Page 1

Cat. No. W394-E1-13

SYSMAC CS Series

SYSMAC CJ Series

SYSMAC One NSJ Series

Programmable Controllers

PROGRAMMING MANUAL

Page 2

Page 3

SYSMAC CS Series

CS1G/H-CPU@@-EV1

CS1G/H-CPU@@H

CS1D-CPU@@H

CS1D-CPU@@S

SYSMAC CJ Series

CJ1H-CPU@@H-R

CJ1G-CPU@@

CJ1G/H-CPU@@H

CJ1G-CPU@@P

CJ1M-CPU@@

SYSMAC One NSJ Series

Programmable Controllers

Programming Manual

Revised August 2008

Page 4

iv

Page 5

Notice:

r

f

OMRON products are manufactured for use according to proper procedures

by a qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this

manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also

capitalized when it refers to an OMRON product, regardless of whether or not

it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON

products, often means “word” and is abbreviated “Wd” in documentation in

this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

OMRON, 2001

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

The following headings appear in the left column of the manual to help you

locate different types of information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 6

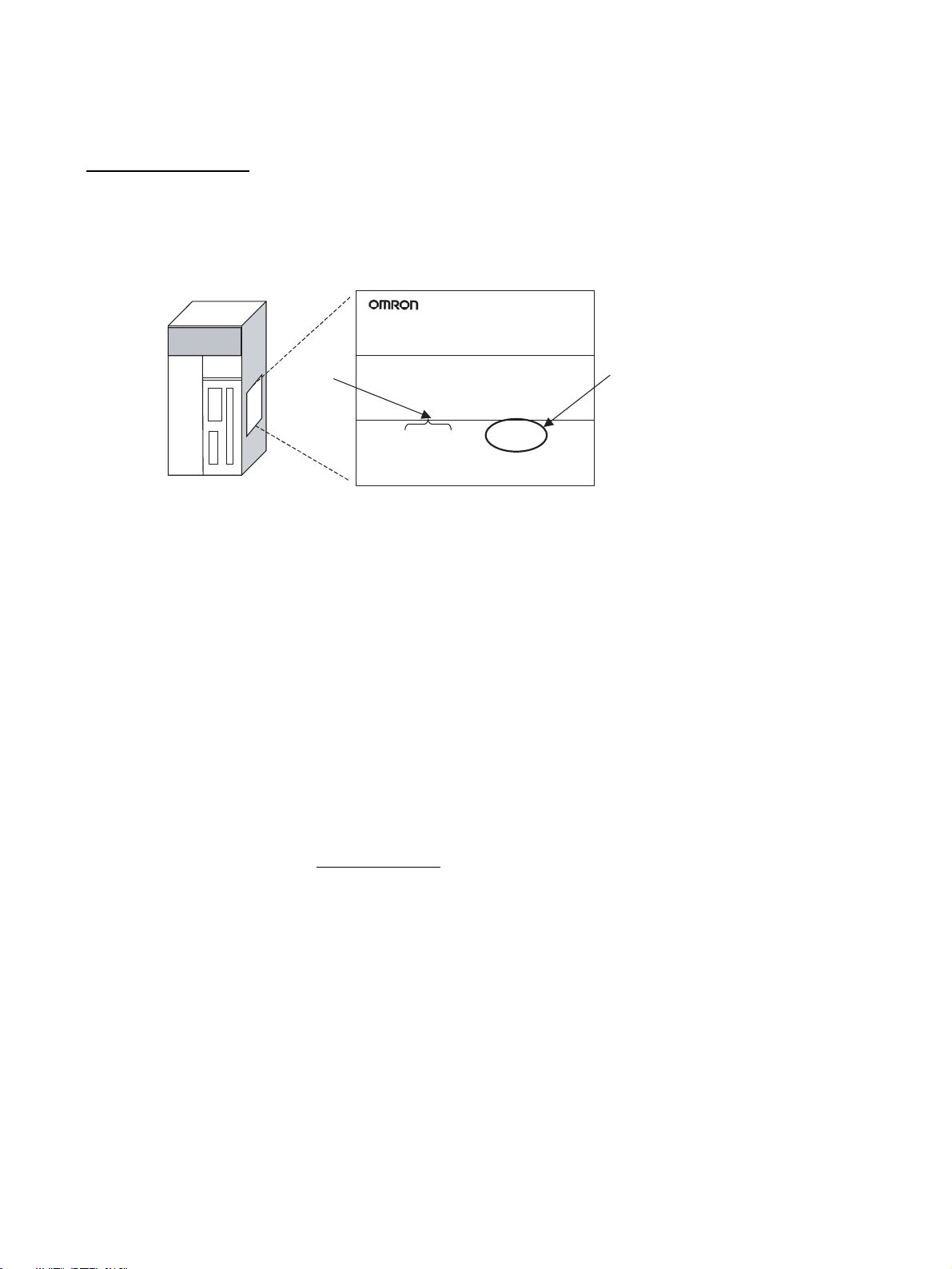

Unit Versions of CS/CJ-series CPU Units

Unit Versions A “unit version” has been introduced to manage CPU Units in the CS/CJ

Series according to differences in functionality accompanying Unit upgrades.

This applies to the CS1-H, CJ1-H, CJ1M, and CS1D CPU Units.

Notation of Unit Versions

on Products

CS/CJ-series CPU Unit

The unit version is given to the right of the lot number on the nameplate of the

products for which unit versions are being managed, as shown below.

Product nameplate

CS1H-CPU67H

CPU UNIT

Lot No.

Lot No. 040715 0000 Ver.3.0

OMRON Corporation MADE IN JAPAN

Unit version

Example for Unit version 3.0

• CS1-H, CJ1-H, and CJ1M CPU Units manufactured on or before November 4, 2003 do not have a unit version given on the CPU Unit (i.e., the

location for the unit version shown above is blank).

• The unit version of the CJ1-H-R CPU Units begins at version 4.0.

• The unit version of the CS1-H, CJ1-H, and CJ1M CPU Units, as well as

the CS1D CPU Units for Single-CPU Systems, begins at version 2.0.

• The unit version of the CS1D CPU Units for Duplex-CPU Systems, begins

at version 1.1.

• CPU Units for which a unit version is not given are called Pre-Ver. @.@

CPU Units, such as Pre-Ver. 2.0 CPU Units and Pre-Ver. 1.1 CPU Units.

