Page 1

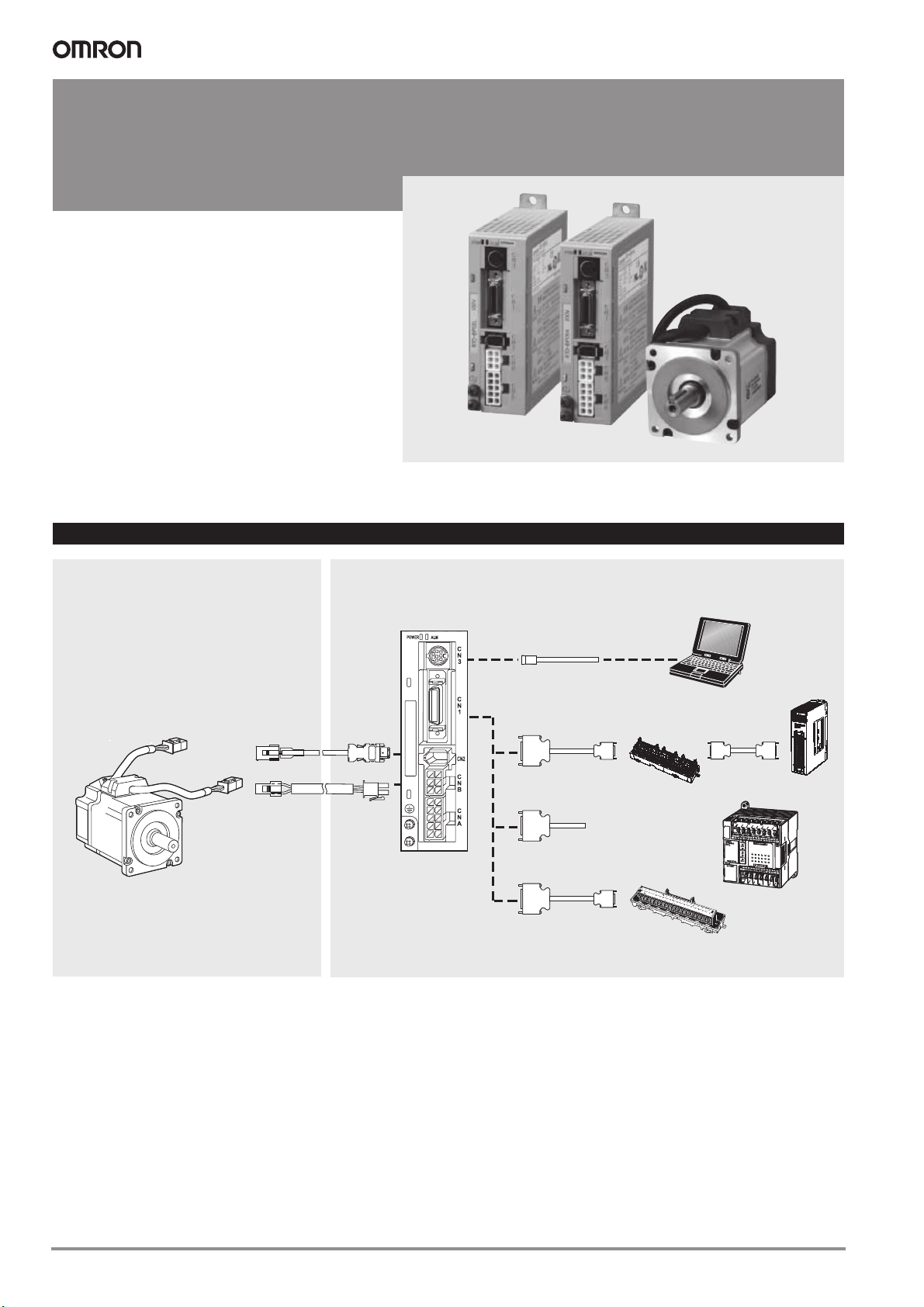

SMARTSTEP 2 SERVO SYSTEM

A new step in servodrive simplicity

Precise and cost-effective »

Ultra-compact design »

Simple to use and set up »

Page 2

SmartStep 2 –

the right step forward...

Omron knows that simplicity and precision are

vital in your positioning application.

The new SmartStep offers an ideal solution for

point-to-point motion applications where

simplicity is essential. SmartStep 2 keeps things

simple whilst combining high performance

in a cost-effective solution.

SmartStep 2 has a completely new compact

design that gives a 50% space saving compared

with the previous model. It also has new

features and functionality to help you to make

your machines more efficient and cost-effective.

Features at a glance:

•

Pulse control servo drive

•

Ultra-compact size

•

Auto-tuning

•

Vibration suppression

•

Adaptive resonance suppression filter

•

Two programmable torque limits

•

Feedback pulse output

•

Power range from 50 W to 750 W

•

Cylindrical and flat servo motors

•

Electronic gear

•

10,000 steps per revolution

…to faster development with great drive simplicity

Getting started quickly

CX-Drive is a single, easy-to-use software tool for configuring,

commissioning and maintaining both inverters and servos.

SmartStep 2 is fully supported with a wide range of features making

the servo drive set-up easier and faster than ever:

•

Auto-tuning

•

Parameter editing and monitoring

•

Speed and position diagrams

•

I/O status and alarms

•

Real-time data trace

Real-time data trace

Frequency analysis

Page 3

A compact design

that’s easy to connect

Although it has more functionality than previous

models, SmartStep 2 has a compact design with an

ultra-small footprint that saves considerable space.

In addition, SmartStep 2 can be easily integrated with

other automation devices such as the CP1L compact

machine controller and NS operator terminals, helping

to make an efficient and cost-effective machine design.

Additional features:

•

Position control via pulse input 500 kpps

•

Rated speed 4,000 rpm; peak 5,000 rpm

•

Wide range of pulse configurations

•

Four internal speed settings switched by external

signal for easy control

•

Servomotors compatible with SmartStep

130 mm

105 mm

160 mm

55 mm

120 mm

35 mm

Compact space-saving design

SmartStep 2 has a footprint 48% smaller than

that of previous models and the volume is

39% smaller, saving cabinet space and costs.

Command pulse

Feedback pulse

CP1H-Yxx

Feedback pulse output

Enables servo position feedback to the

controller for close control position loop and

monitor real positioning; it can be also used to

synchronise with another axis.

AUTO

Adjustment-free operation

Depending on load variations, the real-time

auto-tuning function automatically calculates

and adjusts the optimum gain values for the

machine.

Quickly suppression vibrationVibration

Vibration suppression

An adaptive filter ensures that resonant

frequency changes are automatically followed

to reduce the effect of vibration due to low

mechanical rigidity. A further filter minimises

vibration for better positioning when stopping

the load.

