Page 1

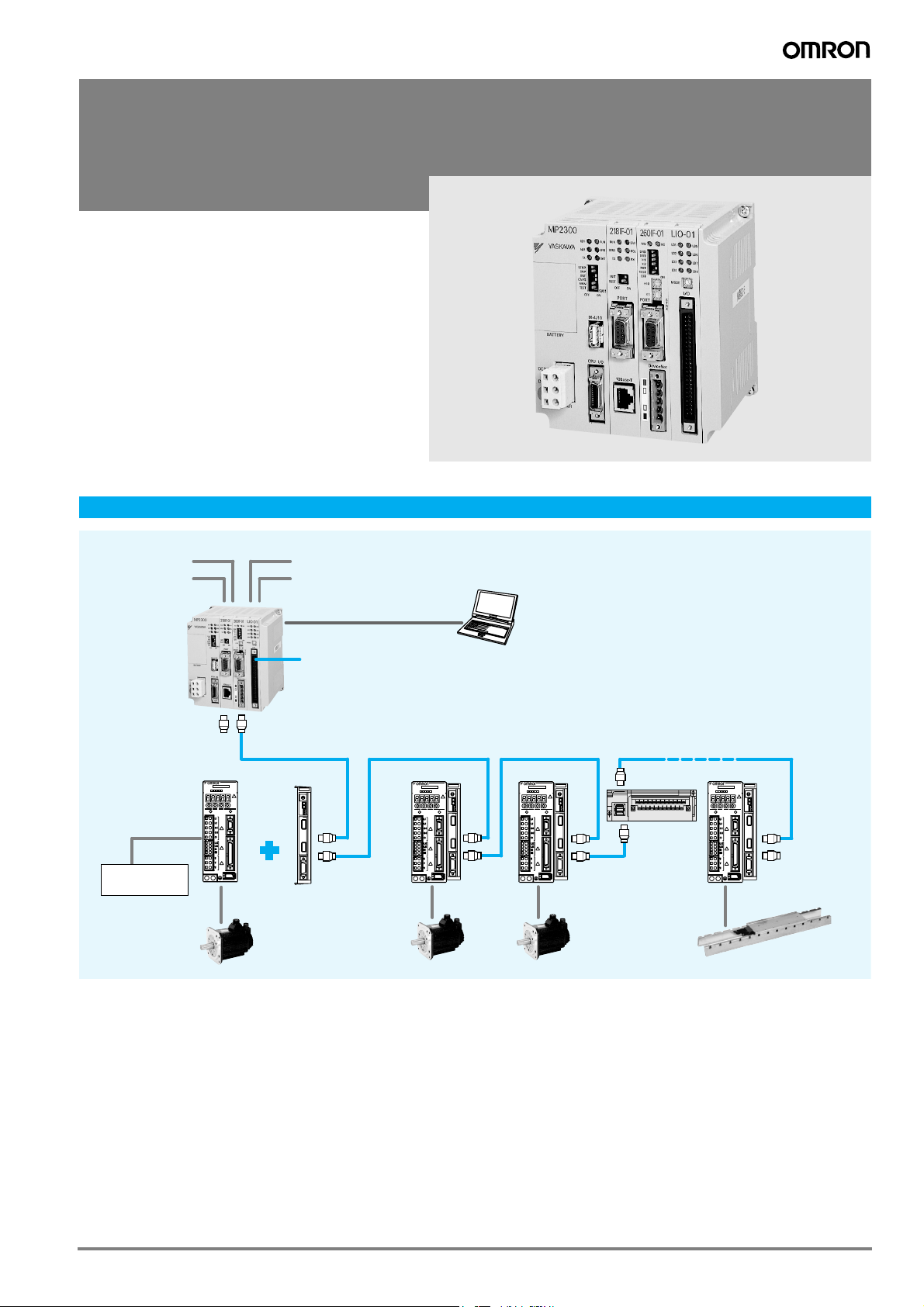

MP2300 - MECHATROLINK-II

Motion controller

Stand-alone solution for advanced

motion control

• Up to 48 axes controlled with minimum wiring

• Self configuration of nodes for an easy setup

• DeviceNet, PROFIBUS and ethernet network interfaces provide easy connectivity to any system

• Supports position, speed and torque control

• Electronic CAM profiles and axes synchronization

• The high-speed bus MECHATROLINK-II is specially

designed for motion control

• Support for I/Os and pulse inputs locally and over the

network

• Access to the complete system from one point.