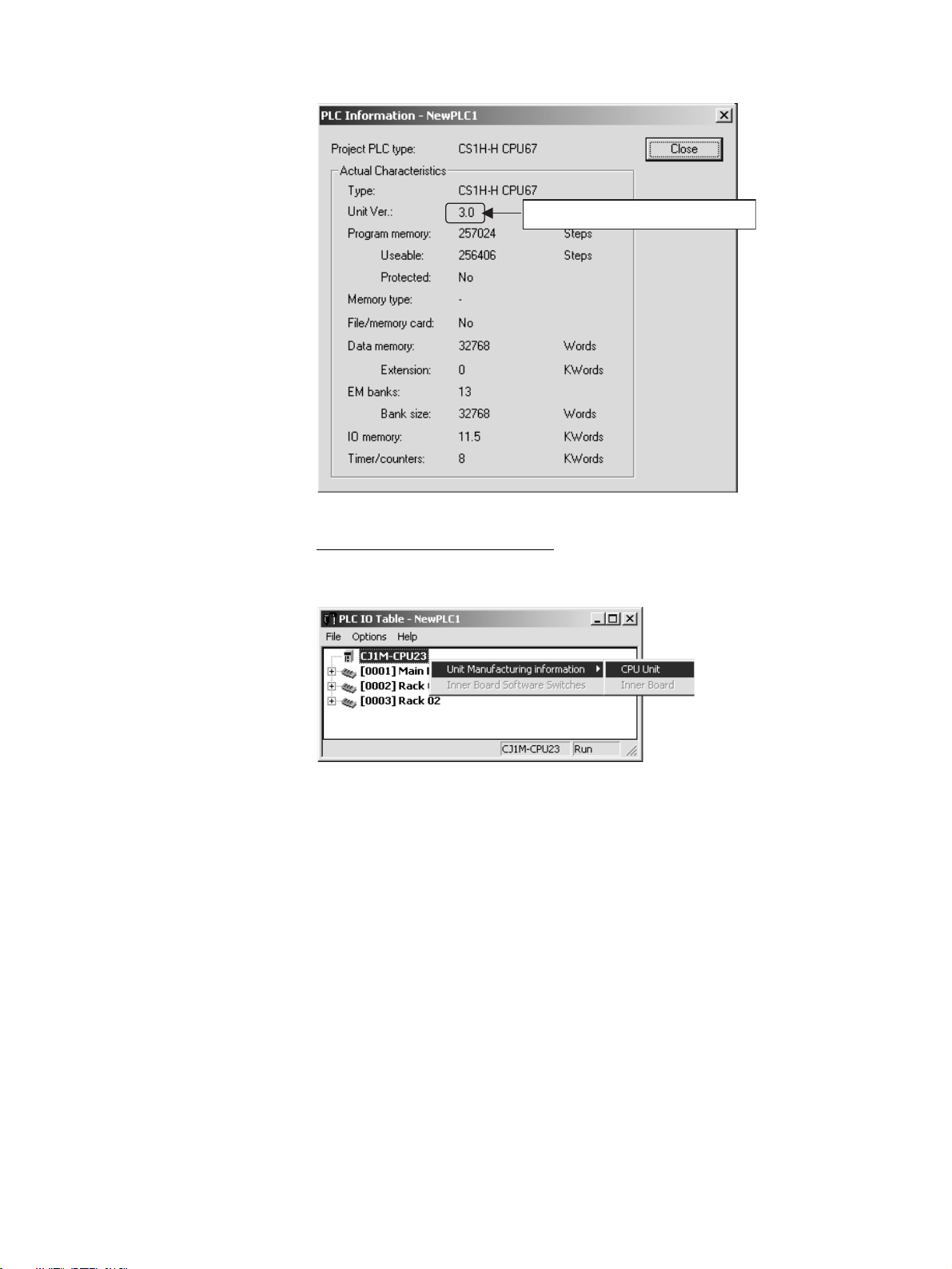

Confirming Unit Versions

with Support Software

CX-Programmer version 4.0 can be used to confirm the unit version using one

of the following two methods.

• Using the PLC Information

• Using the Unit Manufacturing Information (This method can be used for

Special I/O Units and CPU Bus Units as well.)

Note CX-Programmer version 3.3 or lower cannot be used to confirm unit versions.

PLC Information

• If you know the device type and CPU type, select them in the Change

PLC Dialog Box, go online, and select PLC - Edit - Information from the

menus.

• If you don't know the device type and CPU type, but are connected

directly to the CPU Unit on a serial line, select PLC - Auto Online to go

online, and then select PLC - Edit - Information from the menus.

In either case, the following PLC Information Dialog Box will be displayed.

vi

Page 7

Unit version

Use the above display to confirm the unit version of the CPU Unit.

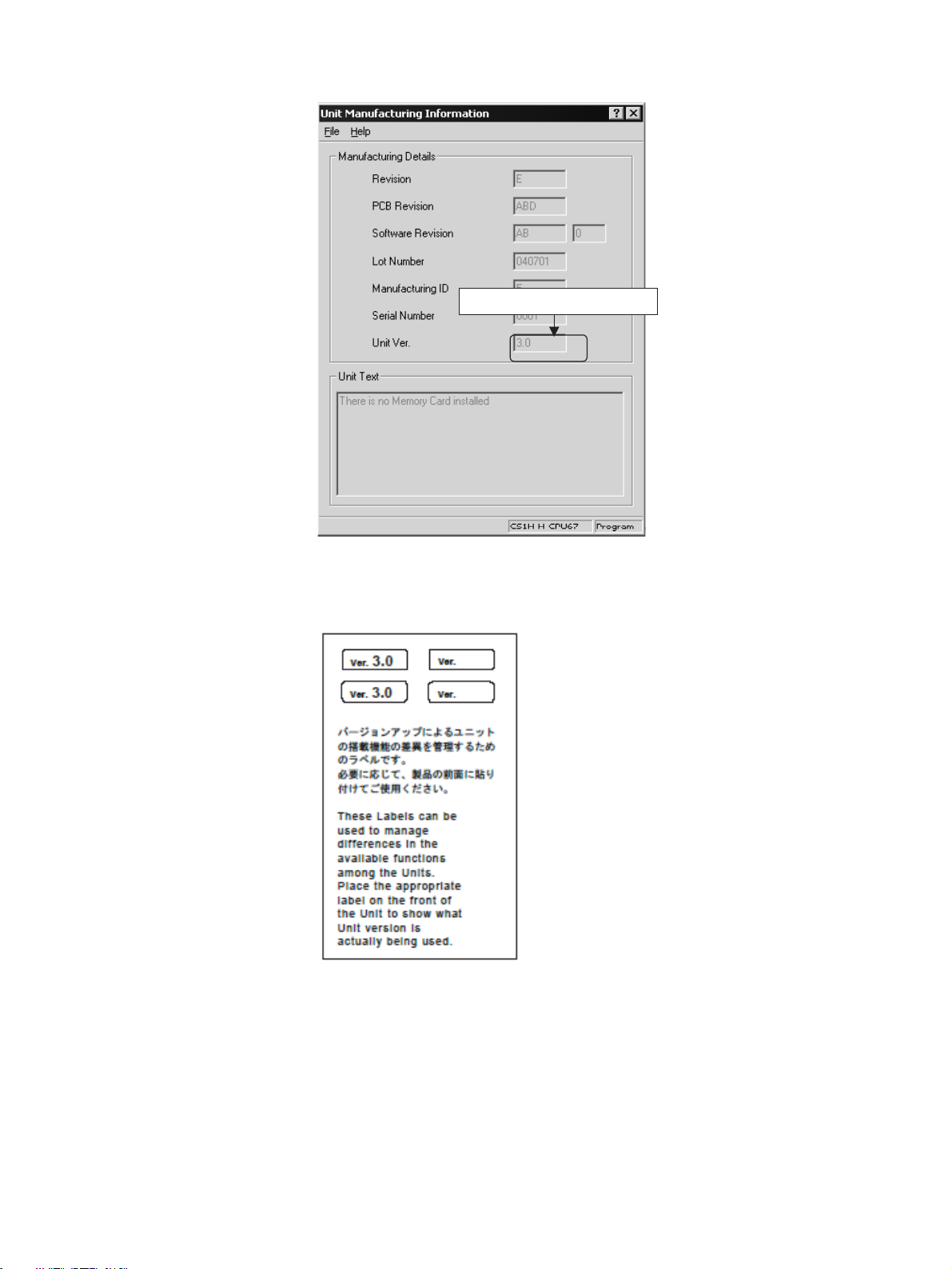

Unit Manufacturing Information

In the IO Table Window, right-click and select Unit Manufacturing information - CPU Unit.

The following Unit Manufacturing information Dialog Box will be displayed.

vii

Page 8

Unit version

Use the above display to confirm the unit version of the CPU Unit connected

online.

