Page 1

Cat. No. W13E-EN-02

SmartSlice GRT1-Series

GRT1-PNT

PROFINET IO

Communication Unit

OPERATION MANUAL

Page 2

Page 3

Notice

OMRON products are manufactured for use by a trained operator and only for the purposes described in this

manual.

The following conventions are used to classify and explain the precautions in this manual. Always heed the

information provided with them.

!WARNING Indicates information that, if not heeded, could possibly result in serious injury

or loss of life.

!Caution Indicates information that, if not heeded, could possibly result in minor or

relatively serious injury, damage to the product or faulty operation.

OMRON product references

All OMRON products are capitalized in this manual.

The first letter of the word Unit is also capitalized when it refers to an OMRON product, regardless of whether it

appears in the proper name of the product.

Visual aids

The following heading appears in the left column of the manual to help you locate different types of information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

1,2,3... Indicates various lists such as procedures, checklists etc.

Trademarks and copyrights

All product names, company names, logos or other designations mentioned herein are trademarks of their

respective owners.

Copyright

Copyright © 2010 OMRON

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual.

Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained in this publication

iii

Page 4

iv

Page 5

TABLE OF CONTENTS

Precautions vii

1 Intended audience..................................................................................................................................viii

2 General precautions ...............................................................................................................................viii

3 Safety precautions.................................................................................................................................. viii

4 Operating environment precautions ........................................................................................................ ix

5 Application precautions ............................................................................................................................ x

6 Conformance to EC Directives................................................................................................................ xi

SECTION 1

Features and specifications 1

1-1 Overview of GRT1-series SmartSlice I/O Units........................................................................................ 2

1-2 GRT1-PNT PROFINET IO Communication Unit ......................................................................................3

1-3 GRT1-END-M memory end unit ............................................................................................................... 9

1-4 GRT1-PNT configuration........................................................................................................................ 10

1-5 Basic operating procedure ..................................................................................................................... 12

SECTION 2

Installation and wiring 15

2-1 GRT1-PNT Unit components .................................................................................................................16

2-2 GRT1-END-M Unit components ............................................................................................................. 22

2-3 Installing the GRT1-PNT Unit................................................................................................................. 23

2-4 Wiring the GRT1-PNT Unit ..................................................................................................................... 28

2-5 Setting up the PROFINET IO network.................................................................................................... 32

2-6 Installation of Configuration Software..................................................................................................... 38

SECTION 3

Set-up and operation 41

3-1 Device name setting and I/O allocation ................................................................................................. 42

3-2 Unit functions.......................................................................................................................................... 46

3-3 GRT1-END-M Unit functions .................................................................................................................. 52

3-4 Set-up the GRT1-PNT Configuration ..................................................................................................... 54

3-5 Monitoring the GRT1-PNT...................................................................................................................... 62

3-6 I/O communication characteristics ......................................................................................................... 65

SECTION 4

Troubleshooting and maintenance 69

4-1 Overview ................................................................................................................................................ 70

4-2 Troubleshooting using the LED indicators..............................................................................................71

4-3 Other errors ............................................................................................................................................ 76

4-4 Maintenance........................................................................................................................................... 79

4-5 Replacing the Unit .................................................................................................................................. 80

v

Page 6

Appendix A

PROFINET IO technology 83

A-1 Introduction to PROFINET ..................................................................................................................... 83

A-2 PROFINET Communication ................................................................................................................... 84

A-3 PROFINET Distributed I/O ..................................................................................................................... 85

A-4 PROFINET Communication Services .................................................................................................... 89

A-5 Alarms.................................................................................................................................................... 90

A-6 FDT/DTM Technology............................................................................................................................ 91

Appendix B

PROFINET IO alarm messages 93

B-1 Introduction ............................................................................................................................................ 93

B-2 Alarm messages .................................................................................................................................... 94

Appendix C

Explicit messages 95

C-1 Basic format of explicit messages.......................................................................................................... 95

C-2 Explicit messages common to all IO devices ......................................................................................... 97

C-3 Example of using explicit messages ...................................................................................................... 98

Revision history 105

vi

Page 7

Precautions

This chapter provides general precautions for using the GRT1-series modules, Programmable Controllers and

related devices.

The information contained in this section is important for the safe and reliable operation of the GRT1PNT PROFINET IO Communication Unit. You must read this section and understand the information

contained before attempting to set up or operate a GRT1-PNT PROFINET IO Communication Unit and

related systems.

Precautions vii

1 Intended audience..................................................................................................................................viii

2 General precautions ............................................................................................................................... viii

3 Safety precautions ................................................................................................................................. viii

4 Operating environment precautions ........................................................................................................ ix

5 Application precautions ............................................................................................................................ x

6 Conformance to EC Directives ................................................................................................................ xi

vii

Page 8

Intended audience 1

1 Intended audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General precautions

The user must operate the product according to the performance

specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment,

amusement machines, safety equipment, and other systems, machines, and

equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for installing and operating using the

OMRON GRT1-PNT PROFINET IO Communication Unit. Be sure to read this

manual before attempting to use the Unit and keep this manual close at hand

for reference during operation.

!WARNING It is extremely important that the Unit is used for the specified purpose and under the

specified conditions, especially in applications that can directly or indirectly affect

human life. You must consult with your OMRON representative before using the Unit in

a system in the above mentioned applications.

3 Safety precautions

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable Controller),

including the following items, to ensure safety in the system if an abnormality occurs

due to malfunction of the PLC or another (external) factor affecting the operation of the

PLC. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits and similar safety measures

must be provided in external control circuits.

• The PLC will stop operation when its self-diagnosis function detects any error or

when a severe failure alarm (FALS) instruction is executed. As a countermeasure

for such errors, external safety measures must be provided to ensure safety in the

system.

• The PLC outputs may remain ON or OFF due to deposits on or burning of the

output relays, or destruction of the output transistors. As a countermeasure for such

problems, external safety measures must be provided to ensure safety in the

system.

• When the 24 VDC output (service power supply to the PLC) is overloaded or shortcircuited, the voltage may drop and result in the outputs being turned OFF. As a

countermeasure for such problems, external safety measures must be provided to

ensure safety in the system.

• SmartSlice I/O Terminals will continue operating even if one or more I/O Units is

removed from or falls out of the SmartSlice I/O Terminal, i.e., the other I/O Units will

continue control operations, including outputs. As a countermeasure for such

problems, external safety measures must be provided to ensure safety in the

system.

viii

Page 9

Operating environment precautions 4

!WARNING The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

PROGRAM mode). Confirm safety thoroughly in advance before changing the status of

any part of memory allocated to Output Units, Special I/O Units, or CPU Bus Units. Any

changes to the data allocated to any Unit may result in unexpected operation of the

loads connected to the Unit. Any of the following operations may result in changes to

memory status.

• Transferring I/O memory data to the CPU Unit from a Programming Device.

• Changing present values in memory from a Programming Device.

• Force-setting/force-resetting bits from a Programming Device.

• Transferring I/O memory files from a Memory Card or EM file memory to the CPU

Unit.

• Transferring I/O memory from a host computer or from another PLC on a network.

!WARNING Never attempt to disassemble any Units or touch the terminal block while power is

being supplied. Doing so may result in serious electrical shock or electrocution.

4 Operating environment precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidities outside the range specified in the

specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Provide proper shielding when installing the Unit in the following locations:

• Locations subject to static electricity or other forms of electric noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the Unit can have a large effect on the longevity and

reliability of the system. Unsuitable operating environments can lead to malfunction,

failure and other unforeseeable problems with the system. Ensure that the operating

environment is within the specified conditions at installation and remains within the

specified conditions during the life of the system. Follow all installation instructions and

precautions provided in the operation manuals.

ix

Page 10

Application precautions 5

5 Application precautions

Observe the following precautions when using the GRT1-PNT PROFINET IO

Communication Unit.

!WARNING Failure to abide by the following precautions could lead to faulty operation of

the Unit or the system. Always heed these precautions:

• Install double safety mechanisms to ensure safety against incorrect signals that

may be produced by broken signal lines or momentary power interruptions.

• When adding a new device to the network, make sure that the baud rate is the

same as other stations.

• When adding a new SmartSlice I/O Unit to the Communication Unit, make

sure that the CJ1W-PNT21 PROFINET IO Communication Unit is powered

down, to prevent unexpected results when starting up the new station.

• Use specified communication cables.

• Do not extend connection distances beyond the ranges given in the specifications.

• Always turn OFF the power supply to the personal computer, Slaves, and

Communication Units before attempting any of the following:

• Mounting or dismounting the CJ1W-PNT21 PROFINET IO Communication Unit,

Power Supply Units, I/O Units, CPU Units, or any other Units.

• Assembling a Unit.

• Setting DIP-switches or rotary switches.

• Connecting or wiring the cables.

• Connecting or disconnecting connectors.

• Be sure that all the mounting screws, terminal screws, Unit mounting screws, and

cable connector screws are tightened to the torque specified in the relevant

manuals. Incorrect tightening torque may result in malfunction.

• Always use the power supply voltage specified in this manual.

• Double-check all the wiring and connection of terminal blocks and connectors

before mounting the Units.

• Take appropriate measures to prevent foreign objects from entering the unit when

mounting or wiring it. Failure to do so, may result in unit damage, electric shock or

fire.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals.

• Observe the following precautions when wiring the communication cable.

• Separate the communication cables from the power lines or high-tension lines.

• Do not bend the communication cables.

• Do not pull on the communication cables.

• Do not place heavy objects on top of the communication cables.

• Be sure to wire communication cable inside ducts.

• Use appropriate communication cables.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied in places where the power supply is unstable. An

incorrect supply power may result in malfunction.

• Install external breakers and take other safety measures against short-circuits in

external wiring. Insufficient safety measures against short-circuits may result in

burning.

• Double-check all the wiring and switch settings before turning ON the power supply.

• When transporting or storing the product, cover the PCB’s with electrically

conductive materials to prevent LSI’s and IC’s from being damaged by static

electricity, and also keep the product within the specified storage temperature

range.

• When transporting the Unit, use special packing boxes and protect it from being

exposed to excessive vibration or impacts during transportation.

• Do not attempt to disassemble, repair, or modify any Units.

• Do not remove the network cable during operation. Removing the network cable

result in communication failures.

!WARNING Failure to abide by the following precautions could lead to faulty operation of

the Unit or the system. Always heed these precautions:

x

Page 11

Conformance to EC Directives 6

• Always connect to a class-3 ground (100 Ω or less) when installing the

Units.

• Fail-safe measures must be taken by the customer to ensure safety in the event of

incorrect, missing, or abnormal signals caused by broken signal lines, momentary

power interruptions, or other causes.Not doing so may result in serious accidents.

6 Conformance to EC Directives

6-1 Applicable directives

• EMC (ElectroMagnetic Compatibility) Directives

• Low-voltage directive

6-2 Concepts

OMRON units complying with EC Directives also conform to related product

standards making them easier to incorporate in other units or machines. The

actual products have been checked for conformity to product standards.

Whether the products conform to the standards in the system used by the

customer, however, must be checked by the customer.

Product related performance of OMRON units complying with EC Directives

will vary depending on the configuration, wiring, and other conditions of the

equipment or control panel in which OMRON devices are installed. The

customer must, therefore, perform final checks to confirm that units and the

overall system conforms to product standards.

A Declaration of Conformity for the GRT1-PNT PROFINET IO Communication

Unit can be requested at your nearest OMRON representative.

6-3 Conformance to EC Directives

PROFINET IO units should be installed as follows, for the complete

configuration to meet the EC directives:

1 The units are designed for installation inside control panels. All units must

be installed within control panels.

2 Use reinforced insulation or double insulation for the DC power supplies

used for the communication power supply, internal circuit power supply,

and the I/O power supplies. Ensure that stable outputs can be provided

even if a 10 ms interruption occurs at the input.

