Page 1

2-Dimensional Code Reader (Fixed Type)

V530-R150E-3, EP-3

Intelligent Light

Source and a Twocamera Unit

Respond to a Wide

Variety of

Applications

V530-R150E-3, EP-3

Features

Intelligent Light Source

Versatile lighting control and a dome shape that minimizes external interference provide stable images for 2-dimensional code

reading.

Ring lighting Intelligent Light Source

Reduces the background effects of metal processed parts.

A Variety of Lighting Methods

The lighting direction and intensity can be changed. In addition,

coaxial lighting is available with the F150-SLC20. Optimal lighting methods can be set for a wide variety of workpieces.

F150-SLC20

(Field of vision: 20 mm)

The light intensity can be

set for each of five lighting

blocks, in eight steps.

2

135

Coaxial

lighting

4

Lighting Controlled from Menus

• The lighting block and intensity can be controlled from the Controller menu. Settings can be easily changed without having to touch

the light itself.

• Because light is handled as scene data, the lighting conditions can

be varied to match model changes on mixed-product lines.

• The Controller manages light settings numerically, for accurate

reproducibility.

Two-camera Unit

Two cameras can be switched by a single Controller.

F150-SLC50

(Field of vision: 50 mm)

The light intensity can be

set for each of eight lighting

blocks, in eight steps.

