Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

Cat. No. V002-E1-3

NT600M

Programmable Terminal

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

NT600M

Programmable Terminal

Operation Manual

Revised October 1997

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

IBM and IBM PC/AT are registered trademarks of International Business Machines Corporation.

MS-DOS is a registered trademark of Microsoft Corporation.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3...

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

OMRON, 1991

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

ii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

About this Manual:

This manual describes the installation and operation of the NT600M Programmable Terminals (PTs) and

includes the sections described below. Further information is provided in manuals on the Host Interface

Units and Support Tool. Refer to the list in

Please read this manual completely and be sure you understand the information provide before attempting to install and operate a Programmable Terminal.

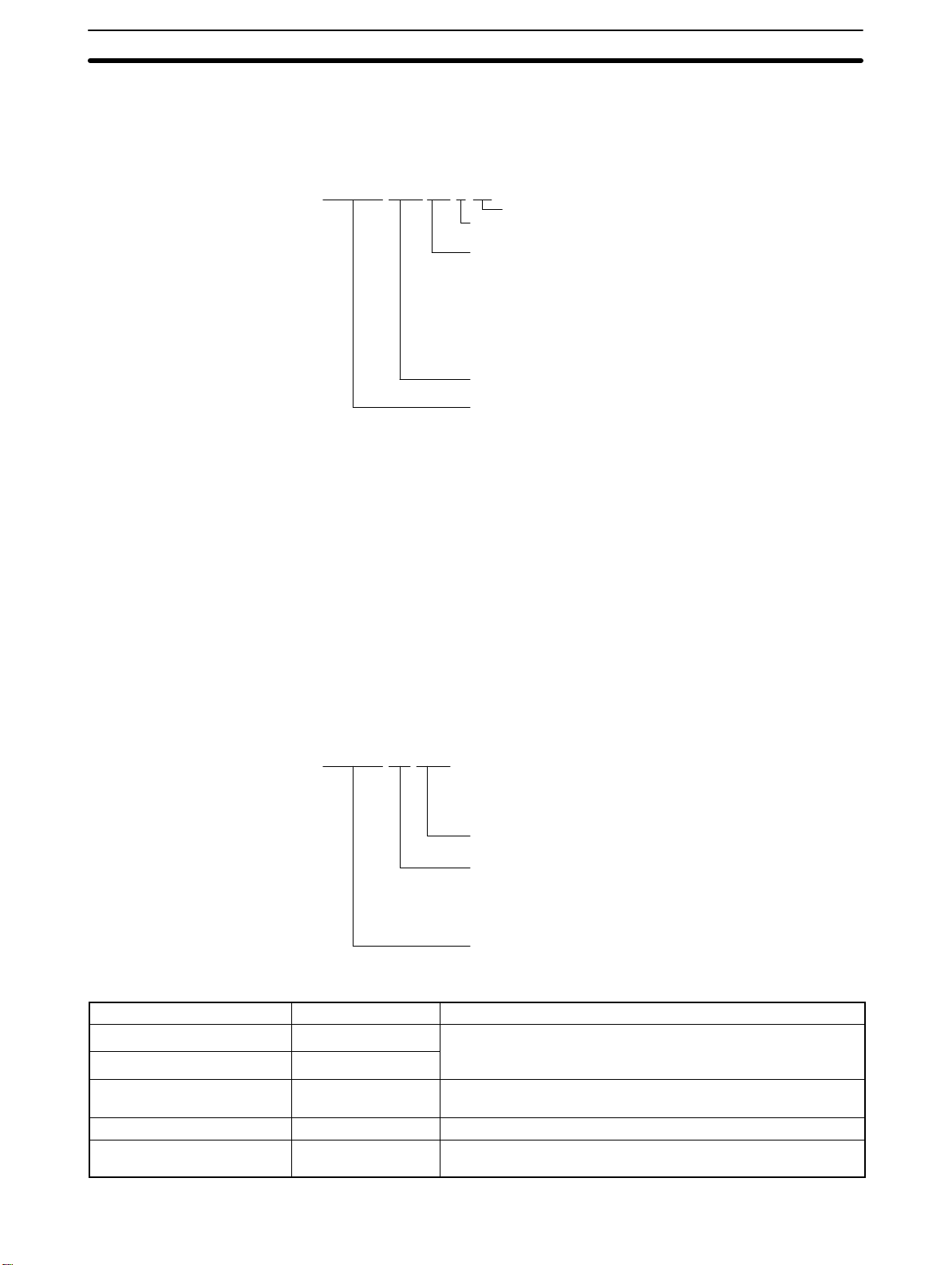

Section 1 Introduction

.

Section 1

of system configurations for programming and operation.

Section 2

switch settings and installation.

Section 3

Section 4

Included is automatic transfer of data from the host computer via character string and numeral tables.

Section 5

the numeral table.

Section 6

Section 7

Section 8

Appendices of OMRON products used with PTs, PT specifications, and a memory check table are

provided at the back of the manual.

introduces the PTs, describes the terminology used in this manual, and provides examples

provides procedures and specifications required to set up a PT system, including hardware

provides steps required for initial PT operation.

describes functions used to create screens and control display attributes on the PT.

describes functions used to input data on-screen and transfer it to the host computer via

describes basic data transfer and maintenance functions.

describes transferring screens online to and from the host computer.

provides troubleshooting and basic maintenance methods, including battery replacement.

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iii

Page 6

TABLE OF CONTENTS

PRECAUTIONS ix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1 – Introduction 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Introduction 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Features 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Terminology and NT-series Manuals 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Models 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-1 NT600M Programmable Terminals 6 . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-2 Screen Data Memory Boards 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-3 System ROM 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-4 Host Interface Units 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-5 12-key Function Key Units (for DN-type) 9 . . . . . . . . . . . . . . . . . . . . .

1-5 Support Tools 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 System Configuration 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7 Nomenclature and Functions 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7-1 Front Panel 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7-2 Rear Panel 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 – Switch Settings, Installation, and Wiring 15 . . . . . . . . . . . . . . .

2-1 Switch Settings 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 System DIP Switch Settings (SW1) 16 . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Mounting System ROM 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-3 Screen Data Memory Board Settings and Installation 18 . . . . . . . . . . . .

2-2 Installation Environment 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 Installation Site 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Mounting Position 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Dimensions 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-1 Terminals with Function Keys (DF-type) 22 . . . . . . . . . . . . . . . . . . . . . .

2-3-2 PTs With (DT-type) and Without (DN-type) Touch Panels 23 . . . . . . . . .

2-4 Installing the NT600M PT in a Panel 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Wiring and Connectors 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-1 Terminal Block 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-2 AC INPUT Terminals 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-3 LG and GR Terminals 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-4 HOST RUN INPUT Terminals 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-5 ALM OUTPUT Terminals 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 RS-232C Interface Connector 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 12-key Function Key Units (for DN-type PTs) 28 . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 Mounting Function Key Units (to DN-type PTs) 28 . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 – Initial Operation 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Powering Up 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Initialization 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-1 Initializing Memory 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-2 Menus 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Transferring Data to and from the Support Tool 35 . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Trial Operation 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

v

Page 7

Table of contents

SECTION 4 – Display Functions 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Character Displays 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-1 Types of Characters 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-2 Designating Display Positions 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-3 Character Scale 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-4 Display Attributes 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Display Graphics 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Normal Screen Changes 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-1 Procedure for Changing Screens 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Continuous Screens 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 Overlapping Screens 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6 Numeric Displays 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7 Character Strings 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8 Bar Graphs 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-9 Lamps 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-10 Graphics Display 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11 Special Controls 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11-1 Backlight ON/OFF 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11-2 Alarm Output On/Off 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11-3 Buzzer On/Off 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11-4 Initialize Display History 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11-5 HOST RUN INPUT 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11-6 Normal/Inverse Display (LCD-type Only) 50 . . . . . . . . . . . . . . . . . . . . .

4-12 Terminal Function 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-13 Display Speed 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5 – Input Functions 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 On-screen Switch Inputs 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-1 Transmitting to the Host 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-2 Creating Touch Switches (DT-type PTs Only) 55 . . . . . . . . . . . . . . . . . .

5-1-3 Function Keys (NT600M-DF122) 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Inputting Numeric Settings 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Standalone Function 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 – System Menu 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Configuration of System Menu 62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 System Menu and Transmit Mode 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-1 Quit 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-2 Transmit Mode 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-3 Maintenance Mode 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-4 Expansion Mode 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-5 Display History 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-6 I/O Checks 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-7 PT Settings Check 69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-8 Initialization 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Memory Switch Settings 71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7 – Online Transfer 75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1 Host to PT 76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 PT to Host 76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

Table of contents

SECTION 8 – Maintenance and Inspection 79 . . . . . . . . . . . . . . . . . . . . . . . . .

8-1 Checking Operation 80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2 Changing the Lithium Backup Battery 80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3 Maintenance and Inspection 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3-1 Spare Terminals 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3-2 Inspection 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3-3 Precautions When Cleaning the PT Screen 82 . . . . . . . . . . . . . . . . . . . . .

8-4 RUN Mode Function Configuration 83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix 85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A – Standard Models 85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B – Specifications 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C – Memory Check Table 91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D – Special Characters 93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

vii

Page 9

PRECAUTIONS

This section provides general precautions for using the Programmable Terminal.

The information contained in this section is important for the safe and reliable application of the Programmable Terminal. You must read this section and understand the information contained befor e attempting to set up or operate a

Programmable Terminal.

1 Intended Audience x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ix

Page 10

Safety Precautions

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement

machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for using the Programmable Terminal. Be sure

to read this manual before attempting to use the software and keep this manual

close at hand for reference during operation.

3

WARNING It is extremely important that Programmable Terminals and related devices be

!

used for the specified purpose and under the specified conditions, especially in

applications that can directly or indirectly affect human life. You must consult

with your OMRON representative before applying Programmable Terminals to

the abovementioned applications.

WARNING Do not use input functions such as PT touch switches for applications where

!

danger to human life or serious damage is possible, or for emergency switch

applications.

3 Safety Precautions

Read these safety precautions carefully and make sure you understand them

before using the Programmable Terminal so that you can use it safely and correctly.

Safety Conventions and

their Meanings

DANGER Indicates information that, if not heeded, is likely to result in loss of life or serious

!

This operation manual uses the following conventions and symbols to indicate

cautions, warnings, and dangers in order to ensure safe use of the PT. The cautions, warnings, and dangers shown here contain important information related

to safety. The instructions in these cautions, warnings, and dangers must be

observed.

The conventions used and their meanings are presented below.

injury.

WARNING Indicates information that, if not heeded, could possibly result in loss of life or

!

serious injury.

Caution Indicates information that, if not heeded, could result in relatively serious or mi-

!

nor injury, damage to the product, or faulty operation.

x

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

Safety Precautions

Caution

!

3

• The ROM may be destroyed if it is mounted while power is being supplied to

the PT.

• Screen memory must be initialized before using a new PT. If the PT is used as

shipped from the factory without initialization, messages indicating errors in

the host will not be displayed.

• After the transfer has been completed, be sure to return to RUN Mode by

pressing the Buzzer Key, Up Key, and Down Key simultaneously. If the power

is turned off or if a reset is executed without having first returned to RUN Mode,

the data that has been transmitted will be corrupted. If that occurs, a message

will be displayed on the screen to indicate that the data has been corrupted.

• If a load (e.g., a buzzer or alarm light) is connected to a 10/02 Terminal or a

32/16 Terminal, it will actually operate. This can be potentially dangerous, so

exercise caution.

• The lithium battery can explode if placed into a fire, or it can explode, burn, or

leak if the + and – terminals are short-circuited or if the battery is recharged or

dismantled. Handle the battery with care.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

xi

Page 12

SECTION 1

Introduction

This section provides information necessary to familiarize you with the features and parts of a PT system.

1-1 Introduction 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Features 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Terminology and NT-series Manuals 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Models 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-1 NT600M Programmable Terminals 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-2 Screen Data Memory Boards 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-3 System ROM 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-4 Host Interface Units 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-5 12-key Function Key Units (for DN-type) 9 . . . . . . . . . . . . . . . . . . . . . .

1-5 Support Tools 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 System Configuration 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7 Nomenclature and Functions 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7-1 Front Panel 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7-2 Rear Panel 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1

Page 13

Introduction Section 1-1

1-1 Introduction

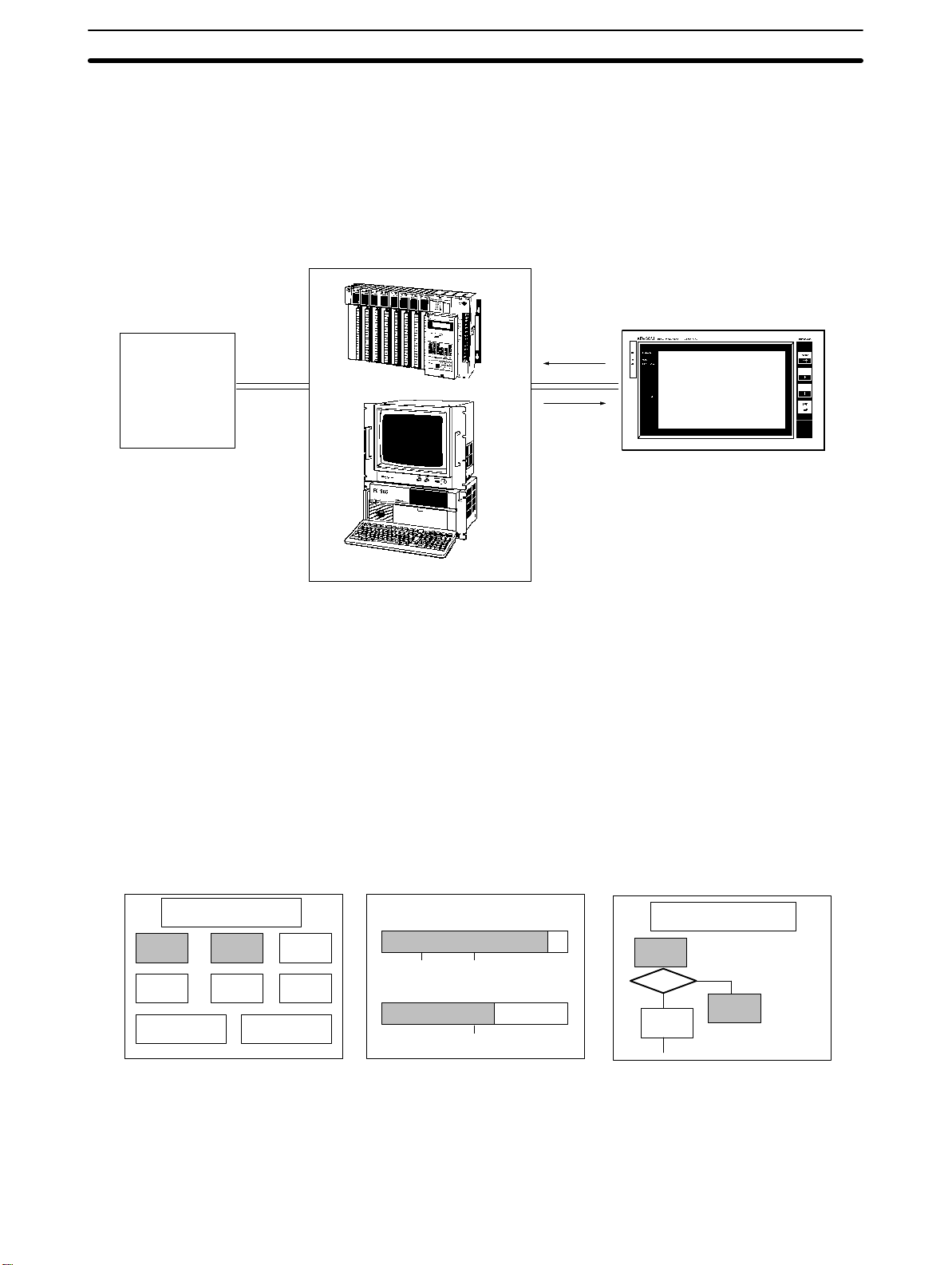

This manual describes the installation and operation of NT600M Programmable Terminals (PTs). Programmable Terminals have three main functions:

1) monitoring operating conditions, 2) directing on-site personnel, and 3) inputting data.

