Page 1

NT-series

NT20M/NT600M Support Tool

Operation Manual

Revised August 1993

Page 2

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to head precautions can result in injury to people or damage to the product.

DANGER! Indicates information that, if not heeded, is likely to result in loss of life or serious

injury.

WARNING Indicates information that, if not heeded, could possibly result in loss of life or

serious injury.

Caution Indicates information that, if not heeded, could result in relative serious or minor

injury, damage to the product, or faulty operation.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

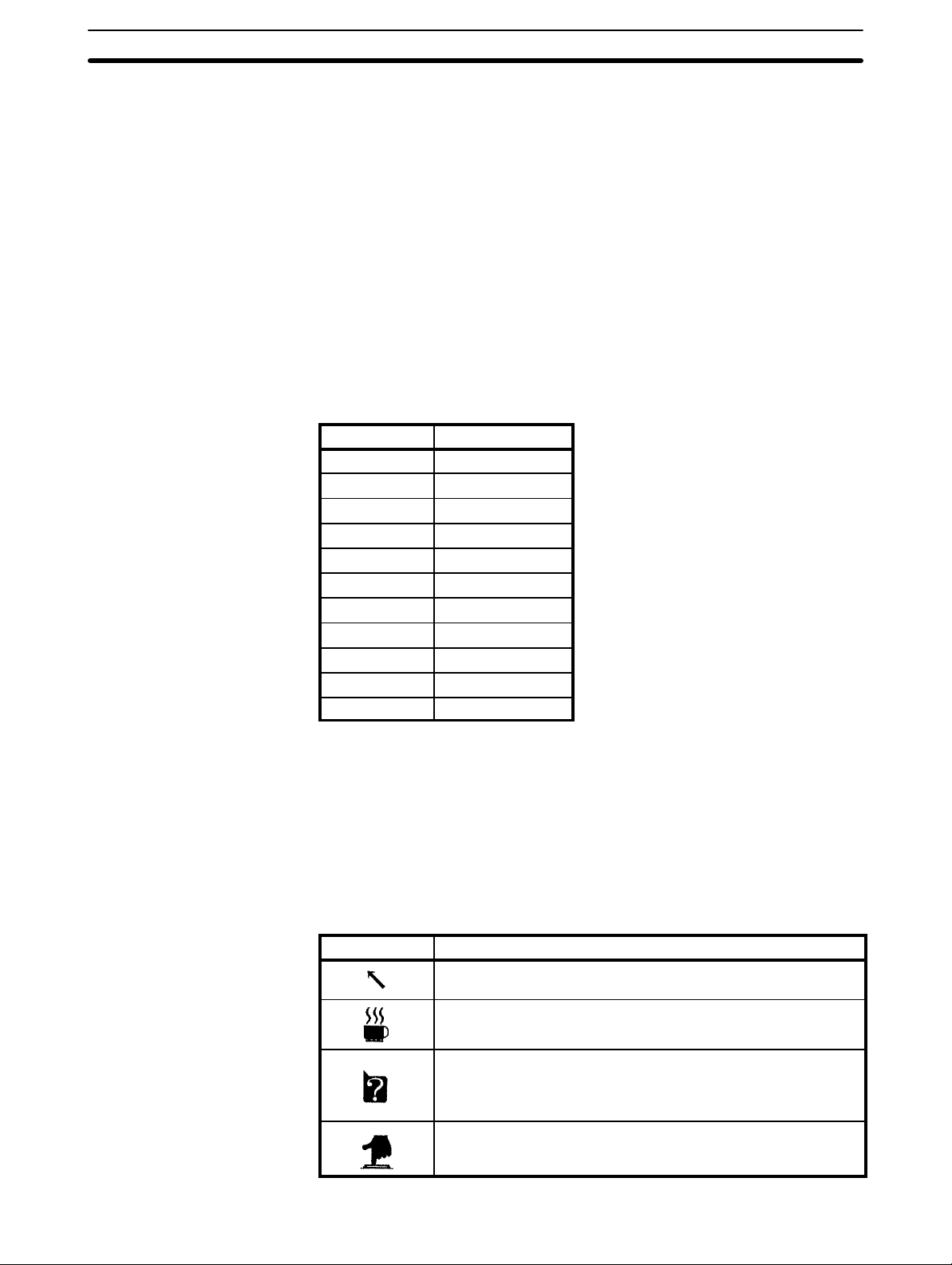

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1991

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note

1, 2, 3...

Indicates information of particular interest for efficient and convenient operation of the product.

Indicates lists of one sort or another, such as procedures, precautions, etc.

v

Page 3

TABLE OF CONTENTS

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Terminology and NT-series Manuals 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Using Older Models 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 System Configuration 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Creating a Work Disk 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Starting and Exiting 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 Main Menu 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7 File Selection 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8 Screen Selection 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9 Inputting Screen Comments, File Names, and Titles 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-10 Editing Screens 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-11 Inputting Character Strings and Numbers 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-12 Basic Operation 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-13 Tool Settings 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-14 Environment Settings 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-15 Direct Connection 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Creating Screens 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Inputting Character Strings 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Numeral Displays 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Character String Displays 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Lamps 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Touch Switches 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 Bar Graphs 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 Editing Memory Tables 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 Numeral Editing 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9 Polylines 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10 Circles 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-11 Continuous and Overlapping Screens 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-12 Screen Attributes 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-13 Screen Check 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-14 Marks 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-15 Stand-alone Operation 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-16 Edit 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Managing Screen Data 89. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Copying Screens 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Deleting Screens 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Changing Screen Comments 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Reading Data from Other Files 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Managing File Data 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Copying Files 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Deleting Files 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Changing File Titles 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Saving PT Histories in Files 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 Setting Initial Screens 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 4

SECTION 5

Printing 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Printing Features 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Printing from the File Selection Display 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Printing from the Screen Selection Display 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6

Transmitting Data 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Connecting to the PT 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Transmitting Data 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Receiving Data 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Deleting PT Screens 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7

PROM Writer Operations 117. . . . . . . . . . . . . . . . . . . . . . . . .

7-1 Connecting to a PROM Writer 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 Transmitting Data to a PROM Writer 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3 Transmitting Data with Verification to a PROM Writer 119. . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4 Receiving Data from a PROM Writer 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix: Special Characters 123. . . . . . . . . . . . . . . . . . . . . .

Index 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 5

About this Manual:

This manual describes the installation and operation of the Support Tool and includes the sections

described below. The Support Tool is a software package for creating and managing displays for the

NT20M and NT600M Programmable Terminals (PTs).

Please read this manual completely and be sure you understand the information provided before attempting to install and operation the Support Tool.

Section 1

ating and input methods common to most Support Tool features are covered. The last section,

Settings

Section 2

Special features include numeral displays, character string displays, lamps, and bar graphs, all of

which can be used to display on-screen data transferred to the PT from the PT’s host, and numeral

editing and touch switches, both of which can be used to input data on-screen for transfer to the host

from the PT.

Section 3

Section 4

Section 5

Section 6

PT. This section also includes remote operations for deleting screens from the PT.

Section 7

PROM writer.

The

provides an overview of Support Tool operation and its operating environment. Basic oper-

, describes how to set Support Tool operating parameters, which affect overall operation.

describes the specific operations used to create displays for Programmable Terminals.

describes how to manage screens as whole units.

describes how to manage files.

describes how to print screen images.

describes the setup and methods for transferring data between the Support Tool and the

describes the setup and methods for transferring data between the Support Tool and a

Appendix

provides a table of English character codes.

Tool

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

ix

Page 6

SECTION 1

Introduction

This section outlines the operations of the Support Tool. It includes general operating procedures and installation procedures, as well as miscellaneous information, such as the functional limitations when creating screens for older PT models. Refer to the other sections in this manual for details on specific operations. Reference pages are given in this section

for many operations.

1-1 Terminology and NT-series Manuals 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Using Older Models 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 System Configuration 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-1 NT20M and NT600M Support Tool Operations 3. . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-2 Menu Configuration 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-3 Support Tool System 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Creating a Work Disk 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Starting and Exiting 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 Main Menu 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7 File Selection 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8 Screen Selection 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9 Inputting Screen Comments, File Names, and Titles 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9-1 Screen Comments 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9-2 File Names and Titles 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-10 Editing Screens 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-11 Inputting Character Strings and Numbers 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-12 Basic Operation 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-12-1 Cursors 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-12-2 Screen Buttons 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-12-3 Mouse 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-12-4 Positioning Operations 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-13 Tool Settings 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-14 Environment Settings 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-15 Direct Connection 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-15-1 Specifying PC Addresses for Direct Connection 18. . . . . . . . . . . . . . . . . . . . . . . . . .

1-15-2 Direct Connection Information 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 7

Using Older Models Section 1-2

1-1 Terminology and NT-series Manuals

Names of items in this manual related to the NT Series of Programmable Terminals and SYSMAC C-series Programmable Controllers are defined next.

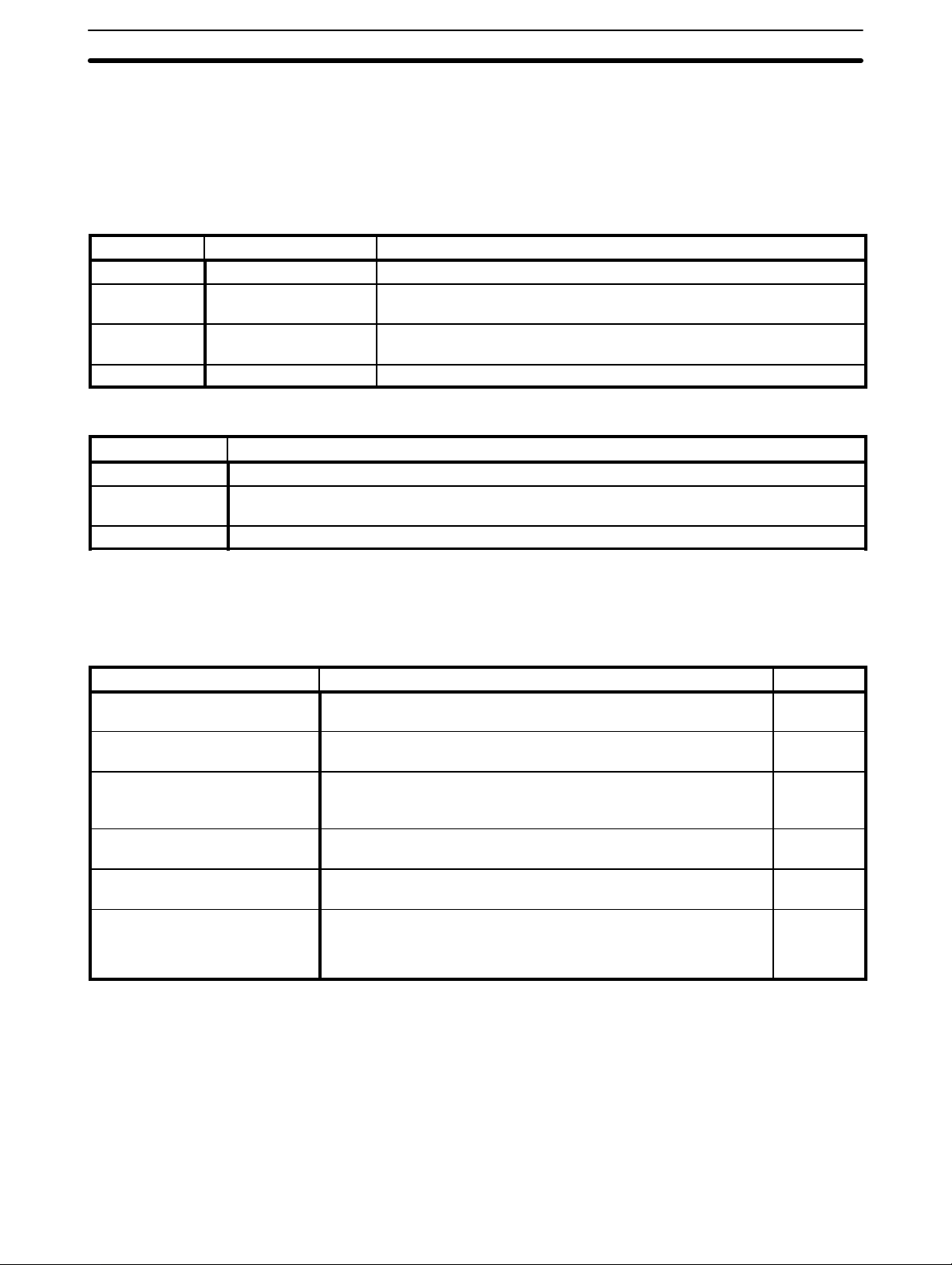

Abbreviations The following abbreviations are used in the text.

Abbreviation Term Meaning

PT Programmable Terminal Refers to an OMRON NT-series Programmable Terminal.

PC Programmable

Controller

I/F interface A communications device that connects the Programmable Terminal with

I/O input/output Refers to PT and PC inputs and outputs.

SYSMAC Terminology

Terminology Explanation

SYSMAC A generic name for OMRON’s Programmable Controllers.

Host Link System

(SYSMAC WAY)

SYSMAC BUS A remote I/O network created between SYSMAC C-series PCs and input/output devices.

A system employing SYSMAC C-series Host Link Units used to create a communications bus

between PCs, between PCs and PTs, etc.

Refers to an OMRON SYSMAC C-series or CV-series Programmable

Controller, or programmable controllers manufactured by other companies.

peripheral devices.

Reference Manuals The NT20M/NT2000M Series and NT600M Series are covered in the six

manuals described below. Actual manual numbers also include suffixes indicating the version of the manual.

Name of Manual Contents Manual No.

NT20M/NT2000M Operation

Manual

NT600M Operation Manual This manual provides specifications, functions, and operating

NT-series Host Interface Unit

Operation Manual

NT20M/NT600M Support Tool

Operation Manual

NT-series Host Interface Unit

Direct Operation Manual

NT-series RS-232C/RS-422

Interface Unit Operation Manual

This manual provides specifications, functions, and operating

instructions for the NT20M and NT2000M Programmable Terminals.

instructions for NT600M Programmable Terminals.

This manual covers the commands, controls, and communications

specifications for operating the NT20M and the NT600M. Refer to

this manual when programming host computer communications.

This manual covers methods for creating screens, including screen

data preparation, switches, lights, and alarms.

This manual covers the Direct Connection feature which has been

added to the Host Interface Unit.

This manual covers the commands, controls, and communications

specifications for operating the NT20M and the NT600M with the

RS-232C/RS-422 Interface Unit. Refer to this manual when

programming host computer communications.

V001

V002

V003

V004

V015

V016

1-2 Using Older Models

The NT Series of Programmable Terminals is constantly being improved to

better serve the needs of our customers. This manual describes features

available for the newest PTs. Not all of these features are available with previous versions of the Host Interface Units and System ROM, as shown in the

following table. Refer to your PT’s operation manuals for details on limitations

when using older models.

2

Page 8

y

System ROM

System Configuration Section 1-3

Host Interface Unit and/or

System ROM

Host Interface Units

Lamps and touch switches Lamp flashing for bit input designations

NT20M-LK201-EV1

NT20M-LK202-EV1

NT20M-LK203-EV1

NT20M-RT121-EV1

stem ROM

S

NT600M-SMR01-E

Bar graphs Vertical displays

Numeral displays Enlarged displays

Numeral tables Keypad layout designations

Stand-alone operation

Backlight red/white color changes and light/flash designations

1-3 System Configuration

The NT20M/NT600M Support Tool is a software package for creating and

maintaining display Screens, memory tables, and custom characters (called

marks) for the NT20M and NT600M Programmable Terminals. The Support

Tool uses a complete system of menus to facilitate operation.

Unsupported features

Round lamp displays

3D frame displays for touch switch

Reverse video display for touch switch inputs

Mark input for labels

Enlarged display widths (2 to 255 dots)

+/– displays

Enlarged percentage displays

Increased display quantity (50)

Increased quantity (50)

1-3-1 NT20M and NT600M Support Tool Operations

The Support Tool can be used to create and modify screens, memory tables,

and marks, and save resulting data as files. Data created on the Support Tool

can be transmitted to the NT20M or NT600M Programmable Terminal. In addition, the Support Tool can receive data from a Programmable Terminal, or

data created on the Support Tool can be transmitted to a PROM writer. Also,

the Support Tool can receive data from PROM writers. The Support Tool can

read history records stored in a Programmable Terminal, and save them in

files.

