Page 1

Cat. No. W454-E1-03

SmartSlice

GRT1-DRT

DeviceNet Communications Unit

OPERATION MANUAL

Page 2

SmartSlice GRT1-DRT DeviceNet Communications Unit

Operation Manual

Revised April 2008

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2005

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xviii

6 EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

SECTION 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Overview of Slice I/O Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Features and System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-3 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-4 List of Available Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 Basic Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

SECTION 2

Component Names and Functions. . . . . . . . . . . . . . . . . . . . . 9

2-1 Nomenclature and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-2 Node Address Settings and I/O Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-3 Unit Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SECTION 3

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3-1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3-2 Power Supply Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3-3 Wiring DeviceNet Communications Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3-4 Connecting the Turnback Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

SECTION 4

Setup and Operating Procedures . . . . . . . . . . . . . . . . . . . . . 51

4-1 Basic Operating Procedure and Example Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4-2 Preparation for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4-3 Setting and Wiring Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4-4 Starting Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

4-5 Checking Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

SECTION 5

Communications Characteristics . . . . . . . . . . . . . . . . . . . . . 61

5-1 Remote I/O Communications Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5-2 Message Communications Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

vii

Page 7

TABLE OF CONTENTS

SECTION 6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6-1 Troubleshooting Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6-2 LED Indicators and Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6-3 Reading the Error History with the DeviceNet Configurator . . . . . . . . . . . . . . . . . . . . . . . . 71

6-4 Other Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Appendices

A DeviceNet Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

B Using Another Company's Master Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

C Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

D Power Consumption Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

E I/O Current Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

viii

Page 8

About this Manual:

This manual describes the installation and operation of the DeviceNet Communications Unit for Slice I/

O Terminals and includes the sections described below. The DeviceNet Communications Unit for Slice

I/O Terminals is an interface Unit that connects Slice I/O Units with a DeviceNet Master.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the DeviceNet Communications Units. Be sure to read the precau-

tions provided in the following section.

The following manuals also cover information related to DeviceNet applications. Use the DeviceNet

Operation Manual together with other required manuals.

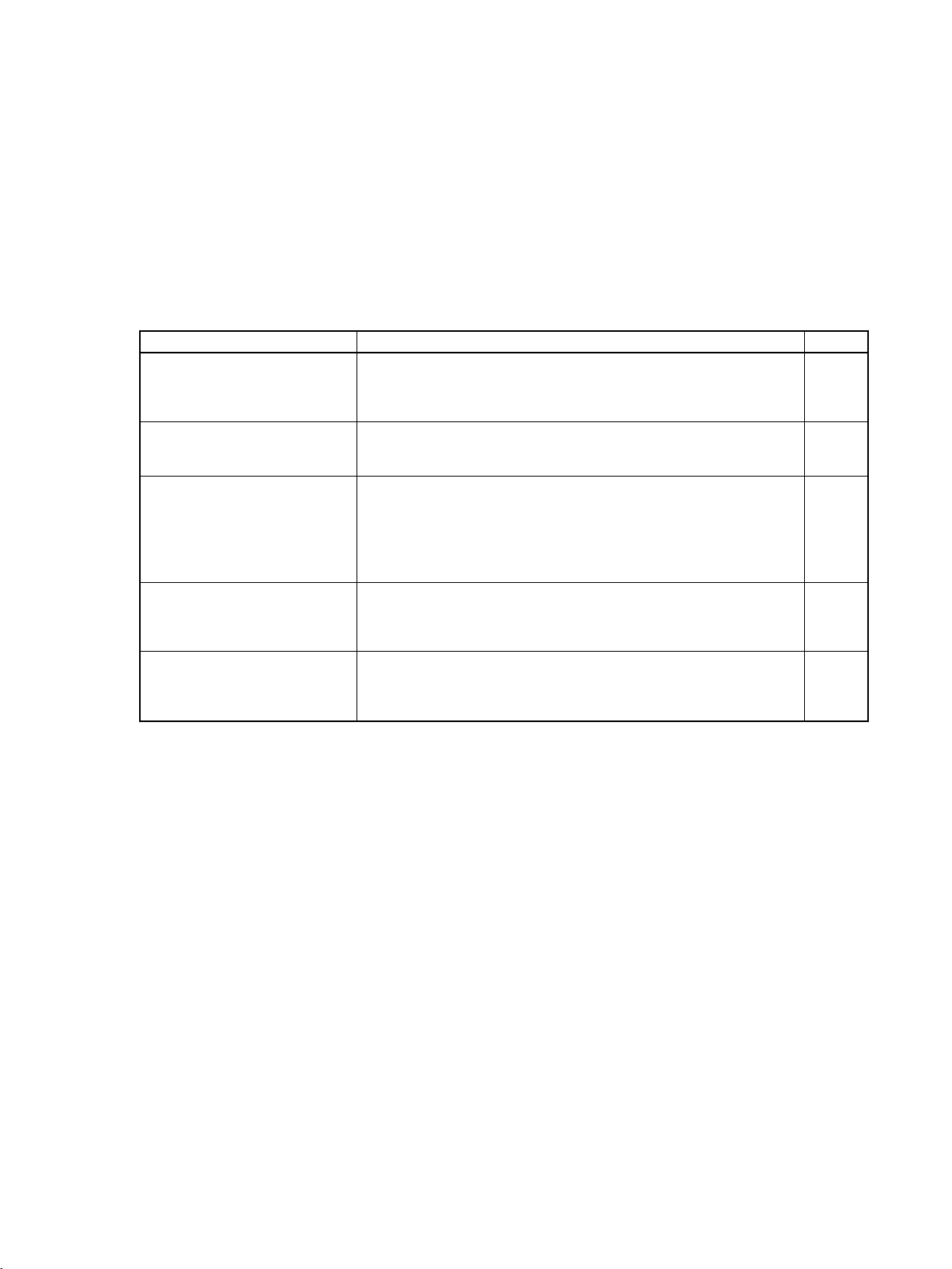

Manual Contents Cat. No.

DeviceNet Communications Unit

for Slice I/O Terminals

Operation Manual

(this manual)

GRT1 Series

Slice I/O Units

Operation Manual

DeviceNet

Operation Manual

CS/CJ Series

DeviceNet Units

Operation Manual

DeviceNet Configurator Ver. 2.@

Operation Manual

Describes the specifications, functions, operating procedures, and

applications of the DeviceNet Communications Unit, which allows

Slice I/O Units to be set, controlled, and monitored through

DeviceNet.

Describes the models, specifications, functions, operating procedures, and applications of GRT1-series Slice I/O Units.

Describes the configuration and construction of a DeviceNet network,

including installation procedures and specifications for cables, connectors, and other connection devices, as well as information on

functions, operating procedures, and applications.

Read this manual carefully and be sure you understand the information provided before attempting to use DeviceNet.

Describes the specifications, functions, operating procedures, and

applications of CS-series and CJ-series DeviceNet Units. (A CS/CJseries DeviceNet Unit can operate as both a DeviceNet master and

DeviceNet slave at the same time.)

Describes the operating procedures of the DeviceNet Configurator.

The DeviceNet Configurator can be used to configure, set, and maintain a DeviceNet system through an easy-to-use graphical interface.

Refer to this manual when necessary.

W454

W455

W267

W380

W382

Precautions provides general precautions for planning, installing, and operating the DeviceNet Communications Unit and related devices.

Section 1 provides an overview of the DeviceNet Communications Unit with information such as the

features and system configuration.

Section 2 describes the DeviceNet Communications Unit’s components, describes the Unit’s functions

in detail, and explains how to allocate I/O.

Section 3 explains how to install and wire the DeviceNet Communications Unit and Slice I/O Terminals.

Section 4 describes the procedures required to begin actual communications between the DeviceNet

Communications Unit and Slice I/O Terminals.

Section 5 provides information on communications using the remote I/O communications function and

message communications function, such as response times and transmission delays.

Section 6 explains how to monitor and correct errors that occur in a DeviceNet Communications Unit

or Slice I/O Unit, interpret the Unit’s LED indicators, and read the error history from the DeviceNet Configurator.

Appendix explains how to handle EDS setting files required for multivendor environments and how to

list the device profile of the DeviceNet Communications Unit and information on related products.

ix

Page 9

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

x

Page 10

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Page 11

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Page 12

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

Page 13

xiv

Page 14

PRECAUTIONS

This section provides general precautions for installing and using the DeviceNet Communications Unit and related devices.

The information contained in this section is important for the safe and reliable application of the DeviceNet

Communications Unit. You must read this section and understand the information contained before attempting to

set up or operate a DeviceNet network using a DeviceNet Communications Unit.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

6 EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

xv

Page 15

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of purchasing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and connecting FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the specifications described

in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with redundant safety mechanisms.

This manual provides information for installing and operating OMRON

DeviceNet products. Be sure to read this manual before operation and keep

this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC system to the above mentioned applications.

3 Safety Precautions

!WARNING Never attempt to disassemble any Units or touch the terminal block while

power is being supplied. Doing so may result in serious electrical shock or

electrocution.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will stop operation when its self-diagnosis function detects any

error or when a severe failure alarm (FALS) instruction is executed. As a

countermeasure for such errors, external safety measures must be provided to ensure safety in the system.

xvi

Page 16

Operating Environment Precautions 4

• The PLC outputs may remain ON or OFF due to deposits on or burning of

the output relays, or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-V DC output (service power supply to the PLC) is overloaded or short-circuited, the voltage may drop and result in the outputs

being turned OFF. As a countermeasure for such problems, external

safety measures must be provided to ensure safety in the system.

• Slice I/O Terminals will continue operating even if one or more I/O Units is

removed from or falls out of the Slice I/O Terminal, i.e., the other I/O Units

will continue control operations, including outputs. As a countermeasure

for such a possibility, external safety measures must be provided to

ensure safety in the system.

!WARNING The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

PROGRAM mode). Confirm safety thoroughly in advance before changing the

status of any part of memory allocated to Output Units, Special I/O Units, or

CPU Bus Units. Any changes to the data allocated to any Unit may result in

unexpected operation of the loads connected to the Unit. Any of the following

operations may result in changes to memory status.

• Transferring I/O memory data to the CPU Unit from a Programming

Device

• Changing present values in memory from a Programming Device

• Force-setting/-resetting bits from a Programming Device

• Transferring I/O memory files from a Memory Card or EM file memory to

the CPU Unit

• Transferring I/O memory from a host computer or from another PLC on a

network

4 Operating Environment Precautions

Install the system properly according to the directions in this manual.