Host

Directing

operations,

monitoring

conditions

Device

Instructions

Programmable Terminal

(Programmable Controller or FA computer)

1) PTs can monitor, in real time, system and equipment operating conditions,

production quantities, and so on. The PT display can show, for example,

whether the production line is operating normally, and what percentage of the

production target has been met. Bar graphs can be continually updated as

data is received from the host. On-screen characters can be displayed as

plain, reverse video, blinking, or reverse blinking. In addition, lamps, bar

graphs, and figures can all be created. Screen data can be registered at the

PT in advance, and can be displayed simply by transmitting the appropriate

screen number from the host.

Lamp Display Bar Graph Display

Operating conditions

Run Air

Run Normal Oil

Emergency

stop

Normal

Error

Rotation (rpm)

0

Oil pressure (kg/cm

0

5.0 10

Graphics Display

Conveyance System

L1-0

36001800

2

)

M10

L1-2

L2-0

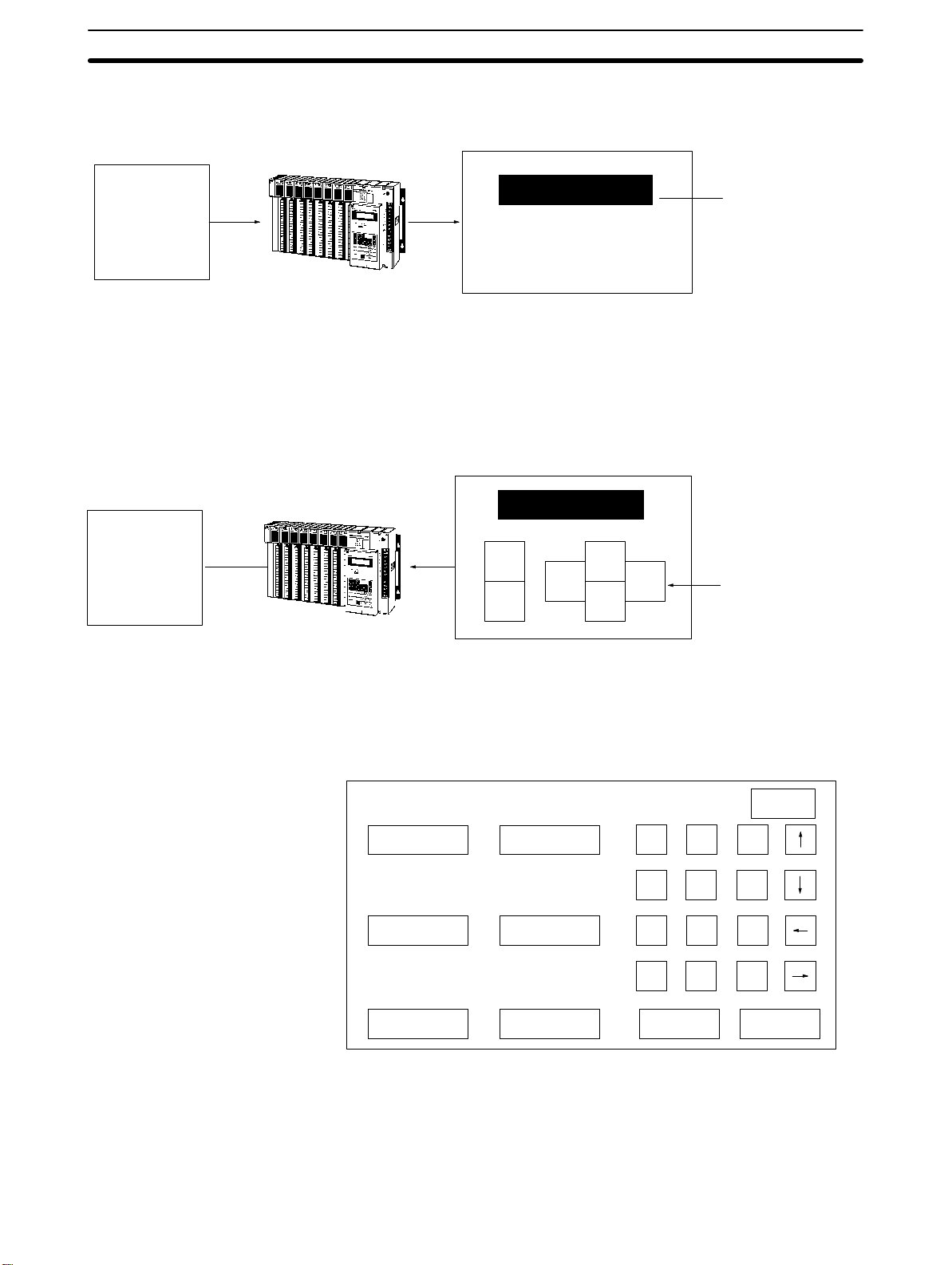

2) PTs can inform on-site personnel of current conditions that need to be addressed. Depending on the nature of the situation, built-in or external buzzers

can be sounded to alert personnel to problems that have developed. Depending on factors such as distance from the host, the number of devices

2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

Introduction Section 1-1

connected, and the response time, any of a variety of communications methods may be selected.

Abnormality

occurs!

Device

Normal

operation

Device

EMERGENCY STOP

Air pressure is abnormal.

Please check

PC

PT

(Flashing display)

3) PTs can input data for controlling certain operations and communicating

information to the host. Setting switches and a ten-key pad allows a PT to be

used as a control panel. In the example shown below, touch switches used

for inputs to the host are displayed. When this screen is displayed, the onsite operator can control a device by means of touch switches.

Crane Operation

Run

Left

Stop

PC

PT

Up

Down

Right

(Touch switches

created by Support

Tool.)

Aside from touch switches, the PT can provide inputs by means of numeric

settings and externally connected switches. The illustration below shows a

numeric setting screen that can be used for inputting numeric data.

Tank A

0654 0650

Tank C

0000 0550

Tank E

0800 0990

Tank B

Tank D

Tank F

1 2 3

4 5 6

7 8 9

HO

0

ME

Change Set

MENU

C

The screens used for these operations can be created in advance by using

the “Support Tool” software on a personal computer. The screen data that is

created using the Support Tool can be printed out, saved to a diskette, or

transferred to the PT. An FA Computer, a Programmable Controller, or a

compatible device can be used as the host.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3

Page 15

2

(V

)

Features Section 1-2

1-2 Features

Wide Selection of Models

Drip-proof Structure

Clear Display

Two-way Communications

with Host

Display Functions

Input Options

The NT600-series PTs provide a choice of three models depending on the

input specifications of your system. You can also choose either of two types

of display devices. Any of six methods can be selected for communicating

with the host, which may be an FA Computer, a Programmable Controller, or

a compatible device.

The PTs have a drip-proof front panel structure when the dust cover is

mounted to protect the display area and the key input area.

Either of two types of display can be selected: an STN liquid crystal display

with a backlight, or a yellow-orange EL (electro-luminescent) display.

Screens at the PT can be changed, messages can be received, and numbers can be displayed from the host. The PT, in turn, can transmit key inputs

and numbers back to the host.

A maximum of 1000 screens can be registered. As many as 64 rectangular

or circular lamps can be created for a single screen, up to a total of 256 and

direct connection can be used without restrictions. Character strings, numerals, bar graphs and simple graphics can also be created and registered.

Depending on the input specifications of the control system, any of three

NT600M types may be selected: the touch panel (DT) type, the non-touchpanel type (DN), and the function key type (DF). DT-type PTs enable the user

to create and use as many as 64 touch switches per screen, up to a total of

256 and direct connection can be used without restrictions. DN-type PTs allow the connection of 12-key Function Key Units, up to a maximum of 32 input points and 16 output points. DF-type PTs enable various inputs by means

of 12 function keys.

Standalone Capability

Screens can be changed on-site, using touch switches, function keys, or external inputs. The screen-changing capability can be allocated to touch

switches or function keys at the time that the screens are created in advance

by the Support Tool.

Online Transfer

Screen data can be written by means of commands from the host when an

RS-232C or RS-422A Host Interface Unit is mounted.

Direct Connection

The direct connection function can be used to directly correlate host data

areas with PT operations. Ordinarily, instructions to the PT and inputs from

the PT are executed in response to commands from the host. Such commands are not required for direct connection, however, and thus the size of

the host program can be greatly reduced. The direct connection can only be

used by DT-type PTs, with the restrictions on Host I/F Units, System ROM,

and Support Tool versions shown in the following table.

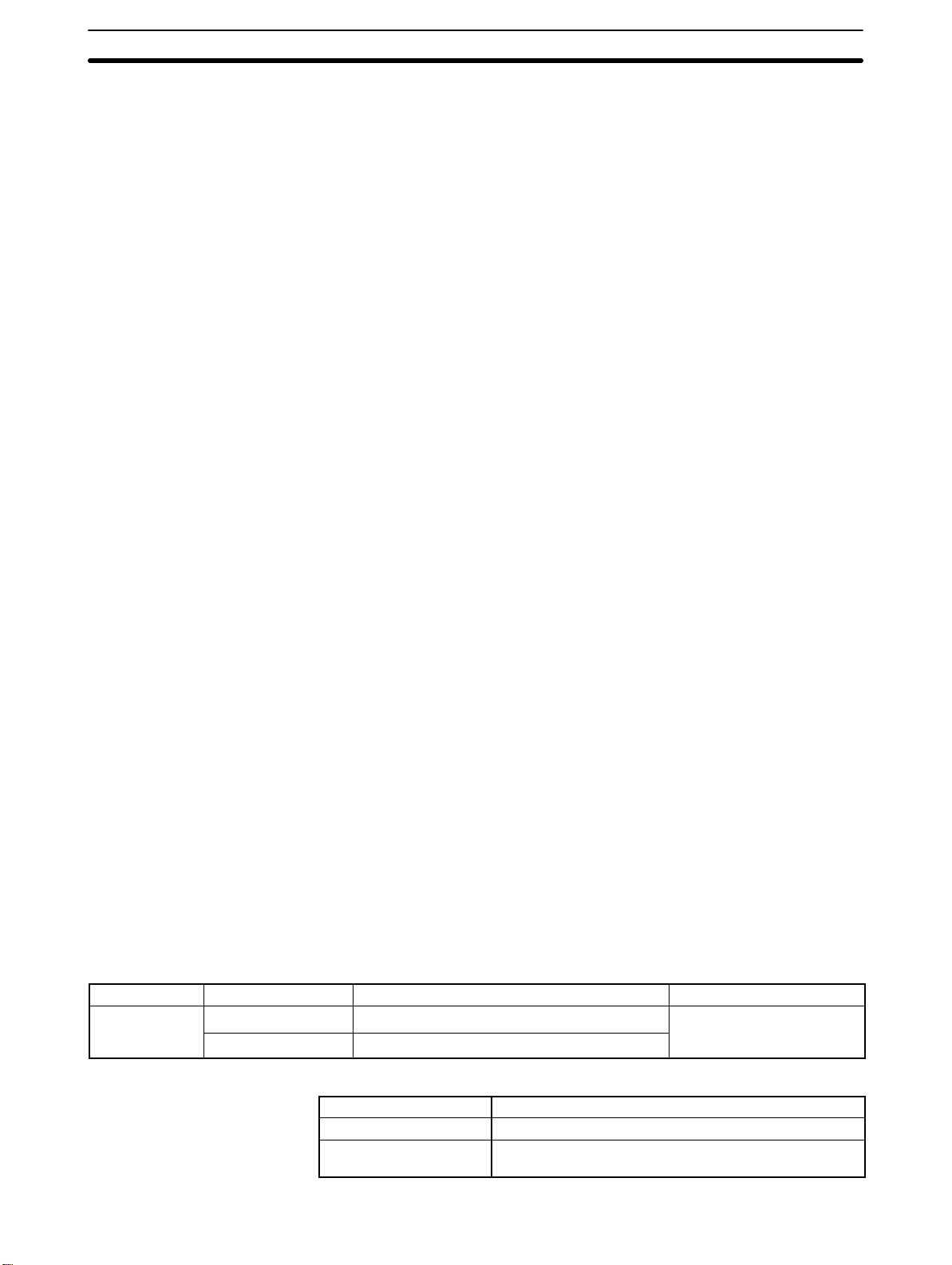

PT System ROM Host Interface Unit Support Tool

NT600M-DT12

NT600M-DT211

NT600M-SMR31-E NT600M-LK201 Host Link Interface Unit

NT600M-SMR32-E NT600M-LB122-V1 C200H Host Interface Unit

NT20M-ZASAT-EV4

ersion 4.0 or later

NT-ZA3AT-EV2

When direct connection is used, the PT data is as follows:

Lamps 255 per screen (with no limit on number registered)

Touch switches 128 per screen (with no limit on number registered)

Character string data

memory

50 places per screen (with a maximum of 512

registered)

4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

Terminology and NT-series Manuals Section 1-3

1-3 Terminology and NT-series Manuals

Names of items in this manual related to the NT-series Programmable Terminals and SYSMAC C-series Programmable Controllers are defined in the

following tables.

Abbreviations The following abbreviations are used in the text.

Abbreviation Term Meaning

PT Programmable Terminal Refers to an OMRON NT-series Programmable Terminal.

