Page 1

K3NP Period Meter

Operation Manual

Produced January 1998

Page 2

iv

Page 3

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to the product.

DANGER Indicates information that, if not heeded, is likely to result in loss of life or serious injury.

!

WARNING Indicates information that, if not heeded, could possibly result in loss of life or serious injury.

!

Caution Indicates information that, if not heeded, could result in relatively serious or minor injury,dam-

!

age to the product, or faulty operation.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Ó OMRON, 1998

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 4

vi

Page 5

TABLE OF CONTENTS

PRECAUTIONS xi.................................

1 General Precautions xii..........................................................

2 Safety Precautions xii...........................................................

3 Application Precautions xii......................................................

4 Noise Prevention xiii............................................................

SECTION 1

Introduction 1....................................

1-1 Features 2...............................................................

1-2 Front of the Meter 3.......................................................

1-3 Rear of the Meter 6........................................................

1-4 Modes 7.................................................................

1-5 Communications Function 8.................................................

SECTION 2

Setup 9..........................................

2-1 Mounting 10..............................................................

2-2 Input Block 11.............................................................

2-3 Output Board 14...........................................................

SECTION 3

Operating Modes 19................................

3-1 Passing Speed: F1 20........................................................

3-2 Cycle: F2 23..............................................................

3-3 Time Difference: F3 25......................................................

3-4 Elapsed Time: F4 28........................................................

3-5 Length Measurement: F5 31..................................................

3-6 Interval: F6 34.............................................................

SECTION 4

Parameter Setting 37...............................

4-1 Overview 38..............................................................

4-2 Setting Mode 39...........................................................

4-3 Protect Mode 69...........................................................

SECTION 5

Operations in RUN Mode 79.........................

5-1 Displaying and Changing Setting Values 80......................................

5-2 Displaying and Resetting of Maximum and Minimum Values 82.....................

5-3 External Input Signals 84....................................................

SECTION 6

Useful Functions 87.................................

6-1 Teaching Function 88.......................................................

6-2 Output Test 90.............................................................

6-3 Maintenanc e Mode 91.......................................................

SECTION 7

BCD Output 93....................................

7-1 Connectors 94.............................................................

7-2 Timing Charts 97...........................................................

SECTION 8

Troubleshooting 99.................................

8-1 Items to Be Checked First 100.................................................

8-2 Display 100................................................................

vii

Page 6

TABLE OF CONTENTS

Appendices

A Specifications 101..............................................................

B List of Settings 105.............................................................

C Available Models 107...........................................................

D Available Parameters 109........................................................

E Setting Examples 113...........................................................

Index 115..........................................

Revision History 119.................................

viii

Page 7

About this Manual:

This manual describes the installation and operation of the K3NP Period Meter and includes the sections

described below.

Please read this manual carefully and be sure you understand the information provided before attempting

to install and operate the K3NP.

Section 1 describes the functions of the K3NP. The main components are also described.

Section 2 provides instructions required for mounting and wiring the K3NP.

Section 3 provides instructions for setting the parameters of the K3NP.

Section 4 provides instructions for operating the K3NP in RUN mode.

Section 5 provides information on the teaching function, output test, and maintenance mode.

Section 6 provides information on the use of the K3NP with the BCD Output Board.

Section 7 provides information for troubleshooting the K3NP

The Appendices provide specifications, a list of settings, a list of standard models, and a list of available

menu items.

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

ix

Page 8

PRECAUTIONS

This section provides precautions for using the K3NP Period Meter and related devices.

The information contained in this section is important for the safe and reliable application of the K3NP .You must read

this section and understand the i nformation contained before attempting to set up or operate the K3NP.

1 General Precautions xii..........................................................

2 Safety Precautions xii...........................................................

3 Application Precautions xii......................................................

4 Noise Prevention xiii............................................................

xi

Page 9

1 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Be sure to read this manual before attempting to use the product and keep this

manual close at hand for reference during operation.

2 Safety Precautions

WARNING Never attempt to disassemble any Units while power is being supplied. Doing so

!

may result in serious electrical shock or electrocution.

WARNING Never touch any of the terminals while power is being supplied. Doing so may

!

result in serious electrical shock or electrocution.

3SectionApplication Precautions

3 Application Precautions

Observe the following precautions when using the product.

· Always use the power supply voltage specified in the specifications.

· Do not use the product in locations subject to flammable gases or combustible

objects.

· Be sure to confirm terminal names when wiring.

· Be sure to tighten the screws on the terminal blocks.

Observe the following precautions when mounting the product.

· Mount the product on level surfaces.

· Mount the product on a panel which has a thickness of 1 to 3.2 mm.

Do not mount the product in the following places.

· Locations subject to strong shock or vibration.

· Locations subject to temperature or humidity exceeding the rated levels or

where icing is liable to occur.

· Locations subject to dust.

· Locations subject to corrosive gases (particularly sulfuric gases or ammonium

gases).

· Locations subject to direct sunlight or outdoor conditions.

· Locations near devices (high-frequency welders or high-frequency sewing

machines) that produce high-frequency noise.

xii

Page 10

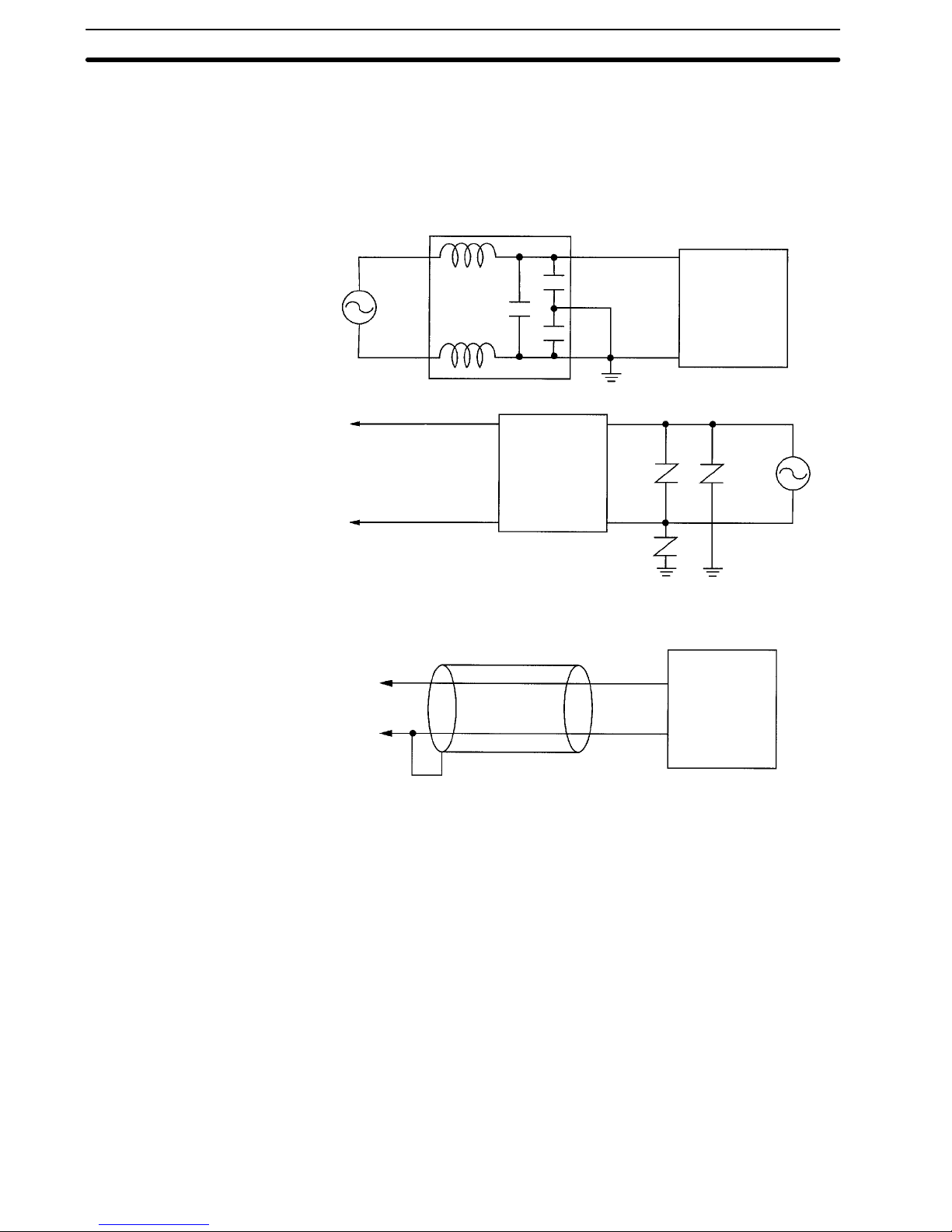

4 Noise Prevention

Provide the following countermeasures when using the product in an environment where the product is exposed to noise.

· Countermeasures for protecting the product against high-frequency noise or

abnormal voltages.

4SectionNoise Prevention

Line filter

Period Meter

Signal

input

+++

Period Meter

--

Power

input

Power

input

· Countermeasures for protecting the product against inductive noise produced

from the input line.

+

Period Meter

--

2-conductor shield wire

xiii

Page 11

SECTION 1

Introduction

This section describes the functions ofthe K3NP. The main components arealso described. Referto the remaining sections of

this manual for the operation of the K3NP and its menus in detail.

1-1 Features 2...............................................................

1-2 Front of the Meter 3.......................................................

1-3 Rear of the Meter 6........................................................

1-4 Modes 7.................................................................

1-5 Communications Function 8.................................................

1

Page 12

Features Section 1-1

1-1 Features

The K3NP Period Meter displays pulse input after performing the numeric conversion of the input.

The K3NP has the following functions.

Measurement The internal system clock counts the period between pulses or pulse-ON time

and displays it in a variety of modes.

In the following example, the internal system clock counts the time (T) between

pulse INA and pulse INB. If there are 100,000 counts during the time (T), a passing speed (F1) of 1,200 (m/min) will be displayed according to the following calculation.

T = 1 system clock count (0.5 ms) x 100,000 = 0.05 s

F1 = 1/T x 60 (m/min) according to the internal calculation method.

Therefore, 1/0.05 s x 60 = 1,200 (m/min)

Example: Passing Speed F1

Internal system

clock

Prescaling Input pulses are converted into a value within a specified range.

Comparative Output

Selection

Linear Output

BCD Output A digital data output format where every four binary bits is numerically equivalent

Communications Output

HOLD

RESET

Output Test This function is convenient for checking a system to which the K3NP is con-

Comparison output patterns can be selected from the standard, level, or zone

output depending on the application.

Refer to Comparative Output Patterns, page 61.

Refer to Linear Output Range, page 64.

to one decimal digit.

Refer to Section 7 BCD Output.

Refer to the Communications Manual.

HOLD is an external input which is used to stop the A/D process and freeze the

display. The comparative, linear, and BCD outputs are also retained.

Refer to 5-3 External Input Signals for details.

RESET is an external input to reset to the initial state and the present maximum

and minimum values. Resetting can be performed using the front panel keys.

Refer to pages 85 and 86.

nected, especially when some inputs cannot be operated. The K3NP simulates

an input to check the output conditions.

Refer to 6-2 Test Mode for details.

Remote/Local Selection The K3NP can be operated remotely through a host computer or locally with key

inputs.

Remote Mode: For programming remotely by downloading setup parameters

Local Mode: Programming is performed with the front panel key input.

Refer to Remote/Local Programming, page 67.

2

from a host computer via RS-232C, RS-485, or RS-422.

Page 13

Front of the Meter

1-2 Front of the Meter

Section 1-2

SV display status

indicators

Escape Key

Comparative output

status indicators

Mode Key

Up Key

PV display

Status indicators

Teaching indicator

Unit of measure

SV display

RESET/TEACH Key

Shift Key

Five-digit (0 to 99999), seven-segment, 14.2-mm-high LED display with a programmable decimal point.

The displays show the process value, maximum value, minimum value, operations/parameters when setting, and error messages.

PV Display K3NP-jjjA Basic Model

RUN Mode: Displays the process, maximum, and minimum values. Also

displays setting values while the SV indicator is lit. When

changing a value, all digits other than those that can be set become dimmer.

Setting Mode: Displays the menu, parameter, or setting value. When chang-

ing a value, all digits other than those that can be set become

dimmer.

K3NP-jjjC Set Value LED Display Model

RUN Mode: Displays the process, maximum, and minimum values.

Setting Mode: Displays the menu and parameters.

SV Display (Setting value

LED Display Models Only)

RUN Mode: Displays comparative set values setting values. When chang-

ing a value, all digits other than those that can be set become

dimmer.

Setting Mode: Displays setting values. When changing a value, all digits other

than those that can be set become dimmer.

Comparative Output Status

Indicates the status of the comparative output.

Indicators

3

Page 14

Front of the Meter

Section 1-2

Status Indicators HOLD Indicator

Lit when the HOLD input signal is ON.

MAX Indicator

Lit when the value displayed on the PV display is the maximum value.

MIN Indicator

Lit when the value displayed on the PV display is the minimum value.

PROG Indicator

Lit when the setting mode menu is displayed. The indicator flashes while parameters are displayed.

Teaching Indicator Lit when displayed parameters can be set in teaching operation. The indicator

flashes when the process value is indicated as a setting value.

SV Display Status Indicators Indicates which set value is on the PV or SV display.

Unit of Measure Attach the appropriate label showing the unit of measure (enclosed).

