Page 1

R7D@, R88D-GP08H

SmartStep 2 servo drive

Another step forward in drive simplicity

• On-line Auto-tuning and Easy set up

• Ultra-compact size. The footprint is only 48% that of

the SmartStep series

• Two torque limits

• Electronic gear, four internal speed settings and

wide range of pulse settings

• Adaptive filters for suppresion of vibration and

resonance

• Configuration and commissioning using CX Drivesoftware

Ratings

• 230 VAC single-phase 50 W to 750 W (0.16 to

2.4 Nm)

System configuration

AC Servo systems

(Refer to G-Series ser vomotors chapter)

G-Series

servo motor

Encoder cable

Power cable

Brake cable

SmartStep 2

servo drive

Position control

unit

Personal computer

software: CX-One

Position control

unit

Connector terminal block

General purpose controller

(with pulse output)

89SmartStep 2 servo drive

Page 2

Servo motor / servo drive combination

Servo motor SmartStep2 servo drive

Family Voltage Speed Rated torque Capacity Model

Cylindric 50 -750 W 230 V 3000 min-10.16 Nm 50 W R88M-G05030H-@S2 R7D-BP01H

0.32 Nm 100 W R88M-G10030H-@S2 R7D-BP01H

0.64 Nm 200 W R88M-G20030H-@S2 R7D-BP02HH

1.3 Nm 400 W R88M-G40030H-@S2 R7D-BP04H

2.4 Nm 750 W R88M-G75030H-@S2 R88D-GP08H

Flat 100-400 W 0.32 Nm 100 W R88M-GP10030H-@S2 R7D-BP01H

0.64 Nm 200 W R88M-GP20030H-@S2 R7D-BP02HH

1.3 Nm 400 W R88M-GP40030H-@S2 R7D-BP04H

Servo drive type designation

R7D-BP01H

SmartStep 2

Servo Drive

Drive Type

P: Pulse input control

Capacity

100 W

01

200 W

02

04

400 W

SmartStep 2

Servo Drive (750 W)

Drive Type

P: Pulse input control

Capacity

08

750 W

Source voltage

H: Single-phase

230 VAC for 100/400 W

HH: Single-phase

230 VAC for 200 W

R88D-GP08H

Source voltage

H: 230 V

90 AC servo systems

Page 3

Servo drive specifications

General specifications

Item Specification

Ambient operating temperature 0 to 55°C

Ambient operating humidity 90% max. (with no condensation)

Ambient storage temperature -20 to 65°C

Ambient storage humidity 90% max. (with no condensation)

Storage/operating atmosphere No corrosive gases.

Vibration resistance 10 to 60 Hz; acceleration : 5.9 m/s² (0.6G) max.

Impact resistance Acceleration 19.6 m/s

Insulation resistance Between power supply/power line terminals and frame ground: 0.5 MΩ min. (at 500 VDC)

Dielectric strength Between power supply/power terminals and frame ground: 1,500 VAC for 1 min at 50/60 Hz

Between each control signal and frame ground: 500 VAC for 1 min

Protective structure Built into panel (IP10).

International standards Approval obtained for UL: UL 508C; cUL: cUL C22.2 No 14

Approval EC : EMC EN55011 class A Group 1, EN 61000-6-2, low voltage EN50178

Performance specifications

Item 200 VAC input type

Continuous output current (rms) 1.0 A 1.6 A 2.5 A 4 A

Momentary maximum output current (rms) 3.3 A 4.9 A 7.8 A 14.1 A

Main-circuit power supply Single-phase 200 to 240 VAC (170 to 264 V), 50/60 Hz Single-phase/three-phase

Control circuit input power - Single-phase 200 to

Control method All-digital method

Feedback 10,000 pulses/revolution incremental encoder

Inverter method PWM method based on IGBT

PWM frequency 12 kHz 6 kHz

Weight 0.35 kg 0.42 kg 0.42 kg 1.5 kg

Compatible motor voltage 200 V

Command pulse response Line drive: 500 kpps

Compatible motor capacity 50 W

Applicable servo motor

(R88M-)