5

1

2684

3

7

C-75V530-R150E-3, EP-3

Page 2

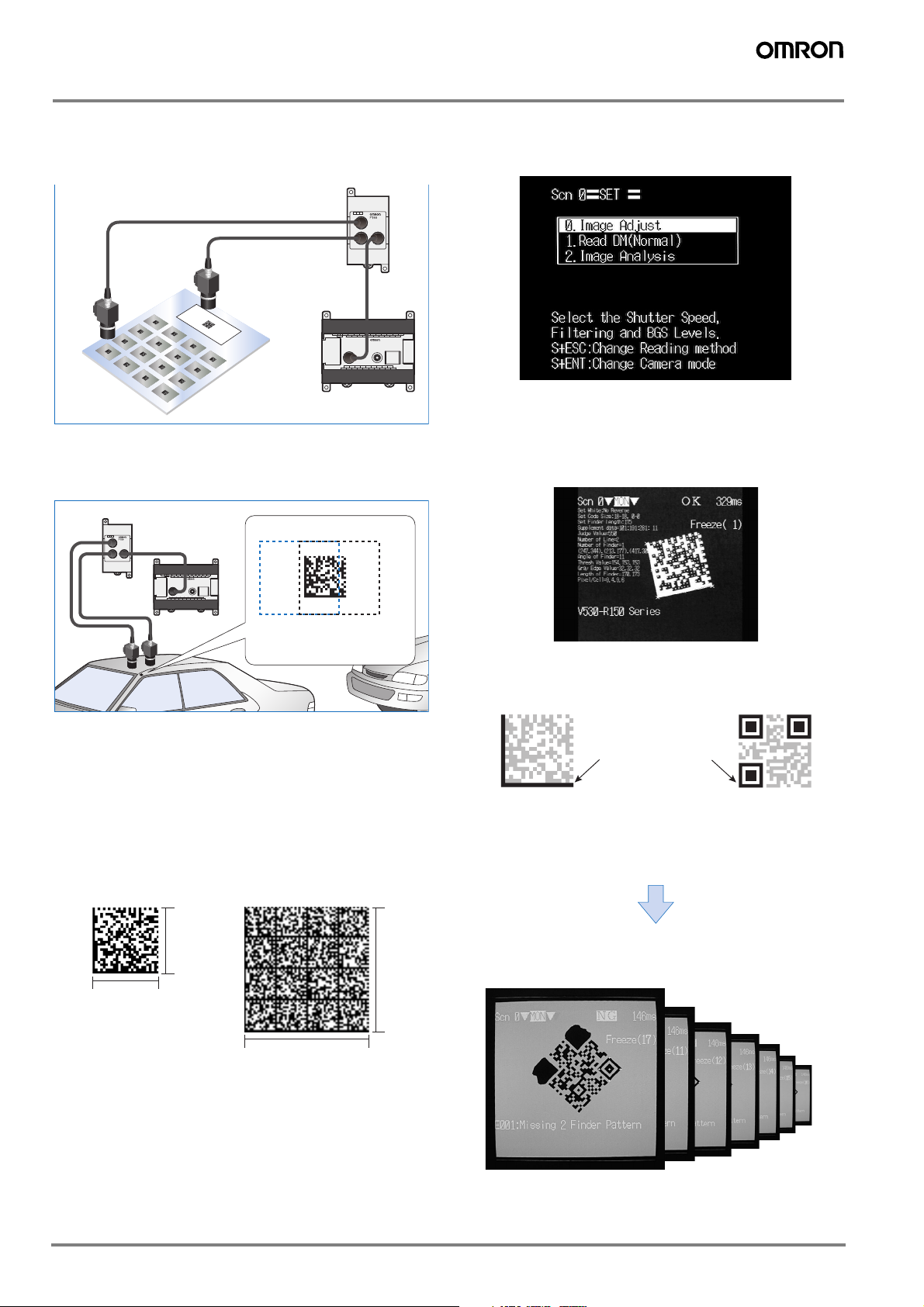

Application Example

Simultaneous single-product and lot management

Single products and lots can be managed simultaneously.

New Guidance Function for the Settings Display

The addition of a guidance function on the display greatly simplifies setting.

Camera 2

Camera 1

Electronic

components

Two-camera Unit

V530-R150

Controller

Greater positioning tolerance

For applications that cannot be covered by the field of view of

only one camera.

Two-camera Unit

V530-R150

Controller

Camera 1 field

ofvision (blue)

Positioning tolerance increased

by using two cameras to

expand the field of vision.

Camera 2 field

ofvision (black)

Easy-to-Read Analytical Data Format

See the reading status at a glance on the reading information

display.

The finder pattern, cell recognition, reading data, etc., can all be

viewed on the display.

Finder pattern (cutting symbol)

Use this pattern to detect the 2-dimensional code position. The

finder pattern is different for each code.

Compatible with Data Matrix Old Version

The V530-R150V3 Controller is also capable of reading the Data

Matrix Old Version. (See note.)

Note: Compatible with ECC000, 050, 080, 100, and 140.

Compatible with Data Matrix ECC200, with

Up to 64 × 64 Cells

To enable the use of more information, ECC200 codes with up to

64 × 64 cells (max. of 418 alphanumeric characters) can be

read.

26

64

26

Max. of 64

alphanumeric

characters.

64

Max. of 418

alphanumeric characters.

Finder pattern

Finder pattern

Data Matrix QR Code

Easy Image Analysis

The image analysis mode helps to detect the cause of marking

problems.

Store up to 24 Defect Images

Use the stored images to confirm defect types.

Stores up to

24 images

Note: Stored images are kept until the power is turned OFF.