Do not operate the control system in the following places.

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to water, oil, or chemicals (General Units)

• Locations subject to acid or chemicals.

• Locations subject to shock or vibration.

Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

xvii

Page 17

Application Precautions 5

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

5 Application Precautions

Observe the following precautions when using the DeviceNet Communications Unit.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Provide external interlock circuits, limit circuits, and other safety circuits in

addition to any provided within the PLC to ensure safety.

• Use the power supplies specified in the operation manuals.

• If the system is installed at a site with poor power supply conditions, take

appropriate measures to ensure that the power supply remains within the

rated voltage and frequency specifications.

• Provide circuit breakers and other safety measures to provide protection

against shorts in external wiring.

• Always ground the system to 100

protect against electrical shock.

• Mount the PLC securely on DIN Track or with screws.

• Always turn OFF the power supply when mounting a DeviceNet Communications Unit.

• Always turn OFF the communications power supply and the power supplies to the PLC and Slaves before attempting any of the following.

• Mounting or removing a Unit such as an I/O Unit, CPU Unit, Memory

Cassette, or Master Unit.

• Mounting or removing Remote I/O Terminal circuit sections.

• Assembling any devices or racks.

• Setting rotary switches.

• Connecting or wiring cables.

• Connecting or disconnecting connectors.

• Do not attempt to disassemble, repair, or modify any Units.

• Be sure that all the terminal screws are tightened to the torque specified

in the relevant manuals. Loose screws may cause fire, malfunction, or

damage the Unit.

• Be sure that all the mounting screws and cable connector screws are

tightened to the torque specified in the relevant manuals.

• Be sure that all the communications connector screws are tightened

securely. (The communications connector screw torque is 0.5 to 0.6 N•m.)

• Do not remove the label from a Unit before wiring. Always remove the

label after completing wiring, however, to ensure proper heat dispersion.

• Use the correct wiring components when wiring.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals.

• Double-check all wiring before turning ON the power supply.

Ω or less when installing the system to

xviii

Page 18

EC Directives 6

• When wiring or performing other tasks, do not allow metal objects such as

wire strands to enter the Unit.

• Always follow the electrical specifications for terminal polarity, communications path wiring, power supply wiring, and I/O jumpers. Incorrect wiring

can cause failures.

• Always wire the Unit as shown in the manual.

• Be sure to press terminals until they are fully seated.

• Mount Units only after checking terminal blocks completely.

• Be sure that the communications cable connectors and other items with

locking devices are properly locked into place.

• Do not drop the Unit or subject the Unit to excessive vibration or shock.

Doing so may cause malfunction or damage to the Unit.

• Use the special packing box when transporting the Unit. Ensure that the

product is handled carefully so that no excessive vibration or impact is

applied to the product during transportation.

• Check the user program for proper execution before actually running it

with the system.

• Do not bend or pull the cables excessively.

• When connecting communications cables, always turn OFF the PLC

power supply, all Slave power supplies, and all communications power

supplies.

• Observe the following precautions when wiring the communications

cables.

• Wire the communications cables separately from the power lines or

high-tension lines.

• Do not bend the communications cables excessively.

• Do not pull on the communications cables excessively.

• Do not place objects on top of the communications cables.

• Route communications cables inside ducts.

• Always enable the scan list before operation.

• Before clearing the scan list of a Unit that has user-allocated remote I/O,

always confirm that no errors occur after the I/O Area setting is changed

to fixed allocation.

• When adding a new node to the network, check that the new node’s baud

rate is the same as the baud rate set on the other nodes.

• Do not extend connection distances beyond the ranges given in the specifications.

6 EC Directives

DeviceNet products conform to EMS and low-voltage level directives as follows:

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards, so that they can more easily be built in to other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards. Whether they conform to the standards in the system used

by the customer, however, must be checked by the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

xix

Page 19

EC Directives 6

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

1,2,3... 1. The DeviceNet Communications Units are designed for installation inside

control panels. All DeviceNet Units must be installed within control panels.

2. Use reinforced insulation or double insulation for the DC power supplies

used for the communications power supply, internal circuit power supply,

and the I/O power supplies. The power supplies must also be able to provide stable output for 10 ms when a momentary power interruption occurs

at the input.

3. The DeviceNet Communications Units conform to the EN61131-2 (Immunity Zone A), EN61000-6-2, and EN61000-6-4 standards, but the radiated

emission characteristics (10-m regulations) may vary depending on the

configuration of the control panel used, other devices connected to the

control panel, wiring, and other conditions. You must therefore confirm that

the overall machine or equipment complies with EC Directives.

The following examples shows how to reduce noise.

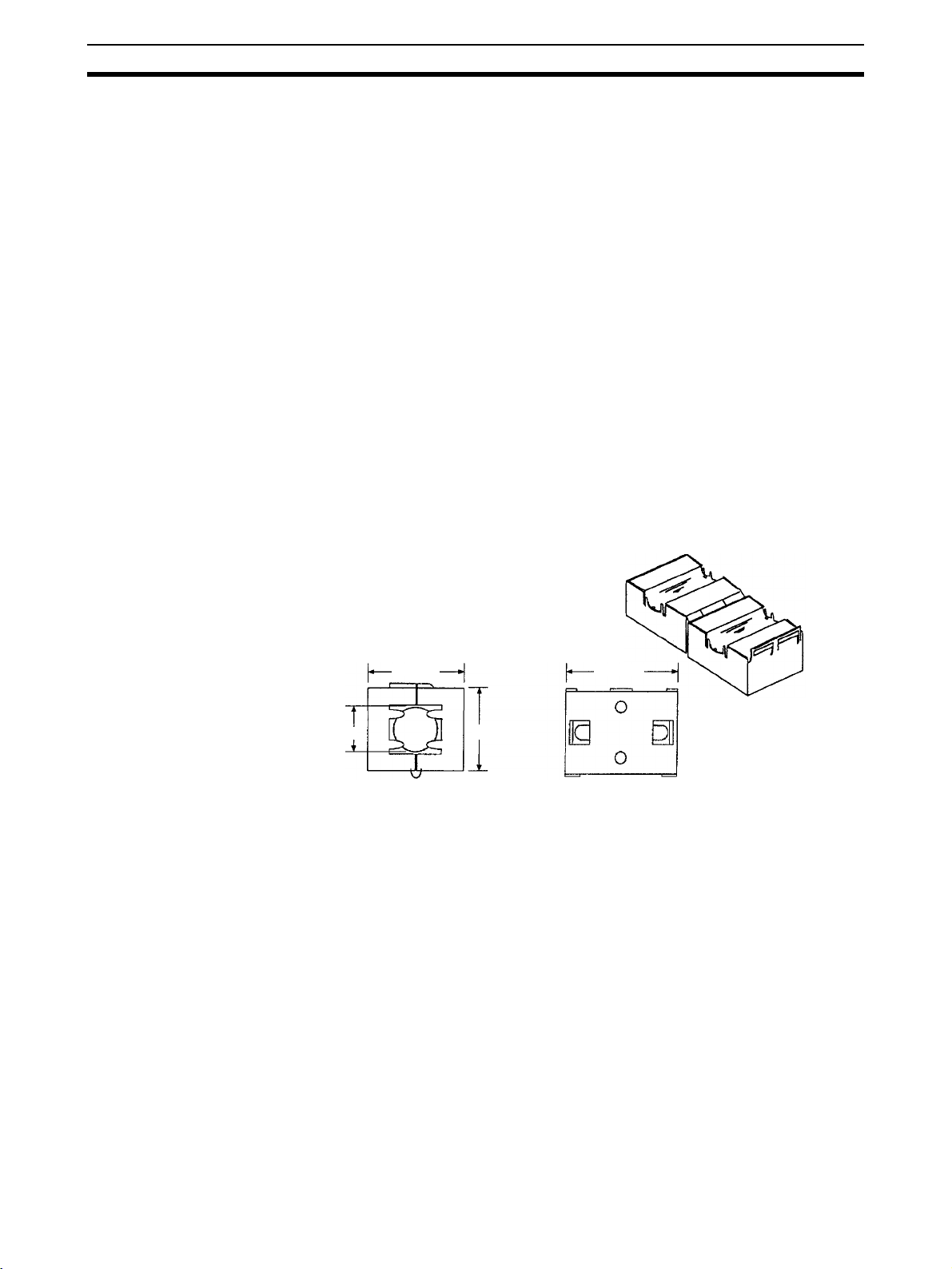

1,2,3... 1. Noise from the communications cable can be reduced by installing a ferrite

core on the communications cable within 10 cm of the DeviceNet Communications Unit.

Ferrite Core (Data Line Filter): 0443-164151 (manufactured by Nisshin Electric)

Impedance specifications

25 MHz: 156 Ω

100 MHz: 250 Ω

33 mm

13 mm

30 mm

29 mm

2. Wire the control panel with as thick and short cables as possible and

ground to 100

Ω min.

3. Keep DeviceNet communications cables as short as possible and ground

to 100

Ω min.

xx

Page 20

SECTION 1

Overview

This section provides an overview of the DeviceNet Communications Unit, including basic information such as the features

and system configuration.

1-1 Overview of Slice I/O Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Features and System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2-2 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3-1 Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3-2 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3-3 DeviceNet Communications Unit Specifications . . . . . . . . . . . . . . . 5

1-4 List of Available Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 Basic Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1

Page 21

Overview of Slice I/O Terminals Section 1-1

1-1 Overview of Slice I/O Terminals

Slice I/O Terminals are building-block style Slaves that can be expanded in

small I/O increments, so a system can be configured to exactly match various

customer applications. Slice I/O Units communicate with the Master by

remote I/O communications through a DeviceNet Communications Unit.

DeviceNet Communications Units are equipped with a network power supply

monitor function and error history for network diagnosis and Slice I/O Units

are equipped with troubleshooting functions such as the I/O power supply

function.

DeviceNet Master Unit

PLC

GRT1-DRT DeviceNet

Communications Unit

Serial connection

(For setting, monitoring, and operating)

DeviceNet

Slice I/O Units

Up to 64 Slice I/O Units can be connected to one DeviceNet Communications Unit.

1-2 Features and System Configuration

Slave

Slice I/O Terminals

1-2-1 Features

The DeviceNet Communications Unit for Slice I/O controls I/O between the

DeviceNet Master and Slice I/O Units over the DeviceNet network.

