Page 1

NT2S-SF121B-E

&

NT2S-SF122B-E

QUICK START GUIDE - V1.03

Version 1.03 Page 1

Page 2

NT2ST QUICK START GUIDE

1. INTRODUCTION ............................................................................................................................................ 3

2. NT2S OPERATION OVERVIEW ...................................................................................................................3

3. NT2ST SOFTWARE OVERVIEW..................................................................................................................4

4. ADD/REMOVE DRIVERS..............................................................................................................................5

5. CREATE NEW PROJECT............................................................................................................................... 6

6. PROJECT SETUP............................................................................................................................................. 7

7. TAG DATABASE............................................................................................................................................ 8

8. EDIT – SCREENS..........................................................................................................................................10

9. NORMAL SCREEN.......................................................................................................................................11

10. LINK SCREEN............................................................................................................................................... 15

11. SPECIAL SCREEN........................................................................................................................................ 16

12. FUNCTION SCREEN.................................................................................................................................... 18

13. SPECIAL PROGRAMMING NOTES ...........................................................................................................20

STR Control from a Function Key ...................................................................................................................... 20

STR Control from the PLC.................................................................................................................................. 20

Function Key Control Definitions.......................................................................................................................20

Entering Text on Second Line of Display............................................................................................................ 21

14. COMMUNICATION CABLES SPECIFICATIONS..................................................................................... 22

Omron Cables ....................................................................................................................................................22

Allen-Bradley Cables.......................................................................................................................................... 24

GE Micro Cables ................................................................................................................................................ 25

Modicon Cables.................................................................................................................................................. 26

Keyence Cables................................................................................................................................................... 27

Toshiba Cables....................................................................................................................................................28

Koyo Cables........................................................................................................................................................ 29

15. NT2S SPECIFICATIONS ..............................................................................................................................30

Version 1.03 Page 2

Page 3

1. INTRODUCTION

NT2ST is used with NT2S-SF121B-E and NT2S-SF122B-E products. These products are

compact but highly functional operator interfaces and NT2ST is designed to be extremely

flexible to take advantage of this functionality.

The bright LED back light and 2 x 16 character screen provide a highly visible display for

showing fixed or scrolling text messages, bit controlled text, and numerical data.

Special screen types exist for simplifying data entry. Navigation can be achieved using

programmed function keys, configuring a LINK screen, or chaining message screens that change

on a timer. Six function keys provide many options for operator control and data entry.

Function keys can be programmed locally for each screen, or globally for the project, to perform

tasks which include momentary, set on, set off, and toggle bit control, as well as numerous

numeric value control tasks.

The Windows based program, NT2ST, provides many tools to achieve flexible solutions. Follow

this quick start guide to gain an overall understanding of the layout of this software tool.

This document assumes the user is familiar with the operation of programs within Windows and

basic PLC concepts. Consult a technical resource for answers to basic PLC questions.

2. NT2S OPERATION OVERVIEW

The screens displayed on the NT2S are stored in the program memory of the unit. The NT2S

displays the screen number currently stored in the Screen Trigger Register (STR), which is a

PLC memory location. The NT2S remembers the last three STR values and will display them in

order when the current screen is finished displaying.

Numeric data is displayed by placing fields on a screen that reference PLC memory locations.

Up to six numeric fields can be placed on a single screen. Bit status can be displayed on the

screen using bit controlled text.

Navigation from screen to screen can be handled in several ways:

Function keys can be programmed to change the STR. F1 can increment the STR by one,

•

and F2 can decrement the STR by 1. Function keys can also change the STR to a specified

number.

Link screens can be created to navigate a series of screens specified by the user. A link

•

screen is a parent screen which displays a series of child screens. Link screens save

programming time because it automatically defaults to F1 being a NEXT key, and F2 being a

PREV key. Programmer does not have to set these functions up on each screen. Call the link

screen number in the STR to activate the link screen.

Chained screens can be used to automatically cycle through a list of screens. When creating a

•

screen, specify to what screen number it is linked. During operation, the NT2S will continue

to change screens at the rate specified in the MIN TIME field of each screen. The screens

will loop until a STR number is called for a screen not in the chain.

Version 1.03 Page 3

Page 4

3. NT2ST SOFTWARE OVERVIEW

It is recommended that programming steps be performed by accessing the Windows menu items

at the top of the program window. Deactivate the Tool Station (the Desktop cartoon image) by

selecting

Options

menu

, Tool Station

. The tool station should disappear.

Select

at any point within NT2ST to view context sensitive help information. The help

Help

document will provide a more thorough explanation than this document will for most functions.

The sections below are roughly in the order in which a project will be created.