100 W 200 W 400 W 750 W

R7D-BP01H R7D-BP02HH R7D-BP04H R88D-GP08H

100 W

G05030H

G10030H

GP10030H

2

max., 3 times each in X, Y, and Z directions,

200 W 400 W 750 W

G020030H

GP20030H

G40030H

GP40030H

200 to 240 VAC (170 to

264 V), 50/60 Hz

240 VAC (170 to 264 V)

G75030H

AC Servo systems

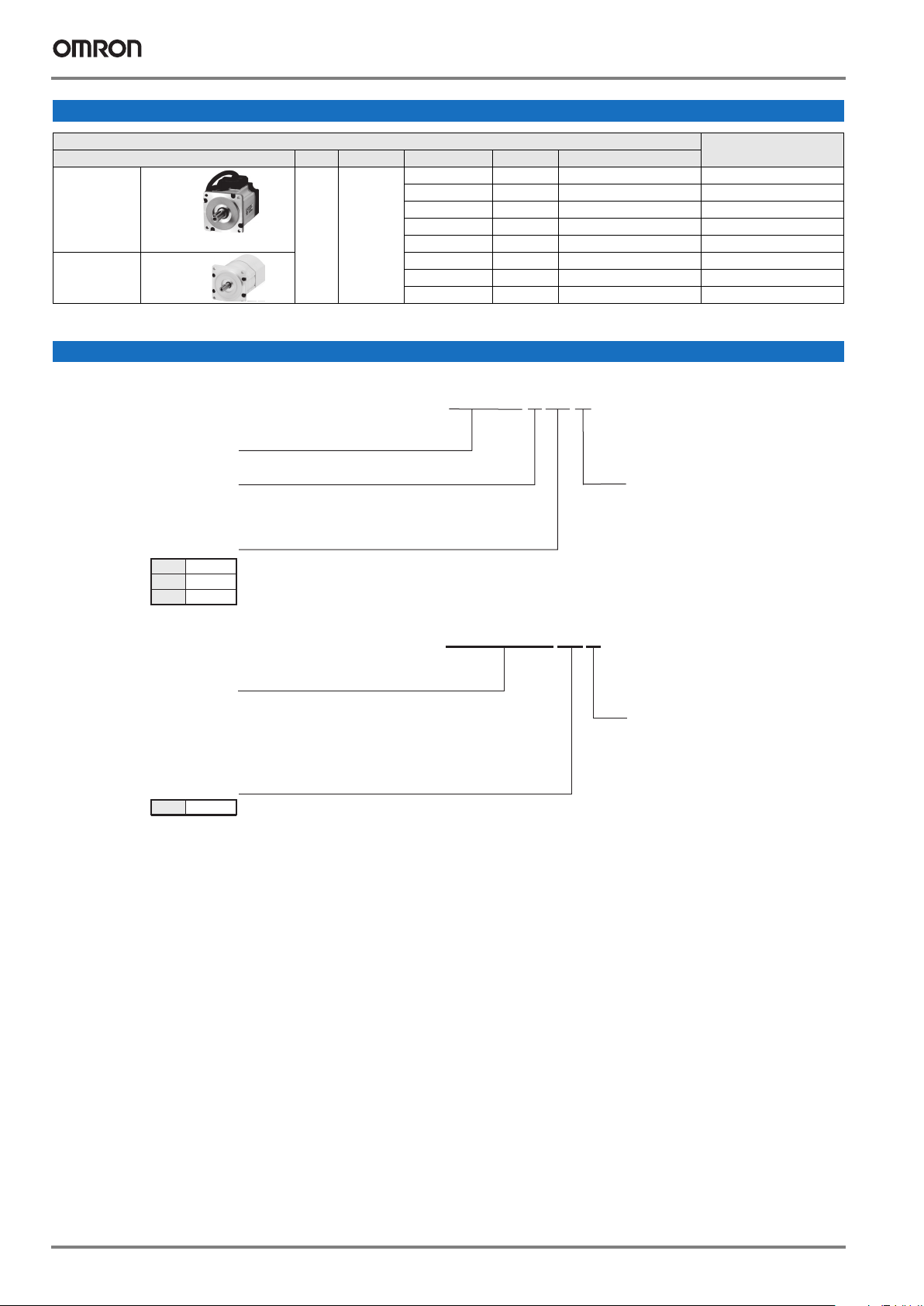

Servodrive part names

SmartStep2 Servo Drive (100 - 400 W models)

