Page 1

USER´S MANUAL

SMARTSTEP Junior

Servomotors/Servo Drivers

MODELS R7M-Z

@@

(Servomotors)

R7D-ZP

@@

(Servo Drivers)

Cat. No. I553-E1-01

Page 2

Thank you for choosing this SMARTSTEP Junior product.

This manual provides information on installation, wiring, and switch setting for the SMARTSTEP Junior

Servomotors and Servo Drivers. For information about troubleshooting, refer to the SMARTSTEP Ju nior

User’s Manual (Cat. No. I553).

Intended Audiences

This manual is intended for the following personnel, who must also have knowledge of

electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems

• Personnel in charge of designing FA systems

• Personnel in charge of managing FA systems and facilities

NOTICE

This manual contains information necessary for the operation of the SMARTSTEP Junior

Servomotors and Servo Drivers. Please read this manual thoroughly and understand its

contents before attempting to operate the product. Please keep this manual handy for

future reference after reading it.

Be sure that this manual accompanies the product to its final user.

OMRON, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to the u se of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparatio n of this manual. Nevertheless, OM RON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Page 3

2

Page 4

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

3

Page 5

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

•

Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

4

Page 6

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

5

Page 7

General Warnings

To ensure safe and proper use of SMARTSTEP Junior Servomotors and Servo Drivers, read the general

warnings provided below along with the rest of this manual to gain sufficient knowledge of the devices, safety

information, and precautions before actual use.

This OPERATION MANUAL is to be delivered to the actual end users of the products.

Please keep this manual close at hand for future reference.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or

damage to property.

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury. Additionally, there may be severe property damage.

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury, or property damage.

6

Page 8

General Warnings

• This manual may include illustrations of the product with protective covers or shields removed in order

to describe the components of the product in detail. Make sure that these protective covers and shields

are on the product before use.

• Consult your OMRON representative when using the product after a long period of storage.

WARNING

Always connect the frame ground terminals of the Servo Driver and the Servomotor to a

class-3 ground (to 100 Ω or less). Not connecting to a class-3 ground may result in electric

shock.

Do not touch the inside of the Servo Driver. Doing so may result in electric shock.

Do not remove the front cover, terminal covers, cables, or optional items while the power is

being supplied. Doing so may result in electric shock.

Installation, operation, maintenance, or inspection must be performed by authorized

personnel. Not doing so may result in electric shock or injury.

Wiring or inspection must not be performed for at least five minutes after turning OFF the

power supply. Doing so may result in electric shock.

Do not damage, press, or put excessive stress or heavy objects on the cables.

Doing so may result in electric shock.

Do not touch the rotating parts of the Servomotor in operation. Doing so may result in injury.

Do not modify the product. Doing so may result in injury or damage to the product.

Provide a stopping mechanism on the machine to ensure safety. The holding brake is not

designed as a stopping mechanism for safety purposes.

Provide an external emergency stopping mechanism that can stop operation and shutting

off the power supply immediately. Not doing so may result in injury.

Do not come close to the machine immediately after resetting momentary power

interruption to avoid an unexpected restart. (Take appropriate measures to secure safety

against an unexpected restart.) Doing so may result in injury.

7

Page 9

General Warnings

CAUTION

Use the Servomotors and Servo Drivers in a specified combination. Using them incorrectly

may result in fire or damage to the products.

Do not store or install the product in the following places. Doing so may result in fire, electric

shock, or damage to the product

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in the

specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to shock or vibration.

• Locations subject to exposure to water, oil, or chemicals.

Do not touch the Servo Driver radiator, Servo Driver regeneration resistor, or Servomotor

while the power is being supplied or soon after the power is turned OFF.

Doing so may result in a skin burn due to the hot surface.

Storage and Transportation Precau tions

CAUTION

Do not hold the product by the cables or motor shaft while transporting it. Doing so may result

in injury or malfunction.

Do not place any load exceeding the figure indicated on the product. Doing so may result in

injury or malfunction.

8

Page 10

General Warnings

Installation and Wiring Precautions

CAUTION

Do not step on or place a heavy object on the product. Doing so may result in injury.

Do not cover the inlet or outlet ports and prevent any foreign objects from entering the product.

Doing so may result in fire.

Be sure to install the product in the correct direction. Not doing so may result in malfunction.

Provide the specified clearances between the Servo Driver and the control panel or with other

devices. Not doing so may result in fire or malfunction.

Do not apply any strong impact. Doing so may result in malfunction.

Be sure to wire correctly and securely. Not doing so may result in motor runaway, injury, or

malfunction.

Be sure that all the mounting screws, terminal screws, and cable connector screws are

tightened to the torque specified in the relevant manuals. Incorrect tightening torque may

result in malfunction.

Use crimp terminals for wiring. Do not connect bare stranded wires directly to terminals.

Connection of bare stranded wires may result in burning.

Always use the power supply voltage specified in the User’s Manual. An incorrect voltage may

result in malfunction or burning.

Take appropriate measures to ensure that the specified power with the rated voltage and

frequency is supplied. Be particularly careful in places where the power supply is unstable. An

incorrect power supply may result in malfunction.

Install external breakers and take other safety measures against short-circuiting in external

wiring. Insufficient safety measures against short-circuiting may result in burning.

Take appropriate and sufficient countermeasures when installing systems in the following

locations. Failure to do so may result in damage to the product.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

9

Page 11

General Warnings

Operation and Adjustment Precautions

CAUTION

Confirm that no adverse effects will occur in the system before performing the test operation.

Not doing so may result in equipment damage.

Check the newly set parameters and switches for proper execution before actually running

them. Not doing so may result in equipment damage.

Do not make any extreme adjustments or setting changes. Doing so may result in unstable

operation and injury.

Separate the Servomotor from the machine, check for proper operation, and then connect to

the machine. Not doing so may cause injury.

When an alarm occurs, remove the cause, reset the alarm after confirming safety, and then

resume operation. Not doing so may result in injury.

Do not use the built-in brake of the Servomotor for ordinary braking. Doing so may result in

malfunction.

Do not operate the Servomotor connected to a load that exceeds the applicable load moment

of inertia. Doing so may result in malfunction.

Maintenance and Inspection Precaution s

CAUTION

Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so may result

in malfunction, fire, or electric shock.

Resume operation only after transferring to the new Unit the contents of the data required

for operation. Not doing so may result in an unexpected operation.

10

Page 12

General Warnings

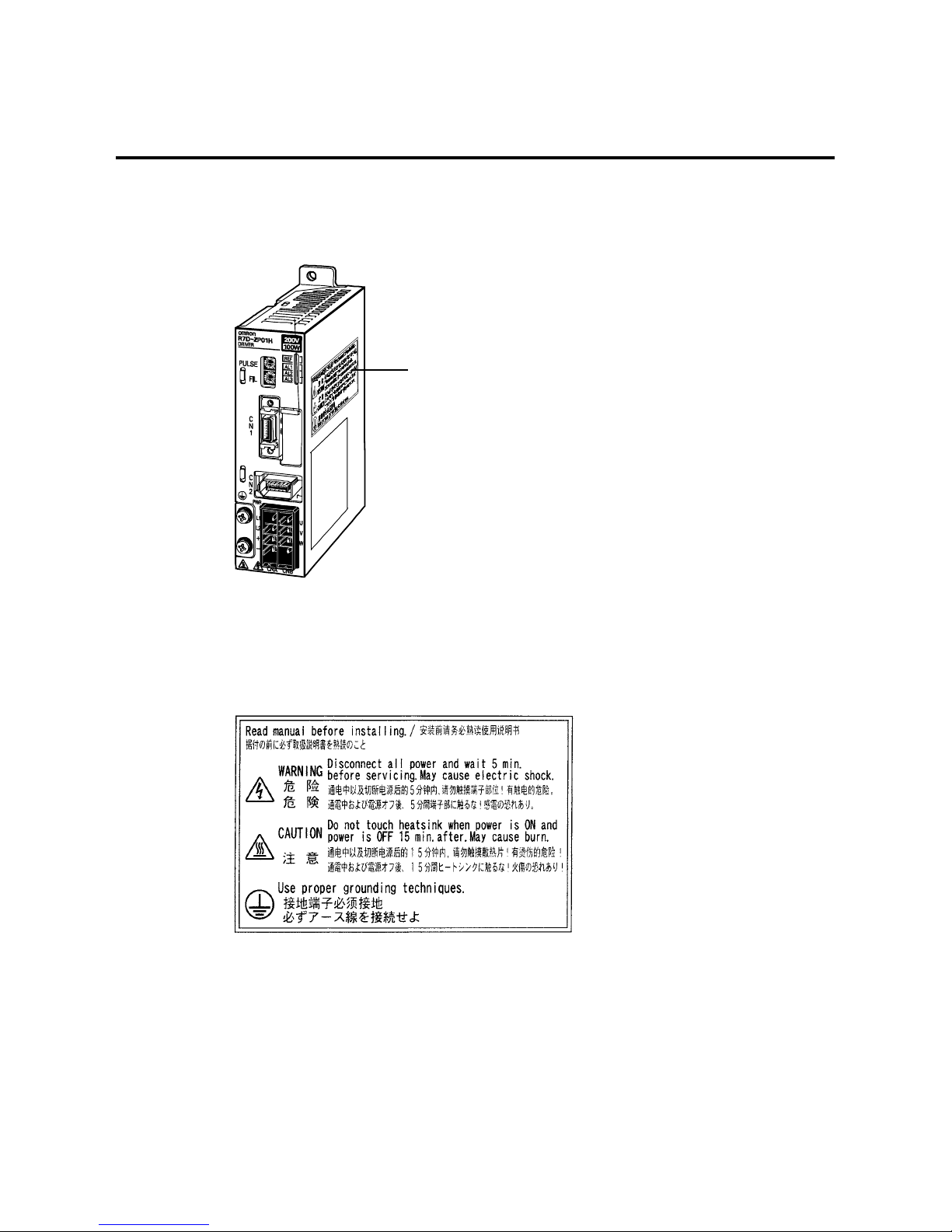

Warning Labels

Warning labels are pasted on the product as shown in the following illustration. Be sure to

follow the instructions given there.

Warning label

Example from R7D-ZP01H

Warning Label Contents

11

Page 13

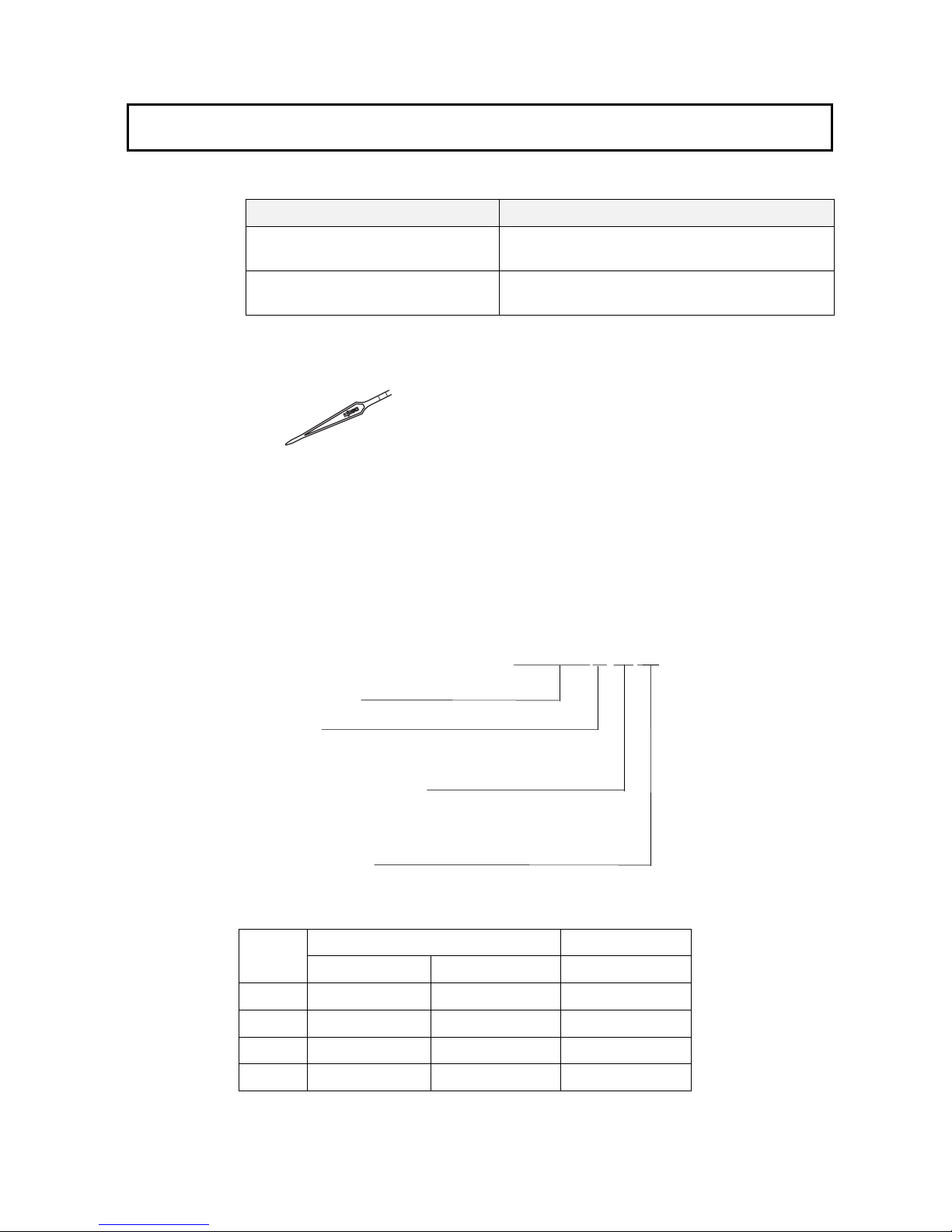

Items to Check When Unpacking

Check the following items after removing the product from the package.

