Page 1

Cat.No. V056-E1-1

Programmable Terminal

NT4S/NT15S/NT18S

OPERATION MANUAL

Page 2

ii

Page 3

iii

NT4S/NT15S/NT18S

Programmable Terminal

Operation Manual

Produced March 1999

Page 4

iv

Page 5

v

OMRON Product References

All OMRON products are capitalized in this manual. The word ‘Unit’ is also capitalized when it refers to an

OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation ‘Ch,’ which appears in some displays and on some OMRON products, often means ‘word’

and is abbreviated ‘Wd’ in documentation in this sense.

The abbreviation ‘PC’ means Programmable Controller and is not used as an abbreviation for anything else.

The abbreviation ‘Host’ means a controller such as an FA computer which controls a PT (programmable

terminal).

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of information.

Note Indicates information of particular interest for efficient and convenient operation of

the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

e OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Page 6

vi

Page 7

vii

TABLE OF CONTENTS

PRECAUTIONS ...................................... xi

1 Intended Audience ............................................................... xii

2 General Precautions .............................................................. xii

3 Safety Precautions ................................................................ xii

SECTION 1

The Terminals of the NT-Series ........................ 1

1.1 Front View ....................................................................... 4

1.2 Keyboard......................................................................... 8

1.3 Rear View........................................................................ 16

1.4 Mounting the Terminals........................................................... 21

1.5 Pin Assignments .................................................................. 31

1.6 Shield ............................................................................ 36

1.7 Display........................................................................... 37

1.8 User-Mode Switch ................................................................ 41

1.9 Battery ........................................................................... 42

1.10 Fuse.............................................................................. 43

1.11 Application Memory.............................................................. 43

SECTION 2

Technical Data ........................................ 45

2.1 NT4S-SF121B-E .................................................................. 47

2.2 NT4S-SF122B-E .................................................................. 48

2.3 NT4S-SF123B-E .................................................................. 50

2.4 NT15S-SF121B-E ................................................................. 51

2.5 NT18S-SF121B-E ................................................................. 53

SECTION 3

Operating Modes ...................................... 55

3.1 Setting the Operating Mode ....................................................... 57

SECTION 4

Standard Mode ........................................ 59

4.1 Setting the Operating Mode ....................................................... 63

4.2 Startup Process ................................................................... 64

4.3 Communication in the Standard Mode............................................. 65

4.4 Operating Concept................................................................ 65

4.5 Masks ............................................................................ 70

4.6 Variables ......................................................................... 72

4.7 Graphics ......................................................................... 124

4.8 Recipes........................................................................... 126

4.9 Message System .................................................................. 136

4.10 Help System ...................................................................... 155

4.11 Function Keys .................................................................... 156

4.12 System Parameters................................................................ 159

4.13 Version Number .................................................................. 161

4.14 Running Time Meter.............................................................. 161

Page 8

viii

4.15 Parallel Outputs .................................................................. 163

4.16 Screen Saver...................................................................... 163

4.17 Image of the Mask Number ....................................................... 164

4.18 Image of the Mode Selector Switch ................................................ 164

4.19 Terminal Clock ................................................................... 164

4.20 Read Coordination Byte .......................................................... 166

4.21 Write Coordination Byte .......................................................... 168

4.22 Cyclic Poll Area .................................................................. 169

4.23 Control Codes .................................................................... 173

4.24 Cyclic Variables .................................................................. 175

4.25 Interface Parameters.............................................................. 175

4.26 Variable Definition ............................................................... 175

4.27 Application Programming ......................................................... 176

4.28 Downloading the User Description ................................................ 180

4.29 Simulation without the Controller ................................................. 184

SECTION 5

Transparent Mode ..................................... 185

5.1 Setting the Operating Mode ....................................................... 187

5.2 Start-up Processes ................................................................ 187

5.3 Communication in the Transparent Mode.......................................... 188

5.4 Function Setup Menu ............................................................. 189

5.5 Display........................................................................... 191

5.6 Keys ............................................................................. 192

5.7 Interface Control Characters ...................................................... 193

5.8 Error Messages ................................................................... 197

SECTION 6

Linking to OMRON Controllers........................ 199

6.1 OMRON Host-Link .............................................................. 201

6.2 OMRON NT-Link................................................................ 205

INDEX................................................ 213

Revision History ....................................... 217

Page 9

ix

About this Manual:

This manual describes the basic functions and operation procedures of the NT-series programmable terminal

NT4S/NT15S/NT18S, its operations when connected to a PC or a Host, and includes the sections described

below.

Please read this manual carefully and be sure you understand the information provided before attempting to

install and operate the NT-series programmable terminal NT4S/NT15S/NT18S.

Section 1

describes the physical size of the terminals and the electrical connections.

Section 2

describes the electrical and mechanical specifications of the terminals.

Section 3

describes the two operation modes, the standard mode and transparant mode and how to set

these.

Section 4

describes the standard mode in detail.

Section 5

describes the transparant mode in detail.

Section 6

describes how to connect to OMRON PLC using hostlink or NT-Link.

Page 10

x

Related Manuals and Their Contents:

The related manuals are listed below.

The n symbol at the end of the manual number is the revision history number.

[Operating the programmable terminal and communicating with the host]

N NT4S/NT15S/NT18S Programmable Terminal Operation Manual

(V056-E1-n)....................................................This manual

This operation manual is the manual for the NT4S/NT15S/NT18S itself.

This operation manual describes the functions and handling of both the program-

mable terminal body and the host interface function.

[Connecting the NT4S/NT15S/NT18S to PLC’s other than Omron.]

N NT4S/NT15S/NT18S Programmable terminal, multi-vendor connections

(V058-E1-n)

The NT4S/NT15S/NT18S can also be connected to other PLC’s then Omron only.

This manual describes how to connect to other PLC’s.

Page 11

xi

PRECAUTIONS

This section provides general precautions for using the Programmable Terminal.

The information contained in this section is important for the safe and reliable application of the Programmable

Terminal. You must read this section and understand the information contained before attempting to set up or

operate a Programmable Terminal.

1 Intended Audience .................................................................. xii

2 General Precautions ................................................................. xii

3 Safety Precautions ................................................................... xii

Page 12

xii

Precautions

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

N Personnel in charge of introducing FA systems into production facilities.

N Personnel in charge of designing FA systems.

N Personnel in charge of installing and connecting FA systems.

N Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual or

applying the product to nuclear control systems, railroad systems, aviation systems, vehicles, combustion systems, medical equipment, amusement machines,

safety equipment, and other systems, machines and equipment that may have a

serious influence on lives and property if used improperly, consult your OMRON

representative.

Make sure that the ratings and performance characteristics of the product are sufficient for the systems, machines, and equipment, and be sure to provide the systems, machines, and equipment with double safety mechanisms.

This manual provides information for using the Programmable Terminal. Be sure to

read this manual before attempting to use the software and keep this manual close

at hand for reference during operation.

WARNING It is extremely important that Programmable Terminals and related devices be

used for the specified purpose and under the specified conditions, especially in

applications that can directly or indirectly affect human life. You must consult with

your OMRON representative before applying Programmable Terminals to the

above-mentioned applications.

WARNING Do not use input functions such as PT keys for applications where danger to human

life or serious damage is possible, or for emergency switch applications.

3 Safety Precautions

Read these safety precautions carefully and make sure you understand them before using the Programmable Terminal so that you can use it safely and correctly.

Safety Conventions and

their Meanings This operation manual uses the following conventions and symbols to indicate

cautions, warnings, and dangers in order to esure safe use of the NT4S/NT15S/

NT18S.

The caustions, warnings, and dangers shown here contain important information

related to safety. This instructions in these cautions, warnings, and dangers must

be observed.

Page 13

xiii

Precautions

The conventions used and their meanings are presented below.

WARNING Indicates information that, if not heeded, could possibly result in loss of life or seri-

ous injury.

CAUTION Indicates information that, if not heeded, could result in relatively serious or minor

injury, damage to the product, or faulty operation.

Explanation of Symbols

This manual uses the following symbols to indicate notes and hazardous situations.

Notes for the User

General Danger

Specific Danger

Page 14

xiv

Page 15

1

SECTION 1

The Terminals of the NT-Series

This section describes the terminal hardware. This includes all the drawings, the description of the function of

the keys, the electrical connections and the dip-switch settings. It also describes how to mount the terminal.

Furthermore it describes how to handle the battery.

1.1 Front View ................................................................................. 4

1.1.1 NT4S-SF121B-E ..................................................................... 4

1.1.2 NT4S-SF122B-E ..................................................................... 5

1.1.3 NT4S-SF123B-E ..................................................................... 6

1.1.4 NT15S-SF121B-E .................................................................... 7

1.1.5 NT18S-SF121B-E .................................................................... 8

1.2 Keyboard ................................................................................... 8

1.2.1 Editing Keys......................................................................... 9

1.2.2 Control Keys ........................................................................ 10

1.2.3 Special Keys ......................................................................... 10

1.2.4 Function Keys ....................................................................... 11

1.2.4.1 Function Key Arrangement ................................................. 11

1.2.4.1.1 NT4S-SF121B-E ................................................. 11

1.2.4.1.2 NT4S-SF122B-E ................................................. 12

1.2.4.1.3 NT4S-SF123B-E ................................................. 12

1.2.4.1.4 NT15S-SF121B-E ................................................ 13

1.2.4.1.5 NT18S-SF121B-E ................................................ 13

1.2.5 Slide-in Identification Strips for the Function Keys .................................... 14

1.2.5.1 NT4S-SF121B-E ............................................................ 14

1.2.5.2 NT4S-SF122B-E ............................................................ 14

1.2.5.3 NT4S-SF123B-E ............................................................ 15

1.2.5.4 NT15S-SF121B-E ........................................................... 15

1.2.5.5 NT18S-SF121B-E ........................................................... 15

1.3 Rear View .................................................................................. 16

1.3.1 NT4S-SF121B-E ..................................................................... 16

1.3.2 NT4S-SF122B-E ..................................................................... 17

1.3.3 NT4S-SF123B-E ..................................................................... 18

1.3.4 NT15S-SF121B-E .................................................................... 19

1.3.5 NT18S-SF121B-E .................................................................... 20

1.4 Mounting the Terminals ..................................................................... 21

1.4.1 Front Panel Dimensions.............................................................. 22

1.4.1.1 NT4S-SF121B-E ............................................................ 22

1.4.1.2 NT4S-SF122B-E ............................................................ 22

1.4.1.3 NT4S-SF123B-E ............................................................ 23

1.4.1.4 NT15S-SF121B-E ........................................................... 23

1.4.1.5 NT18S-SF121B-E ........................................................... 24

1.4.2 Side View, Mounting Depth .......................................................... 24

1.4.2.1 NT4S-SF121B-E ............................................................ 24

1.4.2.2 NT4S-SF122B-E ............................................................ 25

1.4.2.3 NT4S-SF123B-E ............................................................ 26

1.4.2.4 NT15S-SF121B-E ........................................................... 27

1.4.2.5 NT18S-SF121B-E ........................................................... 28

Page 16

2

1.4.3 Panel Cutout ........................................................................ 29

1.4.3.1 NT4S-SF121B-E ............................................................ 29

1.4.3.2 NT4S-SF122B-E ............................................................ 29

1.4.3.3 NT4S-SF123B-E ............................................................ 30

1.4.3.4 NT15S-SF121B-E ........................................................... 30

1.4.3.5 NT18S-SF121B-E ........................................................... 31

1.5 Pin Assignments ............................................................................ 31

1.5.1 Pin Assignment X1 Supply Voltage ................................................... 32

1.5.2 Pin Assignment X3 SER1 TTY / 20 mA Current Loop ................................ 33

1.5.3 Pin Assignment X3 SER1 RS485 ..................................................... 34

1.5.4 Pin Assignment X3 SER1 RS232c .................................................... 35

1.5.5 Pin Assignment X3 SER2 RS232c .................................................... 35

1.5.6 Pin Assignment X4 Parallel Outputs .................................................. 36

1.6 Shield....................................................................................... 36

1.7 Display ..................................................................................... 37

1.7.1 NT4S-SF121B-E, NT4S-SF122B-E, NT4S-SF123B-E .................................. 37

1.7.2 NT15S-SF121B-E .................................................................... 37

1.7.3 NT18S-SF121B-E .................................................................... 38

1.7.4 Contrast Setting ..................................................................... 38

1.7.5 Default Contrast Setting ............................................................. 38

1.7.6 Character Attributes................................................................. 39

1.7.6.1 Font Normal................................................................ 39

1.7.6.2 Font Zoom ................................................................. 39

1.7.6.3 ASCII Character Set Table.................................................. 40

1.8 User-Mode Switch .......................................................................... 41

1.9 Battery ..................................................................................... 42

1.10 Fuse ........................................................................................ 43

1.11 Application Memory ........................................................................ 43

Page 17

3

The Terminals of the NT-Series Section 1

1 The Terminals of the NT-Series

This manual is only valid for the following operating terminals:

- NT4S-SF121B-E

- NT4S-SF122B-E

- NT4S-SF123B-E

- NT15S-SF121B-E

- NT18S-SF121B-E

The terminals of the NT-series are the favourite Man-Machine-Interfaces for all

applications, where an optimum relation of size to function is needed.

All terminals of the NT-series permit sealed installation in accordance with the IP65

degree of protection.

Each terminal is equipped with function keys, that can be individually labelled with

slide-in strips.

A built-in lithium battery buffers the data in the RAM and also supplies the real time

clock with power.

The discharge state of the battery is monitored constantly by the system.

The communication with a controller and logging printer is supported by a universal

interface, unique for all terminals of the NT-series.

The operator guidance is done by means of a comfortable programming software.