Power supply indicator

Communications connector

(CN3)

Control I/O connector

(CN1)

Encoder input connector

(CN2)

Motor connector (CNB)

Main circuit connector

(CNA)

FG terminals for

power supply and

Servomotor power

PWR

Alarm indicator (ALM)

ALM

C

N

3

C

N

1

C

N

2

C

N

B

C

N

A

SmartStep 2 servo drive 91

Page 4

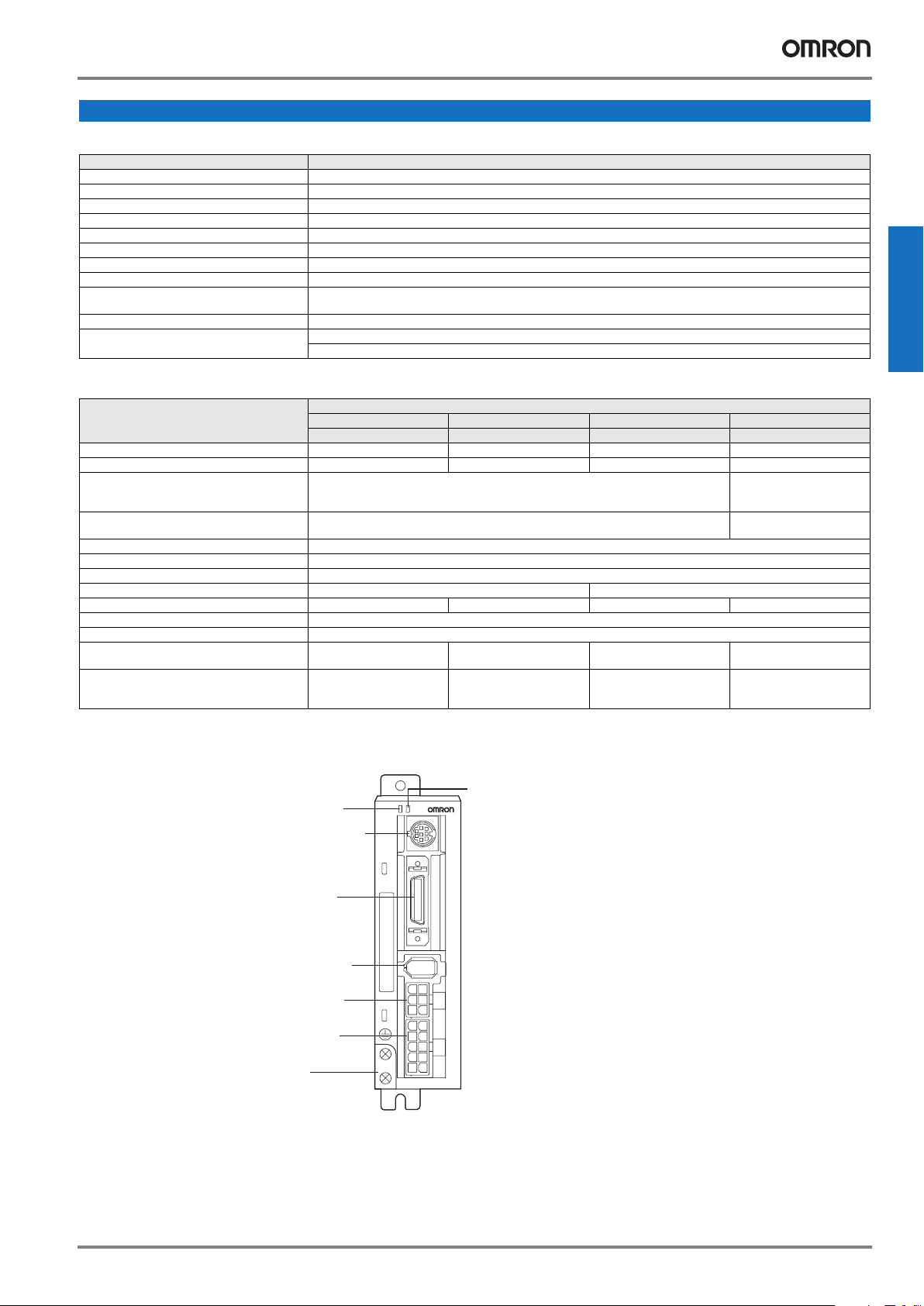

SmartStep2 Servo Drive (750 W model)

Analog monitor outputs

Main-circuit power terminals

Control-circuit power terminals

External regeneration resistor

connection terminals

UNITNo.