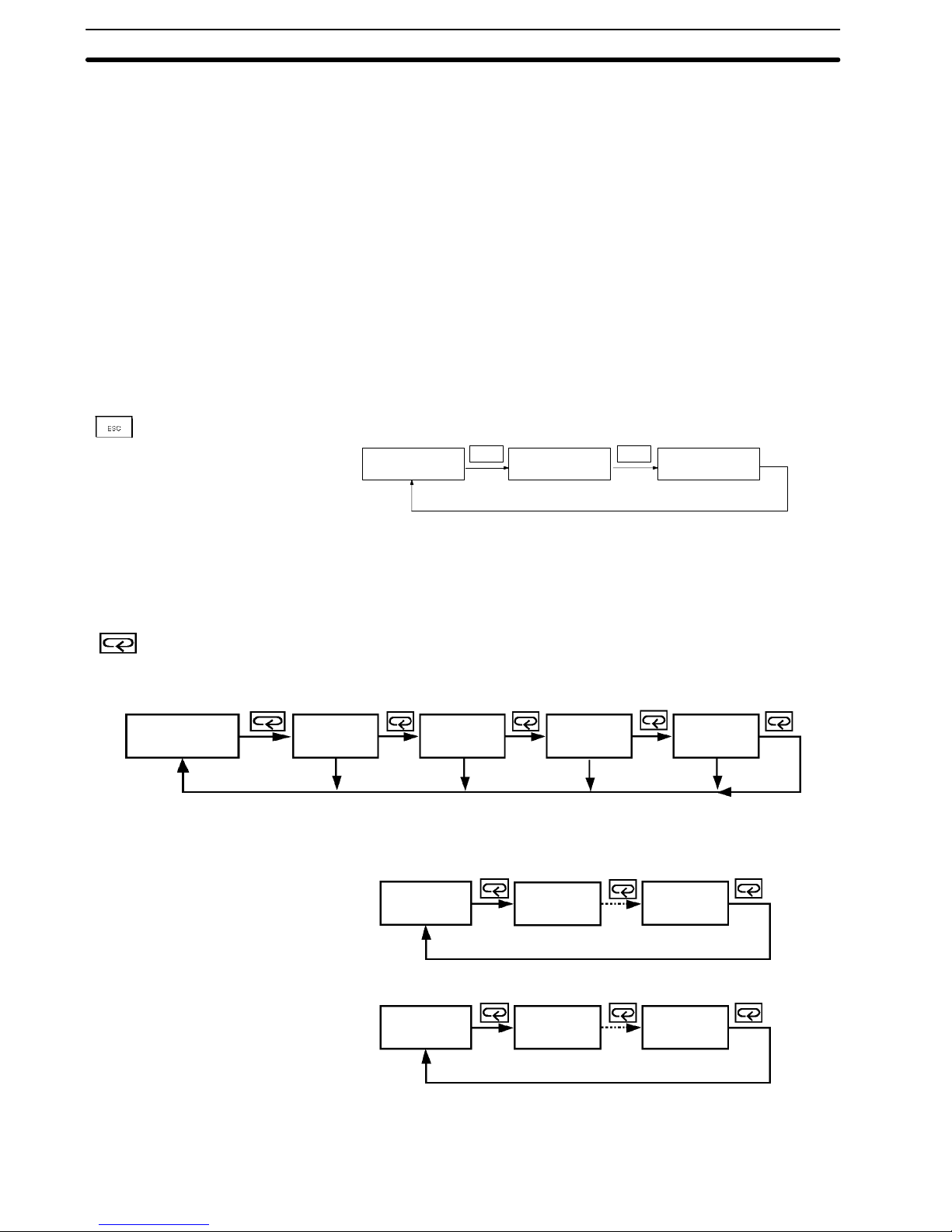

Escape Key

Mode Key

Process value

Maximum value

Minimum value

Used to select the process, maximum, or minimum value to be displayed on the

PV display in RUN mode.

Process value Maximum value Minimum value

ESC ESC

Used to return from the setting, protect, or maintenance mode to the RUN mode.

This key is also used to return to the previous operation during the setting, protect, or maintenance mode.

Displays a setting value (out of HH, H, L, and LL setting values in this order) on

the PV display in RUN mode when this key is pressed. Unless another operation

key is pressed within five seconds after this key has been pressed, the display

automatically changes to the one for process values.

HH is lit.

HH setting

value

No key input

for 5 seconds.

H is lit. L is lit. LL is lit.

H setting

value

No key input

for 5 seconds.

L setting

value

No key input

for 5 seconds.

LL setting

value

No key input

for 5 seconds.

In the RUN mode, this button terminates the measurement process and allows

you to enter the setting mode, advancing through the menus and parameters.

In the setting mode, this button will store changes in the non-volatile memory

while at the same time advancing the display to the next menu item.

4

Menu 1 Menu 2

Parameter 1 Parameter 2 Parameter n

Menu n

Page 15

Front of the Meter

Section 1-2

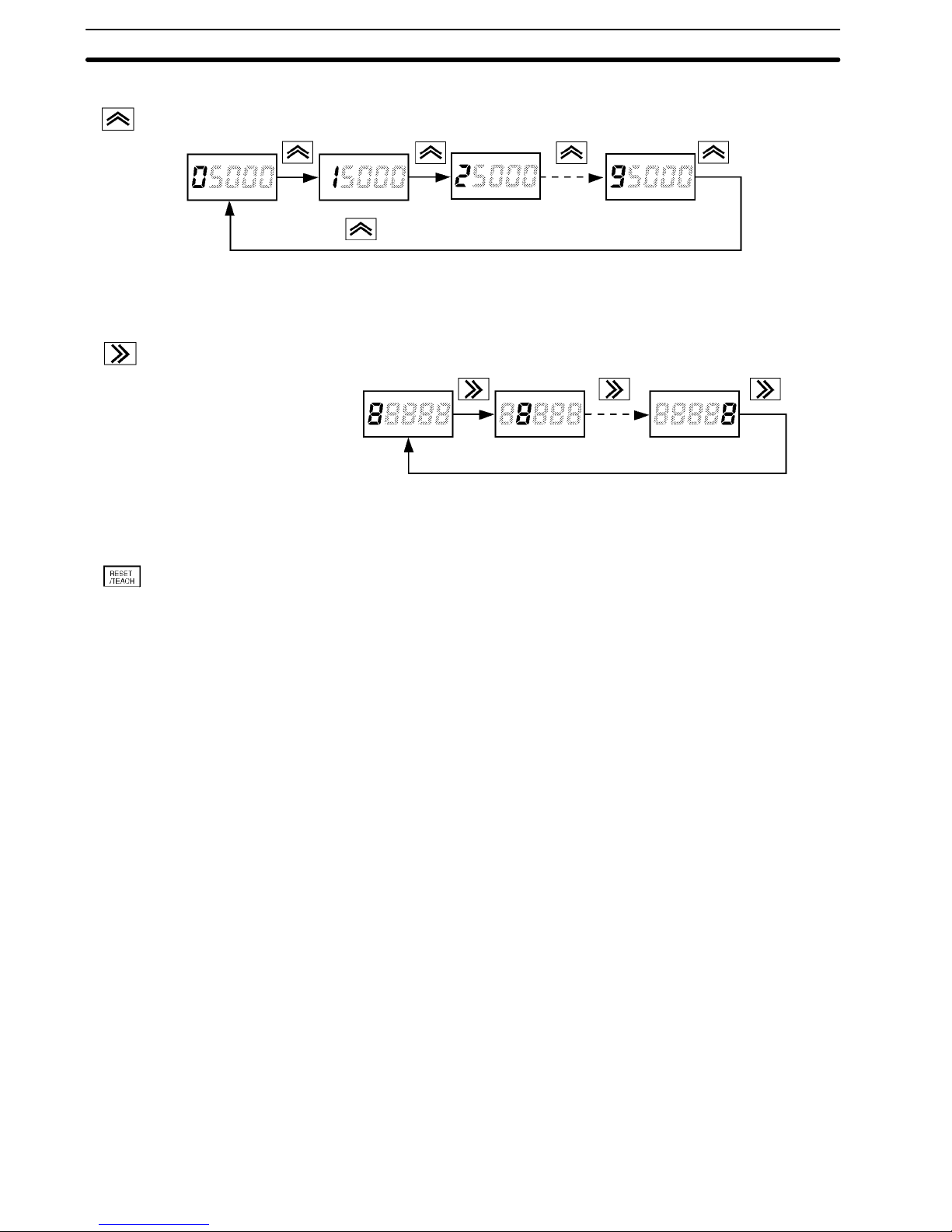

Up Key

Shift Key

Used to select a parameter to be displayed for setting value change.

Used to increment the current digit in the setting value by one.

The value increases in the following order:

0, 1, 2, 3, 4, 5, 6, 7, 8, 9

Used to change the parameter displayed in setting mode.

Used to scroll the digit to the right of the presently displayed digit.

RESET/TEACH Key

Used to reset the K3NP to its initial state or to reset the max./min. value in RUN

mode.

Used to select the teaching function. Refer to 6-1 Teaching Function for details.

5

Page 16

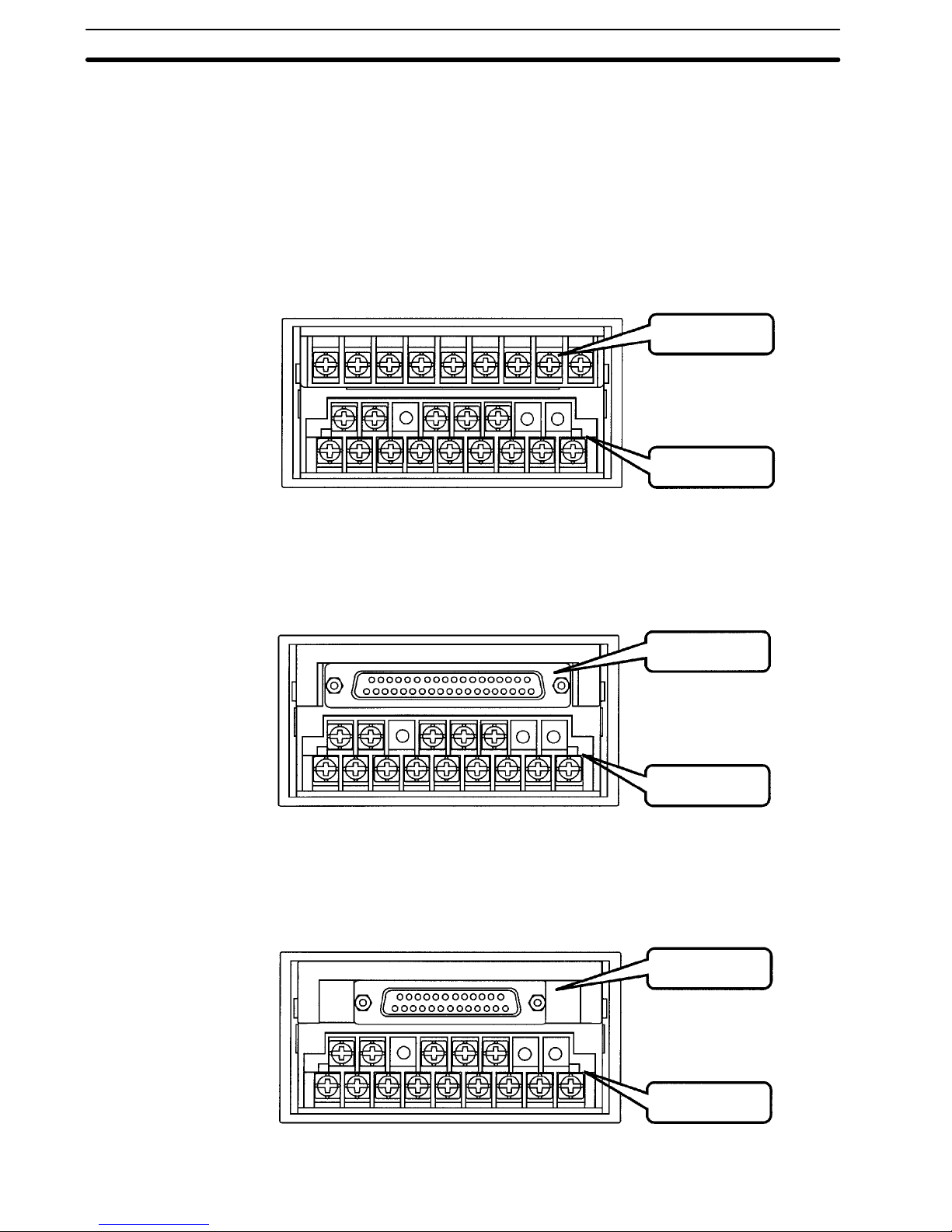

Rear of the Meter

1-3 Rear of the Meter

Terminal arrangement varies depending on the selected Output Board.

For wiring, refer to Section 2 Setup.