Item Method

Has the correct product been delivered? Check the model number on the nameplate on the side of

the product.

Has the product been damaged in

shipping?

Inspect the outs ide of the product and caref ully check that

there has been no damage during shipping.

• Accessories

1. Special screw driver for setting the rotary switch × 1

2. Safety Precautions document × 1

No connectors or mounting screws are provided. Obtain these separately.

If something is missing, the Servo Driver is damaged, or some other fault exists, please

contact the point of purchase or your OMRON representative.

• Interpreting the Model Number

The model number provides information such as the Servo Driver type, the applicable

Servomotor capacity, and the power supply voltage.

R7D-ZP01H

SMARTSTEP Junior

Servo Driver

Driver Type

P: Pulse string input

Applicable Servomotor Capacity

01: 100 W

02: 200 W

04: 400 W

08: 750 W

Power Supply Voltage

H: 200 VAC

• Servo Driver and Servomotor Combinations

Servomotor Servo Driver

Rated

output

Without brake With brake Pulse string input

100 W R7M-Z10030-S1 R7M-Z10030-B S1 R7D-ZP01H

200 W R7M-Z20030-S1 R7M-Z20030-B S1 R7D-ZP02H

400 W R7M-Z40030-S1 R7M-Z40030-B S1 R7D-ZP04H

750 W R7M-Z75030-S1 R7M-Z75030-B S1 R7D-ZP08H

12

Page 14

13

Section 1 Features and System Configuration

Section 2 Standard Models and Dimensions

Section 3 Specifications

Section 4 System Design

Section 5 Operation

Section 6 Troubleshooting

Appendix

Page 15

Contents

Read and Understand this Manual.................................................................................3

Warranty and Limitations of Liability...............................................................................3

Application Considerations.............................................................................................4

Disclaimers....................................................................................................................5

General Warnings..........................................................................................................6

Items to Check When Unpacking.................................................................................12

Contents ..................................................................................................................... 14

Section 1 Features and System Configuration

1-1 Introduction....................................................................................................1-2

1-1-1 Introduction ................................................................................................................... 1-2

1-1-2 SMARTSTEP Junior Features......................................................................................1-2

1-2 System Configuration.....................................................................................1-3

1-3 Nomenclature and Functions.........................................................................1-4

1-3-1 Servo Driver Nomenclature and Functions................................................................... 1-4

1-4 System Block Diagrams.................................................................................1-6

1-4-1 Pulse-train Input Servo Driver....................................................................................... 1-6

1-5 Applicable Standards.....................................................................................1-7

1-5-1 EC Directives ................................................................................................................ 1-7

1-5-2 UL and cUL Standards ................................................................................................. 1-7

Section 2 Standard Models and Dimensions

2-1 Standard Models............................................................................................2-2

2-1-1 Servo Drivers................................................................................................................ 2-2

2-1-2 Servomotors.................................................................................................................. 2-2

2-1-3 Servo Driver-Servomotor Combinations....................................................................... 2-2

2-1-4 Decelerators (Straight Shaft with Key).......................................................................... 2-3

2-1-5 Accessories and Cables ............................................................................................... 2-4

2-2 External and Mounted Dimensions ................................................................2-5

2-2-1 Servo Drivers................................................................................................................ 2-5

2-2-2 Servomotors.................................................................................................................. 2-7

2-2-3 Decelerator Dimensions ............................................................................................... 2-9

Section 3 Specifications

3-1 Servo Driver Specifications............................................................................3-2

3-1-1 General Specifications.................................................................................................. 3-2

3-1-2 Characteristics .............................................................................................................. 3-3

3-1-3 Main Circuit and Servomotor Connector Specifications (CNA and CNB) .................... 3-3

14

Page 16

3-1-4 Control I/O Specifications (CN1)................................................................................... 3-5

3-1-5 Control Input Circuits .................................................................................................... 3-7

3-1-6 Control Input Details ..................................................................................................... 3-8

3-1-7 Control Output Circuits ...............................................................................................3-10

3-1-8 Control Output Details ................................................................................................ 3-10

3-1-9 Encoder Connector Specifications (CN2)................................................................... 3-11

3-2 Servomotor Specifications...........................................................................3-13

3-2-1 General Specifications................................................................................................ 3-13

3-2-2 Characteristics ............................................................................................................ 3-14

3-2-3 Encoder Specifications ............................................................................................... 3-16

3-3 Decelerator Specifications...........................................................................3-17

3-3-1 Standard Models and Specifications .......................................................................... 3-17

3-4 Cable and Connector Specifications............................................................3-18

3-4-1 Control Cable Specifications....................................................................................... 3-18

3-4-2 Servomotor Power Cable Specifications ....................................................................3-19

3-4-3 Encoder Cable Specifications..................................................................................... 3-21

3-4-4

Connector Specifications............................................................................................ 3-22

3-5 Regeneration Resistance Unit......................................................................3-24

3-5-1 Regeneration Resistance Unit (R88A-RG08UA) Specifications ................................ 3-24

3-6 AC Reactors................................................................................................3-26

3-6-1 AC Reactor Specifications.......................................................................................... 3-26

Section 4 System Design

4-1 Installation Conditions....................................................................................4-2

4-1-1 Servo Drivers................................................................................................................ 4-2

4-1-2 Servomotors.................................................................................................................. 4-3

4-1-3 Decelerators.................................................................................................................. 4-5

4-2 Wiring ............................................................................................................4-6

4-2-1 Connecting Cables........................................................................................................ 4-6

4-2-2 Selecting Connecting Cables........................................................................................ 4-7

4-2-3 Peripheral Device Connection Examples ..................................................................... 4-8

4-2-4 Wiring the Main Circuit and Servomotor Connections.................................................. 4-9

4-2-5 Conforming to EMC Directives ................................................................................... 4-11

4-3 Regenerative Energy Absorption .................................................................4-21

4-3-1 Calculating the Regenerative Energy......................................................................... 4-21

4-3-2 Servo Driver Regenerative Energy Absorption Capacity............................................ 4-23

4-3-3 Absorbing Regenerative En erg y with an Extern al Resistor........................................ 4-23

Section 5 Operation

5-1 Operational Procedure...................................................................................5-2

5-1-1 Operational Procedure.................................................................................................. 5-2

5-2 Switch Settings..............................................................................................5-3

5-2-1 Switch Names............................................................................................................... 5-3

15

Page 17

5-2-2 Switch Functions........................................................................................................... 5-3

5-3 Preparing for Operation..................................................................................5-5

5-3-1 Turning ON the Power and Checking Indicators ..........................................................5-5

5-4 Trial Operation...............................................................................................5-7

5-4-1 Preparing for Trial Operation ........................................................................................ 5-7

5-4-2 Trial Operation .............................................................................................................. 5-7

5-5 Operating Functions.......................................................................................5-9

5-5-1 Brake Interlock.............................................................................................................. 5-9

Section 6 Troubleshooting

6-1 Error Processing............................................................................................6-2

6-1-1 Preliminary Checks when a Problem Occurs............................................................... 6-2

6-1-2 Precautions When Troubleshooting.............................................................................. 6-3

6-1-3 Replacing the Servomotor and Servo Driver................................................................ 6-3

6-2 Alarm Table...................................................................................................6-4

6-2-1 Alarm Table...................................................................................................................6-4

6-3 Troubleshooting.............................................................................................6-5

6-3-1 Error Diagnosis using the Alarm Indicators .................................................................. 6-5

6-3-2 Error Diagnosis using the Operating Status ................................................................. 6- 8

6-4 Overload Characteristics (Electronic Thermal Function)...............................6-11

6-4-1 Overload Characteristics Graphs................................................................................ 6-11

6-5 Periodic Maintenance ..................................................................................6-12

6-5-1 Servomotor Maintenance............................................................................................ 6-12

6-5-2 Servo Driver Maintenance .......................................................................................... 6-13

6-5-3 Replacing the Cooling Fan ......................................................................................... 6-13

Appendix

A-1 Connection Examples....................................................................................A-2

Revision History ......................................................................................................... R-1

16

Page 18

Section 1

Configuration

Features and System

Page 19

1-1 Introduction

1-1-1 Introduction

1-1 Introduction

1-1-1 Introduction

The SMARTSTEP Junior is a Servo Driver with a pulse-string input for position control.

The SMARTSTEP Junior is easy to set up and start because it does not require the

complex parameter settings and Servo adjustments normally associated with Servos.

The SMARTSTEP Junior Servomotor and Servo Driver are easy-to-use, yet provide the

responsiveness, high-speed, high-torque, and precision of traditional Servo systems.

This manual describes the SMARTSTEP Junior as a pulse-string input Servo Driver for

position control.

1-1-2 SMARTSTEP Junior Features

The SMARTSTEP Junior has the following features.

No Setup Parameters

No parameter settings are required for setup, so you can start using the Servo Driver

immediately simply by removing it from the box and wiring it. If it is necessary to set the

positioning resolution or reference pulse method, these settings can be set or changed

easily with the rotary switches on the front of the Servo Driver.

No Servo Adjustments Required

With the newest auto-tuning function, it isn’t necessary to adjust the Servo Driver to

achieve excellent responsiveness. Auto-tuning achieves excellent responsiveness while

providing compatibility with a range of stepping motors. A Servomotor with moderate

inertia is used to improve control system stability.

