Page 1

Cat. No. W476-E1-01

SmartSlice

GRT1-CRT

CompoNet Communications Unit

OPERATION MANUAL

Page 2

SmartSlice GRT1-CRT CompoNet Communications Unit

Operation Manual

Produced May 2008

Page 3

iv

Page 4

Introduction

Thank you for buying a SmartSlice CompoNet Communications Unit.

The CompoNet Communications Unit is an interface unit which complies with the CompoNet

standard. It connects SmartSlice I/O Units to a CompoNet Master Unit.

Be sure you understand the functions and performance of the Units fully before you use them.

Intended Audience

This manual is for the personnel below. This personnel must understand electrical systems (must

be an electrical engineer or the equivalent).

Personnel responsible for the selection of FA systems

Personnel responsible for the designs of FA systems

Personnel responsible for the installation of and connections in FA systems

Personnel responsible for the management of FA systems

Precaution

Introduction

This manual contains data which is necessary for you to use a CompoNet Communications Unit.

Read and understand this manual fully before you use the CompoNet Communications Unit. After

you read this manual, keep it in a safe location where it will be available for use when necessary.

Be sure that the end user of the CompoNet Communications Unit has this manual.

v

Page 5

Read and Understand this Manual

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship

for a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

vi

Page 6

Read and Understand this Manual

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions

or uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

vii

Page 7

Read and Understand this Manual

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

key specifications for your application on your request. Please consult with your OMRON representative

at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON's test conditions, and the users

must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

viii

Page 8

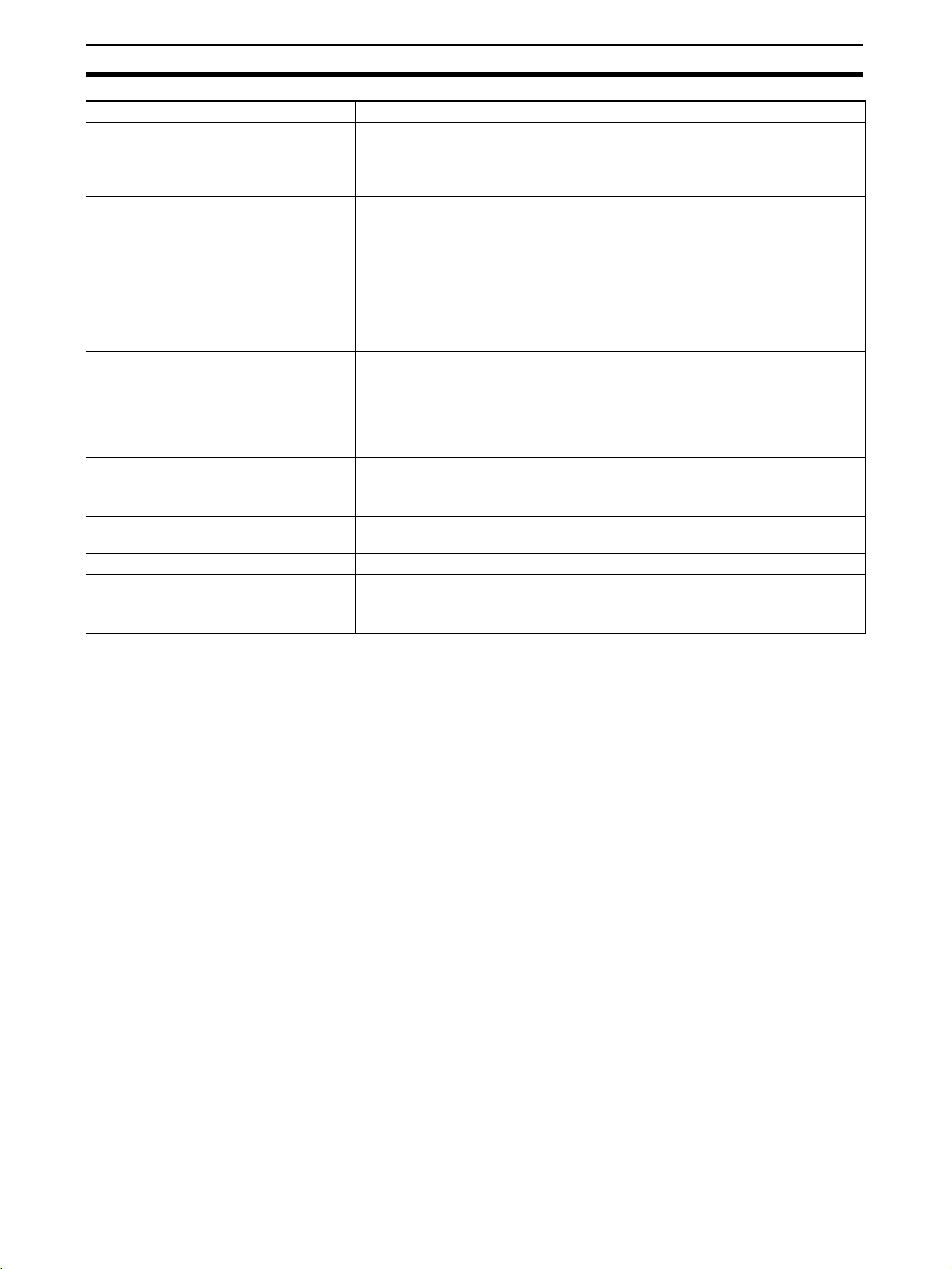

Safety Precautions

Safety Indications

The indications below are used in this manual for safety precautions which are necessary to use the

CompoNet Communications Unit safely. The contents of these safety precautions are important. Always obey them.

These are the indications for safety precautions.

Indicates a potentially hazardous situation which, if not

WARNING

Caution

avoided, could result in death or serious injury.

Additionally, there may be severe property damage.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury, or property

damage.

Safety Precautions

Precaution for

Safe Usage

Precaution for

Correct Usage

• “Precautions for Safe Application” shows the operations that you must do or

not do to use the product safely.

• “Precautions for Correct Application” shows operations that you must do or not

do to make sure that the product operates, prevent malfunctions, and prevent

bad effects on performance and functions.

ix

Page 9

Safety Precautions

Descriptions of Symbols

This symbol shows operations that you must not do.

The specified operation shows in the circle.

This example shows “do not disassemble.”

This symbol shows precautions (including warnings).

The specified operation shows in the triangle.

This example shows a general precaution.

This symbol shows operations that you must do.

The specified operation shows in the circle.

This example shows a general precaution for something that

you must do.

WARNING

Do not try to disassemble a Unit or touch the terminal block while

the power is ON. Doing this can cause electrical shock.

Make sure that the voltage and current input to the Units are in the

specified ranges. If the voltage and current are not in the specified

ranges, there can be Unit malfunctions or fire.

Turn OFF the I/O power supply to a SmartSlice I/O Unit before you

replace it with the online replacement procedure. If there is external

power to a terminal for a Relay Output Slave, for example, turn OFF

the external power before you replace the SmartSlice I/O Unit. If

you replace a Slave I/O Unit with the power ON, incorrect outputs,

incorrect inputs, or electric shock can occur.

x

Page 10

Safety Precautions

Apply safety measures in external circuits (that is, not in the SmartSlice I/O Terminal) to keep safety in the system. These measures

must keep safety if a malfunction in the control system or other external factor which has an effect on the control system causes a

problem. Include the items below. Not doing this can cause serious

accidents.

• There must be emergency stop circuits, interlock circuits, limit circuits, and other safety measures in external control circuits.

• The SmartSlice outputs can stay ON or OFF because of welding

or burning of the output relays, or destruction of the output transistors. As a countermeasure for such errors, there must be external safety measures to keep safety in the system.

• The SmartSlice I/O Terminal will continue operating when one or

more I/O Units are missing from the SmartSlice I/O Terminal. The

other I/O Units will continue the control operations, including the

control of the outputs. As a countermeasure for such errors, there

must be external safety measures to keep safety in the system.

The CPU Unit refreshes I/O when the program is stopped in PROGRAM mode. Fully make sure that it is safe before changing the

status of bits or words in memory allocated to Output Slaves, Special I/O Units, or CPU Bus Units. If you change the bits or words allocated to a Slave or Unit, you could cause incorrect operation of

the loads connected to the Slave or Unit. The operations below will

change memory status.

• Transferring I/O memory data to the CPU Unit from a Programming Device

• Changing present values in memory from a Programming Device

• Force-setting or force-resetting bits from a Programming Device

• Transferring I/O memory files from a Memory Card or EM file

memory to the CPU Unit

• Transferring I/O memory from a host computer or from a PLC on

a network

xi

Page 11

Precautions for Safe Usage

Precautions for Safe Usage

• Put a Unit in the special box during transportation. Make sure that the Unit is moved carefully, and

not given too much vibration or shock during transportation.

• Do not let a Unit fall or give it too much vibration or shock. This can cause malfunction or cause

damage to the Unit.

• Install the SmartSlice I/O Terminal correctly on DIN Track.

• Be sure that you correctly lock the terminal block, the communications cable connectors, and other

items with locking devices.

• Correctly connect the Units as this manual shows.

• Interference between the Flat Cables for more than one CompoNet System can cause operation

that is not stable. Keep the Flat Cables for different CompoNet Systems apart by a minimum of

5 mm. Interference can occur for Sheathed Cable or Unsheathed Cable.

• Do not let metal objects enter the Unit when connecting or installing it.

• Connect ferrules to the wires when you connect the wires. Do not connect stranded wires directly

to terminals.

• Use the specified communications cables and connectors.

• Use the correct polarity when connecting the terminals.

• Put the ferrules fully into the holes.

• Do a full check of the terminal block before you attach it.

• Do not bend the cables to more than their normal bending radius or pull on the cables.

• Obey the following precautions when connecting communications cables.

• Keep the communications cables away from the power lines or high-tension lines.

• Do not bend the communications cables with too much force.

• Do not pull on the communications cables with too much force.

• Do not put objects on the communications cables.

• Put the communications cables in ducts.

• If the power supply conditions are bad, install countermeasures to make sure that the power

supply always has the rated voltage.

• You must make interlock circuits, limit circuits, and other safety measures in circuits that are

external to the control system.

• Use the power supply voltage which this manual specifies.

• Make sure that there will be no problems when the Unit changes to fixed allocations for the I/O

Areas before you clear the Registration Table. (You set user remote I/O allocations in the

Registration Table.)