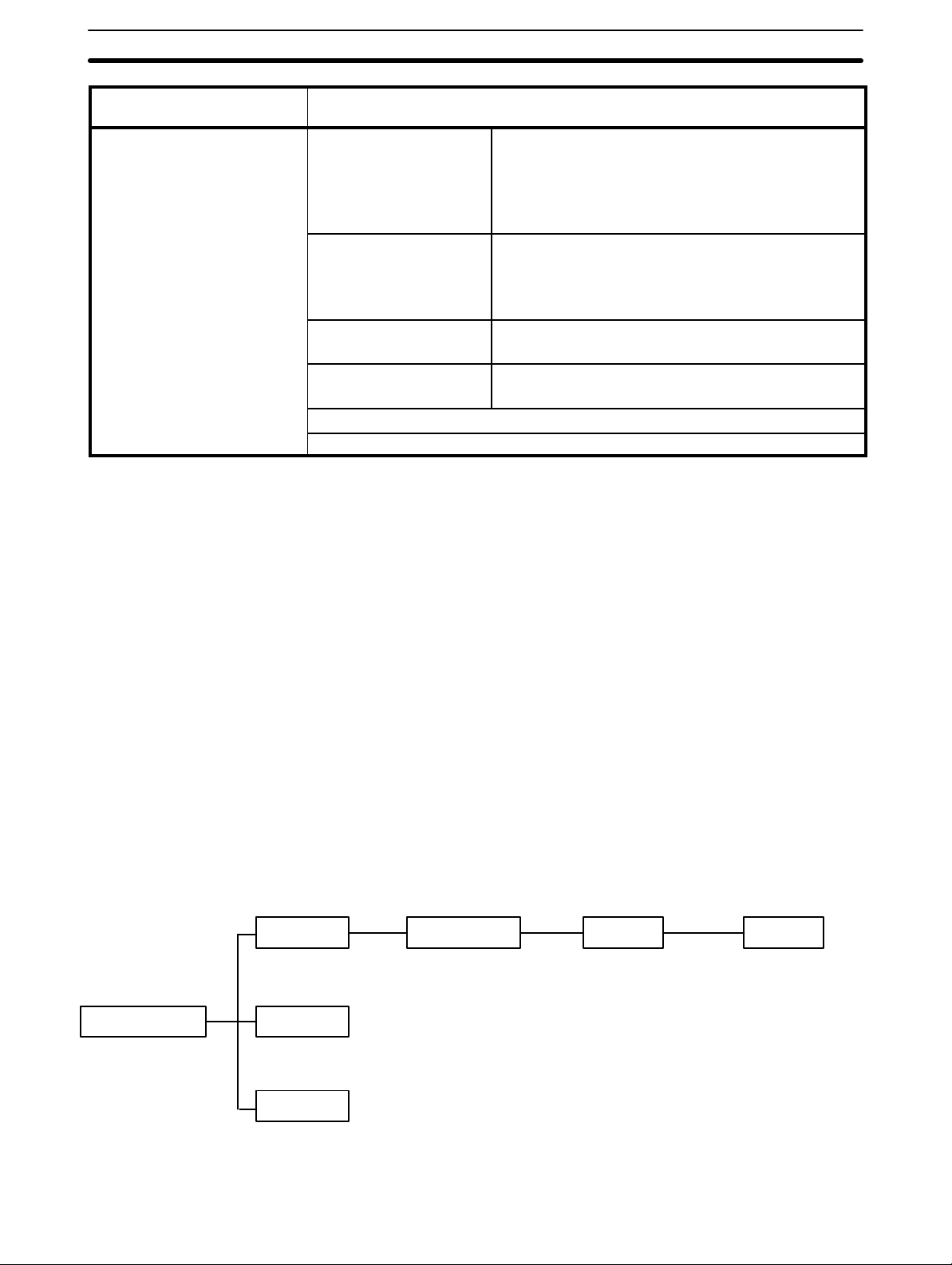

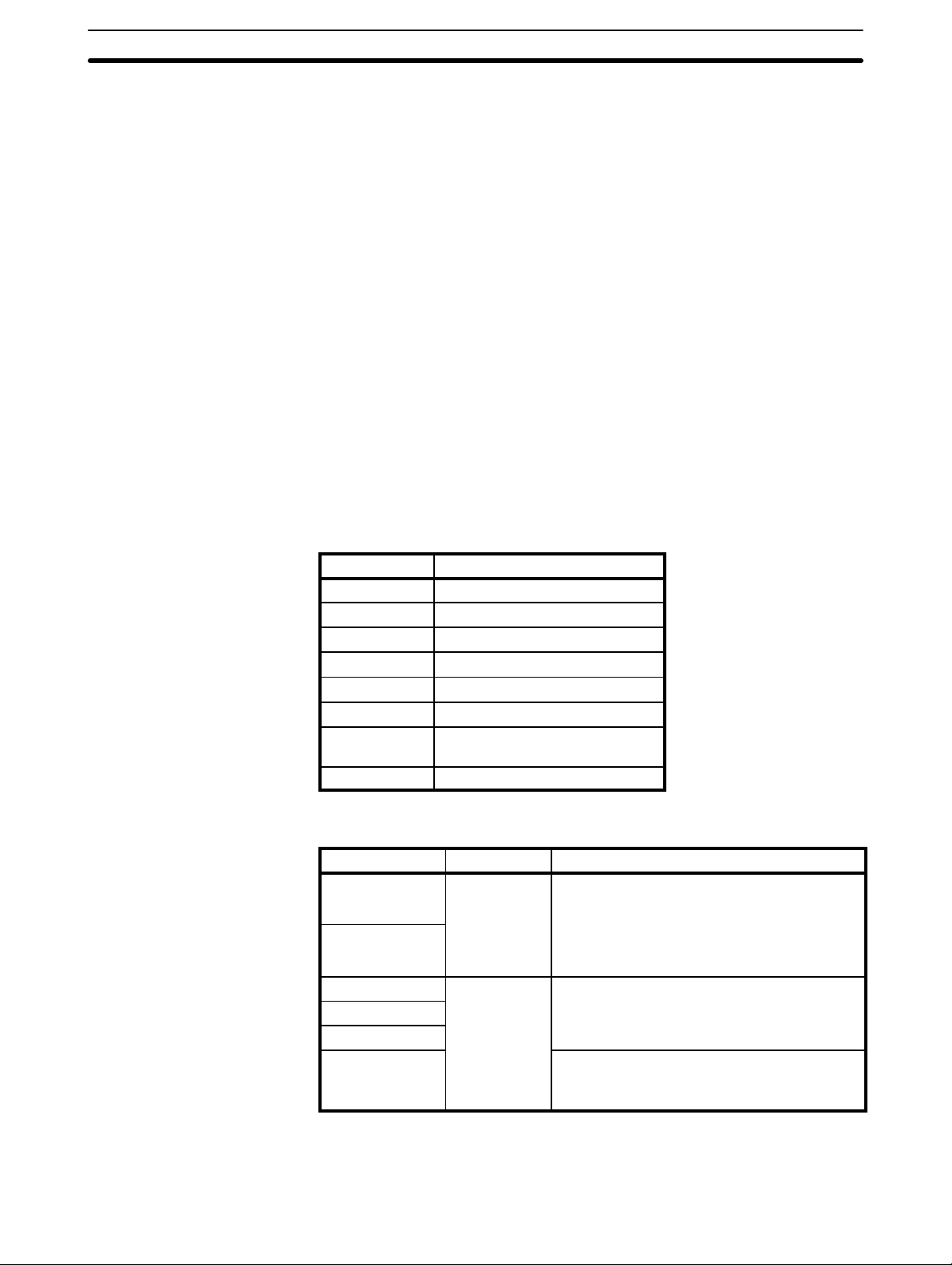

1-3-2 Menu Configuration

Screen

Selection

Copy

Delete

Print

Attributes

Reading from other Files

Table Edit

Transmit

Receive

Continuous/Overlapping

Screens

Check

Marks

Change Comment

Direct Connection Settings

Main Menu

Edit Screen

Tool Settings

See page 15 for

specific settings.

Exit

File Selection

Copy

Delete

Print

Title Change

ROM

History

Transmit

Receive

Initial Screen

Change Capacity

Change Title

Tool Settings

Editing

Input String

Numeral Display

String Display

Lamps

Touch Switches

Bar Graphs

Table Editing

Numeral Editing

Graphics

Marks

Edit

Extended Functions

Environment Settings

3

Page 9

Creating a Work Disk Section 1-4

1-3-3 Support Tool System

Model NT20M-ZA5AT-EV4

System disk 3.5-inch (2DD) and 5-inch (2HD) disks

Applicable computers IBM PC/AT or IBM PC/AT compatible (note 1)

Floppy disk drives necessary One min. (note 2)

Graphic monitor VGA

Printer Epson dot matrix or HP laser printer

PROM writer Commercially available PROM writer (note 3)

Mouse Serial mouse (note 4)

MS-DOS Version 3.3 or later

Note 1. The computer must have 640 KB of memory.

2. The Support Tool can also use built-in RAM or a hard disk.

3. The following communications settings must be supported. The Intel HEX

file format can be used.

Baud rate: 9,600 bps

Stop bits: 1 bit

Data length: 8 bits

Parity: None

4. The mouse.com file must be installed before using the Support Tool with a

mouse.

1-4 Creating a Work Disk

It is recommended that you backup the Support Tool either onto floppy disks

or onto your hard disk, store the originals (the floppy disks, hereafter referred

to as the “master disks”) and use the backup disks (hereafter referred to as

the “work disks”) for routine work. The method for backing up onto a hard

disk is explained below. If there are any points pertaining to MS-DOS which

are unclear, please refer to your MS-DOS manual.

1, 2, 3...

1. Turn on the power to your computer, and start up MS-DOS.

2. Insert the master disk into the floppy disk drive and switch to drive A.

(Input the underlined part from the keyboard.)

3. Type NTINSTAL

Support Tool is to be installed, i.e., the work disk.

or From the A: drive, it is possible to designate the C: drive directory.

C >

C > A:

spaceC:return

to designate the drive onto which the

A >NTINSTAL C:

A >NTINSTAL C:\NT\

4. If the installation program is successfully completed, then the Support

Tool will be installed in the NT directory on the work disk. Switch from

the A: drive to the C: drive. In the C: drive, switch to the NT directory.

A > C:

C >CD \NT

4

Page 10

Main Menu Section 1-6

5. Input NTM

return

to start and use the Support Tool.

C > NTM

This completes the backup. When starting up the next time, change directories to the NT directory and then input “NTM” to start the Support Tool.

C >CD \NT

C > NTM

1-5 Starting and Exiting

Startup Procedure If working from a floppy, insert the start-up disk into disk drive A and a data

disk into disk drive B, then turn on the power. When using a hard disk, first

return

start up MS-DOS from the hard disk, then input NTM

rectory. When the Support Tool has started, the following display will appear.

Main Menu

from the NT di-

Note While the Support Tool is operating with the system disks, do not pull out the

disks from the floppy disk drive or an operation error will result.

Exiting While the Main Menu is displayed, use the Up Key or the Down Key to move

the bar cursor to Exit, and then press the Enter Key. The MS-DOS prompt

will be displayed. At this point, eject the floppy disks and turn off the power to

the computer. Always be sure to follow this procedure when exiting the Support Tool.

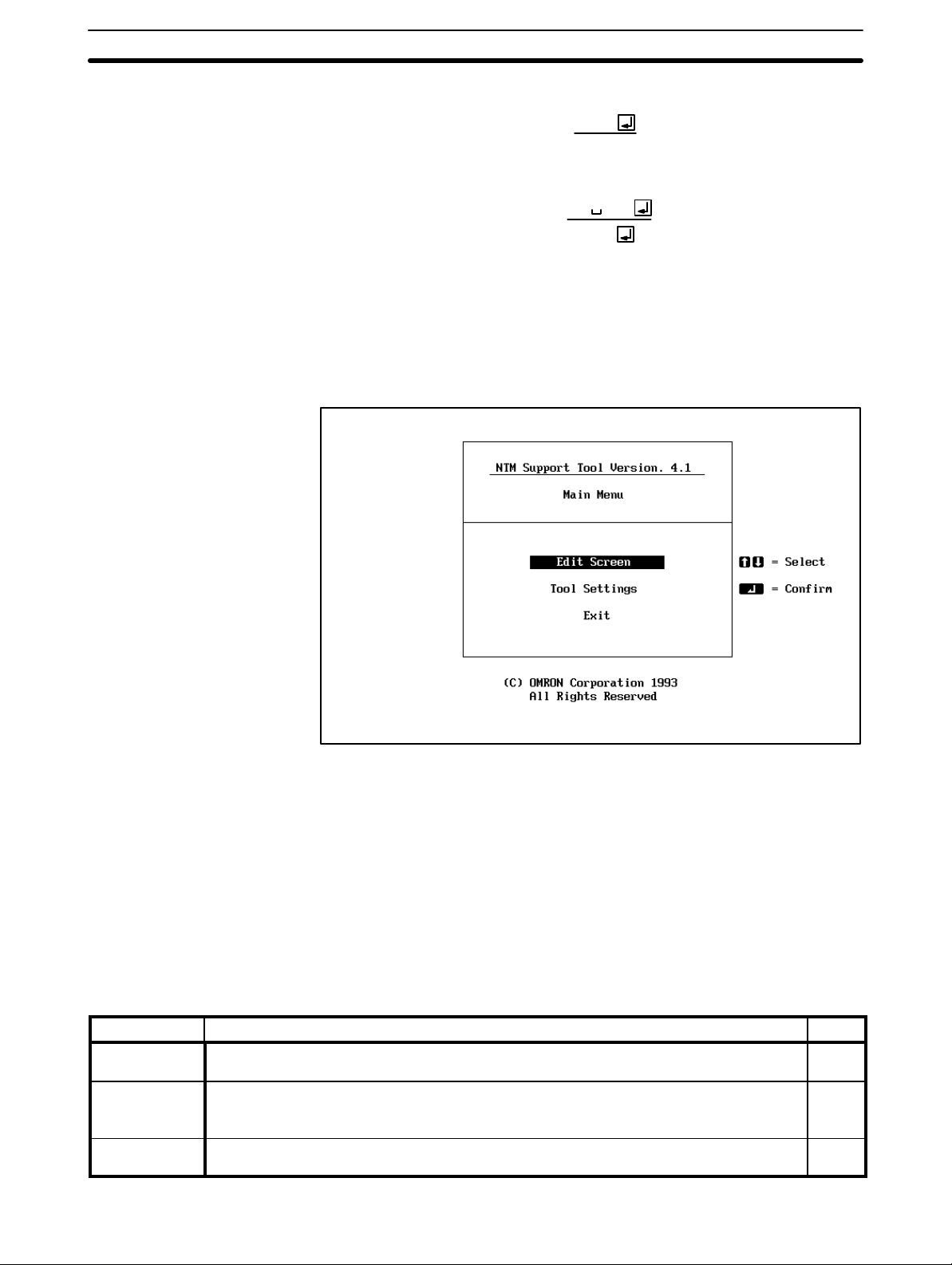

1-6 Main Menu

When you start up the Support Tool, the Main Menu will displayed and the

following items will be available.

Main Menu Items

Item Function Page

Edit Screen When you select Edit Screen from the Main Menu, you can manage files and manipulate

and edit screens.

Tool Settings With this item you select the Programmable Terminal, set the memory capacity, specify the

printer to be used, and make other settings. Perform this operation first. The values that you

set here are saved, so there is no need to reset them unless you want to make a change.

Exit Select

Exit

from the Main Menu when you want to exit the Support Tool. Be sure to exit in

this way when Support Tool operations are finished.

15

11

5

5

Page 11

File Selection Section 1-7

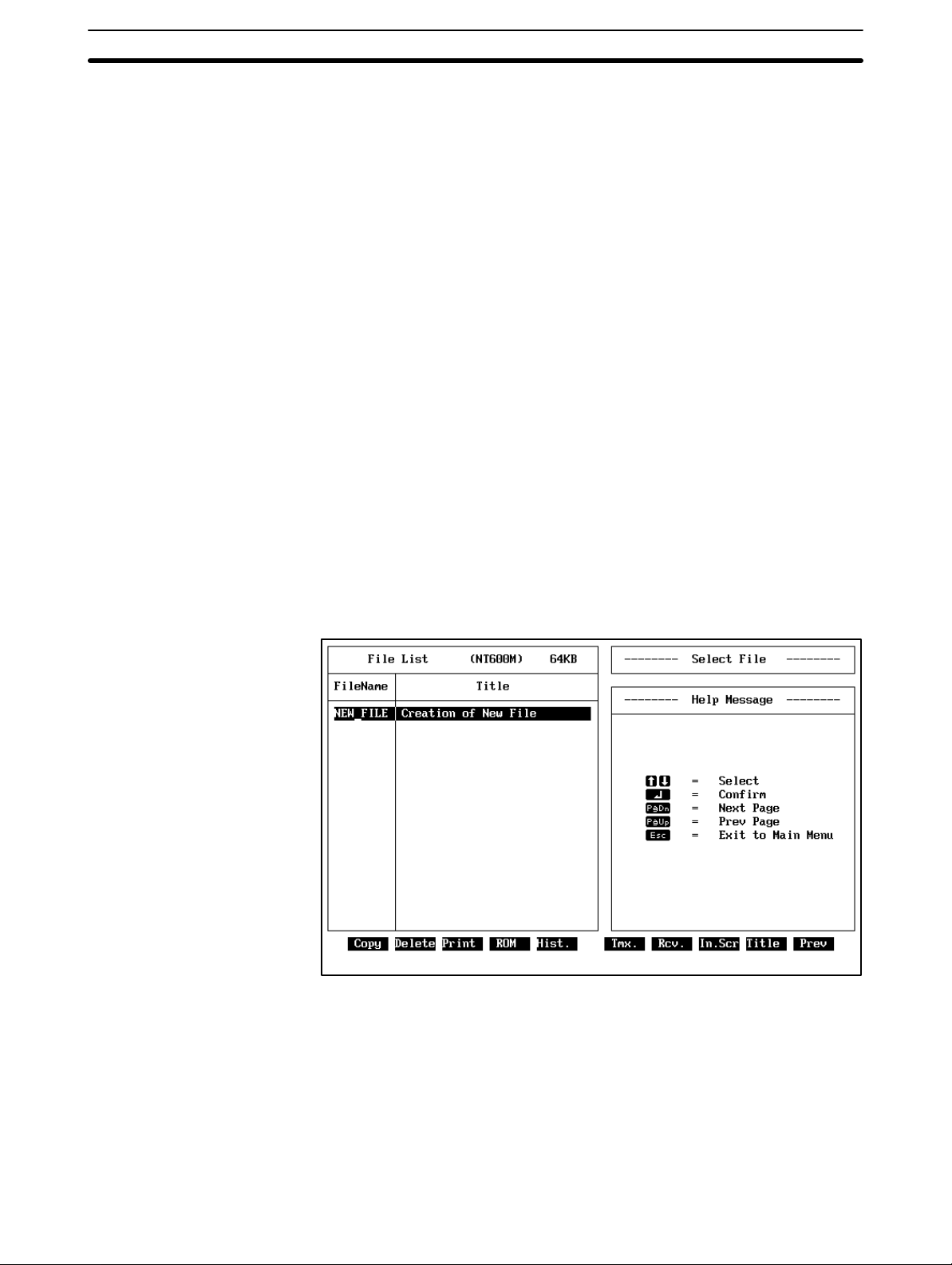

1-7 File Selection

When you select

is displayed. Move the bar cursor to the desired file name and press the Enter Key, or click the desired file name once to move the bar cursor and then

again to open the file.