AC SERVO DRIVER

DATA

Display area

Settings area

RS-485

Communications connector

(CN3A)

RS-232

Communications connector/

Parameter unit connector

(CN3B)

Control I/O connector

(CN1)

Servomotor connection terminals

Protective ground terminals

Encoder connector (CN2)

92 AC servo systems

Page 5

Dimensions

Servo drives

R7D-BP01H (230 V, 100 W) R7D-BP02HH/04H (230 V, 200-400 W)

35

15

20

5

5

5.2 dia.

PWR

ALM

C

N

3

C

N

1

130

120

140

C

N

2

C

N

B

C

N

A

5.1

5.2

70

R88D-GP08H (230 V, 750 W)

65

AC SERVO DRIVER

UNITNo.

DATA

IM SPG

Mounting Hole

Dimensions

Two, M4

140

130±0.5 55

105

15 20

17070

40

15

20

5

5

5.2 dia.

ALMPWR

C

N

3

C

N

1

130

120

140

C

N

2

C

N

B

C

N

A

5.1

5.2

70

4

105

Two, M4

Mounting Hole

Dimensions

55

140

130±0.5

15 25

Two, M4

AC Servo systems

150

150

7.5

±0.5

50

65

Filters

R7A-FIB104-RE R88A-FIK107-RE

44±1

output

flexes

1 x 130 mm

input

terminals

2 x 170 mm

connector

to servo drive

power supply input

M4

input

terminals

40±1

drive

mounts

2 x M4

20

165±1

output

flexes

179±1

190

180

64

40

drive

mounts

output

flexes

±0.5

140

35

Filter model Rated current Leakage current Rated voltage

R7A-FIB104-RE 4 A 3.5 mA 250 VAC single-phase

R88A-FIK107-RE 6.6 A 3.5 mA 250 VAC single-phase

SmartStep 2 servo drive 93

Page 6

Installation

Single-phase, 230 VAC

L1

L2

L3

N

Thermal switch

Contactor

Noise filter

Regeneration

resistor *1

Reverse

pulse

Forward

pulse

12 to 24 VDC

RUN Command

Input

Alarm Reset

Input

+CW

−CW

+CCW

−CCW

24VIN

RUN

RESET 3

L1

L3

22

23

24

25

1

2

P

B1

CNA

4.7 kΩ

220 Ω

220 Ω

4.7 kΩ

.

4.7 kΩ

4.7 kΩ

SMARTSTEP2

Servo drive

(100-400 W)

CN1

CNB

CN2

U

V

W

/ALM

9

Servo motor

Optical encoder

Alarm Output

10

INP

Positioning

Completed

Output

BKIR

11

Brake Interlock

Maximum operating

voltage: 30 VDC

Maximum Output

Current: 50 mA DC

WARN

12

Warning Output

13

OGND

Z

21

Z-phase Output

(open collector output)

14

GND

Deviation Counter

Reset Input

ECRST4

4.7 kΩ

15

16

18

17

19

20

+A

−A

+B

−B

+Z

−Z

Encoder A-phase

Output

Encoder B-phase

Output

Encoder Z-phase

Output

Line driver output

Conforms to

EIA RS-422A

(Load resistance:

220 Ω min.)

Gain Switch

Input

Electronic Gear

Switch Input

Reverse Drive

Prohibit Input

GSEL 5

4.7 kΩ

GESEL 6

4.7 kΩ

NOT 7

4.7 kΩ

Forward Drive

Prohibit Input

POT 8

FGShell, 26

Frame ground

*1. An External Regeneration Resistor can be connected. Connect this resistor if the regenerative energy exceeds regeneration absorption capacity in the Servo Drive.

Note:1. The dynamic brake operates when the main circuit power supply or the control circuit power supply is turned OFF.