Page 18

4

The Terminals of the NT-Series Section 1-1

1.1 Front View

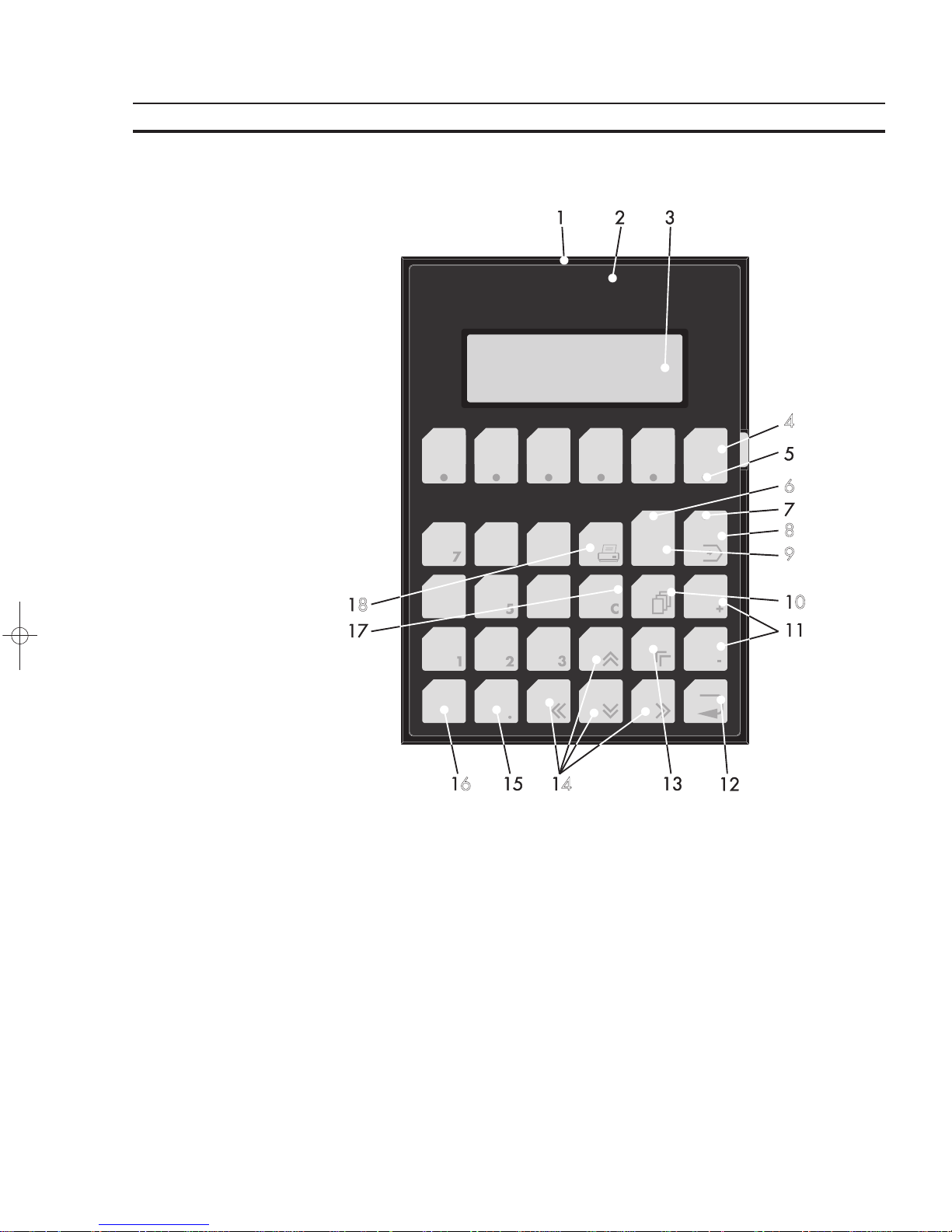

1.1.1 NT4S-SF121B-E

1 Front Panel

2 Front Cover

3 Display

4 Status-LED Function Key (F3)

5 Function Key (F3)

6 Status-LED Function Key (F4)

7 Function Key (F4)

8 Key Enter

9 Key Minus

10 Key Plus

11 Key Cursor Down

12 Key Cursor Left

13 Status-LED Key Help

14 Key Help

15 Status-LED Key Data Release

16 Key Data Release

17 Function Key (F2)

18 Status-LED Function Key (F2)

19 Function Key (F1)

20 Status-LED Function Key (F1)

Page 19

5

The Terminals of the NT-Series Section 1-1

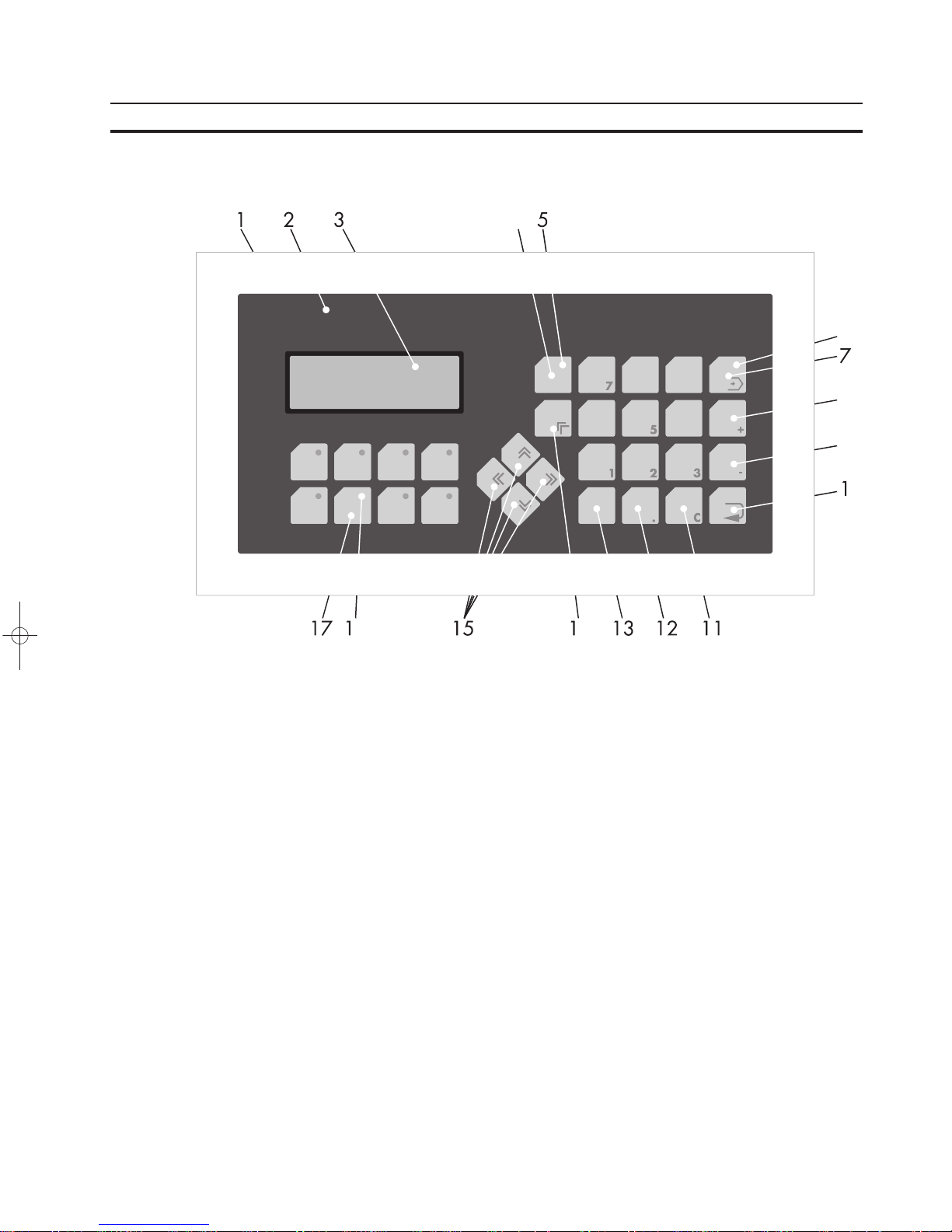

1.1.2 NT4S-SF122B-E

1 Front Panel

2 Front Cover

3 Display

4 Function Key (F6)

5 Status-LED Function Key (F6)

6 Status-LED Key Help

7 Status-LED Key Data Release

8 Key Data Release

9 Key Help

10 Key Scroll

11 Key Plus, Minus

12 Key Enter

13 Key Cursor Home

14 Key Cursor Right, Left, Up, Down

15 Key Dot

16 Keys 0 to 9

17 Key Clear

18 Key Print

Page 20

6

The Terminals of the NT-Series Section 1-1

1.1.3 NT4S-SF123B-E

1 Front Panel

2 Front Cover

3 Display

4 Key Help

5 Status-LED Key Help

6 Status-LED Key Data Release

7 Key Data Release

8 Key Plus

9 Key Minus

10 Key Enter

11 Key Clear

12 Key Dot

13 Keys 0 to 9

14 Key Cursor Home

15 Key Cursor Right, Left, Up, Down

16 Status-LED Function Key (F6)

17 Function Key (F6)

Page 21

7

The Terminals of the NT-Series Section 1-1

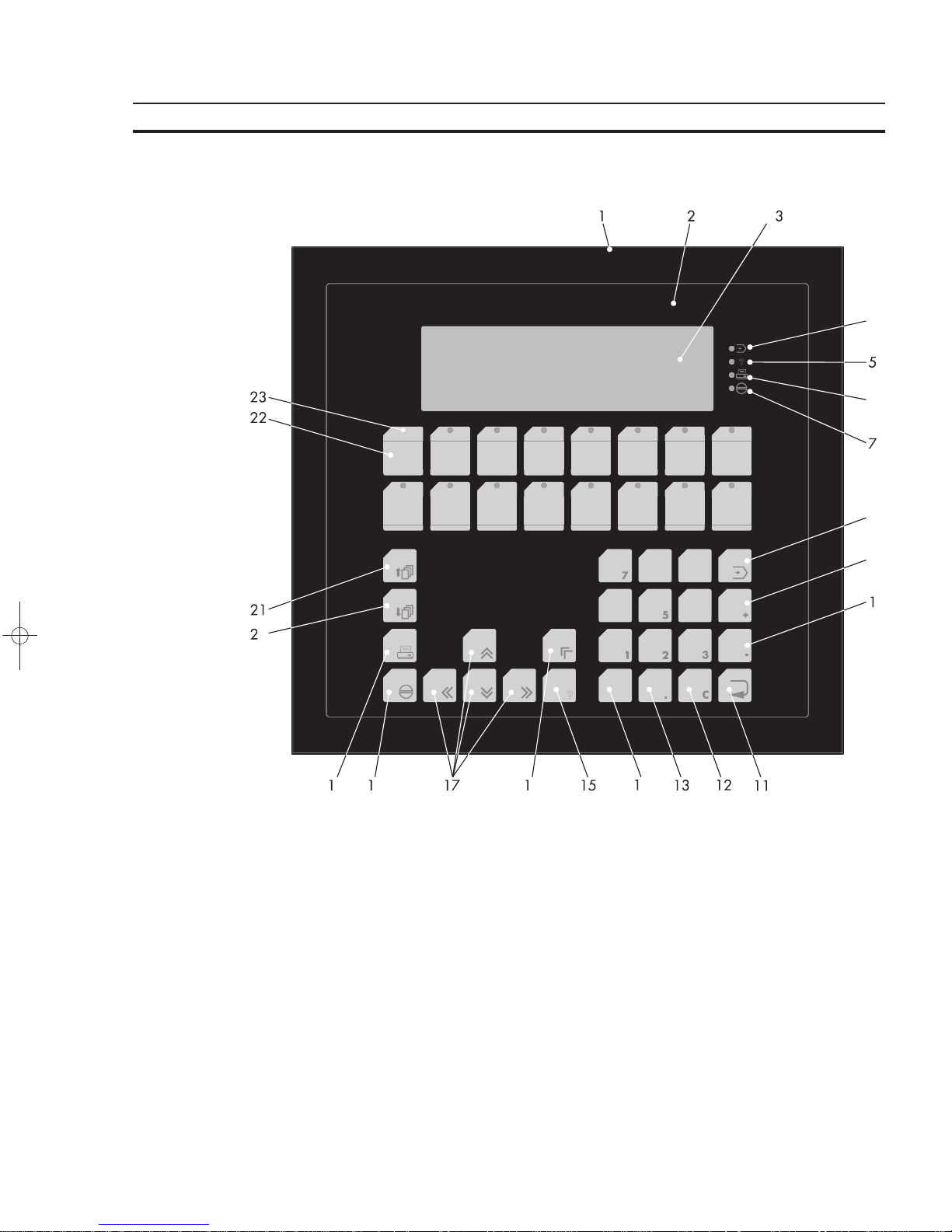

1.1.4 NT15S-SF121B-E

1 Front Panel

2 Front Cover

3 Display

4 Status-LED Data Release

5 Status-LED Help

6 Status-LED Print

7 Status-LED Acknowledge

8 Key Data Release

9 Key Plus

10 Key Minus

11 Key Enter

12 Key Clear

13 Key Dot

14 Keys 0 to 9

15 Key Help

16 Key Cursor Home

17 Key Cursor Right, Left, Up, Down

18 Key Acknowledge

19 Key Print

20 Key Page Down

21 Key Page Up

22 Function Key (F1)

23 Status-LED Function Key (F1)

Page 22

8

The Terminals of the NT-Series Section 1-1

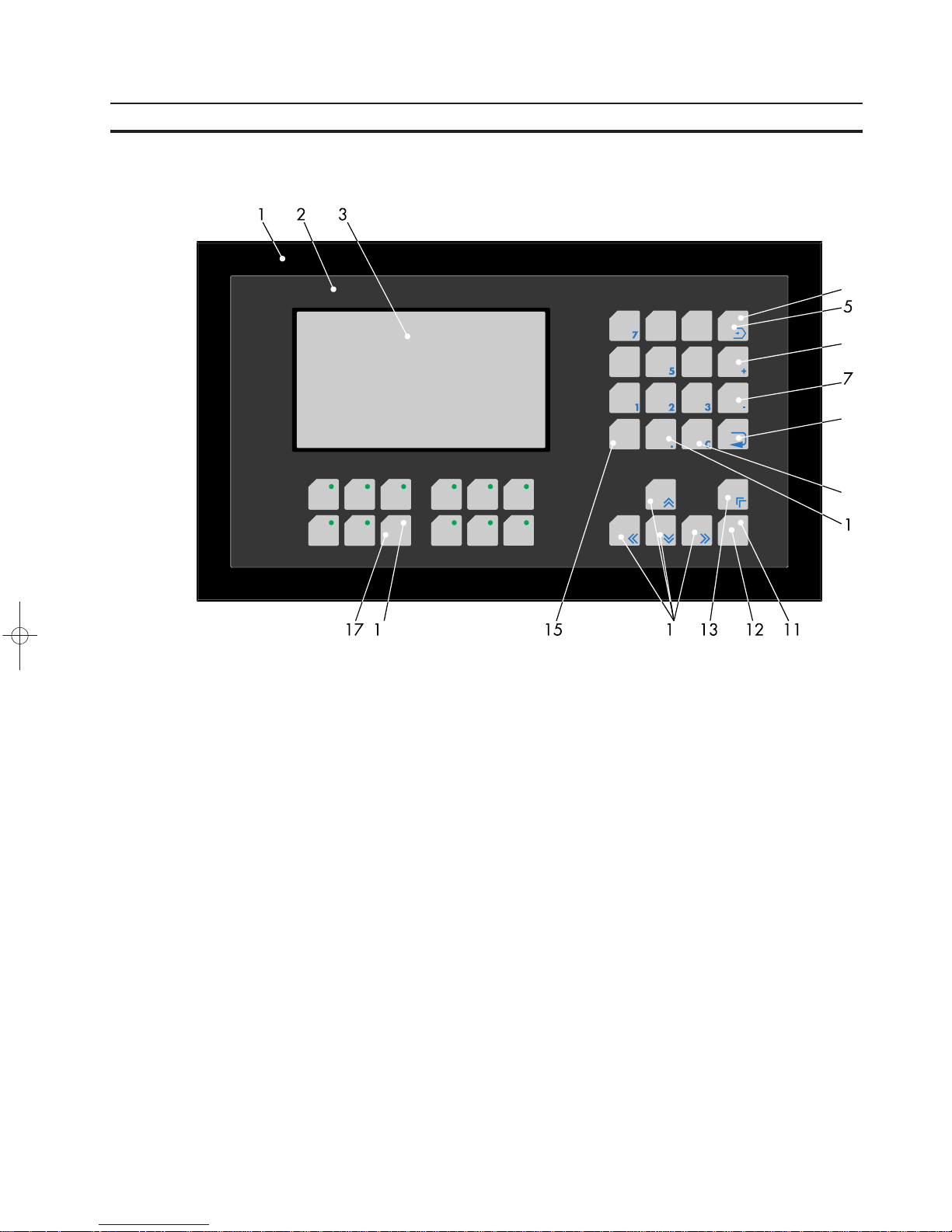

1.1.5 NT18S-SF121B-E

1 Front Panel

2 Front Cover

3 Display

4 Status-LED Key Data Release

5 Key Data Release

6 Key Plus

7 Key Minus

8 Key Enter

9 Key Clear

10 Key Dot

11 Status-LED Key Help

12 Key Help

13 Key Cursor Home

14 Key Cursor Right, Left, Up, Down

15 Keys 0 to 9

16 Status-LED Function Key (F6)

17 Function Key (F6)

1.2 Keyboard

The terminals NT4S-SF121B-E, NT4S-SF123B-E and NT18S-SF121B-E are

equipped with a keyboard made of short-stroke keys. The stroke length is approximately 0.5 mm.

The terminals NT4S-SF122B-E and NT15S-SF121B-E are equipped with a keyboard made of membrane keys. The stroke length is approximately 0.3 mm.

The key area of each key is 16 × 16 mm. The keys are covered by an embossed

polyester sheet which is resistant to environmental effects. These combinations

allows a sensitive use of the keys.

The status-LEDs of the function keys illuminate green. In transparent mode the

keys supply a fixed start and stop code. In standard mode, the function of the keys

is as defined in the application.

Page 23

9

The Terminals of the NT-Series Section 1-2

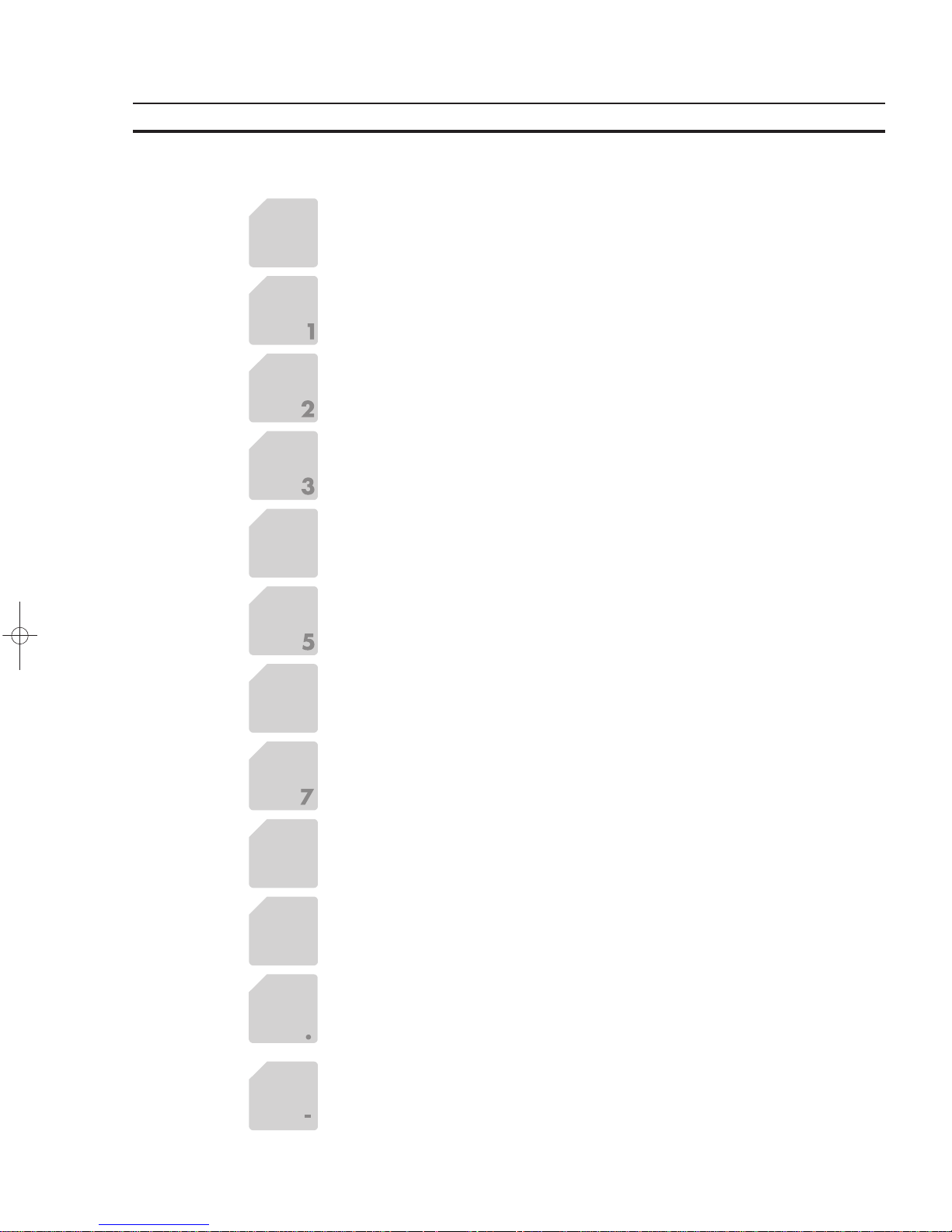

1.2.1 Editing Keys

Key: 0 and ( ) ˚is used to edit data within the editor. If the system variable Shift or

ShiftCase is programmed, the characters ( and ) and ˚can be entered.

