Page 1

Cat. No. W348-E1-05

DRT1-COM

GT1 Series

DeviceNet

MULTIPLE I/O TERMINAL

OPER ATION MANUAL

Page 2

DRT1-COM

GT1 Series

DeviceNet

MULTIPLE I/O TERMINAL

Operation Manual

Revised May 2003

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use accordin g to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to ind icate and classify pr ecautions in this manual . Always heed

the information provided with them . Failure to heed precautions can result in in jur y to people or damage to property.

!DANGER Indicates an immine ntly hazardous situation whi ch, if not avoided, will result in death or

serious inj ury.

!WARNING Indicates a potentially hazardous situatio n which, if not avoided, could resu lt in death or

serious inj ury.

!Caution Indicates a potentially ha zardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which ap pears in some displays and on some OMRON produ cts, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything

else.

Visual Aids

The following headings appear in the left co lumn of the manual to help you locate different types of

information.

Note Indicates information of pa rticular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

Trademarks and Copyrights

COMBICON is a registered trademark of Phoenix Contact K.K.

DeviceNet is a registered trademark of the Open DeviceNet Vendor Association, Inc.

PowerTap is a registered trademark of the Allen-Bradley Company, Inc.

OMRON, 1998

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or tran smit ted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to th e use of the in fo rmation c ontain ed he rein. M oreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

6 EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

SECTION 1

MULTIPLE I/O TERMINAL. . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 MULTIPLE I/O TERMINAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SECTION 2

Hardware Setup and Operational Check. . . . . . . . . . . . . . . 19

2-1 Basic Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-2 Specific Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SECTION 3

Sample Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3-1 Examples of Counter Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SECTION 4

Basic I/O Unit Specifications. . . . . . . . . . . . . . . . . . . . . . . . . 35

4-1 Communications Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4-2 Specifications Common to All Basic I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4-3 Transistor Inpu t Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-4 Transistor Output Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4-5 Relay Output Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

SECTION 5

Special I/O Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . 97

5-1 Analog Input Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

5-2 Analog Output Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

5-3 GT1-TS04T and GT1-TS04P Temperature Input Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

5-4 GT1-CT01 Counter Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

SECTION 6

Communications Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

6-1 Remote I/O Communications Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

SECTION 7

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . 195

7-1 Normal Indication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

7-2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

7-3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Appendices

A Slave Devi ce Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

B Connectable Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .215

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

vii

Page 7

About this Manual:

This manual descri bes the operation of the DeviceNet MULTIPLE I/O TERMINAL and includes the

sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to operate the MULTIPLE I/O TERMINAL.

Section 1 provides an overview of the MULTIPLE I/O TERMINAL, including its features and functions.

Section 2 provides the basic procedure for operation and includes an actual example.

Section 3 provides some examples of programs used with the Counter Unit.

Section 4 provides the basic spec ific ations for the I/O Units incl uding Communicat ions Uni ts, Transi s-

tor Input and Output Units, and Relay Output Units.

Section 5 provides the specifications for Special I/O Units, including the Analog Input Unit, the Analog

Output Unit, the Tempera ture Input Unit, and th e Counter Unit. Setti ng procedures for a Configurator

are also provided.

Section 6 provides characteristics for communications in the DeviceNet Unit and describes how to calculate the times required for communications between Units.

Section 7 provides procedures for dealing with errors as well as basic maintenance procedures.

The Appendices provide Slave device profiles and lists of connectable devices.

!WARNING Failure to read and understand the informati on provided i n this ma nual may result in p er-

sonal injury or death, damage to th e product, or product failure. Please r ea d ea ch section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

ix

Page 8

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) Systems and related devices.

The information contained in this section is important for the safe and reliable application of PC Systems. Y ou must

read this section and understand the information contained before attempting to set up or operate a PC System.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

6 EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

xi

Page 9

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate t he product according to t he performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the produ ct to nuclear control s ystems, railroad systems,

aviation systems, vehicles, combustion systems, me dical equipmen t, amusement machines, safety equipment, and oth er systems, machines, and equi pment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performan ce charact er is ti cs of the pr od uc t are

sufficient for the systems, machi nes, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating OMRON PC

Systems. Be sure to read this manual before attempting to use the software

and keep this manual close at hand for reference during operation.

!WARNING It is extremely importa nt that a PC System and all PC Units be us ed for the

specified pur pose and under the specified conditions, espec ially in applications that can directly or indirectly affect human life. You must consult with

your OMRON representative before applyin g a PC S ystem t o the abovementioned applications.

3 Safety Precautions

!WARNING Never attempt to disassemble any Units while power is being sup plied. Doin g

so may result in serious electrical shock or electrocution.

!WARNING Never touch any of the terminals while power is being supplied. Doing so may

result in serious elec trical shock or electrocution.

4 Operating Environment Precautions

Do not operate the control system in the following places.

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to shock or vibration.

• Locations subject to exposure to water, oil, or chemicals.

xii

Page 10

Application Precautions 5

• Take appropriate and sufficient countermeasures when installing systems

in the following locations.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the PC System ca n have a large effect on the

longevity and reliability of the sy stem. Improper operating environme nts can

lead to malfunction, failure, and other unforeseeable problems with the PC

System. Be sure that the op erating environment is within the sp ecified cond itions at installation and remai ns within the specifi ed conditions dur ing the life

of the system.

5 Application Precautions

Observe the following precautions when using the MULTIPLE I/O TERMINAL.

!WARNING Failure to abide by the following precautions c ould lead to ser ious or pos sibly

fatal injury. Always heed these precautions.

• Always ground the syst em to 100

protect against electrical shock.

• Always turn OFF the power supply to the system before attempting any of

the following. Performing any of the following with the power supply turned

ON may lead to electrical shock:

• Mounting or removing any Units (e.g., Power Suppl y Unit, I/O Units,

CPU Unit, etc.) or memory cassettes.

• Assembling any devices or racks.

• Connecting or disconnecting any cables, connectors, or wiring.

!Caution Failure to abide by the following precautions could lead to faulty operation of

or damage to the MULTIPLE I/O TERMINAL. Always heed these precautions.

• Use the Units only with the power supplies and voltages speci fied in the

operation manuals. Other power supp lies and voltages may damage the

Units.

• Take measu res to stabilize the power suppl y to conform to the rated supply if it is not stable.

• Provide circui t breakers and other safety measures to provide p rotection

against shorts in external wiring.

• Do not a pply vol tages exceeding the rated input voltage to Input Units.

The Input Units may be destroyed.

• Do not a ppl y voltage s exceeding the max imum switching capacity to O utput Units. The Output Units may be destroyed.

• Always disconnect the LG terminal when performing withstand voltage

tests.

• Install all Units according to instructions in the operation manuals.

Improper installation may cause faulty operation.

• Be sure to ti ght en B ackpla ne sc rews, ter mi na l s crews, and cable co nne ctor screws securel y.

• Do not at tempt to take any Units apart, to repair any Units, or to modify

any Units in any way.

Ω or less when installi ng the system to

xiii

Page 11

Application Precautions 5

• Do not u se communi cations cables or I/O cables i n parallel to or close t o

high-tension, high -rate current carr ying lines. Doing s o may cause faulty

operation.

• Be sure to ins tall the MULTIPLE I/O TERMINAL in the pr oper direction.

Not doing so may cause faulty operation.

• When atta ching Units to the DIN track, be sur e to attach them securely.

Not doing so may cause the Units to be damaged.

• Use this product within the specified ranges for communications distances and connection dista nces. Not doing so may lead to faulty operation.

• Use t he sp ecified cables when maki ng c ommunica tions c onnecti ons. Not

doing so may cause faulty operation.

• Be sure to wire the communications paths, the communications power

supplies, the internal power supplies, and the I/O power supplies correctly. Use voltag es for th e power s upplies that are within the specified

ranges. Not doing so may cause malfunction.

• Do not, un der any circumstances, use this p roduct with loads exceeding

the contact rating values. Doing s o may cause deterioration of insulation

and damage.

• The life-expectancy of the r elays depends greatly on the switching conditions. Before practical use of the product, perform a tr ial operation of the

product in the actual conditions in which it will be used. Use the product at

a switching frequency that will allow effici ent operation. Continued use of

the product in cond itions cau sing redu ced ef ficiency will cause deter ioration of insulation and damage.

• Connection Cables

• Before switching ON power supplies, check that the connecto rs are

mounted securely.

• Check that the connectors for the I/O Unit interfaces are securely

locked.

• Tightening Torques

Check that all the screws for the Units are tightened to the correct tor qu e.

Not doing so may cause faulty operation.

• Internal power supplies, I/O power supplies, terminal screws:

0.3 to 0.5 N • m

• Communications cable, communications connector screws:

0.25 to 0.35 N • m

• High-density I/O Unit connector screws: 0.25 to 0.35 N • m

• Cleaning

• Do no t used thinner-bas ed products for clean ing. Doing so m ay dissolve attachment areas or cause discoloration.

• Power Supply

• Use sepa rate power suppli es for communication s power supplies, internal power supplies, I/O power suppli es, load power supplies, and

encoder power supplies. Not doing so may lead to faulty operation.

xiv

!Caution The following precautions are ne cessary to en sure the general safety of the

system. Always heed these precautions.

• Provide double safety mechanisms to handle incorrect signals that can be

generated by broken signal lines or momentary power interruptions.

• Provide external interlock circuits, limit circuits, and other safety circuits in

addition to any provided within the PC System to ensure safety.

Page 12

EC Directives 6

6 EC Directives

The MULTIPLE I/O TERMINAL conforms to EMC as follows:

EMC Directives

OMRON devices that comply with EC Directives also conform to the r elated

EMC standards so tha t they can be more e asil y built in to ot her devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the custo mer, however, must be che cked by

the customer.

EMC-related perfor ma nce o f th e O M RON devices that c omp ly wi th EC Di re ctives will vary depending on the configuration, wi ring, an d other conditio ns of

the equipment or control panel on which the OMRON devices are installed .

The customer must, therefore, perform the fi nal c heck to confir m th at devices

and the overall machine conform to EMC standards.

The MULTIPLE I/O TERMINA L products that com ply wit h EC Direct ives must

be installed as follows:

1,2,3... 1. MULTIPLE I/O TERMINAL products are designed for installation inside

control panels. All MULTIPLE I/O TERMINAL products must be i nstalled

within control panels.

2. Used reinforced insulation or double in sulati on for the DC power supp lies

used for the communications power s upply, internal circuit power supply,

and the I/O power supplies.

3. MULTIPLE I/O TERMINAL products that meet EC Directives also meet the

Common Emission Standard (EN50081-2). However, radiated emission

(at 10 m) will vary with the overall configuration of the contro l panel, other

devices connected to the contr ol panel, and other conditions. You must

theref ore con firm that E C Direct ives are sati sfied f or t he ov era ll machi ne or

device.

4. MULTIPLE I/O TERMINA L products that meet EC Dir ectives have configurations with less than 30 m of I/O wiring, and less than 10 m of power supply wiring.

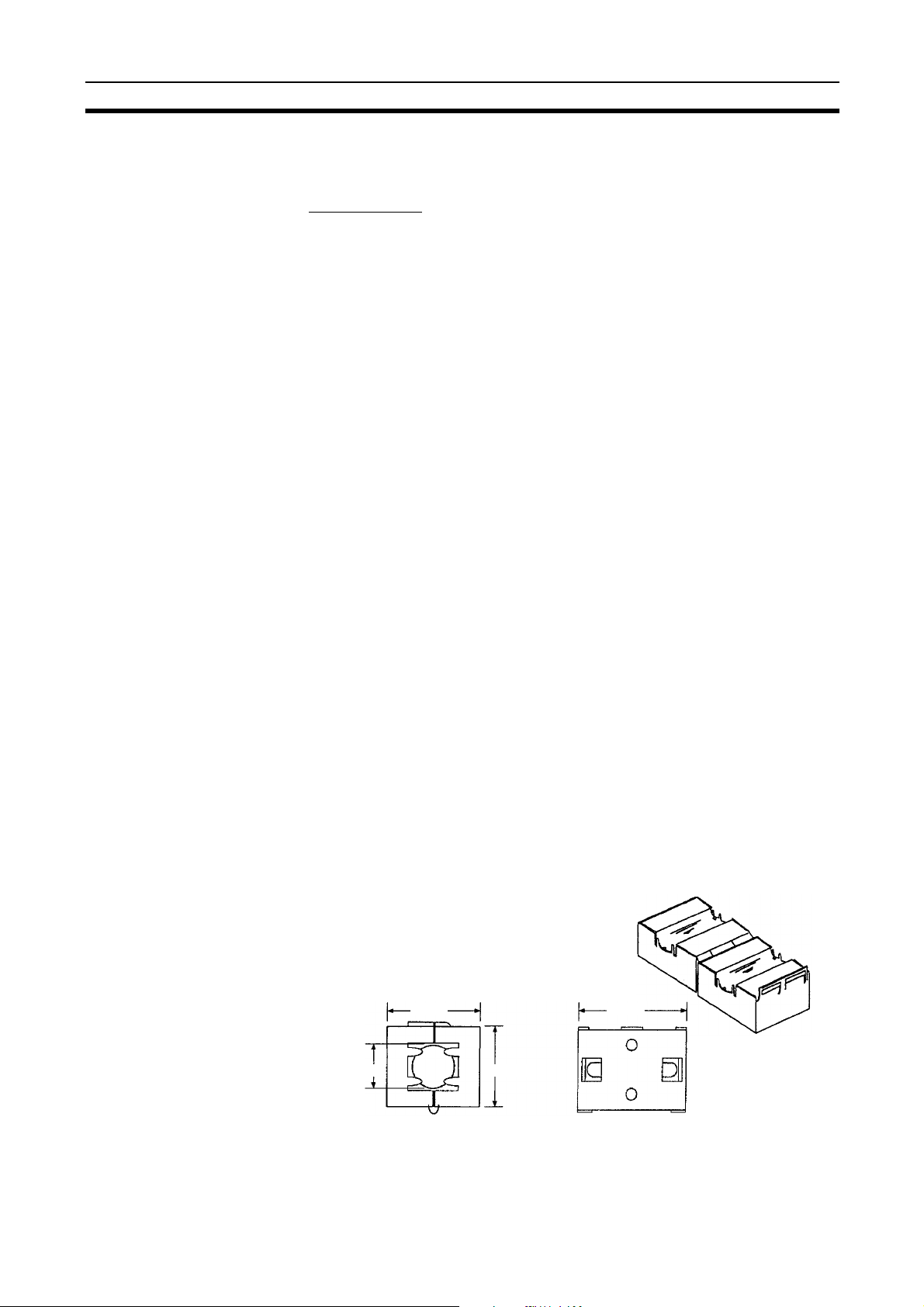

The following examples show means of reducing noise.