Manage More Than One

Slice I/O Units as One

Slave

Remote I/O

Communications

Simplified Startup The DeviceNet Communications Unit can be set up easily, just by wiring the

2

A single DeviceNet Communications Unit with up to 64 connected Slice I/O

Units can be managed as a Slave (a single module) from the DeviceNet Master.

Remote I/O communications can be used to share I/O data between the Master and more than one Slice I/O Units through the DeviceNet Communications

Unit.

In addition to actual I/O data, various status information can be allocated in

the Master by making custom settings with the Configurator.

Unit, setting the DeviceNet node address on the Unit’s rotary switches, and

making simple DIP switch settings.

Page 22

Features and System Configuration Section 1-2

The Unit’s configuration is read automatically when the power is turned ON

and I/O is also automatically allocated in the Slice I/O Units. It is not necessary to make any settings with a special Programming Device.

Simplified I/O Wiring All of the Slice I/O Units that connect to a DeviceNet Communications Unit are

equipped with screw-less clamp terminal blocks. Wiring to external I/O is

accomplished just by inserting the wire into the terminals, eliminating the

need to tighten terminal screws.

Table Registration The configuration of the Slice I/O Units (mounting order and I/O size) con-

nected to a DeviceNet Communications Unit can be registered in a table simply by switching a pin on the DeviceNet Communications Unit’s DIP switch.

Once the table has been registered, the actual configuration is compared to

the registered configuration each time that the power is turned ON. If the configuration does not match, a status flag can be turned ON in the DeviceNet

Master to indicate the error.

Communications Error

History Monitor

Online Replacement of I/O

Units

Parameter Backup and

Restore

Automatic Baud Rate

Recognition

Network Power Supply

Volt a g e M onito r

The communications error history in the DeviceNet Communications Unit can

record the four most recent communications errors in the DeviceNet network

and the 64 most recent Slice I/O Terminal errors. The communications error

information (communications error cause code and communications power

supply voltage when error occurred) can be read with an explicit message

command or from the Configurator.

The Slice I/O Unit’s circuit section can be removed, so it isn’t necessary to

turn OFF the power to replace a Unit. Communications can be maintained in

the remaining (connected) Units.

Before replacing a Slice I/O Unit for maintenance, the parameter data set in

the I/O Unit can be backed up in the DeviceNet Communications Unit by

switching a pin on the Communications Unit’s DIP switch. After the I/O Unit

has been replaced, another DIP switch operation can be used to select the

mode that automatically writes the backed-up parameter data to the appropriate Units.

The DeviceNet Communications Unit automatically detects the Master’s communications baud rate, so it isn’t necessary to set the baud rate. (If the Master’s baud rate has been changed, the DeviceNet Communications Unit must

be turned OFF and then ON again to change its baud rate.)

The DeviceNet network’s power supply voltage values (present, maximum,

and minimum values) are recorded in the DeviceNet Communications Unit.

The Configurator can be used to read the recorded information. Furthermore,

a warning voltage level can be set in the DeviceNet Communications Unit in

order to notify the Master if the voltage drops below that preset warning level.

Unit Power ON Time

Monitor

Unit Comment A user-set name can be assigned to each DeviceNet Communications Unit

This function records the total time that the DeviceNet Communications Unit's

internal circuit power has been ON. The Configurator or explicit messages

can be used to read the information. Furthermore, a warning voltage level can

be set in the DeviceNet Communications Unit in order to notify the Master if

the set warning time is exceeded.

and recorded in the Unit. When making settings or monitoring operation, the

comments make it easy to identify individual Units based on their application

or location.

3

Page 23

Specifications Section 1-3

t

Last Maintenance Date The dates on which maintenance is performed can be written to the

DeviceNet Communications Unit. The recorded date shows when maintenance is required next.

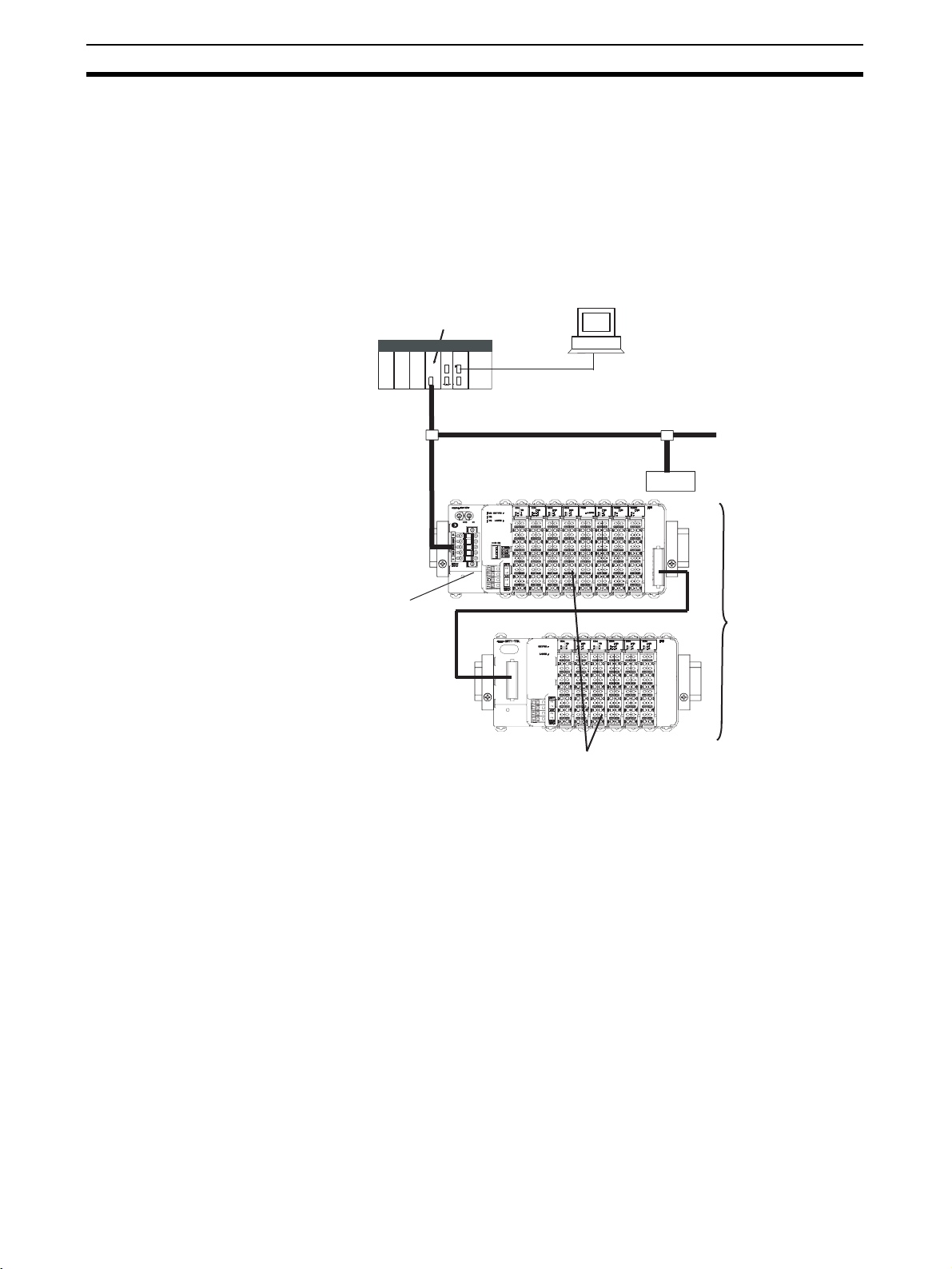

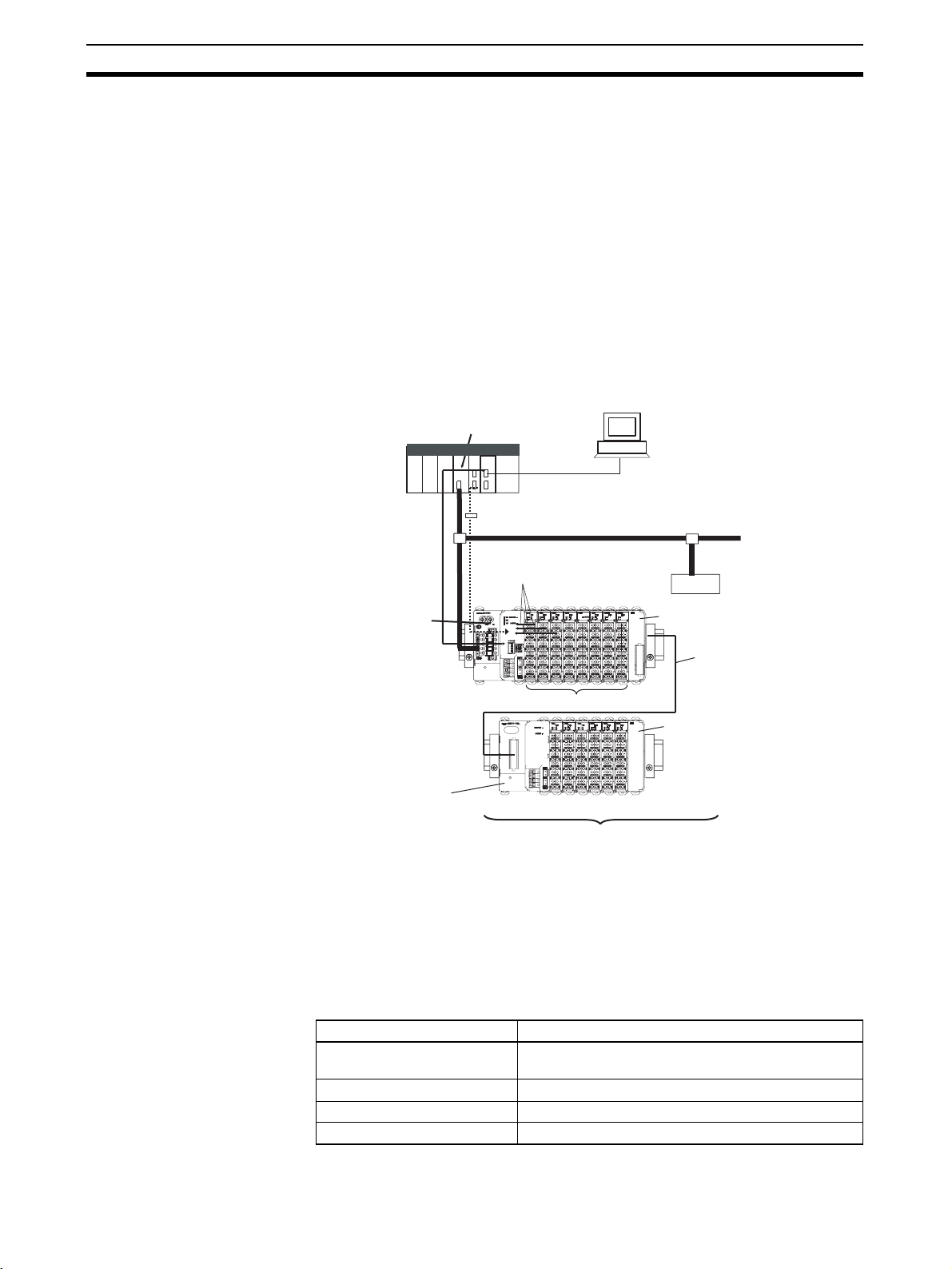

1-2-2 System Configuration

The DeviceNet Communications Unit connects to the Master by a network

cable and it connects to the Slice I/O Units by directly coupling the Units with

slide connectors.