Using the Unit Version

Labels

The following unit version labels are provided with the CPU Unit.

These labels can be attached to the front of previous CPU Units to differentiate between CPU Units of different unit versions.

viii

Page 9

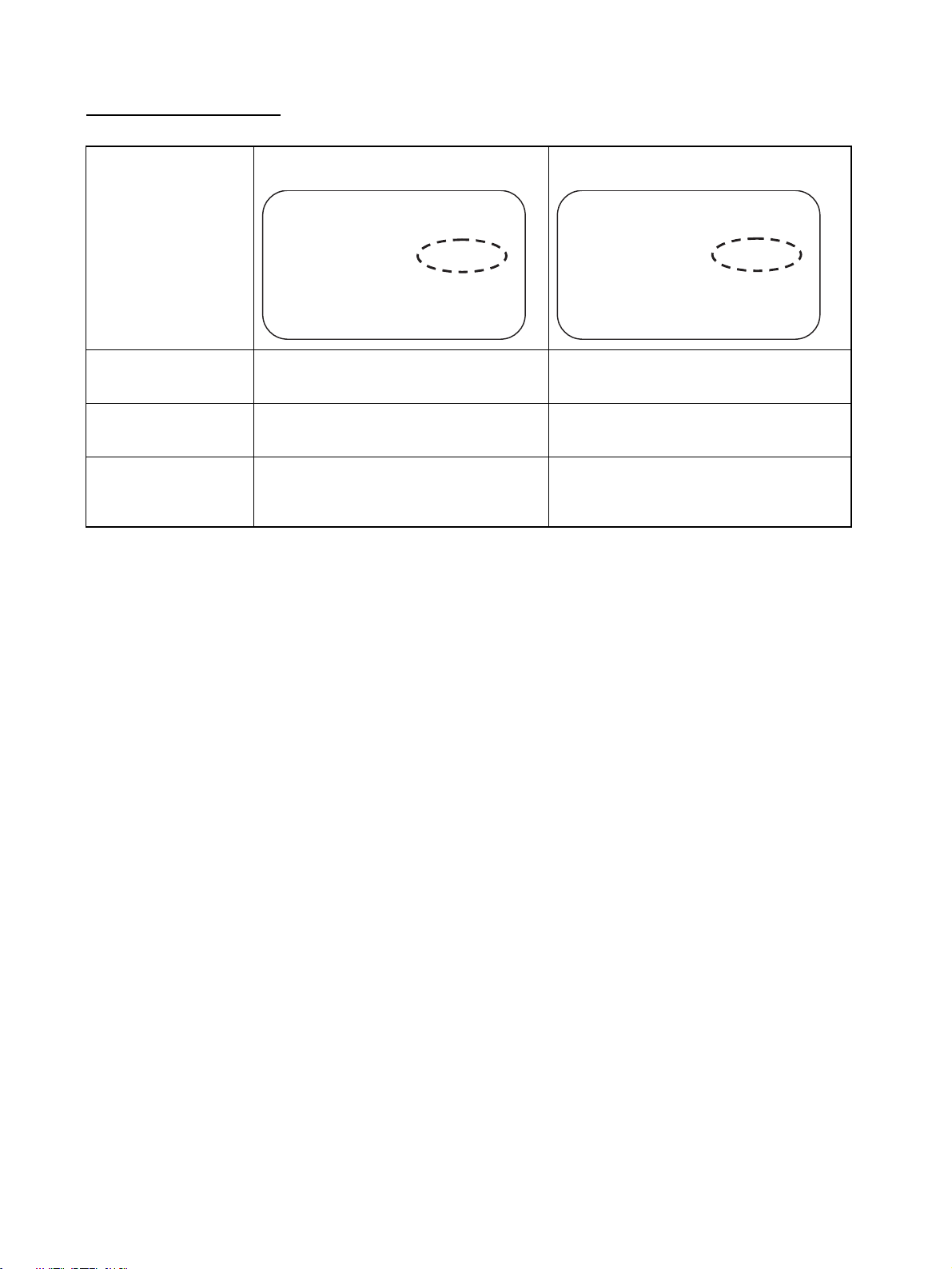

Unit Version Notation In this manual, the unit version of a CPU Unit is given as shown in the follow-

ing table.

Product nameplate

Meaning

Designating individual

CPU Units (e.g., the

CS1H-CPU67H)

Designating groups of

CPU Units (e.g., the

CS1-H CPU Units)

Designating an entire

series of CPU Units

(e.g., the CS-series CPU

Units)

CPU Units on which no unit version is

given

Lot No. XXXXXX XXXX

OMRON Corporation MADE IN JAPAN

Pre-Ver. 2.0 CS1-H CPU Units CS1H-CPU67H CPU Unit Ver. @.@

Pre-Ver. 2.0 CS1-H CPU Units CS1-H CPU Units Ver. @.@

Pre-Ver. 2.0 CS-series CPU Units CS-series CPU Units Ver. @.@

Units on which a version is given

Lot No. XXXXXX XXXX

(Ver. @.@)