Page 4

R7D-BP@, R88D-GP@, R88M-G@

SmartStep 2 servo system

Another step forward in drive simplicity

• On-line Auto-tuning and Easy set up

• Ultra-compact size. The footprint is only 48% that of

the SmartStep series

• Two torque limits

• Electronic gear, four internal speed settings and

wide range of pulse settings

• Adaptive filters for suppresion of vibration and

resonance

• Servomotors with IP65 as standard and shaft oil

seal available

• Motors with brake as option

Ratings

• 230 VAC single-phase 50 W to 750 W (0.16 to

2.4 Nm)

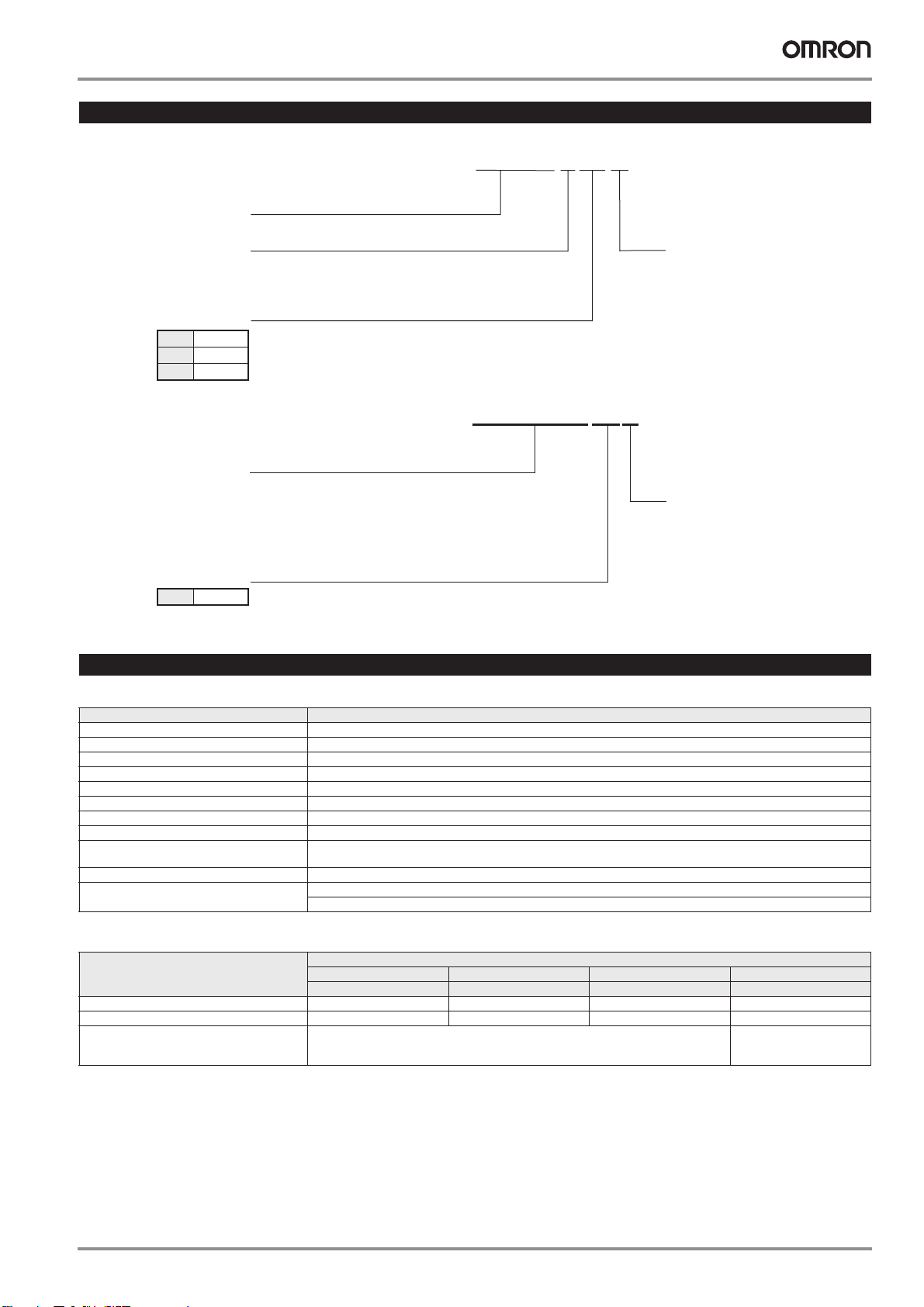

System configuration

(Refer to chapter SmartStep servo motors)

SmartStep 2

Servo Motor

Encoder cable

Power cable

SmartStep 2

Servo Drive

Personal computer

software: CX-One

Position control unit

Position control

unit

Terminal block

General purpose controller

(with pulse output)

6 AC servo systems

Page 5

Servo drive type designation

SmartStep 2

Servo Drive

R7D-BP01H

Drive Type

P: Pulse input control

Source voltage

H: Single-phase

230 VAC for 100/400 W

HH: Single-phase

Capacity

100 W

01

200 W

02

04

400 W

230 VAC for 200 W

R88D-GP08H

SmartStep 2

Servo Drive (750 W)

Drive Type

P: Pulse input control

Capacity

08

750 W

Servo drive specifications

General specifications

Item Specification

Ambient operating temperature 0 to 55°C

Ambient operating humidity 90% max. (with no condensation)

Ambient storage temperature -20 to 65°C

Ambient storage humidity 90% max. (with no condensation)

Storage/operating atmosphere No corrosive gases.

Vibration resistance 10 to 60 Hz; acceleration : 5.9 m/s² (0.6G) max.

Impact resistance Acceleration 19.6 m/s

Insulation resistance Between power supply/power line terminals and frame ground: 0.5 MΩ min. (at 500 VDC)

Dielectric strength Between power supply/power terminals and frame ground: 1,500 VAC for 1 min at 50/60 Hz

Between each control signal and frame ground: 500 VAC for 1 min

Protective structure Built into panel (IP10).

International standards Approval obtained for UL: UL 508C; cUL: cUL C22.2 No 14

Approval EC : EMC EN55011 class A Group 1, EN 61000-6-2, low voltage EN50178

2

max., 3 times each in X, Y, and Z directions,

Source voltage

H: 230 V

Performance specifications

Item 200 VAC input type

Continuous output current (rms) 1.0 A 1.6 A 2.5 A 4 A

Momentary maximum output current (rms) 3.3 A 4.9 A 7.8 A 14.1 A

Main-circuit power supply Single-phase 200 to 240 VAC (170 to 264 V), 50/60 Hz Single-phase/three-phase

100 W 200 W 400 W 750 W

R7D-BP01H R7D-BP02HH R7D-BP04H R88D-GP08H

200 to 240 VAC (170 to

264 V), 50/60 Hz

SmartStep 2 servo system 7

Page 6

Item 200 VAC input type

100 W 200 W 400 W 750 W

R7D-BP01H R7D-BP02HH R7D-BP04H R88D-GP08H

Control circuit input power - Single-phase 200 to

240 VAC (170 to 264 V)

Control method All-digital method

Feedback 10,000 pulses/revolution incremental encoder

Inverter method PWM method based on IGBT

PWM frequency 12 kHz 6 kHz

Weight 0.35 kg 0.42 kg 0.42 kg 1.5 kg

Compatible motor voltage 200 V

Command pulse response Line drive: 500 kpps

Compatible motor capacity 50 W

200 W 400 W 750 W

100 W

Applicable servo motor

(R88M-)