1-2

Page 20

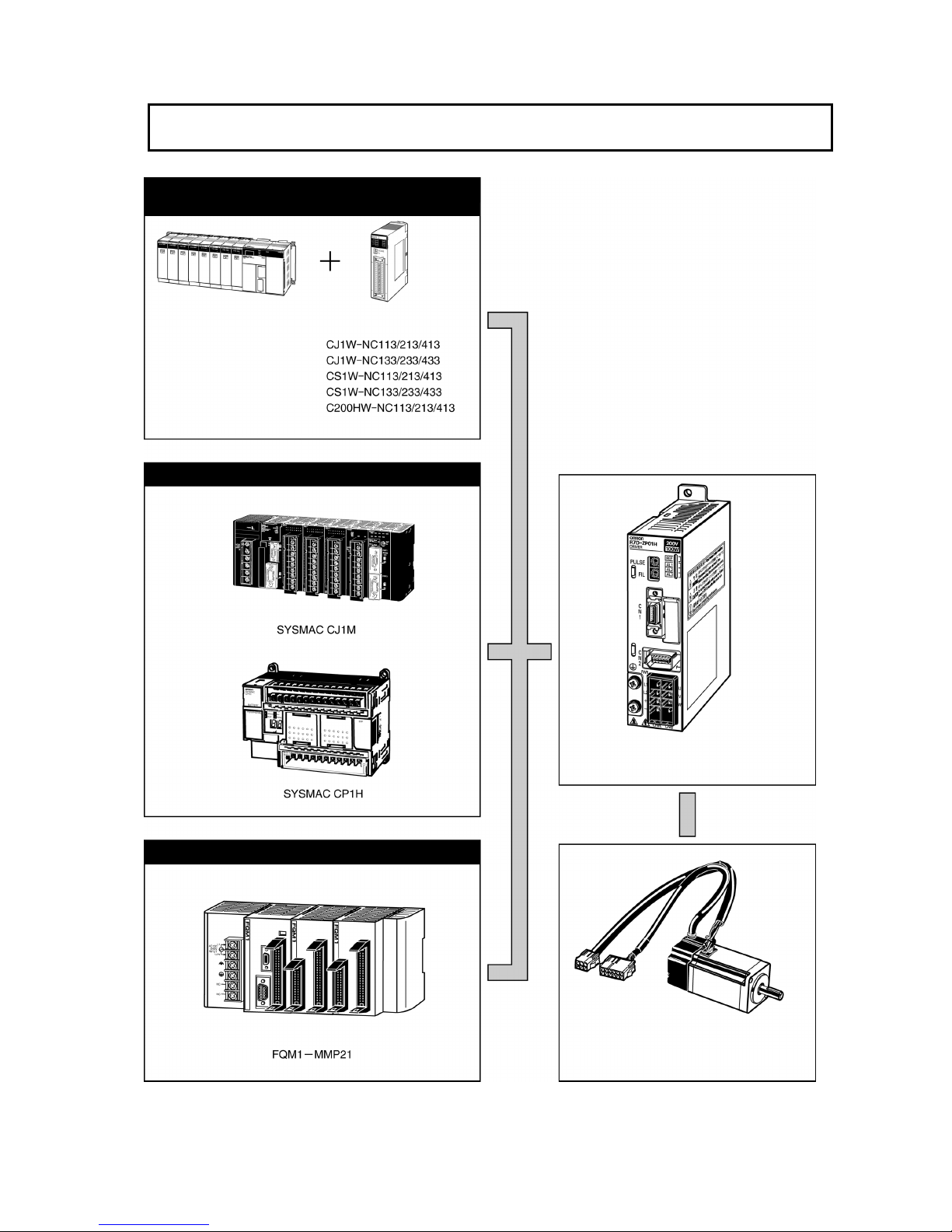

1-2 System Configuration

1-2 System Configuration

SYSMAC PLC + Position Control Unit

with pulse-string output

SYSMAC PLC with pulse output functions

Flexible Motion Controller with pulse I/O

SYSMAC

CJ1/CS1/C-series

Programmable Controlle r

SMARTSTEP Junior Servo Driver

R7D-ZP@

SMARTSTEP Junior Servomotor

R7M-Z@

Pulse string

Position Control Unit

1-3

Page 21

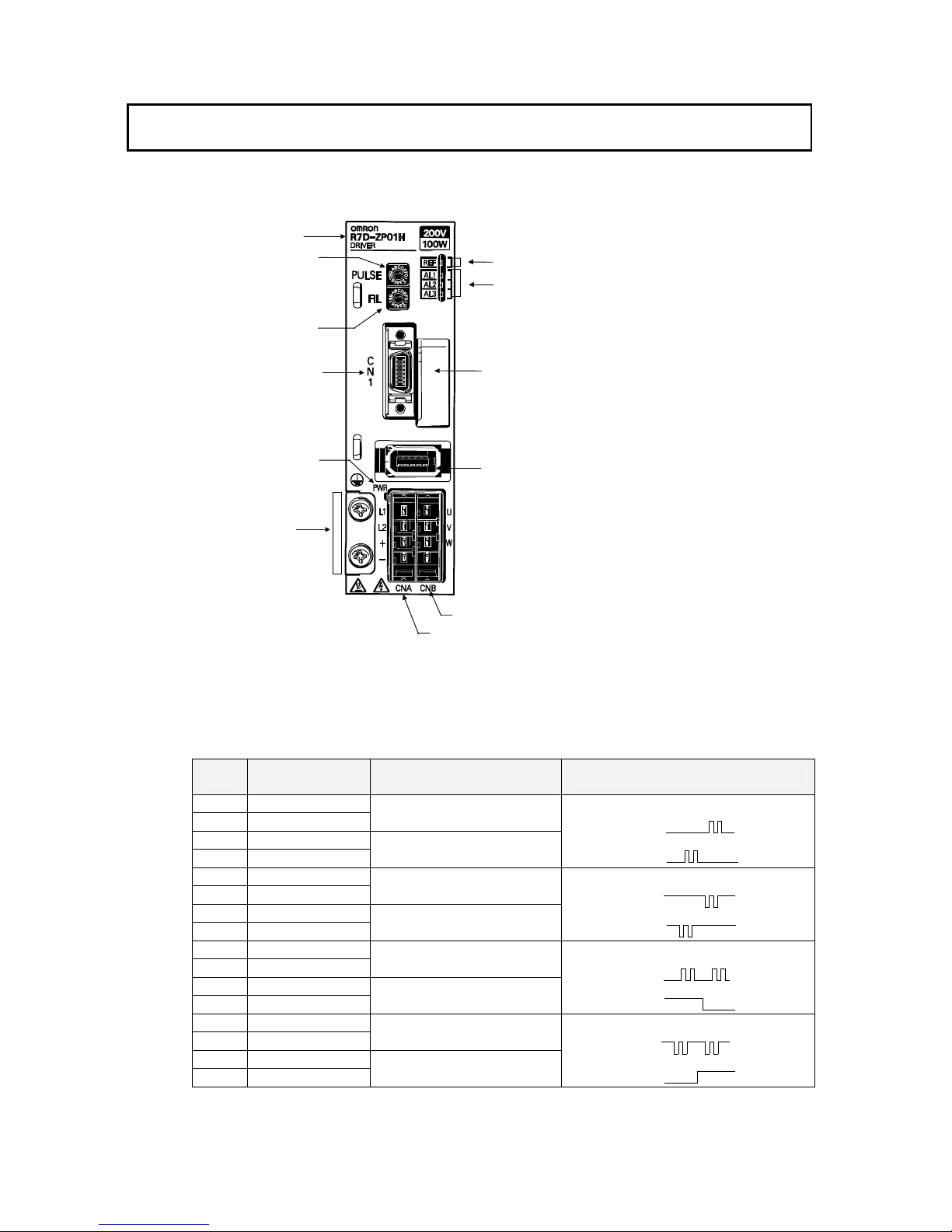

1-3 Nomenclature and Functions

1-3-1 Servo Driver Nomenclature and Functions

1-3 Nomenclature and Functions

1-3-1 Servo Driver Nomenclature and Functions

Model

Rotary switch for setting

command pulse (PULSE) Command indicators (REF)

Alarm indicators (AL1 to AL3)

Note: Do not remove the protective cov ers for

these connectors.

These connectors are for manufacturer

adjustments.

Do not use these connectors.

The Servo Driver may malfunction if

these connectors are used.

Encoder input connector (CN2)

Moto

r

connector (CNB)

Main circuit connector (CNA)

FG terminals fo

r

power supply and

servomotor power

Power supply indicato

r

(PWR)

Rotary switch for setting

command filter (FIL)

Control I/O

connector (CN1)

Rotary Switch for Setting Command Pulse (PULSE)

Always turn OFF the power supply before setting the rotary switch. (The switch is

factory-set to 0.)

Setting

Command pulse

resolution

Command pulse connection

method

Command pulse type

0 1000

1 2500

Open collector or line driver

2 5000

3 10000

Line driver

CW+CCW, positive logic

CW

CCW

4 1000

5 2500

Open collector or line driver

6 5000

7 10000

Line driver

CW+CCW, negative logic

CW

CCW

8 1000

9 2500

Open collector or line driver

A 5000

B 10000

Line driver

Sign + pulse string, positive

logic

PULS

SIGN

C 1000

D 2500

Open collector or line driver

E 5000

F 10000

Line driver

Sign + pulse string, negative

logic

PULS

SIGN

1-4

Page 22

1-3 Nomenclature and Functions

1-3-1 Servo Driver Nomenclature and Functions

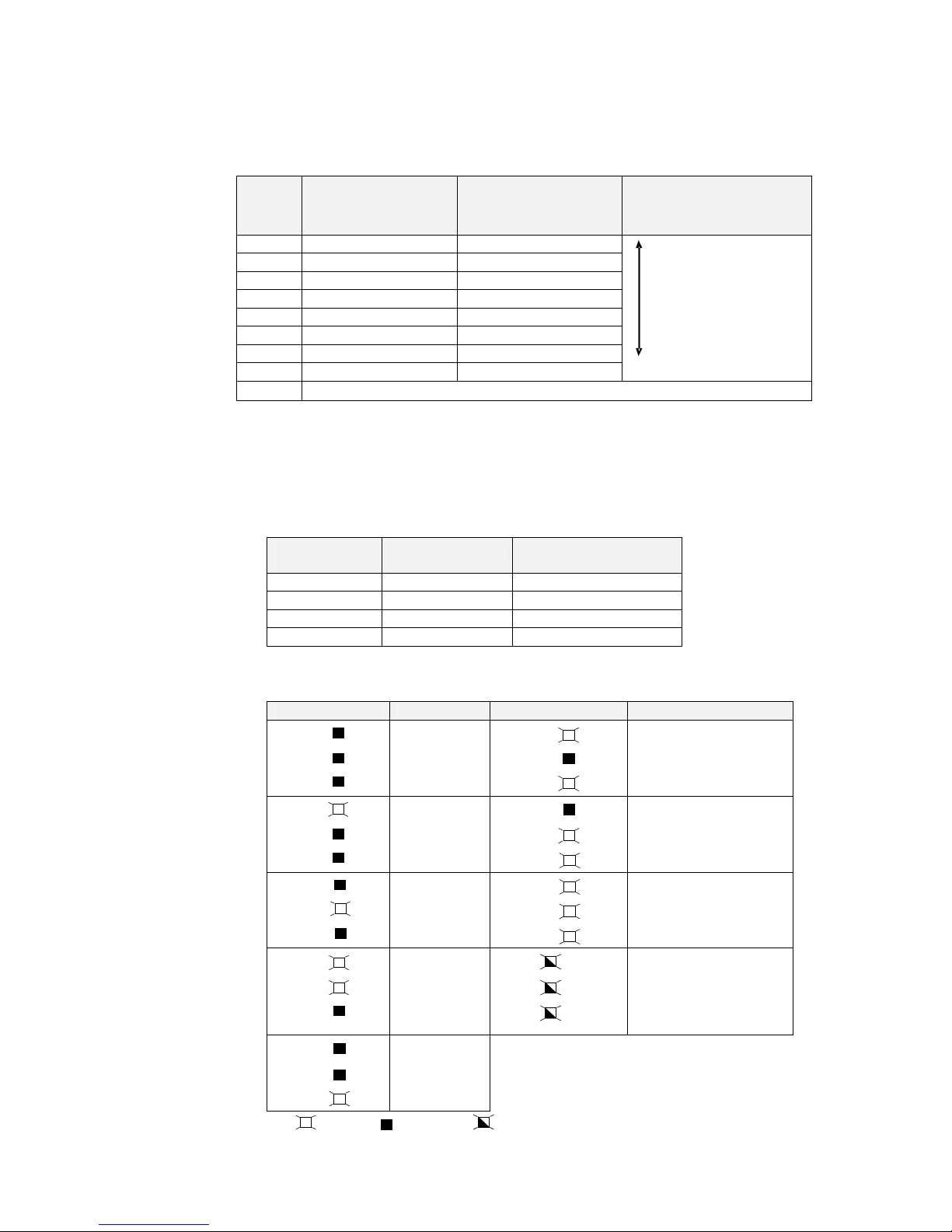

Rotary Switch for Setting Command Filter (FIL)

This switch does not need to be set if the machine is not subject to vibration. (The switch

is factory-set to 0.)

Filter

setting

(See

note 1.)

Acceleration/deceleration

time for STEP command

(See note 3.)

Approx. time from end of

command to end of

positioning (settling time)

(See note 2.)

Description

0 45 ms 100 to 200 ms

1 50 ms 110 to 220 ms

2 60 ms 130 to 260 ms

3 65 ms 150 to 300 ms

4 70 ms 170 to 340 ms

5 80 ms 200 to 400 ms

6 85 ms 250 to 500 ms

7 170 ms 500 to 1,000 ms

Smaller filter time

constant

(short positioning time)

Larger filter time constant

(longer positioning time

with little vibration)

8 to F

Do not set this switch to 8 to F.

Note 1. Increase the value of the filter setting if there is vibration when starting or stopping.

2. The settling time depends on the commanded acceleration/deceleration, the rigidity

of the machine motor drive, the encoder resolution, and other factors.

3. Use the acceleration/deceleration times as a guideline for determining the

Servomotor capacity that can be driven when using STEP commands without

commanded acceleration/deceleration.

Command Indicators (REF)

Indicator

(See note.)

Power to motor Command pulse

Lit orange. OFF None

Flashing orange. OFF Pulse being input.

Lit green. ON None

Flashing green. ON Pulse being input.

Note: The indicator stays lit (yellow) for 1 s when there is a deviation counter reset input.

Alarm Indicators (AL1/AL2/AL3)

Indicator status Alarm Indicator Alarm

AL1

AL2

AL3

Normal

AL1

AL2

AL3

Overcurrent

AL1

AL2

AL3

Overspeed

AL1

AL2

AL3

Servo Driver built- in fan is

stopped

AL1

AL2

AL3

Overload

AL1

AL2

AL3

System error

AL1

AL2

AL3

Encoder error

AL1

AL2

AL3

Flashing at a constant interval.

Rotary switch for setting

command pulse (PULSE)

has been changed.