PC Programmable

Controller

I/F interface A communications device that connects the Programmable Terminal with

I/O input/output Refers to PT and PC inputs and outputs.

Refers to an OMRON SYSMAC C-series or CV-series Programmable

Controller, or programmable controllers manufactured by other companies.

peripheral devices.

SYSMAC Terminology

Terminology Explanation

SYSMAC A generic name for OMRON’s Programmable Controllers.

Host Link System A system employing SYSMAC C-series Host Link Units used to create a communications bus

between PCs, between PCs and PTs, etc.

SYSMAC BUS A remote I/O network created between SYSMAC C-series PCs and input/output devices.

C200H An OMRON SYSMAC C-series Programmable Controller.

Reference Manuals The NT20M/NT2000M Series and NT600M Series are covered in the seven

manuals described below.

Name of Manual Contents Manual No.

NT20M/NT2000M Operation

Manual

NT600M Operation Manual This manual provides specifications, functions, and operating

NT-series Host Interface Unit

Operation Manual

NT20M/NT600M Support Tool

Operation Manual

NT-series Host Interface Unit

Direct Connection Operation

Manual

NT-series RS-232C/RS-422A

Interface Unit Operation Manual

NT-series Support Tool Operation

Manual

This manual provides specifications, functions, and operating

instructions for the NT20M and NT2000M Programmable Terminals.

instructions for NT600M Programmable Terminals.

This manual covers the commands, controls, and communications

specifications for operating the NT20M and the NT600M. Refer to

this manual when programming host computer communications.

This manual covers methods for creating screens, including screen

data preparation, switches, lights, and alarms.

(for NT20M-ZASAT-EV4)

This manual covers the Direct Connection feature which has been

added to the Host Interface Unit.

This manual covers the commands, controls, and communications

specifications for operating the NT20M and the NT600M with the

RS-232C/RS-422 Interface Unit. Refer to this manual when

programming host computer communications.

This manual covers methods for creating screens, including screen

data preparation, switches, lights, and alarms. (NT-ZA3AT-EV2)

V001

V002

V003

V004

V015

V016

V028

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5

Page 17

Varies according to

Screen data memor

y

Models Section 1-4

1-4 Models

1-4-1 NT600M Programmable Terminals

There are three types of NT600M PTs, shown in the following table. There

are also two types of display from which to choose.

PT Display device Model number System ROM Screen data mem.

Touch panel (DT)

Without touch panel (DN) EL NT600M-DN211

Function Key Unit (DF) LCD with backlight NT600M-DF122

LCD with backlight NT600M-DT122

EL NT600M-DT211

NT600M-jj122/211

Type of Unit

DT: Touch-panel

DN: Non-touch-panel

DF: Function-key

Purchased separately.

which Host Interface

Unit is installed. or IC sockets for

Purchased separately.

boards can be SRAM

commercially

available EPROM or

EEPROM.

y

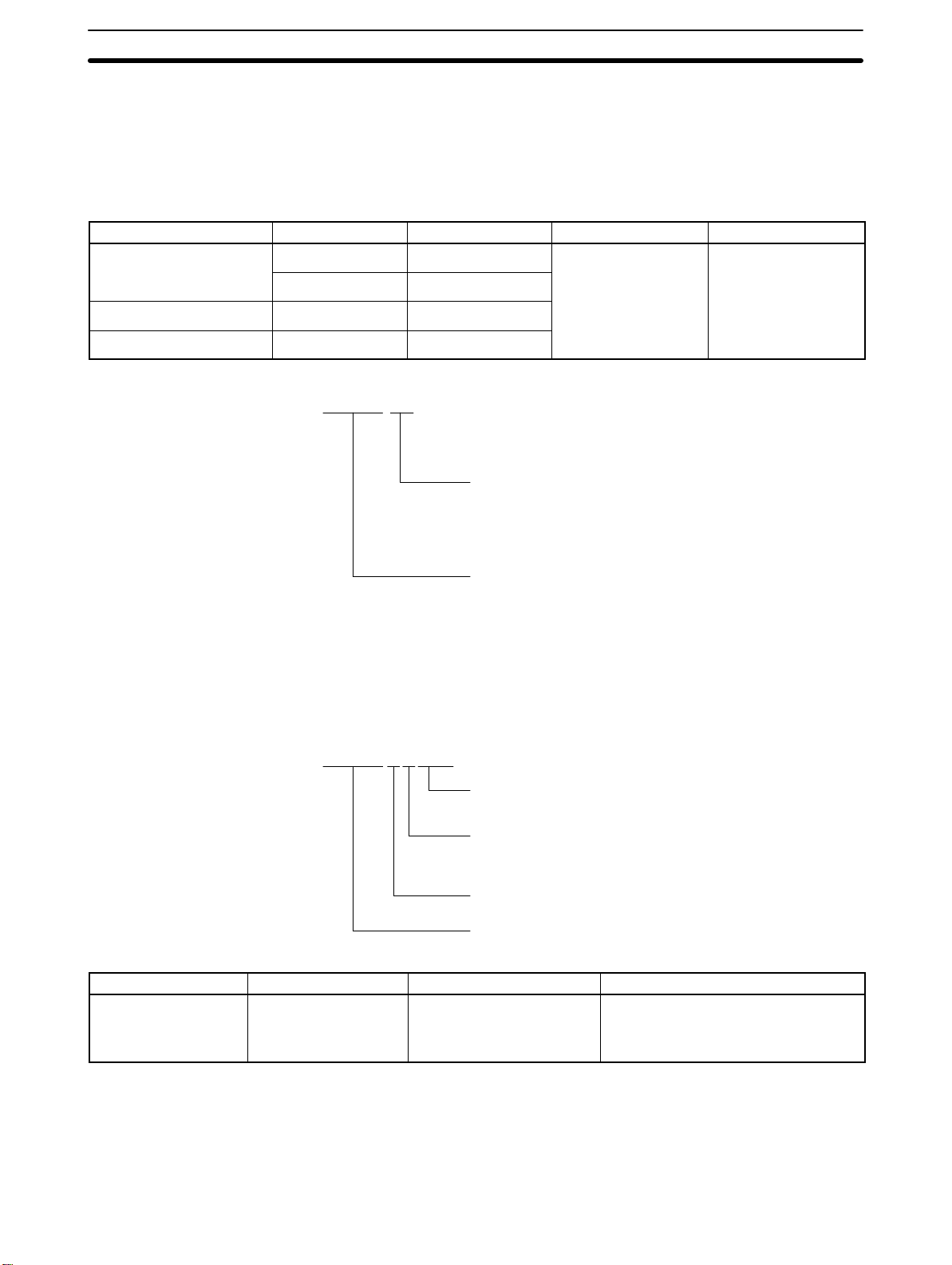

1-4-2 Screen Data Memory Boards

A Screen Data Memory Board is required for registering screen, character

string, and numeric data. The Screen Data Memory Board is not built into the

PT and must be purchases separately.

NT600M-Mjjjj

Model Type of memory Memory capacity Remarks

NT600M-MP251

NT600M-MR641

NT600M-MR151

NT600M-MR251

IC socket type

SRAM

SRAM

SRAM

(Depends on memory chip.)

64K

128K

256K

NT600M-series, basic model

Memory capacity

Type of memory

P: IC socket type

R: SRAM-type

Screen Data Memory Board

NT600M-series, basic model

IC-socket for memory chip*

Type and capacity fixed.

Type and capacity fixed.

Type and capacity fixed.

Memory Chips The memory chips that can be installed in the NT600M-MP251 IC socket are

6

Note *The NT600M-MP251 provides only an IC socket and is not equipped with a

memory chip. The memory chip must be installed by the user.

shown in the table below. Use either the model shown here or an equivalent.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

Models Section 1-4

If an equivalent is not used, the capacity of the memory backup battery may

not be sufficient.

Memory Capacity and

Number of Screens

Type Memory

capacity

SRAM 32K bytes RAM22-15 HM62256ALP-15 (Hitachi).

128K bytes RAM13-10 HM628128LP-10 (Hitachi).

EPROM 64K bytes ROM-KD-B M5M27C512AK-12 (Mitsubishi)

128K bytes ROM13-12B HN27C101AG-12 (Hitachi).

256K bytes ROM23-15B M5M27C201K-15 (Mitsubishi)

EEPROM 32K bytes EER22-20 HN58C256P-20 (Hitachi).

Model Recommended memory chips

Screen memory capacity varies according to which Screen Data Memory

Board is installed. The screen memory capacity, in turn, determines the number of screens that can be registered. Use the table below as a guide to select the amount of memory suitable for your needs.

Screen memory capacity Number of registered screens

32K bytes Mostly messages: 40 screens

Mostly graphics: 15 screens

64K bytes Mostly messages: 120 screens

Mostly graphics: 40 screens

128K bytes Mostly messages: 250 screens

Mostly graphics: 100 screens

256K bytes Mostly messages: 600 screens

Mostly graphics: 200 screens

Note The table above is strictly a guide. If the messages or other display data per

screen increase, the number of screens that can be registered will decrease.

Likewise, if the messages decrease, the number of screens that can be registered will increase.

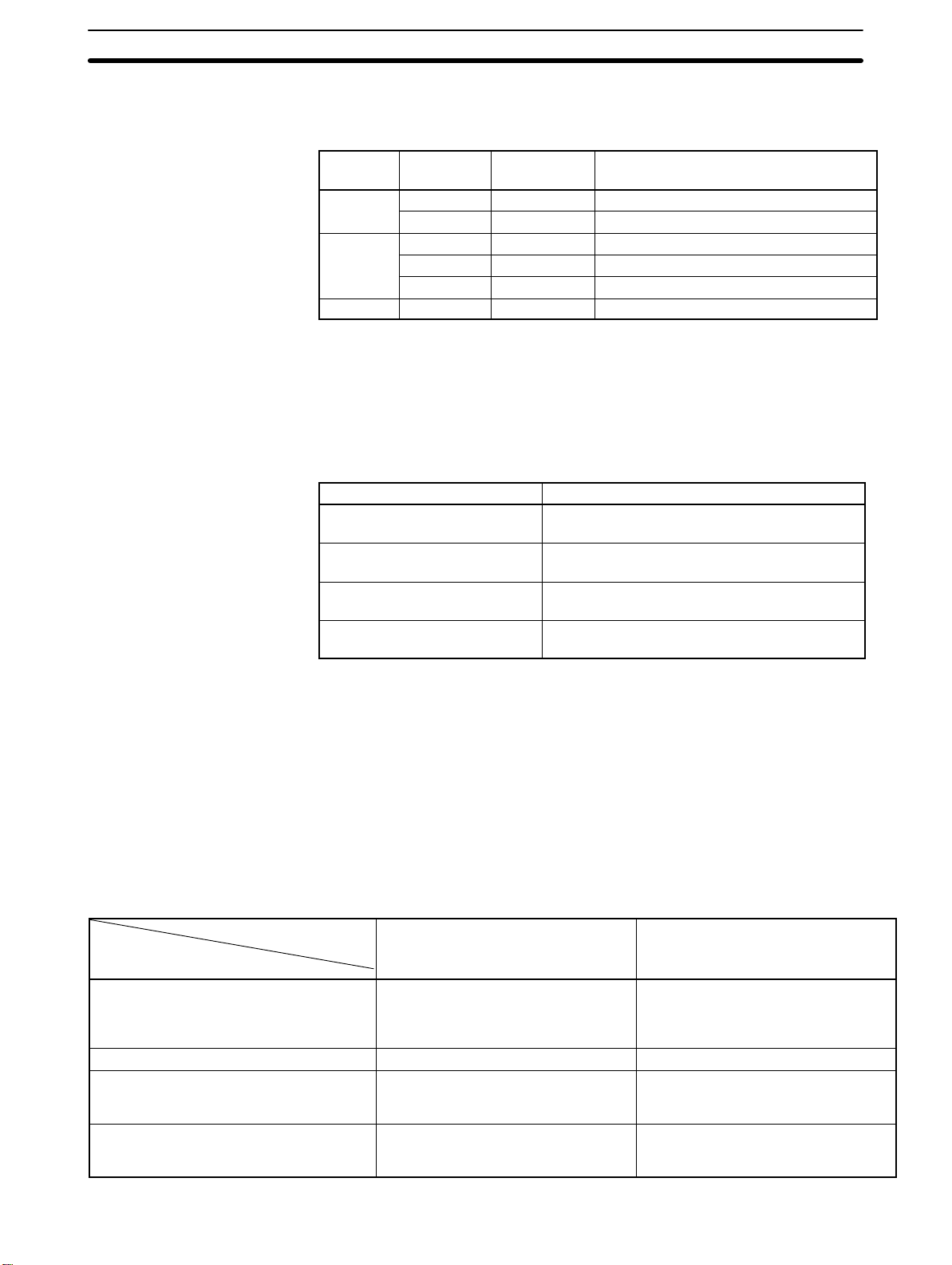

1-4-3 System ROM

Purchase the System ROM according to the NT600M and Host Interface Unit

models that are used.

NT600M

Host I/F Unit

NT600M-LK201 (RS-232C) (see note 1)

NT600M-LK202 (RS-422A)

NT600M-LK201 (Host Link) (see note 1)

NT600M-RT201 (SYSMAC BUS)

NT600M-LB122-V1 (C200H) (see note 1) NT600M-SMR02-EV1 --NT600M-LK201 (see note 1) (Host Link) --- NT600M-SMR31-E (Direct connection

NT600M-LB122-V1 (C200H) (see note 2) --- NT600M-SMR32-E (Direct connection

NT600M-SMR01-EV1 ---

NT600M-DT122/211

NT600M-DN122/211

NT600M-DF122

can be used when version 4 of the

Support Tool is used.)

can be used when version 4 of the

Support Tool is used.)

NT600M-DT122

NT600M-DT211

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

7

Page 19

ith

Models Section 1-4

Note 1. RS-232C Interface Units and Host Link Interface Units are the same

(NT600M-LK201). Change the communications specifications by means

of the internal DIP switch.

NT600M-SMRjj-EVj

Version

Overseas specifications (English)

Communications

01: RS-232C, RS-422A, SYSMAC WAY,

SYSMAC BUS Interface

02: C200H Host Interface

03: SYSMAC BUS/2, 32/32 Parallel Interface

31: Host Interface Direct Connection

32: C200H Host Interface

System ROM

NT600M-series, basic model

2. For the NT600M-LB122-V1, set the pin 4 of the Interface Unit’s DIP switch

SW2 ON or OFF to determine whether to allow direct connection or not.

Without direct connection: Turn ON pin 4 of SW2

With direct connection: Turn OFF pin 4 of SW2.

1-4-4 Host Interface Units

The Host Interface Unit provides the interface for communications between

the PT and the host (either a Programmable Controller or an FA computer).

The Host Interface Unit models that can be used with the NT600M PT are

shown in the table below. Select the Host Interface Unit to match the communications specifications of the system.