G05030H

G10030H

G020030H

GP20030H

G40030H

GP40030H

G75030H

GP10030H

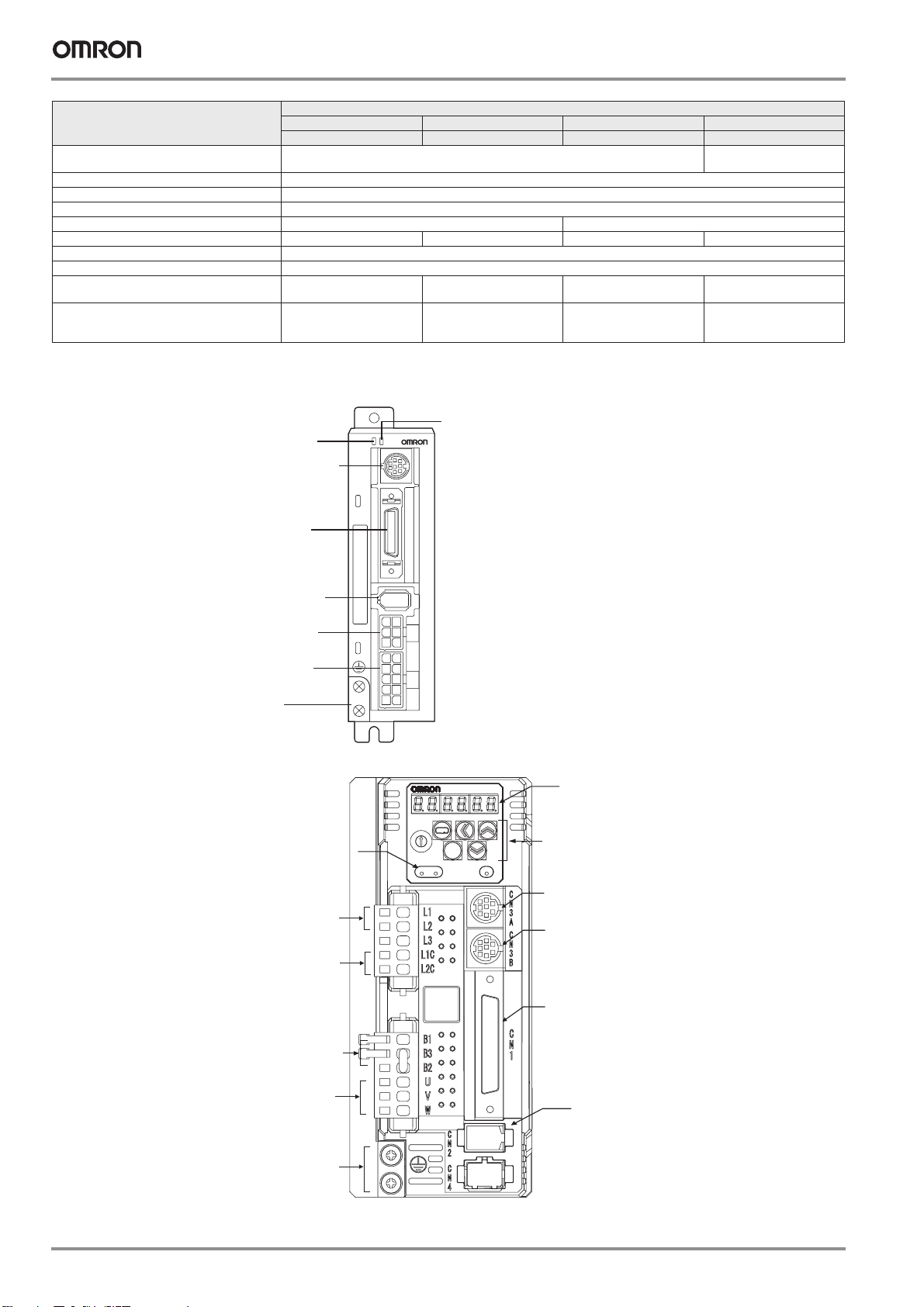

Servodrive part names

SmartStep2 Servo Drive (100 - 400 W models)

Alarm indicator (ALM)

Power supply indicator

Communications connector

(CN3)

PWR

ALM

C

N

3

Control I/O connector

(CN1)

Encoder input connector

(CN2)

Motor connector (CNB)

Main circuit connector

(CNA)

FG terminals for

power supply and

Servomotor power

SmartStep2 Servo Drive (750 W model)

Analog monitor outputs

Main-circuit power terminals

Control-circuit power terminals

UNITNo.

C

N

1

C

N

2

C

N

B

C

N

A

AC SERVO DRIVER

DATA

Display area

Settings area

RS-485

Communications connector

(CN3A)

RS-232

Communications connector/

Parameter Unit connector

(CN3B)

Control I/O connector

(CN1)

External Regeneration Resistor

connection terminals

Servomotor connection terminals

Encoder connector (CN2)

Protective ground terminals

8 AC servo systems

Page 7

Servomotor type designation

R88M-GP10030H-BOS2

SmartStep2 Servomotor

Motor Type

Blank: Cylinder type

P: Flat type

Capacity

050

50 W

100 W

100

200

200 W

400 W

400

750 W

750

Rated Speed (r/min)

3000

30

Shaft end specifications

Straigth shaft, no key

Blank

Straigth, key, tapped

S2

Oil seal specifications

No oil seal

Blank

Oil seal

O

Brake specifications

No brake

Blank

Brake

B

Voltage and encoder specifications

H: 230 V with incremental encoder

Servo motor / servo drive combination

Servo motor

Family Voltage Speed Rated torque Capacity Model

Cylindric 50-750 W 230 V 3000 min

Flat 100-400 W 0.32 Nm 100 W R88M-GP10030H-@S2

-1

0.16 Nm 50 W R88M-G05030H-@S2

0.32 Nm 100 W R88M-G10030H-@S2

0.64 Nm 200 W R88M-G20030H-@S2

1.3 Nm 400 W R88M-G40030H-@S2

2.4 Nm 750 W R88M-G75030H-@S2

0.64 Nm 200 W R88M-GP20030H-@S2

1.3 Nm 400 W R88M-GP40030H-@S2

SmartStep 2 servo system 9

Page 8

Servo motor specifications

General specifications

Item Specification

Ambient operating temperature 0 to 40°C

Ambient operating humidity 85% max. (with no condensation)

Ambient storage temperature −20 to 65°C

Ambient storage humidity 85% max. (with no condensation)

Storage/operating atmosphere No corrosive gases

Vibration resistance 49 m/s

Impact resistance Acceleration of 98 m/s

Insulation resistance 20 MΩ min. at 500 VDC between the power terminals and FG terminal

Dielectric strength 1,500 VAC (50 or 60 Hz) for 1 minute between the power terminals and FG terminal

Run position Any direction

Insulation grade Type B

Structure Totally-enclosed, self-cooling

Protective structure IP65 (excluding the through-shaft portion)

Vibration grade V-15

Mounting method Flange-mounting

International standards Approval obtained for UL, cUL, and EN (EMC directive and low-voltage directive)

Performance specifications

Cylindric servo motors

Item Unit R88M-G05030H R88M-G10030H R88M-G20030H R88M-G40030H R88M-G75030H

Rated output W 50 100 200 400 750

Rated torque N·m 0.16 0.32 0.64 1.3 2.4

Rated rotation speed r/min 3000

Momentary maximum rotation speed r/min 5000 4500

Momentary maximum torque N·m 0.48 0.95 1.78 3.60 7.05

Rated current A (rms) 1.1 1.6 2.6 4

Momentary maximum current A (rms) 3.4 4.9 7.9 12.1

Rotor inertia

Power rate kW/s 10.4 20.1 30.3 62.5 66

Allowable radial load N 68 245 392

Allowable thrust load N 58 98 147

Weight Without brake kg 0.3 0.5 0.8 1.2 2.3

Encoder resolution --- Phase A and B: 2,500 pulses/rotation, Phase Z: 1 pulse/rotation

Radiation shield dimensions --- 100 × 80 × t10 (Al) 130 × 120 × t12 (Al) Brake

specifications

Applicable servo driver R7D-BP01H R7D-BP02HH R7D-BP04H R88D-GP08H

With brake kg 0.5 0.7 1.3 1.7 3.1

Brake inertia

Excitation voltage V 24 VDC ±10%

Power consumption (at 20 °C) W 7 9 10

Current consumption (at 20 °C) A 0.30 0.36 0.42

Static friction torque N·m 0.29 min. 1.27 min. 2.45 min.