The I/O Unit data in the DeviceNet Communications Unit is shared with the

Master’s Input and Output Areas through the DeviceNet network. The I/O

Units’ data is collected in the DeviceNet Communications Unit and exchanged

with the Master asynchronously.

It is also possible to send explicit message commands addressed to the

DeviceNet Communications Unit.

CX-One (CX-Integrator)

CS/CJ-series DeviceNet Unit (master)

Used to monitor operation and write

parameters to the Slice I/O Units or

DeviceNet Communications Unit.

PLC

Remote I/O communications

I/O data is collected from

the connected Slice I/O

Units and exchanged in a

batch with the Master.

GRT1-DRT DeviceNet

Communications Unit

GRT1-TBL Left Turnback Unit

Explicit messages

Up to 64 Slice I/O Units can be connected to one DeviceNet Communications Unit.

Serial connection

(For setting, monitoring, and operating)

DeviceNet

I/O data first goes to the

Communications Unit.

I/O Units

Slave

GRT1-TBR Right Turnback Unit

GCN2-100 Turnback Cable (1 m)

Up to 2 sets of Turnback Units

can be used per Communications Uni

GRT1-END End Unit

Note Always install an End Unit on the last I/O Unit in the last node.

1-3 Specifications

1-3-1 Communications Specifications

Item Specification

Number of connectable Slice

I/O Units

Baud rate 3 Mbps

Communications signal level RS-485

Turnback Cable Length 1 m max., up to 2 cables can be connected.

4

64 Units max.

Page 24

Specifications Section 1-3

Item Specification

Total number of I/O points 1,024 points max. (128 bytes)

Slice I/O Terminal connections

Baseblock power supply Voltage: 24 V DC

Event messaging Supported.

(combined total for inputs and outputs)

Building-block style configuration with slide connectors (Terminals connect with Turnback Cables.)

Current: 4 A

1-3-2 General Specifications

Item Specification

Ambient operating temperature

Ambient operating humidity 25% to 85%

Ambient storage temperature −25 to 65°C (with no icing or condensation)

Noise immunity Conforms to IEC 61000-4-4, 2.0 kV

Vibration resistance 10 to 60 Hz: 0.7 mm double amplitude

Shock resistance

Withstand voltage 500 VAC (between isolated circuits)

Enclosure rating IP20

−10 to 55°C (with no icing or condensation)

60 to 150 Hz: 50 m/s

150 m/s

2

2

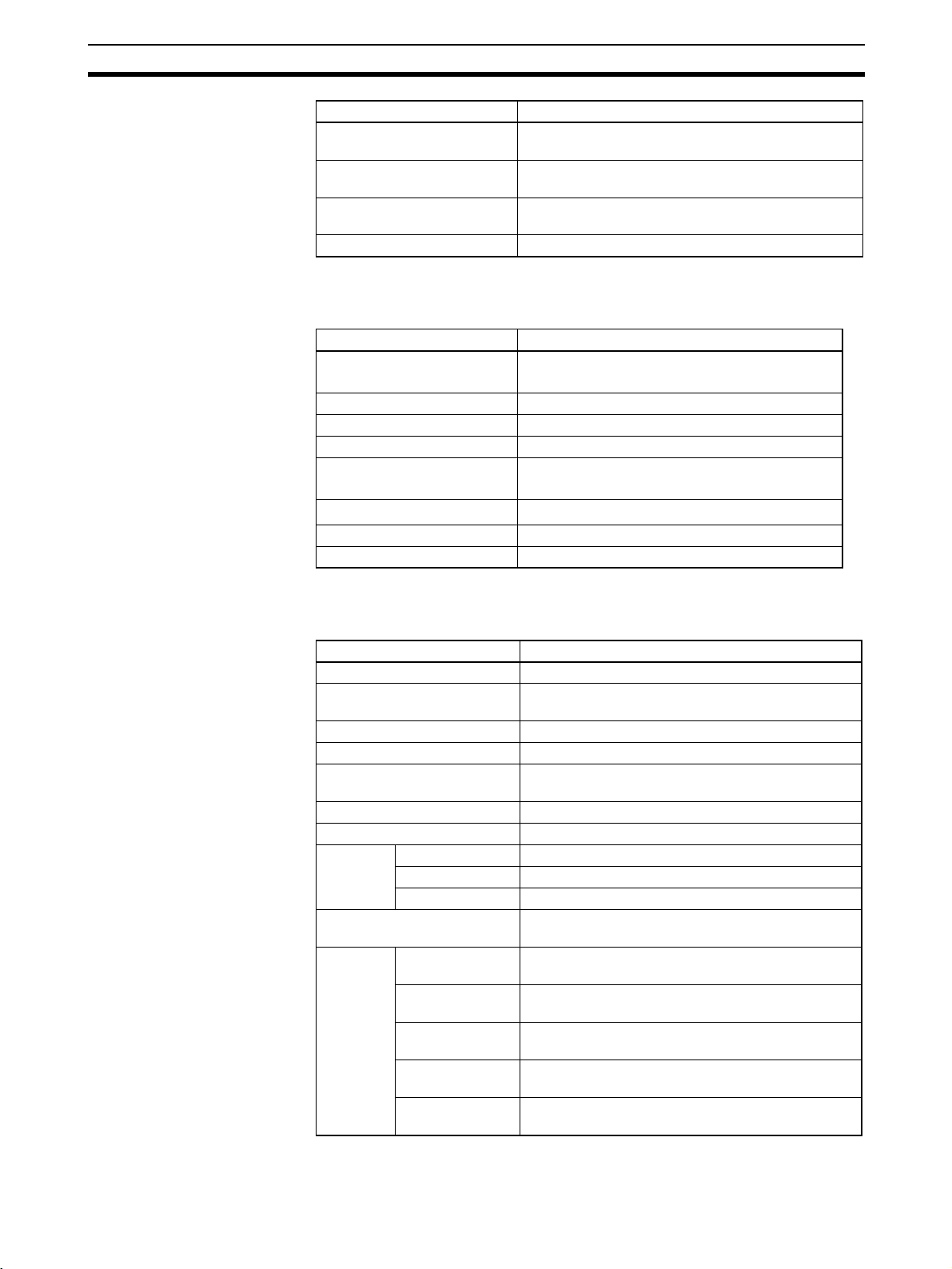

1-3-3 DeviceNet Communications Unit Specifications

Item Specification

Model number GRT1-DRT

Number of I/O points 1,024 points max. (128 bytes)

(combined total for inputs and outputs)

Number of connectable Units 64 Slice I/O Units max.

Slice I/O Unit unit numbers 1 to 64 (assigned automatically)

Slice I/O Unit data size 0, 2, or 4 bits

0 to 16 words (complete words)

Status flags Use 1 word (for Communications Unit status flags)

Parameter backup and restore Can back up and restore up to 2 KB of data per Unit.

Network

power

supply

I/O power supply Voltage: 24 V DC

Indicators MS (Two-color

Voltage 11 to 25 V DC

Current 22 mA

Inrush current 6 A max. (at cold start)

Current: 4 A

LED)

NS (Two-color

LED)

TS (Two-color

LED)

PWR (One-color

LED)

IO PWR (Onecolor LED)

Indicates the DeviceNet Communications Unit’s

operating status

Indicates the host communications (DeviceNet) status.

Indicates the Slice I/O Terminal’s operating status

Indicates the Unit power supply status

Indicates the I/O power supply status

5

Page 25

List of Available Units Section 1-4

Item Specification

Switches Node-address

setting switches

Other switches DIP switch

Connector One open connector for DeviceNet, with screws

Terminals Two terminals for I/O power supply

Power consumption 3 W

Power consumption per block 80 W max. (Unit power supply)

Block separation Basic block plus up to two other blocks

I/O current consumption 4 A max.

Weight 137 g

Accessories XW4G-05C4-TF-D Connector

Decimal rotary switches

Set the Unit’s node address as a DeviceNet Slave.

Pin 1: Create/Enable registered table (Switch from

OFF to ON to register the table. Leave ON to enable

the table.)

Pin 2: Always OFF.

Pin 3: Automatic restore (Auto-restore enabled when

ON.)

Pin 4: Backup trigger (Switch from OFF to ON two

times to backup the parameter data.)

The XWG4-05C4-TF-D Multi-drop Connector can be

connected.

Two terminals for Unit power supply

(If more than 80 W is required, separate into blocks

using Turnback Units.)

For multi-drop node connection. Connector screws

provided.

1-4 List of Available Units

The following table shows the Units that can be used in Slice I/O Terminals as

well as the devices that can be connected. Refer to the GRT1 Series Slice I/O

Units Operation Manual for details, such as Slice I/O Unit specifications.

Model

number

GRT1-DRT DeviceNet Communications Unit (Up to 64 I/O Units can be con-

GRT1-ID4 Slice I/O Unit with 4 DC inputs (NPN)

GRT1-ID4-1 Slice I/O Unit with 4 DC inputs (PNP)

GRT1-OD4 Slice I/O Unit with 4 DC outputs (NPN)

GRT1-OD4-1 Slice I/O Unit with 4 DC outputs (PNP)

GRT1-ROS2 Slice I/O Unit with 2 relay outputs

GRT1-AD2 Slice I/O Unit with 2 analog inputs

GRT1-DA2V Slice I/O Unit with 2 voltage analog outputs

GRT1-DA2C Slice I/O Unit with 2 current analog outputs

GRT1-END End Unit

GRT1-PD2 I/O Power Supply Unit

GRT1-TBR Right Turnback Unit (Mounts to the right side of I/O Terminal.)