Ver. @ @ .@

ix

Page 10

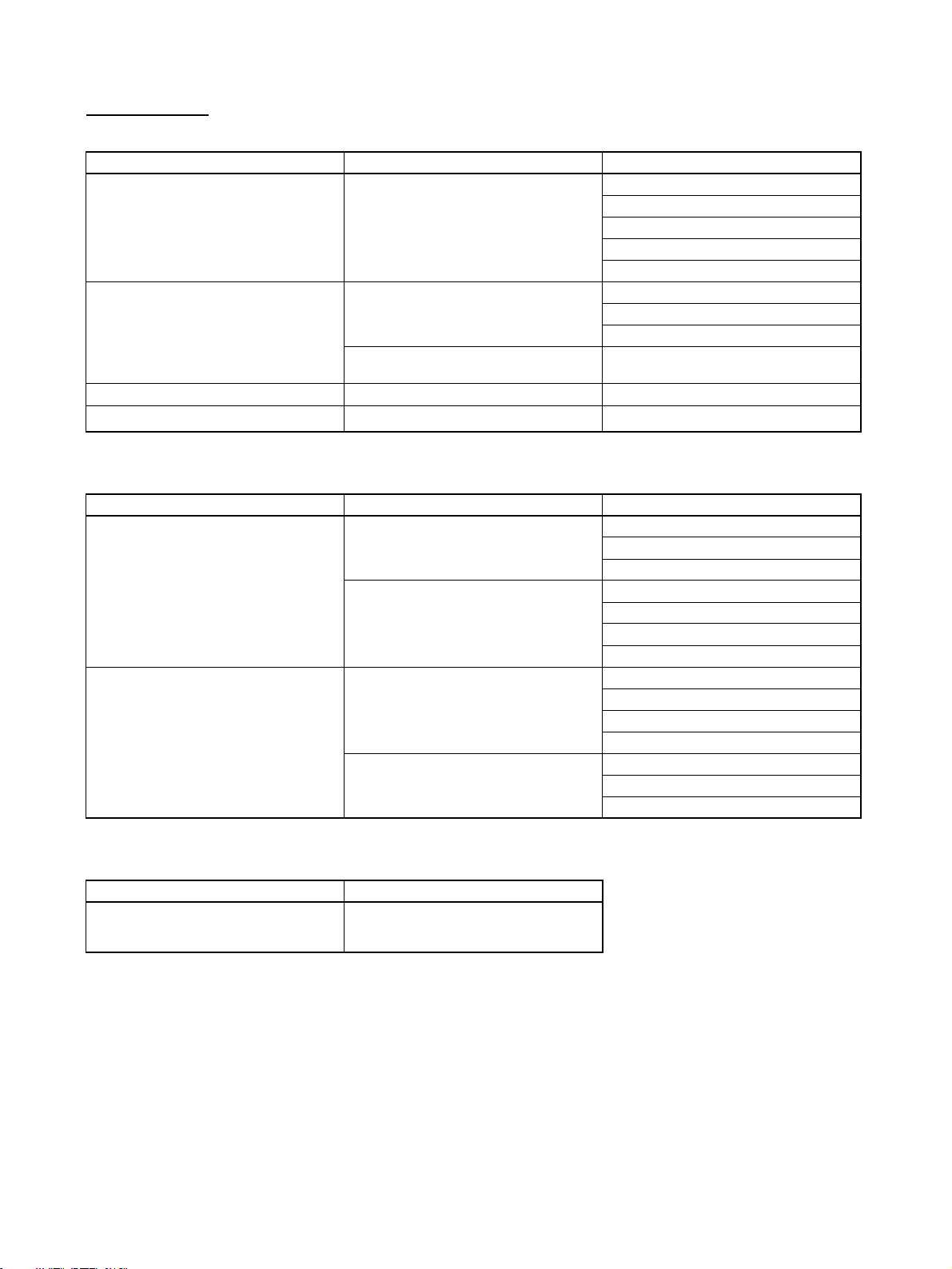

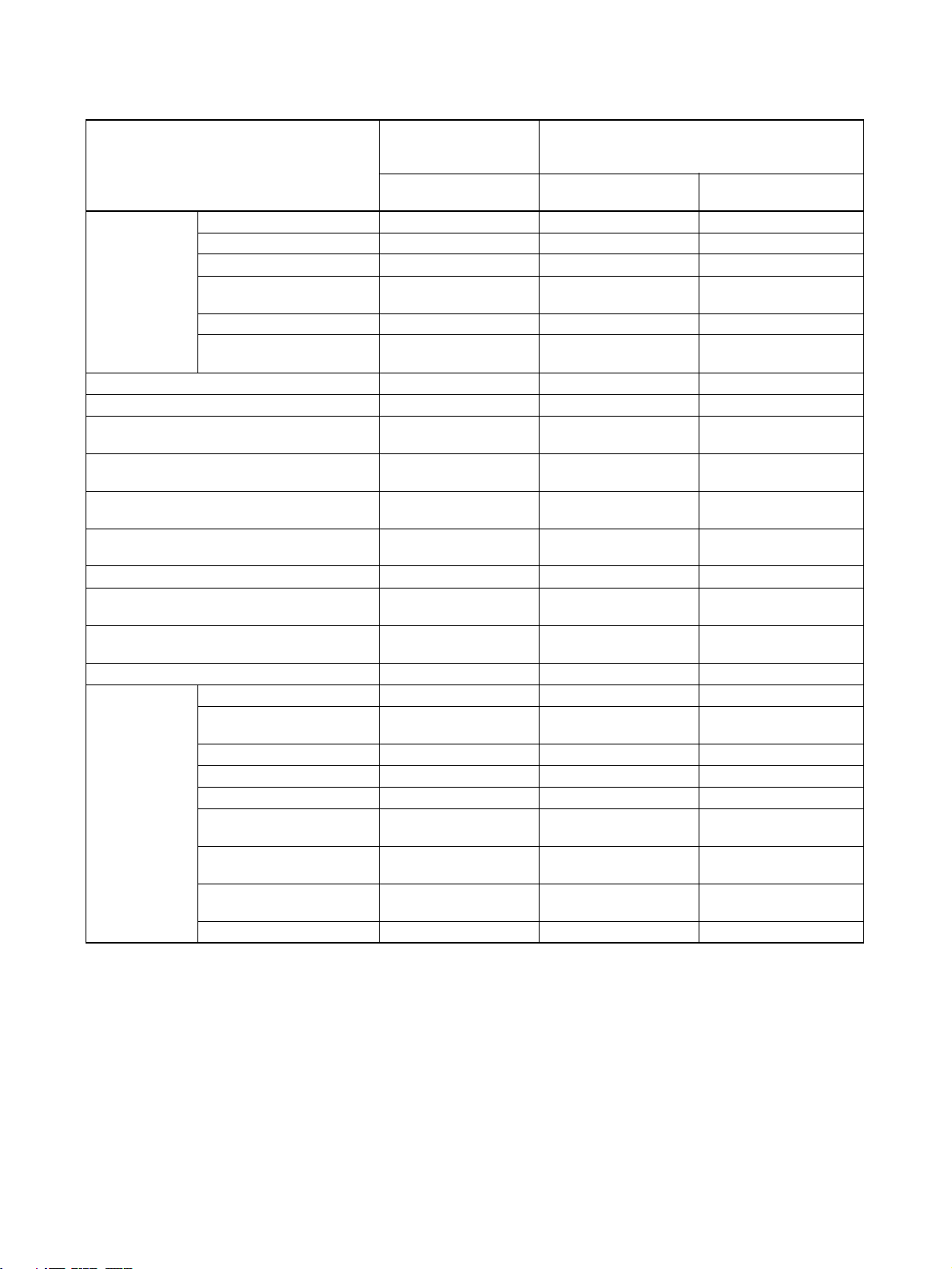

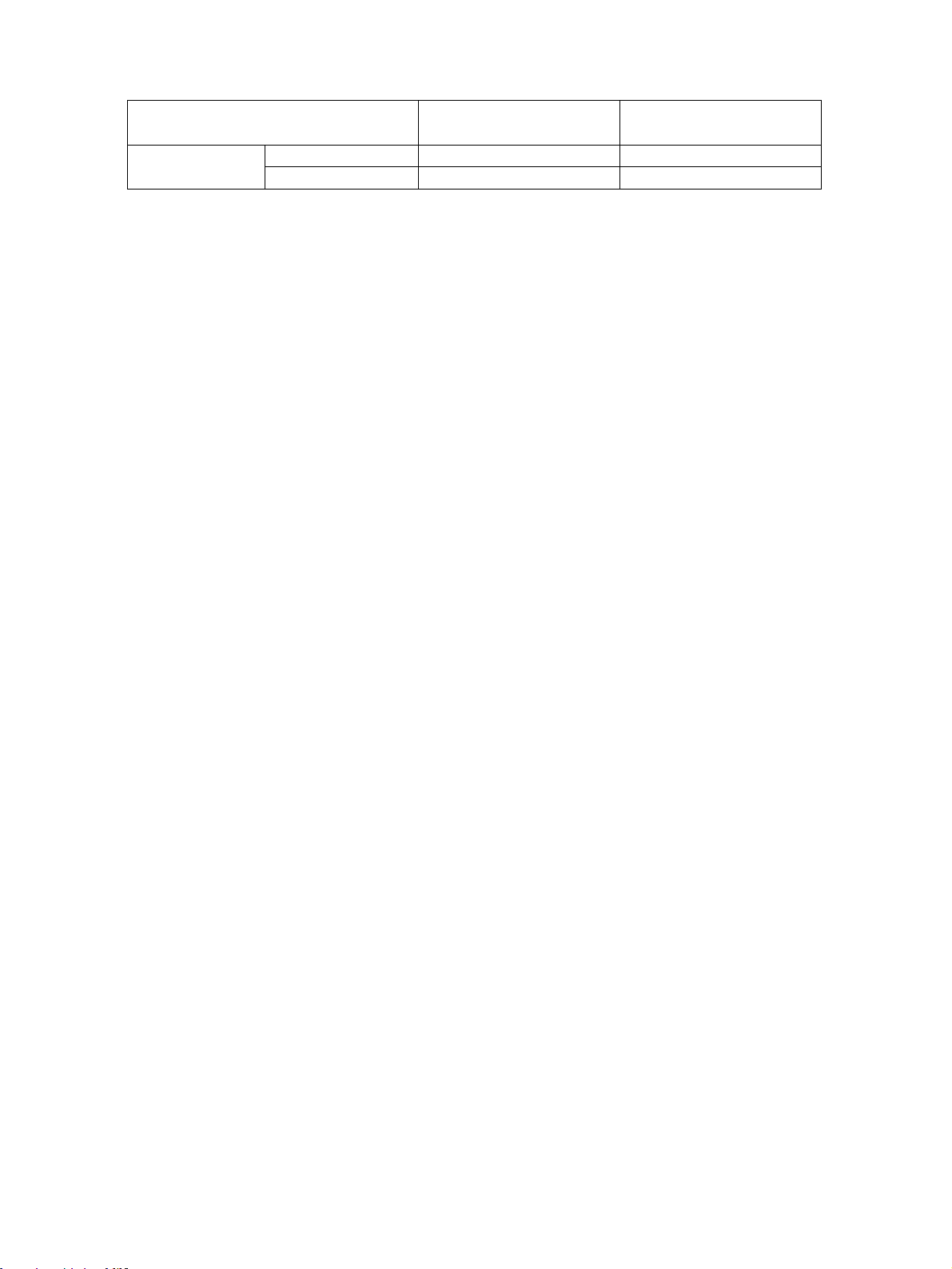

Unit Versions

CS Series

Units Models Unit version

CS1-H CPU Units CS1@-CPU@@H Unit version 4.1

Unit version 4.0

Unit version 3.0

Unit version 2.0

Pre-Ver. 2.0

CS1D CPU Units Duplex-CPU Systems

CS1D-CPU@@H

Single-CPU Systems

CS1D-CPU@@S

CS1 CPU Units CS1@-CPU@@ No unit version.

CS1 Version-1 CPU Units

CS1@-CPU@@-V1 No unit version.

