Page 1

NOTES

N otice :

When unpacking the units, check carefully for any external scratches

1.

or other damage. Also, shake the units gently and check for any

abnormal sound.

2.

Turn OFF the power supply to the PT before mounting or dismounting

I/F Units. Correctly mount the I/F Units according to the User’s Manual

of the PT.

3.

Do not touch the PCBs with bare hands. Discharge static electricity

accumulated in your body in advance.

4.

Tighten the mounting brackets evenly. Make sure the panel is not

dirty or warped and that it is strong enough to hold the units.

5.

Do not let metal particles enter the units when preparing the panel.

6.

Double check all the wiring before turning ON the power supply.

7.

Do not perform a dielectric voltage test.

8.

Make sure that the connector screws are properly tightened.

9.

Always tighten the connector screws after connecting communication

cables.

10.

The max. pull load for cables is 30N. Do not apply loads greater than

this.

NOTES

OMRONOMRON

OMRON

OMRONOMRON

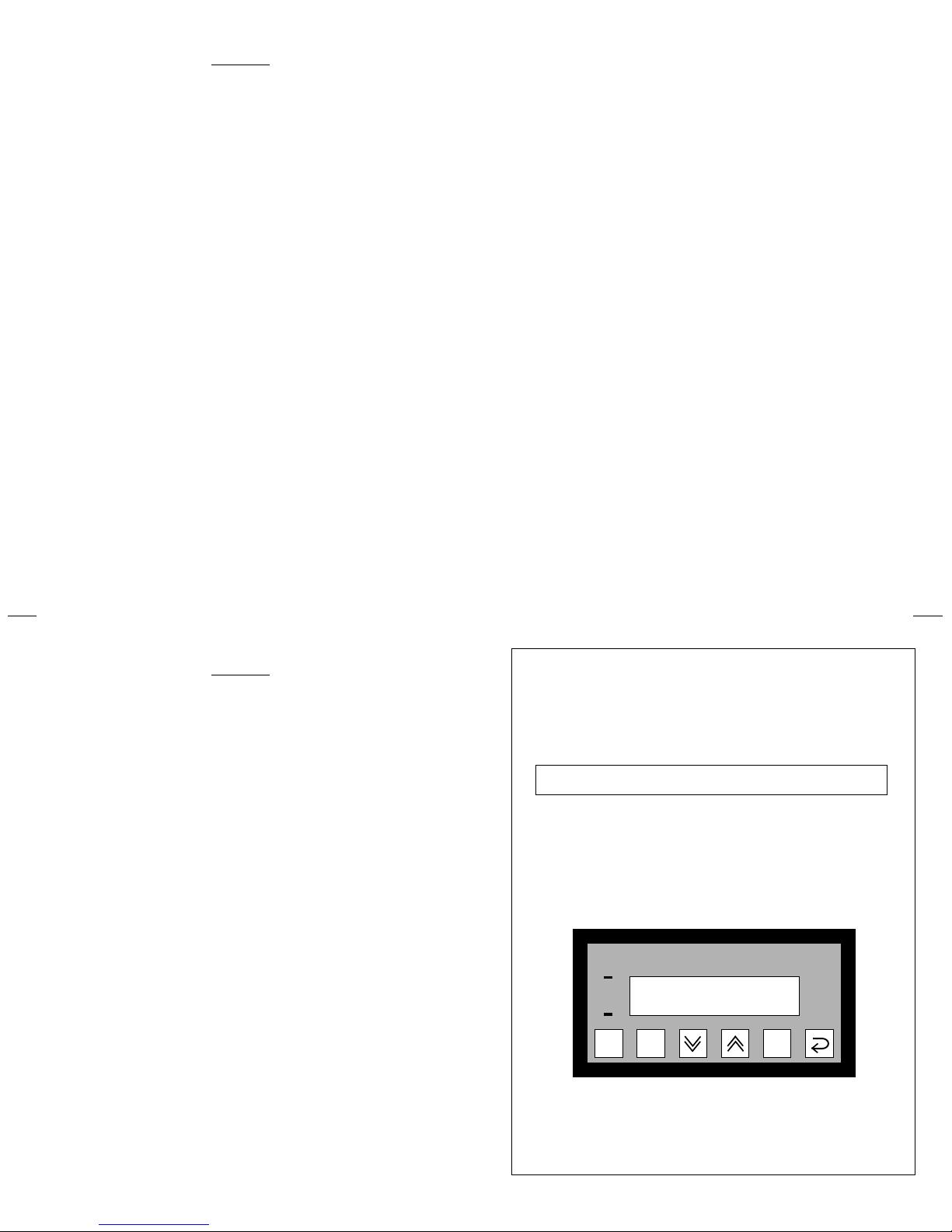

NT2S-SF123B-EV2

Programmable Terminal

INSTRUCTION SHEET

Thank you for purchasing this OMRON product.