AL1

AL2

AL3

Voltage error

Lit: Not lit: Flashing:

1-5

Page 23

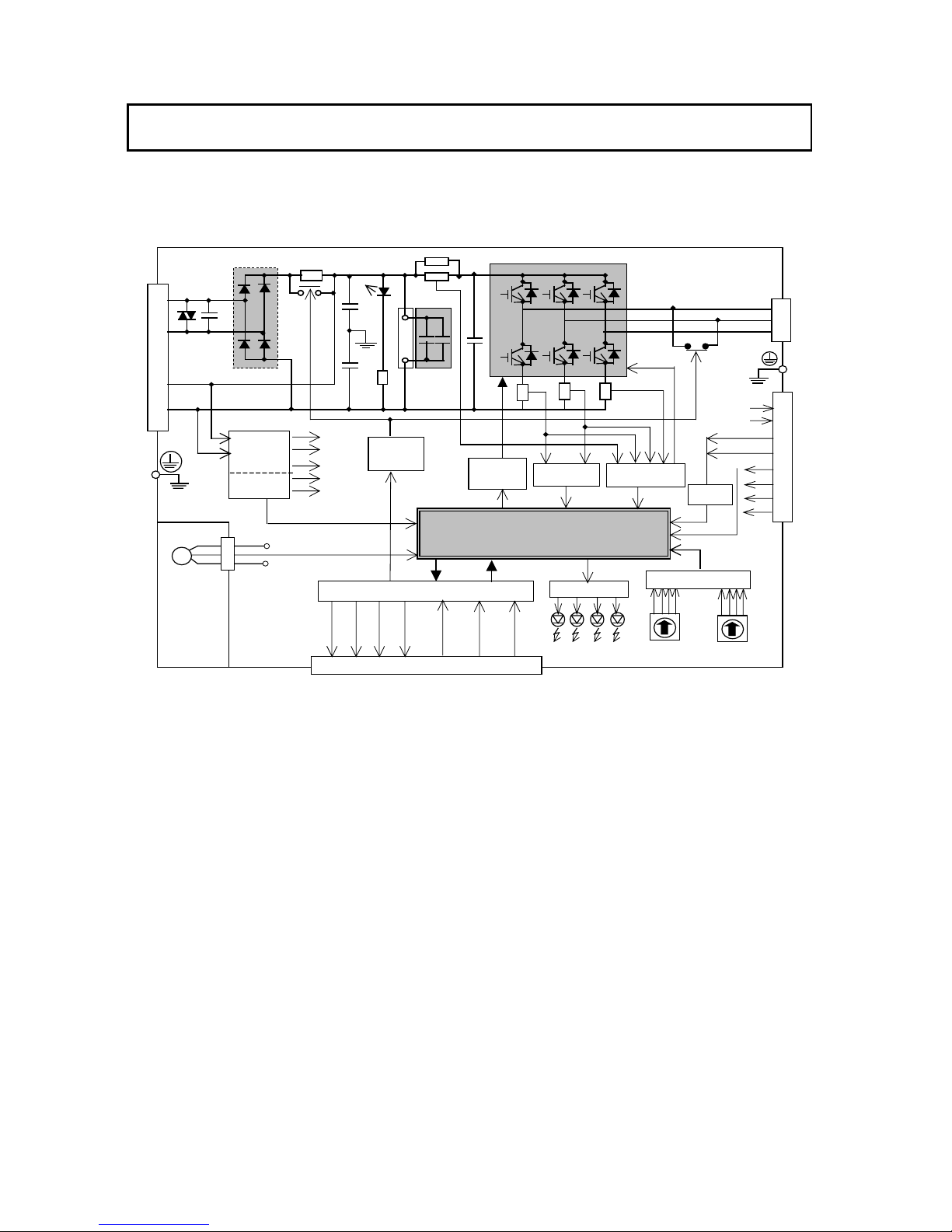

1-4 System Block Diagrams

1-4-1 Pulse-string Input Servo Driver

1-4 System Block Diagrams

1-4-1 Pulse-string Input Servo Driver

15V2

VCC2

+VCC

-VCC

G

Main circuit voltage

detection

Relay

drive

Current

detection

Overcurrent

protection

Gate

drive

MPU & ASIC

Position, speed, and torque processor

ADC

FAN

‡

G

-VCC

Fan alarm

+VCC

G

+A,-A

+B

,

-B

Phase U

Phase V

Phase W

Phase Z

Set value read circuit

Command

format setting

Command filter

setting

I/O and drive circuits

Display circuit

CW input

Alarm

output

INP output

Brake out

p

ut

Origin

output

Run input

CCW input

L1

L2

N

P

U

V

W

GR

GR

Control I/O connector

Encoder si

g

nal input connector

Control power

supply

Main circuit

control

SW power

supply

1-6

Page 24

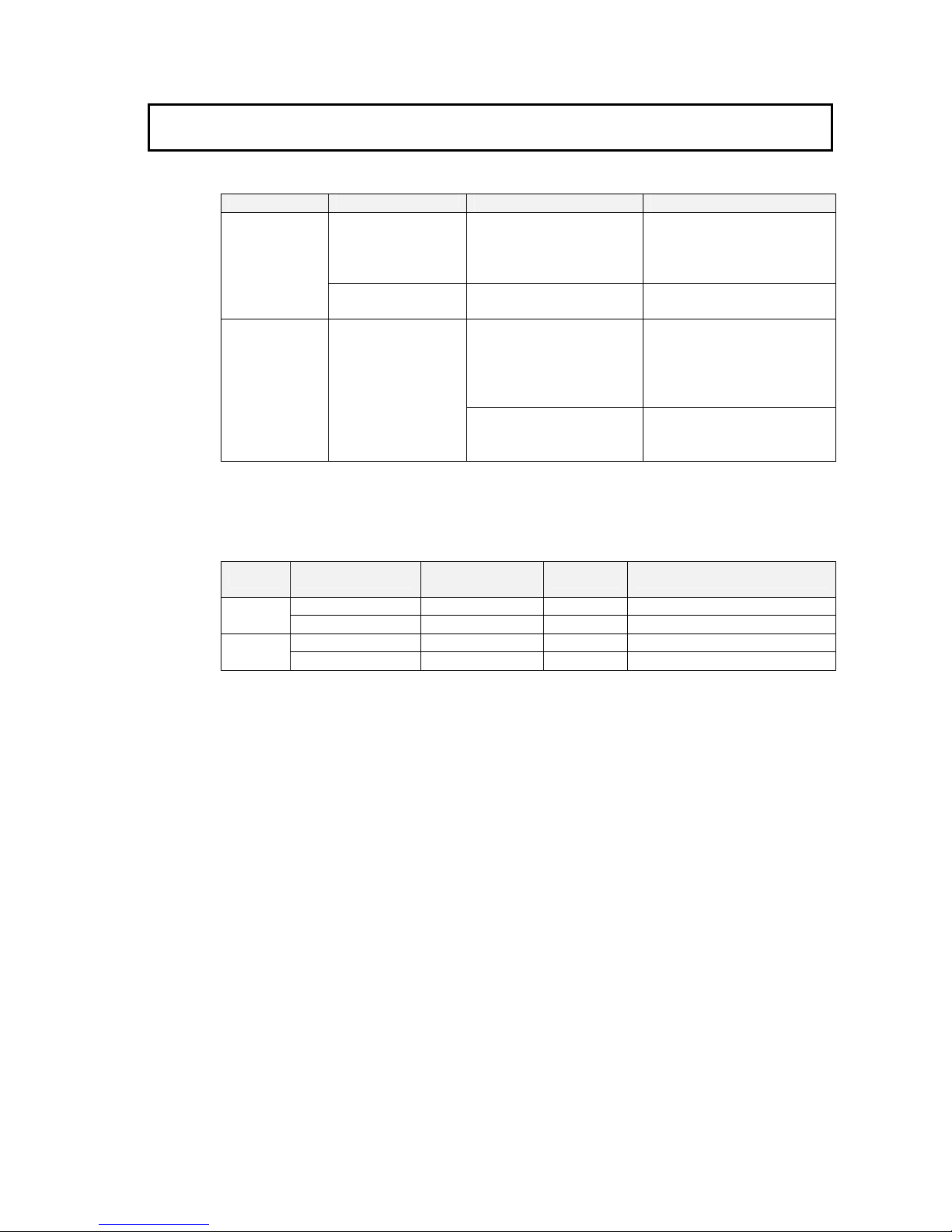

1-5 Applicable Standards

1-5-1 EC Directives

1-5 Applicable Standards

1-5-1 EC Directives

EC Directive Product Applicable standards Comments

AC Servo Drivers EN 50178

Safety requirements f or

electronic equipment for

measurement, control, or

laboratory use

Low Voltage

Directive

AC Servomotors

IEC 60034-1, -5, -8, and -9

EN 60034-1 and -9

Rotating electric machines

EN 550011 Class A Group1

Limits and methods of

measurement of radio

disturbance of industrial,

scientific, and medical

radio-frequency equipment

EMC Directive

AC Servo Drivers and

AC Servomotors

EN 61000-6-2

Electromagnetic compatibility

(EMC): Immunity standard for

industrial envir onments

Note: To conform to EMC Directives, the Units must be installed under the conditions described

in 4-2-5 Conforming to EMC Directives.

1-5-2 UL and cUL Standards

Standard Product

Applicable

standards

File number Comments

AC Servo Drivers UL 508C E179149 Power Conversion Equipment

UL

AC Servomotors UL 1004 E179189 Electric Motors

AC Servo Drivers cUL C22.2 No.14 E179149 Industrial Control Equipment

cUL

AC Servomotors cUL C22.2 No.100 E179189 Motors and Generati on Equipment

1-7

Page 25

1-5 Applicable Standards

1-5-2 UL and cUL Standards

1-8

Page 26

Section 2

Dimensions

Standard Models and

Page 27

2-1 Standard Models

2-1-1 Servo Drivers

2-1 Standard Models

2-1-1 Servo Drivers

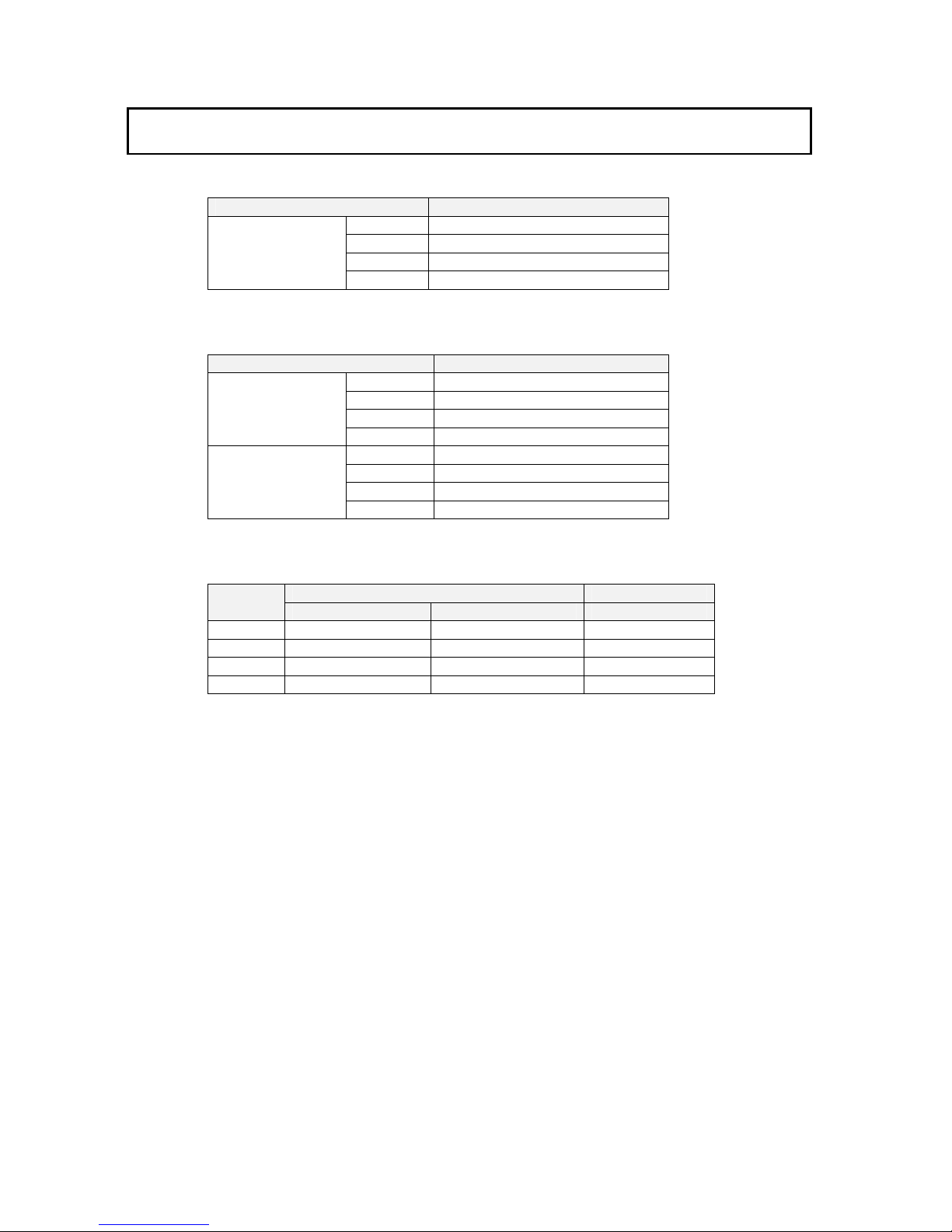

Specifications Model

100 W R7D-ZP01H

200 W R7D-ZP02H

400 W R7D-ZP04H

Pulse string input

750 W R7D-ZP08H

2-1-2 Servomotors

Specifications Model

100 W R7M-Z10030-S1

200 W R7M-Z20030-S1

400 W R7M-Z40030-S1

Without brake

750 W R7M-Z75030-S1

100 W R7M-Z10030-BS1

200 W R7M-Z20030-BS1

400 W R7M-Z40030-BS1

With brake

750 W R7M-Z75030-BS1

2-1-3 Servo Driver-Servomotor Combinations

Servomotor Servo Driver Rated

output

Without brake With brake Pulse string input

100 W

R7M-Z10030-S1 R7M-Z10030-BS1 R7D-ZP01H

200 W

R7M-Z20030-S1 R7M-Z20030-BS1 R7D-ZP02H

400 W

R7M-Z40030-S1 R7M-Z40030-BS1 R7D-ZP04H

750 W

R7M-Z75030-S1 R7M-Z75030-BS1 R7D-ZP08H

Note: Only the Servomotor and Servo Driver combinations listed here can be used. Do not use

other combinations.