Each file contains screen data, memory table data (for numeral and character string tables), and mark data for a maximum of 250 screens for the

NT20M or 1,000 screens for the NT600M. When you want to create a new

file, select

lect from and a file name and title are input when returning to the File Selection Display. Refer to page 10 for name and title input procedures. If you want

to modify a file that has already been created, select the file that you want to

modify.

The help message area will display the direct connection setting and file size

for the file indicated by the bar cursor.

Caution Check the direct connection setting before reading files. If files created with

the direct connection setting turned OFF are read when the Tool Settings is

set to ON, the screens will be converted to direct connection data. It is not

possible to convert from direct connection data to data without direct connection.

Edit Screen

NEW_FILE

from the Main Menu, the File Selection Display

. The Screen Selection Display will then appear to se-

File Selection Menu

Caution Data Compatibility with the Old Version of Software (EV1):

The EV4 version of the software can read and edit data created by the EV1.

However, once the data is read by the EV4, it no longer can be read or edited

by the EV1, even if the file name has not been changed. This occurs

because the EV4 expands the data previously saved with the EV1.

Before using any EV1 data with the EV4, it is recommended that a backup

copy of the EV1 be made.

6

Page 12

Screen Selection Section 1-8

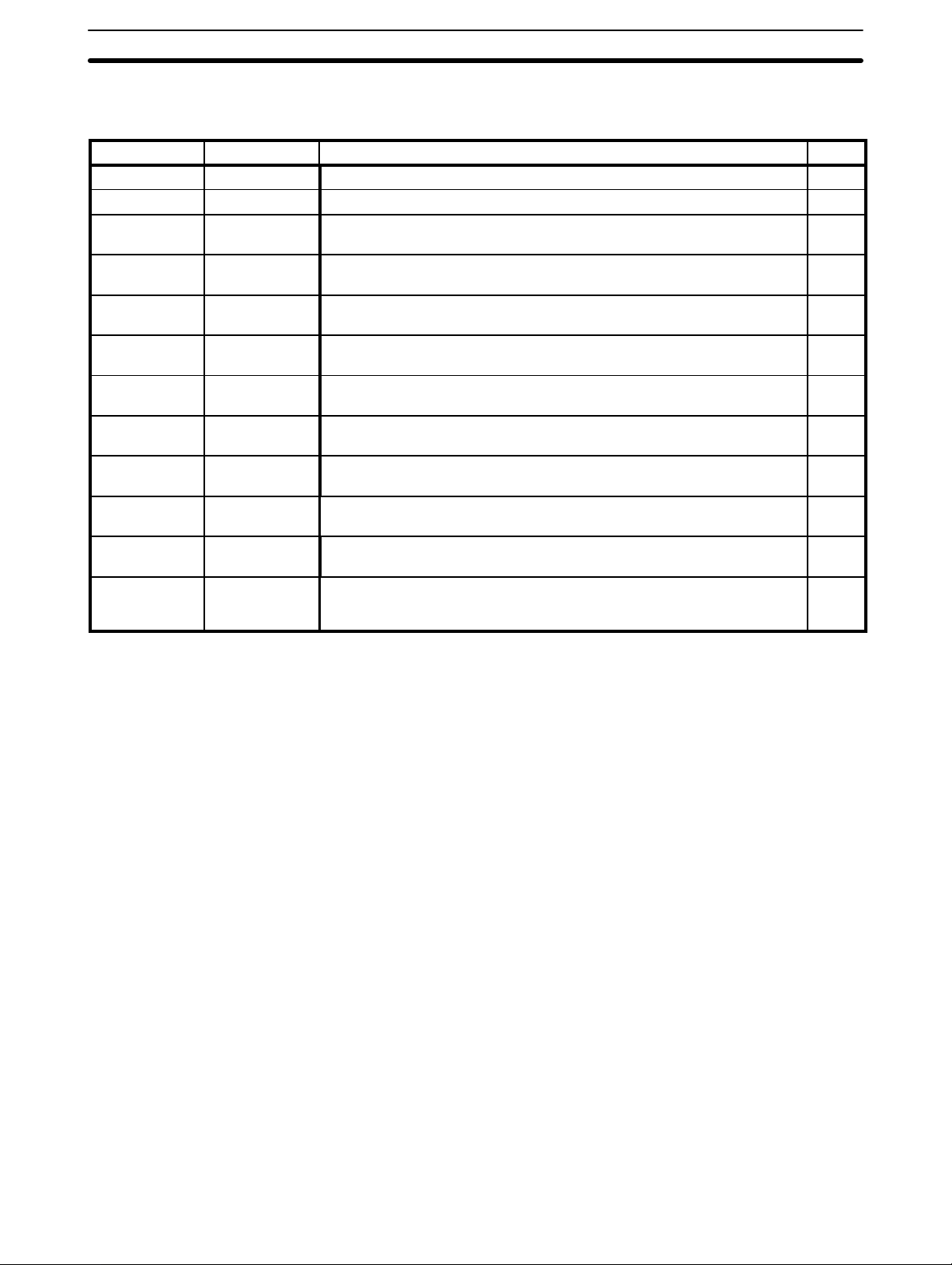

File Operations You can perform file operations by using the function keys while the File Se-

lection Display is being displayed.

Function key Name Function Page

F1 Copy Copies the contents of one file to another file. 96

F2 Delete Completely deletes the contents of a file. 97

F3 Print Prints screen images or data, and cross references of character string and

numeral table usage.

F4 ROM Transmits data from the Support Tool to a PROM writer and receives data

sent from a PROM writer to the Support Tool.

F5 History (HIST.) Receives history records from a Programmable Terminal and saves them

in a file.

F6 Transmit

(TMX.)

F7 Receive (RCV.) Receives screen data sent from a Programmable Terminal to the Support

F8 Initial Screen

(In. Scr)

F9 Title Change

(TITLE)

F10 Next Functions

(NEXT)

NEXT, F1 Tool Settings

(TOOLS)

NEXT, F10 Previous

Functions

(PREV)

Transmits screen data from the Support Tool to a Programmable Terminal.

The data can be sent as file units.

Tool. The data can be received as file units.

Sets the screen number of the first screen to be displayed (the initial

screen) when the Programmable Terminal is powered up or reset.

Changes a file title that has previously been set. 98

Use to change the functions allocated to the function keys. ---

Accesses the Tool Settings menu. 15

Use to change the functions allocated to the function keys. ---

101

117

98

106

110

99

Note 1. The maximum number of files that can be managed by the Support Tool is

254. Any files beyond this number cannot be accessed. If this situation

occurs, use another data directory.

2. The only items displayed on the File Selection Display are the models and

memory capacity that have been set with Tool Settings. For example, if

the NT20M is set as the model and 32 KB is set as the memory, then

NT600M files and 64 KB or 128KB NT20M files will not be displayed. Use

the Memory Capacity Function Key to alter the memory capacity data set

in the file.

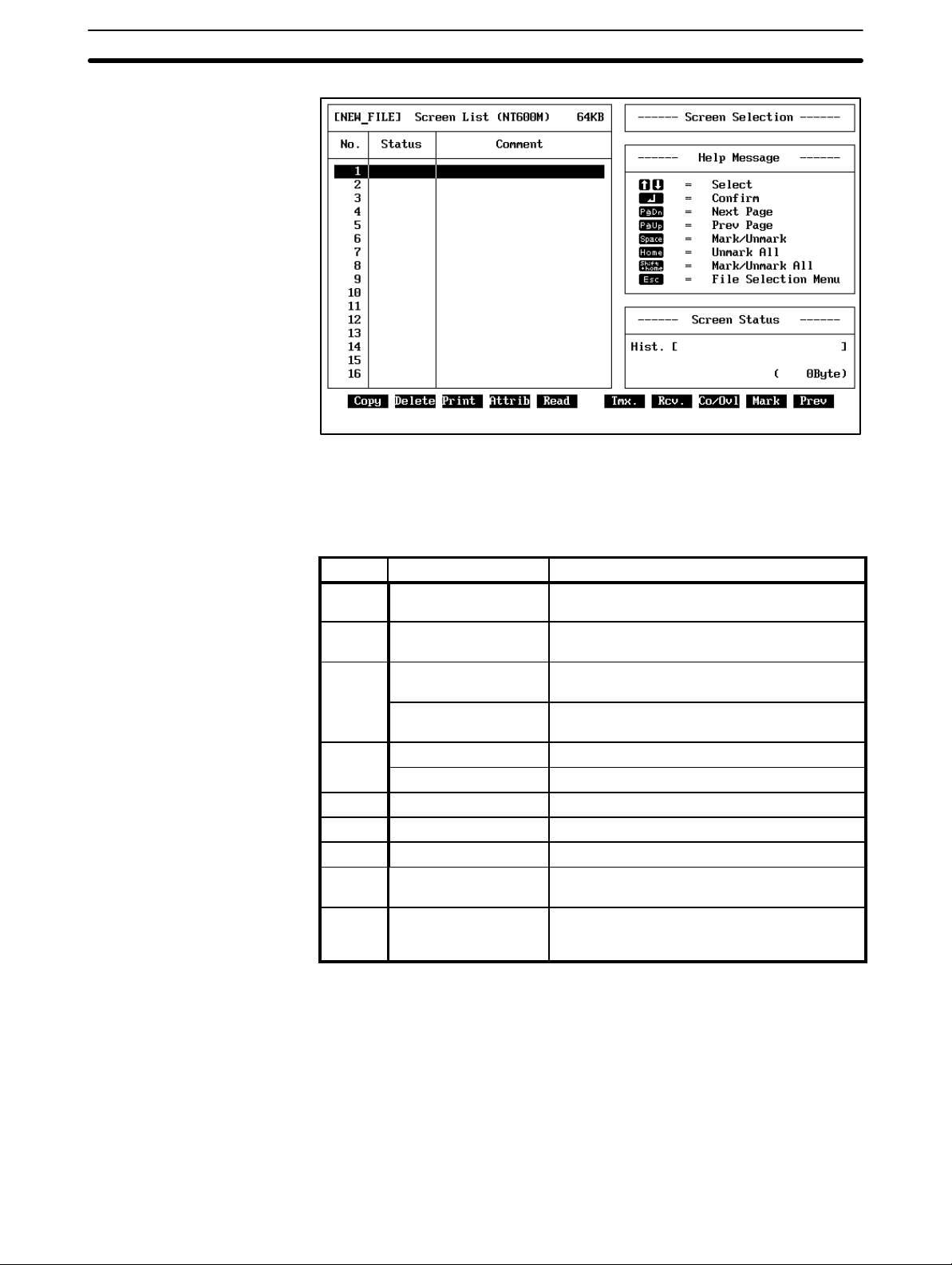

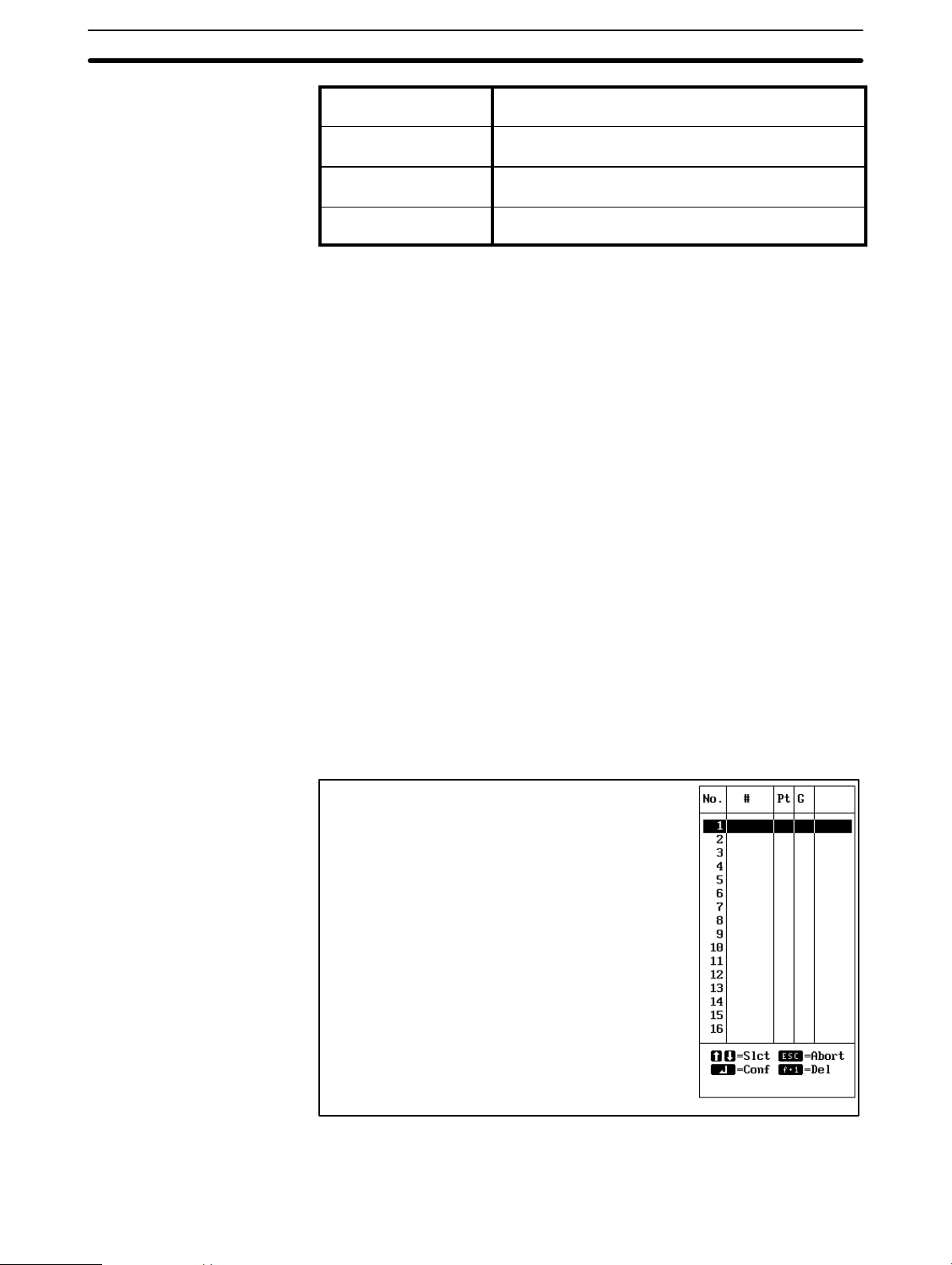

1-8 Screen Selection

When you select either

Display, the Screen Selection Display is displayed. If you select an existing

file, the Screen Listing for that file is displayed. Move the bar cursor to the

desired screen and press the Enter Key, or click the desired screen once to

move the bar cursor and then again to edit the screen.

Screen numbers may be from 1 to 250 for the NT20M and from 1 to 1,000 for

the NT600M. Only screen numbers 1 to 16 are displayed on the first display.

Press the Pg Dn Key to see the next display, and the Pg Up Key to see previous display. When creating a new screen, select a screen number for which

nothing is displayed under Status in the Screen Listing.

NEW_FILE

or an existing file from the File Selection

Screen comments can be input for new screens or for changed screens

when returning from the Edit Display to the Screen Selection Display. Refer

to page 10 for input procedures.

7

Page 13

Screen Selection Section 1-8

Screen Selection Display

Screen Status Symbols displayed in the status column (A to E, !) express screen attribute

settings for the each screen. Symbols displayed in the status column are explained in more detail in the Screen Status box, which is in the lower

right-hand corner of the screen.

Symbol Screen status Meaning

(Blank) No data Indicates a screen for which no data has been

created.

! Data exists Indicates a screen for which data has been

created.

A A: Cont Indicates a parent screen for continuous

screens.

A: Ovlp Indicates a parent screen for overlapping

screens.

B B: Buzz Continuous sound is set as the buzzer attribute.

B: Beep Intermittent sound is set as the buzzer attribute.

C C: Err History attribute is set.

D D: Bit Bit input attribute is set.

E E: Alrm Alarm attribute is set.

F F:Keypad Indicates a keypad has been set for numeral

editing.

G G:Extend Indicates that the backlight has been set to red

or that the backlight has been set to flash for

the NT20-DT131/DN131.