Attraction time ms 35 max. 50 max. 70 max.

Release time ms 20 max. 15 max. 20 max.

Backlash - ±1° max.

Rating - Continuous

Brake life - 10,000,000 operations min.

2

max. in the X, Y, and Z directions

2

kg·m

2

kg·m

2

max. 3 times each in the X, Y, and Z directions

-6

2.5 × 10

-7

2.0 × 10

5.1 × 10

2.0 × 10

-6

-7

1.4 × 10

1.8 × 10

-5

-6

2.6× 10

7.5 × 10

-5

-6

8.7× 10

25 × 10

-5

-6

Torque-speed characteristics

R88M-G05030H

(N·m)

0.5

0.4

Repetitive usage

0.3

0.2

0.1

Continuous usage

0

1000 2000 3000 4000 5000

0.160.16

R88M-G10030H R88M-G20030H

(N·m)

1.0

0.48

0.09

(r/min)

0.8

Repetitive usage

0.6

0.4

0.2

Continuous usage

0

1000 2000 3000 4000 5000

0.320.32

0.95

0.19

(r/min)

(N·m)

2.0

1.82

1.5

Repetitive usage

1.0

0.64

0.5

Continuous usage

0

1000 2000 3000 4000 5000

0.64

1.82 (4300)

1.65

0.36

(r/min)

R88M-G40030H

(N·m)

4.0

3.60

3.0

Repetitive usage

2.0

1.0

Continuous usage

0

1000 2000 3000 4000 5000

R88M-G75030H

(N·m)

3.60

(3200)

1.31.3

2.1

0.88

(r/min)

8.0

7.05

Repetitive usage

4.0

2.4 2.4

Continuous usage

0

1000 2000 3000 4000 5000

7.05 (3600)

4.0

1.0

(r/min

10 AC servo systems

Page 9

Flat servo motors

Item Unit R88M-GP10030H R88M-G20030H R88M-G40030H

Rated output W 100 200 400

Rated torque N·m 0.32 0.64 1.3

Rated rotation speed r/min 3000

Momentary maximum rotation speed r/min 5000

Momentary maximum torque N·m 0.90 1.82 3.60

Rated current A (rms) 1.0 1.6 4.4

Momentary maximum current A (rms) 4.3 6.8 18.6

Rotor inertia

kg·m

2

9.0 × 10

-6

3.4 × 10

-5

6.4 × 10

Power rate kW/s 11.4 11.8 25.5

Allowable radial load N 68 245

Allowable thrust load N 58 98

Weight Without brake kg 0.7 1.3 1.8

With brake kg 0.9 2.0 2.5

Encoder resolution --- Phase A and B: 2,500 pulses/rotation, Phase Z: 1 pulse/rotation

Radiation shield dimensions --- 130 × 120 × t10 (Al) 170 × 160 × t12 (Al)

Brake

specifications

Brake inertia

Excitation voltage V 24 VDC ±10%

kg·m

2

3.0 × 10

-6

9.0 × 10

-6

9.0 × 10

Power consumption (at 20 °C) W 7 10

Current consumption (at 20 °C) A 0.29 0.41

Static friction torque N·m 0.29 min. 1.27 min.

Attraction time ms 50 max. 60 max.

Release time ms 15 max.

Backlash - ±1° max.

Rating - Continuous

Brake life - 10,000,000 operations min.

Applicable servo driver (R7D-) BP01H BP02HH BP04H

Torque-speed characteristics

(r/min)

R88M-GP40030H

(N·m)

4.0

3.60

3.0

2.0

1.0

Repetitive usage

Continuous usage

0

1000 2000 3000 4000 5000

3.60

(3600)

2.0

1.31.3

0.64

(r/min)

R88M-GP10030H R88M-GP20030H

(N·m)

1.0

0.90

0.8

0.6

0.4

0.2

Repetitive usage

Continuous usage

0

1000 2000 3000 4000 5000

0.90

0.320.32

0.16

(r/min)

(N·m)

2.0

1.82

1.5

Repetitive usage

1.0

0.64

0.5

Continuous usage

0

1000 2000 3000 4000 5000

0.64

1.82 (4700)

1.75

0.28

-5

-6

SmartStep 2 servo system 11

Page 10

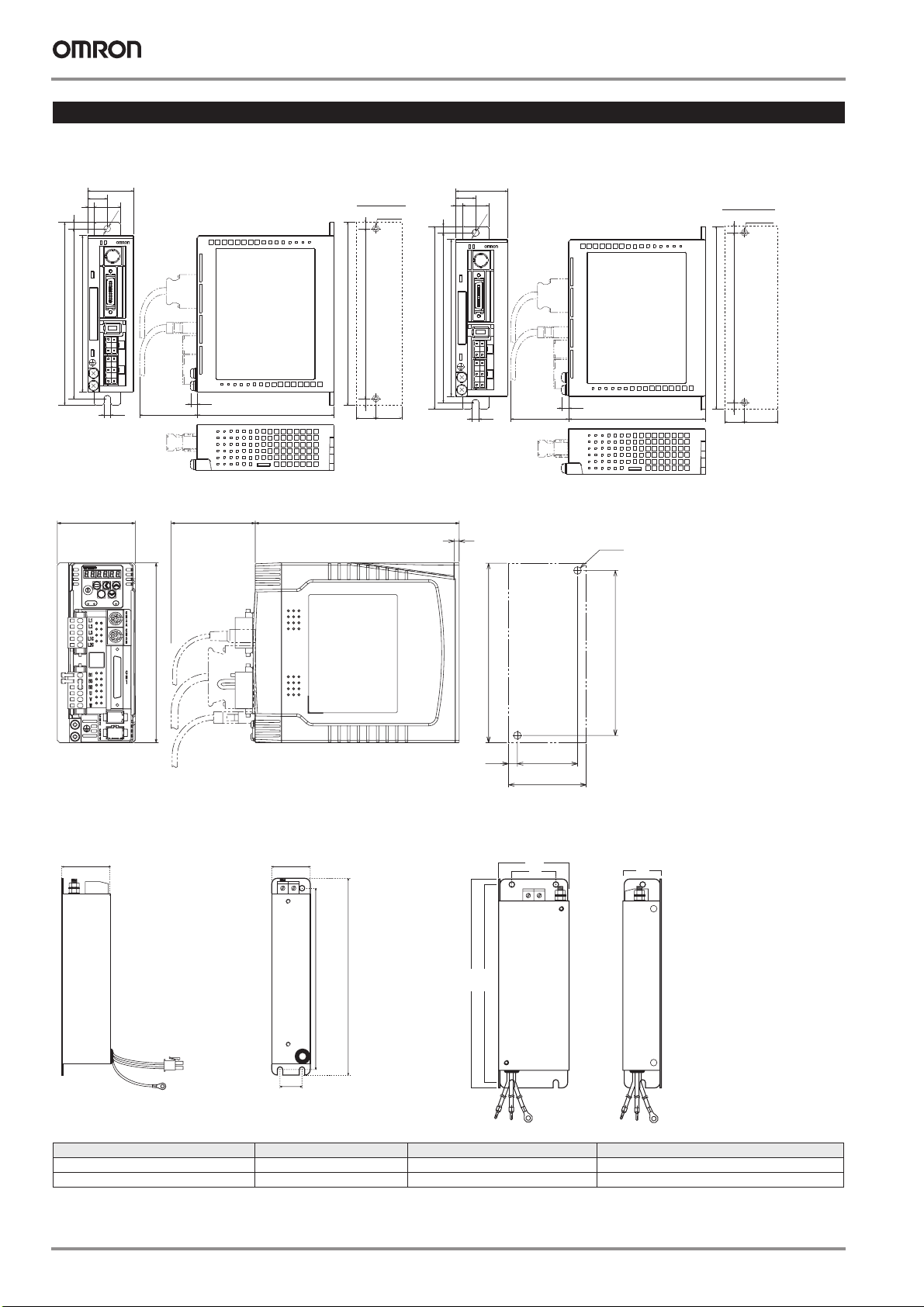

Dimensions

Servo drives

R7D-BP01H R7D-BP02HH/ 04H

35

15

20

5

5

5.2 dia.