Key: 1 and STU is used to edit data within the editor. If the system variableShift or

ShiftCase is programmed, the characters S and T and U can be entered.

Key: 2 and VWX is used to edit data within the editor. If the system variableShift or

ShiftCase is programmed, the characters V and W and X can be entered.

Key: 3 and YZ% is used to edit data within the editor. If the system variableShift or

ShiftCase is programmed, the characters Y and Z and % can be entered.

Key: 4 and JKL is used to edit data within the editor. If the system variableShift or

ShiftCase is programmed, the characters J and K and L can be entered.

Key: 5 and MNO is used to edit data within the editor. If the system variableShift or

ShiftCase is programmed, the characters M and N and O can be entered.

Key: 6 and PQR is used to edit data within the editor. If the system variableShift or

ShiftCase is programmed, the characters P and Q and R can be entered.

Key: 7 and ABC is used to edit data within the editor. If the system variableShift or

ShiftCase is programmed, the characters A and B and C can be entered.

Key: 8 and DEF is used to edit data within the editor. If the system variableShift or

ShiftCase is programmed, the characters D and E and F can be entered.

Key: 9 and GHI is used to edit data within the editor. If the system variableShift or

ShiftCase is programmed, the characters G and H and I can be entered.

Key: Decimal Point and :?! is used to edit data within the editor. If the system

variable Shift or ShiftCase is programmed, the characters : and ? and ! can be

entered.

Key: Minus and \*/ can be used to enter negative values within the editor. In the

increment editor, the variable value is decremented by 1. When the key is held

down, the function is repeated at a rate of repetition that is automatically increased.

If the system variable Shift or ShiftCase is programmed, the characters \ and

* and / can be entered.

Page 24

10

The Terminals of the NT-Series Section 1-2

Key: Plus and ,=. can be used to enter positive values within the editor. In the

increment editor, the variable value is incremented by 1. When the key is held

down, the function is repeated at a rate of repetition that is automatically increased.

If the system variableShift orShiftCase is programmed, the characters , and =

and . can be entered.

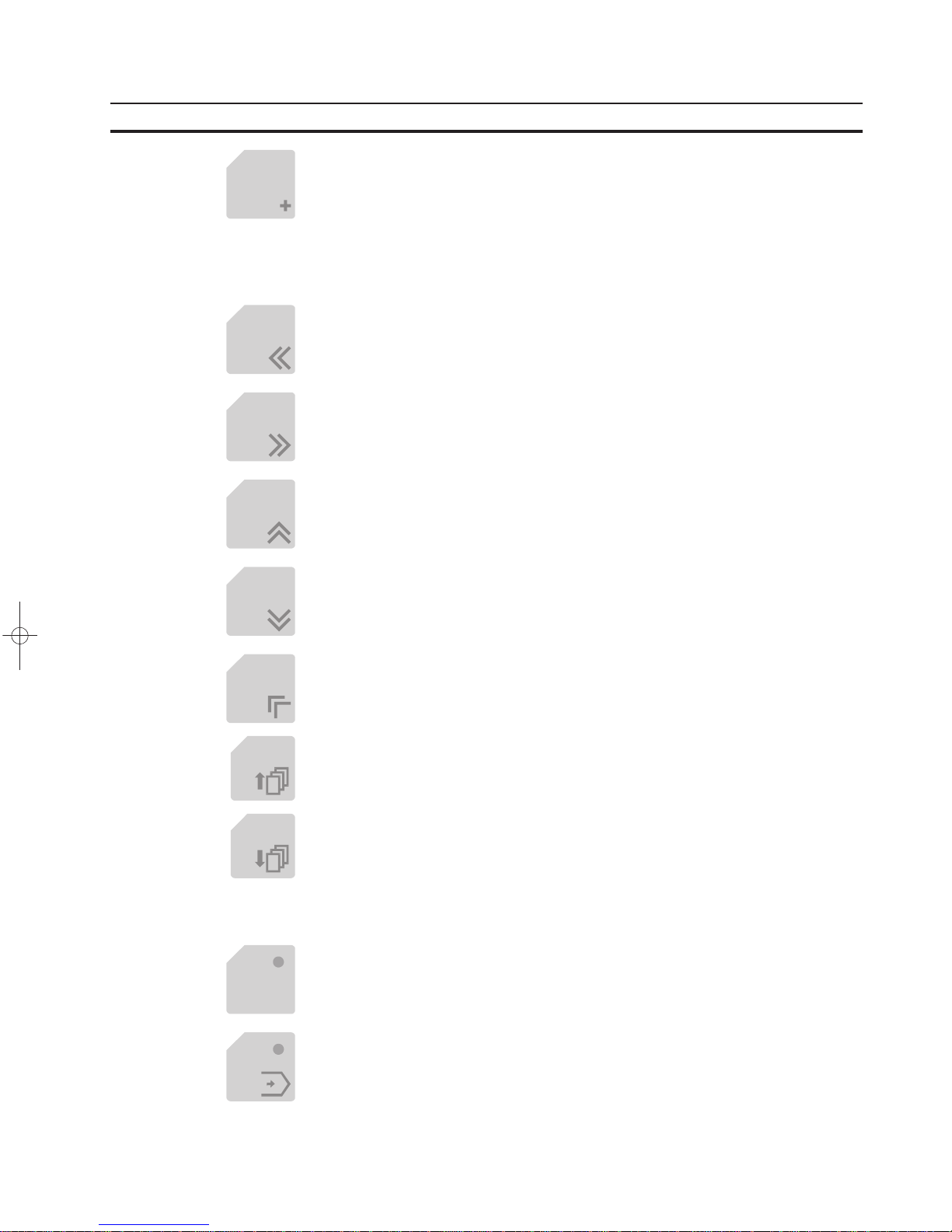

1.2.2 Control Keys

Key: Cursor left can be programmed to directly select I/O masks.

In the editor, it moves the cursor to the left.

Key: Cursor right can be programmed to directly select I/O masks.

In the editor, it moves the cursor to the right.

Key: Cursor up can be programmed to directly select I/O masks.

In the editor, it moves the cursor upwards.

Key: Cursor down can be programmed to directly select I/O masks.

In the editor, it moves the cursor downwards.

Key: Cursor home can be programmed to directly select I/O masks.

In the editor, it moves the cursor to the position of the first input variable.

Key: Page down is used to page through tables, recipes and messages. The func-

tionality corresponds to the system variable ‘TabPgDn’. The key allows data contents towards the bottom of the table to be viewed.

Key: Page upis used to page through tables, recipes and messages. The function-

ality corresponds to the system variable ‘TabPgUp’. The key allows data contents

towards the top of the table to be viewed.

1.2.3 Special Keys

Key: Help keyalways displays the current help text (online help). When the status-

LED help flashes, it signals that an error message is pending. The error or system

message is always displayed in plain-text.

Key: Data Release key is used to switch from a menu into the editor. The status-

LED data release lights up when the editing mode is active. When the Data Release key is pressed within the editor, the editing mode is exited.

Page 25

11

The Terminals of the NT-Series Section 1-2

Key: Enteris used to conclude data entry. When pressed while in the startup mask,

the key switches into the setup mask.

Key: Clear deletes the character beneath the cursor when it is used in an editor.

Deletes the selected messages from the data memory.

Key: Acknowledge is used as an acknowledge key for the message system.

Key: Print can be used as a soft key to activate various print processes.

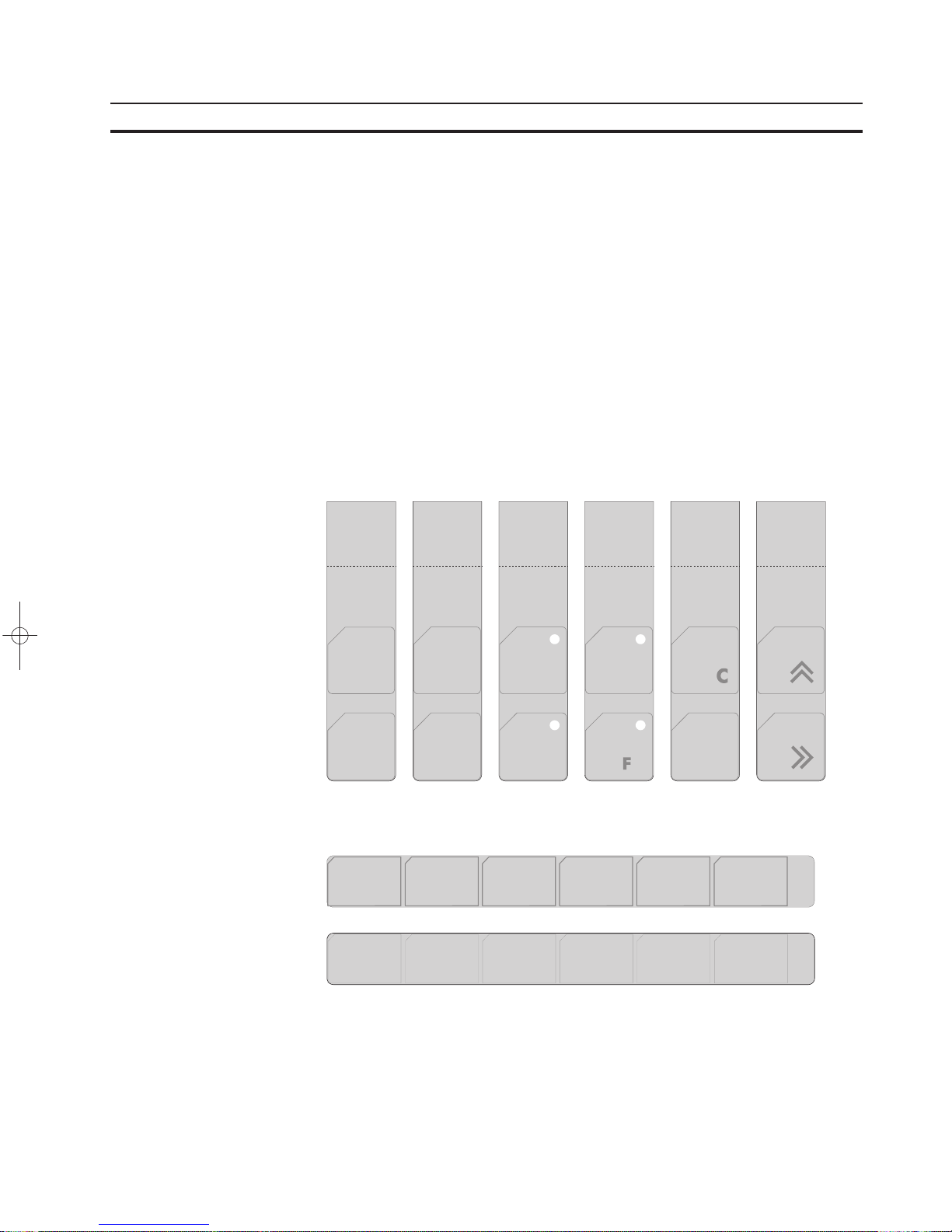

1.2.4 Function Keys

Keys: Function Keys F1 to F16 with status-LEDs for functional feedback. In stan-

dard mode, the key functions can be freely assigned to a soft key functionality;

either as direct keys for menu control or to activate a function in the controller.