8

Page 14

Screen Selection Section 1-8

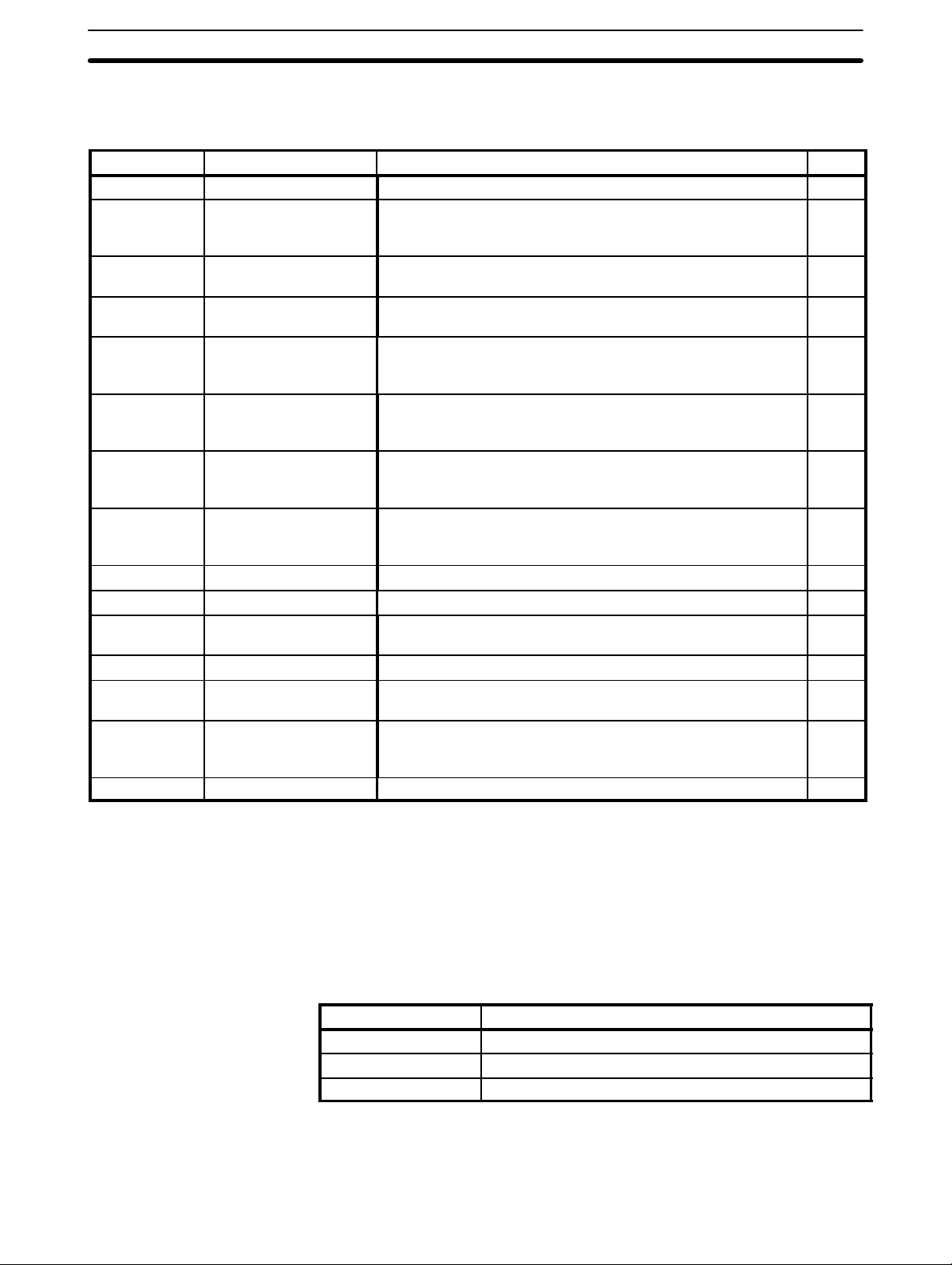

Screen Selection

Operations

Function key Name Function Page

F1 Copy Copies previously created screen data to another screen number. 90

F2 Delete Deletes designated screen data. Can also be used to delete

F3 Print Prints designated screen data. Can also be used to print multiple

F4 Attribute Change

(ATTRIB)

F5 Read Loads screen data from other files. The data can include screens,

F6 Transmit (TMX.) Transmits data from the Support Tool to a Programmable

F7 Receive (RCV.) Receives data sent from a Programmable Terminal to the

F8 Continuous or

Overlapping Screen

Creation (Co/Ovl)

F9 Marks (MARK) Creates and modifies marks. 82

F10 Next Item (NEXT) Use to change the functions allocated to the function keys. --NEXT, F1 Comment Change

(CMNT)

NEXT, F2 Table Edit (TABLE) Edits memory tables 59

NEXT, F3 Check (CHECK) Checks whether there are any errors in continuous or overlapping

NEXT, F4 Direct Connection

(DIRECT)

NEXT, F10 Previous Item (PREV) Use to change the functions allocated to the function keys. ---

You can perform screen operations by using the function keys while the File

Selection Display is displayed.

91,

multiple screens, or to delete screens from the Programmable

Terminal one screen at a time.

screens.

Sets buzzer attributes, bit inputs, history records, and alarms. 78

marks, the numeral table, the character string table, I/O

comments, and direct connection information.

Terminal. The data to be transmitted can be a single screen,

multiple screens, or a memory table.

Support Tool. The data to be received can be a single screen,

multiple screens, or a memory table.

Creates Continuous or Overlapping Screens. 75

Changes screen comments that have previously been set. 92

screens, and displays or prints the results.

Sets data area allocations, comments, and other information for

use with direct connection operation. This function key appears

only if direct connection has been turned ON in the Tool Settings.

114

101

93

108

111

80

17

Handling Multiple Screens

Tags can be used to handle multiple screens simultaneously. For example,

several screens can be deleted at the same time by tagging them and then

Delete

executing

from the Screen Selection Display.

Use the following keys to attach or remove tags.

Key(s) Operation

Space Reverses the tag of the screen with the bar cursor.

Home Clears all tags.

Shift+Home Reverses all tags.

Tags are indicated by asterisks. By using tags effectively, you can handle

multiple screens as a single group.

9

Page 15

Inputting Screen Comments, File Names, and Titles Section 1-9

1-9 Inputting Screen Comments, File Names, and Titles

Screen comments, file names, and file titles can be input whenever new

screens are created or when existing screens are modified. The methods for

inputting these are described in this section.

1-9-1 Screen Comments

Screen comments can be input or changed when shifting from the Edit Display to the Screen Selection Display. Use the following procedure.

1, 2, 3...

1. Press the Escape Key from the Edit Display after creating a new screen

or editing an existing one. A message will appear asking you to confirm

returning to the Screen Selection Display.

2. To confirm and to save the new screen data, press the Enter Key. To

return to the Screen Selection Display without saving the new data,

press the Space Key. To cancel returning to the Screen Selection display and continue editing screen data, press the Escape Key.

3. If the Enter Key is pressed to return to the Screen Selection Display, an

input area will appear for the screen comment. If you have modified an

existing screen, any comment previously input for it will appear. Input or

change the comment as desired (24 characters) and press the Enter

Key. Press the Escape Key to return to step 2.

1-9-2 File Names and Titles

File names and titles can be input when shifting from the Screen Selection

Display to the File Selection Display. Use the following procedure.

1, 2, 3...

1. Press the Escape Key from the Screen Selection Display after creating

new screens and/or editing existing ones. A message will appear asking

if the new data should be saved.

2. To confirm and to save the new screen data, press the Enter Key. To

return to the File Selection Display without saving the new data, press

the Space Key. To cancel returning to the File Selection Display and return to the Screen Selection Display, press the Escape Key.

3. If the Enter Key is pressed to return to the File Selection Display, an input area will appear for the file name. Input the file name (8 characters)

and press the Enter Key. Press the Escape Key to return to step 1.

4. If you specify an existing file name, you will be asked to confirm overwriting the file. Press the Enter Key to confirm overwriting or press any

other key to return to step 3.

5. After the file name is input, and input area for the title will appear. Input

the title as desired (28 characters) and press the Enter Key. Press the

Escape Key to return to step 1.

10

Data will be saved to the specified file when the Enter Key is pressed for the

title input step. The display, however, will not change until the operation is

completed, at which time the File Selection Display will appear.

Page 16

Editing Screens Section 1-10

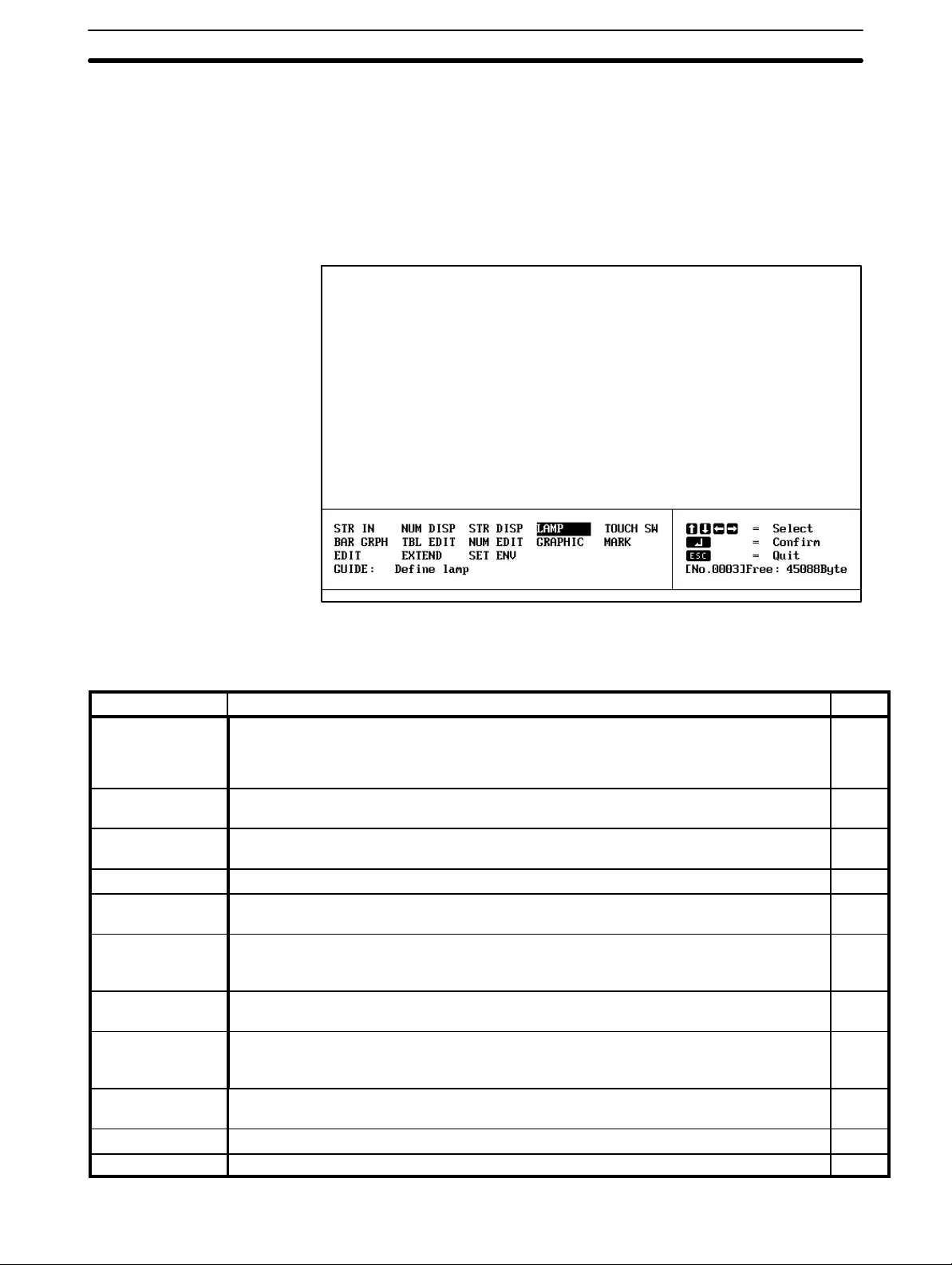

1-10 Editing Screens

If you select a screen number from the Screen Selection Display, the Initial

Edit Display will be displayed. If the NT20M has been selected with Tool Settings, then the NT20M screen image display area will be shown in the rectangular box at the top of the display. If the NT600M has been selected, then the

entire display becomes a display area and this box will not appear.

Initial Edit Display

Screen Edit Operations The following operations can be performed on the Edit Display.

Item Function Page

Input string (STR

IN)

Numeral display

(NUM DISP)

String display (STR

DISP)

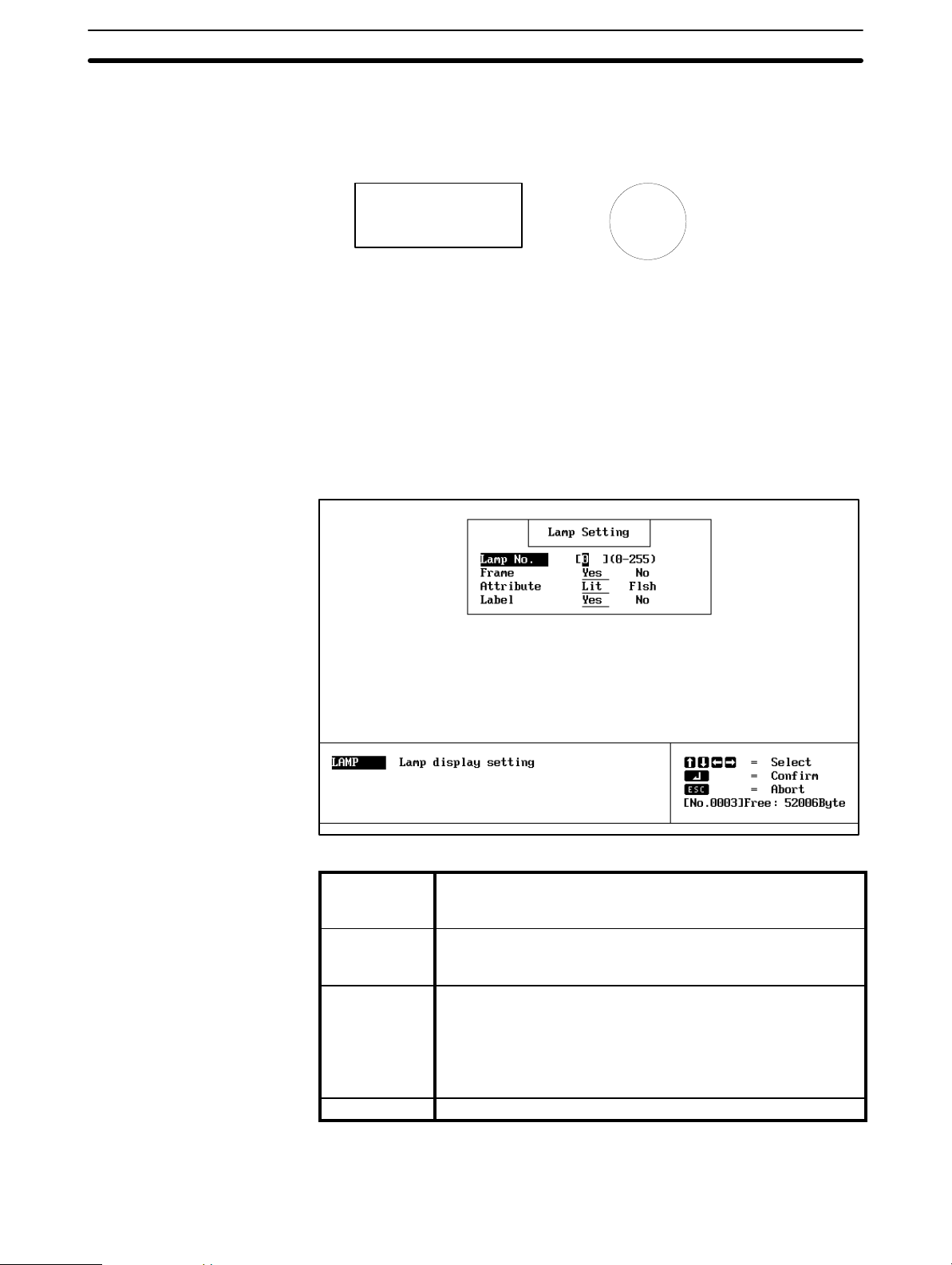

Lamps (LAMP) Sets lamps for the screen by designating the size/shape of lamp areas, numbers, and labels. 40

Touch switches

(TOUCH SW)

Bar graphs (BAR

GRPH)

Table editing (TBL

EDIT)

Numeral editing

(NUM EDIT)

Graphic input

(GRAPHIC)

Marks (MARK) Creates and modifies marks. 82

Edit (EDIT) Copies, moves, or deletes text or graphics on the screen. 87

Inputs character strings to be displayed on the screen and sets their display positions and

the manner in which they are to be displayed. Character strings input in this way are treated

as fixed displays, and their displays cannot be changed while the Programmable Terminal is

operating.

Sets numeric displays for the screen by designating the numeral table entry to be referenced

at the time of display , the display position, and the method of display.

Sets character string displays for the screen by designating the string table entry to be

referenced at the time of display , the display position, and the method of display.

Sets touch switches for the screen by designating the size of touch switch areas, numbers,

and labels.

Sets bar graphs for the screen by designating the numeral table entry to use, the display

positions/directions, and the method of display. The display of percentage calculations is

also set.

Edits numeral table and character string table contents, and is the same as the table editing

operation entered from the Screen Selection Display .

Creates screens for numeric input via function keys, touch switches, or Expansion I/O Units

(32/16 Terminals or Function Key Units (12 keys)) and designates the numeral table to which

the input will be written.