3 The GRT1-PNT PROFINET IO Communication Unit meets the generic

emission standard. However as EMC performance can vary in the final

installation, additional measures may be required to meet the standards. It

should therefore be verified that the overall machine or device also meets

the relevant standards. You must therefore confirm that EC directives are

met for the overall machine or device, particularly for the radiated emission

requirement (10 m).

xi

Page 12

Conformance to EC Directives 6

xii

Page 13

SECTION 1

Features and specifications

This section provides an introductory overview of the GRT1 series SmartSlice I/O Units and the GRT1-PNT

PROFINET IO Communication Unit, its functions and how to set up and configure it for a PROFINET network.

SECTION 1 Features and specifications 1

1-1 Overview of GRT1-series SmartSlice I/O Units ....................................................................................... 2

1-2 GRT1-PNT PROFINET IO Communication Unit ......................................................................................3

1-3 GRT1-END-M memory end unit ............................................................................................................... 9

1-4 GRT1-PNT configuration........................................................................................................................ 10

1-5 Basic operating procedure ..................................................................................................................... 12

1

Page 14

Overview of GRT1-series SmartSlice I/O Units Section 1-1

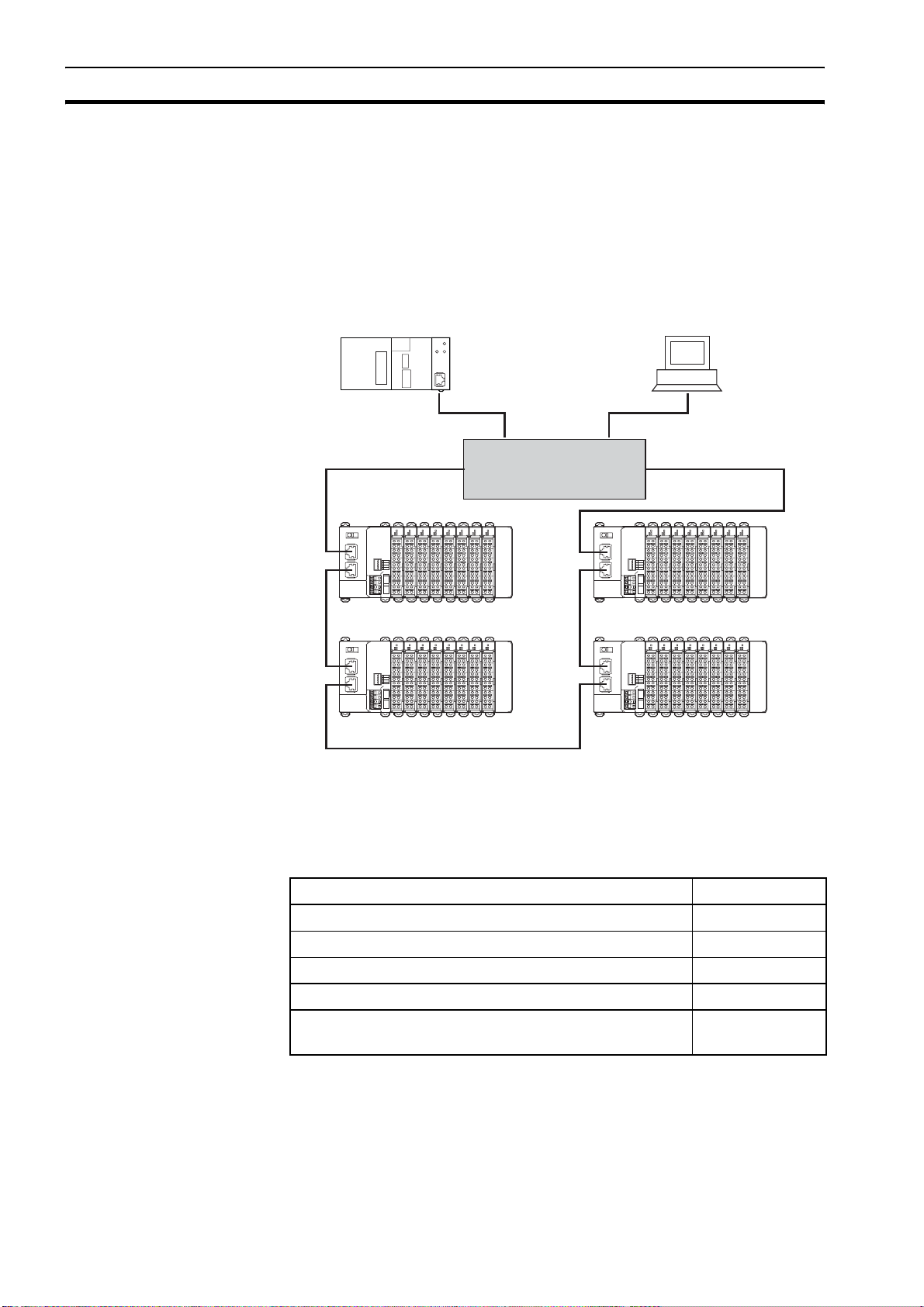

1-1 Overview of GRT1-series SmartSlice I/O Units

The GRT1-Series SmartSlice I/O Units are building-block style I/O Devices,

which can be expanded in small I/O increments. This provides the possibility

to configure I/O systems which exactly match the various customer

applications. SmartSlice I/O Units communicate with the PROFINET IO

Controller Unit by remote I/O communication through a PROFINET IO

Communication Unit. The figure below shows a typical I/O configuration.

Switch / MRP Manager

GRT1-series SmartSlice I/O

and PROFINET IO Units

2

Figure 1.1: GRT1-PNTs connected to an IO Controller through Profinet

The GRT1-Series of SmartSlice I/O Units, Communication Units and

PROFINET IO Units is constantly being expanded with new Units. Refer to the

following manuals.

/i

Name Manual Reference

GRT1 Series SmartSlice I/O Units Operation Manual W455

GRT1-DRT DeviceNet Communication Unit Operation Manual W454

GRT1-PRT PROFIBUS Communication Unit Operation Manual W04E

GRT1-CRT CompoNet Communication Unit Operation Manual W476

SYSMAC CJ-Series CJ1W-PNT21 PROFINET IO Controller

Unit Operation Manual

W12E

Page 15

GRT1-PNT PROFINET IO Communication Unit Section 1-2

1-2 GRT1-PNT PROFINET IO Communication Unit

1-2-1 Features

The GRT1-PNT PROFINET IO Communication Unit for SmartSlice I/O

controls data exchange between the PROFINET IO Controller and SmartSlice

I/O Units over the PROFINET IO network as an IO Device. For an overview of

the PROFINET IO technology refer to Appendix A PROFINET IO technology.

I/O Data Exchange Cyclic I/O data exchange is used to exchange I/O data between the

PROFINET IO Controller and SmartSlice I/O Units through the PROFINET IO

Communication Unit. In addition to I/O data, status information in the

PROFINET IO Communication Unit can be accessed from the PROFINET IO

Controller Unit.

FINS/UDP Interface The PROFINET IO Communication Unit is provided with a FINS/UDP

Interface. This enables not only the PROFINET IO Controller to access the

SmartSlice I/O Units using OMRON FINS messaging, but any device which

supports a UDP interface (such as a Personal Computer using CX-Server

Lite). This allows for configuration and monitoring of the

from remote stations.

SmartSlice I/O Units

Simplified Start-up The PROFINET IO Communication Unit can be set up easily, just by wiring the

Unit, configuring the PROFINET IO network using CX-ConfiguratorFDT and

making simple DIP switch settings. The Unit's configuration is read

automatically when the power is turned ON and I/O is also automatically

allocated in the SmartSlice I/O Units.

Device Name Store In

GRT1-END-M Memory End

Unit

Easy PROFINET IO

Network Layout

MRP Ring Redundancy To avoid a single network failure causing communication failure within a large

Facilitating IO Controller

Redundancy

The separately available GRT1-END-M Memory End Unit facilitates easy

replacement of the PROFINET IO Communication Unit. It optionally replaces

the standard GRT1-END End Unit. No re-configuration using CXConfiguratorFDT is required in case of replacement of the Communication

Unit. The PROFINET IO Device name, used for identification of the

Communication Unit on the PROFINET IO network, is backed up and restored

to and from the GRT1-END-M Memory End Unit.

The PROFINET IO Communication Unit is equipped with two ethernet ports.

The built-in ethernet switch functionality allows for easy line configuration of

the network, as additional external ethernet switches may not be necessary.

part of the network, the units can be set up in a ring topology. MRP Ring

Redundancy as specified in the PROFINET standards ensures

communication to all remaining devices through the redundant path.

To ensure a safe implementation of the application, the PROFINET IO

Communication Unit and the PROFINET IO Controller offer the possibility of

PLC system redundancy. Two IO Controllers (active and standby) are present

in a network connected to all I/O Devices. This feature ensures a fast change

from active to standby PLC / IO Controller in case of malfunction.

Simplified I/O Wiring All SmartSlice I/O Units that connect to a PROFINET IO Communication Unit

are equipped with screw-less clamp terminal blocks. Wiring to external I/O is

accomplished just by inserting the wire into the terminals, eliminating the need

to tighten terminal screws.

3

Page 16

GRT1-PNT PROFINET IO Communication Unit Section 1-2

Table Registration The configuration of the SmartSlice I/O Units (mounting order and I/O size)

connected to a PROFINET IO Communication Unit can be registered in a

table simply by setting a DIP switch. Once the table has been registered, the

actual configuration is compared to the registered configuration each time that

the power is turned ON. If the configuration does not match, a status flag is

turned ON in the PROFINET IO Controller to indicate the error.

On-line Replacement of I/O

Units

The SmartSlice I/O Unit's circuit section can be removed, so it is not

necessary to turn OFF the Communication Unit’s power to replace a Unit.

Communication can be maintained in the remaining (connected) Units.

Parameter Backup and

Restores

Before replacing a SmartSlice I/O Unit for maintenance, the parameter data

set in all SmartSlice I/O Units can be backed up in the PROFINET IO

Communication Unit by toggling a DIP switch. Another DIP selects the mode

to automatically write the back-up parameter data to the replacement

SmartSlice I/O Unit.