NT600M-jjjjj

Model number

Communications specifications

LK: Serial communications

RT: Remote communications

LB: C200H Host Interface

NT600M-series, basic model

Name Model number Remarks

RS-232C Interface Unit NT600M-LK201

RS-422A Interface Unit NT600M-LK202

SYSMAC BUS Interface Unit NT600M-RT121 Can be connected as a Slave Unit in a SYSMAC Wired Remote

Host Link Interface Unit NT600M-LK201 Can communicate one-to-one with a SYSMAC Host Link Unit.

C200H Host Interface Unit NT600M-LB122-V1 Can be connected to a SYSMAC C200H, C20H, C40H, or C60H

Connect for general-purpose communications with an FA

p

computer or personal computer. For communications w

SYSMAC PC, connect to an ASCII Unit.

I/O System.

PC to provide the functions of an Expansion I/O Rack.

p

p

a

8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

Support Tools Section 1-5

1-4-5 12-key Function Key Units (for DN-type)

Function-key input for NT600M non-touch panel (DN) type models is made

possible by attaching an NT600M-FK210 12-key Function Key Unit.

NT600M-DN211 PT

(Without touch panel)

NT600M-FK210

12-key Function Key Unit

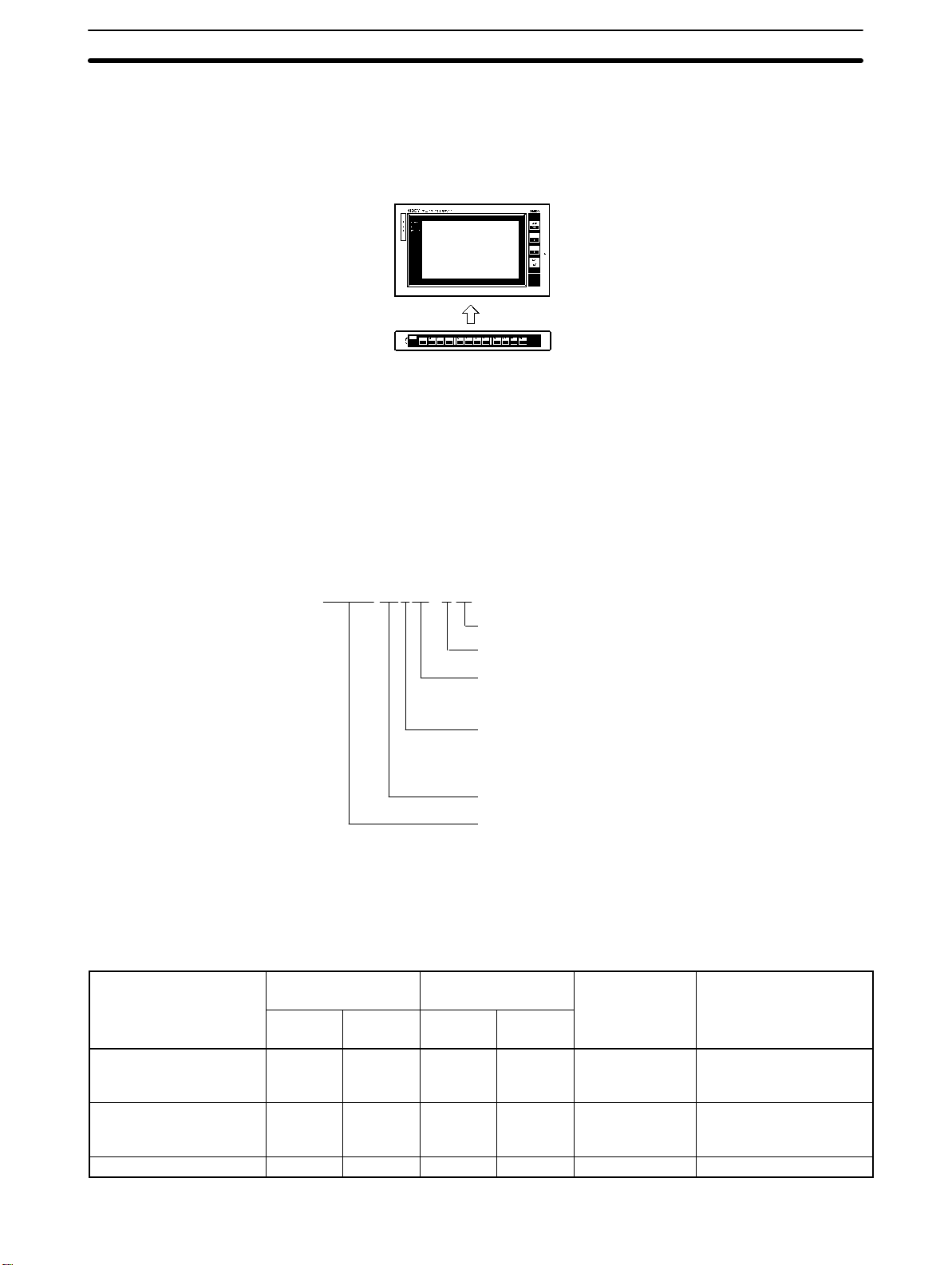

1-5 Support Tools

NT600M screen data, memory table data, and system data are all created by

the Support Tool. In order to fully utilize the functions of the NT600M PTs,

use the NT-ZA3AT-EV2 Support Tool or a version of NT20M-ZASAT-EV4 or

higher.

NT20M-ZASAT-EVj

Version

Overseas specifications (English)

Compatible platform

AT: IBM PC/AT compatible

Floppy disk size

3: 3.5 inch

5: 5.25 inch

S: 3.5 and 5 inch

Support software

NT model

NT: NT Series (common)

NT20M: NT20M Series

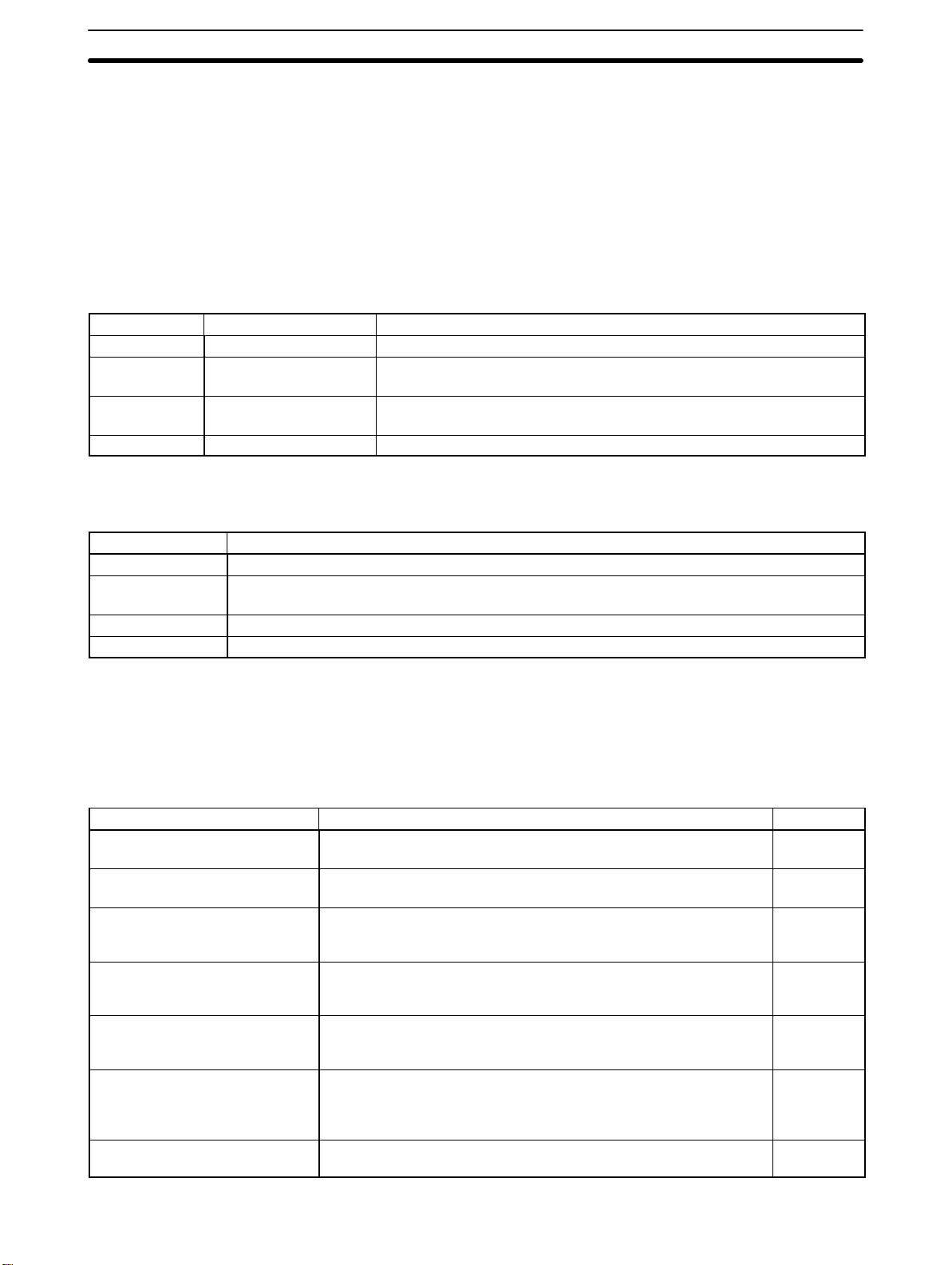

Contrast Between Functions when New and Old Versions of Peripheral Devices are Used

(1) I/O Functions

Function

Lamps (bit designation)

Display attributes: Lit or

flashing

Touch switches: Reverse

video display during input

(yes or no)

Standalone function F X F X All models X: Cannot be used.

NT20M-ZASAT

Support Tool

-EV4

onwards

F X F X All models X: Only “lit” is available

F X F X DT-type only X: Setting not possible.

-EV1 -EV1 -E

NT600M-SMRjjj

System ROM

PT Models Remarks

for bit designation

control.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

9

Page 21

F

F

System Configuration Section 1-6

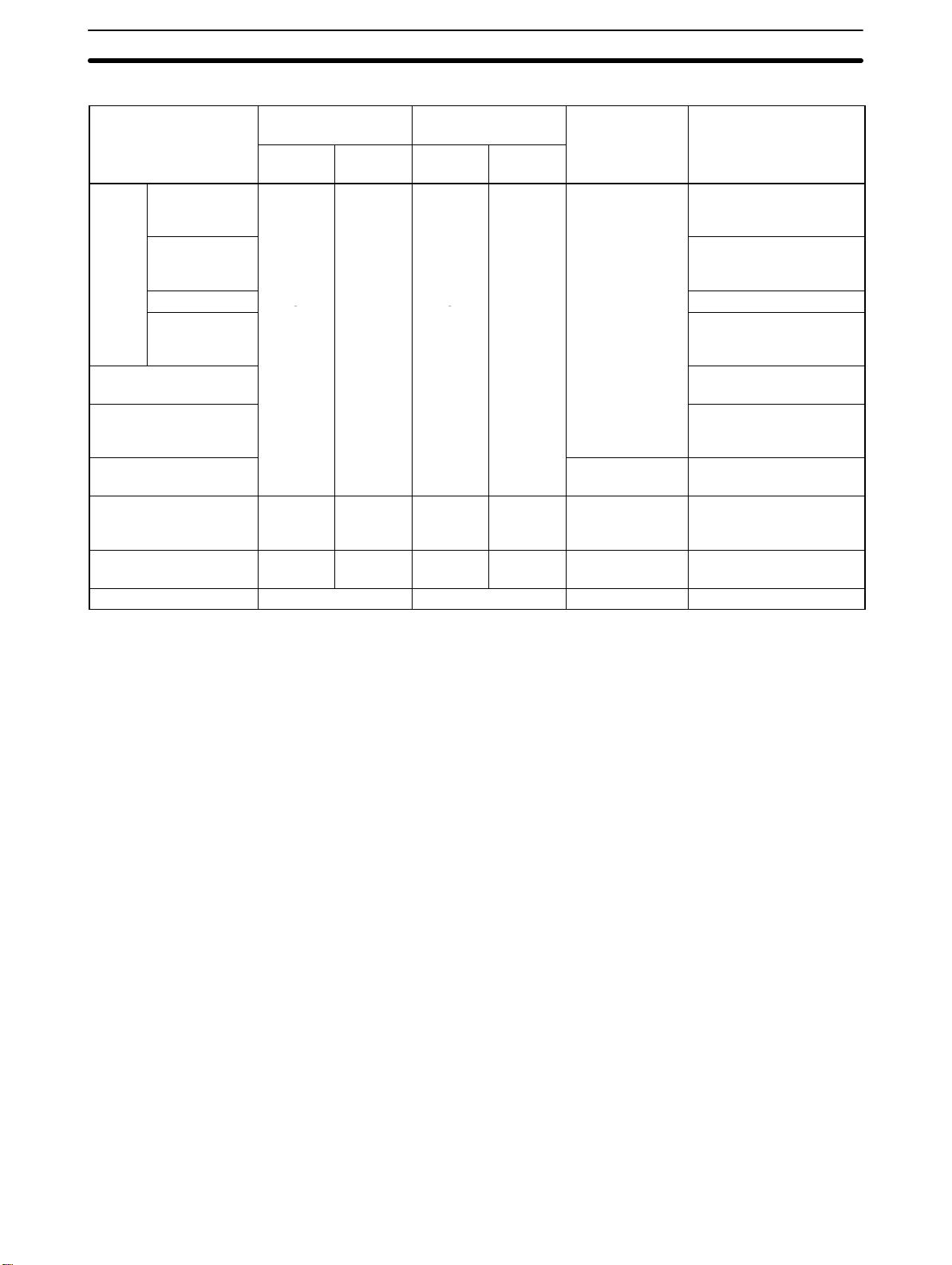

(2) Display Functions

Function

Vertical and

horizontal

display

Bar

graphs

Lamp display:

Rectangular or circular

Lamps/touch switches:

Guide character mark

input

Touch switches: Solid or

rectangular frame

Numeric setting 10-key

layout

Numeric display

enlargement (64x max.)

Direct connection See note 3. SMR 31-E/32-E DT-type only

Display width

enlargement (2

to 255 dots)

+/– display

% value

enlargement

display

NT20M-ZASAT

Support Tool

-EV4

onwards

F X F X All models

F X F X All models

F X F X All models X: Equivalent display

-EV1 -EV1 -E

NT600M-SMRjjj

System ROM

PT Models Remarks

X: Horizontal only.

X: Select either 8 or 16

dots.

X: + direction only.

X: Equivalent display

only.

X: Rectangular only.

X: Mark input not

possible.

DT-type only X: Rectangular frame

only.

