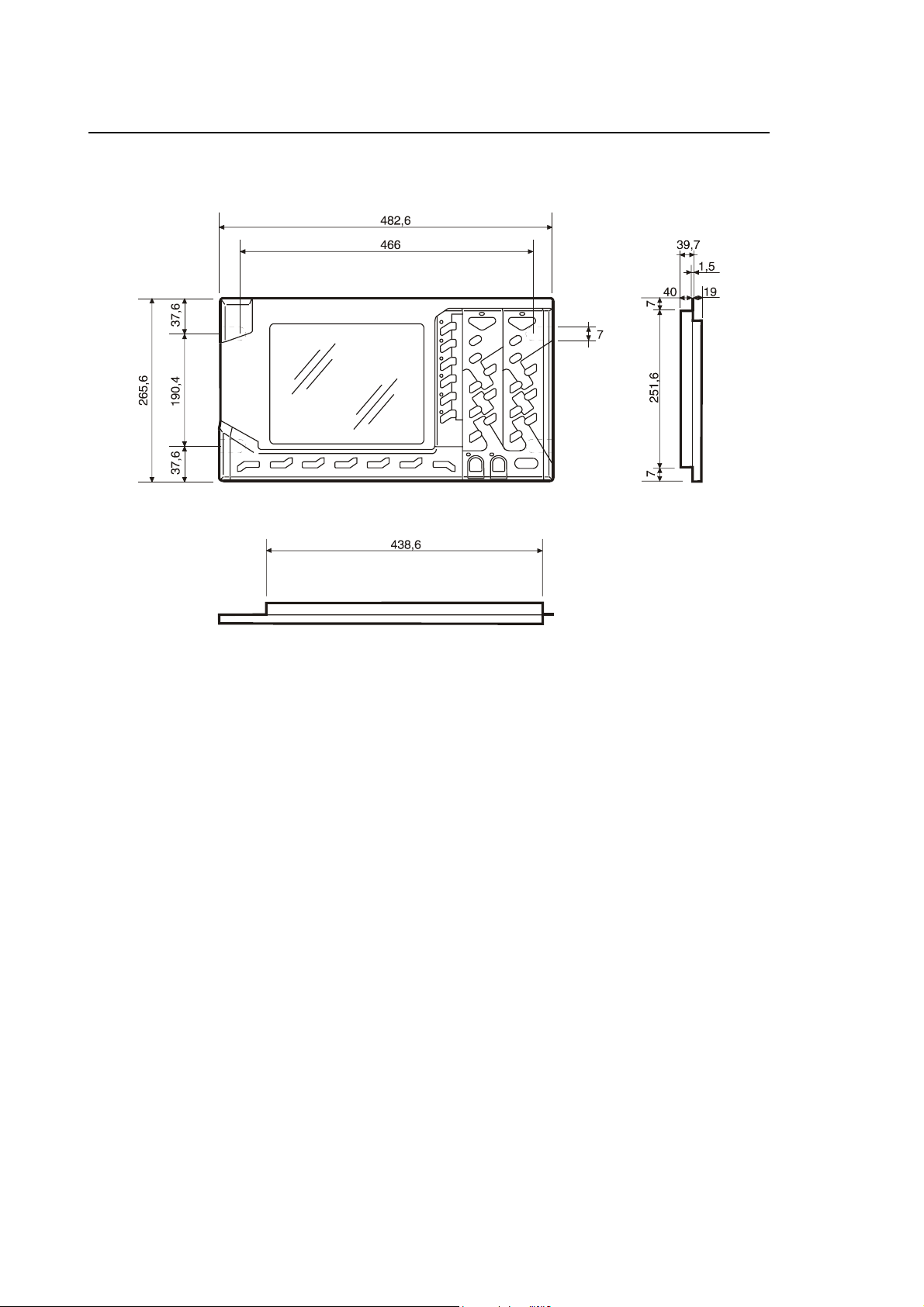

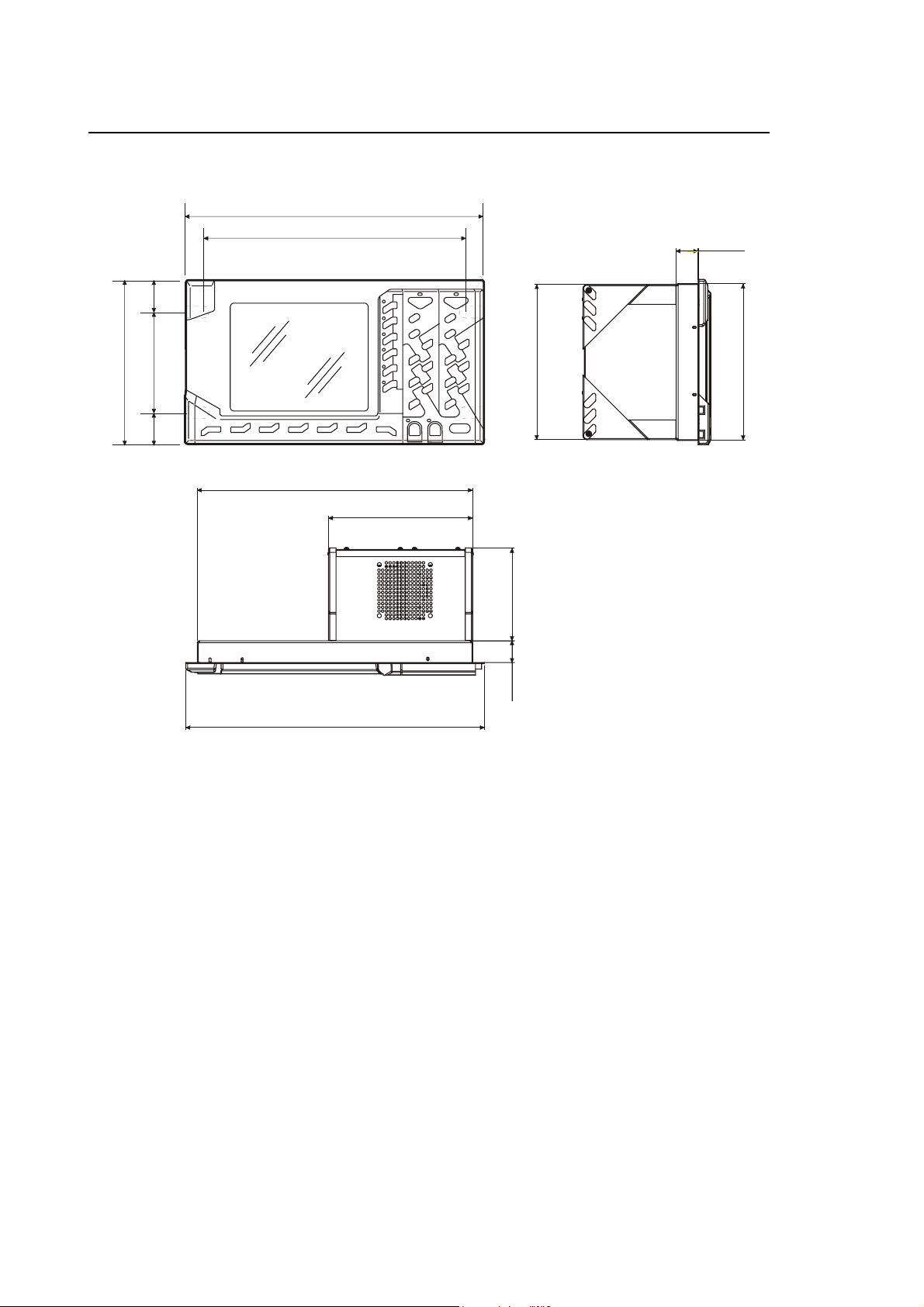

OPLINK 10.4” TFT OPERATOR PANEL

Side, front and upper view

Physical Characteristics

Width 482.6 mm

Height 265.6 mm

Depth 39.7 mm (without cables)

Weight 3.5 Kg

Mounting Rack 19"

Protection IP54

1-2 10 Series Family - Installation Guide (14)