CJ Series

Units Models Unit version

CJ1-H CPU Units CJ1H-CPU@@H-R Unit version 4.2

CJ1@-CPU@@H

CJ1@-CPU@@P

CJ1M CPU Units

CJ1M-CPU12/13

CJ1M-CPU22/23

CJ1M-CPU11/21 Unit version 4.0

Unit version 1.2

Unit version 1.1

Pre-Ver. 1.1

Unit version 2.0

Unit version 4.1

Unit version 4.0

Unit version 4.0

Unit version 3.0

Unit version 2.0

Pre-Ver. 2.0

Unit version 4.0

Unit version 3.0

Unit version 2.0

Pre-Ver. 2.0

Unit version 3.0

Unit version 2.0

NSJ Series

Units Unit version

NSJ@-TQ@@(B)-G5D

NSJ@-TQ@@(B)-M3D

x

Unit version 3.0

Page 11

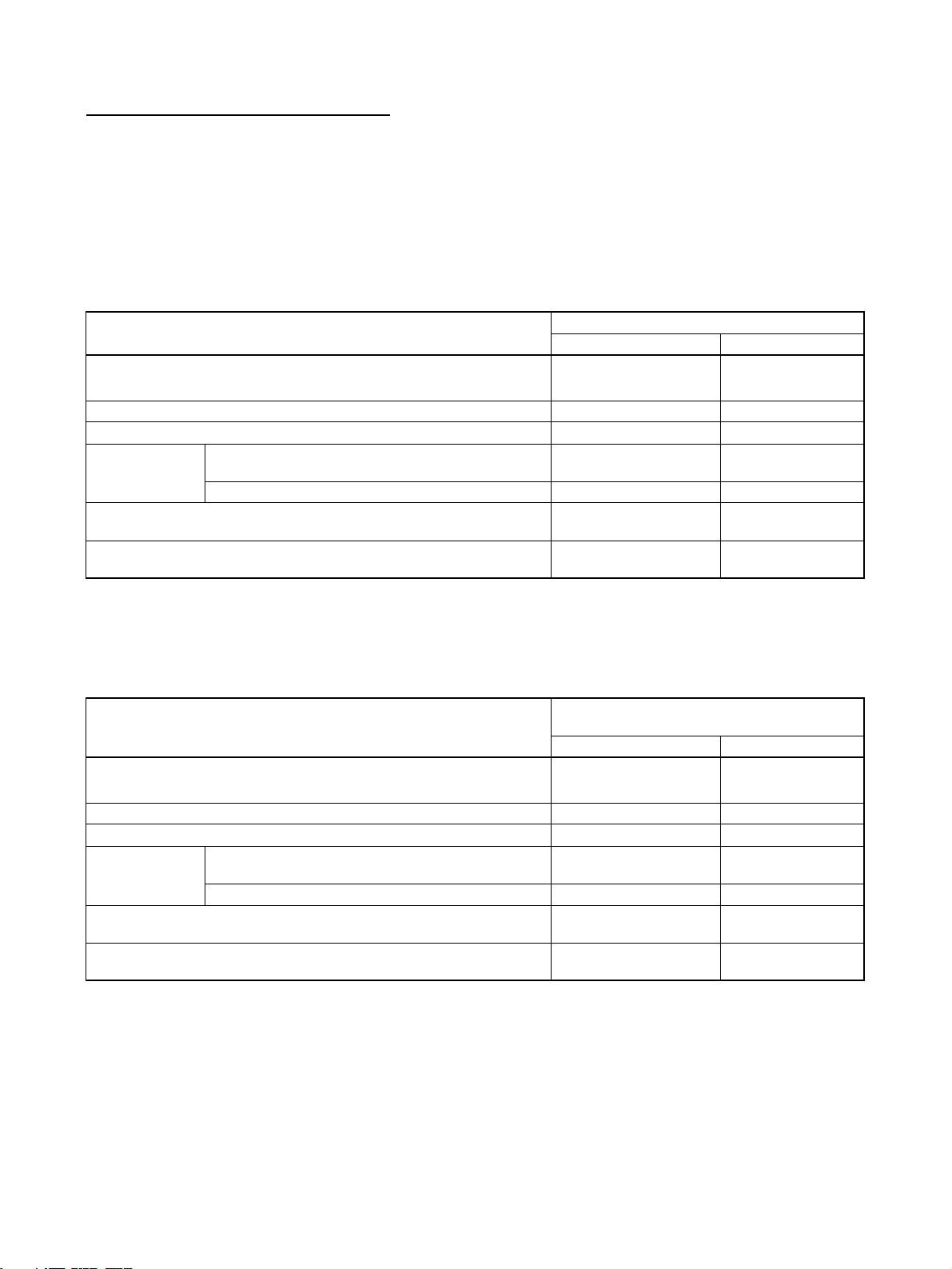

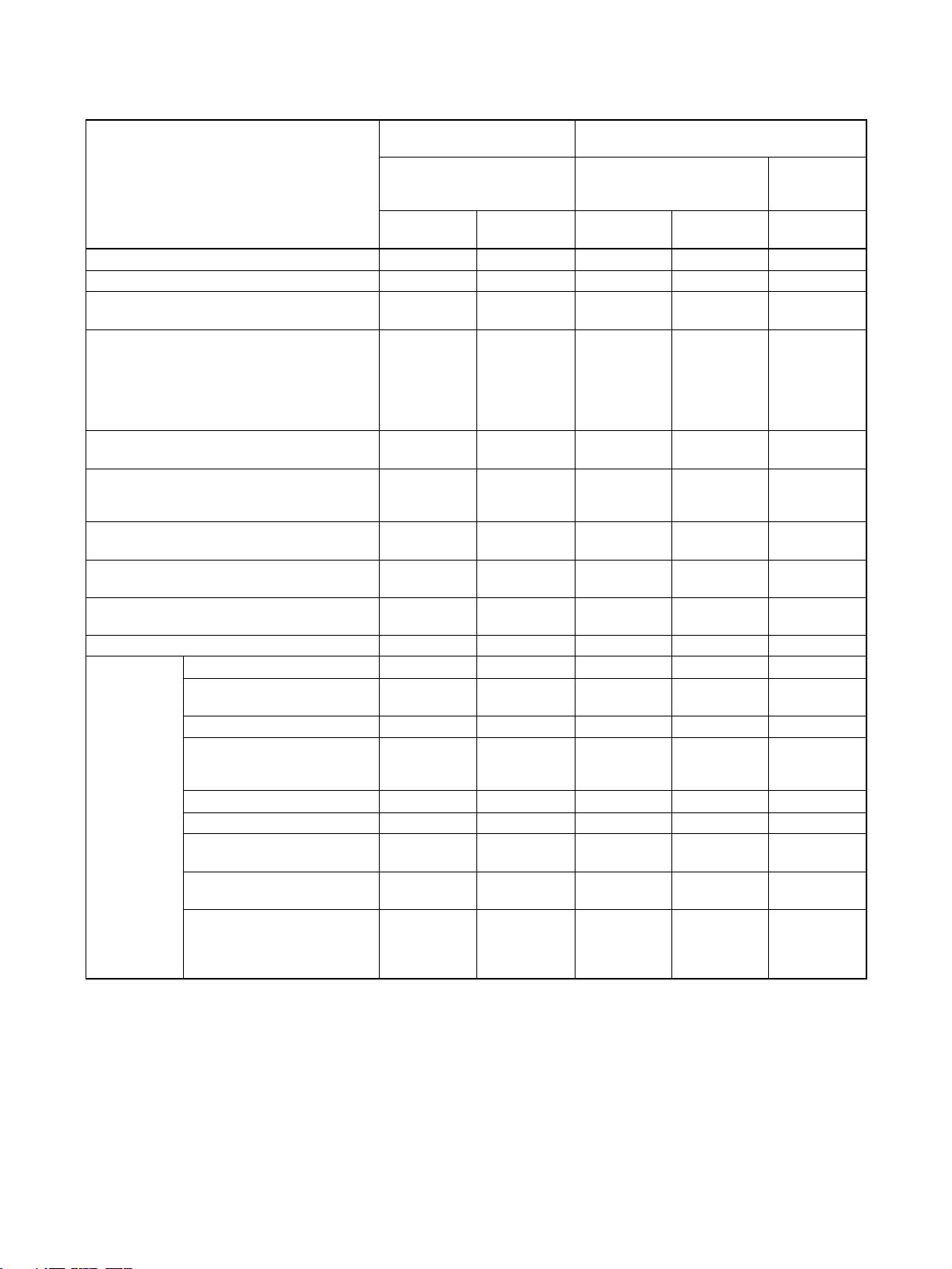

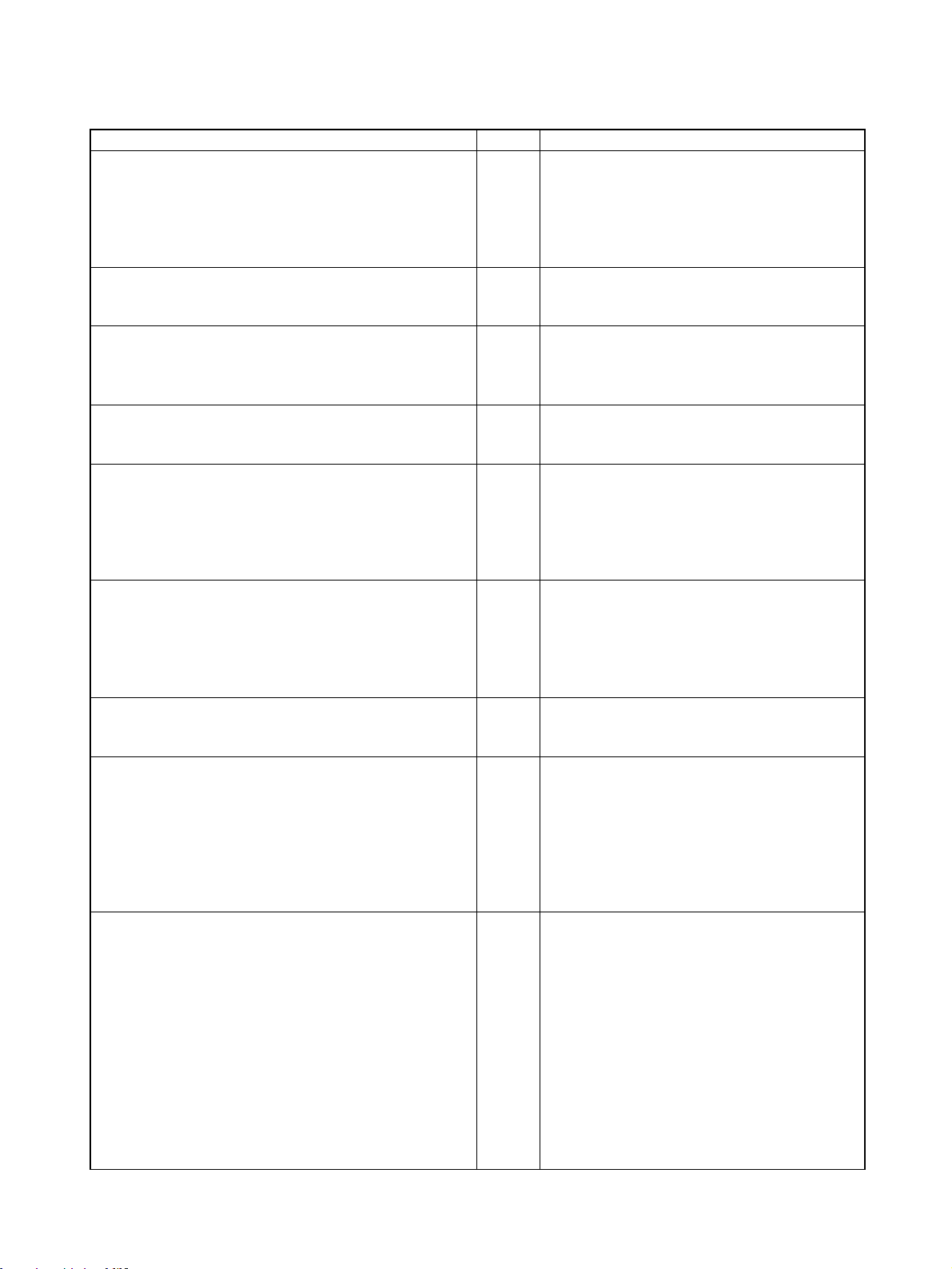

Function Support by Unit Version

• Functions Supported for Unit Version 4.0 or Later

CX-Programmer 7.0 or higher must be used to enable using the functions

added for unit version 4.0.

Additional functions are supported if CX-Programmer version 7.2 or higher is

used.

CS1-H CPU Units

Function CS1@-CPU@@H

Unit version 4.0 or later Other unit versions

Online editing of function blocks

Note This function cannot be used for simulations on the CX-Simulator.