Polylines (a broken line made up of one or more line segments) and circles can be created

on screen.

22

28

34

46

51

59

62

71

11

Page 17

Inputting Character Strings and Numbers Section 1-11

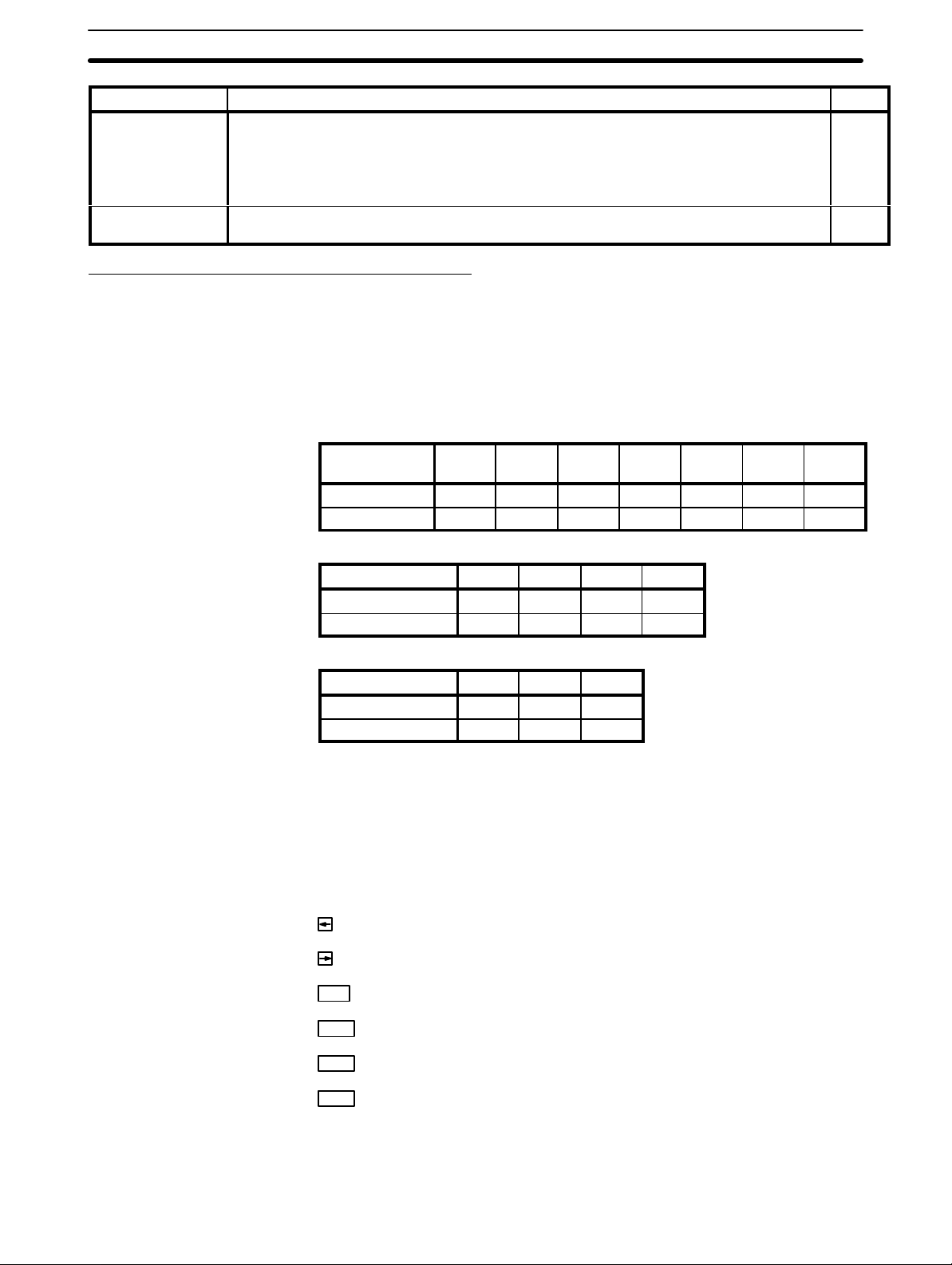

Item PageFunction

Extended

Functions

(EXTEND)

Set Environment

(SET ENV)

Enables usage of stand-alone operation. In stand-alone operation, screens can be changed

from PT touch switches/function keys or from Expansion I/O Units.

Sets data area allocations, comments, and other information for use with direct connection

operation. This function key appears only if direct connection has been turned ON in the Tool

Settings.

Accesses a modified version of the Tool Settings to enable changing certain Support Tool

operating parameters during operation.

85

19

16

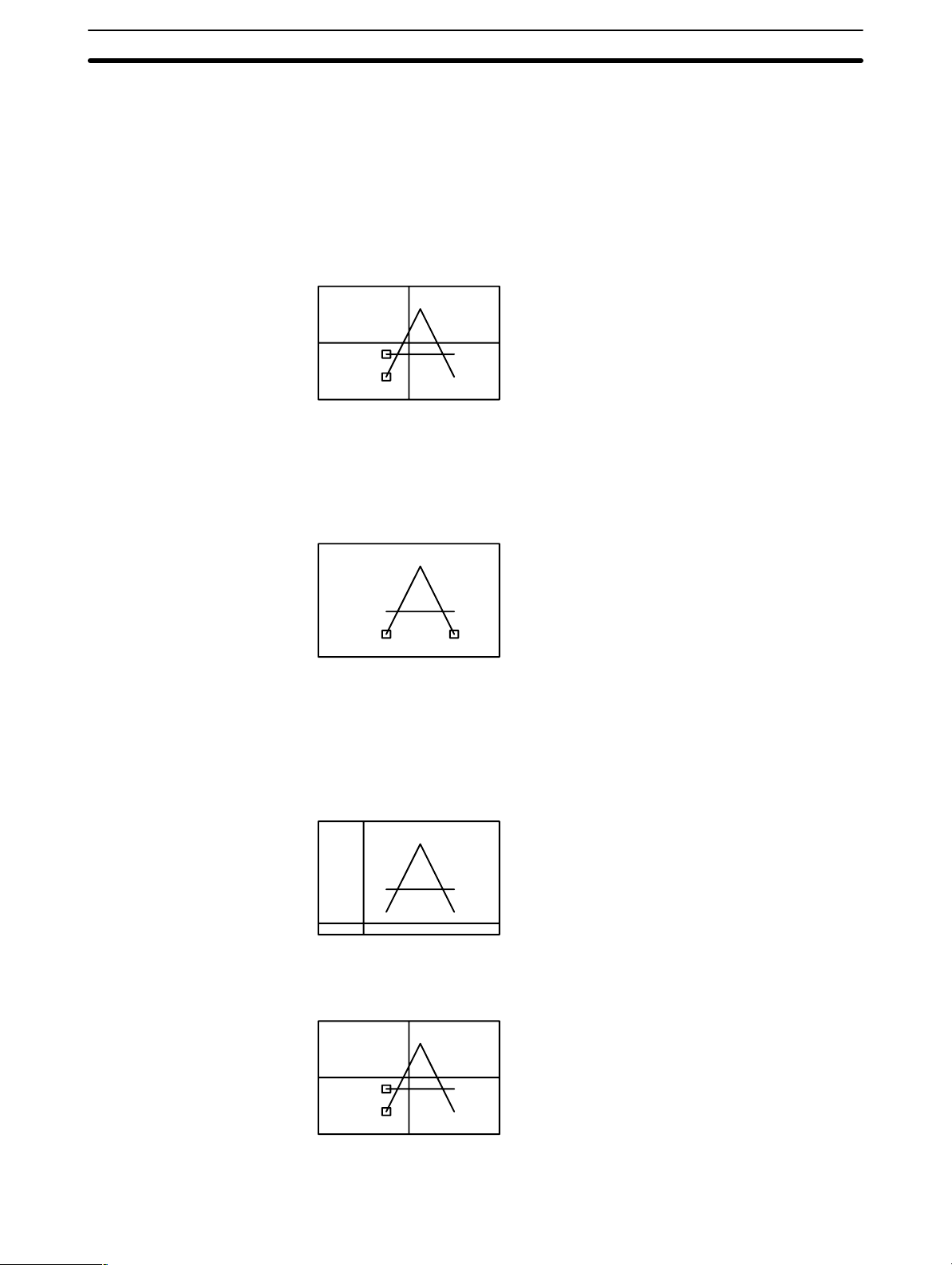

Changing Menu Position and Grid Display

While creating data for the NT600M, there may be times when the screen

data and the menu box overlap, making it difficult to see what you are doing.

In such cases, you cam move or delete the menu box. The grid display can

also be turned ON and OFF for either the NT600M or NT20M by pressing the

Delete Key as long as grid display has been enabled in the tool settings (See

page 15). The display position of the menu box and will change each time

you press the Home Key as shown in the following tables.

NT600M with Grid Enabled

Delete Key

inputs

Menu Bottom Top None Bottom Top None Bottom

Grid ON ON OFF OFF OFF ON ON

Initial 1 2 3 4 5 6

NT600M with Grid Disabled

Delete Key inputs Initial 1 2 3

Menu Bottom Top None Bottom

Grid OFF OFF OFF OFF

NT20M

Delete Key inputs Initial 1 2

Menu Bottom Bottom Bottom

Grid ON OFF ON

Note 1. The display position of the menu cannot be changed for the NT20M.

2. Screen data cannot be created and you cannot switch to the Screen

Selection Display unless the menu is displayed.

1-11 Inputting Character Strings and Numbers

Inputting Character Strings You can use the Left, Right, Backspace, Delete, Insert, and Escape Keys

when inputting character strings. Their functions are described below.

Moves the cursor to the left.

Moves the cursor to the right.

BS

Deletes one character to the left of the cursor.

12

DEL

INS

ESC

Deletes one character at the cursor position.

Switches between insert mode and overwrite mode.

Cancels character input string and returns to previous operation.

In insert mode, the cursor becomes a flashing rectangle and character

strings are inserted at the cursor position. When text is inserted in this way,

character strings to the right of the cursor position move to the right.

Page 18

Basic Operation Section 1-12

In overwrite mode, the cursor becomes a reversed rectangle and character

strings delete previously input characters at the cursor position.

Inputting Numbers Inputting numbers is basically the same as inputting character strings, except

that you cannot change between insert mode and overwrite mode with the

Insert Key. The overwrite mode is always used.

The Home Key can be used to change to 0 any numbers previously input,

and the Minus (–) Key can be used to change between positive and negative

numbers.

Control Key Combinations The Control Key can be used in combination with other keys to move the cur-

sor, delete characters, and achieve other operations. These combinations

are shown in the following table.

Keys Same as

CTRL + S Left Cursor Key

CTRL + D Right Cursor Key

CTRL + E Up Cursor Key

CTRL + X Down Cursor Key

CTRL + R Page Up Key

CTRL + C Page Down Key

CTRL + H Backspace Key

CTRL + G Delete Key

CTRL + I Tab Key

CTRL + M Enter Key

CTRL + [ Escape Key

1-12 Basic Operation

1-12-1 Cursors

Several different cursors will appear depending on Support Tool operation.

Special cursors are described in the following table.

Cursor Meaning

The arrow cursor is used in combination with the cursor to specify

menu items and icons. Refer to page 14 for details on the mouse.

A cup will appear when the Support Tool is accessing data on the

disk. When accessing has finished, the arrow cursor will return.

A question mark will appear when the Support Tool is waiting for

a Yes/No response from the user. Press the Enter Key or the left

mouse button to answer Yes (confirm) or press the Escape Key

or right mouse button to answer No (cancel).

A hand and keyboard will appear at the end of processing to

request user acknowledgement. Press any key or either mouse

button to continue operation.

13

Page 19

Basic Operation Section 1-12

1-12-2 Screen Buttons

There are many buttons in the shape of keys that can appear during Support

Tool operation. These buttons can be clicked with the mouse to achieve the

same operation as the equivalent keyboard keys. Included are the Enter Key

(carriage return arrow), Escape Key, cursor keys, PgUp Key, PgDn Key,

Space Bar, Shift+Home (clear) Key (one button combining two keys), the

Home (clear) Key, and function keys.

1-12-3 Mouse

A mouse can be connected to the Support Tool and used to input coordinates

to specify display positions for text strings or numerals and to create polylines, circles, and other graphics.

To use a mouse, connect a two-button mouse to the computer’s mouse connector and prepare a level, smooth surface, such as a mouse pad, to operate

it on. The mouse can then be used to move labels, the + cursor, and other

objects on the screen (see below).

Procedures in this manual are generally written for operation from the keyboard. There are, however, often three means to execute an operation, i.e.,

from the keyboard, using on-screen buttons, and using the mouse and cursor

directly. It is generally a matter of preference on which method is used; the

results will be the same.

Left Button The left mouse button can be used in place of the Enter Key to achieve the

following.

• To specify items on menus. Click the mouse once to move the cursor and

then again to execute.

• To click on-screen buttons to replace keyboard key inputs. See page 14 for

details.

• Double-clicking to end polyline input (instead of Shift + Enter).

• Dragging to move objects on screen or draw lines.

• To designate display positions for text or numerals

• To designate display positions for touch switches, lamps, and bar graphs

• To designate center, start, and end points for graphics

Right Button The right mouse button can be clicked in place of pressing the Escape Key to

move backward through processing steps or to cancel an operation.

Caution Although either the mouse or the keyboard can be used for most operations,

some operations have been restricted to only keyboard operation for safety. If

the software does not respond when a mouse button is pressed, use the keyboard instead.

1-12-4 Positioning Operations

Grid display can be set via the Tool Settings, and grid display and snap-togrid operation can be set via the Set Environment settings. The grid can be

used either to visually align objects on the display or it can be combined with

snap-to-grid operation to force objects to be positioned exactly on the grid.

Refer to pages 15 and 16 for details.

14

Page 20

Tool Settings Section 1-13

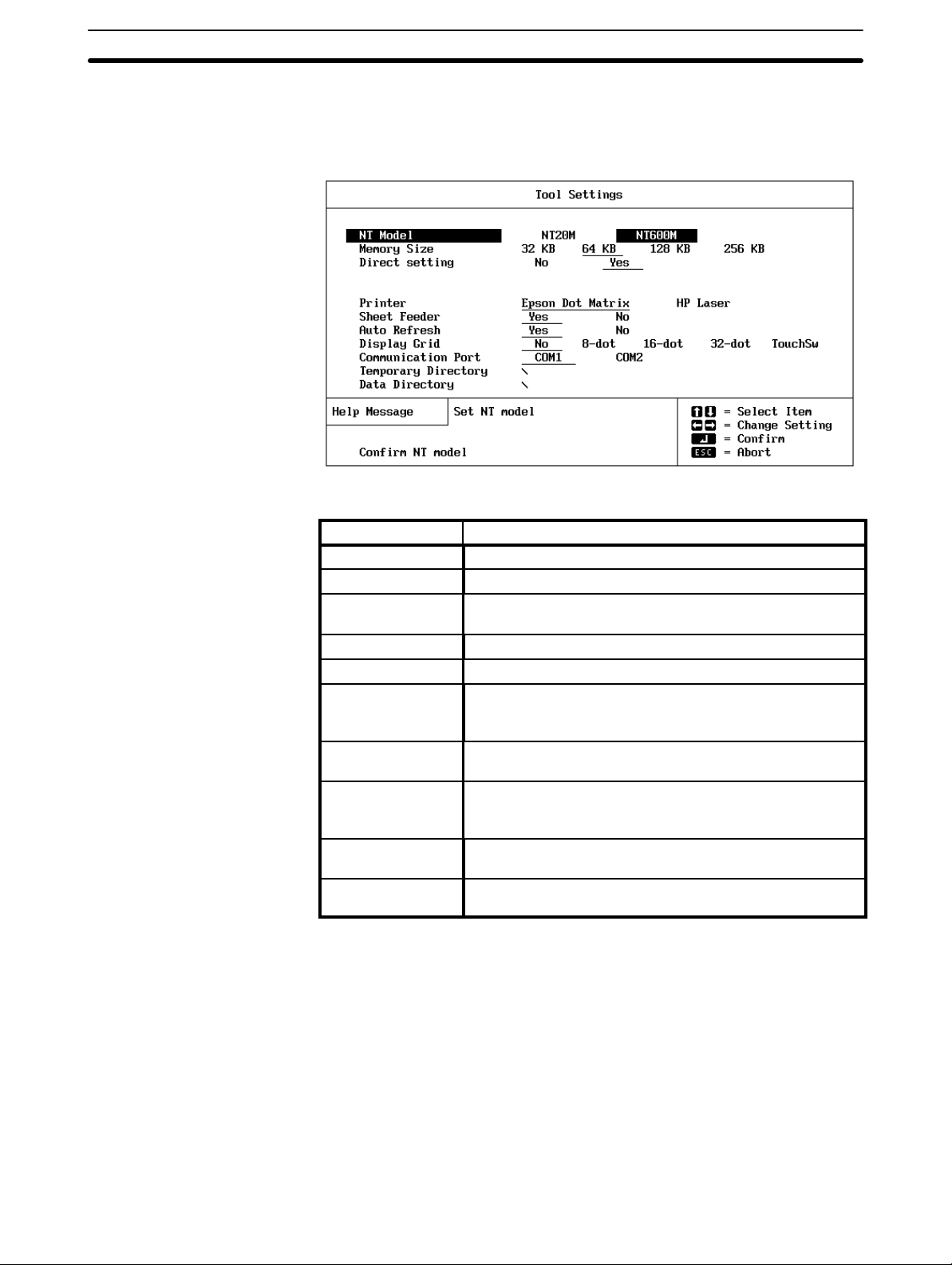

1-13 Tool Settings

If you start up the Support Tool and select Tool Settings from the Main Menu,

the Tool Settings Display will appear.