Please read this Instruction sheet and thoroughly familiarize

yourself with functions and characteristics of the product

before use. Please retain this sheet for future.

For more information on specifications and usage, please

refer to each PT.

Motor is RUNNING

Speed: 1450 RPM

F 6F 5F 4F 3F 2F1

REG

DATA

CLR

Page 3Page 18

Page 20

OMRON

OMRON Corporation 2001. All Rights Reserved. NT2S-2/1001

Page 1

Page 2

11.

Confirm the safety of the system before turning ON or OFF the supply

to the unit.

12.

Start actual application only after sufficiently checking screen data and

the operation of the program in the PLC.

13.

When using the Programming Console functions, confirm system safety

and then perform the following operations :

•

Changing monitor data

•

Changing operation modes

•

Forced setting or resetting

•

Changing preset values or set values.

14.

Do not press the key switch with a force greater than 30N.

15.

Do not accidently press key switches when the backlight is not lit or when

the display does not appear. Confirm the safety of the system before

pressing key switches.

16.

Do not attempt to disassemble, repair or modify the units in any way.

17.

Do not use benzene, paint thinner or other volatile solvents and do not

use chemically treated cloths.

18.

Signals from the key switches may not be input if the switches are

pressed consecutively at high speed. Confirm each input before

proceeding to the next one.

19.

To ensure greater safety for numeric inputs, first check for proper limits

in the PLC.

NOTES

Page 4

Page 17

NOTES

Page 2

Page 19

Page 3

Triggering screens

Pin Connections

As can be seen from the above examples, there are two ways to display

screens with the

1. Keep all the message characters in the data memory ( the Omron

PLCs have lot of data registers which in most applications involving

simple digital controls are not used anyway ) and simply change the

offset register to display different screens.

The user can fill the data memory using the “data display editor” menu of

the PLC programming software.

2. Note that the data memory as well as the program memory can be

used for embedding of data.

Of course, a combination of the two methods can be used to

optimize the memory usage.

NT2S-SF123B-EV2

:

Following are the PLC port pin designations for

PLC port pin # Designation

2, 3, 5 GND

4 VCC (+5V)

6 TXD (Transmit CMOS)

7 RXD (Receive CMOS)

1, 8, 9 N C

NT2S-SF123B-EV2

:

Page 14

OMRON

OMRON Corporation

System Components Division

66 Matsumoto

Mishima-city, Shizuoka 411-8511

Japan.

Tel : (81) 559-77-9633 / Fax : (81) 559-77-9097

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp

The Netherlands

Tel : (31) 2356-81-300 / Fax : (31) 2356-81-388

OMRON ELECTRONICS, INC.

1 East Commerce Drive, Schaumburg, IL 60173

U.S.A.

Tel : (1) 847-843-7900 / Tel : (1) 847-843-8568

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue,

#11-01, UE Square,

Singapore 239920

Tel : (65) 835-3011 / Tel : (65) 835-2711

Note : Specifications subject to change without notice.

Printed in India.

Page 7

20.

Do not install the units in any of the following locations :

•

Locations subject to rapid changes in temperature

•

Locations subject to temperatures or humidities outside the

range specified in the specification

•

Locations subject to condensation as the result of high

humidity

•

Locations subject splashing chemicals or solvents

•

Locations subject to oil splashes

•

Locations subject to corrosive or flammable gases

•

Locations subject to strong shock or vibration

•

Locations outdoors subject to direct wind and rain

•

Locations subject to strong ultraviolet light

21.

Take appropriate and sufficient countermeasures when installing

systems in the following locations :

• Locations subject to static elctricity or other forms of noise

• Locations subject to strong electromagnetic or magnetic fields

• Locations subject to possible exposure to radioactivity

22.