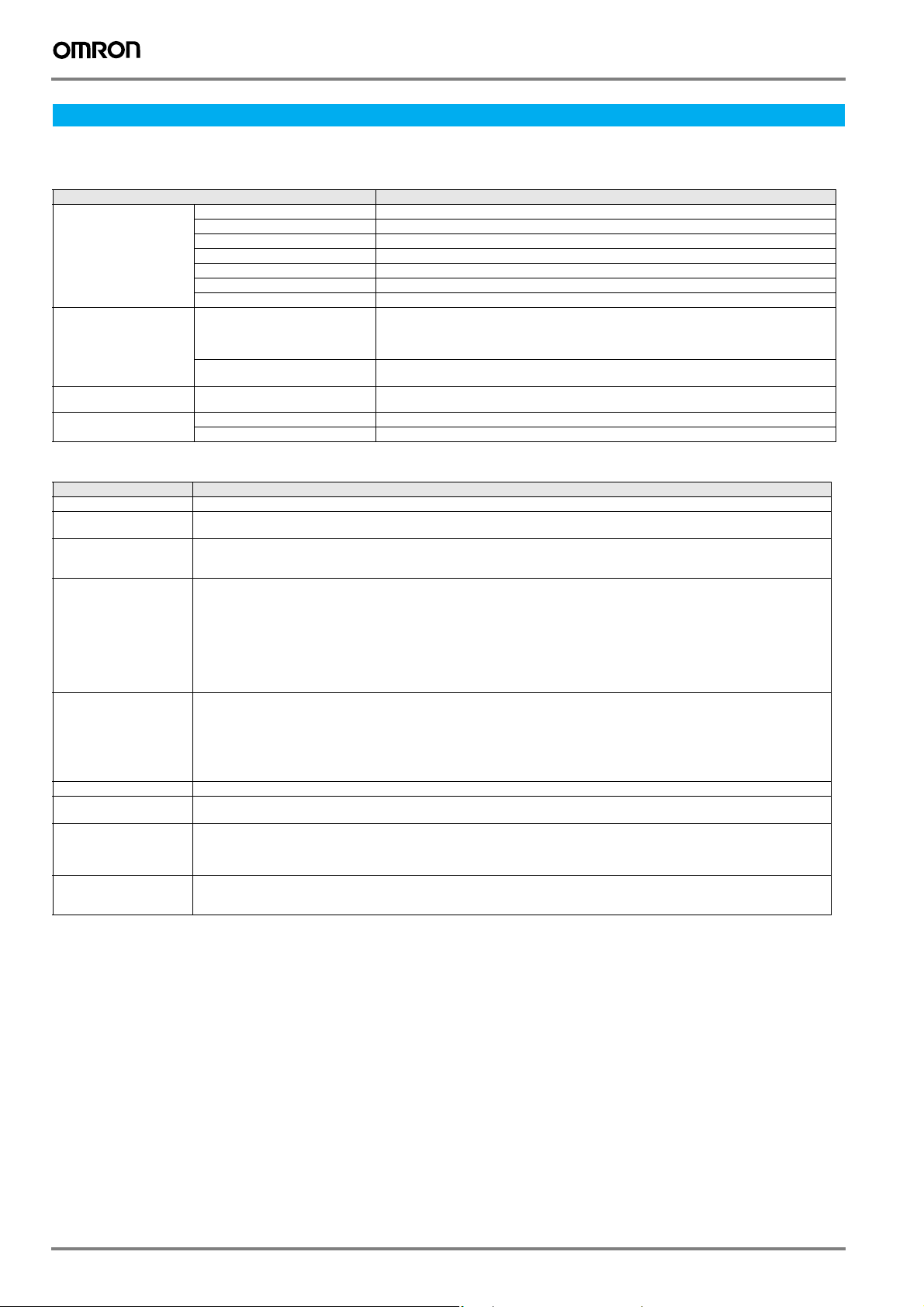

System configuration

DeviceNet

PROFIBUS-DP

Sigma-II series

Servo Drive

Input

Limit switches

contact sensors

Terminator

SGDH-

Ver.

CHARGE POWER

SERVOPACK

200V

CN3

CN1

CN2

Ethernet

RS-232C, RS-422/485

Local I/Os

Motion controller MP2300

(one can handle up to 3 Mechatrolink-II networks)

MECHATROLINK-II

SERVOPACK

NS115

S

W

1

A

R

S

W

2

C

N

6

A

C

N

6

B

C

N

4

JUSP-NS115

SGDH-

200V

Ver.

CHARGE POWER

CN3

CN1

CN2

Mechatrolink-II

unit

Sigma-II series

Servo Motor

Personal computer

Software: MPE720 tool

21 nodes max.

18 servo axes max. + I/O stations

Totel lenght: 50 m

NS115

S

W

1

A

R

S

W

2

C

N

6

A

C

N

6

B

C

N

4

SERVOPACK

NS115

SGDH-

S

200V

Ver.