1,2,3... 1. Noise from the communications cable can be reduced by installing a ferrite

core on the communications cable within 10 cm of the DeviceNet Mas ter

Unit.

Ferrite Core (Data Line Filter): LF130B (Manufactured by Easy Magnet Co.)

Impedance specifications

25 MHZ: 105 Ω

100 MHZ: 190 Ω

13 mm

30 mm

31.5 mm

32 mm

2. Wire the control panel with cables as thick and short as possible and

ground to 100

Ω min.

xv

Page 13

EC Directives 6

3. Keep DeviceNet communications cables as shor t as pos sible and ground

to 100

Ω min.

xvi

Page 14

SECTION 1

MULTIPLE I/O TERMINAL

This section provides an overview of the MULTIPLE I/O TERMINAL, including its features and functions.

1-1 MULTIPLE I/O TERMINAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-3 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-1-4 Communications Units and I/O Units . . . . . . . . . . . . . . . . . . . . . . . 4

1-1-5 List of Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-2-1 I/O Unit Interface Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-2-2 Exchanging Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-2-3 Allocating I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-2-4 I/O Unit Interface Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1-2-5 I/O Configuration Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1

Page 15

MULTIPLE I/O TERMINAL Section 1-1

1-1 MULTIPLE I/O TERMINAL

1-1-1 Overview

A MULTIPLE I/O TERMINAL is a building-block DeviceNet Slave that consists

of a Communications Unit tha t interfaces one o r more I/O Uni ts. The I/O Uni t

interface supports up to 8 I/O Unit s and a total of up to 1,024 I/O poi nts. I/O

Units are connected using simple s nap-on c onnectio ns via I /O Unit Con necting Cables. Allocation and addres s settings on the I/O Unit interface are not

required, enabling simple, flexible distributed I/O control.

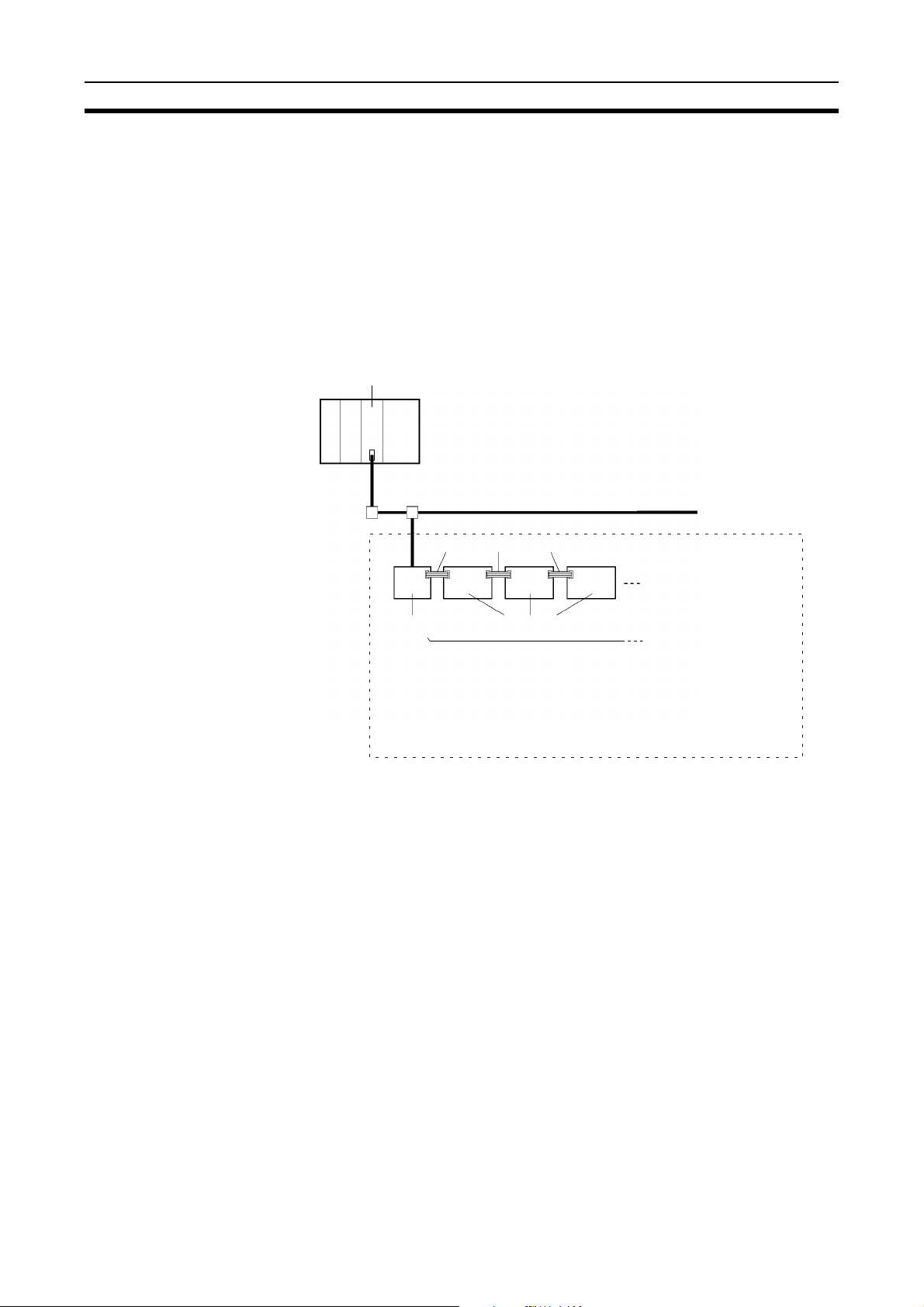

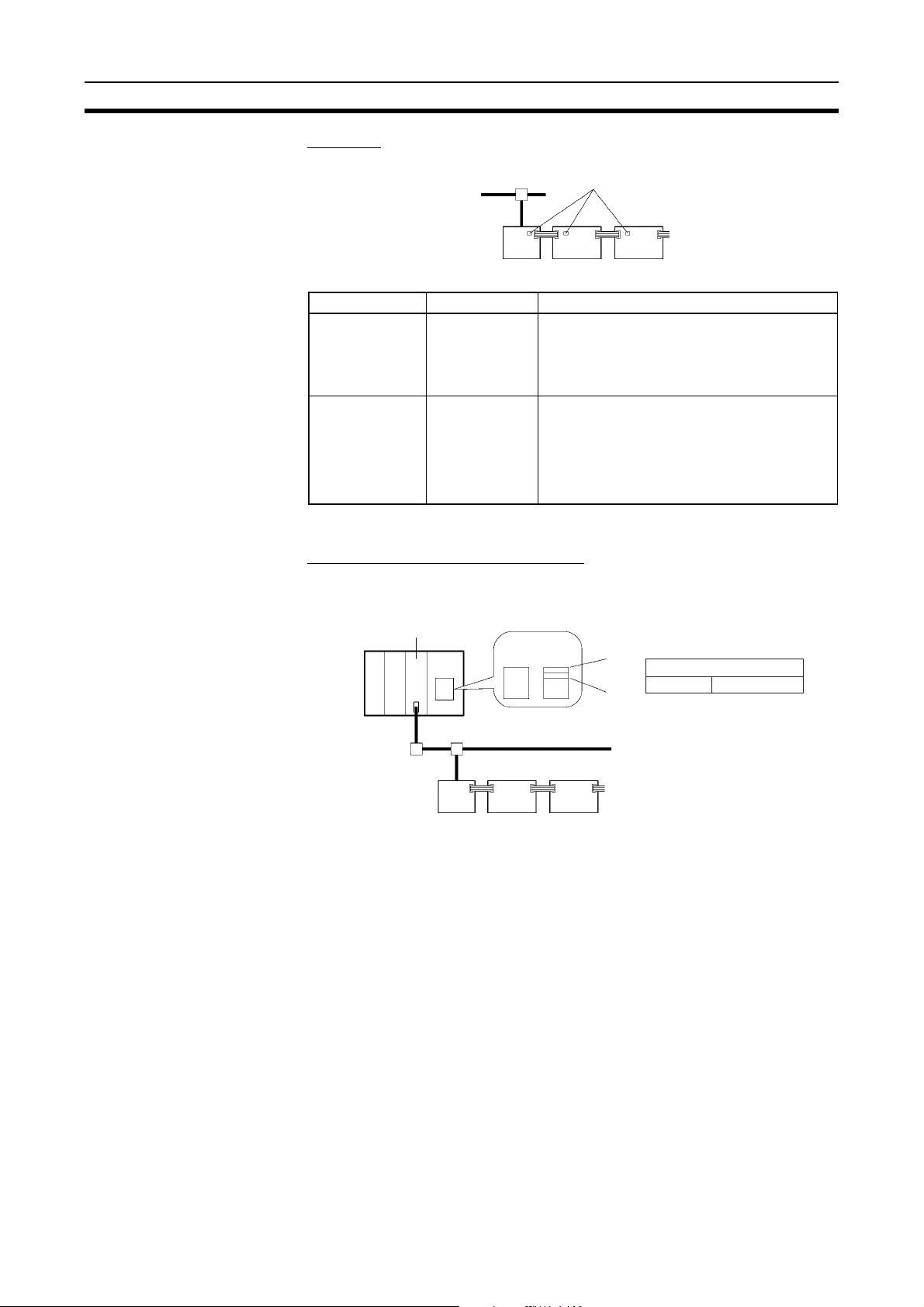

1-1-2 System Configuration

DeviceNet Master Unit

DeviceNet Network

I/O Unit Connecting Cable

Communications

Unit

I/O Unit interface

Maximum of 8 Units; total length: 3 m, 1 m max. between Units

Total number of points (inputs + outputs): 1,024 points

The total number of points must be within the maximum number

supported by the Master.

Example: With C200HW-DRM21-V1 Master, 512 inputs/512 outputs

I/O Units

2

Page 16

MULTIPLE I/O TERMINAL Section 1-1

1-1-3 Features

Simple Connections The Communications Unit and the I/O Units are separate, and the Communi-

cations Unit and the I/O Units ar e con nected by an I/O U nit in terface. I/O can

be expanded simply by connecting additio nal I/O Units to the I/O Unit interface.

Automatic Recognition of

I/O Units

Status Notification Status information about the I/O Unit i nter face can be transm itt ed as inp uts to

Many T ypes of I/O Unit The following I/O Units are available.

An I/O-intensive System

Can be Built at Low Cost

Range Setting by

Configurator

When the power to the Communications Uni t is tur ne d ON, the models of the

I/O Units on the I/O Unit interface are aut oma tic al ly re co gni zed, and the number of remote I/O communication s points with the DeviceNet Master Unit is

automatically determined. This enables I/O to be increased or decreased simply by connecting or disconnecting I/O Units.

the DeviceNet Master Unit (two words).

• 16- or 32-point Transistor Input Units (terminal block, connector, 25-pin Dsub connector, or high-density connector)

• 16- or 32-po int Transist or Output Units (ter minal block, connector, 25-pin

D-sub connector, or high-density connector)

• 8-point/16-point Relay Output Unit (16-point Unit)

• 4- or 8-point Analog Input Unit (terminal block or connector)

• 4-point Analog Output Unit (terminal block or connector)

• 1-point Pulse Input Unit (high-speed counter)

• 4-point Temperature Input Unit

Compared with fixed I/O Terminals, a high cost-performance ratio can be

achieved if I/O Units are used.

The input and out put ranges for the Analog In put, Analog Output, an d Temperature Input Units can be set for each point using the Configurator (with version 1.11 or later). Usin g DIP switches, ranges can be set in 2-point units for

the Analog Input and Analog Output Units, and in 4-point units for the Temperature Input Unit.

3

Page 17

MULTIPLE I/O TERMINAL Section 1-1

1-1-4 Communications Units and I/O Units

Communications Unit The Communications Unit interfaces the I/O Units to the DeviceNet.

• It controls the I/O Units in response to I/O refresh requests from the

DeviceNet Master.

• It automa tical ly rec ogni zes the configuration of the I/O Uni ts wh en th e I/O

Unit interface is initialized.

• It notifie s the con nection stat us or the s tatus informa tion for the I/O Units

to the DeviceNet Master Unit.

• It provides a DIP switch to set the node number and baud rate of the

MULTIPLE I/O TERMINAL as a DeviceNet Slave.

DeviceNet Master Unit

DeviceNet Network

I/O Unit interface

Output area

(Master → Communications Unit)

0

1

Input area

(Communications

Unit → Master)

Status

2

0

Example:

Outputs

1

Example:

Outputs

2

Example:

Inputs

I/O Units There are various I/O Units that can be connected to the I/O Unit interface.

