Page 1

Cat. No. W489-E1-01

GQ-CRM21

CompoNet Gateway Unit for CC-Link

OPER ATION M ANUAL

Page 2

Copyrights and Trademarks

• "Windows" is a registered trademark of Microsoft Corporation.

• Other system names and product names that appear in this manual are the trademarks or registered trademarks of

their respective companies.

OMRON, 2010

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by

any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without notice.

Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Page 3

About this Manual

Thank you for purchasing a GQ-CRM21 CompoNet Gateway Unit for CC-Link.

This manual contains information required to use a GQ-CRM21 CompoNet Gateway Unit for CC-Link.

Please read this manual carefully and be sure you understand the information provided before attempting to use the CompoNet Gateway Unit.

After reading this manual, keep it in a safe and convenient location for future reference.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems

• Personnel in charge of designing FA systems

• Personnel in charge of managing FA systems and facilities

About this Manual

CompoNet Gateway Unit for CC-Link Operation Manual

1

Page 4

Using this Manual

Using this Manual

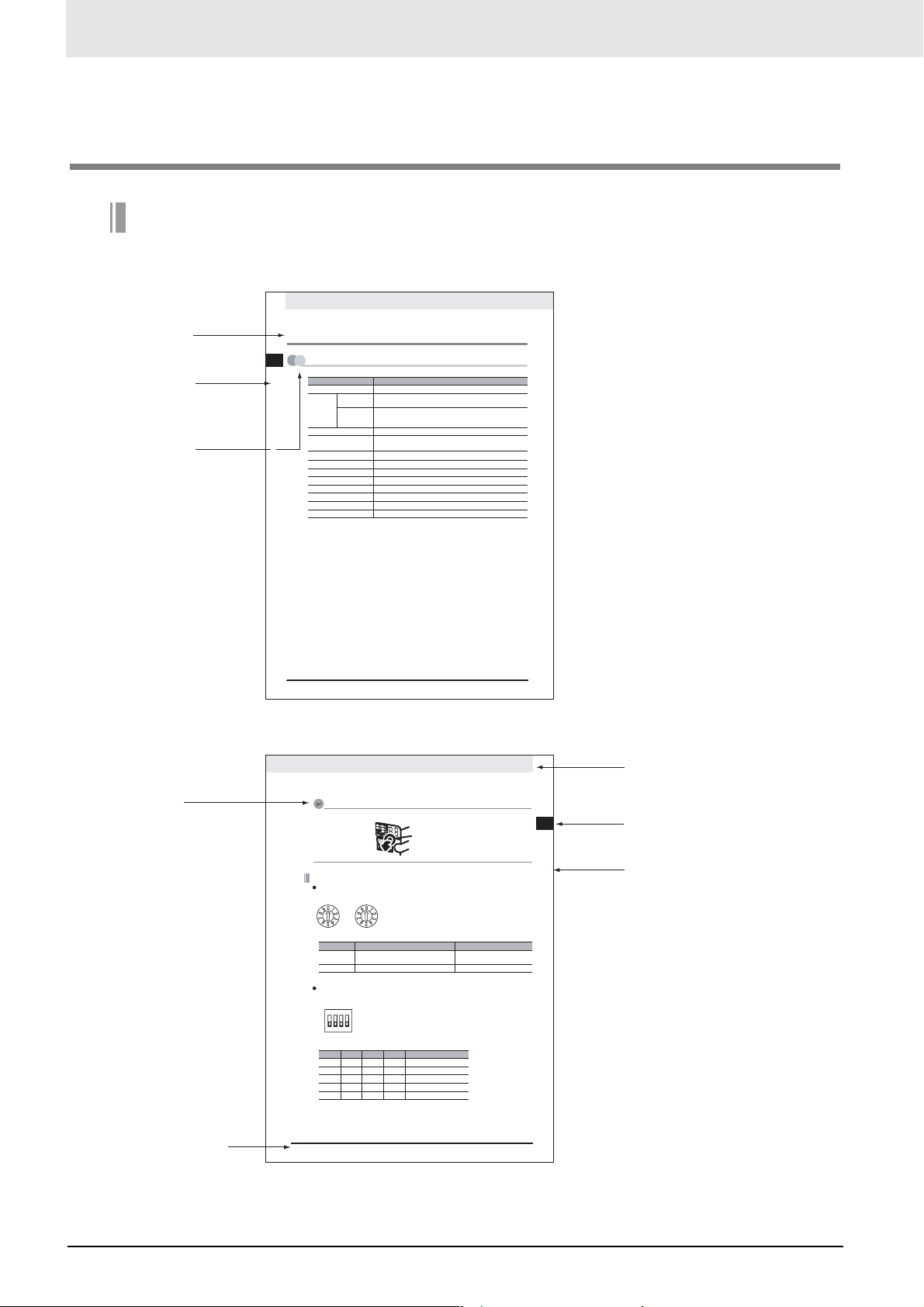

Page Structure

The following page structure is used in this manual.

Level-2 heading

Level-2 heading

Gives the current level-2 heading.

Level-3 heading

Icon

(See next page.)

2-1 Specifications

2

2-1-1 General Specifications

snoit

a

cifi

c

epS

1-2

2 - 1

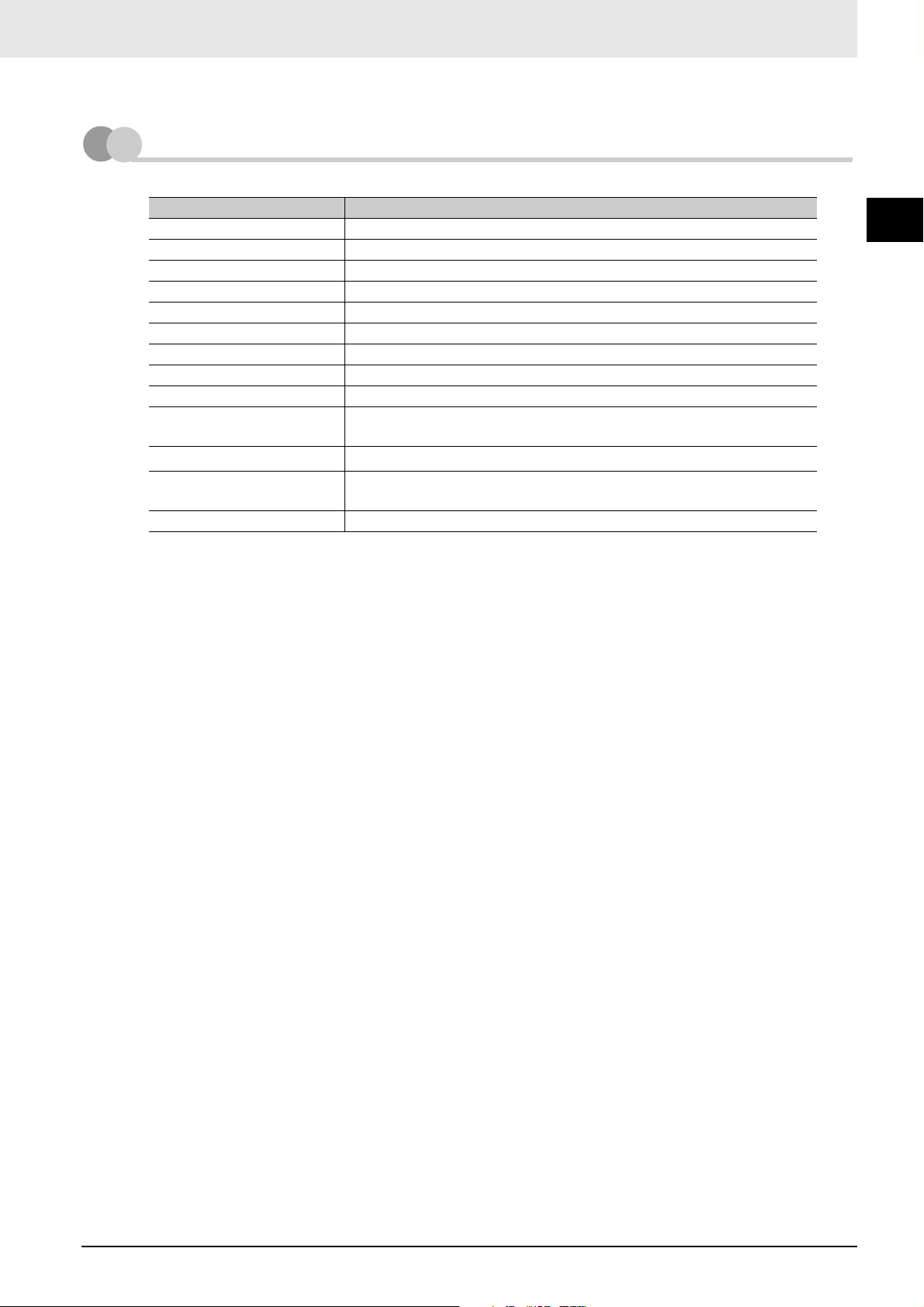

Item Specification

Unit power supply voltage 21.6 to 26.4 VDC (24 VDC ±10%) (Supplied from power supply connector.)

Current

Communications

consumption

Noise immunity Conforms to IEC 61000-4-4, 2.0 kV

Vibration resistance

Shock resistance

Dielectric strength 500 VAC

Installation method Mounted to DIN Track or by using M4 screws

Ambient operating temperature 0 to 55°C

Ambient operating humidity 10% to 90% (with no condensation)

Ambient storage temperature −25 to 65°C

Weight 110 g max.

Ambient operating atmosphere No corrosive gases

Supplemental Information

To press the CompoNet setting buttons, open the cover as shown below.

3.80 A at 24 VDC

power supply

0.13 A at 24 VDC

Internal current

power

consumption

Malfunction: 10 to 60 Hz with 0.7-mm double amplitude, 60 to 150 Hz, 50 m/s

for 80 min in X, Y, and Z directions

2

150 m/s

, 3 times in 6 directions on 3 axes

Open from here.

CompoNet Gateway Unit for CC-Link Operation Manual

Description of Gateway Unit

2

Level-1 heading

Gives the current level-1 heading.

2

Page tab

Gives the number of the level-1 section.

Level-3 heading

Gives the current level-3 heading.

Manual name

CC-Link Communications Section

Station Number Switch

The station number switch sets the station number of the Gateway Unit on the CC-Link network.

X10 X1

Number Description Remarks

1 to 61

Set the station number of the Gateway Unit on the

CC-Link network.

0 or 62 to 99

Do not set. The L ERR indicator will light.

Baud Rate DIP Switch

The baud rate DIP switch sets the baud rate of the Gateway Unit on the CC-Link network.

Set the baud rate of the Gateway Unit to the same value as the CC-Link Master Unit.

O

N

123

4

• Baud Rate Setting

Pin 1 Pin 2 Pin 3 Pin 4*1 Baud rate

OFF OFF OFF OFF

OFF OFF ON O FF

OFF O N OFF OFF

OFF ON ON OFF

ON OFF OFF OFF

*1 Always leave pin 4 turned OFF. It is reserved.

CompoNet Gateway Unit for CC-Link Operation Manual

156 kbps (default)

625 kbps

2.5 Mbps

5 Mbps

10 Mbps

sgnitteS hctiwS 2-2-2

Default: 00

2 - 10

This illustration is provided only as a sample.

The page shown in the illustration does not necessarily appear in this manual.

