Page 1

Cat. No. V084-E1-01

NT11

Programmable Terminal

USER’S MANUAL

Page 2

NT11 Programmable Terminal

User’s Manual

Produced January 2004

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

“Host” means a personal computer that controls the NT11.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Ó OMRON, 2004

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

SECTION 1

Functions of the NT11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Getting Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Role and Operation of NT11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-3 Functions of NT11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-4 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-5 Direct Connection Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1-6 Before Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SECTION 2

Hardware Settings and Connections. . . . . . . . . . . . . . . . . . . 15

2-1 Description of Parts and Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-3 Connecting to the NT Support Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-4 Connection to a PLC by the Host Link (RS-232C Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-5 Connection to a PLC by the Host Link (RS-422A Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2-6 Connection to a PLC by the NT Link (RS-232C Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2-7 Connection to a PLC by the NT Link (RS-422A Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2-8 Connecting a Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

SECTION 3

System Menu Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

3-1 Operation Flow by the System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3-2 Starting the NT11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3-3 Operation Modes and the System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3-4 Initializing Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3-5 Transferring the System Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3-6 Registering the Screen Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

3-7 Setting the Conditions of Communications with the PLC by Using the Memory Switches. 71

3-8 Starting the Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3-9 Backlight OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3-10 System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

vii

Page 7

TABLE OF CONTENTS

SECTION 4

NT11 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4-1 Outline of Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

4-2 Screen Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4-3 Areas for Control/Notification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

4-4 Memory Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4-5 Bar Graphs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

4-6 Numeral Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4-7 Menu Screen Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4-8 Password Screen Display Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

4-9 Display History Screen Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

4-10 Daily Report/Display History Printing Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

SECTION 5

Using Host Link/NT Link. . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5-1 Screen Creation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

5-2 Outline of Host Link/NT Link Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

5-3 Memory Table Entries and Bar Graph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

5-4 Numeral Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

5-5 NT11 Status Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

5-6 Notification of the Operating Status to the PLC (Determining the NT11 Operating Status) 132

SECTION 6

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . 135

6-1 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

6-2 Responding to Displayed Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

6-3 Inspection and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Appendices

A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

B Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

C Transporting and Storing the NT11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

D Making the Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

E Making the Cable for Connecting a Personal Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

F NT11 Internal Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

G Model List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

H Special Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

viii

Page 8

About this Manual:

This manual describes the basic functions and operation procedures of the NT-series programmable

terminal NT11, its operations when connected to a PLC, and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install and operate the NT-series programmable terminal NT11.

Section 1 describes the operation functions, system configuration, and the direct connection function

of the NT11.

Section 2 describes the hardware settings, installation to an operation panel, connection to optional

devices and PLC.

Section 3 describes the operation of the System Menu and the maintenance of the NT11.

Section 4 describes the functions of the NT11 when it is connected to a PLC.

Section 5 describes how to use the NT11 when it is connected to the PLC using the host link or NT

link.

Section 6 describes the procedures to follow when the NT11 does not operate correctly.

APPENDIX describes the specifications and the method for making connecting cables, and includes

an area list for the PLC.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

ix

Page 9

Related Manuals and Their Contents:

The related manuals are listed below.

The @ symbol at the end of the manual number is the revision history symbol.

[Operating the programmable terminal and communicating with the host]

• NT11 Programmable Terminal User’s Manual (V084-E1-@)

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - -- - - -- - - - - This manual

This user’s manual is the manual for the NT11-V@ itself.

The NT11 is a unit which integrates a programmable terminal body. This user’s manual describes the

functions and handling of the programmable terminal body.

[Creating and transferring screen data]

• NT-series Support Tool Operation Manual (V061-E1-@)

The screens displayed on the NT11 are created with the support tool and transferred to the NT11.

This manual describes how to create and transfer screen data.

x

Page 10

PRECAUTIONS

This section provides general precautions for using the Programmable Terminal.

The information contained in this section is important for the safe and reliable application of the Programmable

Terminal. You must read this section and understand the information contained before attempting to set up or

operate a Programmable Terminal.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

xi

Page 11

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems into production facilities.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and connecting FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the user’s manuals.

Before using the product under conditions that are not described in the manual or applying the product to nuclear control systems, railroad systems, aviation systems, vehicles, combustion systems, medical equipment, amusement

machines, safety equipment, and other systems, machines and equipment

that may have a serious influence on lives and property if used improperly,

consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for using the Programmable Terminal. Be

sure to read this manual before attempting to use the software and keep this

manual close at hand for reference during operation.

!WARNING It is extremely important that Programmable Terminals and related devices be

used for the specified purpose and under the specified conditions, especially

in applications that can directly or indirectly affect human life. You must consult with your OMRON representative before applying Programmable Terminals to the above-mentioned applications.

!WARNING Do not use input functions such as PT touch switches for applications where

danger to human life or serious damage is possible, or for emergency switch

applications.

3 Safety Precautions

Read these safety precautions carefully and make sure you understand them

before using the Programmable Terminal so that you can use it safely and correctly.

Safety Conventions and

their Meanings

!WARNING Indicates information that, if not heeded, could possibly result in loss of life or

This user’s manual uses the following conventions and symbols to indicate

cautions, warnings, and dangers in order to ensure safe use of the NT11.

The cautions, warnings, and dangers shown here contain important information related to safety. The instructions in these cautions, warnings, and dangers must be observed.

The conventions used and their meanings are presented below.

serious injury.

xii

Page 12

Safety Precautions 3

Caution Indicates information that, if not heeded, could result in relatively serious or mi-

nor injury, damage to the product, or faulty operation.

WARNING

Do not attempt to take the Unit apart and do not touch any

internal parts while the power is being supplied. Doing either of

these may result in electrical shock.

xiii

Page 13

Safety Precautions 3

xiv

Page 14

SECTION 1

Functions of the NT11

NT11 is a new programmable terminal (PT) which incorporates a host interface unit in a programmable terminal body. It

can be easily installed and used.

This section gives the operation examples and characteristics of the NT11 so that you will understand the applications of

the NT11.

1-1 Getting Starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Role and Operation of NT11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2-1 Operations of NT11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 Functions of NT11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3-2 Principal Functions of NT11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3-3 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-3-4 System Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-4 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-4-1 Peripheral Devices That Can Be Connected. . . . . . . . . . . . . . . . . . . 8

1-5 Direct Connection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-5-1 NT Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-5-2 Functions of the Allocated Bits and Words . . . . . . . . . . . . . . . . . . . 10

1-6 Before Operating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1

Page 15

Getting Starting Section 1-1

1-1 Getting Starting

To ensure that the NT11 works correctly, carefully observe the following when

installing and handling it.

Location Do not install the NT11 in a location subject to the following conditions;

• Near a computer, radio transmitter or receiver, etc.

• Dust, chemicals, or steam

• Severe temperature fluctuations

• High humidity and condensation

• Strong electrical or magnetic fields

• Poor ventilation

• Severe vibration

Handling Do not;

• Subject the NT11 to strong shocks or vibrations

• Put heavy objects on the NT11

• Supply a voltage different from the specified voltage

• Disassemble or modify the NT11

Cautions on Cleaning To clean the front panel, use a soft, dry cloth. If it is very dirty, use diluted (2%)

neutral detergent.

Do not use volatile solvents such as benzene, thinner, or a chemically treated

cloth. Their use will cause deformation or discoloration.

Cautions on Afterimage If the same screen contents are kept displayed for a long time, an afterimage

may occur. To prevent this problem, either set the afterimage prevention function or make a program which periodically changes the displayed screen.

Cautions on Operating the System Keys

Do not operate the system keys with sharply pointed objects, such as your fingernails or a screwdriver.

This could break the film.

1-2 Role and Operation of NT11

NT11 is a programmable terminal used to display and transmit the information

in an FA site. The following gives a general description of the role and operation of the NT11 for those who use a programmable terminal (PT) for the first

time.

Production Line Status Monitoring

The NT11 displays real-time information about the system and equipment

operating status, etc.

Line 1 Status

Machine:NT11-SF121

Product: 137 units

75%

2

Page 16

Role and Operation of NT11 Section 1-2

Messages The NT11 warns of system or equipment failures and prompts the appropriate

remedial action.

Alarm

Assembly line B

Positioning pin

Panel Switch Functions The NT11 can be used in place of external data input equipment such as an

operation panel, to transmit data to a PLC.

Positioning

X-AXIS 100 point

Y-AXIS 150 point

Z-AXIS 80 point

1-2-1 Operations of NT11

Displays Screens The information to be displayed (screen data) can be created on a computer

by using support tools and stored in the NT11. The screen data can be displayed on the NT11 in response to the instructions from a PLC or system keys

operation.

PLC

The screen data designated by

instructions from PLC or System

keys operation is displayed.

Receives Data from a PLC NT11 can be connected to a PLC by a host link or NT link and receive neces-

sary data from the PLC.

Host link, NT link

PLC

OMRON's PLC

Sends Data to a PLC Data input through a numeric key can be sent to a PLC.

Numeric keys

PLC

ON/OFF information,

numeric data, etc.

3

Page 17

Functions of NT11 Section 1-3

Screen Data The screen data to be displayed on the NT11 can be created by a computer

by using support tools. Connect the NT11 to an IBM PC/AT or compatible with

an RS-232C cable so that the screen data are transferred to the NT11.

Create screen data.

RS-232C

Screen data

PC/AT

(support tools)

This connection is made only to

transmit the screen data by using

NT11 and tools.

1-3 Functions of NT11

The NT11 has the following features and functions;

1-3-1 Features

Downsized Body • The NT11 has the thinnest depth (31 mm or less in the panel) in the NT

series.

• It is very compact, with a width of 218 mm and a height of 113 mm.

• Features three ports: for RS-232C, RS-422A, and printer output.

• The tool connectors and the PLC communication connectors are used in

common.

Construction Best Suited to the FA Environment

• Easy-to-read screen even in direct sunlight.

• Waterproofed to a standard equivalent to IP65 and NEMA4.

160 dots

64 dots

Wide angle of visibility ±20°

A Host I/F Unit, Screen Data Memory, and a system program transfer ROM are All Incorporated

• There is no complicated installation work except a simple connection to a

PLC.

• A flash memory is used for the screen data memory. There is no need of

backup battery.

• A host link (direct), and an NT link are standard equipment.

4

Page 18

Functions of NT11 Section 1-3

1-3-2 Principal Functions of NT11

Functions Related to the Data Display

• Character display

Characters of standard and double-width can be displayed. Characters can flash or be

highlighted.

• Memory data display

Contents of the character-string memory table and the numeral memory table can be

displayed. The memory table contents can be changed from the PLC.

• Bar graph display

Bar graphs corresponding to the contents of the numeral table can be displayed.

Functions Related to the Data Input

• Input by the system key

Data can be input, and the displayed screen

changed, by using the numeric keys, function keys,

and arrow keys on the panel of the NT11.

• Numeric setting function

The numeric values can be input at the operation

site by the system key and sent to the PLC.

Other Functions

• Communications with a PLC

The host link, NT link is used to connect to a PLC for data communication.

• System function

The system setting and maintenance can be executed by using the

System Menu on the screen.

• Screen data creation

The screen data can be created by using support tools on the computer

and stored in the unit.