• Do not let the communications distance be higher than the specified value.

• Install circuit breakers and other safety measures to prevent Unit damage which short-circuits in

external wires can cause.

• Install failsafe measures to make sure that the system is safe if disconnected signal lines or short

power interruptions cause incorrect signals.

• Always obey the voltage specifications for power supply connections and I/O jumpers. Incorrect

connections can cause malfunctions.

• Do not apply a voltage or connect a load which is larger than the maximum switch capacity to an

Output Slave.

• Do not apply a voltage which is larger than the rated voltage to an Input Slave.

• Be sure there are no mistakes in connections or switch settings before you turn ON the power

supply.

xii

Page 12

Precautions for Safe Usage

• Be sure to turn OFF the power to the PLC and Slaves before doing these operations.

• Assembling a SmartSlice I/O Terminal

• Setting the rotary switches

• Connecting cables

• Be sure that there will be no bad effects on the system before doing these operations.

• Changing the operating mode of the CPU Unit

• Setting or resetting bits in memory

• Changing set values or present values on the user program

• Before touching a Unit, touch a grounded metal object to release static electricity from your body.

• When you replace a part, be sure that the specifications of the replacement part are correct.

• Do not try to disassemble, repair, or change a Unit.

xiii

Page 13

Precautions for Correct Usage

Precautions for Correct Usage

Correctly install the Units as this manual shows.

Do not install the Units in these locations.

• Locations with direct sunlight

• Locations with temperatures or humidity not in the range specified in the specifications

• Locations with condensation as the result of large changes in temperature

• Locations with corrosive gases or flammable gases

• Locations with dust (specially iron dust) or salts

• Locations with water, acid, oil, or chemicals

• Locations with shock or vibration

Install applicable and sufficient countermeasures if you install the system in these locations.

• Locations with static electricity or other types of noise

• Locations with strong electromagnetic fields

• Locations with possible exposure to radioactivity

• Locations near power lines

xiv

Page 14

EC Directives

Applicable Directives

•EMC Directive

• Low Voltage Directive

Concepts

EMC Directive

The SmartSlice I/O Terminals are electrical devices which are installed in a machine in application.

The Terminals comply with the EMC Directive. This makes it easier for the machine in which a Terminal is installed to more easily comply with the EMC directive. (See note.)

The EMC-related performance of the OMRON devices which comply with EC Directives changes

with the machine in which they are installed. This includes the configuration, connections, and other

conditions of the machine. The customer must do the checks to make sure that the devices and the

machine conform to EMC standards.

Note:

The applicable EMC (electro-magnetic compatibility) standards are EN 61131-2 and EN 61000-6-2

for EMS (electro-magnetic susceptibility) and EN 61131-2 and EN 61000-6-4 for electro-magnetic

interference. The 10-m regulations apply for radiated emissions.

EC Directives

Low Voltage Directive

Devices which operate at voltages from 50 to 1,000 VAC or 75 to 1,500 VDC must comply with the

related safety requirements. The applicable standard is EN 61131-2.

Complying with EC Directives

The SmartSlice I/O Units comply with EC Directives. These measures are necessary for the machine containing a SmartSlice I/O Units to comply with the EC Directives.

1. You must install the SmartSlice I/O Units in a control panel.

2. You must use reinforced insulation or double insulation for the DC power supplies used for the

Unit power supplies, and the I/O power supplies. Make sure that the outputs are stable if a 10-ms

interruption occurs at the input.

We recommend the S82J Power Supply which is made by OMRON. (See note.)

3. The SmartSlice I/O Units which conform to EC Directives conform to the EMI standards (EN

61131-2 (Immunity Zone A), EN 61000-6-2, and EN 61000-6-4). The radiated emission properties (10-m regulations) can change with the configuration of the control panel, other devices

which are connected to the control panel, connections, and other conditions.

You must make sure that the completed machine complies with EC Directives.

4. Compliance tests were done with I/O wires of a maximum length of 30 m.

Note:

Compliance tests for EMC standards were done with the recommended power supply.

xv

Page 15

Related Manuals

Related Manuals

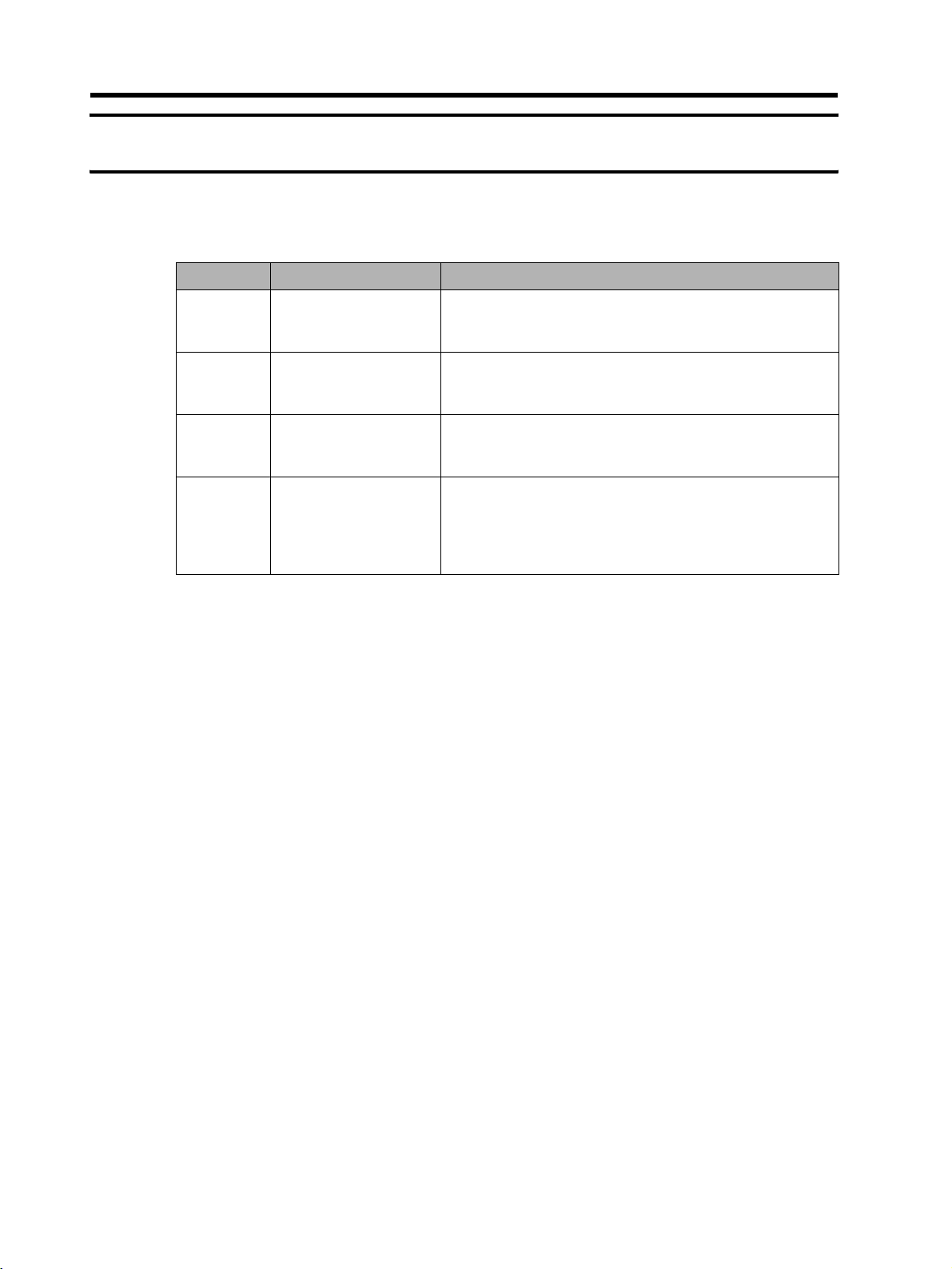

This table shows the manuals which are related to the CompoNet Communications Unit. Read

these manuals together with this Manual.

Cat. No. Manual Contents

W476 (this

manual)

W455

W456

W342

SmartSlice CompoNet

Communications Unit

Operation Manual

GRT1 Series SmartSlice

I/O Units Operation Manual

CS/CJ Series CompoNet

Master Unit Operation

Manual

SYSMAC CS/CJ/CP Series and SYSMAC One

NSJ Series Communications Commands Reference Manual

This manual tells you about the functions, specifications, and

operating procedures of the CompoNet Communications

Unit.

This manual tells you about the models, functions, specifications, and operating procedures of the SmartSlice I/O Units.

This manuals tells you about the CompoNet network, communications specifications, connection procedures, and the CS/

CJ-series CompoNet Master Unit.

This manual tells you about the communications commands

which you can use with the CS/CJ-series CompoNet Master

Unit.