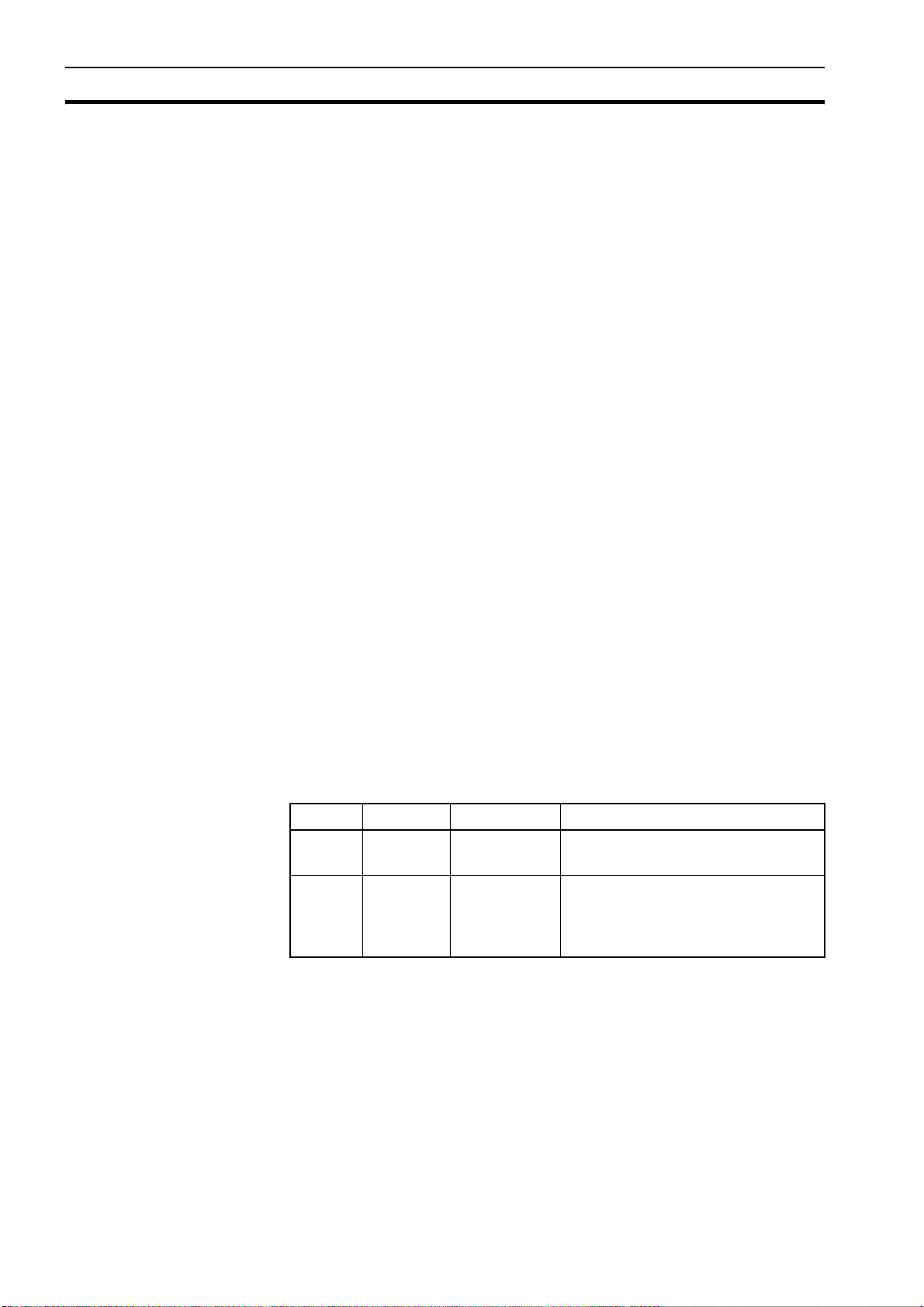

1-2-2 System configuration

The PROFINET IO Communication Unit connects to the IO Controller by an

Ethernet network cable and it connects to the SmartSlice I/O Units by directly

coupling the Units together.

I/O Data Exchange The I/O Unit data in the PROFINET IO Communication Unit is shared with the

IO Controller's Input and Output Areas through the PROFINET IO network.

The I/O Units' data is collected in the PROFINET IO Communication Unit and

exchanged with the IO Controller cyclically.

Messaging Services The GRT1-PNT PROFINET IO Communication Unit also supports messaging

services using FINS/UDP, allowing the user to send acyclic message

commands addressed to the GRT1-PNT Unit or individual SmartSlice I/O

Units. This can be sent from the PLC or for instance the Personal Computer.

End Unit for PROFINET IO Always install an End Unit on the last I/O Unit in the system. For the

PROFINET IO Communication Unit there are two options:

/i

Type I/O points Model number Description

End Unit -- GRT1-END End Unit to be mounted to the end of the

SmartSlice I/O Terminal.

Memory

End Unit

2 input bits GRT1-END-M End Unit to be mounted to the end of the

SmartSlice I/O Terminal.

The unit has a backup of the IO Device

Name of the Communication Unit.

In case of replacement of the PROFINET IO Communication Unit, the

PROFINET IO Device Name will be restored from the GRT1-END-M Unit to

the new Communication Unit. In case of the standard GRT1-END, additional

configuration download using CX-ConfiguratorFDT is required after

replacement.

Note 1 Unlike the standard End Unit, the Memory End Unit will count as one SmartSlice I/O

Unit. Up to 63 SmartSlice I/O Units can be connected to one PROFINET IO Communication Unit when the GRT1-END-M is used.

2 The GRT1-END-M Memory End Unit functionality only applies to the PROFINET IO

Communication Unit. Although the Memory End Unit has the basic End Unit funtionality, the Unit is not aimed to be used together with other Communication Units.

4

Page 17

GRT1-PNT PROFINET IO Communication Unit Section 1-2

1 2

Switch

Figure 1.2: A single GRT1-PNT connects to multiple I/O blocks via Turnback units.

1 Remote I/O data is collected from the connected SmartSlice I/O Units and

exchanged with the IO Controller Unit

2 Acyclic messages are used to monitor operation and write parameters to

the SmartSlice I/O Units.

5

Page 18

GRT1-PNT PROFINET IO Communication Unit Section 1-2

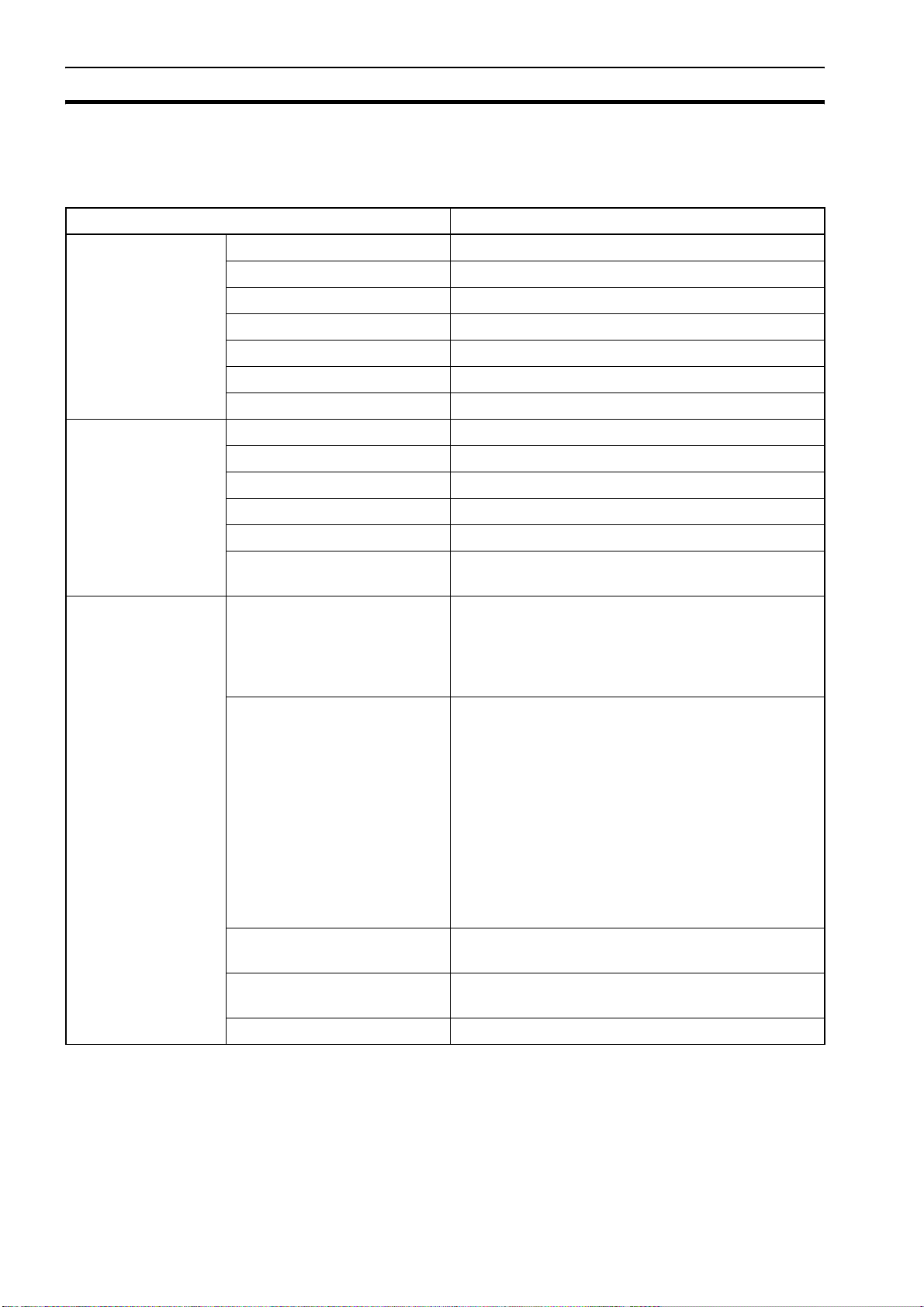

1-2-3 Specifications

Functional specifications

/i

Item Specification

Installation Unit type SmartSlice GRT1 series

Model GRT1-PNT

Mounting position DIN Rail mounted

Power supply 24 V

Current consumption 140 mA (max), 120 mA typical at 24 V

+ 10 % / − 15 % (20.4 VDC to 26.4 VDC)

DC

DC

Dimensions (WxHxD) 58 x 80 x 70 mm

Weight 120 g (typical)

Environment Ambient operating temperature −10 °C to +55 °C (no icing or condensation)

Ambient operating humidity 25 % to 85 % Relative Humidity

Storage temperature −40 °C to +70 °C (no icing or condensation)

Vibration resistance 150 m/s

2

Dielectric strength 500 VAC (between isolated circuits)

Conformance to EMC and

EN 61131-2:2003

Electrical safety standards

Front case DIP-switches 4 DIP switches on the front of the unit:

• Switch 1: Create / Enable registration table

• Switch 2: Not used

• Switch 3: Automatic restore

• Switch 4: Backup Trigger

Indicators 6 LEDs;

Unit status:

• RUN (green LED),

• ERR (red LED),

• UNIT PWR (green LED).

SmartSlice I/O Unit status:

• TS (red/green LED),

• I/O PWR (green LED).

PROFINET IO status:

• BF (red LED).

PROFINET IO Connector 2 x RJ45 8-pin Modular Connector

(conforming to ISO 8877)

Power Screwless push-in connectors

Unit power and I/O power are separated.

Field Ground connector Screwless push-in connector

6

Page 19

GRT1-PNT PROFINET IO Communication Unit Section 1-2

Item Specification

SmartSlice I/O System Number of connectable SmartSlice

I/O Units

Turnback cable Length 1 m, up to 2 cables can be connected.

SmartSlice I/O Unit connections Building-block style configuration (Units connect with Turn-

Base block power supply Voltage: 24 V

Event messaging Supported

64 units max. (including GRT1-END-M Memory Unit)

Connected directly to the GRT1-PNT or via turnback

extension units.

back cables)

DC

Current: 4 A max

Protocol specifications

/i

Item Specification

PROFINET interface Protocol PROFINET IO

PROFINET unit type PROFINET IO Device

Isochronous mode No

Alarms Yes

Minimum Update Rate 8 ms

Transfer specifications Bitrate 100 Mbps (100Base-TX)

Automatic detection of transmission speed Yes

PROFINET IO cable Type LAN balanced of category 5 or higher,

according to ISO/IEC 11801 Edition 2.0

Core cross section AWG 22

Maximum number of connector/socket pairs 6

Max transmission distance 100 m (distance between nodes)