2. When turning OFF the main circuit power supply, turn OFF the RUN Command Input (RUN) signal at the same time.

94 AC servo systems

Page 7

Thermal switch

Position reference

L1

L2

L3

N

Contactor

500 kpps max.

2 Mpps max.

Noise filter

Single-Phase

200 to 230 VAC

Reverse pulse

Forward pulse

Reverse pulse

Forward pu

lse

12 to 24 VDC

Servo ON

Vibration filter

switching

Gain switching

Electronic gear

switching

Deviation counter reset

Alarm reset

Control mode

switching

Pulse prohibition

Reverse run

prohibited

Forward run

prohibited

+24 VCW

+CW

-CW

+24 VCCW

+CCW

-CCW

+CWLD

-CWLD

+CCWLD

-CCWLD

DFSEL

GSEL

L1

L3

L1C

L2C

1

3

4

2

5

6

44

45

46

47

7+24 VIN

29RUN

26

27

28GESEL

30ECRST

31RESET

32TVSEL

33IPG

8NOT

9POT

2.2 kΩ

220 Ω

2.2 kΩ

220 Ω

3 kΩ

110 Ω

3k Ω

3k Ω

110 Ω

3 kΩ

4.7 kΩ

4.7 kΩ

4.7 k

4.7 kΩ

4.7 k

4.7 k

4.7 k

4.7 k

4.7 k

4.7 k

CNA

43 kΩ

43 kΩ

43 kΩ

43 kΩ

Ω

Ω

Ω

Ω

Ω

Ω

Ω

*1

B1

B3

B2

SMARTSTEP2

Servo drive

(750W)

CN1

CNB

1 µF

CN2

100Ω

4.7 kΩ

U

V

W

BKIR

11

BKIRCOM

10

READY

35

READYCOM

34

/ALM37

ALMCOM

36

INP39

INPCOM

38

12

OUTM1

40

OUTM2

41

COM-

19

Z

25 ZCOM

+A21

Encoder phase-A output

-A22

+B49

Encoder phase-B output

-B48

+Z23

Encoder phase-Z output

-Z24

20

SEN

SENGND

13

42

BAT

43

BATGND

50

Servo motor

Optical encoder

Brake release signal output

Servo ready output

Alarm output

Positioning completed output

General-purpose output 1

General-purpose output 2

Phase-Z output

(output collector output)

Line-driver output corresponding

with the EIA RS-422A communications

method (load resistance 120 W min.)

Sensor ON

Backup battery

(3.6 V)

*2

External power supply 12 to 24 VDC

Maximum

service voltage: 30 VDC

Maximum

output current: 50 mADC

*3

*3

AC Servo systems

Shell

*1 B3-B2 are short-circuited. If the internal regenerative resistor is insufficient, remove the wire between B2 and B3 and connect an external regen-

erative resistor between B1 and B2.

*2 Use only when an absolute encoder. If a backup battery is connected, an encoder cable with a battery is not required.

*3 The default values are ZSP (zero-speed detection) for OUTM1 and T-LIMIT (at torque limit) for OUTM2.

SmartStep 2 servo drive 95

Page 8

Ordering information

SmartStep2 Servo Drive Configuration (100-400 W)

(Refer to G-Series ser vo motors chapter)

G-Series

Servo motor

A

Encoder cable

D

Power cable

B

Brake cable

C

E

SmartStep 2 Ser vo drive

(100-40 0W models)

K

Position control

unit

Filter

P

O

F

I

L

M

Personal computer

software: CX-One

Position control unit

-High-speed type-

J

N

G

K

Terminal block

General purpose signals

(with pulse output)

Note: The symbols ABCDE... show the recommended sequence to select the components in a SmartStep 2 servo system

Servo motor

Note: ABCD refer to G-Series motor chapter for detailed motor specifications and selection.