W

1

A

R

S

W

2

CHARGE POWER

CN3

C

N

6

A

CN1

C

N

6

B

C

N

4

CN2

I/O module

RUNTX 1 2 3 4 5 6 7 8 120DDI 34330

C

N

1

C

N

2

SERVOPACK

NS115

SGDH-

S

200V

Ver.

W

1

A

R

S

W

2

CHARGE POWER

CN3

C

N

6

A

CN1

C

N

6

B

Terminator

C

N

4

CN2

Sigma-II series

Linear Motor

67Motion controller

Page 2

Specifications

General specifications

Hardware specifications

Items Specifications

Environmental conditions Ambient operating temperature 0 to 55 °C

Mechanical operating

conditions

Electrical operating

conditions

Installation

requirements

Sequential function specifications

Items Specifications

Control method Sequence: High-speed and low-speed scan methods

Programming language Ladder diagram: Relay circuit

Scanning Two scan levels: High-speed scan and low-speed scan

User drawings, functions

and motion programs

Data memory Common data (M) registers:

Trace memory Data trace: 128 Kwords (32 Kwords, 4 groups), 16 points defined

Memory backup Program memory: Flash memory: 8 MBytes (user area: 5.5 MBytes) definition files,ladder programs, motion programs, etc.

Data types Bit (relay): ON/OFF

Register designation

method

Ambient storage temperature -25 to 85 °C

Ambient operating humidity 30% to 95% (with no condensation)

Ambient storage humidity 5% to 95% (with no condensation)

Pollution level Pollution level 1 (conforming to JIS B 3501)

Corrosive gas There must be no combustible or corrosive gas.

Operating altitude 2,000 m above sea level or lower

Vibration resistance Conforming to JIS B 3502:

Shock resistance Conforming to JIS B 3502:

Noise resistance Conforming to EN 61000-6-2, EN 55011 (Group 1, Class A)

Ground Ground to 100 Ω max.

Cooling method Natural cooling

Text-type language: Numeric operations, logic operations, etc.

High-speed scan time setting: 1 to 32 ms (Integral multiple of MECHATROLINK communication cycle)

Low-speed scan time setting: 2 to 300 ms (Integral multiple of MECHATROLINK communication cycle)

Startup drawings (DWG.A):

Interrupt processing drawings (DWG.I):

High-speed scan process drawings (DWG.H):

Low-speed scan process drawings (DWG.L):

Number of steps:

User functions:

Motion programs:

Revision history of drawings and motion programs

Security function for drawings and motion programs

System (S) registers:

Drawing local (D) registers:

Drawing constant (#) registers:

Input (I) registers:

Output (O) registers:

Constant (C) registers:

Data memory: Battery backup: 256 Kbytes, M registers, S registers, alarm history, trace data

Integer: -32768 to +32767

Double-length integer: -2147483648 to +2147483647

Real number: ± (1.175E-38 to 3.402E+38)

Register number: Direct designation of register number

Symbolic designation: Up to 8 alphanumeric characters (up to 200 symbols per drawing)

With automatic number or symbol assignment

10 to 57 Hz with single-amplitude of 0.075 mm

57 to 150 Hz with acceleration of 1G

10 sweeps each in X, Y, and Z directions (sweep time: 1 octave/min)

2

Peak acceleration of 147 m/s

(15 G) twice for 11 ms each in the X, Y, and Z directions

64 drawings max. up to three hierarchical drawing levels

64 drawings max. up to three hierarchical drawing levels

200 drawings max. up to three hierarchical drawing levels

500 drawings max. up to three hierarchical drawing levels

Up to 1,000 steps per drawing

Up to 500 functions

Up to 256

64 Kwords

8 Kwords

Up to 16 Kwords per drawing

Up to 16 Kwords per drawing

5 Kwords (including internal input registers)

5 Kwords (including internal output registers)

16 Kwords

68 Motion controllers

Page 3

Motion control function specifications

Item Specifications

Interface MECHATROLINK-I, MECHATROLINK-II

Number of controlled axes/module Up to 16 axes

Control

specifications

Reference unit mm, inch, deg, or pulse

Reference unit minimum setting 1, 0.1, 0.01, 0.001, 0.0001, 0.00001

Maximum programmable value -2147483648 to +2147483647 (signed 32-bit value)

Speed reference unit Reference unit/s designation: mm/s, inch/s, deg/s, pulse/s

Acceleration/deceleration type Linear, asymmetric, S-curve, exponent

Acceleration/deceleration reference unit Reference unit/s

Override function Positioning: 0.01% to 327.67% by axis

Coordinate system Rectangular coordinates

Zero point re-

turn

Applicable servo drives SGDH-@@@E-OY + NS115

Applicable frequency inverters Varispeed V7, F7, G7 with MECHATROLINK-II interface