Only when the screen

(See note 1.)

attribute “10-key” is set to

“User.”

only.

Notes 3. Some restrictions may apply, depending on the PT model.

4. In order to use the direct connection function, a Support Tool version of

“-EV4” or higher must be used.

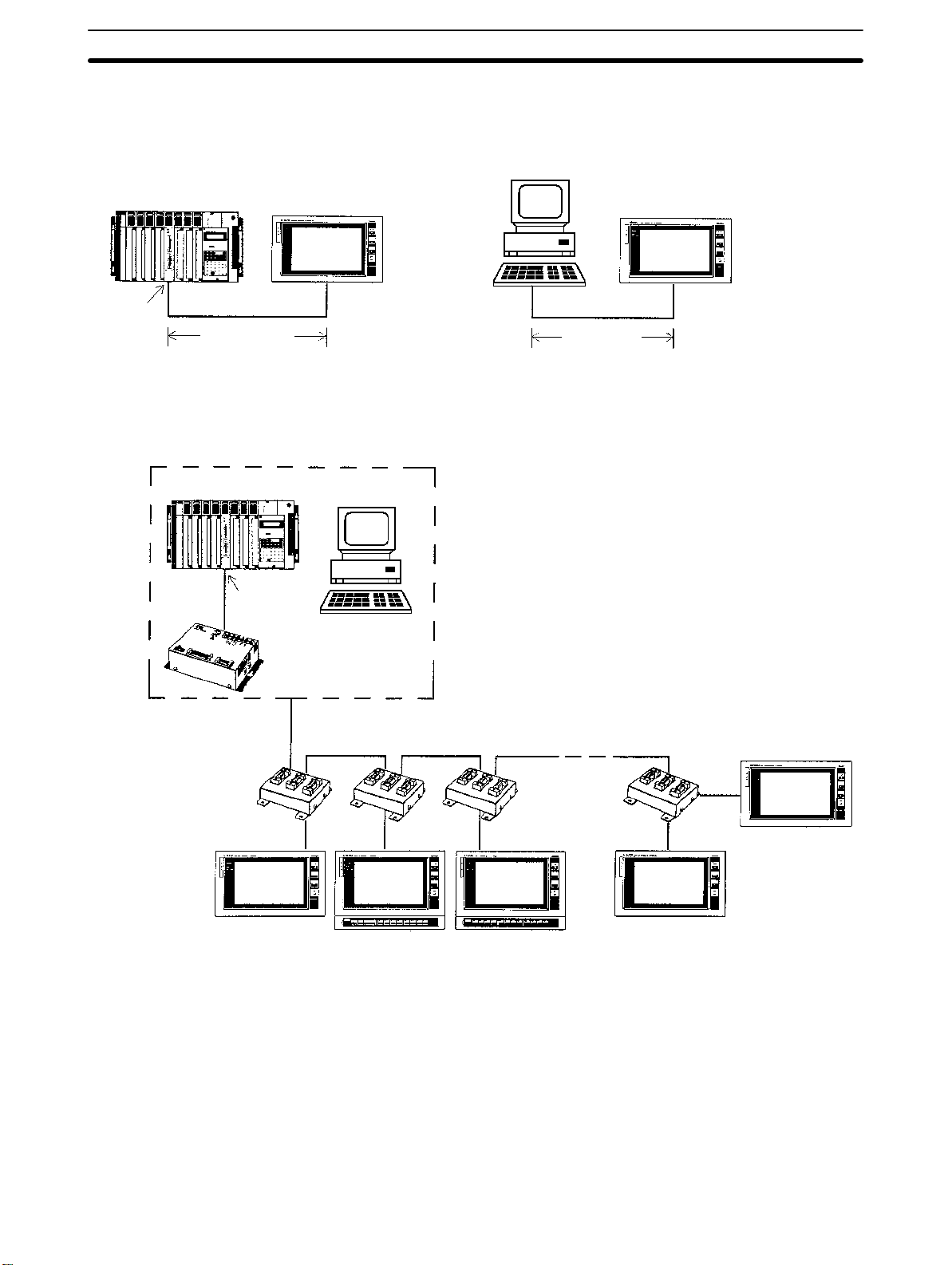

1-6 System Configuration

In order to operate the NT600M, connect a personal computer or a Programmable Controller, to serve as a host, to the Host Interface Unit (sold separately) at the back of the NT600M. For details on connecting the Host Interface Unit, and on host programs, refer to the

Manual

The following interfaces can be used for communications: RS-232C,

RS-422A, Wired Remote I/O System (SYSMAC BUS), Host Link System

(SYSMAC WAY), or C200H Host Interface. A Screen Data Memory Board,

NT600M-MP/MRjjj, is also required and must be purchased separately.

.

Host Interface Unit Operation

10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

System Configuration Section 1-6

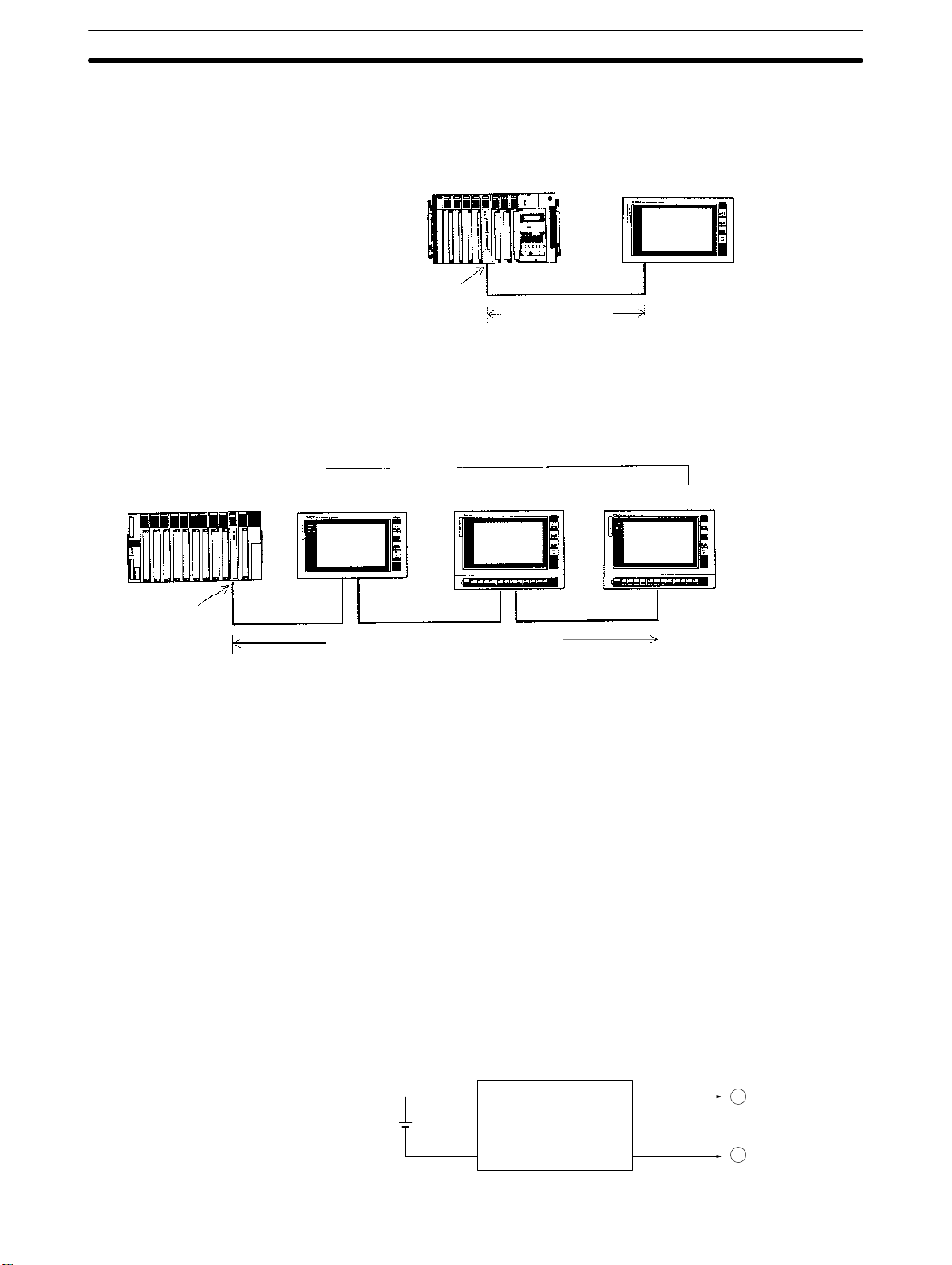

RS-232C Interface Using the NT600M-LK201 Host Interface Unit, the Programmable Terminal

can be connected one-to-one to a personal computer or to an ASCII Unit

mounted to a Programmable Controller.

C200H, C500, C1000H,

or C2000H PC

ASCII Unit

NT600M with

NT600M-LK201

RS-232C

15 m max.

Personal computer

NT600M with

NT600M-LK201

RS-232C

15 m max.

RS-422A Interface Using the NT600M-LK202 Host Interface Unit and 3G2A9-AL004-(P) and

3G2A9-AL001 Link Adapters, up to 16 Programmable Terminals can be connected to a to a PC through an ASCII Unit, or to an FA computer.

C-series PC

ASCII Unit

(RS-232C)

Personal computer

3G2A9-AL001

Link Adapters

NT600M with

NT600M-LK202

3G2A9-AL004-(P)E

Link Adapter

RS-422A

Cable length: 500 m max.

Branch lines: 10 m max. each.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

11

Page 23

System Configuration Section 1-6

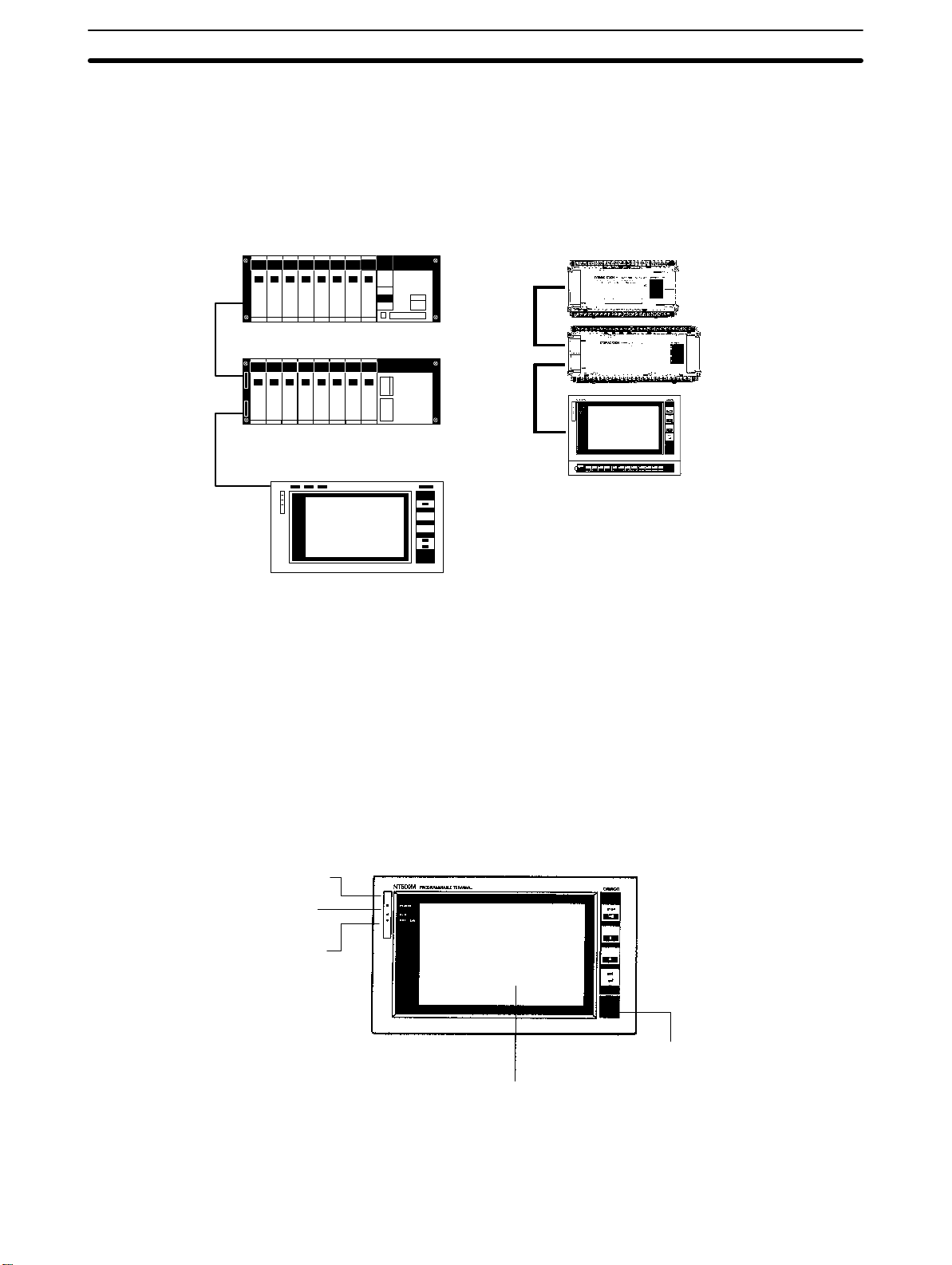

Host Link Interface Using the NT600M-LK201 Host Interface Unit, the Programmable Terminal

can be connected one-to-one to a Host Link Unit mounted to a Programmable Controller.

Mini H-type, C200H, C500, C1000H, C2000H PC

Host Link Unit

RS-232C

15 m max.

NT600M with

NT600M-LK201

SYSMAC BUS Interface Using NT600M-RT121 Host Interface Units, up to 8 Programmable Terminals

can be connected to a PC through a Wired Remote I/O Master Unit.

8 Terminals max.

C200H, C500, C1000H, or

C2000H PC

NT600M with

NT600M-RT121

Remote I/O

Master Unit

200 m max. (2 wire cable)

C200H Host Interface With an NT600M-LB122-V1 (for direct connection) Interface Unit, the inter-

face is set up simply by connecting one-to-one with C200H-CN221 Connection Cable to a C200H CPU Rack or Expansion I/O Rack. It is also possible

to connect a PT to a C20H, C28H, C40H, or C60H CPU Unit or I/O Units. Be

sure to use a noise filter when connecting CjjH. Refer to the

Units Operation Manual

for details.

Host Interface

12

Be sure to use a noise filter (TDK’s ZGB2202-O1U or equivalent) when connecting to the Mini H-type PC.

1, 2, 3...

1. The noise filter must be inserted into the power line of the Mini H-type

PC.

2. The distance between the noise filter and the Mini H-type PC must be as

short as possible.