• I/O Units are connected to the Communications Unit using an I/O Unit

Connecting Cable (included with th e I/O Unit, a 1-m I/O Unit Connecting

Cable (GCN1-100) is also available).

• No address or baud rate settings are required.

• The connection order of I/O Units is flexible.

Units with Connectors

Communications Unit

Units with Terminal Blocks

Transistor Input Unit

Transistor Output Unit

I/O Unit Connecting Cables

Included with Unit: 40 mm

GCN1-100: 1 m (sold separately)

Transistor Input Unit

Transistor Output Unit

Units with High-density

Connectors

Transistor Input Unit

Transistor Output Unit

Relay Output Unit

End connector

Analog Input Unit

Analog Output Unit

4

Page 18

MULTIPLE I/O TERMINAL Section 1-1

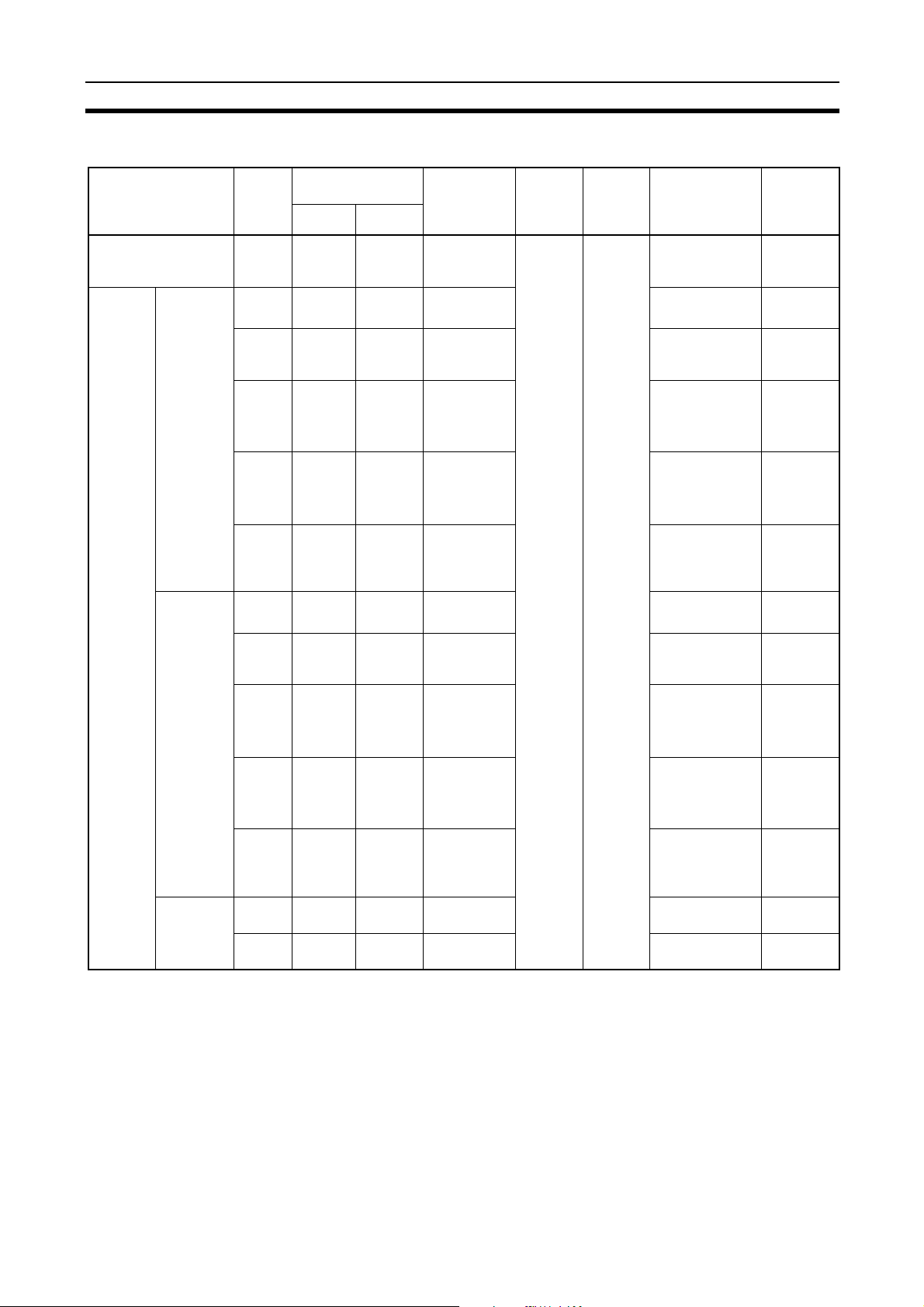

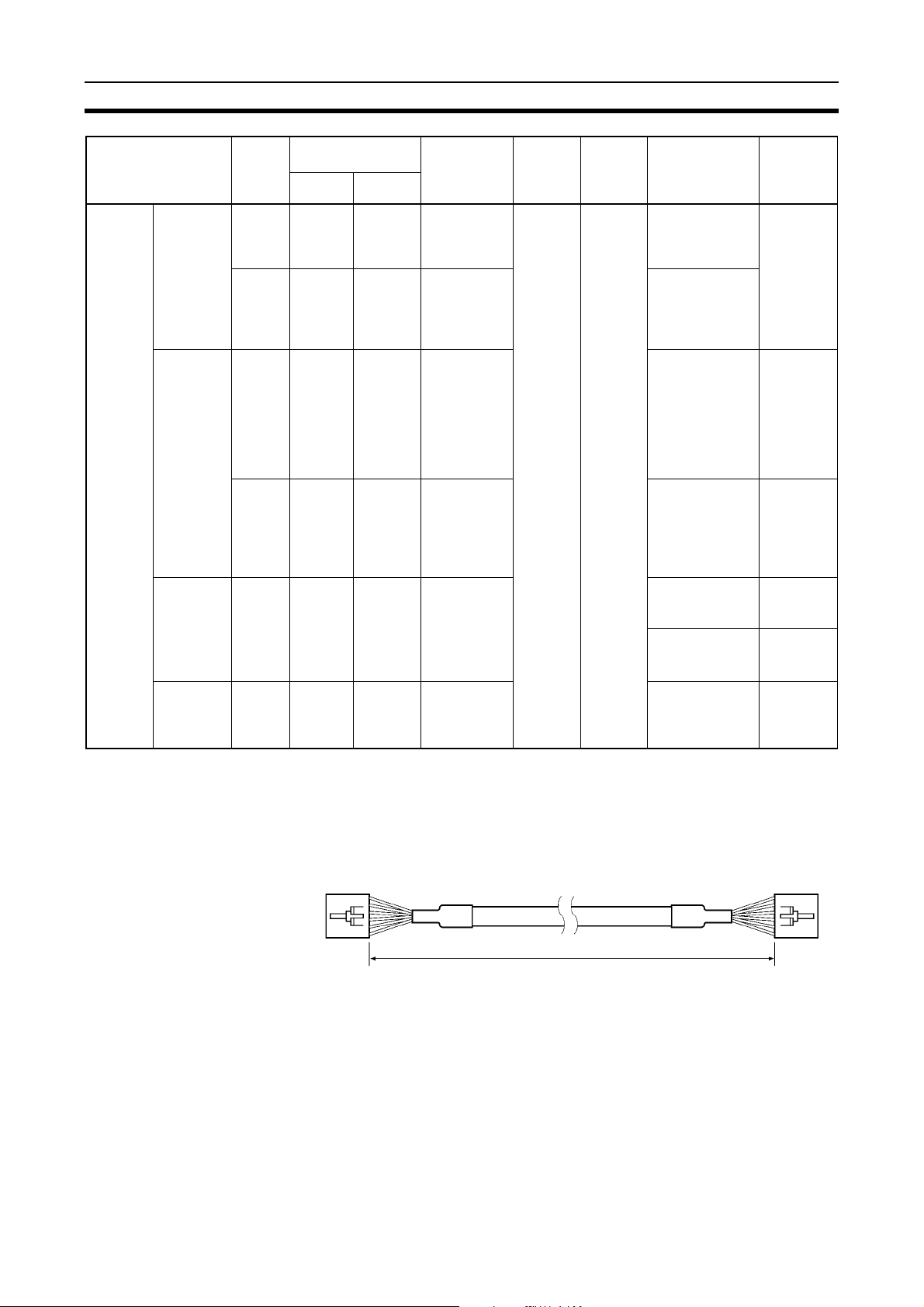

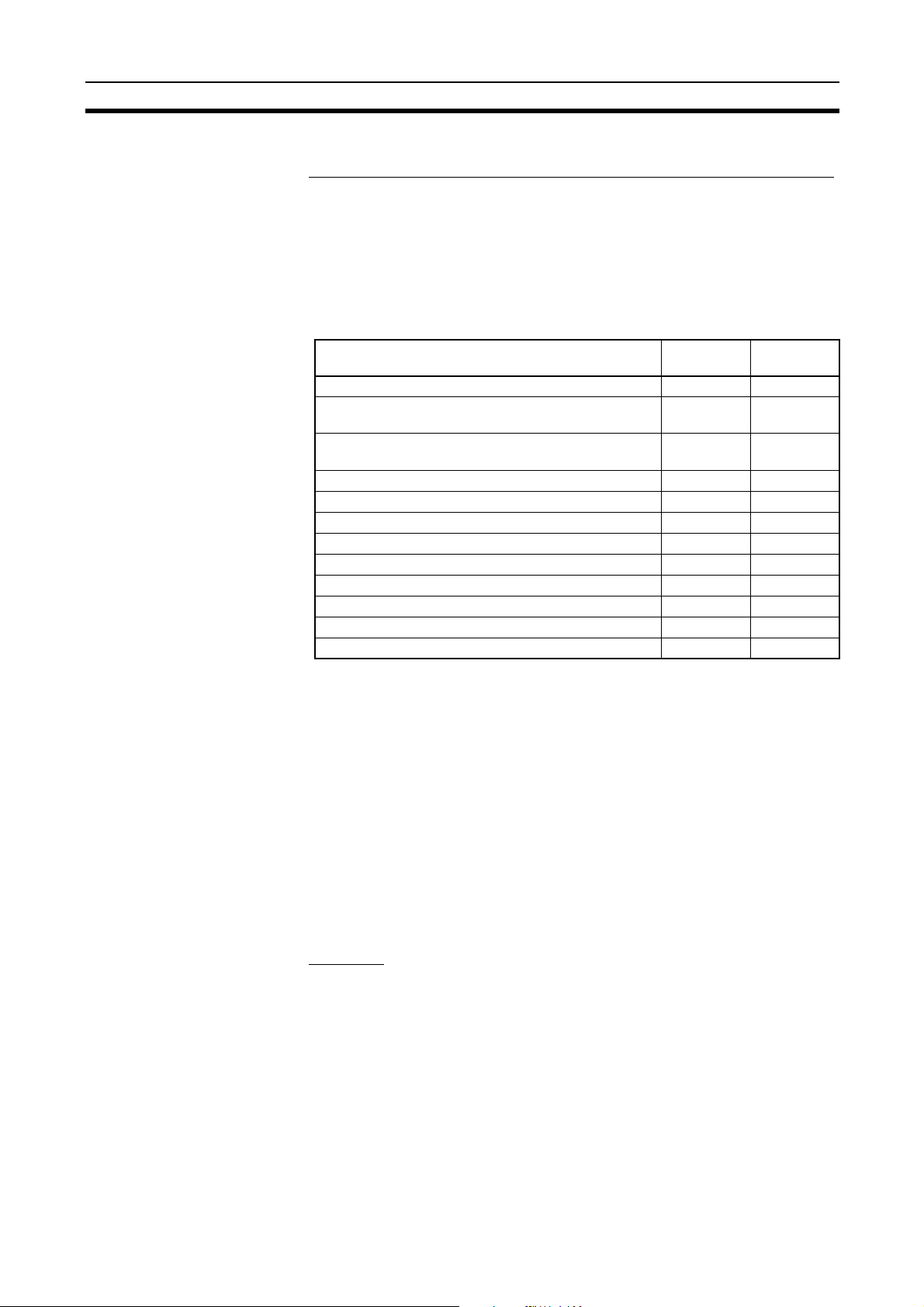

1-1-5 List of Models

Unit I/O

points

Communications Unit None Status

Basic I/O

Units

Transistor

Input Units

Transistor

Output

Units

Relay Output Units

16

inputs

16

inputs

16

inputs

16

inputs

32

inputs

16 outputs

16 outputs

16 outputs

16 outputs

32 outputs

8 outputs

16 outputs

Words allocated

in PC memory

Input Output

two

words

1 word 0 words M3 terminal

1 word 0 words Connectors

1 word 0 words Connectors

1 word 0 words Connectors

2 words 0 words High-density

0 words 1 word M3 terminal

0 words 1 word Connectors

0 words 1 word Connectors

0 words 1 word Connectors

0 words 2 words High-density

0 words 1 word M3 terminal

0 words 1 word M3 terminal

I/O

connections

0 words None 24 VDC

block

(made by

MOLEX)

(made by

FUJITSU)

(25-pin Dsub connectors)

connector

(made by

FUJITSU)

block

(made by

MOLEX)

(made by

FUJITSU)

(25-pin Dsub connectors)

connector

(made by

FUJITSU)

block

block

Unit

power

supply

voltage

(supplied

from outside)

Installa-

tion

DIN track DRT1-COM ---

Model number Remarks

GT1-ID16

GT1-ID16-1

GT1-ID16MX

GT1-ID16MX-1

GT1-ID16ML

(See note 2.)

GT1-ID16ML-1

(See note 2.)

GT1-ID16DS

(See note 2.)

GT1-ID16DS-1

(See note 2.)