Input-output variables in function blocks OK --Text strings in function blocks OK --New application

instructions

ST programming in task programs OK with CX-Program-

SFC programming in task programs OK with CX-Program-

Number-Text String Conversion Instructions:

NUM4, NUM8, NUM16, STR4, STR8, and STR16

TEXT FILE WRITE (TWRIT) OK ---

OK ---

OK ---

mer version 7.2 or higher

mer version 7.2 or higher

---

---

CS1D CPU Units

Unit version 4.0 is not supported.

CJ1-H/CJ1M CPU Units

Function CJ1H-CPU@@H-R, CJ1@-CPU@@H,

CJ1G-CPU@@P, C J1 M - C P U @@

Unit version 4.0 or later Other unit versions

Online editing of function blocks

Note This function cannot be used for simulations on the CX-Simulator.

Input-output variables in function blocks OK --Text strings in function blocks OK --New application

instructions

ST programming in task programs OK with CX-Program-

SFC programming in task programs OK with CX-Program-

Number-Text String Conversion Instructions:

NUM4, NUM8, NUM16, STR4, STR8, and STR16

TEXT FILE WRITE (TWRIT) OK ---

OK ---

OK ---

mer version 7.2 or higher

mer version 7.2 or higher

User programs that contain functions supported only by CPU Units with unit

version 4.0 or later cannot be used on CS/CJ-series CPU Units with unit version 3.0 or earlier. An error message will be displayed if an attempt is made to

download programs containing unit version 4.0 functions to a CPU Unit with a

unit version of 3.0 or earlier, and the download will not be possible.

If an object program file (.OBJ) using these functions is transferred to a CPU

Unit with a unit version of 3.0 or earlier, a program error will occur when operation is started or when the unit version 4.0 function is executed, and CPU

Unit operation will stop.

---

---

xi

Page 12

• Functions Supported for Unit Version 3.0 or Later

CX-Programmer 5.0 or higher must be used to enable using the functions

added for unit version 3.0.

CS1-H CPU Units

Function CS1@-CPU@@H

Unit version 3.0 or

Function blocks OK --Serial Gateway (converting FINS commands to CompoWay/F

commands at the built-in serial port)

Comment memory (in internal flash memory) OK --Expanded simple backup data OK --New application

instructions

Additional

instruction functions

TXDU(256), RXDU(255) (support no-protocol communications with Serial Communications Units with

unit version 1.2 or later)

Model conversion instructions: XFERC(565),

DISTC(566), COLLC(567), MOVBC(568),

BCNTC(621)

Special function block instructions: GETID(286) OK --TXD(235) and RXD(236) instructions (support no-

protocol communications with Serial Communications Boards with unit version 1.2 or later)

OK ---

OK ---

OK ---

OK ---

later

Other unit versions

CS1D CPU Units

Unit version 3.0 is not supported.

CJ1-H/CJ1M CPU Units

Function CJ1H-CPU@@H-R, CJ1@-CPU@@H,

Function blocks OK --Serial Gateway (converting FINS commands to CompoWay/F

commands at the built-in serial port)

Comment memory (in internal flash memory) OK --Expanded simple backup data OK --New application

instructions

Additional

instruction functions

TXDU(256), RXDU(255) (support no-protocol communications with Serial Communications Units with

unit version 1.2 or later)

Model conversion instructions: XFERC(565),

DISTC(566), COLLC(567), MOVBC(568),

BCNTC(621)

Special function block instructions: GETID(286) OK --PRV(881) and PRV2(883) instructions: Added high-

frequency calculation methods for calculating pulse

frequency. (CJ1M CPU Units only)

OK ---

OK ---

OK ---

OK ---

CJ1G-CPU@@P, CJ1M-CPU@@

Unit version 3.0 or

later

User programs that contain functions supported only by CPU Units with unit

version 3.0 or later cannot be used on CS/CJ-series CPU Units with unit version 2.0 or earlier. An error message will be displayed if an attempt is made to

download programs containing unit version 3.0 functions to a CPU Unit with a

unit version of 2.0 or earlier, and the download will not be possible.

If an object program file (.OBJ) using these functions is transferred to a CPU

Unit with a unit version of 2.0 or earlier, a program error will occur when operation is started or when the unit version 3.0 function is executed, and CPU

Unit operation will stop.