Version 1.03 Page 4

Page 5

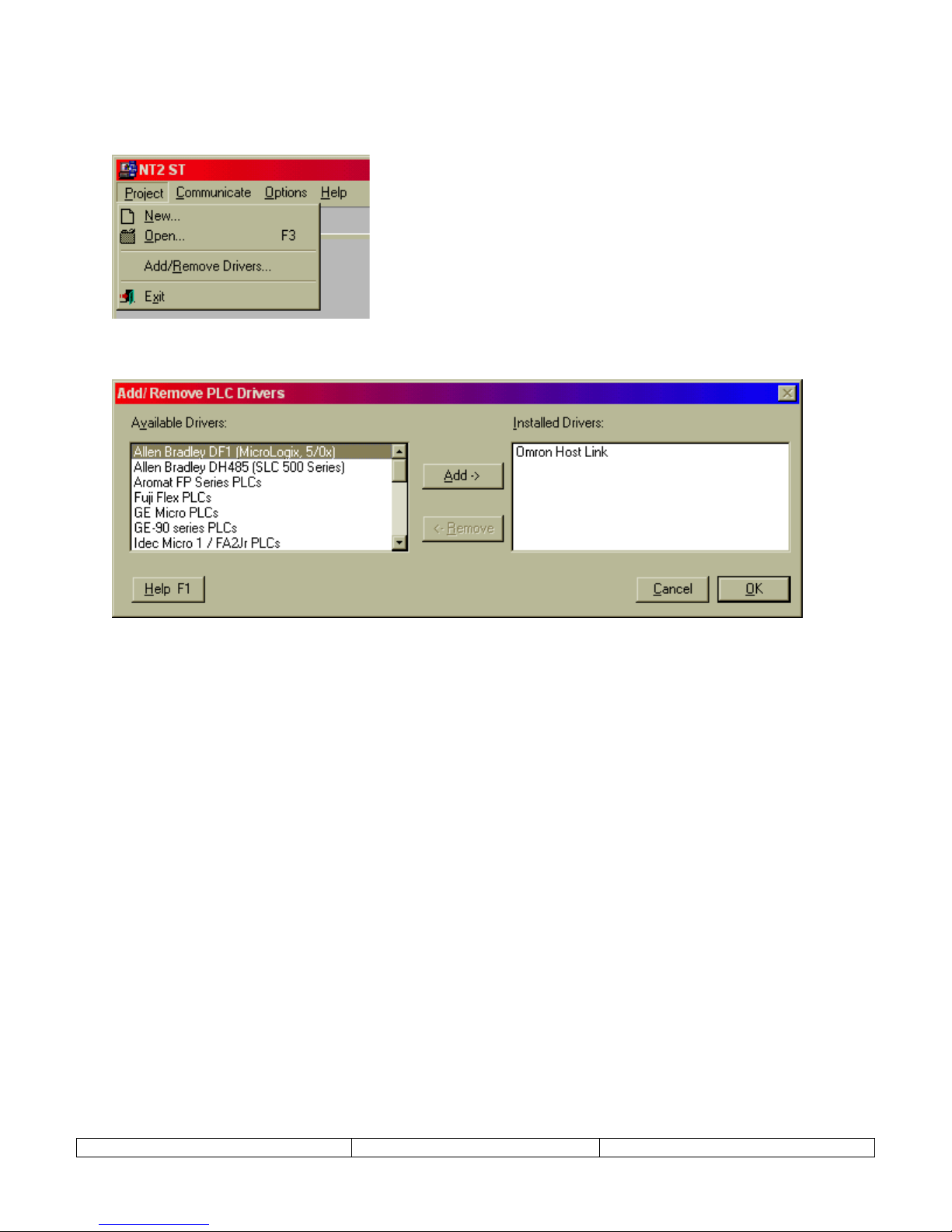

4. ADD/REMOVE DRIVERS

Before beginning the first project, select

Project

and

Add/Remove Drivers

. This menu item is

not available once a project has been created.

A dialog will appear that allows additional PLC models to be added to the PLC selection menu.

Make sure that the PLC needed for the project is included in the list on the right.

Select OK to complete addition of drivers to the project.

Version 1.03 Page 5

Page 6

5. CREATE NEW PROJECT

1. Select

New

from the

Project

menu.

2. In the dialog presented, select the PLC and PLC Model from the New project dialog and

select OK.

The PLC model can be changed at any time during the project. From the

select,

PLC Model

, and select a new PLC model from the list. Accept the change by

Project

menu,

clicking on OK. Care must be taken to verify that the tag addresses are valid for the new

PLC model.

(If the brand of PLC required for the project does not appear, refer to the ADD/REMOVE DRIVERS section

above.)

3. Select the NT2S hardware model that will be used for this project. Choose either NT2SSF121B-E or NT2S-SF122B-E and click the CLOSE button.

(If the incorrect NT2S model is selected, the project can be converted at anytime using the file conversion

utility located on the

select OK.)

Project

menu, and select

Model type

. Just open the project and select this menu item and

Version 1.03 Page 6

Page 7

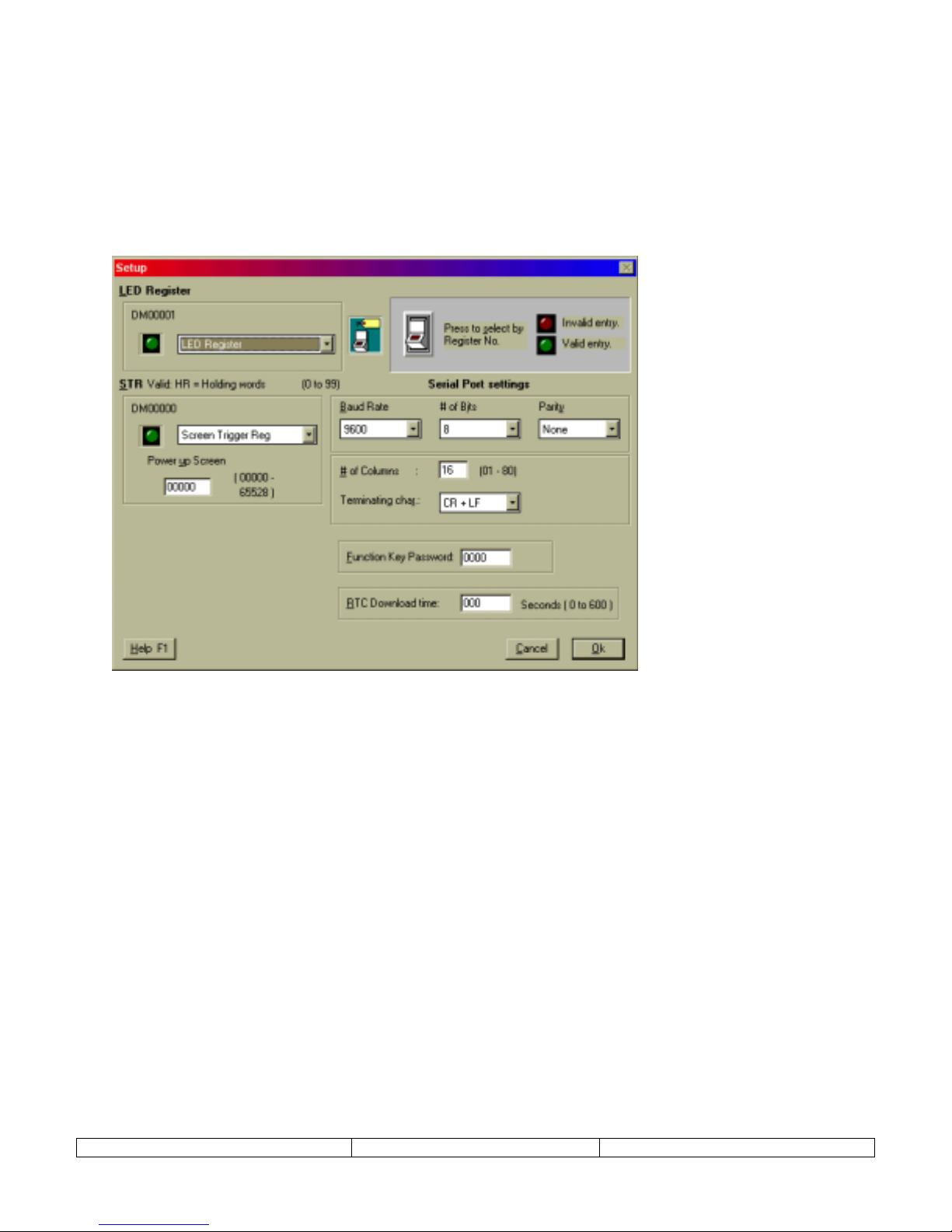

6. PROJECT SETUP

The Setup dialog is used to configure the NT2S operation parameters. Specify the LED register,

screen trigger register, power up screen, serial port settings, function key password, and real time

clock download time. The project setup dialog is accessed from the

Edit

menu,

Setup

menu

item.

