Omron NT2S-SF123B-EV2, NT2S-SF121B-EV2, NT2S-SF122B-EV2, NT2S-SF125B-E, NT2S-SF126B-E User Manual

...Page 1

USER´S MANUAL

Programmable Terminals

NTXS

Cat. No. V03E-EN-02

Page 2

i

Preliminary

Thank you for purchasing NTXS Series product from Omron. NTXS Series Products are versatile

operator interfaces with Microsoft Windows® based configuration Software.

This manual will help you to safely install, configure and operate NTXS Products.

All the safety warnings and precautions must be followed to ensure proper unit performance and per-

sonal safety .

Warnings used in this manual:

DANGER Danger Warnings are used to indicate situations, ocations

and conditions that can cause serious injury or death.

CAUTION Caution Warnings are used to indicate situations and conditions

that can cause operator injury and/or unit damage.

If additional information or technical assistance is needed please contact:

Omron Europe B.V .

Wegalaan 67-69

NL-2132 JD Hoofddorp

The Netherlands

Phone :(+31)23-5681300

Fax :(+31)23 5681388

URL: www.omron-industrial.com

Manual Revisions:

If you contact us in reference to this manual, please include the following document number:

Name: NTXS Manual

Document: V03E-EN-02

IMPORTANT

NTXS Series Products are intended to be operator interfaces, to work with PLCs which

actually take control actions. It is assumed that the user is well acquainted with the PLC

system being used. Never use NTXS units to perform emergency stop applications. It is

advised that separate switches be used outside the PLC for ANY emergency stops.

Any mechanical or electrical modification to the units will

void all warranties.

!

Page 3

ii

Contents

INTRODUCTION 1

1.1 Purpose of this manual 2

1.1.1 HMI Basics 2

1.1.2 Hardware Requirements 3

1.2 NTXS Overview 4

1.2.1 What is NTXS series HMI? 4

1.3 How NTXS Works 5

1.3.1 Specifications of NTXS Series 8

HARDW ARE 19

2.1 Safety Precaution 20

2.2 Installation Instructions 20

2.3 Power Requirements 22

2.4 Wiring Diagram 23

2.5 Communication Ports 23

BEFORE YOU BEGIN 30

3.1 Connecting the HMI to your Computer 31

3.2 Starting NTXS Software 32

3.2.1 Installing NTXS Software 32

3.2.2 Steps for starting NTXS Software 34

3.2.3 Uninstalling NTXS Software 35

3.3 Setting Network Configuration 35

3.3.1 Setting Network Configuration For NT2S Series Products 36

3.3.2 Setting Network Configuration For NT3S Series Products 37

USING NTXS SOFTW ARE 42

4.1 NTXS Menu Structure 43

4.1.1 File Menu 45

4.1.2 Define Menu 46

4.1.3 Communicate Menu 47

4.1.4 Utilities Menu 47

4.1.5 Help Menu 48

4.2 Creating New Application 48

4.3 Creating Screens 54

4.3.1 Protecting Application Using Password 55

4.4 Data Entry Object 55

4.5 Display Data Object 56

4.6 Global And Power On Task 56

4.7 Global Keys 58

4.8 Screen Keys 59

REPRESENTING DA TA BY OBJECTS AND WIZARDS 60

5.1 Alphanumeric Objects 61

5.1.1 Text Objects 61

5.1.2 Data Entry Objects 61

5.1.3 Display Data 63

Page 4

iii

5.1.4 Time 66

5.1.5 Date 66

5.2 Graphic Wizards 69

5.2.1 Line 69

5.2.2 Rectangle 70

5.2.3 Ellipse 70

5.2.4 Rounded Rectangle 71

5.2.5 Bargraph 71

5.2.6 Bitmap 72

5.3 Wizards 73

5.3.1 Bit Button 74

5.3.2 Word Button 78

5.3.3 Bit Lamp 81

5.3.4 Word Lamp 85

5.3.5 Multiple Bargraph 87

5.3.6 Analog Meter 93

5.3.7 Real Time Trend 98

5.3.8 Numeric Keypad 103

TASK MANAGEMENT 108

6.1 Application T askList 109

6.2 Screen TaskList 111

6.3 Key T asklist 113

6.3.1 For Keypad Products 113

6.3.2 For Touch screen Products 115

USING LANGUAGES 131

7.1 Export Functionality 132

7.2 Import Functionality 134

7.3 Language conversion utility 136

7.3.1 File Menu 136

7.3.2 Edit Menu 139

7.3.3 View Menu 139

7.3.4 Help Menu 139

7.4 Multi-Language Text Wizard 139

7.4.1 Configure Languages 140

7.4.2 Displaying Multiple Languages in Unit 143

UPLOADING AND DOWNLOADING FROM UNIT 144

8.1 Upload 145

8.2 Download 146

8.3 Error Catalog 147

ALARMS 149

9.1 Define Alarm 150

9.1.1 Alarm Definition 151

9.1.2 Alarm Object 152

PRINTING 154

10.1 Printing from NTXS unit 155

10.2 Printing from NTXS Software 156

MISCELLANEOUS 158

Page 5

iv

11.1 Convert Application 159

11.2 Memory Configuration Wizard 160

11.3 Font Editor 161

11.4 Image Conversion to bmp 163

DIAGNOSTICS & MAINTENANCE 165

12.1 Diagnostics 166

12.1.1 Erase Keys 166

12.1.2 Touchscreen Calibration Loss 167

12.2 Maintenance 168

APPENDIX 169

A Omron Cable References and Diagrams 170

1 Omron Cable References for connection to PLC’s peripheral ports ........

(CMOS) 170

2 Omron Cable References for connection to PLC’s serial ports (RS232C) ...

170

3 Omron Cable References for Programming cable (PC to NTXS) 170

4 Omron Cable Diagrams for Serial cables 171

4.1 NT2S-CN232-V1 / NT2S-CN235-V1 171

4.2 NT2S-CN242-V1 172

5 Omron Cable Disgram for NT2S / NT3S Programming cable 173

5.1 NT2S-CN002 173

6 Omron Cable Diagram for RS422 Communication cable XtraDrive and.......

NT3S 174

B Non-Omron Cable Diagrams 175

1 AB MICROLOGIX SERIES TO NTXS UNIT 175

2 AB SLC DF1 PORT TO NTXS UNIT 176

3 AROMA T FP0 / FPM T O NTXS UNIT 177

4 AROMA T FP1 TO NTXS UNIT 178

5 AROMA T FP2 TO NTXS UNIT 179

6 CONTROL TECHNIQUES TO NTXS UNIT 180

7 DANFOSS DRIVE TO NTXS UNIT 181

8 GE90 SERIES PLC TO NTXS UNIT 182

9 GE90 SERIES SNP-X PLC TO NTXS UNIT 183

10 IDEC MICRO3 TO NTXS UNIT 184

11 IDEC MICROSMART PLC TO NTXS UNIT 185

12 KEYENCE KV PLC TO NTXS UNIT 186

13 KOYO DL205 PLC TO NTXS UNIT 187

14 LG MASTER K SERIES PLC TO NTXS UNIT 188

15 MITSUBISHI FX SERIES PLC TO NTXS UNIT 189

16 MITSUBISHI FX0 PLC TO NTXS UNIT 190

17 SIEMENS STEP 7 MICRO(S7-200) PLC TO NTXS UNIT 191

18 SIEMENS-S7 300 SERIES PLC TO NTXS UNIT 192

19 TOSHIBA T1 PLC TO NTXS UNIT 193

20 TOSHIBA T2 PLC TO NTXS UNIT 194

21 TOSHIBA T1 LINK PORT T O NTXS UNIT 195

22 TOSHIBA T2 LINK PORT T O NTXS UNIT 196

23 TOSHIBA INVERTER S SERIES TO NTXS UNIT 197

24 TSX(07/37/57) PLC TO NTXS UNIT 198

Page 6

v

25 TWIDO PLC TO NTXS UNIT 199

C List Of Features 200

D List Of Supported Devices 203

E Technical Support 204

Index.................................................... 205

Page 7

Introduction

1

INTRODUCTION

In this chapter. . . .

♦ Purpose of this manual

HMI Basics

Hardware Configuration

♦ NTXS Overview

What is NTXS series HMI?

How NTXS works?

NTXS Series Specifications

Page 8

Introduction

2

1.1 Purpose of this manual

Thank you for purchasing NTXS Series Products from Omron. NTXS Series Products are versatile

operator interfaces with Microsoft Windows based configuration Software. This manual explains the

operation of the NTXS Series and how to implement available features using the NTXS Software. This

manual will help you to install, configure and operate NTXS product.

1.1.1 HMI Basics

Operator Interface Terminals (HMIs) provide much more versatility than traditional mechanical control

panels. An HMI allows a plant floor operator to monitor current conditions of a control system and, if

necessary , to initiate a change in the operation of the system. HMIs connect to programmable logic

controllers (PLCs) typically through the serial communications port. The HMI can be programmed to

monitor and/or change current values stored in the data memory of the PLC.

HMIs can have either text-based or graphics-based displays. A text-based HMI can display printable

text characters but can not print graphics.

The NTXS Series HMIs are available in both Text display based HMI and graphics display based HMIs.

What is a Project?

A project is a user created application in NTXS Software. A project contains information such as NTXS

model, Network Configuration, Screen information, Task information etc.

What is a Screen?

A screen is a visual representation of object s placed on the HMI screen. Any partially sized window is

usually referred to as a popup screen or window. User can create his customized screen according to

his requirements. Popup windows can also appear on the HMI display by pressing buttons on the

touch screen. Maximum number of screens in an application is limited by the application memory size.

A more in depth discussion on screen is covered in chapter 4.

What is an Object?

An object placed on HMI screen can perform actions such as displaying text messages, writing value to

PLC register, or displaying an alarm on HMI screen etc. An object can be classified as Text object and

Graphical object.

For example, a Text Object is used to display text on the HMI. But objects are also used to configure

the HMI to perform some action. For example, a Display Data Object tells the HMI to continuously

monitor a PLC register that is used by the PLC. Some objects can display a graphics shape on the

HMI screen and perform some action. A Bit Button Object creates a graphic object on the HMI that

when pressed, activates a bit in the PLC.

Page 9

Introduction

3

1.1.2 Hardware Requirements

The following basic PC hardware configuration is needed to configure and operate your NTXS

Software.

DEVICE MINIMUM REQUIREMENT

IBM Compatible PC with 266 MHz Pentium® II or higher Pentium

Pentium Processor compatible CPU

Operating System Windows® 2000 and above

System RAM At least 64 megabytes (MB) of RAM, more

memory generally improves responsiveness

Hard Disk 150 MB Free Memory Space

VGA Monitor Color 800 x 600 with 24 bit True Color

Setting Resolution

Serial Port Serial Port for Downloading

Mouse Microsoft® Mouse or compatible pointing device

Keyboard Required

These are the minimum system requirements for running the NTXS application.

Page 10

Introduction

4

1.2 NTXS Overview

1.2.1 What is NTXS series HMI?

NTXS Series operator interfaces provide Human-Machine Interface to the Programmable Logic

Controller. The HMIs communicate with PLCs using their serial communications ports.

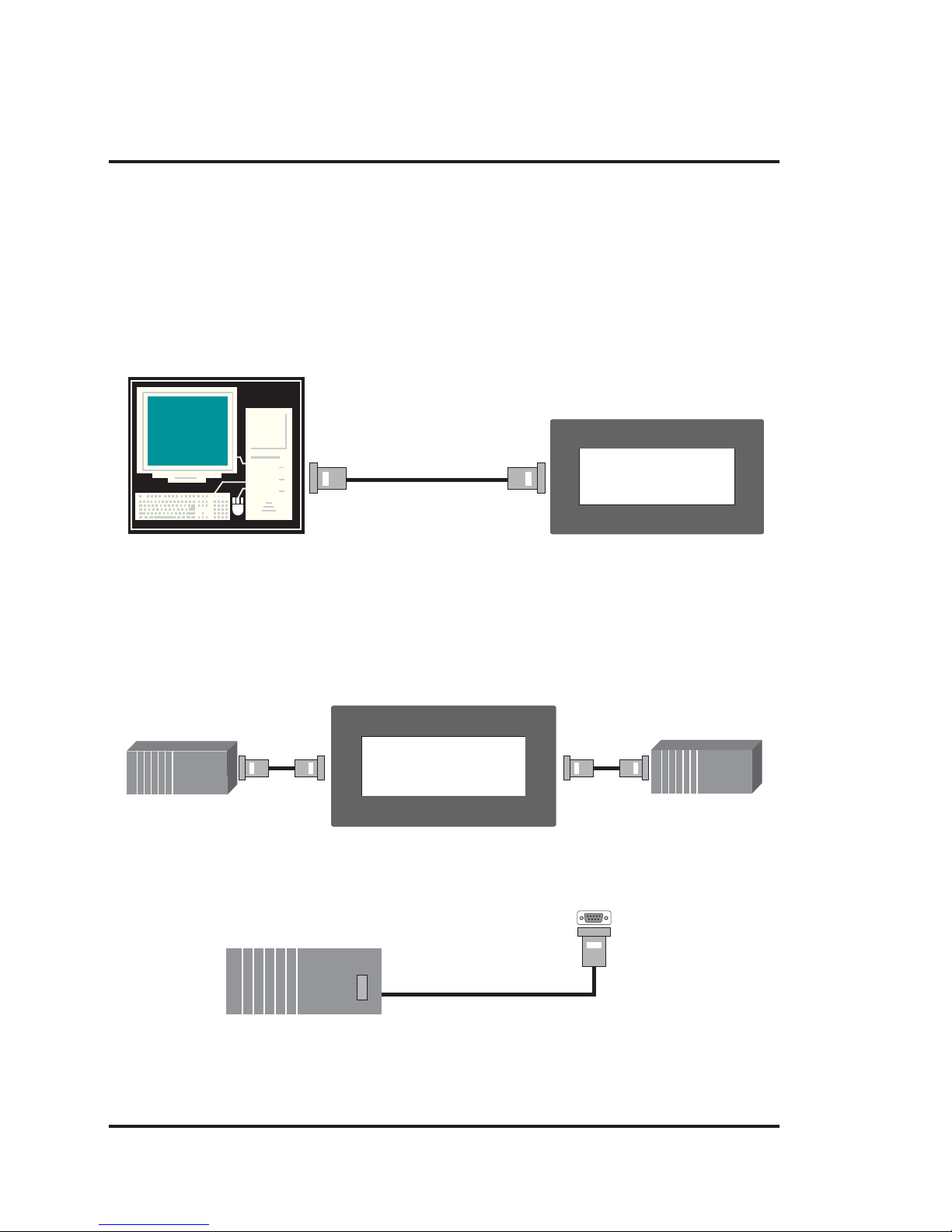

Configuration of NTXS:

Each NTXS unit has to be configured using the NTXS Software before connecting it to the PLC.

NTXS-IBM

Normal Operation:

After configuration is completed, NTXS should be connected with a PLC to start the system.

