Page 1

Cat.No. V034-E1-5

NT30/30C

Programmable Terminal

OPERATION MANUAL

Page 2

NT30/30C Programmable Terminal

Operation Manual

Revised January 2001

Page 3

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

The abbreviation “host” means a controller, such as an FA computer, that controls a PT (Programmable Terminal).

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1995

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates informa t i o n o f particular interest for efficient and convenient operation

of the product.

Reference Indicates supplementary information on related topics that may be of interest to

the user.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 4

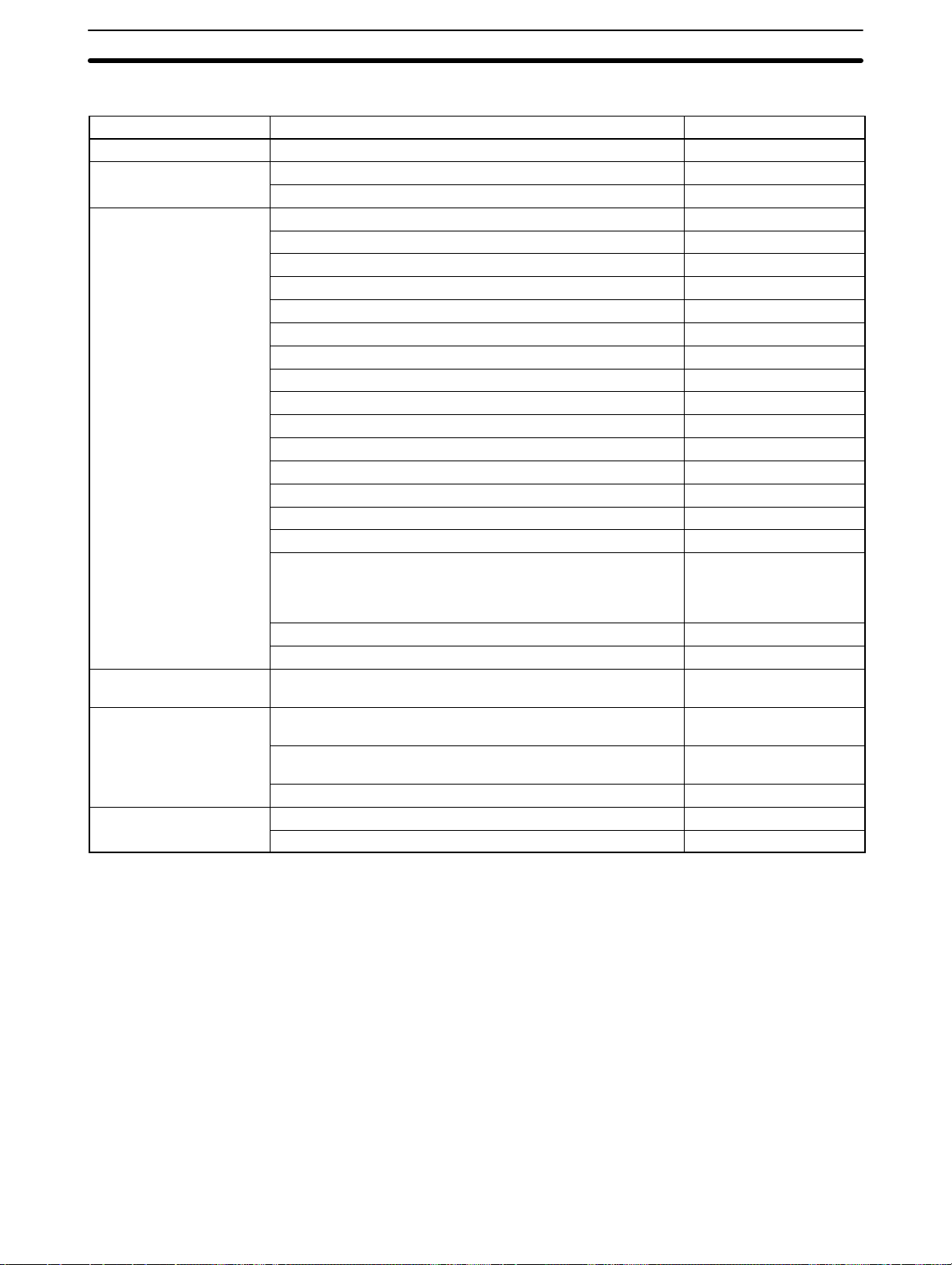

TABLE OF CONTENTS

PRECAUTIONS xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Functions of the NT30/30C 1. . . . . . . . . . . . . . . . . . . . . . . .

1-1 Role and Operation of NT30/30C 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Functions of NT30/30C 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 System Configuration 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Communications Using the Direct Connection Function 8. . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Before Operating 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Hardware Settings and Connections 15. . . . . . . . . . . . . . . .

2-1 Description of Parts and Settings 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Installation 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Connecting to the Support Tool 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Installing the System Program 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Connection to a PC by Host Link via RS-232C 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 Connection to a PC by Host Link via RS-422A 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 Connection to a PC by the NT Link 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 Connecting a Printer 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9 Connection of Expanded I/O 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

System Menu Operation 73. . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Operation Flow by the System Menu 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Starting the NT30/30C 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Operation Modes and the System Menu 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Initializing Memory 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Setting Communications with the PC Using Memory Switches 83. . . . . . . . . . . . . . . . . . . .

3-6 Registering the Screen Data 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7 Starting the Operation 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8 System Settings 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9 System Maintenance 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

NT30/30C Functions 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Creating and Transmitting Screen Data 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Outline of Functions 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Screen Displays 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Memory Tables 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 Graphs 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6 Lamps 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7 Touch Switches 154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8 Numeral Setting 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-9 Character String Setting 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-10 Pop-Up Window Function 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11 Alarm List & History Display Functions 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-12 Operation of B7A Units 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 5

TABLE OF CONTENTS

SECTION 5

Using Host Link and NT Link 189. . . . . . . . . . . . . . . . . . . . . .

5-1 Outline of Host Link and NT Link Operations 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Memory Tables and Graphs 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Lamps and Touch Switches 216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Numeral and Character String Setting 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 Alarm Lists 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6 Clock Function 234. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7 NT30/30C Status Control 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-8 Notifying the PC of PT Operating Status 244. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6

Troubleshooting and Maintenance 247. . . . . . . . . . . . . . . . . .

6-1 Hardware Faults 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Responding to Displayed Error Messages 249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Maintenance of the NT30/30C 252. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Inspection and Cleaning 255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Specifications 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Dimensions 263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Using RS-232C/RS-422A Link Adapters 265. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D NT30/30C Internal Processing 267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E Making the Cable to Connect to the PC 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F Connecting Cable Specifications 281. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G Connection Using RS-232C/RS-422A Link Adapters 283. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H Standard Models 285. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I Options 291. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

J PC Memory Maps 293. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

K Special Characters 295. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 297. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 303. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 6

About this Manual:

This manual describes the basic functions and operating procedures of the NT-series NT30/30C Programmable Terminals and their operation when connected to a PC or other host. It includes the sections

described below.

Please read this manual carefully and be sure you understand the information provided before attempting

to install and operate an NT-series NT30/30C Programmable Terminal.

Section 1 describes the operating functions, system configuration, and the direct connection function of

the NT30/30C.

Section 2 describes the hardware settings, installation to a control panel, connection to optional devices

and connection to a PC.

Section 3 describes the procedure to follow before using the NT30/30C, installation of optional devices,

and convenient functions when using the NT30/30C. Also includes information such as how to check

NT30/30C operation.

Section 4 describes the functions of the NT30/30C when it is connected to a PC.

Section 5 describes how to use the NT30/30C when it is connected to the PC using a Host Link or NT

Link.

Section 6 describes the corrective action to take when the system does not operate normally, and how to

carry out daily maintenance of the NT30/30C.

The Appendices provide information on specifications, dimensions using an RS-232C/RS-422A Link

Adapter, NT30/30C internal processing, making the cable to connect to a PC, connecting cable specifications, connection using an RS-232C/RS-422A Link Adapter, standard models, options, PC memory

maps, and special characters.

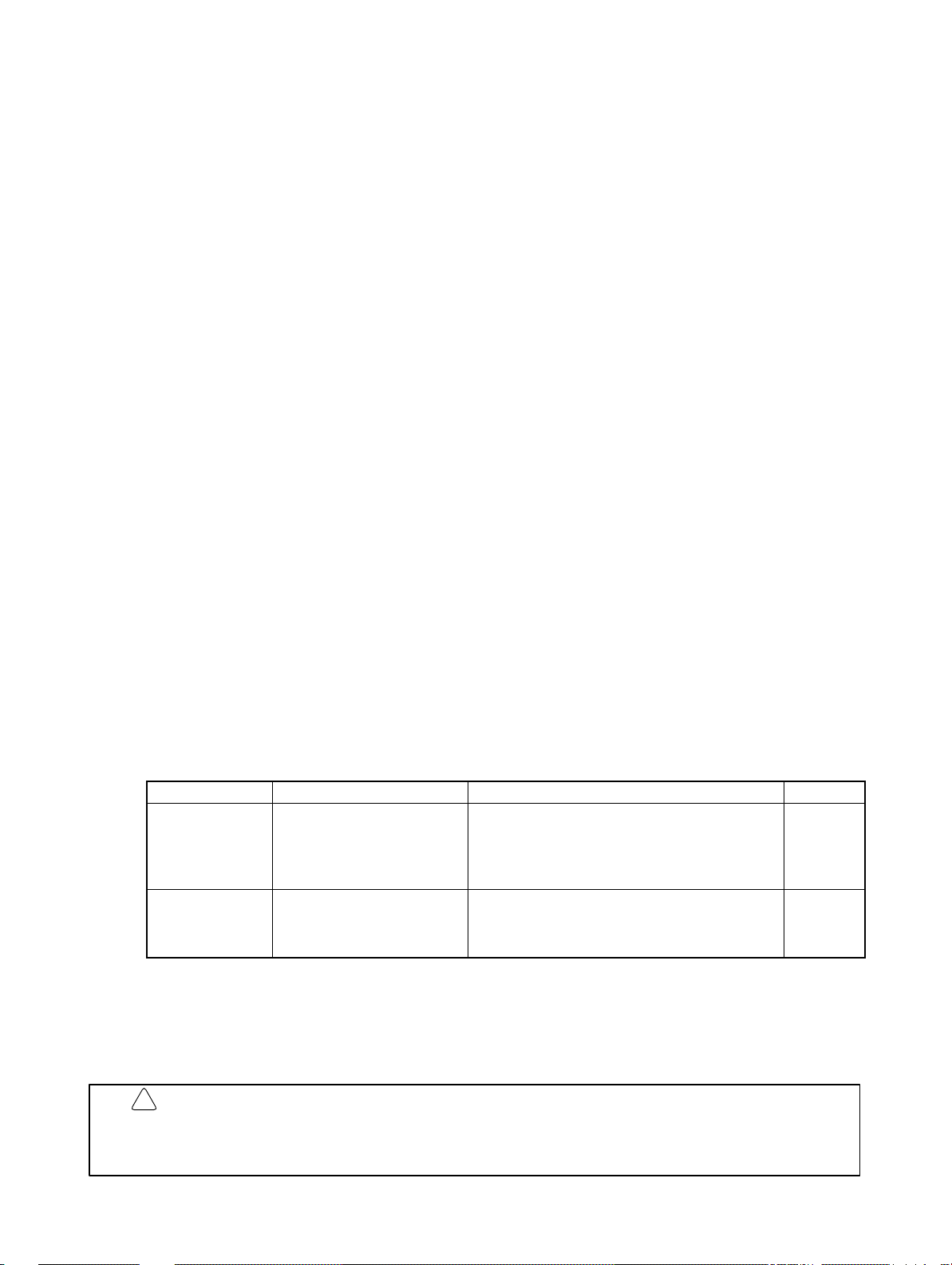

Related Manuals:

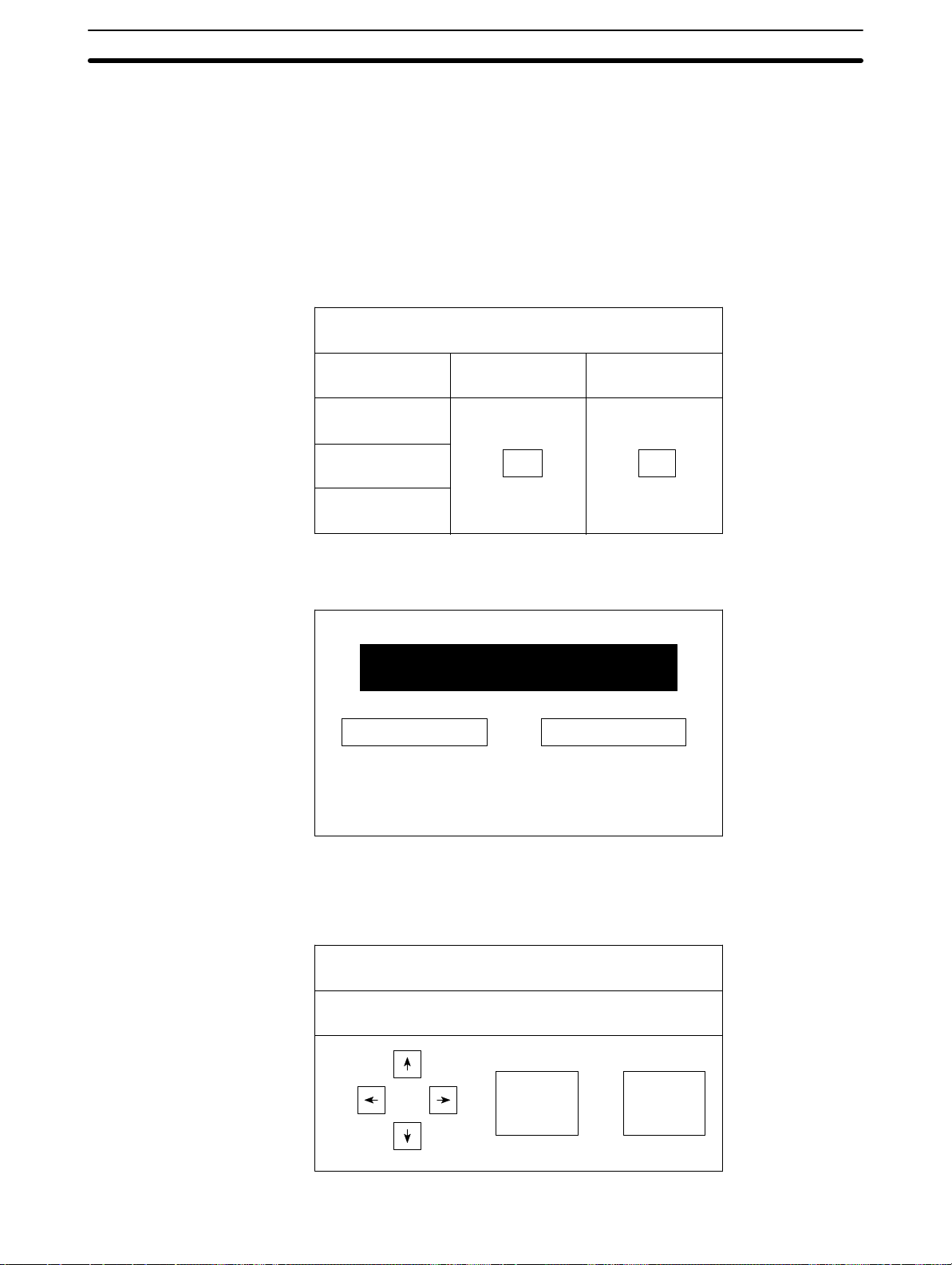

Purpose Name Contents Cat. No.