3. Keep the noise filter away from high-tension lines.

4. The case of the noise filter must be grounded to the FG terminal of the

Mini H-type PC.

Noise filter

1

IN OUT

2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4

3

+

24 V24 V

–

Page 24

Nomenclature and Functions Section 1-7

In a C200H PC System, you can ordinarily connect two Expansion I/O Racks to

the CPU Rack. The C200H Host Interface Unit itself, however, functions as an

Expansion I/O Rack, and therefore when using a C200H Host Interface Unit, you

can only connect one other Expansion I/O Rack. (If the CPU Rack is either

C200H-CPU02 or C200H-CPU22, it is not possible to connect both an Expansion Rack and a PT.)

CPU Rack

C20H/28H/40H/60H

CPU Unit

C200H Expansion I/O

Connection Cable

Expansion I/O Rack

NT600M PT + NT600M-LB122-V1

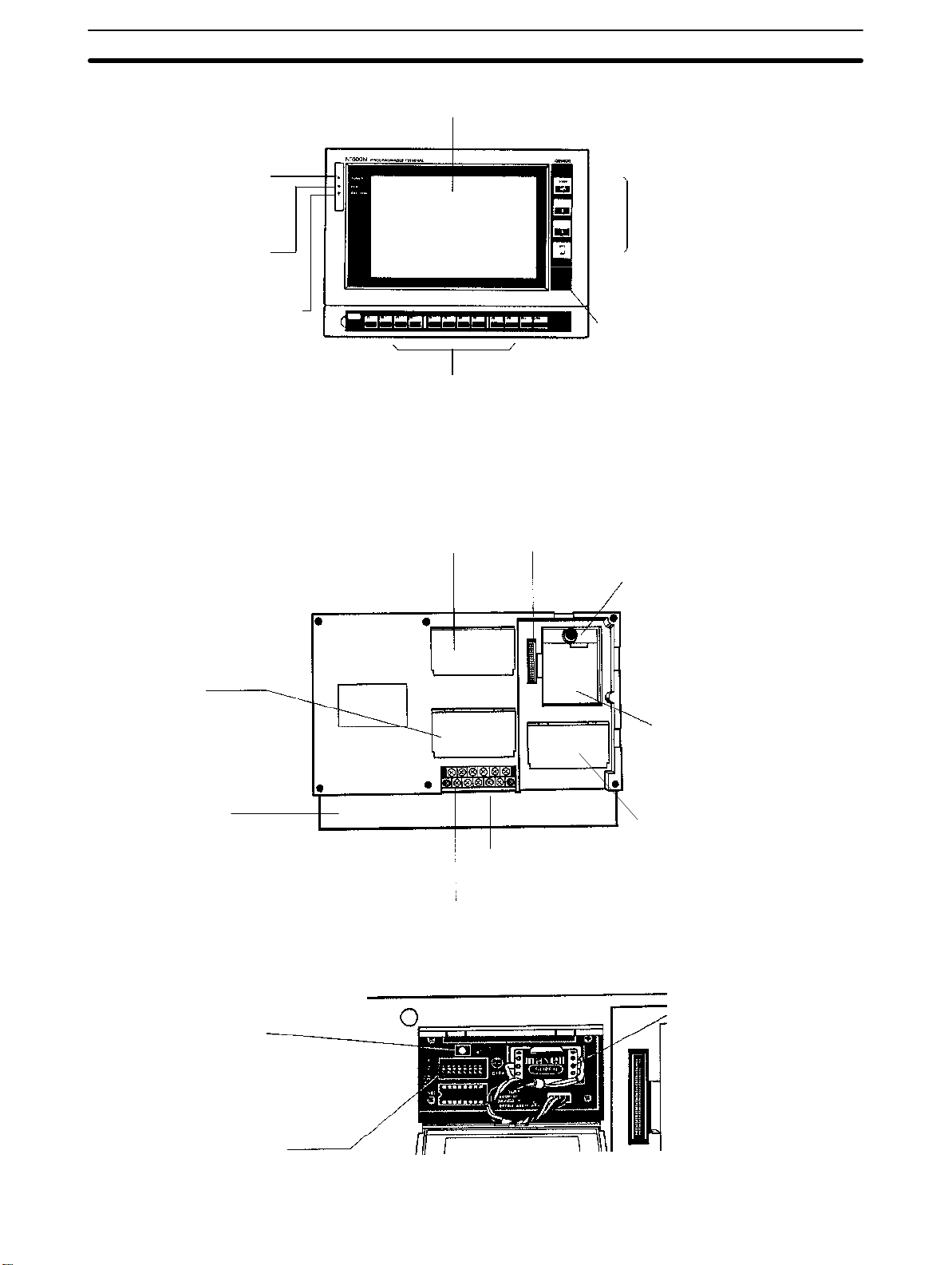

1-7 Nomenclature and Functions

1-7-1 Front Panel

The illustrations below show the front panels of PTs with and without touch

panels (i.e., DT-type and DN-type PTs) and PTs with function keys (i.e., DFtype PTs). A 12-key Function Key Unit can be attached to a DN-type PT to

give it the same outer appearance and functions of a DF-type PT.

CjjH I/O Unit

NT600M PT +

NT600M-LB122-V1

NT600M-DT/DNjjj: Programmable Terminals With and Without a Touch Panel

POWER Indicator (green)

Lit while power is on.

RUN Indicator (green)

Lit during operation

BAT LOW Indicator (red)

Lights if the lithium

battery voltage level

drops.

Display

Touch Switches (touch panel type only)

Used as an input device corresponding to

the display screen.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

System Keys

Used for maintenance of the N600M,

selecting the System Menu, etc. Used

during operation for scrolling the

screen and inputting numeric values.

Dust-proof Cover (liquid crystal type only)

Covers the contrast control. Turning the

contrast control clockwise increases the

contrast.

13

Page 25

Nomenclature and Functions Section 1-7

NT600M-DF122: Programmable Terminals with Function Keys

Display

POWER Indicator (green)

Lit while power is on.

RUN Indicator (green)

Lit during operation

BAT LOW Indicator (red)

Lights if the battery level

drops

Note The operation of the BAT LOW LED will be unstable if a battery is not

installed.

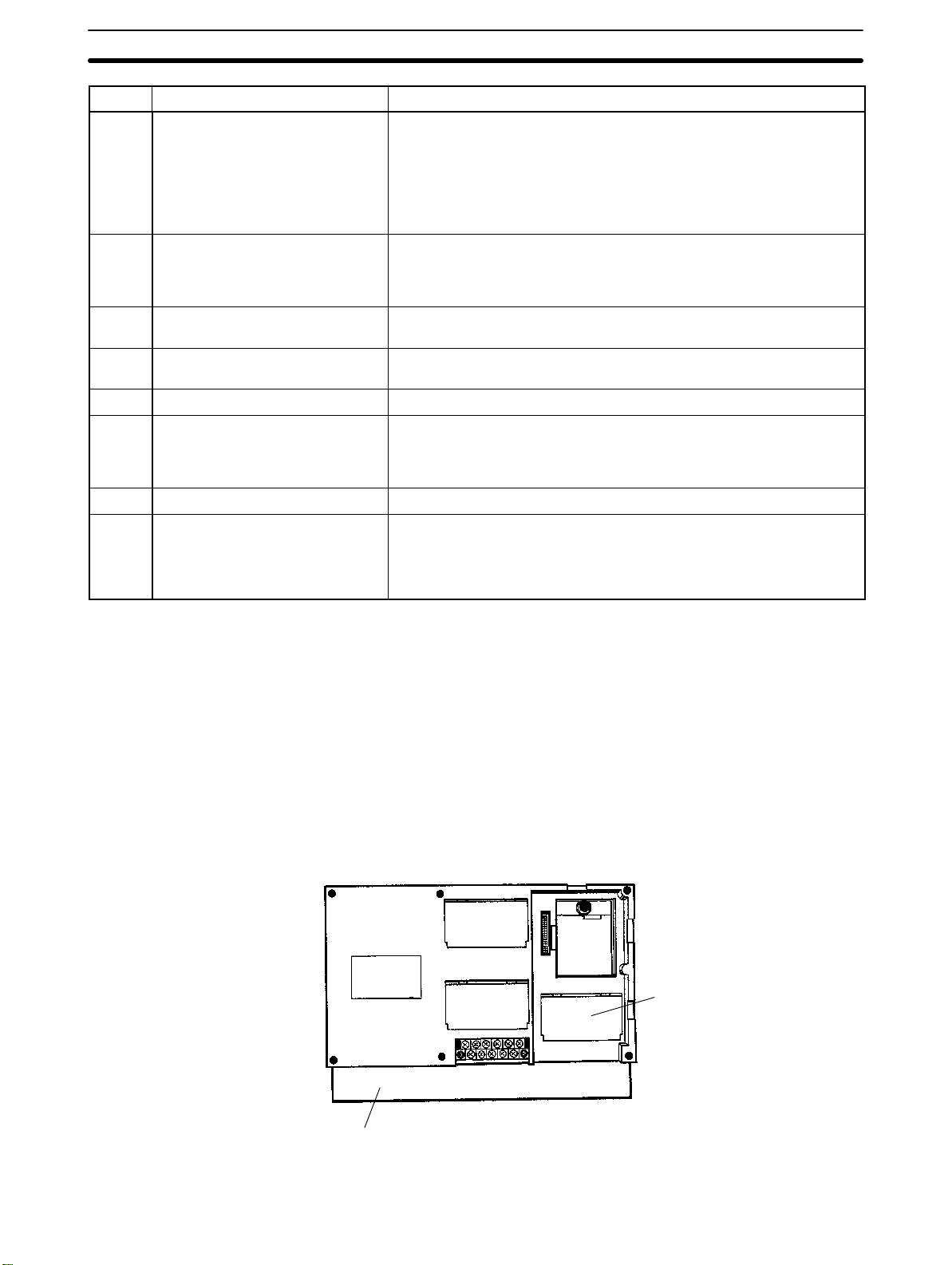

1-7-2 Rear Panel

All Models (NT600M-DT/DN/DFjjj)

Function Keys

Used for input.

Switch cover

System Keys

Used for maintenance of the

NT600M, selecting the System

Menu, etc. Used during operation for scrolling the screen and

inputting numerical values.

Drip-proof Cover (liquid crystal type only)

The contrast control is behind this cover. Turning it clockwise increases the

contrast.

Host Interface Unit connector

This connector is used for connecting

to a Host Interface Unit.

Memory Board fitting

This fitting comes off by pulling up

on the black knob. To put the fitting back on, push down until the

knob snaps into place.

Connector cover

The Support Tool interface connector is located under this cover. This is used when transferring screen data between the

NT600M and Support Tool.

Function Keys

(DF-type only)

Switch Cover Area

Reset switch

Pressing this switch initializes the NT600M.

The status of screen

data before initialization

is retained.

System DIP switch

I/O interface

connector

Terminal block

Memory Board installation space

Insert the Screen Data Memory

Board here.

System ROM cover

Open this cover to access the

System ROM socket.

Lithium battery

14

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

Switch Settings, Installation, and Wiring

This section provides procedures to set hardware switches and install the PT.

2-1 Switch Settings 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 System DIP Switch Settings (SW1) 16 . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Mounting System ROM 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-3 Screen Data Memory Board Settings and Installation 18 . . . . . . . . . . . . .

2-2 Installation Environment 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 Installation Site 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Mounting Position 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Dimensions 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-1 Terminals with Function Keys (DF-type) 22 . . . . . . . . . . . . . . . . . . . . . . .

2-3-2 PTs With (DT-type) and Without (DN-type) Touch Panels 23 . . . . . . . . .

2-4 Installing the NT600M PT in a Panel 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Wiring and Connectors 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-1 Terminal Block 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-2 AC INPUT Terminals 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-3 LG and GR Terminals 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-4 HOST RUN INPUT Terminals 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-5 ALM OUTPUT Terminals 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 RS-232C Interface Connector 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 12-key Function Key Units (for DN-type PTs) 28 . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 Mounting Function Key Units (to DN-type PTs) 28 . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

15

Page 27

Switch Settings Section 2-1

2-1 Switch Settings

There are switches to set under the switch cover on the back of the Terminal

and also on the Host Interface Unit. For Host Interface Unit switch settings,

refer to the

Host Interface Unit Operation Manual

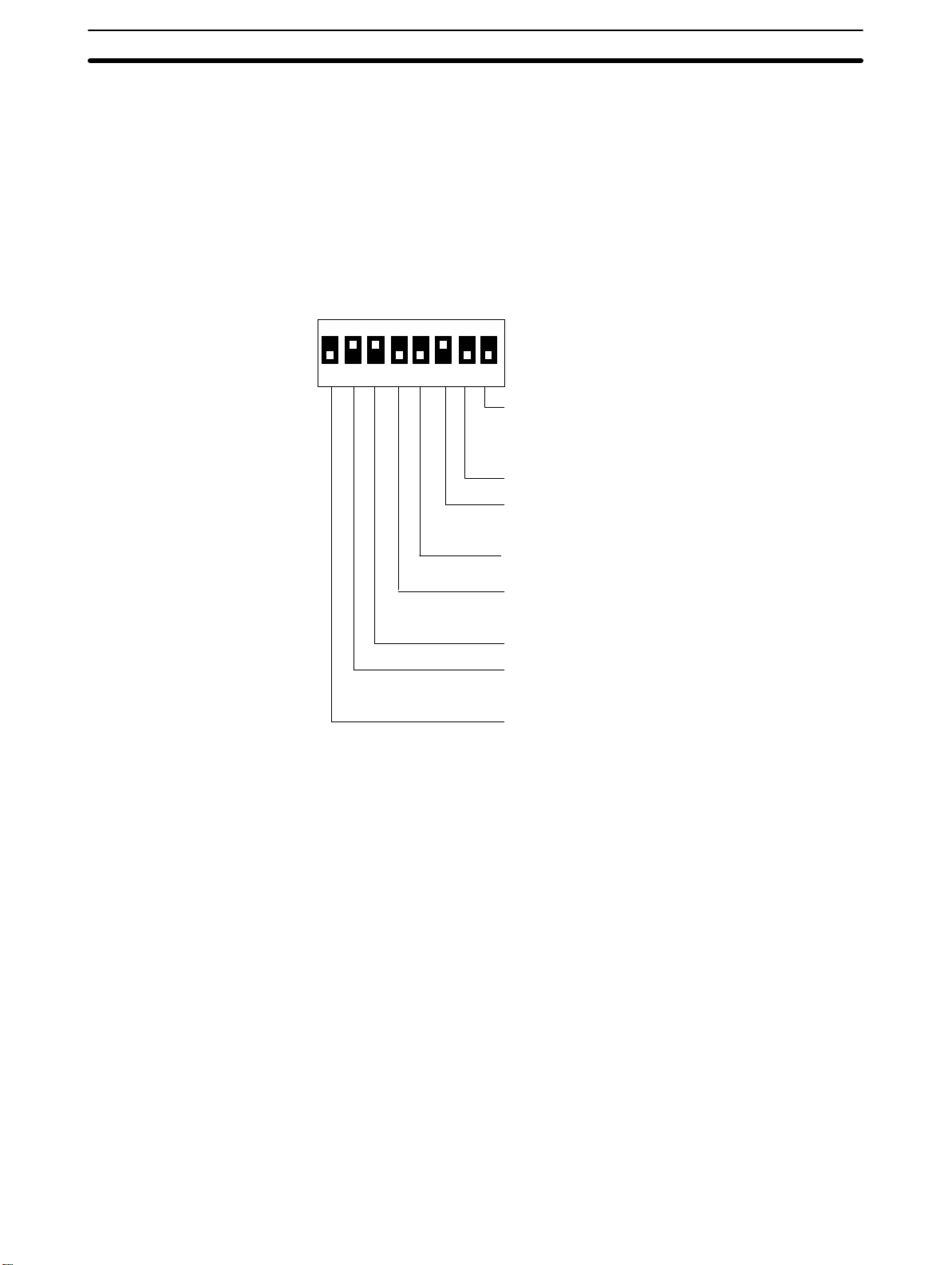

2-1-1 System DIP Switch Settings (SW1)

The 8-position DIP switch for system settings is located under the DIP switch

cover on the back of the Terminal. Be sure that power is off when changing

switch settings.