C-76 Vision Sensors

Page 3

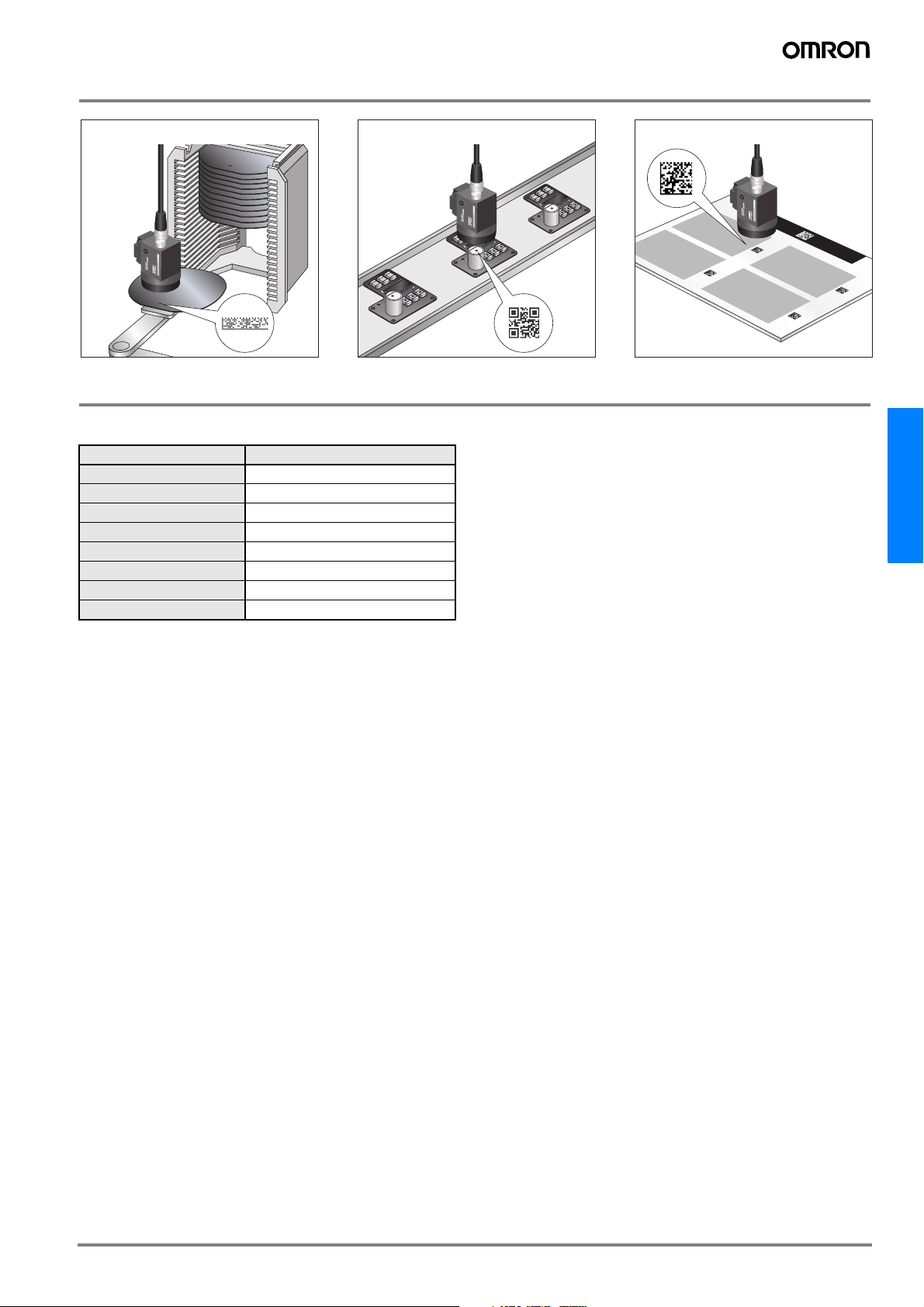

Applications

From batch processing level to

wafer level

Ordering Information

List of Models

Name Model No.

Controller

Console

Camera

Camera Cable (3 m)

Two-camera Unit

Monitor Cable (2 m)