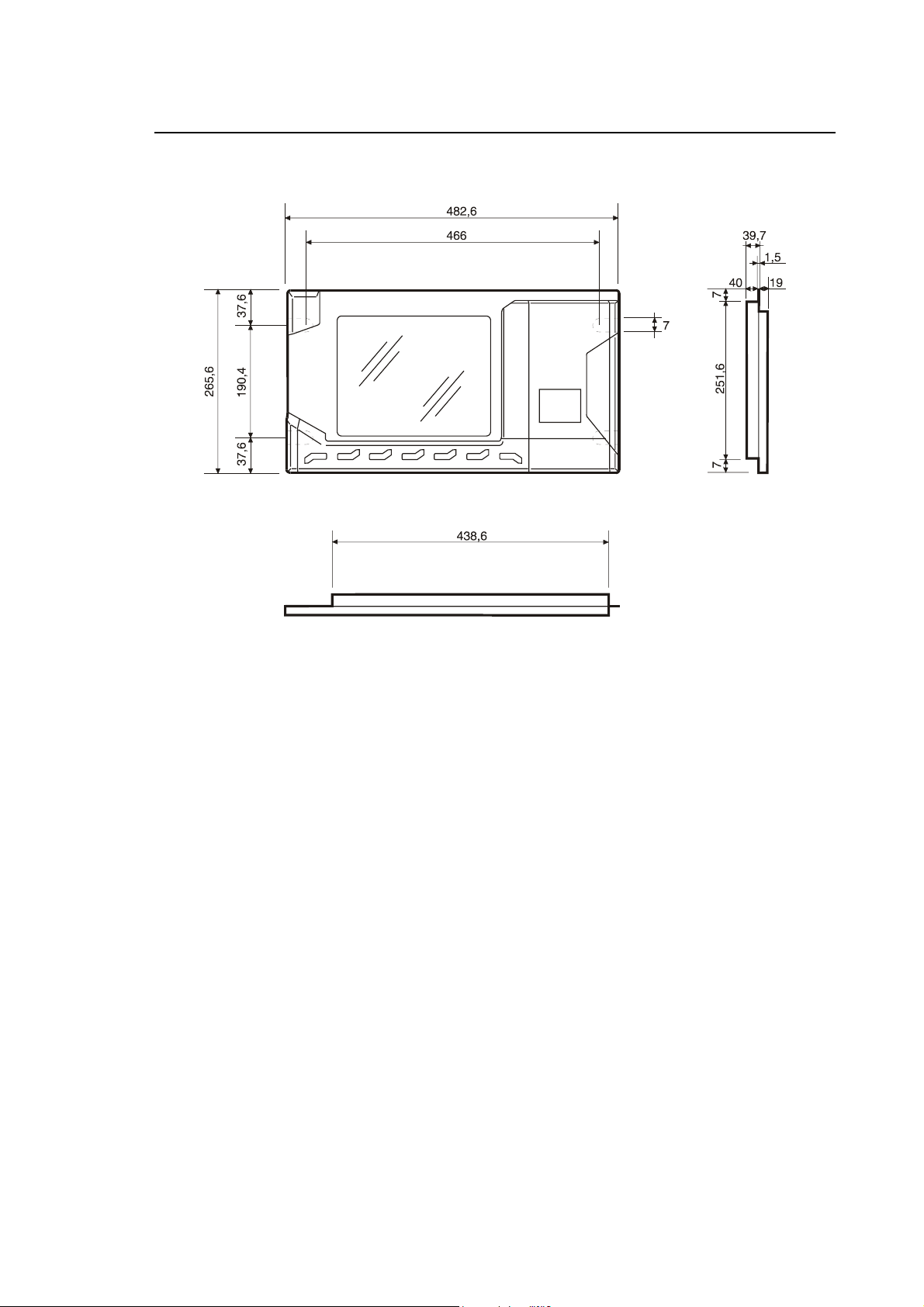

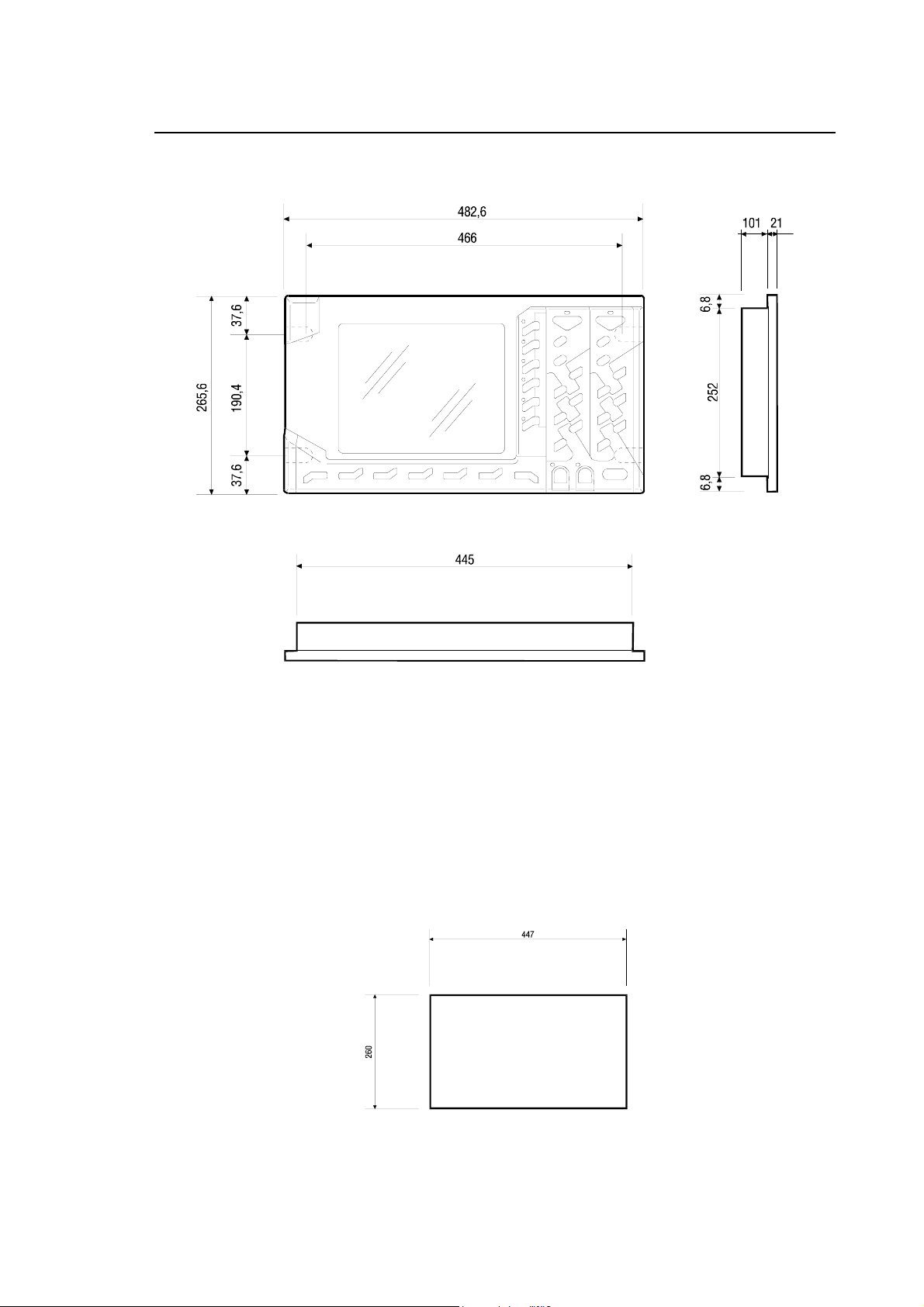

BLINK 10.4” TFT OPERATOR PANEL

Chapter 1

Mechanical Characteristics

Side, front and upper view

Physical Characteristics

Width 482.6 mm

Height 265.6 mm

Depth 39.7 mm (without cables)

Weight 3.3 Kg

Mounting Rack 19"