2-2

Page 28

2-1 Standard Models

2-1-4 Decelerators (Straight Shaft with Key)

2-1-4 Decelerators (Straight Shaft with Key)

Backlash: 3 Arcminutes Max.

Specifications

Motor capacity Gear ratio

Model

1/5 R7G-VRSFPB05B100

1/9 R7G-VRSFPB09B100

1/15 R7G-VRSFPB15B100

100 W

1/25 R7G-VRSFPB25C100

1/5 R7G-VRSFPB05B200

1/9 R7G-VRSFPB09C400

1/15 R7G-VRSFPB15C400

200 W

1/25 R7G-VRSFPB25C200

1/5 R7G-VRSFPB05C400

1/9 R7G-VRSFPB09C400

1/15 R7G-VRSFPB15C400

400 W

1/25 R7G-VRSFPB25D400

1/5 R7G-VRSFPB05C750

1/9 R7G-VRSFPB09D750

1/15 R7G-VRSFPB15D750

750 W

1/25 R7G-VRSFPB25E750

Backlash: 45 Arcminutes Max.

Specifications

Motor capacity Gear ratio

Model

1/5 R7G-RGSF05B100

1/9 R7G-RGSF09B100

100 W

1/15 R7G-RGSF15B100

1/5 R7G-RGSF05B200

1/9 R7G-RGSF09C400

200 W

1/15 R7G-RGSF15C400

1/5 R7G-RGSF05C400

1/9 R7G-RGSF09C400

400 W

1/15 R7G-RGSF15C400

2-3

Page 29

2-1 Standard Models

2-1-5 Accessories and Cables

2-1-5 Accessories and Cables

Control Cables (for CN1 )

Specifications Model

1 m R7A-CPZ001S General-purpose Control Cables

2 m R7A-CPZ002S

Servomotor Pow er Cables (for CNB)

Specifications Model

3 m R7A-CAZ003S

5 m R7A-CAZ005S

Power Cables for Servomotors without B rakes

(connector attached)

10 m R7A-CAZ010S

Cable Only (in 1-m increments) R7A-CAZ001

3 m R7A-CAZ003B

5 m R7A-CAZ005B

Power Cables for Servomotors with Brakes

(connector attached)

10 m R7A-CAZ010B

Cable Only (in 1-m increments) R7A-CAZ01B

Encoder Cables (for CN2)

Specifications Model

3 m R7A-CRZ003C

5 m R7A-CRZ005C

Encoder Cables (connector att ached)

10 m R7A-CRZ010C

Cable Only (in 1-m increments) R7A-CRZ001

Connectors

Specifications Model

Main Circuit Connector (CNA) with Ejector Levers R7A-CNZ01P

Servomotor Connector (CNB) R7A-CNZ01A

Control Input Connector (CN1) R7A-CNA01R

Encoder Input Connector (CN2) R7A-CNZ01R

Servomotor Connector for Encoder Cable R7A-CNZ02R

Servomotor Connector for Servomotor Power Cable R7A-CNZ02A

Regeneration Resistance Unit

Specifications Model

Regeneration current: 8 A

Internal resistance: 50 Ω, 12 W

R88A-RG08UA

External Regeneration Resistor

Specifications Model

Regeneration capacity: 70 W, 47 Ω R88A-RR22047S

AC Reactors

Specifications Model

R7D-ZP01H R88A-PX5052

R7D-ZP02H R88A-PX5053

R7D-ZP04H R88A-PX5054

R7D-ZP08H R88A-PX5056

2-4

Page 30

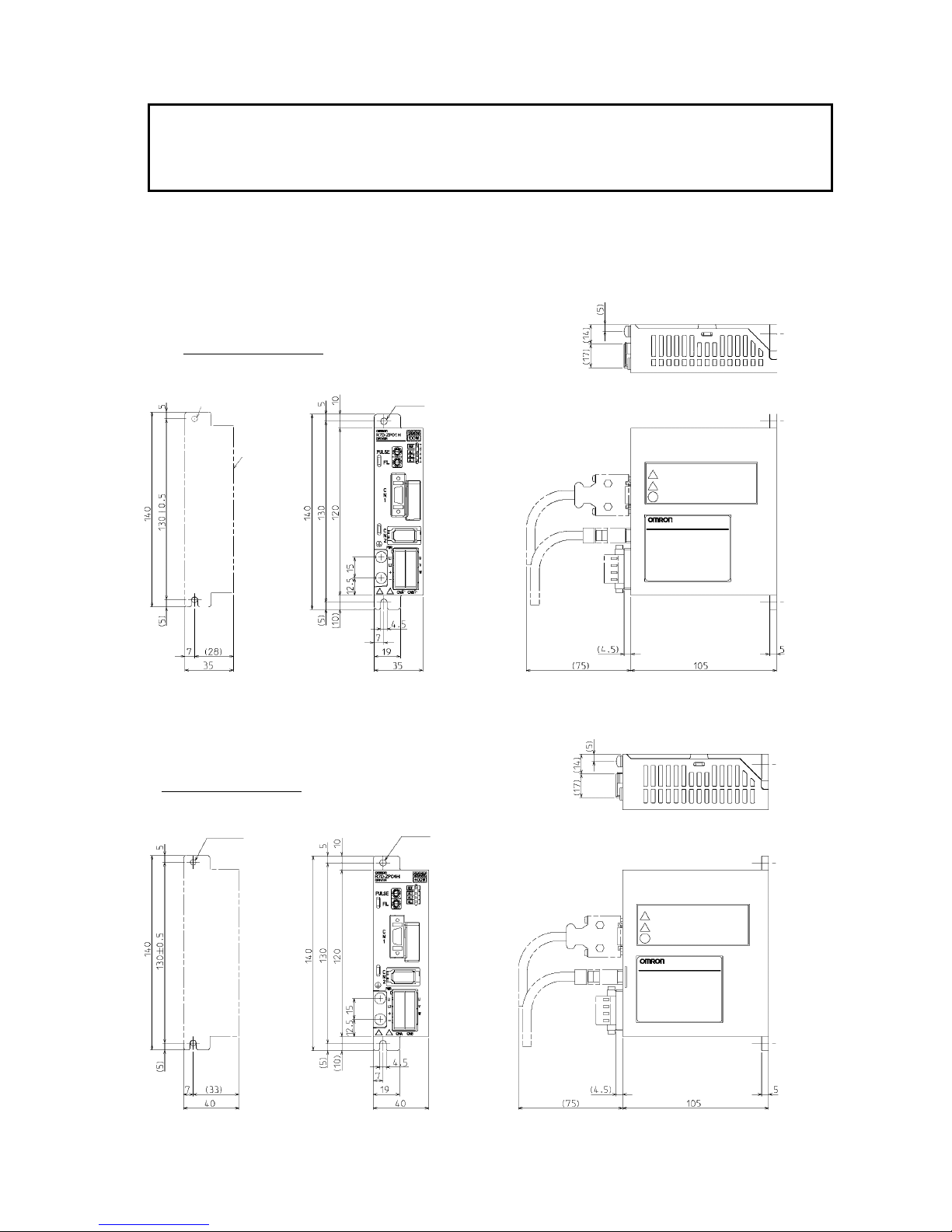

2-2 External and Mounted Dimensions

2-2-1 Servo Drivers

2-2 External and Mounted

Dimensions

2-2-1 Servo Drivers

R7D-ZP01H/-ZP02H (100 W/200 W)

Footprint

4.5-dia. hole

Two, M4 screw holes

Mountin

g

pitch

Mounting Hole Dimensions

R7D-ZP04H (400 W)

4.5-dia. hole

Two, M4 screw holes

Mountin

g

pitch

Mounting Hole Dimensions

2-5

Page 31

2-2 External and Mounted Dimensions

2-2-1 Servo Drivers

R7D-ZP08H (750 W)

Exterior

4.5-dia. hole

Two, M4 screw holes

Mounting pitch

Mounting Hole Dimensi ons

2-6

Page 32

2-2 External and Mounted Dimensions

2-2-2 Servomotors

2-2-2 Servomotors

100-W Servomotor without a Brake

R7M-Z10030-S1

Key groove Key

8 dia., hei

g

ht: 6

46 dia.

Two, 4.3 dia.

30 dia., hei

g

ht: 8

100-W Servomotor with Brake

R7M-Z10030-BS1

Key groove

Key

8 dia., hei

g

ht: 6

30 dia., hei

g

ht: 8

46 dia.

Two, 4.3 dia.

2-7

Page 33

2-2 External and Mounted Dimensions

2-2-2 Servomotors

200-W/400-W/750-W Servomotors without Brakes

R7M-Z20030-S1/Z40030-S1/Z75030-S1

Output Section on 750-W

Servomotor

Key

Key groove

S dia.

D2 dia.

D1 dia.

Model

L

(mm)

LL

(mm)

LM

(mm)

LR

(mm)C (mm)

D1

(mm)

D2

(mm)G (mm)

Z

(mm) S (mm)

QK

(mm)

Output

(w)

R7M-Z20030-S1 125.5 95.5 70 30 60 70 50h8 6

Four,

5.5 dia.

14h6 20 200

R7M-Z40030-S1 148.5 118.5 93 30 60 70 50h8 6

Four,

5.5 dia

14h6 20 400

R7M-Z75030-S1 173 133 107.5 40 80 90 70h8 8

Four,

7 dia

16h6 30 750

200-W/400-W/750-W Servomotors with Brakes

R7M-Z20030-BS1/Z40030-BS1/Z75030-BS1

Output Section on 750-W

Servomotor

Key

Key groove

S dia.

D2 dia.

D1 dia.

Model

L

(mm)

LL

(mm)

LM

(mm)

LR

(mm)C (mm)

D1

(mm)

D2

(mm)G (mm)

Z

(mm) S (mm)

QK

(mm)

Output

(w)

R7M-Z20030-BS1 165.5 135.5 70 30 60 70 50h8 6

Four,

5.5 dia.

14h6 20 200

R7M-Z40030-BS1 188.5 158.5 93 30 60 70 50h8 6

Four,

5.5 dia

14h6 20 400

R7M-Z75030-BS1 216 176 107.5 40 80 90 70h8 8

Four,

7 dia

16h6 30 750

2-8

Page 34

2-2 External and Mounted Dimensions

2-2-3 Decelerator Dimensions

2-2-3 Decelerator Dimensions

Backlash: 3 Arcminutes Max.

Dimensions (mm)

Key dimensions

Model

LM LR C1 C2 D1 D2 D3 D4 E3 F G S T Z1 Z2

A

T(See

note.)

l

QK b h t1

Weight

(kg)

1/5 R7G-VRSFPB05B100 67.5 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.55

1/9 R7G-VRSFPB09B100 67.5 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.55

1/15 R7G-VRSFPB15B100 78 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.7

100

W

1/25 R7G-VRSFPB25C100 92 50 78 40 46 90 70 62 17 3 6 19 30 M4 M6 M3 20 22 6 6 3.5 1.7

1/5 R7G-VRSFPB05B200 72.5 32 52 60 70 60 50 45 10 3 10 12 20 M5 M5 M4 12 16 4 4 2.5 0.72

1/9 R7G-VRSFPB09C400 89.5 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 1.7

1/15 R7G-VRSFPB15C400 100 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 2.1

200

W

1/25 R7G-VRSFPB25C200 100 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 2.1

1/5 R7G-VRSFPB05C400 89.5 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 1.7

1/9 R7G-VRSFPB09C400 89.5 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 1.7

1/15 R7G-VRSFPB15C400 100 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 2.1

400

W

1/25 R7G-VRSFPB25D400 104 61 98 60 70 115 90 75 18 5 8 24 40 M5 M8 M4 20 30 8 7 4 3.2

1/5 R7G-VRSFPB05C750 93.5 50 78 80 90 90 70 62 17 3 10 19 30 M6 M6 M4 20 22 6 6 3.5 2.1

1/9 R7G-VRSFPB09D750 97.5 61 98 80 90 115 90 75 18 5 10 24 40 M6 M8 M4 20 30 8 7 4 3.4

1/15 R7G-VRSFPB15D750 110 61 98 80 90 115 90 75 18 5 10 24 40 M6 M8 M4 20 30 8 7 4 3.8

750

W

1/25 R7G-VRSFPB25E750 135 75 125 80 90 135 110 98 17 5 10 32 55 M6 M10 M4 20 45 10 8 5 7.2

Note: AT is the size of the set bolt.