GT1-ID32ML

GT1-ID32ML-1

GT1-OD16

GT1-OD16-1

GT1-OD16MX

GT1-OD16MX-1

GT1-OD16ML

(See note 2.)

GT1-OD16ML-1

(See note 2.)

GT1-OD16DS

(See note 2.)

GT1-OD16DS-1

(See note 2.)

GT1-OD32ML

GT1-OD32ML-1

GT1-ROP08 ---

GT1-ROS16 ---

NPN

PNP

NPN

PNP

NPN

PNP

NPN

PNP

NPN

PNP

NPN

PNP

NPN

PNP

NPN

PNP

NPN

PNP

NPN

PNP

5

Page 19

MULTIPLE I/O TERMINAL Section 1-1

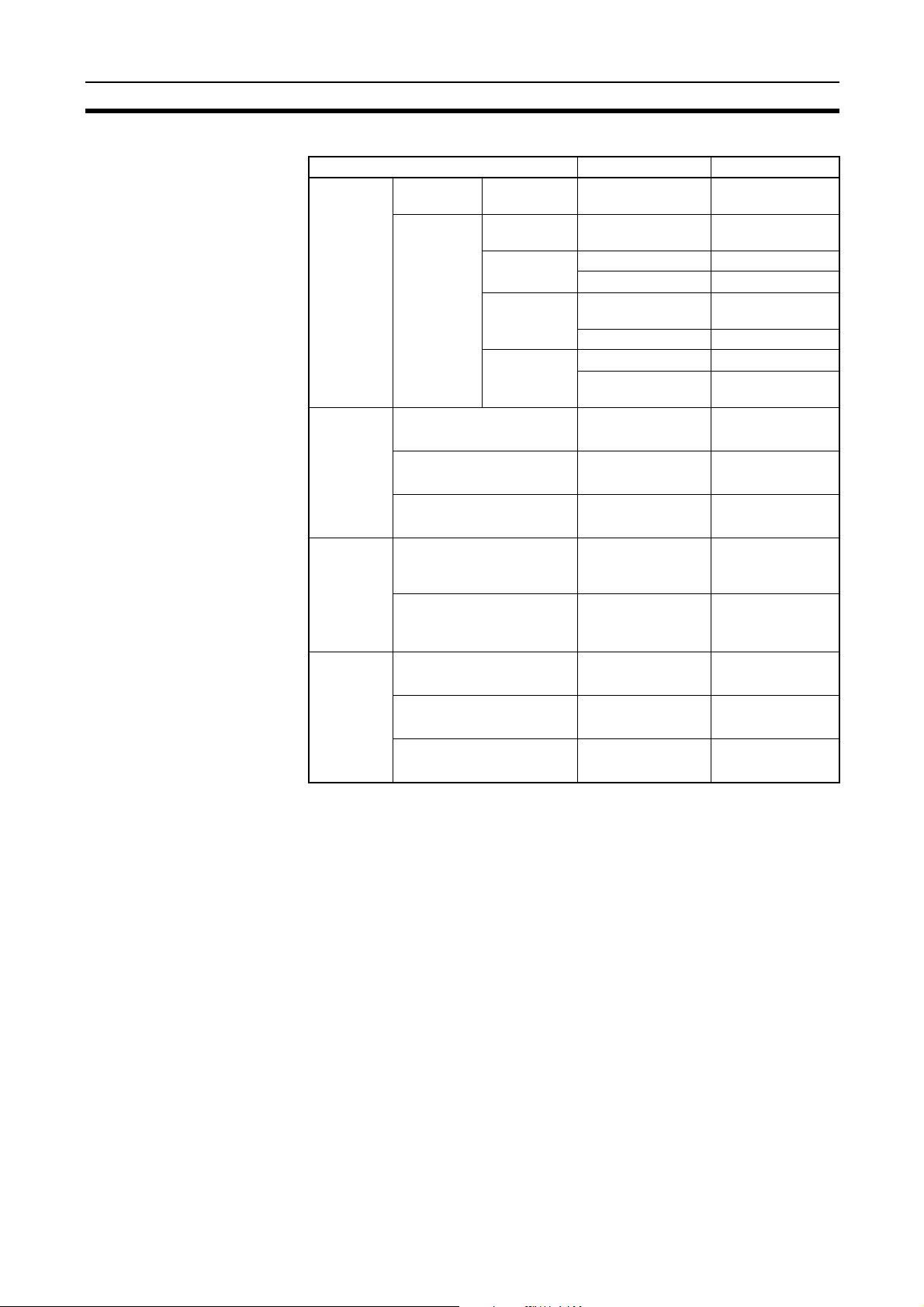

Special I/

O Units

(See

note.)

Unit I/O

Analog

Input Units

Analog

Output

Units

Temperature Input

Units

Counter

Unit

points

4 inputs 4 words 0 word M3 terminal

8 inputs 8 words 0 word Connectors

4 outputs

4 outputs

4 inputs 4 words

1 input 3 words 3 words M3 terminal

Words allocated

in PC memory

Input Output

0 words 4 words M3 terminal

0 words 4 words Connectors

0 words M3 terminal

(8 words

depending on

mode)

I/O

connections

block

(made by

MOLEX)

block

(made by

MOLEX)

block

block

Unit

power

supply

voltage

24 VDC

(supplied

from outside)

Installa-

tion

DIN track GT1-AD04

Model number Remarks

(See note 2.)

GT1-AD08MX

GT1-DA04

(See note 2.)

GT1-DA04MX Outputs:

GT1-TS04T Inputs:

GT1-TS04P Inputs:

GT1-CT01 1 external

Inputs:

4 to

20 mA, 0

to 20 mA,

0 to 5 V,

1 to 5 V,

0 to 10 V,

–10 to

10 V

Outputs:

4 to

20 mA,

0 to 5 V,

1 to 5 V,

0 to 10 V,

–10 to

10 V

0 to 5 V,

1 to 5 V,

0 to 10 V,

–10 to

10 V

R, S, K, J,

T, B, L

Pt100,

JPt100

input

2 external

outputs

Note The front-panel indic ators and o ther parts of An alog Input Units, Analog O ut-

put Units, Temperature Input Units, and Counter Units differ from those of

other I/O Units. These Units belong to a group called Special I/O Units.

An end connector is attache d to the Communications Unit, and a 40-mm I/O

Unit Connecting Cable is included with each I/O Unit. A 1-m I/O Unit Connecting Cable (GCN1-100) is also available.

1 m

6

Page 20

MULTIPLE I/O TERMINAL Section 1-1

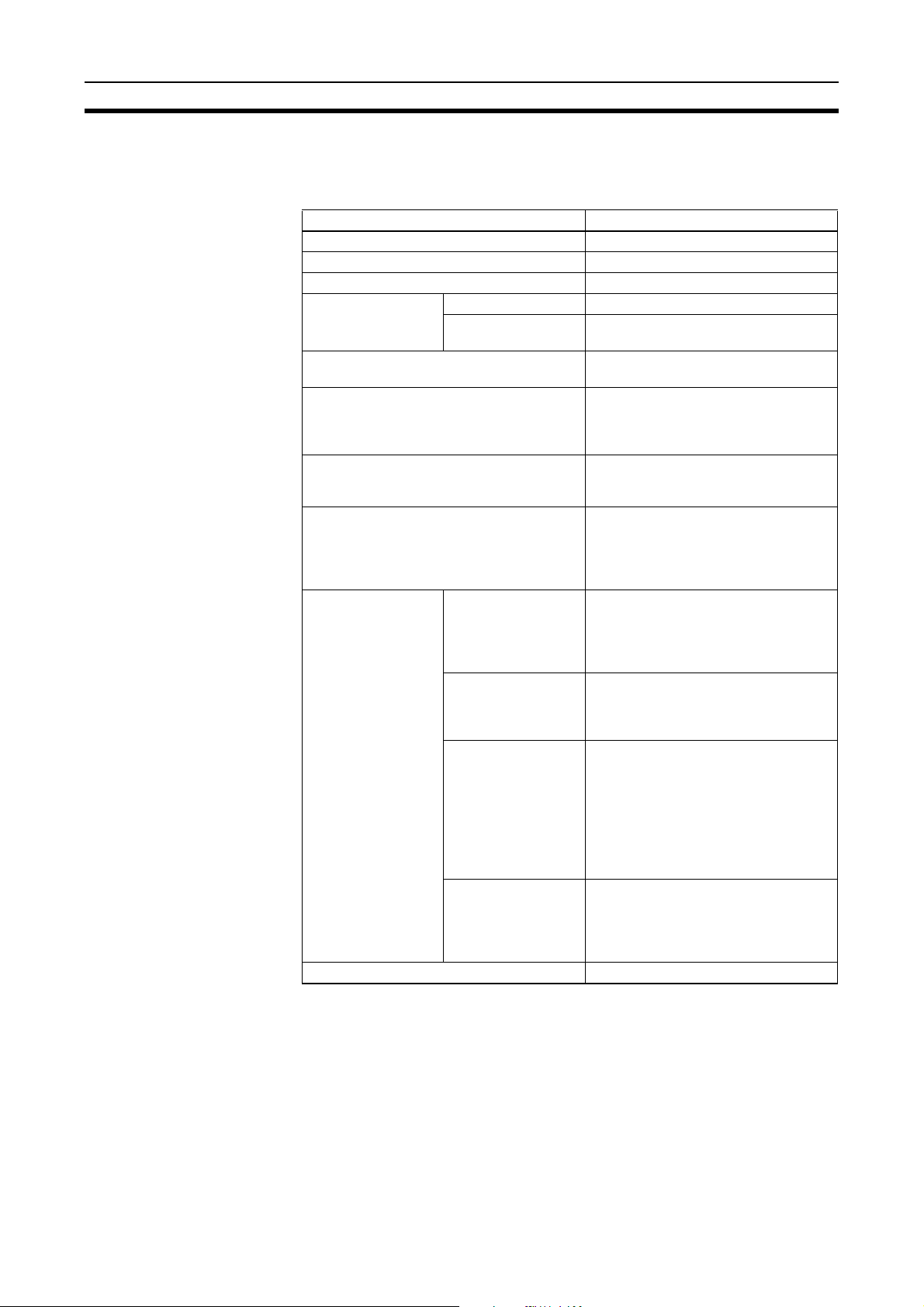

Applicable Connectors The applicable connectors are shown in the following table.

Connector Model number Remarks

Connectors made

by MOLEX

Connectors made

by

FUJITSU

corresponding to 16point connectors

Recommended

connectors

corresponding to 25pin D-sub

connectors

Connectors made

by

FUJITSU

corresponding to highdensity

connectors

Pressurewelded

Crimp Housing 51030-0330

Soldered FCN361J024-AU

Pressure-welded FCN367J024-AU/F

Crimp FCN363J024-AU

Hood XW2S-2513 OMRON

Plug XW2A-2501 OMRON

Soldered FCN361J040-AU

Pressure-welded FCN367J040-AU/F

Crimp FCN363J040-AU

Housing 52109-0390 For AWG#24

(See note.)

Reeled contacts

Loose contacts

Crimping tool 57036-5000 For AWG#22 to 26

50083-8014 For AWG#24 to 30

50084-8014 For AWG#22 to 24

50083-8114

(See note.)

50084-8114 For AWG#22 to 24

57037-5000

(See note.)

For AWG#24 to 30

For AWG#24 to 30

Note Refer to page 219, High-de ns ity Conn ector Cables for MULTIP LE I/ O TE RMI-

NALs for detai ls.

7

Page 21

Functions Section 1-2

1-2 Functions

1-2-1 I/O Unit Interface Specifications

Item Specification

Communications method Special protocol

Number of I/O Units 8 Units max.

Maximum number of points Total inputs/outputs: 1,024 points (bits)

Communications dis-

tance

Communications power supply Supplied from the Commu nications

Relationship to DeviceNet After the I/O Unit interface is estab-

Addresses Automaticall y recogn ized when the

I/O configuration Automaticall y rec ogn ized when the

Self-diagnostic functions

Error detection Frame error ch eck; CRC-CCITT check

Total length 3 m max.

Between Units 1 m max. (Cable included with Unit is

Configuration errors The I/O Unit configuration is constantly

Special I/O Unit

errors

I/O Unit interface

errors

Power supply overload to I/O Units

40 mm.)

Unit to the I/O Unit (0.4 A max.)

lished, Device Net co mm unica tion s continue normally, even if an error occurs

on the I/O Unit interface.

power to the Communi ca tio ns Unit is

turned ON.

power to the Communi ca tio ns Unit is

turned ON. If the configuration is

changed while the pow er sup ply is ON,

a configuration error will occur.

checked while power is supplied. If a

mismatch occurs while the power is

turned ON, I/O refreshing for all I/O

Units is stopped.

Errors are detected in the Special I/O

Units (Analog Input Units, Analog Output Units, Temperature Inpu t Units , and

Counter Units) on the I/O Unit interface.

Communications stop when there is no

communications response from an I/O

Unit.

Communications stop when there is no

specific response from the la st I/O Unit

(terminator).

Communications stop when nine or

more I/O Units are connected.

The power supply to the I/O Un its an d I/

O refreshing for all I/O Units are

stopped when the power supply to the

I/O Units through the Communications

Unit exceeds 0.4 A.

8

Page 22

Functions Section 1-2

I/O Interface Current

Consumption

Make sure that the power supply from the Communications Unit to the I/O

Units is less t han the total rated output cur rent (400 mA). The I/O in terface

current consumption for each I/O Unit is shown in the following table.

I/O Unit I/O interface current consumption

GT1-ID16(-1) 35 mA max.

GT1-ID16MX(-1) 35 mA max.

GT1-ID16ML(-1) 35 mA max.

GT1-ID16DS(-1) 35 mA max.