Generally, there is no need to change the default settings. The only parameters that need to be

set by the user are Power up screen number and the function key password settings.

LED Register –

type can be referenced for this setting. The default TAG is labeled “LED Register”.

This setting tells the NT2S which TAG to reference for the Screen Trigger Register. Any TAG of the proper

STR –

type can be referenced for this setting. The default TAG is labeled “Screen Trigger Reg”.

Power Up Screen –

number is only referenced internally from the NT2S and is not written down to the STR in the PLC.

Serial Port settings:

RS232, Selectable 7 or 8 bit, Odd, Even or No Parity, No handshake, 300, 600, 1200, 2400, 4800, 9600 or 19200

Baud.

NOTE: Serial Communications specifications apply to the Unit - printer setup and do not affect PC to Unit

communications.

Function Key Password –

password will be used throughout the project.

RTC Download Time (NT2S-SF121B-E only) –

here. The values range from 0 to 600 ( seconds ). 0 means the values will be downloaded as fast as possible. Any

other interval will mean that NT2S will wait for the specific time interval before downloading the value into the

PLC.

Version 1.03 Page 7

This setting tells the NT2S which TAG to reference for the LED Register. Any TAG of the proper

Enter the screen number for the screen that should appear at system start-up. This screen

Set the serial port parameters for serial printer connection. The communication is Serial

This password will be applied to any function key that has the password activated. The

Enter the time interval for downloading the RTC tags to the PLC

Page 8

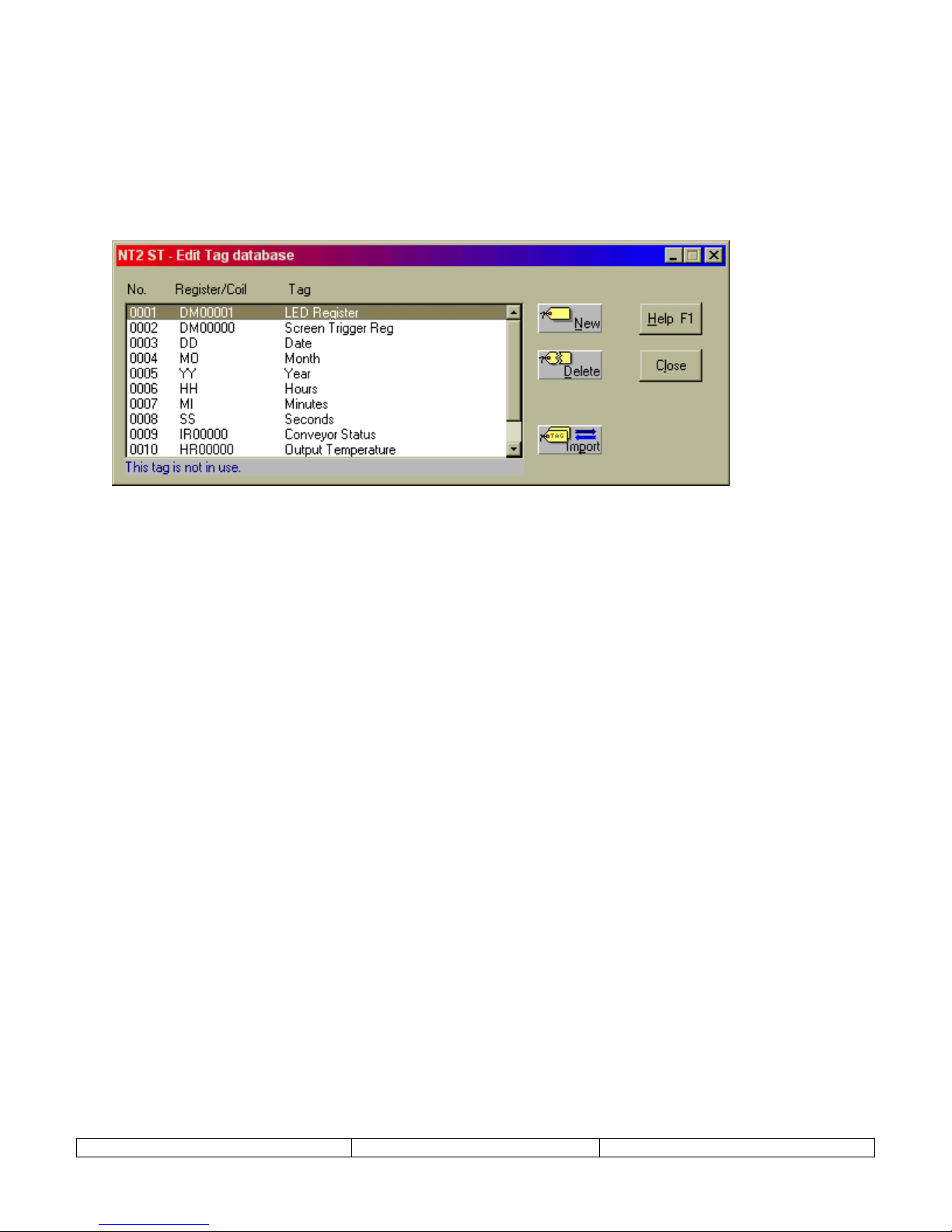

7. TAG DATABASE

Once the project has been created, the very first step should be to define the TAG DATABASE.

The tag database is a list of names (tags) that reference PLC registers or coils (bits). When

programming screens, reference is made to this tag database. Users can choose to reference the

tags either by name or PLC address.

Tags will be referenced while creating the NT2S screens are created. Tags can always be edited

or modified later in the project.

New projects are created a set of default TAGS. For instance, NT2S-SF122B-E has the

following tags:

0001 LED Register |DM00001|

0002 Screen Trigger Reg |DM00000|

NT2S-SF121B-E projects are created with 8 tags. Tags 0003 through 0008 are associated with

the RTC and cannot be directly addressed in NT2ST. Their addresses are offset from the LED

Register address. The tags are defined as follows:

0001 LED Register |DM00001|

0002 Screen Trigger Reg |DM00000|

0003 Date

0004 Month

0005 Year LED Register + 3 (Lower byte) ---- Year (YY)

0006 Hours LED Register + 1 (Higher byte) ---- Hours (HH)

0007 Minutes LED Register + 1 (Lower byte) ---- Minutes (MI)

0008 Seconds LED Register + 2 (Higher byte) ---- Minutes (MI)

LED Register + 2 (Lower byte) ---- Date (DD)

LED Register + 3 (Higher byte) ---- Month (MO)

Version 1.03 Page 8

Page 9

CREATE A REGISTER

A tag can reference an entire word in PLC memory, called a register. Use the following steps to

create a tag for a register:

1. Select

Tag Database

from the

Edit

menu.