Servo drives

Symbol Specifications SmartStep 2 drive model Compatible servo motors A

E

200 VAC 100 W R7D-BP01H R88M-G05030H-@ -

200 W R7D-BP02HH R88M-G20030H-@ R88M-GP20030H-@

400 W R7D-BP04H R88M-G40030H-@ R88M-GP40030H-@

Cylindrical type Flat type

R88M-G10030H-@ R88M-GP10030H-@

H

Position control

unit

Power Supply cables (for CNA)

Symbol Specifications Model Appearance

E

Power Supply Input Cable for Single-Phase Power (connectors attached)

R7A-CLB002S2

Control cables (for CN1)

Symbol Description Connect to Model

F

G

H

Control cable

(line-driver output for 1 axis)

Control cable

(open-collector output for 1 axis)

Control cable

(line-driver output for 2 axis)

Control cable

(open-collector output for 2 axis)

Terminal block cable for external signals

(for input common, forward/reverse run prohibited inputs,

emergency stop input, origin proximity input and interrupt input)

Terminal block for external signals ( with M3 screw and for pin terminals) - XW2B-20G4

Terminal block ext. signals ( with M3.5 screw and for fork/round terminals) - XW2B-20G5

Terminal block ext. signals ( with M3 screw and fork/round pin terminals) - XW2D-20G6

Position control unit (high-speed type)

CJ1W-NC234

CJ1W-NC434

Position control unit (high-speed type)

CJ1W-NC214

CJ1W-NC414

Position control unit (high-speed type)

CJ1W-NC234

CJ1W-NC434

Position control unit (high-speed type)

CJ1W-NC214

CJ1W-NC414

Position control units (high-speed type)

CJ1W-NC234

CJ1W-NC434

CJ1W-NC214

CJ1W-NC414

1 m XW2Z-100J-G12

5 m XW2Z-500J-G12

10 m XW2Z-10MJ-G12

1 m XW2Z-100J-G16

3 m XW2Z-300J-G16

1 m XW2Z-100J-G4

5 m XW2Z-500J-G4

10 m XW2Z-10MJ-G4

1 m XW2Z-100J-G8

3 m XW2Z-300J-G8

0.5 m XW2Z-C50X

1 m XW2Z-100X

2 m XW2Z-200X

3 m XW2Z-300X

5 m XW2Z-500X

10 m XW2Z-010X

96 AC servo systems

Page 9

Symbol Description Connect to Model

I

J

K

L

M

N

Cable from servo relay unit to servo drive CS1W-NC1@3, CJ1W-NC1@3,

Servo relay unit CS1W-NC1@3, CJ1W-NC1@3 or

Position control unit connecting cable CJ1W-NC133 0.5 m XW2Z-050J-A18

General purpose cable For general purpose controllers 1 m R7A-CPB001S

Terminal block cable For general purpose controllers 1 m XW2Z-100J-B28

Terminal block ( with M3 screw and for pin terminals) - XW2B-34G4

Terminal block ( with M3.5 screw and for fork/round terminals) - XW2B-34G5

Terminal block ( with M3 screw and fork/round pin terminals) - XW2D-34G6

C200HW-NC113, CS1W-NC2@3/4@3,

CJ1W-NC2@3/4@3, C200HW-NC213/413,

CQM1H-PLB21 or CQM1-CPU43-V1

CJ1M-CPU21/22/23 1 m XW2Z-100J-B32

C200HW-NC113 position control unit

CS1W-NC2@3/4@3, CJ1W-NC2@3/4@3 or

C200HW-NC213/413 position control unit

CQM1H-PLB21 or CQM1-CPU43-V1 - XW2B-20J6-3B (1 axis)

CJ1M-CPU21/22/23 - XW2B-20J6-8A (1 axis)

CJ1W-NC233/433 0.5 m XW2Z-050J-A19

CS1W-NC133 0.5 m XW2Z-050J-A10

CS1W-NC233/433 0.5 m XW2Z-050J-A11

CJ1W-NC113 0.5 m XW2Z-050J-A14

CJ1W-NC213/413 0.5 m XW2Z-050J-A15

CS1W-NC113

C200HW-NC113

CS1W-NC213/413

C200HW-NC213/413

CJ1M-CPU21/22/23 0.5 m XW2Z-050J-A33

CQM1H-PLB21

CQM1-CPU43-V1

1 m XW2Z-100J-B29

2 m XW2Z-200J-B29

2 m XW2Z-200J-B32

- XW2B-20J6-1B (1 axis)

- XW2B-40J6-2B (2 axes)

XW2B-40J6-9A (2 axes)