PLC

To PLC

Programming Port

PLC port

of unit

Connecting

Cable

PLC1

PLC2

Page 11

Introduction

5

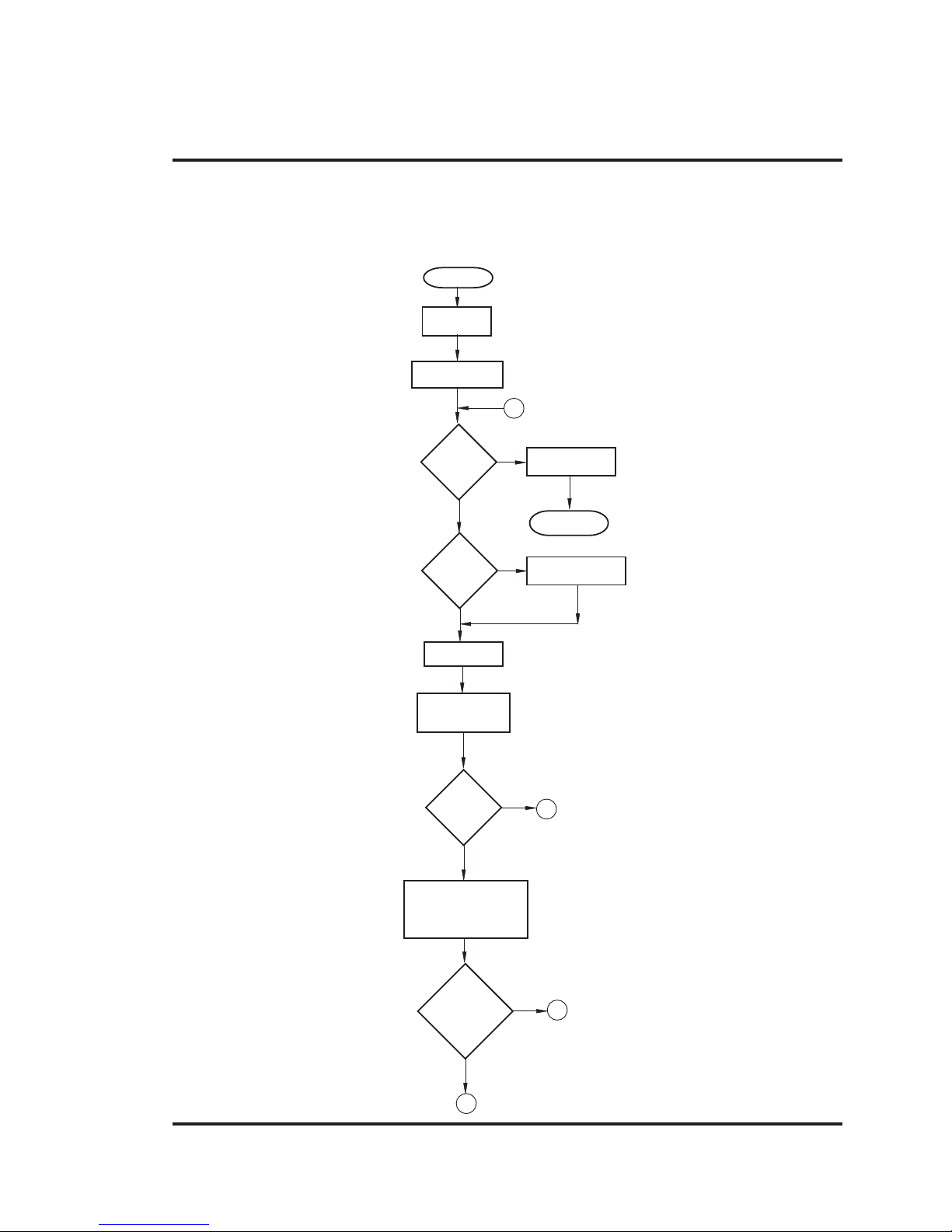

1.3 How NTXS Works

The NTXS follows a specific sequence for performing the tasks defined by the user in the application.

The sequence is as shown below

Power-up

Message

Power up Task

START

IBM

Comm

?

A

Complete IBM

Communication

PLC

Comm

Error

?

Y

N

N

Y

Re-establish PLC

Communication

Re-Start

Global Task

Check Screen

Number

N

Y

Same

Screen

Number

?

C

Perform After Hiding

Task for Previous

Screen

Password

Protected

Screen

?

N

Y

D

B

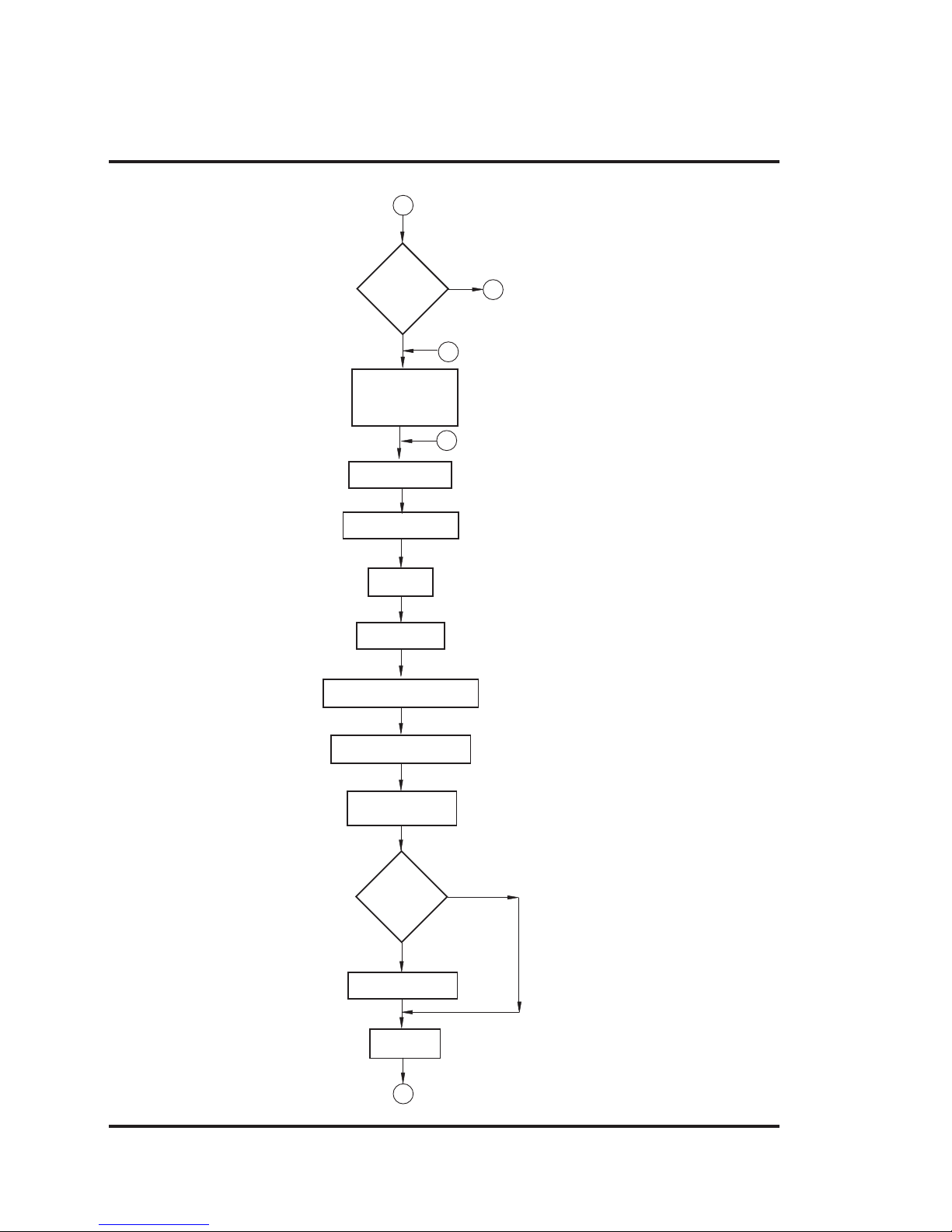

Page 12

Introduction

6

Check if same key

pressed

Upload Alarm Block

Serv Alarm

Display Screen

Display Associated Screens

Serv While Showing Task

Y

N

Key Release task

Same

key

Pressed

?

Load new

keys

I

Valid

Screen

password

?

N

Y

Perform Before

Showing Task List

for new Screen

F

D

C

Upload Tag Block

B

Page 13

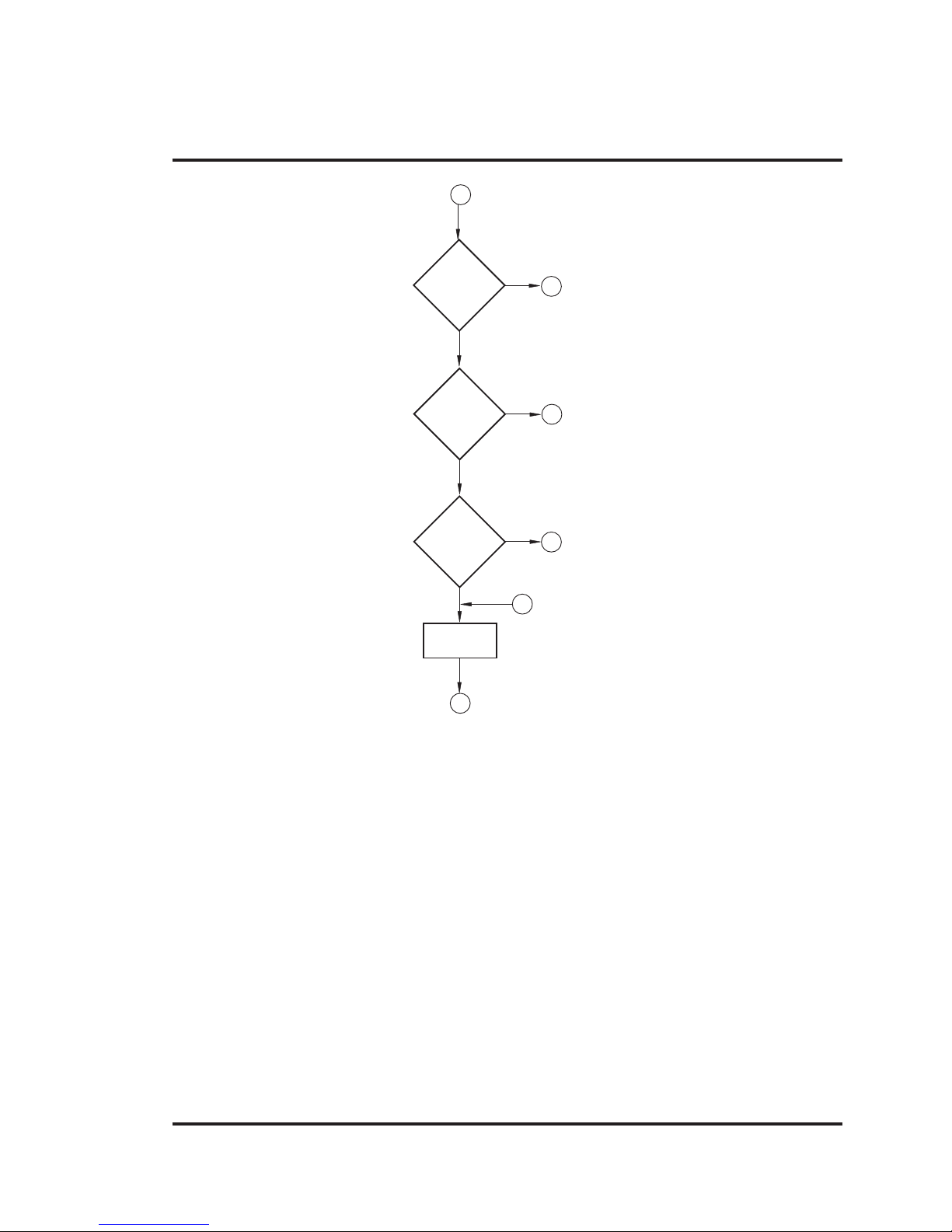

Introduction

7

Y

N

New

key

Pressed

?

A

I

Y

N

Valid Key

Password

?

A

Serv Key

Press Task

Password

Protected

Key ?

Y

G

N

G

A

Page 14

Introduction

8

1.3.1 Specifications of NTXS Series

Models included in the NTXS series are as follows:

NT2S-SF121B-EV2

NT2S-SF122B-EV2

NT2S-SF123B-EV2

NT2S-SF125B-E

NT2S-SF126B-E

NT2S-SF127B-E

NT3S-ST121B-E

NT3S-ST123B-E

NT3S-ST124B-E

NT3S-ST126B-E

Page 15

Introduction

9

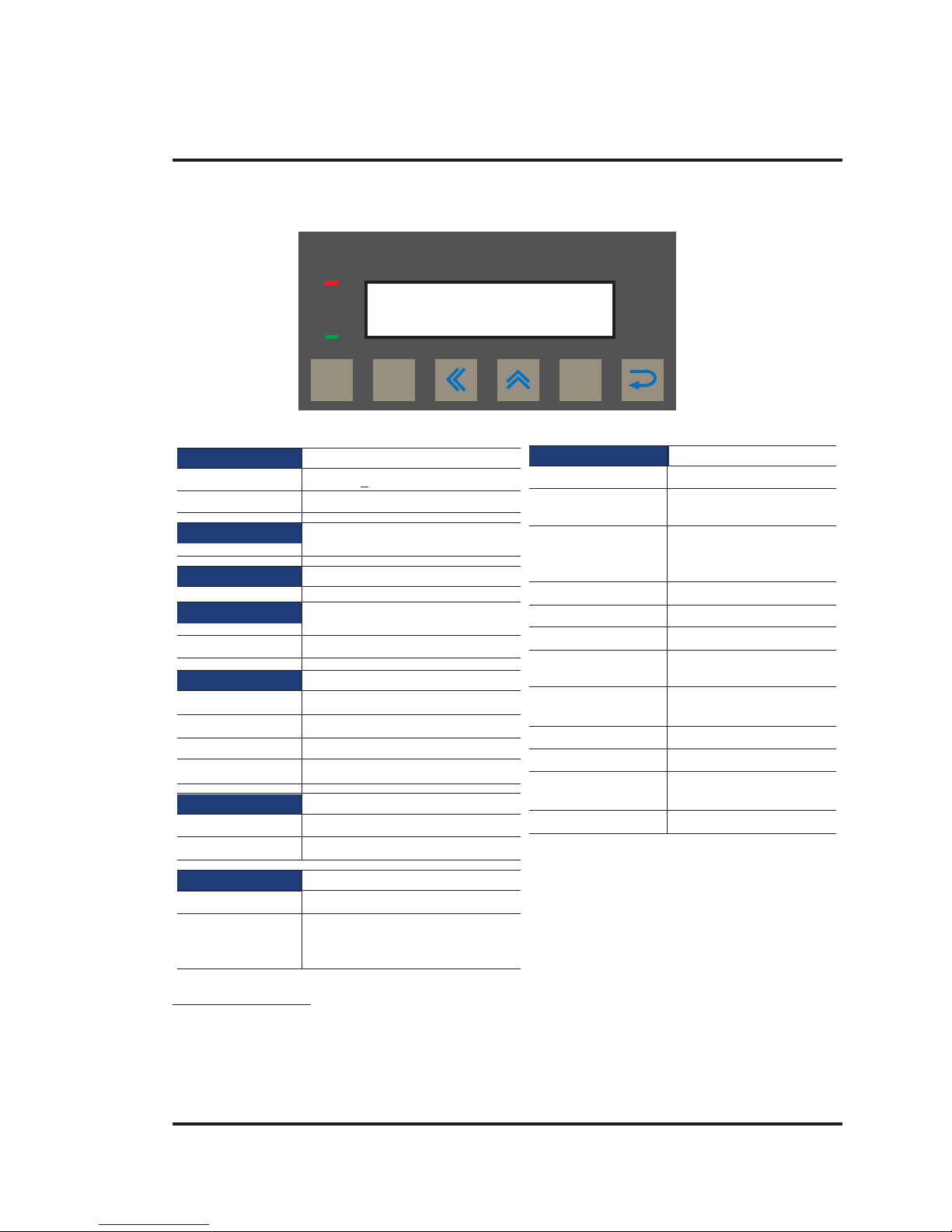

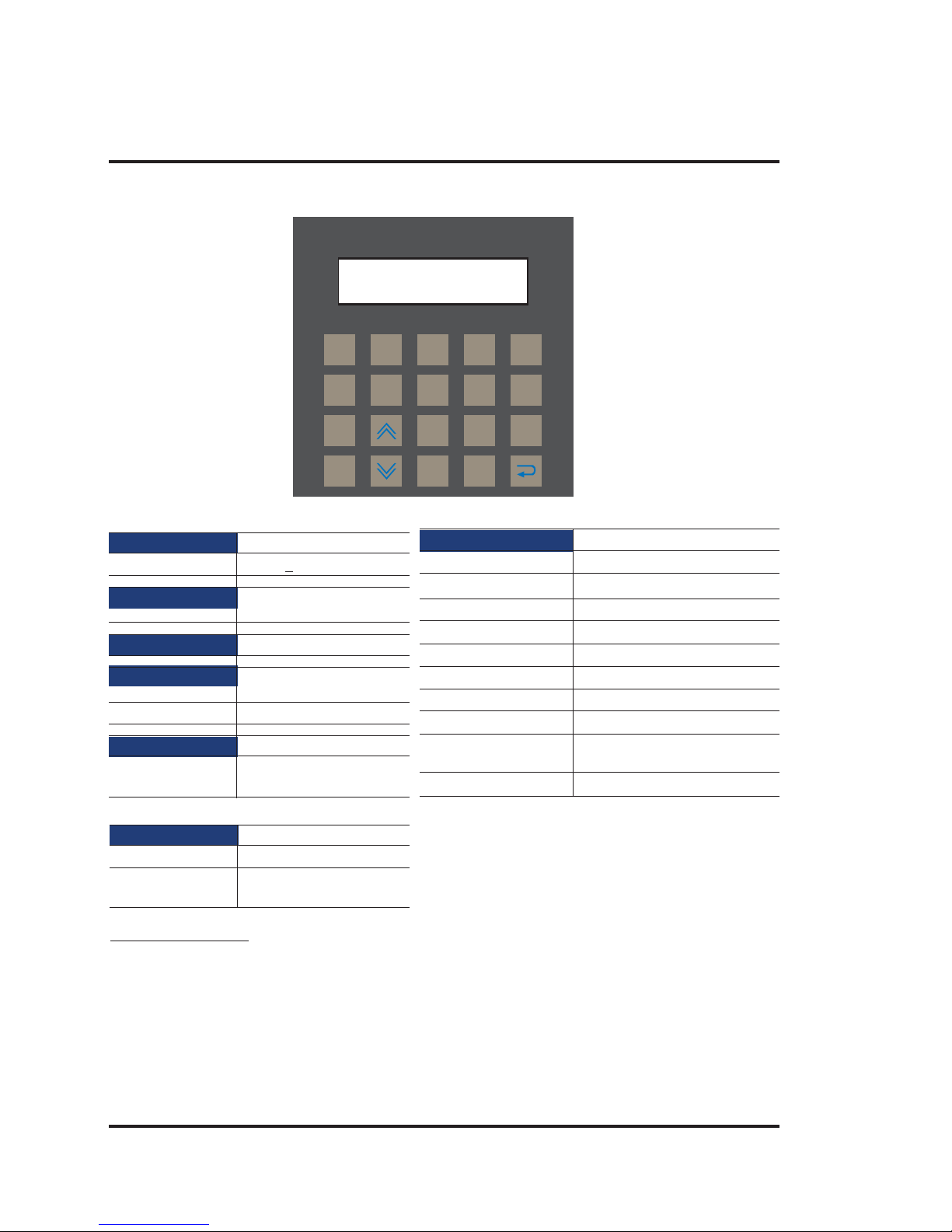

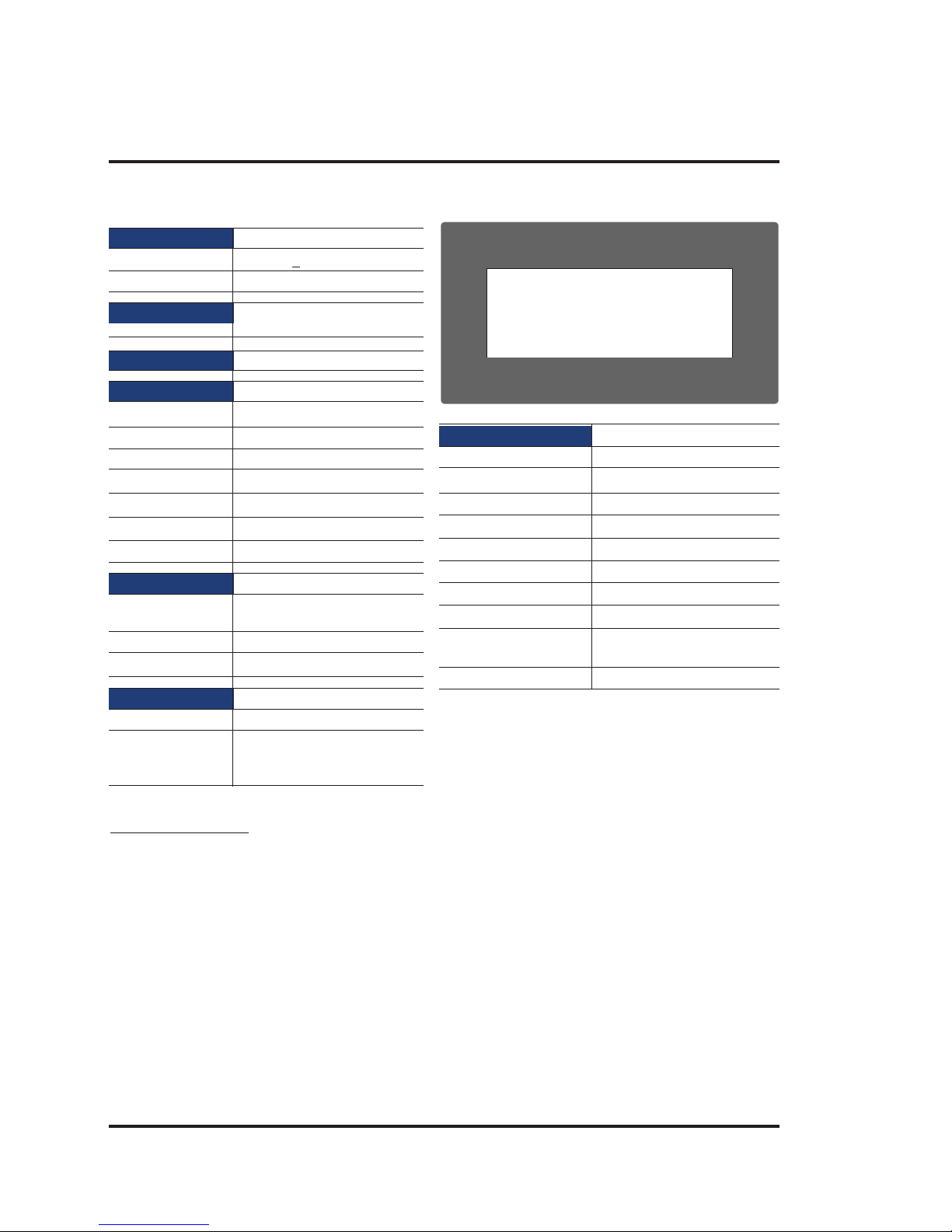

NT2S-SF121B-EV2

System Components:

- Unit with LCD display , Membrane keypad and R TC.

- Power Supply connector.

- Installation Kit: Gasket, Two Mounting clamps

Note: User should order cables separately

Power Supply 24VDC

Voltage Rating 24 VDC

+ 10%

Power Rating 1.5W

Approvals CE, CSA and cULus Class 1

Div.2 Certified

Bezel IP65 Rated Keypad

Keypad Membrane Keypad With Tactile

Feedback Keys

Number Of Keys 6 user Definable keys

Memory

Total Memory 63KB

Application Memory 24KB

Data Register 1000

Retentive Register 1000

Display LCD Text Display

Display Type 2 lines of 16 characters Backlit LCD

LEDs 2 LEDs

Communication

Number of Ports 2

Type One RS232/CMOS port for

connecting to PLC and one RS232

port for programming and printing

PREV CLR

F 1F 2F 3F 4F 5

F 6

NEXT

Miscellaneous

Dimension 92.00 X 45.00 mm

Battery Coin Type, 3V Lithium

Battery 614-CR1225FH

Battery Backup 8 years typical battery

backup for RTC and

System data

Operating Temperature 0

0

C to 50 0C

Storage Temperature -25

0

C to 80 0C

Mounting Method Panel Mounting

Clock(RTC) Real Time Clock

Function(Date & Time)

Humidity 10% To 90%

(Noncondensing)

Immunity to ESD Level 3 as per IEC1000-4-2

Immunity to Transients Level 3 as per IEC1000-4-4

Immunity to Radiated Level 3 as per IEC1000-4-3

RF

Emission EN55011 CISPRA

Page 16

Introduction

10

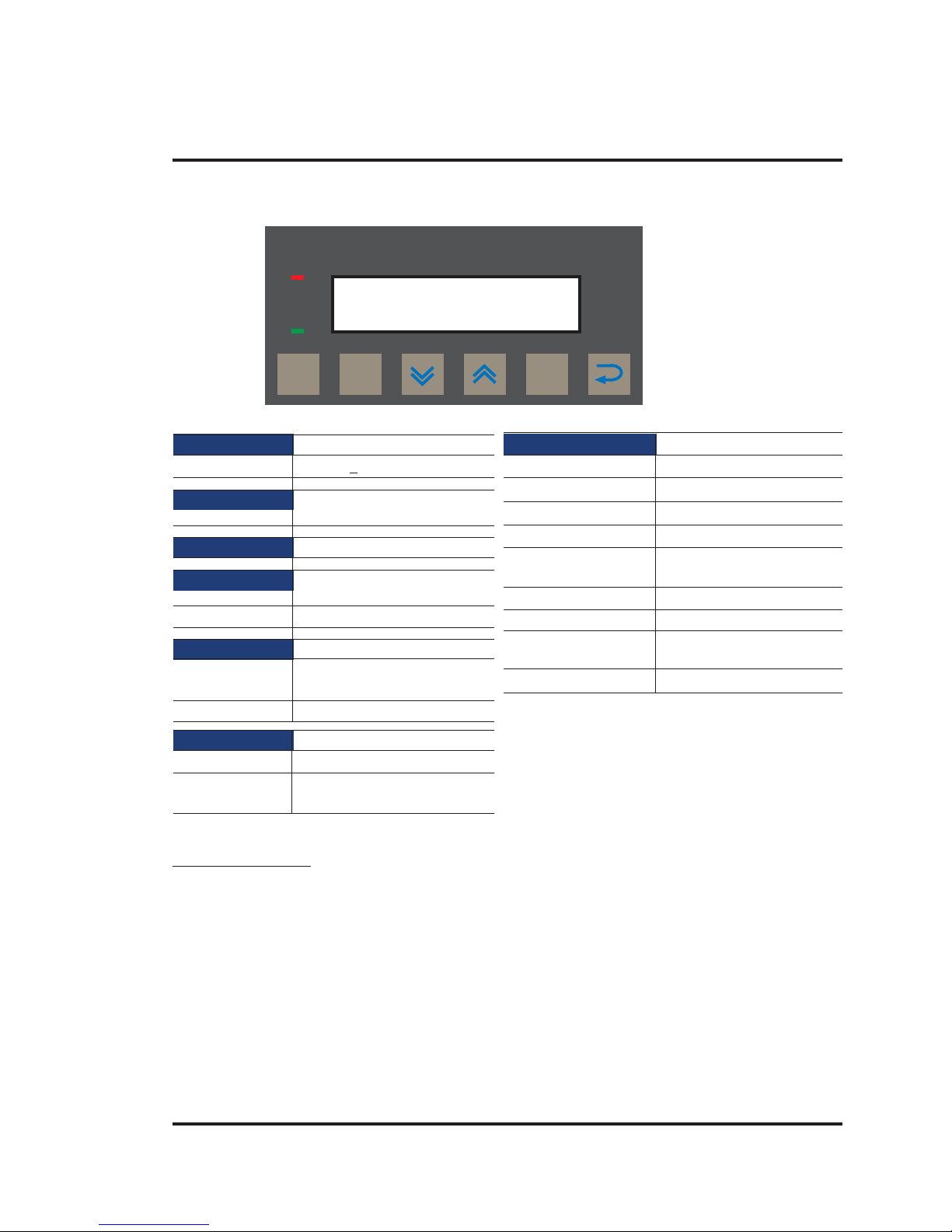

NT2S-SF122B-EV2

System Components:

- Unit with LCD display , Membrane keypa d

- Installation Kit: Gasket, Two Mounting clamps

Note: User should order cables separately

Power Supply 5VDC

Voltage Rating 5 VDC

+ 10% from PLC

Approvals CE, CSA and cULus Class 1

Div.2 Certified

Bezel IP65 Rated Keypad

Keypad Membrane Keypad With Tactile

Feedback Keys

Number Of Keys 6 user Definable keys

Memory

Total Memory 63KB

Application Memory 24KB

Data Register 1000

Retentive Register 1000

Display LCD Text Display

Display Type 2 lines of 16 characters

Backlit LCD

LEDs 2 LEDs

Communication

Number of Ports 2

Type One RS232/CMOS port for

connecting to PLC and one RS232

port for programming and printing

PREV CLR

F 1F 2F 3F 4F 5

F 6

NEXT

Miscellaneous

Dimension 92.00 X 45.00 mm

Operating Temperature 0

0

C to 50 0C

Storage Temperature -25

0

C to 80 0C

Mounting Method Panel Mounting

Humidity 10% To 90%

(Noncondensing)

Immunity to ESD Level 3 as per IEC1000-4-2

Immunity to Transients Level 3 as per IEC1000-4-4

Immunity to Radiated Level 3 as per IEC1000-4-3

RF

Emission EN55011 CISPRA

Page 17

Introduction

11

NT2S-SF123B-EV2

System Components:

- Unit with LCD display , Membrane keypa d

- Installation Kit: Gasket, Two Mounting clamps

Note: User should order cables separately

Power Supply 5VDC

Voltage Rating 5 VDC

+ 10% from PLC

Approvals CE, CSA and cULus Class 1

Div.2 Certified

Bezel IP65 Rated Keypad

Keypad Membrane Keypad With Tactile

Feedback Keys

Number Of Keys 6 keys

Display LCD Text Display

Display Type 2 lines of 16 characters

Backlit LCD

LEDs 2 LEDs

Communication

Number of Ports 1

Type CMOS port for communication

to PLC

DATA CLR

F 1

F 2F 3F 4F 5

F 6

REG

Miscellaneous

Dimension 92.00 X 45.00 mm

Operating Temperature 0

0

C to 50 0C

Storage Temperature -25

0

C to 80 0C

Mounting Method Panel Mounting

Humidity 10% To 90%

(Noncondensing)