2

CompoNet Gateway Unit for CC-Link Operation Manual

Page 5

Using this Manual

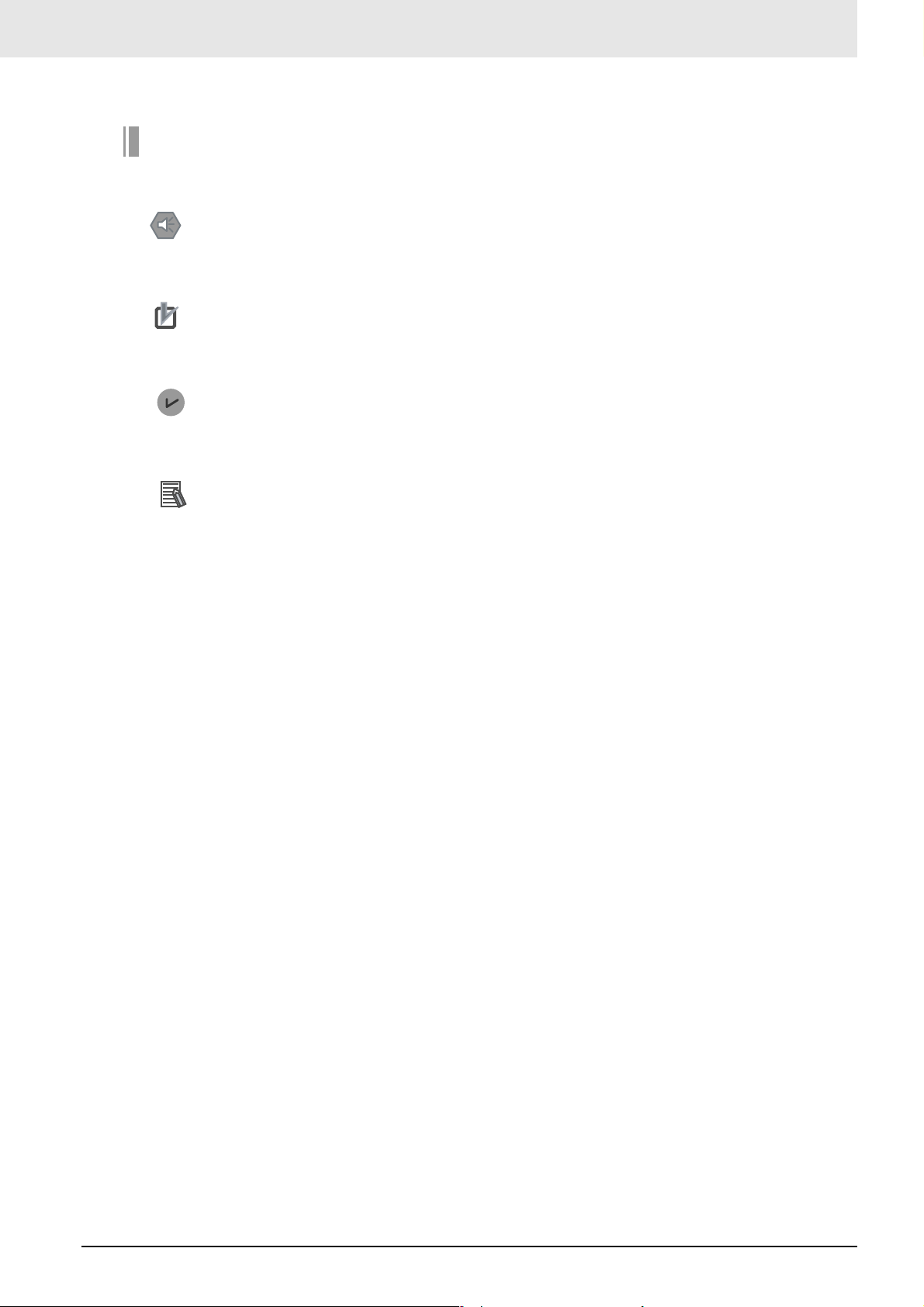

Icons

The following icons are used in this manual.

Precautions for Safe Use

Precautions on what to do and what not to do to ensure using the product safely.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Supplemental Information

Supplemental information to increase understanding.

Additional Information

Additional information or information for reference in product application.

CompoNet Gateway Unit for CC-Link Operation Manual

3

Page 6

Read and Understand this Manual

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

4

CompoNet Gateway Unit for CC-Link Operation Manual

Page 7

Read and Understand this Manual

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

CompoNet Gateway Unit for CC-Link Operation Manual

5

Page 8

Read and Understand this Manual

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

6

CompoNet Gateway Unit for CC-Link Operation Manual

Page 9

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

the CompoNet Gateway Unit for CC-Link.

The safety precautions that are provided are extremely important to safety. Always read and heed the

information provided in all safety precautions.

WARNING

Safety Precautions

Indicates a potentially hazardous situation

which, if not avoided, will result in minor or

moderate injury, or may result in serious

injury or death. Additionally there may be

significant property damage.

Indicates a potentially hazardous situation

Caution

Precautions for Safe Use

Precautions on what to do and what not to do to ensure using the product safely.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

which, if not avoided, may result in minor

or moderate injury, or property damage.

CompoNet Gateway Unit for CC-Link Operation Manual

7

Page 10

Safety Precautions

Symbols

The circle and slash symbol indicates operations that you

must not do.

The specific operation is shown in the circle and explained

in text.

The symbol at the left means "do not disassemble."

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

The symbol at the left is for a general precaution.

The filled circle symbol indicates operations that you must

do.

The specific operation is shown in the circle and explained

in text.

The symbol at the left shows a general precaution for

something that you must do.

8

CompoNet Gateway Unit for CC-Link Operation Manual

Page 11

WARNING

Always input the voltage and current to the Unit within the

specified ranges.

Using a voltage or current outside the specified range may result

in malfunction or fire.

Do not touch any part of the terminal section or disassemble the

Unit and touch internal parts while the power is being supplied.

Do not apply power while the cover is open.

Doing so may result in electric shock.

Safety Precautions

Fail-safe measures must be taken by the customer to ensure

safety in the event of incorrect, missing, or abnormal signals

caused by broken signal lines, momentary power interruptions, or

other causes. Serious accidents may result from abnormal

operation if proper measures are not provided.

Provide safety measures in external circuits (i.e., not in the

Programmable Controller), including the following items, to

ensure safety in the system if an abnormality occurs due to

malfunction of the PLC or an external factor affecting the PLC

operation.

Serious accidents may result from abnormal operation if proper

measures are not provided.

• Emergency stop circuits, interlock circuits, limit circuits, and

similar safety measures must be provided in external control

circuits (i.e., not in Slave Units or Repeater Units).

• The outputs from Slave Units or Repeater Units may remain

ON or OFF due to deposits on or burning of the output relays,

or destruction of the output transistors. As a countermeasure

for such problems, external safety measures (i.e., not in Slave

Units or Repeater Units) must be provided to ensure safety in

the system.

• When the 24-VDC output (service power supply) from a Slave

Unit or Repeater Unit is overloaded or shortcircuited, the

voltage may drop and result in the outputs being turned OFF.

As a countermeasure for such problems, external safety measures (i.e., not in Slave Units or Repeater Units) must be provided to ensure safety in the system.

CompoNet Gateway Unit for CC-Link Operation Manual

9

Page 12

Safety Precautions

Confirm safety at the destination slave device before changing or

transferring parameters to another node. Changing or

transferring parameters without confirming safety may result in

unexpected equipment operation.

The output status from a slave device when problems occur in

communications will depend on the specifications of the slave

device. When using devices with outputs, confirm operating

specifications for communications error and implement suitable

safety measures.

Caution

10

CompoNet Gateway Unit for CC-Link Operation Manual

Page 13

Precautions for Safe Use

Observe the following precautions when using a CompoNet Gateway Unit for CC-Link.

z Power Supply

• Always use the power supply voltages specified in this manual.

• Take appropriate measures to ensure that the specified power with the rated voltage and frequency is

supplied. Be particularly careful in places where the power supply is unstable.

• Always turn OFF the power supply to the PLC, Gateway Unit, Slave Units, and communications

before attempting any of the following.

• Mounting or dismounting any Units

• Assembling Units

• Setting rotary switches

• Connecting or wiring cables

• Connecting or disconnecting connectors

Precautions for Safe Use

z Installation

• Install and wire Units correctly as described in this manual.

• Before touching a Unit, be sure to first touch a grounded metallic object in order to discharge any

static build-up.

• Make sure that the terminal blocks, connectors, communications cables, and other items with locking

devices are properly locked into place.

• When mounting Units to DIN Track or mounting brackets, mount them securely.

• Make sure that all the Unit mounting screws and cable connector screws are tightened to the torque

specified in this manual.

• Use only the specified communications cables and connectors.

• Use correct wiring parts and wiring tools when wiring the cables in the CC-Link and CompoNet systems.

z Wiring

• Wire Units correctly as described in this manual.

• Double-check all wiring and switch settings before turning ON the power supply.

• Confirm polarity before wiring terminals.

• Observe the following precautions when wiring communications cables.

• Separate the communications cables from power lines and high-tension lines.

• Do not fold communications cables.

• Do not pull on the communications cables or bend them past their natural bending radius.

• Always lay communications cable inside ducts.

• Observe voltage specifications when wiring communications paths and power supplies and when wiring I/O crossovers. Incorrect wiring may result in malfunctions.

• Do not apply voltages or connect loads to the Output Units in excess of the maximum switching

capacity.

• When using Flat Cable I (standard or sheathed) or Flat Cable II (sheathed) for more than one CompoNet system, do not bundle the Flat Cables and separate them from each other by at least 5 mm.

• Do not apply power while the cover is open.

• Use only the specified communications cables and connectors.

• Observe the connection distance specifications when connecting communications cables.

• Make sure that metal scraps do not enter a Unit when wiring or processing it.

CompoNet Gateway Unit for CC-Link Operation Manual

11

Page 14

Precautions for Safe Use

z Handling

• Use the special packing box when transporting a Unit. Also, protect the Unit from being exposed to

excessive vibration or impact during transportation.

• Do not drop the Units or expose them to excessive vibration or impact. Doing so may result in failure

or malfunction.

• Check the user program for proper execution before actually running it on the Unit.

• Do not attempt to dismantle the Unit for repairs or modify it in any way.

• Confirm that no adverse effect will occur in the system before attempting any of the following.

• Changing the operating mode of the PLC

• Starting or stopping the user program

• Force-setting/force-resetting any bit in memory

• Changing the present value of any word or any set value in the user program

• Performing I/O tests

• Using the user compensation functions for an Output Unit

• Do not use organic thinners to clean the Unit. Use commercially available alcohol.

z External Circuits

• Install external breakers and take other safety measures against short-circuiting in external wiring.

• Fail-safe measures must be taken by the customer to ensure safety in the event of incorrect, missing,

or abnormal signals caused by broken signal lines, momentary power interruptions, or other causes.

• Construct the control circuits so that the power supply to the CompoNet Gateway Unit turns ON only

after the power supply to I/O Slave Units. If the power supply to I/O Slave Units is turned ON after the

power supply to the CompoNet Gateway Unit, normal operation may be temporarily inhibited.

12

CompoNet Gateway Unit for CC-Link Operation Manual

Page 15

Precautions for Correct Use

• Follow the instructions in this manual to correctly perform installation.

The Unit may fail if it is not installed correctly.

• Observe the voltage specifications when wiring the power supply. An incorrect voltage may result in

malfunctions.