xvi

Page 16

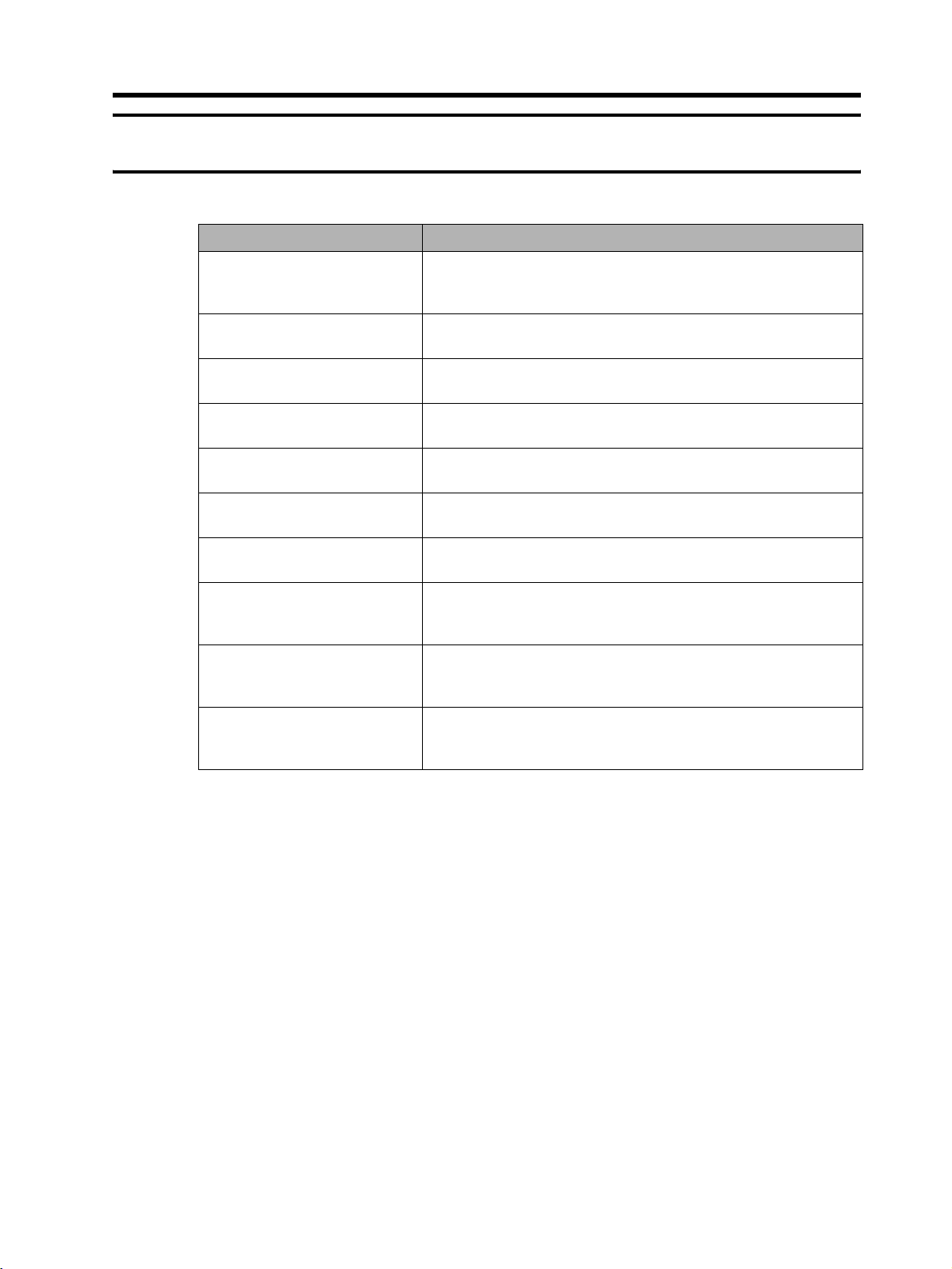

About this Manual

Section Overview

Section 1 tells you about the SmartSlice system. It also tells you

about the features, system configuration, and specifications of the

CompoNet Communications Unit.

Section 2 tells you about the names and functions of the parts of the

CompoNet Communications Unit.

Section 1

Section 2

Features and System

Configuration

Nomenclature and

Functions

About this Manual

Section 3 Installing the Units

Section 4 Connecting the Units

Section 5

Section 6 Smart Functions

Section 7 Basic Operation

Section 8

Section 9 Error Procedures

Appendices

Unit Settings and I/O

Allocations

Remote I/O Communications

Section 3 tells you how to install the CompoNet Communications

Unit and SmartSlice I/O Units.

Section 4 tells you how to connect the CompoNet Communications

Unit and SmartSlice I/O Units.

Section 5 tells you how to set the unit address and unit number. It

also tells how to allocate I/O in the CompoNet Master Unit.

Section 6 tells you about the many smart functions of the SmartSlice

system.

Section 7 gives the procedures for and example of operating a

SmartSlice system.

Section 8 tells you about the communications timing for remote I/O

communications and message communications. It also gives more

information on communications.

Section 9 tells you how to troubleshoot problems that you can have

with the CompoNet Communications Unit and SmartSlice I/O Units.

It also tells how to see the error history with the CX-Integrator.

The appendices give an overview of explicit messages (for example,

to send commands) and a list of command functions. The appendices also give lists of related products.

xvii

Page 17

About this Manual

xviii

Page 18

TABLE OF CONTENTS

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . . . . 1

1-1 The SmartSlice I/O System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Features of the CompoNet SmartSlice I/O Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SECTION 2

Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-1 Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-3 Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SECTION 3

Installing the Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3-1 Installing a SmartSlice I/O Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-2 Installing the Turnback Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

SECTION 4

Connecting the Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4-1 Connecting the Communications Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-2 Connecting the Power Supply Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-3 Connecting the Turnback Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4-4 Precautions When Connecting the Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-5 Connecting the Signal Lines for External Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

SECTION 5

Unit Settings and I/O Allocations . . . . . . . . . . . . . . . . . . . . . 39

5-1 Setting the Node Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

5-2 Unit Numbers for SmartSlice I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5-3 I/O Allocations to CompoNet Master Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

SECTION 6

Smart Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6-1 Overview of Smart Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6-2 Registration Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6-3 Backup Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6-4 Automatic Restore Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6-5 Replacing Units Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6-6 Automatic Baud Rate Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6-7 Software Setting of I/O Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

xix

Page 19

TABLE OF CONTENTS

6-8 Unit Conduction Time Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6-9 Unit Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6-10 Network Communications Error History Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6-11 I/O Communications Error History Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6-12 Last Maintenance Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

SECTION 7

Basic Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7-1 Setting Example and Basic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7-2 Preparing for Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7-3 Hardware Connections and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7-4 Starting Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

7-5 Making Sure That Operation Is Correct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

SECTION 8

Remote I/O Communications . . . . . . . . . . . . . . . . . . . . . . . . 89

8-1 Performance of Remote I/O Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

8-2 Performance of Message Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

SECTION 9

Error Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

9-1 Error Procedures with Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

9-2 Error Procedures with CX-Integrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

9-3 Other Error Causes and Error Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Appendices

A CompoNet Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

B Object Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

C Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

D Power Consumption and Weight Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

E Total I/O Current Consumption Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

xx

Page 20

SECTION 1

Features and System Configuration

This section tells you about the SmartSlice system. It also tells you about the features, system configuration, and

specifications of the CompoNet Communications Unit.

1-1 The SmartSlice I/O System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Features of the CompoNet SmartSlice I/O Terminals. . . . . . . . . . . . . . . . . . . 3

1-3 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-4-1 Specifications of the SmartSlice System . . . . . . . . . . . . . . . . . . . . . 7

1-4-2 Specifications of the CompoNet Communications Unit . . . . . . . . . 7

1-4-3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1

Page 21

The SmartSlice I/O System Section 1-1

1-1 The SmartSlice I/O System

SmartSlice is a building-block style remote I/O system which you make from a

Communications Unit and a number of SmartSlice I/O Units. Each SmartSlice

I/O Unit has a small number of I/O points. You can use a SmartSlice I/O system to decrease wire connection, installation, and space requirements.

The CompoNet SmartSlice System is a new type of network. It has the basic

features of previous CompoNet Slave Units and the features of a SmartSlice

I/O system. The CompoNet Communications Unit and installed SmartSlice

I/O Units together make a “SmartSlice I/O Terminal.” You can mix SmartSlice

I/O Units to make a system for different applications. You can also use many

other functions. The other functions include functions to monitor the operation

of the system.

This is an example of a CompoNet SmartSlice System.

CompoNet Master Unit

PLC

Serial connection

CPU Unit

GRT1-CRT CompoNet

Communications Unit

CompoNet

Slave

ROS2

ROS2

GRT1-CRT

MS

UNIT PWR

NS

WORD

TS

NODE ADR

BS {

BD H

BD L

BS |

DC24V

INPUT

I/O PWR

×10

×1

[0-63]

INX

OUTX

ON

1

REGS

I/O

2

3

ADR

4

BACK

UNIT

V

V

I/O

V

V

DC24V

INPUT

OD4

ID4

ID4

TS

TS

TS

0

0

1

1

0

1

2

2

2

3

3

3

B1

B1

B1

A1

A1

A1

B2

B2

B2

A2

A2

A2

B3

B3

B3

A3

A3

A3

B4

B4

B4

A4

A4

A4

B5

B5

B5

A5

A5

A5

B6

B6

B6

A6

A6

A6

OD4

OD4

PD2

TS

TS

I/O PWR

0

0

1

1

2

2

3

3

B1

B1

A1

A1

A1

B2

B2

A2

A2

A2

B3

B3

A3

A3

A3

B4

B4

A4

A4

A4

B5

B5

A5

A5

A5

B6

B6

A6

A6

A6

TBR

TS

TS

0

0

1

1

B1

B1

B1

A1

A1

B2

B2

B2

A2

A2

B3

B3

B3

A3

A3

B4

B4

B4

A4

A4

B5

B5

B5

A5

A5

B6

B6

B6

A6

A6

Slice I/O Terminal

GRT1-TBL

ID4

TS

0

1

UNIT PWR

2

3

I/O PWR

B1

A1

B2

A2

B3

A3

B4

UNIT

A4

V

V

B5

I/O

A5

V

V

B6

A6

DC24V

INPUT

OD4

ID4

TS

TS

TS

0

1

0

0

1

1

2

2

3

2

3

3

B1

B1

B1

A1

A1

A1

B2

B2

B2

A2

A2

A2

B3

B3

B3

A3

A3

A3

B4

B4

B4

A4

A4

A4

B5

B5

B5

A5

A5

A5

B6

B6

B6

A6

A6

A6

END

TS

TS

0

1

0

1

2

3

2

3

B1

B1

A1

A1

B2

B2

A2

A2

B3

B3

A3

A3

B4

B4

A4

A4

B5

B5

A5

A5

B6

B6

A6

A6

OD4

OD4

ID4

Slice I/O Units

You can connect a maximum of 64 Slice I/O Units to one

CompoNet Communications Unit.

2

Page 22

Features of the CompoNet SmartSlice I/O Terminals Section 1-2

1-2 Features of the CompoNet SmartSlice I/O Terminals

This section tells you the features of a CompoNet SmartSlice System.

Each SmartSlice I/O Terminal Is One CompoNet Node

You can control a CompoNet Communications Unit with a maximum of 64

connected SmartSlice I/O Units as one Slave from the CompoNet Master

Unit.

Remote I/O Communications

You can use remote I/O communications to share I/O data between the CompoNet Master Unit and the SmartSlice I/O Units through the CompoNet Communications Unit. You can also allocate status data of the CompoNet

Communications Unit in the CompoNet Master Unit. You can also use the CXIntegrator or explicit messages to allocate status information on the network

participation status of SmartSlice I/O Units in the CompoNet Master Unit.