GRT1-TBL Left Turnback Unit (Mounts to the left side of I/O Terminal.)

GCN2-100 Turnback Cable (1 m)

Specifications

nected.)

6

Page 26

Basic Operating Procedure Section 1-5

1-5 Basic Operating Procedure

The following procedure shows the basic steps required before using the Slice

I/O Terminals.

Operating Procedure

1,2,3... 1. Connect the DeviceNet Communications Unit to the Master and connect

the desired Slice I/O Units.

2. Turn ON the power supply to the DeviceNet Communications Unit.

3. Turn ON (from OFF to ON) pin 1 of the DIP switch on the front of the DeviceNet Communications Unit. When pin 1 is turned ON, the existing Slice

I/O Unit configuration (connection order and I/O size) is registered in the

DeviceNet Communications Unit as a registered table. (After the table is

registered, leave pin 1 ON to enable the table.)

4. The next time that the power is turned ON, the connected Slice I/O Unit

configuration at that moment is automatically compared to the registered

table and any Slice I/O Units that do not match the registered table (connection order or I/O size) will not participate in I/O communications. I/O

communications will start with the other Slice I/O Units.

Note (1) When a communications error has occurred, the DeviceNet Communica-

tions Unit’s TS indicator will flash red and the affected Slice I/O Unit’s TS

indicator will flash red. At the same time, the error code and error details

code will be stored in the DeviceNet Communications Unit’s error history.

(2) For details on the operating procedures, refer to SECTION 4 Setup and

Operating Procedures.

7

Page 27

Basic Operating Procedure Section 1-5

8

Page 28

SECTION 2

Component Names and Functions

This section describes the names and functions of the components in the DeviceNet Communications Unit.

2-1 Nomenclature and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-1-1 LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-1-2 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-2 Node Address Settings and I/O Allocation. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-2-1 Setting the Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-2-2 Unit Numbers of Slice I/O Units (Automatically Allocated) . . . . . . 15

2-2-3 I/O Allocation to the Slice I/O Terminal’s Master Unit . . . . . . . . . . 16

2-2-4 I/O Allocation with the Configurator (Ver. 2.@ or Higher) . . . . . . . 20

2-3 Unit Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2-3-1 Table Registration Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-3-2 Backup Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-3-3 Automatic Restore Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-3-4 Online Replacement Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-3-5 Automatic Baud Rate Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-3-6 Network Power Supply Voltage Monitor . . . . . . . . . . . . . . . . . . . . . 29

2-3-7 Unit Conduction Time Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-3-8 Unit Comments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-3-9 Network Communications Error History Monitor . . . . . . . . . . . . . . 34

2-3-10 I/O Communications Error History Monitor . . . . . . . . . . . . . . . . . . 35

2-3-11 Last Maintenance Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9

Page 29

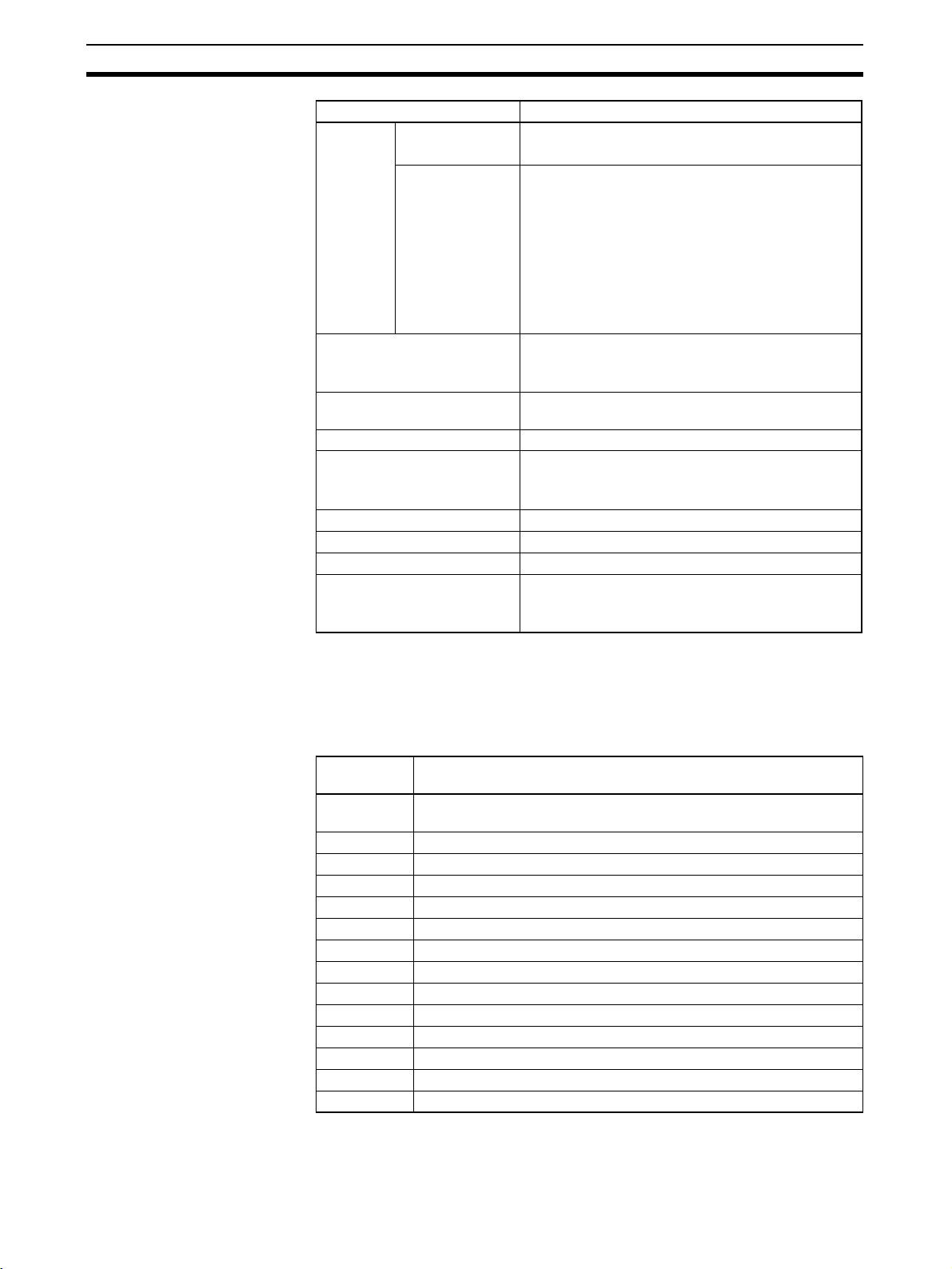

Nomenclature and Dimensions Section 2-1

2-1 Nomenclature and Dimensions

Nomenclature

Rotary switches

Set the Unit's node address as a DeviceNet

Slave. Set a decimal node address between

0 and 63.

DeviceNet communications connector

Connect the DeviceNet network's

communications cable to this connector.

Dimensions (mm)

Indicators

Refer to 2-1-1 LED Indicators for details.

DIP Switch

Sets the I/O allocation method and registers the I/O Unit

configuration information.

SW1 (REGS): Create/enable registration table.

SW2 (I/O): Always OFF

SW3 (ADR): Automatic restore

SW4 (BACK): Backup trigger

Unit power supply terminals

Connect the power supply for the Unit's internal circuits and

the connected Slice I/O Units' internal circuits.

I/O power supply terminals

Connect the power supply for the connected Slice I/O Units'

external I/O.

12

3

10

84

24

40

62

70

58

3

Page 30

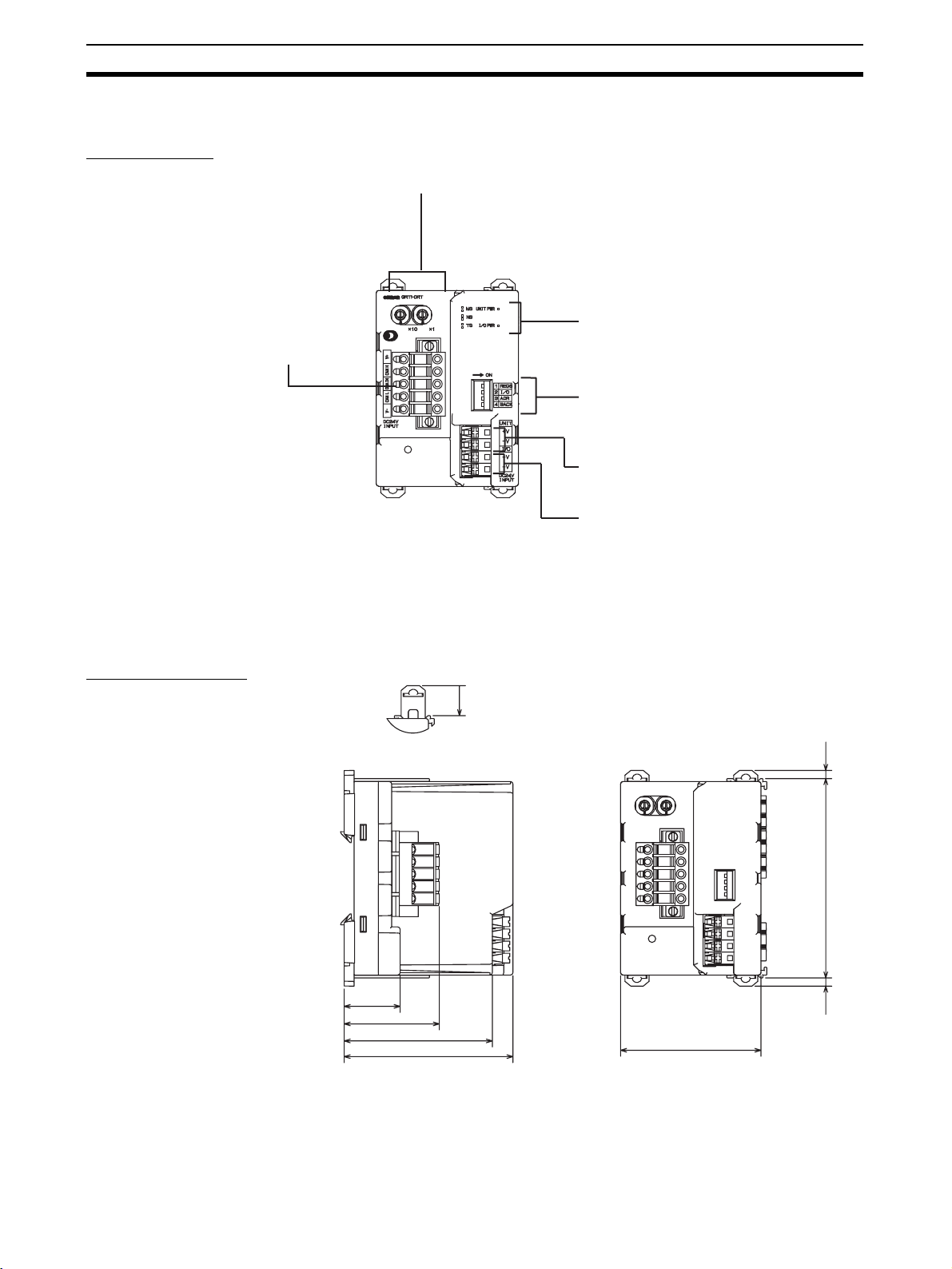

Nomenclature and Dimensions Section 2-1

Slice I/O Unit

Structure

Terminal Block

This is the Slice I/O Unit's terminal block.