Operating the

Programmable

Terminal and

communicating

with the host

Creating and

transferring

screen data

!

WARNING Failure to read and understand the information provided in this manual may result in

NT30/30C Programmable

Terminal Operation Manual

(this manual)

NT-series Support Tool

Operation Manuals

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

Related manuals are listed below. Suffixes have been omitted from the catalog

numbers. Be sure you are using the correct revision of the manual.

This is the manual for the NT30/30C itself. This

operation manual describes the functions and

handling of both the Programmable Terminal

and the host interface function.

The screens displayed on the NT30/30C are

created with the Support Tool and transferred to

the NT30/30C. These manuals describe how to

create and transfer screen data.

V034

V028 and

V061

ix

Page 7

PRECAUTIONS

This section provides general precautions for using the Programmable Terminal.

The information contained in this section is important for the safe and reliable application of the Programmable Terminal. You must read this section and understand the information contained before attempting to set up or operate a

Programmable Terminal.

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xi

Page 8

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

Personnel in charge of installing FA systems.

Personnel in charge of designing FA systems.

Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the PT according to the performance specifications described in the operation manuals.

Before using the PT under conditions that are not described in the manual or applying the PT to nuclear control systems, railroad systems, aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety

equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the PT are sufficient for the systems, machines, and equipment, and be sure to provide the systems, machines, and equipment with double safety mechanisms.

This manual provides information for using the Programmable Terminal. Be sure

to read this manual before attempting to use the software and keep this manual

close at hand for reference during operation.

2General Precautions

If a faulty PT is returned for repairs, write as detailed a description of the fault as

possible and send the description together with the PT to the OMRON address

indicated on the back cover of this book.

When disposing of an NT that is no longer required, be sure to comply with all

local restrictions that apply to its disposal.

WARNING It is extremely important that Programmable Terminals and related devices be

!

used for the specified purpose and under the specified conditions, especially in

applications that can directly or indirectly affect human life. You must consult

with your OMRON representative before applying Programmable Terminals to

the above mentioned applications.

WARNING Do not use input functions such as PT touch switches for applications where

!

danger to human life or serious damage is possible, or for emergency switch

applications.

xii

Page 9

3 Safety Precautions

Read these safety precautions carefully and make sure you understand them

before using the Programmable Terminal so that you can use it safely and correctly.

WARNING

!

Never attempt repairs, modification or disassembly. You could sustain an elec-

tric shock.

Switch OFF the PT power before changing the backlight. You could sustain an

electric shock if you attempt to change the backlight while power is being supplied.

Caution

!

When disposing of a used backlight, comply with all local restrictions that apply

to its disposal.

When replacing the battery, do not allow the battery terminals to touch the

board in the PT.

3Safety Precautions

If not backed up by the built-in battery, the memory switch settings will be initial-

ized to t h e v a l ues set with the NT-series Support Tool when the power is turned

OFF . If a message indicating that the battery is low is displayed while the PT is

being used, replace the built-in battery immediately. For details on how to replace the battery, refer to Replacing the Battery (page 253).

Switch OFF the power supply to both the PT and the B7A Interface Unit before

installing the B7A Interface Unit, otherwise the PT or the B7A Interface Unit

may be damaged.

Switch OFF the power supply to both the PT and the B7A Interface Unit before

changing DIP switch settings.

Do not use input functions, such as PT touch switches, for applications where

danger to human life or serious property damage is possible or for emergency

switch applications.

Do not use the expanded I/O functions of the B7A Unit for applications where

danger to human life or serious property damage is possible or for emergency

switch applications.

On unpacking the PT, check its external appearance and confirm that there is

no damage. Also confirm that there is no abnormal noise on shaking the PT

lightly. The PT may malfunction if it is damaged.

During work at the panel, be sure that no metal scraps enter the PT. Otherwise,

the PT may malfunction.

The thickness of applicable operation panel is 1.6 mm to 4.8 mm. All fittings

must be tightened uniformly to a torque of 0.5 to 0.6 Nm in order to ensure

water- and dust- resistance. The panel must not be soiled or warped, and must

be able to support an installation that will remain secure and strong.

Carefully check wiring before switching ON the power.

xiii

Page 10

Do not apply an AC power supply across the power supply terminals.

Use a DC power supply with a low voltage fluctuation.

When complying with EC low voltage directives use a power supply with rein-

forced insulation.

For the connection to the power supply terminal block, twisted-pair wires with a

2

2 mm

or greater cross sectional area and M 3.5 size crimp terminals must be

used. T ighten the screws on the terminal block to a torque of 0.8 Ncm. Other-

wise fire may occur.

If the DIP switch settings have been changed while power was supplied to the

PT, reset the power to the PT. The changes with the DIP switch become effective only after the power supply is reset.

Before switching ON the power for the first time, set pin 6 of DIP switch SW2 on

the PT to ON (it is set to OFF on shipping). If it is left OFF, messages will not be

displayed normally.

Press the Abort touch switch on the PT when screen data transmission has

been completed. Unless this touch switch is pressed, the screen data will not

be correctly registered. If the Abort touch switch is pressed during transmission, the screen data will not be correctly registered.

3Safety Precautions

Check the operation of screen data and ladder program thoroughly before ac-

tually using them.

Press touch switches with a force of no greater than 30 N. Applying higher force

may cause glass to break, resulting in injuries or preventing operation.

Do not press touch switches carelessly while the backlight is OFF or while

nothing is displayed on the screen. The system may operate unpredictably.

Press touch switches only after confirming system safety.

As far as possible, disconnect all devices connected to the output terminals be-

fore executing the output check. Otherwise, each time an output terminal

comes ON during the check operation, the outputs to the devices may be activated.

xiv

Page 11

SECTION 1

Functions of the NT30/30C

This section gives the operation examples and characteristics of the NT30/30C so that you will understand the applications of

the NT30/30C.

1-1 Role and Operation of NT30/30C 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-1 Operation of an NT30/30C at an FA Production Site 2. . . . . . . . . . . . . . . . . . . . . .

1-1-2 Operations of NT30/30C 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Functions of NT30/30C 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1 Features 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-2 Comparison between NT30 and NT30C 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-3 Principal Functions of NT30/30C 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-4 Displays 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 System Configuration 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Communications Using the Direct Connection Function 8. . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-1 Direct Connection Function 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-2 NT Link 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-3 Functions of the Allocated Bits and Words 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Before Operating 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 12

1-1 Role and Operation of NT30/30C

NT30/30C is a Programmable Terminal used to display and transmit the information in a n FA site. The following gives a general description of the role and operation of the NT30/30C for those who use a Programmable Terminal (PT) for the

first time.

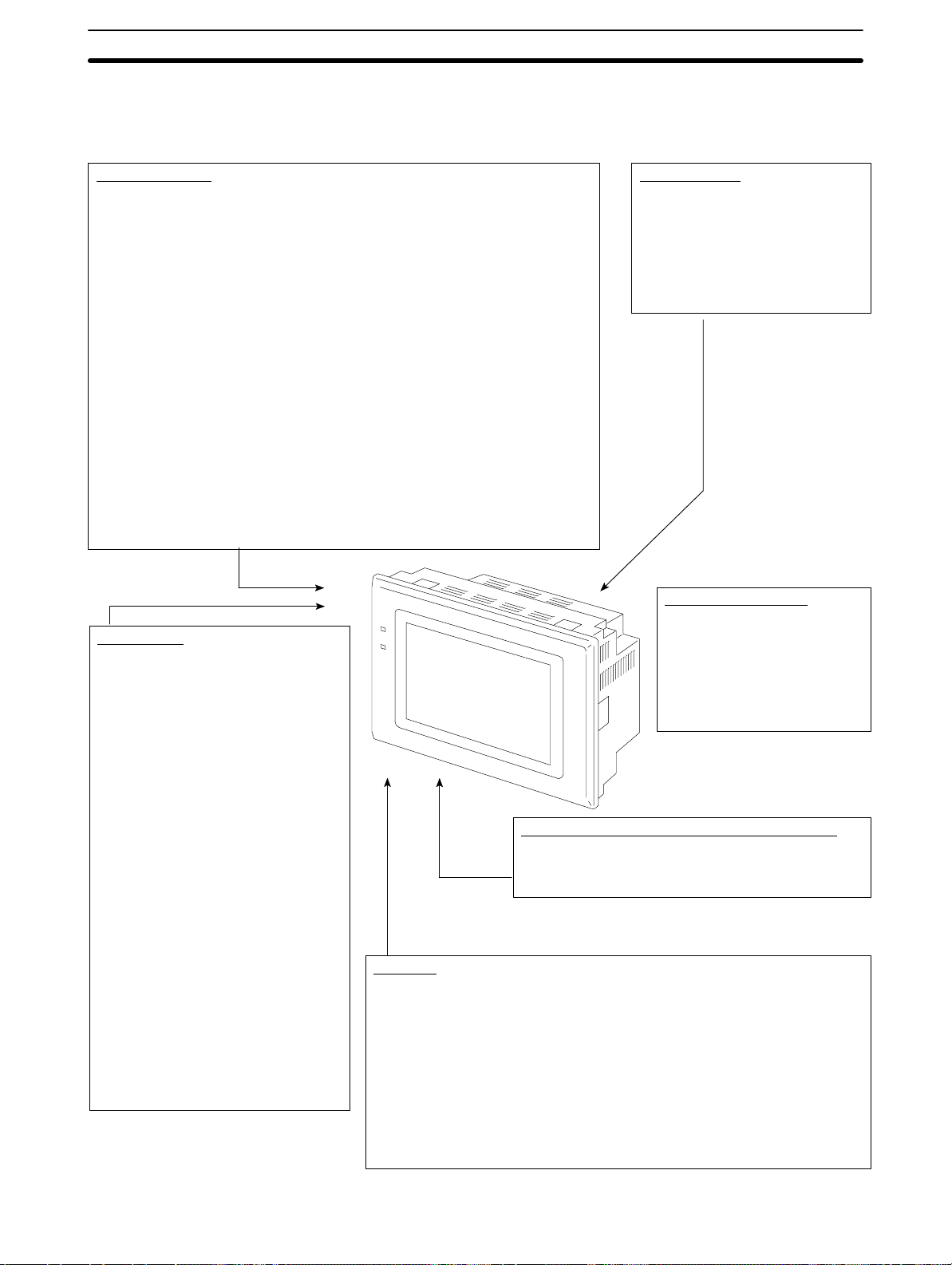

1-1-1 Operation of an NT30/30C at an FA Production Site

1-1SectionRole and Operation of NT30/30C

Production Line Status

Monitoring

Messages The NT30/30C can be used to warn of system or equipment failures and prompts

The NT30/30C can be used to display real-time information about the system

and equipment operating status, etc.

Production Control

Product

Today’s target

Current Production

% achieved

the appropriate remedial action.

NT30 NT30C

560 units

305 units

54.5 %

1994/1/25

441 units

275 units

63.0 %

Alarm

Assembly line B

–

Positioning pin

is defective.

Panel Switch Functions Setting touch switches on the NT30/30C can be set up to allow workers to use the

NT30/30C as a control panel. Production data input to the NT30/30C can be

transmitted to a PC.

Electroplating Control

Transport

Clamp UnClamp

2

Page 13

1-1SectionRole and Operation of NT30/30C

1-1-2 Operations of NT30/30C

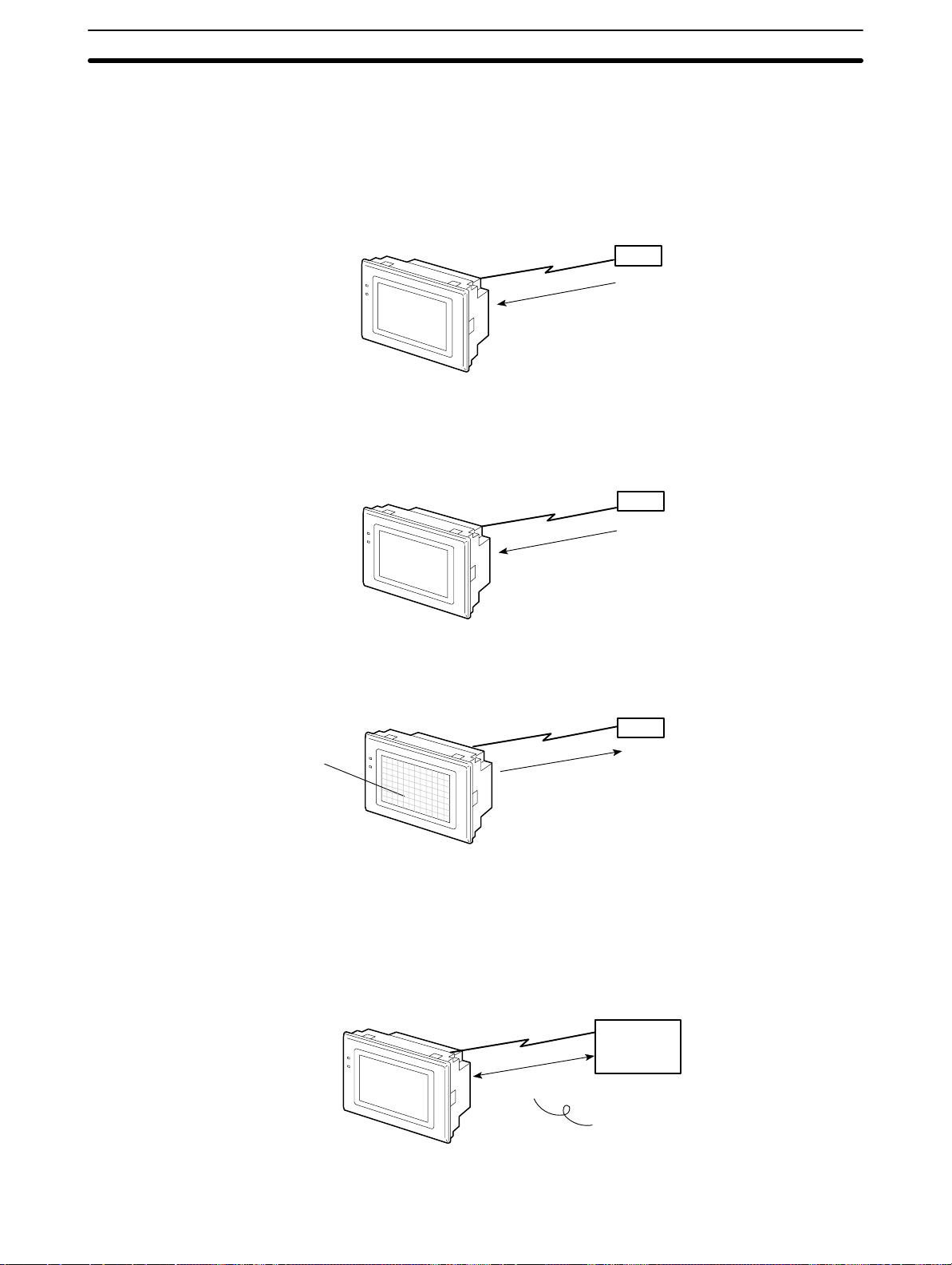

Displays Screens The information to be displayed (screen data) can be created on a computer by

using the NT-series Support Tool and stored in the NT30/30C. The screen data

can be displayed on the NT30/30C in response to the instructions from a PC/

Host or touch switch operation.