PROFINET redundancy Protocol Media Redundancy Protocol (MRP) client

Configuration GSD file GSDML-V2.1-OMRON-GRT1-PNT-

20081205.xml

DTM Included in CX-ConfiguratorFDT

FINS service FINS/UDP Supported

7

Page 20

GRT1-PNT PROFINET IO Communication Unit Section 1-2

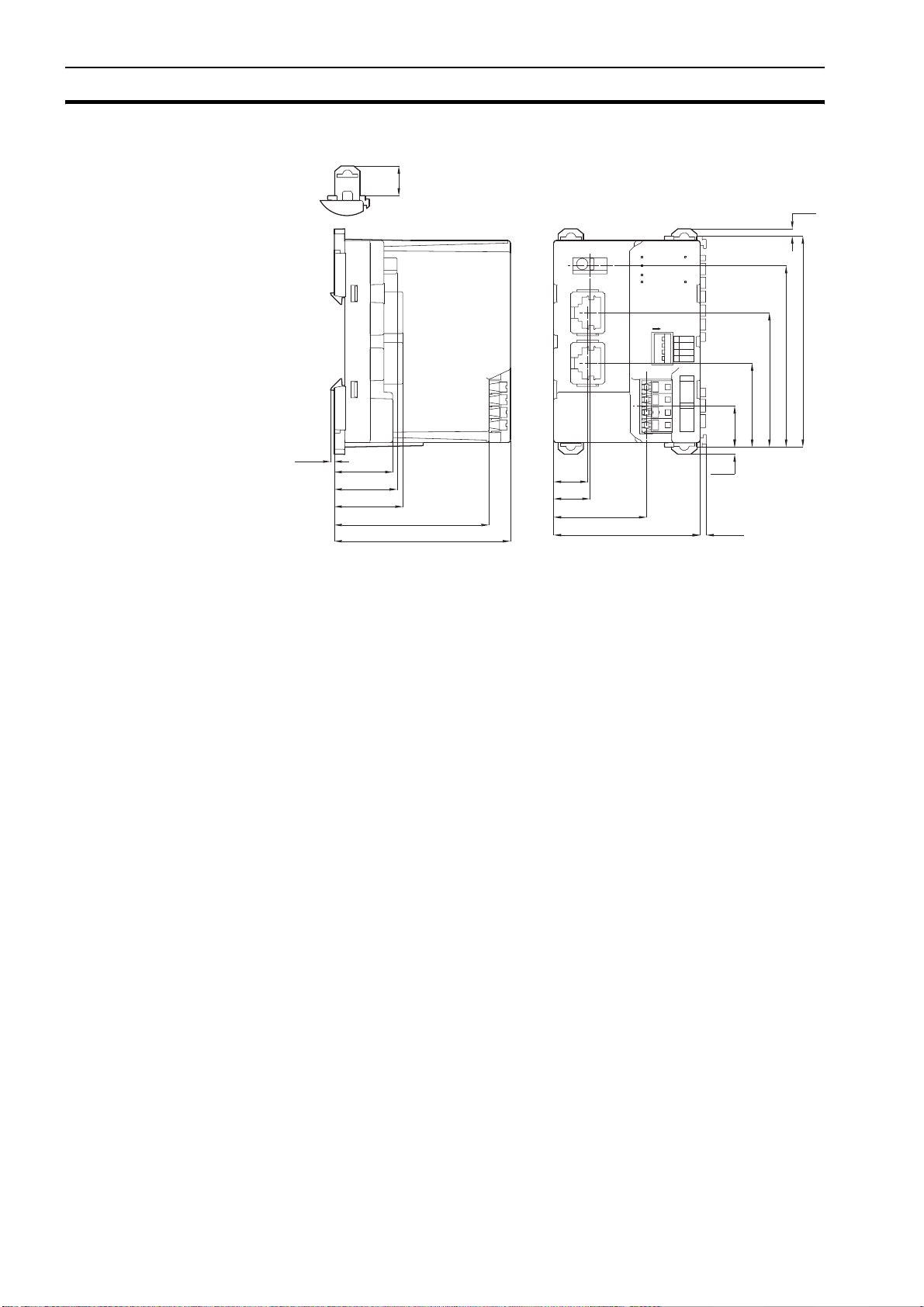

External dimensions

11. 75

2.85

OMRON

1.5

23.1

24.8

27.1

61.2

69.7

LNK1LNK2

13.5

14.3

GRT1-PNT

FG

PORT1PORT2

36.7

UNIT PWR

RUN

ERR

BF

I/O PWR

TS

ON

REGS

1

NC

2

3

ADR

BACK

4

UNIT

+V

-V

I/O

+V

-V

DC24V

INPUT

2.85

58 2.4

83.5

71.7

53.2

33.2

16.3

Figure 1.2.3: GRT1-PNT PROFINET IO Communication Unit external dimensions

8

Page 21

GRT1-END-M memory end unit Section 1-3

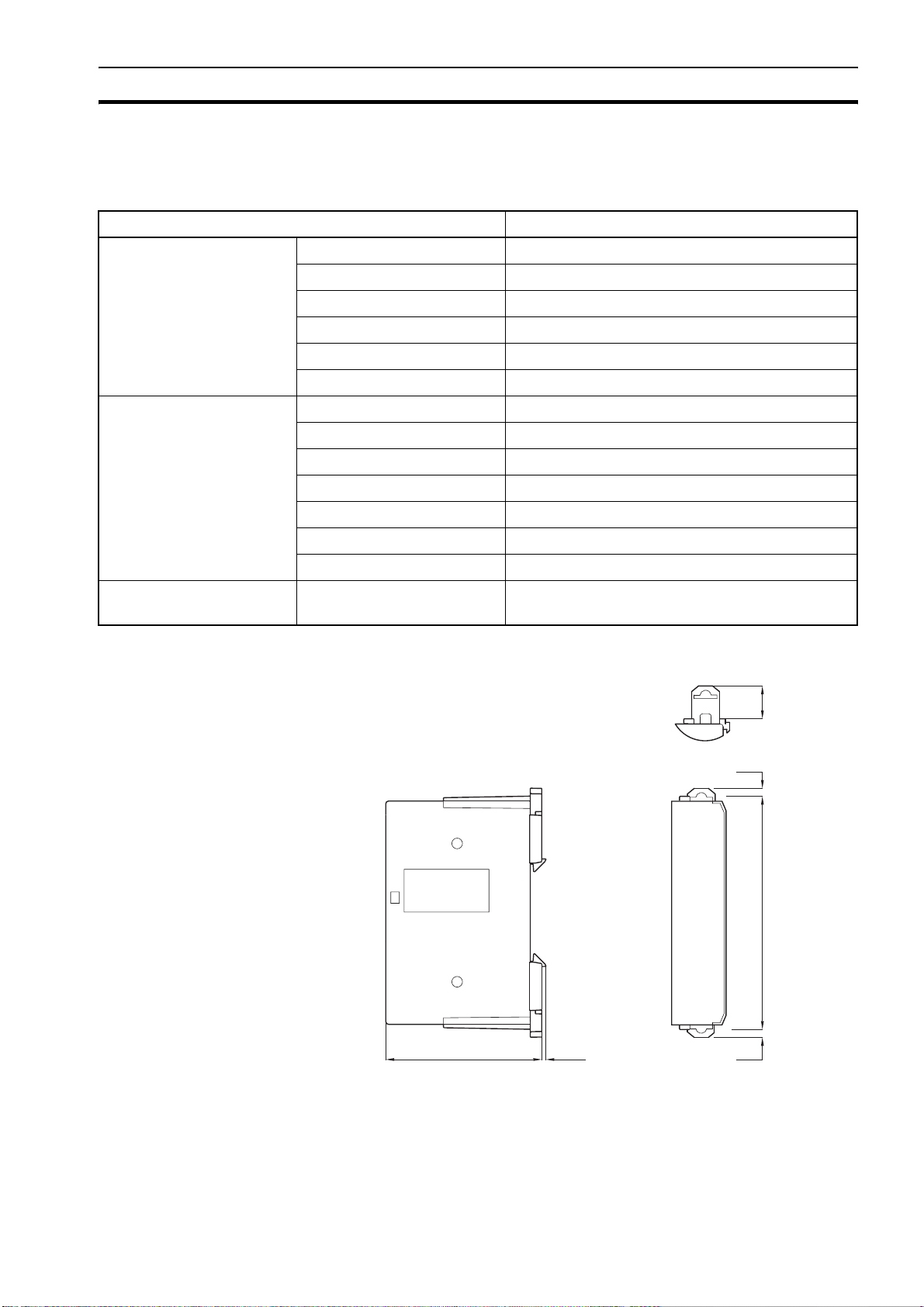

1-3 GRT1-END-M memory end unit

Functional specifications

/i

Item Specification

Installation Unit type SmartSlice GRT1 series

Model GRT1-END-M

Mounting position DIN Rail mounted

Current consumption 30 mA (max), 24 mA typical at 24 V

DC

Dimensions (WxHxD) 19.5 x 83.5 x 55.7 mm

Weight 60 g (typical)

Environment Ambient operating temperature −10 °C to +55 °C (no icing or condensation)

Ambient operating humidity 25 % to 85 % relative humidity

Storage temperature −25 °C to +65 °C (no icing or condensation)

Noise immunity Conforms to IEC61000-4-4, 2.0 kV

Shock resistance 150 m/s

Dielectric strength 500 V

2

AC

Enclosure rating IP20

Front case Indicators TS (Two-colour LED):

indicates the unit’s operating status.

External dimensions

55.7 1.5

END-M

11. 7 5

2.85

TS

83.5

2.85

Figure 1.3: GRT1-END-M memory end unit external dimensions

9

Page 22

GRT1-PNT configuration Section 1-4

1-4 GRT1-PNT configuration

PROFINET IO

Configuration Means

GRT1-PNT Configuration

DTM

GRT1-PNT I/O

Configuration

The PROFINET IO Controller Unit requires a configuration before it can

exchange I/O data with any of its IO Devices. For this configuration information

on the IO device must be available. OMRON provides two means to facilitate

IO Controller Unit configuration.

• A GRT1-PNT DTM

• A GRT1-PNT GSD file

The GRT1-PNT DTM is an executable component, provided by OMRON,

which requires an FDT Container program like OMRON's CXConfiguratorFDT (see also Appendix A PROFINET IO technology, FDT/DTM

Technology). The DTM runs inside this FDT Container and provides its own

User Interface. It can access GRT1-PNT and SmartSlice I/O Unit data using

FINS/UDP and present that to the user. It can also save the settings, using the

features of the FDT Container program. The GRT1-PNT DTM provides the

user with the following features.

• PROFINET I/O Configuration

• Configuration of individual SmartSlice I/O Units

• Monitoring of the SmartSlice I/O System

The I/O Configuration User Interface allows the user to define the

configuration of SmartSlice I/O Units attached to the PROFINET IO

Communication Unit. It also allows the user to make parameter settings for

individual SmartSlice I/O Units.

The I/O Configuration is used by the PROFINET IO Controller Unit when

mapping the I/O data of individual SmartSlice I/O Units onto the PLC memory

areas. It is also sent by the PROFINET IO Controller Unit to the GRT1-PNT for

verification when establishing communication. The I/O Configuration sent by

the PROFINET IO Controller Unit must match the physical configuration

attached to the GRT1-PNT PROFINET IO Communication Unit, in order to

proceed with I/O data exchange.

Monitoring the SmartSlice

I/O System

Configuration via GSD File The GSD file concept is other way of configuration. The GSD file for the

Third-Party IO Controller

Units

The Monitoring User Interfaces allows the user to read information from

individual SmartSlice I/O Units. It also provides a means to read the Error Log

of the GRT1-PNT PROFINET IO Communication Unit.

GRT1-PNT is an XML-based file, which contains all options required to

configure a PROFINET IO Controller Unit. The file can be loaded by the

configuration software of the IO Controller Units, which will then present the

information to the user to allow the appropriate selections to be made.

The drawback of the GSD file is that - unlike the GRT1-PNT DTM - it only

provides setting options for configuring the PROFINET IO. The GSD file does

not provide the means to access data of the SmartSlice I/O Units directly.

The GSD file for GRT1-PNT can be used to configure most third-party I/O

Controller Units. The GRT1-PNT GSD file contains all the necessary

parameters to allow the user to configure the IO Controller Unit for I/O data

exchange.

10

Page 23

GRT1-PNT configuration Section 1-4

Note 1 The GRT1-PNT DTM can also be used in third-party configuration software pro-

vided that this software supports the FDT/DTM concept.

2 With the CX-ConfiguratorFDT FDT Container OMRON also provides a Generic IO

Device DTM, an FDT/DTM interface between the FDT Container program and GSD

files. Alternatively, this DTM can be used to set up an IO Controller Unit, using the

GRT1-PNT GSD file. This Generic IO Device DTM however, does not provide the

means to access data of the SmartSlice I/O Units directly.