Liquid Crystal Monitor

Video Monitor

V530-R150E-3, EP-3

F150-KP

F150-S1A

F150-VS

F150-A20

F150-VM

F150-M05L

F150-M09

From PCB level to component level

From sheet level to piece level

V530-R150E-3, EP-3

C-77V530-R150E-3, EP-3

Page 4

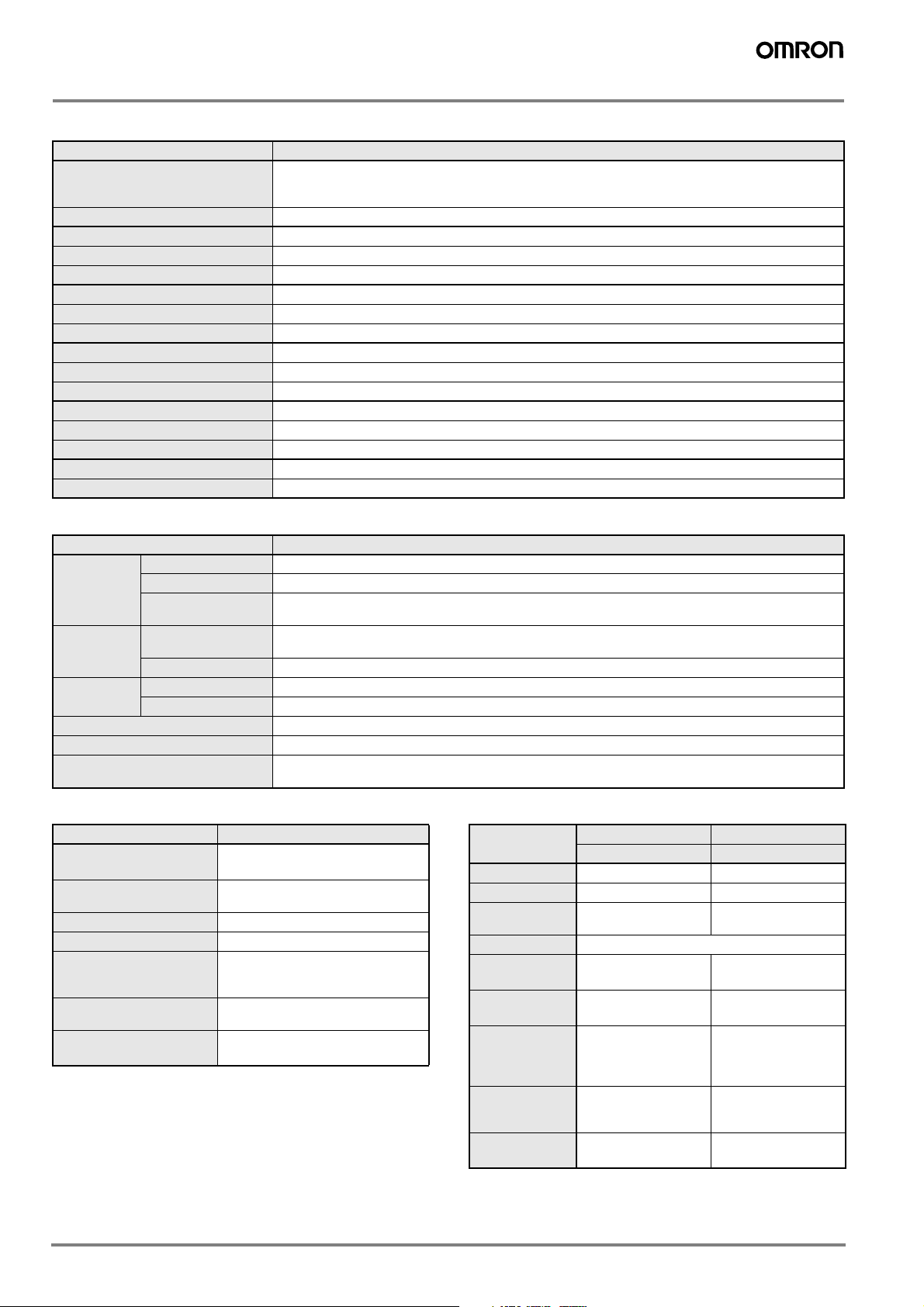

Specifications

Controller

Item V530-R150E-3, EP-3

Data Matrix ECC200: 10 × 10 to 64 × 64, 8 × 18, 8 × 32,12 × 26, 12 × 36,16 × 36,16 × 48

Readable codes

Readable direction

Number of pixels (resolution)

Number of connectable cameras

Number of scenes

Image memory function

Operation method

Processing method

Monitor interface

RS-232C I/F

Parallel I/O

Power supply voltage

Degree of protection

Current consumption

Ambient temperature/humidity

Weight

Camera

Data Matrix Old Ver. (ECC000, 050, 080, 100, 140): 9 × 9 to 25 × 25

QR Code (Model 1, 2): 21 × 21 to 41 × 41 (Version 1 to 6)

360°

512 (H) × 484 (V)

1 (Using F150-A20: 2 max.)

10

Maximum of 24 images stored.

Menu selectable

Gray

1 channel (over scan monitor)

1 channel

3 inputs and 9 outputs including control I/O points

20.4 to 26.4 VDC

IEC 60529: IP 20 (panel mounted)

Approx. 0.5 A

0 to 50°C/35% to 85% (with no condensation)

Approx. 390 g

Item F150-S1A

Picture element

Camera

Effective pixels

Shutter function

Lens

Mounting distance

Field of view

Light

Light source

Lighting method

Ambient temperature

Ambient humidity

Weight (camera only)

1/3” CCD

659 (H) × 494 (V)

Electronic frame shutter

Shutter speed: 1/100, 1/500, 1/2000, or 1/10000 sec (menu selectable)

F150-SLC20: 15 to 25 mmF150-SLC50: 16.5 to 26.5 mm

F150-SL20A: 61 to 71 mmF150-SL50A: 66 to 76 mm

F150-SLC20/SL20A: 20 × 20 mm, F150-SLC50/SL50A: 50 × 50 mm

F150-SLC20/50: Red LED/Green LED, F150-SL20A/50A: Red LED

Pulse (synchronized with camera shutter)

Operating: 0 to 50°C, storage: −25 to 60°C (with no icing or condensation)

Operating/Storage: 35% to 85% (with no condensation)