5

Page 19

Functions of NT11 Section 1-3

1-3-3 Displays

The NT11 can display elements such as characters, numeric value, and bar

graphs on a screen. The screen data displayed on the NT11 are created by

using support tools on a computer.

Characters

(character string)

Characters (text)

Bar graph

Characters (text) Characters and marks which do not need to be changed can be written

directly to the screen.

Characters (character-string memory table)

Character-strings stored in the character-string memory table are displayed.

The display characters can be changed by changing the data stored in the

character-string memory table.

Numeric Values (numeral memory table)

Numbers stored in the numeral memory table are displayed. The display numbers can be changed by changing the data stored in the numeral table. Hexadecimal values can also be displayed.

Line 1 Status

Machine:NT11-SF121

Product:137 units

75%

Numeric value

(Numeral table)

Bar Graphs The bar graph extends and contracts in proportion to the data stored in the

numeral memory table. A percentage value can also be displayed simultaneously.

Marks Marks can be designed, created, and handled like characters by the user.

Comparison with the NT11S

Model NT11 NT11S

Basic performance Dimensions 218 x 113 x 38.2 mm (W x H x D)

Resolution 160 x 64 dots (4.24 inches)

Effective display area 100 x 40 mm

Display color Black & white (with yellow mode)

Panel cut-out size (W x H) 204.2 x 98.8 mm

Max. number of registered screens 250

Screen data capacity 32 KB

Function keys 4

Other Keys Numeric Keys, Cursor Keys, Function Keys

Special functions Emergency transfer mode* DIP switch pin 3 None

Backlight service life 50,000 hours min. 10,000 hours min.

Communications Host Link Speed Up to 115,200 9,600/19,200

Compatibility (Screen data types that can

be used.)

* Emergency transfer mode: When power to the NT11 is turned ON with DIP

switch pin 3 turned ON, data transfer mode will be entered directly without

any other operation.

NT11-V1, NT11S NT11S

6

Page 20

Functions of NT11 Section 1-3

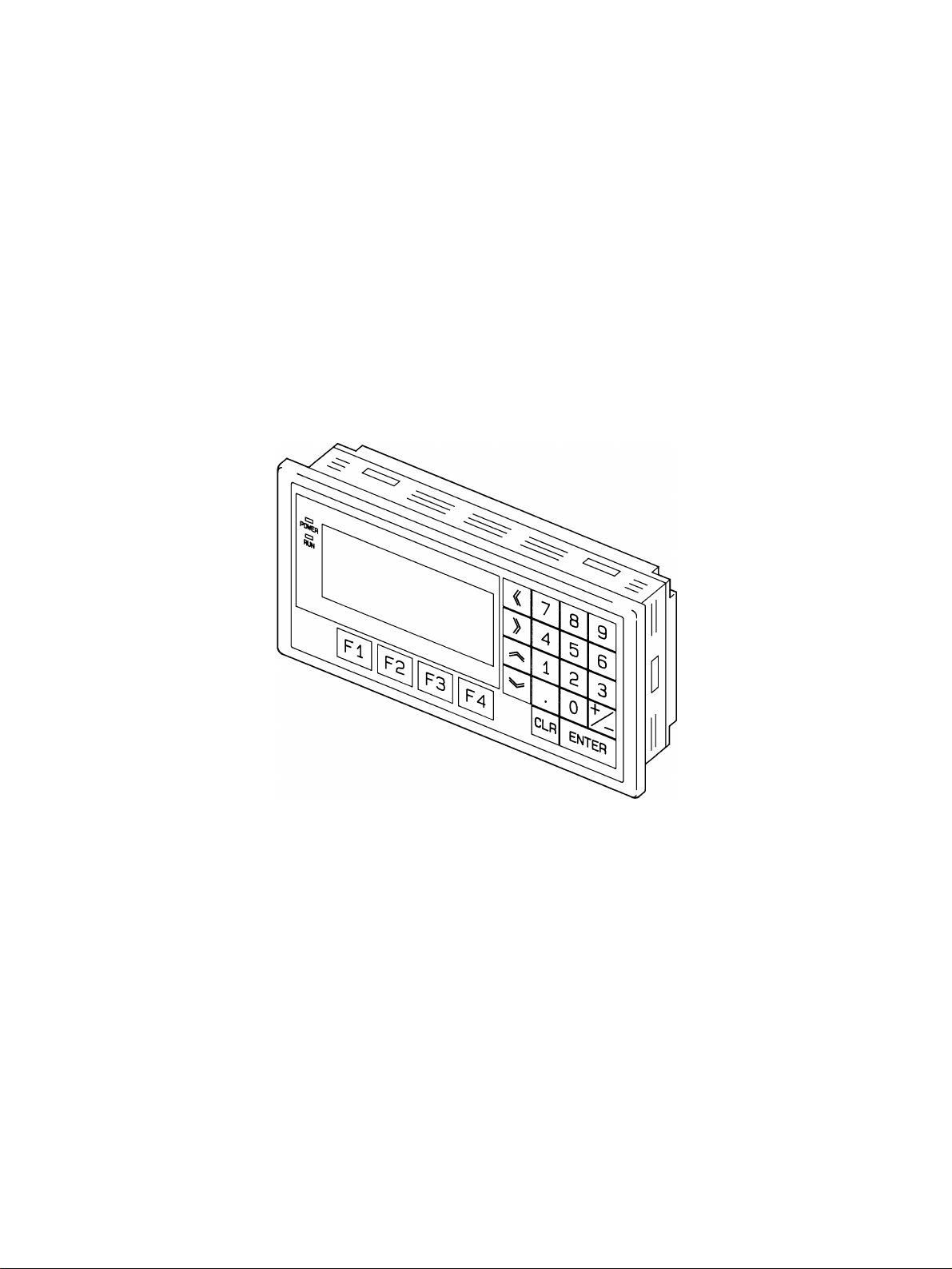

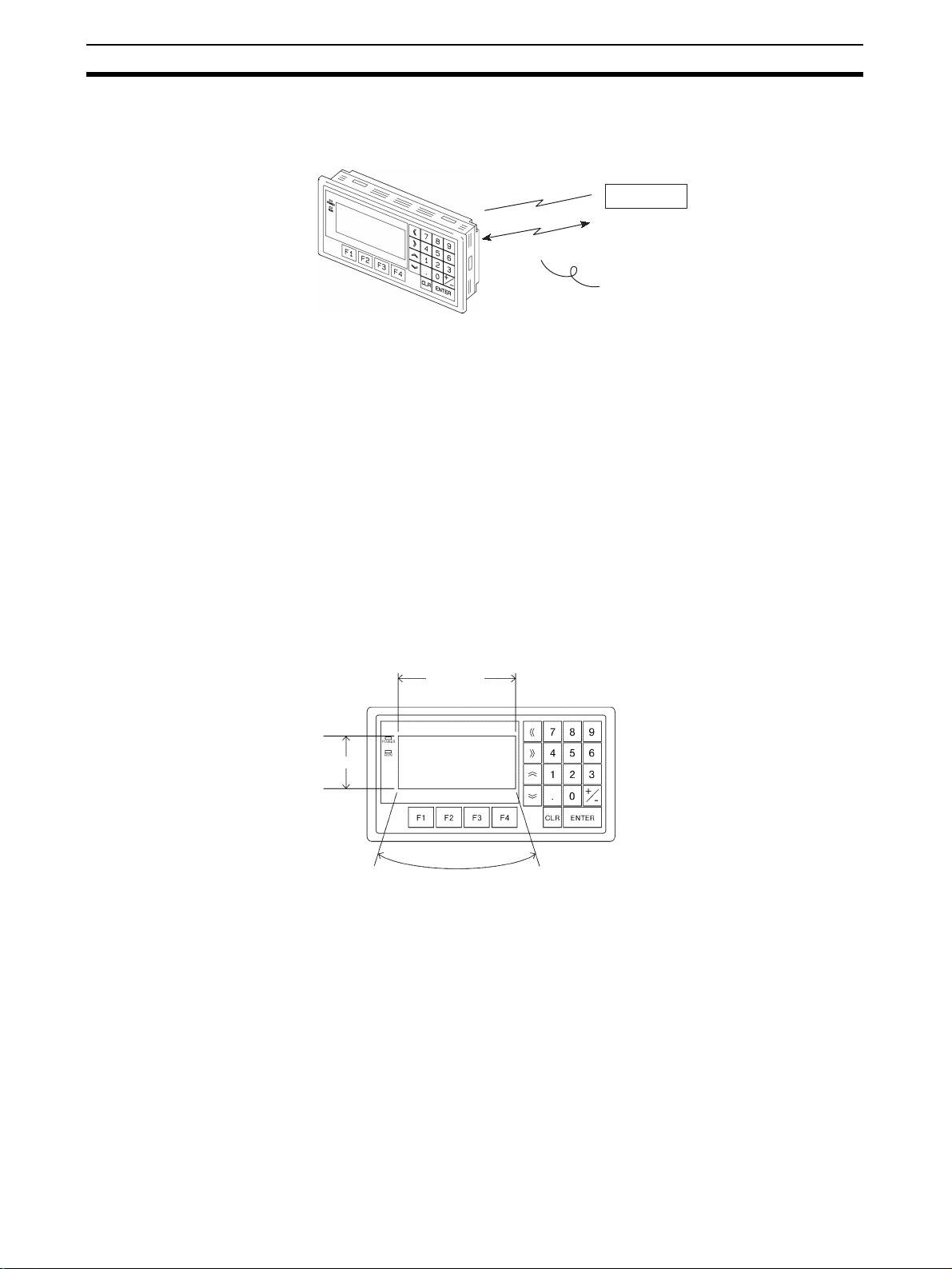

1-3-4 System Keys

The NT11 has system keys on its panel for input functions.

The system keys are used for inputting numerical values and for notifications

to the PLC.

The system keys can be classified into the three types shown below.

- Numeric keys

- Arrow keys

- Function keys

NT11

Screen display

Function keys

Arrow keys

Numeric keys

• Numeric keys

These are the numeral keys from [0] to [9], the decimal point key [.], the

sign key [+/–], the [CLR] key and the [ENTER] key. These keys are used

for inputting numerical values.

• Arrow keys

Used to select the required numerical value input field when there is more

than one on the screen.

• Function keys

Used for notifications from the NT11 to the PLC.

Also used to switch between the RUN mode and the system menu when

the power is switched on.

!Caution Do not use input functions such as PT function keys for applications where

danger to human life or serious property damage is possible, or as the emergency stop switch.

!Caution If function keys are pressed in rapid succession, their inputs may not be suc-

cessfully received. Confirm that the input of a function key has been successfully received before moving on to the next operation.

!Caution Do not press function keys carelessly while the backlight is off or while nothing

is displayed on the screen. Otherwise the system may operate unpredictably.

Only press function keys after confirming system safety.