• Take appropriate and sufficient countermeasures when using the Unit in the following locations:

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power supplies

• Do not install the Unit in the following locations:

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the range specified in the specifications

• Locations subject to condensation as the result of severe changes in temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to exposure to water, oil, or chemicals

• Locations subject to shock or vibration

• Take appropriate and sufficient countermeasures when installing the Unit in the following locations:

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power supplies

Precautions for Correct Use

CompoNet Gateway Unit for CC-Link Operation Manual

13

Page 16

Conformance to EC Directives

Conformance to EC Directives

Applicable Directives

• EMC Directive

Concepts

z EMC Directive

The CompoNet Gateway Unit is an electrical device that is built into other machines. To enable more

easily building it into other machines, it has been checked for conformity to EMC standards.* EMCrelated performance of the Unit will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which it is installed. Whether the products conform to the standards

in the system used by the customer, therefore, must be checked by the customer.

Applicable EMC (Electromagnetic Compatibility) standards are as follows: EMS (Electromagnetic Susceptibility):

*

EN 61131-2 and EN 61000-6-2, EMI (Electromagnetic Interference): EN 61131-2 and EN 61000-6-4 (Radiated

emission: 10-m regulations).

z Conformance to EC Directives

The CompoNet Gateway Unit complies with EC Directives. To ensure that the machine in which the Unit

is used complies with EC Directives, the Unit must be installed as follows:

• The Unit must be installed within a control panel.

• You must use reinforced insulation or double insulation for the DC power supplies for communications, internal power, and I/O. The DC power supplies must provide stable power even when a

momentary power interruption of 10 ms occurs in the input. *

• Products complying with EC Directives also conform to the emission standards (EN 61131-2 and EN

61000-6-4). Radiated emission characteristics (10-m regulations) may vary depending on the configuration of the control panel used, other devices connected to the control panel, wiring, and other conditions.

• Compliance was confirmed for I/O wiring of less than 30 m.

* EMC standard compliance was confirmed with an OMRON S82J Power Supply.

• This is a Class A product (designed for industrial environments). Radio interference may occur if it is

used in a residential area. If that occurs, suitable countermeasures will be required.

14

CompoNet Gateway Unit for CC-Link Operation Manual

Page 17

Trademarks

• “CC-Link” is a registered trademark of Mitsubishi Electric Corporation.

• “GX-Developer” is a registered trademark of Mitsubishi Electric Corporation.

• “CompoNet” is a registered trademark of the ODVA (Open DeviceNet Vendors Association, Inc.).

Other system names and product names that appear in this manual are the trademarks or registered

trademarks of their respective companies.

Trademarks

CompoNet Gateway Unit for CC-Link Operation Manual

15

Page 18

Related Manuals

Related Manuals

The following manuals are related to CompoNet. Use them together with this manual whenever

required.

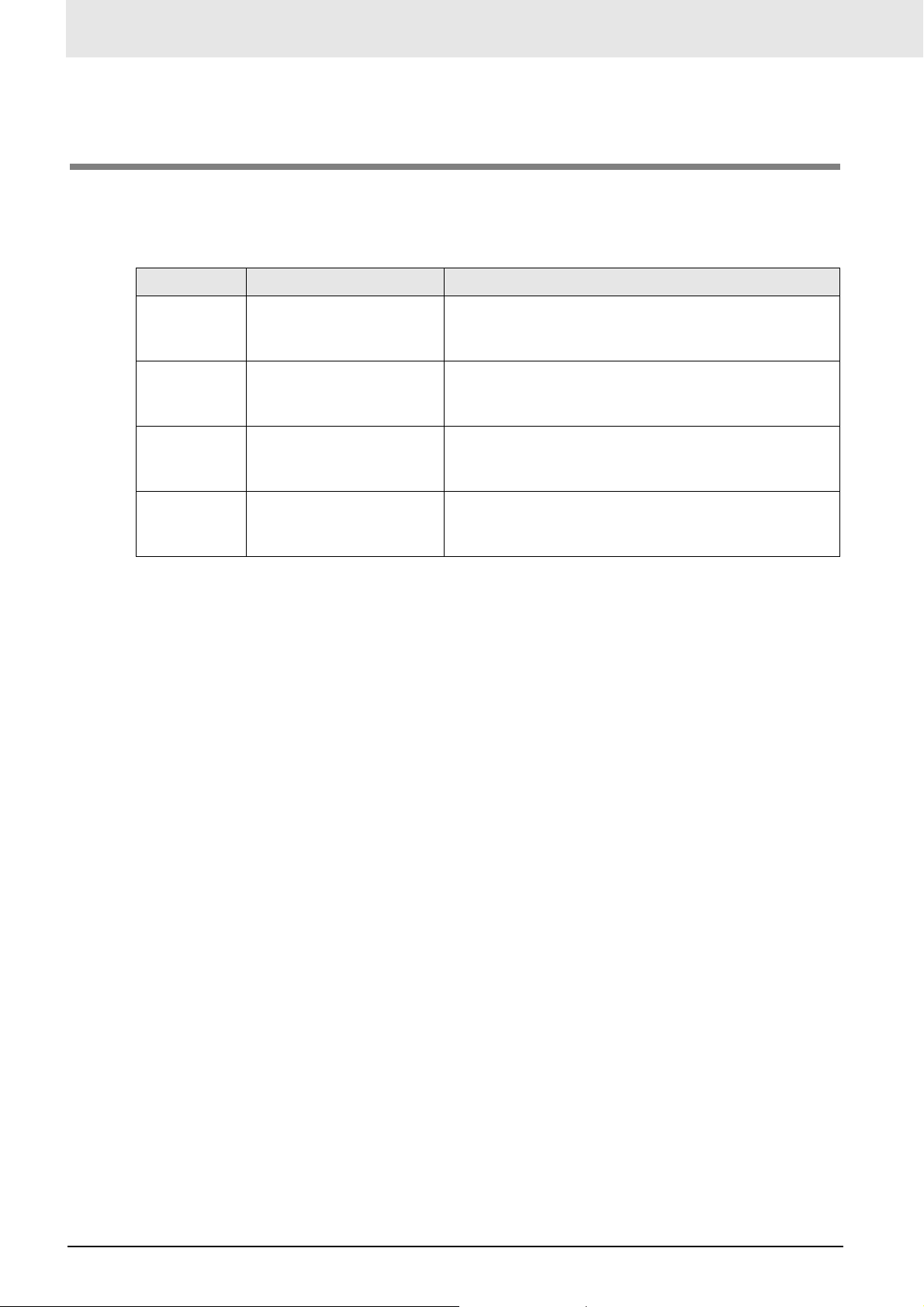

Cat. No. Manual name Contents

W489

(this manual)

W484 CompoNet Analog I/O

W456 CS/CJ-series CompoNet

W457 CompoNet Slave Units and

CompoNet Gateway Unit

for CC-Link Operation

Manual

Slaves with Numerical Indicator Operation Manual

Master Unit Operation

Manual

Repeater Unit Operation

Manual

Specifications and wiring procedures for the GQ-CRM21

CompoNet Gateway Unit for CC-Link.

Specifications for the CRT1-VAD02SD, CRT1VAD02MLD, CRT1-VDA02SD, and CRT1-VDA02MLD

CompoNet Analog I/O Slaves.

CompoNet network overview, communications specifications, and wiring procedures for CS/CJ-series CompoNet Master Units.

Specifications for CompoNet Slaves Units and Repeater

Units.

16

CompoNet Gateway Unit for CC-Link Operation Manual

Page 19

Table of Contents

About this Manual .......................................................................................................................... 1

Using this Manual .......................................................................................................................... 2

Read and Understand this Manual ................................................................................................ 4

Safety Precautions......................................................................................................................... 7

Precautions for Safe Use............................................................................................................. 11

Precautions for Correct Use ........................................................................................................ 13

Conformance to EC Directives ....................................................................................................14

Trademarks .................................................................................................................................. 15

Related Manuals.......................................................................................................................... 16

Overview

1-1 Overview..................................................................................................................................... 1-1

1-1-1 Overview of Gateway Unit............................................................................................................ 1-1

1-1-2 Gateway Unit Features ................................................................................................................ 1-2

Description of Gateway Unit

2-1 Specifications ............................................................................................................................. 2-1

2-1-1 General Specifications................................................................................................................. 2-1

2-1-2 CC-Link Communications Specifications..................................................................................... 2-2

2-1-3 CompoNet Communications Specifications................................................................................. 2-3

2-2 Component Names and Functions ............................................................................................. 2-4

2-2-1 Indications.................................................................................................................................... 2-5

2-2-2 Switch Settings ............................................................................................................................ 2-8

2-2-3 Terminal Arrangement ............................................................................................................... 2-11

2-2-4 Dimensions ................................................................................................................................ 2-12

Wiring and Settings

3-1 Overview of Operating Procedures.............................................................................................3-1

3-1-1 Basic Startup Procedures ............................................................................................................ 3-1

3-1-2 Procedure for Using the Registration Table .................................................................................3-3

3-2 Installation Method ..................................................................................................................... 3-4

3-2-1 Mounting to a Control Panel ........................................................................................................ 3-4

3-3 Wiring ......................................................................................................................................... 3-5

3-3-1 General Wiring Precautions......................................................................................................... 3-5

3-3-2 Special Connector Tools .............................................................................................................. 3-5

3-4 Wiring the Power Supply ............................................................................................................ 3-6

3-4-1 Wiring the Power Supply to the Gateway Unit ............................................................................. 3-6

3-4-2 Power Supply Wiring for CompoNet Slave Units and the CompoNet Network ............................ 3-7

3-5 Wiring the CompoNet Network ................................................................................................. 3-10

3-5-1 Wiring Methods for the CompoNet Network .............................................................................. 3-10

3-6 Wiring the CC-Link Network ..................................................................................................... 3-11

3-6-1 Recommended Materials and Tools .......................................................................................... 3-11

3-6-2 Wiring the Connector ................................................................................................................. 3-12

3-7 Communications Settings......................................................................................................... 3-13

3-7-1 CompoNet Settings.................................................................................................................... 3-13

3-7-2 CC-Link Settings........................................................................................................................ 3-14

Remote I/O Communications

4-1 Exchanging Data ........................................................................................................................ 4-1

4-1-1 Basic Communications Operations.............................................................................................. 4-1

4-1-2 Confirming Normal Slave Unit Operation in Communications Modes 0 to 3 ............................... 4-3

4-1-3 Registration Table ........................................................................................................................ 4-5

Table of Contents

CompoNet Gateway Unit for CC-Link Operation Manual

17

Page 20

Table of Contents

4-2 Memory Map............................................................................................................................... 4-8

4-2-1 Overview ......................................................................................................................................4-8

4-2-2 I/O Memory Allocations According to Communications Modes ................................................... 4-8

4-2-3 Memory Map for Each Communications Mode............................................................................4-9

4-2-4 Status Area Allocations ..............................................................................................................4-10

4-2-5 Node Address Types on the CompoNet Network....................................................................... 4-14

4-2-6 Data Allocations for Word Slave Units........................................................................................4-15

4-2-7 Data Allocations for Bit Slave Units ............................................................................................ 4-21

4-3 Remote I/O Communications Performance .............................................................................. 4-22

Troubleshooting

5-1 Troubleshooting CompoNet Network Errors ............................................................................... 5-1

5-1-1 CompoNet Network Errors ...........................................................................................................5-1

5-1-2 Troubleshooting Sequence When an Error Occurs...................................................................... 5-1

5-2 Troubleshooting CC-Link Network Errors ................................................................................... 5-5