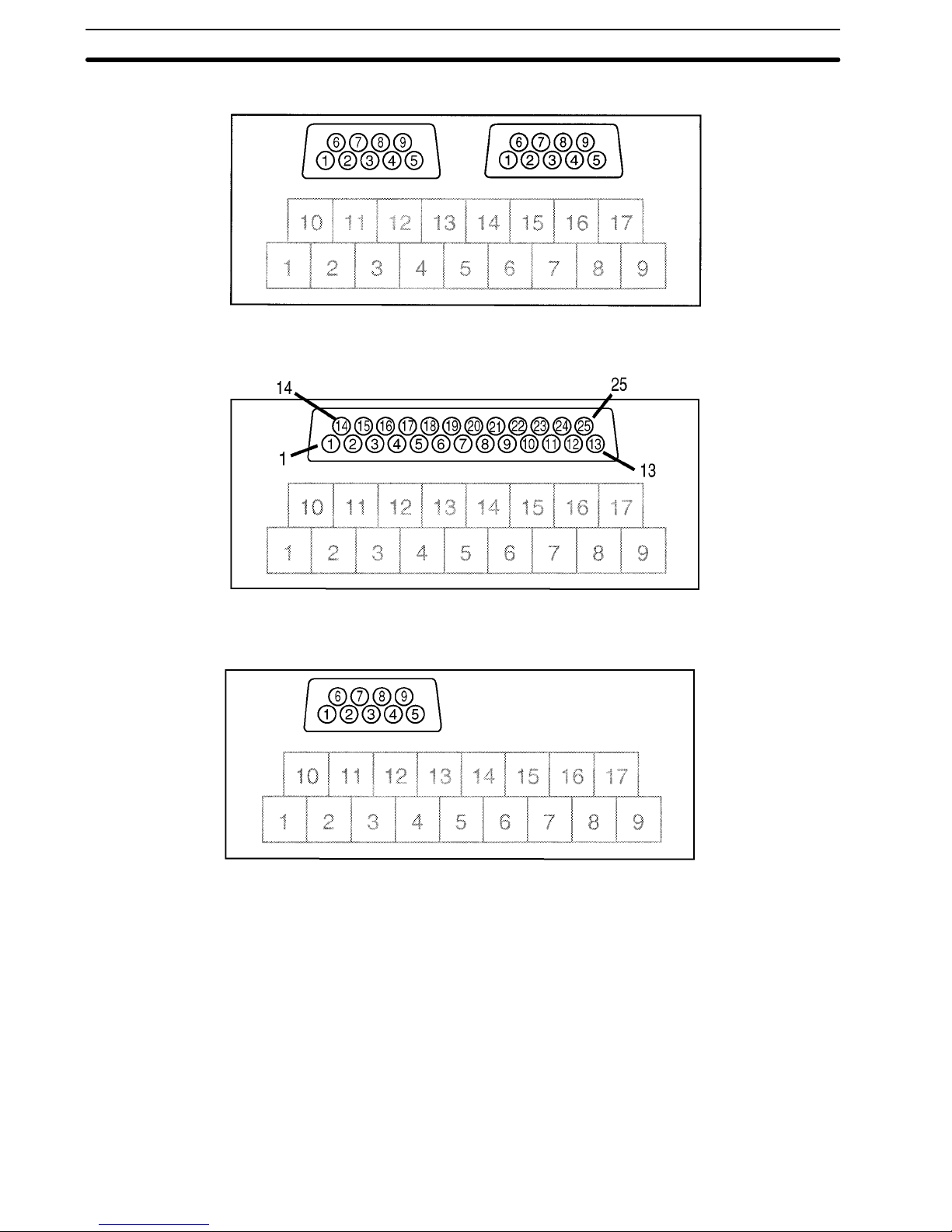

K3NP with Relay Output Board, K31-C1, -C2, -C5

K3NP with Transistor Output Board, K31-T1, -T2

K3NP with Linear Output Board, K31-L1, -L2, -L3, -L4, -L5, -L6, -L7, -L8, -L9, -L10

K3NP with RS-485 Output Board, K31-FLK2, -FLK5

Section 1-3

Output Board

Input Board

K3NP with BCD Output Board, K31-B2, -B4

K3NP with RS-232C Output Board, K31-FLK1

Output Board

Input Board

Communications

Output Board

6

Input Board

Page 17

Modes

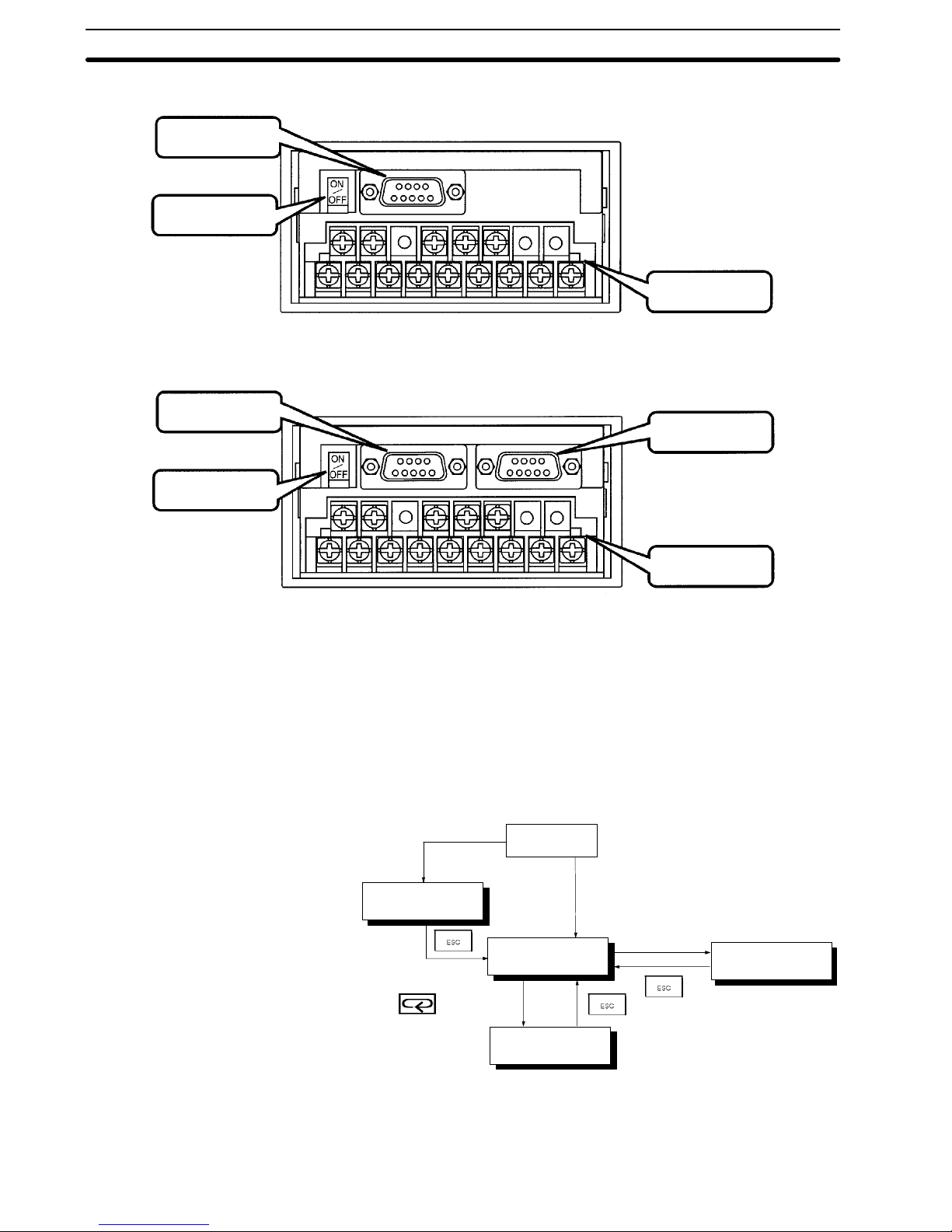

K3NP with RS-422 Output Board, K31-FLK3

Communications

Output Board

Terminator

K3NP with RS232C + Transistor Output Board, K31-FLK4

K3NP with RS-422 + Transistor Output Board, K31-FLK6

Communications

Output Board

Terminator

Section 1-4

Input Board

Transistor

Output Board

1-4 Modes

Input Board

The following four modes are available.

· RUN mode for normal operations (see Section 5 Operations in RUN Mode)

· Setting mode for initializing parameter input (see Section4 ParameterSetting)

· Protect mode for lock-out configuration (see 4-1 Protect Mode)

· Maintenance mode for initialization (see 6-3-2 Initialization)

Refer to the following for the relationship among these modes and selection of

the modes.

Press the Mode and Shift Keys

while turning on the K3NP.

Maintenance mode

1 second

Power on

RUN mode

RUN mode

Press the Escape and up

Keys for 1 second.

Protect mode

RUN Mode K3NP is in RUN when the K3NP is turned ON.

The K3NP in this mode provides an output signal as a result of the comparison of

the measured and setting values.

Setting mode

7

Page 18

Communications Function

The basic model in this mode usually displays the process value. The maximum

and minimum values are displayed by pressing the Escape Key. The parameters and setting values are displayed by pressing the Mode Key.

Refer to Section 5 Operations in RUN Mode for RUN mode in detail.

Setting Mode Values are set in the K3NP in this mode by key input or using the teaching func-

tion.

Refer to Section 4 Parameter Setting for value setting by key input and 6-1

Teaching Function for the teaching function in detail.

Protect Mode Use this mode to prohibit some operations in order to lock out the setting values.

Refer to 4-1 Protect Mode for details.

Maintenance Mode The setting values are reset to factory-set values in this mode. Refer to 6-3-2

Initialization for details.

Section 1-5

1-5 Communications Function

The communications function of the K3NP makes it possible for the host computer to perform the following operations.

· Confirmation and change of setting values. Communications conditions cannot be changed.

· Reading and resetting the maximum and minimum values.

· Forced-zero setting and resetting.

· Confirmation of model data.

Use a model with a Communications Board if the communications function is

required.

Refer to the Communications Manual for the communications function in detail.

RS-232C Use the K31-FLK1 or K31-FLK4 Output Board to use the RS-232C interface.

RS-422 Use the K31-FLK3 or K31-FLK6 Output Board to use the RS-422 interface.

RS-485 Use the K31-FLK2 or K31-FLK5 Output Board to use the RS-485 interface.

8

Page 19

This section provides instructions required for mount ing and wiring the K3NP.

2-1 Mounting 10..............................................................

2-2 Input Block 11.............................................................

2-2-1 Terminal Arrangement 11.............................................

2-2-2 Wiring Precautions 11................................................

2-2-3 Wiring 12..........................................................

2-3 Output Board 14...........................................................

2-3-1 Terminal Arrangement 14.............................................

2-3-2 Relay Output Board 16...............................................

2-3-3 Transistor and Combination Output Board 17.............................

2-3-4 Linear Output Board 17..............................................

2-3-5 BCD Output Board 17................................................

SECTION 2

Setup

9

Page 20

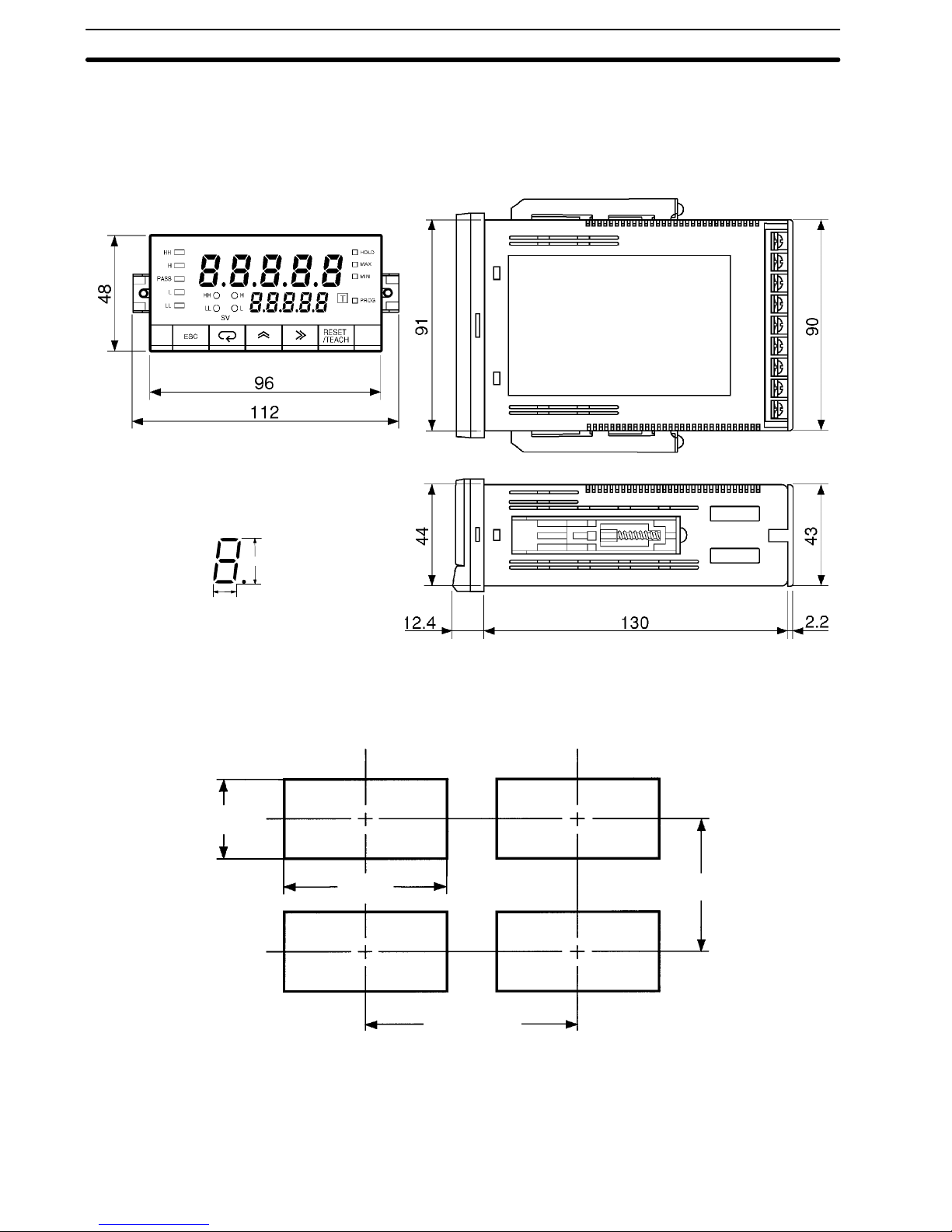

Mounting Section 2-1

2-1 Mounting

Dimensions All dimensions are in millimeters.

Panel Cutouts

PV LED Indicator Size

14.2 mm

8.2 mm

+0.8

45

-- 0

92

+0.8

-- 0

75 min.

Recommended panel thickness is 1 to 3.2 mm.

Do not mount more than one Unit closely in the horizontal or vertical direction. Be

sure to keep the distance between adjacent Units.

10

120 min.

Page 21

Input Block

Mounting Method

Section 2-2

Panel

1, 2, 3... 1. Insert the K3NP into the mounting hole on the panel.

2. Hook the fixture claws onto the side holes.

3. Mount a fixing metal to the right and left sides as shown above and while

keeping them in balance, alternately tighten each screw until the ratchet becomes idle.