Protection IP54

10 Series Family Installation Guide (14) 1-3

Chapter 1

Mechanical Characteristics

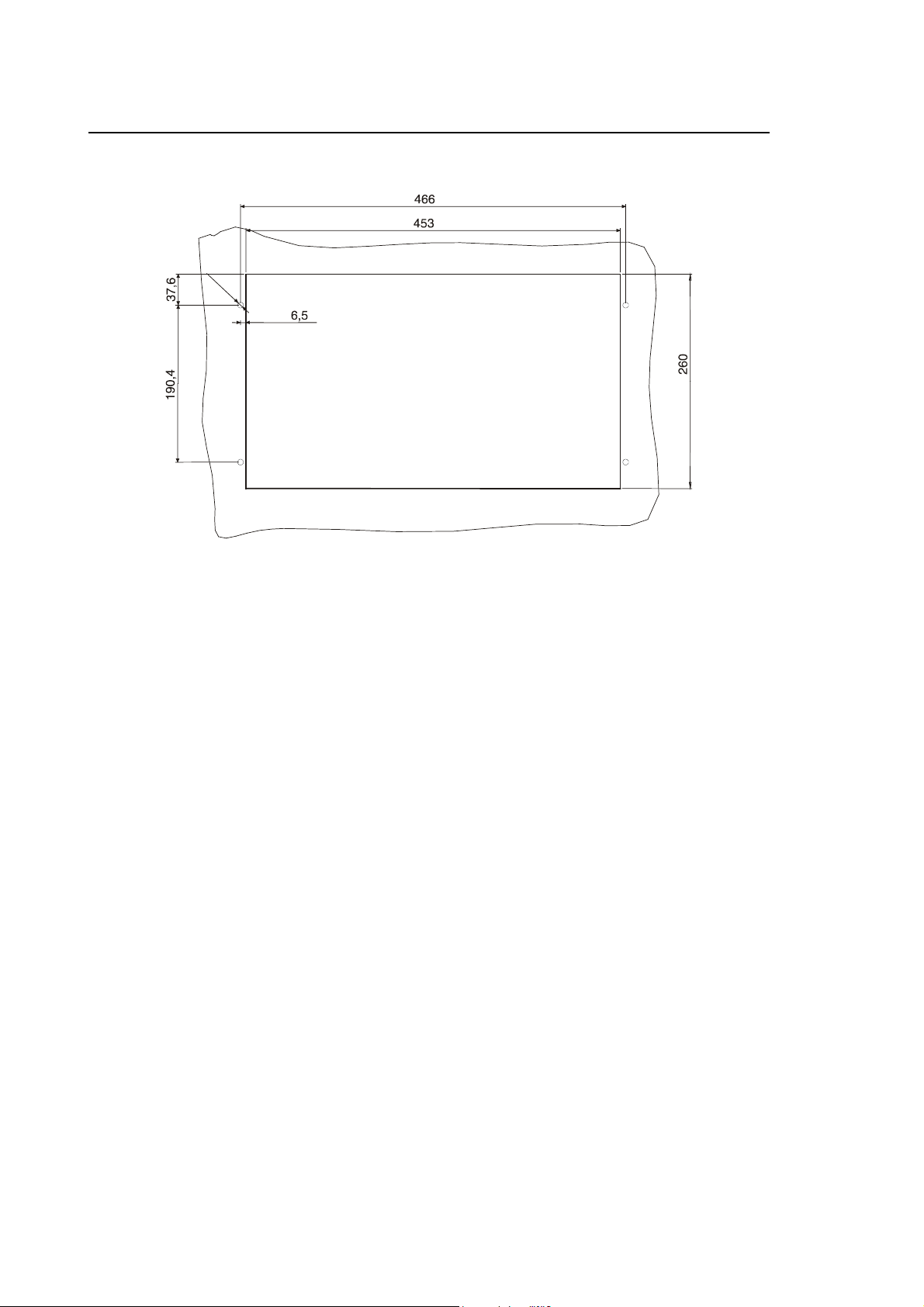

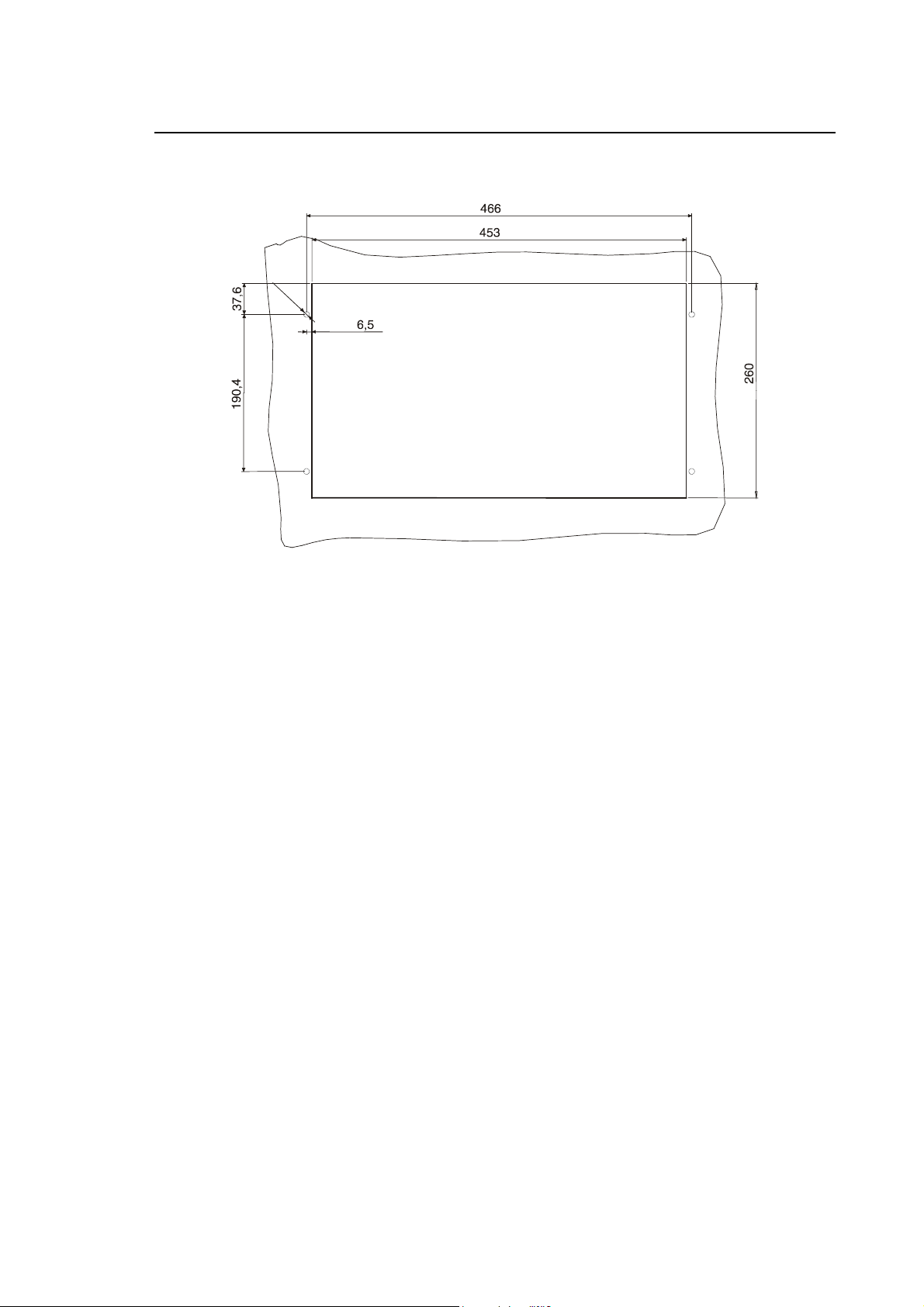

Drilling Template for OPLINK, BLINK operator panel

Ø

7

1-4 10 Series Family - Installation Guide (14)

Chapter 1

Mechanical Characteristics

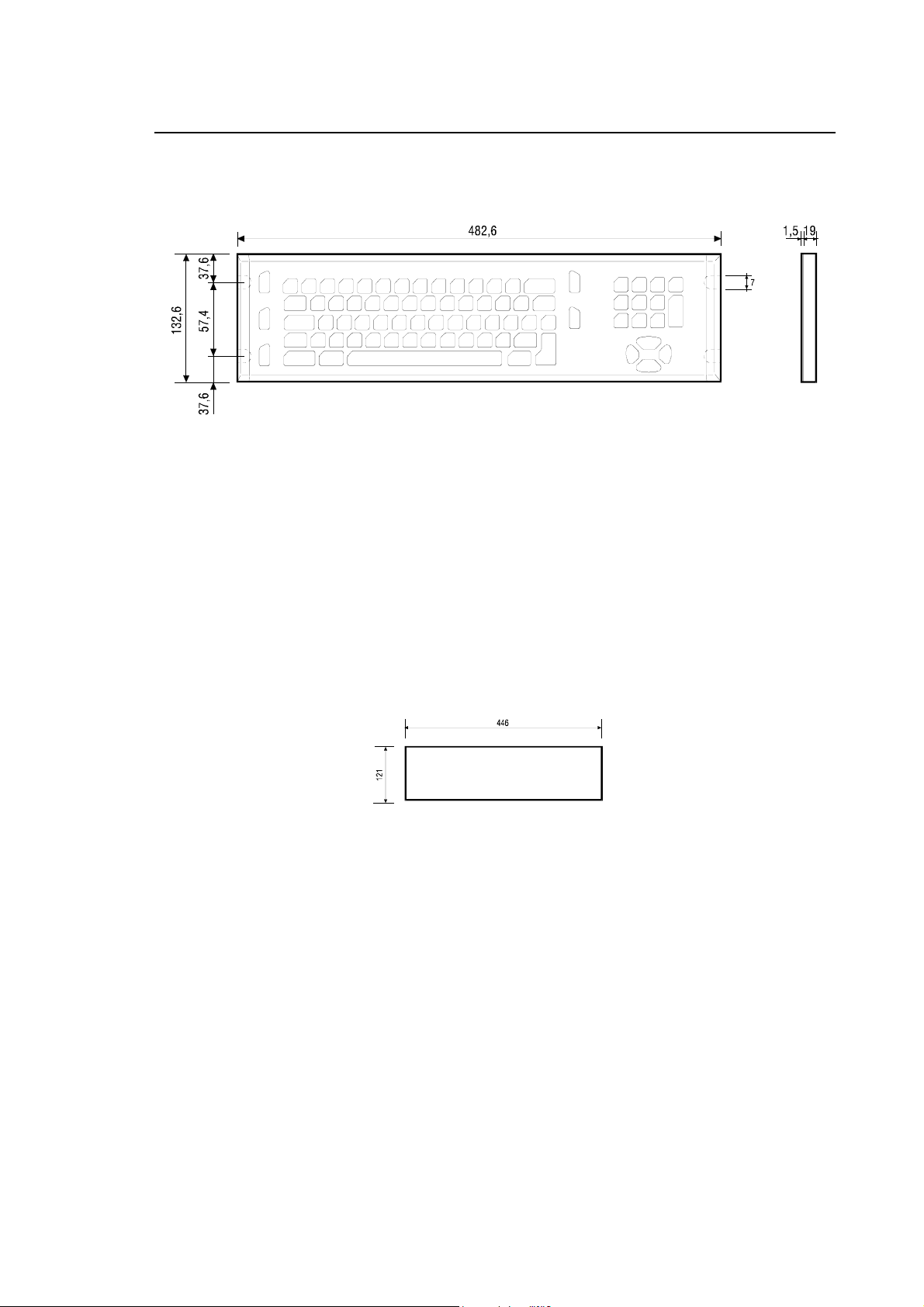

KEYBOARD FOR OPLINK, BLINK OPERATOR PANEL AND THE CONTROL UNIT 10/110

Side and front view

Physical Characteristics

Width 482.6 mm

Height 132.6 mm

Depth 20.5 mm (without cables)