Appendices

A-1 Allocations According to Communications Modes......................................................... Appendix-1

A-2 Status Area Allocations According to Communications Modes ................................... Appendix-12

Revision History

18

CompoNet Gateway Unit for CC-Link Operation Manual

Page 21

Overview

1

1-1 Overview............................................................................ 1-1

Page 22

1

1-1 Overview

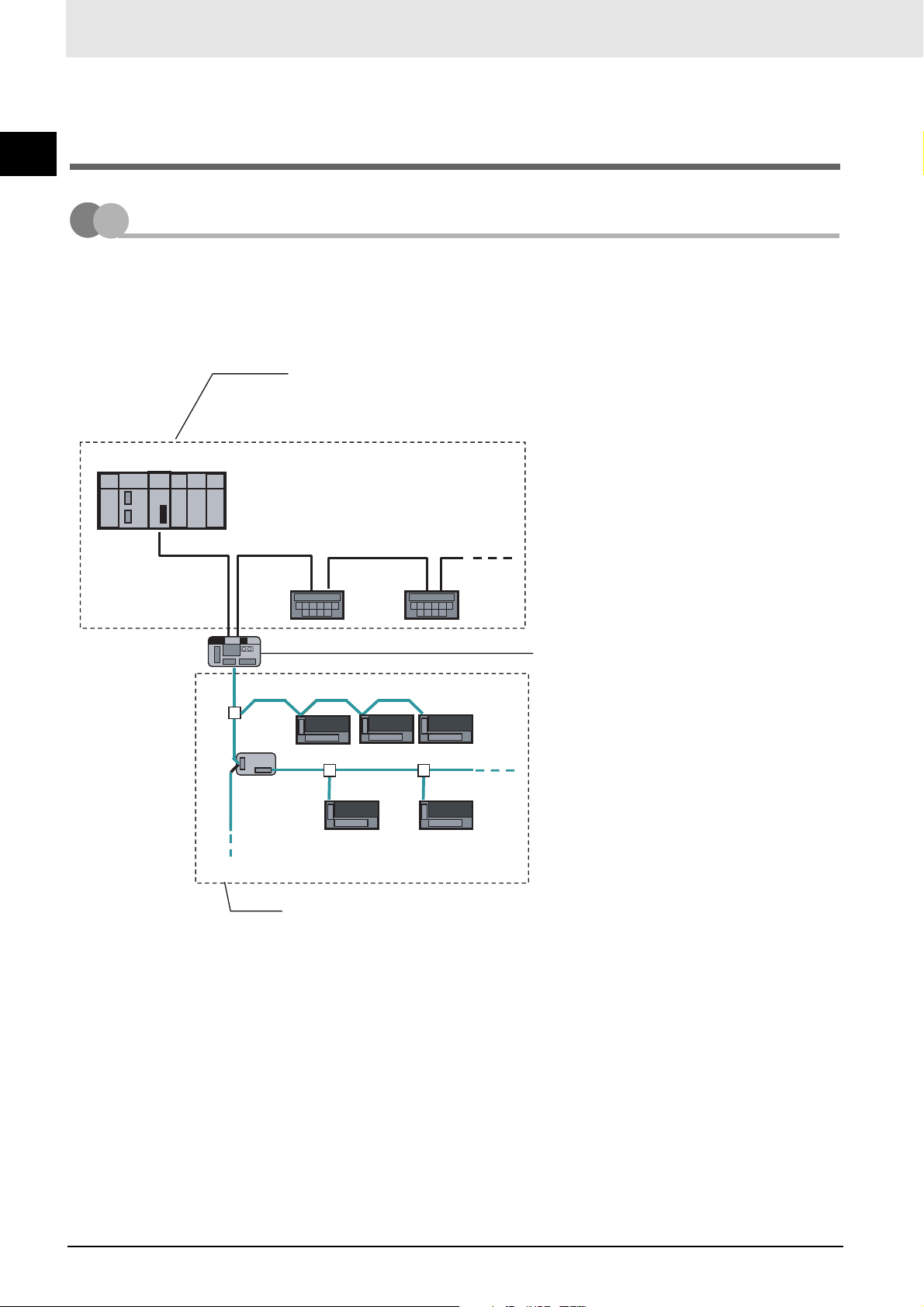

1-1-1 Overview of Gateway Unit

The GQ-CRM21 CompoNet Gateway Unit for CC-Link provides one CC-Link port and one CompoNet

1-1 Overview

CC-Link Master Unit

port. It cyclically transfers I/O data between the CompoNet Slave Units and the CC-Link Master Unit.

The GQ-CRM21 CompoNet Gateway Unit for CC-Link is referred to as the “Gateway Unit” in this manual.

CC-Link Network

Refer to CC-Link documentation from Mitsubishi Electric Corporation

or other sources for details on CC-Link.

Remote

stations

Repeater

Unit

Gateway Unit

In the CC-Link system, the Gateway Unit

is set as a remote device station with a

4-station allocation.

Slave Units

Slave Units

CompoNet Network

Refer to the CompoNet Slave Unit and Repeater Unit Operation Manual

(Cat. No. W457) for the specifications of CompoNet networks.

Refer to documentation for individual Slave Units and Repeater Units for

details on those Units.

Gateway Unit settings and wiring are

described later in this manual.

1 - 1

CompoNet Gateway Unit for CC-Link Operation Manual

Page 23

Overview

1-1-2 Gateway Unit Features

A Gateway Unit can be used to take advantage of CompoNet features to simplify wiring.

z A Selection of Communications Cables

The following communications cables can be used with CompoNet systems: Round Cable I

(2-conductor), Round Cable II (4-conductor), Flat Cable I (standard), and Flat Cable II (sheathed).

Note: Refer to the CompoNet Slave Unit and Repeater Unit Operation Manual (Cat. No. W457) for details on

cable types.

z Multinode Connections

CompoNet systems can be used for multinode, high-density remote I/O communications.

Maximum I/O capacity: 2,560 points

Maximum nodes: 384 nodes per Gateway Unit

Up to 6,144 CompoNet Slave Units can be connected to a CC-Link Master Unit. (Communications

mode 4 must be set.)

z Bit-level Distribution

CompoNet Slave Units with industry-standard e-CON connectors, clamping terminal blocks, or small

connectors can be used to distribute I/O at the bit level. This enables distributed control in distributed

devices, such as sensors and other devices located over a wide area on conveyors or in warehouses.

1

1-1-2 Gateway Unit Features

z Easy Installation and Setup

CompoNet systems can be easily installed and set up.

• Seven-segment Display

The number of connected CompoNet Slave Units is shown on the seven-segment display.

This enables easily checking system operation.

• Participation Flags and Communications Error Flags

The network participation status of CompoNet Slave Units can be checked at the PLC.

When a CompoNet Slave Unit joins the network, a Participation Flag that corresponds to the node

address of the Unit turns ON. If a CompoNet Slave Unit that was participating in the network is

disconnected from the network, a Communications Error Flag that corresponds to the node

address of the Unit turns ON. (Communications mode 0 to 3 must be set.)

• Automatic Baud Rate Detection

The CompoNet Slave Units will automatically detect and use the baud rate that is set in the Gateway Unit. Setting the baud rate is not necessary for any of the CompoNet Slave Units.

z Repeater Units for Greater Flexibility

Repeater Units can be used in a CompoNet network to enable the following network expansions.

• Extending the cable length

• Increasing the number of nodes

• Branching from the trunk line

• Changing the type of cable

Repeater Units can be used to extend up to two segment layers (called sub-trunk lines) from the

trunk line. Up to 64 Repeater Units can be connected per Gateway Unit and up to 32 Repeater Units

can be connected per segment.

Note: Supply communications power to a sub-trunk line from the Repeater Unit.

Refer to the CompoNet Slave Unit and Repeater Unit Operation Manual (Cat. No. W457) for detailed wiring methods.

CompoNet Gateway Unit for CC-Link Operation Manual

1 - 2

Page 24

z Easy Maintenance with Complete System Monitoring Functions

1

1-1 Overview

The CompoNet Network is constantly monitored to enable confirming system safety by quickly identifying errors and checking communications status.

• Gateway Unit Detection of Network Participation, Errors, and Status

When a CompoNet Slave Unit joins the network, a Participation Flag that corresponds to the node

address of the Unit turns ON. If a CompoNet Slave Unit that was participating in the network is

disconnected from the network, a Communications Error Flag that corresponds to the node

address of the Unit turns ON.

Network status, such as communications errors and duplicated Slave Unit node addresses, and

Slave Unit diagnostic results are detected by the Gateway Unit and displayed on the seven-segment display on the front panel and reflected in the Status Flags. (Communications mode 0 to 3

must be set.)

• Registration Table

A table of the Slave Units that should be participating at the nodes (including the node addresses

and corresponding Slave Unit model numbers) can be registered to verify the Slave Units actually

participating in the network and prevent unregistered Slave Units from participating in the network.

• Communications Status on Gateway Unit Seven-segment Display

The seven-segment display on the front of the Gateway Unit can be used to check communications status. The number of connected nodes is normally displayed, but if an error occurs, the

error code is displayed in hexadecimal and the error node address is displayed in decimal.

1 - 3

CompoNet Gateway Unit for CC-Link Operation Manual

Page 25

Description of Gateway Unit

2-1 Specifications ................................................................... 2-1