GT1-ID32ML(-1) 55 mA max.

GT1-OD16(-1 ) 35 mA max.

GT1-OD16MX(-1) 35 mA max.

GT1-OD16ML(-1) 35 mA max.

GT1-OD16DS(-1) 35 mA max.

GT1-OD32ML(-1) 65 mA max.

GT1-ROP08 40 mA max.

GT1-ROS16 50 mA max.

GT1-AD04 50 mA max.

GT1-AD08MX 50 mA max.

GT1-DA04 50 mA max.

GT1-DA04MX 50 mA max.

GT1-TS04T 50 mA max.

GT1-TS04P 50 mA max.

GT1-CT01 90 mA max.

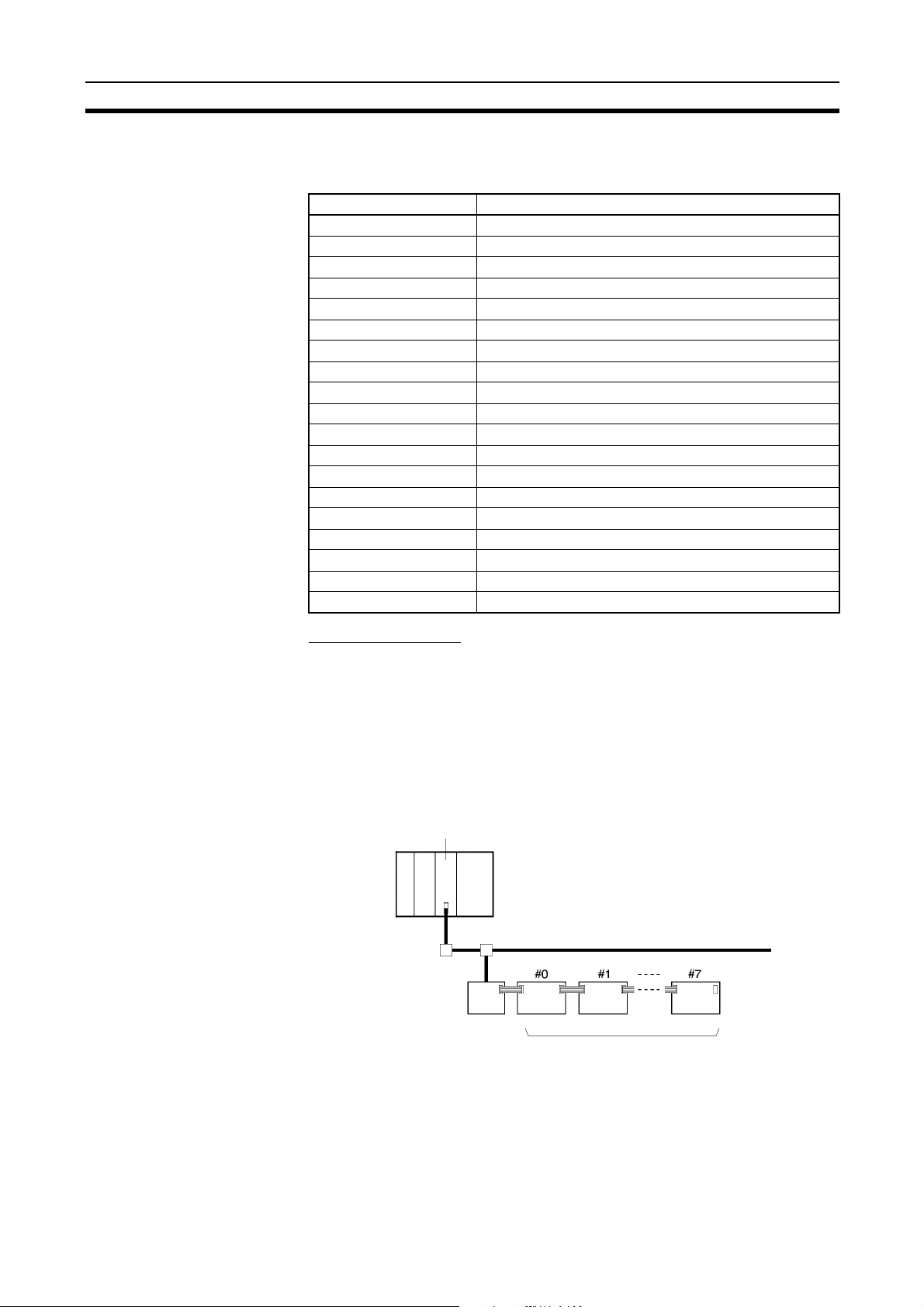

I/O Unit Interface

Addresses

Calculation Example

When five GT1-ID32ML Input Units and three GT1-OD16 Output Units are

used, the total current consumption is calculated as follows:

(GT1-ID32ML current consumption) x 5 Units

+ (GT1-OD16 current consumption) x 3 Units

= 55 mA x 5 + 35 mA x 3 = 380 mA

≤ 400 mA

The addresses of the I/O U nits on the I/O Unit interface are automati cally se t

when the Communications Unit is started. The addres ses are from 0 to 7 in

ascending order from the I/O Units closest to the Communications Unit.

DeviceNet Master Unit

DeviceNet Network

I/O Unit interface

Communications Unit

I/O Unit I/O Unit I/O Unit

Checking the I/O Unit

Interface Status

The following two methods are used to check the I/O Unit interface status:

• Checking the Communications Unit and I/O Unit indicators

• Checking the status of the Communications Unit

9

Page 23

Functions Section 1-2

Indicators

DeviceNet

Network

Communications Unit

TS indicator

I/O Unit I/O Unit

Unit Normal Error

Communications

Unit

TS Indicator:

Lit green

TS indicator

I/O Unit interface error: Lit red

Special I/O Unit error: Flashing green

Maximum power supply

overload to I/O Units: Not lit

I/O Units TS indicator:

Lit green

U.ERR indica-

tor: Not lit

PWR indicator:

Lit green

TS indicator

I/O Unit interface error: Lit red

U.ERR indicator

Special I/O Unit error: Lit red

PWR indicator

No internal power supply: Not lit

For details, refer to page 199, Troubleshooting via Indicators.

Checking the I/O Unit Interface Status

The first two words of the CPU Unit all ocatio n in put area are always allocated

to the status of the I/O Unit interface via the DeviceNet.

DeviceNet Master Unit

Communications Unit

Output

Input

area

area

DeviceNet Network

I/O Unit I/O Unit

Status, two words

0 wd

I/O Unit connection information

Error slaves Registered slaves

+1 wd

For details, see page 15.

1-2-2 Ex changing Data

Initialization When the Communications Unit is started, it automatically recognizes the

configuration of the I/O Units and registers this status as the n ormal co nfiguration (in RAM memor y). At the same time, addr esses 0 to 7 are alloca ted to

the I/O Units in ascend ing order from the I/O Unit c losest to the Communications Unit. The se pr ocesses are performed ea ch t im e th e p ower is turned ON.

10

Page 24

Functions Section 1-2

Remote I/O communications with the DeviceNet Master Uni t are carried out

by a MULTIPLE I/O TERMINAL base d on the registered co nfiguration. Whe n

the power to the Communications Unit is turned ON, the bits allocated to the I/

O Units can be used to check the status (bits 0 to 7 of the first word) of the

Communications Unit.

DeviceNet Network

Communications Unit

At startup

I/O Unit I/O Unit I/O Unit

Automatically recognizes the configuration of the

I/O Units

Communications with the DeviceNet Master Unit

based on this I/O configuration

Note 1. If the configuration of the I/O Units is to be changed, a number of pr ecau-

tions must be noted. For details, see 1-2-5 I/O Configuration Changes.

2. For details of data exchange timing, see 6-1-1 I/O Response Time.

Error Processing Even if an error occurs in the I/O Unit interface after initialization is completed,

DeviceNet communications will continue normally. Therefore, an error processing program section must be included in the CPU Unit to check the status

of the Communications Unit for errors that have occurred and to identify the

error type and location.

1-2-3 Allocating I/O

This section explains how words for a MULTIPLE I/O TERMINAL are allocated in the output area and input area of the Master. For details of remote I/O

functions in the output area and input area of the Master such as word specification, fixed allocation, and user-set al loca tio n, refer to the DeviceNet Opera-

tion Manual (W267).

Fixed Allocation The output area and i nput area corresponding to the Communica tions Unit

node number for a MULTIP LE I/O TERMINAL are as shown in the following

diagram.

Output Area

The output area contains outp ut bits in the orde r that I/O Units are co nnecte d

on the I/O Unit interface.

Input Area

The input area contains the Communications Unit status (two words), and

input bits in the order that I/O Units are connected on the I/O Unit interface.

Output area Input area

Area corresponding to

Communications Unit

node number

Output bits on

the I/O Unit

interface

I/O Unit interface

status

Input bits on the I/O

Unit interface

The input and output bits for the I/O Unit interface are allocated in the

DeviceNet input and output a reas in 16-p oint (one word) increments. With 8point I/O Units, these bits are alloc ated using the r ightmost byte (bits 0 to 7) ,

and the leftmost byte (bits 8 to 15) will be 00 Hex.

11

Page 25

Functions Section 1-2

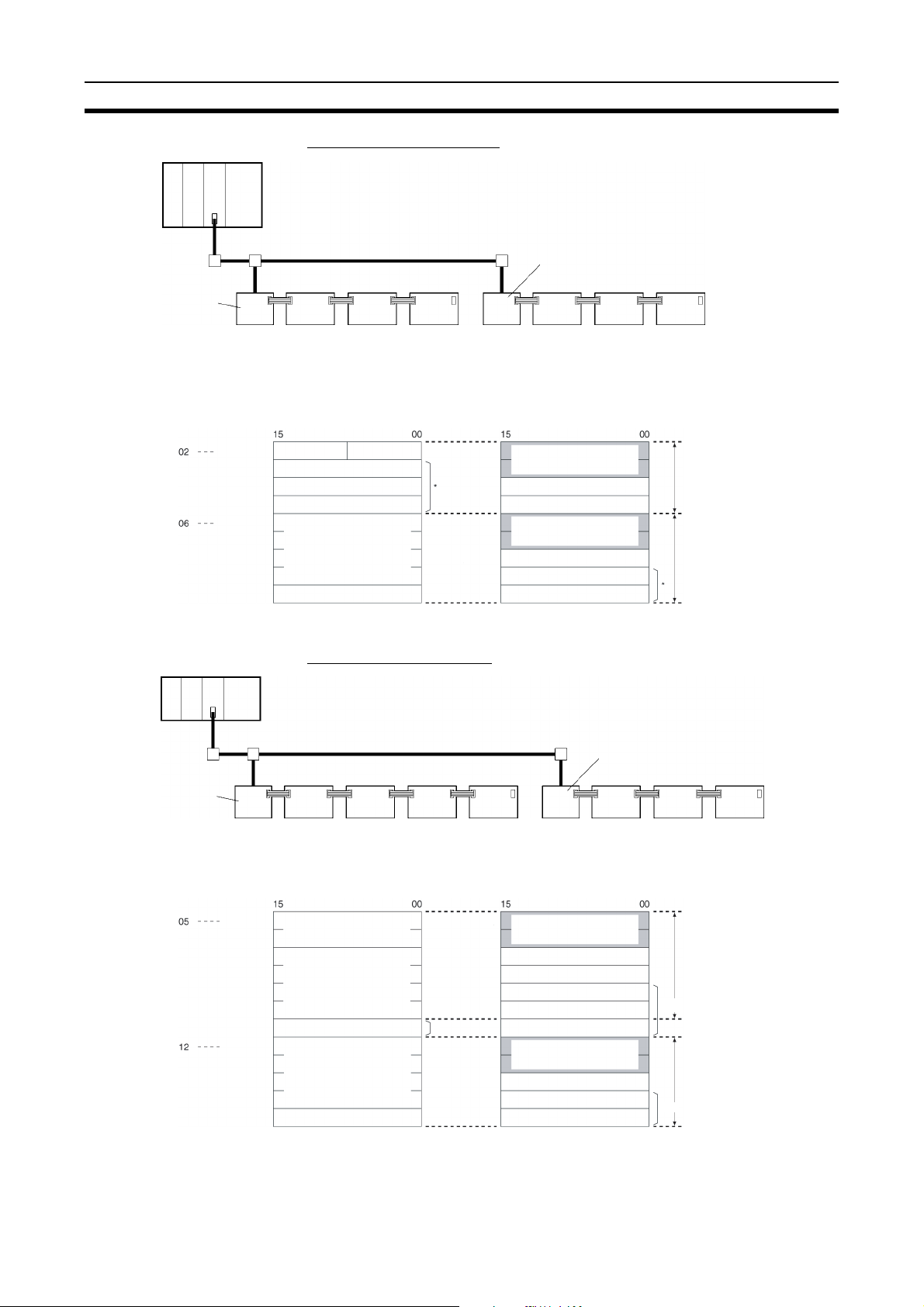

Example: CVM1/CV Series

Communications Unit

node number 02

I/O Unit

addresses

Communications Unit

node number

CIO 1902

CIO 1903

CIO 1904

CIO 1905

CIO 1906

CIO 1907

CIO 1908

CIO 1909

CIO 1910

DeviceNet Network

#0

16 inputs#18 outputs#216 inputs

Output area Input area

00 Hex

8 output bits for

Unit #1

Unused

Unused

Unused

CIO 2002

CIO 2003

CIO 2004

CIO 2005

16 input bits for Unit #0

16 input bits for Unit #2

CIO 2006

4 analog

outputs for

Unit #1

CIO 2007

CIO 2008

16 input bits for Unit #0

CIO 2009

16 output bits for Unit #2

CIO 2010

The unused words can be used as work bits.