Four, Z2 (Effective depth: l)

D2 dia.

D1 dia.

Four, Z1

Set bolt (AT)

Key dimensions

Outline Drawings

Sh6

dia.

D4 dia.

D3h7 dia.

2-9

Page 35

2-2 External and Mounted Dimensions

2-2-3 Decelerator Dimensions

Backlash: 45 Arcminutes Max.

Dime nsions (mm)

Key dimensions

Model

LM LR C1 C2 D1 D2 D3 D4 E3 F G S T Z1 Z2 AT l

QK b h t1

Weight

(kg)

1/5 R7G-RGSF05B100 67.5 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.55

1/9 R7G-RGSF09B100 67.5 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.55

100 W

1/15 R7G-RGSF15B100 78 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.7

1/5 R7G-RGSF05B200 72.5 32 52 60 70 60 50 45 10 3 10 12 20 M5 M5 M4 12 16 4 4 2.5 0.72

1/9 R7G-RGSF09C400 89.5 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 1.7

200 W

1/15 R7G-RGSF15C400 100 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 2.1

1/5 R7G-RGSF05C400 89.5 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 1.7

1/9 R7G-RGSF09C400 89.5 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 1.7

400 W

1/15 R7G-RGSF15C400 100 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 2.1

Note: AT is the size of the set bolt.

Four, Z1

D1 dia.

D2 dia.

Four, Z2 (Effective depth: l)

Set bolt (AT)

Key dimensions

Outline Drawings

Sh6

dia.

D4 dia.

D3h7 dia.

2-10

Page 36

Section 3

Specifications

Page 37

3-1 Servo Driver Specifications

3-1-1 General Specifications

3-2

3-1 Servo Driver Specifications

Select the Servo Driver in combination with the Servomotor being used. (For details, refer to 2-1-3 Servo

Driver-Servomotor Combinations.)

3-1-1 General Specifications

Item Specifications

Ambient operating temperature 0 to 55°C

Ambient operating humidity 90% max. (with no condensation)

Ambient storage temperature −20 to 70°C

Ambient storage humidity 90% max. (with no condensation)

Storage and operating atmosphere

No corrosive gasses, no dust, no iron dust, no exposure to moisture or

cutting oil

Vibration resistance

10 to 55 Hz in X, Y, and Z directions with 0.1-mm double amplitude;

acceleration: 4.9 m/s

2

max.

Impact resistance Acceleration 19.6 m/s2 max., in X, Y, and Z directions, three times

Insulation resistance

Between power supply/power line terminals and frame ground:

0.5 MΩ min. (at 500 V DC)

Dielectric strength

Between power supply/power line terminals and frame ground: 1,500 V

AC for 1 min at 50/60 Hz

Between each control signal and frame ground: 500 V AC for 1 min

Degree of protection Built into panel (IP10).

EMC Directive

EN 55011 Class A Group 1

EN 61000-6-2

EC

Directives

Low Voltage

Directive

EN 50178

UL standards UL 508C

International

standards

cUL standards cUL C22.2 No.14

Note 1. The above items reflect individual evaluation testing. The results may differ under

compound conditions.

2. Depending on the operating conditions, some Servo Driver parts will require maintenance.

Refer to 6-5 Periodic Maintenance in the User’s Manual for details.

3. The service life of the Servo Driver is 50,000 hours at an average ambient temperature of

40°C at 80% of the rated torque (excluding axial-flow fan).

WARNING 意

Never perform withstand-voltage or other megameter tests on the Servo Driver.

Page 38

3-1 Servo Driver Specifications

3-1-2 Characteristics

3-1-2 Characteristics

Control Specifications

R7D-

Item

ZP01H ZP02H ZP04H ZP08H

Continuous output current (rms) 0.84 A 1.1 A 2.0 A 3.7 A

Momentary maximum output current

(rms)

2.5 A 3.3 A 6.0 A 11.1 A

Input power supply

(For main circuit and control circuit)

Single-phase 200 to 230 VAC (170 to 253 V), 50/60 Hz

Main circuit 6 W 8 W 16 W 27 W

Heat generated

Control circuit 8 W 8 W 8 W 8 W

Control method All-digital servo

Inverter method IGBT-driven PWM method

Maximum response frequency

(command pulses)

750 kpps

Weight 0.5 kg 1.0 kg

Applicable motor capacity 100 W 200 W 400 W 750 W

Applicable Servomotors (R7M-) Z10030-S1 Z20030-S1 Z40030-S1 Z75030-S1

3-1-3 Main Circuit and Servomotor Connector Specifications (CNA

and CNB)

R7A-CNZ01P (CNA) Main Circuit Connector Specifications

CNA Connector

Main Circuit Connector (CNA) Pin Arrangement

Signal No. Signal Function Condition

1 L1

2 L2

Main circuits power supply

input

Single-phase 200/230 V AC

(170 to 253 V AC) 50/60 Hz

3 +

4 −

Regeneration Resistance

Unit connection terminals

If regenerative energy is high, connect a

Regeneration Resistance Unit between P and

N.

Frame ground

This is the ground terminal. Ground to a

minimum of 100 Ω (class D, class 3).

3-3

Page 39

3-1 Servo Driver Specifications

3-1-3 Main Circuit and Servomotor Connector Specifications (CNA and CNB)

R7A-CNZ01A (CNB) Servomotor Connector Specifications

CNB Connector

Servomotor Connector (CNB) Pin Arrangement

Pin No.

Terminal

label

Name Function

1 U Red

2 V White

3 W

Servomotor

connection

Terminals

Blue

These are the output terminals to the

Servomotor. Be careful to wire them

correctly.

4 --- Do not connect anything to this terminal.

Frame ground Green/Yellow Connect the Servomotor FG terminal.

3-4

Page 40

3-1 Servo Driver Specifications

3-1-4 Control I/O Specifications (CN1)

3-1-4 Control I/O Specifications (CN1)

Control I/O Signal Connections and External Signal Processing

Shell

Frame ground

Reverse

pulse

Forward

pulse

Deviation

counter

reset

RUN command

Alarm output

Brake

interlock

Positioning

completed

output

Maximum operating

voltage: 30 V DC

Maximum Output

Current: 50 mA DC

Phase Z

3-5

Page 41

3-1 Servo Driver Specifications

3-1-4 Control I/O Specifications (CN1)

Control I/O Signals

CN1 Control Inputs

Pin

No.

Signal name Function Function/Interface

1 +CW/PULS

2 −CW/PULS

Reverse pulses,

feed pulses

3 +CCW/SIGN

4 −CCW/SIGN

Forward pulses,

phase difference

signals

Pulse string input terminals for position commands.

Line-driver input:

Maximum response frequency: 750 kpps

Open-collector input:

Maximum response frequency: 187.5 kpps

Note: Either forward and reverse pulses (CW/CCW ), or

feed pulses and direction signal (PULS/SIGN) can be

selected using the rotary switch for setting command

pulses, located on the front of the Unit.

5 +24VIN

+24-V power supply

input for control DC

Power supply input terminal (+24 V DC) for sequence inputs

(pin 6).

6 RUN

RUN command

input

ON: Servo ON (Starts power to Servomotor.)

8 +ECRST

9 −ECRST

Deviation counter

reset

ON: Pulse commands prohibited and deviation counter

cleared.

Note: Input for at least 20 µs.

CN1 Control Outputs

Pin

No.

Signal

name

Function Function/Interface

10

Z

11 ZCOM

Phase Z output

Outputs the Encoder’s phase Z. (1 pulse/revolution)

Note: Use the rising edge of the ON signal.

12

ALM

Alarm output

When the Servo Driver generates an alarm, the output turns

OFF.

Note: OFF for approx. 2 s after the power is turned ON.

13 BKIR

Brake interlock output

Outputs the holding brake timing signals. Release the holding

brake when this signal is ON.

14 INP

Positioning completed

output

ON when the position deviation is within ±10 pulses.

7 0GND

Output ground

common

Ground common for sequence outputs (pins 12, 13 and 14).

Note: An open-collector output interface is used for sequence outputs (maximum operating

voltage: 30 V DC; maximum output current: 50 mA).

CN1: Pin Arrangement

Pin

No.

Signal name Function Pin No.

Signal

name

Function

1 +CW/PULS

+ reverse pulse,

+ feed pulse

8 +ECRST

+ deviation counter reset

2 −CW/PULS

− feed pulse,

− reverse pulse

9 −ECRST

− deviation counter reset

3 +CCW/SIGN

+ forward pulse,

+ direction signal

10 Z

Encoder phase Z output

4 −CCW/SIGN

− forward pulse,

− direction signal

11 ZCOM

Phase Z output ground

5 +24VIN

Control DC

+24-V input

12

ALM

Alarm output

6 RUN

RUN command input

13 BKIR

Brake interlock output

7 0GND

Output ground common

14 INP

Positioning completed output

3-6

Page 42

3-1 Servo Driver Specifications

3-1-5 Control Input Circuits

CN1 Connectors (14P)

Soldered Connectors

Name Model Manufacturer

Cable plug 10114-3000VE

Cable case (shell kit) 10314-52A0-008

Sumitomo 3M

3-1-5 Control Input Circuits

Position Command Pulse Inputs and Deviation Counter Reset Inputs

Line Driver Input

Controller

Servo Driver

Applicable line driver:

SN75174, MC3487, AM26LS31A equivalent

Input current: 9 mA, 3 V

Open Collector Input

Controller Servo Driver

Input current: 7 to 15 mA

Note: Select a value for resistance R so that the input current will be from 7 to 15 mA.

Vcc R

24 V 1.6 to 2.2 kΩ

12 V 750 to 1 kΩ

5 V 180 Ω

3-7

Page 43

3-1 Servo Driver Specifications

3-1-6 Control Input Details

Sequence Inputs

Photocoupler input:

24 V DC, 7 mA

Minimum ON time: 40 ms

External power supply:

24 V ±1 V DC

Power supply capacity:

50 mA min. (per Unit)

Signal Levels

On level: Minimum (+24 VIN−11)V

OFF level: Maximum (+24 VIN−1)V

3-1-6 Control Input Details

Feed Pulse/Direction Signal, Reverse Pulse/Forward Pulse

CN1 Pin Numbers

CN1 pin 1:

+Reverse Pulse (+CW), +Feed Pulse (+PULS)

CN1 pin 2:

–Reverse Pulse (–CW), –Feed Pulse (–PULS)

CN1 pin 3:

+Direction Signal (+SIGN), +Forward Pulse (+CCW )

CN1 pin 4:

–Direction Signal (–SIGN), –Forward Pulse (–CCW )

Signal Functions

The functions of these signals depend on the setting of the command pulse rotary switch

(PULSE) on the front of the Servo Driver. Turn OFF the Servo Driver’s power before

setting the PULSE Switch. The factory setting is 0.

Setting

Command

pulse

resolution

Command pulse connection

method

Command pulse type

0

1000

1

2500

Open collector or line driver

2

5000

3

10000

Line driver

CW + CCW, positive logic

CW

CCW

4

1000

5

2500

Open collector or line driver

6

5000

7

10000

Line driver

CW + CCW, negative logic

CW

CCW

8

1000

9

2500

Open collector or line driver

A

5000

B

10000

Line driver

+ pulse string,

positive logic

PULS

SIGN

C

1000

D

2500

Open collector or line driver

E

5000

F

10000

Line driver

+ pulse string,

negative logic

PULS

SIGN

3-8

Page 44

3-1 Servo Driver Specifications

3-1-6 Control Input Details

Command Pulse Timing

Command Pulse Mode Timing details

Feed pulse and direction signal

Maximum input frequency

Line driver: 750 kpps

Open collector: 187.5 kpps

t1, t2, and t3 > 3.0 µs

τ ≥ 0.66 µs

T ≥ 1.33 µs

(τ / T) × 100 ≤ 50 (%)

Reverse commandForward command

Direction signal

Feed pulse

Reverse and forward pulses

Maximum input frequency

Line driver: 750 kpps

Open collector: 187.5 kpps

t2 > 3.0 µs

τ ≥ 0.66 µs

T ≥ 1.33 µs

(τ / T) × 100 ≤ 50 (%)

Forward command

Forward pulse

Reverse pulse

Deviation Counter Reset (ECRST)

The CN1 connector input pins are as follows:

+Deviation Counter Reset (8: +ECRST)

−Deviation Counter Reset (9: –ECRST)

Functions

• The value of the deviation counter will be reset when the deviation counter reset signal

turns ON and the position loop will be disabled.