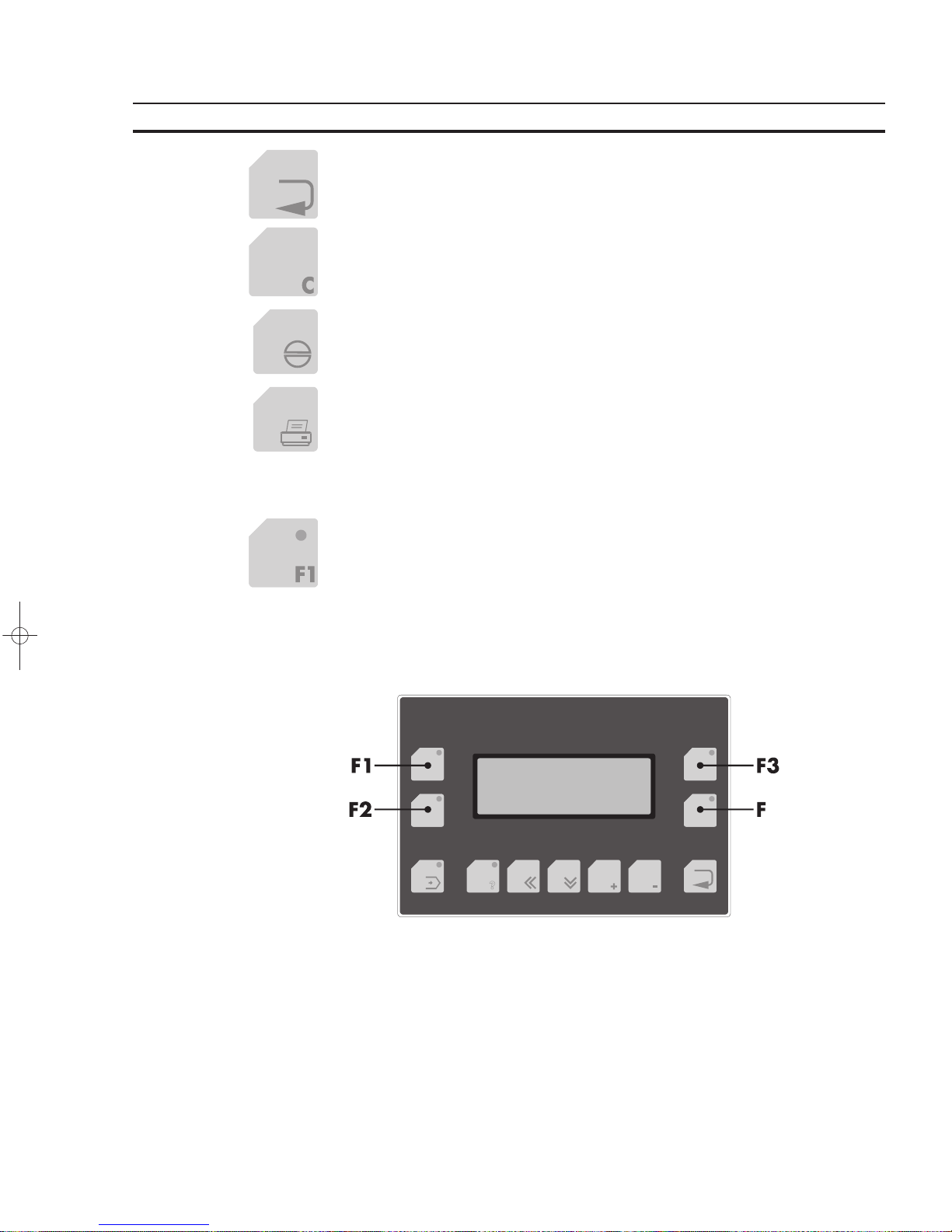

1.2.4.1 Function Key Arrangement

1.2.4.1.1 NT4S-SF121B-E

Page 26

12

The Terminals of the NT-Series Section 1-2

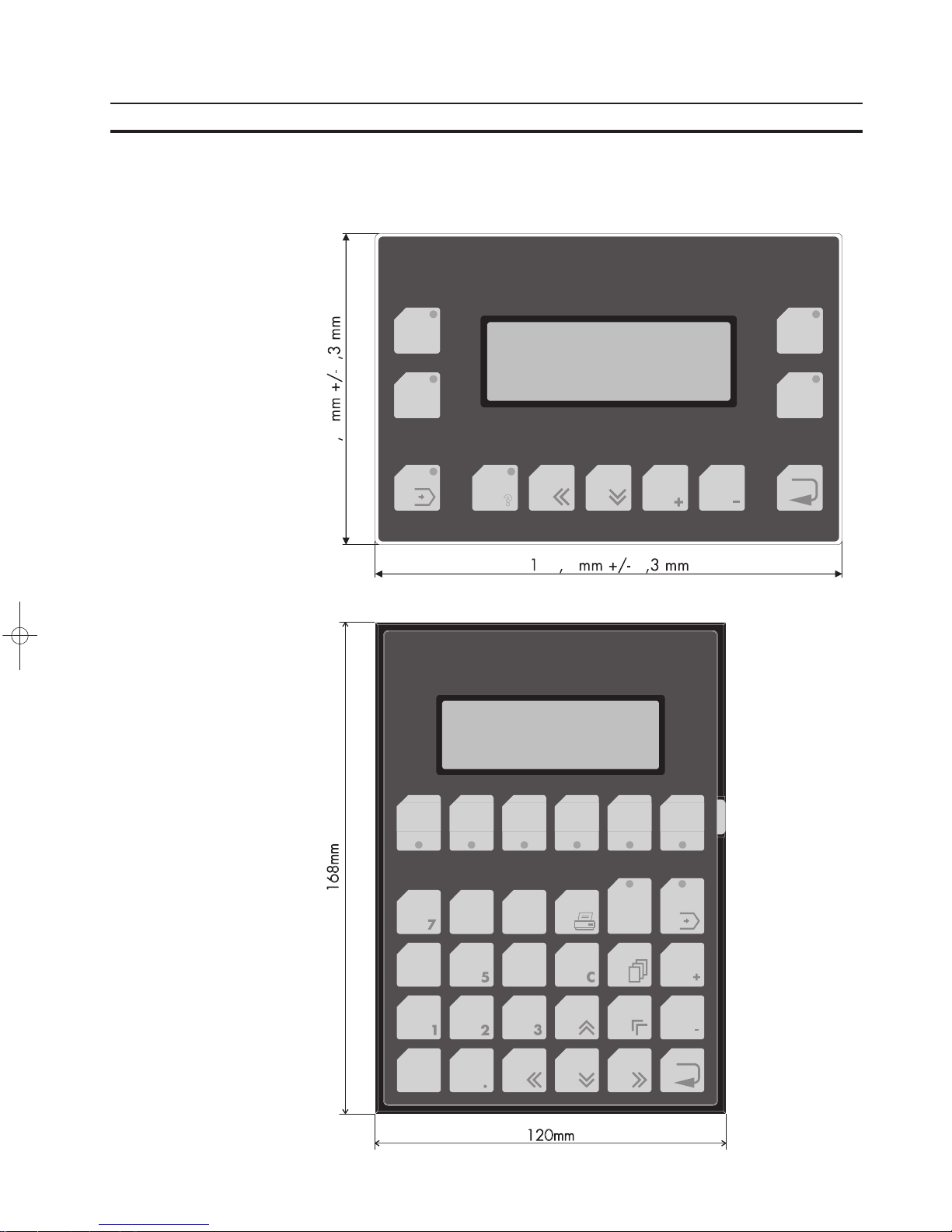

1.2.4.1.2 NT4S-SF122B-E

1.2.4.1.3 NT4S-SF123B-E

Page 27

13

The Terminals of the NT-Series Section 1-2

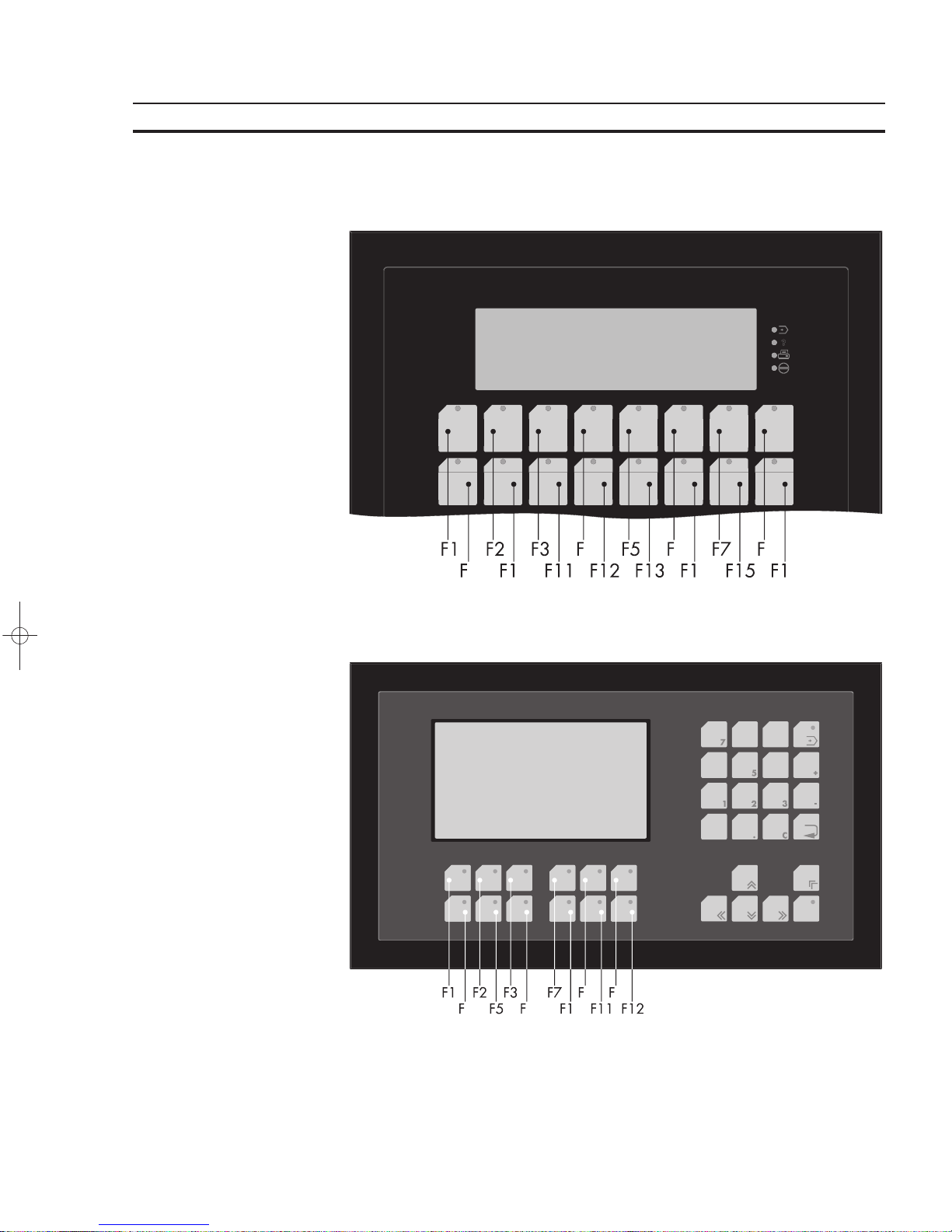

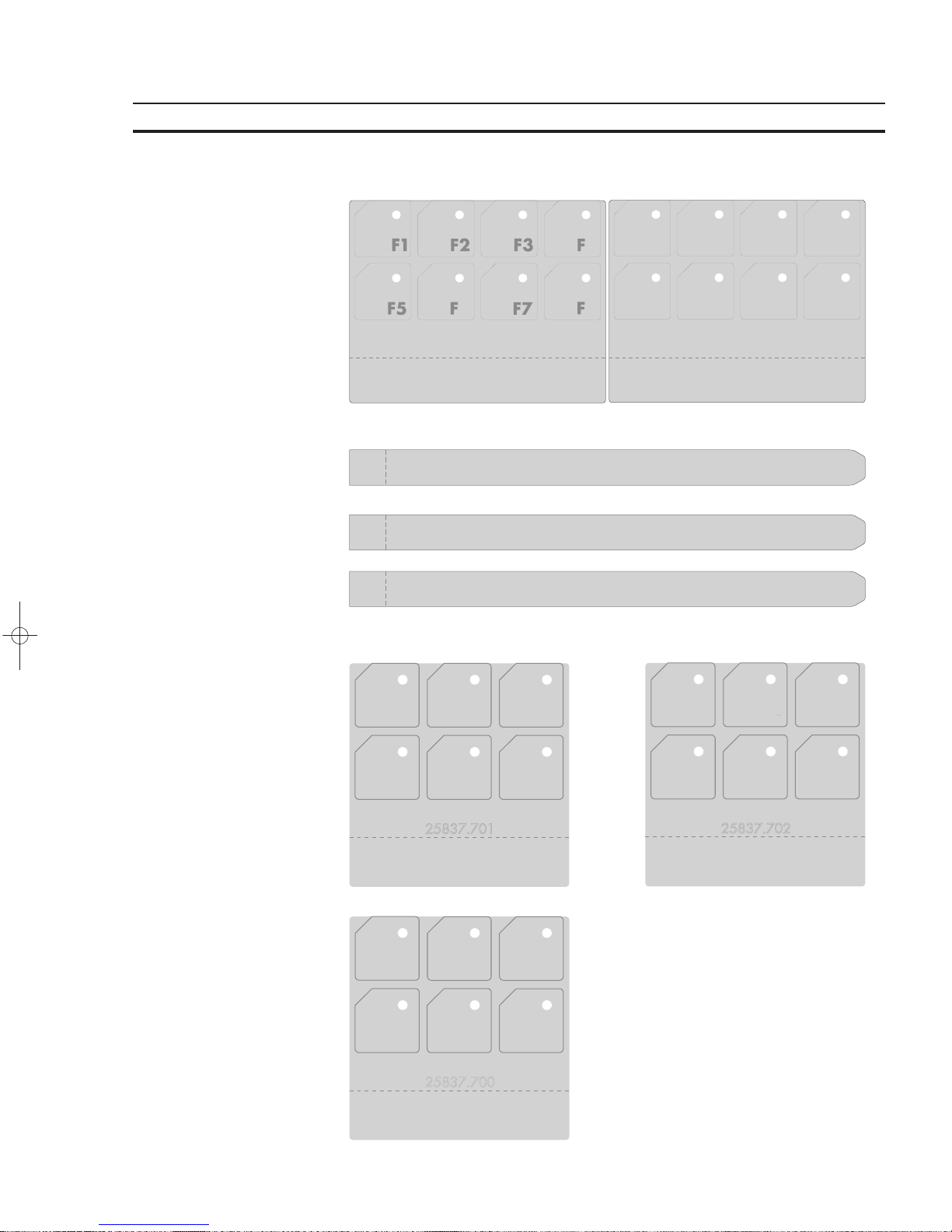

1.2.4.1.4 NT15S-SF121B-E

1.2.4.1.5 NT18S-SF121B-E

Page 28

14

The Terminals of the NT-Series Section 1-2

1.2.5 Slide-in Identification Strips for the Function Keys

The terminals are equipped with a set of slide-in identification strips.

Each set consists of ready-to-use labelled and blank slide-in identification strips.

Various labeling methods are recommended, depending on the number of terminals involved.

Suitable labeling methods for:

single terminal: labeling with an indelible pen

small number of terminals: transparency with laser printing

large number of terminals: identification strips printed according to customer’s

needs

1.2.5.1 NT4S-SF121B-E

1.2.5.2 NT4S-SF122B-E

Page 29

15

The Terminals of the NT-Series Section 1-2

1.2.5.3 NT4S-SF123B-E

1.2.5.4 NT15S-SF121B-E

1.2.5.5 NT18S-SF121B-E

Page 30

16

The Terminals of the NT-Series Section 1-3

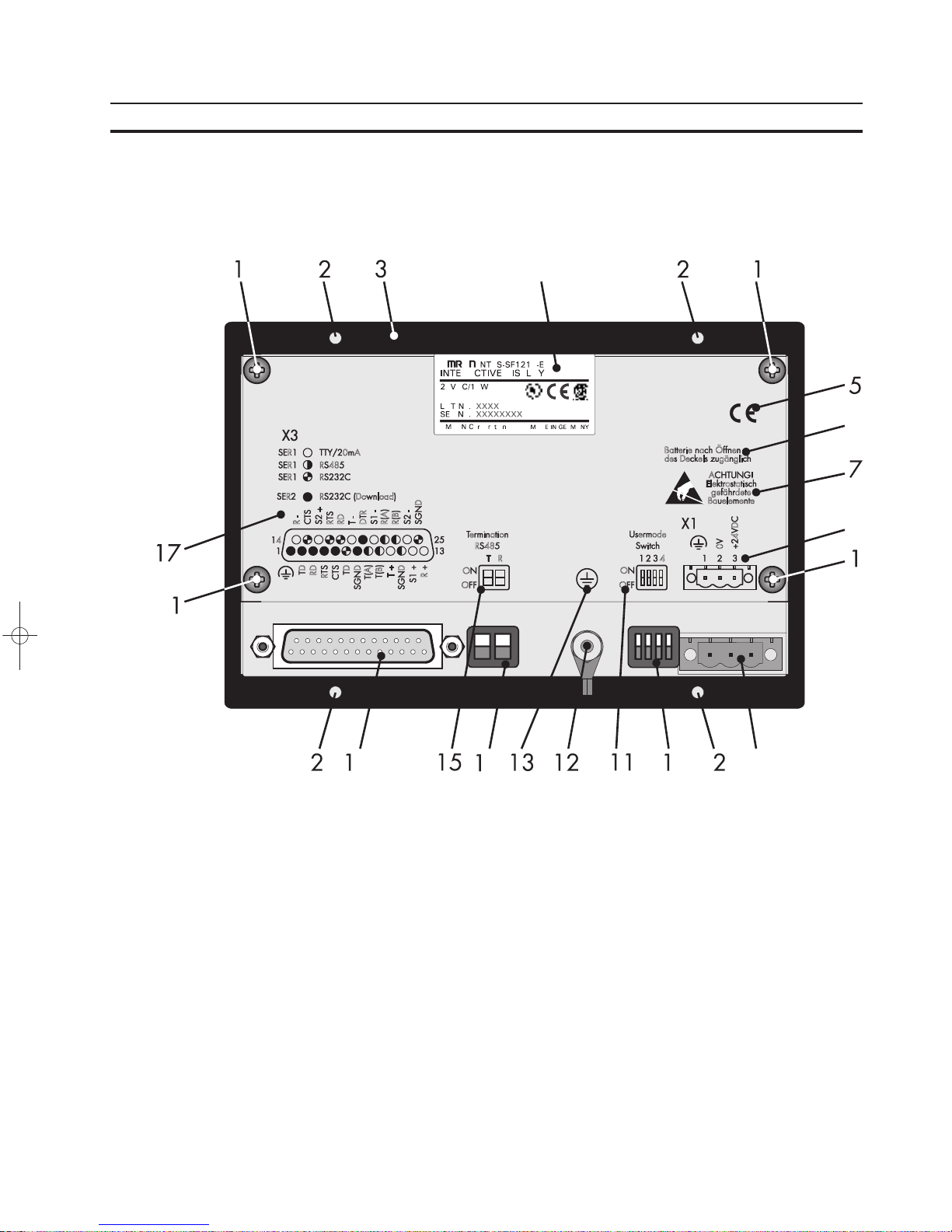

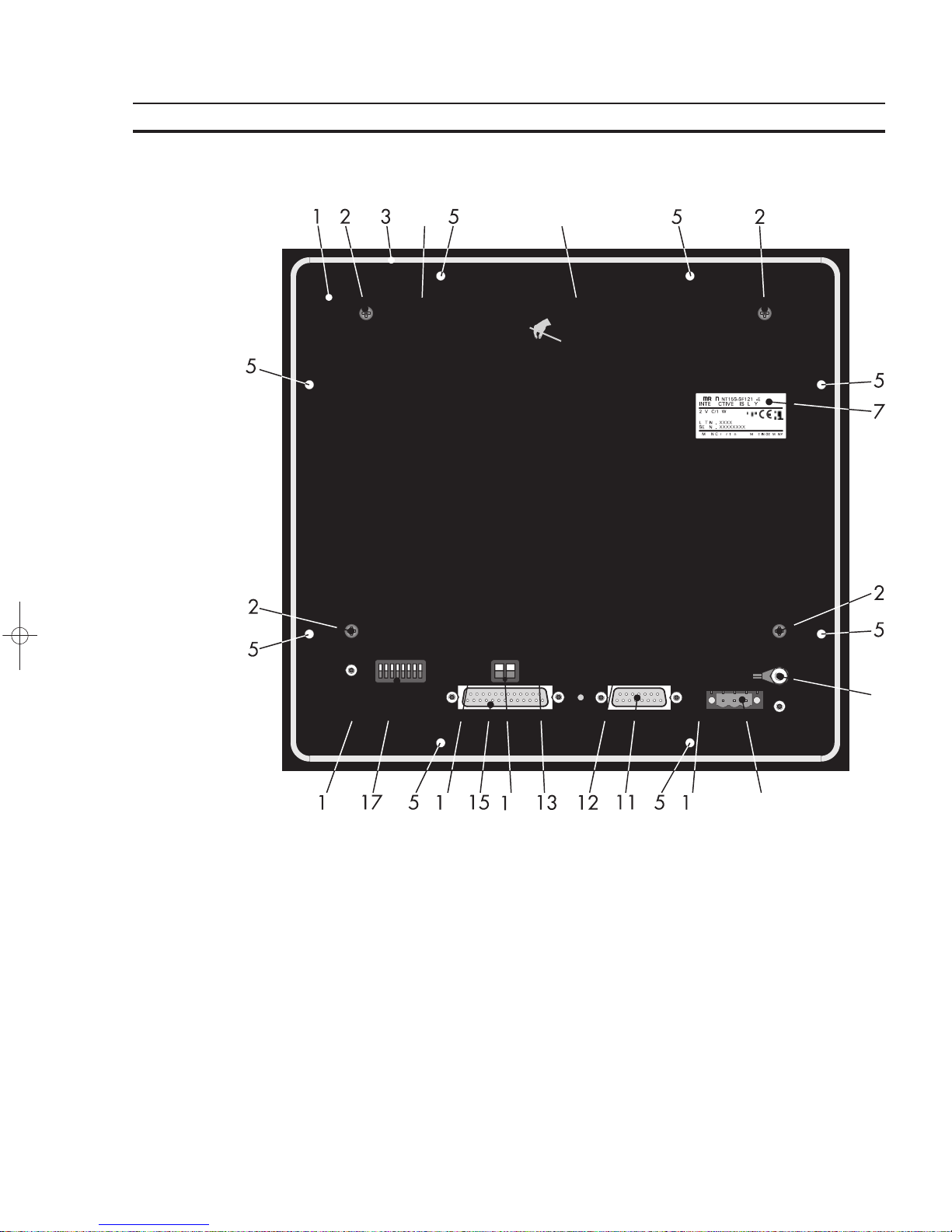

1.3 Rear View

1.3.1 NT4S-SF121B-E

1 Fastening Screw for Enclosure

2 Mounting Bolts

3 Front Panel

4 Name Plate

5 CE-Sign

6 Note for Battery

7 Warning Note

8 Pin Assignment Connector X1

9 Connector X1 (Power Supply)

10 User-Mode Switch

11 Switch Assignment User-Mode Switch

12 Ground Screw

13 Sign for Ground Srew

14 Terminator Switch (RS485)

15 Switch Assignment Terminator Switch

16 Female Connector X2

17 Pin Assignment Female Connector X2

Page 31

17

The Terminals of the NT-Series Section 1-3

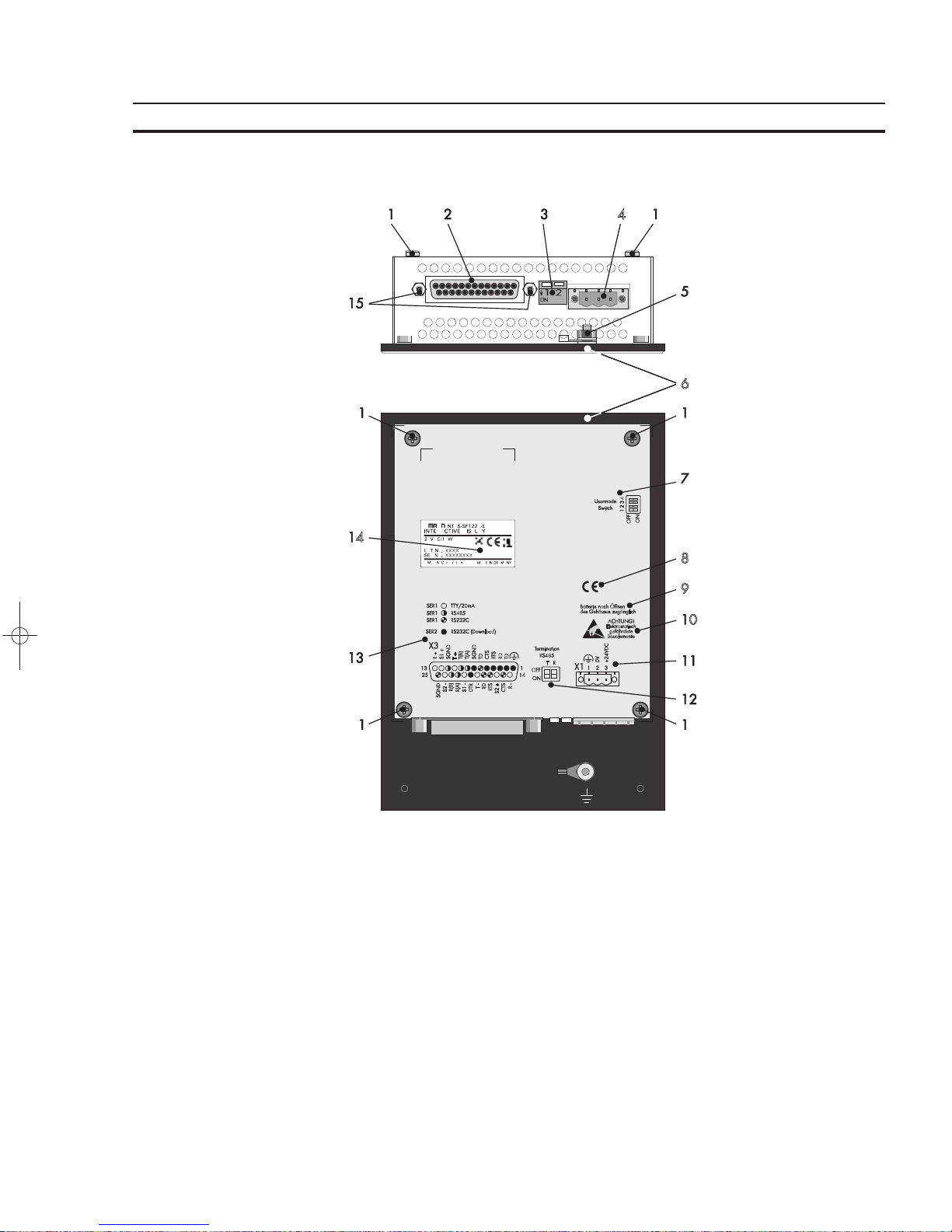

1.3.2 NT4S-SF122B-E

1 Fastening Screw for Enclosure

2 Female Connector X3

3 Terminator Switch (RS485)

4 Connector X1 (Power Supply)

5 Ground Screw

6 Front Panel

7 Switch Assignment User-Mode

Switch

8 CE-Sign

9 Note for Battery

10 Warning Note

11 Pin Assignment Connector X1

12 Switch Assignment Terminator

Switch

13 Pin Assignment Female Connec-

tor X3

14 Name Plate

15 Fastening Screw for Female

Connector X3

Page 32

18

The Terminals of the NT-Series Section 1-3

1.3.3 NT4S-SF123B-E

1 Mounting Bolts

2 Fastening Screw for Enclosure

3 Front Panel

4 Rubber Sealing

5 Name Plate

6 Switch Assignment User-Mode Switch

7 User-Mode Switch

8 Switch Assignment Terminator Switch

9 Terminator Switch (RS485)

10 Pin Assignment Female Connector X3

11 Female Connector X3

12 Fastening Screw for Female Connector X3

13 Pin Assignment Connector X1

14 Connector X1 (Power Supply)

15 Ground Screw

16 Warning Note

17 CE-Sign

18 Note for Battery

Page 33

19

The Terminals of the NT-Series Section 1-3

1.3.4 NT15S-SF121B-E

1 Front Panel

2 Fastening Screw for Enclosure

3 Rubber Sealing

4 Warning Note

5 Mounting Bolts

6 Note for Battery

7 Name Plate

8 Ground Screw

9 Connector X1 (Power Supply)

10 Pin Assignment Connector X1

11 Connector X4 (Parallel Outputs)

12 Pin Assignment Connector X4 (Parallel Outputs)

13 Switch Assignment Terminator Switch

14 Terminator Switch (RS485)

15 Female Connector X3

16 Pin Assignment Female Connector X3

17 User-Mode Switch

18 Switch Assignment User-Mode Switch

Page 34

20

The Terminals of the NT-Series Section 1-3

1.3.5 NT18S-SF121B-E

1 Mounting Bolts

2 Fastening Screw for Enclosure

3 Front Panel

4 Rubber Sealing

5 Warning Note

6 Name Plate

7 Note for Battery

8 Warning Note

9 Switch Assignment Terminator Switch

10 Terminator Switch (RS485)

11 Pin Assignment Female Connector X3

12 Fastening Screw for Female Connector X3

13 Female Connector X3

14 Switch Assignment User-Mode Switch

15 User-Mode Switch

16 Pin Assignment Connector X1

17 Connector X1 (Power Supply)

18 Ground Screw

Page 35

21

The Terminals of the NT-Series Section 1-4

1.4 Mounting the Terminals

The terminals with mounting bolts or lateral mounting slits are mounted from the

rear side. The rear panel mounting is suitable for easy and sealed installation places where the rear side of the unit is accessible.

The terminal NT15S-SF121B-E is mounted from the front side. This type of installation is suitable for easy and sealed installation where the rear side of the unit is

not accessible.

The terminals are particularly suitable for mounting in control cabinets with a

mounting plate thickness of approximately 1 to 10 mm.

The front panels permit sealed installation of the units in accordance with the IP65

degree of protection.

The terminals

- NT4S-SF123B-E

- NT18S-SF121B-E

- NT15S-SF121B-E

have a circumferential groove milled into the rear side of the front plate, containing

a rubber sealing.

The terminals

- NT4S-SF121B-E

- NT4S-SF122B-E

are equipped with a foam sealing on the rear side of the front plate.

All parts for mounting the units are supplied with the spare parts set.

Special care needs to be taken during installation to maintain this high degree of

protection. The appliance is inserted from the front through the mounting panel

cutout and fastened with the fasteners of the spare parts set. The sealing must be

positioned evenly and the fastening elements tightened uniformly.

When installing the terminal, keep a minimum space of 30 mm around the terminal

for adequate air circulation.

The tightness between the front panel and the mounting surface depends on

the care during installation.

Mounting and connection of the operating terminal to the power supply must be

carried out by authorized and qualified personnel with EMC training.

Operating terminals must be grounded according to regulations.

The application-specific safety- and accident prevention regulations must be observed during the mounting and connection to the power supply, e.g.:

- EN 60204, Electrical Equipment of Machines

- EN 292, Safety of Machinery, General Principles for Design

- DIN 57 100 Part 410, Protection against Electric Shock

Hazardous voltages can exist inside electrical installations that can pose a danger

to humans. Coming in contact with live parts may result in electric shock!