SW1

ON

12345678

Communications specification

(only for when NT600M-LK201 is mounted)

ON: Host Link

OFF: RS-232C

Not used.

Mode change enable/disable

ON: Enable

OFF: Disable

Not used.

(The settings at the time of shipping

are as shown on the left.)

.

Bit designation for lamps/touch switches

ON: 0 to 63

OFF: 0 to 111

Reserved for system use. (Always keep ON.)

HOST RUN input enable/disable

ON: Disable

OFF: Enable

Automatic reset after communications error

ON: No automatic reset.

OFF: Automatic reset.

16

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

Switch Settings Section 2-1

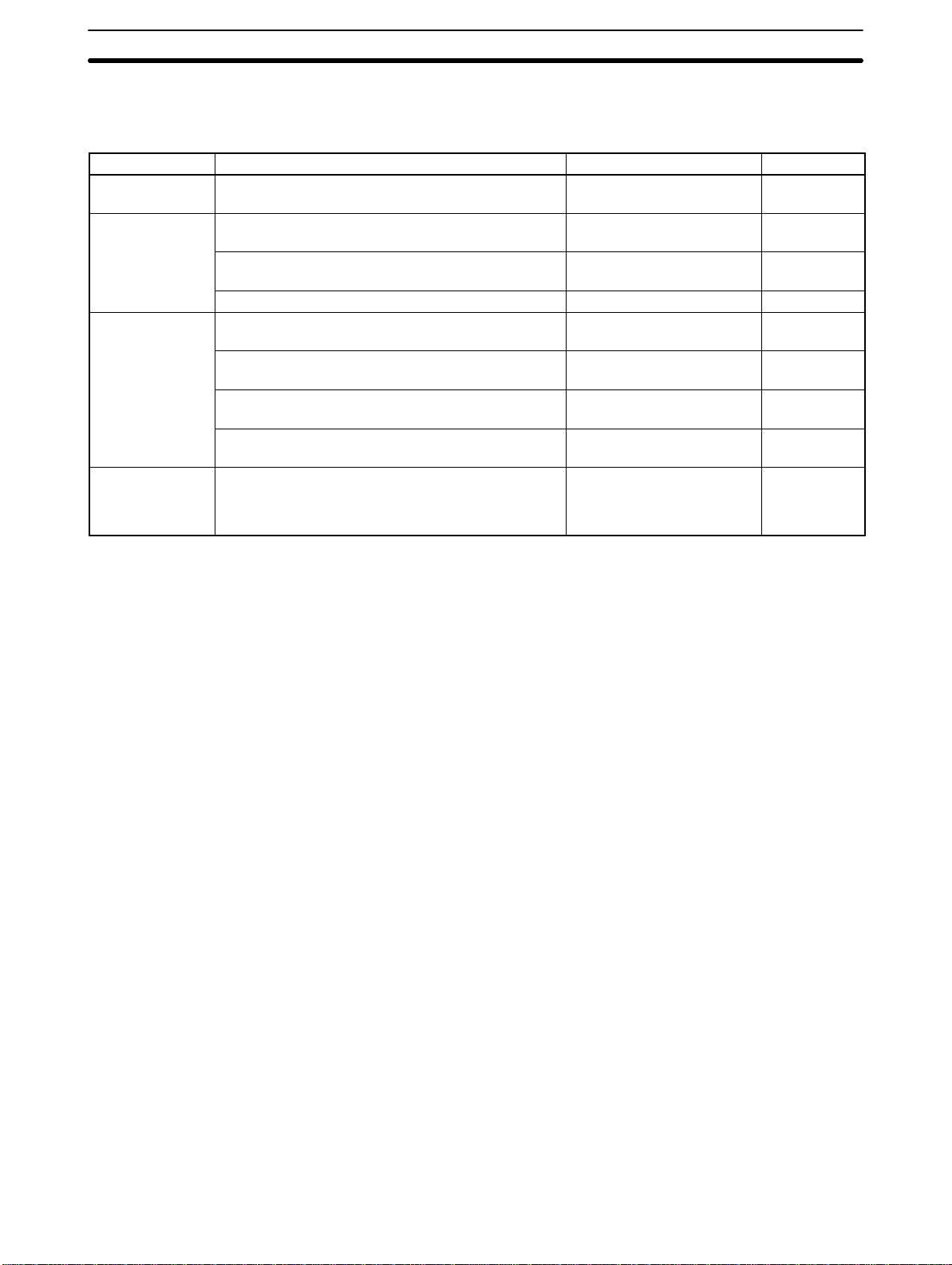

Pin no. Setting Content

1 Automatic reset after

communications error.

ON: No automatic reset.

OFF: Automatic reset.

2 Host RUN input enable/disable

ON: Disable

OFF: Enable

3 ON This pin is reserved for system use, and must remain set to ON. If this

4 Bit designation for lamps and

touch switches

5 Not used. --6 Mode change enabled/disable

ON: Enable

OFF: Disable

7 Not used. --8 Communications specification

setting (only when NT600M-LK201

is used)

ON: Host Link Unit

OFF: RS-232C

“Automatic reset” means that, when an error occurs, no error message

will be displayed and the next command will be executed when received.

“No Automatic reset” means that, when an error occurs, an error message will be displayed and operation will stop. If an RS-232C or RS-422A

Interface Unit is mounted, the host will be notified that an error occurred

and there will be no automatic reset regardless of whether this pin is set

to ON or OFF.

If this pin is turned OFF, then the host RUN input will be enabled and PT

operation can be controlled by external sequences. If this pin is set to

ON, the PT will operate but when the host RUN input turns OFF, Host

Error will be displayed and operation will stop.

pin is set to OFF, messages will not display properly.

This pin designates the bits for lamp and touch switch display control for

when Host Link Interface Units or C200H Host Interface Units are used.

“Mode change” refers to changing between the System Menu and Transmit Mode, Maintenance Mode, or RUN Mode. When an RS-232C or

RS-422A Host Interface Unit is used, mode changes can be prohibited

by means of a command from the host.

The NT600M-LK201 can be used as either a Host Link Interface Unit or

an RS-232C Interface Unit. Operation will not be possible if the setting of

this switch does not match the communications system. If another type

of Host Interface Unit is mounted, this setting will be ignored.

2-1-2 Mounting System ROM

Turn off the power supply to the PT and mount the System ROM into the PT

as described below.

1, 2, 3...

1. Open the System ROM cover on the back of the PT.

NT600M-DF122 only

System ROM cover

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

17

Page 29

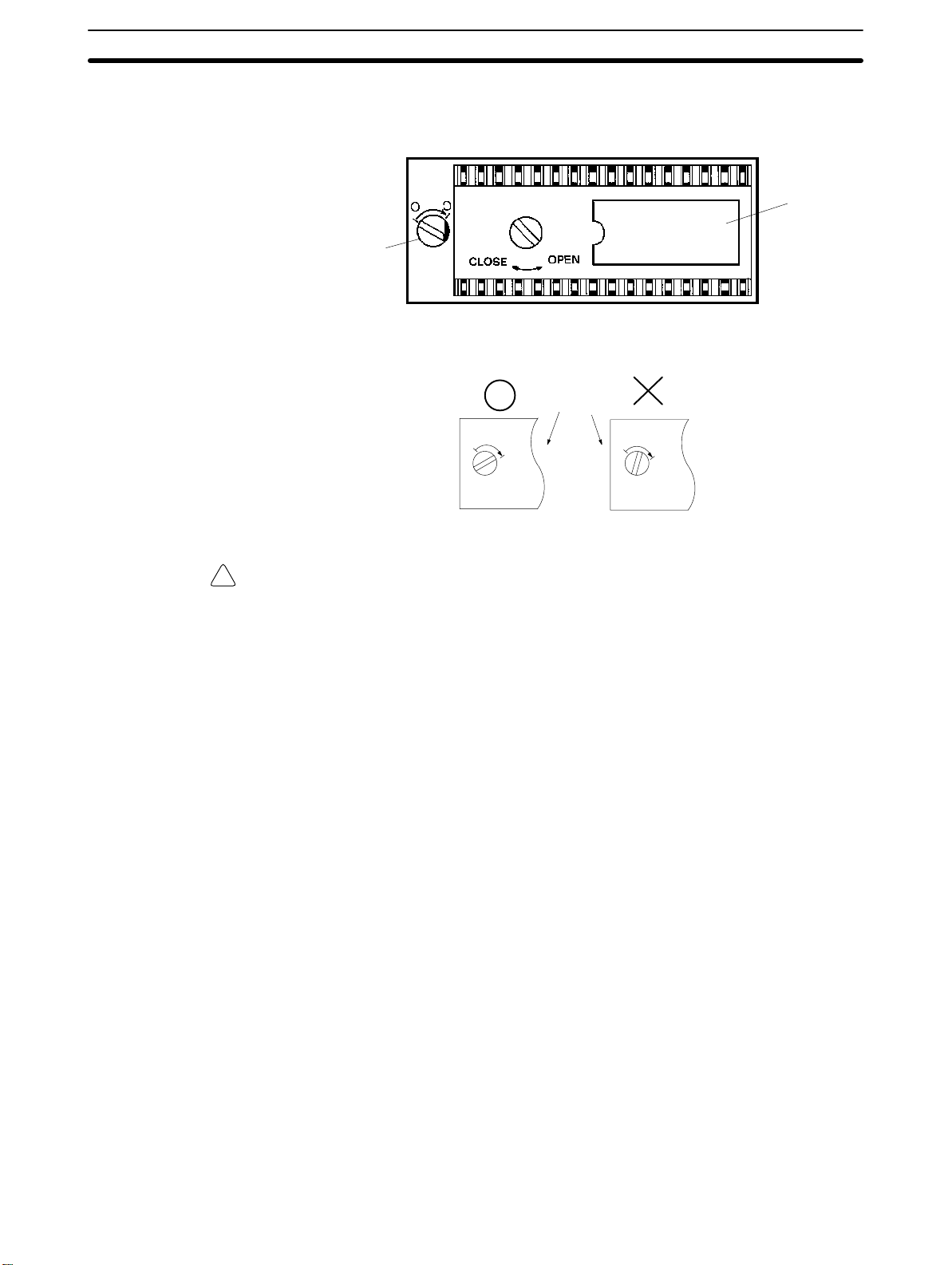

Switch Settings Section 2-1

2. When the System ROM cover is opened, the IC socket will be exposed.

Turn the tightening screw (located to the left of the IC socket) to align

the slot with the O (open).

Label

Tightening

screw

3. Mount the ROM to the socket in the direction indicated on the label and

turn the tightening screw clockwise to the C (close) secure the ROM.

Socket

0

Caution The ROM may be destroyed it mounted while power is being supplied to the PT.

!

0

Insufficiently tightened

Turn off the power supply before mounting the System ROM.

Notes 1. The PT may not operate properly if the IC socket is not completely se-

cured. Be sure to install the System ROM securely.

2. OMRON reserves all copyrights to the programs on the System ROM.

Copying these programs is forbidden.

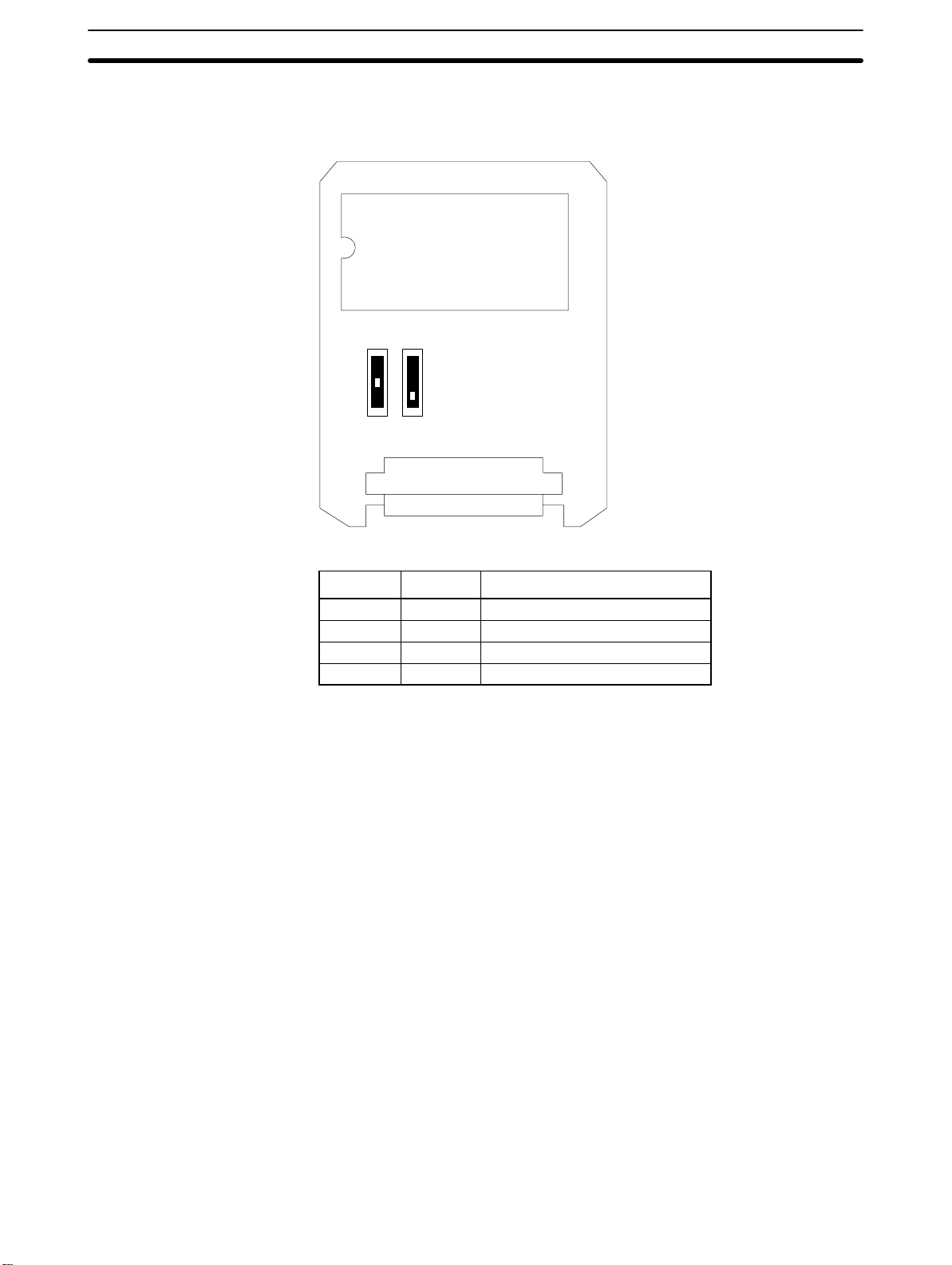

2-1-3 Screen Data Memory Board Settings and Installation

There are two types of Screen Data Memory Board: SRAM type and IC socket type. The NT600M-MP251 Screen Data Memory Board does not come

with a memory chip installed, and the memory chip must be purchased separately.