2-2 Input Block

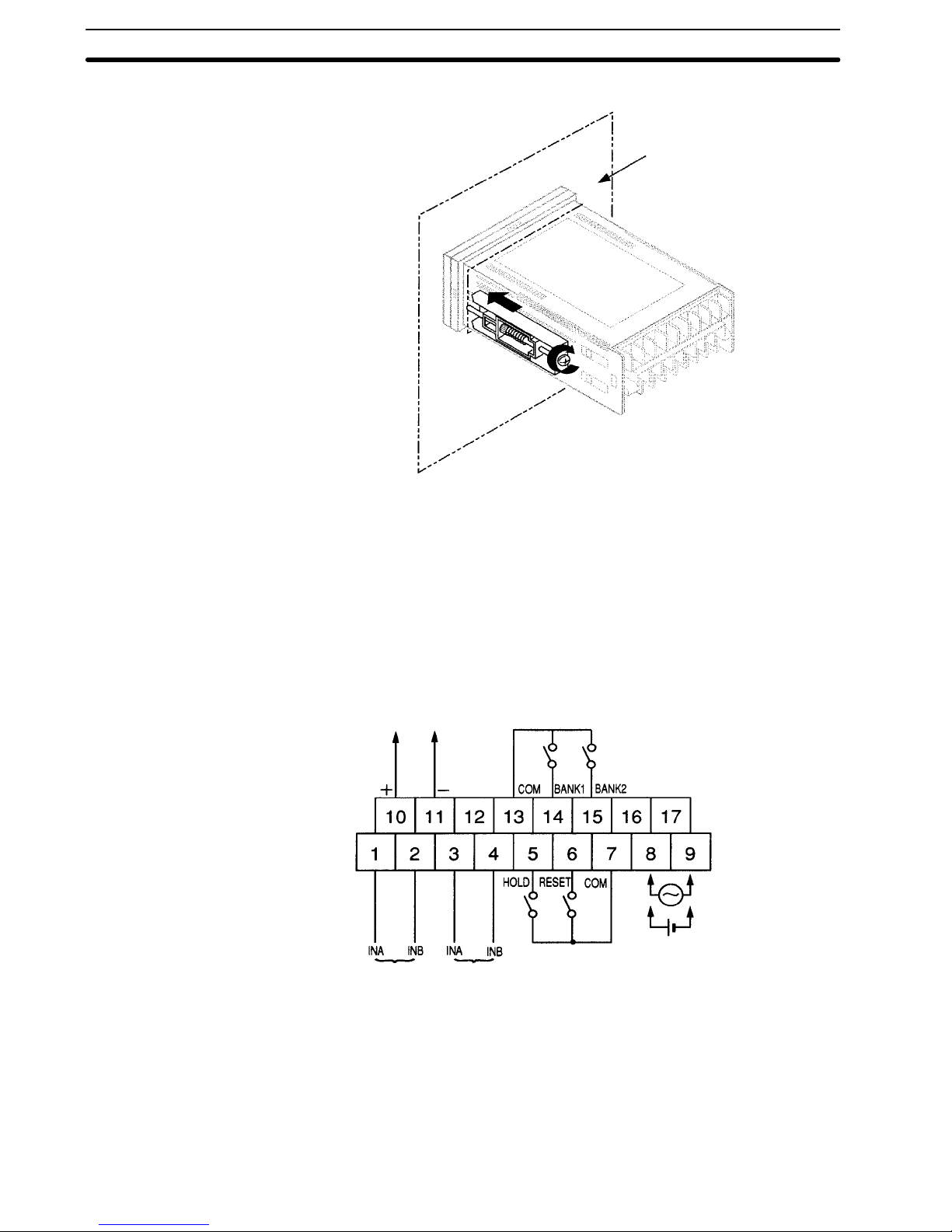

2-2-1 Terminal Arrangement

Sensor power supply

(80mAmax.at12VDC)

100 to 240 to VAC

12 to 24 VDC

Note Voltage pulse input is available for the K3NP-NBjj-jj.

2-2-2 Wiring Precautions

· Do not make any mistake in polarity when supply DC power to the K3NP.

· Do not wire power lines alongside the signal lines of the K3NP in order to pre-

Open collector

input

Voltage pulse

input

vent the K3NP from noise interference.

11

Page 22

Input Block

· Wire the terminal block with crimp terminals.

· Tighten each screw to a torque of 0.78 N S m(8kgfS cm).

2-2-3 Wiring

Power Supply Apply 100 to 240 VAC or 12 to 24 VDC to terminals 8 and 9.

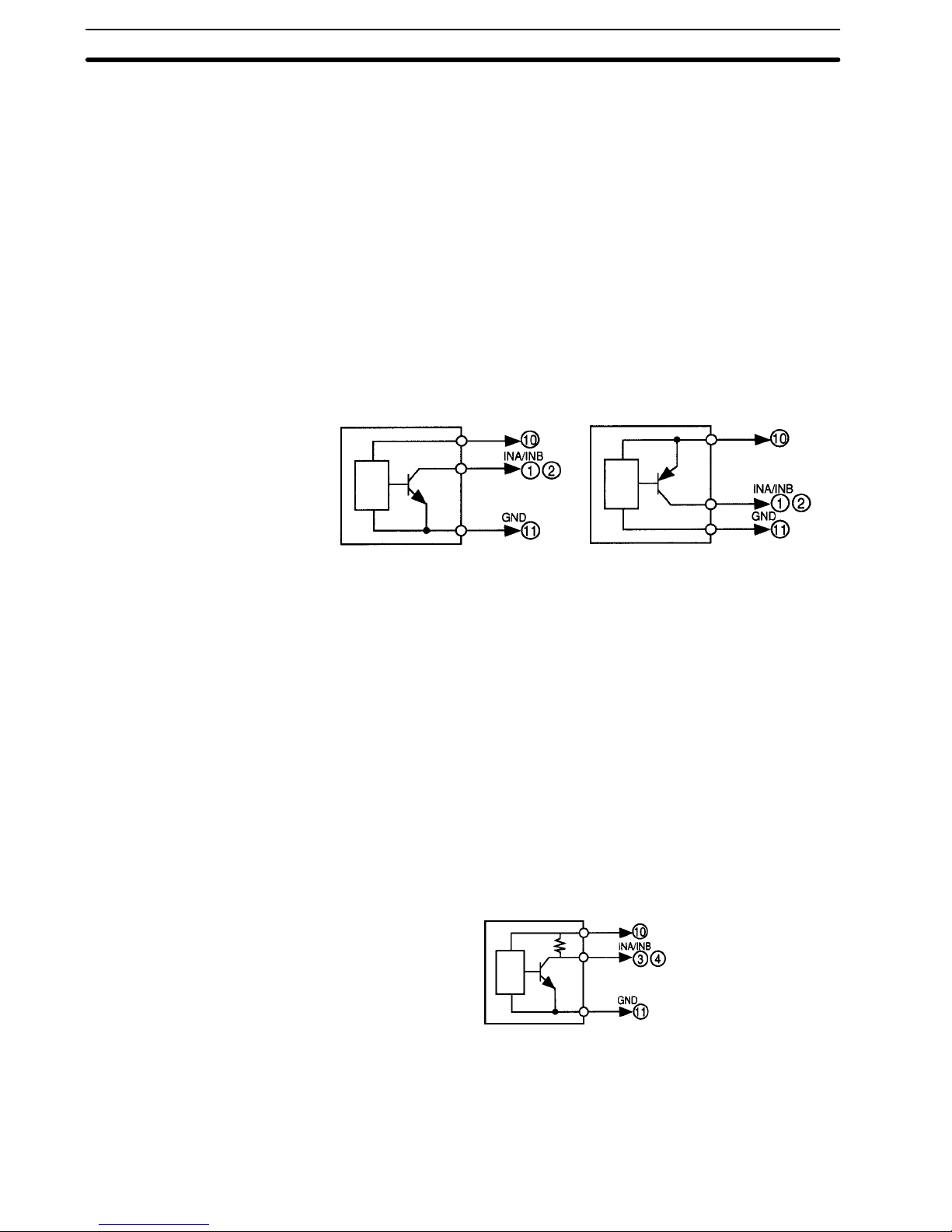

Open Collector Input Connect the pulse output from sensor A to terminal 1.

Connect the pulse output from sensor B to terminal 2.

Terminals 10 and 11 are exclusively used for a power supply with an output of

80 mA at 12 VDC to sensors A or B. If power is supplied to the sensors A or B

from a different power source, do not use terminal 10. Do not connect a sensor

with open collector output to terminal 10.

Refer to the following for sensor connections.

Section 2-2

Sensor (with NPN output)

+12 V

Sensor (with PNP output)

· Residual voltage with sensor turned on: 3 V max.

· Current leakage with sensor turned off: 1.5 mA max.

· Switching load current: 20 mA or greater. Must be able to dependable switch

a load current of 5 mA max.

Photoelectric sensors, proximity sensors, rotary encoders, and relays can be

connected as sensors to the K3NP.

Voltage Pulse Input Connect the pulse output of sensor A to terminal 3.

Connect the pulse output of sensor B to terminal 4.

Terminals 10 and 11 are exclusively used for a power supply with an output of

80 mA at 12 VDC to sensors A or B. If power is supplied to the sensors A or B

from a different power source, do not use terminal 10. Do not connect a sensor

with voltage pulse output to terminal 10.

Refer to the following for sensor connections.

+12 V

H level (sensor output ON): 4.5 to 30 VDC

L level (sensor output OFF): -- 30 to 2 VDC

Auxiliary Power Supply Terminals 10 and 11 are exclusively used for power supply to sensors with an

output of 80 mA at 12 VDC ± 10%.

12

Sensor

+12 V

Page 23

Input Block

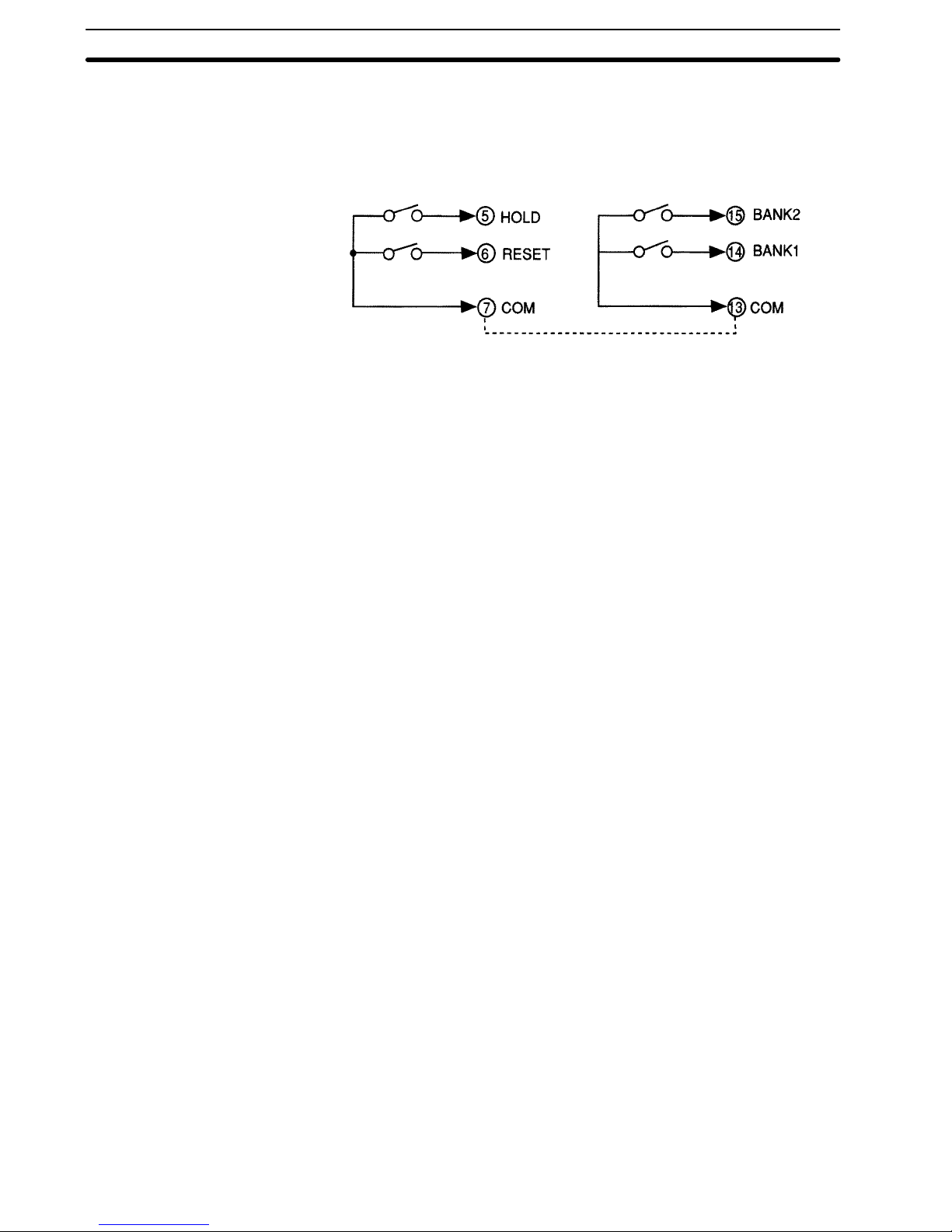

External Signal Input HOLD Input

RESET Input

BANK Input

Connect external signal inputs to terminals 5 through 7 and 13 through 15. Terminals 7 and 13 are connected to each other internally.

Connect HOLD input to terminal 5.

Connect RESET input to terminal 6.

Connect BANK inputs to terminals 14 and 15 for BANK1 and BANK2.

If open collector input is used as external signal input, the transistor must satisfy

the following conditions.

· Residual voltage with transistor turned on: 3 V max.

· Current leakage with transistor turned off: 1.5 mA max.

· Switching load current: 20 mA or greater.

Approximately 5 V is imposed between COM and terminals 5 to 7 with a current

flow of approximately 18 mA (a nominal value) at the time of external input shortcircuiting.