F150-ALC20: Approx. 280 g, F150-FLC50: Approx. 370 g,

F150-SL20A/50A: Approx. 135 g, F150-S1A: Approx. 80 g

Two-camera Unit Monitor

Item F150-A20

Number of connectable

2

cameras

Camera mode

Power supply voltage

Current consumption

Ambient temperature

Ambient humidity

Weight (2-camera unit

2-camera selectable

Single, independent (camera 0/1)

20.4 to 26.4 VDC

Approx. 0.3 A

Operating: 0 to 50°C

storage: −25 to 60°C

(with no icing or condensation)

Operating/Storage: 35% to 85%

(with no condensation)

Approx. 220 g

only)

Item

Size

Type

Resolution

Input signal

Power supply

voltage

Current con-

sumption

Ambient temperature

Ambient humidity

Weight (monitor

only)

Liquid Crystal Monitor Video Monitor

F150-M05L F150-M09

5.5 inches 9 inches

Liquid crystal color TFT CRT monochrome

320 × 240 dots 800 TV lines min. (at

NTSC composite video (1.0 V/75 Ω)

20.4 to 26.4 VDC 100 to 240 VAC

Approx. 700 mA Approx. 200 mA

Operating: 0 to 50°C

storage: −25 to 60°C

(with no icing or condensation)

Operating/Storage:

35% to 85%

(with no condensation)

Approx. 1 kg Approx. 4.5 kg

center)

(−15%, +10%)

Operating: −10 to 50°C

storage: −20 to 65°C

(with no icing or condensation)

10% to 90%

(with no condensation)

C-78 Vision Sensors

Page 5

System Configuration

Cameras

F150-SLC20 Camera with

Intelligent Light Source

(Field of vision: 20 mm)

F150-SLC50 Camera with

Intelligent Light Source

(Field of vision: 50 mm)

F150-SL20A Camera

with Light Source

(Field of vision: 20 mm)

F150-SL50A Camera

with Light Source

(Field of vision: 50 mm)

V530-R150E-3, EP-3

Controller

F150-VS Camera Cable

(3 m)

Camera Unit Cable (15 cm)

(Provided with the F150-A20)

Power

Supply

Synchronous Sensor

RS-232C

F150-VM Monitor

Cable (2 m)

F150-KP Console

(Cablelength: 2 m)

Programmable

Controller

Personal

Computer

V530-R150E-3, EP-3

F150-S1A Camera

Refer to page B-8 concerning the

use of this camera.

Note: If the field of vision doesnot

match the size of the targetobject

you can use an ordinary CCTV

lens and lighting.

F150-A20 Twocamera Unit

F150-VS Camera Cable

BNC Jack (Provided

with the F150-VM)

Monitors

F150-M05L Liquid

Crystal Monitor

(pin input)

F150-M09 Video

Monitor (BNC input)

Note: In addition to the F150-M05L and

F150-M09, NTSC monitors with external

video input terminals can be used.

C-79V530-R150E-3, EP-3

Page 6

Lighting Methods

Select the appropriate lighting method for the material of the marked object.

Back Lighting

Codes on transparent objects such as glass PCBs can be read

by detecting the contrast between transmitted and blocked light.

Applications: Transparent objects such as LCD glass

Oblique Lighting

Ring lighting close to the marked object

For codes inscribed with a laser maker onto PCBs and other relatively glossy surfaces, oblique lighting provides stable detection

by distinguishing between regular and diffuse reflected light.

Applications: Direct marking on PCBs and electronic parts

Camera

Marked object

(2-dimensional code)

Glass

Light source

Reflected Lighting

Ring Lighting

For codes printed onto paper or other light-diffusing objects, ring

lights can be used to illuminate the marked object. The difference in the reflection factors of the background and the marking

enables stable detection.

Applications: Paper labels and corrugated cardboard

Camera

Light source

Marked object

(2-dimensional code)

Paper

Camera

Light source

Marked object (2-dimensional code)

PCB

Coaxial Lighting

For codes marked directly onto wafers and other mirror-like surfaces, a stable image with few shadows from surface irregularities can be obtained from the marked object by using coaxial

lighting, because it detects only regular reflected light. (The surface of the object must be perpendicular to the optical axis.)

Applications: Mirror-like objects such as wafers

Camera

Light source

Marked object

(2-dimensional code)

Half mirror

Wafer

C-80 Vision Sensors

Page 7

Data Capacity

Data Matrix ECC200

The relation between matrix size (number of cells) and data

capacity is shown in the table below. In this example, the matrix

size is 12 × 12 cells.