PC

The screen data designated by

instructions from PC/Host or

touch switch operation is

displayed.

Receives Data from a PC NT30/30C can be connected to a PC by a Host Link or NT Link and receive nec-

essary data from the PC.

Host Link, NT Link

PC

Sends Data to a PC Data input through a touch panel can be sent to a PC.

PC

Touch panel

ON/OFF information,

numeric data, etc.

Receives Screen Data The screen data to be displayed on the NT30/30C can be created by a computer

using the NT-series Support Tool. Connect the NT30/30C to an IBM PC/AT or

compatible with an RS-232C cable so that the screen data are transferred to the

NT30/30C.

RS-232C

Create screen data.

Screen data

IBM PC/AT or

compatible

running the

Support Tool

When using RS-232C to connect to the

PC, the connection is made only to transfer

screen data between the NT30/NT30C and

the NT-series Support Tool.

3

Page 14

1-2 Functions of NT30/30C

The NT30/30C has the following features.

1-2-1 Features

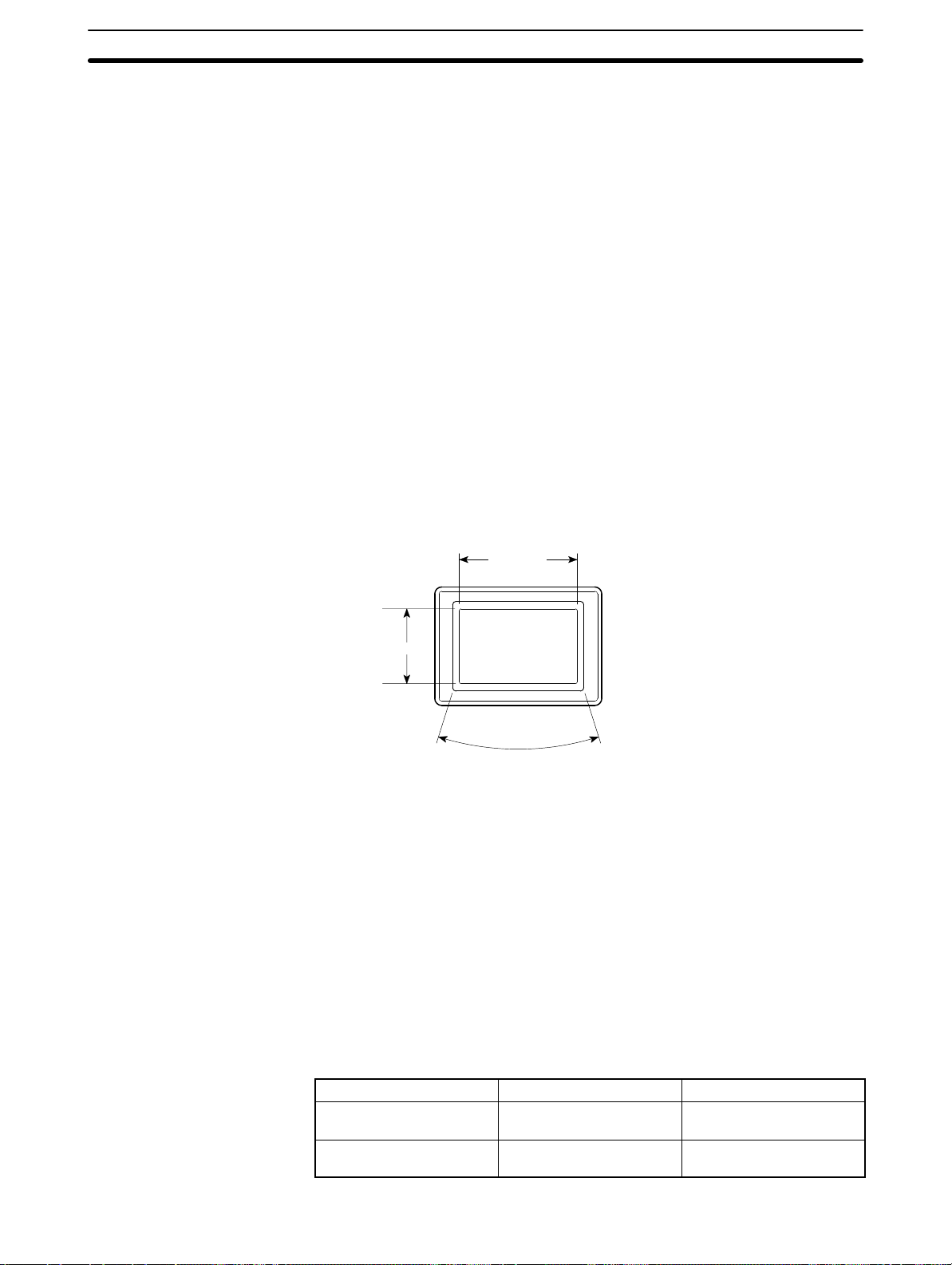

Downsized Body

• Slim body (50 mm or less in the panel).

• The communication cable connectors are housed in the Unit so that they do

not protrude from the Unit.

• The same connector is used to connect to the the Support Tool and to the host.

Construction Best Suited to the FA Environment

• Easy-to-read screen even in direct sunlight.

• The panel is a LCD panel with white/red backlight for the NT30, and an STN

color LCD panel with backlight for the NT30C.

• Its backlight unit and battery can be replaced at the operation site.

• Waterproofed to a standard equivalent to IP65.

1-2SectionFunctions of NT30/30C

320 dots

POWER

RUN

240 dots

Wide angle of visibility, 35

Touch Switch Operation The System Menu can be displayed by using the touch switches located in four

corners of the screen.

Compatibility with

NT612G/610C

Existing screen data and user programs are compatible. (Modification required

according to screen size.)

1-2-2 Comparison between NT30 and NT30C

Two models are available: The NT30 is capable of versatile graphic displays and

the NT30C provides the same features, but is also capable of color displays. The

differences between the NT30 and NT30C are listed below.

Function NT30 NT30C

Model NT30-ST131-E (Beige)

NT30-ST131B-E (Black)

Display panel Monochrome LCD type

(with white/red backlight)

NT30C-ST141-E (Beige)

NT30C-ST141B-E (Black)

STN color LCD type

(with backlight)

4

Page 15

1-2-3 Principal Functions of NT30/30C

The following are the principal functions of the NT30/30C.

1-2SectionFunctions of NT30/30C

Data Displays

Character Displays

Characters of various sizes can be displayed. Characters can be flashed and highlighted.

Figure Displays

Solid lines, squares, polygons, circles, circular arcs, and fan shapes can be displayed. They can also be painted with various patterns, flashed, or highlighted.

Memory Data Displays

Entries in the character string memory table or numeral table can be displayed. The

memory table contents can be changed from the PC.

Graph Displays

Not only bar graphs, but also broken line graphs and trend graphs can be displayed

using the numeral table.

Lamp Displays

Lamps can be turned ON or flashed from the PC.

Alarm List Displays

In response to the status of PC bits, warning messages can be automatically listed.

When and how many times the messages appeared can also be displayed.

Data Input

Touch Switches

Data can be input by simply touching

the screen. There are various touch

switch functions, such as those for

sending input data to the PC.

Pop-up Windows

A window overlaying the currently displayed screen can be opened and

closed by pressing a touch switch. In

addition to fixed displays, numeric keys

and character keys can be set inside

the window. The window need be

opened only when input is required, to

enable effective screen usage.

Numeric V alues/Character

Strings

Touch switch keys and expanded I/O

on a B7A Unit can be allocated numeric

values or character strings so that

these values and character strings can

be input at the operation site or even

written onto the numeric or character

string table and sent to the PC. It is

also possible to disable inputs from the

PC.

System

System Functions

System settings and maintenance can be performed by selecting from system menus displayed on the screen.

Creating Screen Data

Screen data created by using the NT-series Support Tool on a personal computer

can be transferred and stored in the built-in image data memory.

System Program Installation

Using the System Installer (purchased separately), the system programs for the

NT30 and NT30C can be replaced.

Expanded I/O Functions on B7A Units

Data Output

Buzzer

A built-in buzzer can be sounded.

Screen Printing

A hard copy of the screen may be

printed to the printer connected to

the NT30/30C.

Communications

The NT30/30C communicates

with PC through a Host Interface Unit or NT Link so that

data may be received from PC

or information entered from

touch switches may be sent to

the PC.

The NT30/30C can receive a switching input from a B7A

Unit, and turns ON/OFF the output.

A B7A Interface Unit is required to connect a B7A Unit.

5

Page 16

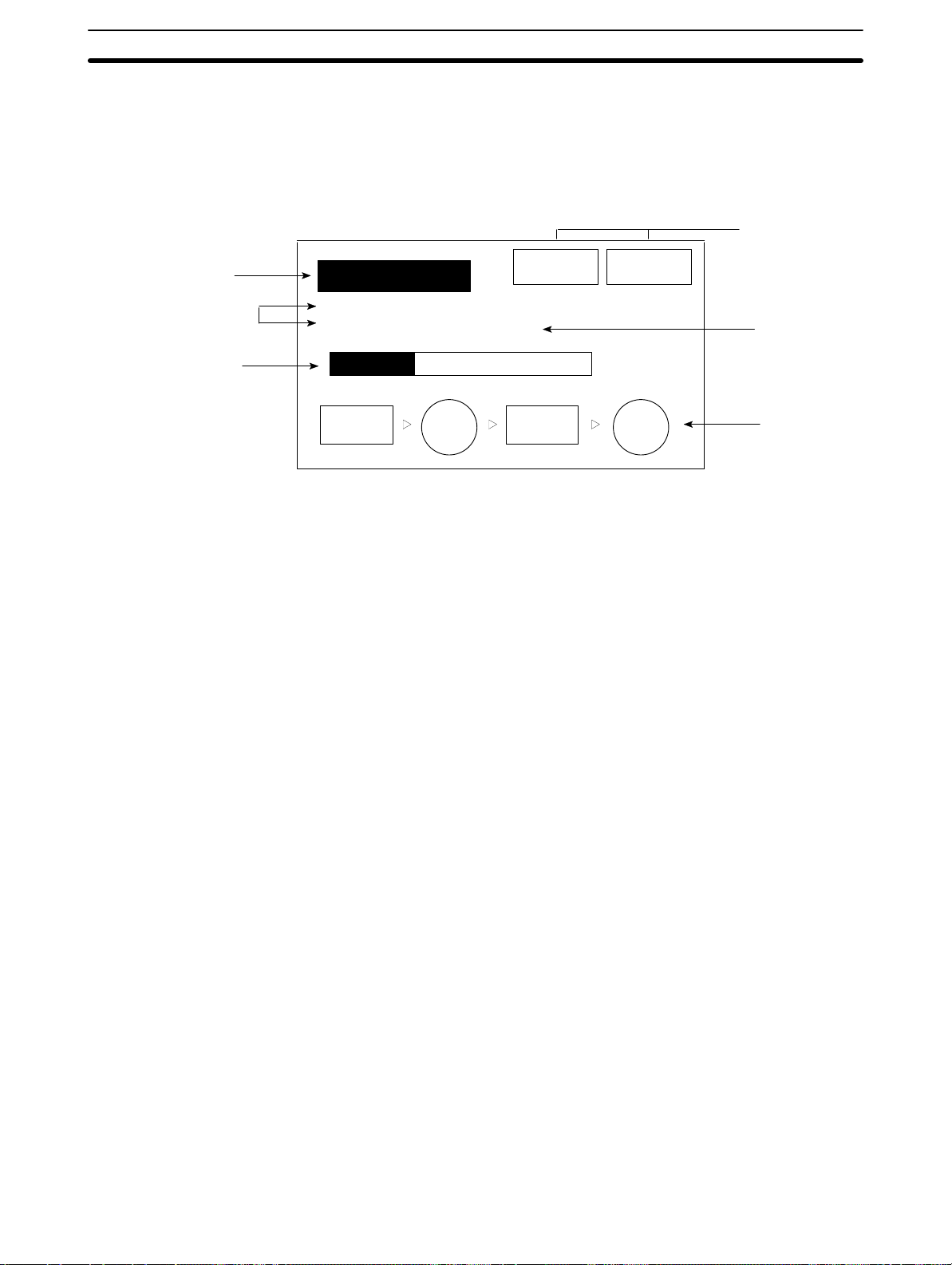

1-2-4 Displays

Characters

(character string

table)

Characters (text)

Bar graph

1-2SectionFunctions of NT30/30C

The NT30/30C can display various kinds of elements such as characters, numeric value, lamps, touch switches, and graphs on a screen. The screen data displayed on the NT30/30C are created by using the NT-series Support Tool on a

computer.

Touch

switches

Line 1 Status

Machine name: NT30C-ST141

Production qty.: 137 units

0% 50% 100%

Stop Restart

Numeric value

(numeral table)

30%

Stage 1 Stage 2

Characters (Text)

Marks and image data that do not need to be changed can be written directly to

the screen.

Characters (Character String Memory Table)

Character strings stored in the character string memory table can be displayed. The display characters can be changed by changing the data stored in

the character string memory table.

Numeric Values (Numeral Memory Table)

Numbers stored in the numeral memory table can be displayed. The display

numbers can be changed by changing the data stored in the numeral table.

Hexadecimal values can be displayed.

Lamps

Lamps can be used to indicate operating status. Squares, circles, fans, and

polygons can be used. They are controlled by the PC and can be lit (reversed)

or made to flash (alternates normal and reversed displays).

Touch Switches

Touch switches can be set anywhere on the screen. Pressing the part of the

screen where a touch switch has been set can have the following effects: No ti fication of the fact that the switch has been pressed to the PC (PC notification

function); screen switching; input of a numerical value or character string (input

key function); copying of a numerical value or character string (copy key function); shifting to another numerical value or character string input field (cursor

moving key function); and obtaining a hard copy of the screen (screen print key

function). Touch switches are controlled from the PC and can be made to light

or flash in the same way as lamps.