Section 2-2

Short-circuited together internally.

13

Page 24

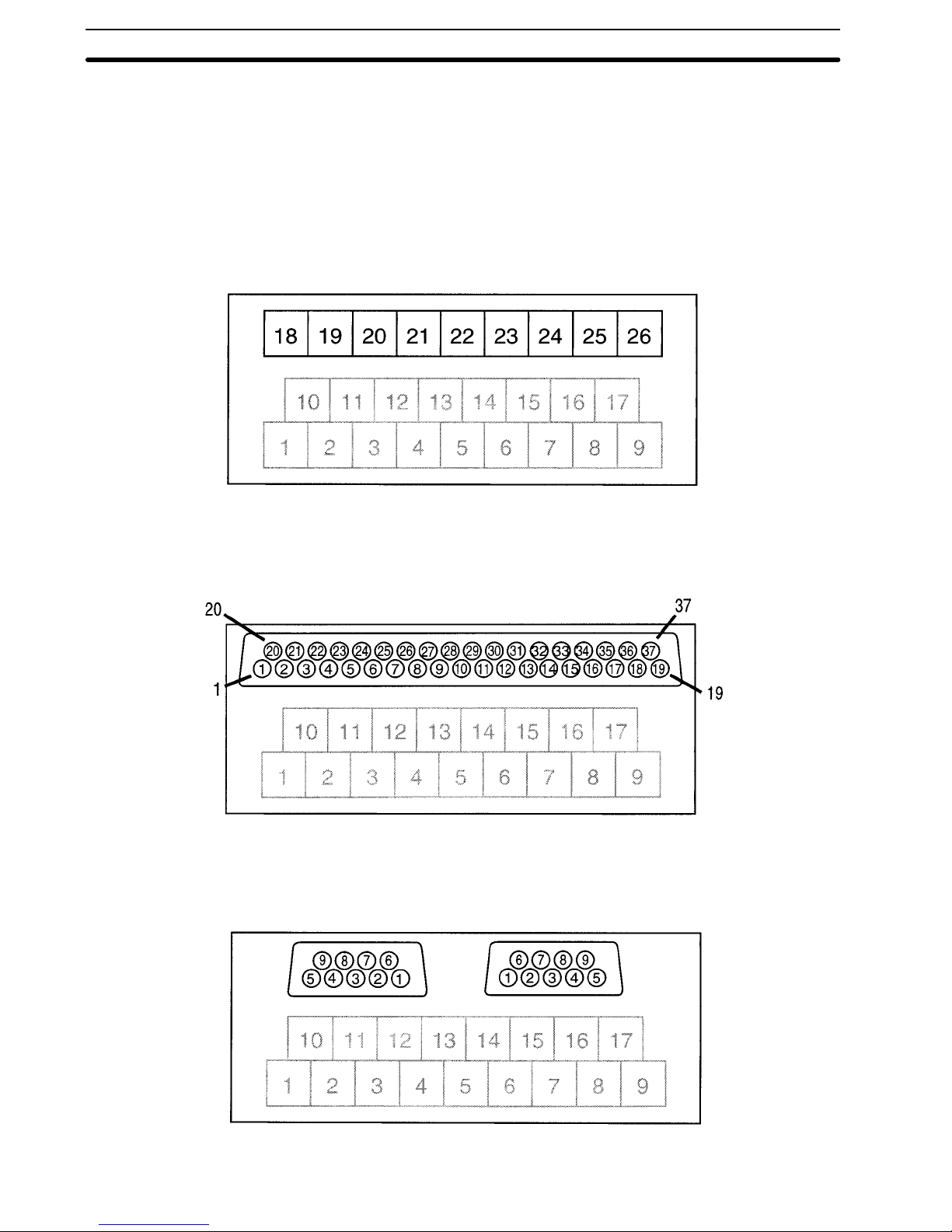

Output Board

2-3 Output Board

2-3-1 Terminal Arrangement

K3NP with Relay Output Board, K31-C1, -C2, -C5

K3NP with Transistor Output Board, K31-T1, -T2

K3NP with Linear Output Board, K31-L1, -L2, -L3, -L4, -L5, -L6, -L7, -L8, -L9, -L10

K3NP with RS-485 Output Board, K31-FLK2, -FLK5

Section 2-3

K3NP with BCD Output Board, K31-B2, -B4

K3NP with RS232C + Transistor Output Board, K31-FLK4

14

Page 25

Output Board

K3NP with RS-422 + Transistor Output Board, K31-FLK6

K3NP with RS-232C Output Board, K31-FLK1

Section 2-3

K3NP with RS-422 Output Board, K31-FLK3

15

Page 26

Output Board

K3NP with RS-422 Output Board, K31-FLK3

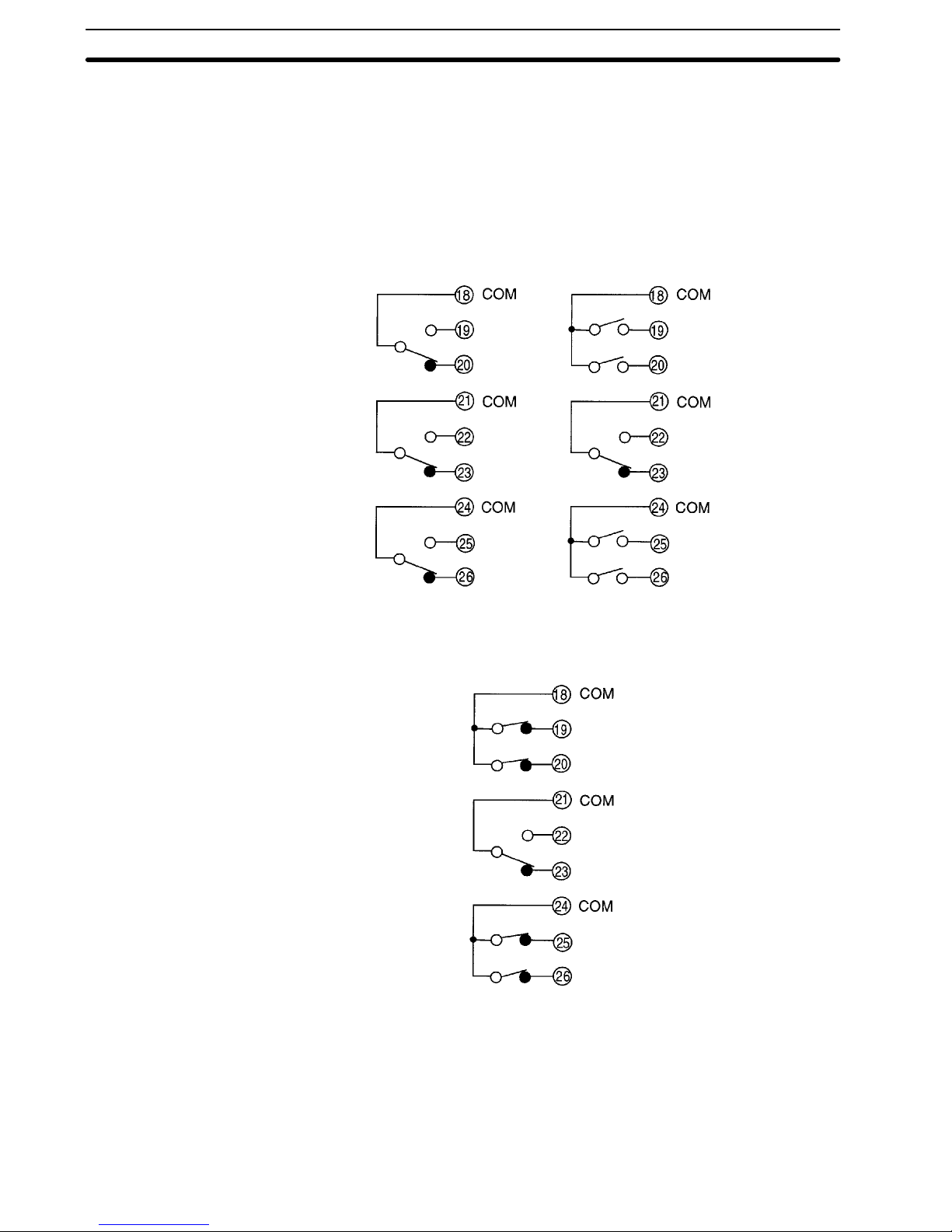

2-3-2 Relay Output Board

The following figures show the connections for relay output.

Section 2-3

K3NP with 3 Relay

Output Boards,

K31-C1

H

comparative

output

PASS

output

L

comparative

output

K3NP with 5 Relay

Output Boards,

K31-C5

K3NP with 5 Relay

Output Boards,

K31-C2

HH comparative

output

H comparative

output

PASS

output

L comparative

output

LL comparative

output

HH comparative

output

H comparative

output

PASS

output

L comparative

output

LL comparative

output

The following contact output conditions are required.

5 A (resistive load) at 250 VAC

1.5 A (inductive load) at 250 VAC

5 A (resistive load) at 30 VDC

1.5 A (inductive load) at 30 VDC

16

Page 27

Output Board

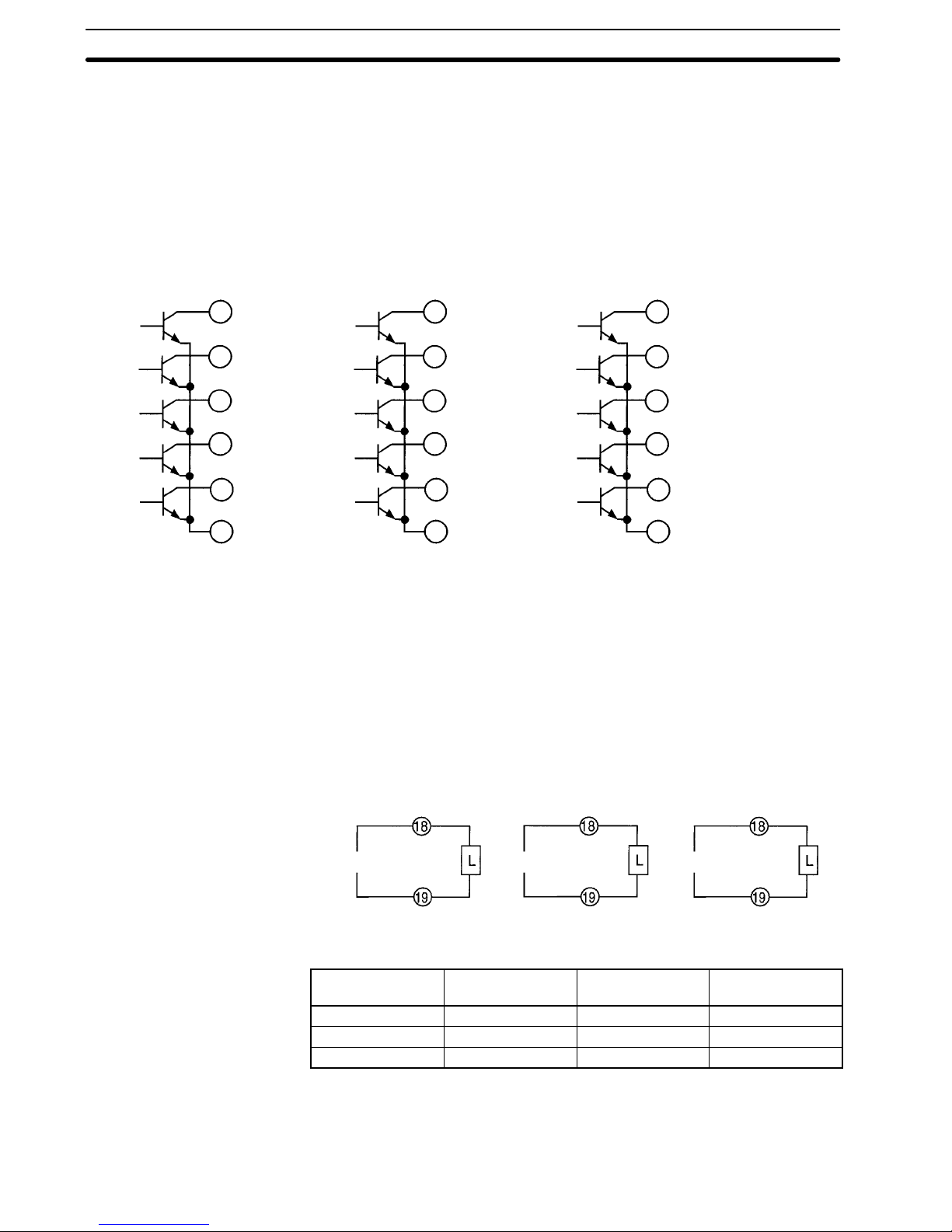

2-3-3 Transistor and Combination Output Board

Section 2-3

K3NP with Transistor Output

Board, K31-T1 or K31-T2

K3NP with Linear Output Board,

K31-L4, -L5, -L6, -L9, -L10

K3NP with RS-485 + 5 Relay

Output Boards, K31-FLK5

HH comparative

21

output

H comparative

22

output

PASS output

23

L comparative

24

output

LL comparative

25

output

26

COM

The following transistor output conditions are required.

Maximum rated voltage: 24 VDC

Load current: 50 mA

Current leakage with transistor turned off: 100 mA.

K3NP with BCD Output

Board, K31-B2 or K31-B4

HH comparative

32

output

H comparative

33

output

PASS output

34

L comparative

35

output

LL comparative

36

output

COM

37

K3NP with RS232C + 5

Transistor Output Boards,

K31-FLK4

K3NP with RS-422 + 5

Transistor Output Boards,

K31-FLK6

HH comparative

1

output

H comparative

2

output

PASS output

4

L comparative

5

output

LL comparative

6

output

3

COM

2-3-4 Linear Output Board

The following figures show connections for linear output.

4to20mA 1to5V

The following linear output conditions are required.