If a faulty Unit is being replaced, the wiring can be

left attached and just the Main Block replaced.

The Slice I/O Unit is made up of three blocks, as shown in the following diagram. When replacement is necessary, individual blocks can be replaced.

Base Block

This is the Slice I/O Unit's bus connector.

If a faulty Unit is being replaced, this

Main Block

block can be left attached during online replacement.

Note Refer to the GRT1 Series Slice I/O Units Operation Manual (W455) for details

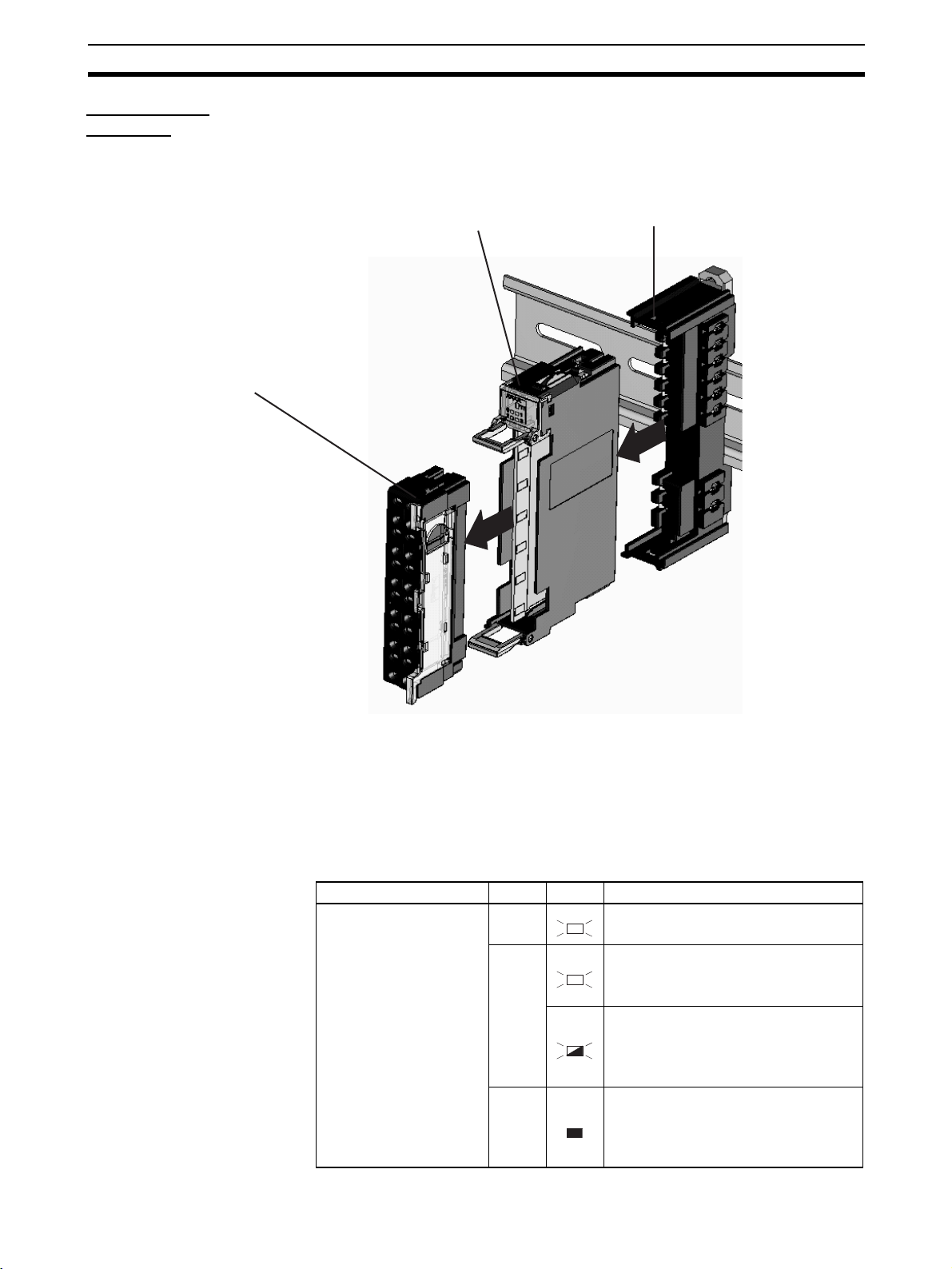

2-1-1 LED Indicators

such as Slice I/O Unit specifications and standard models.

The DeviceNet Communications Unit’s LED indicators indicate the status of

the Unit, the DeviceNet network, and communications between the Unit and

Slice I/O Units.

Name Color Status Meaning

MS

DeviceNet Communica-

tions Unit status

Green Normal status (DeviceNet Communica-

Red Non-recoverable, fatal error occurred.

--- No power

MS

tions Unit operating normally)

MS

• Watchdog timer error

• RAM error

Recoverable, non-fatal error occurred.

• EEPROM checksum error

MS

• Parameter setting logic error

• EEPROM hardware error

• The Unit’s power supply is OFF.

MS

• The Unit is being reset.

• The Unit is waiting for initialization.

11

Page 31

Nomenclature and Dimensions Section 2-1

Name Color Status Meaning

NS

DeviceNet network status

TS

Slice I/O Terminal com-

munications status

Green Unit is online with communications

NS

established (normal network status).

Unit is online, but communications are

NS

not established (waiting for communications from Master).

Red Fatal communications error occurred.

(Network communications are not pos-

NS

sible.)

• Node address duplicated

• Bus Off error

Non-fatal communications error

NS

occurred.

• Communications timeout

--- Offline or power OFF

• Waiting for completion of node

NS

address duplication check by Master.

• Power is not being supplied to the

DeviceNet Communications Unit.

Green Communicating with I/O Unit (commu-

TS

nications established).

I/O Unit joining system.

TS

(Flashing once every 1 s)

Backup/Restore function operating.

TS

(Flashing once every 0.5 s)

• Restoring settings to I/O Unit, backup

function operating

• Downloading I/O Unit settings.

Red Fatal communications error occurred.

TS

UNIT PWR

Unit power supply status

IOPWR

External I/O power sup-

ply status

Failure occurred while restoring set-

TS

tings to I/O Unit or downloading I/O

Unit settings.

(Lit for 2 s)

Non-fatal communications error

TS

occurred.

• Communications timeout

• Verification error occurred with registered table.

• Different model Unit detected after I/O

Unit replacement.

--- • Power not being supplied.

TS

• Communications haven’t started with

I/O Unit.

• Overcurrent detected.

Green 24 V is being supplied to the Unit

MS

power supply.

Unit power supply is OFF.

MS

Red 24 V is being supplied to the I/O power

MS

supply.

I/O power supply is OFF.

MS

12

Page 32

Nomenclature and Dimensions Section 2-1

2-1-2 Switch Settings

Note The DeviceNet Communications Unit detects the Master’s communications

baud rate automatically, so it is not necessary to set the baud rate.

Rotary Switches

5

4

3

2

1

0

×10

Use the rotary switches to set the Unit’s DeviceNet node address between 00

and 63. (Do not set values 64 to 99.)

DIP Switch The DIP switch is used for the Unit settings and operations described below.

The DIP switch functions are only introduced here. For details, refer to 2-3

Unit Functions.

ON

5

6

7

8

9

6

4

7

3

2

DeviceNet

8

9

1

0

Node address setting

×1

1

REGS

I/O

2

ADR

3

4

BACK

Create/Enable

Registration Table

(REGS, pin 1)

I/O Allocation Mode

(I/O, pin 2)

Automatic Restore

(ADR, pin 3)

If pin 1 is turned from OFF to ON while the Unit’s power is ON, the existing

Slice I/O Unit configuration (connection order and I/O size) is registered in the

DeviceNet Communications Unit as a registered table.

If pin 1 is ON when the Unit’s power is turned ON, the actual Slice I/O Unit

configuration at startup is automatically compared to the registered table. Any

Slice I/O Units that do not match the registered table will not participate in

Slice I/O communications.

Switch setting Function

ON Registered table is enabled. (If there is a verification error, the

affected Unit will not participate in communications.)

OFF Registered table is disabled. (All Units participate in communica-

tions.)

OFF to ON Register I/O Unit table. (Of course, pin 1 must be turned OFF to

ON while the Unit is ON.)

ON to OFF Clear registered table.

Always leave pin 2 set to OFF.

When pin 1 is ON (r

egistered table enabled) and pin 3 is ON, parameter data is

automatically restored to the Slice I/O Units that had parameter data backed

up.

Switch setting Function

ON Automatic restore function enabled (when pin 1 is ON).

OFF Automatic restore function disabled.

13

Page 33

Node Address Settings and I/O Allocation Section 2-2

Backup Trigger

(BACK, pin 4)

When pin 1 is ON (registered table enabled) and pin 4 is turned OFF to ON, the

parameter data of all connected Slice I/O Units is backed up in the Communications Unit.