2. From the Tag Database editor dialog (shown above), choose NEW.

3. Select the Register button.

4. Choose the PLC memory location from the provided list box.

5. Select the specific register number in the address box provided.

6. Enter a tag name in the lower text box.

7. Select ADD button to complete the creation of the register tag.

CREATE A COIL

A tag can reference a bit in PLC memory, called a coil. Use the following steps to create a tag

for a coil:

1. Select

Tag Database

from the

Edit

menu.

2. From the Tag Database editor dialog, choose NEW.

3. Select the Coil button.

4. Choose the PLC memory location from the provided list box.

5. Select the specific register and bit number in the address box provided.

6. Enter a tag name in the lower text box.

7. Select ADD button to complete the creation of the coil tag.

Version 1.03 Page 9

Page 10

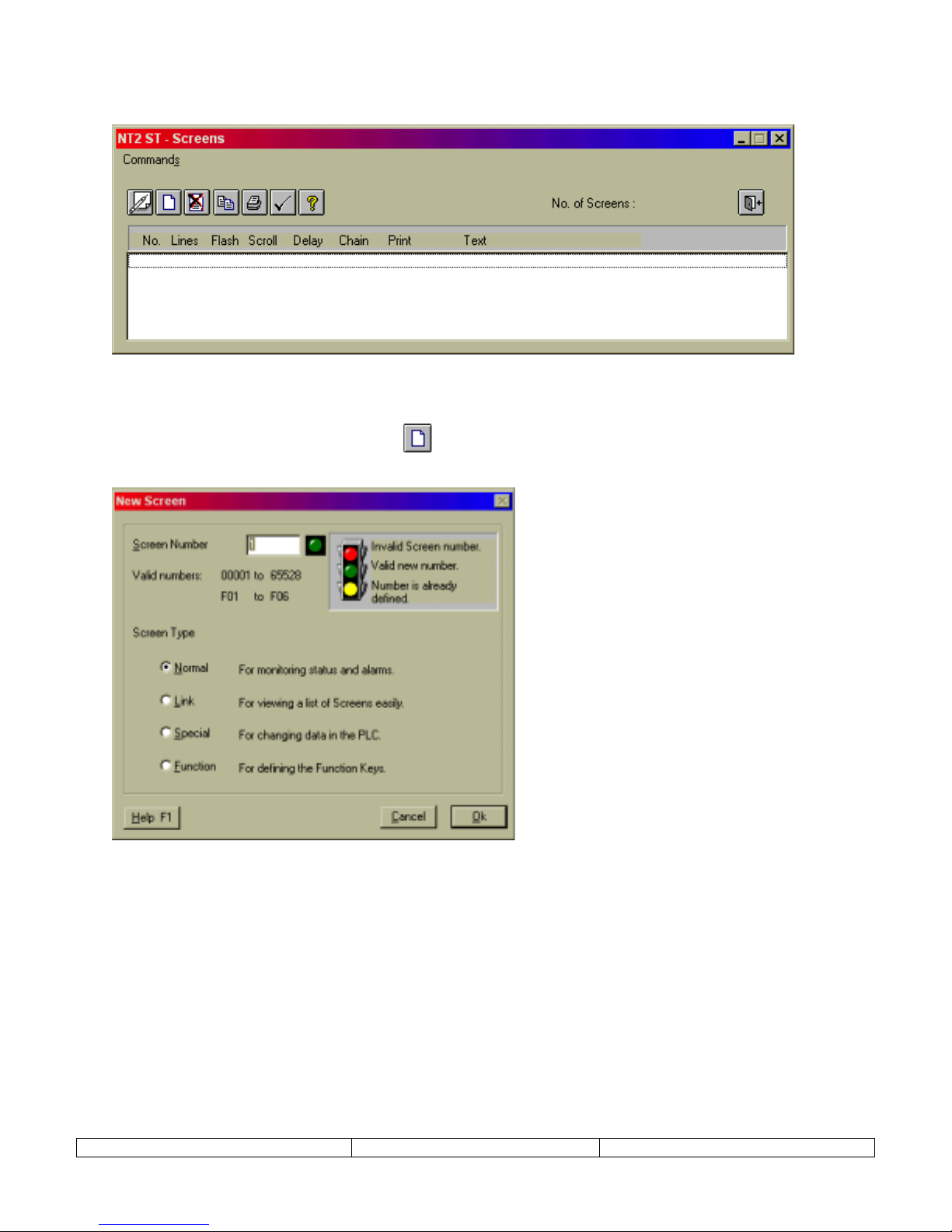

8. EDIT – SCREENS

Launch Screen Editor from EDIT menu. Select SCREENS menu item.

1. From the Edit menu, select the Screens item.

2. Click on the new screen button ! to launch the screen type selection dialog, New

Screen.

3. Four different types of screens can be selected from the New Screen dialog: Normal, Link,

Special, and Function. The following sections will discuss each type of screen. Choose a

screen type, enter a screen number, and select OK to launch the Editing Screen dialog.

Version 1.03 Page 10

Page 11

9. NORMAL SCREEN

Normal screens will make up 90% of all project screens. This type can be used for text message

display, scrolling text messages, display of bit controlled text, display of analog values, and

function key control. The function keys, in red below, can be programmed uniquely for each

normal screen.

The text window in the upper left corner represents the NT2S display window. Some Normal

screen settings include:

DISPLAY HALF – set display for ALL, TOP, or BOTTOM. This is primarily for use with scrolling messages. If

ALL is selected, the scrolling rolls in from the bottom right and then pauses on the top line as the message continues

to scroll in on the bottom. If TOP is selected the message forms a continuous scroll acro ss the top line. Likewise

for the BOTTOM setting.

SCROLL – Set scroll to NO, SLOW, MEDIUM, FAST. Activates scrolling message s. Scro lling messages cannot

display imbedded coil or register values. During NT2S operation, scrolling messages cannot be interrupted. Screen

cannot be changed until the entire scrolling message has been d i splayed.

FLASH – Selection box that allows the NT2S message to blink.

PRINT – Selection box that allows the NT2S screen data to print out the top serial port.

MIN TIME – A minimum time can be assigned to assure an operator can view the screen. If a number is entered in

this field, screens will display for the specified minimum time. This is useful when displaying chained messages,

confirming function key action, or displaying alarm/err or message s .

CHAIN TO – If a screen number is placed in this box, the current screen will be displayed following the specified

screen. The screens in a “chain” will each display for the specified time in the MIN TIME box.