Weight 1.3 Kg

Mounting Rack 19"

Drilling template for keyboard

10 Series Family Installation Guide (14) 1-5

Chapter 1

Mechanical Characteristics

FDU KIT

Two FDU kits are available for mounting on the system: Standard and Reduced. The reduced FDU

kit does not include either the FDU aluminium plate with related door and the COM1 serial interface

extension cable.

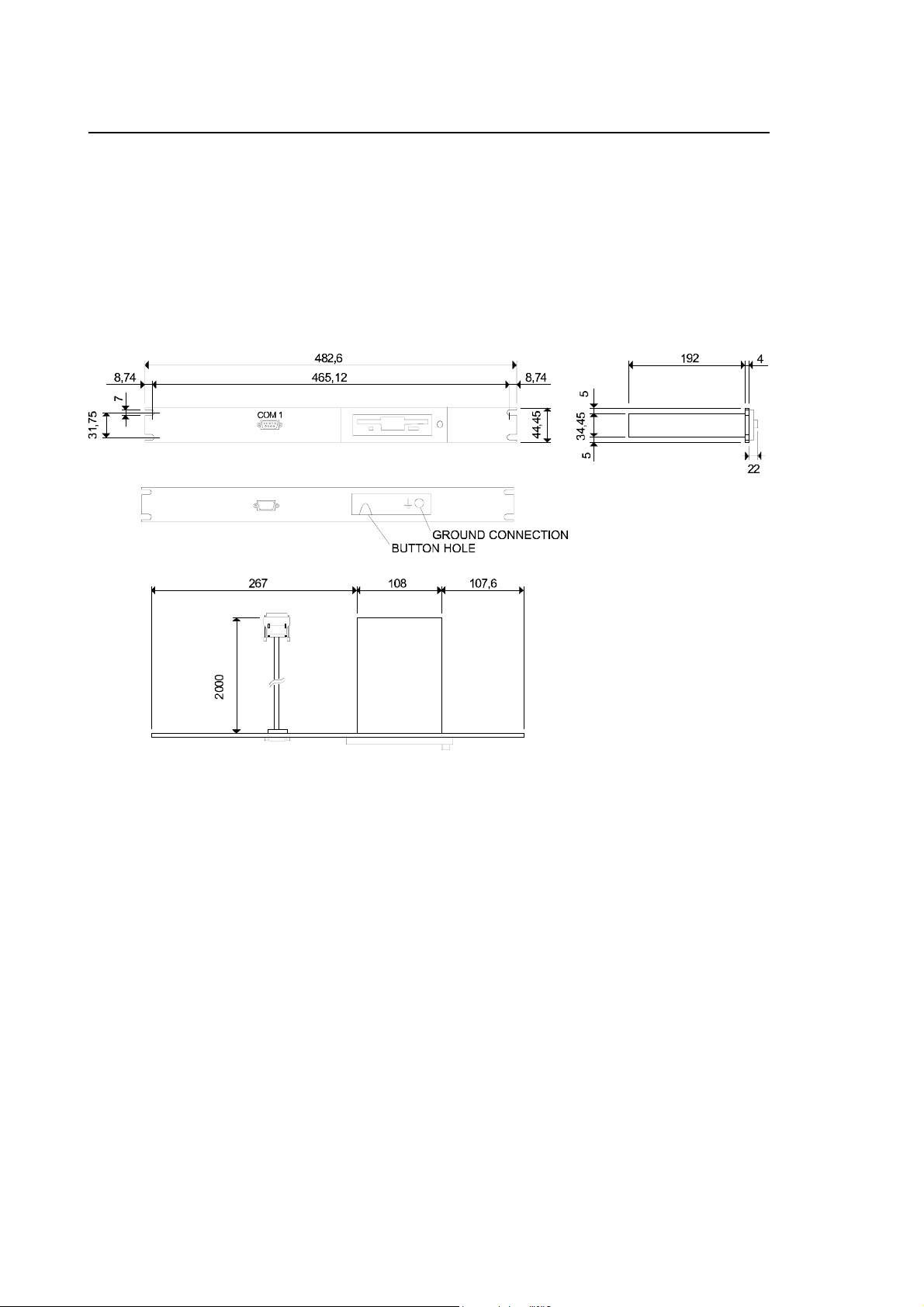

Normal FDU Kit

Front, side and upper view of the Standard FDU kit

Physical characteristics

Width 482.6 mm

Height 43.7 mm

Depth 218 mm (without cables)

Weight 1 kg

Mounting 19" rack

Protection FDU front plate

1-6 10 Series Family - Installation Guide (14)

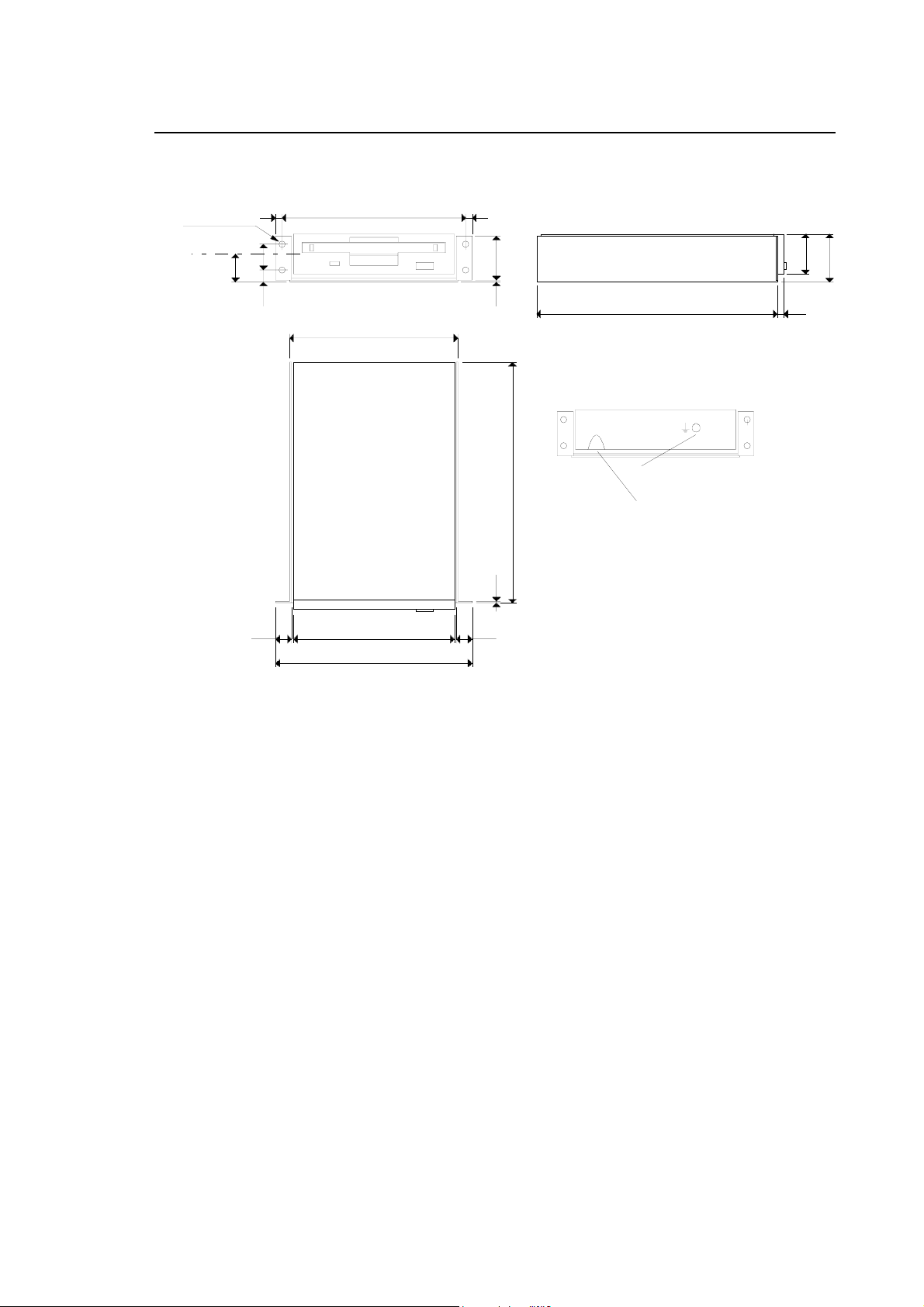

Reduced FDU Kit

Chapter 1

Mechanical Characteristics

4 Ø 4 HOLES

Floppy disk axis

17

11444

16

7,5

104,6

101,6 9,99,9

122

1,2 27,81,2

192

151 4

GROUND CONNECTION

BUTTONHOLE

25,4

30,2

Front, side and upper view of the reduced FDU kit

Physical characteristics

Width 122 mm

Height 30,2 mm

Depth 192 mm (without cables)