Contents of Tool Settings

Name Content

NT Model Sets the model of Programmable Terminal being used.

Memory Size Sets the memory capacity of the Programmable Terminal.

Direct Setting Turns ON and OFF the direct connection operation. Refer to

page 17 for details.

Printer Sets the printer model to be used.

Sheet Feeder Sets a sheet feeder for the printer.

Auto Refresh Sets whether or not the screen will be automatically

refreshed when you make screen data additions, deletions,

or modifications.

Display Grid Controls the grid display. If “TouchSW” is specified, each grid

unit will be the size of a touch switch.

Communication

Port

Temporary

Directory

Data Directory Sets directory names for saving screen data which is

Specify the port on the computer to be used to communicate

with the PT. If possible, do not specify the same port as the

one used for the mouse.

Sets the file name for the work file that is temporarily used by

the Support Tool.

created.

Press the Enter Key when you want to save the contents of the Tool Settings.

Then either press the Enter Key again to return to the Main Menu, or press

the Escape Key to return to the Tool Settings Display to correct settings.

If you press the Space Key, the tool settings will be changed without being

saved to a file, and you will be returned to the Main Menu.

Press the Escape Key to cancel changing tool settings.

Auto Refresh When screen data is added, deleted, or modified with the Support Tool, the

screen display may be temporarily disordered. If Auto Refresh is set to “Yes,”

then the screen display will be automatically rewritten when you return to the

Initial Edit Screen. When creating large amounts of screen data, however,

some time may be required for screen refreshing. Auto Refresh can be set to

15

Page 21

Environment Settings Section 1-14

“No” to save time. You can manually rewrite the screen by pressing the Tab

Key during operation.

Temporary Directory The Support Tool will create a temporary work file when creating screens or

transferring data to or from ROM. Most write operations are performed on

this temporary file. To increase overall operating speed, this file should be

created on your hard disk or in RAM.

Tool Settings File File settings are saved in the root directory for the Support Tool, i.e., the di-

rectory from which the Support Tool is started. The file name is

NTMSET.ENV. If this file exists in the root directory when the Support Tool is

started, the setting in the file will be read and the Support Tool will operate

according to them. Tool settings files can be used to eliminate the need to

reset tool setting each time the Support Tool is started.

Display Grid A grid can be displayed to aid in positioning objects when creating screens.

The Tool Settings can be used to disable the grid or to set its size to 8, 16, or

32 dots. The grid size can also be set to the same size as a touch switch by

specifying “TouchSW.” The grid, once enabled, can be turned ON or OFF as

desired during operation. Refer to page 12 for details.

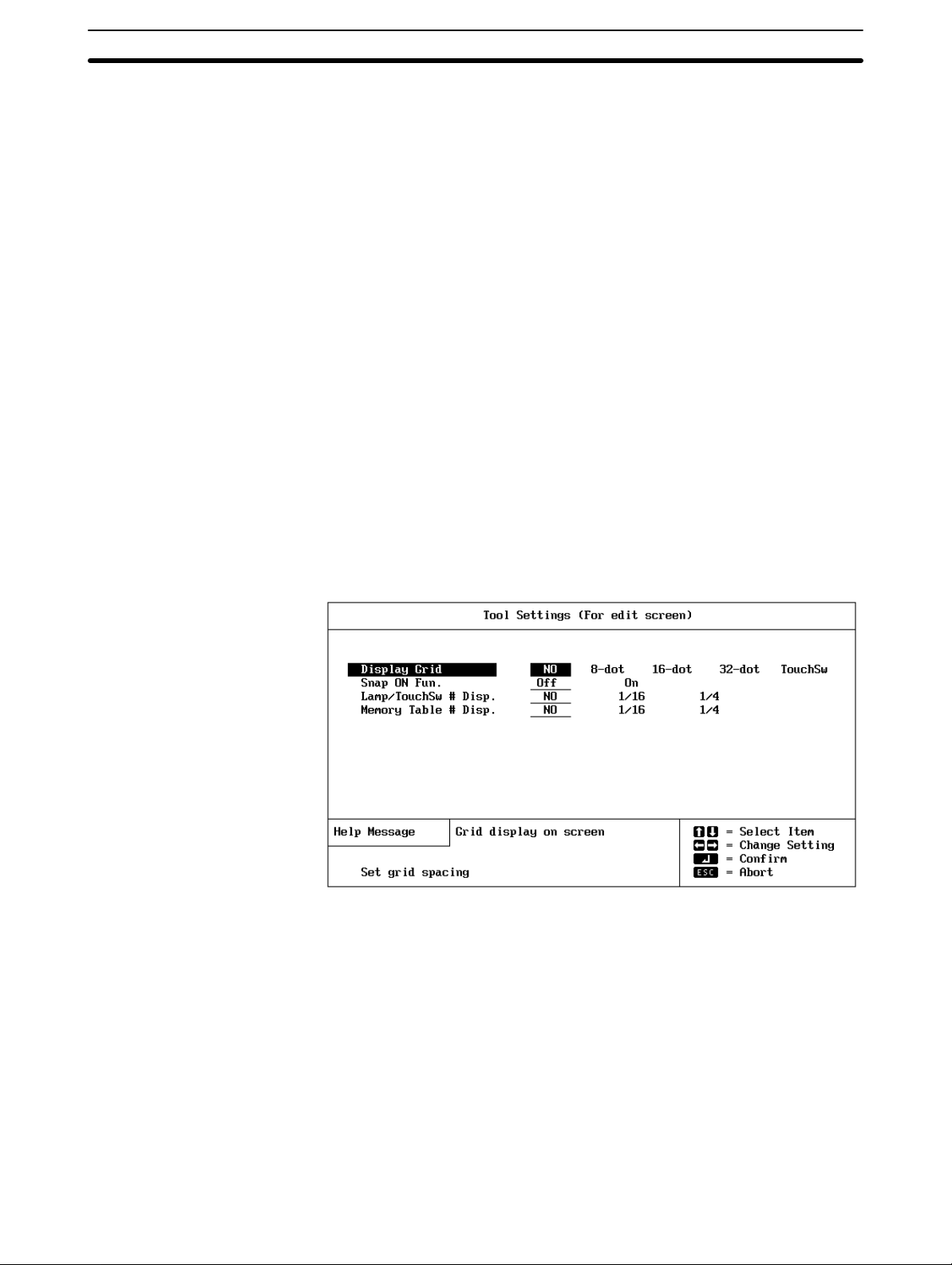

1-14 Environment Settings

A modified version of the Tool Settings can be accessed from the Initial Edit

Display. The following display will appear when SET ENV is specified.

Set the PT operating environment as described in the following table.

16

Page 22

yg

y

Direct Connection Section 1-15

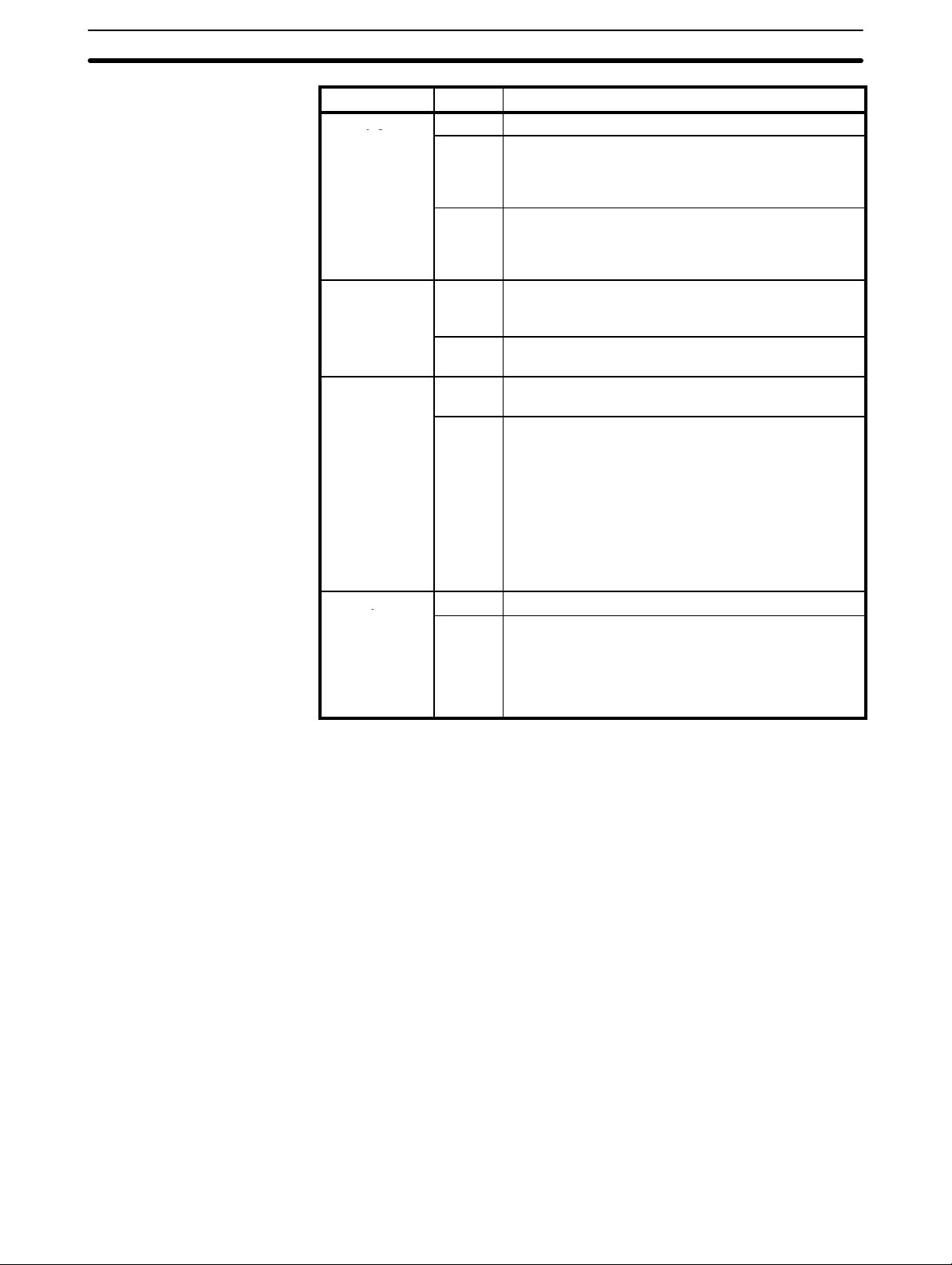

Item Settings Setting

Display grid

Snap ON

function

Lamp/touch

switch number

display

Memory table

entry number

display

No Display grid is not displayed.

8-dot

16-dot

32-dot

Touch

switch

Off Allows graphics to be drawn and screen objects to be

On Allows graphics to be drawn and screen object to be

No Lamp/touch switch numbers or bit addresses are not

1/16

1/4

No Memory table entry numbers are not displayed.

1/16

1/4

Display grid is displayed at the specified width. Screen

objects can be snapped to the grid if one of these

settings is made and the snap ON function is turned

ON (see below).

Display grid is displayed at the minimum width for

touch switches. This setting is useful to draw lamps to

the same size as touch switches. It functions the same

way as the other grids.

positioned without interference from the grid, i.e., the

grid, if displayed, is used only as a visual guide.

positioned only to the intersection points of the grid.

displayed.

Indicates lamp/touch switch specifications and the

allocated lamp/touch switch number or the allocated

PC bit on the display at the specified character size.

For example, “LH001015” would be displayed for a

lamp display allocated to HR 1015 using direction

connection, “TA001012”would be displayed for a touch

switch display allocated to AR 1012 using direction

connection, L000 would be displayed for lamp #0 when

not using direction connection, and T010 would be

displayed for touch switch #10.

Indicates the allocated memory table number on the

display at the specified character size for numeral

displays, character string displays, bar graphs, and

numeral editing areas. “N” is also displayed for

numeral table entry numbers and “S” is displayed for

character string table entry numbers.

1-15 Direct Connection

1, 2, 3...

The PT can be set for direct connection to an OMRON PC to allow numeral

displays, character displays, numeral editing, lamps, touch switches, and bar

graphs to be directly connected to specific bits and words in PC memory. Bits

can also be set that will change the displayed screen. This is possible only

when the NT600M-DT121/DT211 or NT20M-DT121-V1/DT131 PTs and only

when a NT600M-LK201 SYSMAC WAY Host Interface Unit is used. Also,

either an NT600M-SMR31 or NT20M-SMR31 System ROM must be used in

the PT.

The direct connection setting in the Tool Settings greatly affects the operation

of the screen functions that read or write PC memory. Although using direction connection will greatly reduce programming burden for the PC, careful

preparation is required to coordinate PC memory and programming with the

PT settings for direct connection. The general procedure for this is as follows:

1. Design the required PT screens.

2. Allocate PC memory to the function elements of the screens, i.e., those

elements that will directly read or write PC memory. Be sure to list specific PC memory addresses, including areas, and to consider numeral

table and character string table capacities.

3. Turn ON direct connection operation in the Tool Settings.

17

Page 23

bit

ificati

()

Direct Connection Section 1-15

4. Create the required screens, making all settings required for direct connection.

5. Save the screens.

6. Transfer the screens to the PT or write them to ROM.

Conversion Screen files that were created with direct connection turned OFF can be

loaded with direct connection turned ON to convert the screens for use with

direct connection. Once files are created for or converted to direct connection, they cannot be loaded with direct connection turned OFF in the Tool

Settings and cannot be converted back for use without direct connection.

Indication on Displays Displays on the File Selection Display and the Screen Selection display will

indicate whether or not direct connection has been set. If direct connection

has been set, “-O” (for OMRON) will be added after the PT model name following the “File List” title on the File Selection Display. The help message

area on the Screen Selection Display will also indicate whether or not direct

connection has been used together with the file size.

1-15-1 Specifying PC Addresses for Direct Connection

The function keys are allocated as shown in the following table when specifying bit and word addresses in PC memory. The values in parentheses indicate the maximum word address possible for the largest PC memory. Actual

memory sizes vary, however, with the model of PC. Refer to your PC’s operation manual for specific limits.

Key Area

F1 AR (511)

F2 HR (99)

F3 LR (63)

F4 DM (9999)

F5 CNT (1023)

F6 TIM (1023)

F7 CIO, IR, SR (2555) (displayed as

I/S)

Home None

The areas that can be designated for direct connection are as shown in the

following table.

Item Memory unit Designation

Lamps

Touch switches

Numeral display

Bar graphs

Numeral editing

Character string

display

Bit IR, SR (CIO), AR, or LR bit addresses.

DM word address can also be designated with

p

spec

Timers and counters cannot be designated.

(See note.)

Word IR, SR (CIO), AR, LR, or DM word addresses.

Timer and counter numbers can also be

specified to designate PVs.

IR, SR (CIO), AR, LR, or DM word addresses.

Timer and counter numbers cannot be

specified.

ons.

18

Note If touch switches are set to write to bits in the DM area (notify bits), the touch

switch will control the status of the specified bit and all other bits in the specified word will be turned OFF (0).

Page 24

Direct Connection Section 1-15

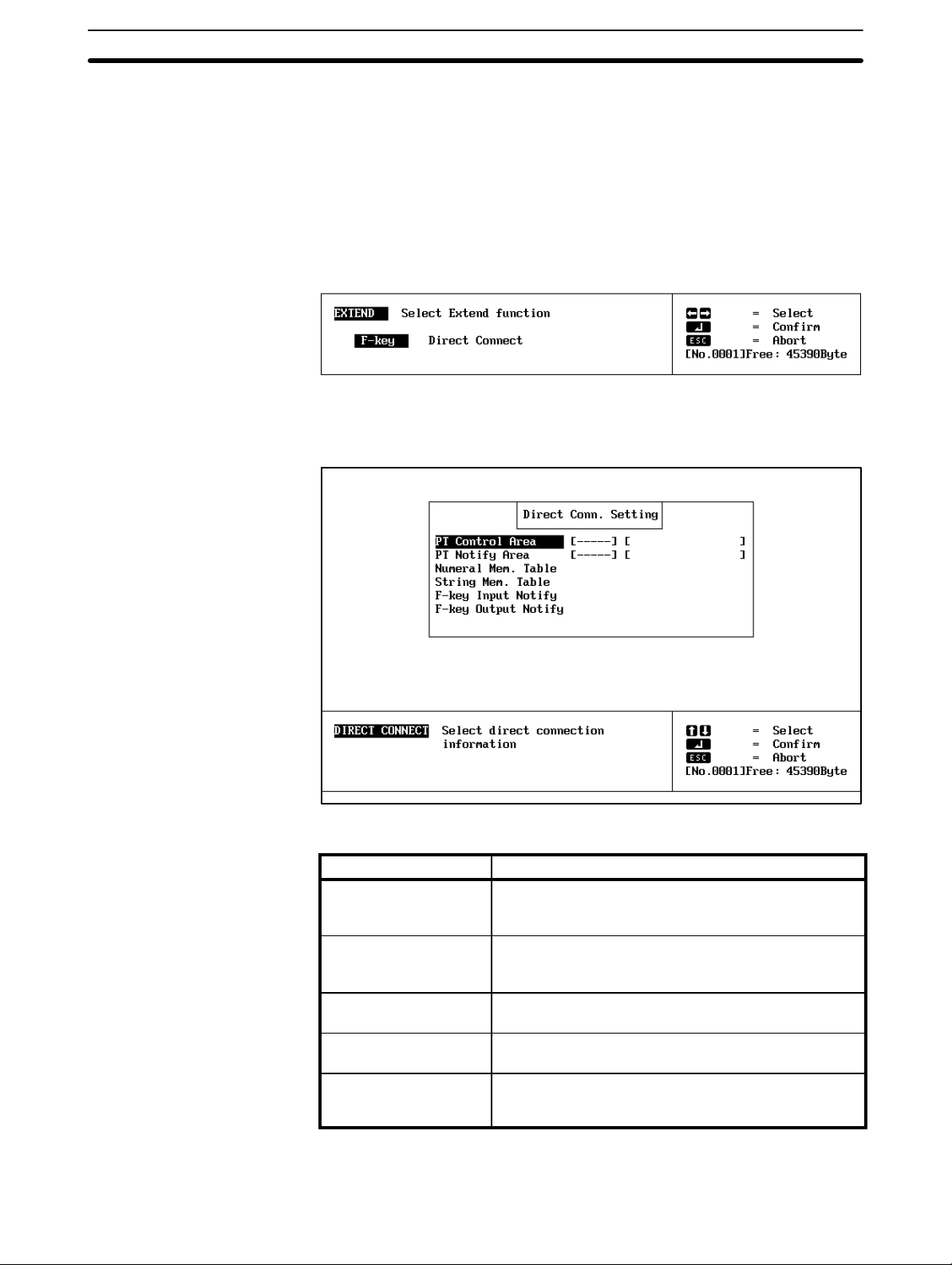

1-15-2 Direct Connection Information

Settings for the direct connection information are made from the extended

functions display. Direct connection information settings will not appear on

the extended function display unless direct connection is turned ON in the

Tool Settings.