Page 36

22

The Terminals of the NT-Series Section 1-4

1.4.1 Front Panel Dimensions

1.4.1.1 NT4S-SF121B-E

1.4.1.2 NT4S-SF122B-E

Page 37

23

The Terminals of the NT-Series Section 1-4

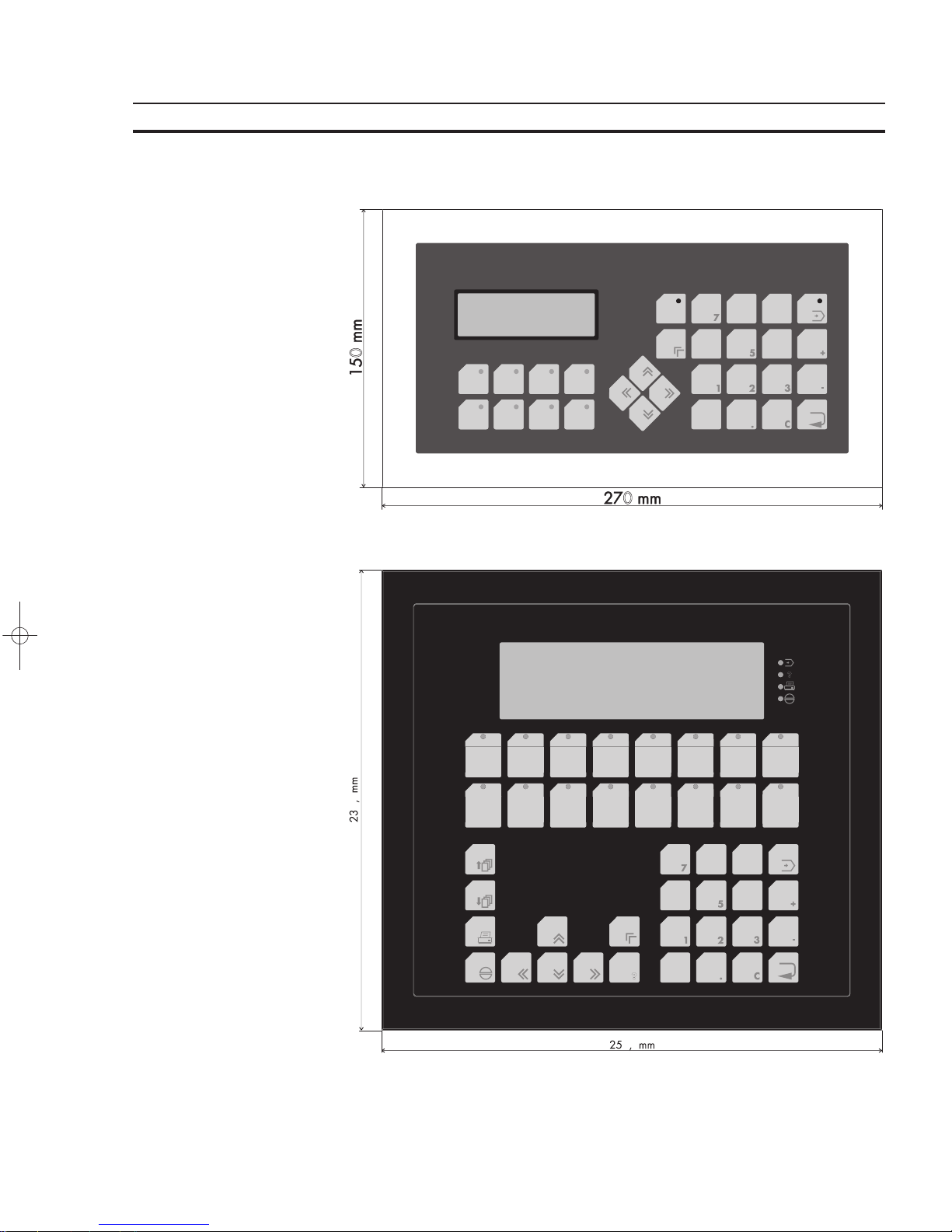

1.4.1.3 NT4S-SF123B-E

1.4.1.4 NT15S-SF121B-E

Page 38

24

The Terminals of the NT-Series Section 1-4

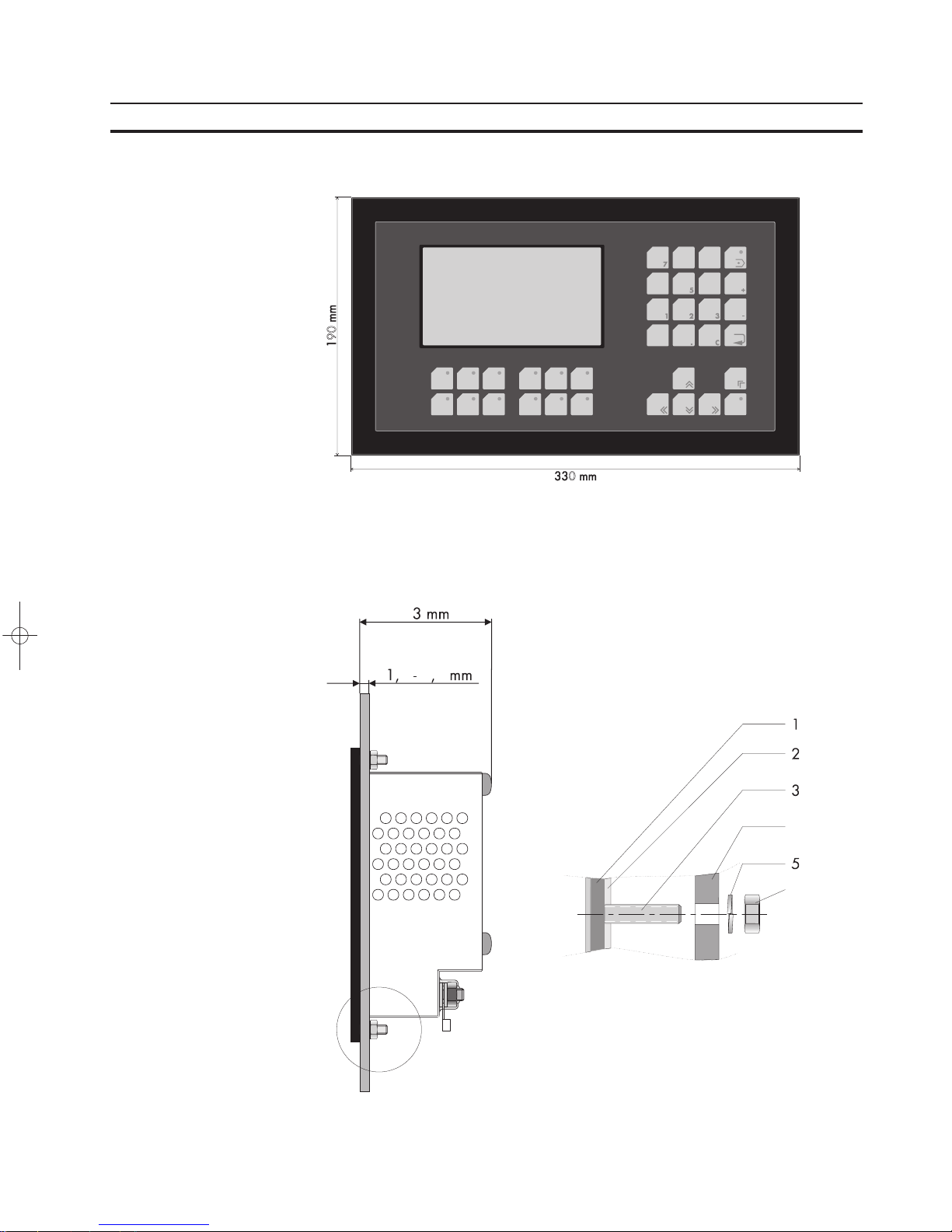

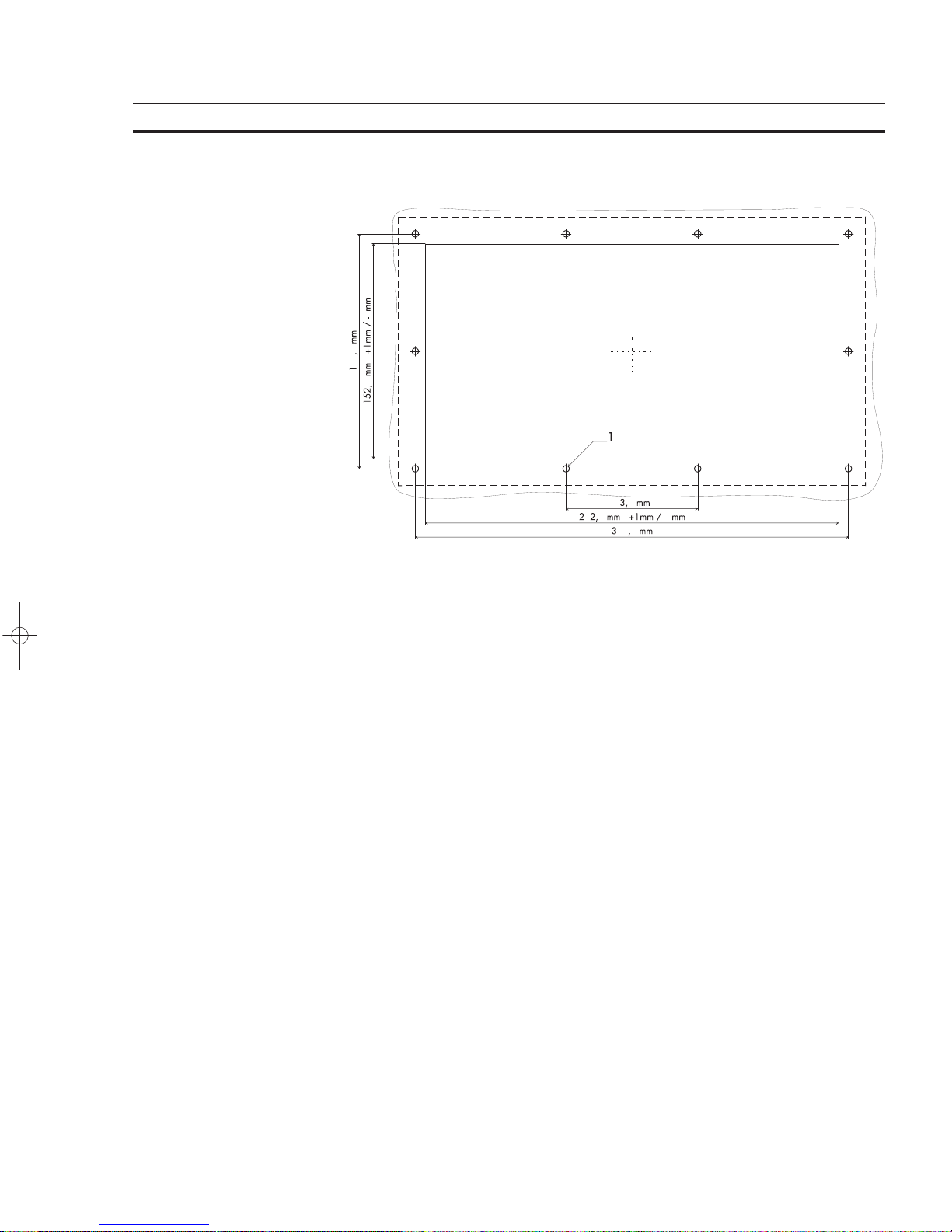

1.4.1.5 NT18S-SF121B-E

1.4.2 Side View, Mounting Depth

1.4.2.1 NT4S-SF121B-E

1 Front Panel

2 Foam Sealing

3 Press-In Threaded Bolt M3 x 9

4 Mounting Surface Thickness 1 to 6 mm

5 Spring Lock Washer B3 DIN127 Form B

6 Nut M3 DIN934

Page 39

25

The Terminals of the NT-Series Section 1-4

1.4.2.2 NT4S-SF122B-E

1 Front Panel

2 Foam Sealing

3 Monting Surface Thickness 1 to

14 mm

4 Threaded Pin DIN 914 M4 x 35

5 Mounting Bracket

Page 40

26

The Terminals of the NT-Series Section 1-4

1.4.2.3 NT4S-SF123B-E

1 Front Panel

2 Circumferential Rubber Sealing

3 Press-In Threaded Bolt M4 x 16

4 Mounting Surface Thickness 1 to 10 mm

5 Spring Lock Washer B4

DIN127 Form B

6 Nut M4 DIN934

Page 41

27

The Terminals of the NT-Series Section 1-4

1.4.2.4 NT15S-SF121B-E

1 Front Panel

2 Circumferential Rubber Sealing

3 Press-In Threaded Bolt M4 x 16

4 Mounting Surface Thickness 1 to

10 mm

5 Spring Lock Washer B4 DIN127

Form B

6 Nut M4 DIN934

Page 42

28

The Terminals of the NT-Series Section 1-4

1.4.2.5 NT18S-SF121B-E

1 Front Panel

2 Circumferential Rubber Sealing

3 Press-In Threaded Bolt M4 x 16

4 Mounting Surface Thickness 1 to

10 mm

5 Spring Lock Washer B4 DIN127

Form B

6 Nut M4 DIN934

Page 43

29

The Terminals of the NT-Series Section 1-4

1.4.3 Panel Cutout

1.4.3.1 NT4S-SF121B-E

1 4 Holes with a Diameter of 3.5 mm

1.4.3.2 NT4S-SF122B-E

Page 44

30

The Terminals of the NT-Series Section 1-4

1.4.3.3 NT4S-SF123B-E

1 6 Holes with a Diameter of 4.5 mm

1.4.3.4 NT15S-SF121B-E

1 8 Holes with a Diameter of 4.5 mm

Page 45

31

The Terminals of the NT-Series Section 1-5

1.4.3.5 NT18S-SF121B-E

1 10 Holes with a Diameter of 4.5 mm

1.5 Pin Assignments

The operating terminals are equipped with a universal interface by default. This

universal interface combines several interface standards within one physical connector. The connector is divided into two channels. The channel for communication

(SER1) is divided from the channel for download/upload/printer (SER2). The channels can operate independent of each other.

The channel for communication (SER1) can handle - specified by protocol - only

one of the three interface standards.

Connector X1 .........24 VDC ...........Supply Voltage

Connector X3 SER1 . ..TTY / 20 mA ......Communication

Connector X3 SER1 . ..RS485 ............Communication

Connector X3 SER1 . ..RS232c ...........Communication

Connector X3 SER2 . ..RS232c ...........Download/Upload/Logging Printer

The operating terminal NT15S-SF121B-E has additional parallel outputs:

Connector X4 .........Parallel Outputs

The parallel outputs are suitable for access of PLC-inputs.

Page 46

32

The Terminals of the NT-Series Section 1-5

1.5.1 Pin Assignment X1 Supply Voltage

The supply voltage is connected via the connector X1.

Connector in the terminal: 3-pin male connector strip Phoenix COMBICON

MSTBV 2,5/3-GF

Pin Designation Function

1

Signal Ground

2 0 V Supply Voltage 0 V

3 24 VDC Supply Voltage 24 VDC

The supply voltage is connected via a plug-in 3-pin female connector strip. The

cable is secured in the female connector strip by means of screw terminals. Cables

with fine wires with a cross-section of up to 2.5mm

2

can be used. The female connector strip is secured in position by means of a screw-type locking.

The female connector strip of the type Phoenix COMBICON MSTB 2.5/3-STF is

supplied.

Hazardous voltages can exist inside electrical installations that can pose a danger

to humans. Coming in contact with live parts may result in electric shock!

Please note with respect to pin assignment:

If shielded connecting cables are used for the supply voltage, the shield should be

connected to the ground screw.

Any protective conductors in the cable must be connected with pin 1.

Separate ground screw for protective grounding

A separate ground conductor must be provided for the ground screw in each case.

The minimum cross-section of the ground conductor must be 1.5 mm

2

. Compliance

with this information increases the operational safety.

Page 47

33

The Terminals of the NT-Series Section 1-5

1.5.2 Pin Assignment X3 SER1 TTY / 20 mA Current Loop

TTY / 20 mA current loop, passive

Pin Designation Channel Function

10 T+ SER1 Transmit Data, Positive Polarity

13 R+ SER1 Receive Data, Positive Polarity

14 R- SER1 Receive Data, Negative Polarity

19 T- SER1 Transmit Data, Negative Polarity

TTY / 20 mA current loop, active

Pin Designation Channel Function

10 T+ SER1 Transmit Data, Positive Polarity

12 S1+ SER1 Power Source 2, Positive Polarity

13 R+ SER1 Receive Data, Positive Polarity

14 R- SER1 Receive Data, Negative Polarity

16 S2+ SER1 Power Source 1, Positive Polarity

19 T- SER1 Transmit Data, Negative Polarity

21 S1- SER1 Power Sink 1, Negative Polarity

24 S2- SER1 Power Sink 2, Negative Polarity

Termination:

When using the channel SER1 as current loop the terminator switches for RS485

must be

switched OFF!

The interface can be connected as either an active or passive current loop depending on the wiring. The transmit line and the receive line are provided with separate

20mA power sources. The compliance voltage is approximately 24 VDC.

The maximum baud rate is 19200Bd. The maximum cable length depends on the

baud rate and rate of transmission errors.

For longer cable lengths, the 20mA power supply should be fed by the transmitting

unit. This can decrease crosstalk on the signal lines considerably.

In idle state (signal logical 1) a current loop of 20 mA can be measured on the cable.

Signal logical 1 - Current flow 20mA

Signal logical 0 - Current flow is interrupted

A shielded cable with twisted pair wires (cable type LiYCY-TP) and a minimum

cross section of 0.08 mm

2

must be used. The maximum cable length is 100 m.

Connect the cable shield to the metal hoods of the connectors over as large a

surface as possible!

Page 48

34

The Terminals of the NT-Series Section 1-5

1.5.3 Pin Assignment X3 SER1 RS485

The interface RS485 is suitable for point-to-point connections and multipoint connections.

Termination for point-to-point connection:

For operation with point-to-point connection the termination must

always be acti-

vated.

Termination for multipoint connection:

For operation with multipoint connections only the termination at the cable end

must be activated.

The signals of the interface are electrically isolated.

The configuration of the hardware can be adapted to different systems. The associated wires are marked with ‘A’ and ‘B’. Some descriptions refer to the pins with ‘+’

and ‘-’, where the following applies: A = + and B = -. The voltage levels comply with

the standards and are defined as follows:

Signal logical 1 - U

A

- UB,= -0.3 V i.e. (UA, UB)

Signal logical 0 - U

A

- UB.= +0.3 V i.e. (UA. UB)

Pin Designation Channel Function

8 T(A) SER1 Transmit Data Channel A

9 T(B) SER1 Transmit Data Channel B

11 SGND SER1 Signal Ground

22 RD(A) SER1 Receive Data Channel A

23 RD(B) SER1 Receive Data Channel B

A shielded cable with twisted pair wires (cable type LiYCY-TP) and a minimum

cross section of 0.34 mm

2

(for 400 m) must be used. The maximum cable length is

400 m.

Connect the cable shield to the metal hoods of the connectors over as large a

surface as possible!

Page 49

35

The Terminals of the NT-Series Section 1-5

1.5.4 Pin Assignment X3 SER1 RS232c

Interface for communication with controller.

Pin Designation Channel Function

1 Shield SER1 Shield

6 TD SER1 Transmit Data

15 CTS SER1 Clear To Send

17 RTS SER1 Request To Send

18 RD SER1 Receive Data

25 SGND SER1 Signal Ground

A shielded cable with stranding in layers (cable type LiYCY) and with a minimum

cross-section of 0.25 mm

2

must be used. The maximum cable length is 15 m.

Connect the cable shield to the metal hoods of the connectors over as large a

surface as possible!

1.5.5 Pin Assignment X3 SER2 RS232c

Interface for download, upload and logging printer.

Pin Designation Channel Function

2 TD SER2 Transmit Data

3 RD SER2 Receive Data

4 RTS SER2 Request to Send

5 CTS SER2 Clear To Send

7 SGND SER2 Signal Ground

20 DTR SER2 Data Terminal Ready

A shielded cable with stranding in layers (cable type LiYCY) and with a minimum

cross-section of 0.25 mm

2

must be used. The maximum cable length is 15 m.

Connect the cable shield to the metal hoods of the connectors over as large a

surface as possible!

Page 50

36

The Terminals of the NT-Series Section 1-5

1.5.6 Pin Assignment X4 Parallel Outputs

Open-collector-outputs, which switch the positive potential, are used as parallel

outputs. These outputs are suitable for direct control of PLC inputs. The outputs

can be activated by means of function keys or the controller. The assignment of

these functions is carried out in the programming software. The parallel outputs are

designed for use in standard mode only.

Technical Data:

Input voltage 24VDC in accordance with EN61131-2

Output Current max. 0.2 A

The outputs are short-circuit-proof!

The voltage supply must be provided externally. Pins 9 through 13 for the negative

potential are connected internally.

Connector in the operating terminal: 15-pin SubminD male connector strip

Pin Designation Function

1 A1 Output 1

2 A2 Output 2

3 A3 Output 3

4 A4 Output 4

5 A5 Output 5

6 A6 Output 6

7 A7 Output 7

8 A8 Output 8

9 0V Negative Potential

10 0V Negative Potential

11 0V Negative Potential

12 0V Negative Potential

13 0V Negative Potential

14 nc Not Connected

15 +U

E

Positive Potential

1.6 Shield

The shield must be connected to the metal hoods of the connector housings at both

ends and over as large a surface as possible. It should be noted that a potential

equalization line with a minimum cross-section equal to 10 times that of the shield

may be necessary as a result of the grounding on both sides.

Page 51

37

The Terminals of the NT-Series Section 1-7

1.7 Display

The displays of the operating terminals either consist of backlight LCD modules of

different sizes and different amounts of functions.

All displays have an optimum viewing angle of approximately 90!.

Also all displays are capable of displaying the enhanced ASCII character set (semi

graphics).

The contrast of the display is stabilized over the full temperature range.

The default contrast can be adjusted at operating time by means of a system variable.

If the display is damaged, do not swallow or breathe in the liquids or gases being

emitted and avoid direct contact with skin.

Danger of Poisoning! Could Result in Burns!

1.7.1 NT4S-SF121B-E, NT4S-SF122B-E, NT4S-SF123B-E

Overview of the technical data:

Type : LCD-Module

Graphics Capability : Semi Graphics Capability

Backlight : LED-Backlight

Background Colour : Yellow-green

Lines (Font Normal) : 4

Characters/Line (Font Normal) : 20

Character Matrix : 5 x 7 Dots + Cursor

Character Height (Font Normal) : 4.3 mm

Visible Display Size : 74.0 mm x 23.0 mm

1.7.2 NT15S-SF121B-E

Overview of the technical data:

Type : LCD-Module

Resolution : 240 x 64 Dots

Graphics Capability : Full Graphics Capability

Backlight : LED-Backlight

Background Colour : Yellow-green

Lines (Font Normal) : 8

Characters/Line (Font Normal) : 40

Character Matrix (Font Normal) : 6 x 8 Dots

Character Matrix (Font Zoom) : 12 x 16 Dots

Dot Colour : Black

Dot Size : 0.49 mm x 0.49 mm

Dot Gap Size : 0.04 mm

Visible Display Size : 134.0 mm x 40.4 mm

Page 52

38

The Terminals of the NT-Series Section 1-7

1.7.3 NT18S-SF121B-E

Overview of the technical data:

Type : LCD-Module

Resolution: 240 x 128 Dots

Graphics Capability: Full Graphics Capability

Backlight : LED-Backlight

Background Colour : White

Lines (Font Normal) : 16

Characters/Line (Font Normal) : 40

Character Matrix (Font Normal) : 6 x 8 Dots

Character Matrix (Font Zoom) : 12 x 16 Dots

Dot Colour : Black

Dot Size : 0.49 mm x 0.49 mm

Dot Gap Size : 0.04 mm

Visible Display Size : 131.0 mm x 72.0 mm

1.7.4 Contrast Setting

The contrast for the display can be adjusted by means of the software. This requires the system variable LCDContrast to be set up in an I/O mask of the application. The value can then be modified using any editor that can handle integer numbers.

The limit values for the contrast must be set to

Lower level: -25

Upper level: +70

If this variable is not defined in the menus or the value is out of the range of values,

the default setting (value 25) will be loaded when the system is initialized.

The system variable can be stated in any I/O-mask of the application!

1.7.5 Default Contrast Setting

If the contrast of the display should be such that the masks are no longer legible, the

default contrast setting can be restored using the user mode switch.

Position of the switch to restore the contrast:

S1 ON

S2 OFF

S3 OFF

S4 ON

This switch position coincides with ‘activating download by hardware’. The contrast

will be reset before the warning is displayed. The warning will be displayed in a

legible manner. Upon display of this warning, switch off the terminal, set the switch

4 to the OFF-position and switch the terminal on again. The application description

is not lost.

Page 53

39

The Terminals of the NT-Series Section 1-7

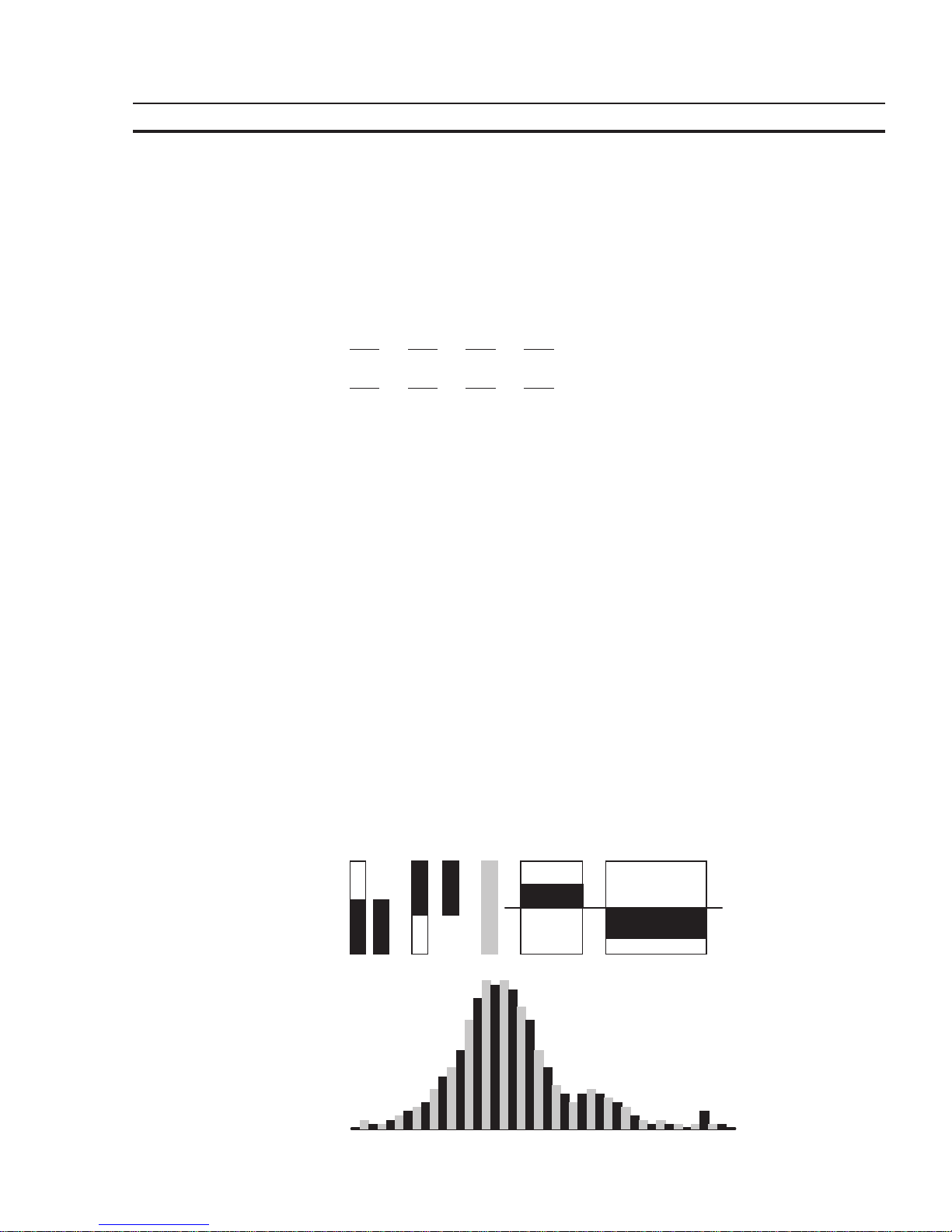

1.7.6 Character Attributes

The characters of the fonts Normal and Zoom can be displayed with different

attributes.