Weight 0,7 kg

10 Series Family Installation Guide (14) 1-7

Chapter 1

Mechanical Characteristics

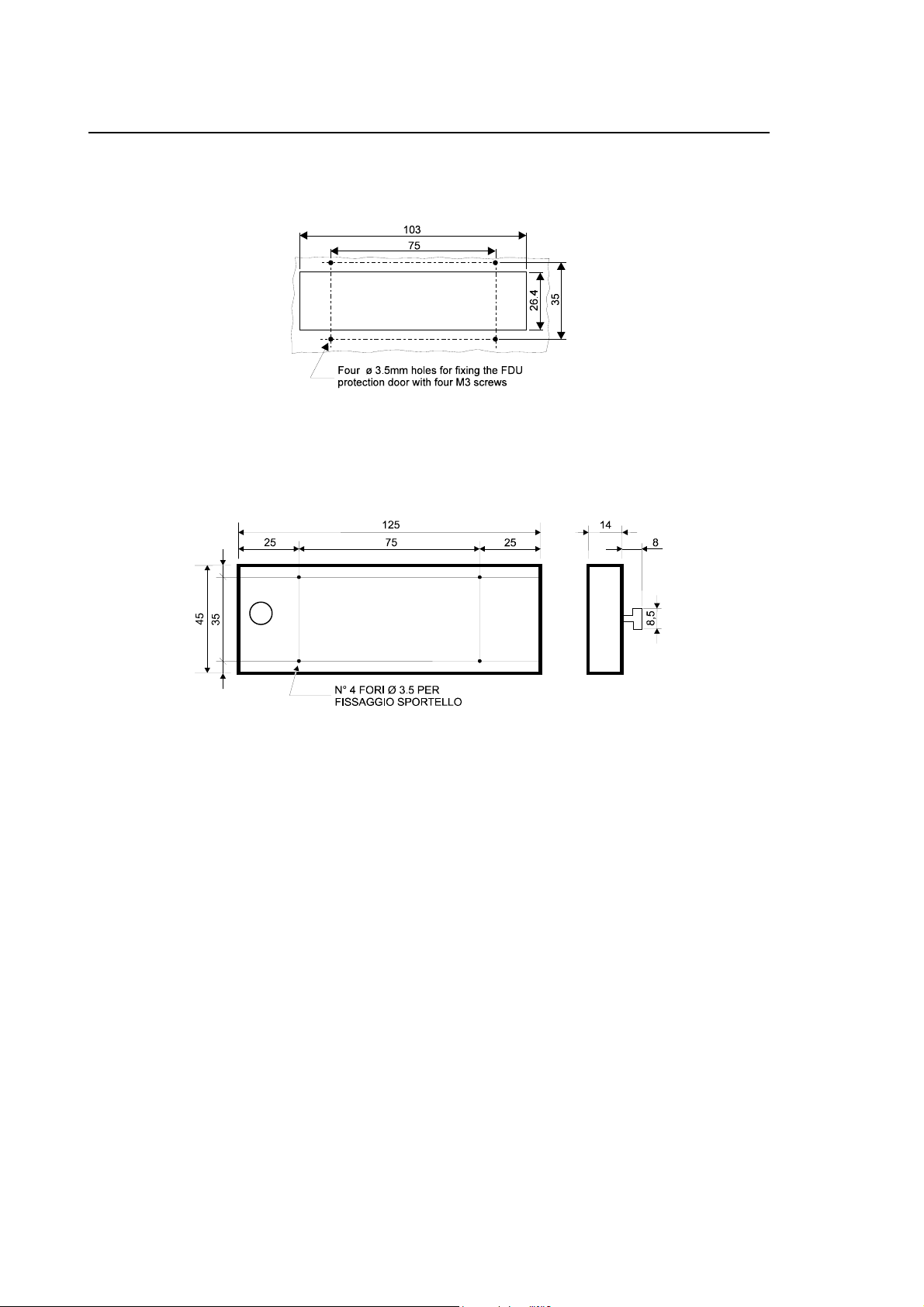

Drilling template for FDU access and fixing and the corresponding

protection door

Dimensions of the protection door

1-8 10 Series Family - Installation Guide (14)

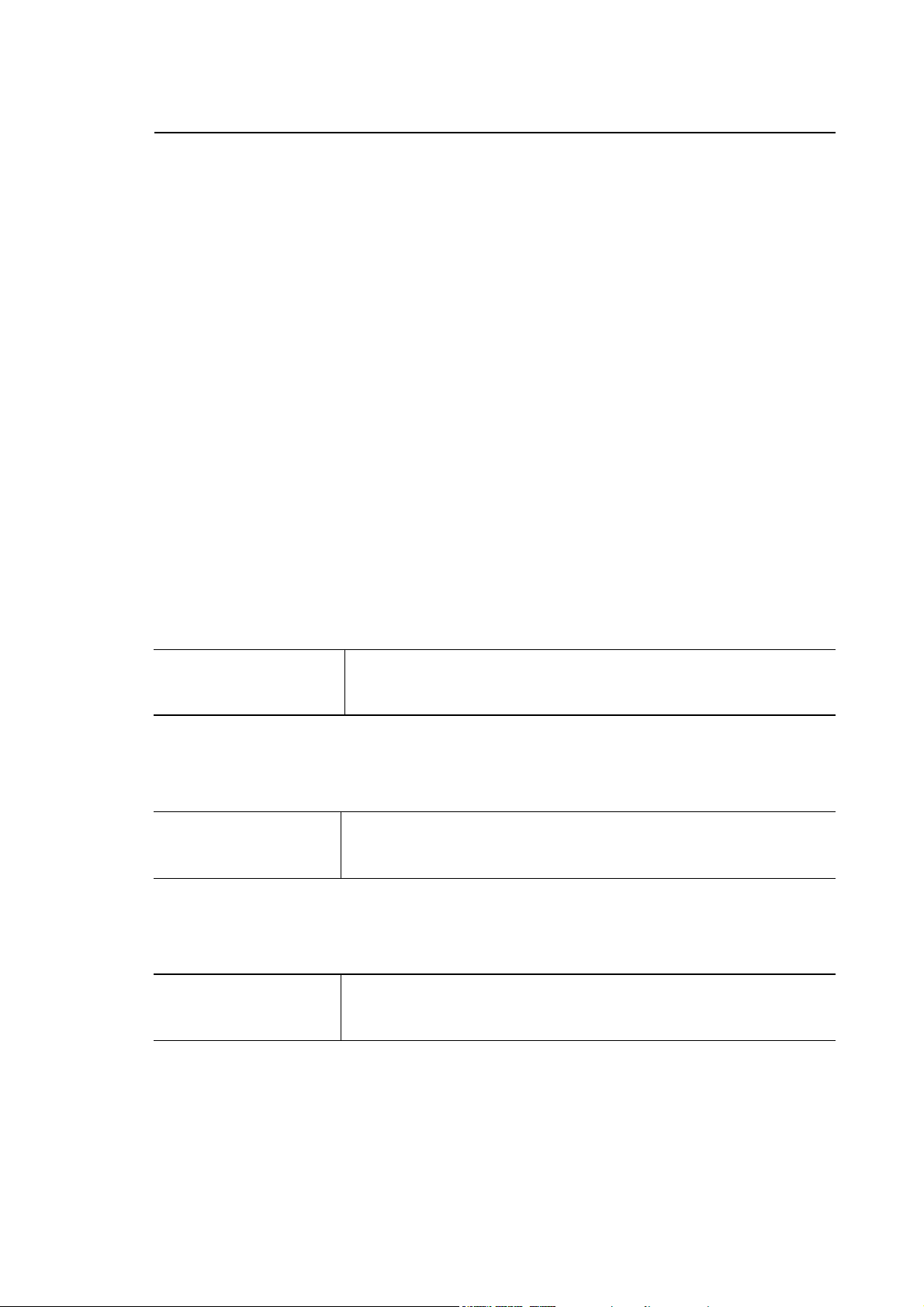

10/110 CONTROL UNIT

Chapter 1

Mechanical Characteristics

Physical characteristics

Width 482.6 mm

Height 265.6 mm

Depth 122 mm (without cables)