Immunity to ESD Level 3 as per IEC1000-4-2

Immunity to Transients Level 3 as per IEC1000-4-4

Immunity to Radiated Level 3 as per IEC1000-4-3

RF

Emission EN55011 CISPRA

Page 18

Introduction

12

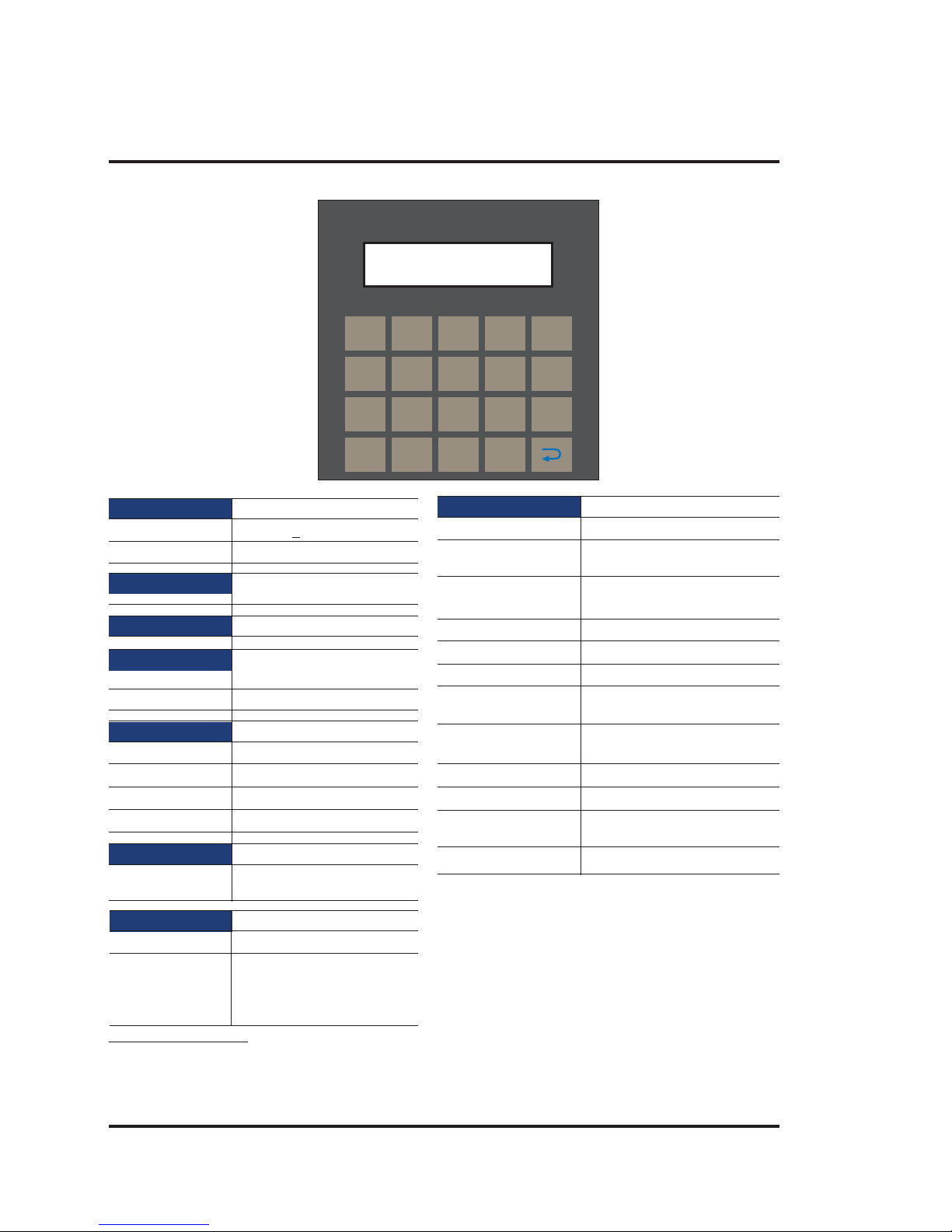

NT2S-SF125B-E

System Components:

- Unit with LCD display , Membrane keypad and R TC.

- Power Supply connector.

- Installation Kit: Gasket, T wo Mounting clamp s

Note: User should order cables separately

Communication

Number of Ports 2

Type One RS232/CMOS port for

connecting to PLC and one

RS232 port for Programming

and Printing

Power Supply 24VDC

Voltage Rating 24 VDC

+ 10%

Power Rating 1.5W

Approvals CE and cULus Class1 Div. 2

Certified

Bezel IP65 Rated Keypad

Keypad PCB based Keypad With

Tactile Feedback Keys

Number Of Keys 20 keys

Memory

Total Memory 63KB

Application Memory 24KB

Data Register 1000

Retentive Register 1000

Display LCD Text Display

Display Type 2 lines of 16 characters

Backlit LCD

1

4

7

CLR

2

5

8

0

3

6

9

+/-

F1

F2

F3

F4

F5

F6

F7

F8

Miscellaneous

Dimension 92.00 X 92.00 mm

Battery Coin Type, 3V Lithium Battery

614-CR1225FH

Battery Backup 8 years typical battery backup

for RTC and System data

Operating Temperature 0

0

C to 50 0C

Storage Temperature -25

0

C to 80 0C

Mounting Method Panel Mounting

Clock(RTC) Real Time Clock Function

(Date & Time)

Humidity 10% To 90%

(Noncondensing)

Immunity to ESD Level 3 as per IEC1000-4-2

Immunity to Transients Level 3 as per IEC1000-4-4

Immunity to Radiated Level 3 as per IEC1000-4-3

RF

Emission EN55011 CISPRA

Page 19

Introduction

13

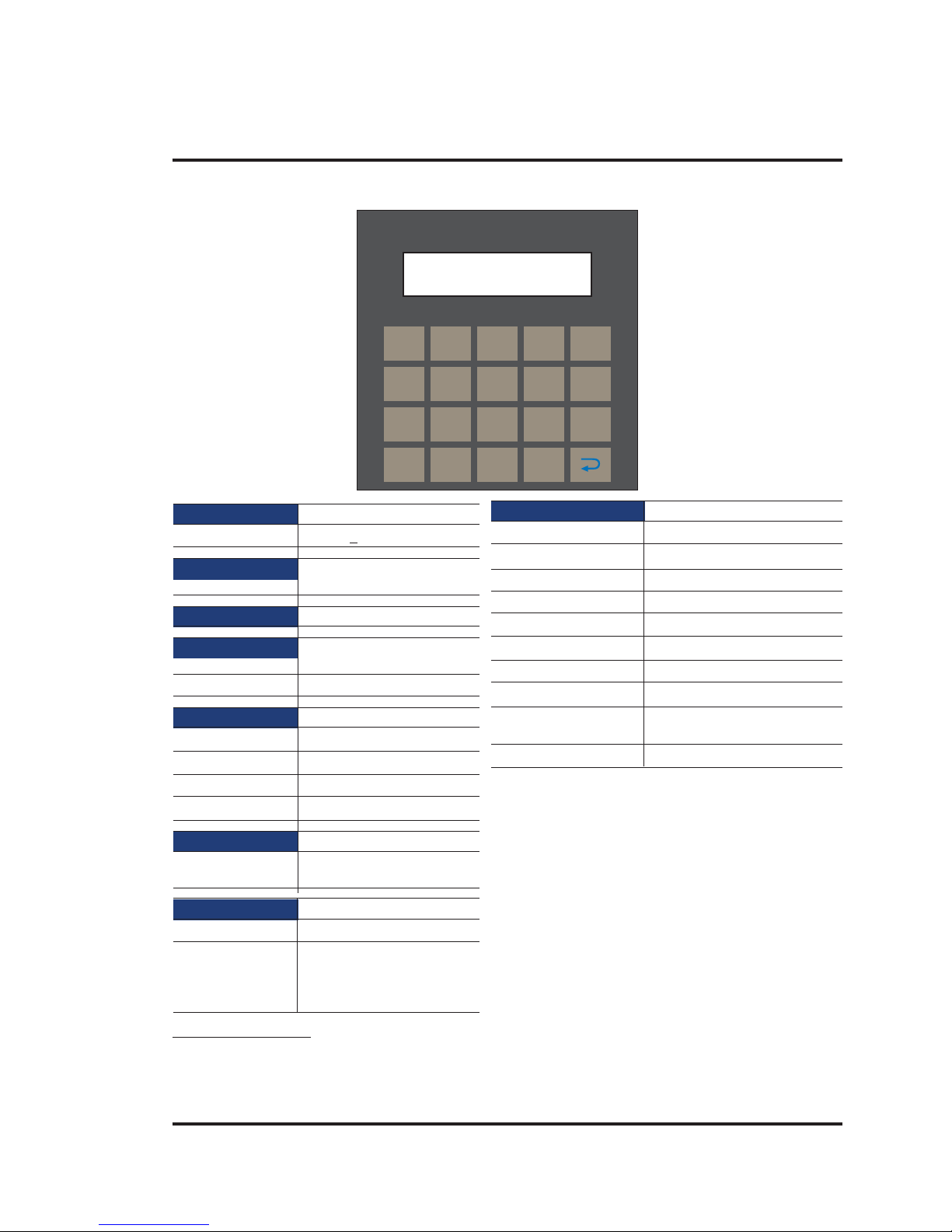

NT2S-SF126B-E

System Components:

- Unit with LCD display , Membrane keypa d

- Installation Kit: Gasket, Two Mounting clamps

Note: User should order cables separately

Communication

Number of Ports 2

Type One RS232/CMOS port for

connecting to PLC and one

RS232 port for Programming

and Printing

Power Supply 5VDC

Voltage Rating 5 VDC

+ 10% from PLC

Approvals CE and cULus Class1 Div. 2

Certified

Bezel IP65 Rated Keypad

Keypad PCB based Keypad With

Tactile Feedback Keys

Number Of Keys 20 User definable keys

Memory

Total Memory 63KB

Application Memory 24KB

Data Register 1000

Retentive Register 1000

Display LCD Text Display

Display Type 2 lines of 16 characters

Backlit LCD

1

4

7

CLR

2

5

8

0

3

6

9

+/-

F1

F2

F3

F4

F5

F6

F7

F8

Miscellaneous

Dimension 92.00 X 92.00 mm

Operating Temperature 0

0

C to 50 0C

Storage Temperature -25

0

C to 80 0C

Mounting Method Panel Mounting

Clock(RTC) Does not support RTC

Humidity 10% To 90% (Noncondensing)

Immunity to ESD Level 3 as per IEC1000-4-2

Immunity to Transients Level 3 as per IEC1000-4-4

Immunity to Radiated Level 3 as per IEC1000-4-3

RF

Emission EN55011 CISPRA

Page 20

Introduction

14

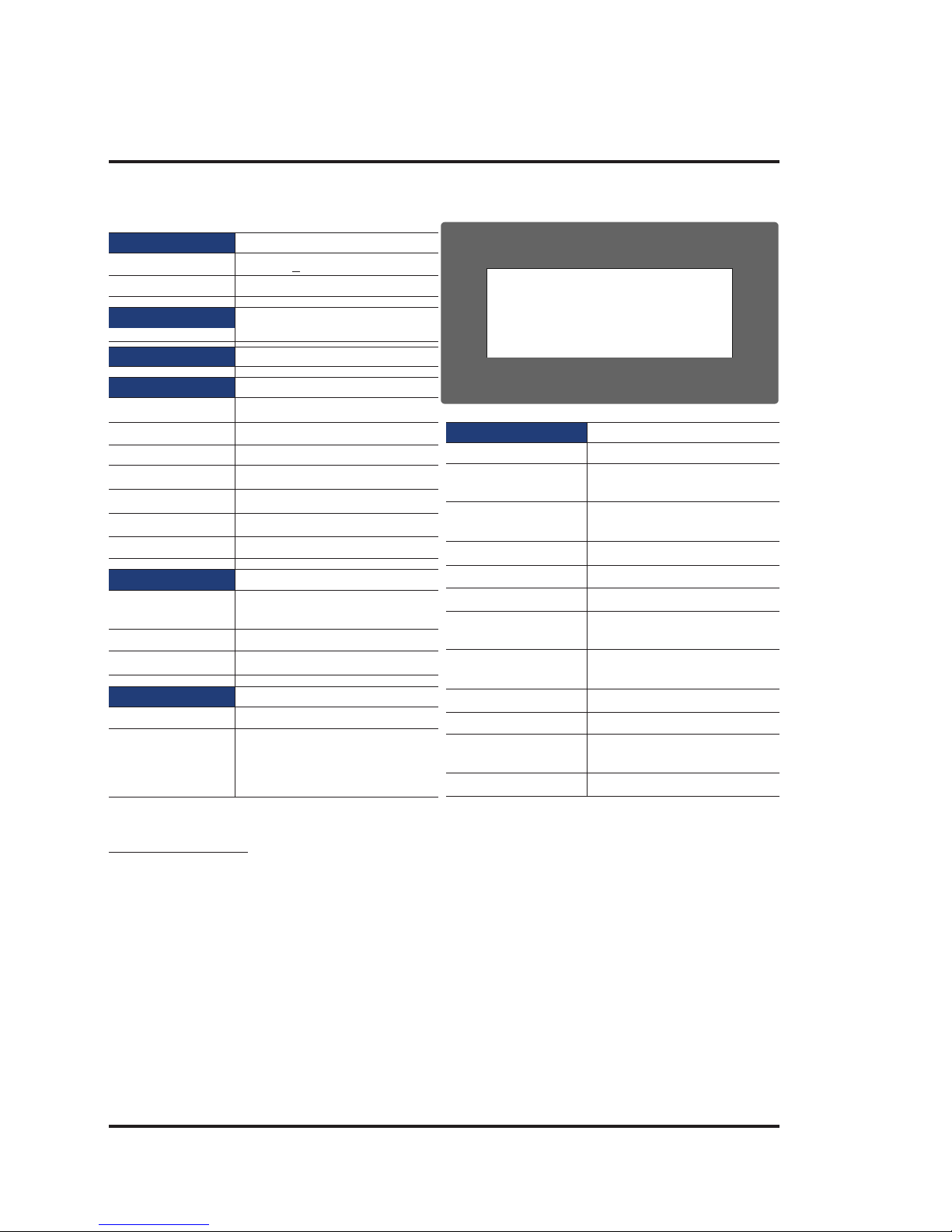

NT2S-SF127B-E

System Components:

- Unit with LCD display , Membrane keypa d

- Installation Kit: Gasket, Two Mounting clamps

Note: User should order cables separately

Power Supply 5VDC

Voltage Rating 5 VDC

+ 10% from PLC

Approvals CE and cULus Class1 Div.2

Certified

Bezel IP65 Rated Keypad

Keypad PCB based Keypad With

Tactile Feedback Keys

Number Of Keys 20 keys

Display LCD Text Display

Display Type 2 lines of 16 characters

Backlit LCD

Communication

Number of Ports 1

Type CMOS port for connecting

to PLC

1

4

7

CLR

2

5

8

0

3

6

9

+/-

F1

F2

F3

F4

REG

DATA

Miscellaneous

Dimension 92.00 X 92.00 mm

Operating Temperature 0

0

C to 50 0C

Storage Temperature -25

0

C to 80 0C

Mounting Method Panel Mounting

Clock(RTC) Does not support RTC

Humidity 10% To 90% (Noncondensing)