PWR

ALM

130

120

140

5.2

R88D-GP08H

65

AC SERVO DRIVER

UNITNo.

DATA

IM SPG

Mounting Hole

Dimensions

Two, M4

C

N

3

C

N

1

C

N

2

C

N

B

C

N

A

5.1

70

105

140

130±0.5 55

15 20

17070

40

15

20

5

5

5.2 dia.

ALMPWR

C

N

3

C

N

1

130

120

140

C

N

2

C

N

B

C

N

A

5.2

70

4

5.1

Two, M4

Mounting Hole

Dimensions

Two, M4

55

140

130±0.5

105

15 25

150

150

7.5

±0.5

50

65

Filters

R7A-FIB104-RE R88A-FIK107-RE

44±1

output

flexes

1 x 130 mm

input

terminals

2 x 170 mm

connector

to servo drive

power supply input

M4

input

terminals

40±1

drive

mounts

2 x M4

20

165±1

output

flexes

179±1

190

180

64

40

drive

mounts

output

flexes

±0.5

140

35

Filter model Rated current Leakage current Rated voltage

R7A-FIB104-RE 4 A 3.5 mA 250 VAC single-phase

R88A-FIK107-RE 6.6 A 3.5 mA 250 VAC single-phase

12 AC servo systems

Page 11

Servo motors

Cylindrical type 3000 r/min (230 V, 50 - 100W)

Dimensions (mm) Without brake With brake LN Aprox. Mass (Kg)

Model LL LL Without brake With brake

R88M-G05030H-@S2 72 102 26.5 0.3 0.5

R88M-G10030H-@S2 92 122 46.5 0.5 0.7

Encoder

Connector

230

Brake Connector

Motor Connector

LL 25

200

LN

36

8 dia., height: 6

30 dia., height: 7

Two, 4.3 dia.

(Dimensions of shaft end

46 dia.

with key and tap)

12.5

3

3, height: 9

1.8

M3

(depth: 6)

40 × 40

32

Cylindrical type 3000 r/min (230 V, 200 - 750W)

Dimensions (mm) Without

brake

Model LL LL D1 D2 C G Z S QK b h M t1 L Without brake With brake

R88M-G20030H-@S2 79.5 116 30 43 70 50 60 6.5 4.5 11 18 4h9 4 M4 2.5 8 0.8 1.3

R88M-G40030H-@S2 99 135.5 14 22.5 5h9 5 M5 3 10 1.2 1.7

R88M-G75030H-@S2 112.2 149.2 35 53 90 70 80 8 6 19 22 6h9 6 M5 3.5 10 2.3 3.1

With

LR KL1 Flange surface Shaft end Aprox. Mass (Kg)

brake

Encoder connector

220

Brake connector

LL LR

Servomotor connector

200

3G

(Straight shaft with key)

QK

Four,

Z dia.

C × C

h

b

t1

M (depth: L)

.

a

KL1

S dia., height: 6

D2 dia., height: 7

D1 di

Flat type 3000 r/min (230 V, 100 W - 400 W)

Dimensions (mm) Without

brake

Model LL LL D1 D2 C F G Z S QK b h t1 Tap x

R88M-GP10030H-@S2 60.5 84.5 25 43 70 50 60 3 7 4.5 8 12.5 3h9 3 1.8 M3x6 0.7 0.9

R88M-GP20030H-@S2 67.5 100 30 53 90 70 80 5 8 5.5 11 18 4h9 4 2.5 M4x8 1.3 2

R88M-GP40030H-@S2 82.5 115 14 22.5 5h9 5 3.0 M5x10 1.8 2.5

connector

With

LR KL1 Flange surface Shaft end Aprox. Mass (Kg)

brake

LL LR

(7)

220

Servomotor connector

G

(7)

200

F

Break connector

Four,

Z-dia.

S dia., height: 6

KL1

D2 dia., height: 7

C x C

D1 dia.

(Straight shaft with key)

QK

h

b

t1

Tap x Depth

Without brake With brake

depth

SmartStep 2 servo system 13

Page 12

Installation

Single-phase, 230 VAC

L1

L2

L3

N

Thermal switch

Contactor

Noise filter

Regeneration

resistor *1

Reverse

pulse

Forward

pulse

12 to 24 VDC

RUN Command

Input

Alarm Reset

Input

+CW

−CW

+CCW

−CCW

24VIN

RUN

RESET 3

L1

L3

22

23

24

25

1

2

P

B1

CNA

4.7 kΩ

220 Ω

220 Ω

4.7 kΩ

4.7 kΩ

4.7 kΩ

Servo motor

CNB

U

V

W

SMARTSTEP2

Servo drive

(100-400 W)

CN2

CN1

/ALM

9

10

INP

BKIR

11

.

12

13

21

14

WARN

OGND

Z

GND

Optical encoder

Alarm Output

Positioning

Completed

Output

Brake Interlock

Warning Output

Z-phase Output

(open collector output)

Maximum operating

voltage: 30 VDC

Maximum Output

Current: 50 mA DC

Deviation Counter

Reset Input

ECRST4

4.7 kΩ

15

16

18

17

19

20

+A

−A

+B

−B

+Z

−Z

Encoder A-phase

Output

Encoder B-phase

Output

Encoder Z-phase

Output

Line driver output

Conforms to

EIA RS-422A

(Load resistance:

220 Ω min.)

Gain Switch

Input

Electronic Gear

Switch Input

Reverse Drive

Prohibit Input

GSEL 5

4.7 kΩ

GESEL 6

4.7 kΩ

NOT 7

4.7 kΩ

Forward Drive

Prohibit Input

POT 8

FGShell, 26

Frame ground

*1. An External Regeneration Resistor can be connected. Connect this resistor if the regenerative energy exceeds regeneration absorption capacity in the Servo Drive.

Note: 1.The dynamic brake operates when the main circuit power supply or the control circuit power supply is turned OFF.

Note: 2.When turning OFF the main circuit power supply, turn OFF the RUN Command Input (RUN) signal at the same time.

14 AC servo systems

Page 13

Thermal switch

Position reference

L1

L2

L3

N

Contactor

500 kpps max.