Check 1 Check 2

Lamps

Graphs

6

Bar graphs, trend graphs, and broken line graphs can be displayed according

to the numerical values stored in numeral memory table. These values can

also be represented as percentages displayed together with the graphs.

Page 17

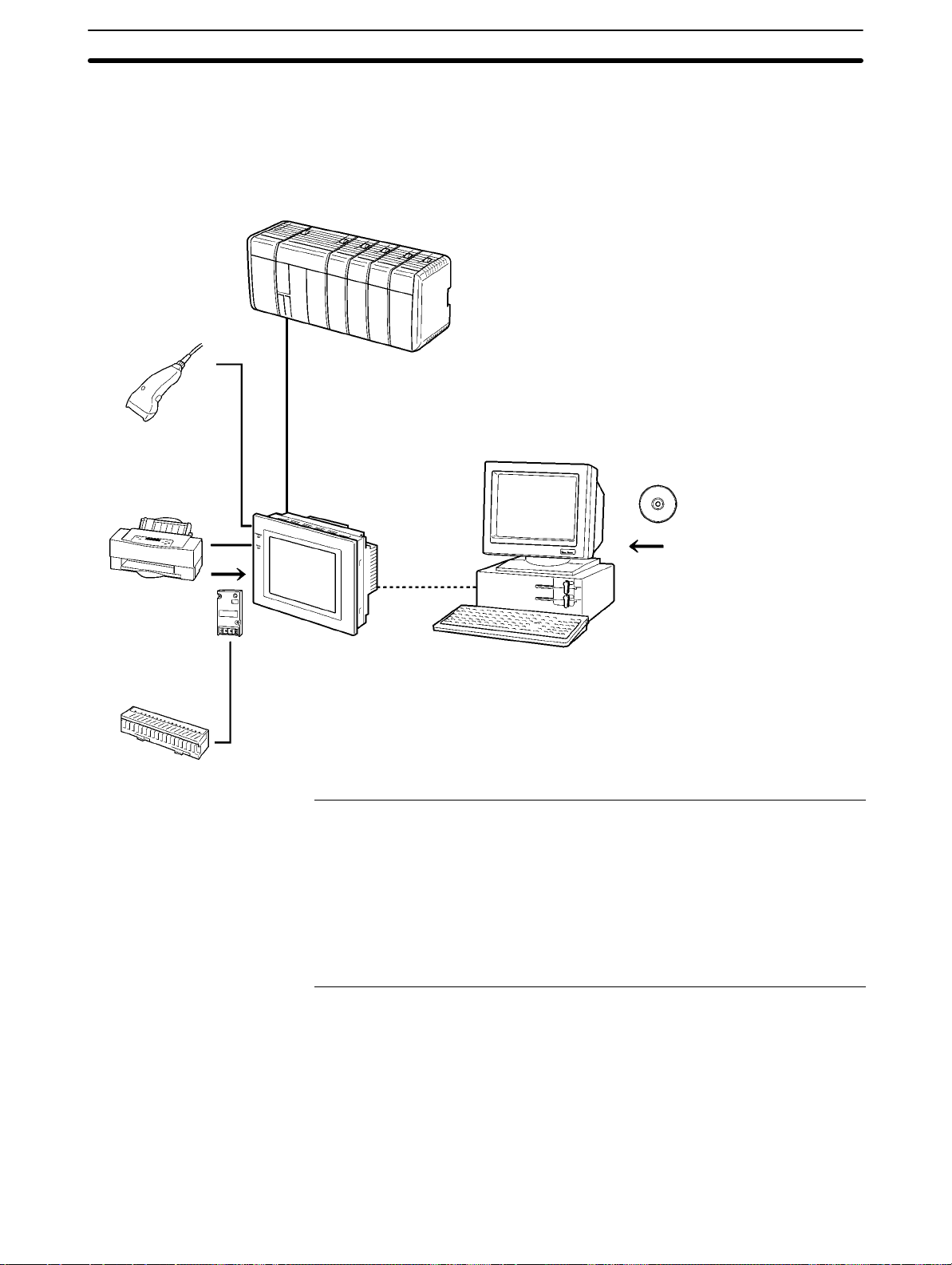

1-3 System Configuration

This section gives the basic configuration of a system that uses an NT30/30C.

Use an RS-232C cable or an RS-422A cable to connect to a PC. Refer to the

manuals for individual devices for information on devices other than the

NT30/30C in the system.

Bar code reader

Enables reading of bar

codes as character strings.

(Cannot be used with

memory link.)

RS-232C cable

(for Host Link)

(Max. 15 m)

Printer

The screen display of the

NT30/NT30C can be

printed out.

or RS-422A cable

(for Host Link)

(Max. 500 m)

OMRON PC

Controls the NT30/30C as required while controlling machines and

monitoring the production line.

Host Link: C-series PC, CVM1/CV-series PC, SRM1

NT Link: CPM1, CQM1, C200HS, C200HX/HG/HE,

NT30/30C can be connected to CPU Units, Host Link

Units, and an SRM1. Connection to some models of CPU

Unit and some models of the SRM1, however, is not

possible (see pages 23 and 40).

CVM1/CV-series PC, SRM1

NT30/30C can be connected to CPU Units and the

SRM1. Connection to some models of CPU Unit and

some models of the SRM1, however, is not possible (see

page 56).

1-3SectionSystem Configuration

NT-B7A16 B7A

Interface Unit

NT30/30C

Provides displays of production line

monitoring information and instructions to the

operation site and notifies switch ON/OFF

status and numeric value inputs to the PC.

B7A Unit

A B7A Unit can be connected to expand I/O.

Reference

NT-series Support Tool

Computer (NT-series Support Tool)

Connected to the NT30/30C as required and used to transfer

the NT30/30C screens and make settings for the NT30/30C.

Computer: IBM PC/AT or compatible

Software: NT-series Support Tool

Refer to 3-5 Setting Communications with the PC Using Memory Switches

(page 83) for setting procedures. It is impossible to connect a personal computer

running the NT-series Support Tool and a PC at the same time.

Typical optional devices for the NT30/30C include the following.

B7A Interface Unit NT-B7A16

Backlight (spare) NT30-CFL01 (for NT30)

NT30C-CFL01 (for NT30C)

Protective Sheets NT30-KBA04 (5 sheets/pack)

Battery C500-BAT08

7

Page 18

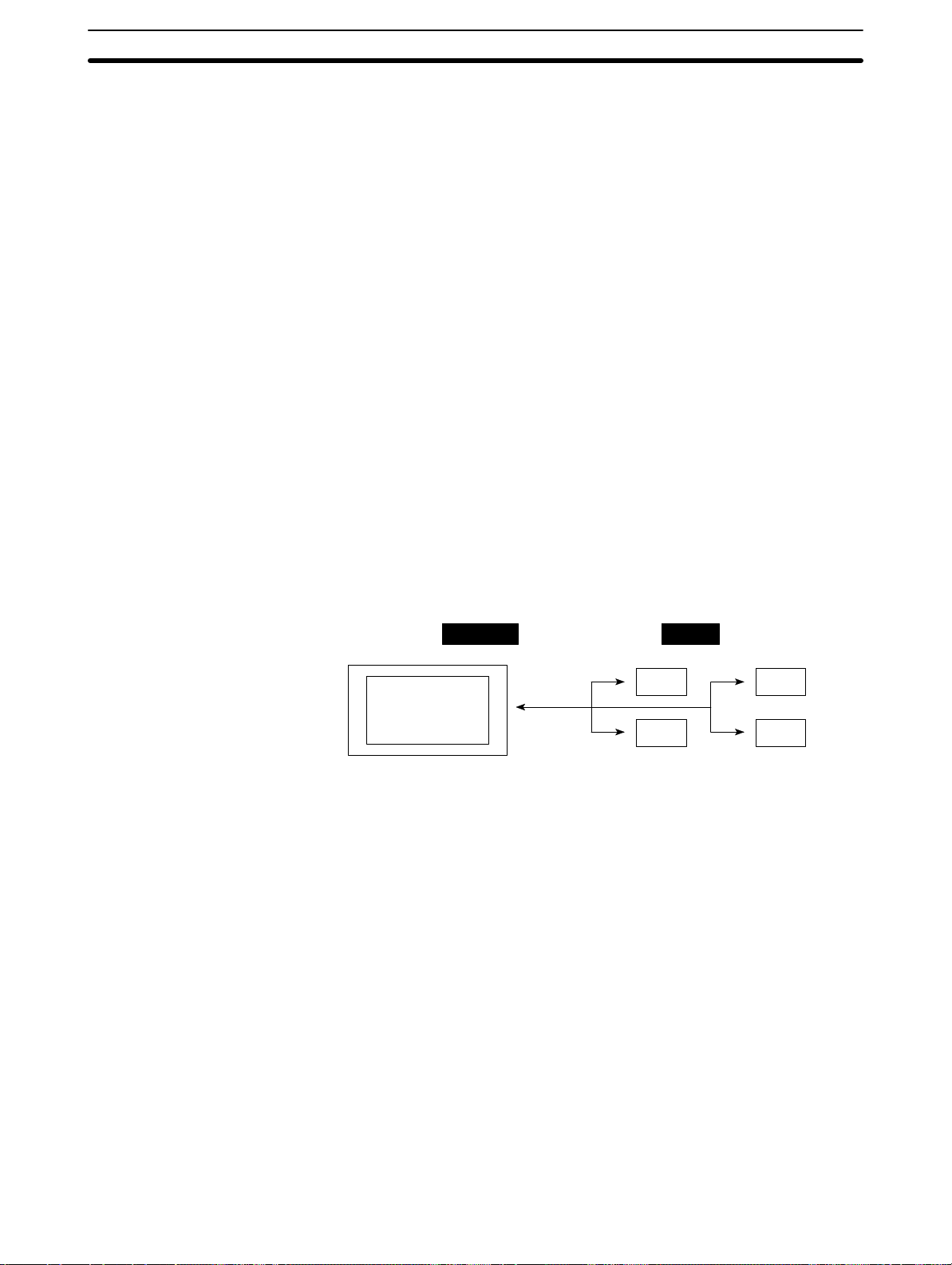

1-4 Communications Using the Direct Connection Function

1-4-1 Direct Connection Function

The communications method applied between the NT and the PC is either a Host

Link or NT Link.

The NT30/30C can be used to access data for the display or to allocate the bits

and words for storing input data in essentially any area in the PC. The NT30/30C

can directly write and read the allocated bits and words to change the display elements, control operating status, and notify status.

This function is called the direct connection function. The NT30/30C is designed

specially for use with a direct connection.

The bits and words allocated by the direct connection function are called allocated bits and allocated words.

A direct connection enables reading the data to be displayed on the NT30/30C

from a memory area in the PC and writing it to a memory table in the NT30/30C.

Also, the data input at the NT30/30C can be written to a PC memory area. The

NT30/30C screen status can be switched according to PC memory area data,

and NT30/30C status data can be written to a PC memory area.

1-4SectionCommunications Using the Direct Connection Function

Features

NT30/30C PC

DM Area IR/CIO Area

AR Area

• The bits and words used to access operating status and work instructions and

those for storing input data can be allocated in almost any part of PC I/O memory. Bits and words in the PC are accessed from memory table entries.

• The NT30/30C can directly access PC bit and word data so that it can be connected to a PC without changing the PC program that controls the current production line.

• The area to control and notify the NT30/30C status, including display screens,

display/no display status, and buzzers, can be allocated in almost any part of

PC I/O memory.

Timer/Counter

Area

The direct connection function allows the NT30/30C to directly read and write almost all bits and words in the PC and to automatically change the NT30/30C

screen display . This function can reduce the load on the PC to improve the program development efficiency of the PC.

8

Page 19

1-4-2 NT Link

Features of the NT Link

1-4SectionCommunications Using the Direct Connection Function

The NT Link is a new communications method between the PT and a PC.

The NT Link uses the direct connection function and can execute high-speed

communications with a CPM1, CPM2A, CPM2C, CQM1, CQM1H, C200HS,

C200HX/HG/HE(-Z), CS1-s e r i e s , C V M1 , C V-series, or SRM1 CPU Unit (built-in

Host Link).

• High-speed communications with specific types of PCs can be executed.

• Writing in units of bits to the PC memory area is possible (except the DM Area.

.This enables the bit in a word data to which a touch switch has been allocated

to be used for other purposes (e.g., to control a lamp).

• This can be used even when the PC is in RUN mode. (With Host Link, if the PC

is in RUN mode, the NT30/NT30C switches the mode to MONITOR mode.)

Either the NT Link or the Host Link can be used for connection without changing

the NT30/30C screen data or the PC program.

1-4-3 Functions of the Allocated Bits and Words

Elements displayed on the NT30/30C and the NT30/30C status can be allocated

to the bits and words of the PC. By changing the contents of the bits and words,

the NT30/30C can be controlled by the PC. It is also possible to send data to the

PC by pressing the touch switches on the NT30/30C.

S Controlling the NT30/30C by a PC

The following NT30/30C functions can be controlled by a PC.

Screens: Display of designated screens, confirmation

of screen numbers, etc.

Memory tables: Writing to a memory table entry, copying from

a memory table entry to another memory

table entry, etc.

Lamps and touch switches: Display instructions, confirmation of display

status, etc.

System control: Buzzer ON/OFF, display/no display status,

screen printing, and other NT30/30C statuses

S Notifying from the NT30/30C to a PC

Data in the NT30/30C is sent to a PC when a touch switch is pressed. The following types of data can be sent to the PC.

• NT30/30C status

• Touch switch status

• Numeric values and character strings input with numeral/character string

setting functions using touch switches.

• Changes in a memory table entry after copying between memory table en tries

9

Page 20

Display Elements

1-4SectionCommunications Using the Direct Connection Function

S Lamps (page 151)

Allocated to: Bits

NT30/30C

Lamp #1 (IR/CIO 000100)

Lit

Unlit

Lamp #2 (IR/CIO 000101)

PC

Switch 1: ON (IR/CIO 000100)

Switch 2: OFF (IR/CIO 000101)

The PC’s bit status can be displayed by lamps on the NT30/30C.

The lamp lights or flashes when the PC’s bit status (i.e., the lamp bit) is ON (1),

and goes OFF when it is OFF (0).

Image/library lamps can also be created to switch the displayed image or li-

brary data according to the ON (1)/OFF (0) status of the lamp bit.

S Touch Switches (page 154)

Allocated to: Bits

Touch switch #12

IR/CIO 009012

NT30/30C

PC

IR/CIO 009012: ON

The PC bit allocated for the touch switch turns ON (1) and OFF (0) when the

touch switch is pressed to notify the PC of the status of the touch switch.

S Numeral Memory Table (page 138)

Allocated to: Words

Numeral memory

table entry 1 (TIM003)

Numeral memory table entry 150 (IR/CIO 0005)

NT30/30C

PC

The numeral memory table is allocated to words in the PC. If word contents

change when corresponding numeral memory table entry is displayed on the

screen, the value on the screen will also change, enabling the contents of

words to be easily monitored.