Use the following procedure to set the direct connection information settings.

1, 2, 3...

1. Specify EXTEND from the Initial Edit Display. The following display will

appear at the bottom of the screen

2. Specify direct connection. (F-key is not supported by PTs with touch

panels and cannot be specified.) The following display will appear.

3. Set the direct connection information as described in the following table.

Item Setting

PT control area Set the address of the first word in the PC to be used to

control PT status. This setting must be made. A user

comment may also be input if desired.

PT notify area Set the address of the first word in the PC to be used to

store PT status. This setting must be made. A user

comment may also be input if desired.

Numeral mem. table The contents of the numeral table used in the file can be

seen in list form. Data can be input or changed.

String mem. table The contents of the character string table used in the file

can be seen in list form. Data can be input or changed.

F-key input/output notify Function keys cannot be set for PTs with touch panels.

These settings are not required and will be ignored if

input.

4. When the settings have been completed, press the Escape Key once to

return to the beginning of the operation and twice to end.

19

Page 25

SECTION 2

Creating Screens

This section describes the procedures used to create and check screens and to input screen attributes. The procedures for

creating special display characters, called marks, and for controlling screens during stand-alone operation are also provided here.

2-1 Inputting Character Strings 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 New Character Strings 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Deleting Character Strings 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-3 Modifying Character Strings 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Numeral Displays 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 Normal Numeral Displays 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Direct Connection Numeral Displays 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Character String Displays 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-1 Normal Character String Displays 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-2 Direct Connection Character String Displays 37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Lamps 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4-1 Normal Lamps 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4-2 Direct Connection Lamps 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Touch Switches 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-1 Normal Touch Switches 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-2 Direct Connection Touch Switches 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

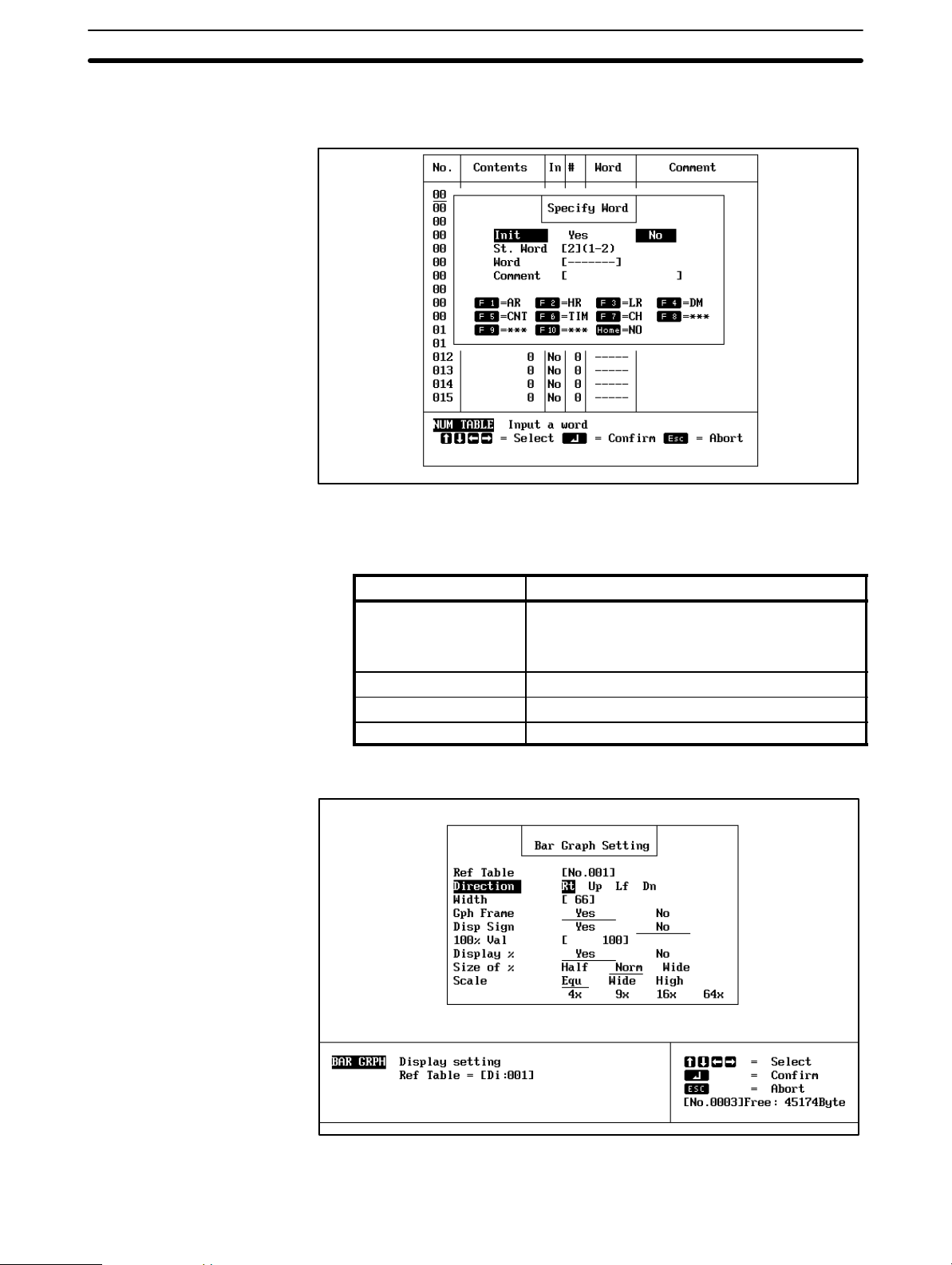

2-6 Bar Graphs 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6-1 Creating Normal Bar Graphs 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6-2 Direct Connection Bar Graphs 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 Editing Memory Tables 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7-1 Normal Operation 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7-2 Direction Connection Operation 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 Numeral Editing 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8-1 Normal Numeral Editing 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8-2 Direct Connection Numeral Editing 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8-3 Precautions for Numeral Editing 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9 Polylines 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9-1 Creating New Polylines 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9-2 Deleting Polylines 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9-3 Modifying Polylines 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10 Circles 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10-1 Creating New Circles 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10-2 Deleting Circles 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10-3 Modifying Circles 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-11 Continuous and Overlapping Screens 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-12 Screen Attributes 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-13 Screen Check 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-14 Marks 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-15 Stand-alone Operation 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-16 Edit 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

Page 26

Inputting Character Strings Section 2-1

2-1 Inputting Character Strings

With the Character Input Display, you set characters to be displayed on the

PT. You set character sizes, character scaling factors, manner of display, and

display positions.

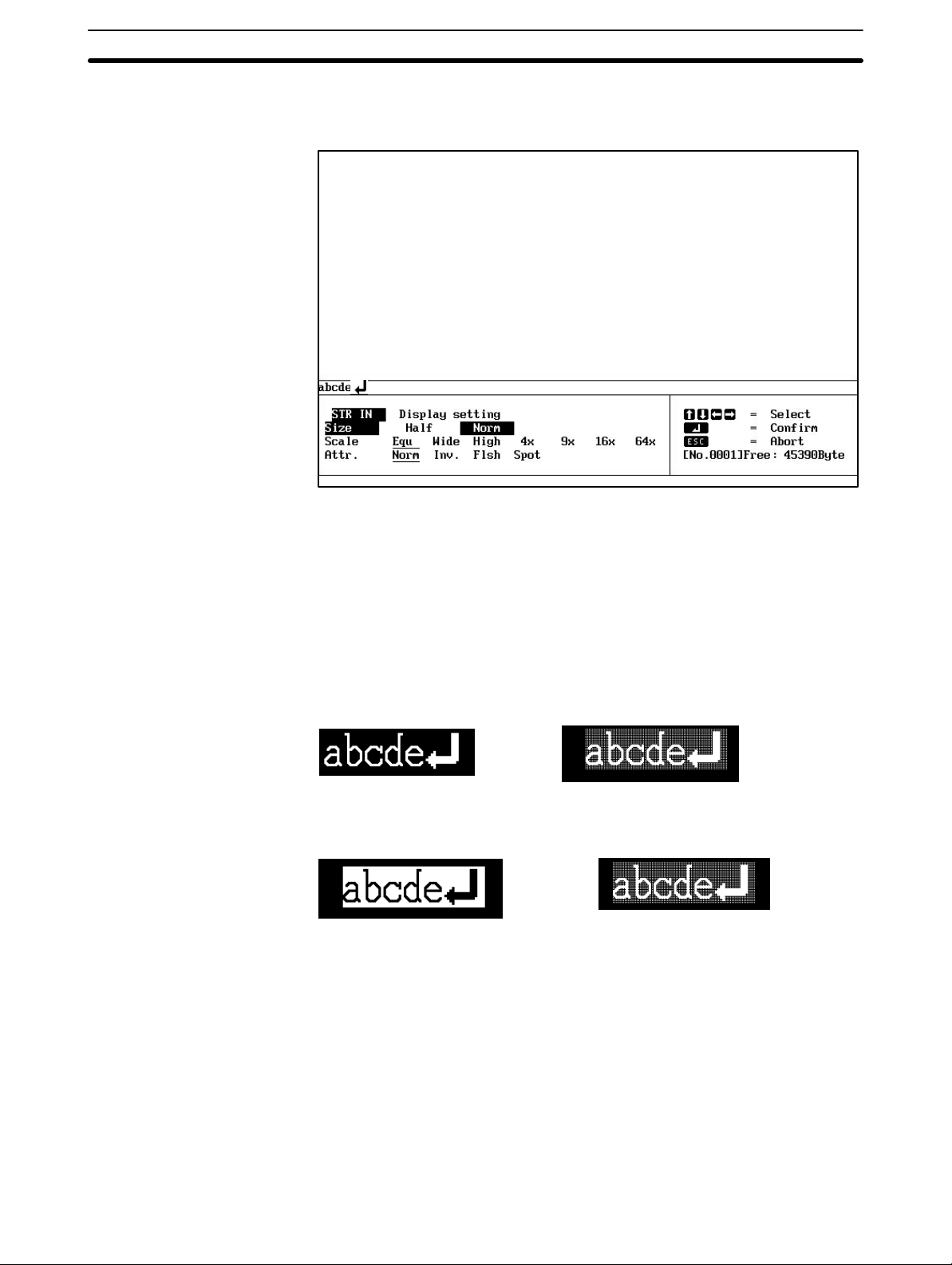

If you select STR IN from the Initial Edit Display, the Initial Character Input

Display will appear.

Initial Character Input Display

The following pages explain how to use this display, taking the creation of

NT20M screen data as an example.

2-1-1 New Character Strings

Inputting Strings This example shows how to input the roman letters “abcde.”

You can display up to 32 characters per line on a NT20M screen, and up to

80 per line on a NT600M screen.

1, 2, 3...

1. Specify CREATE.

2. Input the characters, e.g., “abcde.” The following display will appear.

22

Page 27

Inputting Character Strings Section 2-1

3. If the input is correct, press the Enter Key to enter the characters and go

String Attributes

to the

can also be input as display characters as described below.

Special Characters Characters not on the keyboard can be input via character codes. A list of

character codes is provided at the end of the manual. To input a character

code, press the ALT Key followed by the decimal code.

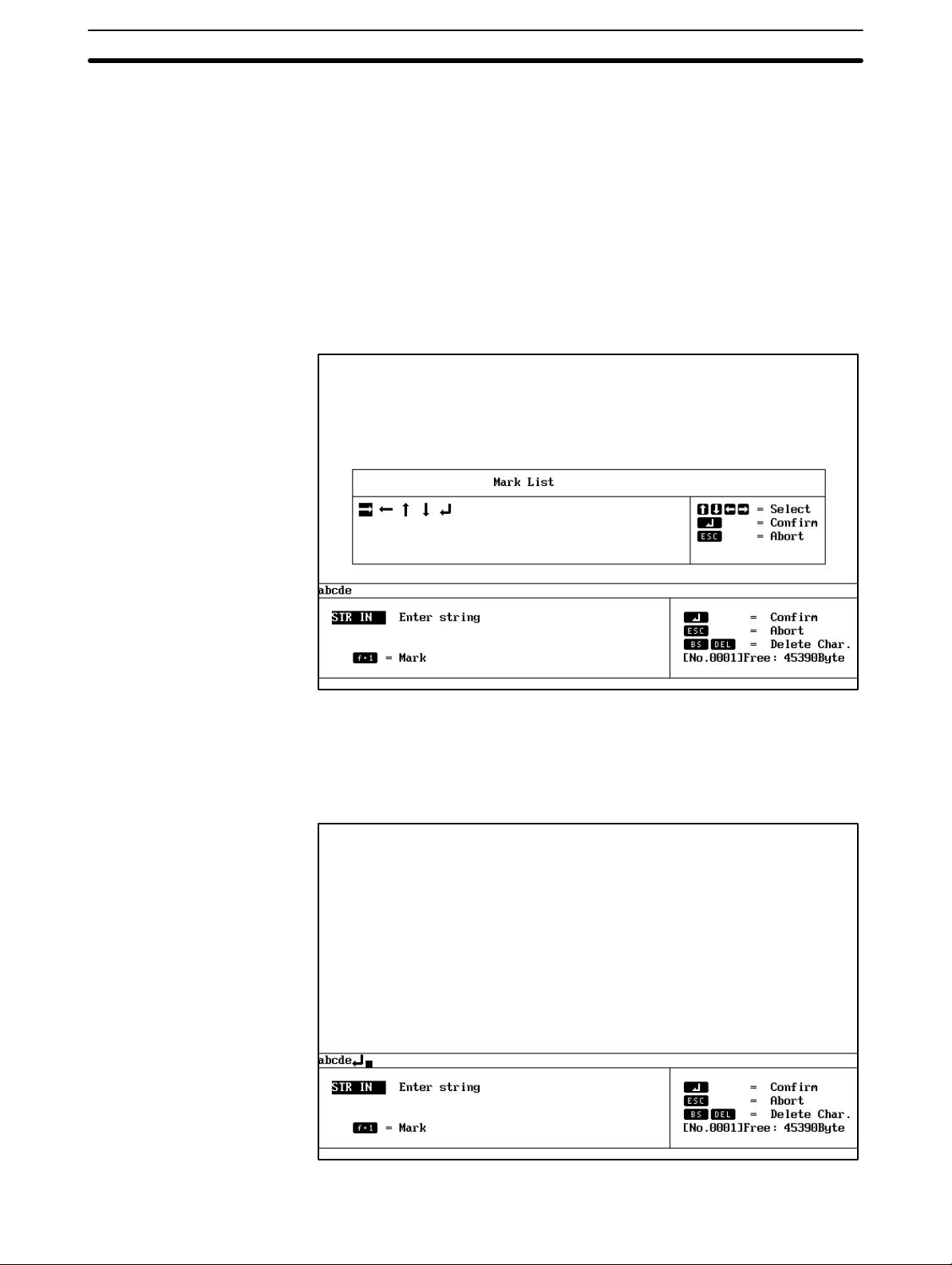

Marks You can input marks while inputting characters.

section on page 24. Special characters or Marks

1, 2, 3...

1. Press F1 (Mark) while inputting a string. The Mark List will appear.

2. Use the direction keys to select the mark you want to input, and then

press the Enter Key to enter them, or press the Escape Key to cancel

mark input and return to character input.

23

Page 28

Inputting Character Strings Section 2-1

String Attributes Here you set the size, scale, and attributes for character strings that have

been input.

1, 2, 3...

1. Set the size to be used for each 1-byte character.

2. Set the scale factor for the characters. NT600M strings can be set to

64X in addition to the ones shown in the above display.

3. Set display attributes. “Spot” is for flashing characters in reverse video.

Display attributes will be displayed on the computer screen as shown

below. (Although the contrast of most displays in this manual is reversed, the contrast of these examples is the same of that on the

screen.