2 Mpps max.

Noise filter

Single-Phase

200 to 230 VAC

Reverse pulse

Forward pulse

Reverse pulse

Forward pulse

12 to 24 VDC

Servo ON

Vibration filter

switching

Gain switching

Electronic gear

switching

Deviation counter reset

Alarm reset

Control mode

switching

Pulse prohibition

Reverse run

prohibited

Forward run

prohibited

+24 VCW

+CW

-CW

+24 VCCW

+CCW

-CCW

+CWLD

-CWLD

+CCWLD

-CCWLD

DFSEL

GSEL

1

3

4

2

5

6

44

45

46

47

7+24 VIN

29RUN

26

27

28GESEL

30ECRST

31RESET

32TVSEL

33IPG

8NOT

9POT

L1

L3

L1C

L2C

2.2 kΩ

220 Ω

2.2 kΩ

220 Ω

3

kΩ

110 Ω

3k Ω

3k Ω

110 Ω

3 kΩ

4.7 kΩ

4.7 kΩ

4.7 k

4.7 kΩ

4.7 k

4.7 k

4.7 k

4.7 k

4.7 k

4.7 k

CNA

Ω

Ω

Ω

Ω

Ω

Ω

Ω

43 kΩ

43 kΩ

43 kΩ

43 kΩ

*1

B1

B3

B2

SMARTSTEP2

Servo drive

(750W)

CN1

CNB

1 µF

CN2

100Ω

4.7 kΩ

U

V

W

BKIR

11

BKIRCOM

10

READY

35

READYCOM

34

/ALM37

ALMCOM

36

INP39

INPCOM

38

12

OUTM1

40

OUTM2

41

COM-

19

Z

25 ZCOM

+A21

Encoder phase-A output

-A22

+B49

Encoder phase-B output

-B48

+Z23

Encoder phase-Z output

-Z24

20

SEN

SENGND

13

42

BAT

43

BATGND

50

Servo motor

Optical encoder

Brake release signal output

Servo ready output

Alarm output

Positioning completed output

General-purpose output 1

General-purpose output 2

Phase-Z output

(open collector output)

Line-driver output corresponding

with the EIA RS-422A communications

method (load resistance 120 W min.)

Sensor ON

Backup battery

(3.6 V)

*2

External power supply 12 to 24 VDC

um

Maxim

service voltage: 30 VDC

Maximum

output current: 50 mADC

*3

*3

Shell

*1 B3-B2 are short-circuited. If the internal regenerative resistor is insufficient, remove the wire between B2 and B3 and connect an external regen-

erative resistor between B1 and B2.

*2 Use only when an absolute encoder. If a backup battery is connected, an encoder cable with a battery is not required.

*3 The default values are ZSP (zero-speed detection) for OUTM1 and T-LIMIT (at torque limit) for OUTM2.

SmartStep 2 servo system 15

Page 14

Ordering information

SmartStep2 Servo Drive Configuration (100-400 W)

(Refer to chapter SmartStep servo motors)

SmartStep 2

Servo Motor

A

Encoder cable

D

Power cable

B

Brake cable

C

E

SmartStep 2 Servo Drive

(100-400W models)

K

Position control

unit

Filter

P

O

F

I

L

M

Personal computer

software: CX-One

Position control unit

-High-speed type-

G

J

N

H

K

Position control

unit

Terminal block

General purpose signals

(with pulse output)

Note: The symbols ABCDE... show the recommended sequence to select the components in a SmartStep 2 servo system

Servo motor

Cylindrical servo motors (3,000-r/min)

Symbol Specifications Servo motor model Compatible servo drives E

A Straight shaft with

Design Rated torque Capacity SmartStep 2

key and tap

Without brake 0.16 Nm 50 W R88M-G05030H-S2 R7D-BP01H

0.32 Nm 100 W R88M-G10030H-S2

0.64 Nm 200 W R88M-G20030H-S2 R7D-BP02HH

1.3 Nm 400 W R88M-G40030H-S2 R7D-BP04H

With brake 0.16 Nm 50 W R88M-G05030H-BS2 R7D-BP01H

0.32 Nm 100 W R88M-G10030H-BS2

0.64 Nm 200 W R88M-G20030H-BS2 R7D-BP02HH

1.3 Nm 400 W R88M-G40030H-BS2 R7D-BP04H

Flat servo motors (3,000-r/min)

Symbol Specifications Servo motor model Compatible servo drives E

A Straight shaft with

Design Rated torque Capacity SmartStep 2

key and tap

Without brake 0.32 Nm 100 W R88M-GP10030H-S2 R7D-BP01H

0.64 Nm 200 W R88M-GP20030H-S2 R7D-BP02HH

1.3 Nm 400 W R88M-GP40030H-S2 R7D-BP04H

With brake 0.32 Nm 100 W R88M-GP10030H-BS2 R7D-BP01H

0.64 Nm 200 W R88M-GP20030H-BS2 R7D-BP02HH

1.3 Nm 400 W R88M-GP40030H-BS2 R7D-BP04H

Servo drives

Symbol Specifications SmartStep 2 drive model Compatible servo motors A

E

200 VAC 100 W R7D-BP01H R88M-G05030H-@ -

200 W R7D-BP02HH R88M-G20030H-@ R88M-GP20030H-@

400 W R7D-BP04H R88M-G40030H-@ R88M-GP40030H-@

Cylindrical type Flat type

R88M-G10030H-@ R88M-GP10030H-@

Power Supply cables (for CNA)

Symbol Specifications Model Appearance

E

Power Supply Input Cable for Single-Phase Power (connectors attached)

R7A-CLB002S2

16 AC servo systems

Page 15

Servo motor cables

Power cables (for CNB)

Symbol Specifications Model Appearance

B

Power cables for SmartStep 2 Servo motors 1.5 m R7A-CAB001-5SR-E

3 m R7A-CAB003SR-E

5 m R7A-CAB005SR-E

10 m R7A-CAB010SR-E

15 m R7A-CAB015SR-E

20 m R7A-CAB020SR-E

Brake cables

Symbol Specifications Model Appearance

C

Brake cables for SmartStep 2 Servo motors 1.5 m R88A-CAGA001-5BR-E

3 m R88A-CAGA003BR-E

5 m R88A-CAGA005BR-E

10 m R88A-CAGA010BR-E

15 m R88A-CAGA015BR-E

20 m R88A-CAGA020BR-E

Encoder cables (for CN2)

Symbol Specifications Model Appearance

D

Encoder cables for SmartStep 2 Servo motors 1.5 R88A-CRGB001-5CR-E

3 m R88A-CRGB003CR-E

5 m R88A-CRGB005CR-E

10 m R88A-CRGB010CR-E

15 m R88A-CRGB015CR-E

20 m R88A-CRGB020CR-E

Note: B, D Flexible and shielded cable

C Flexible cable

Control cables (for CN1)

Symbol Description Connect to Model

F

G

H

I

J

Control cable

(line-driver output for 1 axis)

Control cable

(open-collector output for 1 axis)

Control cable

(line-driver output for 2 axis)

Control cable

(open-collector output for 2 axis)

Terminal block cable for external signals

(for input common, forward/reverse run prohibited inputs,

emergency stop input, origin proximity input and interrupt input)

Terminal block for external signals ( with M3 screw and for pin terminals) - XW2B-20G4

Terminal block ext. signals ( with M3.5 screw and for fork/round terminals) - XW2B-20G5

Terminal block ext. signals ( with M3 screw and fork/round pin terminals) - XW2D-20G6

Cable from servo relay unit to servo drive CS1W-NC1@3, CJ1W-NC1@3,

Servo relay unit CS1W-NC1@3, CJ1W-NC1@3 or

Position control unit (high-speed type)

CJ1W-NC234

CJ1W-NC434

Position control unit (high-speed type)

CJ1W-NC214

CJ1W-NC414

Position control unit (high-speed type)

CJ1W-NC234

CJ1W-NC434

Position control unit (high-speed type)