Immunity to ESD Level 3 as per IEC1000-4-2

Immunity to Transients Level 3 as per IEC1000-4-4

Immunity to Radiated Level 3 as per IEC1000-4-3

RF

Emission EN55011 CISPRA

Page 21

Introduction

15

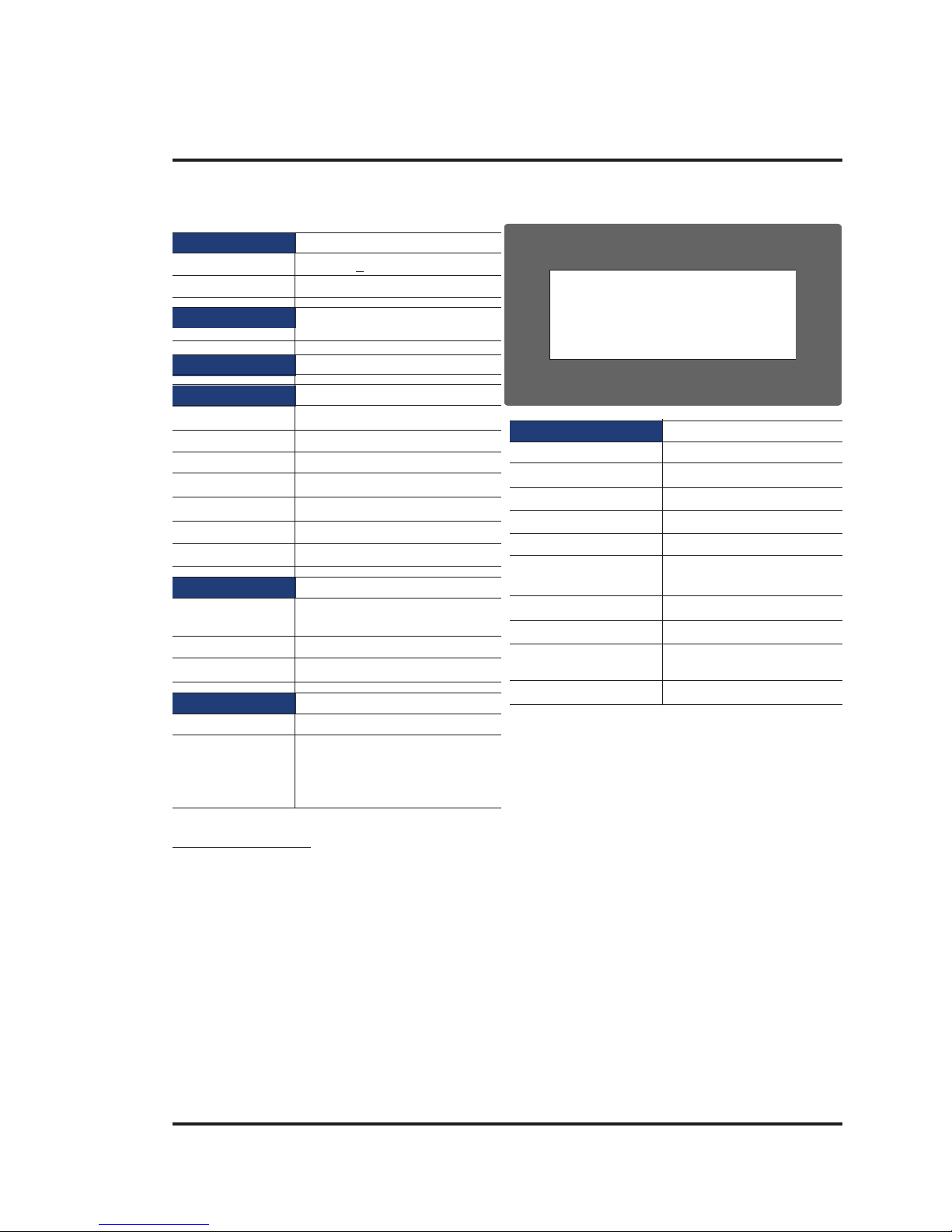

NT3S-ST121B-E

Miscellaneous

Dimension 132.00 X 69.00 mm

Battery Coin Type, 3V Lithium

Battery 614-CR1225FH

Battery Backup 8 years typical battery backup

for RTC and System data

Operating Temperature 0

0

C to 50 0C

Storage Temperature -25

0

C to 80 0C

Mounting Method Panel Mounting

Clock(RTC) Real Time Clock Function

(Date & Time)

Humidity 10% To 90%

(Noncondensing)

Immunity to ESD Level 3 as per IEC1000-4-2

Immunity to Transients Level 3 as per IEC1000-4-4

Immunity to Radiated Level 3 as per IEC1000-4-3

RF

Emission EN55011 CISPRA

System Components:

- Unit with LCD display , touch screen and R TC

- Power Supply connector.

- Installation Kit: Gasket, Two Mounting clamps

Note: User should order cables separately

Power Supply 24VDC

Voltage Rating 24 VDC

+ 10%

Power Rating 3.5W

Approvals CE and cULus Class 1 Div.

2 Certified

Bezel IP65 Rated

Memory

Total Memory 512KB

Application Memory 120KB

Data Register 1000

Retentive Register 1000

System Register 64

System Coil 100

Internal Coil 5000

Display LCD Graphic Display

Display Type Monochrome Backlit

LCD Display

Display Resolution 192 X 64 Pixels

Touch Screen 4 wire, Analog Resistive

Communication

Number of Ports 2

Type RS232/CMOS/RS485/RS422

for connecting to PLC,

Programming and Printing

Page 22

Introduction

16

NT3S-ST123B-E

System Components:

- Unit with LCD display , touch screen and R TC

- Power Supply connector.

- Installation Kit: Gasket, T wo Mounting clamp s

Note: User should order cables separately

Miscellaneous

Dimension 132.00 X 69.00 mm

Battery Coin Type, 3V Lithium

Battery 614-CR1225FH

Battery Backup 8 years typical battery backup

for RTC and System data

Operating Temperature 0

0

C to 50 0C

Storage Temperature -25

0

C to 80 0C

Mounting Method Panel Mounting

Clock(RTC) Real Time Clock Function

(Date & Time)

Humidity 10% To 90%

(Noncondensing)

Immunity to ESD Level 3 as per IEC1000-4-2

Immunity to Transients Level 3 as per IEC1000-4-4

Immunity to Radiated Level 3 as per IEC1000-4-3

RF

Emission EN55011 CISPRA

Power Supply 24VDC

Voltage Rating 24 VDC

+ 10%

Power Rating 3.5W

Approvals CE and cULus Class 1

Div. 2 Certified

Bezel IP65 Rated

Memory

Total Memory 512KB

Application Memory 120KB

Data Register 1000

Retentive Register 1000

System Register 64

System Coil 100

Internal Coil 5000

Display LCD Graphic Display

Display Type Monochrome Backlit

LCD Display

Display Resolution 192 X 64 Pixels

Touch Screen 4 wire, Analog Resistive

Communication

Number of Ports 2

Type One RS232/CMOS/RS485/RS422

and one RS232/CMOS for

connecting to PLC, Programming

and Printing

Page 23

Introduction

17

NT3S-ST124B-E

Miscellaneous

Dimension 132.00 X 69.00 mm

Operating Temperature 0

0

C to 50 0C

Storage Temperature -25

0

C to 80 0C

Mounting Method Panel Mounting

Clock(RTC) Does not support RTC

Humidity 10% To 90%

(Noncondensing)

Immunity to ESD Level 3 as per IEC1000-4-2

Immunity to Transients Level 3 as per IEC1000-4-4

Immunity to Radiated Level 3 as per IEC1000-4-3

RF

Emission EN55011 CISPRA

Power Supply 24VDC

Voltage Rating 24 VDC

+ 10%

Power Rating 3.5W

Approvals CE and cULus Class 1

Div. 2 Certified

Bezel IP65 Rated

Memory

Total Memory 512KB

Application Memory 120KB

Data Register 1000

Retentive Register 1000

System Register 64

System Coil 100

Internal Coil 5000

Display LCD Graphic Display

Display Type Monochrome Backlit

LCD Display

Display Resolution 192 X 64 Pixels

Touch Screen 4 wire, Analog Resistive

Communication

Number of Ports 2

Type One RS232/CMOS/RS485/RS422

and One RS232/CMOS port for

connecting to PLC, Programming

and Printing

System Components:

- Unit with LCD display , touch screen

- Power Supply connector.

- Installation Kit: Gasket, Two Mounting clamps

Note: User should order cables separately

Page 24

Introduction

18

NT3S-ST126B-E

Miscellaneous

Dimension 132.00 X 69.00 mm

Operating Temperature 0

0

C to 50 0C

Storage Temperature -25

0

C to 80 0C

Mounting Method Panel Mounting

Clock(RTC) Does not support RTC

Humidity 10% To 90% (Noncondensing)

Immunity to ESD Level 3 as per IEC1000-4-2

Immunity to Transients Level 3 as per IEC1000-4-4

Immunity to Radiated Level 3 as per IEC1000-4-3

RF

Emission EN55011 CISPRA

System Components:

- Unit with LCD display , touch screen

- Power Supply connector.

- Installation Kit: Gasket, T wo Mounting clamp s

Note: User should order cables separately

Power Supply 24VDC

Voltage Rating 24 VDC

+ 10%

Power Rating 3.5W

Approvals CE and cULus Class 1

Div. 2 Certified

Bezel IP65 Rated

Memory

Total Memory 512KB

Application Memory 120KB

Data Register 1000

Retentive Register 1000

System Register 64

System Coil 100

Internal Coil 5000

Display LCD Graphic Display

Display Type Monochrome Backlit

LCD Display

Display Resolution 192 X 64 Pixels

Touch Screen 4 wire, Analog Resistive

Communication

Number of Ports 2

Type RS232/CMOS for connecting

to PLC, Programming and

Printing

Page 25

Hardware

19

HARDW ARE

In this chapter. . . .

♦ Safety Precautions

♦ Installation Instructions

♦ Power Requirements

♦ Wiring Diagram

♦ Communication Ports

Page 26

Hardware

20

2.1 Safety Precaution

Please observe the following precautions when installing the unit. Failure to comply with these restrictions could result in loss of life, serious personal injury , or equipment damage.

Warning: Do not operate the HMI in areas subject to explosion due to flammable

gases, vapors, or dusts.

Warning: Do not connect the HMI to an AC power source. Y ou will cause permanent

damage to the HMI.

Warning: Do not attempt to use a DC power supply that does not meet HMI power

requirements. You may cause malfunction or permanent damage to HMI.

Warning: Do not power the HMI with a DC power supply used for inductive loads or for

input circuitry to the programmable logic controller. Severe volt age spikes

caused by these devices may damage the HMI.

2.2 Installation Instructions

The NTXS should be mounted on a panel. Gasket, mounting clamps are provided with each NTXS unit

for proper mounting.

Environmental Considerations:

Make sure that the unit is installed correctly and that the operating limits are followed (see S pecifications

for NTXS).

Do not operate NTXS in areas subject to explosion hazards due to flammable gases, vapors or dusts.

NTXS should not be installed where fast temperature variations are present. Highly humid areas are

also to be avoided. High humidity causes condensation of water in the unit.

Location Considerations:

Care should be taken when locating equipment behind the NTXS to ensure that AC power wiring, PLC

output modules, contactors, starters, relays and any other source of electrical interference are located

away from NTXS. Particular care should be taken to the position of V ariable speed drives and switching

power supplies away from the NTXS.

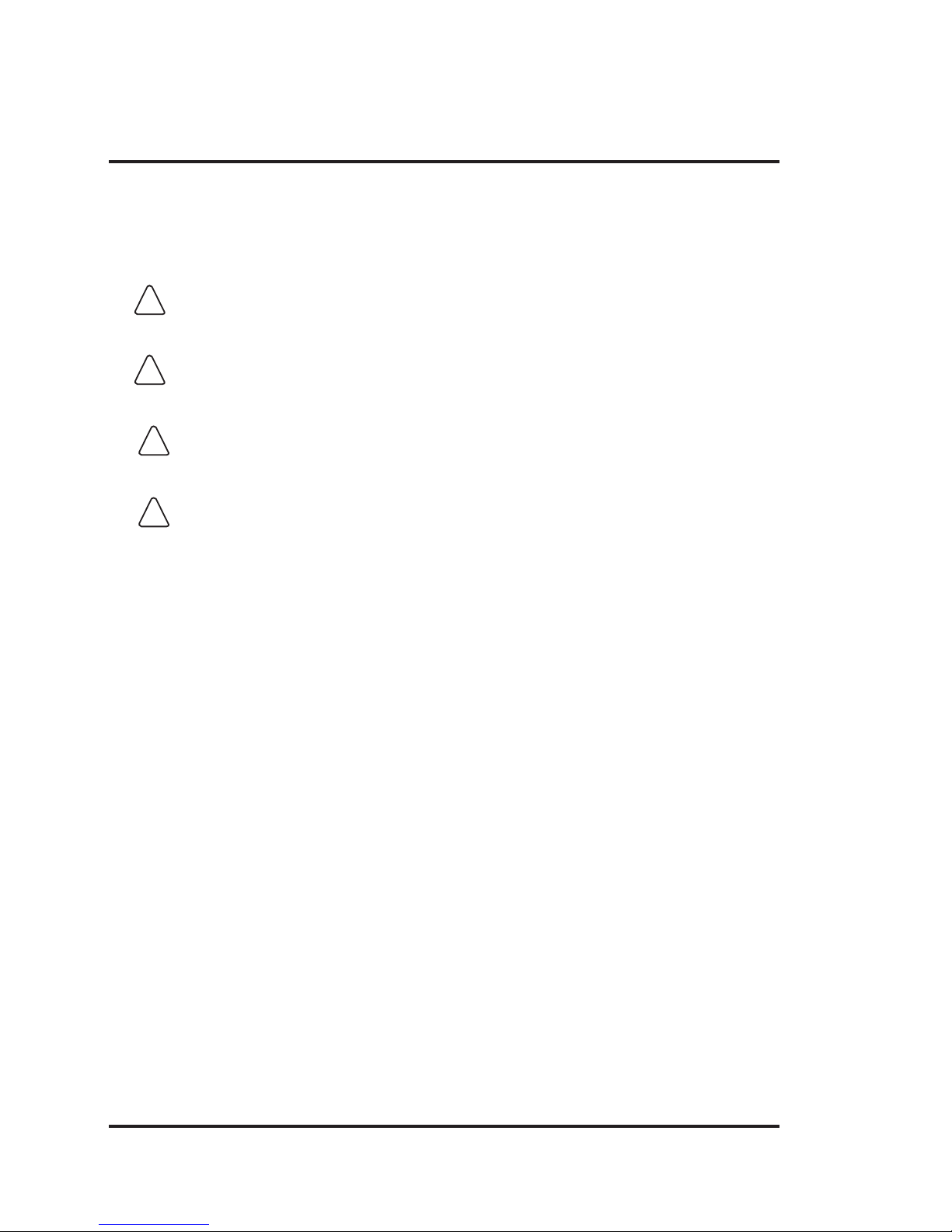

Panel Mounting

This section presents the dimensional sketches and panel cutouts for NTXS models.

(All dimensions are in mm. Not to Scale.)

!

!

!

!

Page 27

Hardware

21

NT2S-SF121B-EV2, NT2S-SF122B-EV2 and NT2S-SF123B-EV2

Panel cutout: 92.00 mm x 45.00 mm

All Dimensions are in mm.

108.30

91.20

44.18

60.50

Panel

Gasket

Bezel

Clamp

27.10

Mounting

Screw

NT2S-SF125B-E, NT2S-SF126B-E and NT2S-SF127B-E

Panel Cutout: 92.00 mm x 92.00 mm

All Dimensions are in mm.

2-4

106.88

91.30

91.30

106.88

Panel

25.80

Gasket

Mounting

Screw

Clamp

Bezel

12345

12345

NT3S-ST121B-E, NT3S-ST123B-E, NT3S-ST124B-E and NT3S-ST126B-E

Panel cutout: 132.00 mm x 69.00 mm

All Dimensions are in mm.

131.00

140.00

68.00

77.20

1234567890

1234567890

31.80

Mounting

Screw

Panel

Gasket

Mounting

Clamp

Bezel

Page 28

Hardware

22

2.3 Power Requirements

Supply voltage requirements for NTXS series models is as follows:

NT2S-SF121B-EV2 +24VDC + 10%, 1.5W maximum on Power Port

NT2S-SF122B-EV2 +5VDC + 10% on PLC port

NT2S-SF123B-EV2 +5VDC + 10% on PLC port

NT2S-SF125B-E +24VDC + 10%, 1.5W maximum on Power Port

NT2S-SF126B-E +5VDC + 10% on PLC port

NT2S-SF127B-E +5VDC + 10% on PLC port

NT3S-ST121B-E +24VDC + 10%, 3.5W maximum on Power Port

NT3S-ST123B-E +24VDC + 10%, 3.5W maximum on Power Port

NT3S-ST124B-E +24VDC + 10%, 3.5W maximum on Power Port

NT3S-ST126B-E +24VDC + 10%, 3.5W maximum on Power Port

Please follow the instructions given below while making power supply connections for models:

1. Follow the wiring diagram on the sticker of the unit which shows terminals.

2. To make a connection strip about 7mm of insulation of the wire, turn the connector screw

counter-clock wise until the gap is wide open. Insert the wire all the way in and turn the screw

clockwise until it is tight.

3. Wire lengths should be minimum. Wires should run in pairs with a neutral or common paired

with a live or signal wire.

4. NTXS +24VDC model is fused internally with a self resetting 60V , 400mA fuse. It is recom

mended that all input power lines be protected from product failure by a fuse or breaker.

5. Adequate strain relief must be provided for the power connector, to ensure that vibration does

not cause the power connector to be pulled out.

6. All the NTXS products are housed in a moulded ABS plastic case which eliminates any

electrical shock hazard. Hence Safety Earth is not required to be connected to the chassis of

the unit.