10

Reading and writing are executed so that the contents of allocated words are

kept the same as those of the numeral memory table entries.

Page 21

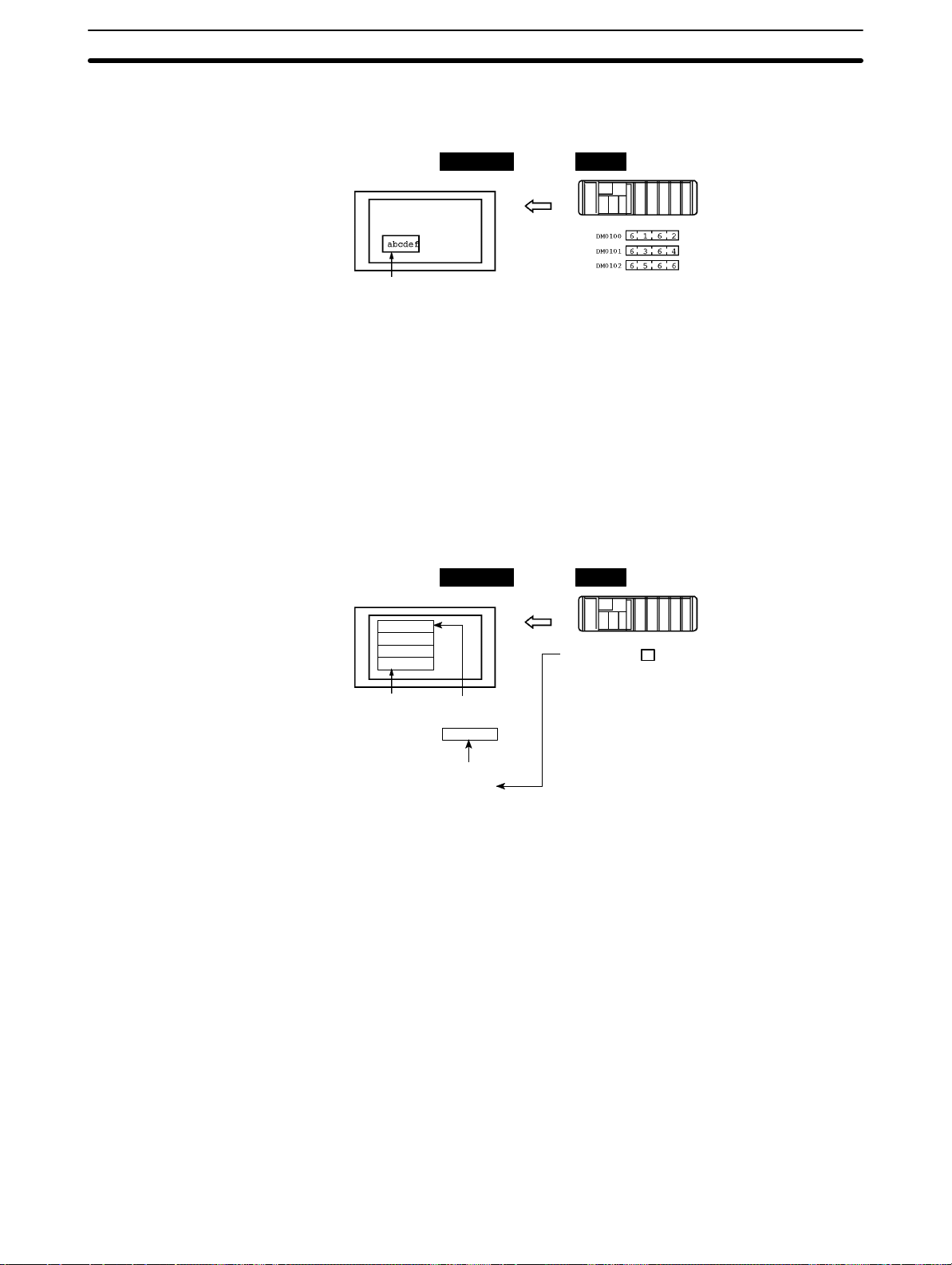

S Character String Memory Table (page 136)

Allocated to: Words

NT30/30C PC

(“a”, “b”)

(“c”, “d”)

(“e”, “f”)

Character string memory table entry 1

Number of words allocated: 3 words

First word: DM0100

The character string memory table is allocated to words in the PC. If word contents change when the corresponding character string memory table entry is

displayed on the screen, the value on the screen will also change, enabling

messages to be easily displayed.

Reading and writing are executed so that the contents of allocated words are

kept the same as those of the character string memory table entries.

1-4SectionCommunications Using the Direct Connection Function

S Alarm List (Bit Memory Table) (pages 140 and 180)

Allocated to: Bits

NT30/30C PC

Material low

1

Alarm list

Character string memory

table entry 120

Material low

Bit memory table entry 23

IR/CIO 010009

Character string memory

table entry 120

IR/CIO 010009

When the corresponding PC bit turns ON (1), the contents of the character

string memory table entry registered for the bit memory table entry is displayed

in the alarm list. When the bit returns to the OFF (0) status, the character string

memory table entry display is automatically cleared.

11

Page 22

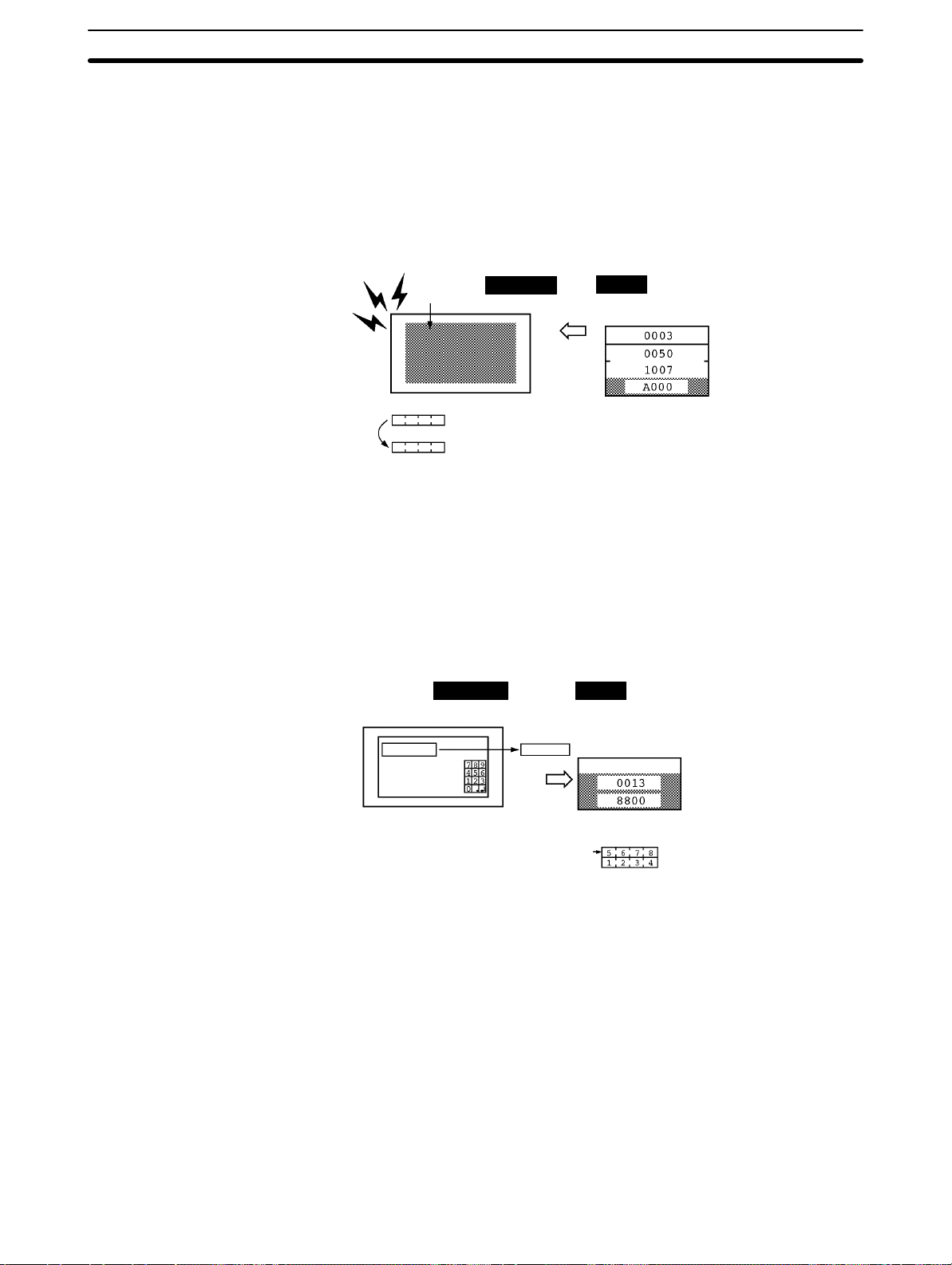

PT Status Control Area (PC to NT30/30C)

The PT Status Control Area is used to control the NT30/30C status. When data is

written to th is area in the PC, the NT30/30C reads the contents and operates according to the contents.

Example of PT Status Control Area Application

When data is written to the PT Status Control Area, the NT30/30C will operate as

illustrated below (page 191).

1-4SectionCommunications Using the Direct Connection Function

Continuous

buzzer sound

Copy

PT Status Notify Area (NT30/30C to PC)

The PT Status Notify Area is used to notify the PC of changes in the NT30/30C

status. When a change is made in the NT30/30C status, the change is written to

this area in the PC. By reading the data from the area, the NT30/30C status can

be checked from the PC.

Example of PT Status Notify Area Application

When a change is made in the NT30/30C status, the change will be indicated in

the PT Status Notify Area as illustrated below (page 193).

Screen 3

display

Numeral memory table entry 50

Numeral memory table entry 7

NT30/30C

12345678

NT30/30C

Numeral memory table entry 13

12345678

PC

PT Status Control Area

Screen switch setting

Memory table entry

Copy setting

PT status control bits

PC

PT Status Notify Area

Currently display screen

Content update memory table entry

PT status

12

Allocated word (numeral table entry 13)

12345678

Start

Start + 1

Page 23

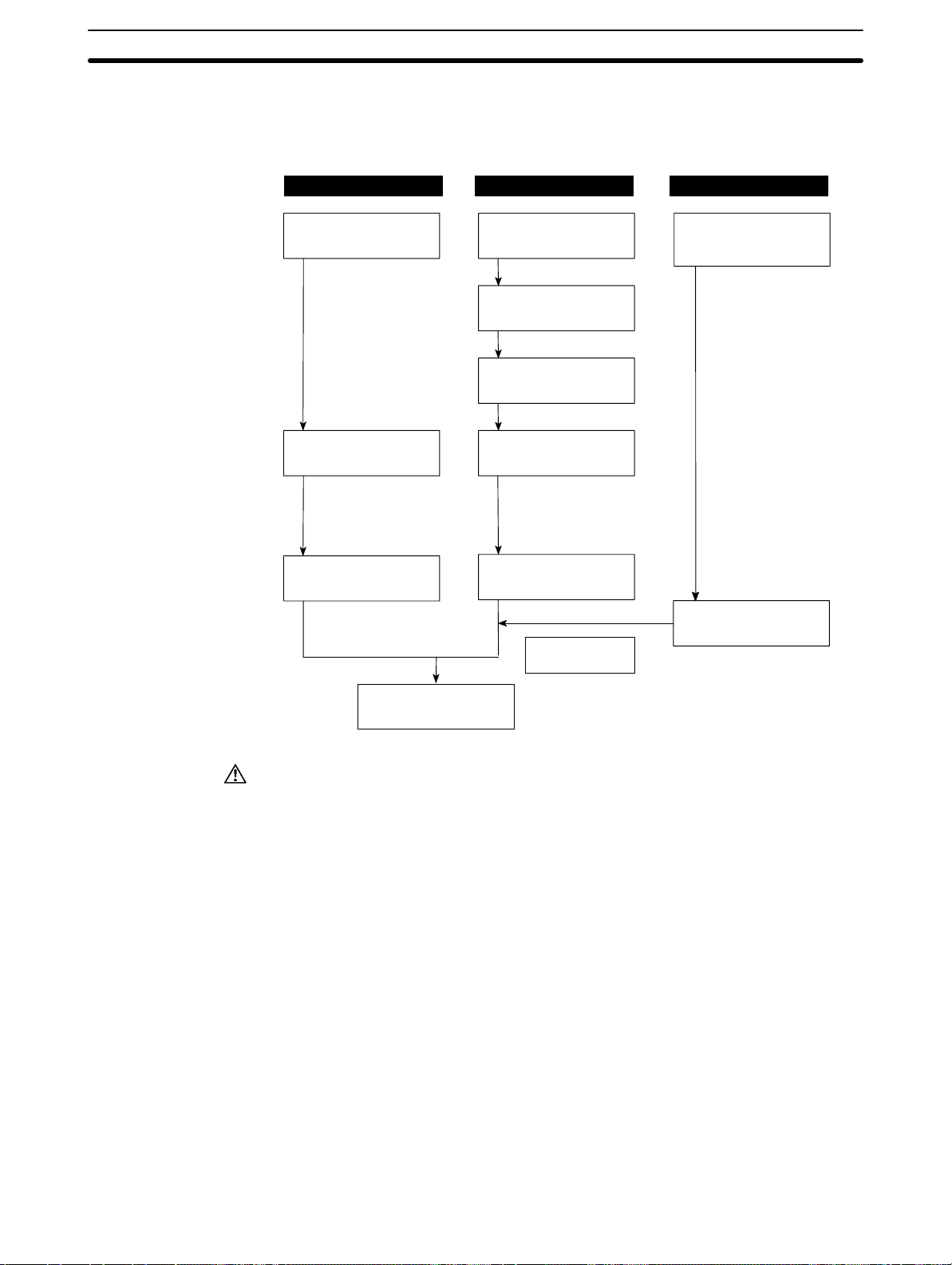

1-5 Before Operating

Use the procedure given below to start the NT30/30C.

1-5SectionBefore Operating

PC NT30/30C NT-series Support Tool

Check and change

the PC settings.

For the Host Link, refer

to page 27 (RS-232C),

page 40 (RS-422A)

and the manuals for

the Host Link Unit and

Programming Devices.

For the NT Link,

refer to page 56.

Connect to the

NT30/30C.

Create the PC

program.

Start operation.

Set the DIP switch.

(page 18)

Install to the operation panel.

(page 19)

Connect the power

supply.

(page 20)

Connect to the PC.

(Host Link:

page 25 (RS-232C)

page 42 (RS-422A))

(NT Link: page 56)

Check the settings

and communications.

Transfer the

screen data.

(page 89)

Install NT-series

Support Tool on the

computer.

(Refer to the manuals

for the NT-series

Support Tool.)

Create the screens.

(Refer to Section 4 and

the manuals for the

NT-series Support Tool.)

Caution

Be sure to confirm that correct operation is possible with the screen data and the

host program before actual operation.