QR Code Model 2

The relation between matrix size (number of cells) and data

capacity is shown in the table below. In this example, the matrix

size is 21 × 21 cells.

7 cells

12 cells

7 cells

7 cells

14 cells

Maximum data capacity

Alphanu-

meric

charac-

ters (up-

JIS8

per case

Matrix size

Num-

bers

12 cells

Maximum data capacity

Alphanu-

meric

charac-

Symbols

ters

Japa-

nese

Kanji

(Shift

JIS)

JIS8

Matrix size

(version)

Error

correc-

tion

7 cells

Num-

bers

only)

10 × 10

12 × 12

14 × 14

16 × 16

18 × 18

20 × 20

22 × 22

24 × 24

26 × 26

32 × 32

36 × 36

40 × 40

44 × 44

48 × 48

52 × 52

64 × 64

8 × 18

8 × 32

12 × 26

12 × 36

16 × 36

16 × 48

Note: 1. Maximum Data Capacity

The maximum amount of data that can be stored in a code varies with the code size. In other words, if there is a large amount of data to be stored, then the

code size must also be large. The maximum data capacity will also vary with the type of characters used. With a QR Code or Data Matrix, the numeric capacity (numbers only) is larger than the alpha numeric capacity (numbers and letters), which is in turn larger than the Japanese Kanji (Shift JIS) capacity.

The order and combinations of different characters also affects the data capacity.

2. The matrix size of a QR Code is indicated by the version. "Version 1" indicates that a QR Code contains (the minimum) 21 cells both horizontally and vertically.

The larger the version number, the larger the number of cells per side.

633---1

106513

16 10 9 3 6

24 16 14 5 10

36 25 22 8 16

44 31 28 10 20

60 43 38 14 28

72 52 46 17 34

88 64 57 21 42

12491813060

172 127 113 42 84

228 169 150 56 112

288 214 190 71 142

348 259 230 86 172

408 304 270 101 202

560 418 372 139 278

106513

20 13 12 4 8

32 22 20 7 14

44 31 28 10 20

64 46 41 15 30

98 72 64 23 47

21 × 21

(version 1)

25 × 25

(version 2)

29 × 29

(version 3)

33 × 33

(version 4)

37 × 37

(version 5)

41 × 41

(version 6)

L (7%) 41 25 17 10

M (15%)342014 8

Q (25%)271611 7

H (30%) 17 10 7 4

L (7%) 77 47 32 20

M (15%)63382616

Q (25%)48292012

H (30%)342014 8

L (7%) 127 77 53 32

M (15%) 101 61 42 26

Q (25%)77473220

H (30%)58352415

L (7%) 187 114 78 48

M (15%) 149 90 62 38

Q (25%) 111 67 46 28

H (30%)82503421

L (7%) 255 154 106 65

M (15%) 202 122 84 52

Q (25%) 144 87 60 37

H (30%) 106 64 44 27

L (7%) 322 195 134 82

M (15%) 255 154 106 65

Q (25%) 178 108 74 45

H (30%) 139 84 58 36

Japa-

nese

Kanji

(Shift

JIS)

V530-R150E-3, EP-3

C-81V530-R150E-3, EP-3

Page 8

Cameras with Light Source

Cameras with Intelligent Light Source

20-mm field of view

50-mm field of view

Note: These models consist of an F150-S1A Camera with Lens and Intelligent

Light Source.

Using the Camera with Intelligent Light Source or Camera

with Light Source

• The Lens has a fixed focus. Because there is a certain amount of

variation in the field of view and focus of each Lens, the mounting

distance must be adjusted each time the Lens or Camera is

replaced.

• The camera mounting distance is approximate. Use a mounting

method that allows the distance to be adjusted back and forth in

the direction of the 2-dimensional code.

F150-SLC20

F150-SLC50

Lenses

2-Dimensional Code Reader Distance vs. Field of

view

Mount the Camera at a distance that will provide accurate imaging of the 2-dimensional codes.

F150-SLC20 F150-SLC50

2-dimensional

code

Field of view (20 mm × 20 mm) Field of view (50 mm × 50 mm)

2-dimensional code

Camera distance:

15 to 25 mm

Camera distance:

16.5 to 26.5 mm

CCTV Lenses

CCTV Lenses

Model

3Z4S-LEB1214D-2 3Z4S-LEC1614A 3Z4S-LEB2514D 3Z4S-LEB5014A

42 dia.