1 m XW2Z-100J-A18

1 m XW2Z-100J-A19

1 m XW2Z-100J-A10

1 m XW2Z-100J-A11

1 m XW2Z-100J-A14

1 m XW2Z-100J-A15

0.5 m XW2Z-050J-A6

1 m XW2Z-100J-A6

0.5 m XW2Z-050J-A7

1 m XW2Z-100J-A7

1 m XW2Z-100J-A33

0.5 m XW2Z-050J-A3

1 m XW2Z-100J-A3

2 m R7A-CPB002S

2 m XW2Z-200J-B28

AC Servo systems

Cable for CN3

Symbol Name Lengh Model

O

Personal Computer Monitor Cable 2 m R88A-CCG002P2

Filters

Symbol Applicable servo drive Rated current Rated voltage Filter model

P

Connectors

Specifications Model

Main Circuit Connector (CNA) R7A-CNB01P

Servomotor Connector (CNB) R7A-CNB01A

Control I/O Connector (CN1) R88A-CNW01C

Encoder Input Connector (CN2) R88A-CNW01R

Servomotor Connector for Encoder Cable R88A-CNG02R

Servomotor Connector for Servomotor Power Cable R88A-CNG01A

Brake Cable Connector R88A-CNG01B

R7D-BP01H/ 02HH/ 04H 4 A 1 pH, 230 V R7A-FIB104-RE

External regeneration resistor cable

Specifications Model

External Regenerative Resistor Connection Cable, 2

meters

R7A-CLB002RG

Parameter unit & computer software

Specifications Model

Parameter copy unit (with cable) R88A-PR02G

Configuration and monitoring software tool for servo

drives and inverters. (CX-drive version 1.8 or higher)

CX-drive

External regeneration resistor

Specification Model

80 W, 50 Ω R88A-RR08050S

80 W, 100 Ω R88A-RR080100S

220 W, 47 Ω R88A-RR22047S

SmartStep 2 servo drive 97

Page 10

SmartStep2 Servo Drive Configuration (750W)

(Refer to G-Series ser vo motors chapter)

SmartStep 2 Servo drive

B

(750W model)

Personal computer

software: CX-One

O

G-Series

A

Servo motor

Q

Power cable

D

Encoder cable

C

P

Filter

External regenerative

resistor

Position control

unit

Position control unit

-High -speed type-

F

I

J

G

K

L

Brake cable

E

M

N

Terminal block

General purpose signals

(with pulse output)

Note: The symbols ABCDE... show the recommended sequence to select the components in a SmartStep 2 servo system.

Servo motor

Note: ACDE refer to G-Series motor chapter for detailed motor specifications and selection.

Servo drives

Symbol Specifications Servo drive model A Compatible rotary servo motors

Cylindric type

B 1 phase 200 VAC 750 W R88D-GP08H R88M-G75030H-@

Terminal block

for external signals

H

Position control

unit

Control cables (for CN1)

Symbol Description Connect to Model

F

G

H

I

J

Control cable

(line-driver output for 1 axis)

Control cable

(open-collector output for 1 axis)

Control cable

(line-driver output for 2 axis)

Control cable

(open-collector output for 2 axis)

Terminal block cable for external signals

(for input common, forward/reverse run prohibited inputs,

emergency stop input, origin proximity input and interrupt

input)

Terminal block for external signals (M3 screw, pin terminals) - XW2B-20G4

Terminal block ext. signals

Terminal block ext. signals

Cable from servo relay unit to servo drive CS1W-NC1@3, CJ1W-NC1@3, C200HW-NC113/213/413,

Servo relay unit CS1W-NC1@3, CJ1W-NC1@3 or C200HW-NC113

(M3.5 screw, fork/round terminals) - XW2B-20G5

(M3 screw, fork/round terminals) - XW2D-20G6

Position control units (high-speed type)

CJ1W-NC234

CJ1W-NC434

Position control units (high-speed type)

CJ1W-NC214

CJ1W-NC414

Position control units (high-speed type)

CJ1W-NC234

CJ1W-NC434

Position control units (high-speed type)

CJ1W-NC214

CJ1W-NC414

Position control units (high-speed type)