Downloading the

configuration

After setting up the configuration, it must be downloaded to the PROFINET IO

Controller Unit. The download process depends on the IO Controller Unit

used.

11

Page 24

Basic operating procedure Section 1-5

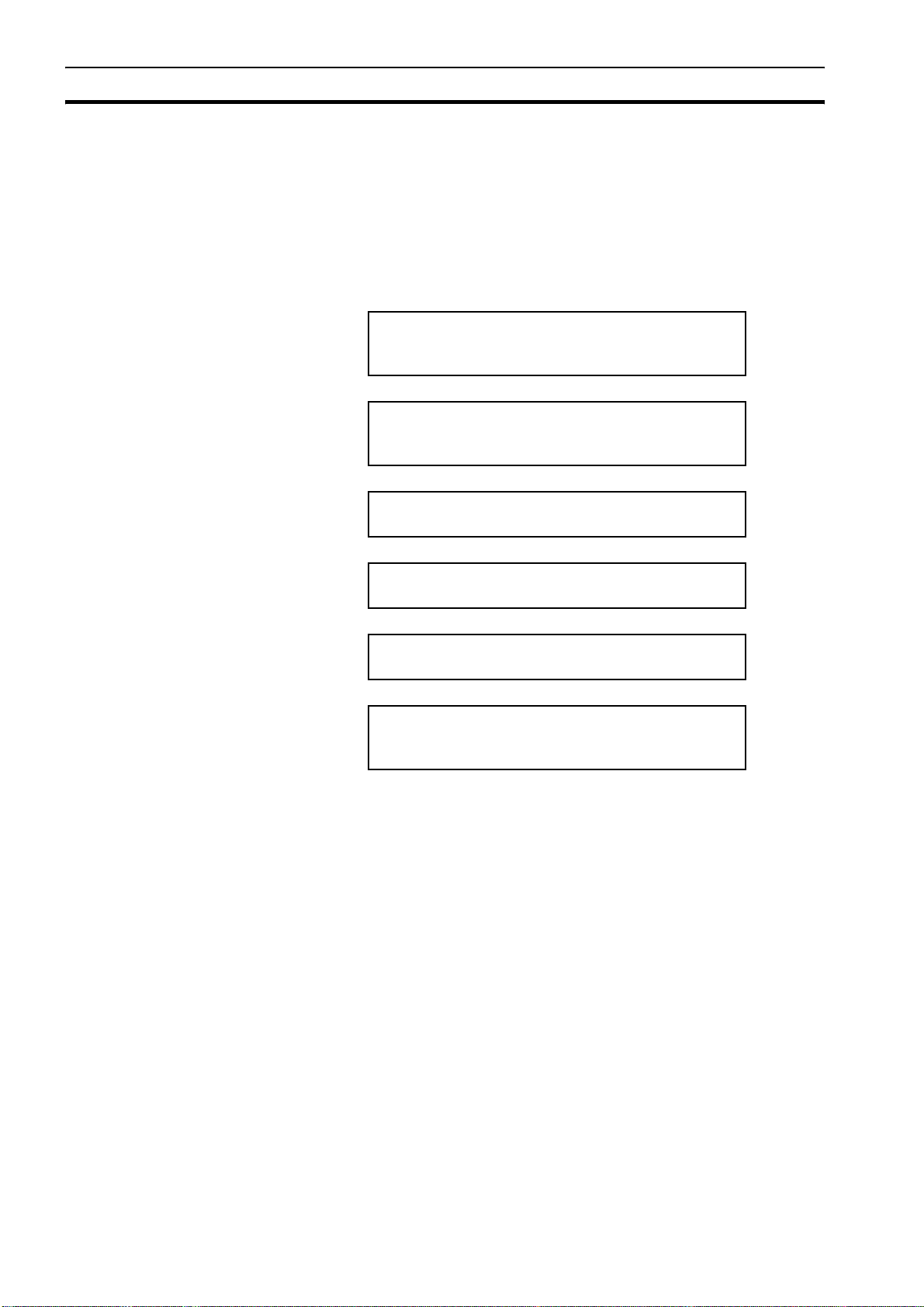

1-5 Basic operating procedure

1-5-1 Overview

The following diagram provides an overview of the installation procedures. For

experienced installation engineers, this may provide sufficient information. For

others, cross-references are made to various sections of this manual where

more explicit information is given.

/i

Mount the GRT1-PNT PROFINET IO Unit and the

SmartSlice I/O Units including the GRT1-END-M Unit.

(See section 2-3 Installing the GRT1-PNT Unit).

T

Wire the GRT1-PNT PROFINET IO Communication Unit

and the SmartSlice I/O Units.

(See section 2-3 Installing the GRT1-PNT Unit).

T

Setup the PROFINET IO network.

(See section 2-4 Wiring the GRT1-PNT Unit).

T

Power up the GRT1-PNT and perform initial setup.

(See section 3-4 Set-up the GRT1-PNT Configuration).

T

Configure the PROFINET IO Controller Unit.

(See section 3-4 Set-up the GRT1-PNT Configuration).

T

PROFINET IO starts communicating, confirmed by the BF

LED being not lit. Check status of other LED Indicators.

(See section 3-5 Monitoring the GRT1-PNT).

12

Page 25

Basic operating procedure Section 1-5

1-5-2 Preparations for use

The following procedure shows the basic steps required before using the

PROFINET IO Communication Unit and the SmartSlice I/O Units.

Initial setup procedure 1 Mount the GRT1-PNT Unit and the SmartSlice I/O system on the DIN rail.

The maximum number of SmartSlice I/O Units can be 64 (including GRT1END-M End Unit).

2 Wire the SmartSlice I/O Units and the GRT1-PNT Unit's power supply.

3 Wire the PROFINET IO network, to connect the Communication Unit to the

PROFINET IO Controller Unit.

4 Turn ON the power to the Unit and the I/O.

5 Turn ON (from OFF to ON) DIP switch 1 on the front of the PROFINET IO

Communication Unit. When switch 1 is turned ON, the existing SmartSlice

I/O Unit configuration (connection order and I/O size) is registered in the

PROFINET IO Communication Unit as a registered table. After the table is

registered, leave pin 1 ON to enable the table.

Note The next time the power is turned ON, the actual SmartSlice I/O Unit configuration at

power on is automatically compared to the registered table. Any SmartSlice I/O Units

that do not match the registered table (connection order or I/O size) will not participate

in I/O communication. I/O communication will start with the other SmartSlice I/O Units.

Configuration procedure Use the following procedure to configure the IO Controller Unit together with

the PROFINET IO Communication Unit using CX-ConfiguratorFDT and the IO

Controller and IO Device DTMs:

1 Turn ON the PLC power supply and the power supplies of the IO Devices

on the network.

2 In CX-ConfiguratorFDT, create a network and define the parameters and

I/O configurations for the PROFINET IO Controller Unit settings and the

allocated IO Devices. Choose the update rate for each IO Device.

3 Use the PROFINET IO Controller DTM to assign Device Names to the

actual IO Devices in the network.

4 Download the network configuration to the PROFINET IO Controller Unit.

After downloading the configuration, CX-ConfiguratorFDT will restart the

PROFINET IO Controller Unit.

5 After restarting the PROFINET IO Controller Unit it will automatically start

communication when the PLC goes into RUN/MONITOR mode.

13

Page 26

Basic operating procedure Section 1-5

14

Page 27

SECTION 2

Installation and wiring

This section shows the GRT1-series PROFINET IO Communication Unit and identifies its controls and

indicators. It contains the procedures for installing and wiring the Communication Unit as well as the GRT1series SmartSlice I/O Units. It also contains the procedures for setting up the PROFINET IO network.

SECTION 2 Installation and wiring 15

2-1 GRT1-PNT Unit components ................................................................................................................. 16

2-2 GRT1-END-M Unit components............................................................................................................. 22

2-3 Installing the GRT1-PNT Unit................................................................................................................. 23

2-4 Wiring the GRT1-PNT Unit..................................................................................................................... 28

2-5 Setting up the PROFINET IO network ................................................................................................... 32

2-6 Installation of Configuration Software .................................................................................................... 38

15

Page 28

GRT1-PNT Unit components Section 2-1

2-1 GRT1-PNT Unit components

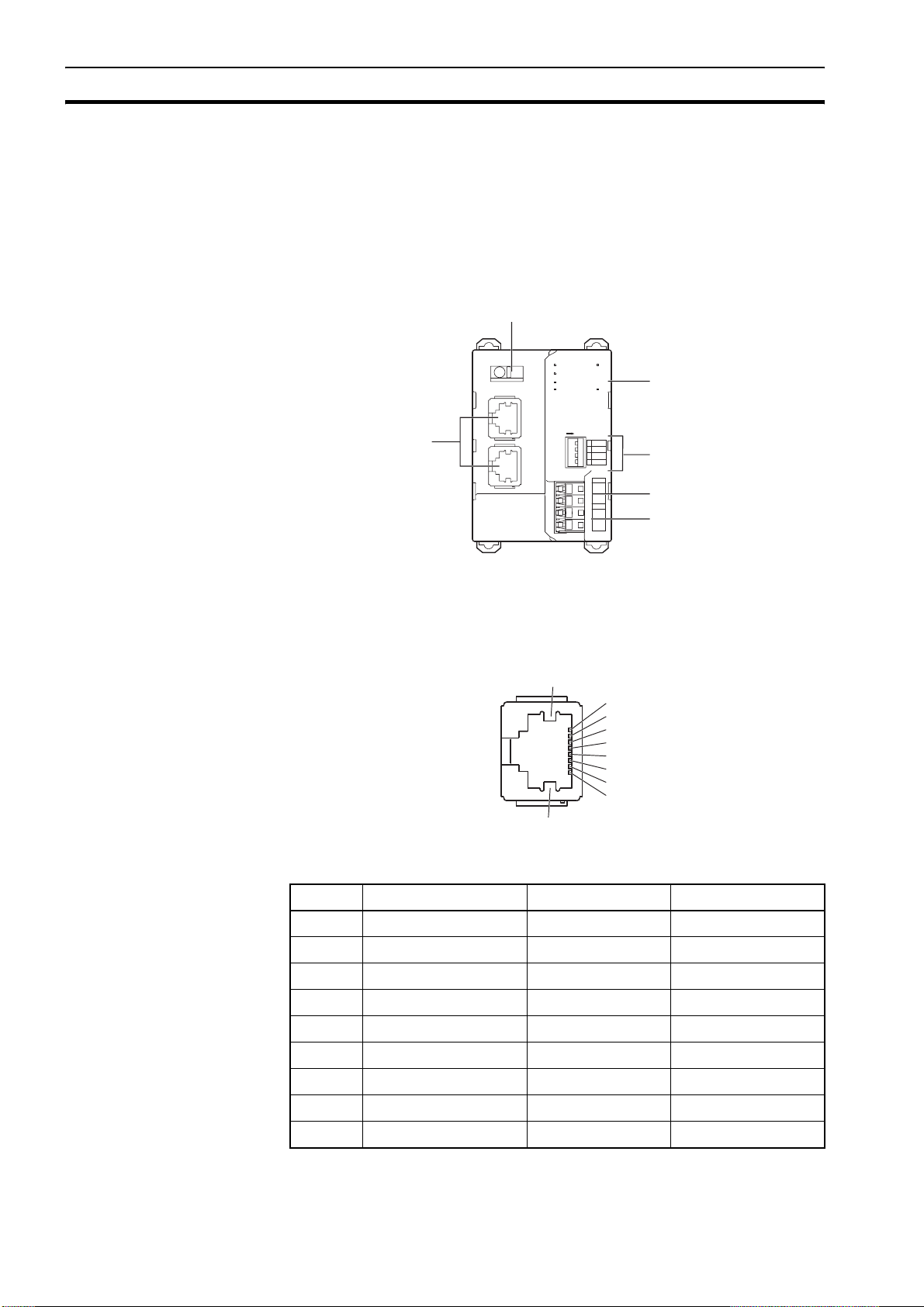

2-1-1 Overview

The illustration below shows the two PROFINET IO Ethernet connectors with

Link activity LED indicators (1), the Status LED indicators (3), the Field Ground

Terminal (2), the DIP switches (4) and the power supply terminals (5 and 6) on

the front side of the PROFINET IO Communication Unit. Each of these

components is explained in the following sections.