Example: C200HX/HG/HE

Communications Unit

node number 06

#0

16 inputs

I/O Unit interface status

for node number 02

I/O Unit interface status

for node number 06

#1

4-point

Analog

Output

Unit

Unused

Unused

#2

16 outputs

Area allocated to

Communications Unit

for node number 02

Area allocated to

Communications Unit

for node number 06

Communications Unit

node number 05

I/O Unit

addresses

Communications Unit

node number

DeviceNet Network

#0

32 outputs

#1

4-point

Analog

Output Unit

#2

16 inputs

#3

16 inputs

Communications Unit

node number 12

#0

16 inputs#14-point

Analog

Output Unit

Output area Input area

(See

note 1.)

CIO 355

CIO 356

CIO 357

CIO 358

CIO 359

CIO 360

CIO 361

CIO 362

CIO 363

CIO 364

CIO 365

CIO 366

I/O Unit interface status

for node number 05

16 input bits for Unit #2

16 input bits for Unit #3

Unused

Unused

Unused

I/O Unit interface status

for node number 12

16 input bits for Unit #0

Unused

Unused

Area allocated to

Communications Unit

for node number 05

(See note 1.)

Area allocated to

Communications Unit

for node number 12

(See note 2.)

CIO 55

CIO 56

CIO 57

CIO 58

CIO 59

CIO 60

CIO 61

CIO 62

CIO 63

CIO 64

CIO 65

CIO 66

32 output bits for

Unit #0

4 analog outputs

for Unit #1

Unused

4 analog outputs

for Unit #1

16 output bits for Unit #2

Note 1. The unused words between I/O areas that are used cannot be used as work bits.

2. The unused words (not between I/O areas that are used) can be used as work bits.

#2

32 outputs

12

Page 26

Functions Section 1-2

User-set Allocation The Configurator can be used to set the Communi cations Unit node number,

first word, and number of bytes to all ocate (allocation size) for input block 1

and 2 and for output block 1 and 2, as shown in the following diagram.

Output block 1 or 2: Output bits in the order I/O Units are connected on

the I/O Unit interface

Input block 1 or 2: I/O Unit interface status (two words), and input bits in

the order I/O Units are connected on the I/O Unit

interface

Communications Unit

node number 02

I/O Unit

addresses

Allocation settings for node number 02

First word: CIO 1952

Allocation size: 2 bytes (1 word)

Allocation settings for node number 06

First word: CIO 1954

Allocation size: 10 bytes (5 words)

Output block 1 or 2

First word

Output bits on the

I/O Unit interface

Example: CVM1/CV Series

DeviceNet Network

#0

16 inputs

#1

8 outputs

# 2

16 inputs

Input block 1 or 2

First word

Allocation size

Communications Unit

node number 06

#0

16 inputs

Allocation settings for node number 02

First word: CIO 1904

Allocation size: 8 bytes (4 words)

Allocation settings for node number 06

First word: CIO 1901

Allocation size: 6 bytes (3 words)

I/O Unit interface

status

Input bits on the

I/O Unit interface

#1

4-point

Analog

Output Unit

#2

16 outputs

Allocation size

First word

of node

number 02

First word

of node

number 06

CIO 1950

CIO 1951

CIO 1952

CIO 1953

CIO 1954

CIO 1955

CIO 1956

CIO 1957

CIO 1958

Output block 2

00 Hex

4 analog outputs

for Unit #1

16 input bits for Unit #2

8output bits for

Unit #1

First word

of node

number 06

Size of node

number 02

First word

of node

number 02

Size of node

number 06

CIO 1900

CIO 1901

CIO 1902

CIO 1903

CIO 1904

CIO 1905

CIO 1906

CIO 1907

Input block 1

I/O Unit interface status

for node number 06

16 input bits for Unit #0

I/O Unit interface status

for node number 02

16 input bits for Unit #0

16 input bits for Unit #2

Size of node

number 06

Size of node

number 02

13

Page 27

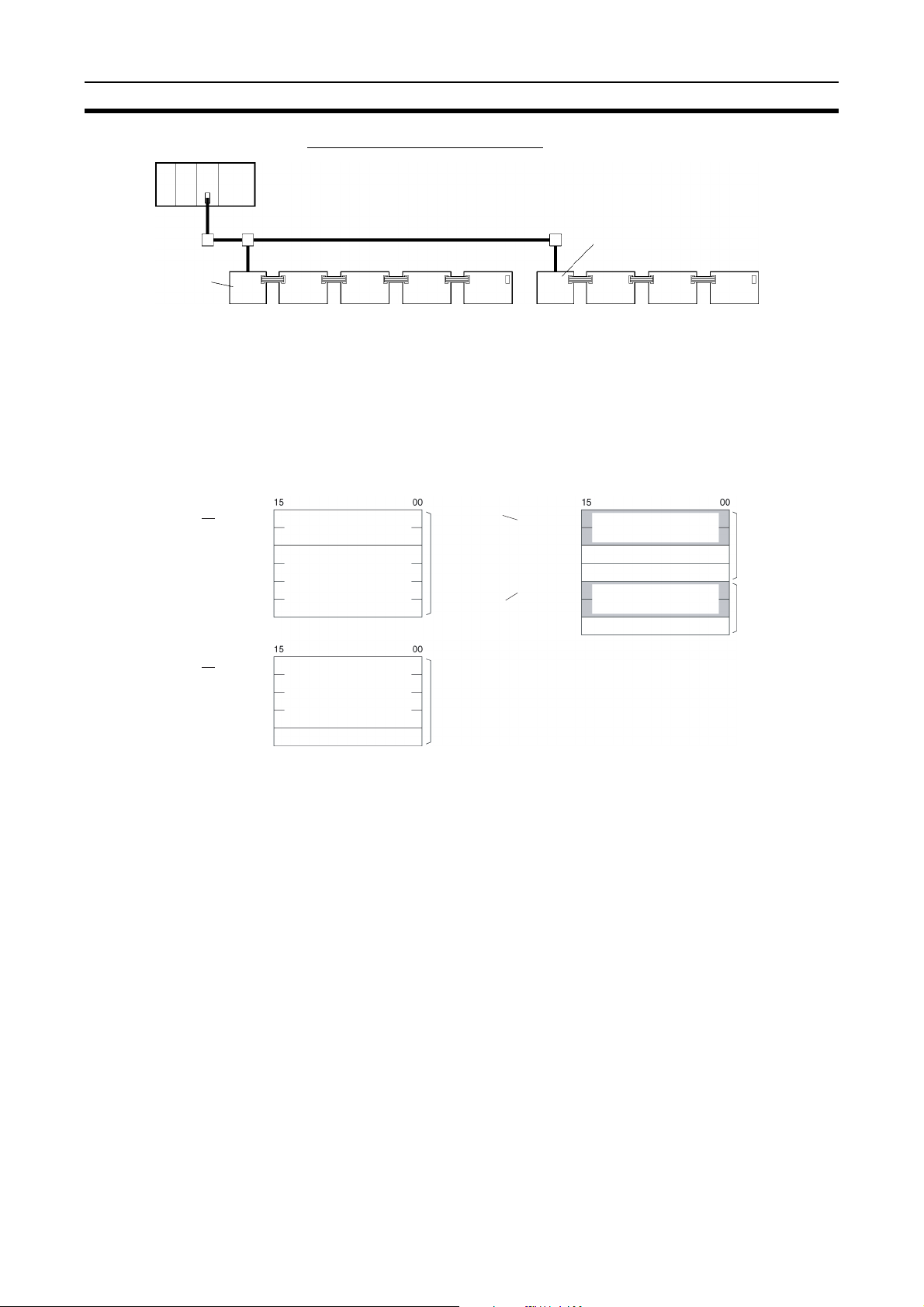

Functions Section 1-2

Example: C200HX/HG/HE Series

Communications Unit

node number 05

I/O Unit

addresses

First word

of node

number 05

First word

of node

number 12

DeviceNet Network

#0

32 outputs

Allocation settings for node number 05

First word: CIO 50

Allocation size: 12 bytes (6 words)

Allocation settings for node number 12

First word: CIO 120

Allocation size: 10 bytes (5 words)

CIO 50

CIO 51

CIO 52

CIO 53

CIO 54

CIO 55

CIO 120

CIO 121

CIO 122

CIO 123

CIO 124

32 output bits for

Unit #0

16 output bits for Unit #2

#1

4-point

Analog

Output Unit

Output block 1

4 analog outputs

for Unit #1

Output block 2

4 analog outputs

for Unit #1

#2

16 outputs

# 3

16 inputs

First word

of node

number 05

Size of node

number 05

First word

of node

number 12

Size of node

number 12

Communications Unit

node number 12

#0

16 outputs

Allocation settings for node number 05

First word: CIO 360

Allocation size: 3 bytes (4 words)

Allocation settings for node number 12

First word: CIO 363

Allocation size: 8 bytes (3 words)

CIO 360

CIO 361

CIO 362

CIO 362

CIO 363

CIO 364

CIO 365

16 input bits for Unit #2

16 input bits for Unit #3

16 input bits for Unit #0

#1

4-point

Analog

Output Unit

Input block 1

I/O Unit interface status

for node number 05

I/O Unit interface status

for node number 12

#2

16 outputs

Size of node

number 05

Size of node

number 12

14

Page 28

Functions Section 1-2

Allocation Precautions Note the following precautions when starting the DeviceNet Network.

Limits on the Total Number of Input and Output Points for a Master Unit

A maximum of 1,024 in puts and outpu ts can be c ontrolled by one Com munications Unit (DRT1-COM). The number of I/O points for each node, however,

depends on the Master Unit. For example, with the CV-series Master Unit

(CVM1-DRM21-V1) or the C200HX/HG/HE and C200HS Master Unit

(C200HW-DRM21-V1), up to 512 inputs and up to 512 outputs can be used at

each node. Therefore, connect I/O Uni ts within a range that does not exceed

the number of I/O points for each Master Unit node. The following table shows

the I/O size of each Unit.

Unit model Number of

inputs

DRT1-COM 32 points 0 point

GT1-ID16(-1), GT1-ID16MX(-1), GT1-ID16ML(-1)*,

GT1-ID16DS(-1)*

GT1-OD16(-1), GT1-OD16MX(-1), GT1-OD16ML(-1)*,

GT1-OD16DS(-1)*, GT1-ROS16, GT1-ROP08

GT1-ID32ML(-1) 32 points 0 point

GT1-OD32ML(-1) 0 points 32 points

GT1-AD04* 64 points 0 points

GT1-AD08MX (With 8-input mode) 128 points 0 points

GT1-AD08MX (With 4-input mode) 64 points 0 points

GT1-DA04*, GT1-DA04MX 0 points 64 points

GT1-TS04T, GT1-TS04P (With Normal Mode) 64 points 0 points

GT1-TS04T, GT1-TS04P (With 2-decimal-place Mode) 128 points 0 points

GT1-CT01 48 points 48 points

16 points 0 point

0 points 16 points

Number of

outputs

The GT1-ROP08 (Relay Output Unit with Power Relay) has 8 actual outputs

but, as a MULTIPL E I/O TERMINAL, the number of outputs allocated to the

Master Unit is 16.

Calculation Example

When one GT1-DA04MX Analog Output Unit and three GT1-AD08 Analog

Input Units are used, th e tot al num ber of inp u t p oin ts and outp ut p oin ts is calculated as follows:

Total Number of Input Points:

Communications Unit (Status) + Analog Input Units x 3

= 32 points + 128 points x 3 = 416 points

Total Number of Output Points:

Analog Output Units x 1

= 64 points

Reference

For information on dealing with oth er problems c onc erning the MULTIPLE I/O

TERMINAL, refer to SECTION 7 Troubleshooting and Maintenance. For information on problems concer ning the DeviceNet, refer to DeviceNet Operation

Manual (W267).

1-2-4 I/O Unit Interface Status

The following I/O Unit interface status is maintained in the CPU Unit.