Encoders Incremental encoder

PTP control Linear, rotary, and infinite-length

Interpolation Up to 16 linear axes, 2 circular axes, and 3 helical axes

Speed reference output Yes

Torque reference output Yes

Phase control Yes

Position

control

DEC1+ phase-C pulse Yes

ZERO signal Yes

DEC1+ ZERO signal Yes

Phase-C pulse Yes

Only phase-C pulse Yes

POT and

POT Yes

Home limit switch and

HOME Yes

NOT and

NOT Yes

INPUT and

INPUT Yes

Positioning Yes

External positioning Yes

Zero point return Yes

Interpolation Yes

Interpolation with position

detection function

JOG operation Yes

STEP operation Yes

Parameter changes during

motion command execution

Reference unit/min. designation: mm/min, inch/ min, deg/min, pulse/min

Percentage designation: Percentage of rated speed

2

Acceleration/deceleration time constant: Time from 0 to rated speed (ms)

phase-C pulse

phase-C pulse

phase-C pulse

phase-C pulse

(for inverter version support contact your OMRON sales office)

Yaskawa absolute encoder

designation: mm/s2, inch/s2, deg/s2, pulse/s

Yes

Yes

Yes

Yes

Yes

Yes

2

MP2300 CPU (basic module)

Items Specifications Appearance

Model JEPMC-MP2300

Power supply Input power voltage: 24 VDC±20%

Motion network One channel for MECHATROLINK-II:

I/O signals Digital input: 8 points (one point can be used for interrupts),

Slot for optional modules 3 slots

Dimensions (mm) 130x120x108 (HxWxD)

Weight 500 g

Current consumption:1 A

Inrush current: 40 A or less

Twenty-one stations, including servo drives and I/O equipment, can be connected.

(16 axes for servo drives and inverters)

Transmission speed: 10Mbps (MECHATROLINK-II)

Transmission distance: See “MECHATROLINK-II repeater”

Digital output: 4 points, 24 VDC, 100 mA, open collector, and sink mode output (NPN)

24 VDC, 4 mA, and source mode or sink mode input

Motion controller 69

Page 4

General-purpose serial communication module (217IF-01)

Items Specifications Appearance

Model JAPMC-CM2310

Port For RS-232C communication For RS-422/485 communication

Interface One port One port (RS-422 or -485)

Connector D-sub 9 pins (female) MDR 14 pins (female)

Max. transmission

distance

Transmission speed 76.8 kbps 76.8 kbps

Access mode Asynchronous (start-stop synchronization) Asynchronous (start-stop synchronization)

Communication protocols MEMOBUS (master or slave)

Media access control

method

Transmission format

(can be set)

15 m 300 m

MELSEC, HostLink, or non-protocol

1:1 1:1 (RS-422), 1:N (RS-485)

Data bit length: 7 or 8 bits

Stop bits: 1 or 2 bits

Parity bits: even, odd, or none

MEMOBUS (master or slave)

MELSEC, HostLink, or non-protocol

Data bit length: 7 or 8 bits

Stop bits: 1 or 2 bits

Parity bits: even, odd, or none

Ethernet communication module (218IF-01)

Items Specifications Appearance

Model JAPMC-CM2300

Port For ethernet communication Port For RS-232C communication

Interface One port (10BaseT)

Max. segment length 100 m Connector D-sub 9 pins (female)

Transmission speed 10 Mbps Max. transmission

Access mode IEEE802.3 Transmission

Flame format Ethernet ver.2 (conforming to DIX) Access mode Asynchronous (Start-stop synchronization)

Connections TCP/UDP/IP/ARP Communication

Max. number of words

in transmission

Communication

protocols

Max. number of

connections

(RJ-45 modular jack)

512 words

(1024 bytes)

Extended MEMOBUS,

MEMOBUS, MELSEC-A,

non-protocol, or MODBUS/TCP

20 stations

Interface One port

distance

speed

protocols

Media access

control method

Transmission

format

(can be set)

15 m

76.8 kbps

MEMOBUS (master or slave)

MELSEC, HostLink, or non-protocol

1:1

Data bit length: 7 or 8 bits

Stop bits: 1 or 2 bits

Parity bits: even, odd, or none

DeviceNet communication module (260IF-01)

Items Specifications Appearance

Model JAPMC-CM2320

Port For DeviceNet communication Port For RS-232C communication

Number of circuits 1 Interface One port

Applicable

communication

I/O

communication

Message

communication

(only for

master)