Operating Terminal Normal Flashing Underlined Inverse

NT4S-SF121B-E Yes Yes No No

NT4S-SF122B-E Yes Yes No No

NT4S-SF123B-E Yes Yes No No

NT15S-SF121B-E Yes Yes Yes Yes

NT18S-SF121B-E Yes Yes Yes Yes

1.7.6.1 Font Normal

1.7.6.2 Font Zoom

Page 54

40

The Terminals of the NT-Series Section 1-7

1.7.6.3 ASCII Character Set Table

Page 55

41

The Terminals of the NT-Series Section 1-8

1.8 User-Mode Switch

The user-Mode switch is placed at the side of the terminal NT4S-SF122B-E and at

the rear side of all other terminals.

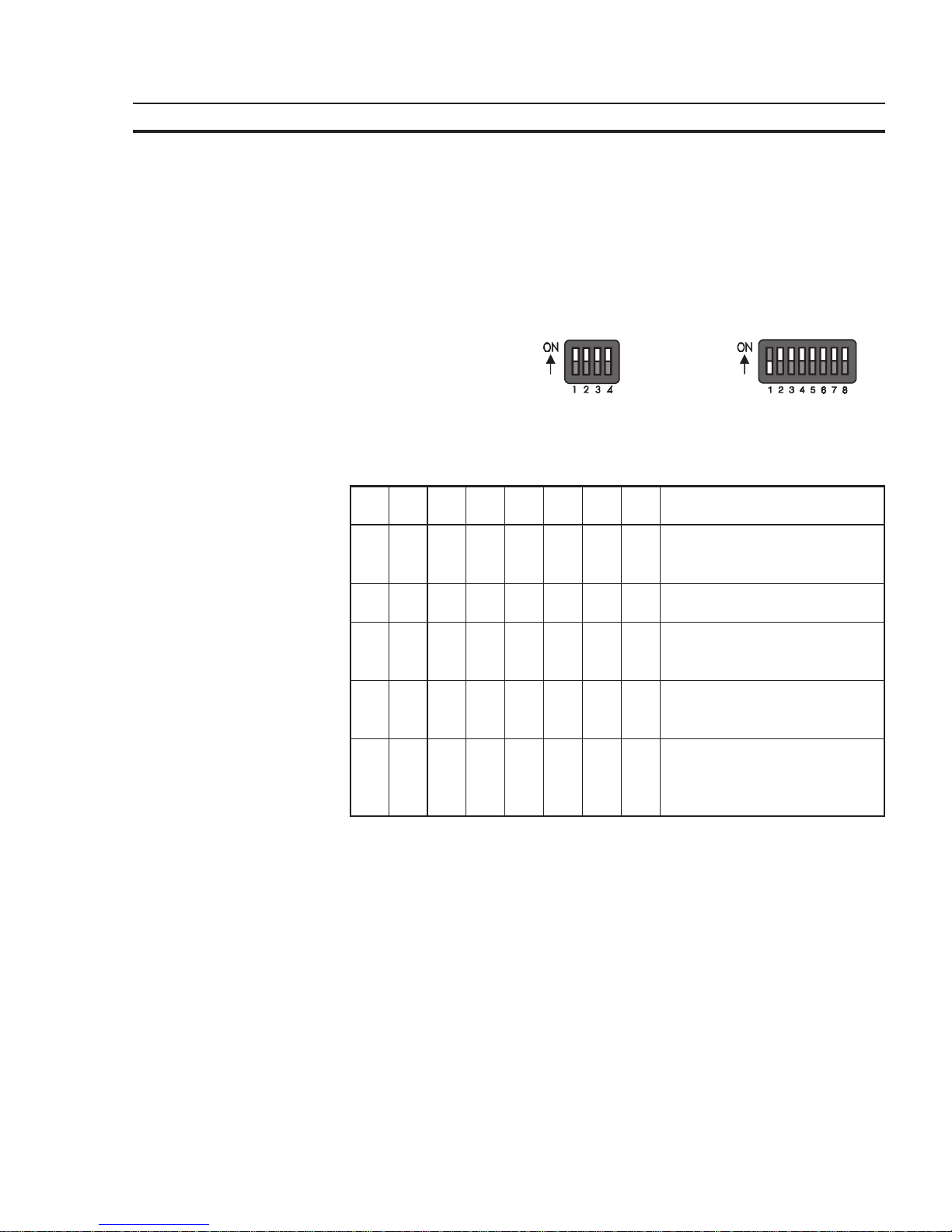

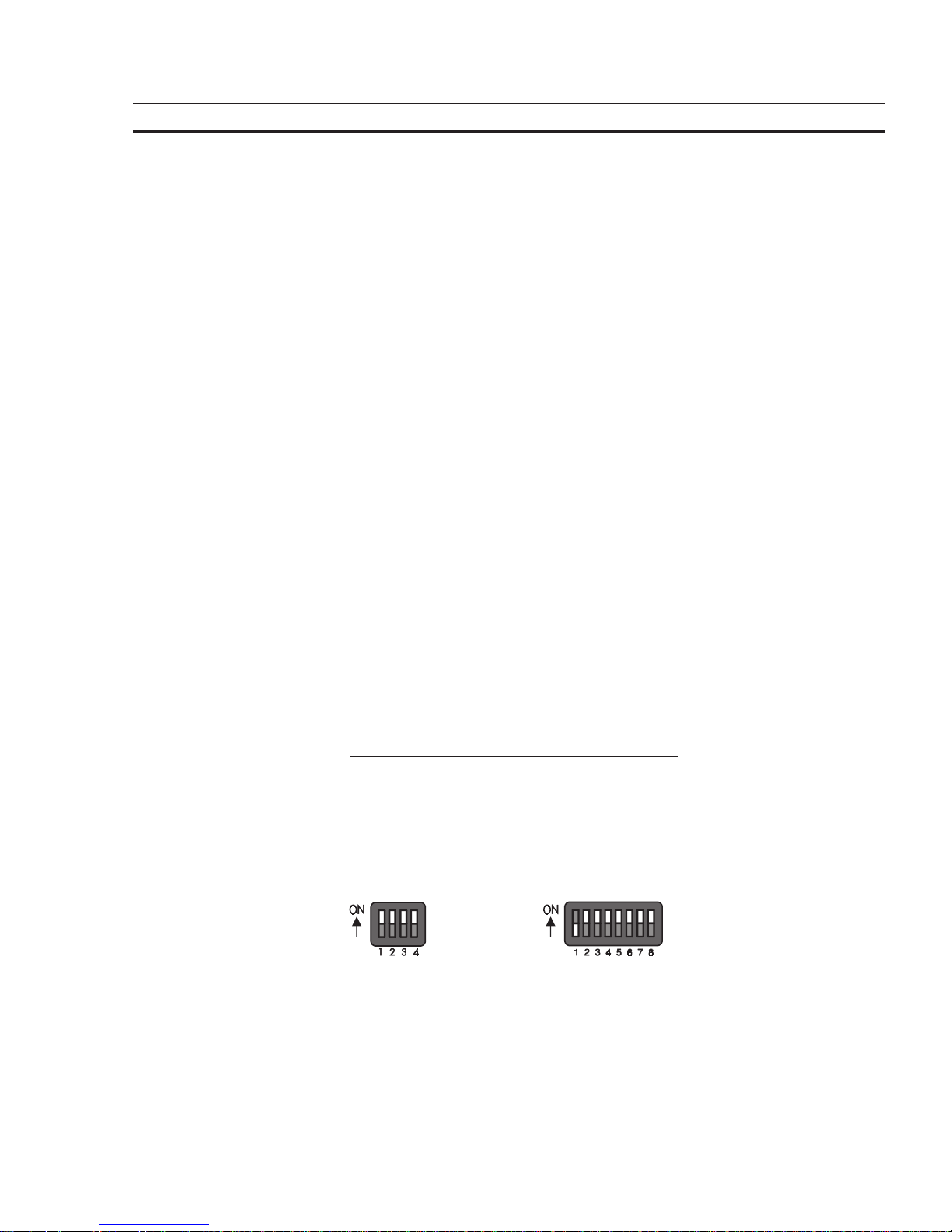

User-Mode Switch 4 Switches 8 Switches

NT4S-SF121B-E NT4S-SF123B-E

NT4S-SF122B-E NT15S-SF121B-E

NT18S-SF121B-E

The switches S5 to S8 can be used by the operator as needed. The switch positions

are stored at initialization time and afterwards they can be overtaken to the controller.

S1 S2 S3 S4 S5 S6 S7 S8 Function

IX- -XXXXStandard-Mode with PLC (de-

livery state)

IXI -XXXXStandard-Mode without PLC

- I - - XXXXTransparent-Mode with start

and stop code of the keys

- - - I XXXXTransparent-Mode without stop

code of the keys

I - - I XXXXActivate download (deletes ap-

plication memory) and default

contrast setting

Table Legend:

I = Switch position ON

- = Switch positionOFF

X = Switch position irrelevant

Page 56

42

The Terminals of the NT-Series Section 1-9

1.9 Battery

A built-in lithium battery buffers the data in the RAM memory and also supplies the

real-time clock with power. The discharge degree of the battery is monitored constantly to prevent any loss of data.

The battery provides a minimum life of 5 years, even under unfavourable operating

conditions.

If the battery is drained the system message ‘change battery’ is generated.

A new battery is supported by OMRON EUROPE.

Replacing the battery:

The battery can be replaced while the operating voltage is connected to ensure that

the message data and time setting are not lost. Mind the safety instructions!

- Remove the mounting bolts of the 25-pin interface connector

- Remove the fastening screws of the enclosure and remove the enclosure

- Replace the cable fastener, which is used to fasten the battery

- Plug off the cable of the battery and replace the discharged battery

- Plug on the cable of the new battery

- Fasten the new battery on the plastic holder on the printed circuit board

OBSERVE THE CORRECT POLARITY OF (−) AND (+)

- Place the enclosure on the rear side of the terminal

- At first fasten the bolts of the interface connector and at last fasten the screws of

the enclosure properly

Changing the battery may only be performed by qualified and authorized personnel!

Sewage and refuse disposal:

Dispose only drained batteries into the collection box of the community or of the

local dealer. The battery is stated as drained when the message ‘change battery’

appears on the display of the terminal.

To prevent short circuitry in the collection boxes insulate the poles of each battery

with insulation tape or put each single battery into a plastic bag.

Do not put lithium batteries in fire or heat them above 100 !C and do not recharge

them. Danger of Explosion!

Do not open lithium batteries. Danger of Poisoning!

Hazardous voltages can exist inside electrical installations that can pose a danger

to humans. Coming in contact with live parts may result in electric shock!

Electrostatic discharges can damage electronic components! ESD protective measures must be observed!

Page 57

43

The Terminals of the NT-Series Section 1-11

1.10 Fuse

A semiconductor fuse is used to prevent damage to the operating terminal. Once

the fuse has been activated, the device must be disconnected from the supply

voltage to allow the semiconductor fuse to regenerate. With an ambient temperature of 20 !C, the regeneration takes about 20 seconds. The higher the ambient

temperature, the longer the regeneration period.

The semiconductor fuse is not designed to be replaced.

Hazardous voltages can exist inside electrical installations that can pose a danger

to humans. Coming in contact with live parts may result in electric shock!

Electrostatic discharges can damage electronic components! ESD protective measures must be observed!

1.11 Application Memory

A 256 kByte flash memory is used as an application memory for each operating

terminal . This memory area is available to store the user application, the loadable

protocol driver, the fonts and the recipe data. The advantage of the flash memory is

that programming and deleting processes can be carried out directly in the terminal.

Changing the application memory may only be performed by qualified and authorized personnel!

Hazardous voltages can exist inside electrical installations that can pose a danger

to humans. Coming in contact with live parts may result in electric shock!

Electrostatic discharges can damage electronic components! ESD protective measures must be observed!

Page 58

Page 59

45

SECTION 2

Technical Data

This section lists all the electrical and mechanical specifications of the terminals.

2.1 NT4S-SF121B-E ............................................................................ 47

2.2 NT4S-SF122B-E ............................................................................ 48

2.3 NT4S-SF123B-E ............................................................................ 50

2.4 NT15S-SF121B-E ........................................................................... 51

2.5 NT18S-SF121B-E ........................................................................... 53

Page 60

46

Page 61

47

Technical Data Section 2-1

2 Technical Data

2.1 NT4S-SF121B-E

Keyboard a Total of 11 Keys, Mechanical with Tactile Feedback

Divided into

2 Control Keys

4 Function Keys with LEDs and Slide-in Identification Strips

1 Special Key without LED

2 Special Keys with LEDs

2 Editing Keys

Display Backlit LCD Module, 4 Lines with 20 Characters Each,

Display Area 23 × 74 mm (H × W)

with Glare Suppression for Increased Contrast

Interface X3 Variable Baud Rates and Data Formats

600 to 19200 Bd

SER1 RS485, Electrically Isolated Communication

SER1 TTY / 20 mA, Electrically Isolated Communication

SER1 RS232c, Electrically Isolated Communication

SER2 RS232c, Not Electrically Isolated Download/Logging Printer

Central Unit Z80-CPU, 10 MHz, Watchdog Timer, Real-Time Clock, Programmable Interface

Parameters, Temperature Compensation of the Display, Adjustment of Contrast,

Battery Monitoring, User Mode Switch

Memory 256 Kbyte Flash Memory, Application Memory

256 kByte Flash Memory, Firmware

128 Kbyte stat. CMOS-RAM, Battery-Backed

Fuse Semiconductor Fuse

Connection System Plug-in Type, via SubminD Female Connector Strip

Supply Voltage 24 V Direct Voltage, Residual Ripple Max. 10%

Minimum Voltage 19.2 V

Maximum Voltage 30.2 V

Typ. Power Consumption ,0.3 A

Peak Current (10 ms) ,0.5 A

Connected Load , 10 W

Page 62

48

Technical Data Section 2-2

Noise Immunity EC Electromagnetic Compatibility Directive 89/336/EEC

EN 55011 Limit Class B

EN 50081-1 Table A1

EN 50082-2

EN 61000-4-2

EN 61000-4-3

EN 61000-4-4

EN 61000-4-5

EN 61000-4-6

Environmental Test DIN40040 Operation Storage

Code Letter - Temperature KW HU

Code Letter - Humidity F F

Degrees of Protection DIN 40050 Mechanical Degrees of Protection

Front: IP65

Rear: IP20

Front Panel Aluminum, Black Anodized with Affixed Polyester Cover, Circumferential Polyu-

rethane Foam Seal at Rear Side of Front Panel

96.0 × 144.0 × 3.5 mm (H × W × D)

Panel Cutout 82 × 138 mm (H × W)

Mounting Depth 43 mm without Connector

Enclosure Zinc-Coated Steel Plate

Total Weight Approx. 400 g

2.2 NT4S-SF122B-E

Keyboard a Total of 30 Keys, Membrane with Tactile Feedback

Divided into

6 Control Keys

6 Function Keys with LEDs and Slide-in Identification Strips

2 Special Keys with LEDs

3 Special Keys without LEDs

13 Editing Keys

Display Backlit LCD Module, 4 Lines with 20 Characters Each,

Display Area 23 × 74 mm (H × W)

with Glare Suppression for Increased Contrast

Interface X3 Variable Baud Rates and Data Formats

600 to 19200 Bd

SER1 RS485, Electrically Isolated Communication

SER1 TTY / 20 mA, Electrically Isolated Communication

SER1 RS232c, Electrically Isolated Communication

SER2 RS232c, Not Electrically Isolated Download/Logging Printer

Page 63

49

Technical Data Section 2-2

Central Unit Z80-CPU, 10 MHz, Watchdog Timer, Real-Time Clock, Programmable Interface