Weight 5,5 kg

Mounting 19" rack

Protection IP54 (front only)

Drilling Template for 10/110 Control Unit

10 Series Family Installation Guide (14) 1-9

Chapter 1

Mechanical Characteristics

10/510S/I LIGHT CONTROL UNIT

10/510S/i Light System

1-10 10 Series Family - Installation Guide (14)

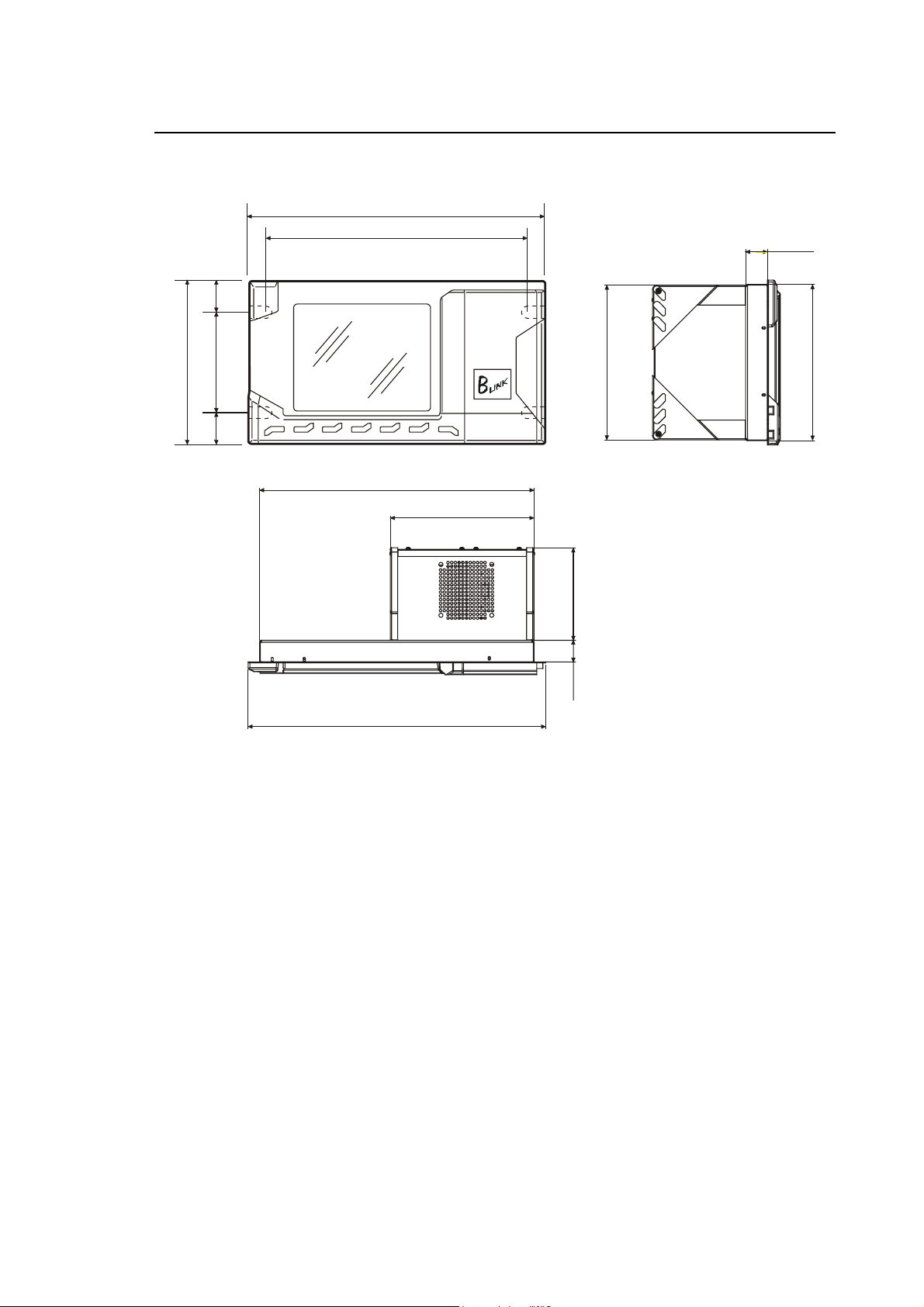

10/510i BLINK CONTROL UNIT

265

482,6

466

37,6

Chapter 1

Mechanical Characteristics

35,3

,6

190,437,6

Physical Characteristics

445

233

482,6

10/510i Blink System

249,5

150

35,3

252

Width 482.6 mm

Height 265.6 mm

Depth 290 mm (exit cables included)

Weight 6.4 Kg (boards included)

Mounting in 19” rack

Protection IP54 (only front)

Voltage 24Vdc (20÷30V)

Current 3A max (24Vdc)

10 Series Family Installation Guide (14) 1-11

Chapter 1

Mechanical Characteristics

10/510i OPLINK CONTROL UNIT

482,6

466

37,6

35,3

265,6

190,437,6

Physical Characteristics

Width 482.6 mm

445

233

482,6

10/510i OpLink system

150

35,3

249,5

252

Height 265.6 mm

Depth 290 mm (exit cables included)

Weight 6.4 Kg (board included)

Mounting in 19” rack

Protection IP54 (only front)

Voltage 24Vdc (20÷30V)

Current 3A max (24Vdc)

1-12 10 Series Family - Installation Guide (14)

Drilling template for 10/510i Oplink/Blink Control Unit

Ø

7

Chapter 1

Mechanical Characteristics

10 Series Family Installation Guide (14) 1-13

Chapter 1

235

159

Mechanical Characteristics

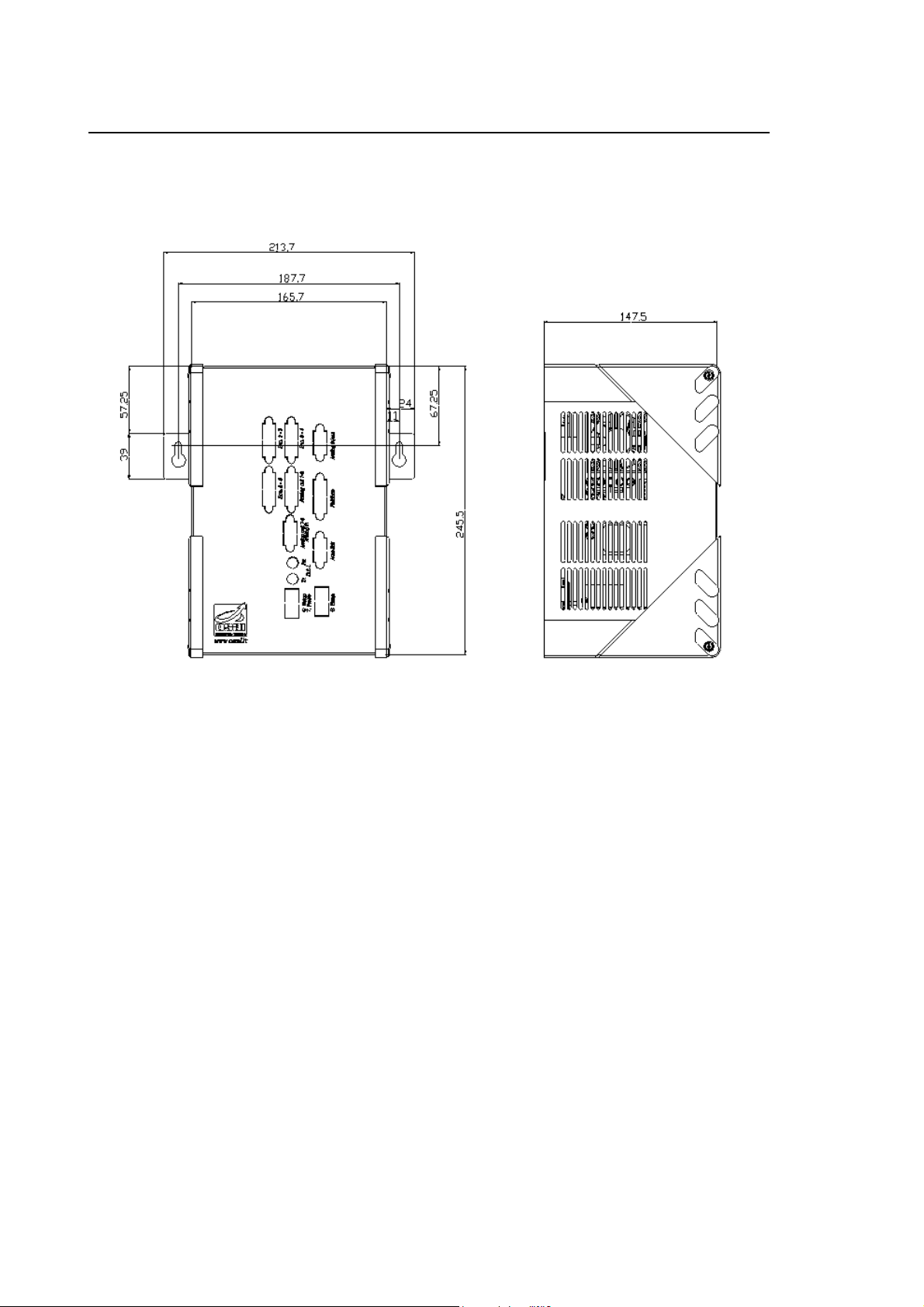

10/510i CONTROL UNIT

159

27,02

257,1

233

9

235

10/510i system

Physical Characteristics

Width 235 mm

Height 311,14 mm

Depth 259 mm (exit cables included)