Switches on the front Two rotary switches: Node address set-

Indicators 2 LEDs: MS or NS Media access

Power voltage for

communication

Max. current

consumption

Max. number

of slaves

Max. I/O bytes 1024 bytes, 256 bytes per node

Max. number

of nodes

Max. message

length

Executed

functions

Conforms to DeviceNet master or slave

-

I/O transmission

(polled I/O and bisstrobed I/O)

- Explicit messaging

63 nodes Max. transmission

63 nodes (synchronous communications possible: 8 nodes)

256 bytes

MSG-SND function Access mode Asynchronous (start-stop synchronization)

tings

DIP switch: Settings for transmission

speed and switching master or slave

24 VDC±10%

(using the specially designed cable)

Communication power: 45 mA

(supplied by transmission connectors)

Connector D-sub 9 pins (female)

distance

Transmission

speed

Communication

protocols

control method

Transmission

format

(can be set)

15 m

76.8 kbps

MEMOBUS (master or slave)

MELSEC, HostLink, or non-protocol

1:1

Data bit length: 7 or 8 bits

Stop bits: 1 or 2 bits

Parity bits: even, odd, or none

70 Motion controllers

Page 5

PROFIBUS communication module (261IF-01)

Items Specifications Appearance

Model JAPMC-CM2330

Port For PROFIBUS communication Port For RS-232C communication

Functions DP slave Interface One port

Transmission speed 12M/6M/4M/3M/1.5M/750k/500k/

Configuration By PROFIBUS master

Slave address 1 to 64 Transmission

I/O processing

Diagnostic functions

Cyclic communication

(DP standard function)

187.5k/93.75k/19.2k/9.6kbps

(automatic detection)

Total capacity of IW/OW registers:

64 words

Max. I/O allocation (IN and OUT each):

64 words

Display for status and slave status

using the EWS.

I/O error display for SW registers

Connector D-sub 9 pins (female)

Max. transmission

distance

speed

Access mode Asynchronous (start-stop synchronization)

Communication

protocols

Media access

control method

Transmission

format

(can be set)

15 m

76.8 kbps

MEMOBUS (master or slave)

MELSEC, HostLink, or non-protocol

1:1

Data bit length: 7 or 8 bits

Stop bits: 1 or 2 bits

Parity bits: even, odd, or none

Analogue reference motion control module (SVA-01)

Items Specifications Appearance

Model JAPMC-MC2300

Number of axes 2 axes (CN1 & CN2) analogue output and encoder input.

Digital inputs (per axis) 6 inputs, PNP or NPN (including alarm, ready, zero and latch)

Digital outputs (per axis) 6 outputs (including servo_on, alarm_reset, control_mode_select and SEN)

Encoder input (per axis) Differential line-driver (A,/A,B,/B,Z,/Z). 4 Mpps (before multiplication).

Analog outputs (per axis) 2 outputs ±10 V 16 bits (typically speed and torque references)

Analog inputs (per axis) 2 inputs ±10 V 16 bits

External supply 24 VDC (in CN3)

LED's RUN (green) ERR(red)

MECHATROLINK-II motion control module (SVB-01)

Items Specifications Appearance

Model JAPMC-MC2310

Communication circuits 1 circuit

Communication ports 2 ports

Terminator External resistor (JEPMC-W6022 required)

Transmission speed 10 Mbps

Communication cycle 0.5ms, 1ms, 1.5ms, 2ms

Number of connecting

stations

Retry function Available with MECHATROLINK-II

Slave function Available with MECHATROLINK-II

Transmission distance See “MECHATROLINK-II repeater”

21 stations (16 axes for servo drives and inverters) /2 ms, 15 stations (15 axes for servo drives) /1.5 ms,

9 stations (9 axes for servo drives) /1ms, 4 stations (4 axes for servo drives) /0.5 ms

I/O modules (LIO-01/-02)

Items Specifications Appearance

Models JAPMC-IO2300 (NPN output), JAPMC-IO2301 (PNP output)

Digital I/O

Pulse input

Others Coincident detection; preset and clear functions for counter values.

Input signals 16 points (all connected) and 24 VDC±20%, 5 mA (TYP)

Output signals 16 points (all connected) and 24 VDC±20%, 100 mA max.

Number of channels 1 (Phase A, B, or Z input)

Input circuit Phase A/B: 5V differential inputs, no insulation, and max. frequency 4 MHz

Input method A/B (1, 2, or 4 multipliers), sign (1 or 2 multipliers), UP/DOWN (1 or 2 multipliers)

Latch input Pulse latch with phase Z or DI-01

Sink mode or source mode input and photocoupler isolation

Min. ON voltage/current: 15V/1.6 mA

Max. OFF voltage/current: 5V/1.0 mA

Max. response time: OFF

Interruption (DI-00): DI-00 can be used for interruptions. If an interruption is enabled, the interrupt drawing

Pulse latch (DI-01): DI-01 can be used for pulse latching. If pulse latching is enabled, the pulse counter is

Open collector: Sink mode output (LIO-01 module)

Photocoupler isolation and max. OFF current: 0.1 mA

Max. response time:OFF

Output protection: Fuse (for protection against fires caused by an overcurrent when outputting after a short

Phase Z: 5 V/12 V photocoupler inputs and max. frequency 500 kHz

Min. response time: 5 µs when input with phase Z; 60 µs when input with DI-01

ÎON 1 ms and ONÎOFF 1 ms

is started when DI-00 is set to ON.

latched when DI-01 is set to ON.

