Opel Movano 2009 Owner Manual

Contents

Introduction............................. 0-1

Tipper ..................................... 1-1

Dropside ................................. 2-1

Double cab ............................. 3-1

Auxiliary heating systems ....... 4-1

0-1 Introduction

Back to overview

Introduction

This manual contains supplementary

information regarding the operation

and use of specific conversions

available for your vehicle. This

manual should be used in conjunction

with the vehicle Owner's Manual.

You must always comply with the

specific laws of the country that you

are travelling through. These laws

may differ from the information in this

manual.

When instructed to consult a

workshop, we recommend that you

consult an Opel Service Partner. All

Opel Service Partners offer first-class

service at reasonable prices.

You will receive quick, reliable and

individual service.

Experienced mechanics, trained by

Opel, work according to specific Opel

instructions.

This manual should always be kept

together with the Owner’s Manual

and Service Booklet in the vehicle:

Ready to hand in the glove

compartment.

Make use of this manual:

Yellow arrows in the illustrations

serve as points of reference or

indicate some action to be

performed.

Black arrows in the illustrations

indicate a reaction or a second

action to be performed.

Directional data, e.g. left or right, or

front or back, in the descriptions

always relates to the direction of

travel.

Page references are indicated

with 3. 3 means “see page”.

9 Warning, Caution

Vehicle passengers should be

informed accordingly.

9 Warning

Text marked 9 Warning provides

information on risk of accident or

injury. Disregard of these

instructions may result in injuries.

Caution

Text marked Caution provides

information on possible damage to

the vehicle. Disregard of these

instructions may lead to vehicle

damage.

1-1Tipper

Back to overview

Tipper

Loading ................................... 1-1

Tailboard................................. 1-2

Sideboards.............................. 1-3

Lashing points......................... 1-3

Tipper operation...................... 1-4

Isolation switch ....................... 1-4

Safety cable ............................ 1-6

Safety prop ............................. 1-6

Cleaning.................................. 1-7

Owner's checks....................... 1-7

Technical data ........................ 1-8

Maintenance ........................... 1-10

Confirmation of hydraulic fluid

change.................................. 1-11

Loading

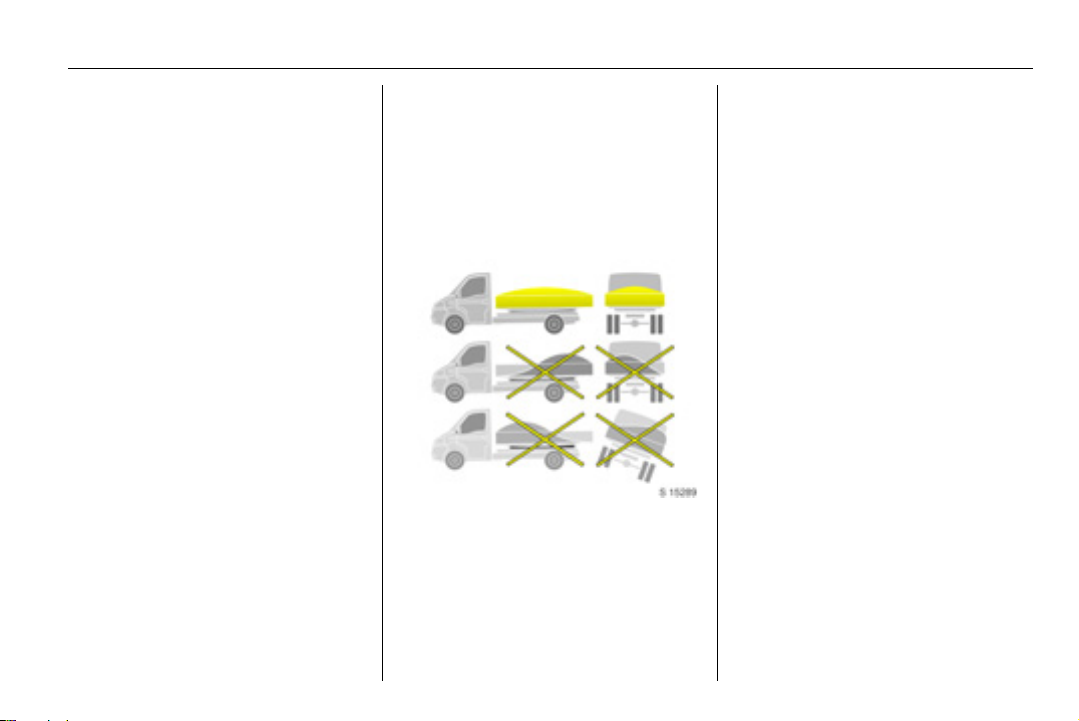

The three-way tipper is designed for

carrying bulk materials that can be

discharged by tipping.