CJ1W-NC214

CJ1W-NC414

Position control units (high-speed type)

CJ1W-NC234

CJ1W-NC434

CJ1W-NC214

CJ1W-NC414

C200HW-NC113, CS1W-NC2@3/4@3,

CJ1W-NC2@3/4@3, C200HW-NC213/413,

CQM1H-PLB21 or CQM1-CPU43-V1

CJ1M-CPU21/22/23 1 m XW2Z-100J-B32

C200HW-NC113 position control unit

CS1W-NC2@3/4@3, CJ1W-NC2@3/4@3 or

C200HW-NC213/413 position control unit

CQM1H-PLB21 or CQM1-CPU43-V1 - XW2B-20J6-3B (1 axis)

CJ1M-CPU21/22/23 - XW2B-20J6-8A (1 axis)

1 m XW2Z-100J-G12

5 m XW2Z-500J-G12

10 m XW2Z-10MJ-G12

1 m XW2Z-100J-G16

3 m XW2Z-300J-G16

1 m XW2Z-100J-G4

5 m XW2Z-500J-G4

10 m XW2Z-10MJ-G4

1 m XW2Z-100J-G8

3 m XW2Z-300J-G8

0.5 m XW2Z-C50X

1 m XW2Z-100X

2 m XW2Z-200X

3 m XW2Z-300X

5 m XW2Z-500X

10 m XW2Z-010X

1 m XW2Z-100J-B29

2 m XW2Z-200J-B29

2 m XW2Z-200J-B32

- XW2B-20J6-1B (1 axis)

- XW2B-40J6-2B (2 axes)

XW2B-40J6-9A (2 axes)

SmartStep 2 servo system 17

Page 16

Symbol Description Connect to Model

K

L

M

N

Position control unit connecting cable CJ1W-NC133 0.5 m XW2Z-050J-A18

CJ1W-NC233/433 0.5 m XW2Z-050J-A19

CS1W-NC133 0.5 m XW2Z-050J-A10

CS1W-NC233/433 0.5 m XW2Z-050J-A11

CJ1W-NC113 0.5 m XW2Z-050J-A14

CJ1W-NC213/413 0.5 m XW2Z-050J-A15

CS1W-NC113

C200HW-NC113

CS1W-NC213/413

C200HW-NC213/413

CJ1M-CPU21/22/23 0.5 m XW2Z-050J-A33

CQM1H-PLB21

CQM1-CPU43-V1

General purpose cable For general purpose controllers 1 m R7A-CPB001S

Terminal block cable For general purpose controllers 1 m XW2Z-100J-B28

Terminal block ( with M3 screw and for pin terminals) - XW2B-34G4

Terminal block ( with M3.5 screw and for fork/round terminals) - XW2B-34G5

Terminal block ( with M3 screw and fork/round pin terminals) - XW2D-34G6

1 m XW2Z-100J-A18

1 m XW2Z-100J-A19

1 m XW2Z-100J-A10

1 m XW2Z-100J-A11

1 m XW2Z-100J-A14

1 m XW2Z-100J-A15

0.5 m XW2Z-050J-A6

1 m XW2Z-100J-A6

0.5 m XW2Z-050J-A7

1 m XW2Z-100J-A7

1 m XW2Z-100J-A33

0.5 m XW2Z-050J-A3

1 m XW2Z-100J-A3

2 m R7A-CPB002S

2 m XW2Z-200J-B28

Cable for CN3

Symbol Name Lengh Model

O

Personal Computer Monitor Cable 2 m R88A-CCG002P2

Filters

Symbol Applicable servo drive Rated current Rated voltage Filter model

P

R7D-BP01H/ 02HH/ 04H 4 A 1 pH, 230 V R7A-FIB104-RE

Connectors

Specifications Model

Main Circuit Connector (CNA) R7A-CNB01P

Servomotor Connector (CNB) R7A-CNB01A

Control I/O Connector (CN1) R88A-CNW01C

Encoder Input Connector (CN2) R88A-CNW01R

Servomotor Connector for Encoder Cable R88A-CNG02R

Servomotor Connector for Servomotor Power Cable R88A-CNG01A

Brake Cable Connector R88A-CNG01B

External regeneration resistor

Specification Model

80 W, 50 Ω R88A-RR08050S

80 W, 100 Ω R88A-RR080100S

220 W, 47 Ω R88A-RR22047S

External regeneration resistor cable

Specifications Model

External Regenerative Resistor Connection Cable, 2 meters R7A-CLB002RG

Parameter unit & computer software

Specifications Model

Parameter copy unit (with cable) R88A-PR02G

Configuration and monitoring software tool for servo drives and inverters. (CX-drive version 1.8 or higher) CX-drive

18 AC servo systems

Page 17

SmartStep2 Servo Drive Configuration (750W)

(Refer to chapter SmartStep servo motors)

SmartStep 2 Servo Drive

B

(750W model)

Personal computer

software: CX-One

O

A

SmartStep 2

Servo Motor (750W)

Power cable

D

Encoder cable

C

External regenerative

Q

resistor

P

Filter

Position control

unit

Position control unit

-High-speed type-

F

I

J

G

K

L

Brake cable

E

M

N

Terminal block

General purpose signals

(with pulse output)

Note: The symbols ABCDE... show the recommended sequence to select the components in a SmartStep 2 servo system.

Servo drives

Symbol Specifications Servo drive model A Compatible rotary servo motors

Cylindric type

B 1 phase 200 VAC 750 W R88D-GP08H R88M-G75030H-@

Encoder Cables

Symbol Specifications Model Appearance

C

Encoder cable

R88M-G75030H-@

1.5 m R88A-CRGB001-5CR-E

3 m R88A-CRGB003CR-E

5 m R88A-CRGB005CR-E

10 m R88A-CRGB010CR-E

15 m R88A-CRGB015CR-E

20 m R88A-CRGB020CR-E

Terminal block

for external signals

H

Position control

unit

Power cables

Symbol Specifications Model Appearance

D

For 750W servomotors without brake

R88M-G75030H-S2

For servomotors with brake, a separate cable

(R88A-CAGA@BR-E) is needed

1.5 m R88A-CAGA001-5SR-E

3 m R88A-CAGA003SR-E

5 m R88A-CAGA005SR-E

10 m R88A-CAGA010SR-E

15 m R88A-CAGA015SR-E

20 m R88A-CAGA020SR-E

Brake cable

Symbol Specifications Model Appearance

E

Brake cable only.

For R88M-G75030H-BS2 servomotors.