Version 1.03 Page 11

Page 12

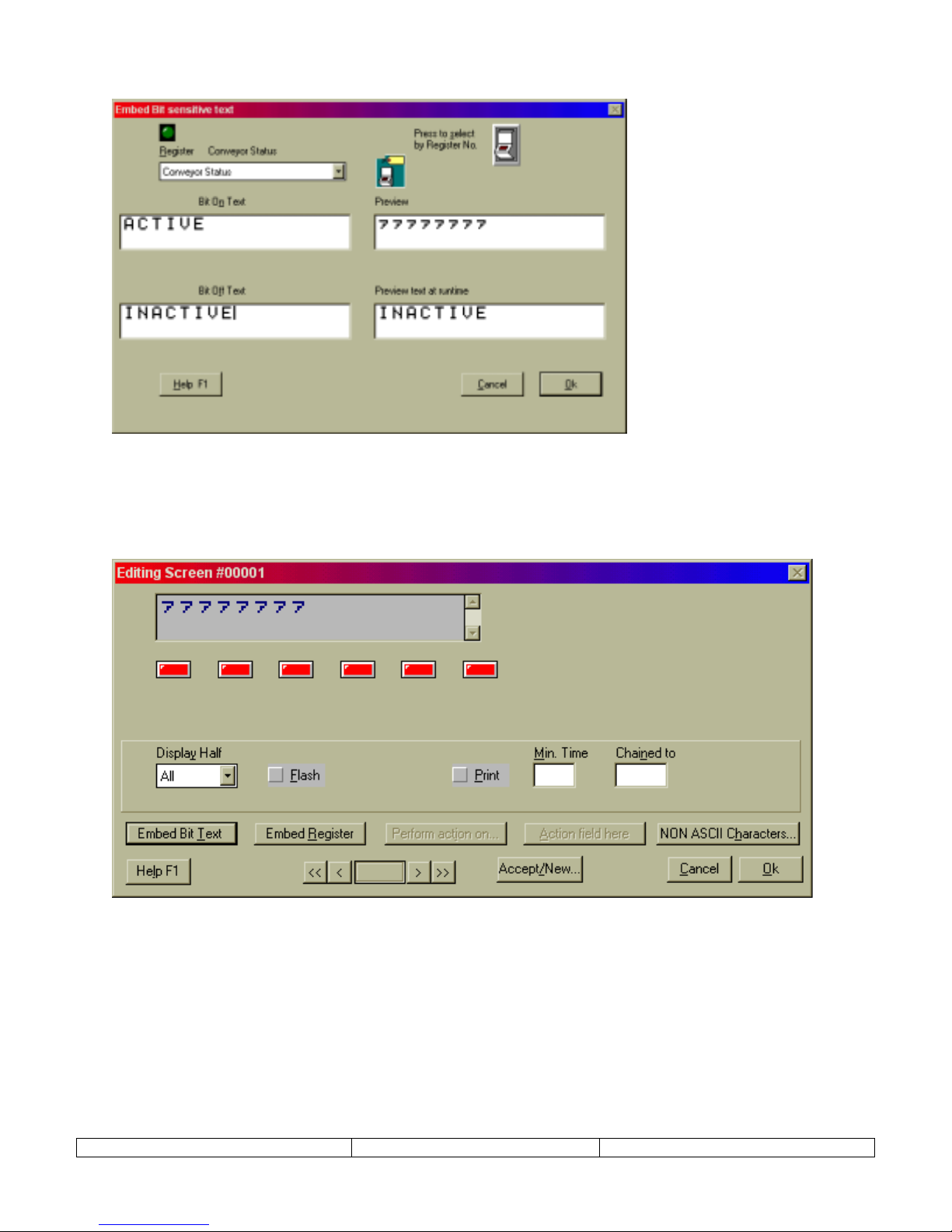

EMBED BIT TEXT – This selection button launches an editing window where letters are assigned to bit val ues.

Once the text is assigned to bit values and OK is selected, text placeholders will appear in the display window.

These placeholders can be positioned by adding characters before the placeholders. In this case, spaces were added

at the far left of the second line to center the text.

The Embedded Bit Text can be edited by selecting a placeholder in the NT2S display window. Choose EDIT from

the menu that will be presented. A DELETE selection will also be pr esented.

Multiple Bit Text elements can be placed on a single NT2S screen. The program will allow up to 32 single

character bit text messages per screen. It is also possible to have one of the states, On or Off, to have no text

displayed.