Easy Startup

All you must do to start operation is to set the node address with the rotary

switches and to set the DIP switch. These switches are on the CompoNet

Communications Unit. When you turn ON the power supply, the CompoNet

Master Unit automatically reads the Unit configuration and allocates I/O to the

SmartSlice I/O Terminals. You do not have to set parameters with special software.

Easy I/O Connections

All SmartSlice I/O Units connected to the CompoNet Communications Unit

have screwless clamp terminals. All you must do is to put 10-mm ferrules on

the wires and then push the ferrules into the screwless clamp terminals. It is

not necessary to tighten screws.

Table Registration

You can use the DIP switch on the CompoNet Communications Unit to record

the connected SmartSlice I/O Units in a table. The table tells the sequence

and I/O capacity of each SmartSlice I/O Unit. After you complete registration,

the CompoNet Communications Unit will compare the configuration with the

table each time that the power is turned ON. You can set a status flag in the

CompoNet Master Unit to show when the configurations do not agree.

Back Up and Restore Parameters

You can use the DIP switch on the CompoNet Communications Unit to back

up the parameters in the I/O Units to memory in the CompoNet Communications Unit. You can do this for maintenance, for example, when you replace an

I/O Unit. You can also use the DIP switch to restore the parameters in the

CompoNet Communications Unit to the I/O Units after you replace an I/O Unit.

Online Replacement of I/O Units

SmartSlice I/O Units have a base block, main block, and terminal block. You

can disconnect these blocks. With this block structure, you do not have to turn

OFF the Unit power supply to replace SmartSlice I/O Units.

Note You must turn OFF the I/O power supply to the SmartSlice I/O Unit before you

replace it. If there is external power to a terminal on the SmartSlice I/O Unit,

also turn OFF the external power before you replace the SmartSlice I/O Unit.

Automatic Baud Rate Recognition

The CompoNet Communications Unit automatically finds the communications

baud rate of the CompoNet Master Unit. It is not necessary to set the baud

rate.

3

Page 23

Features of the CompoNet SmartSlice I/O Terminals Section 1-2

Software Setting of I/O Allocations

You can record the node addresses and I/O configurations of Dummy Units in

the registration table to prepare for expansion of SmartSlice I/O Units. When

you add the I/O Units, it will not be necessary for you to set the node

addresses or I/O configurations. It will also not be necessary to change the

ladder programming very much. You can also write the ladder programming

for the full configuration and set the Units that you will add as Dummy Units.

When you change the unit configuration, it will not be necessary to change the

I/O map.

Unit Conduction Time Monitor

The Unit Conduction Time Monitor records the total time that the internal circuit power in DeviceNet Communications Unit is ON. You can set a threshold

in the CompoNet Communications Unit to tell the CompoNet Master Unit

when the conduction time is longer than the threshold. You can set the threshold or read the conduction time with the CX-Integrator or with an explicit message.

Unit Comments

You can set a comment (for example, a name or the application) for each

CompoNet Communications Unit to record the name in the CompoNet Communications Unit. You can use the comments to easily identify CompoNet

Communications Units when you set or monitor parameters with the CX-Integrator. You can set or read the comments with the CX-Integrator or with an

explicit message.

Communications Error History Monitor

There is a communications error history in the CompoNet Communications

Unit. It records the four newest errors in communications with the CompoNet

network and the 64 newest errors in communications in the SmartSlice I/O

Terminal. You can read the communications error status with the CX-Integrator or with an explicit message.

Last Maintenance Date

You can record the last date on which you did maintenance in the CompoNet

Communications Unit. You can write the last maintenance date with the CXIntegrator or with an explicit message.

4

Page 24

System Configuration Section 1-3

(4)

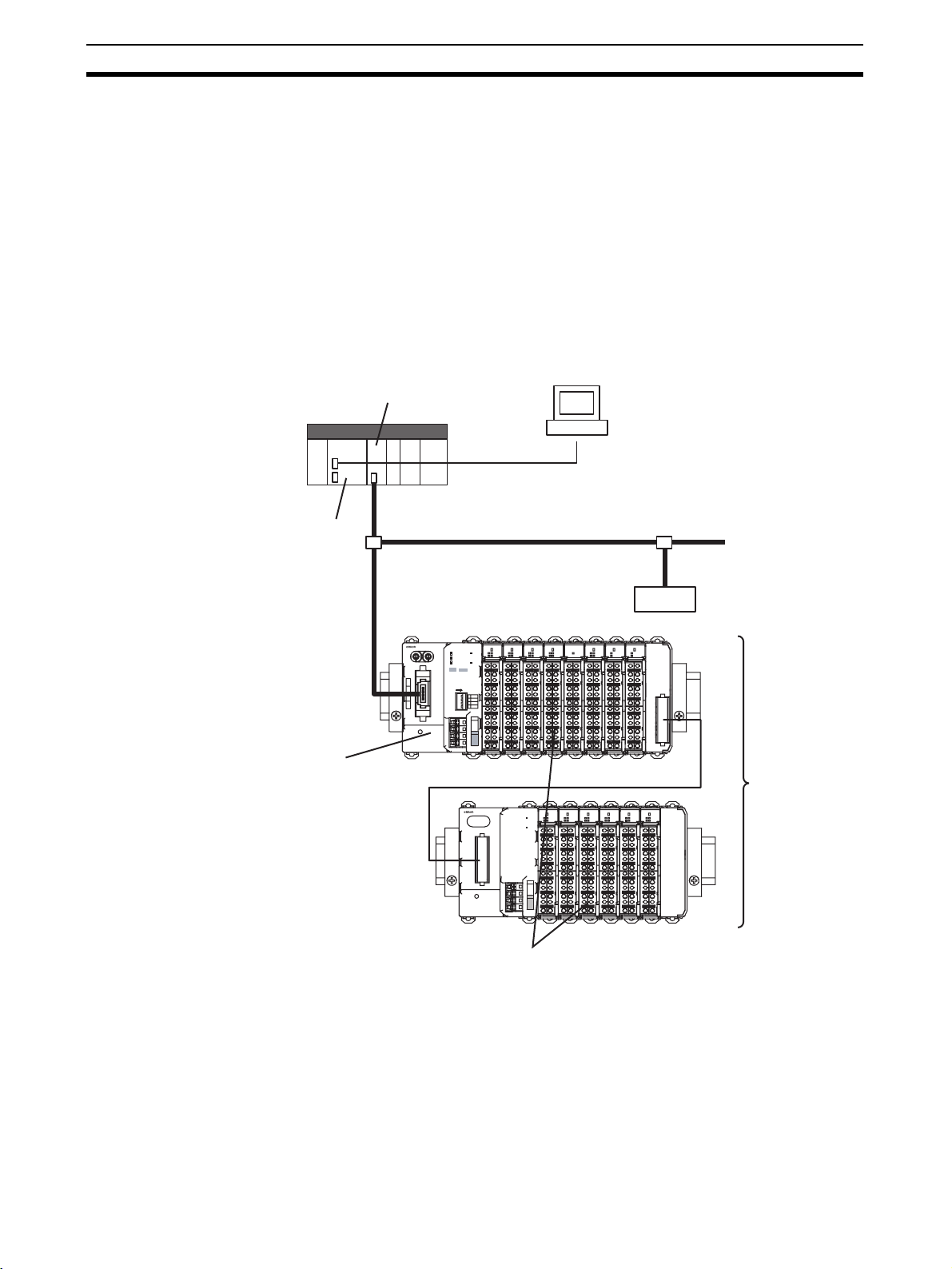

1-3 System Configuration

This is an example of a CompoNet SmartSlice System.

(7) CX-Integrator

(1) CompoNet Master Unit

PLC

Explicit message

Remote I/O

Communications

CompoNet

GRT1-CRT

WORD

NODE ADR

×10

(0-63)

BS {

BD H

BD L

BS |

DC24V

INPUT

(2) CompoNet Communications Unit

Left Turnback Unit

I/O data

Slave

ROS2

ROS2

OD4

OD4

OD4

ID4

ID4

TS

0

0

1

MS

UNIT PWR

2

2

3

NS

TS

I/O PWR

×1

OUTX

INX

B1

A1

A1

B2

A2

A2

ON

1

REGS

2

I/O

B3

3

ADR

A3

A3

4

BACK

B4

A4

A4

UNIT

V

V

B5

A5

A5

I/O

V

V

B6

A6

A6

DC24V

INPUT

PD2

TS

TS

TS

1

3

I/O PWR

0

0

0

1

1

2

2

2

3

3

B1

B2

B3

B4

B5

B6

B1

B1

B1

A1

A1

A2

A3

A4

A5

A6

A1

A1

B2

B2

B2

A2

A2

A2

B3

B3

B3

A3

A3

A3

B4

B4

B4

A4

A4

A4

B5

B5

B5

A5

A5

A5

B6

B6

B6

A6

A6

A6

TBR

TS

TS

TS

0

0

1

1

1

3

B1

B1

B1

A1

A1

B2

B2

B2

A2

A2

B3

B3

B3

A3

A3

B4

B4

B4

A4

A4

B5

B5

B5

A5

A5

B6

B6

B6

A6

A6

(4) Right Turnback Unit

(5) Turnback Cable (1 m)

(3) Slice I/O Units

OD4

OD4

ID4

GRT1-TBL

ID4

0

UNIT PWR

2

I/O PWR

A1

A2

A3

UNIT

A4

V

V

I/O

A5

V

V

A6

DC24V

INPUT

OD4

ID4

TS

TS

TS

0

1

1

0

0

1

2

2

3

3

2

3

B1

B1

B1

A1

A1

A1

B2

B2

B2

A2

A2

A2

B3

B3

B3

A3

A3

A3

B4

B4

B4

A4

A4

A4

B5

B5

B5

A5

A5

A5

B6

B6

B6

A6

A6

A6

END

TS

TS

TS

0

1

0

1

1

2

3

2

3

3

B1

B1

A1

A1

B2

B2

A2

A2

B3

B3

A3

A3

B4

B4

A4

A4

B5

B5

A5

A5

B6

B6

A6

A6

B1

B2

B3

B4

B5

B6

(6) End Unit

5

Page 25

System Configuration Section 1-3

No. Name Function

1 CompoNet Master Unit The CompoNet Master Unit controls the CompoNet network and transfers data

2 CompoNet Communications Unit

(GRT1-CRT)

3 SmartSlice I/O Units The SmartSlice I/O Units do communications with the CompoNet Master Unit

4 Turnback Units

(Right Turnback Unit: GRT1-TBR,

Left Turnback Unit: GRT1-TBL)

5 Turnback Cable (GCN2-100) You use a Turnback Cable to connect a Left Turnback Unit to a Right Turnback

6 End Unit (GRT1-END) You connect an End Unit to the end of the SmartSlice I/O Terminal.

7 CX-Integrator You use the CX-Integrator to write the parameters in the CompoNet Communi-

to and from all Slave Units.