• Input the reset signal for 20 µs minimum. The counter will not be reset if the signal is

too short.

RUN Command Input (RUN)

RUN Command Input (pin 6: RUN)

Functions

This is the input that turns ON the power drive circuit for the main circuit of the Servo

Driver. If this signal is not input (i.e., servo-OFF status), the Servomotor cannot operate

except for JOG operations.

3-9

Page 45

3-1 Servo Driver Specifications

3-1-7 Control Output Circuits

3-1-7 Control Output Circuits

Phase Z Output

Servo Driver

Controller

Maximum operating voltage: 30 V DC

Maximum output current: 50 mA

Sequence and Alarm Outputs

Servo Driver

Maximum operating voltage: 30 V DC

Maximum outp ut current: 50 mA

External power suppl

y

:

24 V DC ±1 V

Di: Diode for preventing surge volt age (Use speed diodes.)

3-1-8 Control Output Details

Control Output Sequence

Power supply input

(L1 and L2)

Positioning Completed Output

(INP)

Brake Interlock output (BKIR)

Run command input

(RUN)

Approx. 2 s

0 to 35 ms 2 ms

30 s max.

Alarm output (ALM )

3-10

Page 46

3-1 Servo Driver Specifications

3-1-9 Encoder Connector Specifications (CN2)

Phase Z Output (Z)

The following CN1 connector pins are used for the phase Z output.

Pin No. 10: Phase Z output (Z)

Pin No. 11: Phase Z output ground (ZCOM)

Function

• The Encoder phase Z is output.

• One pulse is output for each rotation.

Alarm Output ( )

• Pin No.12: Alarm Output ( )

Function

• The alarm output is turned OFF when the Servo Driver detects an error.

• This output is OFF at startup and turns ON when the initial processing has been

completed. (Approx. 2 s is required for initial processing.)

Brake Interlock Output (BKIR)

Pin No.13: Brake Interlock output (BKIR)

Function

• The external brake timing signal is output.

Positioning Completed Output (INP)

Pin No.14: Positioning Completed Output (INP)

Function

• The INP signal turns ON when the number of accumulated pulses in the deviation

counter is less than 10.

3-1-9 Encoder Connector Specifications (CN2)

Pin No. Signal Name Function/interface

1 E5V Encoder power supply, +5 V

2 E0V Encoder power supply, GND

Power supply output for the encoder

5 V, 70 mA

3 Phase A+ Encoder phase +A input

4 Phase A– Encoder phase –A input

Differential sine-wave input

5 Phase B+ Encoder phase +B input

6 Phase B– Encoder phase –B input

Differential cos-wave input

7 Phase Z Encoder phase Z input Open collector input

8 Phase U Pole sensor phase U input Open collector input

9 Phase V Pole sensor phase V input Open collector input

10 Phase W Pole sensor phase W input Open collector input

Shell FG Shield ground Cable shield ground

Connectors for CN2 (10-pin)

Soldered Connector

Name Model Maker

Plug, Cable, and Cover Set 54599-1005

Plug Connector 51593-1011

Molex Japan Co.

A

LM

ALM

3-11

Page 47

3-1 Servo Driver Specifications

3-1-9 Encoder Connector Specifications (CN2)

Crimped (Solderless) Connector

Name Model Maker

Plug, Cable, and Cover Set 54559-1005

Plug Housing 51209-1001

Crimp Terminal 59351-8187 (Loose wire)

Crimping Tool 57401-5300

Molex Japan Co.

3-12

Page 48

3-2 Servomotor Specifications

3-2-1 General Specifications

3-2 Servomotor Specifications

Select a Servomotor based on the mechanical system’s load conditions and the installation environment.

There are various options available on the Servomotors, such as brakes.

3-2-1 General Specifications

Item Specifications

Ambient operating temperature 0 to 40°C

Ambient operating humidity 20% to 80% (with no condensation)

Ambient storage temperature −20 to 60°C

Ambient storage humidity 20% to 80% (with no condensation)

Storage and operating atmosphere No corrosive gases

Vibration resistance

10 to 2,500 Hz, with a 0.2-mm double amplitude or acceleration of

24.5 m/s

2

(whichever is smaller) in the X, Y, and Z directions

Impact resistance 98 m/s2 max. (twice in vertical direction)

Insulation resistance

10 MΩ min. at 500 VDC between the power terminals and FG

terminal

Dielectric strength

1,500 VAC (50 or 60 Hz) for 1 minute between the power terminals

and FG terminal

Operating position Any direction

Insulation class Type B

Construction Totally-enclosed, self-cooling

Degree of protection IP55 (excluding the through-shaft portion)

Vibration class V-15

Mounting method Flange-mounting

EN 550011 Class A, Group1

EMC Directive

EN 61000-6-2

EC

Directives

Low Voltage

Directive

IEC 60034-1, -5, -8, and -9

EN 60034-1 and -9

UL standards UL 1004

International

standards

cUL standards cUL C22.2 No. 100

Motor Rotation Directions

In this manual, the Servomotors rotation directions are defined as forward and reverse.

Viewed from the end of the motor’s output shaft, counterclockwise (CCW ) rotation is

forward and clockwise (CW) rotation is reverse.

Forward

Reverse

3-13

Page 49

3-2 Servomotor Specifications

3-2-2 Characteristics

3-2-2 Characteristics

Item Unit

R7M-

Z10030-S1

R7M-

Z20030-S1

R7M-

Z40030-S1

R7M-

Z75030-S1

Rated output (See note 1.) W 100 200 400 750

Rated torque (See note 1.) N⋅m 0.318 0.637 1.27 2.39

Rated rotation speed r/min 3,000

Max. momentary speed r/min 4,500

Max. momentary torque (See note 1.) N⋅m 0.955 1.91 3.82 7.16

Rated current (See note 1.) A (rms) 0.84 1.1 2.0 3.7

Max. momentary current (See note 1.) A (rms) 2.5 3.3 6.0 11.1

Rotor inertia

kg·m2

(GD

2

/4)

6.34 × 10

-6

3.30 × 10-5 6.03 × 10-5 1.50 × 10-4

Power rate (See note 1.) kW/s 16.0 12.3 26.7 38.1

Allowable radial load (See notes 5 and

6.)

N 78 245 245 392

Allowable thrust load (See note 5.) N 54 74 74 147

Without brake kg 0.5 0.9 1.3 2.6

Weight

With brake kg 0.7 1.5 1.9 3.5

Radiation shield dimensions (material) t6×@250 (Al)

Applicable load inertia (See note 2.) kg⋅m

2

6.0 × 10-5 (9.5 ×) 3.0 × 10

-4

(9.1 ×) 5.0 × 10-4 (8.3 ×) 1.0 × 10-3 (6.7 ×)

Brake inertia

kg⋅m

2

(GD

2

/4)

7.54 × 10

-7

6.4 × 10-6 6.4 × 10-6 1.71 × 10

-5

Excitation voltage (See note 3.) V 24 VDC ±10%

Power consumption (at 20°C) W 6 7 7 7.7

Current consumption (at 20°C) A 0.25 0.29 0.29 0.32

Static friction torque N⋅m 0.318 min. 0.637 min. 1.27 min. 2.45 min.

Attraction time (See note 4.) ms 60 max. 80 max.

Release time (See note 4.) ms 30 max. 20 max.

Backlash --- 1° max.

Brake specifications

Rating --- Continuous

Applicable Servo

Drivers (R7D-)

Pulse-train models

ZP01H ZP02H ZP04H ZP08H

Note 1. These are the values when the Servomotor is combined with a Servo Driver and the armature winding

temperature is 100°C. Other values are at normal conditions (20°C, 65%). The momentary maximum torque

shown above indicates the standard value.

2. This is the value without an accessory, such as an external Regeneration Resistance Unit.

3. The brakes operate when the circuit is open (i.e., they are released when voltage is applied).

4: The operation time is the measured value (reference value) with a varistor installed as a surge suppressor.

5. The allowable radial and thrust loads are the values determined for a service life of 20,000 hours at normal

operating temperatures.

6. The value indicated for the allowable radial load at the location shown in the following diagram.

Radial load

Thrust load

3-14

Page 50

3-2 Servomotor Specifications

3-2-2 Characteristics

Torque and Rotation Speed Characteristics

The following graphs show the characteristics with a 3-m standard cable and a 200-V AC

input.

R7M-Z10030-S1

Repetitive usage

Continuous usage

R7M-Z20030-S1

R7M-Z40030-S1 R7M-Z75030-S1

Repetitive usage

Continuous usage

Repetitive usage

Continuous usage

Repetitive usage

Continuous usage

3-15

Page 51

3-2 Servomotor Specifications

3-2-3 Encoder Specifications

Temperature Characteristics of the Servomotor and Mechanical

System

• SMARTSTEP Junior Servomotors use rare earth magnets (neodymium-iron

magnets). The temperature coefficient for these magnets is approximately –0.13%/°C.

As the temperature drops, the Servomotor's maximum momentary torque increases,

and as the temperature rises, the Servomotor's maximum momentary torque

decreases. The maximum momentary torque is about 4% higher at –10°C compared to

the normal temperature of 20°C. Conversely, the maximum momentary torque

decreases about 8% when the Servomotor warms up to 80°C from the normal

temperature of 20°C.

• Generally, when the temperature drops in a mechanical system, the friction

torque and the load torque increase. For that reason, overloading may occur at low

temperatures. In particular, in systems that use a Decelerator, the load torque at low

temperatures may be nearly twice the load torque at normal temperatures. Check with

a current monitor to see whether there is overloading at low temperatures. Also check

operation at high temperatures to see whether there is abnormal Servomotor

overheating or alarms.

• An increase in load friction torque visibly increases load inertia. Therefore, even

if the Servo Driver parameters are properly adjusted at a normal temperature, the

Servomotor may not operate optimally at low temperatures. Check operation at low

temperatures to see whether operation is optimal in those conditions, too.

3-2-3 Encoder Specifications

Item Specification

Encoder method Optical encoder (incremental encoder)

Number of output pulses

Phase A, B: 256 waves/revolution

Phase Z: 1 pulse/revolution

Power supply voltage 5 VDC ±5%

Power supply current 70 mA max.

Output signals +A, –A, +B, –B, Z, U, V, and W

+A, –A, +B, and –B Sine wave voltage output

Output interface

Z, U, V, and W Transistor output

3-16

Page 52

3-3 Decelerator Specifications

3-3-1 Standard Models and Specifications

3-3 Decelerator Specifications

3-3-1 Standard Models and Specifications

The following Decelerators are available for use with SMARTSTEP Junior Servomotors.

Select a Decelerator to match the Servomotor capacity.

• Backlash: 3 arcminutes max.

• Backlash: 45 arcminutes max.

There are four reduction ratios: 1/5, 1/9, 1/15, and 1/25.