The three-way tipper is not designed

for carrying people or unsuitable/

unsafe materials

Ensure the vehicle tailboard and

sideboards are securely closed

before loading.

1)

Observe the national regulations on

securing loads.

1)

.

Load the vehicle evenly,

distributing the load across the

body.

Secure any solid loads with

additional lashing equipment.

Place loads from the minimum

practicable height. Do not drop

loads onto the tipper body.

Do not overload the tipper body.

Ensure the load will not fall out or

endanger other road users.

Do not drive with the body tipped.

Do not drive with the tailboard or

sideboards down.

Do not attempt to tip loads from the

body when body sides or tailboard

are closed.

1-2 Tipper

Back to overview

Tailboard

Opening

To open the tailboard, pull up the

release levers to disengage the locks

and lower the tailboard fully.

To close the tailboard, raise the

tailboard and push firmly into

position. Push down the release

levers ensuring locks engage fully.

Swinging

9 Warning

Before using the swinging

tailboard, check the release levers

are securely latched on both sides.

To release, pull the remote lever

located on the rear left side of the

body. The tailboard is disengaged

and will swing from its upper hinges.

To lock, engage the lower tailboard

hinges and push the remote lever to

lock position. Check the tailboard is

secure

.

Removing

9 Warning

Two people are required to carry

out this operation.

Pull the remote lever located on the

rear left side of the body. The

tailboard is disengaged and will swing

on its upper locks.

With the help of an assistant, support

the tailboard weight and pull up the

release levers. Remove the tailboard

from the tipper body.

1-3Tipper

Back to overview

To reinstall: Install the tailboard onto

the upper hinges and push down the

release levers ensuring locks engage

fully.

Insert the tailboard into the lower

hinges and push the remote lever to

lock position.

Check the tailboard is secure.

Sideboards

To open, pull up the release levers to

disengage the locks. Lower the

sideboard fully.

To close, raise the sideboard and

push firmly into position. Push down

the release levers ensuring locks

engage fully.

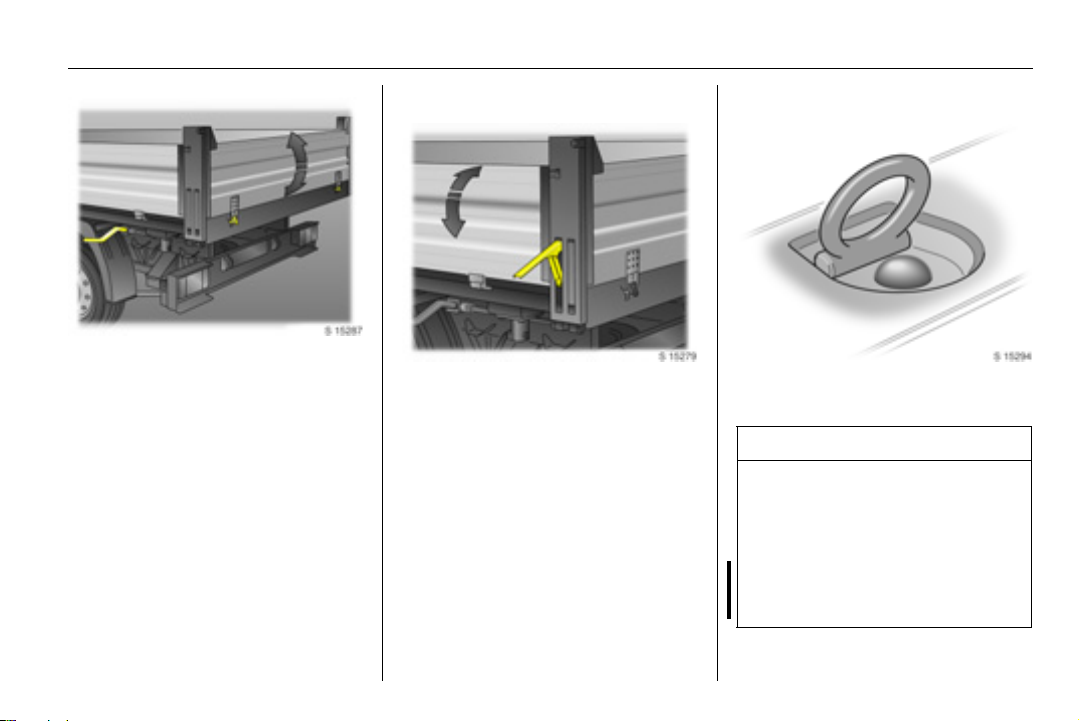

Lashing points

Secure heavy objects with lashing

straps attached to the lashing points.

Caution

When loading heavy or bulk items,

the lashing point eyes must be flush

with the body floor to avoid causing

any damage.