The CompoNet Master Unit can send explicit messages to the CompoNet

Communication Unit.

The CompoNet Communications Unit is the interface with the CompoNet network. You connect it to the CompoNet Master Unit. You connect each CompoNet Communications Unit to SmartSlice I/O Units with the number of I/O points

which is necessary in each location. The CompoNet Communications Unit

does communications with the SmartSlice I/O Units.

The CompoNet Communications Unit temporarily keeps the I/O data from the

SmartSlice I/O Units which are connected to it. I/O data is transferred to and

from the CompoNet Master Unit all at one time during remote I/O communications.

through the CompoNet Communications Unit.

You can normally connect a maximum of 64 SmartSlice I/O Units to one Com-

poNet Communications Unit. There are restrictions in the number of SmartSlice I/O Units if the total data size is too large or power supply capacity is too

small.

You use a Turnback Unit to expand or divide a SmartSlice I/O Terminal.

Unit.

cations Unit and SmartSlice I/O Units and to monitor these parameters.

The CX-Integrator runs on a Windows computer.

6

Page 26

Specifications Section 1-4

1-4 Specifications

This section tells you the specifications of the SmartSlice System and the

CompoNet Communications Unit.

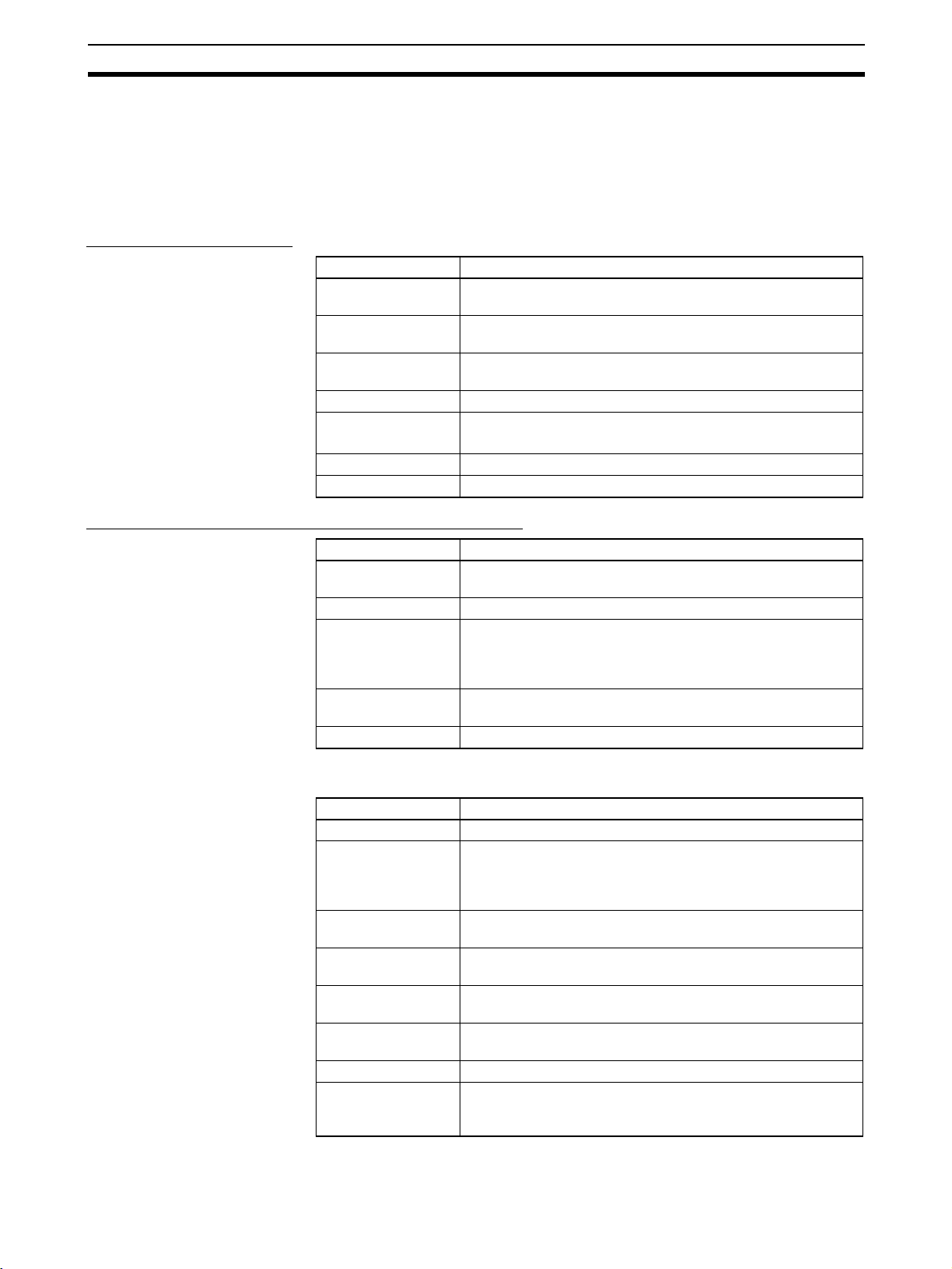

1-4-1 Specifications of the SmartSlice System

General Specifications

Item Specification

Ambient operating

temperature

Ambient operating

humidity

Ambient storage

temperature

Noise immunity Complies with IEC 61000-4-4, 2.0 kV.

Vibration resistance 10 to 60 Hz: 0.7-mm double amplitude

Withstand voltage 500 VAC (between isolated circuits)

Enclosure rating IP20

SmartSlice Bus Communications Specifications

Item Specification

Types of communications

Turnback Cables Length: 1 m, Maximum number of cables: 2

Connections

between Units in

SmartSlice I/O Terminal

Base block power

supply

Event messages You can use event messages.

−10 to 55°C (with no icing or condensation)

25% to 85%

−25 to 65°C (with no icing or condensation)

60 to 150 Hz: 50 m/s

I/O communications and message communications

Building-block structure with slide connectors

Voltage: 24 VDC, Current: 4 A

2

1-4-2 Specifications of the CompoNet Communications Unit

Item Specification

Model GRT1-CRT

I/O points Inputs: 32 bytes maximum (including status and areas which

the Unit does not use)

Output: 32 bytes maximum (including areas which the Unit

does not use)

Maximum number of

SmartSlice I/O Units

Status area 1 word (This word shows the status of the CompoNet Commu-

Parameter backup

and restore

Network power supply

I/O power supply 20.4 to 26.4 VDC

Baud rate The CompoNet Communications Unit uses the baud rate of

64 (Do not count the End Unit.)

nications Unit.)

You can back up or restore a maximum of 2 KB of data for one

CompoNet Communications Unit.

14 to 26.4 VDC

the CompoNet Master Unit (93. 75 kbps, 1.5 Mbps, 3 Mbps, or

4 Mbps).

7

Page 27

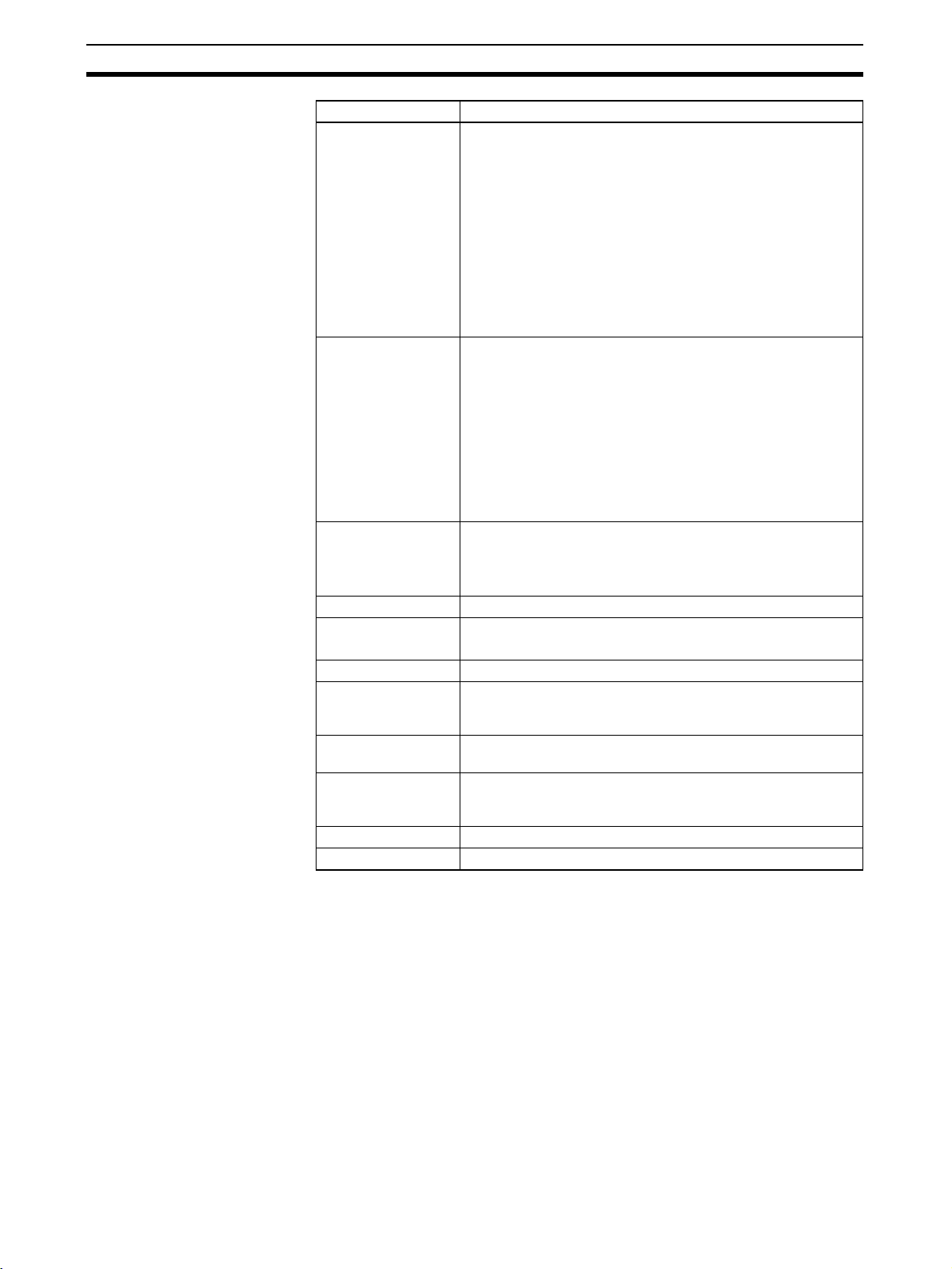

Specifications Section 1-4

Item Specification

Communications

media

Indicators MS (green/red): This indicator shows the status of the Compo-

Switches Rotary switches: There are two rotary switches. You use them

Connectors There is one CompoNet communications connector.