7

Page 21

System Configuration Section 1-4

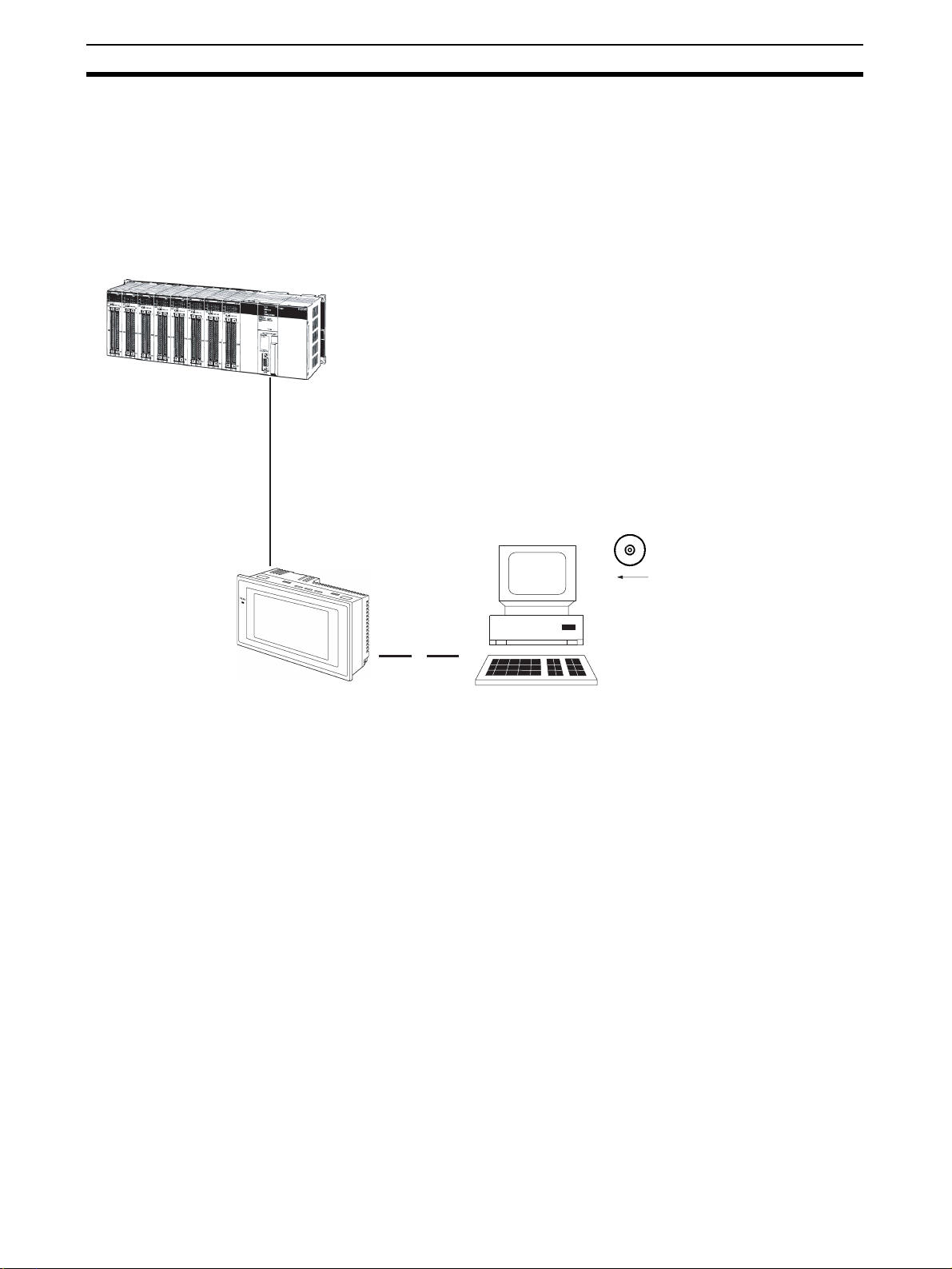

1-4 System Configuration

This section shows the configuration of a system that uses an NT11. For

details on product models, refer to Appendix G Model List (page 159).

1-4-1 Peripheral Devices That Can Be Connected

The following peripheral devices can be connected to an NT11.

Host

Controls the NT11 as required while controlling machines and monitoring the

production line.

Host Link: CS-series/CJ-series/C-series PLCs, CVM1/CV-series PLCs, SRM1

Can be connected to CPU Units, Host Link Units, and SRM1. However,

connection is not possible to some models of CPU Unit and SRM1

(pages 23 and 39).

NT Link: C-series PLCs, CVM1/CV-series PLCs, SRM1

RS-232C cable

(15 m max.)

An RS-422A/485 cable

(500 m max.) can be

connected through an

RS-232C/RS-422A

Adapter.

Can be connected to CPU Units and SRM1. However, connection is not

possible to some models

Personal computer

Running Windows 95, 98,

NT, 2000, Me, XP

(pages 51 and 55).

NT Support Tool

Used to create screens for the

NT11 at the personal computer

and transfer them to the NT11,

and to make NT11 settings.

NT11

Displays production line monitoring and

commands to the operation site, and

notifies the switch ON/OFF status and

numeric value inputs to the host.

• NT Support Tool (page 22)

NT-series Support Tool Version 4.7 for Windows (Made by OMRON)

• NT-ZJCAT1-EV4.7 (CD-ROM version for IBM PC/AT or compatible

computers)

• System installer (page 22)

System Installer (made by OMRON)

The System Installer is supplied as a standard accessory with the NT Sup-

port Tool (NT-ZJCAT1-EV4.7).

System installer

Used to change the system

program of the NT11.

8

Page 22

Direct Connection Function Section 1-5

1-5 Direct Connection Function

The communication method applied between the NT11 and the PLC is either

a host link or NT link.

The NT11 can be used to refer to the contents necessary for the display information or to allocate the bits and words used for storing the input data to any

area in the PLC. The NT11 can directly write and read such allocated bits and

words so as to change the display elements, control the operating status, and

notify the status.

This function is called the “direct connection function”. The NT11 is designed

exclusively for use with the direct connection.

The bits and words allocated by the direct connection function are called “allocated bit” and “allocated word” respectively.

This function allows to read the information to be displayed on the NT11 from

the memory area in the PLC and to write it to the memory table in the NT11.

Also, the data input on the NT11 can be written to the PLC’s memory area.

The NT11 screen status can be switched according to the PLC’s memory

area, and the NT11’s status data can be written to the PLC’s memory area.

NT11 PLC

Data memory area Internal relay area

Features of the Direct Connection Function

• The bits and words referring to operating status and work instruction information and those for storing input data can be freely allocated to almost

any part of the PLC memory. Bits and words in the PLC can be referenced from any memory table.

• The NT11 can directly refer to PLC bit and word data so that it can be

connected to a PLC without changing the PLC program which controls

currently running production line.

• The area to control and notify the NT11 status, including display screens,

ON/OFF of the backlight, and printing of daily reports and display histories, can be freely allocated to any part of the PLC memory.

The direct connection function allows the NT11 to directly read and write

almost all bits and words in the PLC and to automatically change the NT11

screen display. This function can reduce the load on the PLC so that the program development efficiency of the PLC improves.

1-5-1 NT Link

The NT link is a new communication method applied between the NT11 and a

PLC.

The NT link uses the direct connection function and can execute high speed

communications with a CPU (built-in NT link) of the CQM1, C200HS, and

other PLCs.

Auxiliary relay area

Timer/counter

Features of the NT Link • High speed communications with specific types of PLCs can be executed.

• Writing in units of bits to the PLC memory area is possible. (*)

9

Page 23

Direct Connection Function Section 1-5

)

• This can be used even when the PLC is in the RUN mode.

(*) Except a DM area.

The NT link is compatible with the host link. The NT11 screen data and the

PLC programs handled by the host link direct connection can be used with for

the NT link as they are.

1-5-2 Functions of the Allocated Bits and Words

Elements displayed on the NT11 and the NT11 status can be allocated to the

bits and words of the PLC. By changing the contents of the bits and words, the

NT11 can be controlled by the PLC. It is also possible to send data to the PLC

by pressing the function keys on the panel of the NT11.

• Controlling the NT11 by a PLC

The following NT11 functions can be controlled by a PLC.

Screens: Display of designated screens, confirmation of screen

numbers, etc.

Memory tables: Writing to a memory table, copying from a memory table

to another memory table, etc.

System control: ON/OFF of backlight, control of output of daily reports and

display histories at a printer.

• Notifying from the NT11 to a PLC

Data in the NT11 is sent to a PLC when a numeric key is pressed. The fol-

lowing types of data are sent to a PLC.

- NT11 status

- Password input status

- Numeric values input by the numeral keys

- Function key input status

Functions of Display Elements

• Numeral memory table

Allocation destination: Word

Numeral memory

table entry 1

(TIM003)

Numeral memory table entry 150 (CIO/IR 0005

NT11

PLC

CIO/IR 0005

Allocate numeral memory table entries to arbitrary words in the PLC. If word

contents change when corresponding numeral memory table entry is displayed on the screen, the value on the screen will also change. Monitoring of

words can also be made easily.

Reading and writing are executed so that the contents of allocated words are

always the same as those of the numeral memory table entries.

10

Page 24

Direct Connection Function Section 1-5

g

• Character-string memory table

Allocation destination: Word

NT11 PLC

("a", "b")

("c", "d")

("e", "f")

Character-string memory table entry 1

Number of allocated words: 3

First word: DM0100

Allocate character-string memory table entries to arbitrary words in the PLC. If

word contents change when corresponding character-string memory table

entry is displayed on the screen, the value on the screen will also change.

Messages can be displayed easily.

Reading and writing are executed so that the contents of allocated words are

always the same as those of the character-string memory table entries.

Functions of the PT Status Control Area (PLC to NT11)

The “PT status control area” is used to control the NT11 status. When data is

written to this area in the PLC, the NT11 reads the contents and operates

according to the contents.

[Example of the PT status control area application]

When data is written to the PT status control area, the NT11 will operate as

given below.

Copy

Screen 3

display

Numeral memory table entry 50

Numeral memory table entry 7

Printin

NT11

of daily reports or display histories

Functions of the PT Status Notify Area (NT11 to PLC)

The “PT status notify area” is used to notify the changes of the NT11 status.

When a change is made in the NT11 status, the change is written to this area

in the PLC. By reading the data from the area, the NT11 status can be

checked.

PLC

PT status control area

0003

0050

1007

8010

Screen switch setting

Memory table entry

Copy setting

PT status control bits

11

Page 25

Before Operating Section 1-6

[Example of the PT status notify area application]

When a change is made in the NT11 status, such change will be notified to

the PT status notify area as mentioned below.