9

27,02

Weight 6 Kg (board included)

Mounting Mounting Bracket

Voltage 24Vdc (20÷30V)

Current 3A max (24Vdc)

1-14 10 Series Family - Installation Guide (14)

Mounting Bracket for unit 10/510i

Chapter 1

Mechanical Characteristics

Mounting Bracket for 10/510i

10 Series Family Installation Guide (14) 1-15

Chapter 1

265,6

Mechanical Characteristics

10/510I WINLINK USB CONTROL UNIT

482,6

466

37,6

190,437,6

444

7

249

150 35,3

15035,3

252

482,6

10/510i WinLink system

Physical Characteristics

Width 482.6 mm

Height 265.6 mm

Depth 290 mm (exit cables included)

Weight 10,1 Kg (board included)

Mounting in 19” rack

Protection IP54 (only front)

Voltage 24Vdc (20÷30V)

Current 6A max (24Vdc)

1-16 10 Series Family - Installation Guide (14)

Drilling template for 10/510i WINLINK USB Control Unit

Ø

7

Chapter 1

Mechanical Characteristics

10 Series Family Installation Guide (14) 1-17

Chapter 1

Mechanical Characteristics

INSTRUCTIONS FOR MOUNTING THE CONTROL UNIT TO THE PANEL

The control unit must be mounted in an enclosure providing protection against dust, oil and other

environmental agents.

This module must not be cooled with incoming external air.

IMPORTANT

If the control unit is installed in the same electrical cabinet as the power groups it is advisable to

insulate it by mounting a metal sheet or to allow at least 30 cm between the base unit and devices

such as drives, transformers or power generators. This permits to minimise electrical noise.

Since both the spindle and the axes drives dissipate a lot of heat it is recommended to mount them

above the unit.

To reduce shut down times and cost the control unit must be easily accessible to maintenance

technicians and facilitate troubleshooting.

Allow at least 10 cm around the module to ensure proper ventilation. In addition,

allow at least 20 cm between the module and the upper side of enclosure to

accommodate the board connectors and cables. Connector screws must be

tightened with a screwdriver.

INSTALLATION INFORMATION

Proper installation may be crucial to correct system operation. Please read the following guidelines

before planning the system layout:

• check that the wire channels do not exceed the allowed lengths for connections between

components.

• allow good ventilation or cooling of the electric cabin. This topic is discussed in the following

section.

• distribute the system components so that the operator enjoys a good view of both the

machining process and the front control panel. The operator must be located in a point that

facilitates access to the system controls and push buttons.

• make sure that the cabinet doors can fully open. These doors must be always closed except

during maintenance operations.

• mount the control in the enclosure allowing easy access to connectors and other components.

1-18 10 Series Family - Installation Guide (14)

Chapter 1

Mechanical Characteristics

COOLING

Cooling requirements

Like all electronic components, 10 Series modules dissipate power in the form of heat.

This means that they must be cooled on a permanent basis to prevent overheating.

Proper cooling must be ensured by forcing air circulation inside the electric cabinet in which the

unit has been installed.

If the air contains dirt and dust, these could build up on the board inside the

systems and lead to defects due to reduced insulation.

CAUTION

Therefore the cabinet should be tight. In this case air conditioning or a heat

exchanger have to be installed in order to maintain the temperature within the

specified range.

The temperature inside the cabinet with the controller must never exceed the values indicated in

the following tables:

Environment Specifications

CONTROL UNIT AND OPERATOR PANEL

Operating temperature

Storage temperature

Humidity (without condensation)

Humidity (without condensation)

Because reliability of electronic components increases at low temperatures, keeping temperatures

below the specified values permit to obtain greater MTBF (mean time between failures) values.

+5 ÷ +47 °C

-25 ÷ +60 °C

10 ÷ 90 %

20 ÷ 80% for FDU kit

10 Series Family Installation Guide (14) 1-19

Chapter 1

Mechanical Characteristics

Heat exchanger or air-conditioner

When the airflow inside the electric cabinet does not permit an appropriate heat exchange with the

cabinet walls it is necessary to install a heat exchanger or an air-conditioner.

To size the heat exchanger or the air-conditioner you need to calculate the total energy dissipated

inside the cabin. This energy is the sum of the energy dissipated by each of the devices installed in

the cabin.

If the energy dissipated by a device is unknown, total dissipated energy can nevertheless be

calculated from other known values.

Example:

to calculate the energy dissipated by an axes-drive system (transformer plus drive) dissipated

when the motor power is 1000 W you may assume the following:

Transformer efficiency = 0.95

Drive efficiency = 0.85

Average system efficiency = (0.95 x 0.85) = 0.8

Input power =

Input power =

Dissipated power = input power - motor power

Dissipated power = 1250 - 1000 = 250 W

motor power

system efficiency

1000

= 1250 W

0,8

1-20 10 Series Family - Installation Guide (14)

Chapter 1

Mechanical Characteristics

Heat exchanger

The heat exchanger cools the cabinet by forcing ventilation between. Internal air flows around the

heat exchanger, whose shape maximises the contact surface, whereas forced external air

circulates on the other side of the wall. The gradient of the heat exchanger is the ratio between the

dissipated energy and the variation of temperature.

For example, if the energy dissipated by the heat exchanger dissipates is 1000 W and the

difference of between external and internal temperature remains 11 °C, the gradient of the heat

exchanger will be:

1000W

However, since heat is also exchanged through the other walls, the internal cabinet temperature

depends on the dissipated power, the cabinet vertical surface (top and bottom excluded) and on

the heat exchanger gradient.

To calculate the difference between internal and external temperature you can use this formula:

∆t =

where:

∆t = difference of temperature in °C

Q = dissipated power in W

A = vertical surface in m

R = heat exchanger gradient in W/°C

For example:

Dissipated power: 2000W

Vertical surface: 21 m

Heat exchanger gradient: 90 W/°C

11°C

5.68A+R

= 90 W/°C

Q

²

²

∆t =

10 Series Family Installation Guide (14) 1-21

2000

[(5.68 x 21) + 90]

= 9.5°C

Chapter 1

Mechanical Characteristics

Air conditioner

Air conditioners provide continuous cooling through a refrigeration system.

The difference of temperature is given by the energy to be dissipated, the vertical surface and the

air conditioner power.

To calculate the approximate difference in temperature use these formulas:

if Q > PC + ∆t =

if Q < PC - ∆t =

where:

∆t = difference of temperature in C

Q = dissipated power in W

PC = air conditioner power in W

A = vertical surface in m

Example:

To dissipate 2000 W with a 1000 W air conditioner in a cabinet whose vertical surface is 15 m²,

use this formula:

+ ∆t =

IMPORTANT

To help assure adequate external airflow, do not mount any obstructions within 60

cm of the intake and exhaust ports of any heat exchanger or air conditioner.

Q - PC

5.68 A

Q - PC

7.37 A

²

2000-1000

5.68 A

= 11.7 °C

FIRE PROTECTION

Fire enclosures

The electric cabinet must act as a “FIRE ENCLOSURE”, in order to protect external environmental

against fire due to fault conditions of enclosed parts.

1-22 10 Series Family - Installation Guide (14)

Chapter 1

Mechanical Characteristics

VIBRATIONS, SHOCK

The OSAI Modules described in this manual will work correctly (in operating state) and not be

damaged (when not in operating state, stored or in transport) under the following vibration

conditions on the three axes:

Working conditions

Vibrations

10-57 Hz 0.15 mm peak-peak

57-200 Hz 1.00 g

Shock

15 g peak 11 msec (semisinusoidal pulse)

Non Working conditions

10-57 Hz 0.38 mm peak-peak

57-200 Hz 2.50 g

Transport and Storage

Shock

60 g peak 11 msec (semisinusoidal pulse)

10 Series Family Installation Guide (14) 1-23

Chapter 1

Mechanical Characteristics

END OF CHAPTER

1-24 10 Series Family - Installation Guide (14)

Chapter 2

ELECTRICAL CONNECTIONS

Before connecting the system to the mains check its power supply requirements, which are listed

in the tables below:

UNIT POWER SUPPLY SPECIFICATIONS

BLink and OPLink Operator Panel

No external power supply. This is provided by the connection cables from the Control Unit.