Version 1.03 Page 12

Page 13

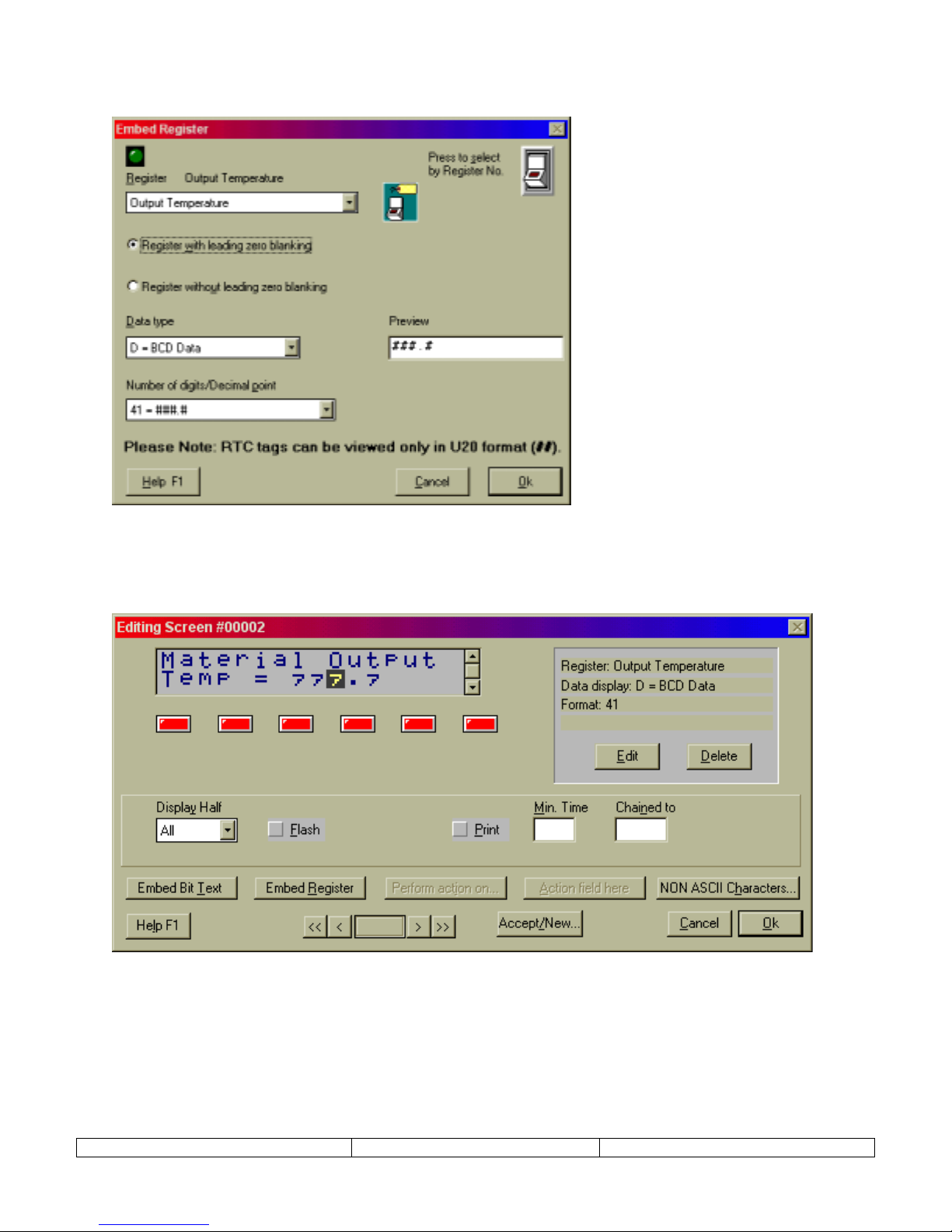

EMBED REGISTER – This selection button launches an editing window for specifying numeric data display. This

editing window allows the selection of data TAG, type, and format.

Once the register is assigned and formatted, select OK. Text placeholders will appear in the display window at the

cursor location. These placeholders can be positioned by adding characters before the placeholders.

The Embedded Register can be edited by selecting a placeholder in the NT2S display window. Choose EDIT from

the menu that will be presented. A DELETE selection will also be pr esented.

Version 1.03 Page 13

Page 14

KEYS FOR SCREEN – The buttons shown in the lower right hand side of the screen dialog are for editing the

function keys for that screen. This would be considered l ocal programming for function keys , effective only for th e

current screen number. Global programming must be performed by creating a Function Key screen, or using the

Edit

menu ,

Function Keys

.

Red keys have not been programmed yet. Green keys have been pr ogrammed.

Double click on the red key to program, or green keys to change programming. The following Editing Key

screens will be displayed. The first dialog box below will be displayed if a register tag is chosen in the register

list box. Choosing a coil tag will display dialog box at the bottom.

Bits can be controlled in several ways. Turn Off and Turn On functions force set the bit to the 0 or 1 positio n.

Toggle alternates the bit between 1 and 0 as the function key is pressed. Hold Off and Hold On set the bit to a 0 or a

1 as long as the function key is held (momentary switch).

Version 1.03 Page 14

Page 15

10. LINK SCREEN

A link screen is a parent screen on which a series of child screens can be displayed. The link

screen is assigned a screen number which can be called by the Screen Trigger Register (STR).

When the link screen number is in the STR, the NEXT(F1) and PREV(F2) function keys can be

used to navigate through the list of specified child screens.

The child screens of the Link Screen can be any existing NORMAL or SPECIAL screen type.

NEXT and PREV functions of the link screen will override any function key programming on F1

and F2 of the child screens.

The progression of screens will follow the order listed in the right window. The order can be

changed using the UP and DOWN keys. Pressing the Next button will show how linked screens

will progress on the NT2S.

Version 1.03 Page 15

Page 16

11. SPECIAL SCREEN

Special screens are used to enter analog values or set digital states. Generally digital states are

more easily set from the Normal screens using function keys and bit controlled text. Only the F1

and F2 keys can be programmed on special screens. F3, F4, F5, and F6 are preprogrammed for

data entry functions.

When creating a Special screen, the first screen to be displayed will be the Edit Action field

dialog.

Operations can be performed on register or coil tags. (Recommend using Special screens only

for changing registers, not coils. Use the function keys of a normal screen for changing coils.)

Operation on Tag include:

-

Edit One Word

Values are entered into the NT2S field using the enter key (F6), up arrow (F3), and left arrow (F4). When

the special screen is displayed, begin the number entry process by pressing the Enter key. The right most

digit will begin blinking. Increment to the digit to the desired value and press the left arrow to shift it over.

Increase the digits and shift them to the left until the desired number is displayed. Then press enter again to

accept the value.

- Numbers are entered highest digit first. Entering the number 521, the user will enter the 5 first, shift it left,

enter the 2 next, shift it left, and then enter a 1 and press enter.

– Assign a value to the sp ecified PLC register using the prepr ogrammed function keys.

A special screen can also perform the following functions.

-

Unsigned Integer - Sends a specified unsigned integer constant value to the specified tag.

-

HEX constant - Sends a specified HEX constant value to the specified tag.

-

Binary constant - Sends a specified Binary constant value to the specified tag.

-

BCD constant - Sends a specified BCD value to the specified tag.

-

Add constant - Sends a specified HEX value to the specified tag.

-

Subtract constant - Sends a specified HEX value to the specified tag .

However, NORMAL screens are recommended for writing constants to memory locations, as

they are much easier to implement.

Version 1.03 Page 16

Page 17

After selecting OK on the Edit Action Field screen, the Editing Screen dialog will appear. The

previous dialog defined the Action Field. Insert the Action Field on to the NT2S screen by

clicking on the ACTION FIELD HERE button on the lower right. Enter text to complete this

screen. Click on the OK button.

Version 1.03 Page 17

Page 18

12. FUNCTION SCREEN

Function screens allow function keys to be defined globally. Function key screens, which can be

created for each key, can have the screen numbers F01, F02, F03, F04, F05, F06. A pop-up

message can be programmed to appear when the function key is pressed. This feature is not

available when programming NORMAL screen function keys. The pop up message is an easy

way to confirm function key key-strokes.

The programming of these Global function keys can be overridden by local function key

programming. It will NOT replace local programming that has already been done. Only keys

with no local programming will perform the global tasks.

Programming begins by clicking on the function key that requires programming. Configure the

action of the function key by clicking on PERFORM ACTION ON button.

Once the action is set, you may choose to enter text in the text window at the upper left. If text is

entered here, a message will be displayed when that function key is pressed. If the field is left

blank, the screen will not change from the current screen.

Bit controlled text, and register information can be placed on the function key pop-up screen

using the EMBED BIT TEXT and EMBED REGISTER buttons in the lower left corner of the

screen.

Select ACCEPT CHANGES TO KEY button when finished programming a function key. Select

another function key number to edit, or select the CLOSE button.

When utilizing the pop-up window feature for the global function keys, it is necessary to enter a

MIN TIME for the screen to display. If no MIN TIME is specified the screen will appear to

quickly to read. Follow the instructions below for editing a Function Key screen to gain access

to this setting.