12345678

1-6 Before Operating

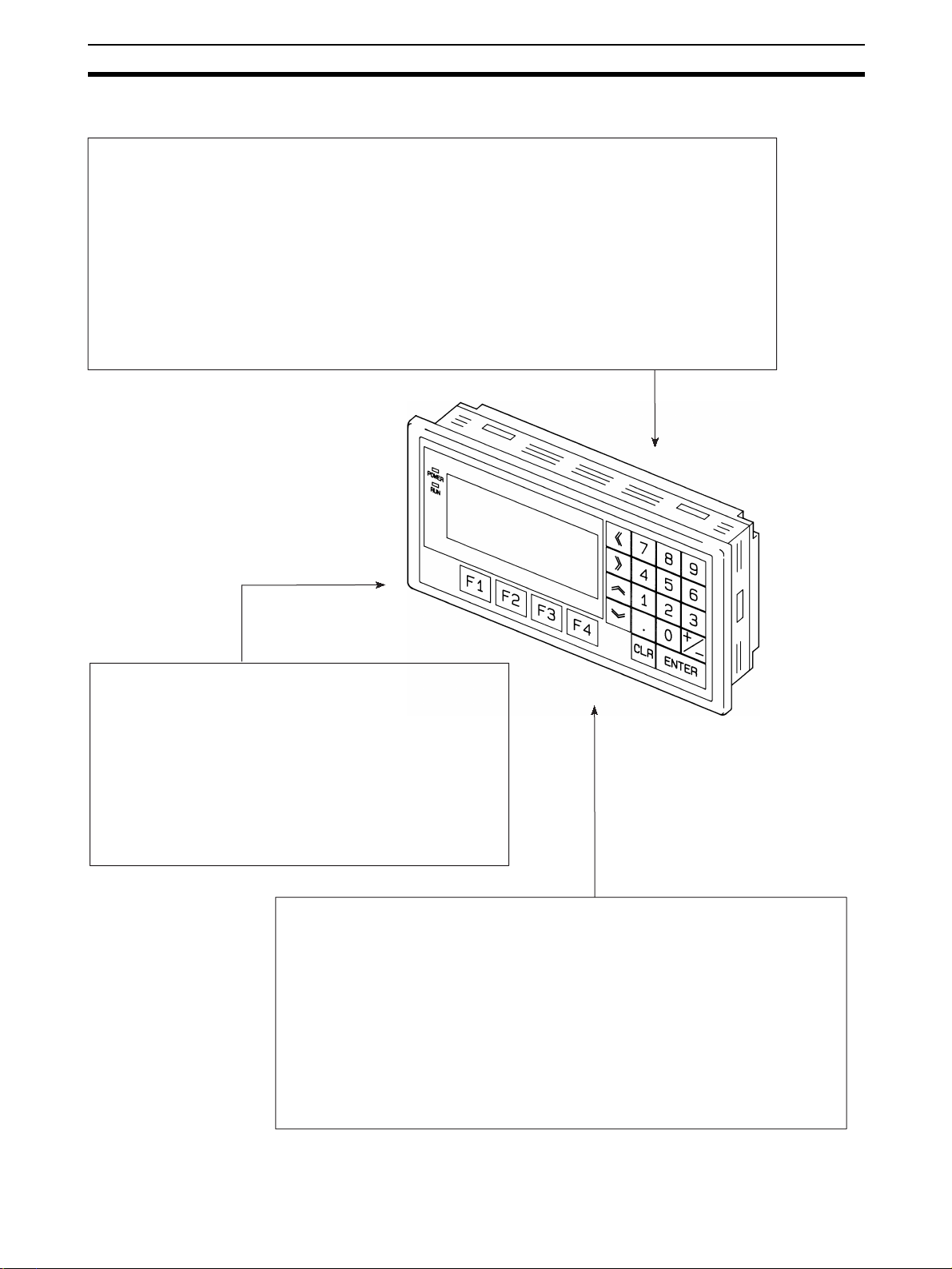

Follow the procedure given below to start the system of the NT11.

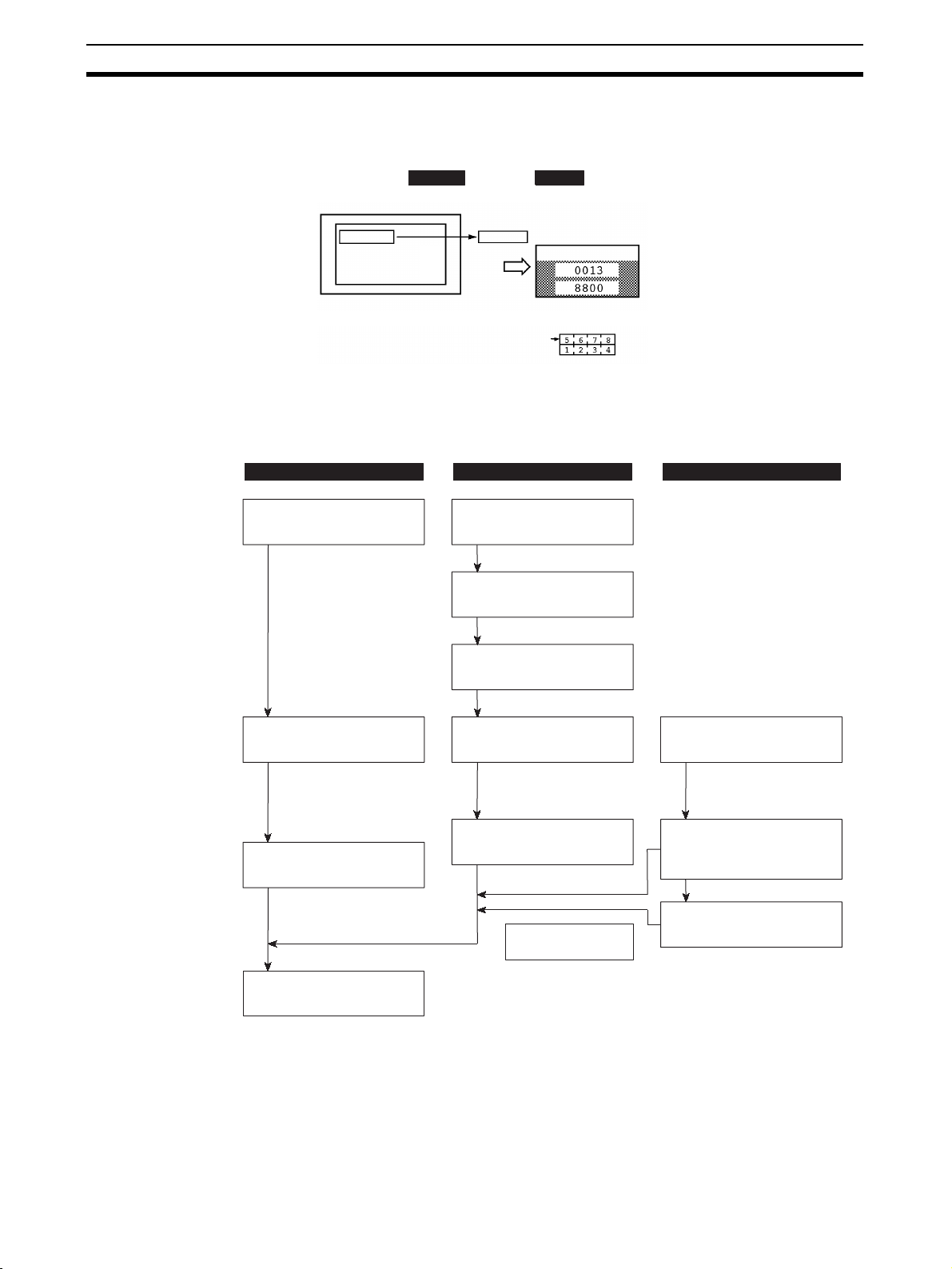

PLC NT11 Support tool

Check and change the

PLC settings.

· For the host link, refer

to page 22 and the

manuals for the host

link unit and peripheral

tools.

· For the NT link, refer to

page 50.

NT11

Numeral memory table entry 13

12345678

12345678

Set the DIP switches.

(page 18)

Install to the operation

panel.

(page 19)

Connect the power supply.

(page 20)

PLC

PT status notify area

Currently display screen

Content update memory table entry

PT status

Allocated word (numeral table 13)

Start

Start + 1

Connect to the NT11.

Create the PLC program.

Start operation.

Connect to the PLC.

· (Host link: page 22)

· (NT link: page 50)

Check the settings and

communications.

Transfer the

screen data.

(page 69)

Install the support tool

in the computer.

Transfer the system

program by using the

system transfer tool.

Create the screens.

(refer to Section 4 and the

manuals for the support tools)

12

Page 26

Before Operating Section 1-6

Reference Use support tool NT-series Support Tool (NT-ZJCAT1-EV4.7).

!Caution Carefully check the operation of all screen data and host programs before

using them.

Otherwise the system may operate unpredictably.

Refer to the following manuals for the equipment and software.

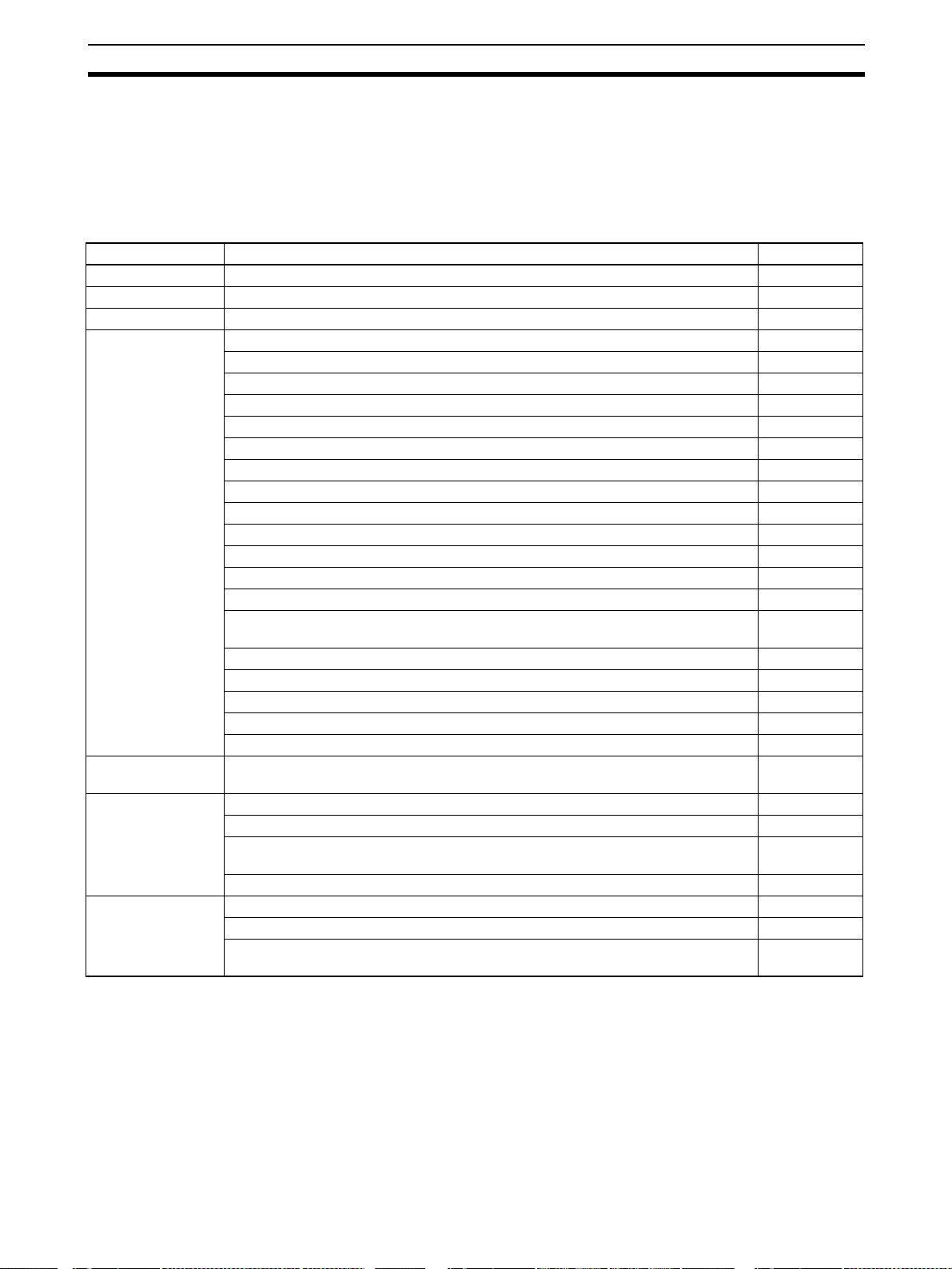

Device or Software Manual Title Cat. No.