Reference 1. Use the System Installer provided with the NT-series Support Tool for Win-

dows.

2. Use the NT-series Support Tool for Windows.

13

Page 24

Refer to the following manuals for the product information.

Product Manual Title Cat No.

System Installer NT-series Support Tool for Windows Operation Manual

NT-series Support Tool NT-series Support Tool Operation Manual

NT-series Support Tool for Windows Operation Manual

PCs SYSMAC CPM1 Operation Manual

SYSMAC CPM1A Operation Manual

SYSMAC CPM2A Operation Manual

SYSMAC CPM2C Operation Manual

SYSMAC C20H/C28H/C40H/C60H Programming Manual

SYSMAC C200H Operation Manual (CPU01-E/03-E/11-E)

SYSMAC C200H Operation Manual (CPU21-E/23-E/31-E)

SYSMAC C200HS Operation Manual

SYSMAC C200HS Installation Guide

SYSMAC C200HX/HG/HE-CPU-E/ZE Installation Guide W302-E1-

SYSMAC C200HX/HG/HE Operation Manual

SYSMAC C1000H/C2000H Operation Manual

SYSMAC C200HX/HG/HE-CPU-ZE Operation Manual W322-E1-

SYSMAC CQM1 Reference Manual

SYSMAC CQM1H Operation Manual

SYSMAC CV500/CV1000/CV2000 Operation Manual: Ladder

Diagrams

* For a PC of the CVM1 Series, refer to the SYSMAC

CV500/CV1000/CV2000 Operation Manual.

SYSMAC CS1-series Operation Manual

SYSMAC CS1-series Programming Manual

CompoBus/S

Master Control Unit

Programming Devices SYSMAC C-series and CVM1 PCs SYSMAC Support Software

Host Link Unit SYSMAC C-series Host Link Unit Operation Manual

SRM1 Operation Manual

Operation Manual: C-series PCs

SYSMAC C-series and CVM1 PCs SYSMAC Support Software

Operation Manual: CVM1 PCs

CX-Programmer Operation Manual ---

SYSMAC CVM1/C-series Host Link Operation Manual

1-5SectionBefore Operating

V061-E1-

V028-E1-

V061-E1-

W262-E1-

W317-E1-

W352-E1-

W356-E1-

W176-E1-

W130-E1-

W217-E1-

W235-E1-

W236-E1-

W303-E1-

W140-E1-

W228-E1-

W363-E1-

W202-E1-

W339-E1-

W340-E1-

W318-E1-

W248-E1-

W249-E1-

W143-E1-

W205-E1-

14

Page 25

SECTION 2

Hardware Settings and Connections

This section describes the settings of the NT30/30C, connections to a PC, and other hardware settings.

2-1 Description of Parts and Settings 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 Description of Parts 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 DIP Switch Settings 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Installation 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 Installation to the Operation Panel 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Power Supply Connection 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-3 Ground Wire Connection 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Connecting to the Support Tool 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Installing the System Program 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Connection to a PC by Host Link via RS-232C 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-1 Compatible PCs 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-2 Connecting the NT30/30C 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-3 PC Switch Settings 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 Connection to a PC by Host Link via RS-422A 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6-1 Compatible PCs 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6-2 Parts Required for Connection 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6-3 Method for Connection 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6-4 Connector Specifications and Wiring for Each Unit 43. . . . . . . . . . . . . . . . . . . . . . .

2-6-5 PC Switch Settings 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 Connection to a PC by the NT Link 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7-1 Compatible PCs 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7-2 Connecting the NT30/30C 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7-3 PC Switch Settings (RS-232C at PC Side) 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7-4 PC Switch Settings (RS-422A at PC Side) 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 Connecting a Printer 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8-1 How to Connect 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9 Connection of Expanded I/O 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9-1 Connectable B7A Units 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9-2 B7A Interface Unit Specifications 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9-3 B7A Interface Unit Part Names 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9-4 Installing the B7A Interface Unit 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9-5 B7A Interface Unit Settings 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9-6 Connecting the B7A Unit to the B7A Interface Unit 67. . . . . . . . . . . . . . . . . . . . . .

15

Page 26

2-1 Description of Parts and Settings

Before getting to the operation, confirm the names and functions of parts. Also

set the DIP switch on the NT30/30C.

2-1SectionDescription of Parts and Settings

Caution

On unpacking the NT30/30C, check its external appearance and confirm that

there is no d a m age. Also confirm that there is no abnormal noise on shaking the

Unit lightly. The product may malfunction if it is damaged.

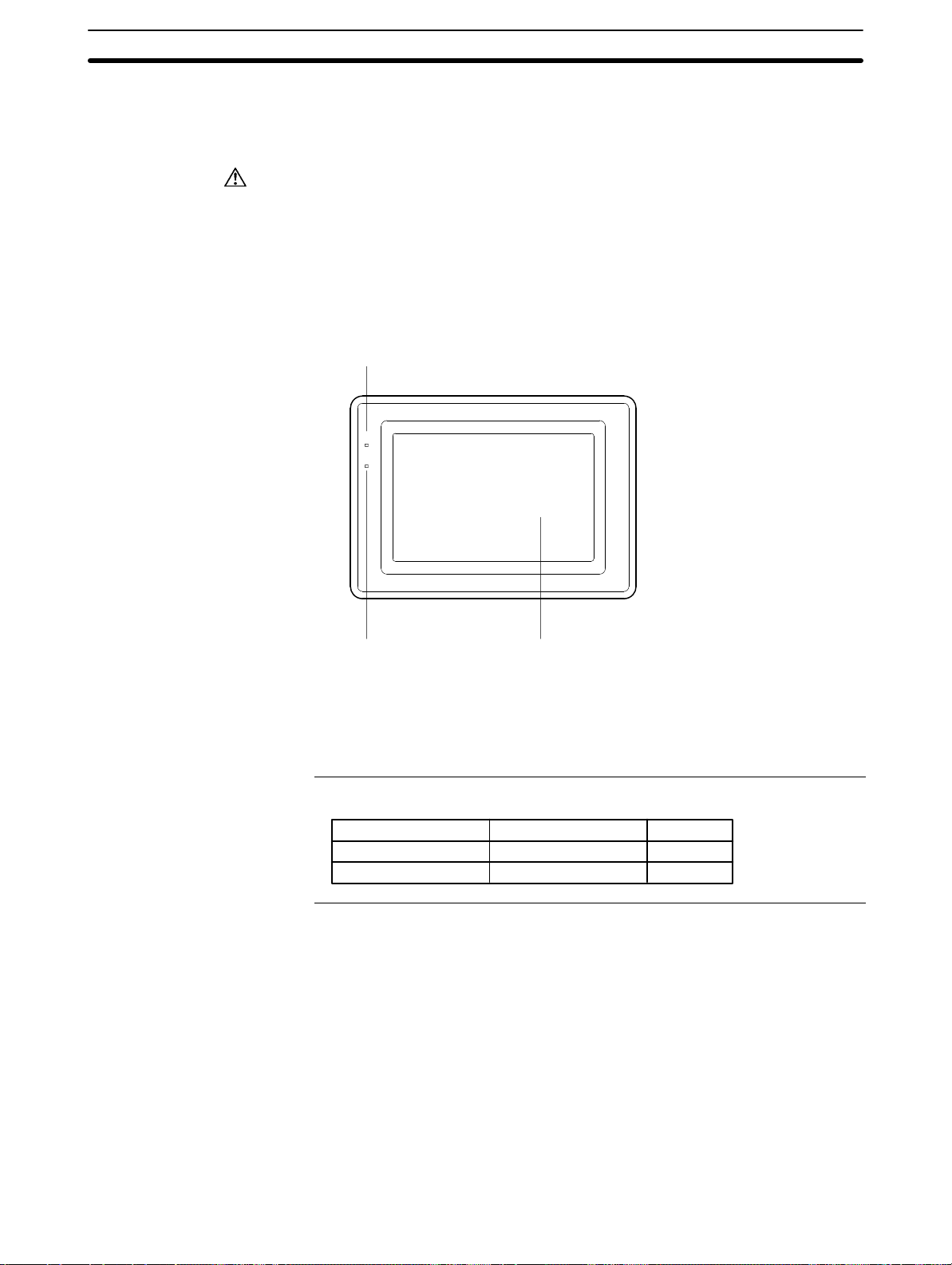

2-1-1 Description of Parts

Front View

POWER indicator

Lit when the power is

supplied.

POWER

RUN

Reference

RUN indicator

Lit in green while the PT

is in the RUN mode.

Lit in orange or red when

the battery is low (orange

in the RUN mode, red in

other modes)

Display

The NT30 has a monochrome LCD screen

with a white/red backlight, and the NT30C

has an STN color LCD screen. The whole

area of the screen is a touch panel that

works as an input device.

The NT30/30C comes in two body colors.

NT30 NT30C Body Color

NT30-ST131-E NT30C-ST141-E Beige

NT30-ST131B-E NT30C-ST141B-E Black

16

Page 27

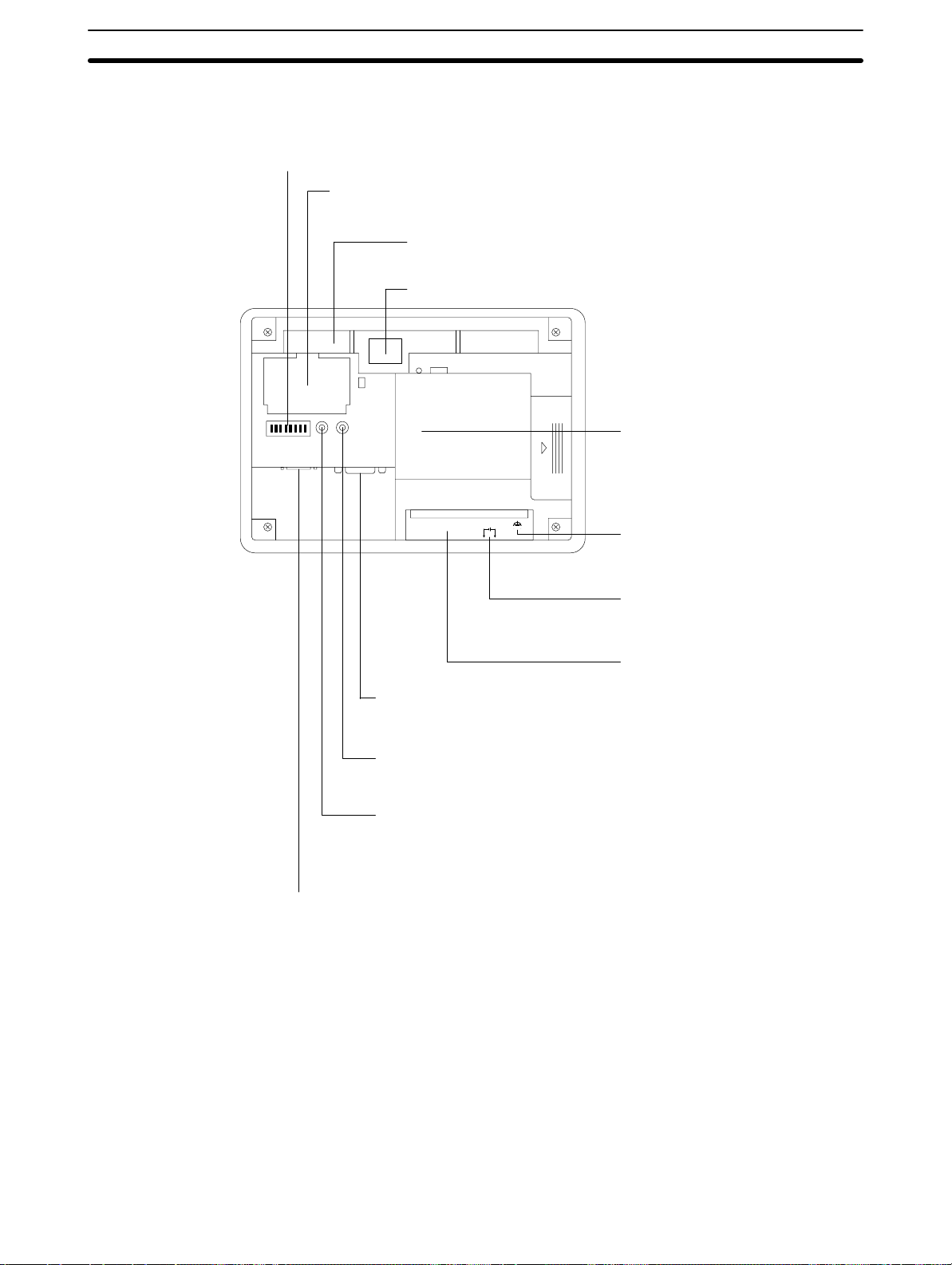

Rear View

2-1SectionDescription of Parts and Settings

DIP switch (SW2)

Set the system settings with

this DIP switch.

Battery cover

The battery is secured underneath this cover.

Backlight unit

Backlight integrated with a connector.

Warning label

SW2 RESET –CONTRAST

PRINTER RS-232C

B7A interface connector (under the

label)

When using a B7A Interface Unit, peel

off the label and connect it here.

SDA SDB RDA RDB

24 VDC

+

GR terminal

Grounding terminal to prevent

malfunction due to noise

Power input terminals

Connect the power to the NT30/30C

at these terminals.

RS-422A terminal block

When making the connection to the PC

RS-232C Host I/F tool connector

with RS-422A, connect the cable here.

Connect the cable from a PC or

NT-series Support Tool here.

Contrast control

Use a fine flat-blade screwdriver. Turn

clockwise to increase the brightness.

Reset switch

Used to initialize all the statuses of the NT30/30C.

However, the screen data memory and memory

switches retain their statuses before initialization.

Printer connector

Connect the printer cable here. Output

conforms to Centronics specifications.