Parameters, Temperature Compensation of the Display, Adjustment of Contrast,

Battery Monitoring, User Mode Switch

Memory 256 Kbyte Flash Memory, Application Memory

256 kByte Flash Memory, Firmware

128 Kbyte stat. CMOS-RAM, Battery-Backed

Fuse Semiconductor Fuse

Connection System Plug-in Type, via SubminD Female Connector Strip

Supply Voltage 24 V Direct Voltage, Residual Ripple Max. 10%

Minimum Voltage 19.2 V

Maximum Voltage 30.2 V

Typ. Power Consumption ,0.3 A

Peak Current (10 ms) ,0.5 A

Connected Load , 10 W

Noise Immunity EC Electromagnetic Compatibility Directive 89/336/EEC

EN 55011 Limit Class B

EN 50081-1 Table A1

EN 50082-2

EN 61000-4-2

EN 61000-4-3

EN 61000-4-4

EN 61000-4-5

EN 61000-4-6

Environmental Test DIN40040 Operation Storage

Code Letter - Temperature KW HU

Code Letter - Humidity F F

Degrees of Protection DIN 40050 Mechanical Degrees of Protection

Front: IP65

Rear: IP20

Front Panel Aluminum, Black Anodized with Affixed Polyester Cover, Circumferential Rubber

Sealing around rear of front panel

168.0 × 120.0 × 4.0 mm (H × W × D)

Panel Cutout 160 × 112 mm (H × W)

Mounting Depth 40 mm without Connector

Enclosure Zinc-Coated Steel Plate

Total Weight 500 g

Page 64

50

Technical Data Section 2-3

2.3 NT4S-SF123B-E

Keyboard a Total of 30 Keys, Mechanical with Tactile Feedback

Divided into

5 Control Keys

8 Function Keys with LEDs and Slide-in Identification Strips

2 Special Key without LED

2 Special Keys with LEDs

13 Editing Keys

Display Backlit LCD Module, 4 Lines with 20 Characters Each,

Display Area 23 × 74 mm (H × W)

with Glare Suppression for Increased Contrast

Interface X3 Variable Baud Rates and Data Formats

600 to 19200 Bd

SER1 RS485, Electrically Isolated Communication

SER1 TTY / 20 mA, Electrically Isolated Communication

SER1 RS232c, Electrically Isolated Communication

SER2 RS232c, Not Electrically Isolated Download/Logging Printer

Central Unit Z80-CPU, 10 MHz, Watchdog Timer, Real-Time Clock, Programmable Interface

Parameters, Temperature Compensation of the Display, Adjustment of Contrast,

Battery Monitoring, User Mode Switch

Memory 256 Kbyte Flash Memory, Application Memory

256 kByte Flash Memory, Firmware

128 Kbyte stat. CMOS-RAM, Battery-Backed

Fuse Semiconductor Fuse

Connection System Plug-in Type, via SubminD Female Connector Strip

Supply Voltage 24 V Direct Voltage, Residual Ripple Max. 10%

Minimum Voltage 19.2 V

Maximum Voltage 30.2 V

Typ. Power Consumption ,0.35 A

Peak Current (10 ms) ,0.5 A

Connected Load , 10 W

Noise Immunity EC Electromagnetic Compatibility Directive 89/336/EEC

EN 55011 Limit Class B

EN 50081-1 Table A1

EN 50082-2

EN 61000-4-2

EN 61000-4-3

EN 61000-4-4

EN 61000-4-5

EN 61000-4-6

Page 65

51

Technical Data Section 2-4

Environmental Test DIN40040 Operation Storage

Code Letter - Temperature KW HU

Code Letter - Humidity F F

Degrees of Protection DIN 40050 Mechanical Degrees of Protection

Front: IP65

Rear: IP20

Front Panel Aluminum, Black Anodized with Affixed Polyester Cover, Circumferential Sealing

Around Rear of Front Panel

150.0 × 270.0 × 3.0 mm (H × W × D)

Panel Cutout 112 × 232 mm (H × W)

Mounting Depth 48 mm without Connector

Enclosure Zinc-Coated Steel Plate

Total Weight approx. 800 g

2.4 NT15S-SF121B-E

Keyboard a Total of 42 Keys, Mechanical with Tactile Feedback

Divided into

7 Control Keys

16 Function Keys with LEDs and Slide-in Identification Strips

2 Special Key without LED

4 Special Keys with LEDs

13 Editing Keys

Display Backlit LCD Module, 8 Lines with 40 Characters Each,

Display Area 40.4 × 134.0 mm (H × W)

with Glare Suppression for Increased Contrast

Interface X3 Variable Baud Rates and Data Formats

600 to 19200 Bd

SER1 RS485, Electrically Isolated Communication

SER1 TTY / 20 mA, Electrically Isolated Communication

SER1 RS232c, Electrically Isolated Communication

SER2 RS232c, Not Electrically Isolated Download/Logging Printer

Central Unit Z80-CPU, 10 MHz, Watchdog Timer, Real-Time Clock, Programmable Interface

Parameters, Temperature Compensation of the Display, Adjustment of Contrast,

Battery Monitoring, User Mode Switch

Memory 256 Kbyte Flash Memory, Application Memory

256 kByte Flash Memory, Firmware

128 Kbyte stat. CMOS-RAM, Battery-Backed

Page 66

52

Technical Data Section 2-4

Fuse Semiconductor Fuse

Connection System Plug-in Type, via SubminD Female Connector Strip

Supply Voltage 24 V Direct Voltage, Residual Ripple Max. 10%

Minimum Voltage 19.2 V

Maximum Voltage 30.2 V

Typ. Power Consumption ,0.4 A

Peak Current (10 ms) ,0.6 A

Connected Load , 10 W

Noise Immunity EC Electromagnetic Compatibility Directive 89/336/EEC

EN 55011 Limit Class B

EN 50081-1 Table A1

EN 50082-2

EN 61000-4-2

EN 61000-4-3

EN 61000-4-4

EN 61000-4-5

EN 61000-4-6

Environmental Test DIN40040 Operation Storage

Code Letter - Temperature KW HU

Code Letter - Humidity F F

Degrees of Protection DIN 40050 Mechanical Degrees of Protection

Front: IP65

Rear: IP20

Front Panel Aluminum, Black Anodized with Affixed Polyester Cover, Circumferetial Rubber

Sealing at Rear Side of Front Panel

230.0 × 250.0 × 4.0 mm (H × W × D)

Panel Cutout 188 × 204 mm (H × W)

Mounting Depth 50 mm without Connector

Enclosure Zinc-Coated Steel Plate

Total Weight Approx. 1200 g

Page 67

53

Technical Data Section 2-5

2.5 NT18S-SF121B-E

Keyboard a Total of 34 Keys, Mechanical with Tactile Feedback

Divided into

5 Control Keys

12 Function Keys with LEDs and Slide-in Identification Strips

2 Special Key without LED

2 Special Keys with LEDs

13 Editing Keys

Display Backlit LCD Module, 16 Lines with 40 Characters Each,

Display Area 72 × 131 mm (H × W)

with Glare Suppression for Increased Contrast

Interface X3 Variable Baud Rates and Data Formats

600 to 19200 Bd

SER1 RS485, Electrically Isolated Communication

SER1 TTY / 20 mA, Electrically Isolated Communication

SER1 RS232c, Electrically Isolated Communication

SER2 RS232c, Not Electrically Isolated Download/Logging Printer

Central Unit Z80-CPU, 10 MHz, Watchdog Timer, Real-Time Clock, Programmable Interface

Parameters, Temperature Compensation of the Display, Adjustment of Contrast,

Battery Monitoring, User Mode Switch

Memory 256 Kbyte Flash Memory, Application Memory

256 kByte Flash Memory, Firmware

128 Kbyte stat. CMOS-RAM, Battery-Backed

Fuse Semiconductor Fuse

Connection System Plug-in Type, via SubminD Female Connector Strip

Supply Voltage 24 V Direct Voltage, Residual Ripple Max. 10%

Minimum Voltage 19.2 V

Maximum Voltage 30.2 V

Typ. Power Consumption ,0.7 A

Peak Current (10 ms) ,3.0 A

Connected Load , 20 W

Noise Immunity EC Electromagnetic Compatibility Directive 89/336/EEC

EN 55011 Limit Class B

EN 50081-1 Table A1

EN 50082-2

EN 61000-4-2

EN 61000-4-3

EN 61000-4-4

EN 61000-4-5

EN 61000-4-6

Page 68

54

Technical Data Section 2-5

Environmental Test DIN40040 Operation Storage

Code Letter - Temperature KW HU

Code Letter - Humidity F F

Degrees of Protection DIN 40050 Mechanical Degrees of Protection

Front: IP65

Rear: IP20

Front Panel Aluminum, Black Anodized with Affixed Polyester Cover, Circumferential Sealing

Around Rear of Front Panel

190.0 × 330.0 × 3.0 mm (H × W × D)

Panel Cutout 152 x 292 mm (H x W)

Mounting Depth 60 mm without Connector

Enclosure Zinc-Coated Steel Plate

Total Weight approx. 1500 g

Page 69

55

SECTION 3

Operating Modes

This section describes the two available operation modes, the standard mode and the transparant mode

and indicates how to select the operation mode.

3.1 Setting the Operating Mode ................................................................. 57

Page 70

56

Page 71

57

Operating Modes Section 3-1

3 Operating Modes

There are two types of operating modes available in the operating terminals, the

standard mode of operation and the transparent mode of operation.

Terminals operating in the transparent mode represent full-size ANSI-terminals.

Each key generates a press and release code, which will be transmitted via the

interface SER1 in the form of an ASCII character. The displays and the key LEDs

are controlled via ESC sequences. The number of character sets and character

attributes varies with the type of display. For a detailed description please refer to

the chapter ‘Transparent Mode’.

In the standard mode of operation, the entire operating system is integrated in the

terminal. The standardized operating concept

completely frees the connected controller from any operator guidance tasks as well as data display.In standard mode, a

decoding of the keys or selection of masks from within the controller is not required.

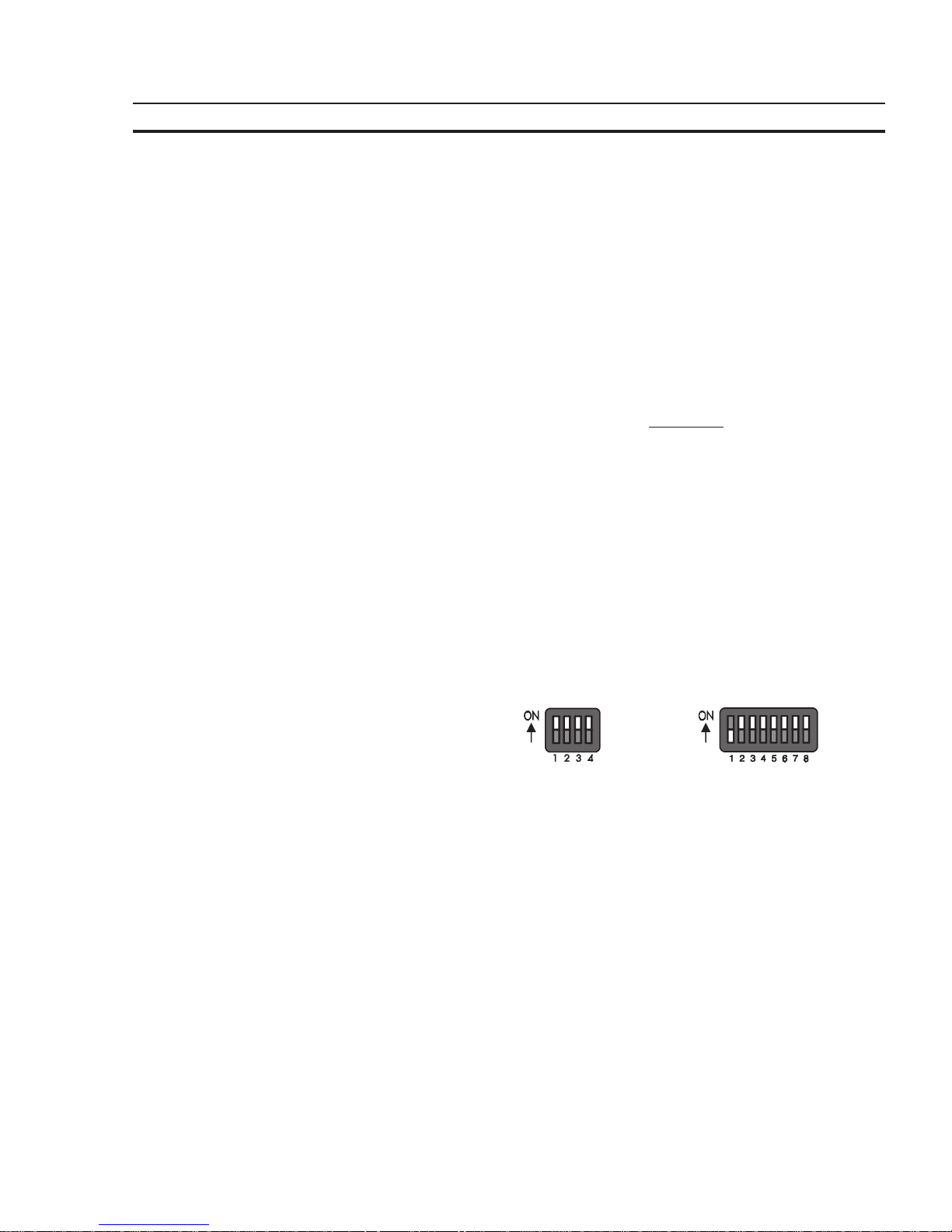

3.1 Setting the Operating Mode

The operating mode can be set by means of the User-Mode-Switch. The terminals

are factory-set to the standard mode of operation.

The user-mode switch is accessible at the side of the terminal NT4S-SF122B-E

and at the rear side of all other operating terminals.

User-Mode Switch 4 Switches 8 Switches

NT4S-SF121B-E NT4S-SF123B-E

NT4S-SF122B-E NT15S-SF121B-E

NT18S-SF121B-E

Page 72

58

Operating Modes Section 3-1

The switches S5 to S8 can be used by the operator as needed. The switch positions

are stored at initialization time and afterwards they can be overtaken to the controller.

S1 S2 S3 S4 S5 S6 S7 S8 Function

IX- -XXXXStandard-Mode with PLC (delivery state)

IXI -XXXXStandard-Mode without PLC

- I - - XXXXTransparent-Mode with start and stop code

of the keys

- - - I XXXXTransparent-Mode without stop code of the

keys

I - - I XXXXActivate download (deletes application

memory) and default contrast setting

Table Legend:

I = Switch position ON

- = Switch position OFF

X = Switch position irrelevant

Page 73

59

SECTION 4

Standard Mode

This section describes the standard operation mode in detail. This section contains all detailed information to understand all features of the terminal in order to make a terminal application.

4.1 Setting the Operating Mode ................................................................. 63

4.2 Startup Process.............................................................................. 64

4.2.1 Startup Process without a Valid User Description ..................................... 65

4.3 Communication in the Standard Mode ....................................................... 65

4.4 Operating Concept .......................................................................... 65

4.4.1 Mask Structure ...................................................................... 65

4.4.2 External Mask Selection ............................................................. 66

4.4.3 Password Protection, Access Authorization ........................................... 66

4.4.3.1 Reactivating the Password Protection........................................ 69

4.4.3.2 Password Management...................................................... 69

4.4.3.3 Password Mask and Password Functionality.................................. 69

4.5 Masks ...................................................................................... 70

4.5.1 Mask Parameters .................................................................... 70

4.5.2 System Masks ....................................................................... 70

4.5.2.1 Setup Mask................................................................. 71

4.5.2.1.1 Password Protection - Setup Mask ................................ 71

4.5.2.1.2 Function Without the Setup Mask ................................ 71

4.5.2.2 Start Mask.................................................................. 71

4.5.2.3 Password Mask ............................................................. 72

4.5.2.4 I/O Mask ................................................................... 72

4.6 Variables ................................................................................... 72

4.6.1 Output Variables .................................................................... 73

4.6.1.1 ‘Decimal Number’ Representation........................................... 76

4.6.1.1.1 ‘Standard’ Variable Type ........................................ 76

4.6.1.1.2 ‘Timer’ Variable Type ........................................... 76

4.6.1.1.3 ‘Counter’ Variable Type ......................................... 77

4.6.1.1.4 ‘BCD-Number’ Variable Type ................................... 78

4.6.1.2 ‘Alphanumerical’ Representation ........................................... 78

4.6.1.3 ‘Selection Text’ Representation ............................................. 78

4.6.1.4 ‘Selection Image’ Representation ........................................... 79

4.6.1.5 ‘Floating Point Number’ Representation .................................... 80

4.6.1.6 ‘Hexadecimal Number’ Representation ..................................... 80

4.6.1.7 ‘Binary Number’ Representation ............................................ 81

4.6.1.8 Bar Representation ........................................................ 81

4.6.1.9 Curve Representation (Trendline) ........................................... 82

4.6.2 Input Variables ...................................................................... 83

4.6.3 System Variables .................................................................... 85

4.6.3.1 Basic Functions ............................................................. 85

4.6.3.2 Communication SER1 ...................................................... 87

4.6.3.3 Error Statistics SER1 ....................................................... 89

4.6.3.4 Communication SER2 ...................................................... 90

4.6.3.5 Real-Time Clock ........................................................... 92

4.6.3.6 Serial Message System ...................................................... 93

Page 74

60

4.6.3.7 Parallel Message System .................................................... 96

4.6.3.8 Printer Control ............................................................. 98

4.6.3.9 Menu Control / Keys........................................................ 99

4.6.3.10 Password ................................................................... 106

4.6.3.11 Recipes .................................................................... 107

4.6.3.12 Running Time Meter........................................................ 112