The maximum force applied to the

lashing point eyes should not

exceed 5000N at 30°.

1-4 Tipper

Back to overview

Tipper operation

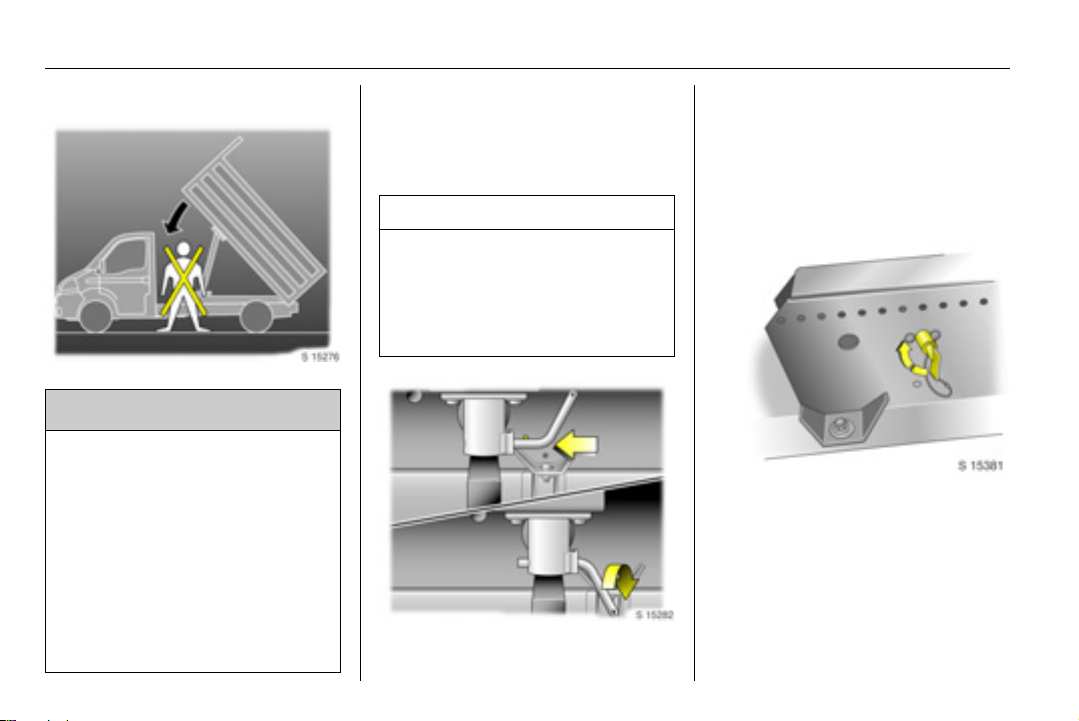

9 Warning

The operator must remain at the

control to ensure tipping and

lowering are performed correctly.

Do not allow anyone in or onto the

tipper body whilst operating the

tipper.

Ensure the vehicle is on level

ground and that the tipper body

can be raised to the maximum

height without fouling overhead

obstructions.

The tipper body has two locking pins

with each pin having a locator on its

upper edge. The locking pins are

used to obtain any one of the three

tipping positions.

Caution

The tipper must not be operated with

locking pins incorrectly installed.

Pins installed diagonally opposite or

in both front pivot positions will result

in damage if tipping is attempted!

To insert locking pin into pivot, ensure

the handle and locator are facing up.

Rotate the locking pin away from the

upright position to ensure the pin is

secured.

Isolation switch

The system must be activated using

the isolation switch located on the left

side tipper frame behind the cab.

Insert and turn the isolator key in the

switch.

When the tipper is not in use, turn the

isolator key to the off position and

remove it.

1-5Tipper

Back to overview

Raising and lowering the tipper

The tipper is operated using the

remote control located on the seat

base.

The remote control enables the user

to supervise the operation of the

tipper from outside the vehicle.

The remote control is magnetic and

can be stored on the seat base when

not in use.

1.With the isolation switch activated,

depress the à switch on the

remote control to raise; or the Ä

switch to lower. The tipper can be

stopped at any time by releasing

the switch.

2. The tipper body will cease moving

automatically when it reaches

maximum height.

An acoustic signal will sound to

indicate when the tipper control is

activated.

Tipping to the rear

Fully insert locking pins into the left

and right-hand rear pivots, ensuring

the handle and locator are facing up.

Rotate the locking pin away from the

upright position to ensure the pin is

secured.

Tipping to the side

To tip to the left side, fully insert

locking pins into the front and rear

left-hand pivots. Ensure the handle

and locator on both locking pins are

facing up. Rotate both locking pins

away from the upright position to

ensure the locking pins are secured.