Version 1.03 Page 18

Page 19

There are two ways to edit a programmed function key screen. Use the

on the

menu item to access the Function Key editing dialog above. Or, click on the screen

Edit

Function Keys

number, F0#, as it appears in the SCREENS dialog, as highlighted below.

The following screen will appear.

selection

Click on the PERFORM ACTION ON button to change global function key program. Enter

MIN TIME to control the time of display of function key message.

Version 1.03 Page 19

Page 20

13. SPECIAL PROGRAMMING NOTES

STR Control from a Function Key

Any function key can be programmed to change the screen by sending a new value to the STR in

the PLC. The STR is defined in the tag database as the Screen Trigger Register tag. The PLC

register will store the value in HEX, so select HEX Constant for the function key operation. If

the user needs to change to screen 25, enter the value 25 in the HEX constant field and the NT2S

will send the HEX value 19 to the STR. Screen 25 will be displayed.

STR Control from the PLC

Since the display can have screen numbers up to 65,528 and the STR is only a four digit register,

the STR is always Hexadecimal. Manipulate the STR in HEX when changing screens from the

PLC. For example, if screen 12 is to be displayed, write the value 000C to the STR. This is

usually done with a copy type command in the PLC ladder program.(Function 21-MOV for

Omron)

Function Key Control Definitions

When programming function keys to control bits in the PLC there are five options for the type of

bit control. After selecting one of the keys you must define a coil tag or address. Next you

choose one of five “Operations” on that tag. The Five Operations and there effect on the PLC

address are as follows:

TURN ON –

Performs a FORCE SET of that bit in the PLC. No other bits in that register are affected

TURN OFF –

Performs a FORCE RESET of that bit in the PLC. No other bits in that register are affected

TOGGLE –

Performs a FORCE SET first time the key is pressed then a FORCE RESET the next time. No

other bits in that register are affected

HOLD ON –

If the bit is ON, there will be no change to the bit. If the bit is OFF the display performs a

FORCE SET of that bit when the key is pressed and a FORCE RESET when released. No other

bits in that register are affected

HOLD OFF –

If the bit is OFF, there will be no change to the bit. If the bit is ON the display performs a

FORCE RESET of that bit when the key is pressed and a FORCE SET when released. No other

bits in that register are affected

Version 1.03 Page 20

Page 21

Entering Text on Second Line of Display

An NT2S can display messages on the top and bottom line for a particular screen. NT2ST

requires a simple step to begin typing text on the second line of the display. Enter characters on

the top line until the cursor is just past the end of the line.

Type any character on the keyboard to initiate the second line. This character will be the first

character on the second line.

Type the second line as it should appear on the NT2S display.

If the characters need to be centered on the second line, click on the first character of the second

line with the mouse button and add spaces using the keyboard.

Remember, the second line can begin with a space, but it cannot be initiated with a space.

Version 1.03 Page 21

Page 22

14. COMMUNICATION CABLES SPECIFICATIONS

OMRON CABLES

NT2S Program Download Cable

Use the standard Omron PLC and NT programming cables:

C200HS-CN220-EU

C200H-CN229-EU

NT2S-SF121B-E pin Designations

NT2S Port PIN #

Designation

Female DB9 Port

2 TX232 (Transmit RS232)

3 RXD (Receive RS232/CMOS)

4&5 Circuit GND

6 VCC (+5V)

7 TXD (Transmit CMOS)

8 PLC Attach

9 Direction Control

NT2S-SF122B-E pin Designations

NT2S Port PIN #

Designation

Male DB9 Port

2 Direction Control

3 TX232 (Transmit RS232)

4 VCC (+5V)

5 Circuit GND

6 TXD (Transmit CMOS)

7 RXD (Receive RS232/CMOS)

8 (same as 7) RXD (Receive RS232/CMOS)

NT2S-SF123B-E pin Designations

NT2S Port PIN #

Designation

Male DB9 Port

4 VCC (+5V)

5 Circuit GND

6 TXD (Transmit CMOS)

7 RXD (Receive CMOS)

8 (same as 7) RXD (Receive CMOS)

Version 1.03 Page 22

Page 23

Omron PLC Peripheral Port Cable (NT2S-SF121B-E):

NT2S Port PIN #

Omron Peripheral Port PIN #

Male DB9

7 TXD (CMOS) 5 RXD

3 RXD 7 TXD

5&9 10 Ground

Short 3, 15, & 17

Short 11 & 16

Metal cover to shield Metal cover to shield

NT2S-CN21#

Omron PLC Peripheral Port Cable (NT2S-SF122B-E and NT2S-SF123B-E):

NT2S Port PIN #

Omron Peripheral Port PIN #

NT2S-CN22#

Male DB9

1&5 shorted

4 Green VCC (+5V) 1 5V source

6 White TXD (CMOS) 5 RXD

7 Yellow RXD (CMOS) 7 TXD

1&5 Brown (GND) 10 Ground

Short 3, 15, & 17

Short 11 & 16

Metal cover to shield Metal cover to shield

Omron PLC Serial Port Connection with NT2S-SF

121

B-E

Tested an NT2S-SF121B-E by connecting it to the Host Link (RS-232C) port on a CQM1 PLC

and it worked fine. This cable is needed to connect to Host Link and has the following pinouts:

NT2S Port PIN #

Male DB9 on cable

Omron Serial Port PIN #

Male DB9 on cable

2 TXD (RS232) 3 RXD

3 RXD 2 TXD

5&9 Ground 9 Ground

1 to shield

4 to 5 short

Omron PLC Serial Port Connection with NT2S-SF

Tested an NT2S-SF122B-E connection to the following PLCs:

- C200H

- CQM1 – directly to serial port

- CPM2A - directly to serial port

- CQM1H – Con nect to Serial Port

- CPM2C – Connect to CPM2C-CN111

– directly to serial port

α

NT2S Port PIN #

Female DB9 on cable

3 TXD (RS232) 3 RXD

4 VCC (+5V) 6 5V Source

2 & 5 Ground 9 Ground

7 RXD (RS232) 2 TXD

Version 1.03 Page 23

B-E

122

Omron Peripheral Port PIN #

Male DB9 on cable

1 to shield

4 to 5 short

Page 24

Allen-Bradley Cables

MicroLogix (DF1 protocol)

NT2S-SF121B-E Port PIN #

Male DB9 on cable

AB Micrologix 1000 & 1500

8 PIN MINIDIN (from AB)

2 TXD (RS232) 4 RXD

3 RXD 7 TXD

5&9 Ground 2 Ground

2 to shield

Allen Bradley SLC 5/0x (DF1 protocol)