• I/O Unit connection information (I/O Unit interface status)

• Registered I/O Unit addresses

15

Page 29

Functions Section 1-2

• Error I/O Unit addresses

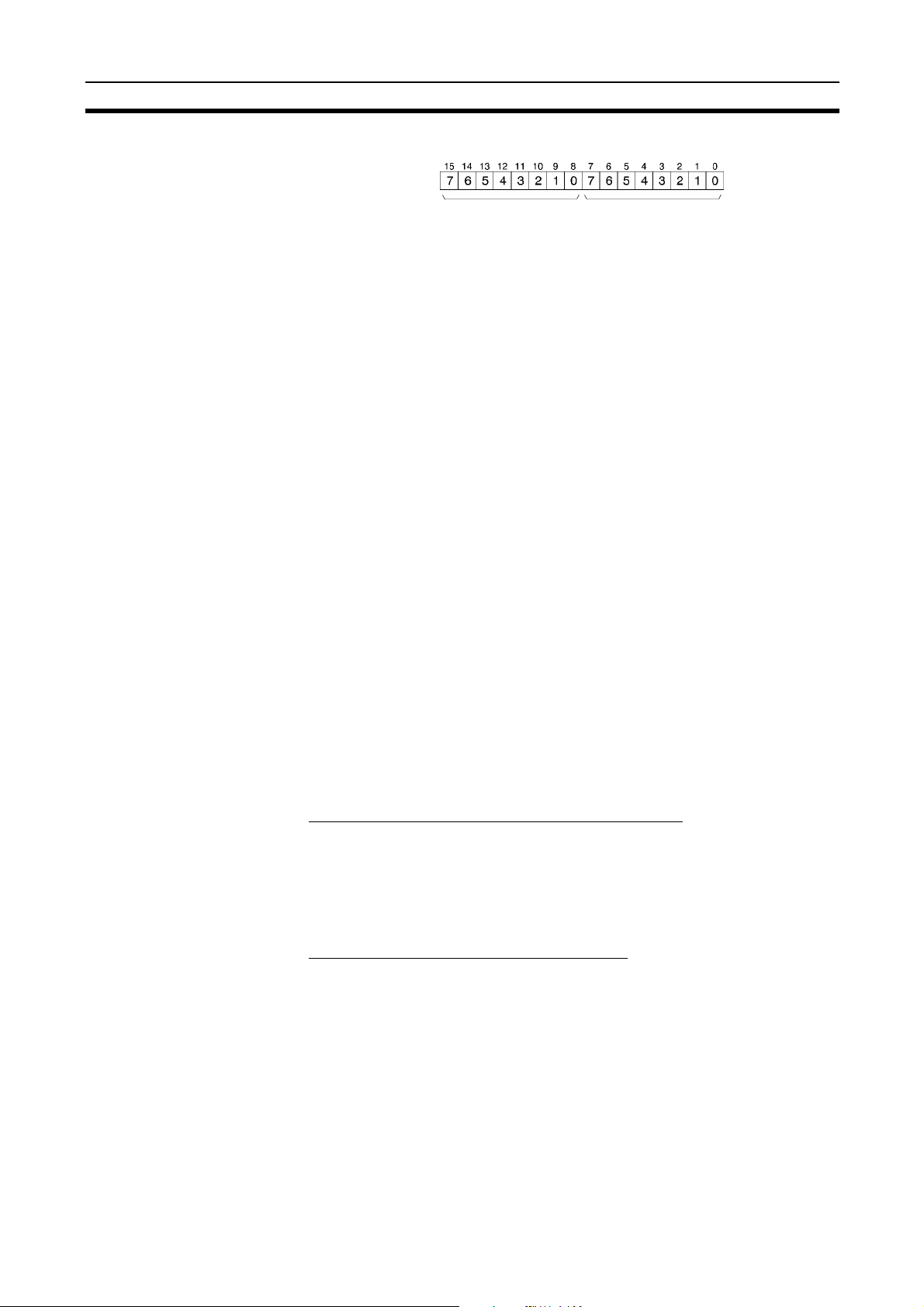

As shown in the following diagram, the status consists of two words. The first

two words of the Communic ations Unit alloc ation input are a in the CPU Uni t

are allocated for this status. Include a program section in the CPU Unit to

check this status and perform error processing.

I/O Unit Connection Information

0 wd

1: Error (OR of bits 0 to 4)

1: Refreshing I/O

Bit Flag name Meaning Content

15 Refreshing I/O Refreshing I/O 1: Communications between the

14 Error OR of bits 0 to 4 1: Any one of bits 0 to 4 is ON

4 High-density

I/O Unit Error

3 I/O Unit Pow er

Supply Overload

2 I/O Unit Inter-

face Error

1 Configuration

Error

0 Special I/O

Unit Error

0 wd

+1 wd

A high-density I/O Un it error w as

detected.

An overcurrent to an I/O Unit

was detected.

An I/O Unit interface error was

detected.

Data Transfer Error:

In the I/O Unit interfa ce, there

was no response to a command after the fixed time has

elapsed. Alternatively, the

response expected to be

returned from the end I/O Unit

(terminator) was not received.

Too many I /O Units:

Nine or more I/O Units are

connected.

The I/O con figuration was

changed when the Communications Unit was started.

An error occurred in a Special

I/O Unit.

Error I/O Unit addresses Registered I/O Unit addresses

I/O Unit connection information

Bit

1: Special I/O Unit Error

1: Configuration Error

1: I/O Unit Interface Error

1: I/O Unit Power Supply Overload

1: High-density I/O Unit Error

Communications Unit and I/O Units

is normal.

0: Communications error (no

response is received from an I/O

Unit)

0: Bits 0 to 4 are all OFF

1: Unit error

0: Unit normal

1: Overcurrent detected

0: Normal

1: I/O Unit interface error

0: Normal

1: I/O configuration change during

startup

0: No I/O configuration change during

startup

1: Special I/O Unit error

0: Special I/O Unit normal

16

Page 30

Functions Section 1-2

Abnormal I/O Unit Addresses and Registered I/O Unit Addresses

Bit

+1 wd

1-2-5 I/O Configuration Changes

The I/O Unit interface automatically recognizes the I/O Unit configuration each

time the Communications Unit is star ted up, and stores this as the normal

configuration.

Note 1. If the I/O Unit configuration is c hanged wh ile the Communications Unit is

turned ON, a configuration error will occur. Do not change the I/O Unit configuration while power is being supplied to the Communications Unit.

2. If a configuration error occurs on the I/O Unit interface, I/O refreshing of all

I/O Units will stop. Even if a configuration er ror occurs, communications

with the DeviceNet Network will continue, using the initial I/O Unit configuration. An error processi ng p rogram se cti on mus t the re fore be includ ed i n

the CPU Unit to regular ly check whether or not a configuratio n error has

occurred (status bit 1) and to process abnormal I/O Unit addresses.

If the I/O Unit configuration is changed, perform the following operations,

according to the DeviceNet area al loc at ion meth od. For details abou t I/O all ocation, refer to DeviceNet Operation Manual (W267).

The bits corresponding

to I/O Unit with errors

are turned ON. Bits 8 to

15 correspond to

addresses 0 to 7.

1: Error

0: No error, or not

part of network

The bits corresponding

to registered I/O Units

are turned ON. Bits 0 to

7 correspond to

addresses 0 to 7.

1: Registered

0: Not registered

Default Allocations Because the allocation size of the Communications Unit changes together

with changes to th e I/O Unit configuration, a verification er ror will occur on

DeviceNet if the scan list is enabled, as follows:

• Master Unit 7-segment display will show d6, Slave I/O size mismatch.

• Master status bits 14 and 7 will turn ON.

Perform the following operations, according to the status of the input/output

areas.

Allocation Areas Do Not Overlap with Other Slaves

Remote I/O communication s will be performed unchanged wi th the new configurat io n. C heck the V erif ic at i o n Error Bit and, if require d, pe r form processing

to disable the allocated words in the CPU Unit. Also check the number of

points for the changed I/O Unit and its allocation ar ea on the I/O Unit interface, and re-register the scan list (first set the Scan List Enable software

switch to OFF, and then set it to ON after checking the I/O size).

Allocation Areas Overlap with Other Slaves

In this case, I/O area duplication will also occur on the DeviceNet, as follows:

• Master Unit 7-segment display will show d0, I/O area duplication.

• Master status bits 14 and 4 will turn ON.

Check the Verification Error Bit, and per form processing to disable the allocated words in the CPU Unit. Also ch ang e the S lave node number so that th e

allocation area doe s not overlap with any other, and re-register the sca n list

(first set the Scan Lis t Enable software switch to OFF, and then set it to ON

after checking the I/O size).

Note If the scan list is disabled, there will be no changes made in the DeviceNet

Master Unit, even if the Communication s Unit input/output sizes ch ange. Be

sure to use the Scan List Enable Mode for normal operations.

17

Page 31

Functions Section 1-2

User-set Allocations The sizes of the allocated areas for the Communications Unit will change with

changes to the I/O Un it con figuration , ca using a Verification Error to occur o n

DeviceNet if the scan list is enabled, as follows:

• Master Unit 7-segment display will show d6, a Slave I/O size mismatch.

• Master status bits 14 and 7 will turn ON.

Perform the following operations, according to the status of the input/output

areas.

Allocation Areas Do Not Overlap with Other Slaves

Remote I/O communication s will be performed unchanged wi th the new configuration data. Check the Verification Error Bit and , if required, perform processing to disable the allocated words in the CPU Unit. A lso, perform change

the allocations using the Configurator.

Allocation Areas Not Overlap with Other Slaves

In this case, I/O area duplication will also occur on the DeviceNet, as follows:

• Master Unit 7-segment display will show d0, I/O area duplication.

• Master status bits 14 and 4 will turn ON.

Check the Verification Error Bit, and per form processing to disable the allocated words in the CPU Unit. Also, perform change allocations using the Configurator.

18

Page 32

Hardware Setup and Operational Check

This section provides the basic procedure for operation and includes an actual example.

2-1 Basic Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-2 Specific Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SECTION 2

19

Page 33

Basic Procedure Section 2-1

2-1 Basic Procedure

The basic operating procedure is shown below. For details about settings and

connections, re fer to DeviceNet Operation Manual (W267). For explanations

about Slave Units, refer to SECTION 4 Basic I/O Unit Specifications and SEC-

TION 5 Special I/O Unit Specifications.

Inputs: Number of points/input type/connection type

1

Determine the MULTIPLE

I/O TERMINAL I/O

specifications.

Outputs: Number of points/input type/connection type

Analog inputs: Number of points

Analog outputs: Number of points

Temperature inputs: Number of points

Pulse inputs (counter): Number of points

2

Select the I/O Units.

3

Check the specifications.

4

Mount and connect the

Communications Unit and

I/O Units.

Set the DIP switches for the

5

Communications Unit,

Analog Input Units, Analog

Output Units, and

Temperature Input Units.

6

Connect to the DeviceNet

Master Unit.

Communications

Unit (1)

+

Transistor Input

Terminal

Connec-

block

tor

16 points 16 points 32 points 16 points 16 points 32 points 16 points 8 points 4 points8 points

Unit

Unit Unit Unit Unit Unit Unit Unit Unit Unit

High-density connector

+

Terminal

block

Transistor Output

Connec-

High-den-

tor

sity connector

Relay Output Analog

Terminal

block

+

Input Output

Analog

Counter

Input

1 points

Unit

The combined total of input points and output points for each Communications Unit is 1,024 max.

The total current supplied from the Communications Unit to each I/O Unit (I/O Unit interface current

consumption) is 0.4 A max.

Mount Units on DIN track (DIN 35-mm track: all Units).

Connect I/O Unit Connecting Cabled and end connector.

Connect Communications Unit internal power supply (24 VDC −15%/+10%).

Connect I/O power supply (24 VDC −15%/+10%) for each Transistor Input/Output Unit and Relay

Output Unit.

Connect I/O power supply (24 VDC −15%/+10%) for each Analog Input/Output Unit and

Temperature Input Unit, as well as power supply for each Counter Unit encoder, using a separate

power supply from the above.

Connect I/O to each I/O Unit.

Set the node number of the Communications Unit as a DeviceNet Slave, and the hold/clear output

settings for the baud rate and communications errors.

Set the Analog Input Unit, Analog Output Unit, and Temperature Input Unit ranges and other

specifications. (When setting the Analog Input Unit, Analog Output Unit, and Temperature Input

Unit ranges from the Configurator, set the DIP switch to Software Setting Enable.)

Connect the Communications Unit to the DeviceNet Master Unit using the DeviceNet

Communications Cable.

7

Turn ON the power.

8

Set using the Configurator.

9

Set the Scan List Enable

switch.

10

Check the operation.

20

Turn ON the PC power supply.

Turn ON the DeviceNet communications power supply.

Turn ON the Communications Unit internal power supply.

Turn ON the I/O power supply to individual I/O Units.

Set as required for the Communications Unit, Analog Input Units, Analog Output Units, and

Temperature Input Units using the DeviceNet Configurator (versions 1.11 and later).

Set to enable the DeviceNet Master Unit scan list (from a PC Peripheral Device or

the Configurator).

Check the I/O Unit interface status.

Check the indicators on all Units.

The following indications are normal:

Communications Unit MS indicator: Lit green

Communications Unit NS indicator: Lit green

TS indicators for I/O Units: Lit green

Check that the data for the I/O words allocated in the I/O memory (with default allocations, in the

DeviceNet area) of the CPU Unit of the PC is being correctly read and written by the CPU Unit.

Page 34

Specific Example Section 2-2

2-2 Specific Example

1,2,3... 1. Determine the MULTIPLE I/O TERMINAL I/O specifications.

Each Communications Unit for the MUL TIPLE I/O TERMINAL can be connected to a combined total of 1,024 input and output points (64 words)

max. (This figure does not incl ude the 2 words of the inp ut area all ocate d

to the I/O Unit interface status.)

In this example, the following configuration will be used:

• Inputs: 16 points

• Outputs : 16 points

• Analog Input: 8 inputs (8 words)

• Analog Output: 4 outputs(4 words)

2. Select the I/O Units.

• DRT1-COM Communications Unit: 1 Unit

• GT1-ID16 Transistor Input Unit, 16 points with terminal block: 1 Unit

• GT1-OD16MX Transistor Output Unit, 16 points with connector:1 Unit

• GT1-AD08MX Analog Input Unit, 8 inputs: 1 Unit

• GT1-DA04MX Analog Output Unit: 4 outputs: 1 Unit

3. Check the specifications.

• Check that the total number of input and output po in ts (words) is less

than 1,024 (64). In this example, the number of points is calculated as

follows:

Inputs (16 poin ts) + O utp uts (16 points) + Anal og Inp ut (8 wor ds x 1 6

points) + Analog Output (4 words x 16 points)

= 224 points

Note There are DeviceNet Master Units that have restrictions on the num-

ber of input and output points per Slave Unit. Make sure that the

number of input and output point s does not exceed the limit for the

Master Unit. (For example, the C200 HW-DRM21-V1 has an upper

limit of 512 for both input and output points.) The maximum number

of input and output points for the Master Unit, includ es the 2 words

allocated to the I/O Unit i nterface status. When calcula ting the total

number of input and output points, be sure to include this (32 points)

in the calculation.