2-2 Component Names and Functions .................................2-4

2

Page 26

2-1 Specifications

2

2-1 Specifications

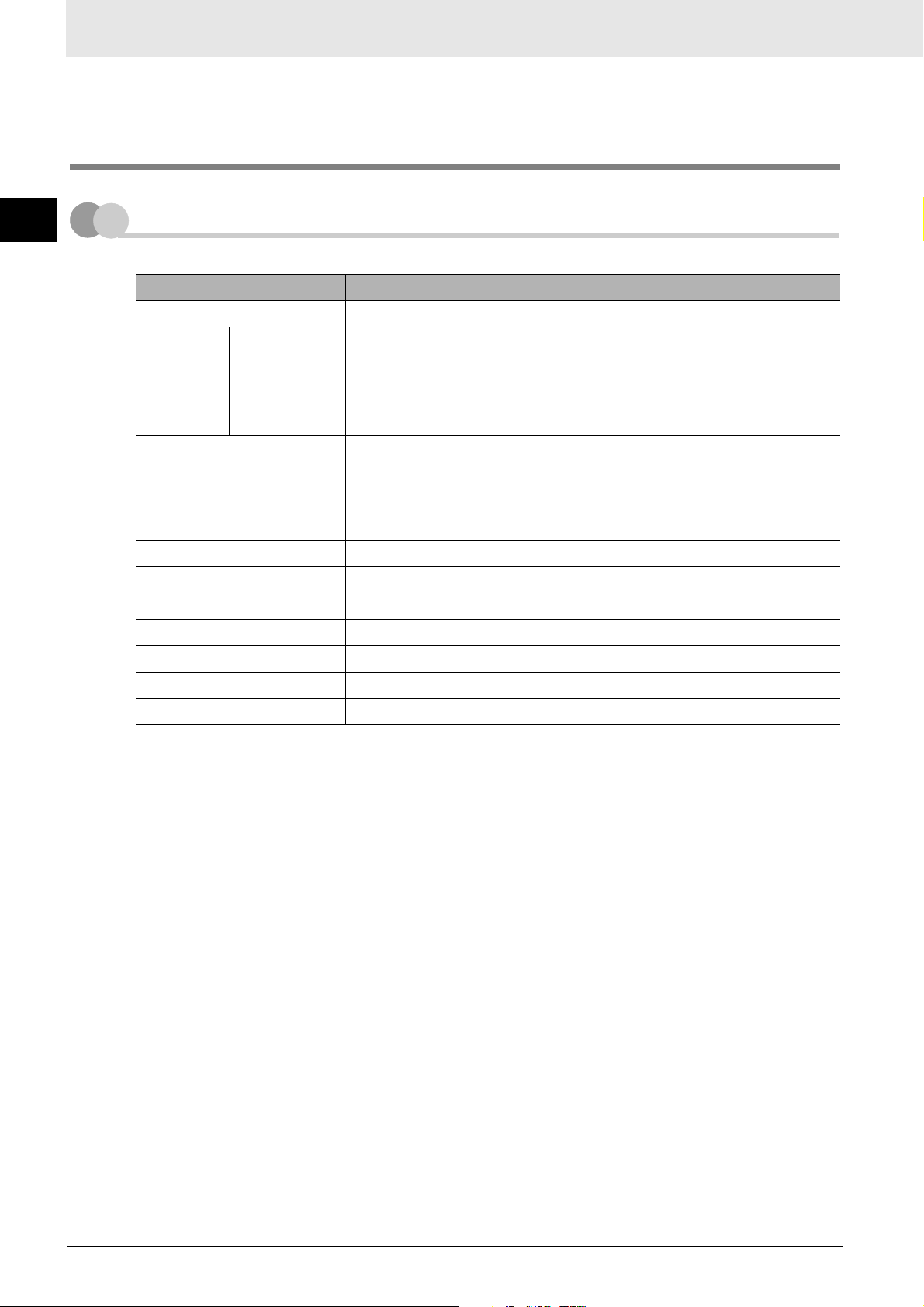

2-1-1 General Specifications

Item Specification

Unit power supply voltage 21.6 to 26.4 VDC (24 VDC±10%) (Supplied from power supply connector.)

Current

consumption

Noise immunity Conforms to IEC 61000-4-4, 2.0 kV

Vibration resistance

Shock resistance

Dielectric strength 500 VAC

Installation method Mounted to DIN Track or by using M4 screws

Ambient operating temperature 0 to 55°C

Ambient operating humidity 10% to 90% (with no condensation)

Ambient storage temperature −25 to 65°C

Weight 110 g max.

Ambient operating atmosphere No corrosive gases

Communications

power supply

Internal current

power

consumption

3.80 A at 24 VDC

0.13 A at 24 VDC

Malfunction: 10 to 60 Hz with 0.7-mm double amplitude, 60 to 150 Hz, 50 m/s

for 80 min in X, Y, and Z directions

150 m/s

2

, 3 times in 6 directions on 3 axes

2

2 - 1

CompoNet Gateway Unit for CC-Link Operation Manual

Page 27

Description of Gateway Unit

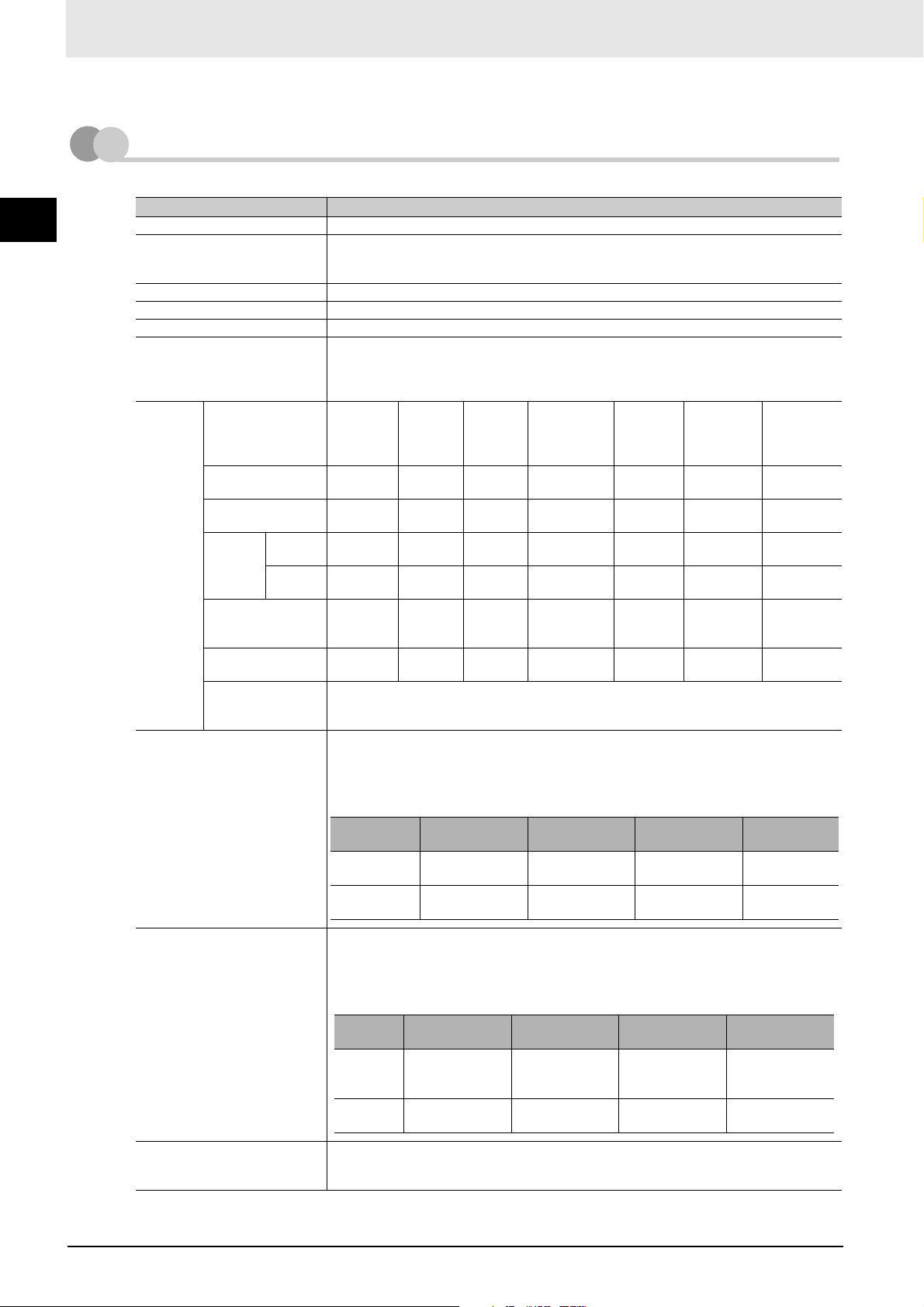

2-1-2 CC-Link Communications Specifications

Item Specification

Version CC-Link version 1.10 or 2.00 (Selected using mode switch.)

Baud rate 156 kbps, 625 kbps, 2.5 Mbps, 5 Mbps, or 10 Mbps

Communications method Broadcast polling

Synchronization method Frame synchronization

Encoding NRZI

Transmission path Bus (Conforms to RS-485.)

Transmission format Conforms to HDLC.

Communications media CC-Link cable (shielded, 3-core twisted-pair cable)

Number of connected nodes Must meet specifications of the Master Unit.

Remote stations 1 to 61 (Four station numbers are allocated starting from the specified

station number.)

Error control

RAS functions Automatic recovery function, slave cutoff, data link status checks, offline

Allocated station numbers Allocated four stations numbers as a remote device station

CRC (X16 + X12 + X5 + 1)

testing

2

2-1-2 CC-Link Communications Specifications

CompoNet Gateway Unit for CC-Link Operation Manual

2 - 2

Page 28

2-1-3 CompoNet Communications Specifications

2

2-1 Specifications

Item Specification

Communications protocol CompoNet protocol

Baud rate 93.75 kbps, 1.5 Mbps, 3 Mbps, or 4 Mbps*1

*1 A baud rate of 4 Mbps is not supported for branch lines and thus cannot be used for

Slave Units with Cables.

Modulation Baseband

Coding Manchester code

Error control Manchester code rules, CRC

Communications media Round Cable I (2-conductor cable, JIS C3306)

Round Cable II (4-conductor cable, JIS C3306)

Flat Cable I (DCA4-4F10 Standard Flat Cable)

Flat Cable II (DCA5-4F10 Sheathed Flat Cable)

Communications

distance

Maximum I/O capacity Word Slave Units: 1,024 inputs and 1,024 outputs (2,048 I/O points total)

Baud rate Max.

segment

length

4 Mbps* 30 m

3 Mbps* 30 m

1.5 Mbps

(Round

Cable I)*

1.5 Mbps (Round

Cable II or Flat

Cable I/II)

93.75 kbps (Round

Cable I)

93.75 kbps (Round

Cable II or Flat

Cable I/II)

No

branches

Branches 30 m

(90 m)

(90 m)

100 m

(300 m)

(90 m)

30 m

(90 m)

500 m

(1,500 m)

Unrestricted wiring is enabled for a total length of 200 m per segment.

Bit Slave Units: 256 inputs and 256 outputs (512 I/O points total)

Branch

length per

segment

0 m 0 m --- --- --- ---

0.5 m 8 m 3 branches/m 1 0 m 0 m

2.5 m 25 m 3 branches/m 3 --- ---

2.5 m 25 m 3 branches/m 3 0.1 m 2 m

6 m 120 m 3 branches/m 3 --- ---

To t al

branch

length per

segment

--- --- --- --- --- ---

Branch

location

restriction

Connected

nodes per

branch

Max. subtrunk length

per segment

Total subtrunk length

per segment

When the Gateway Unit is used, I/O capacities are as follows depending on the CompoNet

communications mode.

Max. number of connected

nodes

Max. number of connected

nodes per trunk line or sub-trunk

line

Communications

mode 0 or 4

Word Slave

Units

Bit Slave Units

Word Slave Units: 64 input nodes and 64 output nodes

Bit Slave Units: 128 input nodes and 128 output nodes

When the Gateway Unit is used, the maximum number of connected nodes is as follows

depending on the CompoNet communications mode.

Word

Slave

Units

Bit Slave

Units

32 nodes (number of Slave Unit and Repeater Unit nodes)

1,024 inputs and

1,024 outputs

256 inputs and

256 outputs

Communications

mode 0 or 4

IN0 to IN63 and

OUT0 to OUT63

IN0 to IN127 and

OUT0 to OUT127

Communications

mode 1 or 5

512 inputs and

512 outputs

192 inputs and

192 outputs

Communications

mode 1 or 5

IN0 to IN31 and

OUT0 to OUT31

IN0 to IN95 and

OUT0 to OUT95

* Lengths given in parentheses are for when two Repeater Units are used.