NT11 User’s Manual V084-E1-@

System Installer NT-series Support Tool for Windows (Ver. 4.7) Operation Manual V061-E1-@

NT Support Tool NT-series Support Tool for Windows (Ver. 4.7) Operation Manual V061-E1-@

PLC SYSMAC CPM1 Operation Manual W262-E1-@

SYSMAC CPM1A Operation Manual W317-E1-@

SYSMAC CPM2A Operation Manual W352-E1-@

SYSMAC CPM2C Operation Manual W356-E1-@

SYSMAC C200H Operation Manual (for CPU01/03/11) (Programming) W130-E1-@

SYSMAC C200H Operation Manual (for CPU21/23/31) (Programming) W217-E1-@

SYSMAC C200HS Installation Guide W236-E1-@

SYSMAC C200HS Operation Manual (Programming) W235-E1-@

SYSMAC C200HX/HG/HE (-Z) Installation Guide W302-E1-@

SYSMAC C200HX/HG/HE Operation Manual W303-E1-@

SYSMAC C200HX/HG/HE-Z Operation Manual W322-E1-@

SYSMAC CQM1/CPM1/CPM1A/SRM1 Programming Manual W228-E1-@

SYSMAC CQM1H Operation Manual W363-E1-@

SYSMAC CVM1/CV500/CV1000/CV2000/CVM1 Operation Manual: Ladder Dia-

grams

CS Series Programmable Controllers Operation Manual W339-E1-@

CJ Series CJ1G-CPU@@-E Programmable Controllers Operation Manual W393-E1-@

CS/CJ Series Programming Manual W394-E1-@

CS/CJ Series Serial Communications Boards/Units Operation Manual W336-E1-@

SYSMAC CQM1H Series Serial Communications Board Operation Manual W365-E1-@

CompoBus Master

Control Unit

Programming Tools SYSMAC Support Software Operation Manual: C-series PLCs W248-E1-@

Host Link Unit/

Serial Communications Board

SRM1 (-V2) Operation Manual W318-E1-@

SYSMAC Support Software Operation Manual: CVM1 PLCs W249-E1-@

SYSMAC CPT User Manual and Quick Start Guide W332-E1-@

CX-Programmer Ver. 4 User Manual W425-E1-@

SYSMAC C Series Host Link Unit System Manual W143-E1-@

SYSMAC CVM1/CV Series Host Link Operation Manual W205-E1-@

SYSMAC C200HW-COM01 C200HW-COM02-V1 to C200HW-COM06-EV1 Com-

munications Board Operation Manual

W202-E1-@

W333-E1-@

W304-E1-@

13

Page 27

Before Operating Section 1-6

14

Page 28

Hardware Settings and Connections

This section describes the settings of the NT11, connections to a PLC, and other hardware settings.

2-1 Description of Parts and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-1-1 Description of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-1-2 DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-2-1 Installation to the Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-2-2 Power Supply Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-2-3 Wiring the Ground Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-3 Connecting to the NT Support Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-4 Connection to a PLC by the Host Link (RS-232C Type) . . . . . . . . . . . . . . . . 22

2-4-1 Compatible PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2-4-2 Connecting the NT11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-4-3 PLC Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2-5 Connection to a PLC by the Host Link (RS-422A Type) . . . . . . . . . . . . . . . . 38

2-5-1 Compatible PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2-5-2 Parts Required for Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2-5-3 Method for Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2-5-4 Connector Specifications and Wiring for Each Unit . . . . . . . . . . . . 41

2-5-5 PLC Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2-6 Connection to a PLC by the NT Link (RS-232C Type) . . . . . . . . . . . . . . . . . 50

2-6-1 Compatible PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2-6-2 Connecting the NT11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

2-7 Connection to a PLC by the NT Link (RS-422A Type) . . . . . . . . . . . . . . . . . 55

2-8 Connecting a Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2-8-1 How to Connect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

SECTION 2

15

Page 29

Description of Parts and Settings Section 2-1

2-1 Description of Parts and Settings

Before getting to the operation, confirm the names and functions of parts.

Also set the DIP switches on the NT11.

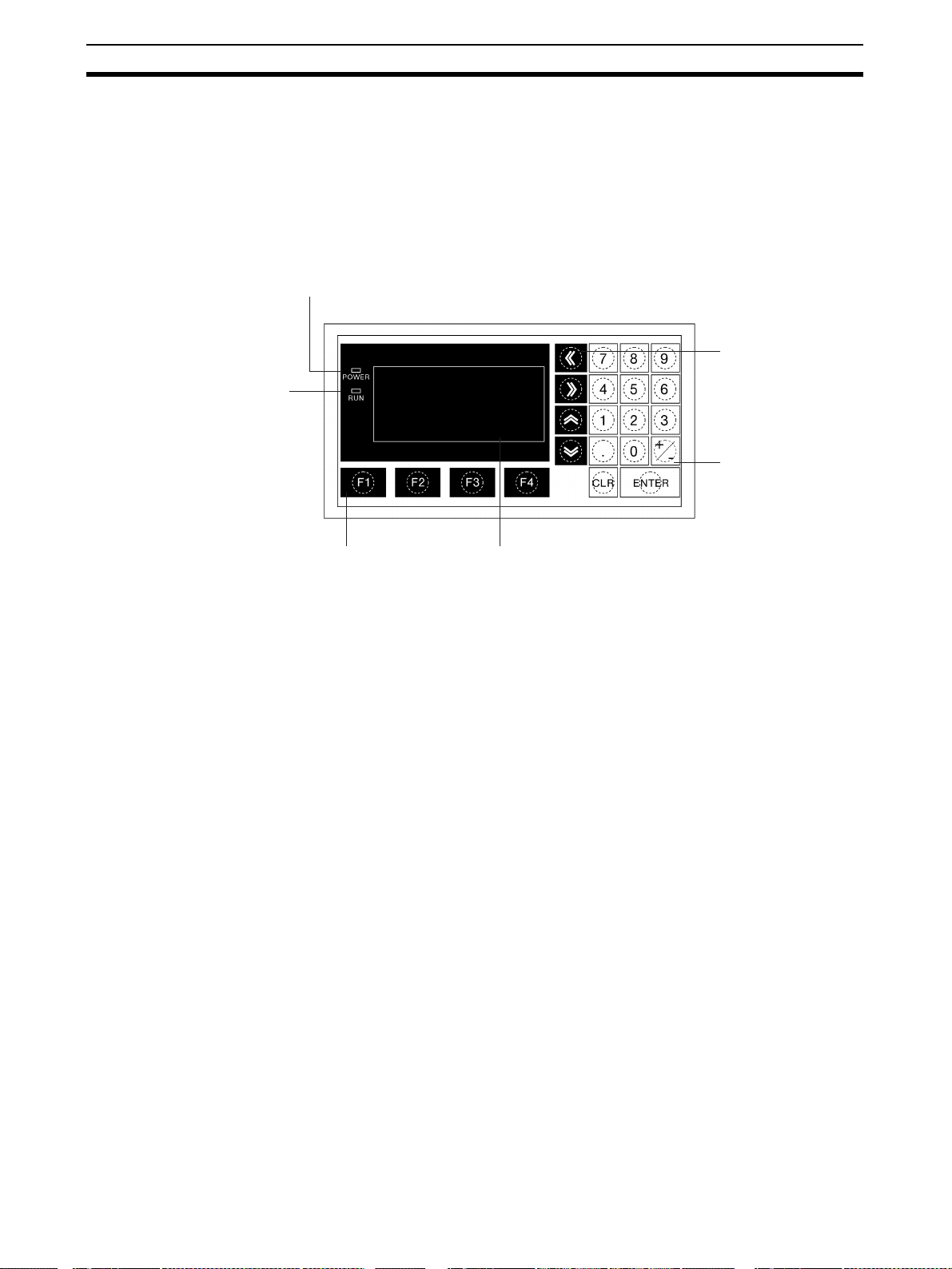

2-1-1 Description of Parts

Front View

POWER LED

Lit when the

power is supplied.

Arrow keys

Used to select the

RUN LED

Lit when the

communication

status is normal.

required numerical

value input field when

there is more than one

on the screen.

Numeric keys

Used for inputting

numerical values on

screens that require

numerical value input.

Function keys

Used for direct

notifications to the PLC.

Display

An LCD screen with a backlight.

Reference The NT11 comes in two body colors.