Terminals Clamp terminals for Unit power supply (24 VDC)

Power consumption 2.5 W

Power consumption

for each SmartSlice

I/O Terminal block

SmartSlice I/O Terminal blocks

Current consumption for I/O power

supply

Weight 125 g

Accessories None

You can use these cables:

2

Round Cable I (JIS C 3306, VCTF 2-core 0.75-mm

pair cable)

Round Cable II (JIS C 3306, VCTF 4-core 0.75-mm

pair cable)

Flat Cable I (without sheath, DCA4-4F10)

Flat Cable II (with sheath, DCA5-4F10)

Note The Round Cable I, Round Cable II, Flat Cable I, and

Flat Cable II are different types of cable. You must use a

Repeater to divide a branch line from the main line to

use more than one type of cable.

Net Communications Unit.

NS (green/red): This indicator shows the communications sta-

tus of the CompoNet network.

TS (green/red): This indicator shows the status of the Smart-

Slice I/O Terminal.

UNIT PWR (green): This indicator shows the status of the Unit

power supply.

I/O PWR (green): This indicator shows the status of the I/O

power supply.

to set the node address.

DIP switch: There is one DIP switch with four pins. You use

them to set the operating mode.

Clamp terminals for I/O power supply (24 VDC)

80 W max.

(You must divide the I/O Terminal into blocks to use more than

80 W.)

Main block and a maximum of two expansion blocks

4 A max.

twisted-

2

twisted-

8

Page 28

Specifications Section 1-4

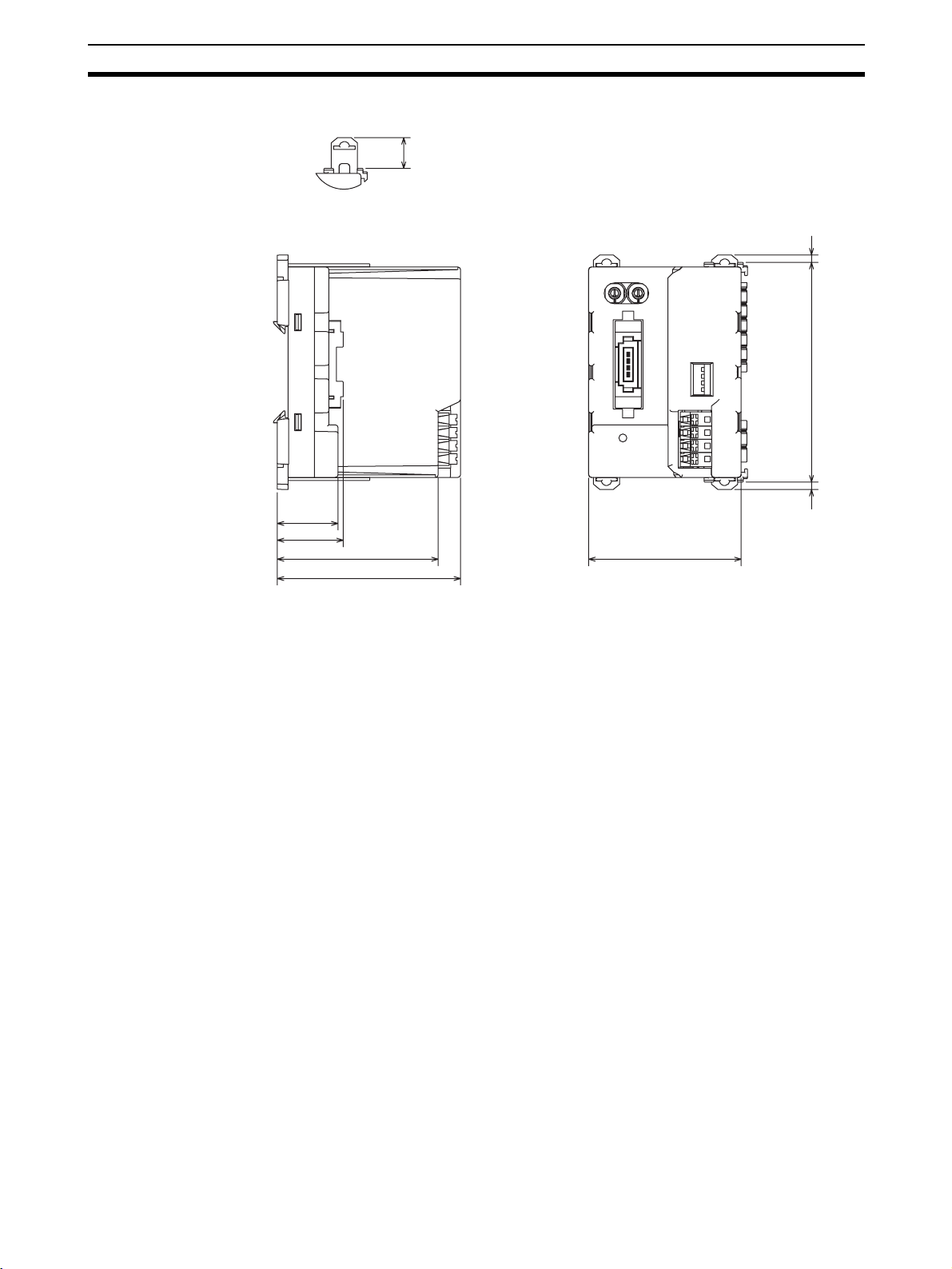

1-4-3 Dimensions

12

3

23.1

25.1

61.2

69.7

384

58

(mm)

9

Page 29

Specifications Section 1-4

10

Page 30

SECTION 2

Nomenclature and Functions

This section tells you about the names and functions of the parts of the CompoNet Communications Unit.

2-1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-1-1 CompoNet Communications Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-1-2 SmartSlice I/O Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-2 Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-2-1 MS Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-2-2 NS Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-2-3 TS Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2-4 UNIT PWR Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-2-5 I/O PWR Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-3 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-3-1 Rotary Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-3-2 DIP Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

11

Page 31

Nomenclature Section 2-1

2-1 Nomenclature

This section tells you about the names and functions of the parts of the CompoNet Communications Unit.

2-1-1 CompoNet Communications Unit

(1)

WORD

NODE ADR

BS

BD H

BD L

BS

DC24V

INPUT

GRT1-CRT

×1

×10

[0-63]

(2)

IN

(3)

MS

UNIT PWR

NS

TS

I/O PWR

X_

X_

OUT

(7)

(4)

ON

1

REGS

I/O

2

3

ADR

4

BACK

UNIT

I/O

DC24V

INPUT

V

V

V

V

(5)

(6)

No. Name Function

1 CompoNet commu-

nications connector

Connect the communications cable for the CompoNet

network to this connector.

2 Rotary switches Set the node address of the CompoNet Communica-

tions Unit as a CompoNet slave.

3 Indicators These indicators show the status of communications

and the Units.

4 DIP switch Use this DIP switch to create the registration table, set

the I/O allocation mode, back up SmartSlice I/O Unit

parameters, and restore SmartSlice I/O Unit parameters.

5 Terminals for Unit

power supply

Use these terminals to send 24-VDC power to the internal circuits of the CompoNet Communications Units

and the SmartSlice I/O Units.

6 Terminals for I/O

power supply

Use these terminals to send 24-VDC power to the

external I/O which connect to the SmartSlice I/O Units.

7 Device label This label shows the I/O memory area that the Unit

uses. The Unit has an input area and an output area.

The sizes of the areas change if the SmartSlice I/O Unit

configuration changes.

12

Page 32

Nomenclature Section 2-1

2-1-2 SmartSlice I/O Units

A SmartSlice I/O Unit has three blocks. You can remove each block.

(1)

(2)

(3)

No. Name Function

1 Base Block This is the bus between the SmartSlice I/O Units.

You do not have to disconnect the Base Block when you

replace the Main Block, for example, when there is damage

to the Main Block.

2 Main Block This is the primary part of the SmartSlice I/O Unit.

3 Terminal Block This block has the terminals for the SmartSlice I/O Unit.

You do not have to disconnect the wires from the Terminal

Block when you replace the Main Block.

Refer to the GRT1 Series SmartSlice I/O Units Operation Manual (Cat. No.

W455) for information on each model of SmartSlice I/O Unit and specifications.

13

Page 33

Indicators Section 2-2

2-2 Indicators

This section tells you the specifications of the LED indicators on the front

panel of the CompoNet Communications Unit.

2-2-1 MS Indicator

The MS indicator shows the status of the CompoNet Communications Unit.

MS

UNIT PWR

NS

TS

Color Status

Green Lit Normal status

Red Lit Fatal error

--- Not lit No power

I/O PWR

• Unit hardware error

• Watchdog timer error

• EEPROM memory error

Flashing Non-fatal error

• Switch setting error (Pin 1 (REGS) and pin 2 (I/O) are ON

on the DIP switch when the Unit power supply came ON.)

• Logic error in parameter settings

• The Unit power supply is OFF.

• The Unit is being reset.

• Unit initialization is not complete.

14

Page 34

Indicators Section 2-2

2-2-2 NS Indicator

The NS indicator shows the communications status of the CompoNet network.

MS

UNIT PWR

NS

TS

Color Status

Green Lit The Unit is online and the communications connection is

Red Lit A fatal communications error occurred. (The CompoNet

--- Not lit The Unit is offline or the power supply is OFF.