Linear output Permissible load

4to20mA 600 W max. 4096 ±0.5% FS

1to5V 500 W min. 4096 ±0.5% FS

1 mV/10 digit 1kW min. 4096 ±1.5% FS

2-3-5 BCD Output Board

Refer to Section 7 BCD Output for the terminal arrangement and interface.

K3NP with Linear

Output Board,

K31-L1 or K31-L4

+

--

K3NP with Linear

Output Board,

K31-L2 or K31-L5

resistance

K3NP with Linear

Output Board,

K31-L3 or K31-L6

+

1 mV/10 digit

--

Resolution Output error

+

--

17

Page 28

Operating Modes

This section provides information on the ba sic operation of the K3NP in operating mode.

SECTION 3

3-1 Passing Speed:

3-2 Cycle:

3-3 Time Difference:

3-4 Elapsed Time:

3-5 Length Measurement:

3-6 Interval:

f2 23..............................................................

f1 20........................................................

f3 25......................................................

f4 28........................................................

f6 34.............................................................

f5 31..................................................

19

Page 29

Passing Speed:

f1

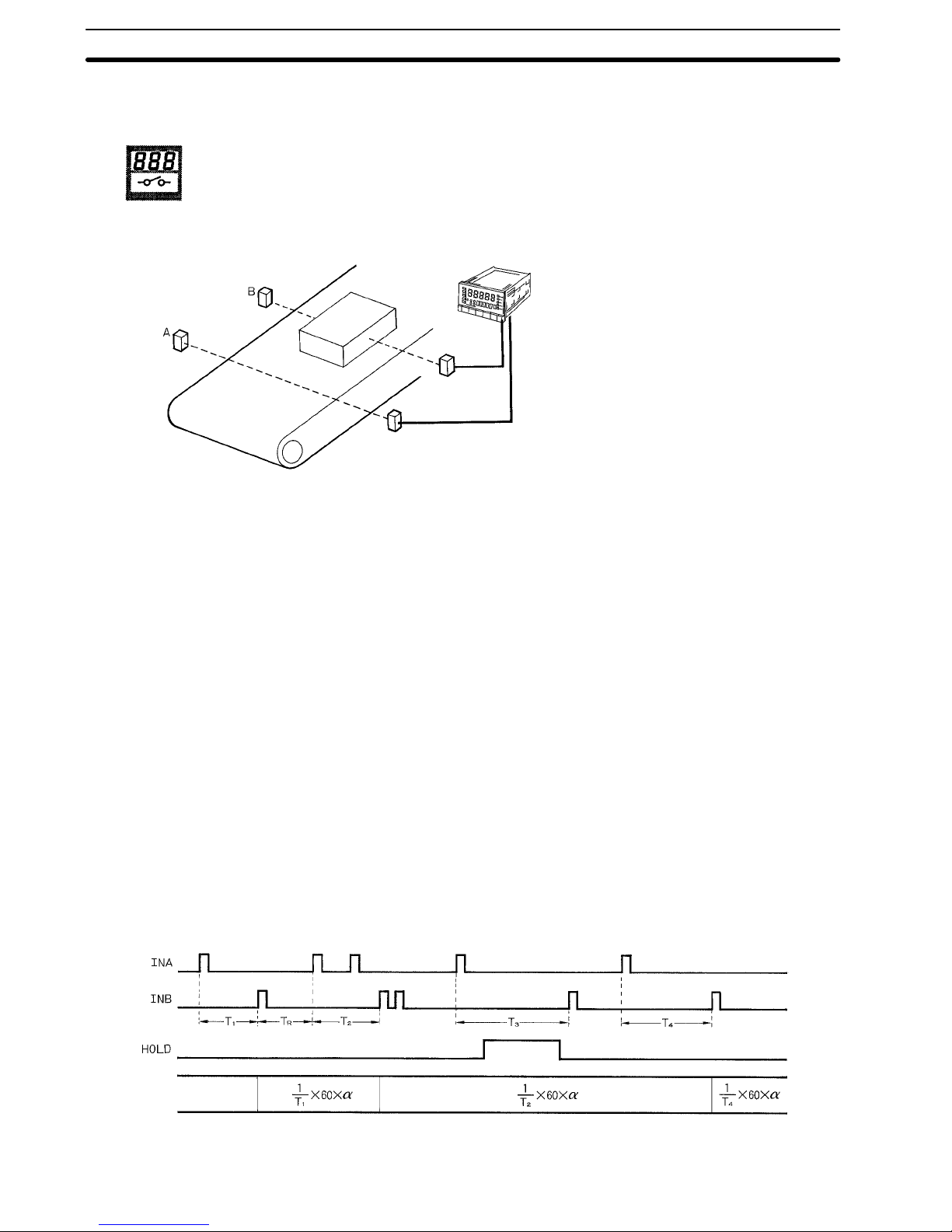

3-1 Passing Speed: f1

FUNCTION

Application example

Section 3-1

Measures the time taken by an object

to travel the distance between A and B.

Basic Operation

Displays the speed of an object passing between A and B. The speed is obtained

by multiplying the reciprocal of T by 60. T (time) is the time interval between INA

turning ON and INB turning ON. If the distance between the INA sensor and INB

sensor is 1 m, the displayed value is m/min. If the distance is other than 1 m, or if

another unit of measurement is required, input an appropriate prescale value.

Obtain display value D as follows:

D (m/min) = 1/T x 60 x a

T: Time interval between INA turning ON and INB turning ON (sec)

a: Prescale value

Hold Measured Value

When the HOLD input turns ON while the K3NP is measuring, the measuring

operation is canceled and the K3NP holds the last measured value (displayed

value). While the HOLD input is ON, the K3NP holds comparative output and

BCD output. Measurement will not begin while the K3NP is in HOLD status. This

is illustrated in the following diagram.

When the comparative output terminals of the output board and the HOLD

input terminals are connected, the value measured immediately after the occurrence of an error can be obtained.

Display

Value previously

measured

20

TR: Recovery time

Page 30

Passing Speed:

SETTING

REFERENCE

f1

Section 3-1

Refer to the following table to set the most suitable prescaling value.

Mode Unit of display Prescale value

Passing speed mm/sec 1000L/60

m/sec L/60

m/min L

cm/sec 100L/60

cm/min 100L

km/h 0.06L

Where,

L = Distance between sensors (m)

Refer to 4-2 Setting Mode.

Performance Characteristics

Accuracy of measurement

Measurement range 10 ms to 3200 s

Response time of HOLD input 20 ms max.

Recovery time (TR) 20 ms min.

ON/OFF pulse width

Response time Output configuration

Relay output Transistor

Comparative output 25 ms max. 20 ms max. 35 ms max. 35 ms max. 20 ms max .

BCD output --- --- Refer to page 93. --- ---

Linear output --- --- --- 40 ms max. ---

Response Time of HOLD

Input

±0.08% rdg ± 1 digit (ambient temperature: 23°C ± 5°C)

Sensor with transistor output: 9 msmin.

Sensor with relay output: 15 ms min.

output

BCD and

transistor output

Linear and

transistor output

Communication

and transistor

output

The response time of the HOLD input is the time required for the K3NP to

accept HOLD input after the HOLD input turns ON.

Recovery Time (T

) Recovery time is the period required for the K3NP to become ready for the

R

next measuring operation after a measuring operation is completed. For

Transistor Output Models, comparative output remains ON during recovery

time. For other models, comparative output requires more time to turn ON.

When the comparative output terminals of the output board and the HOLD

input terminals are connected, set a sufficient recovery period, considering

the response time of the HOLD input. This is illustrated in the following diagram.

21

Page 31

(

)

Passing Speed:

f1

Operating Mode F1 (Transit Speed)

Section 3-1

Measurement

starts

T

Comparative output

Delay in comparative

outputs

HOLD input

Acceptance of

HOLD input

1

Measurement

completed

Recovery time

(20 ms min.)

T

2

Response time of HOLD input

(20 ms max.)

Available functions in this mode are indicated as “Yes” in the following table.

Menu Function Displayed

Character

--- Max./Min. value display and reset --- Yes 82

sUset (note 1)

Set value bank no. of set values s.bank

HH set value sU*.hh

Hsetvalue sU*.h

Lsetvalue sU*.l

LL set value sU*.ll

pscl

Set value bank no. of prescale values p.bank Yes

Prescaling value of input A

X (mantissa)

Y (exponent)

ps*.ax

ps*.ay

Decimal point position decp.* Ye s

setup

Operating mode func Yes 50

Input A sensor type ina Ye s

Input B sensor type inb Ye s

Time unit time No 54

Communications unit no. (note 1) u- no Ye s

Baud rate (note 1) bps Ye s

Word length (note 1) len Ye s

Stop bits (note 1) sbit Yes

Parity bits (note 1) prty Yes

opt

Output pattern (note 1) c-out Yes 61

H linear output range (note 1) lset.h Yes

L Linear output range (note 1) lset.l Yes

Remote/Local programming (note 1) r- l Yes 67

Availability Reference

Yes 42

46

Yes

52

56

58

64

page

Note 1. The availability of the parameters depends on the type of selected Output

22

Board.

2. The selected bank number will be displayed where the asterisk (

*) appears.

Page 32

Cycle:

f2

3-2 Cycle: f2

Section 3-2

FUNCTION

Application example

Measures the cycle with

which items pass a sensor.

Basic Operation

Displays in seconds the interval between successive occurrences of INA turning

ON. Input an appropriate prescale value to display units other than seconds. Obtain display value D as follows:

D (sec) = T x a

T: Interval between successive occurrences of INA turning ON

a: Prescale value

By using

time in the time unit display setting parameter, the passing time can

be displayed in units of hours, minutes, and seconds.

Display

SETTING

T

1

Value previously

measured

To set a prescale value, refer to 4-2-4 Prescaling Menu.

T

2

T

1

T

3

T

T

4

2

T

5

T

5

Refer to the following table to set the most suitable prescaling value.

Mode Unit of display

value

Cycle sec 1

min 1/60

Prescale value

Where,

INB input is disregarded for operating mode 2.

Note The K3NP can display time, minute, and second. Refer to page 54 for details.

Refer to 4-2 Setting Mode.

REFERENCE

23

Page 33

(

)

Cycle:

f2

Performance Characteristics

Section 3-2

Accuracy of measurement

Measurement range 20 ms to 3200 s

Response time of HOLD input 20 ms max.

Recovery time (TR) 20 ms min.

ON/OFF pulse width

Response time Output configuration

Relay output Transistor

Comparative output 25 ms max. 20 ms max. 35 ms max. 35 ms max. 20 ms max .

BCD output --- --- Refer to page 93. --- ---

Linear output --- --- --- 40 ms max. ---

Response Time of HOLD

Input

±0.08% rdg ± 1 digit (ambient temperature: 23°C ± 5°C)

Sensor with transistor output: 9 msmin.

Sensor with relay output: 15 ms min.

output

BCD and

transistor output

Linear and

transistor output

Communication

and transistor

output

The response time of the HOLD input is the time required for the K3NP to

accept HOLD input after the HOLD input turns ON. This is illustrated in the

following diagram.

Available functions in this mode are indicated as “Yes” in the following table.

Menu Function Displayed

Character

--- Max./Min. value display and reset --- Yes 82

sUset (note 1)

pscl

setup

opt

Set value bank no. of set values s.bank

HH set value sU*.hh

Hsetvalue sU*.h

Lsetvalue sU*.l

LL set value sU*.ll

Set value bank no. of prescale values p.bank Yes

Prescaling value of input A

X (mantissa)

Y (exponent)

Decimal point position decp.* Ye s

Operating mode func Yes 50

Input A sensor type ina Ye s

Input B sensor type inb No

Time unit time Yes 54

Communications unit no. (note 1) u- no Ye s

Baud rate (note 1) bps Ye s

Word length (note 1) len Ye s

Stop bits (note 1) sbit Yes

Parity bits (note 1) prty Yes

Output pattern (note 1) c-out Yes 61

H linear output range (note 1) lset.h Yes

L Linear output range (note 1) lset.l Yes

Remote/Local programming (note 1) r- l Yes 67

ps*.ax

ps*.ay

Availability Reference

Yes 42

46

Yes

52

56

58

64

page

Note 1. The availability of the parameters depends on the type of selected Output

24

Board.

2. The selected bank number will be displayed where the asterisk (

*) appears.

Page 34

Time Difference:

f3

3-3 Time Difference: f3

Section 3-3

FUNCTION

Application example

Measures the time taken by an

object to pass between A and B.

Basic Operation

Displays the time (T) in seconds between INA turning ON and INB turning ON. If

another unit of measurement is required, input an appropriate prescale value.

Obtain the display value D as follows:

D (m/min) = T x a

T: The time (sec) between INA turning ON and INB turning ON

a: Prescale value

To set a prescale value, refer to 4-2-4 Prescaling Menu.

Display

SETTING

REFERENCE

Value previously

measured

T

R

T

: Recovery time

R

Refer to the following table to set the most suitable prescaling value.

Mode Unit of display

value

Time difference sec 1

min 1/60

Prescale value

Note The K3NP can display time, minute, and second. Refer to page 54 for details.

Refer to 4-2 Setting Mode.

25

Page 35

Time Difference:

f3

Section 3-3

Performance Characteristics

Accuracy of measurement

Measurement range 10 ms to 3200 s

Response time of HOLD input 20 ms max.

Recovery time (TR) 20 ms min.

ON/OFF pulse width

Response time Output configuration

Relay output Transistor

Comparative output 25 ms max. 20 ms max. 35 ms max. 35 ms max. 20 ms max .

BCD output --- --- Refer to page 93. --- ---

Linear output --- --- --- 40 ms max. ---

±0.08% rdg ± 1 digit (ambient temperature: 23°C ± 5°C)

Sensor with transistor output: 9 msmin.

Sensor with relay output: 15 ms min.

output

BCD and

transistor output

Linear and

transistor output

Communication

and transistor

output

Response Time of HOLD

Input

The response time of the HOLD input is the time required for the K3NP to

accept HOLD input after the HOLD input turns ON. This is illustrated in the

following diagram.