NT2S-SF121B-E Port PIN #

Male DB9 on cable

AB SLC 5/0x

Male DB9 on cable

2 TXD (RS232) 2 RXD

3 RXD 3 TXD

5&9 Ground 5 Ground

5 to shield

Version 1.03 Page 24

Page 25

GE Micro Cables

Communication cable connections

HMI end Designation PLC end

SPECIFICATION NOT YET AVAILABLE

: GE Micro

Version 1.03 Page 25

Page 26

Modicon Cables

Modicon (Modbus master)

NT2S-SF121B-E Port PIN #

Male DB9 on cable

Modicon Modbus Master

8 x 8 Modular Connector

2 TXD (RS232) 4 RXD

3 RXD 3 TXD

5&9 Ground 5 Ground

5 to shield

Version 1.03 Page 26

Page 27

Keyence Cables

Keyence KV Series

NT2S-SF121B-E Port PIN #

Male DB9 on cable

Keyence KV Series PLC

4 x 4 Modular Connector

2 TXD (RS232) 3 RXD

3 RXD 1 TXD

5&9 Ground 1 Ground

1 to shield

Version 1.03 Page 27

Page 28

Toshiba Cables

Toshiba PLC T1

NT2S-SF121B-E Port PIN #

Male DB9 on cable

Toshiba PLC T1

8 PIN Minidin Connector

2 TXD (RS232) 8 RXD

3 RXD 6 TXD

5&9 Ground 5 Ground

5 to shield

Toshiba PLC T2

NT2S-SF121B-E Port PIN #

Male DB9 on cable

Toshiba PLC T2

8 PIN Minidin Connector

2 TXD (RS232) 2 RXD

3 RXD 3 TXD

5&9 Ground 5 Ground

5 to shield

Version 1.03 Page 28

Page 29

Koyo Cables

Koyo 405 Series

NT2S-SF121B-E Port PIN #

Male DB9 on cable

Koyo 405 Series

8PIN Minidin Connector

2 TXD (RS232) 3 RXD

3 RXD 2 TXD

5&9 Ground 13, 14, 15 Ground

13, 14, 15 Shield

1, 7, 8 Short

Koyo DL 205

NT2S-SF121B-E Port PIN #

Male DB9 on cable

Koyo 205 Series

6 x 6 Modular

2 TXD (RS232) 3 RXD

3 RXD 4 TXD

5&9 Ground 1 Ground

1 Shield

Koyo DL 305

NT2S-SF121B-E Port PIN #

Male DB9 on cable

Koyo 305 Series

4 x 4 Modular

2 TXD (RS232) 1 RXD

3 RXD 2 TXD

5&9 Ground 4 Ground

4 Shield

Version 1.03 Page 29

Page 30

15. NT2S SPECIFICATIONS

Features Description NT2S-SF121B-E NT2S-SF122B-E

Programming package Windows Software Package - NT2ST Yes Yes

ASCII Controlled Messages ASCII in PLC registers is displayed on the NT2S screen. Pointer in PLC

memory tells NT2S which register to display. Pointers placed in that

PLC register point to data value to be displayed.

Multi-vendor support Omron, Allen-Bradley Micrologix and SLC 5/0x, GE Micro, Modicon,

Keyence KV Series, Toshiba T Series, Koyo 305, 405, and DL205

Series.

Memory type EEPROM 8k 8k

Power 24vdc Term i nals or PLC Peripheral Port 5 vdc 24 vdc 5 vdc

Enclosure ratings IP65 Yes Yes

Standards CE, cCSAus Yes Yes

Ambient Op Rating 0 to 50 C Ok Ok

Storage temp -20 to + 60 C Ok Ok

Ambient Humidity 35 to 85 % with no condensation Ok Ok

Ambient Environment No c o rrosive gasses Ok Ok

Weight 400 g Ok Ok

Panel Fitting 2 c l amps Ok Ok

Face Dimensions Dimensions of NT2S Front Bezel (mm) 109W x 60H 109W x 60H

Rear Unit Dimensions Dimensions for portion of NT2S that enters panel (mm) 91W x 44H x 44D 91W x 44H x 44D

Panel Cutout Recommended panel cutout Dimensions (mm) 1/8 DIN 92W x 45H 92W x 45H

Display Specifications

Display Lines * Characters 2 * 16 2 * 16

Character Height mm 4.35 mm 4.35 mm

Backlit LED Backlight Ok Ok

Effective display area mm 60 x 13 mm 60 x 13 mm

Indicators Red and Green LED indicators. Yes Yes

Number of screens Max number of screens if only text messages are used. Adding function

keys, scrolling messages, etc. decreases the maximum number of

screens.

Data Format HEX, BCD, OCT, BIN, signed, unsigned Ok Ok

Function Keys

Available Function keys Number of user programmable function keys 6 6

Global Function Key Program Function key can be programmed for global functions. Key program is

effective throughout the NT2S program.

Local Function Key Program Function key can be programmed uniquely for each screen. Yes Yes

No No

Yes No

250 250

Yes Yes

Function Key Binary Action Momentary, Toggle On, Toggle Off, Set On, Set Off. Yes Yes

Function Key Numeric Action Set constant value, increment, or decrement by a constant value to PLC

register.

Numeric Entry S pecial screen uses arrow, clear, and enter keys to input numeric values

to PLC register.

Function Key Screen Global Function key actions can be linked to a Function Key screen that

displays upon activation of that function key. This can be used to

confirm function key action.

Password Protect Any Key Password can be activated for any function key. Yes Yes

Yes Yes

Yes Yes

Yes Yes

Version 1.03 Page 30

Page 31

Communications

COM port 1 Programming & Printi ng port DB9 connector

COM port 2 Host PLC Communicati ons DB9 connector

Special functions

Real Time Clock 2-digit Year, Month, Date, Hour, Minut e, Second Yes NA

2 User definable LEDs Red and Green LED can be controlled from PLC Yes Yes

Scrolling Messages Scroll messages up to 256 characters. Yes Yes

Flashing Display Specify for backli ght t o flash. Yes Yes

Minimum Display Time Define minimum display time for a screen. Yes Yes

Screen chaining Chained screens will display in sequential fashion, each displaying for

the set minimum display time.

Link Screen Create a list of screens that can be navigated using the NEXT (F1) and

PREVIOUS (F2) keys.

Bar Graph Display Displ ay numeric values as a bargraph. Yes Yes

Print Functions

Print Screen Configure serial communications port to commumicate with a printer.

Print screen text and displayed PLC data values can be printed.

RS-232 Port

CMOS/RS-232 port

Yes Yes

Yes Yes

Yes Yes

DB9 connector

RS-232 Port

DB9 connector

CMOS port

Version 1.03 Page 31

Loading...

Loading...