1.5 m R88A-CAGA001-5BR-E

3 m R88A-CAGA003BR-E

5 m R88A-CAGA005BR-E

10 m R88A-CAGA010BR-E

15 m R88A-CAGA015BR-E

20 m R88A-CAGA020BR-E

Control cables (for CN1)

Symbol Description Connect to Model

F

Control cable

(line-driver output for 1 axis)

Control cable

(open-collector output for 1 axis)

Control cable

(line-driver output for 2 axis)

Control cable

(open-collector output for 2 axis)

Position control units (high-speed type)

CJ1W-NC234

CJ1W-NC434

Position control units (high-speed type)

CJ1W-NC214

CJ1W-NC414

Position control units (high-speed type)

CJ1W-NC234

CJ1W-NC434

Position control units (high-speed type)

CJ1W-NC214

CJ1W-NC414

1 m XW2Z-100J-G9

5 m XW2Z-500J-G9

10 m XW2Z-10MJ-G9

1 m XW2Z-100J-G13

3 m XW2Z-300J-G13

1 m XW2Z-100J-G1

5 m XW2Z-500J-G1

10 m XW2Z-10MJ-G1

1 m XW2Z-100J-G5

3 m XW2Z-300J-G5

SmartStep 2 servo system 19

Page 18

Symbol Description Connect to Model

G

H

I

J

K

L

M

N

Terminal block cable for external signals

(for input common, forward/reverse run prohibited inputs,

emergency stop input, origin proximity input and interrupt

input)

Terminal block for external signals (M3 screw, pin terminals) - XW2B-20G4

Terminal block ext. signals

Terminal block ext. signals

Cable from servo relay unit to servo drive CS1W-NC1@3, CJ1W-NC1@3, C200HW-NC113/213/413,

Servo relay unit CS1W-NC1@3, CJ1W-NC1@3 or C200HW-NC113

Position control unit connecting cable CQM1H-PLB21 0.5 m XW2Z-050J-A3

General purpose cable For general purpose controllers 1 m R88A-CPG001S

Terminal block cable For general purpose controllers 1 m XW2Z-100J-B24

Terminal block (M3 screw and for pin terminals) - XW2B-50G4

Terminal block (M3.5 screw and for fork/round terminals) - XW2B-50G5

Terminal block (M3 screw and for fork/found terminals) - XW2D-50G6

(M3.5 screw, fork/round term inals) - XW2B-20G5

(M3 screw, fork/round terminals) - XW2D-20G6

Position control units (high-speed type)

CJ1W-NC234

CJ1W-NC434

CJ1W-NC214

CJ1W-NC414

CS1W-NC2@3/4@3, CJ1W-NC2@3/4@3 or

CQM1H-PLB21

CJ1M-CPU21/22/23 1 m XW2Z-100J-B31

position control unit

CS1W-NC2@3/4@3, CJ1W-NC2@3/4@3 or

C200HW-NC213/413 position control unit

CQM1H-PLB21 - XW2B-20J6-3B (1 axis)

CJ1M-CPU21/22/23 - XW2B-20J6-8A (1 axis)

CS1W-NC113 or C200HW-NC113 0.5 m XW2Z-050J-A6

CS1W-NC213/413 or C200HW-NC213/413 0.5 m XW2Z-050J-A7

CS1W-NC133 0.5 m XW2Z-050J-A10

CS1W-NC233/433 0.5 m XW2Z-050J-A11

CJ1W-NC113 0.5 m XW2Z-050J-A14

CJ1W-NC213/413 0.5 m XW2Z-050J-A15

CJ1W-NC133 0.5 m XW2Z-050J-A18

CJ1W-NC233/433 0.5 m XW2Z-050J-A19

CJ1M-CPU21/22/23 0.5 m XW2Z-050J-A33

0.5 m XW2Z-C50X

1 m XW2Z-100X

2 m XW2Z-200X

3 m XW2Z-300X

5 m XW2Z-500X

10 m XW2Z-010X

1 m XW2Z-100J-B25

2 m XW2Z-200J-B25

2 m XW2Z-200J-B31

- XW2B-20J6-1B (1 axis)

- XW2B-40J6-2B (2 axes)

XW2B-40J6-9A (2 axes)

1 m XW2Z-100J-A3

1 m XW2Z-100J-A6

1 m XW2Z-100J-A7

1 m XW2Z-100J-A10

1 m XW2Z-100J-A11

1 m XW2Z-100J-A14

1 m XW2Z-100J-A15

1 m XW2Z-100J-A18

1 m XW2Z-100J-A19

1 m XW2Z-100J-A33

2 m R88A-CPG002S

2 m XW2Z-200J-B24

Computer cable (for CN3)

Symbol Name Model

O

Computer cable RS232 2 m R88A-CCG002P2

Filter

Symbol Applicable

P

servodrive

R88D-GP08H R88A-FIK107-RE 6.6 A 3.5 mA 250 VAC

Filter model Rated

current

Leakage

current

Rated

voltage

singlephase

Connectors

Specifications Model

I/O connector kit -50 pins- (for CN1) R88A-CNU11C

Power cable connector (motor side) R88A-CNG01A

Encoder connector (Servo drive side CN2) R88A-CNW01R

Incremental encoder cable connector (motor side) R88A-CNG02R

Computer software

Specifications Model

Configuration and monitoring software tool for servo drives

and inverters (CX-drive version 1.91 or higher).

CX-Drive

External regenerative resistor

Symbol Regenerative resistor unit model Specifications

Q

R88A-RR08050S 50 Ω, 80 W

R88A-RR080100S 100 Ω, 80 W

R88A-RR22047S 47 Ω, 220 W

R88A-RR50020S 20 Ω, 500 W

20 AC servo systems

Page 19

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD, Hoofddorp, The Netherlands. Tel: +31 (0) 23 568 13 00 Fax: +31 (0) 23 568 13 88 www.industrial.omron.eu

Austria

Tel: +43 (0) 2236 377 800

www.industrial.omron.at

Belgium

Tel: +32 (0) 2 466 24 80

www.industrial.omron.be

Czech Republic

Tel: +420 234 602 602

www.industrial.omron.cz

Denmark

Tel: +45 43 44 00 11

www.industrial.omron.dk

Finland

Tel: +358 (0) 207 464 200

www.industrial.omron.fi

France

Tel: +33 (0) 1 56 63 70 00

www.industrial.omron.fr

Germany

Tel: +49 (0) 2173 680 00

www.industrial.omron.de

Hungary

Tel: +36 1 399 30 50

www.industrial.omron.hu

Italy

Tel: +39 02 326 81

www.industrial.omron.it

Netherlands

Tel: +31 (0) 23 568 11 00

www.industrial.omron.nl

Norway

Tel: +47 (0) 22 65 75 00

www.industrial.omron.no

Poland

Tel: +48 (0) 22 645 78 60

www.industrial.omron.pl

Portugal

Tel: +351 21 942 94 00

www.industrial.omron.pt

Russia

Tel: +7 495 648 94 50

www.industrial.omron.ru

South-Africa

Tel: +27 (0)11 579 2600

www.industrial.omron.co.za

Spain

Tel: +34 913 777 900

www.industrial.omron.es

Sweden

Tel: +46 (0) 8 632 35 00

www.industrial.omron.se

Switzerland

Tel: +41 (0) 41 748 13 13

www.industrial.omron.ch

Turkey

Tel: +90 216 474 00 40

www.industrial.omron.com.tr

United Kingdom

Tel: +44 (0) 870 752 08 61

www.industrial.omron.co.uk

More Omron representatives

www.industrial.omron.eu

KPP_SmartStep2_EN_INT01A

Automation Systems

• Programmable logic controllers (PLC) • Human machine interfaces (HMI) • Remote I/O

• Industrial PC’s • Software

Motion & Drives

• Motion controllers • Servo systems • Inverters

Control Components

• Temperature controllers • Power supplies • Timers • Counters • Programmable relays

• Digital panel indicators • Electromechanical relays • Monitoring products • Solid-state relays

• Limit switches • Pushbutton switches • Low voltage switch gear

Sensing & Safety

• Photoelectric sensors • Inductive sensors • Capacitive & pressure sensors

• Cable connectors • Displacement & width-measuring sensors • Vision systems

• Safety networks • Safety sensors • Safety units/relay units • Safety door/guard lock switches

Although we strive for perfection, Omron Europe BV and/or its subsidiary and affiliated companies do not warrant

or make any representations regarding the correctness or completeness of the information described in this document.

We reserve the right to make any changes at any time without prior notice.

Loading...

Loading...