• Check that the total I/O Unit interface current consumption is less than

0.4 A. In this example, the total is calculated as follows:

Transistor Input Unit (35 mA) + Transistor Output Unit (35 mA) + Analog Input Unit (50 mA) + Analog Output Unit (50mA)

=170 mA

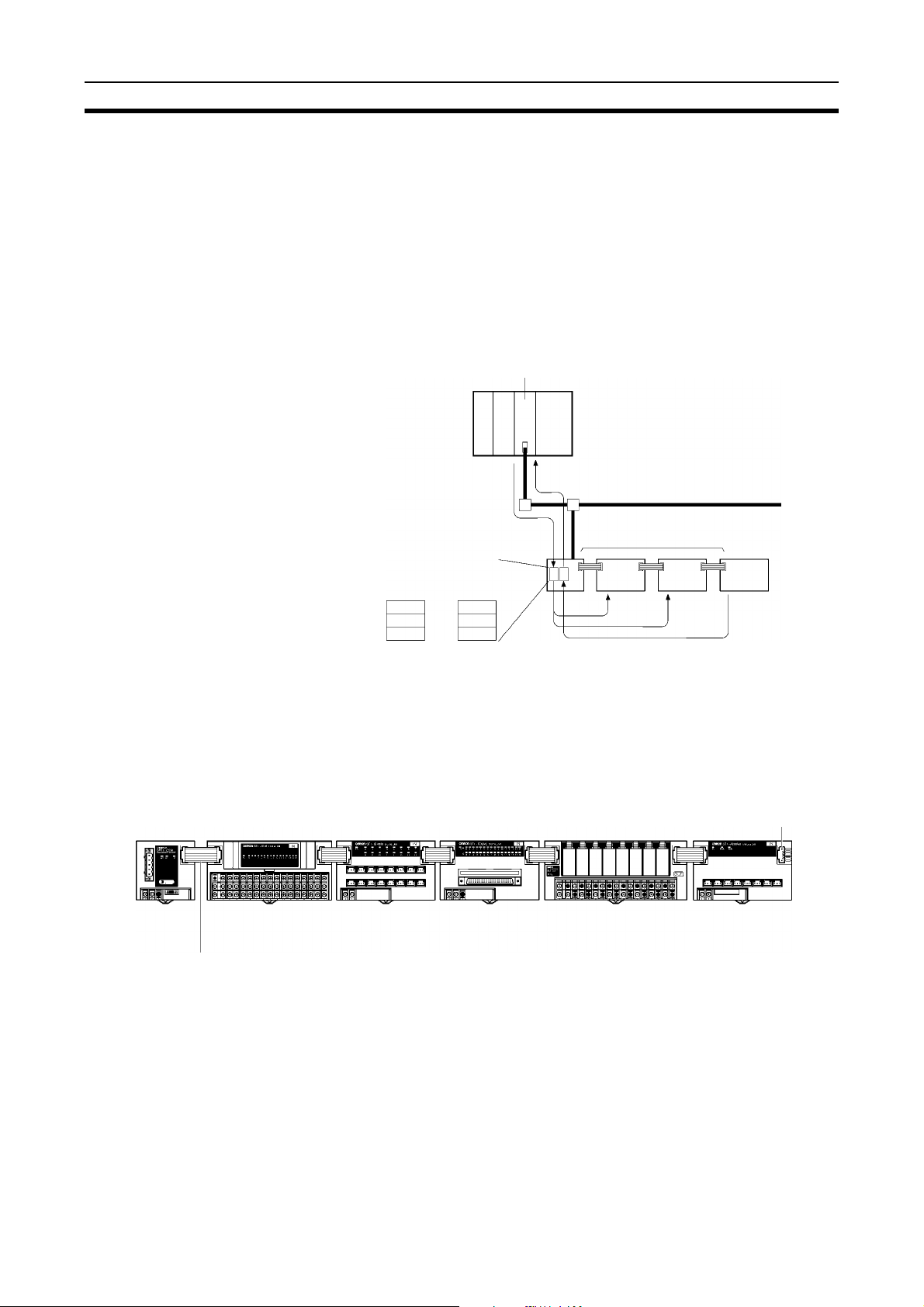

4. Mount and connect the Communications Unit and I/O Units.

• Mounting on the DIN Track

Communications

Unit

Transistor Input Unit:

with terminal block

Transistor Input Unit

with connector

Analog Input Unit

Analog Output Unit

DIN track

21

Page 35

Specific Example Section 2-2

• Connecting I/O Unit Connecting Cable

GT1-ID16

GT1-OD16MX

I/O Unit Connecting Cable

Standard cable: 40 mm

GCN1-100: 1 m

(One cable is included with

each I/O Unit.)

GT1-AD08MX

Same I/O Unit Connecting

Cable as at left

End connector

(One is provided with the

Communications Unit.)

To connect each pair of Units, con nect I/ O Unit in terface communic ations

connector 2 o n the Unit cl oser t o the Co mmunica tions U nit to I/O U nit i nterface communications connector 1 on the Unit closer to the end Unit.

Note The connecting cable for the I/O Unit is shown below.

Accessory Cable

GT1-DA04MX

Communications

Unit

24-VDC

power supply

GCN1-100

Transistor Input Unit

with terminal block

24-VDC

power supply

40 mm

1 m

• Connecting Communications Unit and I/O Unit Power

Transistor Input Unit

with connector

Analog Input Unit Analog Output Unit

24-VDC

power supply

Note Be sure to separate the communi cations power supply, the internal

power supply for the Communications Unit and the CPU Bus Unit,

and the power supplies for the I/O Units. If the same power supply is

used, malfunction due to noise may occur.

The capacity required for the Communications Unit internal power supply,

can be obtained using the following formula:

Communications Unit internal power supply current

= Communications Unit internal current consumption + Sum of I/O Unit Interface current consumption

22

Page 36

Specific Example Section 2-2

Note T he ab ove formula appl ies when a voltage o f 2 4 VDC is su ppl ie d t o

the Commun icati ons Un it int ernal po we r suppl y terminal s. If the su pplied voltage become s lower, the current c on su mpti on wi ll in cre as e.

Select a device for the power supply that will allow a degre e of variation.

When selecting a power supply, take inrush c urrent into consideration.

The following OMRON products are recommended for the 24-V DC

power supply:

S82K-05024: 100 to 120/200 to 240 VAC, 50 W

S82K-10024: 100 to 120/200 to 240 VAC, 100 W

S82J-5524: 100 to 120 VAC, 50 W

S82J-5024: 100 to 120 VAC, 100 W

For details of the I/O Unit interface current consumption for the Units,

refer to page 9, I/O Interface Current Consumption.

Select power supplies for the I/O Units that are suitable for the load currents to

be used and the Units’ internal drive currents (refer to page 41).

• Connecting I/O Units to I/O

Communications

Unit

Transistor Input Unit

with terminal block,

16 points

Transistor Output Unit

with connector,

16 points

Analog Input Unit,

8 input

Analog Output Unit,

4 outputs

5. Set the DIP switches for the Communications Unit, Analog Input Unit, and

Analog Output Unit.

Communications Unit Analog Input Unit Analog Output Unit

Node

number

Baud rate

Hold/clear

outputs for

communications

errors

Input range Operating

specifications

• Averaging

• 4 or 8 inputs

• Software Setting

Enable/Disable

Output

range

Operating

specifications

• Output when an

• Software Setting

Enable/Disable

I/O Unit interface

error occurs

Note a) If a DeviceNet Configurator (versions 1.1 1 and later) is used, the

input range for Analog Input Units, the output range for Analog

Output Uni ts, and I/O Unit int erf ace error ou tput (hig h-clear ou tput/

low-clear output) can be set via the network. When setting from

the Configurator, use the DIP switch to set the Software Setting

Enable/Disable setting to Enable. For details, refer to 5-1 An alog

Input Units and 5-2 Analog Output Units.

23

Page 37

Specific Example Section 2-2

b) You must also use the DIP switch a nd the Conf igurator to s et the

Temperature Input Unit. For details, refer to 5-3 GT1-TS04T and

GT1-TS04P Temperature Input Units.

Left side of

cassette

Operating specifications

• T emperature unit

• Number of decimal places used

• Enable/disable software settings

• Input type

• Input range

6. Connect to the DeviceNet Master Unit.

Communications

power supply

24 VDC

Communications

Unit

DeviceNet Network

Temperature Input Unit

I/O Unit

7. Turn ON the power.

8. Set using the Configurator.

Using version 1.11 or later versions of the DeviceNet Configurator, it is

possible, via the network, to set the following:

• Input range for Analog Input Units.

• Output range for Analog Output Units.

• I/O Unit i nterface error output (low-clear output/hi gh-clear output) for

Analog Output Units.

Note a) When using a DIP switch, the input and output ranges for the An-

alog Input and Output Units can be set in 2-point units, whereas

with a Configurator, a setting can be made for each point.

b) You can set the Temperature Input Unit input range as well as the

I/O Unit settings us in g th e Co nfi gura tor. For details, refer to 5-3-2

Settings Using the Configurator.

9. Create the scan list.

24

Set the Scan List Enable switch (PC software switch) to ON. For example,

for a DeviceNet Master Unit with unit address 0 installed in a C200HX/HG/

Page 38

Specific Example Section 2-2

HE(-Z) PC, turn ON IR 10000. For details of the DeviceNet startup procedure, refer to the DeviceNet Operation Manual (W267).

10. Check the operation.

• Checking Indicators

With normal operations, all indicators should be lit green.

MS NS

TS TS TS TS TS

U.ERR is

not lit.

U.ERR is

not lit.

IR 50

IR 51

IR 52

IR 53

IR 54

IR 55

IR 56

IR 57

IR 58

IR 59

IR 60

IR 61

IR 62

IR 63

Output area

For another node

16 outputs for Unit #1

4 analog outputs

for Unit #3

Unused

Unused

Unused

Unused

Unused

Unused

Unused

For another node

#0

Input:

16 points

#1

Output:

16 points

#2

Analog

input:

8 inputs

(words)

#3

Analog output:

4 outputs

(words)

• Checking the I/O Unit Interface Status

Example:

The following allocations will be used for status w hen the default allocations are used for a Communications Unit with node number 01 connected

to a C200HX/HG/HE(-Z) DeviceNet Master Unit with unit address 0.

Node

number

(First)

(Last)

Input area

For another node

I/O Unit interface

status

16 inputs for Unit #0

8 analog outputs

for Unit # 2

For another node

IR 350

IR 351

IR 352

IR 353

IR 354

IR 355

IR 356

IR 357

IR 358

IR 359

IR 360

IR 361

IR 362

IR 363

Check the I/O Unit

interface status. If

normal, the status

will be as follows:

IR 351

IR 352

• The first two words of the input a rea i s autom atica lly allo ca ted for the

I/O Unit interface status information. This allocation cannot be

changed.

• Words are alloca ted for the input/output data for each I/O U nit in the

order that the I/O Units are co nnec te d (I/O Un it in ter face address es 0

to 3) in the input area (input) and the output area (output).

• The in put/output areas are allocated in the words corresponding to

node numbers 01 to 11.

25

Page 39

This section provides some examples of programs used with the Counter Unit.

3-1 Examples of Counter Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3-1-1 Counter Unit Word Allocation for Functions. . . . . . . . . . . . . . . . . . 28

3-1-2 Present Count Value Reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-1-3 Counter Setting and Execution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-1-4 Count Restart Operation after Error Clearance . . . . . . . . . . . . . . . . 33

SECTION 3

Sample Programs

27

Page 40

Examples of Counter Unit Operation Section 3-1

3-1 Examples of Counter Unit Operation

This section, using the system configuration shown below as an example,

explains how to use the Counter Unit.

C200HW-DRM21-V1 Master Unit

(node number 0, unit number 0)

C200HX

DeviceNet Network

GT1-CT01

Counter Unit (#0)

DRT1-COM Communications Unit

(node number 1)

3-1-1 Counter Unit W ord Allocation for Functions

Setting and control for the Counter Unit is executed by writing to the allocate d

area in the output area of the Master, and status check and monitoring is executed by reading the alloc ated area in the input area of the Master. The allocated area for the Counter Unit, with the system configuration shown above, is

given below (this example is for fixed allocation). For details about area allocation for a MULTIPLE I/O TERM INAL (Communications Unit) on a DeviceNet

Master, refer to the DeviceNet Operatio n Manual (W267). For details about

area allocation for a Counter Unit in the area used by a MULTIPLE I/O TERMINAL, refer to 1-2-3 Allocating I/O.

Encoder

Communications

node number

CIO 51

CIO 52

CIO 53

CIO 54

CIO 55

Output area

Counter Unit #0

(For setting and

writing in)

Unused

Unused

CIO 351

CIO 352

CIO 353

CIO 354

CIO 355

Input area

I/O Unit interface status

for node number 01

Counter Unit #0

(For status check

and reading)

Functions are allocate d to the wo rds as sh own bel ow. This is only a basic list.

For details, refer to 5-4 GT1-CT01 Counter Unit.

28

Page 41

Examples of Counter Unit Operation Section 3-1

Output Area

• Hexadecimal

(Negative numbers specified with

the complement of 2 in 24 bits)

Wd n+0

Wd n+1

Wd n+2

Output area

Count Value

• BCD

(O: positive, F: negative)

Setting Value

• BCD

Output conditions:

000 Present value ≥ Set value

Not 000 Present value ≤ Set value

(O: positive, F: negative)

Bit

Bit 00: Set value 1 (0: Not set, 1: Set)

Bit 01: Set value 2 is set (0: Not set, 1: Set)

Bit 02: Count value is set (0: Not set, 1: Set)

Bit 03: Data code change (0: BCD, 1: Hex.)

Bit 04: Set value 1 reading (0: Not read, 1: Read)

Bit 05: Set value 2 reading (0: Not read, 1: Read)

Bit 06: Count value reading (0: Not read, 1: Read)

Bit 07: Internal resetting (0→1: Resetting)