• NT11-SF121-EV1:Beige

• NT11-SF121B-EV1:Black

16

Page 30

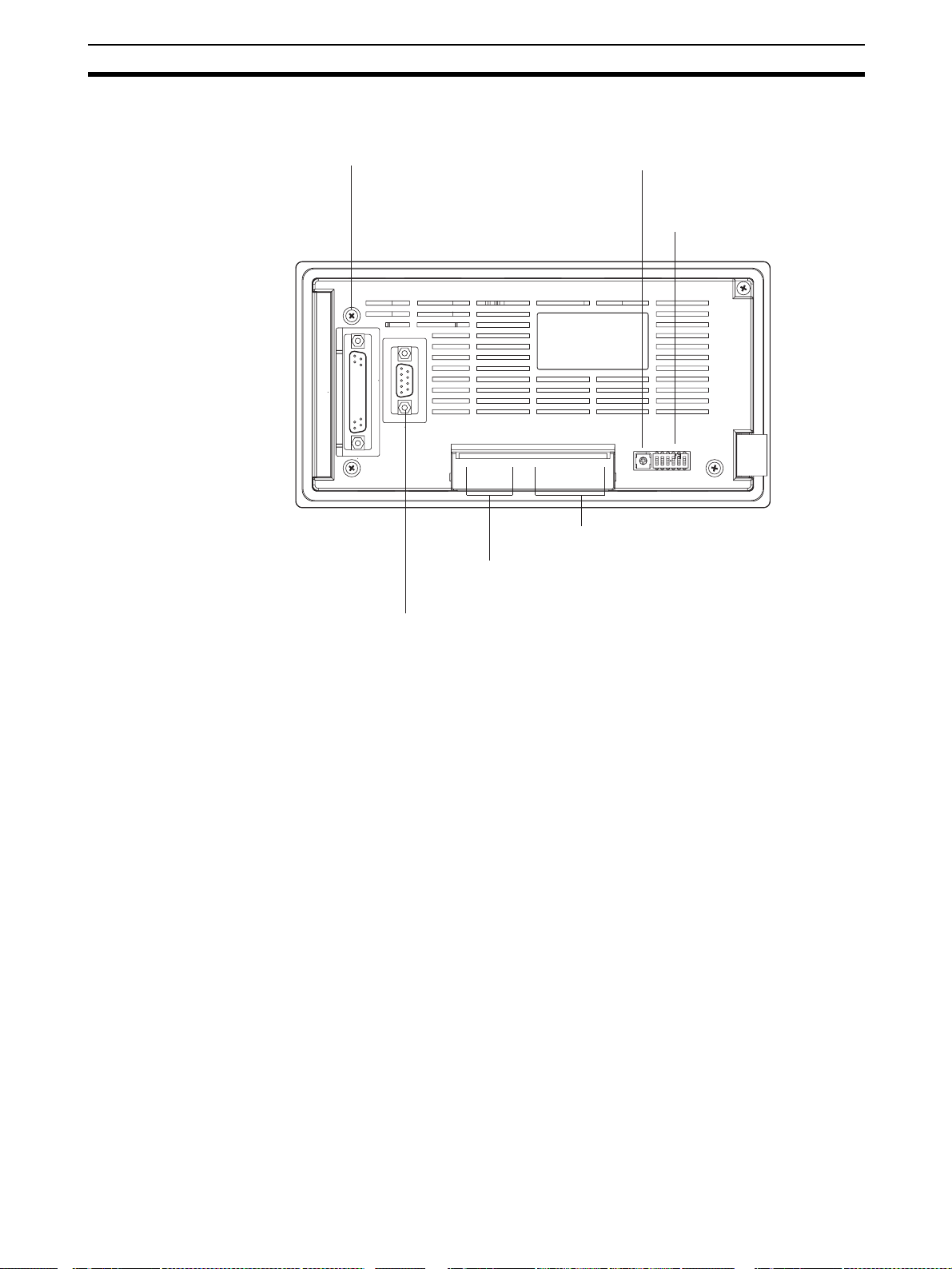

Description of Parts and Settings Section 2-1

Rear View

Connector for parallel interface connection

Connect the printer cable here.

(Interface conforms to Centronics specifications)

Contrast control

Use a fine phillips screwdriver.

Turn clockwise to increase the brightness.

DIP switch

Set various system statuses

with these switches.

RS-422A terminal block

Connect the PLC cable here.

Power input terminals

Connect the power to the

NT11 at these terminals.

RS-232C connector

Connect the cable that connects

the PLC or support tool here.

17

Page 31

Description of Parts and Settings Section 2-1

2-1-2 DIP Switch Settings

Set the NT11 operation status with the DIP switches located in the bottom

right corner on the rear side of the body.

DIP Switch Settings Factory setting: ALL OFF

DIP Switch Pin Function

SW1 1 RS-422A terminating resistance used

0 Not used

SW2 1 Screen data forced initialize effective

0 Ineffective

SW3 1 Emergency transfer mode

0 Ineffective

SW4 1 Switching to the System Menu disabled

0Enabled

SW5 Reserved.

SW6 1 System program erase enabled

0Disabled

Emergency transfer mode: When power to the NT11 is turned ON with DIP

switch pin 3 turned ON, data transfer mode will be

entered directly without any other operation.

!Caution In addition to the DIP switches, set also the “Comm. Method”, “Host Link

Speed”, “Automatic Reset”, etc. at the memory switches. For these settings,

refer to 3-7 Setting the Conditions of Communications with the PLC by Using

the Memory Switches (page 71).

!Caution After changing the switch settings, always press the reset switch or turn the

power off and back on.

Otherwise the system will not operate as expected.

!Caution Confirm system safety before turning the power ON/OFF or resetting.

Otherwise the system may operate unpredictably.

Correct Use Use the “System program erase” function only when changing the system

program.

It the system program is erased, it will not be possible to use the functions of

the NT11 unless another system program is transferred.

18

Page 32

Installation Section 2-2

If the DIP switch settings have been changed when the NT11 is powered,

reset the power to the NT11. The changes with the DIP switches become

effective only after the power supply is reset.

2-2 Installation

Install the NT11 to the operation panel and connect the power to the NT11 as

described below.

1. Do not install the unit at sites subject to the following conditions.

Otherwise, the product may malfunction.

• Severe temperature variations

• Temperature or humidity outside the ranges stated in the specifications

• High humidity, condensation

• Splashing chemical agents

• Severe oil splashing

• Corrosive or flammable gases

• Strong vibrations or shocks

• Direct exposure to wind and rain (outdoor sites)

• Strong ultra-violet irradiation

2. Take adequate measures to ensure shielding if the unit is used at a location subject to any of the following conditions. Otherwise, the product may

malfunction.

• Static electricity, or noise from other equipment

• Strong electromagnetic fields

• Nearby power cables

• Potential exposure to radioactivity

2-2-1 Installation to the Operation Panel

The NT11 can be flush mounted to an operation panel.

Use the panel fittings and tools included in the product package and follow the

procedure below.

!Caution On unpacking the unit, check its external appearance and confirm that there is

no damage. Also confirm that there is no abnormal noise on shaking the unit

lightly. The product may malfunction if it is damaged.

!Caution During work at the panel, take care to ensure that no metal scraps enter the

unit.

Otherwise, the product may malfunction.

!Caution The thickness of applicable operation panel is 1.6 mm to 4.8 mm. All fittings

must be tightened uniformly to a torque of 0.5 to 0.6 N·m in order to ensure

water- and dust-resistance. The panel must not be soiled or warped, and must

be able to support an installation that will remain secure and strong.

1,2,3... 1. Open a hole, shown below, in the panel and install the NT11 from the front

side of the panel.

19

Page 33

Installation Section 2-2

+0.5 mm

98.8

0 mm

+0.5 mm

204.2

0 mm

2. Attach the panel fittings at four positions for the upper/lower sides and at

two positions for the right and left sides, shown below, on the rear side of

the NT11.

Fit the hook of the fitting in the square hole in the body and tighten the

screw with a Phillips head screwdriver while lightly pulling the fitting.

2-2-2 Power Supply Connection

Connect a 24 VDC power supply to the power input terminals.

!Caution Carefully check the wiring before switching ON the power.

!Caution Do not connect AC power to the DC terminals.

!Caution Use DC and AC power supplies with low voltage and frequency fluctuations.

!Caution Do not perform withstand voltage test. Performing withstand voltage test may

result in malfunction.

0 V 24 V

+

• Noise prevention

The NT11 has a noise preventive feature against the power supply line

noise. To further reduce noise, connect a noise filter to the power line.

This will drastically reduce the ground noise.

Breaker

24 VDC Power Supply

20

Page 34

Installation Section 2-2

• Power supply

Applicable power supply specifications are as follows.

Item Value

Power supply voltage 24 VDC

Allowable power supply voltage

fluctuation range

Power supply capacity 10 W or lower

• Parts used for connection

Use crimp terminals to connect the power supply to the power input terminals. Recommended crimp terminals for M3.5 are given below.

20.4 VDC to 26.4 VDC

(24 VDC –15%, +15%)

!Caution For the connection to the power supply terminal block, twisted wires of 2 mm

or greater cross sectional area and M 3.5 size crimp terminals must be used.

Tighten the screws on the terminal block to a torque of 0.5 N

×m.

Otherwise fire may occur.

Fork type Round type

7 mm or less

7 mm or less

[Recommended terminals]

Maker Type

(fork type)

Japan Solderless Terminal MFG 2-YS3A 2-3.5

Fuji Terminal 2-YAS3.5 V2-S3.5

Nichifu Terminal 2Y-3.5 2-3.5

Type

(round type)

Applicable Wire

(stranded wire)

1.04 to 2.63 mm

2

Note When surge noise occurs in the DC power supply, connect a Transistor Volt-

age Suppressor (TVS) between the 24-V and 0-VDC terminals.

Recommended TVS model: 1.5KE33CA

Manufacturers: Vishay Intertechnology Inc, STMicroelectronics

24 VDC

2

2-2-3 Wiring the Ground Wire

The PT is provided with a functional ground (FG: ) terminal.

Wire the FG terminal according to the following conditions.

1. Ground according to Figure when there is difference in potential between

the PT and host. Do not ground the functional ground of the PT if it is far

from the host and one-point grounding is difficult.

2. Do not ground the functional ground (FG: ) of the PT if it is mounted to

the same panel as devices that generate noise, such as motors and inverters.

TVS

21

Page 35

Connecting to the NT Support Tool Section 2-3

PT Host

One-point

grounding

Note Ground correctly to prevent malfunctions caused by noise.

2-3 Connecting to the NT Support Tool

In order to install the system program in the NT11, or to transmit screen data

created with the NT Support Tool to the NT11, the NT11 must be connected to

a personal computer with an RS-232C cable.

The NT11 connects with the RS-232C cable from a personal computer at the

RS-232C serial port.

Serial port A

(RS-232C, 9-pin)

Communication Conditions

The communication conditions are automatically set when the system installer

and NT Support Tool are started.

Recommended Connector Cable

Use the cable indicated below.

• XW2Z-S002 (length: 2 m), made by OMRON

(D-SUB 9-pin, male Û D-SUB 9-pin, female)

For details on making a connector cable, refer to Appendix E Making the

Cable for Connecting a Personal Computer (page 155).

2-4 Connection to a PLC by the Host Link (RS-232C Type)

Connect the NT11 to an OMRON PLC by using RS-232C type the host link

method.

In order to make a connection to the PLC using the host link method (RS232C type), the “Comm. Type” memory switch of the NT11 must be set to

“host link”, and the “Comm. Port” memory switch must be set to “RS-232C”.

For details on memory switch settings, refer to 3-7-1 Selecting the Host Com-

munication Method (page 73).

22

Page 36

Connection to a PLC by the Host Link (RS-232C Type) Section 2-4

2-4-1 Compatible PLCs

Some models and series of OMRON PLCs have the host link function built in.

Check the model and series of the PLC against the type of host link unit

before making the connections.

The compatible PLCs are listed in the table below.