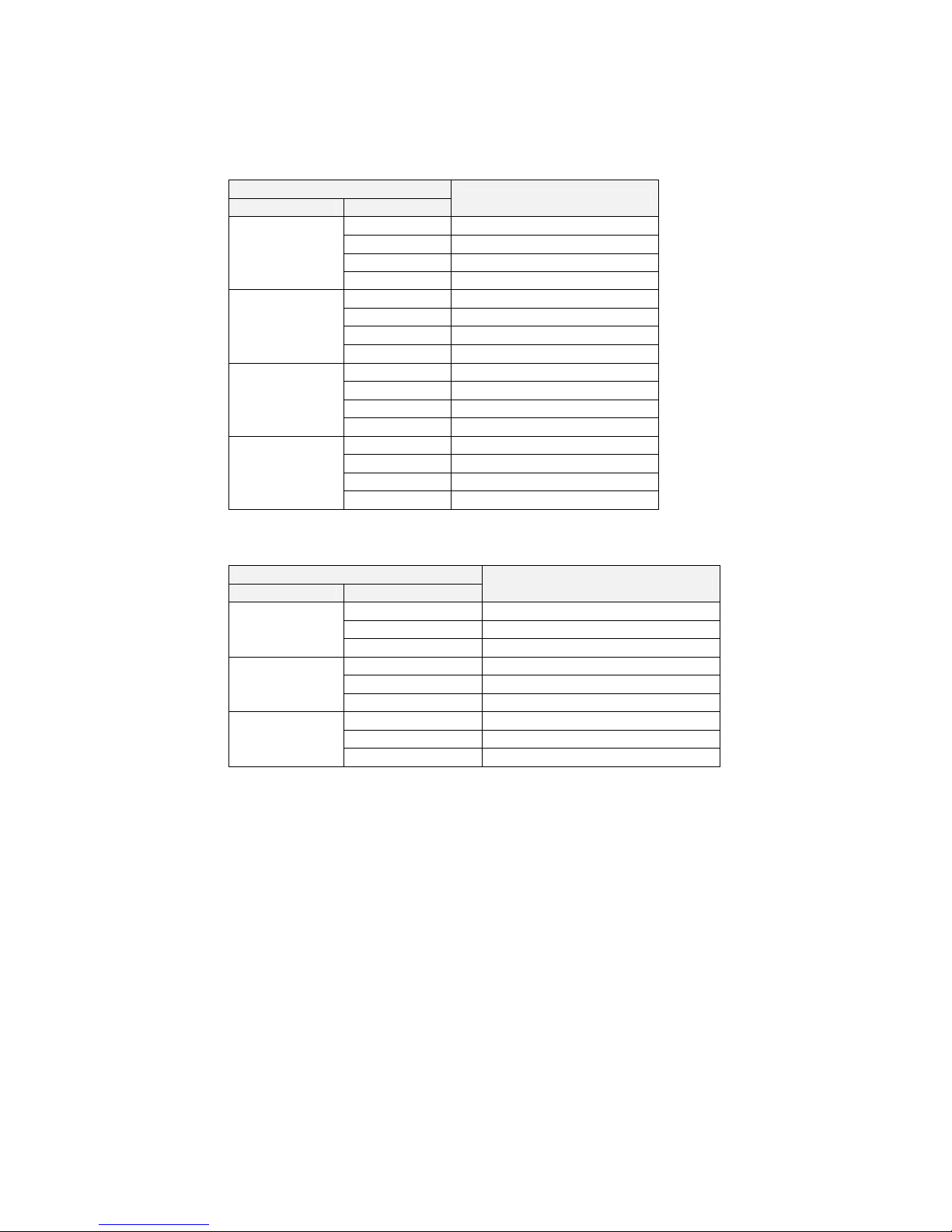

Backlash: 3 Arcminutes Max.

Rated

speed

Rated

torque

Ratio

Maximum

momentary

speed

Maximum

momentary

torque

Decelerator

inertia

Allowable

radial load

Allowable

thrust load

Model

r/min N·m % r/min N·m kg·m

2

N N

1/5 R7G-VRSFPB05B100 600 1.19 75 900 3.60 4.08 × 10-6 392 196

1/9 R7G-VRSFPB09B100 333 2.29 80 500 6.91 3.43 × 10-6 441 220

1/15 R7G-VRSFPB15B100 200 3.82 80 300 11.5 3.62 × 10-6 588 294

100

W

1/25 R7G-VRSFPB25C100 120 6.36 80 180 19.2 3.92 × 10

-6

1323 661

1/5 R7G-VRSFPB05B200 600 2.71 85 900 8.12 1.53 × 10-5 392 196

1/9 R7G-VRSFPB09C400 333 3.78 66 500 11.3 2.68 × 10-5 931 465

1/15 R7G-VRSFPB15C400 200 6.31 66 300 18.9 2.71 × 10-5 1176 588

200

W

1/25 R7G-VRSFPB25C200 120 11.1 70 180 33.4 2.67 × 10

-5

1323 661

1/5 R7G-VRSFPB05C400 600 5.40 85 900 16.2 3.22 × 10-5 784 392

1/9 R7G-VRSFPB09C400 333 9.49 83 500 28.5 2.68 × 10-5 931 465

1/15 R7G-VRSFPB15C400 200 15.8 83 300 47.6 2.71 × 10-5 1176 588

400

W

1/25 R7G-VRSFPB25D400 120 26.4 83 180 79.3 2.79 × 10

-5

1617 808

1/5 R7G-VRSFPB05C750 600 10.8 90 900 32.0 7.17 × 10-5 784 392

1/9 R7G-VRSFPB09D750 333 18.3 85 500 54.3 6.50 × 10-5 1176 588

1/15 R7G-VRSFPB15D750 200 30.5 85 300 90.5 7.09 × 10-5 1372 686

750

W

1/25 R7G-VRSFPB25E750 120 50.8 85 180 151 7.05 × 10

-5

2058 1029

Note 1. The Decelerator inertia is the Servomotor shaft conversion value.

2. The enclosure rating for Servomotors with Decelerators is IP44.

3. The allowable radial load is the value at the center of the shaft.

Backlash: 45 Arcminutes Max.

Rated

speed

Rated

torque

Ratio

Maximum

momentary

speed

Maximum

momentary

torque

Decelerator

inertia

Allowable

radial

load

Allowable

thrust

load

Model

r/min N·m % r/min N·m kg·m

2

N N

1/5 R7G-RGSF05B100 600 1.19 75 900 3.60 4.08 × 10-6 392 196

1/9 R7G-RGSF09B100 333 2.29 80 500 6.91 3.43 × 10-6 441 220

100 W

1/15 R7G-RGSF15B100 200 3.82 80 300 11.5 3.62 × 10

-6

588 294

1/5 R7G-RGSF05B200 600 2.71 85 900 8.12 1.53 × 10-5 392 196

1/9 R7G-RGSF09C400 333 3.78 66 500 11.3 2.68 × 10-5 931 465

200 W

1/15 R7G-RGSF15C400 200 6.31 66 300 18.9 2.71 × 10

-5

1176 588

1/5 R7G-RGSF05C400 600 5.40 85 900 16.2 3.22 × 10-5 784 392

1/9 R7G-RGSF09C400 333 9.49 83 500 28.5 2.68 × 10-5 931 465

400 W

1/15 R7G-RGSF15C400 200 15.8 83 300 47.6 2.71 × 10

-5

1176 588

Note 1. The Decelerator inertia is the Servomotor shaft conversion value.

2. The enclosure rating for Servomotors with Decelerators is IP44.

3. The allowable radial load is the value at the center of the shaft.

3-17

Page 53

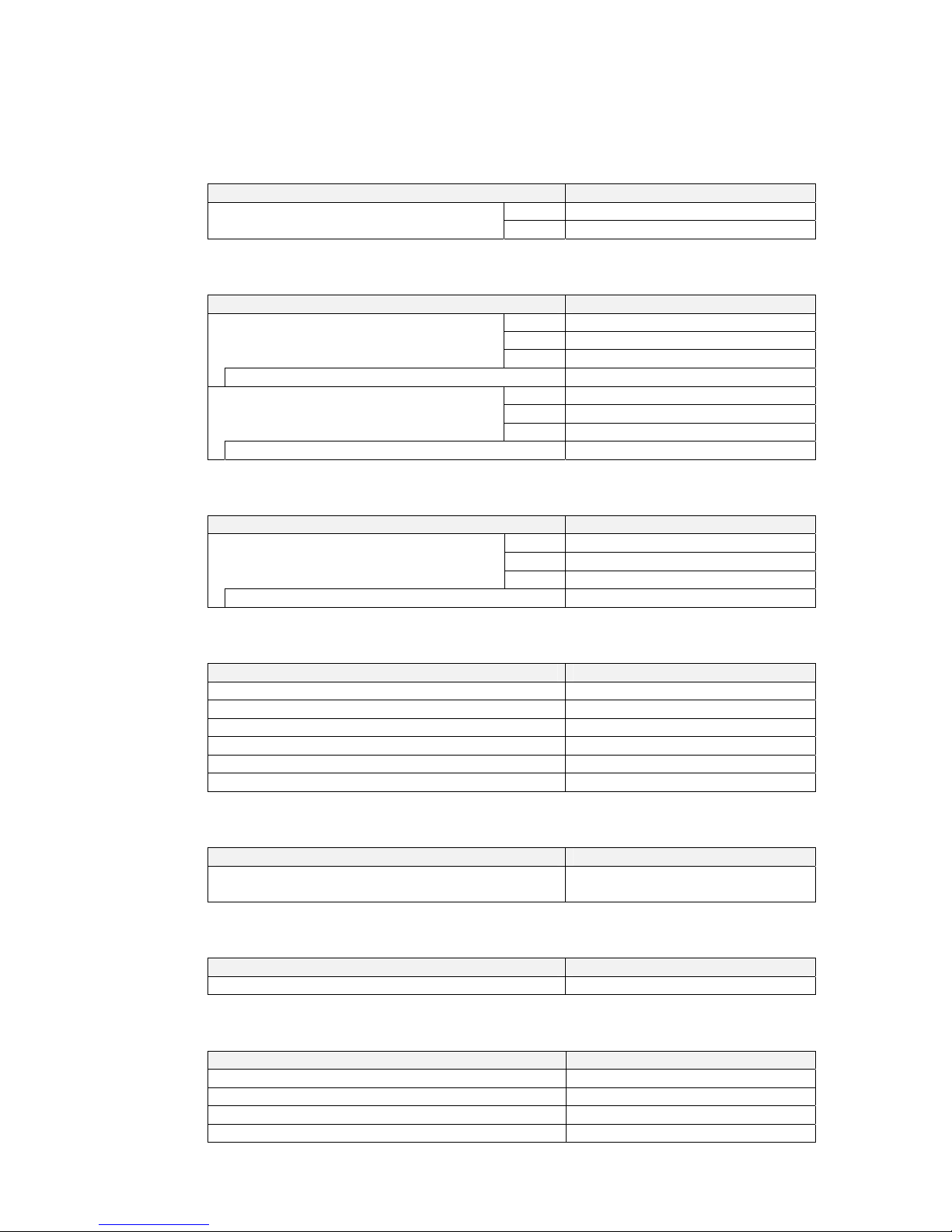

3-4 Cable and Connector Specifications

3-4-1 Control Cable Specifications

3-4 Cable and Connector

Specifications

3-4-1 Control Cable Specifications

General-purpose Control Cables (R7A-CPZ@@@S)

A General-purpose Control Cable connects to the Servo Driver’s Control I/O Connector

(CN1). There is no connector on the controller end. Wire a connector to match the

controller if you are connecting to a Position Control Unit and a compatible cable is not

available or connecting to a controller manufactured by another company.

Cable Models

Model Length (L) Outer diameter of cable Weight

R7A-CPZ001S 1 m Approx. 0.1 kg

R7A-CPZ002S 2 m

5.6 dia.

Approx. 0.2 kg

Connection Configuration and Dimensions

Controller end Servo Driver end

R7D-ZP

@

Wiring

No. Wire color/Mark color Signal

1 Orange/Red (−) +CW /PULS

2 Orange/Black (−) −CW/PULS

3 Gray/Red (−) +CCW/SIGN

4 Gray/Black (−) −CCW/SIGN

5 White/Red (−) +24VIN

6 Yellow/Black (−) RUN

7 White/Black (−) OGND

8 Pink/Red (−) +ECRST

9 Pink/Black (−) −ECRST

10 Orange/Red (−−) Z

11 Orange/Black (−−) ZCOM

12 Gray/Red (−−) /ALM

13 Gray/Black (−−) BKIR

14 Yellow/Red (−) INP

Connector plug: 10114-3000VE (Sumitomo 3M)

Connector case: 10314-52A0-008 (Sumitomo 3M)

Cable: AWG24 × 7P UL20276

Wires with the same wire color and the same number of marks are a twisted pair.

Connector Pin Arrangement

1

3

5

7

2

4

6

9

11

13

8

10

12

14

3-18

Page 54

3-4 Cable and Connector Specifications

3-4-2 Servomotor Power Cable Specifications

3-4-2 Servomotor Power Cable Specifications

The Servomotor Cable supplies power between the Servo Driver and Servomotor.

Servomotor Power Cables are available in two forms: Servomotor Power Cables with an

attached CNB Connector and Servomotor Power Cables without a connector (Cable

Only). Select the Cable to match the Servomotor being used.

Note: When connecting to moving parts, use robot cable and make a custom cable.

Power Cables with CNB Connector for Servomotors without Brakes

Cable Models

Model Length (L) Outer diameter of cable Weight

R7A-CAZ003S 3 m Approx. 0.4 kg

R7A-CAZ005S 5 m Approx. 0.8 kg

R7A-CAZ010S 10 m

7.4 dia.

Approx. 1.2 kg

Note: The maximum distance between the Servo Driver and Servomotor is 20 meters.

Connection Configuration and Dimensions

Servo Driver end Servomotor end

R7M-Z

@R7D-ZP@

Wiring

Servo Driver

No.

1

2

3

4

5

6

Signal

Servomotor

No.

1

2

3

4

Signal

Phase U

Phase V

Phase W

---

Phase U

Phase V

Phase W

FG

---

---

Connector plug

04JFAT-SAYGF-N (JST Mfg. Co., Ltd.)

Connector plug

5557-06R-210 (Molex Japan)

Connector case

5556TL (Molex Japan)

AWG20, Red

AWG20 , W hi te

AWG20, Blue

Green/Yellow