17

Page 28

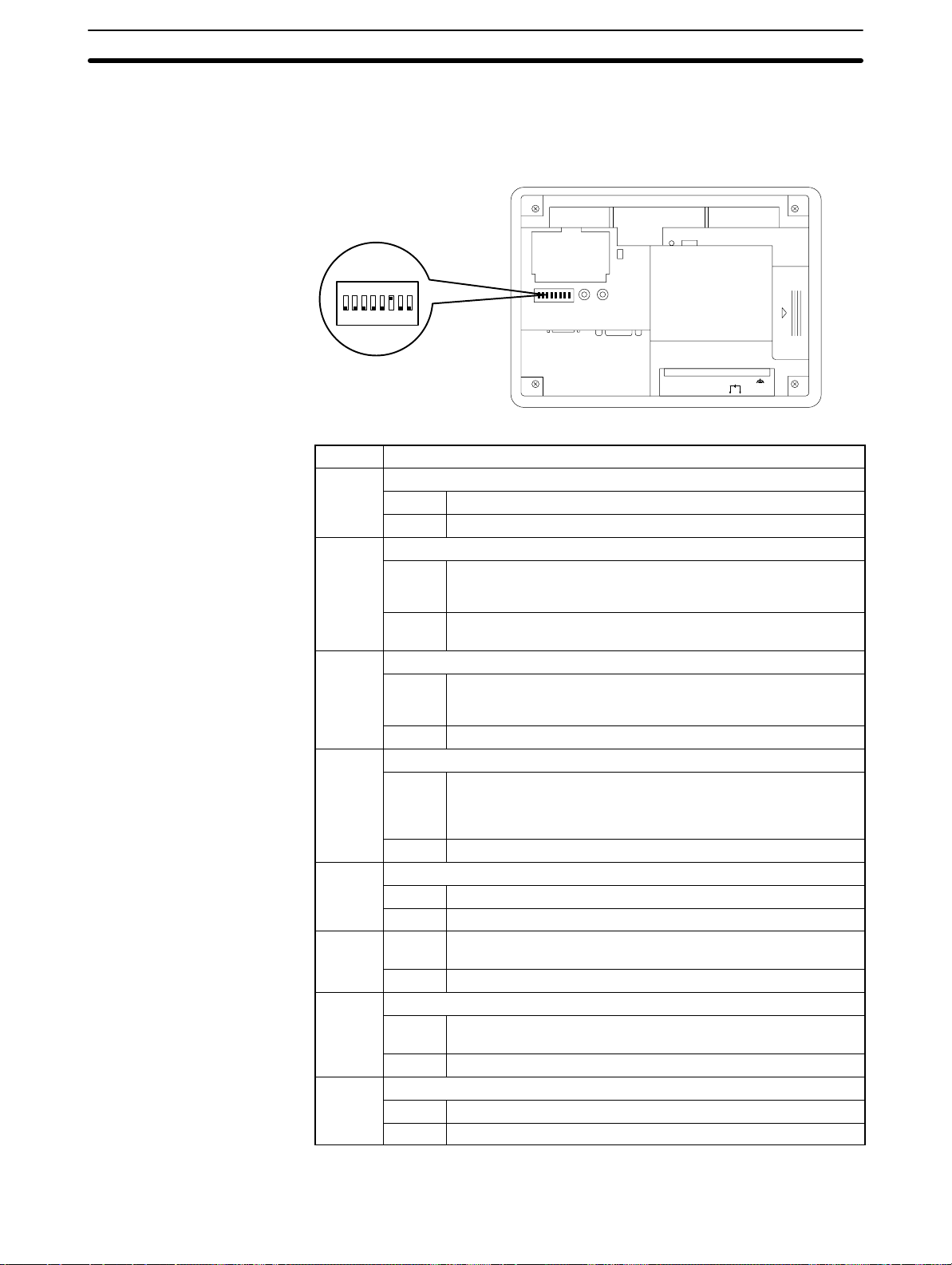

2-1-2 DIP Switch Settings

Set the NT30/30C operation status with the DIP switch located in the bottom right

corner on the rear side of the body.

ON

12345678

2-1SectionDescription of Parts and Settings

SW2 RESET –CONTRAST

PRINTER RS-232C

SDA SDB RDARD

24 VDC

+

B

Pin Function

1 Not used.

ON

[OFF]

2 Memory protect

ON Data cannot be written to the screen data memory, and screen

data transmission and initialization of the screen data memory

are not possible.

[OFF] Screen data transmission and screen data memory initialization

are not possible.

3 Switching to the System Menu enabled/disabled

ON The System Menu cannot be displayed. If an error occurs dur-

ing a start-up, the System Menu will be automatically displayed.

However, RUN Mode cannot be entered.

[OFF] The System Menu can be displayed.

4 Screen data initialize effective/ineffective

ON The NT30/30C will start in a special RUN mode in which the

screen data memory is initialized. When it is started, the

memory initialization menu will be displayed. For the initialization procedure, refer to 3-4 Initializing Memory (page 78).

[OFF] The NT30/30C will start in normal RUN mode.

5 Not used.

ON

[OFF]

6 [ON] When you set the DIP switch pin 7 ON, NT-series System

Installer messages are displayed in English.

OFF Messages are displayed in Japanese

7 System installation effective/ineffective

ON System program installation is effective (special mode) at the

time when the power turn ON.

[OFF] Starts normal RUN mode.

8 Terminator setting when using RS-422A

ON When connecting to the PC with RS-422A

[OFF] When connecting to the PC with RS-232C

18

[ ] indicates factory setting.

Page 29

2-2SectionInstallation

Caution

Reference

2-2 Installation

Correct use

If the DIP switch settings have been changed when the NT30/30C is powered,

reset the power to the NT30/30C. The changes with the DIP switches become

effective only after the power supply is reset. Before switching ON the power for

the first time, set DIP switch pin 6 of the NT30/30C to ON (they are set to OFF on

shipping). If they are left OFF, messages will not be displayed normally.

In addition to the DIP switch settings, set also the host communications, port,

baud rate, etc., in the memory switches. For these settings, refer to 3-5 Setting

the Conditions of Communications with the PC by Using the Memory Switches

(page 83).

Install the NT30/30C to the operation panel and connect the power to the

NT30/30C as described below.

Do not install the NT30/30C at sites subject to the following conditions.

Otherwise, the product may malfunction.

- Severe temperature variations

- Temperatures or humidities outside the ranges stated in the specifications

- High humidity, condensation

- Splashing chemical agents

- Severe oil splashing

- Corrosive or flammable gases

- Strong vibrations or shocks

- Direct exposure to wind and rain (outdoor sites)

- Strong ultra-violet irradiation

Take adequate measures to ensure shielding if the NT30/30C is used at a

location subject to any of the following conditions. Otherwise, the product may

malfunction.

- Static electricity, or noise from other equipment

- Strong electromagnetic fields

- Nearby power cables

- Potential exposure to radioactivity

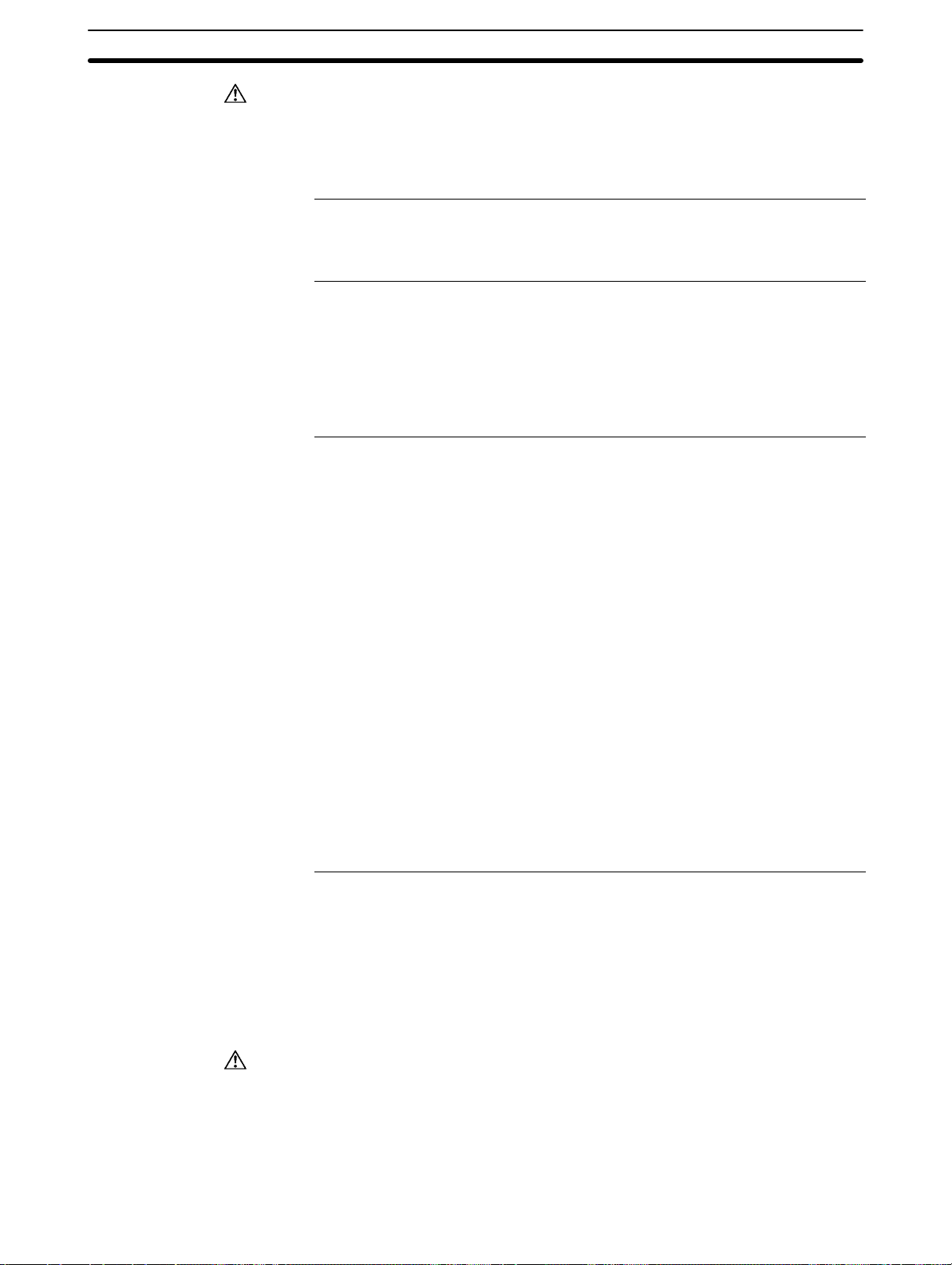

2-2-1 Installation to the Operation Panel

The NT30/30C is mounted on an operation panel by embedding it in the panel.

Use the panel fittings and tools included in the product package and follow the

procedure below.

Caution

During work at the panel, take care to ensure that no metal scraps enter the

Unit. Otherwise, the product may malfunction.

The thickness of applicable operation panel is 1.6 mm to 4.8 mm. All fittings

must be tightened uniformly to a torque of 0.5 to 0.6 Nm in order to ensure

water- and dust-resistance. The panel must not be soiled or warped, and must

be able to support an installation that will remain secure and strong.

19

Page 30

2-2SectionInstallation

(1) Open a hole, shown below , in the panel and install the NT30/30C from the

front side of the panel.

+0.5 mm

131.0

0 mm

+0.5 mm

184.0

0 mm

(2) Attach the panel fittings at four positions for the upper/lower sides and at two

positions for the right and left sides, shown below, on the rear side of the

NT30/30C.

Fit the hook of the fitting in the square hole in the body and tighten the screw

with a Phillips head screwdriver while lightly pulling the fitting.

SW2 RESET –CONTRAST

PRINTER RS-232C

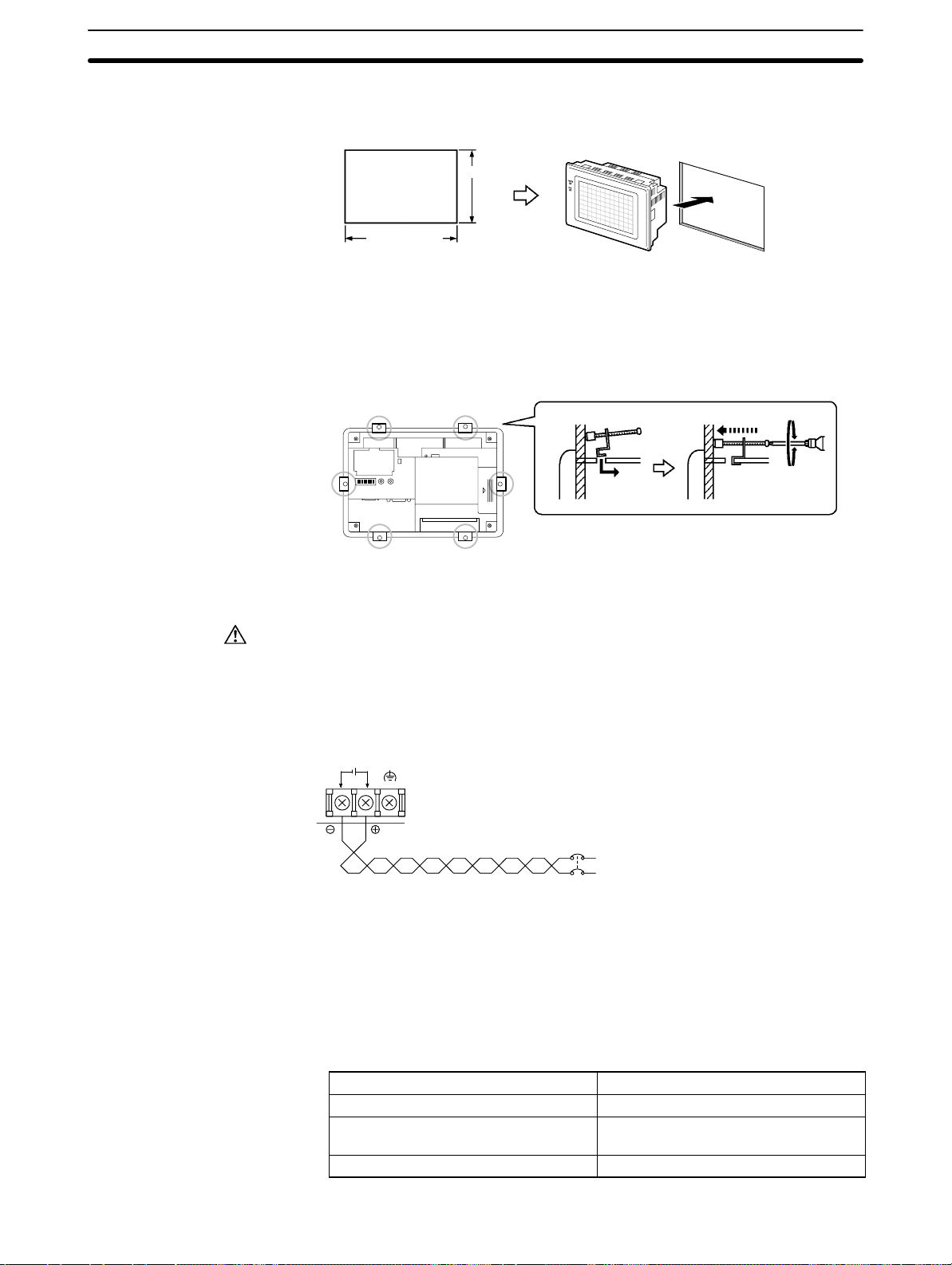

2-2-2 Power Supply Connection

Connect a 24 VDC power supply to the power input terminals.

Caution

Do not apply an AC power supply across the power supply terminals.

Use a DC power supply with a low voltage fluctuation stipulation

When complying with EC directives (low voltage directives) use a power sup-

ply with reinforced insulation.

Carefully check the wiring before switching ON the power.

24 VDC

+

S Noise Prevention

The NT30/30C has a noise preventive feature against the power supply line

noise. To further reduce noise, connect a noise filter to the power line.