Communications

mode 2 or 6

256 inputs and

256 outputs

96 inputs and 96

outputs

Communications

mode 2 or 6

IN0 to IN15 and

OUT0 to OUT15

IN0 to IN47 and

OUT0 to OUT47

Communications

mode 3

128 inputs and

128 outputs

32 inputs and

32 outputs

Communications

mode 3

IN0 to IN7 and

OUT0 to OUT7

IN0 to IN15 and

OUT0 to OUT15

2 - 3

CompoNet Gateway Unit for CC-Link Operation Manual

Page 29

Description of Gateway Unit

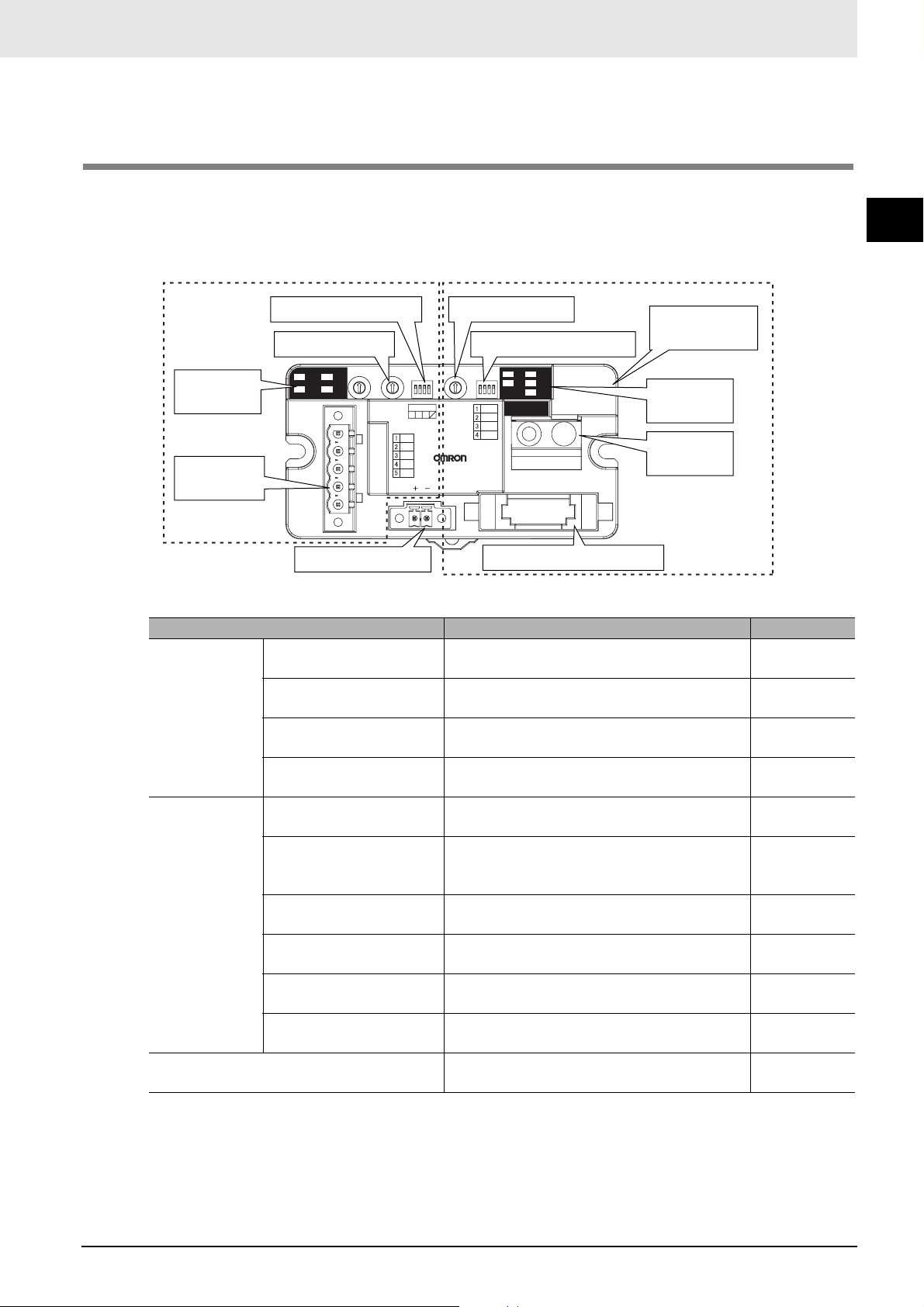

2-2 Component Names and Functions

The Gateway Unit is separated into sections, one for CC-Link communications and one for CompoNet

communications.

CompoNet Communications SectionCC-Link Communications Section

Baud rate DIP switch

Station number switch

RUN

L

CC-Link

communications

indicators

CC-Link

communications

connector

SD

L

ERR

RD

Power connector

X10 MODEX1 B.RATE

STATION No.

DA

DB

DG

SLD

FG

DC24V INPUT

Part Description Reference

CC-Link

communications

section

CC-Link communications

indicators

Station number switch Sets the station number of the Gateway Unit on

Baud rate DIP switch Sets the baud rate of the Gateway Unit on the

CC-Link communications

connector

CompoNet

communications

section

CompoNet communications

indicators

CompoNet seven-segment

display

Mode switch Sets the CompoNet communications mode. 2-2-2 Switch

CompoNet DIP switch Enables or disables the baud rate setting and

CompoNet setting buttons Creates the registration table on the CompoNet

CompoNet communications

connector

Power connector Connects to the power supply for the Gateway

Mode switch

124

GQ-CRM21

CompoNet DIP switch

SDNSMS

.

RD

REG

REGIST RESET

DR0

DR1

DCN

REGS

CompoNet communications

connector

.

8 8

CompoNet sevensegment display

CompoNet

communications

indicators

CompoNet

setting buttons

Used to check CC-Link data link status. 2-2-1

Indications

2-2-2 Switch

the CC-Link network.

Settings

2-2-2 Switch

CC-Link network.

Settings

Connects to the CC-Link cable. 2-2-3 Terminal

Arrangement

Used to check the communications status of

CompoNet remote I/O.

Normally shows the number of connected

CompoNet Slave Units. An error code is

2-2-1

Indications

2-2-1

Indications

displayed if a communications error occurs.

Settings

2-2-2 Switch

registration table on the CompoNet network.

Settings

2-2-2 Switch

network, resets the Gateway Unit, etc.

Settings

Connects the CompoNet network cable. 2-2-3 Terminal

Arrangement

2-2-3 Terminal

Unit.

Arrangement

2

CompoNet Gateway Unit for CC-Link Operation Manual

2 - 4

Page 30

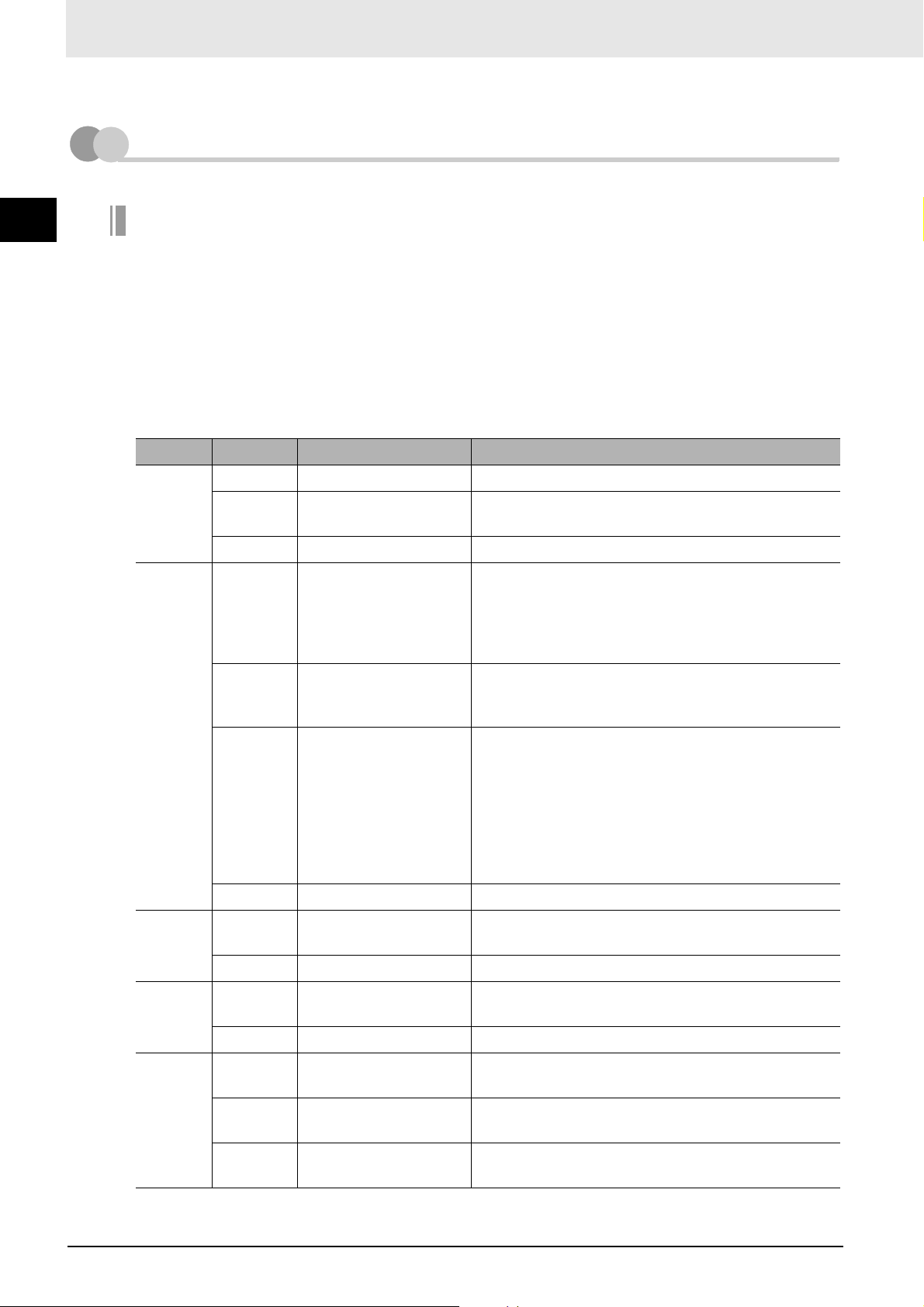

2-2-1 Indications

Indications of both CompoNet and CC-Link status are provided on the Gateway Unit.

2

2-2 Component Names and Functions

CompoNet Communications Section

z CompoNet Communications Indicators

The following LED indicators are provided for CompoNet communications.

MS (Module Status): Shows the status of the node itself (two colors: green and red).

NS (Network Status): Shows the status of communications (two colors: green and red).

SD (Send Data): Shows the transmission status from the Gateway Unit to CompoNet (one

color: yellow).

RD (Receive Data): Shows the reception status from CompoNet to the Gateway Unit (one color:

yellow).

REG (Registration): Shows if the registration table is enabled or disabled (one color: green).

Indicator Status Status definition Meaning

MS Lit green Normal The Unit is operating normally.

Lit red Fatal error Unit hardware error, such as a watchdog timer error

(WDT)

Not lit Power OFF/Preparing Power OFF, resetting, or initializing

NS Lit green Online with remote I/O

communications in

progress

Flashing

green

Online with no remote I/O

communications in

progress

Power is being supplied, remote I/O communications have

started, there are no communications errors at any Slave

Unit or Repeater Unit, there are no registration table

errors, and there are no node address duplication errors

for Slave Units or Repeater Units.

Remote I/O communications have not started or have

stopped.

Flashing

red

Not lit Power OFF/Preparing Power OFF, resetting, or initializing

SD Lit yellow Normal transmission Frames are being sent normally from the Gateway Unit to

Not lit No transmission Data is not being sent by the Gateway Unit

RD Lit yellow Normal reception Frames are being received normally from CompoNet

Not lit No reception Data is not being received by the Gateway Unit.

REG Lit green Registration table enabled The registration table has been created and is enabled.

Flashing

green

Not lit Registration table

Non-fatal communications

error

Registration table creation The registration table is being created.

disabled

A communications error has occurred at one or more

Slave Units or Repeater Units.

A verification error (non-existent or unregistered Slave

Unit) has occurred at one or more Slave Units.