Source mode output (LIO-02 module)

ÎON 1 ms and ONÎOFF 1 ms

circuit occurred).

If circuit protection is required, provide a fuse for each output circuit.

Motion controller 71

Page 6

I/O modules (LIO-04)

Items Specifications Appearance

Model JAPMC-IO2303

Input signals 32 points (8 points common) and 24 VDC±20%, 5 mA (TYP)

Output signals 32 points (8 points common) and 24 VDC±20%, 100 mA max.

Sink mode or source mode input and photocoupler isolation

Min. ON voltage/current: 15 V/1.6 mA

Max. OFF voltage/current: 5 V/1.0 mA

Max. response time: OFF

Interruption (DI-00, DI-01, DI-16, DI-17):

DI-00, DI-01, DI-16, and DI-17 can be

used for interruptions. If an interruption is

enabled, the interrupt drawing is started

when DI-00, DI-01, DI-16, or DI-17 is set to ON.

Note: See right for the derating conditions

ÎON 0.5 ms and

ÎOFF 0.5 ms

ON

Open collector: Sink mode output (NPN) and photocoupler isolation

Max. OFF current: 0.1 mA

Max. response time: OFF

Output protection: Fuse (for protection against fires caused by an overcurrent when outputting after a

ÎON 0.5 ms and ONÎOFF 1 ms

short circuit occurred)

If circuit protection is required, provide a fuse for each output circuit.

(%)

100

90

80

70

60

50

40

Input ON Ratio

30

20

10

0

10 20 30 40 50 55 (°C)

Number of Input ON Points Temperature Derating

Ambient Temperature

22 points

ON enabled

at 24V

14 points

ON enabled

at 28.8V

MECHATROLINK-II, 64 point I/O module (IO2310)

Items Specifications Appearance

Model JEPMC-IO2310

I/O signals Input: 64 points, 24 VDC, 5 mA, sink/source mode input

Module power supply 24 VDC (20.4 V to 28.8 V)

Weight 590 g

Output: 64 points, 24 VDC, 50 mA when all points ON,

(the max. rating is 100 mA per point) sink mode output (NPN)

Signal connection method: Connector (FCN360 series)

Rated current: 0.5 A

Inrush current: 1 A

MECHATROLINK-II, counter module (PL2900)

Items Specifications Appearance

Model JEPMC-PL2900

Number of input

channels

2

Functions Pulse counter, notch output, registration input

Pulse input method Sign (1/2 multipliers), A/B (1/2/4 multipliers), UP/DOWN (1/2 multipliers)

Max. counter speed 1200 kpps (4 multipliers)

Pulse input voltage 3/5/12/24 VDC

External power supply For input signal: 24 VDC, For dividing load: 24 VDC, For module: 24 VDC (20.4 V to 26.4 V), 120 mA or less

Weight 300 g

MECHATROLINK-II, pulse output module (PL2910)

Items Specifications Appearance

Model JEPMC-PL2910

Number of output

channels

2

Functions Pulse positioning, JOG run, zero-point return

Pulse output method CW, CCW pulse, sign

Max. output speed 500kpps

Pulse output voltage 5VDC

Pulse interface circuit Open collector output

External control signal Digital input: 8 points/module, 5 VDC x 4 points, 24 VDC x 4 points

5VDC, 10mA/circuit

Digital output: 6 points/module, 5 VDC x 4 points, 24 VDC x 2 points

Weight 300 g

MECHATROLINK-II, analog input module (AN2900)

Items Specifications Appearance

Model JEPMC-AN2900

Number of input

channels

Input voltage range -10 V to +10 V

Input impedance 1 MΩ min.

Data format Binary, -32000 to +32000

Input delay time 4 ms max.

Error ± 0.5% F.S. (at 25 °C), ± 1.0% F.S. (at 0 °C to 60 °C)

External power supply

Weight 300 g

4

24VDC (20.4VDC to 26.4VDC), 120mA max.