1 s 1 s 1 s

ON OFF ON

The backup operation starts after pin 4 is turned

from ON to OFF to ON within 3 seconds.

Switch setting Function

ON Switch ON to OFF to ON to start the parameter backup (when pin

OFF ---

1 is ON).

Note The factory setting is OFF for all DIP switch pins.

2-2 Node Address Settings and I/O Allocation

I/O words in the Master (the CPU Unit’s I/O memory) are allocated to the Slice

I/O Terminal based on the DeviceNet Communications Unit’s node address

setting. Once the DeviceNet node address is set, I/O will be allocated to the

Slice I/O Terminal by default and remote I/O communications will start automatically.

Note When the power is turned ON, unit numbers are allocated automatically to the

Slice I/O Units in the Slice I/O Terminal.

2-2-1 Setting the Node Address

The Slice I/O Terminal’s node address as a DeviceNet Slave is set with the

rotary switches on the front of the DeviceNet Communications Unit. The node

address determines the starting word of the area allocated to the Slice I/O

Terminal.

DeviceNet

Master Unit

Set the first allocated

word with the node

address setting.

DeviceNet

Communications Unit

CPU Unit

I/O memory

Slice I/O

Terminal

Slice I/O Terminal

The DeviceNet Communications

Unit's DeviceNet node address

setting determines the first word

of the I/O memory area allocated

in the CPU Unit.

14

Page 34

Node Address Settings and I/O Allocation Section 2-2

DeviceNet Node Address

Setting

The left rotary switch sets the ten's digit, and the right rotary switch sets the

one's digit. Any number in the allowed range (00 to 63) can be set as long as

it is not set on another node (Master, Slave, or Configurator) in the network.

DeviceNet node

address setting

×10

×1

Note (1) Always turn OFF the DeviceNet communications power supply and De-

viceNet Communications Unit’s power supply before setting the node address.

(2) The factory default setting for the node address is 00.

(3) If the node address is duplicated on another node, a node address dupli-

cation error will occur and the Unit will not be able to join the network.

2-2-2 Unit Numbers of Slice I/O Units (Automatically Allocated)

The numbers used to identify the Slice I/O Units in a Slice I/O Terminal are

called the Slice I/O Units’ unit numbers. These unit numbers are allocated

automatically from left to right starting from #1, when the power is turned ON.

It is not necessary for the user to set these numbers.

The Slice I/O Units' unit numbers are allocated

automatically in order, from left to right.

DeviceNet

Communications Unit

I/O

#1

I/O

#2

I/O #3I/O

#4

I/O

:

:

#64

Note The unit numbers allocated automatically to the Slice I/O Units are unrelated

to the DeviceNet node address set with the rotary switches.

15

Page 35

Node Address Settings and I/O Allocation Section 2-2

2-2-3 I/O Allocation to the Slice I/O Terminal’s Master Unit

The Slice I/O Terminal’s I/O data is allocated in the I/O memory of the CPU

Unit in which the Master Unit is mounted and the I/O memory location is

determined by the DeviceNet Communications Unit’s DeviceNet node

address.

The user can set the Slice I/O Terminal’s allocated data freely with a

DeviceNet Configurator.

CS/CJ-series

DeviceNet Unit

Data is allocated to I/O memory in the order

that the Units are connected, from lowest to

highest.

I/O Units with bit allocation are allocated data

from the rightmost to leftmost bit, in 2-bit units.

I/O Units with word allocations are allocated

data from the lower to higher word address.

CPU Unit

16

Order of allocation

DeviceNet

Communications

Unit

I/O memory

8

CD

B

E

A

A

0

BC

(1) Communications Unit status

(2) Each Slice I/O Unit's I/O data.

(3) Slice I/O Unit network

participation status.

D

E

Connected order

Slice I/O Terminals (Slaves)

16

Page 36

Node Address Settings and I/O Allocation Section 2-2

I/O Allocation

Example

Input area

Word

15 8

First word

+1

+2

+3

Communications Unit status

Unused

Some areas may be unused

when data is allocated.

I/O data is allocated to the I/O Units in the order that they are connected to the

Communications Unit, regardless of the I/O Units’ models. Unless special

allocation data settings are selected with the Configurator, data is allocated

from the first word starting with the Communications Unit’s status flags and

then the leftmost I/O Unit’s data.

Data in the Master’s input and output areas is allocated to the Slice I/O Units

based on their unit numbers.

#2

#3

#4

AD2

#5

OD4

#6

ROS2

Word

First word Unused

Output area

15 8

#4

Communications

Unit

0

#1 #3 #2

#1

ID4

ID4

ID4

Note I/O Units with bit allocation (such as the GRT1-ID4/OD4) are allocated data in

2-bit units. I/O Units with word allocation (such as the GRT1-AD2) are allocated data in 1-word units. The following example shows the allocation to an

Output Unit.

Slice I/O Terminal configuration

0

#5

#6

Allocated Data

Patterns

Data Allocated to Master

Communications

Unit

Word

+0

+1

+2

+3

#1

OD4

#2

OD4

15

#3

OD4

#4 #5

Unused

#4

ROS

Data is allocated in 2-bit units

to I/O Units that require 4 bits,

so there may be unused areas

as shown in the following table.

8

#6

#5

2

OD4

#2 #3

#6

DA2

0

#1

#5

The following kinds of data can be allocated in the Master. The Configurator

can be used to freely select the kinds/combination of data allocated. If the

Configurator isn’t used to select the data pattern, the default setting is used,

which is I/O data + Communications Unit status flags (pattern number 1 in the

following table).

Allocated data pattern

1 I/O data (inputs) + Communications Unit status flags

2 I/O data (inputs and outputs) only

3 Communications Unit status flags only

4 Slice I/O Unit communications participating/withdrawn flags only

Note The Communications Unit’s status flags and Slice I/O Units’ communications

participating/withdrawn flags cannot be allocated in the output area.

17

Page 37

Node Address Settings and I/O Allocation Section 2-2

Allocated Data Size

Data type Data size

I/O data (input and output) When only the actual I/O data is allocated:

Communications Unit status flags 1 word

Slice I/O Unit communications

participating/withdrawn flags

I/O data (inputs) + Communications Unit status flags

64 input words max. or 64 output words max.

The GRT1-ID4(-1) and GRT1-OD4(-1) use 4 bits

per Unit.

The GRT1-ROS2 uses 2 bits.

Participating flags: 4 words

Withdrawn flags: 4 words

Total: 8 words

Amount of I/O data being used + 1 word

Note When allocating data, be sure that it does not exceed the maximum that can

be allocated (64 words).

Status Flags The status flags can be allocated in the Master independently or together with

the I/O data. There are two kinds of status flags, the Communications Unit’s

status flags and I/O Units’ communications participating/withdrawn flags, and

these status flags must be allocated in separate areas.

Communications Unit’s

Status Flags

First word

DeviceNet

Communications Unit

These flags can be used to monitor the status of the connection with the Master and the status of Slice I/O Units connected to the Communications Unit.

The status flags take up 2 words and the information is transferred to the Master.

With the default data pattern (pattern 1), these status flags are allocated in the

Master together with the I/O data. The status flags can also be read with the

Configurator or an explicit message command.

Master CPU Unit

Input Area

Status flags (16 bits)

I/O data (4 bits)

Status flags

Slice I/O Unit (4 inputs)

18

Bit Content Description

0 Slice I/O Bus Communications Error Flag Monitors the status of Slice I/O Terminal communications.

1 Reserved ---

2 Slice I/O Unit Warning Flag

0: Normal; 1: Error detected

3 Reserved ---

4 Slice I/O Unit Alarm Flag

0: Normal; 1: Error detected

Indicates a major Slice I/O Unit error. This flag goes ON when

there is an error in any one of the connected Slice I/O Units.

Indicates a minor Slice I/O Unit error. This flag goes ON when

there is an error in any one of the connected Slice I/O Units.

Page 38

Node Address Settings and I/O Allocation Section 2-2

Bit Content Description

5 Reserved ---

6 Reserved ---

7 Reserved ---

8 Reserved ---

9 Reserved ---

10 Reserved ---

11 Network Power Supply Voltage Monitor

Error Flag

0: Normal; 1: Error (monitor value reached)

12 Unit Maintenance Flag

0: Normal; 1: Error (monitor value reached)

13 Automatic Restore Monitor Flag

0: Restore successful; 1: Restore failed

14 Communications Unit Error Flag

0: Normal; 1: Error occurred

15 I/O Refreshing Flag

0: I/O communications stopped

1: I/O communications normal

Monitors the network power supply voltage using the voltage

threshold set with the network power supply voltage monitor

function.

Monitors the Unit’s operating time the power ON time threshold set with the Unit power ON time monitor function.

Indicates whether or not the automatic parameter restoration

to the Slice I/O Units was completed properly. This flag will be

ON if the restore operation failed and OFF if data was restored

properly to all Units.

This is the overall Unit status flag. This flag will be ON if any

one of the other flags (bits 0 to 13) is ON.

Indicates whether I/O data is being exchanged normally.

Slice I/O Unit

Participating/Withdrawn

Flags

0

Participating

table

Withdrawn

table

+1

+2

+3

+4

+5

+6

+7

These flags can be used to monitor the connection status (participating or

withdrawn) of the Slice I/O Units connected to the Communications Unit.

There are always 8 words allocated to the Participating/Withdrawn Flags (4

words for the Participating Flags and 4 words for the Withdrawn Flags),

regardless of the number of I/O Units that are connected.

These flags are not allocated in the Master by default. The flags must be allocated with the Configurator.

These flags can be read with the Configurator or an explicit message command.

Table name Description

Participating table ON: Participating (properly allocated to Master)

OFF: Not participating (An I/O Unit will not join communications if the registered table is enabled and a verification error

occurred with the Unit.)

Withdrawn table ON: Communications error occurred or the Unit was with-

drawn after participating in communications.

OFF: Never joined communications or participating normally.

15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18

48 47 46 45 44 43 42 41 40 39 38 37 36 35 34

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18

48 47 46 45 44 43 42 41 40 39 38 3 36 35 34

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50

6 Bit

5 Bit 4 Bit 3 Bit 2 Bit 1 Bit

0 Bit

1

17

33

49

1

17

33

49

Note (1) Each bit corresponds to the unit number of a connected Slice I/O Unit.

(Up to 64 Units can be monitored.)

(2) Each Unit’s status can also be monitored with the TS indicator on the front

of the I/O Unit.