PLC

Series

CS Series CS1G-CPU42/43/44/45-EV1

CJ Series CJ1G-CPU44/45 CJ1G-CPU44/45 CJ1W-SCU41 CJ1G

C Series --- C200HS-CPU01/03/21/23/31/

CVM1

Series (*3)

CompoBus/S

Master

Unit

Units with Built-in Host Link

Function

CS1H-CPU63/64/65/66/67-EV1

CS1G-CPU42H/43H/44H/45H

CS1H-CPU63H/64H/65H/66H/

67H

C200HS-CPU21/23/31/33-E --- --- C200HS

C200HE-CPU42-E

C20HE-CPU42-ZE

C200HG-CPU43/63-E

C200HG-CPU43/63-ZE

C200HX-CPU44/64-E

C200HX-CPU44/64/65/85-ZE

CPM1-10/20/30CDR-@

+CPM1-CIF01

CPM1A-10/20/30/40CD@-@

+CPM1-CIF01

CPM2A-30/40/60CD@@-@

+CPM1-CIF01

(Peripheral port connection)

CPM2C-10/20@@@@@@-@

(*1)

CQM1-CPU21-E

CQM1-CPU41/42/43/44-EV1

CQM1H-CPU11/21/51/61 (*2) CQM1H-CPU51/61 CQM1H-SCB41 CQM1H

CVM1-CPU01-EV2

CVM1-CPU11-EV2

CVM1-CPU21-EV2

SRM1-C02-V1 --- --- SRM1

CPU Units Connectable with

Host Link Units or Expansion

Communication Board

CS1G-CPU42/43/44/45-EV1

CS1H-CPU63/64/65/66/67-EV1

CS1G-CPU42H/43H/44H/45H

CS1H-CPU63H/64H/65H/66H/

67H

33-E

C200HE-CPU11/32/42-E

C200HE-CPU11/32/42-ZE

C200HG-CPU33/43/53/63-E

C200HG-CPU33/43/53/63-ZE

C200HX-CPU34/44/54/64-E

C200HX-CPU34/44/54/64/65/

85-ZE

C200HE-CPU32/42-E

C200HE-CPU32/42-ZE

C200HG-CPU33/43/53/63-E

C200HG-CPU33/43/53/63-ZE

C200HX-CPU34/44/54/64-E

C200HX-CPU34/44/54/64/65/

85-ZE

--- --- CPM1

--- ---

--- --- CPM2A

--- --- CPM2C

--- --- CQM1

CVM1-CPU01-EV2

CVM1-CPU11-EV2

CVM1-CPU21-EV2

Host Link Unit/

Communication

Board

CS1W-SCU21

CS1W-SCB21

CS1W-SCB41

C200H-LK201-EV1 C200HS

C200HW-COM02/04/

05/06-EV1

CV500-LK201 CVM1

Connectable

CS1G

CS1H

CS1G-H

CS1H-H

C200HE

C200HE-Z

C200HG

C200HG-Z

C200HX

C200HX-Z

C200HE

C200HE-Z

C200HG

C200HG-Z

C200HX

C200HX-Z

to

*1: Use a CPM2C-CN111 or CS1W-CN114/118 Connecting Cable, CPM1-CIF01 RS-232C Adapter, or CPM1-

CIF11 RS-422A Adapter to connect.

23

Page 37

Connection to a PLC by the Host Link (RS-232C Type) Section 2-4

*2: The CQM1H-CPU11 does not have a built-in RS-232C port, so connect to the PT at the peripheral port

with a CS1W-CN118 Connecting Cable.

*3: CPU Units of CVM1/CV-series PLCs without the suffix -EV@ cannot be connected.

2-4-2 Connecting the NT11

Refer to the illustrations below to select the appropriate cable for the unit connectors and connect the NT11 to the PLC.

To make a connector cable, refer to Appendix D Making the Cable (page 153).

!Caution Before inserting or removing the connectors, make sure that the NT11 and the

PLC are turned OFF.

!Caution After connecting a communication cable, always secure it with the screws.

Otherwise the cable may disconnect, causing operation to fail.

!Caution The cable’s tensile load is 30 N. Do not subject it to loads greater than this.

Otherwise a discontinuity may occur, causing operation to fail.

Connecting to a PLC with a 25-pin Connector

Use a connector cable with a 25-pin connector on one end and a 9-pin connector on the other end (NT11 side) to connect the NT11 to a PLC with a 25pin connector.

Host I/F connector

(RS-232C 9-pin type)

9-pin connector 25-pin connector

Connecting to a PLC with a 9-pin Connector

Use a connector cable with a 9-pin connector on both ends to connect the

NT11 to a PLC with a 9-pin connector.

Host I/F connector

(RS-232C 9-pin type)

9-pin connector

The method for connection between the RS-232C ports of the NT11 and the

host is described here.

NT11

NT11

RS-232C connector cable

RS-232C connector cable

Host link unit/CPU unit

Host link unit/CPU unit

9-pin connector

C200H,

C200HS

C200H,

C200HS

24

Recommended Connector Cable

When making the connector cable, as far as possible use the recommended

connectors, connector hoods, and cables indicated in the table below. Some

Units come supplied with one connector and one connector hood.

Page 38

Connection to a PLC by the Host Link (RS-232C Type) Section 2-4

Check the required components and prepare them in advance.

Name Model Remarks Delivered with

CS-series CS1G/CS1H,

CS1G-H/CS1H-H

CJ-series CJ1G

Connector

Connector

hood

Connector

set

Cable

XM2A-0901

XM24-2501

XM2S-0911

XM2S-0913

XM2S-0911-E

XM2S-2511

XM2S-0911S003

AWG28´5P

IFVV-SB

CO-MA-VV-SB

5P´28AWG

9-pin

Made by OMRON

25-pin

Made by OMRON

9-pin

Made by OMRON

9-pin

Made by OMRON

9-pin

Made by OMRON

25-pin

Made by OMRON

9-pin

Made by OMRON, connector and hood included

Multi-core shielded cable

Made by Fujikura, Ltd.

Multi-core shielded cable

Made by Hitachi Cable,

Ltd.

C-series CQM1, C200HS,

C200HX/HG/HE(-Z)E,

CVM1/CV-series CPU

Units

CV500-LK201

CV500-LK201

C200H-LK201-EV1

C-series CQM1, C200HS,

C200HX/HG/HE-(Z)E,

CVM1/CV-series CPU

Units

CV500-LK201

---

CS-series CS1G/CS1H,

CS1G-H/CS1H-H

CJ-series CJ1G

CV500-LK201

C200H-LK201-EV1

---

---

---

Note After connecting a communication cable, always secure it with the screws.

Note The cable’s tensile load is 30 N. Do not subject it to loads greater than this.

Wiring for a Host Link Unit

(25-pin) Connection

Otherwise the cable may disconnect, causing operation to fail.

OMRON Cables with Connectors

The OMRON cables listed below can be used when connecting with a method

other than the memory link method.

Model Cable Length Connector Specification

XW2Z-200S 2 m

XW2Z-500S 5 m

XW2Z-200T 2 m

XW2Z-500T 5 m

9-pin Û 25 pin

9-pin Û 9-pin

Otherwise a discontinuity may occur, causing operation to fail.

Applicable Units: C200H-LK201-EV1

CV500-LK201 (communication port 1)

Compatible cables with attached connectors:

XW2Z-200S (9-pin

XW2Z-500S (9-pin

Û 25-pin, 2 m)

Û 25-pin, 5 m)

25

Page 39

Connection to a PLC by the Host Link (RS-232C Type) Section 2-4

CVM1/CV-series Host Link Units (CV500-LK201) have two types of connector; a 25-pin connector (communication port 1), and a 9-pin connector (communication port 2). When using communication port 2, refer to Wiring for

Other Connections (Other Than the Memory Link Method) (page 26).

1

5

Wiring for Other

Connections

6

9

NT11

RS-232C

interface

(9-pin type)

Abbreviation

FG

SD

RD

RS

CS

+5V

5G

Pin

number

Connector

hood

1

2

3

4

5

6

7

8

9

Shield

PLC (Host Link Unit)

Pin

Abbreviation

number

Connector

FG

hood

2

SD

3

RD

4

RS

5

CS

6

*

-

7

5G

8

-

-

-

-

-

-

-

-

ER

RS-232C

interface

114

(25-pin type)

13 25

* For Units that have a CTS setting selector switch, RS and CS do not have to

be shorted if this switch is set to 0 V.

Applicable Units:

CV500-LK201 (communication port 2)

CS1W-SCU21 CJ1W-SCU41

CPM1-10CDR-@ CPM1-20CDR-@

CPM1-30CDR-@

CPM1A-10CD@-@ CPM1A-20CD@-@

CPM1A-30CD@-@ CPM1A-40CD@-@

CPM2A-30CD@-@ CPM2A-40CD@-@

CPM2A-60CD@-@

CPM2C-10@@@@@@-@ CPM2C-20@@@@@@-@

CQM1-CPU21-E

CQM1-CPU41-EV1 CQM1-CPU42-EV1

CQM1-CPU43-EV1 CQM1-CPU44-EV1

CQM1H-CPU11 CQM1H-CPU21

CQM1H-CPU51 CQM1H-CPU61

CS1G-CPU42-E(V1) CS1G-CPU43-E(V1)

CS1G-CPU44-E(V1) CS1G-CPU45-E(V1)

CS1H-CPU63-E(V1) CS1H-CPU64-E(V1)

CS1H-CPU65-E(V1) CS1H-CPU66-E(V1)

CS1H-CPU67-E(V1)

CS1G-CPU42H CS1G-CPU43H

CS1G-CPU44H CS1G-CPU45H

CS1H-CPU63H CS1H-CPU64H

CS1H-CPU65H CS1H-CPU66H

CS1HCPU67H

CJ1G-CPU44 CJ1G-CPU45

C200HS-CPU21-E, -EC C200HS-CPU23-E

C200HS-CPU31-E C200HS-CPU33-E

C200HE-CPU32-(Z)E C200HE-CPU42-(Z)E

C200HG-CPU33-(Z)E C200HG-CPU43-(Z)E

C200HG-CPU53-(Z)E C200HG-CPU63-(Z)E

C200HX-CPU34-(Z)E C200HX-CPU44-(Z)E

26

Page 40

Connection to a PLC by the Host Link (RS-232C Type) Section 2-4

C200HX-CPU54-(Z)E C200HX-CPU64-(Z)E

C200HX-CPU65-ZE C200HX-CPU85-ZE

CVM1-CPU01-EV2 CVM1-CPU11-EV2

CVM1-CPU21-EV2

SRM1-C02-V2

Compatible cables with attached connectors:

XW2Z-200T (9-pin

XW2Z-500T (9-pin

CPU Units of CVM1/CV-series PLCs without the suffix -EV@ cannot be connected by any connection method.

Û 9-pin, 2 m)

Û 9-pin, 5 m)

1

5

6

9

NT11 PLC (Host Link Unit)

Abbreviation

FG

-

SD

RD

RS-232C

RS

interface

CS

+5V

−

−

SG

(9-pin type)

2-4-3 PLC Switch Settings

When the NT11 and PLC are connected to each other, set the conditions at

the PLC host link unit or the CPU as given in the table below.

The following is a general description of switch settings.

Refer to the manual for respective units for the details of the switch settings.

I/O port RS-232C

Baud rate Set the same baud rate as the NT11. (*1)

Transfer code ASCII 7 data bits, 2 stop bits

Parity Even

1-to-1/1-to-N 1-to-N (*2)

Instruction level Level 1, 2, 3

Unit No. 00

1

Pin

number

Connector

hood

1

2

3

4

5

6

7

8

9

Shield

*

Pin

number

Connector

hood

2

3

4

5

6

7

8

9

(9-pin type)

Abbreviation

FG

SD

RD

RS

CS

−

−

−

SG

RS-232C

interface

5

Item Switch Setting

6

9

*1 Set the host link baud rate up to 115,200 bps with the memory switch for

“host link baud rate”. For the details, refer to 3-7-2 Selecting the Host Link

Communication Speed (page 74).

*2 The 1-to-N setting enables BCC (Block Check Character). The 1-to-1 con-

nection cannot be used to connect the NT11 to a host link unit.