72 Motion controllers

Page 7

MECHATROLINK-II, analog output module (AN2910)

Items Specifications Appearance

Model JEPMC-AN2910

Number of output

channels

Output voltage range -10V to +10V

Max. allowable

load current

Data format Binary, -32000 to +32000

Output delay time 1ms

Error ± 0.2% F.S. (at 25 °C), ± 0.5% F.S. (at 0 °C to 60 °C)

External power supply

Weight 300 g

2

± 5 mA (2 kΩ)

24 VDC (20.4 VDC to 26.4 VDC), 120 mA max.

MECHATROLINK-II, repeater

Items Specifications Appearance

Model JEPMC-REP2000

Communication type MECHATROLINK-II

Cable length Between controller and repeater: 50 m., after repeater: 50 m

Max. connected

stations

Restrictions Between controller and repeater

Power supply 24 VDC, 100 mA

Weight 340 g

Dimensions (mm) 30x160x77 (HxWxD)

Total stations on both sides of repeater: 30

(limited to the max. number of connectable stations of the controller (e.g., 21 stations for the MP2300 series))

- Total cable length

- 30 m < total cable length

After repeater:

- Total cable length

- 30 m < total cable length

≤ 30 m: 15 stations max. including I/O and servo, etc.

≤ 50 m: 14 stations max. including I/O and servo, etc.

≤ 30 m: 16 stations max. including I/O and servo, etc.

≤ 50 m: 15 stations max. including I/O and servo, etc.

MECHATROLINK-II, servo drive interface unit

Item Details

Type JUSP-NS115

Applicable servo drive SGDH-@@@E models (version 38 or later)

Installation method Mounted on the SGDH servo drive side: CN10.

Basic

specifications

MECHATROLINK -II

communications

Command format Operation specification Positioning using MECHATROLINK-I/II communications.

Position control

functions

Fully closed

system

specifications

Input signals in the

servo drive

Internal functions Position data latch function Position data latching is possible using phase C, and external signals 1, 2, 3

Power supply method Supplied from the servo drive control power supply.

Power consumption 2W

Baud rate/transmission cycle 10 Mbps / 1 ms or more. MECHATROLINK-II communications

Reference input MECHATROLINK-I/II communications

Acceleration/deceleration method Linear first/second-step, asymmetric, exponential, S-curve

Fully closed control Position control with fully closed feedback is possible.

Encoder pulse output in the

servo drive

Fully closed encoder pulse signal A quad B line-driver

Maximum receivable frequency

for servo drive

Power supply for fully closed

encoder

Signal allocation

changes possible

Protection Parameters damage, parameter setting errors, communications errors,

LED indicators A: alarm, R: MECHATROLINK-I/II communicating

Commands: position, speed, torque, parameter read/write, monitor output

5 V differential line-driver output (complies with EIA Standard RS-422A)

1 Mpps

To be prepared by customer.

Forward/reverse run prohibited, zero point return deceleration LS

External latch signals 1, 2, 3

Forward/reverse torque control

WDT errors, fully closed encoder detecting disconnection

NS115

MECHATROLINK-II, frequency inverter interface units

Item Details

Type SI-T/V7 SI-T

Applicable inverter CIMR-V7 / 3G3-MV

Installation method Mounted on the inverter

Power supply Supplied from the inverter

MECHATROLINK-II communications 10 MHz, 0.5 ms to 8 ms for MECHATROLINK-II

Operation Read and write registers, read monitors, inverter operation, speed reference, torque reference

Inputs and outputs The inputs and outputs in the inverter can be read and set by the MLII master

Connectors ML-II bus connector. DPRAM connector for the inverter

Switches Rotary switch for ML-II address (low byte)

(firmware 5740 or newer)

Contact your OMRON sales office for information about firmware compatibility

(G7/F7 only).

Dip switch for: ML-II address (high bit). ML-II/ML-I selection. 17 byte/32 byte data length selection.

CIMR-G7 / CIMR-F7

(firmware 656x/for G7 / 4011 or newer for F7)