Recovery Time (TR) Recovery time is the period required for the K3NP to become ready for the

next measuring operation after a measuring operation is completed. For transistor output Models, comparative output remains ON during recovery time.

For other models, comparative output requires more time to turn ON. When

the comparative output terminals of the output board and the HOLD input

terminals are connected, set a sufficient recovery period, considering the response time of the HOLD input. This is illustrated in the following diagram.

Comparative output

HOLD input

Acceptance of

HOLD input

Measurement

starts

T

Delay in comparative

outputs

1

Measurement

completed

Recovery time

(20 ms min.)

T

2

Response time of HOLD input

(20 ms max.)

26

Page 36

(

)

Time Difference:

f3

Section 3-3

Available functions in this mode are indicated as “Yes” in the following table.

Menu Function Displayed

Character

--- Max./Min. value display and reset --- Yes 82

sUset (note 1)

pscl

setup

opt

Set value bank no. of set values s.bank

HH set value sU*.hh

Hsetvalue sU*.h

Lsetvalue sU*.l

LL set value sU*.ll

Set value bank no. of prescale values p.bank Yes

Prescaling value of input A

X (mantissa)

Y (exponent)

Decimal point position decp.* Ye s

Operating mode func Yes 50

Input A sensor type ina Ye s

Input B sensor type inb Ye s

Time unit time Yes 54

Communications unit no. (note 1) u- no Ye s

Baud rate (note 1) bps Ye s

Word length (note 1) len Ye s

Stop bits (note 1) sbit Yes

Parity bits (note 1) prty Yes

Output pattern (note 1) c-out Yes 61

H linear output range (note 1) lset.h Yes

L Linear output range (note 1) lset.l Yes

Remote/Local programming (note 1) r- l Yes 67

ps*.ax

ps*.ay

Availability Reference

Yes 42

46

Yes

52

56

58

64

page

Note 1. The availability of the parameters depends on the type of selected Output

Board.

2. The selected bank number will be displayed where the asterisk (

*) appears.

27

Page 37

Elapsed Time:

f4

3-4 Elapsed Time: f4

Section 3-4

FUNCTION

Application example

Measures the pressing time of a printing machine.

Basic Operation

Displays in seconds the time period (T) that INA is ON. If another unit of measurement is required, input an appropriate prescale value. Obtain display value

D as follows:

D (s) = T x a

T: Time period (sec) INA is ON

a: prescale value

HOLD

Display

SETTING

INA

Value previously

measured

To set a prescale value, refer to 4-2-4 Prescaling Menu.

T

1

T

R

T

2

T

3

T

4

T4X aT2X aT1X a

: Recovery time

T

R

Refer to the following table to set the most suitable prescaling value.

Mode Unit of display

value

Elapsed time sec 1

min 1/60

Prescale value

Where,

with operating mode 4, INB input is disregarded.

Note The K3NP can display time, minute, and second. Refer to page 54 for details.

Refer to 4-2 Setting Mode.

REFERENCE

28

Page 38

Elapsed Time:

f4

Performance Characteristics

Section 3-4

Accuracy of measurement

Measurement range 10 ms to 3200 s

Response time of HOLD input 20 ms max.

Recovery time (TR) 20 ms min.

ON/OFF pulse width

Response time Output configuration

Relay output Transistor

Comparative output 25 ms max. 20 ms max. 35 ms max. 35 ms max. 20 ms max .

BCD output --- --- Refer to page 93. --- ---

Linear output --- --- --- 40 ms max. ---

Response time of HOLD

Input

±0.08 rdg ± 1 digit (ambient temperature: 23°C ± 5°C)

Sensor with transistor output: 9 msmin.

Sensor with relay output: 15 ms min.

output

BCD and

transistor output

Linear and

transistor output

Communication

and transistor

output

The response time of the HOLD input is the time required for the K3NP to

accept HOLD input after the HOLD input turns ON. This is illustrated in the

following diagram.

Recovery Time (T

) Recovery time is the period required for the K3NP to become ready for the

R

next measuring operation after a measuring operation is completed. For transistor output Models, comparative output remains ON during recovery time.

For other models, comparative output requires more time to turn ON. When

the comparative output terminals of the output board and the HOLD input

terminals are connected, set a sufficient recovery period, considering the response time of the HOLD input. This is illustrated in the following diagram.

Measurement starts Measurement completed

INA

Comparative output

Delay in comparative outputs

HOLD input

Acceptance of HOLD input

T

1

Response time of HOLD input

(20 ms max.)

Recovery time (20 ms min.)

29

Page 39

(

)

Elapsed Time:

f4

Section 3-4

Available functions in this mode are indicated as “Yes” in the following table.

Menu Function Displayed

Character

--- Max./Min. value display and reset --- Yes 82

sUset (note 1)

pscl

setup

opt

Set value bank no. of set values s.bank

HH set value sU*.hh

Hsetvalue sU*.h

Lsetvalue sU*.l

LL set value sU*.ll

Set value bank no. of prescale values p.bank Yes

Prescaling value of input A

X (mantissa)

Y (exponent)

Decimal point position decp.* Ye s

Operating mode func Yes 50

Input A sensor type ina Ye s

Input B sensor type inb No

Time unit time Yes 54

Communications unit no. (note 1) u- no Ye s

Baud rate (note 1) bps Ye s

Word length (note 1) len Ye s

Stop bits (note 1) sbit Yes

Parity bits (note 1) prty Yes

Output pattern (note 1) c-out Yes 61

H linear output range (note 1) lset.h Yes

L Linear output range (note 1) lset.l Yes

Remote/Local programming (note 1) r- l Yes 67

ps*.ax

ps*.ay

Availability Reference

Yes 42

46

Yes

52

56

58

64

page

Note 1. The availability of the parameters depends on the type of selected Output

Board.

2. The selected bank number will be displayed where the asterisk (

*) appears.

30

Page 40

Length Measurement:

f5

3-5 Length Measurement: f5

FUNCTION

Application example

Basic Operation

Counts the number of pulses of INA while INB is ON and displays the result. Obtain display value D as follows:

Section 3-5

Measures the length of an object.

INA

INB

HOLD

Display

SETTING

C

1

Value previously

measured

D (pulse count) = C x a

C: Pulse count of INA while INB input is ON

a: Prescale value

To set a prescale value, refer to 4-2-4 Prescaling Menu.

C

T

R

C1X a C2X a C4X a

2

C

3

C

4

TR: Recovery time

Refer to the following table to set the most suitable prescaling value.

Mode Unit of display

value

Length measurement mm

cm

m

Prescale value

1000 pDa/Na

100 pDa/Na

pDa/Na

Na: Number of pulses per revolution at A input

pDa: Circumference (m) per revolution from A input

Note The K3NP can display time, minute, and second. Refer to page 54 for details.

Refer to 4-2 Setting Mode.

REFERENCE

31

Page 41

Length Measurement:

f5

Section 3-5

Performance Characteristics

Maximum input frequency of INA Sensor with transistor output: 50 kHz

Sensor with relay output: 30 Hz

Measurement range (C) 0 to 4 G (with 32-bit c ounter)

Response time of HOLD input 20 ms max.

Recovery time (TR) 20 ms min.

ON/OFF pulse width

Response time Output configuration

Relay output Transistor

Comparative output 25 ms max. 20 ms max. 35 ms max. 35 ms max. 20 ms max .

BCD output --- --- Refer to page 93. --- ---

Linear output --- --- --- 40 ms max. ---

Sensor with transistor output: 9 msmin.

Sensor with relay output: 15 ms min.

BCD and

output

transistor output

Linear and

transistor output

Communication

and transistor

output

Maximum Input Frequency The maximum input frequency is the maximum number of INA input pulses

that the K3NP can count accurately.

Response Time of HOLD

Input

The response time of the HOLD input is the time required for the K3NP to

accept HOLD input after the HOLD input turns ON. This is illustrated in the

following diagram.

Recovery Time (T

) Recovery time is the period required for the K3NP to become ready for the

R

next measuring operation after a measuring operation is completed. For transistor output Models, comparative output remains ON during recovery time.

For other models, comparative output requires more time to turn ON. When

the comparative output terminals of the output board and the HOLD input

terminals are connected, set a sufficient recovery period, considering the response time of the HOLD input. This is illustrated in the following diagram.

Measurement starts

INA

Measurement completed

INB

Comparative output

Delay in comparative outputs

HOLD input

Acceptance of HOLD input

C

1

32

Recovery time (20 ms min.)

C

2

Response time of HOLD input

(20 ms max.)

TR

Page 42

(

)

Length Measurement:

f5

Section 3-5

Available functions in this mode are indicated as “Yes” in the following table.

Menu Function Displayed

Character

--- Max./Min. value display and reset --- Yes 82

sUset (note 1)

pscl

setup

opt

Set value bank no. of set values s.bank

HH set value sU*.hh

Hsetvalue sU*.h

Lsetvalue sU*.l

LL set value sU*.ll

Set value bank no. of prescale values p.bank Yes

Prescaling value of input A

X (mantissa)

Y (exponent)

Decimal point position decp.* Ye s

Operating mode func Yes 50

Input A sensor type ina Ye s

Input B sensor type inb Ye s

Time unit time No 54

Communications unit no. (note 1) u- no Ye s

Baud rate (note 1) bps Ye s

Word length (note 1) len Ye s

Stop bits (note 1) sbit Yes

Parity bits (note 1) prty Yes

Output pattern (note 1) c-out Yes 61

H linear output range (note 1) lset.h Yes

L Linear output range (note 1) lset.l Yes

Remote/Local programming (note 1) r- l Yes 67

ps*.ax

ps*.ay

Availability Reference

Yes 42

46

Yes

52

56

58

64

page

Note 1. The availability of the parameters depends on the type of selected Output

Board.

2. The selected bank number will be displayed where the asterisk (

*) appears.

33

Page 43

Interval:

f6

3-6 Interval: f6

Section 3-6

FUNCTION

Application example

Measures the distance between the slits.

Basic Operation

Counts the number of pulses of INA between successive instances of INB turning ON and displays the result. Obtain display value D as follows:

D (pulse count) = C x a

C: Pulse count of INA while INB input is ON

a: Prescale value

To set a prescale value, refer to 4-2-4 Prescaling Menu.

INA

INB

HOLD

Display

SETTING

C

1

Value previously

measured

C

T

R

C1X a C2X a C4X a

2

C

3

C

4

TR: Recovery time

Refer to the following table to set the most suitable prescaling value.

Mode Unit of display

value

Interval mm

cm

m

Prescale value

1000 pDa/Na

100 pDa/Na

pDa/Na

Na: Number of pulses per revolution at A input

pDa: Circumference (m) per revolution from A input

Note The K3NP can display time, minute, and second. Refer to page 54 for details.

Refer to 4-2 Setting Mode.

REFERENCE

34

Page 44

Interval:

f6

Section 3-6

Performance Characteristics

Maximum input frequency of INA Sensor with transistor output: 50 kHz

Sensor with relay output: 30 Hz

Measurement range (C) 0 to 4 G (with 32-bit c ounter)

Response time of HOLD input 20 ms max.

Recovery time (TR) 20 ms min.

ON/OFF pulse width

Response time Output configuration

Relay output Transistor

Comparative output 25 ms max. 20 ms max. 35 ms max. 35 ms max. 20 ms max .

BCD output --- --- Refer to page 93. --- ---

Linear output --- --- --- 40 ms max. ---

Sensor with transistor output: 9 msmin.

Sensor with relay output: 15 ms min.

BCD and

output

transistor output

Linear and

transistor output

Communication

and transistor

output

Maximum Input Frequency The maximum input frequency is the maximum number of INA input pulses

that the K3NP can count accurately.

Response Time of HOLD

Input

The response time of the HOLD input is the time required for the K3NP to

accept HOLD input after the HOLD input turns ON. This is illustrated in the

following diagram.

Recovery Time (T

) Recovery time is the period required for the K3NP to become ready for the

R

next measuring operation after a measuring operation is completed. For transistor output Models, comparative output remains ON during recovery time.

For other models, comparative output requires more time to turn ON. When

the comparative output terminals of the output board and the HOLD input

terminals are connected, set a sufficient recovery period, considering the response time of the HOLD input. This is illustrated in the following diagram.

Measurement starts

INA

Measurement completed

INB

Comparative output

Delay in comparative outputs

HOLD input

Acceptance of HOLD input

C

1

Recovery time (20 ms min.)

C

2

Response time of HOLD input

(20 ms max.)

TR

35

Page 45

(

)

Interval:

f6

Section 3-6

Available functions in this mode are indicated as “Yes” in the following table.

Menu Function Displayed

Character

--- Max./Min. value display and reset --- Yes 82

sUset (note 1)

pscl

setup

opt

Set value bank no. of set values s.bank

HH set value sU*.hh

Hsetvalue sU*.h

Lsetvalue sU*.l

LL set value sU*.ll

Set value bank no. of prescale values p.bank Yes

Prescaling value of input A

X (mantissa)

Y (exponent)

Decimal point position decp.* Ye s

Operating mode func Yes 50

Input A sensor type ina Ye s

Input B sensor type inb No

Time unit time Yes 54

Communications unit no. (note 1) u- no Ye s

Baud rate (note 1) bps Ye s

Word length (note 1) len Ye s

Stop bits (note 1) sbit Yes

Parity bits (note 1) prty Yes

Output pattern (note 1) c-out Yes 61

H linear output range (note 1) lset.h Yes

L Linear output range (note 1) lset.l Yes

Remote/Local programming (note 1) r- l Yes 67

ps*.ax

ps*.ay

Availability Reference

Yes 42

46

Yes

52

56

58

64

page

Note 1. The availability of the parameters depends on the type of selected Output

Board.

2. The selected bank number will be displayed where the asterisk (

*) appears.