I/O PWR

completed. (The network status is normal.)

Flashing The Unit is online but the communications connection is

not completed. (The baud rate is synchronized, but the

CompoNet Master Unit is completing the connection.)

Communications Unit found an error for which communications on the CompoNet network are not possible.)

• Communications error

• Duplication of node addresses

• Bus Off error

Flashing Non-fatal communications error

• Communications timeout

• There is no power supply to the CompoNet Communications Unit.

• The check for node address duplication is not completed

at the CompoNet Master Unit.

15

Page 35

Indicators Section 2-2

2-2-3 TS Indicator

The TS indicator shows the status of the communications with the SmartSlice

I/O Units.

MS

UNIT PWR

NS

TS

Color Status

Green Lit The CompoNet Communications Unit is in communica-

Red Lit • Fatal communications error

--- Not lit • No power

I/O PWR

tions with the SmartSlice I/O Units.

Flashing each

second

Flashing

each 0.5

second

Flashing

each 2

seconds

Flashing Non-fatal communications error

The SmartSlice I/O Units are joining communications at

this time.

• The CompoNet Communications Unit is backing up

parameters from the SmartSlice I/O Units.

• The CompoNet Communications Unit is restoring parameters to the SmartSlice I/O Units.

• The CompoNet Communications Unit could not back up

the parameters from the SmartSlice I/O Units.

• The CompoNet Communications Unit could not restore

the parameters to the SmartSlice I/O Units.

• The CompoNet Communications Unit could not make the

Registration Table.

• Pin 1 (REGS) of the DIP switch turned ON when pin 2

(I/O) was ON. You turn ON pin 1 to allocate I/O using

software. You turn ON pin 2 to allocate I/O with the Registration Table.

• Communications timeout

• Registration Table verification error

• A replaced SmartSlice I/O Unit is the incorrect model.

• The CompoNet Communications Unit did not start communications with the SmartSlice I/O Units.

• The CompoNet Communications Unit found an overcurrent.

16

Page 36

Indicators Section 2-2

2-2-4 UNIT PWR Indicator

The UNIT PWR indicator shows the status of the Unit power supply.

MS

UNIT PWR

NS

Color Status

Green Lit The 24-VDC Unit power supply to the CompoNet Commu-

--- Not lit The Unit power supply is OFF.

2-2-5 I/O PWR Indicator

The I/O PWR indicator shows the status of the I/O power supply.

TS

MS

NS

TS

I/O PWR

nications Unit is ON.

UNIT PWR

I/O PWR

Color Status

Green Lit The 24-VDC I/O power supply to the CompoNet Commu-

nications Unit is ON.

--- Not lit The I/O power supply is OFF.

17

Page 37

Switches Section 2-3

2-3 Switches

This section tells you the functions of the rotary switches and the DIP switch

on the front panel of the CompoNet Communications Unit.

2-3-1 Rotary Switches

Use the rotary switches to set the node address of the CompoNet Communications Unit as a slave on the CompoNet network. Set the node address as a

decimal number between 0 and 63.

Set the 10s digit on the left rotary switch and set the 1s digit on the right rotary

switch.

The setting of the switches is read when the Unit power supply turns ON.

×10

×1

2-3-2 DIP Switch

Use the DIP switch to create the registration table, set the I/O allocation

mode, back up SmartSlice I/O Unit parameters, and restore the SmartSlice

I/O Unit parameters.

ON

1

REGS

I/O

2

3

ADR

4

BACK

Note All pins on the DIP switch are OFF in the factory settings.

Pin 1: REGS Use pin 1 to make or change the Registration Table. The setting of pin 1 when

the Unit power supply turns ON enables or disables the Registration Table.

While the Unit power supply is ON, turn ON pin 1 to make the registration

table.

• The Pin Setting When the Unit Power Supply Turns ON

Pin setting Description

ON If there is no Registration Table, the CompoNet Communications Unit

OFF The CompoNet Communications Unit will disable the Registration

will record the connected SmartSlice I/O Units in a table. The table

tells the sequence and I/O capacity of each SmartSlice I/O Unit. If

there is a Registration Table, the CompoNet Communications Unit will

automatically compare the connected SmartSlice I/O Units with the

Registration Table. If the connected SmartSlice I/O Units do not agree

with the Registration Table, communications will not start for all

SmartSlice I/O Units.

Table and will do communications with all SmartSlice I/O Units.

18

• Changing the Pin Setting While the Unit Power Supply Is ON

Pin setting Description

OFF to ON The CompoNet Communications Unit makes the Registration Table.

Note The setting of pin 1 is enabled when pin 2 (I/O) is OFF (Automatic I/O Alloca-

tion Mode).

Page 38

Switches Section 2-3

Pin 2: I/O Use pin 2 to set the Software I/O Allocation Mode.

Pin setting Description

ON The Software I/O Allocation Mode is set.

You can make a Registration Table with the CX-Integrator to allocate

I/O. For each SmartSlice I/O Unit in the table, you can specify if the

Unit is installed or not. When you turn ON the power, the Communications Unit will do a check only for installed Units. The Units which are

not installed will have empty spaces in the I/O data for the CompoNet

Master Unit.

OFF The Automatic I/O Allocation Mode is set.

Use this mode to automatically detect SmartSlice I/O Units when the

power supply turns ON.

Note The CompoNet Communications Unit reads the setting of pin 2 when the Unit

power supply turns ON.

Pin 3: ADR Use pin 3 to control the automatic restore function.

Pin setting Description

ON If pin 1 (REGS) or pin 2 (I/O) is ON, the CompoNet Communications

Unit will automatically restore the parameters to the SmartSlice I/O

Units.

OFF The CompoNet Communications Unit will not restore the parameters.

Pin 4: BACK Use pin 4 to back up the parameters of all installed SmartSlice I/O Units.

If you turn pin 4 ON, OFF, ON in 3 s or less when pin 1 (REGS) or pin 2 (I/O)

is ON, the parameters of all the SmartSlice I/O Units will be backed up to the

CompoNet Communications Unit. While the parameters are being backed up,

the TS indicator will flash green each 0.5 s.

3 s or less

Pin setting

ON OFF ON

19

Page 39

Switches Section 2-3

20

Page 40

SECTION 3

Installing the Units

This section tells you how to install the CompoNet Communications Unit and SmartSlice I/O Units.

3-1 Installing a SmartSlice I/O Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-1-1 Installing the CompoNet Communications Unit . . . . . . . . . . . . . . . 22

3-1-2 Installing the First SmartSlice I/O Unit . . . . . . . . . . . . . . . . . . . . . . 23

3-1-3 Installing the Other SmartSlice I/O Units. . . . . . . . . . . . . . . . . . . . . 24

3-1-4 Installing the End Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3-1-5 Installing the End Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3-2 Installing the Turnback Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

21

Page 41

Installing a SmartSlice I/O Terminal Section 3-1

k

3-1 Installing a SmartSlice I/O Terminal

This section tells you how to install the CompoNet Communications Unit and

SmartSlice I/O Units.

3-1-1 Installing the CompoNet Communications Unit

You install the CompoNet Communications Unit and SmartSlice I/O Units on

DIN Track.

Necessary Tools

Name Model Remarks

35-mm DIN Tracks PFP-50N Length: 50 cm

PFP-100N Length: 100 cm

PFP-100N2 Length: 100 cm

End Plate PFP-M Two End Plates are necessary

Installation Direction You can install the SmartSlice I/O Terminal in these directions.

for each SmartSlice I/O Terminal block.

Installation Procedure

1,2,3... 1. Install the DIN Track.

22

Use one screw for each three holes in the DIN Track. There must be a

screw for each 105 mm or less.

DIN Trac

One screw for each three holes

Page 42

Installing a SmartSlice I/O Terminal Section 3-1

2. Press the CompoNet Communications Unit with force until you hear it lock

on the DIN Track.

After you install the CompoNet Communications Unit, make sure that it is

locked correctly on the DIN Track.

(2) Make sure that the installation hooks on

the Unit are locked on the DIN Track.

CompoNet Communications Unit

Installation hook

DIN Track

(1) Press with force.

Installation hook

Note If the installation hooks do not lock correctly, release the hooks first, push the

CompoNet Communications Unit against the DIN Track, and then lock the

hooks. The subsequent page shows how to release the hooks.

Removal Procedure Use a flat-blade screwdriver or equivalent tool to pull out the hooks. This will

unlock them. Then pull out the CompoNet Communications Unit in a perpendicular direction to the DIN Track.

Flat-blade screwdriver

Installation hook

DIN Track

Installation hook

CompoNet

Communications Unit

3-1-2 Installing the First SmartSlice I/O Unit

Press the SmartSlice I/O Unit along the side of the CompoNet Communications Unit to install it. It must engage with the CompoNet Communications

Unit.

Press the SmartSlice I/O Unit until you hear it lock on the DIN Track.

23

Page 43

Installing a SmartSlice I/O Terminal Section 3-1

CompoNet Communications Unit

Slice I/O Unit

3-1-3 Installing the Other SmartSlice I/O Units

Install the other SmartSlice I/O Units with the same procedure as the first

SmartSlice I/O Unit.

You can normally connect a maximum of 64 SmartSlice I/O Units to one CompoNet Communications Unit. (There are restrictions in the number of SmartSlice I/O Units if the total data size is too large or power supply capacity is too

small.)

24

Slice I/O Unit

Page 44

Installing a SmartSlice I/O Terminal Section 3-1

3-1-4 Installing the End Unit

You must install an End Unit (GRT1-END) to the end of the last block in the

SmartSlice I/O Terminal. You connect it with the same procedure as for

SmartSlice I/O Units.

Precaution for

Correct Usage

End Unit

• Make sure that the guides on the Units are locked together when you install

the Units.

Guide

25

Page 45

Installing a SmartSlice I/O Terminal Section 3-1

3-1-5 Installing the End Plates

You must install an End Plate on each end of each block in a SmartSlice I/O

Terminal. The End Plates prevent the blocks from moving.

1,2,3... 1. Put the bottom of the End Plate on the DIN Track. Then put the top of the

End Plate on the DIN Track and pull down on the End Plate.

2. Install one End Plate on the left side and one on the right side of the SmartSlice I/O Terminal. Then tighten the screws.