Motion controller 73

Page 8

Dimensions

MP2300 basic module

4.5

RDY

ALM

TX

STOP

SUP

INIT

CNFG

MON

TEST

SW1

ON

OFF

M-4/10

BATTERY

CPU I/O

DC24V

DC 0V

POWER

IO2310 I/O module

4.5 4.5

4.5

121

130

120

RUN

ERR

BAT

218IF-01

RUN

STRX

TX

INIT

TEST

PORT

10Base-T

4.5111

LIO-01

LIO-01

LD1

LD1

LD5

ERR

LD2

LD2

LD6

COL

LD3

LD3

LD7

RX

LD4 LD8

LD4 LD8

MODE

MODE

ONOFF

I/O

I/O

4.5

LD5

LD6

LD7

130

18

108

Mounting hole diagram

111 0.2

4-tapped holes M4

121 0.2

4.5 121

120

111

108

Mounting hole diagram

111 0.2

4-tapped holes M4

121 0.2

4.5

I/O modules PL2900, PL2910, AN2900, AN2910

4.5

89.8

79

RUN TX 1 2 3 4 5 6 7 8 120 DDI 343 30

4.5

RUN TX 1 2 3 4 5 6 7 8 120 DDI 343 30

44

C

N

1

C

N

2

MECHATROLINK-II servo drive interface unit

Units: mm Approx. weight: 0.2 kg

FG terminal

M4

Connector

to SERVOPACK

152

161

152

CN6A

CN6B

CN4

24

NS115

100

2

S

W

1

A

R

S

W

2

C

N

6

A

142

C

N

6

B

C

N

4

Name

plate

20

128

74 Motion controllers

Page 9

Ordering information

MP2300 - motion controller main unit

Name Model name Model

MP2300 basic module (CPU module included),1 channel for MECHATROLINK-II, I/O MP2300 JEPMC-MP2300

MP2300 - motion control modules

Name Model name Model

Analogue reference motion control module (2 axes) SVA-01 JAPMC-MC2300

1 additional MECHATROLINK-II communication channel SVB-01 JAPMC-MC2310

MP2300 - communication modules

Name Model name Model

General-purpose serial communication module (RS-232C / RS422 communication) 217IF-01 JAPMC-CM2310

Ethernet communication module (RS-232C / ethernet communication) 218IF-01 JAPMC-CM2300

DeviceNet communication module (RS-232C / DeviceNet communication) 260IF-01 JAPMC-CM2320

PROFIBUS communication module (RS-232C / PROFIBUS communication) 261IF-01 JAPMC-CM2330

MP2300 - I/O modules

Name Model name Model

16-point input, 16-point output (sink mode output / NPN), and 1-point pulse input LIO-01 JAPMC-IO2300

16-point input, 16-point output (source mode output / PNP), and 1-point pulse input LIO-02 JAPMC-IO2301

32-point input and 32-point output LIO-04 JAPMC-IO2303

MECHATROLINK-II - related devices

Name Remarks Model

Distributed I/O modules 64-point input and 64-point output JEPMC-IO2310

MECHATROLINK-II cables 0.5 meter JEPMC-W6003-A5

MECHATROLINK-II terminator Terminating resistor JEPMC-W6022

MECHATROLINK-II

interface unit

MECHATROLINK-II repeater MECHATROLINK-II repeater JEPMC-REP2000

Reversible counter: 2 channels JEPMC-PL2900

Pulse output: 2 channels JEPMC-PL2910

Analog input: -10 V to +10 V, 4 channels JEPMC-AN2900

Analog output: -10 V to +10 V, 2 channels JEPMC-AN2910

1 meter JEPMC-W6003-01

3 meters JEPMC-W6003-03

5 meters JEPMC-W6003-05

10 meters JEPMC-W6003-10

20 meters JEPMC-W6003-20

30 meters JEPMC-W6003-30

For Sigma-II series servo drives. (Firmware version 38 or later) JUSP-NS115

For Varispeed V7 inverter

(for inverter version support contact your OMRON sales office)

For Varispeed F7, G7 inverter

(for inverter version support contact your OMRON sales office)

SI-T/V7

SI-T

I/O cables

I/O cable for LIO-01, 02 With connector on the LIO-01, -02 side 0.5 JEPMC-W2061-A5

I/O cable for LIO-04 With connector on the LIO-04 side 0.5 JEPMC-W6060-05

I/O cable for MP2300 With connector on the MP2300 side 0.5 JEPMC-W2060-A5

I/O cable for IO2310 With connector on the IO2310 side 0.5 JEPMC-W5410-05

Remarks Lenght m Model

1.0 JEPMC-W2061-01

3.0 JEPMC-W2061-03

1.0 JEPMC-W6060-10

3.0 JEPMC-W6060-30

1.0 JEPMC-W2060-01

3.0 JEPMC-W2060-03

1.0 JEPMC-W5410-10

3.0 JEPMC-W5410-30

Accessories

Name Model

Battery ER3V 3.6V JZSP-BA01

Empty slot cover JEPMC-OP2300

Brackets for DIN rail JEPMC-OP300

Motion controller 75

Page 10

Computer software

Specifications Model

Programming software to support from system design to maintenance.

Intuitive ladder programming and editing functions. CAM data generation

Windows-based (Windows 95/98/NT4.0/2000/XP)

CPMC-MPE720

Servo system

Note: Refer to servo systems section for detailed information

Frequency inverters

Note: Refer to frequency inverters section for detailed information

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. I34E-EN-01

In the interest of product improvement, specifications are subject to change without notice.

76 Motion controllers

Loading...

Loading...