Communications have stopped due to a communications

error, an illegal configuration error (number of Repeater

Units) has occurred, or an address duplication error has

occurred at one or more Slave Units or Repeater Units.

CompoNet.

Slave Units.

The registration table has been created.

The registration table is disabled or has not been created.

2 - 5

CompoNet Gateway Unit for CC-Link Operation Manual

Page 31

Description of Gateway Unit

z CompoNet Seven-segment Display

The display operates as shown below during normal operation and when an error occurs.

The information shown on the display during normal operation can be changed by setting pin 3 on

the CompoNet DIP switch (pin 3: DCN (details of connected nodes).

Status

Normal CompoNet DIP

switch pin 3 (DCN

(details of connected

nodes)): OFF

(default)

Displayed

contents

Number of

connected

nodes

Description

Displays the number of Slave Units connected to CompoNet.

If more than 99 Slave Units are connected, the value of the 100s digit is

shown by the dot indicators.

100s digit = 1

Only the left dot is lit.

(Display example for 123)

100s digit = 2

Only the right dot is lit.

2

2-2-1 Indications

CompoNet DIP

switch pin 3 (DCN

(details of connected

nodes)): ON

Detailed

connection

information

• Baud rate

• Number of

nodes for

each Unit

type

(Display example for 233)

100s digit = 3

Both the left and right dots are lit.

(Display example for 323)

• The display will change in the following order.

Baud rate

↓

Total number of nodes

↓

Number of Word Slave Units

i** (Word Input Slave Units) → o** (Word Output Slave Units) →

↓

Number of Bit Slave Units

bi** (Bit Input Slave Units) → bo** (Bit Output Slave Units) →

↓

Baud rate

• The baud rate is indicated as follows:

“_0”: 4 Mbps

“_1”: 3 Mbps

“_2”: 1.5 Mbps

“_3”: 93.75 kbps

• The display of the number of connected nodes is the same as when pin 3

on the CompoNet DIP switch is OFF.

CompoNet Gateway Unit for CC-Link Operation Manual

2 - 6

Page 32

Status

Error Initialization error Error code The error code is shown on the display in hexadecimal.

Communications error The error

2

Displayed

contents

code, node

type, and

applicable

node address

are displayed

in order.

Description

Error code (2-digit hexadecimal) → Slave Unit type →

Node address (3-digit decimal: 100s digit is indicated with 1 bit dot) are

displayed in order (for each error cause).

Note: Error codes are different for inputs and outputs.

Example Error code Slave Unit type

Communications

error

Display Display

appearance

d9 i IN

Display Display

appearance

oOUT

bi Bit Input

Meaning

Unit

2-2 Component Names and Functions

Node address

duplication

Verification error:

Slave Unit

missing.

Verification error:

Unregistered

Slave Unit

Operating error

Note: “Operating errors”

are all errors

except for communications

errors that occur

during Unit operation.

Error code The error code is shown on the display in 2-digit hexadecimal.

Example Error code ---

Illegal

registration table

CC-Link Communications Section

z CC-Link Communications Indicators

bo Bit Output

Unit

r Repeater

Unit

d0 Same as above.

d5 Same as above.

d6 Same as above.

Display Display

appearance

E8 ---

2 - 7

Indicator Status Status definition

L RUN Lit green CC-Link data links are active.

Not lit Communications for CC-Link data links have been interrupted.

L ERR Lit red • A CC-Link data link communications error has occurred or the baud rate of the

Gateway Unit is different from the baud rate of the CC-Link Master Unit.

• The station number switch is set out of range.

Flashing red The setting of the baud rate DIP switch or station number switch was changed while

power was ON.

SD Lit yellow Data is being transmitted normally.

Not lit No data is being transmitted.

RD Lit yellow Data is being received normally.

Not lit No data is being received.

CompoNet Gateway Unit for CC-Link Operation Manual

Page 33

2-2-2 Switch Settings

CompoNet Communications Section

z Mode Switch

This switch sets the communications mode number for the Gateway Unit. It is set to between 0 and 6 on

a decimal rotary switch. The expanded cyclic setting (a network parameter set with the GX-Developer)

in the station information must be set according to the communications mode as shown below.

Description of Gateway Unit

2

2-2-2 Switch Settings

Mode

number

0

(default)

1 Communications

2 Communications

3 Communications

4 Communications

5 Communications

Name

Communications

mode 0

mode 1

mode 2

mode 3

mode 4

mode 5

Connectable node

addresses

Word Slave Unit: IN0 to

IN63 and OUT0 to OUT63

Bit Slave Unit: IN0 to IN127

and OUT0 to OUT127

Word Slave Unit: IN0 to

IN31 and OUT0 to OUT31

Bit Slave Unit: IN0 to IN95

and OUT0 to OUT95

Word Slave Unit: IN0 to

IN15 and OUT0 to OUT15

Bit Slave Unit: IN0 to IN47

and OUT0 to OUT47

Word Slave Unit: IN0 to IN7

and OUT0 to OUT7

Bit Slave Unit: IN0 to IN15

and OUT0 to OUT15

Word Slave Unit: IN0 to

IN63 and OUT0 to OUT63

Bit Slave Unit: IN0 to IN127

and OUT0 to OUT127

Word Slave Unit: IN0 to

IN31 and OUT0 to OUT31

Bit Slave Unit: IN0 to IN95

and OUT0 to OUT95

Control points

Word Slave Unit: 1,024

inputs and 1,024 outputs

Bit Slave Unit: 256 inputs

and 256 outputs

Word Slave Unit: 512

inputs and 512 outputs

Bit Slave Unit: 192 inputs

and 192 outputs

Word Slave Unit: 256

inputs and 256 outputs

Bit Slave Unit: 96 inputs

and 96 outputs

Word Slave Unit: 128

inputs and 128 outputs

Bit Slave Unit: 32 inputs

32 outputs

Word Slave Unit: 1,024

inputs and 1,024 outputs

Bit Slave Unit: 256 inputs

and 256 outputs

Word Slave Unit: 512

inputs and 512 outputs

Bit Slave Unit: 192 inputs

and 192 outputs

CC-Link version and

expanded cyclic

setting

Version 2, octuple

(default)

Version 2, quadruple

Version 2, double

Version 1

Version 2, quadruple

Version 2, double

6 Communications

mode 6

7 to 9 Reserved --- --- ---

Note: Do not set communications mode numbers 7 to 9. They are reserved.

CompoNet Gateway Unit for CC-Link Operation Manual

Word Slave Unit: IN0 to

IN15 and OUT0 to OUT15

Bit Slave Unit: IN0 to IN47

and OUT0 to OUT47

Word Slave Unit: 256

inputs and 256 outputs

Bit Slave Unit: 96 inputs

and 96 outputs

Version 1

2 - 8

Page 34

z DIP Switch

O

N

2

2-2 Component Names and Functions

123

4

• Baud Rate Setting

Pin 1 Pin 2

DR0 DR1

OFF OFF

ON OFF

OFF ON

ON ON

4 Mbps (default)

3 Mbps

1.5 Mbps

93.75 kbps

Description

The CompoNet Slave Units will automatically detect and use the baud rate that is set on pin 1 (DR0)

and pin 2 (DR1). Setting the baud rate is not necessary for any of the Slave Units.

• Details of Connected Nodes

Pin Name ON OFF

3 Details of Connected Nodes

(DCN)

Details of the connected nodes

will be displayed.

The total number of

connected nodes will be

displayed.

If pin 3 (DCN) is turned ON, details on the connected nodes (baud rate, total number of connected

nodes, numbers of I/O Word Slave Units, and numbers of I/O Bit Slave Units) will be displayed on

the seven-segment display. If pin 3 is turned OFF, only the total number of connected nodes will be

displayed.

Refer to 2-2-1 Indications for information on the displays for the details of connected nodes.

• Registration Table Enable Setting

Pin Name ON OFF

4 Registration Table Enable

Setting (REGS)

Registration table enabled. Registration table disabled.

If pin 4 (REGS) is ON, the registration table that was created with the REGIST CompoNet setting

button will be enabled when the power supply is turned ON. Only registered Slave Unit will participate in the network. Registered Slave Units will be compared with the connected Slave Units. If they

do not agree, the Registration Table Verification Error Flag at status bit 01 will turn ON.

Refer to 4-1-2 Confirming Normal Slave Unit Operation in Communications Modes 0 to 3 for infor-

mation on the registration table.

z CompoNet Setting Buttons (REGIST and RESET Buttons)

• REGIST Button

If the REGIST Button is pressed for at least 2 seconds while pin 4 on the DIP switch is OFF, the

Slave Unit configuration that is currently connected to the CompoNet network will be registered in

the registration table.

The REGS indicator will flash while the table is being created and then light when creating the table

has been finished.

• RESET Button

If the RESET Button is pressed for at least 2 seconds, the Gateway Unit will be reset.

To enable the registration table that was created with the REGIST button, turn ON the registration

table enable setting (pin 4) and reset the Gateway Unit.

2 - 9

CompoNet Gateway Unit for CC-Link Operation Manual

Page 35

Description of Gateway Unit

Supplemental Information

To press the CompoNet setting buttons, open the cover as shown below.

2

Open from here.

CC-Link Communications Section

z Station Number Switch

The station number switch sets the station number of the Gateway Unit on the CC-Link network.

X10 X1

Number Description Remarks

1 to 61

0 or 62 to 99

Set the station number of the Gateway Unit on the

CC-Link network.

Do not set. The L ERR indicator will light.

Default: 00

2-2-2 Switch Settings

z Baud Rate DIP Switch

The baud rate DIP switch sets the baud rate of the Gateway Unit on the CC-Link network.

Set the baud rate of the Gateway Unit to the same value as the CC-Link Master Unit.

O

N

1

2

3

4

• Baud Rate Setting

Pin 1 Pin 2 Pin 3 Pin 4*1 Baud rate

OFF OFF OFF OFF

OFF OFF ON OFF

OFF ON OFF OFF

OFF ON ON OFF

ON OFF OFF OFF

*1 Always leave pin 4 turned OFF. It is reserved.

156 kbps (default)

625 kbps

2.5 Mbps

5 Mbps

10 Mbps

CompoNet Gateway Unit for CC-Link Operation Manual

2 - 10

Page 36

2

2-2-3 Terminal Arrangement

Gateway Unit/Communications Power Connector

This connector supplies power to the Gateway Unit.

Depending on the type of communications cable that is used for CompoNet, it also supplies power to

Slave Units and Repeater Units on the trunk line connected to the CompoNet communications connector.

− (0 V)

+ (24 VDC)

CompoNet Communications Connector

2-2 Component Names and Functions

BS − (communications power negative side)

BDL (communications data low)

BDH (communications data high)

BS + (communications power positive side)

Note: BS − and BS + terminals output the communications power that is supplied from the power connector. (They

also supply power to Slave Units and Repeater Units on the trunk line.)

CC-Link Communications Connector

Terminal

name

DA Signal line Blue*1

DB Signal line White*1

DG Communications ground Yellow

SLD*2 Communications cable shield

FG*2 Frame ground

*1 Insert terminating resistance at the last station.

*2 SLD and FG are connected inside the Unit.

Signal type Signal line color

---

---

2 - 11

CompoNet Gateway Unit for CC-Link Operation Manual

Page 37

2-2-4 Dimensions

Description of Gateway Unit

52.9

RUN

L

SD

L

ERR

RD

X10 MODEX1 B.RATE

STATION No.