(2)

(1)

ROS2

ROS2

GRT1-CRT

MS

UNIT PWR

NS

WORD

TS

I/O PWR

×1

NODE ADR

×10

(0-63)

INX

OUTX

BS {

BD H

BD L

BS |

DC24V

INPUT

ON

1

REGS

I/O

2

3

ADR

4

BACK

UNIT

V

V

I/O

V

V

DC24V

INPUT

OD4

ID4

ID4

TS

TS

TS

0

0

1

1

0

1

2

2

2

3

3

3

B1

B1

B1

A1

A1

A1

B2

B2

B2

A2

A2

A2

B3

B3

B3

A3

A3

A3

B4

B4

B4

A4

A4

A4

B5

B5

B5

A5

A5

A5

B6

B6

B6

A6

A6

A6

OD4

OD4

PD2

TS

TS

I/O PWR

0

0

2

A1

A2

A3

A4

A5

A6

1

1

2

3

3

B1

B1

B1

A1

A1

B2

B2

B2

A2

A2

B3

B3

B3

A3

A3

B4

B4

B4

A4

A4

B5

B5

B5

A5

A5

B6

B6

B6

A6

A6

TBR

TS

TS

0

0

1

1

B1

B1

A1

A1

B2

B2

A2

A2

B3

B3

A3

A3

B4

B4

A4

A4

B5

B5

A5

A5

B6

B6

A6

A6

DIN Track

Screw

End Plate

End Plate

26

Page 46

Installing the Turnback Units Section 3-2

3-2 Installing the Turnback Units

Note You can use Turnback Units to expand or divide a SmartSlice I/O Terminal.

Install a Right Turnback Unit (GRT1-TBR) on the right side of the block. Install

a Left Turnback Unit (GRT1-TBL) on the left side of the expansion or divided

block. Then install the necessary SmartSlice I/O Units.

Connect the Right Turnback Unit to the Left Turnback Unit with a Turnback

Cable (GCN2-100). (Refer to Connecting the Turnback Cables on page 35.)

There can be three blocks in a SmartSlice I/O Terminal, one main block and

two expansion blocks.

Right side of block

Slice I/O Unit

Right Turnback Unit

Left side of expansion or divided block

Left Turnback Unit

Slice I/O Unit

Precaution for

Correct Usage

• You must install an End Unit (GRT1-END) on the end of the last block in the

SmartSlice I/O Terminal.

• There are limits for each block to the capacity of the Unit power supply and the

I/O power supply. If the Unit power consumption of the SmartSlice I/O Units in

one block is higher than 80 W, you must divide the SmartSlice I/O Terminal.

Refer to Precautions When Connecting the Power Supplies on page 36 for

more information.

27

Page 47

Installing the Turnback Units Section 3-2

28

Page 48

SECTION 4

Connecting the Units

This section tells you how to connect the CompoNet Communications Unit and SmartSlice I/O Units.

4-1 Connecting the Communications Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-1-1 Using Flat Cables I/II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-1-2 Using Round Cables I/II. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-2 Connecting the Power Supply Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-2-1 Types of Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-2-2 Recommended Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-2-3 Power Supply Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-2-4 Connecting the Unit Power Supply Cables. . . . . . . . . . . . . . . . . . . . 33

4-2-5 Connecting the I/O Power Supply Cables . . . . . . . . . . . . . . . . . . . . 34

4-3 Connecting the Turnback Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4-4 Precautions When Connecting the Power Supplies . . . . . . . . . . . . . . . . . . . . 36

4-5 Connecting the Signal Lines for External Devices . . . . . . . . . . . . . . . . . . . . . 38

29

Page 49

Connecting the Communications Cables Section 4-1

4-1 Connecting the Communications Cables

You can use different types of communications cable in a CompoNet network.

You can use the connector on the CompoNet Communications Unit for Flat

Cable or round cable.

4-1-1 Using Flat Cables I/II

1,2,3... 1. Connect a Flat Cable Branch Line Connector (DCN4-BR4 or DCN5-BR4)

to the communications cable. Refer to the CS/CJ-series CompoNet Master

Unit Operation Manual (Cat. No. W456) for the connection procedure.

2. Connect the CompoNet cable to the connector on the CompoNet Communications Unit. Push in until you hear the connector lock.

Flat Connector Plug

4-1-2 Using Round Cables I/II

1,2,3... 1. Connect a Screw Terminal Block Adapter (DCN4-TB4) to the communica-

tions connector on the CompoNet Communications Unit.

Open Connector

WORD

NODE ADR

DC24V

INPUT

GRT1-CRT

WORD

NODE ADR

BS

BD H

BD L

BS

DC24V

INPUT

GRT1-CRT

×1

×10

[0-63]

BS

BD H

BD L

BS

MS

NS

TS

×1

×10

[0-63]

X

IN

MS

UNIT PWR

NS

TS

I/O PWR

X

X

IN

OUT

ON

1

REGS

I/O

2

3

ADR

4

BACK

UNIT

V

V

I/O

V

V

DC24V

INPUT

UNIT PWR

OUT

ID4

TS

0

1

2

3

I/O PWR

X

A1

A2

ON

1

REGS

I/O

2

3

ADR

A3

4

BACK

A4

UNIT

V

V

A5

I/O

V

V

A6

DC24V

INPUT

ID4

ID4

TS

TS

0

1

0

1

2

2

3

3

B1

A1

A1

B2

A2

A2

B3

A3

A3

B4

A4

A4

B5

A5

A5

B6

A6

A6

OD4

ID4

TS

TS

0

0

1

0

1

2

3

B1

A1

B2

A2

B3

A3

B4

A4

B5

A5

B6

A6

OD4

TS

0

1

2

3

B1

A1

B2

A2

B3

A3

B4

A4

B5

A5

B6

A6

0

2

2

3

2

B1

B1

A1

A1

B2

B2

A2

A2

B3

B3

A3

A3

B4

B4

A4

A4

B5

B5

A5

A5

B6

B6

A6

A6

0

2

B1

A1

B2

A2

B3

A3

B4

A4

B5

A5

B6

A6

30

2. Open the terminal cover on the Screw Terminal Block Adapter and connect

the cable conductors to BDH (communications data high signal) and to

BDL (communications data low signal) on the terminal block. For Round

Cable II, also connect BS+ (communications power supply +) and BS

(communications power supply −).

Note Do not connect the BS+ and BS

−

− terminals.

Page 50

Connecting the Power Supply Cables Section 4-2

4-2 Connecting the Power Supply Cables

You connect the power supply cables to the power supply terminals on the

CompoNet Communications Unit. Network power is not necessary if you connect the Communications Unit to a host network.

4-2-1 Types of Power Supply

You must connect two types of power supply to the CompoNet Communications Unit.

■ Unit Power Supply

The Unit power supply is for the internal circuits in the CompoNet Communications Unit and connected SmartSlice I/O Units. The connectors on the Base

Blocks send the power to the SmartSlice I/O Units.

■ I/O Power Supply

The I/O power supply is for the external I/O devices which connect to the

SmartSlice I/O Units. The connectors on the Base Blocks send the power to

the SmartSlice I/O Units.

Unit power

supply (24 VDC)

I/O power

supply

(24 VDC)

CompoNet

Communications Unit

Terminals for

I/O power

supply

Internal

circuits

Terminals for Unit power supply

4-2-2 Recommended Power Supplies

Use an SELV power supply with overcurrent protection.

An SELV power supply has redundant or reinforced insulation between the I/

O, an output voltage of 30 Vr.m.s and a 42.4-V peak or maximum of 60 VDC.

We recommend these Power Supplies.

• S82K-10024 (from OMRON)

• S82J-10024D (from OMRON)

4-2-3 Power Supply Terminals

The power supply terminals on the CompoNet Communications Unit and

Turnback Units are screwless clamp terminals. If you connect ferrules on the

wires, all you must do to connect the wires is to push the ferrules into the terminals.

Internal

circuits

External

device

Slice I/O Units

End Unit

Slice bus

31

Page 51

Connecting the Power Supply Cables Section 4-2

Applicable Wires for Screwless Clamp Terminals

■ Types and Sizes

Type Applicable wire gauge

Stranded wires

Solid wires

Ferrules

■ Stripping Length for Stranded Wires and Solid Wires

■ Conductor Length for Ferrules

We recommend the ferrules in the table below.

Manufacturer Model Applicable wire Crimping Tool

Phoenix Contact AI0.5-10WH

Weidmüller H0.5/16 OR

AWG20 to AWG16 (0.5 to 1.25 mm2)

7 to 10 mm

8 to 10 mm

2

(AWG 20)

2

(AWG 18)

2

(AWG 16)

2

(AWG 18)

AI0.75-10GY

AI1.5-10BK

H0.75/16 W

H1.5/16 R

0.5 mm

0.75 mm

1.25 mm

0.5 mm2 (AWG 20)

0.75 mm

1.25 mm2 (AWG 16)

CRIMPFOX UD6 (order

number 1204436) or

CRIMPFOX ZA3 Series

PZ1.5 Crimping Tool (order

number 990599)

Connecting Wires or Ferrules

■ Connecting Wires with Ferrules

Push the ferrule fully into the wire hole of the screwless clamp terminal.

Push the ferrule fully into the hole.

32

Page 52

Connecting the Power Supply Cables Section 4-2

r

■ Connecting Wires without Ferrules

Press in the release button adjacent to the connection hole of the screwless

clamp terminal with a small flat-blade screwdriver. Then push the wire fully

into the wire hole of the screwless clamp terminal and release the button.

Small flat-blade screwdrive

Release button

Disconnecting Wires or Ferrules

Press in the release button adjacent to the connection hole of the screwless

clamp terminal with a small flat-blade screwdriver. Then pull out the wire or

ferrule and release the button.

Small flat-blade screwdriver

Release button

We recommend this screwdriver to connect or disconnect wires or ferrules.

Model: SZF1 Flat-blade Screwdriver

Manufacturer: Phoenix Contact

Side Front

0.6 mm

3.5 mm

4-2-4 Connecting the Unit Power Supply Cables

Connect the Unit power supply cable (24 VDC) to the power supply terminals

on the CompoNet Communications Unit. These terminals send power to the

internal circuits of the CompoNet Communications Units and the SmartSlice I/

O Units.

33

Page 53

Connecting the Power Supply Cables Section 4-2

Connection holes for power

supply wires or ferrules

UNIT

24 VDC

Unit power supply lines

+V