1-6 Tipper

Back to overview

Safety cable

To tip to the right side, fully insert

locking pins into the front and rear

right-hand pivots. Ensure the handle

and locator on both locking pins are

facing up. Rotate both locking pins

away from the upright position to

ensure the locking pins are secured.

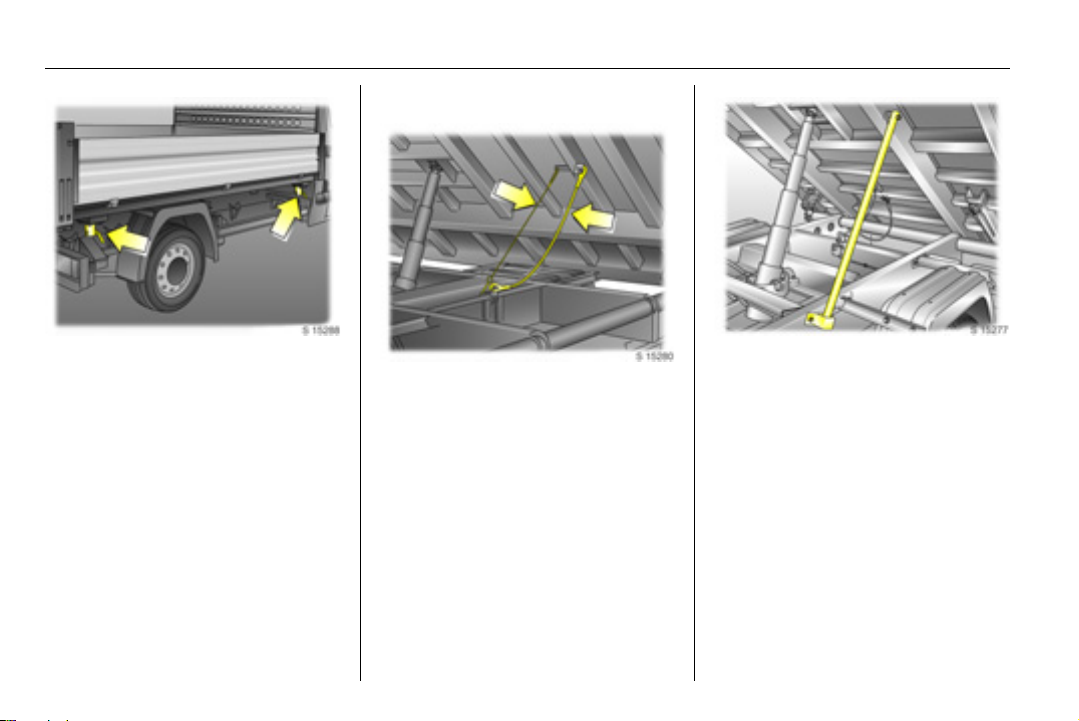

The safety cable attached to the

tipper body prevents the tipper body

being raised too far. Should a safety

cable become damaged it must be

replaced immediately. Seek the

assistance of a workshop.

Safety prop

The safety prop is located under the

left-hand side of the tipper body and

is provided only to assist in

supporting the tipper body when

tipped to the rear, for carrying out

visual inspection of the vehicle

components.

Using the safety prop:

1.Prepare the tipper body for tipping

to the rear.

2.Raise the tipper body sufficiently

enough to access the safety prop.

3.Release the safety prop from the

underside of the tipper body and

fold down.

4.Swing the safety prop downwards

to align with support.

5.Carefully guide the safety prop into

the support position then lower the

tipper body.

1-7Tipper

Back to overview

Stowing the safety prop:

1.Raise the tipper body sufficiently to

release the safety prop from its

support.

2. Fold the safety prop into the stowed

position and secure in the spring

clip.

3.Lower the tipper body.

Cleaning

Dirt or mud which remains dry on the

body may become abrasive and can

damage paint, seals, locks and

hinges.

Clean the following parts if they

become contaminated with dirt:

Sideboard and tailboard locking

latches and hinges.

Tipper body pivot pins and locating

holes.

Caution

Do not spray high-pressure water

directly at the hydraulic seals, pump,

reservoir, hydraulic ram ball joints,

or guide clamps.

After cleaning, check and if

necessary lubricate the components

listed in the owner's checks.

Owner's checks

Check regularly the following items.

Every week:

Lubricate the tailboard and

sideboard locking latches with

high-pressure grease and check for

correct operation.

Lubricate the tailboard and

sideboard hinges with lube oil and

check for correct operation.

Every month:

Visually check the subframe

mountings, the safety cables and

the hydraulic system. If any of the

components appear loose,

defective or leaking, seek the

assistance of a workshop to rectify

the cause of the fault.

Every 6 months:

Lubricate the tipper body pivots

and the safety prop hinge with high-

pressure grease.

9 Warning

Do not venture under the tipper

body when raised.

Loading...

Loading...