7. The DC ground is not directly coupled to Earth ground internally. The unit is designed to

operate properly whether or not the DC ground is connected to the Earth ground. We do recom

mend, however, that if the DC ground has to be connected to the Earth ground, the Earth

connection should be made to a central star point as poor site earths can introduce noise into a

system.

8. Do not power unit and inductive loads with the same power supply even though there is

enough immunity in the NTXS to withstand the transients present on these lines. A void using

power supplies with large capacitive outputs which may cause problems if power is cycled within

a short time period.

9. If wiring is to be exposed to lightening or surges, use appropriate surge suppression devices.

10. Keep AC, high energy and rapidly switching DC wiring sep arate from signal wires.

1 1. Connecting high voltages or AC power mains to the DC input will make unit unusable and

may create an electrical shock hazard to personnel. Such a failure or shock could result in

serious personal injury , loss of life and/or equipment damage. DC voltage sources should

provide proper isolation from main AC power and similar hazards.

Page 29

Hardware

23

2.4 Wiring Diagram

If wiring is to be exposed to lightening or surges, use appropriate surge suppression devices. Keep AC,

high energy and rapidly switching DC wiring separate from signal wires.

Connecting high voltages or AC power mains to the DC input will make unit unusable and may create an

electrical shock hazard to personnel. Such a failure or shock could result in serious personal injury , loss

of life and/or equipment damage. DC voltage sources should provide proper isolation from main AC

power and similar hazards.

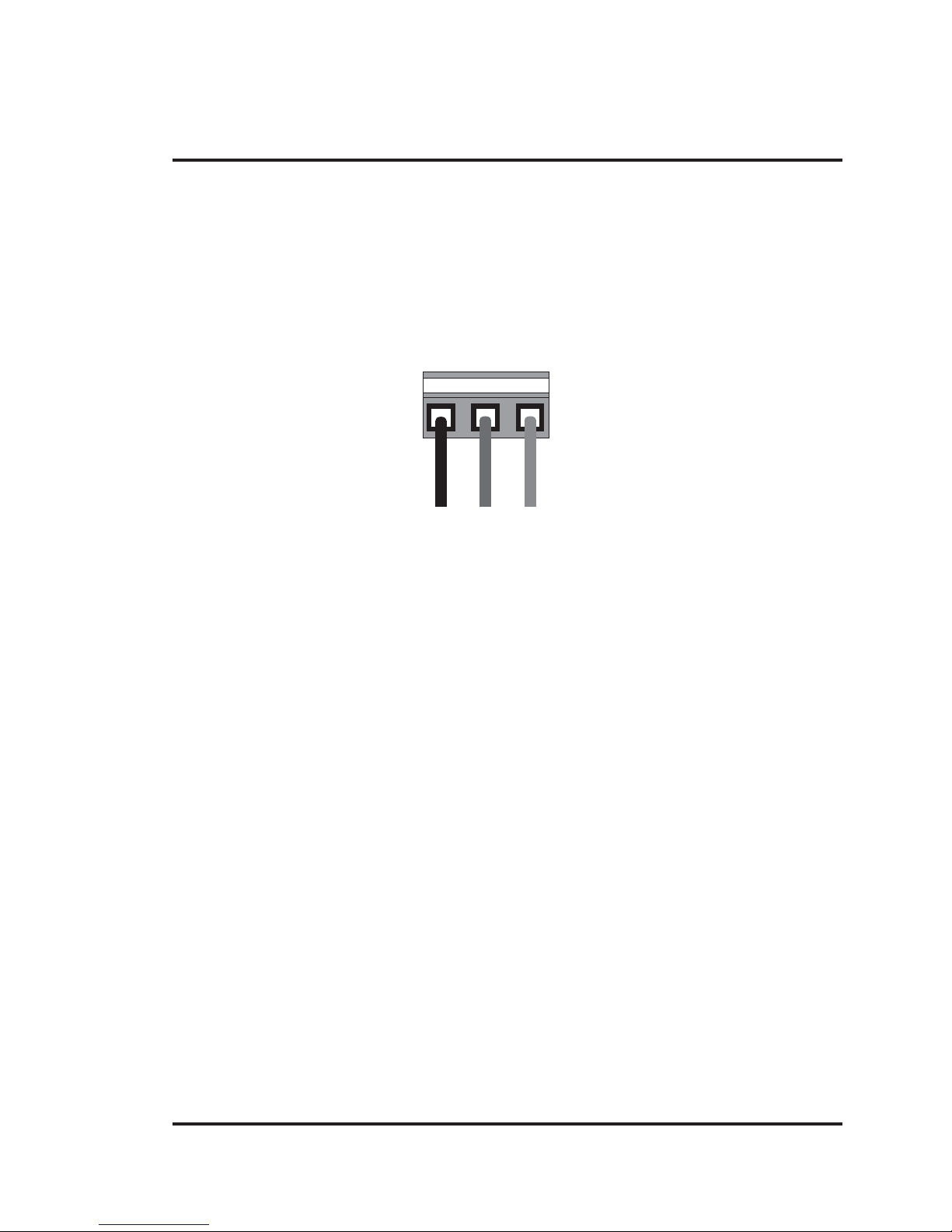

Pin description of the power connector for NTXS Models is as follows:

DC+ DC- Earth

24Vdc

123

2.5 Communication Ports

NTXS unit has 2 types of communication ports.

One port of NT2S models has RS232/CMOS signals. This port is used to connect to PLC. The other

port has RS232 signals which is used for receiving configuration setup and printing.

Note: NT2S-SF123B-EV2 and NT2S-SF127B-E units have only a PLC port with CMOS signals.

NT3S has multi-signal ports meaning RS232/RS485/CMOS signal level ports.

Note: NT3S-ST126B-E unit has only RS232 and CMOS signal level ports.

NT3S units can simultaneously communicate with two devices on these serial ports. Units can receive

data from PC on either of the ports. Both the ports are also capable of Serial Printing. Each port has to

be configured for their function. Even if both the ports are configured for PLC connection, user can

download data from NTXS software on either of the ports. For Programming cable details, please refer

to Appendix.

Different cables are required for different devices. Cable details for any p articular device are given in the

Operation Manual of that device. Pin description of the communication Ports for NT2S and NT3S

models is as given in following pages.

Page 30

Hardware

24

NT3S-ST121B-E

Com1 and Com2 Ports

Port Type: DB9 Female

Pin Name Description

Number

1 TX+ Transmit +

2 232TXD Transmit 232

3 RXD Receive 232 / CMOS

4 RX+ Receive +

5 GND Circuit Ground

6 VCC +5 VDC

7 CMOSTXD Transmit CMOS

8 TX- Transmit 9 RX- Receive -

NT3S-ST123B-E / NT3S-ST124B-E

Com1 Port

Port Type: DB9 Female

Pin Name Description

Number

1 TX+ Transmit +

2 232TXD Transmit 232

3 RXD Receive 232 / CMOS

4 RX+ Receive +

5 GND Circuit Ground

6 VCC +5 VDC

7 CMOSTXD Transmit CMOS

8 TX- Transmit 9 RX- Receive -

Page 31

Hardware

25

NT3S-ST123B-E / ST124B-E

Com2 Port

Port Type: DB9 Female

Pin Name Description

Number

1NCNC

2 232TXD Transmit 232

3 RXD Receive 232 / CMOS

4NCNC

5 GND Circuit Ground

6 VCC +5 VDC

7 CMOSTXD Transmit CMOS

8NCNC

9NCNC

NT3S-ST126B-E

Com1 and Com2 Ports

Port Type: DB9 Female

Pin Name Description

Number

1NCNC

2 232TXD Transmit 232

3 RXD Receive 232 / CMOS

4NCNC

5 GND Circuit Ground

6 VCC +5 VDC

7 CMOSTXD Transmit CMOS

8NCNC

9NCNC

Page 32

Hardware

26

NT2S-SF121B-EV2 / SF125B-E

Com1 Port (PLC Port)

Port Type: DB9 Female

Pin Name Description

Number

1 GND Circiut Ground

2 232TXD Transmit 232

3 RXD Receive 232 / CMOS

4 GND Circuit Ground

5 GND Circuit Ground

6 VCC +5 VDC

7 CMOSTXD Transmit CMOS

8 DIR Direction Control

9 PLC ATTACH Attach PLC. Should be grounded inside the cable

NT2S-SF122B-EV2 / SF126B-E

Com1 Port (PLC Port)

Port Type: DB9 Male

Pin Name Description

Number

1NCNC

2 DIR Direction Control

3 232TXD Transmit 232

4 VCC +5 VDC

5 GND Circuit Ground

6 CMOSTXD Transmit CMOS

7 RXD Receive 232 / CMOS

8 RXD Receive 232 / CMOS

9NCNC

Page 33

Hardware

27

NT2S-SF121B-EV2 / SF122B-EV2 / SF125B-E / SF126B-E

Com2 Port (Serial Port)

Port Type: DB9 Female

Pin Name Description

Number

1NCNC

2 TXD Transmit RS232

3 RXD Receive RS232

4NCNC

5NCNC

6NCNC

7NCNC

8NCNC

9 GND Circuit Ground

NT2S-SF123B-EV2 / SF127B-E

Com1 Port (PLC Port)

Port Type: DB9 Male

Pin Name Description

Number

1NCNC

2NCNC

3NCNC

4 VCC +5 VDC

5 GND Circuit Ground

6 CMOS TXD Transmit CMOS

7 RXD Receive CMOS

8 RXD Receive CMOS

9NCNC

Page 34

Hardware

28

NT2S-SF121B-EV2 / SF125B-E

Com1 Port (PLC Port)

Port Type: DB9 Female

Pin Name Description

Number

1 GND Circiut Ground

2 232TXD Transmit 232

3 RXD Receive 232 / CMOS

4 GND Circuit Ground

5 GND Circuit Ground

6 VCC +5 VDC

7 CMOSTXD Transmit CMOS

8 DIR Direction Control

9 PLC ATTACH Attach PLC. Should be grounded inside the cable

NT2S-SF122B-EV2 / SF126B-E

Com1 Port (PLC Port)

Port Type: DB9 Male

Pin Name Description

Number

1NCNC

2 DIR Direction Control

3 232TXD Transmit 232

4 VCC +5 VDC

5 GND Circuit Ground

6 CMOSTXD Transmit CMOS

7 RXD Receive 232 / CMOS

8 RXD Receive 232 / CMOS

9NCNC

Page 35

Hardware

29

NT2S-SF121B-EV2 / SF122B-EV2 / SF125B-E / SF126B-E

Com2 Port (Serial Port)

Port Type: DB9 Female

Pin Name Description

Number

1NCNC

2 TXD Transmit RS232

3 RXD Receive RS232

4NCNC

5NCNC

6NCNC

7NCNC

8NCNC

9 GND Circuit Ground

NT2S-SF123B-EV2 / SF127B-E

Com1 Port (PLC Port)

Port Type: DB9 Male

Pin Name Description

Number

1NCNC

2NCNC

3NCNC

4 VCC +5 VDC

5 GND Circuit Ground

6 CMOS TXD Transmit CMOS

7 RXD Receive CMOS

8 RXD Receive CMOS

9NCNC

Page 36

Before you Begin

30

BEFORE YOU BEGIN

In this chapter. . . .

♦ Connecting the HMI to a Computer

♦ Starting NTXS Software

♦ Setting Network Configuration

Page 37

Before you Begin

31

3.1 Connecting the HMI to your Computer

Before you start your first project, the HMI should be connected to the computer so that the project can

be downloaded after creating it. You should also connect the PLC that you are using with the HMI so that

you can test the operation of the HMI after you have finished creating the sample project.

• To connect your HMI to the computer

1. Connect a +24VDC power supply to the HMI.

2. Connect the programming cable to the computer and HMI.

• Connect IBM cable to the communication port of NTXS.

• Download Firmware i.e. driver for the PLC. The NTXS unit cannot communicate with

PLC till the required driver is downloaded.

3. Apply power to the HMI.

• To connect your PLC to HMI

NTXS can communicate with any PLC without any change in the NTXS hardware. To communi

-cate with a PLC, NTXS unit needs:

1. Proper Communication Driver for the PLC

2. NTXS - PLC communication cable

1. Communication Driver for the PLC:

Each PLC has a defined protocol for communicating with any device. Communication Driver is

downloaded into NTXS unit along with the firmware. Communication driver varies from PLC to

PLC. This driver enables unit to talk to a specific PLC, such as OMRON PLC.

2. NTXS:

PLC Communication Cable: Proper NTXS - PLC cable is required for error free communication

with a PLC.

Page 38

Before you Begin

32

3.2 Starting NTXS Software

3.2.1 Installing NTXS Software

System requirements for installing NTXS on your PC:

Windows Version : Microsoft Windows® 2000 or higher

Processor : 266 MHz Pentium® II or higher

Pentium-compatible CPU

Hard disk Space : 150 MB free memory space

Serial Mouse : Microsoft® mouse or compatible pointing

device

RAM : At least 64 megabytes (MB) of RAM; more

memory generally improves responsiveness

Display resolution : 800x600 with 24 bit true color

Serial Port : One Serial Port for Downloading Required

To install NTXS Software:

1. Open Microsoft Windows.

2. Select Run and Pop up window appears. Type the p ath for inst alling the Setup.

This will install NTXS Setup Software.

3. When you click on OK, Welcome window appears on the screen. Click on Next.

4. Enter User name and Company name.

Page 39

Before you Begin

33

5. Select the destination folder where Setup will install the files.

Page 40

Before you Begin

34

3.2.2 Steps for starting NTXS Software

1. In Windows click the Start button.

2. Select Programs.

3. Select NTXS V1.03.

4. Select NTXS V1.03.

5. Select New Application either from Tool station or from File Menu.

6. Select the model and product type that you would like to set by clicking on picture of the product in

the list.

7. Define the Unit Settings and Network Configuration.

8. Next step is to define Tag Database and then define the screens according to your application.

7. Installation starts. A dialog box indicating the status of progress of installation will display.

A screen is displayed to inform you when inst allation is completed.

This procedure installs NTXS Software in Start Menu (in selected folder).

6. Select the Program folder.

Page 41

Before you Begin

35

5. When you click on Yes, it will uninstall NTXS V1.03 from your computer.

If you want to install NTXS V1.03, then you have to follow the steps as explained in section 3.2.1.

3.3 Setting Network Configuration

Unit can communicate with any PLC without any changes in the hardware. To communicate with PLC

unit needs proper communication driver. Each PLC has a defined protocol for communicating with any

device. PLC driver is downloaded into unit alongwith the firmware. This driver enables the unit to talk to

a specific PLC.

Using this configuration screen you can set the node address and node name for each port. For NT2S

units, node

address can be set from 0 to 255 but for NT3S units, the highest node address is 32. You can change

default values generated by editing these two fields. Protocol selection box displays list of all supported

PLCs. By clicking this selection box you can see list of Model Numbers in PLC Model selection Box.

Select PLC Name from PLC selection box and PLC Model name from PLC Model selection box.

PLC specific data button is activated only if selected PLC has Special PLC specific dat a to be set.

3.2.3 Uninstalling NTXS Software

1. In Windows click the St art button.

2. Select Programs.

3. Select NTXS V1.03.

4. Select Uninstall NTXS V1.03.

Following screen will be displayed. The screen will ask you for the confirmation for uninstalling NTXS

V1.03.

Page 42

Before you Begin

36

3.3.1 Setting Network Configuration For NT2S Series Products

Unit can be configured for PLC Communication.

Node Address: User can assign unique node address starting from 0 to 255.

Node Name: User can specify node name, maximum upto 15 characters.

PLC: User can select desired PLC from the list of available PLCs.

PLC Model: User can select model for the desired PLC.

Add a Node: A new node is added in the network.

Delete the Node: The selected node can be deleted from the network.