Normal Flashing

Inverse Spot (Inverse Blinking)

4. Press the Enter Key after checking the settings.

A display for designating string position will appear next.

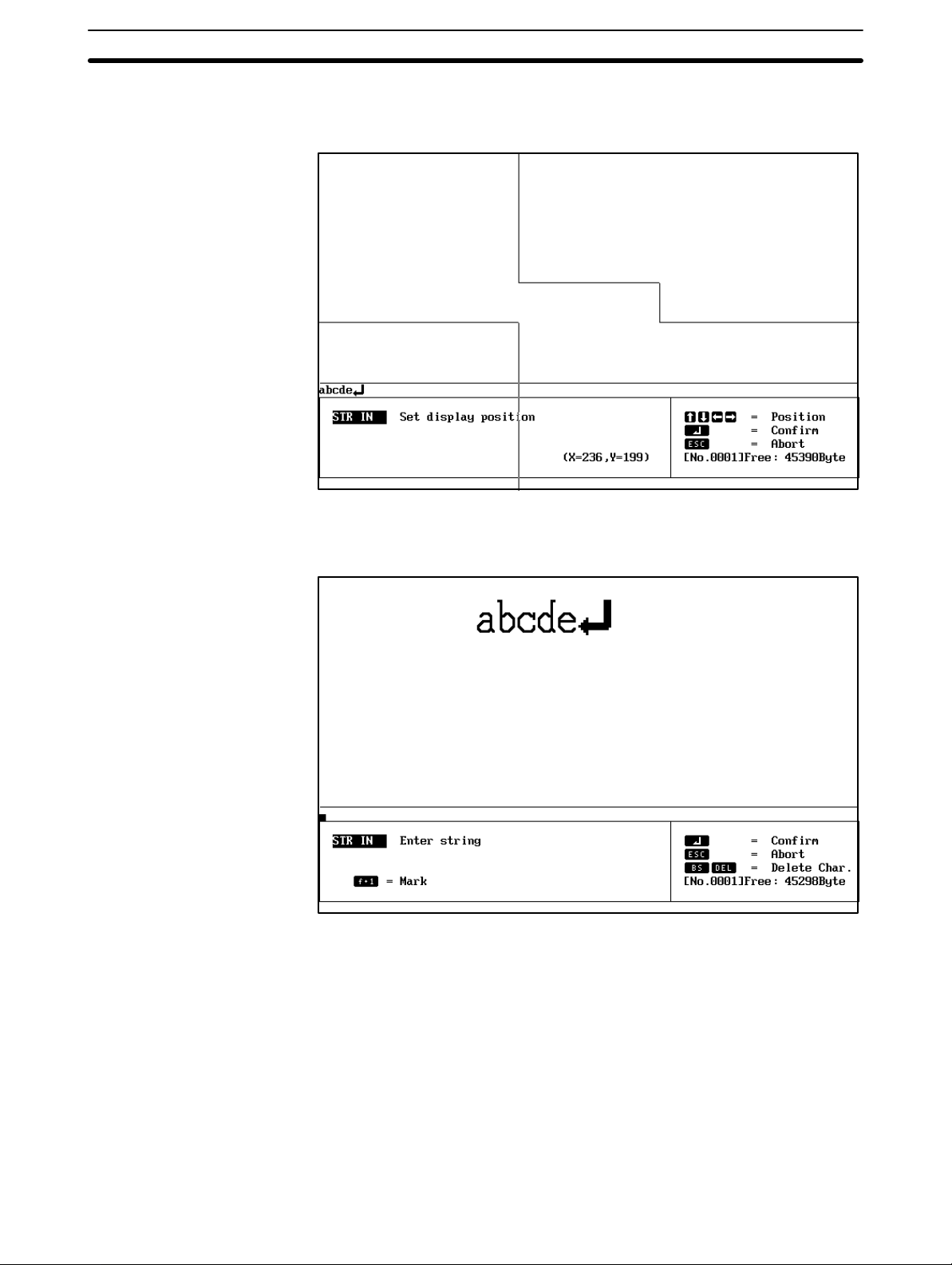

Designating Display

Position

24

1, 2, 3...

Designate the display position for the string.

1. A rectangular guide box showing the size of the input character string

will be displayed. The guide box is displayed according to the number of

characters input to that point, and the scale which has been set. Set the

display position on the screen with the direction keys. By operating the

direction keys while pressing the Shift Key, you can move the guide box

16 dots at a time. The X and Y coordinates of the display position (the X

and Y coordinates of the lower left-hand corner of the guide box) are

Page 29

Inputting Character Strings Section 2-1

displayed. You cannot set a display position that allows the guide box to

extend off the screen.

Guide box

Cross-shaped cursor

2. When you have set the display position, press the Enter Key.

3. You will be returned to the Initial Text Input Display, and the contents set

up to this point are displayed. At this time, a message again appears in

the command box instructing you to enter text. If you are inputting text to

different places on the same screen, repeat the operations described

above. When you have finished inputting text, press the Escape Key.

You will be returned to the Initial Edit Display.

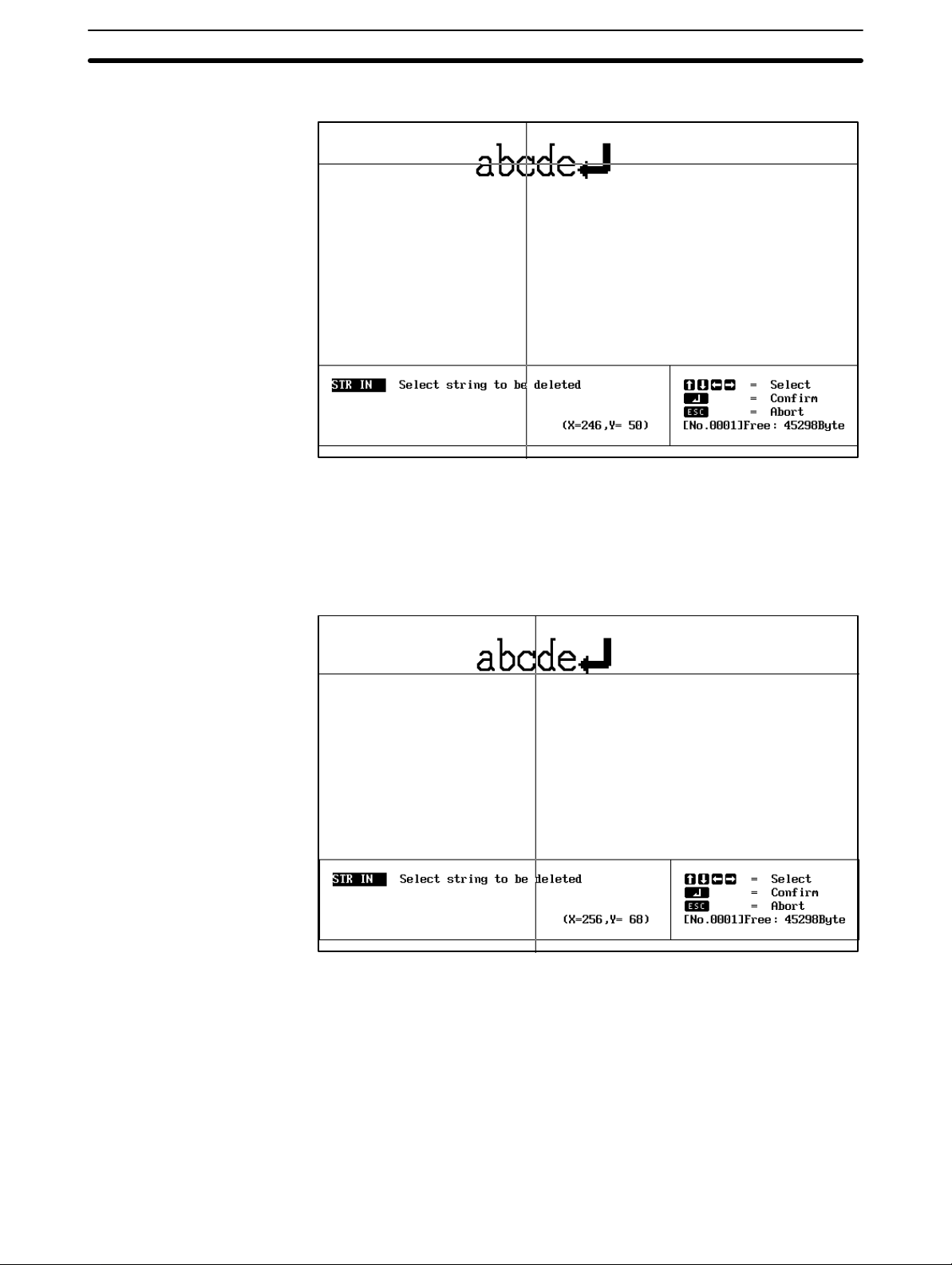

2-1-2 Deleting Character Strings

You can delete strings that have already been set by using the procedure

given below. When you delete a string, a portion of the display may be left

empty. If this happens, press the TAB Key to rewrite the display.

25

Page 30

Inputting Character Strings Section 2-1

1, 2, 3...

1. Specify DELETE. The cross-shaped cursor will be displayed.

2. Line up the center of the cross-shaped cursor with the string you want to

delete, and press the Enter Key. The string which you have selected will

be outlined by a guide box. A message will appear in a comment box to

verify whether you actually want to delete that string. If a number of

characters have been input at one time, then it makes no difference

which character you place the cross-shaped cursor on.

3. To delete the string, press the Enter Key, or to cancel, press any key

other than the Enter Key.

The basic delete operation for other data on the Edit Display, e.g., numeral

displays, is the same.

Note If the screen is not properly displayed after deleting, press the Tab Key to

rescan the display.

2-1-3 Modifying Character Strings

You can modify strings that have already been set.

26

Page 31

Inputting Character Strings Section 2-1

1, 2, 3...

1. Press MODIFY. The cross-shaped cursor will be displayed.

2. Line up the center of the cross-shaped cursor with the string you want to

change, and press the Enter Key. The character which you have selected will be outlined by a guide box, and at the right of the screen a

box will be displayed for you to select the items to be modified.

3. Use the Up and Down Keys to select the item to modified, and then

press the Enter Key. You can return to step 2 by pressing the Escape

Key. For items selected for change, data input methods are the same as

when the string was created.

4. To end the modification, press the Escape Key. A message will appear

asking whether you want to save the modified contents.

5. Press the Enter Key to save any changes made, or if you do not wish to

save the modified contents, press the Space Key to cancel all modifications and restore the previous data.

6. To return to step 3, press the Escape Key.

The procedure for modifying data with the Edit Display is the same as that for

other functions such as numeral and character displays.

27

Page 32

Numeral Displays Section 2-2

2-2 Numeral Displays

Values from numeral tables can be displayed on a screen. The numeral table

entry to be referenced, the display position, and the manner of display are

set. You can set a maximum of 50 numeral displays per screen.

For the NT20M, numeral table entries are numbered from 0 to 127, for a total

of 128. For the NT600M, numeral table entries are numbered from 0 to 255,

for a total of 256.

The procedure for setting number displays depends on whether or not direct

connection is ON or OFF in the Tool Settings. Both procedures are given below.

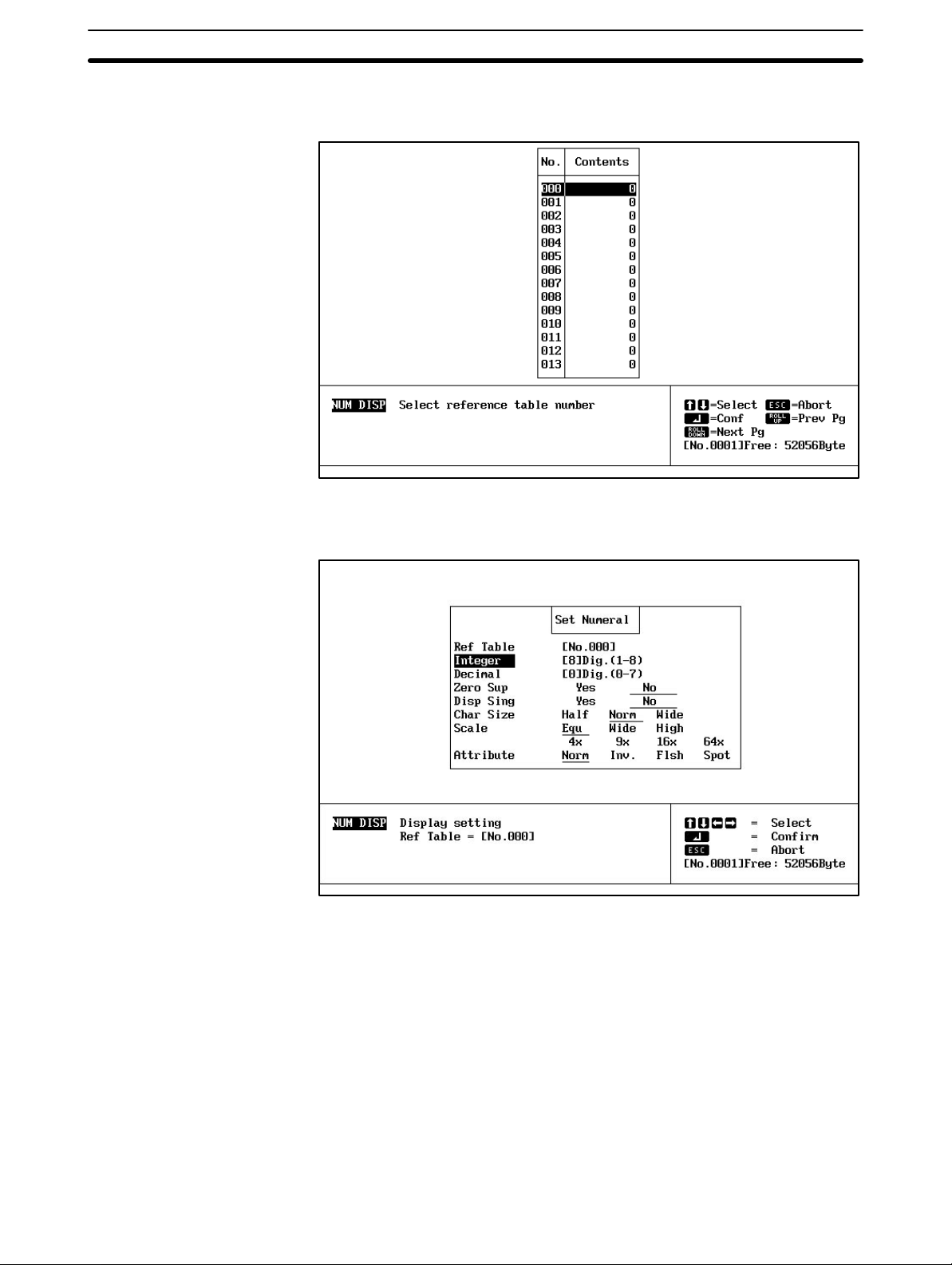

2-2-1 Normal Numeral Displays

Select NUM DISP from the Initial Edit Display, the Initial Display for Numeral

Display will appear.

Designating Numeral Table

References

Initial Display for Numeral Display

Only table number entries 0 to 13 are displayed first. To display the next entries, press the Pg Dn Key; to return to previous entires, press the Pg Up

Key.

Select the numeral table entry that you want to reference and then press the

Enter Key.

Inputting Initial Values The initial value for the selected memory table reference is input next. Refer

to page 12 for details on input methods. You can input numbers from

–99999999 to 99999999. Numeral displays can display decimal numbers, but

you enter them here without the decimal point. For example, if you want to

28

Page 33

Numeral Displays Section 2-2

input –123.456, then just input –123456. The distinction between the integer

portion and the decimal portion is specified in the next step.

Input the number, and then press the Enter Key.

Numeral Display Settings

Set the way in which the display will appear on the screen. Refer to the examples on page 30.

29

Page 34

Numeral Displays Section 2-2

Numeral Display Examples

Number of

integer digits

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Number of

decimal digits

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Note _ indicates a blank space.

Reference table entry

(Reference Table)

Number of integer

digits (Integer)

Number of decimal

digits (Decimal)

Zero suppress (Zero

Sup)

Display sign (Disp

Sign)

Character size (Char

Size)

Scale Set the scale factor for the display. The NT600M can be

Attributes Sets display attributes for the screen. Refer to page 24

Set the number of the item to be referenced in the

numeral table.

Set the number of digits for the integer portion of the

number.

Set the number of digits for the decimal portion of the

number.

Set whether or not leading zeros are to be displayed on

the screen.

Set whether or not negative signs are to be displayed on

the screen. The positive sign is not displayed.

Set the size of characters to be displayed on the screen.

set to 64X in addition to those shown above.

for examples of how attributes are displayed on screen.

Press the Enter Key after checking all of these settings.

Zero suppress Code display Contents of

numeral table

No

No

No

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

Yes

Yes

Yes

Yes

No

No

No

No

Yes

Yes

Yes

Yes

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

12

1234

–12

–1234

12

1234

–12

–1234

12

1234

–12

–1234

12

1234

–12

–1234

12

1234

–12

–1234

12

1234

–12

–1234

12

1234

–12

–1234

12

1234

–12

–1234

1

1

1

1

Display

012

***

012

***

_012

****

–012

****

_12

***

_12

***

__12

****

_–12

****

00.1

01.2

****

01.2

****

_00.1

_01.2

*****

–01.2

*****

_0.1

_1.2

****

_1.2

****

__0.1

__1.2

*****

_–1.2