2

OMRON

GRT1-PNT

FG

LNK1LNK2

PORT1PORT2

1

RUN

ERR

BF

TS

UNIT PWR

I/O PWR

ON

1

2

3

4

REGS

NC

ADR

BACK

UNIT

+V

-V

I/O

+V

-V

DC24V

INPUT

3

4

5

6

2-1-2 Ethernet connectors

The GRT1-PNT contains two Ethernet connector ports. The ports are

functionally the same and enable bus line network topology.

/i

Pin Signal Abbreviation Signal direction

1 Transmission data + TD+ Output

2 Transmission data - TD- Output

3 Reception data + RD+ Input

4 Not used --- ---

Figure 2.1: GRT1-PNT overview

9

1

2

3

4

5

6

7

8

9

Figure 2.1.2: GRT1-PNT ethernet connector

16

5 Not used --- ---

6 Reception data - RD- Input

7 Not used --- ---

8 Not used --- ---

9 Field Ground FG ---

Page 29

GRT1-PNT Unit components Section 2-1

The following standards and specifications apply to the connectors for the

Ethernet twisted-pair cable.

• Electrical specifications: Conforming to IEEE 802.3 standards

• Shielded twisted-pair (STP) cable: minimum category CAT5

• Connector structure: RJ45 8-pin Modular Connector (conforming to

ISO 877)

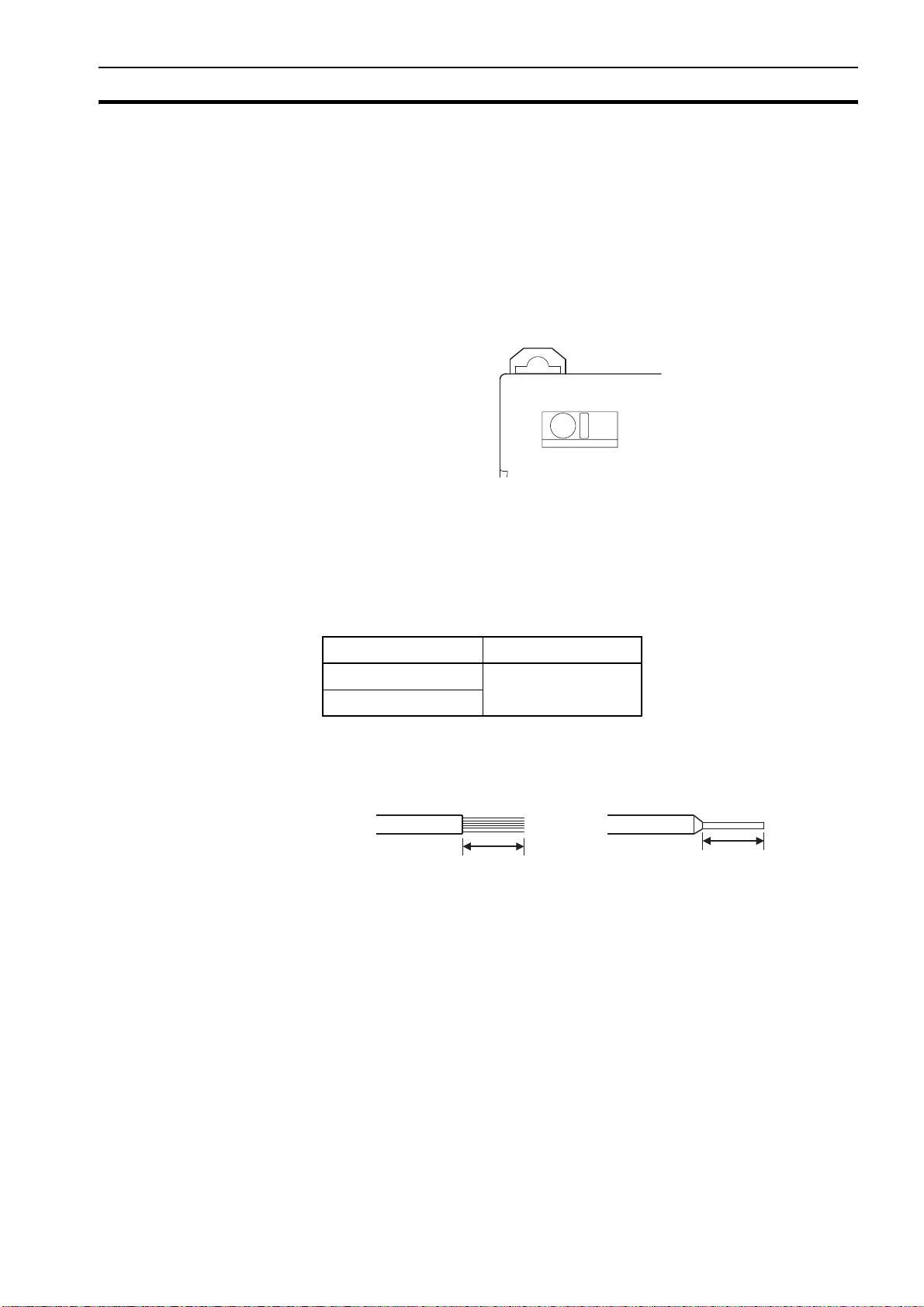

2-1-3 Field Ground Terminal

The GRT1-PNT PROFINET IO Communication Unit provides a Field gGround

Terminal at the front side.

OMRON

GRT1-PNT

FG

Figure 2.1.3: GRT1-PNT Field Ground Terminal

Recommended Wire

Strip Length

Pin Terminal Length

2-1-4 LED indicators

To help prevent electrical shock and/or if noise is a significant source of errors,

ground the Field Ground Terminal with a ground resistance of less than 100 Ω

using a 14-gauge wire (minimum cross-sectional area of 2 mm

/i

Type Gauge

Stranded wire 20 AWG to 14 AWG

Pin terminal

(0.5 to 2.0 mm

2

)

2

).

Strip wire between 8 mm and 10 mm of insulation at the ends of the wires

(stranded or solid wire) or use pin terminals with a pin (conductor) length of

8 mm to 10 mm.

Strip 8 to 10 mm.

Pin length: 8 to 10 mm

The GRT1-PNT PROFINET IO Communication Unit uses the following LED

indicators.

• Six LEDs to indicate status of the Unit and the PROFINET IO network

• Two LEDs at the Ethernet ports to indicate the Link activity of the ports

17

Page 30

GRT1-PNT Unit components Section 2-1

RUN

ERR

BF

TS

UNIT PWR

I/O PWR

RUN

UNIT PWR

ERR

BF

TS

I/O PWR

Figure 2.1.4: GRT1-PNT LED indicators

Status indicator

/i

specification

Indicator Colour Status Meaning

RUN

Unit status

ERR

Unit error

BF

PROFINET IO

failure

TS

SmartSlice I/O

system

communication

status

Green Not lit • Start-up test failed, unit not operational.

• Fatal error: Operation stopped.

Lit Initialization successful, unit is in normal operation.

Red Not lit Unit is in normal operation.

Flashing A start-up error has occurred.

Lit Fatal error in system execution.

Red Not lit • No PROFINET IO communication errors occurred.

• I/O data exchange in progress.

Flashing The configuration settings sent by the PROFINET IO Controller unit are

invalid. No I/O data exchange is possible.

Lit No PROFINET IO communication has been detected by the unit.

--- Not lit • No power supplied.

• Communication has not started with SmartSlice I/O Unit.

• Over current detected.

Green Flashing once

SmartSlice I/O Unit added to the system

per second

Flashing twice

per second

Backup/Restore function operating:

• Restoring settings to SmartSlice I/O Unit, backup function operating.

• Downloading SmartSlice I/O Unit settings.

Lit Communication with SmartSlice I/O Unit established.

Red Flashing Non-fatal communication error occurred:

• Communication time out.

• Verification error occurred with registered table.

• Different model Unit detected after SmartSlice I/O Unit replacement.

Lit for 2

seconds

Failure occurred while restoring settings to SmartSlice I/O Unit or

downloading SmartSlice I/O Unit settings.

Lit Fatal communication error occurred.

UNIT PWR Green Not lit Power supply to the Unit is not present (All other LED indicators are also

OFF).

Lit Power supply to the Unit is present.

I/O PWR Green Not lit Power supply to the SmartSlice I/O Unit is not present. The SmartSlice I/O

Units may be operative, but no output is available.

Lit Power supply to the SmartSlice I/O Unit is present.

18

Page 31

GRT1-PNT Unit components Section 2-1

Link activity specification /i

Indicator Colour Status Meaning

LINK Green Not lit No ethernet communication on corresponding port.

Lit Transmission/reception is in progress with connected switch/IO Controller

for corresponding port.

2-1-5 DIP switches

Four DIP switches on the front of the Communication Unit are provided for

operational settings. The factory setting is OFF for all DIP switches.

ON

1

REGS

NC

2

ADR

3

4

BACK

Figure 2.1.5: GRT1-PNT DIP switches

/i

DIP Switch Caption Description

1 REGS Create / Enable Registration Table

2 NC Not Used (Always OFF)

3 ADR Automatic Restore

4 BACK Backup Trigger

Note It is recommended to use the features that are made available by DIP switches 1, 3 and

4 (as discussed on the next page).

DIP Switch 1: REGS If DIP switch 1 is turned from OFF to ON while the Unit’s power is ON, the

existing SmartSlice I/O Unit configuration (connection order and I/O size) is

registered in the PROFINET IO Communication Unit as a registered table.

If DIP switch 1 is ON when the Unit’s power is turned ON, the actual

SmartSlice I/O Unit configuration at start-up is automatically compared to the

registered table. Any SmartSlice I/O Unit that does not match the registered

table will not participate in SmartSlice I/O communication.

/i

Switch 1 REGS Function

ON Registered table is enabled: if there is a verification error, the

affected Unit will not participate in communication.

OFF Registered table is disabled: all Units always participate in

communication.

OFF to ON Register I/O Unit table

(Unit Power must be ON)

ON to OFF Clear registered I/O Unit table

(Unit Power must be ON)

DIP Switch 2: NC DIP switch 2, marked NC, is not used and should always be set to OFF.

19

Page 32

GRT1-PNT Unit components Section 2-1

DIP Switch 3: ADR When DIP switch 1 is ON (registered table enabled) and DIP switch 3 is

switched to ON, parameter data is automatically restored to the SmartSlice

I/O Units that had parameter data backed up.

/i

Switch 3 ADR Function

OFF Automatic restore function disabled.

OFF to ON Automatic restore function enabled (when pin 1 is ON).

DIP Switch 4: BACK When DIP switch 1 is ON (registered table enabled) and DIP switch 4 is turned

OFF to ON, the parameter data of all connected SmartSlice I/O Units is

backed up in the Communication Unit.

/i

Switch 4 BACK Function

ON Switch ON to OFF to ON to start the parameter backup (when

DIP switch 1 is ON).

OFF ---

max 3 s

ON OFF ON

The backup operation starts after DIP switch 4 is

turned from ON to OFF to ON within 3 seconds.

20

Page 33

GRT1-PNT Unit components Section 2-1

2-1-6 Power supply connector

The PROFINET IO Communication Unit has two 24 VDC power supply

terminals on the front of the Unit.

Holes for wires

(pin terminals)

System Power supply terminals

External I/O Power supply terminals

/i

Power supply terminals Function

System These terminals supply power to the internal circuits of

both the PROFINET IO Communication Unit and the

connected SmartSlice I/O Units (through the SmartSlice

bus).

External I/O These terminals supply power to the external I/O that is

connected to the connected SmartSlice I/O Units.