Page 43

Before you Begin

37

3.3.2 Setting Network Configuration For NT3S Series Products

Unit can communicate with any PLC without any change in hardware. To communicate with PLC unit

needs proper communication driver. Each PLC has a defined protocol for communicating with any

device. PLC driver is downloaded in to unit along with the firmware. This driver enables the unit to talk to

a specific PLC.

Unit can be configured in following ways:

1. For IBM Communication

2. For Serial Printing

3. For PLC Communication

Either of the ports can be configured for the ways mentioned above. Depending on the type of communi-

cation, user may require to define certain parameters.

The following table displays number of nodes connected on Com1 and Com2 with their Node address,

node name, node type (unit / PLC), total number of blocks used in application.

Note: Default Node address for unit is 0 for COM1 and COM2. This address needs to be changed if

settings for PLC address is same as unit address.

Page 44

Before you Begin

38

1. For IBM Communication

This is default communication setting. If user wants IBM communication, no other setting is required. In

this case both communication ports can be used for download / upload purpose.

Page 45

Before you Begin

39

2. For Serial Printing

User can set either of the ports for serial printing. This is done by selecting Protocol as “Serial printer”. In

the above example, user has configured Com1 for serial printing. However, when this port is not being

used for printing, it will be used for IBM Communication.

User has to define parameters for serial printing, by using ‘Comm Settings’ option.

Page 46

Before you Begin

40

Following serial printing parameters can be set-

Baud Rate - Supported Baud rates are 4800, 9600, 19.2K, 38.4K, 57.6K and

1 15.2K.

Parity - Can be None, Even or Odd.

Number of Bits - Can be 7 or 8.

Number of columns - Can be from minimum 1 to maximum 80.

Terminating character - Can be None, CR(Carriage Return), LF(Line Feed) or CR+LF.

Number of characters - Can be from minimum 1 to maximum 256.

to print

Click ‘Ok’ to set printer setting.

3. For PLC Communication

Protocol - User can select desired PLC from the list of available drivers. In the example shown above,

user has selected Omron Host Link at Com1.

Page 47

Before you Begin

41

User can set PLC communication parameters like Baud Rate, Parity , Dat a Bit s and Stop Bits.

Click ‘Ok’ to set parameters.

Model - User can select desired PLC model from the list available. In the example shown

above, user has selected ‘CJ1’ model.

Address - Unique PLC node address ( 0 to 32 ).

Name - User can specify node name, which can be maximum up to 15 characters.

Add a Node - User can add a node in the network.

Change a Node -

User can change PLC or PLC related information. First of all user has to select the

node. Then change the information and finally click the button ‘Change a Node’.

PLC specific data -

If additional information is required for PLC, user can select the node. Then this button

is activated. Now by clicking on this button user can provide the desired information.

Delete node - To delete a node, first of all user has to delete all the tags defined for the node. Then

user has to select the node and click the Delete button.

Omron Frame delay can be set using the screen shown below:

Port Settings -

Page 48

Using NTXS Software

42

USING NTXS SOFTW ARE

In this chapter. . . .

♦ NTXS Menu Structure

♦ Creating New Application

♦ Creating Screens

♦ Data Entry Object

♦ Display Data Object

♦ Global And Power On Tasks

♦ Global Keys

♦ Screen Keys

Page 49

Using NTXS Software

43

4.1 NTXS Menu Structure

From Windows Task Bar, click the Start button and select the NTXS V1.03.

The following Window will appear.

The Program displays a Splash screen on Start-up. This dialog can be closed by pressing any key or just

by clicking mouse or waiting 10 seconds for it to automatically go to the next screen (i.e. Toolstation).

Page 50

Using NTXS Software

44

Menu bar operates like any standard Windows Menu bar . To open a particular Menu click it with the help

of Mouse or use key alongwith ALT key just like any other st andard Windows based software. When no

application is opened above Menu bar will be displayed.

Page 51

Using NTXS Software

45

The Tool-Station consist s of icons. When the mouse point s to any icon, a tool-tip is displayed. Click on

the icon to select the particular menu.

Now we will study the different Menus in the Menu Bar .

4.1.1 File Menu

File Menu handles the File related functions. File Menu consists the functions like New Application,

Close Application, Save Application, Print and Exit NTXS. Using Information option user can set or

change NTXS application information such as application title, user name etc.

New - Creates a new application.

Open - Opens a saved application.

Close - Closes currently opened application.

Save - Saves currently opened application.

Save as - Saves the current application with a different name.

Information - Configure application specific information such as application title, author,

password etc.

Import - All the text data associated with wizards (On / Off text, labels etc.) can be

imported. (Refer to USING LANGUAGES Chapter for more information)

Export - Exports data from NTXS projects and put it into a user specified file.

(Refer to USING LANGUAGES Chapter for more information)

Print - Either prints all the current application information such as Project information,

Unit settings, NTXS nodes, tags, screens, application tasklist, screen tasklist,

alarms or the selected attributes.

Exit - Exits NTXS Software.

Page 52

Using NTXS Software

46

4.1.2 Define Menu

This menu defines the application. In the main window of NTXS Software, bottom line of the icons is

dedicated for this menu.

Unit Settings - Defines Unit settings. Normally there is no need to change these

settings.

Network Configuration - Defines PLC node, node ID etc.

Tag DataBase - Defines tags to be used in the application.

Screens - Defines screens.

Application Keys - Defines application keys.

Alarms - Defines alarms in the application.

Application Task-List - Defines Power-on and Global Tasklist.

Hide Project Tools - When checked, hides the project toolbox.

Page 53

Using NTXS Software

47

4.1.3 Communicate Menu

Communicate Menu has options like selecting COM port, downloading or uploading NTXS application

etc.

Communication Port - Sets COM port for communicating with NTXS.

Download - Downloads Application to NTXS Unit.

Upload - Uploads Application from NTXS Unit.

4.1.4 Utilities Menu

Utilities Menu informs the user about the memory used for the application. This menu has other options

like Font Editor, image conversion and Convert application.

Convert Application - Converts opened application.

NTXS Memory status - Displays statistics of the memory used by the current

application.

Font Editor - User can edit the fonts by using the Font Editor utility .

Image Conversion to bitmap - Converts images from any type of picture format to bitmaps.

Page 54

Using NTXS Software

48

4.1.5 Help Menu

Help menu offers help for the user application and information about the NTXS version.

Index - Lists all the Help topics

About NTXS Software - Displays the software version number.

4.2 Creating New Application

A User can create a new application either from Menu Bar or from Tool Bar.

♦ Creating a New Application from Menu Bar:

Click on New From File Menu or New Application icon from Toolbar. It will create new

application.

Click on the New Application icon either from File Menu Bar or Tool Bar. Following screen will be appeared.

OR

Page 55

Using NTXS Software

49

This screen shows list of all NTXS units. Select the required product from the list of products that you

would like to set by clicking on the picture of the product in the list. An enlarged picture of the product is

also shown below the list.

On clicking Ok product type selection screen will display -

Page 56

Using NTXS Software

50

Select the type of Product and then click OK to start the Application.

Steps for creating a new application are as follows:

1) Start a new project using either File Menu or Tool section New command.

2) Define Unit Settings.

3) Define Network Configuration for selected unit and PLCs.

4) Define the tags in the Tag database required for the project / application.

4) Define the screens.

5) Define Power-on, Global and Screen tasks.

6) Save your application.

7) Download firmware to the unit.

8) Download your application to the unit.

Tag Database

This is the central database for the tags which need to be used in the application. Once the tags are

defined (as register or coils) and their attributes selected, the tags can be used in the application on

screens, tasks, alarms etc. This screen helps you to define Tags associated with defined Nodes. Tag is

nothing but a Register or Coil or Individual bit of any register. Select type of the tag from Tag Type field

which is either Register or Coil Type.

If type of tag selected is register then number of bytes to be fetched varies from 1, 2, 4, etc. For displaying or editing float data number of bytes of tag must be 4. Tag Name field is user definable. Tag is not

added in Tag list unless you define Tag name. Once you define all these fields click on Add button for

adding Tag in Tags List Box. Block field of this tag database defines Block starting address followed by

Block size.

For example : Tag M0214 is within a block ( M0214 : 1 ) whose starting address is M0214 and block size

is 1. This block size is optimized automatically depending on address of PLC Tag.

Default block size is either 1 or 16. This setting varies from PLC to PLC.

Attributes of existing Tag can be changed by clicking on Change button. Note that Change button is

activated only if tag in the tag list is selected. Existing Tag can be removed from Tag list by clicking on

Delete button. However , user can delete the tags only if they are not used in any screen.

Page 57

Using NTXS Software

51

Tag Database for NT2S Series:

Add - User can add tag with this button. Before clicking this button user has to select

1. Node : For which tag is going to be defined.

2. Read : Write Register or coil - User can select Read only or Read-Write type

tag.

3. Tag Type : Register / Coil or Bit addressed Register. User has to choose the

register number or coil number within the limit shown.

4. Tag name : Each register / coil in the unit /PLC memory has a unique and specific

name to identify it. User can define name up to 40 characters.

5. Byte(s) : If selected t ag is of register type then user can define it as a 1- byte (

Low-byte / High-byte), 2-byte, 4-byte.

Change – User can change tag information (like register/coil number, t ag name, Byte(s)) by selecting

tag. Change the information and then click on Change button.

Delete - Select the tag and click on Delete button to delete the tag. Before deleting any tag, the user

must delete any references to the tag in screens and tasks. Otherwise it can not be deleted.

Page 58

Using NTXS Software

52

Tag Database for NT3S Series

Add - User can add tag with this button . Before clicking this button user has to select

1. Node : For which tag is going to be defined.

2. Read : Write Register or coil - User can select Read only or Read-Write type

tag.

3. Tag Type : Register / Coil or Bit addressed Register. User has to choose the

register number or coil number within the limit shown.

4. Tag name : Each register / coil in the unit /PLC memory has a unique and specific

name to identify it. User can define name up to 40 characters.

5. Byte(s) : If selected tag is of register type then user can define it as a 1- byte (

Low-byte / High-byte), 2-byte, 4-byte.

Change – User can change tag information (like register/coil number, t ag name, Byte(s)) by selecting

tag. Change the information and then click on Change button.

Delete - Select the tag and click on Delete button to delete the tag. Before deleting any tag, the user

must delete any references to the tag in screens and tasks. Otherwise it can not be deleted.