The whole system may stop, depending on how the power supply is

turned ON or OFF. Turn ONor OFF the power supply according to the

specified procedure.

Page 16

Page 5

Page 4

123456789

123456789

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

General:

The

NT2S-SF123B-EV2

is intended to be used as a low cost Operator

interface for PLCs which are rich in program memory or data memory

areas such as the Omron C Series PLCs.

The

NT2S-SF123B-EV2

has the following features:

Feature NT2S-SF123B-EV2

Display Backlit 2X16 LCD

LEDs 2

Keys 6

ASCII screens 32 characters

Embedded variables 16

Key definitions:

Each key is mapped from work bits 201.00 to 201.05. Every time a key is

pressed, the corresponding bit as shown in the table below is held on while

the key is pressed. The keys also have alternate functions.

Key Work Bit Register mode function

F1/REG 201.00 Changes register prefix

F2/DATA 201.01 Enters data entry mode

F3/DOWN 201.02 Increments register number or data

depending on mode

F4/UP 201.03 Decrements register number or data

depending on mode

F5/CLR 201.04 Clears data field to 0 / Register field to

first register value

F6/ENT 201.05 Accepts new data and sends to the PLC

Page 8

g.

Put 03032E03H in words DM0213 and DM0214. The

NT2S-SF123B-EV2

will read data in DM0003 and embed in xx.x format.

h.

Move “s “ into DM0215. This command completes the screen by

appending the “s ” to bake time.

This will put the following data in the data words below:

("b" is used for a space, i.e. 20H)

Word ASCII Hex Word ASCII Hex

DM0200 Do #446F DM0208 BA #4241

DM0201 or #6F72 DM0209 KE #4B45

DM0202 :b #3A20 DM0210 T I #5449

DM0203 CL #434C DM0211 ME #4D45

DM0204 OS #4F53 DM0212 :b #3A20

DM0205 ED #4544 DM0213 #0303

DM0206 bb #2020 DM0214 #2E03

DM0207 bb #2020 DM0215 sb #7320

Page 13

How is the unit panel mounted?

Panel

Screw to hold clamp

and unit on Panel

Mounting Clamp

Gasket

Fig. A

Panel

Fig. B

Power Supply

The power supply to the NT2S-SF123B-EV2 is from the PLC. The figure below

shows the connection between the PLC and the unit through a cable.

PLC PORT

DB9 MALE

CONNECTOR

DB9 FEMALE

CONNECTOR

To PLC

Page 6

Programming Port

PLC

Connecting

Cable

Register mode:

In the register mode, the operator can access all the registers and bits

in the PLC.

By pressing the REG key, the operator can scroll through the register

prefixes. By using the UP / DOWN keys, the register numbers can be

accessed. Data can be changed in the registers by pressing the DATA

key. The data field will blink to indicate that the unit is ready to accept

new data. At this time, the UP / DOWN keys can be used to edit data

followed by the ENT key.

It is advisable to create a “password” screen which can block the usage

of the register mode.

Bar Graph:

NT2S-SF123B-EV2

values to be displayed. If Offset register points to DM0200 then put

Hex value 0C0C into DM0200 onwards to display bar graph with the

value in DM0012.

Example:

Put 0C0C into DM0200, DM0201, DM0202, DM0203 and 200 into

DM0020. This will display bar graph 8 characters wide. Maximum

length is 16 characters. Each character on display can display five

vertical lines. To display full bar graph put # 80 into DM0012 and

0C0C from DM0200 to DM0207.

To display Bar Graph with value in DM0013, put 0D0D in DM0200

onwards.

uses DM0012 to DM0015 registers to hold bar graph

Page 15

Page 5

E

xample 2: Embed a variable in the screen

Unit Operations:

Suppose the following screen needs to be displayed on the

NT2S-SF123B-EV2

Door: CLOSED

BAKETIME: 13.6s

Suppose the bake time is available in data word DM0100 and the oven

status is given by bit 001.00.

To display this screen, do the following:

a.

Move number 200 in DM0020 since the screen will be stored in DM0200

onwards.

b.

Move character string “Door:” into 2 words, i.e. DM0200 and DM0201.

c.

Move characters “OPEN” if bit 001.00 is ON or characters “CLOSED” if

001.00 is OFF.

This is a way to implement bit sensitive screens.

e.

In a similar manner, embed the characters “BAKETIME: ” into 5 words

from DM0208.

f.