36

Page 46

SECTION 4

Parameter Setting

This sectionprovides instructions for setting the parameters of theK3NP.Be sure to read this section before using the K3NP

Period Meter for the first time.

4-1 Overview 38..............................................................

4-1-1 Heading Symbols 38.................................................

4-1-2 Setting Procedures 38................................................

4-2 Setting Mode 39...........................................................

4-2-1 Selecting Setting Mode 39............................................

4-2-2 Menu Overview 40..................................................

4-2-3 Setting Value Menu (

Bank No. of Set Value (

HH Set Value (

HSetValue(

LSetValue(

LL Set Value (

4-2-4 Prescaling Menu (

Bank No. of Prescale (

Prescaling Value X (Mantissa) of Input A (

Prescaling Value Y (Exponent) of Input A (

Decimal Point Position (

4-2-5 Setup Menu (

Operating Mode (

Sensor Type (

Time Unit (

Communications Unit Number (

Baud Rate (

Word Length (

Stop Bits (

Parity Bits (

4-2-6 Option Menu (

Comparative Output Pattern (

Upper Limit (H) of Linear Output Range (

Lower Limit (L) of Linear Output Range (

Remote/Local Programming (

4-3 Protect Mode 69...........................................................

4-3-1 Selecting Protect Mode 69............................................

4-3-2 Menu Overview 70..................................................

4-3-3 Protect Menu (

All Key Protect (

Setting Value Change Prohibit (

Reset Prohibit (

Security (

sU*.hh)42................................................

sU*.h)42..................................................

sU*.l)42..................................................

sU*.ll)42.................................................

setup)50..............................................

func)50...............................................

ina, inb)52................................................

time)54....................................................

bps)56.....................................................

len)58...................................................

sbit)58.....................................................

prty)58....................................................

all)71.................................................

reset)74................................................

secr)76......................................................

sUset)42........................................

s.bank)42.........................................

pscl)46............................................

p.bank)46..........................................

ps*.ax)46..........................

ps*.ay)46.........................

decp.*)46........................................

u- no)56....................................

opt)61...............................................

c-out)61.....................................

lset.h)64..........................

lset.l)64..........................

r- l)67.......................................

prot)71..............................................

sUset)72...................................

37

Page 47

Overview Section 4-1

4-1 Overview

4-1-1 Heading Symbols

The following symbols are used for headings in this section.

This symbol precedes an explanation of the parameter’s meaning and function.

FUNCTION

This symbol precedes a description of the settings, setting range, and default

value.

SETTING

This symbol precedes an explanation of procedures for parameters that specify

operations.

PROCEDURE

This symbol precedes a listing of references and related parameters.

REFERENCE

This symbol precedes a listing of the models in which this parameter can be

used.

MODELS

4-1-2 Setting Procedures

· The K3NP has four modes: RUN mode for normal operations, Setting mode for

initial parameter input, Protect mode for lock-out configuration, and Maintenance mode for initializing set values. The parameters that are accessible on

any individual K3NP will vary depending on the Output Board installed. Refer

to Appendix D Available Parameters.

· The K3NP is in RUN mode when the K3NP is turned on. Parameter settings in

protect or setting mode are described below on the basis that the parameters

are set for the first time.

For the operation in RUN mode, refer to Section 5 Operations in RUN Mode.

· The setting examples are provided on condition that the factory-set values of

the K3NP have not been changed.

38

Page 48

Setting Mode

4-2 Setting Mode

4-2-1 Selecting Setting Mode

· The K3NP in RUN mode will go into setting mode if the Mode Key is pressed for

1 s minimum.

· The K3NP in setting mode will go into RUN mode if the Escape Key is pressed.

Press the Mode and Shift Keys

while turning the K3NP on.

Section 4-2

Power On

Maintenance mode

1 second

RUN mode

RUN mode

Setting mode

Press the Escape and Up

Keys for 1 second.

Protect mode

· The menu in each mode changes whenever the Mode Key is pressed.

· If the Mode Key is pressed for more than one second while a menu is dis-

played, a parameter will be displayed.

· The parameter changes whenever the Mode Key is pressed.

· If the Shift Key is pressed while a parameter is displayed, the parameter will be

ready to change.

· Press the Up Key to change parameters.

· The digit of a set value is selected with the Shift Key and changed with the Up

Key.

· The PROG indicator is lit while a menu or parameter is displayed.

· The PROG indicator flashes during a set value change.

Note If the operating mode is changed, all the other parameters will be set to default

values except for communication settings and set values in protect mode.

Therefore, set the operating mode and sensor type first.

39

Page 49

Setting Mode

4-2-2 Menu Overview

Power On

RUN Mode

Refer to Section 5 Operations in RUN Mode.

Press the Mode and Shift Keys

while turning the K3NP on.

Press the Escape and

Up Keys for 1 second.

Section 4-2

Maintenance Mode

Refer to Section 6 Useful Functions.

Protect Mode

Setting Mode

Output Test

Press the

Mode Key

for 1 second.

Setting value menu

Press the Mode Key for 1 second.

Bank no. of set

value

HH setting value

H setting value

L setting value

LL setting value

1to4

Refer to 4-3 Protect Mode.

Prescaling menu

Bank no. of prescale

Presc aling value of input A

X ( mantiss a))

Presc aling value of input A

Y ( exponent)

Decimal point

position

Press the Mode Key for 1 second.

Refer to Section 6

Useful Functions.

Note 1. When making new settings or changing settings of each parameter, press the

Shift Key to the setting state.

2. The K3NP stops measurement in setting mode.

Some menus cannot be set according to the Output Board selected.

If the operating mode is changed, all the other parameters will be set to default

values except communication setting and set values in protect mode. Therefore, set the operating mode and sensor type.

40

Page 50

Setting Mode

Section 4-2

Setup menu

Operating mode

Input A sensor

type

Input B sensor

type

Time unit

Communications

unit no.

Baud rate

Word length

Press the Mode Key for 1 second.

Option menu

Comparative output pattern

H linear output

range

L linear output

range

Remote/Local

programming

Press the Mode Key for 1 second.

Stop bits

Parity bits

41

Page 51

Setting Mode

4-2-3 Setting Value Menu (sUset)

Section 4-2

s.bank

sU*.hh

sU*.h

sU*.l

sU*.ll

FUNCTION

SETTING

Bank No. of Set Value

HH Set V

HSetV

alue

alue

LSetValue

LL Set Value

· There are two basic methods for setting HH, H, L, and LL set values: by entering during RUN mode via the front-panel buttons, setting in Setting mode, or by

the teaching function.

Setting Setting range Default

Set value bank 1to4 1

HH set value 0 to 99999 99,999

Hsetvalue 0 to 99999 99,999

Lsetvalue 0 to 99999 0

LL set value 0 to 99999 0

MODELS

Set the decimal point position in the prescaling menu.

· The menu is only available for the K3NP, with Comparative Output Board.

42

Page 52

Setting Mode

Section 4-2

SETTING

EXAMPLE

Follow the steps described below to input the following.

Setting value bank = 2

HH setting value = “8000”

H setting value = “6000”

L setting value = “4000”

LL setting value = “2000”

Set Value LED Display Model Basic Model

1, 2, 3... 1. Press the Mode Key for more than one second while the sUset setting value

menu is displayed. The

Set Value LED Display Model Basic Model

s.bank setting value bank setting will be displayed.

2. Press the Shift Key to display the set value 1 for changing. The PROG indicator will flash.

Set Value LED Display Model Basic Model

3. Press the Up Key to set the value to 2. The input will be validated automatically if no change is made for five seconds. The

s.bank setting value bank

setting will be displayed again.

Note Press the Mode Key to enter the set value immediately. The

sU2.hh

HH setting value setting of bank 2 will be displayed for setting the next

parameter.

Set Value LED Display Model Basic Model

4. Press the Mode Key to display the sU2.hh HH setting value of bank 2 setting.

Set Value LED Display Model Basic Model

5. Press the Shift Key to display the set value 99999 for changing. The PROG

indicator will flash.

Set Value LED Display Model Basic Model

43

Page 53

Setting Mode

Section 4-2

6. Press the Up and Shift Keys to set the value to 8000. The input will be validated automatically if no change is made for five seconds. The

setting value of bank 2 setting will be displayed again.

sU2.hh HH

Note Press the Mode Key to enter the set value immediately. The

sU2.h H

setting value of bank 2 setting will be displayed for setting the next

parameter.

Set Value LED Display Model Basic Model

7. Press the Mode Key to display the sU2.h H setting value of bank 2 setting.

Set Value LED Display Model Basic Model

8. Press the Shift Key to display the set value 99999 for changing. The PROG

indicator will flash.

Set Value LED Display Model Basic Model

9. Press the Up and Shift Keys to set the value to 6000. The input will be validated automatically if no change is made for five seconds. The

sU2. h Hset-

ting value setting will be displayed again.

Note Press the Mode Key to enter the set value immediately. The

sU2. l L

setting value of bank 2 setting will be displayed for setting the next

parameter.

Set Value LED Display Model Basic Model

10. Press the Mode Key to display the sU2.l L setting value of bank 2 setting.

Set Value LED Display Model Basic Model

1 1. Press the Shift Key to display the set value 00000 for changing. The PROG

indicator will flash.

Set Value LED Display Model Basic Model

44

Page 54

Setting Mode

Section 4-2

12. Press the Up and Shift Keys to set the value to 4000. The input will be validated automatically if no change is made for five seconds. The

ting value of bank 2 setting will be displayed again.

sU2. l Lset-

Note Press the Mode Key to enter the input immediately. The

sU2.ll LL

setting value setting will be displayed for setting the next parameter.

Set Value LED Display Model Basic Model

13. Press the Mode Key to display the sU2.ll LL setting of bank 2 value setting.

Set Value LED Display Model Basic Model

14. Press the Mode Key to display the set value 00000 for changing. The PROG

indicator will flash.

Set Value LED Display Model Basic Model

15. Press the Up and Shift Keys to set the value to 2000. The input will be validated automatically if no change is made for five seconds. The

sU2.ll LL

setting value setting will be displayed again.

Note Press the Mode Key to enter the set value immediately. The

s.bank

setting bank setting will be displayed for setting the next parameter.

Set Value LED Display Model Basic Model

16. Press the Escape Key to display the sUset setting value menu.

Set Value LED Display Model Basic Model

Set Value LED Display Model Basic Model

45

Page 55

Setting Mode

4-2-4 Prescaling Menu (pscl)

Section 4-2

p.bank

ps*.ax

ps*.ay

decp.*

FUNCTION

SETTING

Bank No. of Prescale

Prescaling Value X (Mantissa) of Input

Prescaling Value Y (Exponent) of Input

Decimal Point Position

The measured data of passing speed or cycle is displayed after being multiplied

by a preset value (i.e., prescaling value).

Display value = Measured data x Prescaling value

Input type Setting Default

p.bank: Bank no. of prescale off/1 to 4 off

ps*.ax: Prescaling value X (mantissa)

of input A

ps*.ay: Prescaling value Y (exponent)

of input A

decp.*: Decimal point position One of the 1st to 4th digits

0.0001 to 9.9999 1.0000

--9to9 0

from the right

A

A

No decimal

point

position

setting

REFERENCE

SETTING

EXAMPLE

Refer to Section 3 Operating Modes.

Follow the steps described below to input the following.

Operating mode = F1

Prescaling bank = OFF

Prescaling value X (mantissa) of input A = 0.5000

Prescaling value Y (exponent) of input A = --1

Decimal point = jjjj.j (First digit from the right)

Set Value LED Display Model Basic Model

1, 2, 3... 1. Press the Mode Key for more than one second while the pscl prescaling

menu is displayed. The

Set Value LED Display Model Basic Model

p.bank prescaling bank setting will be displayed.

46

Page 56

Setting Mode

Section 4-2

2. Press the Shift Key to display off for changing. The PROG indicator will

flash.

Set Value LED Display Model Basic Model

3. Press the Up Key to change the prescaling bank setting. The input will be

validated automatically if no change is made for five seconds. The

prescaling bank setting will be displayed again.

Note Press the Mode Key to enter the set value immediately. The

prescaling value X (mantissa) of input A setting will be displayed for

setting the next parameter.

Set Value LED Display Model Basic Model

4. Press the Mode Key to display the ps.ax prescaling value X (mantissa) of

input A setting.

Set Value LED Display Model Basic Model

p.bank

ps.ax

5. Press the Shift Key to display the set value 1.0000 for changing. The PROG

indicator will flash.

Set Value LED Display Model Basic Model

6. Press the Up and Shift Keys to set the value to 0.5000. The input will be validated automatically if no change is made for five seconds. The

ps.ax pres-

caling value X (mantissa) of input A setting will be displayed again.

Note Press the Mode Key to enter the set value immediately. The

ps.ax

prescaling value X (mantissa) of input A setting will be displayed for

setting the next parameter.

Set Value LED Display Model Basic Model

7. Press the Mode Key to display the ps.ay prescaling value Y of input A setting.

Set Value LED Display Model Basic Model

47

Page 57

Setting Mode

Section 4-2

8. Press the Shift Key to display the set value 10 00 for changing.

Set Value LED Display Model Basic Model

9. Press the Up and Shift Keys to set the value to 10 -1. The input will be validated automatically if no change is made for five seconds. The

caling value Y (exponent) of input A setting will be displayed again.

ps.ay pres-

Note Press the Mode Key to enter the set value immediately. The

decimal point position setting will be displayed for setting the next parameter.

Set Value LED Display Model Basic Model

10. Press the Mode Key to display the decp decimal point position setting.

Set Value LED Display Model Basic Model

1 1. Press the Shift Key to display %%%%% for changing.

Set Value LED Display Model Basic Model

decp

12. Press the Shift Key to set %%%%.%. The input will be validated automatically if

48

no change is made for five seconds. The

decp decimal point position setting

will be displayed again.

Note Press the Mode Key to enter the set value immediately. The

prescaling bank setting will be displayed for setting the next parameter.

Set Value LED Display Model Basic Model