Page 59

Using NTXS Software

53

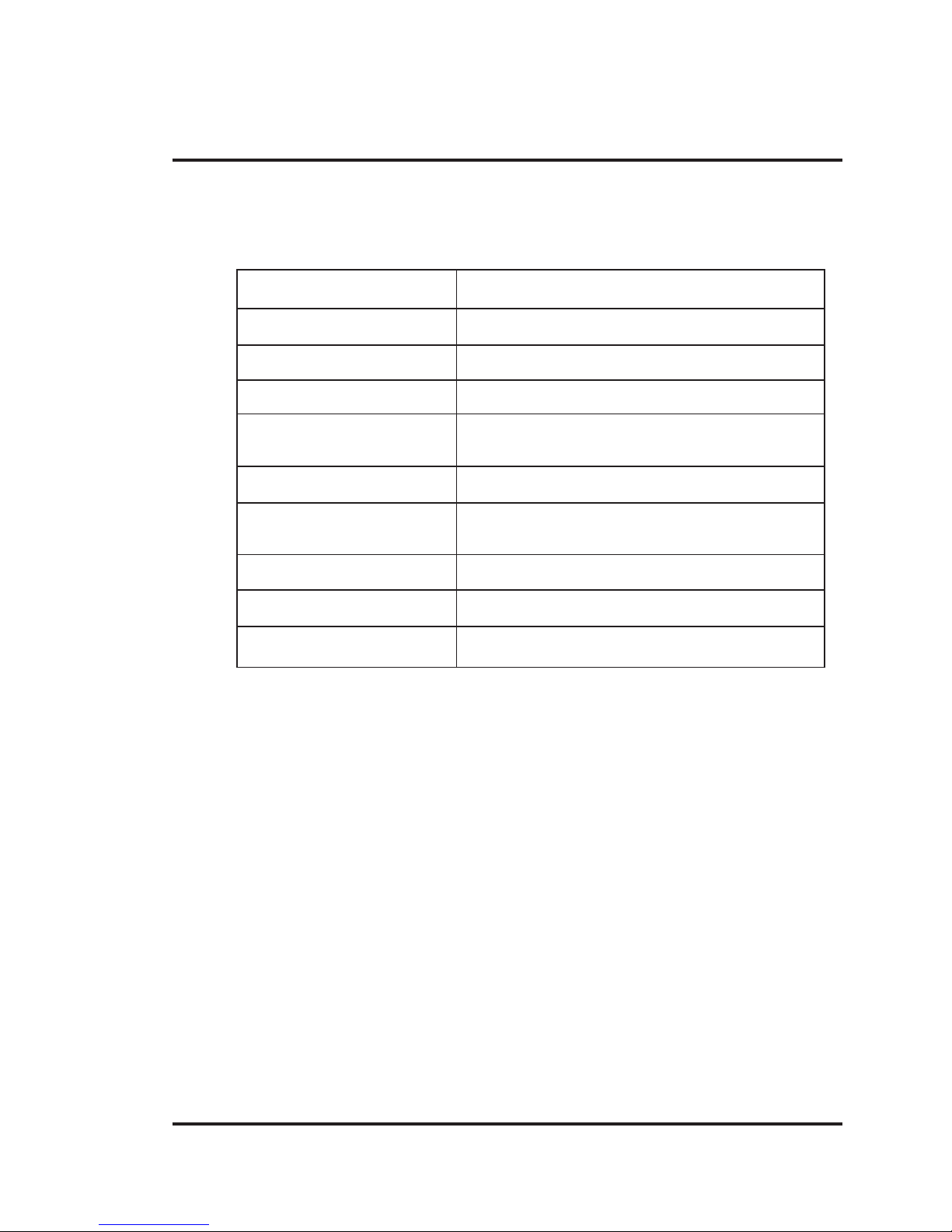

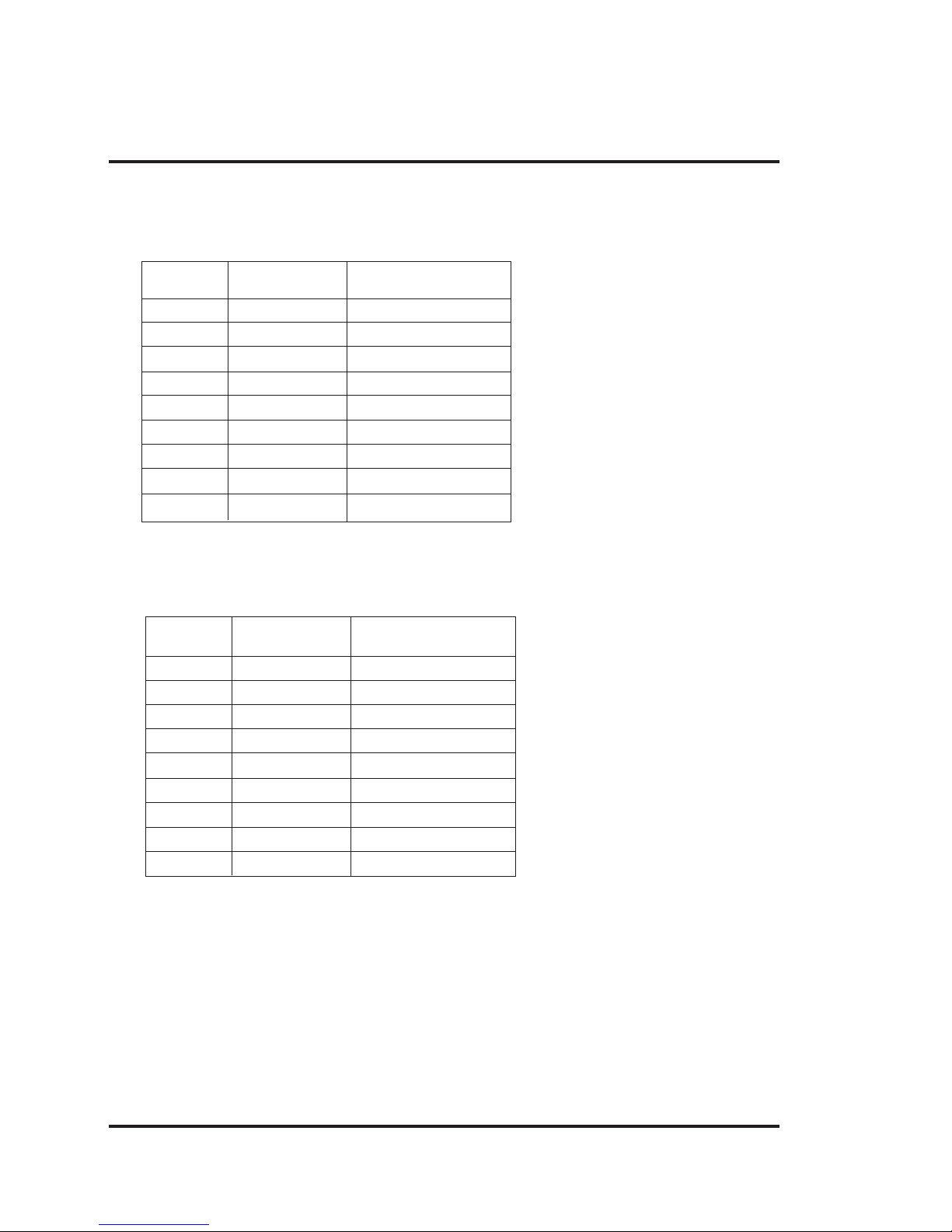

Default System T ags

1. System Registers

Tags Tag Name Read / Write Description

S0001 Language Read / Write Writing the value will change languages

used in any wizard

S0003_14 Comm1 status Read Only 0 = Communication Error

1 = Communicating with PLC

S0003_15 Comm2 status Read Only 0 = Communication Error

1 = Communicating with PLC full status

S0004 Number of Historical Read Only Shows number of alarms stored in

memory Alarms

S0005 Screen Trigger Read / Write Shows active screen no. User can

change Register screen by writing any

valid screen no in this register

S0007 Battery Vol tage Read Only Indicates battery voltage in #.# format

S0008 Error code for Read only Error code byte for Xtradrive for Com1

Xtradrive Com1

S0009 Error code for Read only Error code byte for Xtradrive for Com2

Xtradrive Com2

2. System Bits

T ags Tag Name Read / Write Description

s0009 Beeper On /Off Read / Write 0: Enable Beeper

1: Disable Beeper

User can change this bit at Run time.

s0010 Battery Status Read only 0: Battery voltage is OK (i.e.above 2.2 V)

1: Low Battery (i.e. below 2.2V)

s0011 Start / Stop jog Read / Write Used in jog operation of Xtradrive for port1

for Xtradrive Com1

1: Continuous jog operation on port1

0: Stop jog operation on port1

s0013 Start / Stop jog Read / Write Used in jog operation of Xtradrive for port2

for Xtradrive Com2

1: Continuous jog operation on port2

0: Stop jog operation on port2

Page 60

Using NTXS Software

54

4.3 Creating Screens

Screens are the most important part of any application as they display the information required by the

operator. NTXS has various objects to make a screen operator-friendly. Click on Screens icon to define

screens.

In the Screens dialog box, enter the screen number, name and p assword. Select screen properties and

screen type.

Screen Number : Screen number can be from 1 to 65534 for NT2S models. For NT3S

models screen number can be from 1 to 65000 as shown in the follow

ing screen. The screen number is unique.

Screen Name : Screen name can be upto 20 characters. It is displayed only in software

configuration.

Password : User can protect screen information by giving password to the screen.

User can assign any number from 1 to 9999 as screen password.

Screen Properties -

1. Display only : If the screen property is ‘Display only’ then the screen information is displayed on LCD.

2. Print Only : Screen, having this property , will not be displayed. Alphanumeric data on the screen goes

to serial printer only once and control jumps back to last displayed screen. User has to define the port

as ‘Serial Printer’ port if he wants to assign this property to screen. Either of the ports can be configured

for printing. When the print screen is activated, the print data will be sent from the printer port.

3. Print Once / display : If screen has this property , first of all Alphanumeric data on the screen goes to

serial printer and then the screen is displayed on LCD. User has to define the port as ‘Serial Printer’ port

for assigning this property to the screen. Either of the ports can be configured for printing. When the

print screen is activated, the print data will be sent from the printer port.

Page 61

Using NTXS Software

55

Description : User can write the information about the screen for the reference. This description is only

for software configuration. It is not displayed on the unit.

Associated Screens : Associated screen is useful in the case where one or more object s are common

between different screens. The common data from all the screens is placed in a screen and this screen

is associated with the other screens.

Advantage of associated screen -

1. It saves application memory .

2. It saves time of the application programmer.

Note : Only one screen can be associated to any screen.

No data entry objects can be placed in the screen to be associated.

Embedding any PLC information is not supported in associated screen.

User can ‘unassociate’ a screen.

Available Screens - List of available screens is displayed.

Click ‘Ok’ to edit the screen.

4.3.1 Protecting Application Using Password

NTXS application can be password protected. This protection is applicable for both during uploading an

application and during opening NTXS application. To make application password protected define

password in application information screen. Define password for application and download or save the

application. Following screen will appear during application uploading or during opening an application.

4.4 Data Entry Object

Any register or coil from the unit or PLC memory , except Read-only registers and coils, can be edited

using the numeric keypad.

Procedure -

1. Click on the Data Entry button from objects toolbar.

2. The mouse pointer will change to the tool shape. Now place the mouse pointer at desired

location and click the left mouse button. The data entry dialog box will appear.

Data Entry objects are explained in detail in chapter 5.

Page 62

Using NTXS Software

56

4.5 Display Data Object

This object is used to display the contents of the register or coil.

Procedure-

1. Click on ‘Display Data’ from object s toolbar. The mouse pointer will change to the tool shape.

2. Now place the mouse pointer at desired location and click the left mouse button. The data entry dialog

box will appear.

Display data object is explained in detail in chapter 5.

4.6 Global And Power On Task

1. Power-on Tasks - Tasks specified under this option execute only once when unit is powered on.

2. Global Tasks - Tasks specified under this option execute continuously as long as unit is powered.

Page 63

Using NTXS Software

57

Select a T ask to add

This drop down list allows the user to select a task to be executed. A task list contains multiple tasks.

Close - Accepts the selected task.

Up arrow - Shifts the selected task upwards.

Down arrow - Shifts the selected task downwards.

Delete - Deletes the selected task.

Page 64

Using NTXS Software

58

4.7 Global Keys

Define tasks for these key events -

Press T asks – These tasks are performed only once when the key is pressed.

Pressed T asks – These tasks are performed as long as the key is pressed.

Released T asks – These tasks are performed when the key is released.

Tasks defined for Global Keys are executed for whole application, independent of which screen is being

displayed.

Close - Accepts the selected t ask.

Up arrow -Shif ts the selected t ask upwards.

Down arrow -Shifts the selected task downwards.

Delete -Deletes the selected task.

Show used double keys -Shows the list of combination keys used to define the tasks.

Single Key -If this option is selected, a task is defined on a single key .

T wo simult aneous keys -If this option is selected, a task is defined on a combination of

two keys.

Note: Global keys Task list is applicable for only NT2S Products.

Page 65

Using NTXS Software

59

4.8 Screen Keys

Define tasks for key events for a specific screen -

Press T asks – These tasks are performed only once when the key is pressed.

Pressed T asks – These tasks are performed as long as the key is pressed.

Released T asks – These tasks are performed when the key is released.

Task defined under this option are executed only for the currently displayed screen . These are screen

dependent tasks.

Close -Accepts the selected task.

Up arrow -Shifts the selected task upwards.

Down arrow -Shifts the selected task downwards.

Delete -Deletes the selected task.

Used double keys -Shows list of combination keys used to define the task..

Single Key -If this option is selected, a task is defined to one key.

T wo simultaneous keys-If this option is selected, a task is defined to a combination of

two Keys.

Note: Screen Keys’ Tasklist has higher priority over Global Keys’ Tasklist when the screen is displayed.

Page 66

Representing Data

60

REPRESENTING DA TA BY OBJECTS AND WIZARDS

In this chapter. . . .

♦ Alphanumeric Objects

♦ Graphics Objects

♦ Wizards

Page 67

Representing Data

61

5.1 Alphanumeric Objects

Alphanumeric objects are text objects with certain properties or attributes. By using various attributes,

the designer can emphasize the importance of a particular text object. The alphanumeric objects in

models with a graphics display have some additional attributes.

Alphanumeric Object

Alphanumeric Objects T ypes:

1. Text Object

2. Data Entry

3. Display Data

4. Time

5. Date

5.1.1 Text Objects

Text object is useful for displaying any message for the operator. Plain text objects do not depend on the

PLC.

Procedure

1. Click on the Text button in screen Objects Toolbar or Menu option. The shape of the mouse pointer

will change.

2. Now place the mouse pointer at desired location and mark the area of text object while holding the left

mouse button.

3. A block cursor will blink at the location inside the text outline. Now enter the text. Last character will be

overwritten If insert mode (Computer Keyboard) is disabled, else new character will not be accepted.

5.1.2 Data Entry Objects

Any read/write register or coil from the unit or PLC memory can be edited using the numeric keypad.

Page 68

Representing Data

62

This box will allow user to select either Coil Data Entry or Register Data entry. By default Coil data entry

is selected

1. Coil-Tag : Select Coil tag from the list.

2. On Te xt : Enter On text maximum up to 40 characters.

3. Off Text : Enter Off text maximum up to 40 characters.

4. Popup : If user wants data entry with popup keypad then user has to check Keyp ad option and also

select popup screen number from the list. If user don’t want popup data entry then he has to add static

numeric keypad object on screen.

To edit a register, select Register Data Entry .

Register Data Entry dialog box allows user to select the -

1. Register-Tag : This is a list of tags available in the application. The list will not display any read only

registers that can not be modified.

2. Data Type : This selects the type of data to be entered. Choices are Unsigned Integer, Signed

Integer, Hexadecimal, BCD, Binary (1 word), Float.

3. Format : Determines the format of the data to be displayed.

4. Low-limit : Data entered can be limited by assigning Low limit.

5. High-limit : Data entered can be limited by assigning High limit.

6. 1st-operation : User can define math operations like addition(+), subtraction(-), multiplication(*),

Division (/). By default selection is NOP i.e. no operation.

7. 2nd- operation : User can define math operations like addition(+), subtraction(-), multiplication(*),

Division (/). By default selection is NOP i.e. no operation

Page 69

Representing Data

63

8. Popup : If user wants to enter data with popup keyp ad then user has to check Keyp ad option and

also select popup screen number from list. If user don’t want popup data entry then he has to add static

numeric keypad object on screen .

Note:- Math operations operate only on unsigned values and unsigned result e.g. If first operation is

divided by 100 and tag value is 25 then result will be stored as zero and not 0.25.

Click ‘Ok’ button to add the object on screen.

5.1.3 Display Data

Procedure

1. Click on ‘Display Data’ from object toolbar. The mouse pointer will change to the tool shape.

2. Now place the mouse pointer at desired location and click the left mouse button. The data entry dialog

box will appear.

Type- Bit Text

This object displays text depending on the bit status.

1. Coil-Tag : Select Coil tag from the list.

2. On T ext : Enter On text maximum up to 40 characters.

3. Off Text : Enter Off text maximum up to 40 characters.

Click ‘Ok’ button to add the object on the screen.

Page 70

Representing Data

64

Type – Register Value

1. Register-Tag : This is a list of tags available in the application. The list will not display any read only

registers that can not be modified.

2. Data Type : This selects the type of data to be entered. Choices are Unsigned Integer, Signed Integer,

Hexadecimal, BCD, Binary (1 word), Float.

3. Format : Determines the format of the data to be displayed.

4. Leading zeros blank : Leading Zeros blank option decides whether zeros preceding the value will be

displayed or not. If this option is enabled then register value will be displayed without Leading zeros.

5. 1st-operation : User can define math operations like addition(+), subtraction(-), multiplication(*),

Division(/). By default selection is NOP i.e. no operation

7. 2nd-operation : User can define math operations like addition(+), subtraction(-), multiplication(*),

Division(/). By default selection is NOP i.e. no operation.

Page 71

Representing Data

65

Type – Register Text

This object displays text depending on value of a register. User can define dif ferent text for different

ranges.

1. Register-Tag : This is a list of tags available in the application. The list will not display any read only

registers that can not be modified.

2. Show table : Table shows list of text string defined for different ranges.

3. Define new range : User can define new range with low and high limits and text in following edit box.

4. Delete : User can delete entry from table.

5. Accept : Using this button edited range is accepted and added in the table.

6. Discard : Using this button edited limit and text is disabled.

Click ‘Close’ button to add object on the screen.

Page 72

Representing Data

66

Time is displayed in 24 hour format without leading zeros. If NTXS hardware is without RTC this object

will display ‘?’

5.1.5 Date

1. Click on ‘Date’ from objects toolbar. The mouse pointer will change to the tool shape.

2. Now place the mouse pointer at desired location and click the left mouse button.

Object is placed in default format DD/MM/YY without leading zeroes.

User can change format by double clicking on object.

By selecting Day check box day will be displayed ( ‘SUN’, ‘MON’…..).

If NTXS hardware is without RTC this object will display ‘?’.

5.1.4 Time

1. Click on ‘Time’ from object s toolbar. The mouse pointer will change to the tool shape.

2. Now place the mouse pointer at desired location and click the left mouse button.

Object is placed in default format HH:MM:SS.

User can change format by double clicking on the object.

Page 73

Representing Data

67

Attributes of Alphanumeric Objects

Font Size

Text objects have four font sizes: 5 X 7 Dots, 7 X 14 Dots, 10 X 14 Dots and 20 X 28 Dots. Default font

size is 5 X 7 Dots.

Text Foreground:

Text foreground can be changed by user. Two options are available: black and white. Default Text

Foreground is Black.

Text Background

Text Background can be changed by user. Two options are available: black and white. Default Text

Background is white.

Border -Single or Double

Any text object can be highlighted using single or double border This enhances its importance.

Unconditional Flash

User can assign flashing attribute to any text object. An object can flash at three dif ferent speeds: Slow,

Medium and Fast. By default no object is assigned the flashing attribute. If flashing is defined, slow

flashing is selected by default.

Note: Data Entry objects (Coil and register) do not have flash attribute.

Following attributes are available on NTXS Models with Graphic Display .

Animation Properties:

All the objects have Animation Properties. Animation Property is a property of an object which changes

with the value of the Tag associated with it. Animation Property help s user to create a screen that will

have a better user interface. Animation properties are of two types-

1. Show / Hide Animation

2. Flash

Page 74

Representing Data

68

1. Show / Hide Animation: Object is displayed only when the condition specified by the user is true. For

example, the object is displayed when a value of tag is within 100(Low) and 200(High). When this

condition is false, the object is not displayed.

2. Flashing Animation: Object can be flashed at three speeds – Slow , Medium and Fast, only when the

condition specified by the user is true. For example, object is flashed when a value of tag is within

100(Low) and 200(High). When this condition is false, the object is not flashed.

Page 75

Representing Data

69

5.2 Graphic Wizards

Graphic objects can be used to make the screen more user friendly by drawing pictures. Graphic objects

are available only in NT3S units.

Graphics Object

Following are the Graphical Objects :

1. Line

2. Rectangle

3. Ellipse

4. Rounded Rectangle

5. Bargraph

6. Bitmap

5.2.1 Line

Draws a line of required length in any direction and at required location.

Procedure

1. Click on the ‘Line’ button in screen Objects Toolbar or Menu option. The shape of the mouse pointer

will change.

2. Now place the mouse pointer at the desired location and mark the area of object while holding the left

mouse button.