The memory type and capacity must be set for the NT600M-MP251.

Switches SW M1 and SW M2 are used to set the type and capacity of the

screen data memory chip installed in the top socket of the Screen Data

18

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

Switch Settings Section 2-1

Memory Board. Set these switches to match the memory chip which is installed.

NT600M-MP251

Socket

The factory-set default setting is shown at the left.

Top

Middle

Bottom

SW M2 SW M1

Connector

Settings

Installation

SW M2 SW M1

Top Bottom 64K, EPROM

Middle Bottom 128K, EPROM

Bottom Bottom 256K, EPROM

Top Middle 32K, EEPROM

Screen data memory

Note 1. Be sure that the power is off when changing the settings. If settings are

made with the power on, memory may be lost or damaged.

2. Carefully check the switch settings and the memory chip before turning

the power on. If the memory is different from that specified on the switch

settings, the PT will not operate correctly.

Install the Screen Data Memory Board in the order shown below. If the Host

Interface Unit is mounted, remove it before installation.

1, 2, 3...

1. Turn off the power supply to the PT.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

19

Page 31

Installation Environment Section 2-2

2. Place the Screen Data Memory Board on the main rail, push the spacer

in the direction of the arrow until it makes a clicking sound, and line the

board up with the connector.

Rail

Spacer

Connector

Lined up with connector

3. Holding the Memory Board’s installation fitting as shown in diagram A,

insert the black latch on the bottom into the hole in the main unit and

press the black knob down until it clicks into place.

When the knob is

pulled up, it looks

like Illustration A

on the left.

Installation fitting

Black knob

Black latch

AB

Installation fitting

Spacer

Screen Data Memory Board

When removing the Screen Data Memory Board, first turn off the power to

the PT and then remove the installation fitting by pulling up on the black

knob. Then pull the Memory Board’s spacer in the opposite direction of that

shown above and take out the Memory Board.

2-2 Installation Environment

The NT600M has strong environmental resistance and high reliability, but you

can maximize system reliability and make the most of its functions by observing the following considerations during installation.

2-2-1 Installation Site

Avoid installing the NT600M where any of the following conditions exist.

• Ambient temperatures exceeding a range of 5°C to 40°C for liquid crystal

display PTs or 0°C to 50°C for EL display PTs.

• Abrupt temperature changes and condensation.

20

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

Installation Environment Section 2-2

• Relative humidity exceeding a range of 35% to 85%.

• Corrosive or inflammable gasses.

• Strong magnetism.

• Excessive dust, salt, or iron dust.

• Direct vibration or shock.

• Direct sunlight.

• Spray from water, oil, or chemicals (the front panel is basically drip-proof).

2-2-2 Mounting Position

Mounting Location PTs with LCD display have a field of vision of 20° up, 30° down, and 30° right

and left. Install the Terminal at a height and direction that make it easy for the

operator to see.

Ambient Temperature The ambient operating temperature range is 5°C to 40°C for liquid crystal

display PTs and 0°C to 50°C for EL display PTs. Take the following factors

into consideration.

• Leave sufficient ventilation space.

• Do not install directly above machinery that puts out a lot of heat (e.g.,

heaters, transformers, high-capacity resistors).

• If the ambient temperature of a PT with LCD display rises above 40%C or

that of a PT with EL display rises above 50%C, set up a fan or air conditioner.

Control panel

Louver

Fan

PT

Operation and Maintenance For safety during operation and maintenance, place the Terminal as far as

possible from high-voltage machinery and power equipment.

Improving Noise Resistance Do not install in a panel with high-voltage devices and install at least 200 mm

from electric power lines. To avoid noise interference from external devices,

separate them with a transformer or noise filter when wiring.

Power line

200 mm min.

PT

200 mm min.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

21

Page 33

Dimensions Section 2-3

• When installing the Terminal near devices with strong electrical or magnetic

fields (such as solenoids), allow a distance of at least 40 mm, more if necessary.

Solenoid

40 mm min.

Solenoid

NT600M

40 mm min.

2-3 Dimensions

All dimensions are in millimeters.

2-3-1 Terminals with Function Keys (DF-type)

The dimensions illustrated below are for PTs with function keys (i.e., DF-type

PTs). PTs without a touch panel (i.e., a DN-type PT) will have the same outer

appearance and dimensions as a DF-type PT.

313

238

186

226

22

325

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

12

105

Page 34

Installing the NT600M PT in a Panel Section 2-4

2-3-2 PTs With (DT-type) and Without (DN-type) Touch Panels

313

198

325

2-4 Installing the NT600M PT in a Panel

The NT600M is designed to be inserted in a panel. Install as follows:

1, 2, 3...

1. Cut a hole in the panel in accordance with the recommended dimensions shown below. The panel should be between 1.6 and 4.8 mm thick.

All dimensions are in millimeters.

NT600M-DF122 or NT600M-DNjjj

Installation

space

227 mm

+0.5

–0

186

12

105

+ 12-key Function Key Unit

314 mm+0.5

NT600M-DTjjj/DNjjj

Installation

space

314 mm+0.5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

186.5 mm

+0.5

–0

23

Page 35

Installing the NT600M PT in a Panel Section 2-4

2. Insert the PT into the hole from the front of the panel.

3. Use the accessory metal fittings and tool to fasten the PT to the panel

surface. Do not use a screwdriver. A screwdriver may damage the fittings or the PT.

After setting the PT in the panel, secure it as shown below.

(1)

Fitting

(1) First pass the plastic part of the fit-

ting through slot (a).

Plastic

(2)

(2) Next, put the hook of the fitting into

slot (b) and pull so that the leg

NT600M

(a)

(b)

catches in the PT case.

Accessory tool

(3) Turn the screw with the tool that

NT600M

comes with the PT, and secure

the PT to the panel. There are six

places to be secured. When you

are finished, rotate the tool in the

inverse direction and remove it

from the screw.

24

4. To remove the PT from the panel, use a flat-blade screwdriver.

6 panel installation fittings

NT600M

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

–

Standard screwdriver

Page 36

Wiring and Connectors Section 2-5

2-5 Wiring and Connectors

2-5-1 Terminal Block

The terminal block shown in the following illustration is located on the PT’s

rear panel.

HOST

RUN

INPUT

50/60 Hz

ALARM

OUTPUT

Terminal screws: M4

LG GR100 to 240 VAC

Use crimp-style terminals for wiring. If twisted wires are connected directly,

there is a possibility of poor contact or short-circuiting. Use crimp-style terminals with holes to match M3.5 screws.

Fork-type

7 mm max.

Round-type

8 mm max.

Recommended Crimp-style Terminals

Maker Fork-type Round-type Conforming wire (twisted)

Japan Solderless Terminal MFG 2-YS3A 2-3.5 1.04 to 2.63 mm

Fuji Terminals 2-YAS3.5 V2-S3.5

Nichifu Terminals 2Y-3.5 2-3.5

2-5-2 AC INPUT Terminals

These terminals are the power supply input terminals to run the NT600M.

MCCB

100 to 240 VAC

50/60 Hz

Power Supply Wiring

Insulated

transformer

• Provide a 100 to 240 VAC power.

• Use a power supply within the allowable voltage range.

Power supply voltage Allowable voltage range

100 to 240 VAC 85 to 264 VAC

2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

25

Page 37

Wiring and Connectors Section 2-5

• Insulated Transformer

The NT600M has built-in anti-noise features which are sufficient for handling general noise from power lines, but ground noise can be greatly reduced by supplying power through a 1:1 insulated transformer. The secondary side of the insulated transformer should be an isolated neutral system.

• Power Capacity

Use a rated power supply (100 to 240 VAC; 50/60 Hz) of at least 50 VA.

2

• If power lines are long, then use wires of at least 2 mm

to avoid a drop in

voltage.

• Use twisted-pair cables.

2-5-3 LG and GR Terminals

HOST

RUN

INPUT

100 to 240 VAC

50/60 Hz

ALARM

OUTPUT

LG GR

Terminal screws are M4.

• GR is the ground terminal. In order to avoid electric shock, use separate

2

ground wire (at least 2 mm

) and a class-3 ground (ground resistance

100 W or less).

• LG is the noise filter neutral terminal. If malfunction results from excessive

noise, or to prevent electrical shock, short-circuit LG and GR and use a

class-3 dedicated ground.

• The ground line should be 20 m or less.

• Sharing a ground line with other machinery or grounding to the girders of a

building may be harmful.

2-5-4 HOST RUN INPUT Terminals

Use the HOST RUN INPUT when you want to monitor the RUN status of the

host.

Enable: Turn OFF SW1, pin 2.

Disable: Turn ON SW1, pin 2.

Host

24 VDC

Host RUN status

with transistor ON.

26

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HOST

RUN

INPUT

620 W

5.6 kW

(This terminal has no polarity.)

1,000 PF

Internal circuit

Page 38

RS-232C Interface Connector Section 2-6

Item Content

Rated input voltage 24 VDC

Input impedance 5.6 kW

Input current 4.1 mA typical (at 24 VDC)

ON voltage 14.4 V min.

OFF voltage 5.0 V max.

+10%

/

–15%

If host RUN input goes OFF when this terminal is enabled, a host error is displayed regardless of other conditions and processing is halted. This status is

maintained until the host RUN is restored. When errors are displayed on the

PT screen, it allows for rapid recognition of problems at the host.

2-5-5 ALM OUTPUT Terminals

DC Load

100 to 240 VAC input

External device

Load

ALM output

Item

Output type Relay output

Rated load 0.5 A at 100 VAC or 1 A at 24 VDC

Maximum load current 1 A

Minimum switching capacity 10 mA at 5 VDC

2-6 RS-232C Interface Connector

The RS-232C interface connector is used during communications between

the NT600M and Support Tool. It is located under the RS-232C interface connector cover on the back of the NT600M.

Internal circuit

Content

Pin Allocation

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Pin no. Symbol Name

1 FG Frame Ground (not used)

2 SD Send Data

3 RD Receive Data

4 RS Request to Send

5 CS Clear to Send

9 SG Signal Ground

27

Page 39

Mounting Function Key Units (to DN-type PTs) Section 2-8

Connection Diagram

Personal computer

(25 pins)

SD

RD

RS

CS

SG

FG

2

3

4

5

7

1

Note RS-232C communications conditions are set automatically by the Support

Tool. Connectors can be put on and taken off even with power on.

RS-232C NT600M

2

3

4

5

9

1

Shielded wire

D-SUB connector,

9 pins

SD

RD

RS

CS

SG

FG

Applicable Connectors

(Cable Side)

Plug: XM2A-0901 (OMRON) or equivalent.

Hood: XM2S-0911 (OMRON) or equivalent.

Recommended Cable AWG28 x 5P IFVV-SB (Fujikura, Ltd.)

CO-MA-VV-SB 5P x 28 AWG (Hitachi Cable, Ltd.)

Cable Set CV500-CN228 (OMRON)

Cable length: 2 m

2-7 12-key Function Key Units (for DN-type PTs)

12-key Function Key Unit

(NT600M-FK210)

Connector (for connecting to PT)

12-key Function Key Units can be connected to NT600M-DN122-E and

NT600M-DN211-E Programmable Terminals.

PT mounting screws and rubber packing are included

with 12-key Function Key Units.

2-8 Mounting Function Key Units (to DN-type PTs)

Mounting Procedure

1, 2, 3...

1. Remove the rubber packing and bottom connector seal from the DN-type

PT.

2. Mount the 12-key Function Key Unit to the PT, matching the connectors. Using a Phillips screwdriver, tighten the five mounting screws.

NT600M-DNjjj

Programmable Terminal

28

Phillips screwdriver

NT600M-FK210 12-key

Function Key Unit

Mounting screws (4 places)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

Mounting Function Key Units (to DN-type PTs) Section 2-8

3. Attach the rubber packing that comes with the 12-key Function Key Unit.

Rubber packing

4. Mount to the panel.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

29

Page 41

SECTION 3

Initial Operation

This section provides an introduction to the operations necessary to use a PT for the first time and to the menus and keys

used to control PT operation.

3-1 Powering Up 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Initialization 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-1 Initializing Memory 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-2 Menus 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Transferring Data to and from the Support Tool 35 . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Trial Operation 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

31

Page 42

Initialization Section 3-2

3-1 Powering Up

When first starting up the system, do not connect the Host Interface Unit to

the host. When power is turned on to the PT, either a “Connecting to host”

message or the initial screen set by the Support Tool will be displayed. The

“Connecting to host” message will be displayed if a Host Link Interface Unit,

a SYSMAC BUS Interface Unit, or a C200H Host Interface Unit is mounted.

The initial screen will be displayed if an RS-232C or RS-422A Interface Unit

is mounted.

If there is no screen data registered for the PT, or if there is an error in the

screen data that is registered, then the System Menu will be displayed

instead, with an error message at the bottom. In that case, it will be necessary to initialize the memory and transmit the correct data.

3-2 Initialization

Initialize the memory in the PT using the procedure described below. This

procedure can also be used later to completely delete data from the PT. Data

will be initialized regardless of the setting for the resume function. Always be

careful not to initialize and delete essential data.

3-2-1 Initializing Memory