24 VDC

24 VDC

Release button

Both the SmartSlice I/O System power supply and the external I/O power

supply are connected with screwless clamping-type terminals.

Note System power supply and External I/O power supply are not transferred through the

GCN2-100 Turnback cable. The GRT1-TBR Right Turnback Units provide the same set

of Power Supply terminals as the PROFINET IO Communication Unit.

21

Page 34

GRT1-END-M Unit components Section 2-2

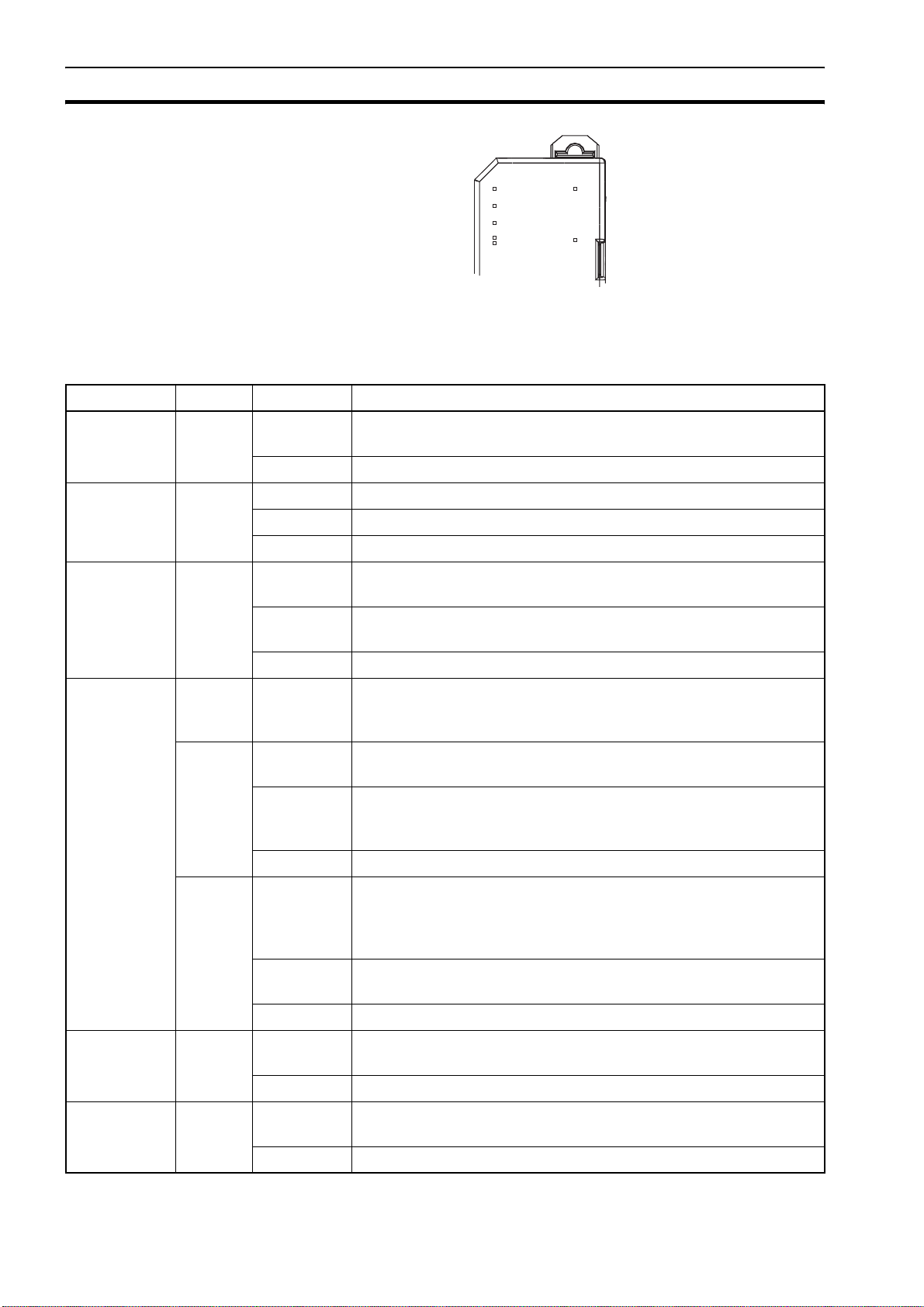

2-2 GRT1-END-M Unit components

2-2-1 Overview

The illustration below shows the front view of the GRT1-END-M with the TS

LED indicator (1).

END-M

TS

1

2-2-2 LED Indicators

Figure 2.2.1: GRT1-END-M overview

The GRT1-END-M Memory End Unit uses a single LED indicator to indicate

the

SmartSlice I/O Unit status.

END-M

TS

Figure 2.2.2: GRT1-END-M LED indicators

/i

Name Colour Status Meaning

TS Green Lit Normal status Normal unit status.

Normal network status.

Flashing Operating The automatic restore / backup

function is operating.

Red Lit Fatal error Unit hardware error (EEPROM error

or WDT error)

22

Flashing Non-fatal error Communication time out, etc.

--- Not lit No power • Unit power supply if OFF.

• Unit is waiting for initialization.

• Unit is being reset.

Page 35

Installing the GRT1-PNT Unit Section 2-3

x10x1x1

BUS

ON

+V

+V

-V

UNIT

DC24V

INPUT

REGS

NC

ADR

BACK

RUN

ERR

BF

TS

UNIT PWR

I/O PWR

2-3 Installing the GRT1-PNT Unit

2-3-1 Handling precautions

When installing the PROFINET IO Communication Unit and the SmartSlice I/O

Units, observe the following handling precautions.

• Always turn OFF the power supply to the PROFINET IO Communication

Unit, the SmartSlice I/O Units and the external I/O, before mounting or

dismounting a Unit or connecting or disconnecting cables.

• Do not connect or disconnect the PROFINET IO Communication Unit’s

communication cable while the PROFINET IO network is operating.

• Ensure that the power supplies for the PROFINET IO Communication Unit,

the SmartSlice I/O Units and the external I/O are wired correctly.

• Provide separate conduits or ducts for the control lines to prevent noise

from high-tension lines or power lines.

The SmartSlice I/O system is installed and set up as a PROFINET IO Device.

A PROFINET IO communication cable connects the PROFINET IO

Communication Unit and the IO Controller. Up to 64 SmartSlice I/O Units can

be connected to one GRT1-PNT Unit.

PROFINET

IO Controller

PROFINET

Communication Unit

OMRON GRT1-PRT

RUN

UNIT PWR

5

5

6

6

4

4

7

7

3

3

8

8

ERR

2

2

9

9

1

1

0

0

BF

x10

TS

I/O PWR

ON

BUS

24 VDC

for Unit

24 VDC

for I/O

Slide SmartSlice I/O Units

in from the front to install.

REGS

1

NC

2

ADR

3

BACK

4

UNIT

+V

-V

I/O

+V

-V

DC24V

INPUT

SmartSlice I/O Units (64 max.)

2-3-2 Installation on a DIN Rail

The GRT1-PNT and SmartSlice I/O Units must be mounted on a DIN Rail.

Attach the DIN Rail with screws in every third mounting hole.

Attach the track with screws at a

maximum spacing of 105 mm

between adjacent screws.

23

Page 36

Installing the GRT1-PNT Unit Section 2-3

SmartSlice I/O System

The system can be mounted in any of the following 6 directions.

Orientation

Note Please note the vertical orientations are not recommended because the heat dissipa-

tion may limit product life time.

Installing a unit To install a PROFINET IO Communication Unit on the DIN Rail, press the Unit

onto the DIN Rail from the front. Press the Unit firmly until it clicks, indicating

that the Unit’s DIN Rail Mounting Hooks have all locked onto the DIN Rail.

When the Unit is pushed onto the DIN Rail,

verify that the Mounting Hooks have locked.

Mounting Hooks

Press firmly towards the DIN Rail.

Press firmly until you hear a click,

indicating that the Mounting Hooks

have locked.

Removing a unit Use a standard screwdriver to release the DIN Rail Mounting Hooks at the top

and bottom of the Unit and pull the Unit straight away from the DIN Rail.

24

Page 37

Installing the GRT1-PNT Unit Section 2-3

g

2-3-3 Connecting the PROFINET IO Unit and SmartSlice I/O Units

Connect the first SmartSlice I/O Unit to the PROFINET IO Communication

Unit by aligning the sides of the Units and sliding in the SmartSlice I/O Unit

from the front. Insert the Unit until it clicks, indicating that the Unit has locked

onto the DIN Rail. Normally it is not necessary to release the Unit’s mounting

hooks when mounting the Unit.

Slide the Slice I/O Unit toward the DIN Track from

the front. Insert the Unit until you hear a click,

which indicates that the Unit has locked on the Track.

It is normally not necessary to release the DIN Track

mounting hook when mounting the Unit.

!Caution Do not touch the connector on the Unit’s base block.

2-3-4 Connecting additional SmartSlice I/O Units

Connect additional SmartSlice I/O Units by aligning the sides of the Units and

sliding in the next Unit from the front. Insert each Unit until it clicks, indicating

that the Unit has locked onto the DIN Rail. Normally it is not necessary to

release the Unit’s mounting hooks when mounting the Unit.

Up to 64 SmartSlice I/O Units can be connected to one PROFINET IO

Communication Unit.

Slide the Unit to the DIN Track from the front.

Insert the Unit until you hear a click, which indicates

that the Unit has locked on the Track.

It is normally not necessary to release the DIN Track

mountin

hook when mounting the Unit.

Connecting Turnback Units When a SmartSlice I/O System is divided into blocks, connect a GRT1-TBR

Right Turnback Unit to the right end of the first block and connect a GRT1-TBL

Left Turnback Unit to the left side of the expansion block. Mount these

Turnback Units on the DIN Rail in the same way as the SmartSlice I/O Units.

Use a GCN2-100 Turnback Cable to connect the Turnback Units together.

Mount additional SmartSlice I/O Units on the expansion block.

25

Page 38

Installing the GRT1-PNT Unit Section 2-3

(

)

(

)

Turnback Cable connectors

GRT1-TBR Tur nback Unit

for right side of block

GRT1-TBL Tur nback Unit

for left side of block

Note The Turnback Units can be used to divide a SmartSlice I/O System into up to three

blocks.

Connecting an End Unit At the end of the last block, mount a GRT1-END End Unit or a GRT1-END-M

Memory End Unit. Mount the Unit on the DIN Rail in the same way as the

SmartSlice I/O Units.

GRT1-END End Unit

26

Page 39

Installing the GRT1-PNT Unit Section 2-3

x10x1x1

BUS

ON

+V

+V

-V

DC24V

INPUT

REGS

NC

ADR

BACK

RUN

ERR

BF

TS

UNIT PWR

I/O PWR

Mounting End Plates Always secure the SmartSlice I/O System on the DIN Rail by installing End

Plates on both sides of the System.

1 First hook the bottom of the End Plate on the bottom edge of the DIN Rail.

2 Attach the top of the End Plate, and pull the End Plate down onto the top

edge of the DIN Rail.

3 Tighten the End Plate’s securing screw.

End Plate

OMRON GRT1-PRT

5

6

4

3

2

9

1

0

x10

BUS

End Unit

RUN

UNIT PWR

5

6

4

7

7

3

8

8

ERR

2

9

1

0

BF

TS

I/O PWR

ON

REGS

1

NC

2

ADR

3

BACK

4

+V

-V

+V

-V

DC24V

INPUT

End Plate

2

1

27

Page 40

Wiring the GRT1-PNT Unit Section 2-4

2-4 Wiring the GRT1-PNT Unit

2-4-1 Connecting the SmartSlice I/O System Power Supply

The GRT-PNT PROFINET IO Communication Unit has two sets of power

supply terminals. See section 2-1-6 Power supply connector.

The following wiring example shows how power can be supplied to the various

units in the SmartSlice I/O system.