CJ1W-NC234

CJ1W-NC434

CJ1W-NC214

CJ1W-NC414

CS1W-NC2@3/4@3, CJ1W-NC2@3/4@3 or

CQM1H-PLB21

CJ1M-CPU21/22/23 1 m XW2Z-100J-B31

position control unit

CS1W-NC2@3/4@3, CJ1W-NC2@3/4@3 or

C200HW-NC213/413 position control unit

CQM1H-PLB21 - XW2B-20J6-3B (1 axis)

CJ1M-CPU21/22/23 - XW2B-20J6-8A (1 axis)

1 m XW2Z-100J-G9

5 m XW2Z-500J-G9

10 m XW2Z-10MJ-G9

1 m XW2Z-100J-G13

3 m XW2Z-300J-G13

1 m XW2Z-100J-G1

5 m XW2Z-500J-G1

10 m XW2Z-10MJ-G1

1 m XW2Z-100J-G5

3 m XW2Z-300J-G5

0.5 m XW2Z-C50X

1 m XW2Z-100X

2 m XW2Z-200X

3 m XW2Z-300X

5 m XW2Z-500X

10 m XW2Z-010X

1 m XW2Z-100J-B25

2 m XW2Z-200J-B25

2 m XW2Z-200J-B31

- XW2B-20J6-1B (1 axis)

- XW2B-40J6-2B (2 axes)

XW2B-40J6-9A (2 axes)

98 AC servo systems

Page 11

Symbol Description Connect to Model

K

L

M

N

Position control unit connecting cable CQM1H-PLB21 0.5 m XW2Z-050J-A3

1 m XW2Z-100J-A3

CS1W-NC113 or C200HW-NC113 0.5 m XW2Z-050J-A6

1 m XW2Z-100J-A6

CS1W-NC213/413 or C200HW-NC213/413 0.5 m XW2Z-050J-A7

1 m XW2Z-100J-A7

CS1W-NC133 0.5 m XW2Z-050J-A10

1 m XW2Z-100J-A10

CS1W-NC233/433 0.5 m XW2Z-050J-A11

1 m XW2Z-100J-A11

CJ1W-NC113 0.5 m XW2Z-050J-A14

1 m XW2Z-100J-A14

CJ1W-NC213/413 0.5 m XW2Z-050J-A15

1 m XW2Z-100J-A15

CJ1W-NC133 0.5 m XW2Z-050J-A18

1 m XW2Z-100J-A18

CJ1W-NC233/433 0.5 m XW2Z-050J-A19

1 m XW2Z-100J-A19

CJ1M-CPU21/22/23 0.5 m XW2Z-050J-A33

1 m XW2Z-100J-A33

General purpose cable For general purpose controllers 1 m R88A-CPG001S

2 m R88A-CPG002S

Terminal block cable For general purpose controllers 1 m XW2Z-100J-B24

2 m XW2Z-200J-B24

Terminal block (M3 screw and for pin terminals) - XW2B-50G4

Terminal block (M3.5 screw and for fork/round terminals) - XW2B-50G5

Terminal block (M3 screw and for fork/found terminals) - XW2D-50G6

AC Servo systems

Computer cable (for CN3)

Symbol Name Model

O

Computer cable RS232 2 m R88A-CCG002P2

Filter

Symbol Applicable

P

servodrive

R88D-GP08H R88A-FIK107-RE 6.6 A 3.5 mA 250 VAC

Filter model Rated

current

Leakage

current

Rated

voltage

singlephase

External regenerative resistor

Symbol Regenerative resistor unit model Specifications

Q

R88A-RR08050S 50 Ω, 80 W

R88A-RR080100S 100 Ω, 80 W

R88A-RR22047S 47 Ω,220 W

R88A-RR50020S 20 Ω, 500 W

Connectors

Specifications Model

I/O connector kit -50 pins- (for CN1) R88A-CNU11C

Power cable connector (motor side) R88A-CNG01A

Encoder connector (Servo drive side CN2) R88A-CNW01R

Incremental encoder cable connector (motor side) R88A-CNG02R

Computer software

Specifications Model

Configuration and monitoring software tool for servo drives

and inverters (CX-drive version 1.91 or higher).

CX-Drive

SmartStep 2 servo drive 99

Page 12

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. I106E-EN-02A

In the interest of product improvement, specifications are subject to change without notice.

100 AC servo systems

Loading...

Loading...