19

Page 39

Node Address Settings and I/O Allocation Section 2-2

2-2-4 I/O Allocation with the Configurator (Ver. 2.@ or Higher)

The following procedure shows how to use the Configurator to select and allocate particular I/O data or status flags in the Master instead of using the

default settings.

Allocating I/O Data

from the Master Unit

1,2,3... 1. In the Master’s Edit Device Parameters Window, select the DeviceNet

Communications Unit to be set, and specify the connection in the Advanced Setting Window. Select the I/O data (pattern) in the connection

path setting.

2. In the Master’s Edit Device Parameters Window, allocate Slave I/O.

Note For details on connections and connection paths, refer to Appendix

B DeviceNet Connections in the DeviceNet Units Operation Manual

(W380).

The following setting example shows how to allocate 4 inputs + Communications Unit status flags as the data.

Example: 4 inputs + 4 inputs + Status flags

Bits 15 8 0

CIO 3300

CIO 3301 Unused

Communications Unit status flags

4 inputs 4 inputs

Procedure

1,2,3... 1. In the Network Configuration Window, select the Master Unit, and double-

click or click the right mouse button and select Parameter – Edit – Gener-

al, and then select the Smart Slave to be set.

20

Page 40

Node Address Settings and I/O Allocation Section 2-2

2. Click the Advanced Setup Button, click the Connection Tab, and select

User Setup. Select Use Poll Connection and Use COS Connection and

then select output data, input data, and generic status for the respective

connection paths. In this example, the IN size for COS connection is set to

generic status, the IN size for poll connection is set to input data, and

OUT size for poll connection is set to output data.

3. Click the OK Button.

Note If there are checks in the check boxes but the connection path settings are left

blank, the following settings will be made automatically.

IN (Smart Slave to Master Unit) OUT (Master Unit to Smart Slave)

Poll Input Data + Generic Status Output Data

Bit-Strobe Input Data + Generic Status Not set.

COS Input Data + Generic Status Not set.

Cyclic Input Data + Generic Status Not set.

21

Page 41

Node Address Settings and I/O Allocation Section 2-2

4. Click the I/O Allocation (IN) Tab and edit the I/O allocations.

Select the Smart Slave to be set and click the Edit Button to display the

Edit I/O Allocate Window.

Set the Poll settings (indicates input data) to block 1, allocated 3300.

Set the COS settings (indicates generic data) to block 2, allocated 3500.

5. Click the OK Button.

22

Page 42

Unit Functions Section 2-3

6. In the same way as above, click the I/O Allocation (OUT) Tab and edit the

I/O allocations. Set to block 1, allocated 3200.

7. Return to the General Tab Page and click Download.

Note When Auto allocation as is registered. is selected in the General Tab Page,

each time the connection path is set, a message will be displayed indicating

that the current I/O allocations have been deleted because the connection

has been changed. To set the connection path, deselect Auto allocation as is

registered. before registering the Slaves.

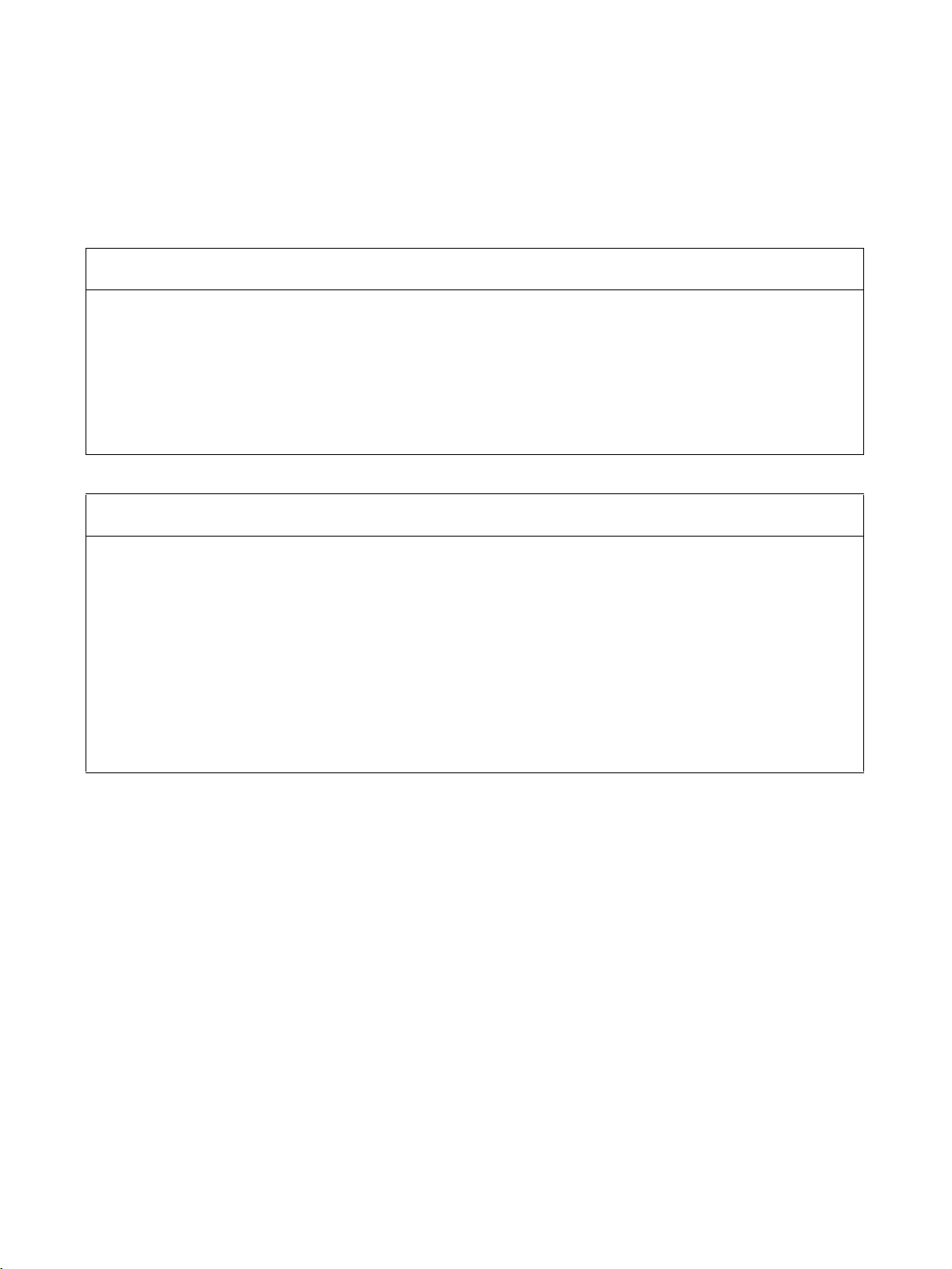

2-3 Unit Functions

Function List The following table lists the DeviceNet Communications Unit’s functions.

Function name Summary Setting/monitoring method

Table registration Reads the configuration of the Slice I/O Units connected to the

Backup Records the parameter data of all connected I/O Units in the Com-

Automatic restore Automatically downloads the backed-up parameter data to the

Online replacement I/O Units can be replaced without turning the power OFF. No setting required.

Automatic baud rate

recognition

Network power supply voltage monitor

Unit power ON time

monitor

Unit comment A user-set name can be assigned to the Communications Unit. Set/read with Configurator or

Network communications error history

Communications Unit and registers that information in a table.

munications Unit.

appropriate Unit.

The Master's communications baud rate is automatically detected

and adopted.

The DeviceNet network's power supply voltage values are

recorded in the DeviceNet Communications Unit.

Records the total time that the DeviceNet Communications Unit's

internal circuit power has been ON.

A communications error history from the viewpoint of the Communications Unit can be collected in the Communications Unit.

Set with DIP switch.

Set with DIP switch.

Set with DIP switch.

No setting required.

Set/read with Configurator or

explicit message.

Set/read with Configurator or

explicit message.

explicit message.

Set/read with Configurator or

explicit message.

23

Page 43

Unit Functions Section 2-3

g

Function name Summary Setting/monitoring method

I/O communications

error history

Last maintenance

date

A history of communications errors with connected I/O Units can

be collected in the Communications Unit.

The date on which maintenance was performed can be written to

the Communications Unit.

Set/read with Configurator or

explicit message.

Set/read with Configurator or

explicit message.

2-3-1 Table Registration Function

Function Overview This function registers the configuration of the Slice I/O Units connected to the

DeviceNet Communications Unit in a table within the Unit, so that the registered I/O table can be automatically compared with the actual configuration

each time that the power is turned ON. The configuration is registered simply

by turning ON (OFF to ON) pin 1 of the DeviceNet Communications Unit’s DIP

switch while the Slice I/O Terminal’s power supply is ON. The registered table

is enabled if pin 1 is ON when the power is turned ON. If pin 1 is OFF when

the power is turned ON, the registered table is disabled and the Communications Unit will automatically detect the actual I/O configuration and start communications.

Creating a New

Registration Table

The Slice I/O Terminal’s present I/O configuration can be read and registered

in the table just by turning DIP switch pin 1 (REGS) from OFF to ON while the

DeviceNet Communications Unit’s power supply is ON. If the registration table

is being refreshed, the old registration table will be erased.

Figure 1

4

4

4

contact

contact

contact

inputs

outputs

#2 #3 #4

istration table, and records the table.

Power ON

Turn pin 1 from

OFF to ON with

the power ON.

Registration table

DeviceNet

Communications

Unit

inputs

#1

Reads the configuration information, creates

the re

Note The configuration information shows the order that the Slice I/O

Units are connected and the I/O size (input or output, number of

bits) of each Slice I/O Unit. The I/O Unit model numbers are not recorded.

2

relay

outputs

24

Page 44

Unit Functions Section 2-3

Comparison with the

Registered Table

When DIP switch pin 1 (REGS) is ON and an I/O configuration table has been

registered in the Communications Unit, the actual I/O configuration is automatically compared to the registered table when the power is turned ON. A

verification error will occur if a registered I/O Unit cannot join I/O communications or an unregistered I/O Unit is detected.

If there are verification errors, the affected Slice I/O Units will not join in I/O

communications. I/O communications will start with the other Slice I/O Units.

■ Example of Comparison between Figure 1 and Figure 2

I/O

From left

#1

#2

#3

#4

Registered table

Figure 2

Pin 1 ON when power

was turned ON.

Input

Input

Output

Output