I/O

power

supply

I/O

(IN)

I/O

(AD)

PROFINET

Communication Unit

CPU

Connector

Power supply

(24 VDC)

I/O

power

supply

GRT1-TBL Turnback Unit (Left)

GRT1-PD2 I/O Power Supply Unit

I/O

(IN)

I/O

(AD)

I/O

(OUT)

I/O

power

supply

I/O

I/O

(AD)

(AD)

(AD)

(OUT)

I/O

I/O

I/O

(OUT)

(OUT)

End Unit

Fig. 2-4-1 Wiring example

GRT1-TBR Turnback Unit (Right)

I/O

I/O

(OUT)

Connector

Power is not supplied through

the Turnback Cable.

Do not exceed 80 W

power consumption

in one block.

Do not exceed 80 W

power consumption

in one block.

Evaluating the Power Supply Requirements

Unit Power Supply The maximum power consumption for SmartSlice I/O Units is 80 W per block.

1,2,3... 1 Calculate the power consumption of all SmartSlice I/O Units connected to

the PROFINET IO Communication Unit (including other Units like Turnback

Units and End Unit). Refer to the GRT1 Series SmartSlice I/O Units

Operation Manual (W455) for the power value for each SmartSlice I/O Unit.

2 If the power consumption exceeds 80 W, mount a Right Turnback Unit

(GRT1-TBR) on the SmartSlice I/O Unit at the point where the power

consumption still is less than 80 W.

3 Connect the 24 V

Unit power supply to the Left Turnback Unit (GRT1-

DC

TBL) of the next expansion block.

Note 1 The GRT1-TBL is equipped with separate power supply terminals for the Unit power

supply and I/O power supply.

2 When dividing the supply power, always wire (supply) the power from the

same power supply, as shown in the wiring example above.

28

Page 41

Wiring the GRT1-PNT Unit Section 2-4

I/O Power Supply The maximum I/O current consumption is 4 A.

1,2,3... 1 Calculate the total current consumption used by all external I/O of the

connected SmartSlice I/O Units (including other Units like the Memory End

Unit). Refer to the GRT1 Series SmartSlice I/O Units Operation Manual

(W455) for the (maximum) current value for each SmartSlice I/O Unit.

2 If the current consumption exceeds 4 A or you want to provide separate

systems for inputs and outputs, divide the SmartSlice I/O Units at the

desired point with a GRT1-PD2 I/O Power Supply Unit and provide a

separate external I/O power supply.

3 It is also possible to provide a separate external I/O power supply at a Left

Turnback Unit (GRT1-TBL).

Note 1 The GRT1-TBL is equipped with separate power supply terminals for the Unit power

supply and I/O power supply.

2 Always use isolated power supplies for the power supplies.

3 Power is not supplied through the GCN2-100 Turnback Cable from one block to the

next, as shown in the wiring example above.

2-4-2 Wiring Methods

Connect the power supply wires (24 VDC) to the PROFINET IO

Communication Unit’s screwless clamping power supply terminals. Apply pin

terminals to the wire ends before inserting them in the wire terminals.

Recommended Power

Supplies

Recommended Wire

Strip Length

Pin Terminal Length

Use a SELV power supply with over current protection.

A SELV power supply has redundant or increased insulation between the I/O,

an output voltage of 30 V

and a 42.4 V

RMS

or maximum of 60 VDC.

peak

Recommended power supply: S82K-01524 (OMRON) or S8TS-06024

(OMRON).

/i

Type Gauge

Stranded wire 20 AWG to 16 AWG

Solid wire

Pin terminal

(0.5 to 1.25 mm

2

)

Strip wire between 7 mm and 10 mm of insulation at the ends of the wires

(stranded or solid wire) or use pin terminals with a pin (conductor) length of

8 mm to 10 mm.

Strip 8 to 10 mm.

Pin length: 8 to 10 mm

29

Page 42

Wiring the GRT1-PNT Unit Section 2-4

Supplying Power to the

Units

Holes for wires

(pin terminals)

Release button

Press the release button with

a screwdriver and pull out the

wire (pin terminal).

Supplying I/O Power

These terminals supply power to both

the PROFINET Communication Unit's

internal circuits and the connected

SmartSlice I/O Units' internal circuits.

24 VDC

The upper two terminals supply power to the internal circuits of the PROFINET

IO Communication Unit and of the connected SmartSlice I/O Units.

Holes for wires

(pin terminals)

These terminals supply power to the

external I/O devices connected to the

SmartSlice I/O Units.

Release button

Press the release button with

a screwdriver and pull out the

wire (pin terminal).

24 VDC

The lower two terminals supply power to the external I/O Devices connected to

the SmartSlice I/O Units.

Note The GRT1-TBL Left Turnback Unit and GRT1-PD2 I/O Power Supply Unit have the

same screwless clamping power supply terminals as the PROFINET IO

Communication Unit. These terminals are wired in the same way as the PROFINET IO

Communication Unit’s terminals, by inserting the power supply wires.

Removing Wires To remove the wires press the release button above the terminal hole using a

slotted precision screwdriver and pull out the wire.

30

Page 43

Wiring the GRT1-PNT Unit Section 2-4

x10x1x1

BUS

ON

+V

-V

UNIT

DC24V

INPUT

REGS

NC

ADR

BACK

RUN

ERR

BF

TS

UNIT PWR

I/O PWR

2-4-3 Connecting the Turnback units

When a SmartSlice I/O System is divided into blocks to expand the system,

connect the GRT1-TBR Right Turnback Unit of one block to the GRT1-TBL

Left Turnback Unit of the next block with a GCN2-100 Turnback Cable, as

shown in the following diagram. A single PROFINET IO Communication Unit

can be expanded with up to two additional blocks, connected with two

Turnback Cables (2 m total).

GRT1-TBR Tur nback Unit

OMRON GRT1-PRT

RUN

UNIT PWR

5

5

6

6

4

4

7

7

3

3

ERR

8

8

2

2

9

9

1

1

0

0

BF

TS

I/O PWR

x10

ON

BUS

REGS

1

NC

2

ADR

3

BACK

4

UNIT

+V

-V

DC24V

INPUT

GCN2-100 Turnback Cable

GRT1-TBL Tur nback Unit

Insert the cable's connector fully

until it clicks, which indicates that

the connector's top and bottom

latches have locked.

Insert each cable connector fully until it clicks, which indicates that the

connector’s top and bottom latches have locked.

Note The GCN2-100 Turnback Cable does not propagate supply power from one block to the

next one. Always wire (supply) the power to the GRT1-TBL Left Turnback Unit from the

same power supply that supplies the PROFINET IO Communication Unit.

31

Page 44

Setting up the PROFINET IO network Section 2-5

2-5 Setting up the PROFINET IO network

2-5-1 Network structure

Various configurations are possible.

When connecting GRT1-PNT unit within a network, the following precautions

apply:

- Please be aware any additional Ethernet communication may influence the

PROFINET IO Communication.

- It is recommended to separate the PROFINET IO network from the other

(IT) network.

- Severely overloading the built-in Ethernet switch with traffic may cause the

switch to temporarily block the ports, interrupting all traffic including

PROFINET IO communication.

2-5-1-1 Line

A line topology consists of placing multiple IO Devices in series. Many IO

Devices, such as the GRT1-PNT Unit, have an ethernet switch integrated in

the Unit. This creates an easy way to connect the IO Devices.

Switch

Benefits:

• For bigger networks this topology implies lower cabling effort.

• This is a traditional field bus structure (compare PROFIBUS-DP).

• The Ethernet Switch is optional.

Disadvantages:

• Communication paths through many switches affect transmission times.

• A malfunction of a single integrated device will result in disconnecting part

of the network.

/i

Part Recommendation

Switch (optional) Industrial Ethernet Switch (either managed or unmanaged).

32

Page 45

Setting up the PROFINET IO network Section 2-5

2-5-1-2 Star

The star topology is the standard-most topology for Ethernet networks. A

central switch will allow communication to all individually attached devices.

Switch

Benefits:

• Flexible adding and removing devices without interrupting the network.

• Easy monitoring and diagnostics of the network.

Disadvantages:

• Cabling effort.

• Error state of switch will fail complete network.

/i

Part Recommendation

Switch Industrial Ethernet Switch (either managed or unmanaged).

33

Page 46

Setting up the PROFINET IO network Section 2-5

2-5-1-3 Tree

The tree topology is a hierarchial combination of multiple star topologies

interconnected with each other.

Switch

Switch

Benefits:

• Shorter data communication at local node. Avoiding excessive traffic

through a single switch.

• Hierarchy enables better transparency of the network

Disadvantages:

• Cabling effort.

• Error state of switch will fail complete network.

/i

Part Recommendation

Switch Industrial Ethernet Switch (either managed or unmanaged).

34

Page 47

Setting up the PROFINET IO network Section 2-5

2-5-1-4 Ring

The ring topology is achieved by closing both ends of a line. A network

redundancy ring protocol such as MRP (see section 2-5-2 MRP Ring

Redundancy) will provide a method of monitoring the state of the network and

switch the communication path in case of problems.

Switch / MRP Manager

Benefits:

• Malfunction of a single switch / IO Device will not result in disconnecting

part of the network. The network redundancy mechanism will automatically

maintain the connection with the other devices.

/i

Part Recommendation

Switch Industrial Ethernet Switch supporting MRP manager protocol. Suggestion:

Hirschmann Automation and Control GmbH, Series RS20/30/40, Software

Version 4 or higher.

2-5-2 MRP Ring Redundancy

The internal Ethernet Switch in the GRT1-PNT Unit supports the Media

Redundancy Protocol (MRP). This protocol, which is part of the PROFINET IO

Specification, enables the Unit to be part of a ring-shaped network structure.

This ring network structure will give network redundancy.

In case one of the line connections fails, the MRP ensures communication to

all IO Devices remains possible through the redundant path. The ring structure

can contain up to 50 Units and typically switches to the redundant path within

150 ms (max 500 ms).

The network requires an MRP manager to facilitate the redundancy. As an

MRP client, there are no specific settings required for the GRT1-PNT Unit.

Please refer to the manual of the used MRP manager unit for details on how to

set up and operate the MRP network.

35

Page 48

Setting up the PROFINET IO network Section 2-5

Switch Switch Switch

In case a connection fails, MRP Ring Redundancy ensures communication to

all devices through the alternative path.

2-5-3 PROFINET IO Controller redundancy

The PROFINET IO Controller redundancy feature ensures seamless changeover of active PLC / IO Controller to the standby PLC / IO Controller in case of

malfunction. To support the PROFINET IO Controller redundancy, a

redundancy Function Block can be downloaded from the OMRON website.

Both the active as the standby IO Controller have data exchange with all IO

Devices in the network. Only the active IO Controller is in control of the output

of the IO Devices.

In case of malfunction of the active IO Controller, the Function Block will

transfer control to the standby PLC system. In order to avoid momentary

changes in output data during this control change, the Data Hold parameter

should be set high enough for the standby IO Controller to take over. This

value should be determined experimentally.

For details about setting the PROFINET IO Controller redundancy refer to

PROFINET IO Controller manual (W12E).

Switch

36

Page 49

Setting up the PROFINET IO network Section 2-5

2-5-4 Establishing the PROFINET IO network

This section describes how to create, connect to and configure the PROFINET

IO network using the CX-ConfiguratorFDT software and the Device DTMs.

1 Select the Network Components (see previous section) and build network.

2 Connect the Personal Computer to the ethernet network.

- The PROFINET Scan Tool to assign the IO Device names can only

operate connected to the ethernet network.

- The parameter settings and monitoring of the GRT1 Slice I/O Units is

done directly on the ethernet network.

3 Start the CX-ConfiguratorFDT software. Install the appropriate GSD files

and DTMs for the connected IO Devices.

4 Configure the system to communicate with PLC / Profinet IO Controller.

Add the PROFINET IO Controller as parent to the network.

• Set IP address in DTM.