Voltage

Max. input current

12 Vdc

0.8 A (Average power draw: 8 W)

WINMEDIA ETX

Voltage:

Current:

24 Vdc ± 20%

2.5 A @ 24 Vdc

Analog/OS-Wire 10/110 control units

Voltage:

Current:

24 Vdc NOM (18 ÷ 30 V)

2.2 A at 24 Vdc (Average power draw: 40 W)

10 Series Family - Installation Guide (15) 2-1

Chapter 2

Electrical Connections

10/510S/i Light and 10/510i control units

Voltage

Current

24 Vdc, rated (20 to 30 V)

2.2 A max at 24 Vdc (Average power draw: 40 W)

10/510i OpLink-Blink Control Unit

Voltage:

Current:

24 Vdc NOM (20 ÷ 30 V)

3 A max at 24 Vdc (Average power draw: 60 W)

10/510i WinLink USB Control Unit

Voltage:

Current:

24 Vdc NOM (20 ÷ 30 V)

6 A max at 24 Vdc (Average power draw: 110 W)

2-2 10 Series Family - Installation Guide (15)

UNIT POWER SUPPLY CONNECTION AND PROTECTION GND

Analog/OS-Wire 10/110 control unit

The 10/110 Control Unit requires power of 24 Vdc nominal.

The power terminals are on the back of the Unit as shown in the following figure:

FDU

Chapter 2

Electrical Connections

Analog out 5

R

R

W

W

P

P

.

t

d

u

o

p

e

o

O

M

C

D

V

4

2

b

t

o

s

C

r

E

P

D

.

.

D

V

G

T

N

G

4

2

Enc. 4

11

Module power supply

Out section power supply 24V

Analog 10/110, detailed view of power supply connector

TX RX

Com 2 Port

Com 1 Port

Ethernet

t

l

u

a

F

Input 25-48 Input 1-24 Output 1-24

Enc. 2

Enc. 1

Analog out 1-4

Analog in Enc. 3

Keyboard

10 Series Family - Installation Guide (15) 2-3

Chapter 2

Electrical Connections

R

R

W

W

P

P

.

t

d

u

o

p

e

o

O

M

C

D

V

4

2

b

t

o

s

C

r

E

P

D

.

.

D

V

T

G

N

4

2

G

Led rosso

Red LED

FDU

Com 2 Port

Com 1 Port

Ethernet

11

Analog in Input 25-48 Input 1-24 Output 1-24

Keyboard

Led verde

Green LED

OS-Wire

Module power supply

Out section power supply 24V

OS-Wire 10/110, detailed view of power supply connector

The power has to be connected with an AWG16 having a cross section of 1.3 mm², stripping of 8

mm and using the terminal boards supplied with the module. In addition, the module case has to be

connected to ground (using an M6 screw as shown in the figure; see the “Grounding and Noise

Suppression” chapter).

NOTE

The units are protected against inversion of polarity.

2-4 10 Series Family - Installation Guide (15)

The 10/110 Control Unit is protected by a 125 V, 5 A subminiature fuse.

This is located on the motherboard in the position shown in the following figure.

For accessing it you have to open the Unit's housing. Operation not allowed !

Chapter 2

Electrical Connections

OS-Wire 10/110 Fuse Analog 10/110

Fuse location on the main board

10 Series Family - Installation Guide (15) 2-5

Chapter 2

Electrical Connections

10/510 Series Control Unit

The Units in Series 10/510, consisting of a single module and two modules, have to be supplied

with direct current of nominally 24 Vdc. The power supply terminals of each module are in the

lower part of the unit as shown in the following figures.

10/510S/i Light Control Unit

24Vdc

Ground bolt

10/510S/i Light Unit power supply

2-6 10 Series Family - Installation Guide (15)

10/510i Control Unit

Chapter 2

Electrical Connections

+24 Vdc GND

10/510i Unit power supply

GROUND BOLT

5.08 PITCH CONN.

10 Series Family - Installation Guide (15) 2-7

Chapter 2

Electrical Connections

10/510i OpLink/Blink Control Unit

GROUND BOLT

5.08 PITCH CONN.

+24 Vdc

GND

10/510i OpLink/BLink Unit power supply

2-8 10 Series Family - Installation Guide (15)

10/510i WinLinK USB control Unit

Chapter 2

Electrical Connections

GROUND BOLT

+ 24Vdc

+ 24Vdc

5.08 PITCH CONN.

10/510i WinLink USB Unit power supply

5.08 PITCH CONN.

GROUND BOLT

10 Series Family - Installation Guide (15) 2-9

Chapter 2

Electrical Connections

NOTE:

For the power supply connection use an AWG16 wire with a cross section of 1.3 mm² having

removed the isolation for 8 mm and the terminal board supplied with the module.

Connect the grounding bolt (M4 screw) of the module of the chassis with ground (only one rack for

the WinLink unit) as shown in the figure. Check the "Ground Connection and Noise" Chapter.

Each rack is protected against pole inversion and has a subminiature fuse (125V 5A) on the 24

Vdc supply line.

If is fitted to a base on the back board as shown in the following figure.

To access it you have to open the unit's back panel (OPERATION NOT PERMITTED!).

Another resettable type fuse protects the FDU external peripheral, if fitted.

EXTERNAL FDU FUSE

PWR IN FUSE

J19

1 2

+ -

BOARD POWER SUPPLY

Fuse locations on OS8502 Back Board

(10/510i, 10/510i OpLink/BLink, 10510i WinLink USB)

2-10 10 Series Family - Installation Guide (15)

Electrical Connections

POWER

ALIMENTATORE

SUPPLY UNIT

+5V @ 10 A

+12V @ 2 A

-12V @ 250 mA

-5V @ 30 mA

Chapter 2

EXTERNAL FDU FUSE

BOARD POWER SUPPLY

Identification of fuses on OS8505 Back Board

(10/510S/i Light)

PWR IN FUSE

J8

12

24V

+

ALIM. PIASTRA

-

10 Series Family - Installation Guide (15) 2-11

Chapter 2

Electrical Connections

General interconnection diagram

OPERATOR PANEL

Power connections to Series 10/510 modules in their various versions

NOTE:

The operator panel is not present in versions 10/510S/i Light and 10/510i. In the case of unit

10/510i WinLink USB two modules have to be powered.

END OF CHAPTER

2-12 10 Series Family - Installation Guide (15)

Chapter 3

GROUNDING AND NOISE SUPPRESSION

All the devices connected to a machine tool controlled by a 10 SERIES system must be properly

grounded in order to guard against electric shock to people who touch them. Grounding also helps

reduce the effect of electromagnetic noise.

All earth grounding connections must be continuous and permanent. A grounding connection must

not be interrupted by a switch.

The connections of grounding wires must comply with Article 13 of the IEC 204-1 code.

IMPORTANT

Use copper conductors for all connections to ground. If conductors are isolated,

insulation can be yellow or green.

EARTH GROUNDING

Each subset installed in the electrical cabinet must have its own connection to ground. In other

words, the grounding terminal strip of each subset must be connected separately to the cabinet's

ground bus bar. Keep the wires used for this connection as short as possible.

If a subset needs a connection to earth for the AC power supply terminal strip, this point must be

also connected to the cabinet's ground bus bar.

If the system is made up of various cabinets, the bus bar of each cabinet must be connected to the

bus bar of the main power cabinet, which is in turn connected to the earth ground system of the

plant.

10 Series Family - Installation Guide (06) 3-1

Chapter 3

Grounding and Noise Suppression

Cabinet earth grounding

Each cabinet must be connected to its bus bar through any stud or bolt bonded to the structure of

the cabinet.

Carefully remove all paint or insulating material from the contact area. Use a ring terminal at the

end of each conductor.

Grounding connection scheme

3-2 10 Series Family - Installation Guide (06)

Chapter 3

Grounding and Noise Suppression

ELECTRICAL NOISE

General information

Electrical noise is any unwanted electrical signal.

Electrical devices to which voltage is applied are typical noise sources. Electrical noise is

characterised by its frequency, waveform and intensity.

Here are the main three types of electrical noise:

1 electrostatic noise:

this type of noise is produced by an alteration of the electrical field that is transferred to the

circuit by a capacitive action;

2 magnetic noise:

is produced by an alteration of the magnetic field that is transferred to the circuit by an inductive

action;

3 electromagnetic noise:

is a combination of electrical and magnetic noises.

Noise sources

One of the main sources of electrical noise is the rapid variation of current in an inductive circuit.

The maximum exchange of current occurs when the circuit opens.

An overcurrent peak generates a sudden increase of voltage in the opening contact of the circuit.

10 Series Family - Installation Guide (06) 3-3

Chapter 3

Grounding and Noise Suppression

Noise suppression

The overvoltage generated by opening an inductive circuit must be suppressed by installing a

suppressor next to the overvoltage generator, as shown in the figure below:

+ V

100

Ω

Load

0,5µF

Installing a noise suppressor

3-4 10 Series Family - Installation Guide (06)

Chapter 3

Grounding and Noise Suppression