NT2S-SF123B-EV2

Here we select DM0003 to be used for embedding. So, move the data of

DM0100 into DM0003 so that embedding can be done.

:

uses DM0000 to DM0011 registers for embedding data.

The work bits 200.00 to 200.15 control the mode of operation of the unit.

Work Bit

200.00 Controls LED0

200.01 Controls LED1

200.02 & 200.03 Not used

200.04 to 200.07 Reserved for future use

200.08 & 200.09 00: Screen mode 01: Register mode

200.10 & 200.11 Timeout to screen mode from Operator mode

200.12 to 200.14 Reserved for future use

200.15 To disable data entry in Screen mode

From the above table, it is clear that the unit will display ASCII text (see section

on Screens for more details on this ) if 200.08 and 200.09 are OFF. To allow

operators to view and edit the registers, 200.08 is to be kept ON. If 200.08 is OFF,

the unit will not display any registers and the function keys will only act as push

buttons mapped to the corresponding bits from 201.00. Refer to “Register Mode”

for details. If 200.09 is ON, REG key press will allow an operator to view the registers.

The REG key will scroll through the available register types whereas the UP and

DOWN arrow keys will scroll through the register/bit numbers. After timeout

specified by bits 10 and 11 and if no key is pressed, the unit will switch back to

the Screen mode and display screens. Thus Operator mode is a combination

of Register as well as Screen modes.

Function

10: Operator mode 11: Invalid

00: 10 seconds 01: 20 seconds

10: 30 seconds 11: 40 seconds

(ON : Disable)

Page 12

Page 9

Page 6

Screens

E

xample 1: Display a static screen

The unit displays 32 characters from the PLC memory. These characters

are taken from the PLC data registers.

The unit tracks register DM0020 ( the Offset register ) in the PLC. The number

in DM0020 gives the start address of the data register block which contains the

characters to be displayed. For example, if DM0020 has number 124 in it, the

unit will read 16 registers from DM0124, i.e. from DM0124 to DM0139 and display

the corresponding characters.

Each register contains two bytes. Each ASCII character to be displayed is

one byte. So, each word contains two characters that can be displayed. All the

PLC ladder logic has to do is to put the correct words in the registers being read

by the unit so that a proper screen can be displayed.

As mentioned above, the starting address of the screen data block is

controlled by the Offset register, i.e DM0020. Hence, there can be two methods

of changing the screen to be displayed. One is to keep the value in DM0020

constant and change the data in the screen registers by the ladder logic. Second

is to keep the screen text in the data memory (by editing DM registers) and change

the value in DM0020 so as to point to the correct memory address to display the

desired screen.

It is possible to embed registers in the screens. The unit reads 16 registers

from DM0000 to DM0015 (in which DM0012 to DM0015 are used for Bar Graph)

in every scan. The data in these registers can be embedded in the screens. To

do so, use hex bytes 0 to B (C to F used for Bar Graph) corresponding to register

DM0000 to DM0011 respectively in the screen. Refer to the example given which

explains the embedding of registers. It is possible to embed one data entry field

in screens. It is similar to embedding register, only instead of 0 to F use 10 to 1F

hex bytes to address DM0000 to DM0015. The registers DM0000 to DM0015 can

be edited with this feature one at a time in a screen.

Page 10

Suppose the following screen needs to be displayed on the

NT2S-SF123B-EV2

Last Rinse Cycle

Water pump is on

To display this screen, do the following:

a.

Move number 200 in DM0020 since the screen text will be stored

in DM0200 onwards.

b.

Move character string “Last Rinse Cycle” into 8 words from DM0200.

c.

In a similar manner, the characters “Water pump is on” can be embeded

into 8 words from DM0208. (i.e. from DM0208 to DM0215).

This will put the following data in data words below: ("b" is used for a space)

:

Word ASCII Hex Word ASCII Hex

DM0200 La #4C61 DM0208 Wa #5761

DM0201 st #7374 DM0209 te #7465

DM0202 bR #2052 DM0210 rb #7220

DM0203 in #696E DM0211 pu #7075

DM0204 se #7365 DM0212 mp #6D70

DM0205 bC #2043 DM0213 bi #2069

DM0206 yc #7963 DM0214 sb #7320

DM0207 le #6C65 DM0215 on #6F6E

Page 11

Loading...

Loading...