27

Page 41

Connection to a PLC by the Host Link (RS-232C Type) Section 2-4

Connecting to a C-series Host Link Unit

C200H/C200HS/C200HE/HG/HX (-Z)E Rack-mounted Unit:

C200H-LK201-V1

Setting the Front Switches

Set each switch with a flat blade screwdriver so that the values or symbols in

the setting value window agree with the following.

LK201

RUN

RCV

SW1

SW3

XMT

ERROR

SW2

0

0

SW4

2

5

•

Unit # (SW1, SW2)

Set these switches to 0.

•

Command level, parity, and transfer code (SW4)

Set this switch to 2.

• Baud rate (SW3)

Set this switch to 5 to select 9,600 bps.

Set this switch to 6 to select 19,200 bps.

Setting the Rear Switches

ON

1

2

3

CTS selector switch

External

0 V (ON)

4

• 1-to-1/1-to-N selection (DIP switch)

Set pin 3 to ON.

• CTS selection (selector switch)

Set this always to 0 V (ON).

Connecting to a CVM1/CV-series Host Link Unit

CVM1/CV-series Rack-mounted Unit: CV500-LK201

A CVM1/CV-series Host Link Unit (CV500-LK201) has two connectors (communication ports 1 and 2). Either of these ports can be used for connection to

an NT11 by the RS-232C method. However, since the connectors at these

ports are of different types, a cable that matches the connector must be prepared.

• Communication port 1

Communication port 1 is a 25-pin connector for RS-232C use only.

• Communication port 2

Communication port 2 is a 9-pin connector that allows selection of the

RS-232C or RS-422A method. When this port is used with the RS-232C

method, the I/O port selector switch on the front of the Unit must be set to

RS-232C (the upper position).

28

Page 42

Connection to a PLC by the Host Link (RS-232C Type) Section 2-4

CPU Bus Unit Settings

When connecting to a CVM1/CV-series Host Link Unit, set the following communication conditions for the CPU Bus Unit settings.

Item Setting at Host

Baud rate

Set the same baud rate as set at the NT11

Transfer code ASCII, 7 data bits, 2 stop bits

Parity Even

1-to-1, 1-to-N

1-to-N

(*2)

Command level Level 1, 2, 3

*1 Set the Host Link baud rate up to 115,200 bps with the memory switch at

the NT11. For details, refer to Setting the Host Link Method (page 74).

*2 The 1-to-N setting enables BCC (Block Check Character). It is not actually

possible to connect more than one NT11 in a single Host Link.

Set the CPU Bus Unit settings directly from a Programming Device (e.g.,

SYSMAC Support Software).

For details on the CPU Bus Unit settings, refer to the SYSMAC CVM1/CV-

series Host Link Unit Operation Manual (W205-E1-@).

Setting the Front Switches

(*1)

Communications port 1

(RS-232C)

Communications port 2

(RS-232C/RS-422A)

I/O port selector switch

RS-232C

RS-422A

Connecting to a CS/CJ-series Serial Communications Unit

CS/CJ-series Rack-mounted Unit: CS1W-SCU21CJ-series:

CJ1W-SCU41 (Port 2 is an RS-232C Port.)

• Unit # (SW3, SW4)

When using communication port 2, set these

switches to 0.

• I/O port selection (selector switch)

Set this to RS-232C.

• CTS selection (Pins 2 and 3)

Set pin 2 or 3 to ON. (Set this always to 0 V.)

To use communication port 1, turn ON pin 2.

To use communication port 2, turn ON pin 3.

• Communication condition setting (Pin 1)

Set this pin to OFF.

Communication is executed in accordance with the

CPU Bus Unit system settings made at the PLC. The

initial values for the system settings are as follows.

- Baud rate: 9,600 bps

- Parity: Even

- Xon/Xoff control: Not executed

- Communication method: Full duplex

- Stop bits: 2 stop bits

- Data length: 7 bits

Setting the Front Switches

Set the unit number of the Serial Communications Unit by using the rotary

switch located on the front panel. Set each switch with a flat blade screwdriver

29

Page 43

Connection to a PLC by the Host Link (RS-232C Type) Section 2-4

so that the values or symbols in the setting value window agree with the following.

CS1W-SCU21

SCU21

RUN

ERC

SD1

RD1

CJ1W-SCU41

Allocation DM Area Settings for CPU Unit

Settings are written from the Programming Device (a Programming Console

or CX-Programmer) directly into the allocated DM Area (PLC Setup) of the

CPU Unit. After the settings are written, they become effective by turning the

power ON, restarting the Unit, restarting the communication port, or execution

of the STUP instruction.

The following table shows the words allocated in the DM Area and the settings.

m = DM30000 + 100

RDY

ERH

SD2

RD2

UNIT

F

0

E

1

No.

C

´ unit number

Set the unit number to 0 through F so

that it will not duplicate the numbers

used in other Units.

Set the unit number to 0 through F so

that it will not duplicate the numbers

used in other Units.

Allocated DM word Value Settings

Port 1 Port 2

m m+10 8000 Host Link mode, 2 stop bits, even parity, data

length 7 bits

m+1 m+11 0000 Baud rate 9,600 bps

0007 Baud rate 19,200 bps

0008 Baud rate 38,400 bps

0009 Baud rate 57,600 bps

000A Baud rate 115,200 bps

m+2 m+12 0000 Transmit delay time 0 ms

m+3 m+13 0000 No CTS control Unit No. 0 for Host Link

Connecting to a CPU Unit CV-series and CVM1/CV-series (-EV

CVM1-CPU01-EV2/CVM1-CPU11-EV2/CVM1-CPU21-EV2

PLC Setup

When connecting to a CVM1/CV-series CPU Unit, set the following communication conditions for the PLC Setup.

Item Setting at Host

Baud rate

Stop bits 2 stop bits

Parity Even

Data length ASCII 7 bits

Unit # 00

Set the same baud rate as set at the NT11

@) CPU Units

(*1)

30

*1 Set the Host Link baud rate at 9,600 bps with the memory switch at the

NT11. For details, refer to Setting the Host Link Method (page 74).

Page 44

Connection to a PLC by the Host Link (RS-232C Type) Section 2-4

Either set PLC Setup directly from a Programming Device (e.g., SYSMAC

Support Software), or transmit the PLC Setup made at a Programming Device

to the CPU Unit.

For details on the PLC Setup, refer to the SYSMAC CVM1/CV500/1000/2000

Operation Manual: Ladder Diagrams (W202-E1-@).

Setting the Front Switches

• Host Link Communication method

(selector switch)

Set this to RS-232C.

• System setting (Pin 4)

To effect the existing DIP switch settings,

set SW4 to ON.

To effect the existing PLC Setup, set pin 4

I/O port selector switch

RS-232C

RS-422A

to OFF.

Note

For CPU Units manufactured before or

during June 1995 (lot No. @@65), the

existing DIP switch settings differ from

the existing PLC Setup as follows.

- DIP switch settings:

2,400 bps, 1 stop bit, even parity, 7 bit

data length

- PLC Setup:

9,600 bps, 2 stop bits, even parity, 7 bit

data length

For CPU Units manufactured from July

1995 onward (lot No. @@75), the

stipulated values in the DIP switch

settings also are 9,600 bps and 2 stop

bits.

C-series C200HS, C200HX/HG/HE(-Z)E, CPM1, CPM2A, CPM2C, CQM1,

CQM1H CPU Units and SRM1

The connection method depends upon the model of PLC being used, as

shown in the following table.

PLC model Connection method

C200HS, CQM1 Connect to the CPU Unit’s built-in RS-232C port.

C200HX/HG/HE(-Z)E • Connect to the CPU Unit’s built-in RS-232C port.

• Connect to one of the RS-232C ports (port A or port B) on

a Serial Communications Board.

CQM1H • Connect to the CPU Unit’s built-in RS-232C port.

• Connect to the peripheral port through a CS1W-CN118

Connecting Cable.

• Connect to the RS-232C port (port 1) on a Serial Communications Board.

CPM1 Connect to the peripheral port through a CPM1-CIF01 RS-

232C Adapter.

31

Page 45

Connection to a PLC by the Host Link (RS-232C Type) Section 2-4

PLC model Connection method

CPM2A, SRM1 • Connect to the CPU Unit’s built-in RS-232C port.

• Connect to the peripheral port through a CPM1-CIF01 RS232C Adapter.

CPM2C Connect to the CPU Unit’s RS-232C port or the peripheral

PLC Setup Settings

When connecting to a C200HS, C200HX/HG/HE(-Z)E, CPM1, CPM2A,

CPM2C, CQM1, or CQM1H CPU Unit, or SRM1, set the following communication conditions for the PLC Setup.

Item Setting at Host

Communication mode Host Link mode

Baud rate

Stop bits 2 stop bits

Parity Even

Data length ASCII 7 bits

Unit # 00

port through a Connecting Cable (CPM2C-CN111, CS1WCN118, or CS1W-CN114).

(The CPM2C-CN111 splits the Unit’s Communication Port

into a RS-232C port and a peripheral port. A CPM1-CIF01

RS-232C Adapter is also required to connect to this peripheral port.)

Set the same speed as set at the NT11

(*1)

*1 Set the Host Link baud rate at 9,600 bps or 19,200 bps with the memory

switch at the NT11. For details, refer to Settings the Host Link Method

(page 74).

Set the PLC Setup settings directly from a Programming Device (e.g., the CXProgrammer Support Software).

For details on operations relating to the PLC Setup, refer to the manual for the

PLC which is used.

The PLC Setup area word addresses and settings to be made depending on

the Unit and port to which the connection is made are shown below.

CPM2A, CPM2C, CQM1H, or SRM1: Peripheral port connection

Word Writing Value Settings

DM6650 0001 Host Link mode, no CTS control

Communication conditions set by the contents of DM

DM6651 0303 Data length 7 bits, 2 stop bits, even parity, baud rate:

9,600 bps

0304 Data length 7 bits, 2 stop bits, even parity, baud rate:

19,200 bps

DM6653 0000 Unit # 00

32

Page 46

Connection to a PLC by the Host Link (RS-232C Type) Section 2-4

C200HS, C200HX/HG/HE(-Z)E, CPM2A, CPM2C, CQM1, CQM1H (other

than the CPU11), or SRM1: Built-in RS-232C port connection

Word Writing Value Settings

DM6645 0001 Host Link mode, no CTS control

Communication conditions set by the contents of DM

DM6646 0303 Data length 7 bits, 2 stop bits, even parity, baud rate:

9,600 bps

0304 Data length 7 bits, 2 stop bits, even parity, baud rate:

DM6648 0000 Unit # 00

C200HX/HG/HE(-Z)E: Serial Communications Board port A

CQM1H: Serial Communications Board port 1

Word Writing Value Settings

DM6555 0001 Host Link mode, no CTS control

DM6556 0303 Data length 7 bits, 2 stop bits, even parity, baud rate:

0304 Data length 7 bits, 2 stop bits, even parity, baud rate:

DM6558 0000 Unit # 00

19,200 bps

Communication conditions set by the contents of DM

9,600 bps

19,200 bps

C200HX/HG/HE(Z)E: Serial Communications Board port B

Word Writing Value Settings

DM6550 0001 Host Link mode, no CTS control

Communication conditions set by the contents of DM