124

DA

DB

DG

SLD

FG

DC24V INPUT

GQ-CRM21

95

Mounting Hole Dimensions (mm)

88±0.2

DR0

DR1

DCN

REGS

REGIST RESET

SDNSMS

RD

REG

50

25

Two, 4.2 dia. or M4

37.9

32.5

2

2-2-4 Dimensions

(Unit: mm)

CompoNet Gateway Unit for CC-Link Operation Manual

2 - 12

Page 38

2

2-2 Component Names and Functions

2 - 13

CompoNet Gateway Unit for CC-Link Operation Manual

Page 39

Wiring and Settings

3-1 Overview of Operating Procedures................................. 3-1

3-2 Installation Method........................................................... 3-4

3-3 Wiring................................................................................. 3-5

3-4 Wiring the Power Supply ................................................. 3-6

3-5 Wiring the CompoNet Network........................................ 3-10

3-6 Wiring the CC-Link Network ............................................ 3-11

3-7 Communications Settings ............................................... 3-13

3

Page 40

3-1 Overview of Operating Procedures

3-1-1 Basic Startup Procedures

The basic steps required to use the Gateway Unit are given below.

3

1) Mounting and Wiring Refer to 3-2 to 3-6.

Network Wiring and Power Supply Wiring

• Use the special CC-Link cables.

• Use compliant cables for CompoNet.

▼

2) Setting the Station Number Refer to 2-2-2.

Use the station number switch in the CC-Link communications section to set the station number of

the Gateway Unit on the CC-Link network.

▼

3) Setting the Network Baud Rate Refer to 2-2-2.

3-1 Overview of Operating Procedures

Use pins 1 to 3 on the baud rate DIP switch in the CC-Link communications section to set the baud

rate of the CC-Link network.

Set the baud rate of the Gateway Unit to the same value as the CC-Link Master Unit.

Use pin 1 (DR0) and pin 2 (DR1) on the CompoNet DIP switch to set the baud rate of the CompoNet

network.

▼

4) Setting the Communications Mode Refer to 2-2-2.

Select the communications mode based on the system response speed and number of CompoNet

Slave Units that are connected.

▼

5) Setting the Node Addresses of the CompoNet Slave Units

▼

6) Power Application

The CompoNet system will start and the number of CompoNet Slave Units that are connected will

be displayed on the seven-segment display on the Gateway Unit.

If pin 3 (DCN) on the CompoNet DIP switch is turned ON, detailed connection information will be

displayed.

▼

3 - 1

CompoNet Gateway Unit for CC-Link Operation Manual

Page 41

Wiring and Settings

7) Settings from the GX-Developer

Set up the Gateway Unit using the network parameters and write the parameters to the PLC.

▼

8) Confirming Operation

• Confirming CC-Link Network Communications ---Refer to 2-2-2.

Check the communications status using the

indicators and displays on the CC-Link Master Unit

and Gateway Unit.

• Confirming Participation of CompoNet Slave Units ---Refer to 4-1-2.

Check the Participation Flags. ---Refer to 4-1-3.

If the registration table is being used, also check

the Registration Table Verification Error Flag. ---Refer to 4-1-3.

▼

9) Operation

---Refer to 3-7-2.

3

3-1-1 Basic Startup Procedures

CompoNet Gateway Unit for CC-Link Operation Manual

3 - 2

Page 42

3-1-2 Procedure for Using the Registration Table

Use the following procedure to register the CompoNet Slave Units in the registration table.

1. Turn OFF pin 4 (REGS) on the CompoNet DIP switch and press the REGIST CompoNet setting

button for at least 2 seconds.

The Slave Unit configuration in the CompoNet system will be registered in the registration table.

3

3-1 Overview of Operating Procedures

2. Turn ON pin 4 (REGS) on the CompoNet DIP switch.

3. Press the RESET CompoNet setting button for at least 2 seconds.

The Gateway Unit will be reset and the registration table will be enabled.

Precautions for Correct Use

When using a communications mode between 4 to 6, start the Gateway Unit in the communications mode between 0 and 2 that has the same number of control points, confirm participation of

the CompoNet Slave Units, and then register the CompoNet Slave Units.

3 - 3

CompoNet Gateway Unit for CC-Link Operation Manual

Page 43

3-2 Installation Method

3-2-1 Mounting to a Control Panel

• When using a DIN Track to mount the Gateway Unit in the control panel, use End Plates (PFP-M,

sold separately) to secure the Gateway Unit on the DIN Track.

• When using screws to mount the Gateway Unit in the control panel, open mounting holes in the control panel and tighten the specified size of screws to a suitable torque to secure the Gateway Unit.

Use M4 screws and tighten them to between 0.6 and 0.98 N⋅m.

• There are no restrictions in the mounting orientation of the Gateway Unit.

Wiring and Settings

3

3-2-1 Mounting to a Control Panel

CompoNet Gateway Unit for CC-Link Operation Manual

3 - 4

Page 44

3-3 Wiring

3-3-1 General Wiring Precautions

• Always turn OFF the power supply before performing any wiring operations on the Gateway Unit. The

3

3-3 Wiring

3-3-2 Special Connector Tools

external devices that are connected to the Gateway Unit may operate in an unexpected manner if the

Gateway Unit is wired while the power supply is ON.

• Be careful not to pinch your fingers when attaching connectors.

• Incorrect wiring will reduce safety functions. Perform all wiring correctly and confirm operation before

using the Gateway Unit.

Special Screwdrivers

We recommend using the following Special Screwdrivers to tighten wiring screws when wiring the

power supply or connecting connector cables to connect accessories.

Model Manufacturer (supplier)

XW4Z-00C OMRON

SZF-1 Phoenix Contact

3 - 5

CompoNet Gateway Unit for CC-Link Operation Manual

Page 45

3-4 Wiring the Power Supply

3-4-1 Wiring the Power Supply to the Gateway Unit

Power (24 VDC) is supplied directly from a power source to the Gateway Unit.

Wiring and Settings

3

RUN

L

SD

L

ERR

RD

Power connector

X10 MODE X1 B.RATE

STATION No.

1 2 4

DA

DB

DG

SLD

GQ-CRM21

FG

DC24V INPUT

Communications

power supply

(24 VDC)

MS

NS

DR0

REGIST

DR1

DCN

REGS

3 m max.

RESET

SD

RD

REG

. .

Communications

Connector

Precautions for Correct Use

Do not allow the wiring between the Gateway Unit and the power supply to exceed 3 m.

3-4-1 Wiring the Power Supply to the Gateway Unit

z Selecting a DC Power Supply

The DC power supply must satisfy the following conditions.

Item Specification

Output voltage 24 VDC ± 10%

Output ripple 600 mVp-p

Output current The capacity of the power supply must be equal to the sum of the

following current consumptions or greater.

• Current consumptions of all Word Slave Units and Repeater Units

• Current consumptions of all Bit Slave Units plus the current

consumptions of the external I/O

Isolation The output must be isolated from both the AC power supply and the

case ground.

For Slave Units with network power supply, the power for external I/O is also supplied from the

power supply connected to the Gateway Unit (through the Flat Cable). When determining the output

current of the power supply, always include the actual load currents and the current consumptions of

the external I/O.

Refer to documentation for each Slave Unit for information on Slave Unit current consumptions.

CompoNet Gateway Unit for CC-Link Operation Manual

3 - 6

Page 46

3-4-2 Power Supply Wiring for CompoNet Slave Units and the CompoNet Network

The following power supplies are required to operate the CompoNet network.

• Communications power supply: Required for Slave Unit communications and internal operation.

• I/O power supply: Required for external I/O operation for the Slave Units.

The power supply method for communications and I/O depends on the cables and the Slave Units that

3

are used, as shown below.

Slave Unit Power Supply Types and Cables

The cables that can be used for each type of Slave Unit power supply are given in the following table.

Refer to the CompoNet Slave Unit and Repeater Unit Operation Manual (Cat. No. W457) for details on

cable types.

Slave power supply

3-4 Wiring the Power Supply

Multi-power supply Can be used. Can be used.

Network power supply Cannot be used. Can be used.

types

Round Cable I

Cable types

Round Cable II, Flat Cable I, or

Flat Cable II

3 - 7

CompoNet Gateway Unit for CC-Link Operation Manual

Page 47

Wiring and Settings

Power Supply Methods According to Slave Unit Power Supply Types

An overview of the power supply methods for each Slave Unit power supply type is given in this section.

Refer to the CompoNet Slave Unit and Repeater Unit Operation Manual (Cat. No. W457) for details on

wiring methods.

z Multi-power Supply (Round Cable I)

Supply power separately to the communications power terminals (BS+ and BS− ) and the I/O power

terminals (V+ and G− ) on each Slave Unit.

L

Slave Unit

BS

BS

+

−

I/O power

supply terminals

VG

I/O power

supply

24 VDC

When complying with UL standards, install a

device to limit the current between the external

power supply and the Gateway Unit to 4 A or

less for the communications power supply.

Power

supply

24 VDC

Communications

power supply terminals

BDHBD

3

3-4-2 Power Supply Wiring for CompoNet Slave Units and the CompoNet

Overcurrent

protection

(current limit: 4 A)

Gateway Unit

Power supply connector on Gateway Unit

z Multi-power Supply (Round Cable II, Flat Cable I, or Flat Cable II)

Communications power (BS+ and BS−) is supplied from the Gateway Unit.

I/O power (V+ and G− ) is supplied separately.

When complying with UL standards, install a

device to limit the current between the external

power supply and the Gateway Unit to 4 A or

less for the communications power supply.

Power

supply

24 VDC

Round Cable I

Overcurrent

protection

(current limit: 4 A)

BS−

BDLBDHBS+

When complying with UL

standards, install a device to limit

the current between the external

Communica-

tions power

supply

24 VDC

power supply and the Gateway

Unit to 4 A or less for the

communications power supply.

Slave Unit

Communications power

supply terminals

BDHBD

BS

+

L

I/O power supply

BS

VG

−

terminals

I/O power

supply

24 VDC

Overcurrent

protection

(current limit: 4 A)

Gateway Unit

Power supply connector on Gateway Unit

CompoNet Gateway Unit for CC-Link Operation Manual

Round Cable II,

Flat Cable I, or

Flat Cable II

BS−

BDLBDHBS+

3 - 8

Page 48

z Network Power Supply

The communications power (BS+ and BS− ) and the I/O power (V and G) are supplied together.

They do not have to be supplied separately.

Both communications power and I/O power are supplied from the Gateway Unit.

Slave Unit

3

When complying with UL standards,

install a device to limit the current

between the external power supply

and the Gateway Unit to 4 A or less for

the communications power supply.

Power

supply

24 VDC

3-4 Wiring the Power Supply

Overcurrent

protection

(current limit: 4 A)

Gateway Unit

BDHBD

BS

BS

+

L

−

Round Cable II,

Flat Cable I, or

Flat Cable II

Power supply connector on Gateway Unit

BS−

BDLBDHBS+

3 - 9

CompoNet Gateway Unit for CC-Link Operation Manual

Page 49

Wiring and Settings

3-5 Wiring the CompoNet Network

3-5-1 Wiring Methods for the CompoNet Network

Refer to the CompoNet Slave Unit and Repeater Unit Operation Manual (Cat. No. W457) for basic

wiring specifications, cable wiring methods, cable processing and mounting methods, and cable types.

3

3-5-1 Wiring Methods for the CompoNet Network

CompoNet Gateway Unit for CC-Link Operation Manual

3 - 10

Page 50

3-6 Wiring the CC-Link Network