30 dia.

30 dia.

48 dia.

Dimensions

37.3

48

Locking mecha-

50

33

Focus/iris locking mechanism

nism

Note: Refer to the following optical graph to select the Lens and Extension Tube according to the field of view and camera mounting distance being

used.

Extension Tubes

Model

Length

3Z4S-LE EX-C6

A set of six Extension Tubes that are 40, 20, 10,

5, 1, and 0.5 mm in length respectively.

C-82 Vision Sensors

Page 9

Optical Graph

15

355555

Point: Based on the necessary field of view and workpiece, select the Lens and Extension Tube to suit the working distance (WD).

Lengthening the Extension Tube lowers the brightness, and increasing distance WD increases the depth of field.

Note: Slight differences exist between cameras. When mounting the Lens, provide a means of adjusting the camera mounting distance. For example, to obtain a cam-

era mounting distance WD of about 30 mm with a field of view of 10 mm, mount a 5-mm Extension Tube to the 3Z4S-LEC1614A.

Optical Graph

50

0

450

400

350

300

250

200

Working distance (mm)

150

35 to 55

35

100

50

0

20

25

30

10

15

15

20

510

1

5

10

1

1

15

1

1

5

5

5

0203040

Field of view L (mm)

1

The values in the graph indicate the

Note:

3Z4S-LEB5014A

3Z4S-LEB2514D

3Z4S-LEC1614A

3Z4S-LEB1214D-2

3Z4S-LE@focal length

F-stop

length (in mm) of the Extension tubes.

Reading the Optical Graph

The X axis of the graph shows field of view L in millimeters, and

the Y axis shows the camera mounting distance A in millimeters.

The curves on the graph indicate different Lenses, and the “t”

values indicate the lengths of the Extension Tubes.

V530-R150E-3, EP-3

Working

distance WD

(mm)

Camera

Extension Tube

Lenses

Field of view L (mm)

C-83V530-R150E-3, EP-3

Page 10

Dimensions

Note: All units are in millimeters unless otherwise indicated.

2-Dimensional Code Reader

V530-R150E-3, V530-R150EP-3

Console

F150-KP

13

50

1.5

4.1

Four, 4.5 dia.

90

120

100

77.6

120

130

Camera

F150-SLC20

(Camera with F150-LTC20 Intelligent Light Source)

70

12 12

2.5

70

2.5

12 12

40

42.5

Mounting

dimensions

73 40

96.25

86.25

F150-SLC50

(Camera with F150-LTC50 Intelligent Light Source)

90

16

90

16

16

2.5

52.5

2.5

16

60

Mounting

dimensions

80 40

103.25

93.25

F150-S1A (Camera only)

14.5

15.5

25

40

37

11

Mounting

dimensions

48

8

(40)

1.5

30.5

16.75

31.25

2021.25

Two, M4 holes

with depth of 10

1/4-20UNC with

depth of 10

6.75

16.75

20

20

F150 connector

(85)

Two, M4 holes

with depth of 10

1/4-20UNC with

depth of 10

6.75

(85)

16.75

Two, M4 holes

with depth of 10

1/4-20UNC with

depth of 10

6.75

31

50

F150 light

connector

12 dia.

2000

Two-camera Unit

F150-A20

Mounting holes

100±0.2

Two,

56±0.2

M4

Liquid Crystal Monitor

F150-M05L

(100)

185

174

Panel cut diagram

Video Monitor

F150-M09

233

143

5

23

66

100

56

Allowable panel thickness for mounting:

1.6 to 4.8

(145)

132

143

(5.5)

F150-VM Monitor Cable

Tolerance: ±1 mm

42.2

Dimensions inside parentheses ( ) are reference values.

+0.5mm

175.5

0

222

190

50

87

5

50

3.3

Two, 4.5 dia.

(mounting holes)

(46 max)

Mounting bracket

(155)

50 min

+0.5mm

133.5

0

250

160

22

12.5

10

90 110

C-84 Vision Sensors

Page 11

V530-R150E-3, EP-3

C-85V530-R150E-3, EP-3

Page 12

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. Q12E-EN-01

In the interest of product improvement, specifications are subject to change without notice.

C-86 Vision Sensors

Loading...

Loading...