SDA SDBRD

24 VDC

RDB

A

Breaker

24 VDC Power Supply

20

S Power Supply

In order to comply with EC directives, use a SELV power supply.

Applicable power supply specifications are as follows.

Item Value

Power supply voltage 24 VDC

Allowable power supply voltage

fluctuation range

Power supply capacity 15 W or over

20.4 VDC to 26.4 VDC

(24 VDC –15%, +10%)

Page 31

S Parts Used for Connection

Caution

For the connection to the power supply terminal block, twisted wires of 2 mm

or greater cross sectional area and M 3.5 size crimp terminals must be used.

Tighten the screws on the terminal block to a torque of 0.8 Ncm.

Otherwise fire may occur.

Use crimp terminals to connect the power supply to the power input terminals.

Recommended crimp terminals for M3.5 are given below.

7 mm or less 7 mm or less

2-2-3 Ground Wire Connection

The NT30/NT30C has a functional ground terminal. T o prevent malfunctions due

to excessive noise, or to prevent electric shocks, wire the NT30/NT30C to a

ground of 100 Ω or less using a separate ground wire (2 mm

wire should be connected to a point at a distance of 20 m or less. Do not use the

same ground wire for other devices, or connect the ground wire to a beam in a

building. To further reduce the influence of noise, connect a noise filter.

Fork type Round type

2-3SectionConnecting to the Support Tool

2

min.). The ground

2

NT30/

NT30C

Connect to a

ground of

100 Ω or

less.

Provide separate ground wires.

Correct use

Other

devices

In order to prevent malfunctions due to noise, perform grounding correctly.

NT30/

NT30C

Other

devices

Do not use a common ground wire.

2-3 Connecting to the Support Tool

Connect the NT30/30C to a computer with an RS-232C cable to transfer the

screen data created by using the NT-series Support Tool to the NT30/30C.

An NT30/30C cannot be connected to both a personal computer running the NTseries Support Tool and a PC at the same time. Connect the personal computer

only when transmitting screen data.

SW2 RESET –CONTRAST

PRINTER RS-232C

NT30/

NT30C

Other

devices

SDA SDBRD

24 VDC

RDB

A

21

Page 32

S Communication Conditions

NT Link (1:1)

NT30C-ST141(B)-EV1 at the time of

Communication conditions are set when the NT-series Support Tool is started.

S Recommended Connecting Cable

Use the cables indicated below.

CV500-CN228 (length: 2 m), made by OMRON

(D-sub, 9-pin, male ↔ D-sub, 25-pin, male)

XW2Z-S001 (conversion cable), made by OMRON

(D-sub, 25-pin, female ↔ Half-pitch, 14-pin, male, used together with the

CV500-CN228)

XW2Z-S002 (length: 2 m), made by OMRON

(D-sub, 9-pin, male ↔ D-sub, 9-pin, female, for IBM PC/AT or compatible

computer)

To make a connector cable, refer to the appendix Connecting Cable Specifica-

tions (page 281).

2-4 Installing the System Program

With the NT30/NT30C, the system program is not fixed and can be installed (or

re-installed). This means that the system program can be easily replaced when

grading up or changing the system configuration.

2-4SectionInstalling the System Program

Reference

If the system program is erased, it will become completely impossible to use

the NT30/NT30C without reinstalling the system program. Before erasing the

system program, confirm that the System Installer and the system program

are at hand. Screen data and memory switch settings, however, will be saved.

The following software is used to install the system program.

S System Installer

Model Number Communications Method Remarks

NT30-ZS3PC-EV1 Host Link

NT30-ZS3DV-EV1

NT-ZJCMX-EV4 Host Link

Reference

NT Link (1:1)

The system program that is included in the NT30-ZS3-EV1 is installed in

the NT30/NT30C at the time of delivery.

All of the system programs and System Installers required for the

NT30/NT30C are provided with the NT-series Support Tool for Windows

(Ver. 4).

A simple explanation of the system program installation method is given here.

For a detailed explanation about setting up System Installer on a computer and

System Installer operations, refer to the manual provided with the System

Installer.

S Installing the System Program

Install the system program onto the NT30/NT30C using the following procedure.

(1) Initialized the NT30/NT30C

If another system program is already installed, erase that system program

first.

With the power supply to the NT30/NT30C turned OFF, turn ON DIP switch

(SW2) pin 7 and then turn ON the power supply. When the confirmation message is displayed, execute erasing the system program

Installed in the NT30-ST131(B)-EV1/

-S

delivery.

For Windows

-

22

Page 33

2-5SectionConnection to a PC by Host Link via RS-232C

(2) Put the NT30/NT30C on Standby for Installation

Turn OFF the power supply and return DIP switch pin 7 that was turned ON

in step 1 to OFF. After that, turn ON the power supply again. The

NT30/NT30C will go into standby, waiting for system program installation.

(3) Transfer the System Program

Connect the NT30/NT30C to the computer, start up System Installer, and

transfer and install the system program.

For details of operation, refer to the manual provided with the System

Installer.

S System Installer Settings

In the System Installer settings, specify the type of PT to which the system program is installed.

Specify either NT30 or NT30C as the PT model (with DOS versions, the setting

is as the NT-series model under the tool settings). Make other settings according

to the operating conditions of the System Installer.

S Selecting the System Program to be Transferred

Select the name of the desired system program from the communications methods displayed in the system program list in the System Installer.

For details, refer to the the manual provided with the System Installer.

2-5 Connection to a PC by Host Link via RS-232C

Connect the NT30/30C to an OMRON PC by using the RS-232C Host Link method.

In order to make a connection to the PC using the Host Link method via

RS-232C, the host communications memory switch of the NT30/30C must be set

to Host Link, and the port memory switch must be set to RS-232C. For details on

memory switch settings, see Selecting the Host Communication Method

(page 85) and Selecting the Host Link Communication Port (page 87).

2-5-1 Compatible PCs

Some models and series of OMRON PCs have the Host Link function built in.

With CS1-series and CQM1H PCs, Host Link communications are possible by

adding a Serial Communications Board. Also, there are some C200HX/HG/HE

CPU Units that support Host Link communications when a Communications

Board is mounted.

Check the model and series of the PC, and the model of Communications Board

mounted, before making connections.

The PCs that can be connected by Host Link via RS-232C are listed in the table

below.

23

Page 34

2-5SectionConnection to a PC by Host Link via RS-232C

CO 0 /0 /05/06

PC Series CPU Units with the Host Link

CS1G-CPU42/43/44/45 (-EV1)

CS1 Series

C Series

CV series (*3) CV500-CPU01-EV1 CV500-CPU01-EV1 CV500-LK201 CV500

CVM1 series

(*3)

CompoBus/S

Master Control Unit

CS1H-CPU63/64/65/66/67

(-EV1)

C20H/C28H/C40H/C60H --- ---

---

---

C200HS-CPU21/23/31/33 --- --- C200HS

C200HE-CPU42-(Z)E C200HE-CPU32/42-(Z)E

C200HG-CPU43/63-(Z)E C200HG-CPU33/43/53/63-(Z)E

C200HX-CPU44/64/65/85-(Z)E

---

---

CPM1-10/20/30CDR- +

CPM1-CIF01

CPM1A-10/20/30/40CD- +

CPM1-CIF01

CPM2A-30/40/60CD- +

CPM1-CIF01 (when connected

via peripheral port)

CPM2C-10/20-

(*1)

CQM1-CPU21-E

CQM1-CPU41/42/43/44(-EV1)

CQM1H-CPU11/21/51/61-E (*2) CQM1H-CPU51/61-E CQM1H-SCB41 CQM1H

CV1000-CPU01-EV1 CV1000-CPU01-EV1 CV1000

CV2000-CPU01-EV1 CV2000-CPU01-EV1 CV2000

CVM1-CPU01-EV

CVM1-CPU11-EV

CVM1-CPU21-EV

SRM1-C02-V2 --- --- SRM1

Function Built In

CPU Units Connectable Using

a Host Link Unit or Communica-

tions Board

CS1G-CPU42/43/44/45 (-EV1)

CS1H-CPU63/64/65/66/67

(-EV1)

C1000H-CPU01-EV1

C2000H-CPU01-EV1

C200HSCPU01/03/21/23/31/33-E

C200HE-CPU11/32/42-(Z)E

C200HG-CPU33/43/53/63-(Z)E

C200HX-CPU34/44/54/64-(Z)E

C200HXCPU34/44/54/64/65/85-Z

C1000H-CPU01-EV1

C2000H-CPU01-EV1

C1000H-CPU01-EV1

C1000HF-CPUA1-EV1

C2000H-CPU01-EV1

--- ---

--- ---

--- --- CPM2A

--- --- CPM2C

--- --- CQM1

CVM1-CPU01-EV

CVM1-CPU11-EV

CVM1-CPU21-EV

Host Link Unit or

Communications

Board

CS1W-SCU21

CS1W-SCB21

CS1W-SCB41

C120-LK201-V1

C200H-LK201-V1

C200HWCOM02/04/05/06-V1

C500-LK201-V1

C500-LK203

CV500-LK201 CVM1

Connect-

able PC

CS1G

CS1H

CH

C1000H

C2000H

C200HS

C200HE

C200HE-Z

C200HG

C200HG-Z

C200HX

C200HX-Z

C200HE

C200HE-Z

C200HG

C200HG-Z

C200HX

C200HX-Z

C1000H

C2000H

C1000H(F)

C2000H

CPM1

(*1) The CPM2C-CN111 or CS1W-CN114/118 Connecting Cable, or the CPM1-CIF01 RS-232C Adapter is re-

(* 2) The CQM1H-CPU11 is not equipped with an RS-232C port, so connect to the CS1W-CN118 Connecting

(* 3) CVM1/CV-series CPU Units without “-V” at the end of the model number cannot be directly connected.

24

quired.

Cable, and connect the peripheral port of the CS1W-CN118 to the PT.

With these CPU Units, connect to the PT using a Host Link Unit.

Page 35

2-5-2 Connecting the NT30/30C

Refer to the illustrations below to select the appropriate cable for the Unit connectors and connect the NT30/30C to the PC.

To make a connector cable, refer to the appendix Making the Cable for Connec-

tion to the PC (page 271).

2-5SectionConnection to a PC by Host Link via RS-232C

Correct use

After connecting a communication cable, always secure it with the screws.

Otherwise the cable may disconnect, causing operation to fail.

The cable’s tensile load is 30 N. Do not subject it to loads greater than this.

Otherwise a discontinuity may occur, causing operation to fail.

Connecting to a PC with a 25-pin Connector

Use a connector cable with a 25-pin connector on one end and a 9-pin connector

on the other end (NT30/30C side) to connect the NT30/30C to a PC with a 25-pin

connector.

9-pin connector 25-pin connector

Use the following recommended cables (OMRON);

Connector

Specification

p

25-pin to 9-pin

p

NT30/30C

SW2 RE-

–CON-

SET

TRAST

PRIN

RS-2

TER

32C

RDB

24 VDC

SD

A

RS-232C connector cable

Model Cable Length

XW2Z-200S 2m

XW2Z-500S 5m

Host Link Unit/CPU Unit

SYSMAC C-series

PC,

CVM1/CV-series

PC

Host I/F connector

(RS-232C 9-pin)

Applicable

Host Link Unit

C500-LK203

C500-LK201-V1

C120-LK201-V1

C200H-LK201

CV500-LK201

25

Page 36

Connecting to a PC with a 9-pin Connector

Use a connector cable with a 9-pin connector on both ends to connect the

NT30/30C to a PC with a 9-pin connector.

2-5SectionConnection to a PC by Host Link via RS-232C

NT30/30C

SW2 RE-

–CON-

SET

TRAST

PRIN

RS-2

TER

32C

RDB

24 VDC

SD

A

9-pin connector

Host I/F connector

(RS-232C 9-pin)

RS-232C connector cable

The connector cable wiring for the C-series CPU Unit (CH) is different from

that for the other PCs. For details, refer to the appendix Making the Cable for

Connection to the PC (page 271).

Connecting the NT30/30C to a CVM1/CV-series Host Link Unit

Two types of connectors are provided to CV500-LK201 Host Link Unit. Both of

these connector types can connect to the NT30/30C with an RS-232C connector

cable. Select the connector cable that matches the connector type.

S To Connect to Communication Port 1

Communications

port 1

(RS-232C)

Communications

port 2

(RS-232C/

RS-422A)

I/O port

selector

switch

RS-232C

↔

RS-422A

This is a 25-pin RS-232C connector. Use a connector cable with a 25-pin connector on one end and a 9-pin connector on the other end (NT30/30C side).

S To Connect to Communication Port 2

This is a 9-pin RS-232C/RS-422A connector . Use a connector cable with a 9-pin

connector on both ends.

Set the I/O port selector switch to the RS-232C side (upper side) to use this port.

Host Link Unit/CPU Unit

SYSMAC

CS1-series PC

C-series PC,

CVM1/CV-series PC

9-pin connector

Connecting the NT30/30C to a C-series CQM1, SRM1 PC

CQM1, SRM1 can connect to the NT30/30C by the RS-232C method. Use an

RS-232C 9-pin connector cable.

S To Connect to the RS-232C Port

This is a 9-pin RS-232C connector. Use a connector cable with a 9-pin connector

on both ends.

Connecting the NT30/30C to a C-series C200HX/HG/HE(-Z) PC

When using a C-series C200HX/HG/HE(-Z) PC, the NT30/30C can be connected to the standard port of the CPU Unit or ports A/B of a Serial Communications Board. Use a connector cable with a 9-pin RS-232C connector.

For details on the specifications and connecting method for the Serial Communication Board used for connection, refer to the C200HX/HG/HE Serial Commu-

nication Board Operation Manual (W304).

Connecting the NT30/30C to a C-series CPM1 or CPM2A

Connect the CPM1 or CPM2A via an RS-232C Adapter (CPM1-CIF01).

Prepare a connector cable with a 9-pin RS-232C connector.

26

Page 37

Connecting the NT30/30C to a C-series CPM2C

The CPM2C has only one connector, which is the same shape as the CS1-series

peripheral port. The signals in this connector, however, are divided internally into

those for the RS-232C port and those for the peripheral port. Therefore, when

using the CPM2C, make separate settings for the RS-232C port and the peripheral port according to the connecting cables and ports used, in the way shown in

the following table. For details, refer to the CPM2C Operation Manual (W356).

Port Connected to the PT PC Setup

RS-232C port of the CS1W-CN111 (D-sub, 9-pin) Perform settings for the RS-232C port.

Peripheral port of the CS1W-CN111 Perform settings for the peripheral port.

Port of the CS1W-CN118 (D-sub, 9-pin) Perform settings for the RS-232C port.

Port of the CS1W-CN114 (peripheral port) Perform settings for the peripheral port.

2-5SectionConnection to a PC by Host Link via RS-232C

Peripheral port

CPM2C-CN111

RS-232C port

(D-sub, 9-pin, female)

CPM2C

RS-232C port

(D-sub, 9-pin, female)

Connecting the NT30/30C to a C-series CQM1H