Other unit versions

xii

Page 13

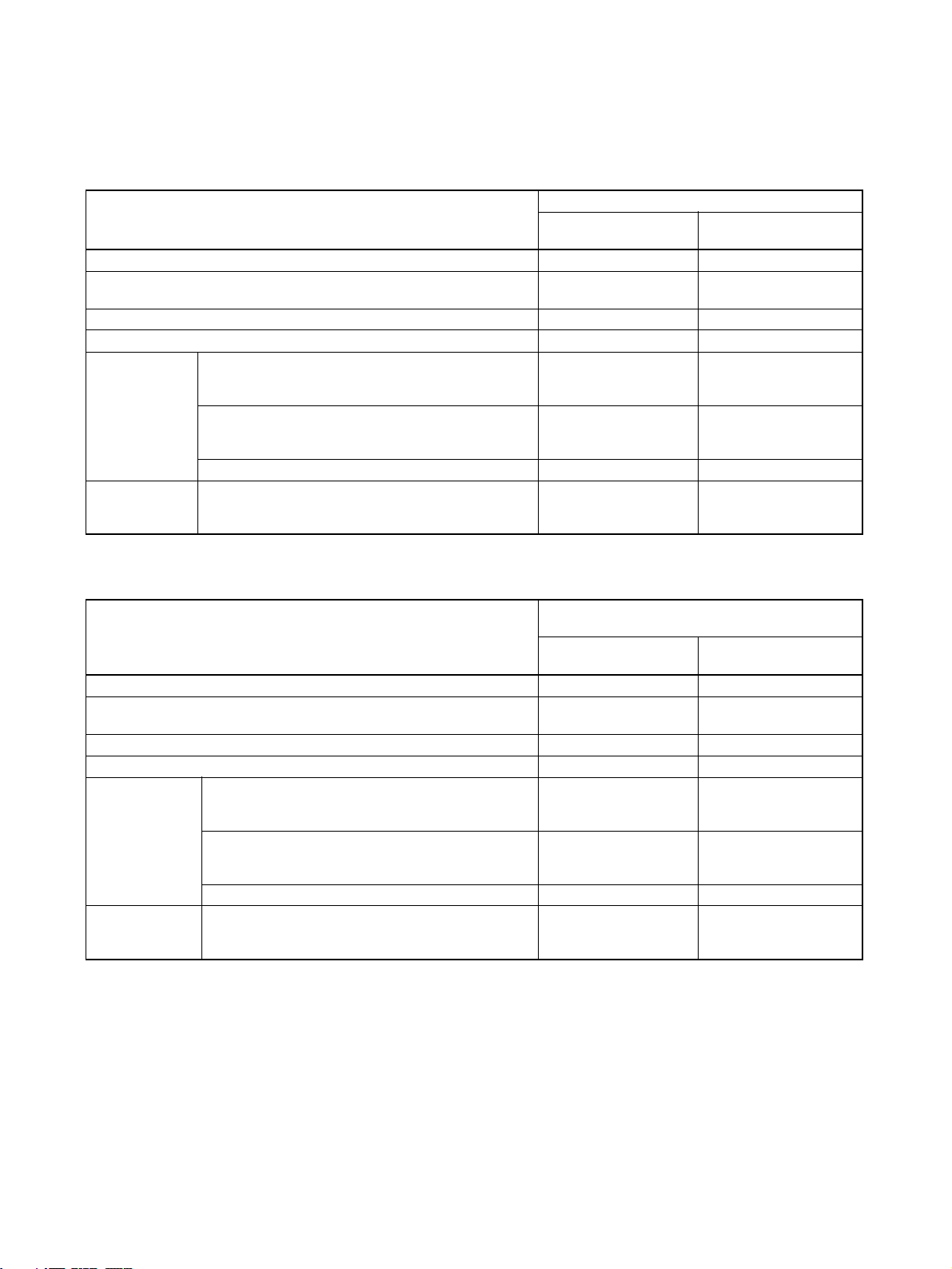

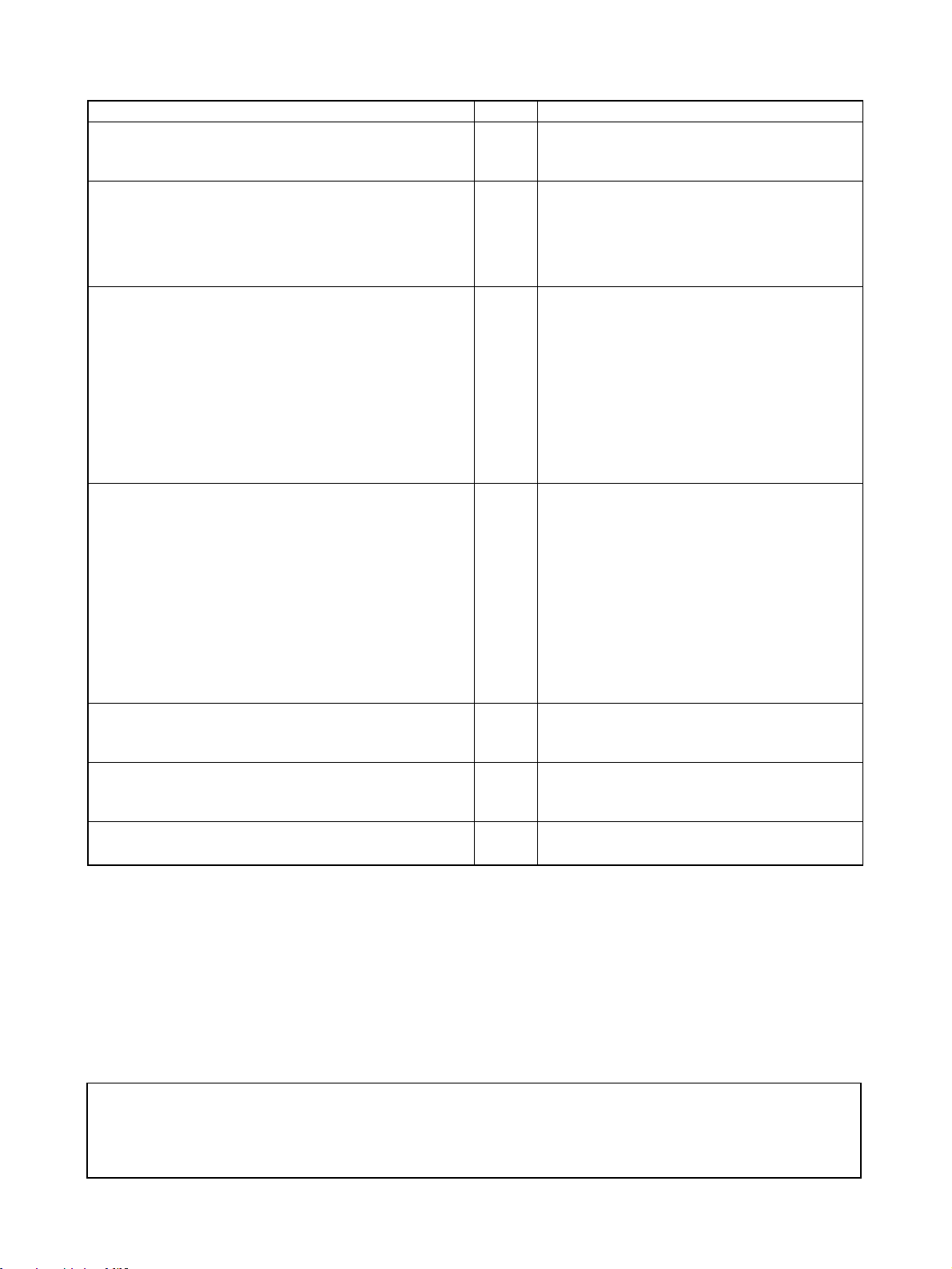

• Functions Supported for Unit Version 2.0 or Later

CX-Programmer 4.0 or higher must be used to enable using the functions

added for unit version 2.0.

CS1-H CPU Units

Function CS1-H CPU Units

Unit version 2.0 or later Other unit versions

Downloading and Uploading Individual Tasks OK --Improved Read Protection Using Passwords OK --Write Protection from FINS Commands Sent to CPU

Units via Networks

Online Network Connections without I/O Tables OK --Communications through a Maximum of 8 Network Lev-

els

Connecting Online to PLCs via NS-series PTs OK OK from lot number 030201

Setting First Slot Words OK for up to 64 groups OK for up to 8 groups

Automatic Transfers at Power ON without a Parameter

File

Automatic Detection of I/O Allocation Method for Auto-

matic Transfer at Power ON

Operation Start/End Times OK --New Application

Instructions

MILH, MILR, MILC OK --=DT, <>DT, <DT, <=DT, >DT, >=DT OK --BCMP2 OK --GRY OK OK from lot number 030201

TPO OK --DSW, TKY, HKY, MTR, 7SEG OK --EXPLT, EGATR, ESATR, ECHRD,

ECHWR

Reading/Writing CPU Bus Units

with IORD/IOWR

PRV2 --- ---

OK ---

OK ---

OK ---

--- ---

OK ---

OK OK from lot number 030418

(CS1@-CPU@@H)

xiii

Page 14

CS1D CPU Units

Function CS1D CPU Units for

Functions

unique to CS1D

CPU Units

Downloading and Uploading Individual Tasks OK --- --Improved Read Protection Using Passwords OK --- --Write Protection from FINS Commands Sent

to CPU Units via Networks

Online Network Connections without I/O

Ta bl e s

Communications through a Maximum of 8

Network Levels

Connecting Online to PLCs via NS-series

PTs

Setting First Slot Words OK for up to 64 groups --- --Automatic Transfers at Power ON without a

Parameter File

Automatic Detection of I/O Allocation Method

for Automatic Transfer at Power ON

Operation Start/End Times OK OK --New Applica-

tion Instructions

Duplex CPU Units --- OK OK

Online Unit Replacement OK OK OK

Duplex Power Supply Units OK OK OK

Duplex Controller Link

Units

Duplex Ethernet Units --- OK OK

Unit removal without a

Programming Device

MILH, MILR, MILC OK --- --=DT, <>DT, <DT, <=DT,

>DT, >=DT

BCMP2 OK --- --GRY OK --- --TPO OK --- --DSW, TKY, HKY, MTR,

7SEG

EXPLT, EGATR, ESATR,

ECHRD, ECHWR

Reading/Writing CPU Bus

Units with IORD/IOWR

PRV2 OK --- ---

Single-CPU Systems

(CS1D-CPU@@S)

Unit version 2.0 Unit version 1.1 or

OK OK OK

--- OK (Unit version 1.2 or

OK --- ---

OK --- ---

OK --- ---

OK --- ---

OK --- ---

--- --- ---

OK --- ---

OK --- ---

OK --- ---

OK --- ---

CS1D CPU Units for Duplex-CPU

Systems (CS1D-CPU@@H)

later

later)

Pre-Ver. 1.1

---

xiv

Page 15

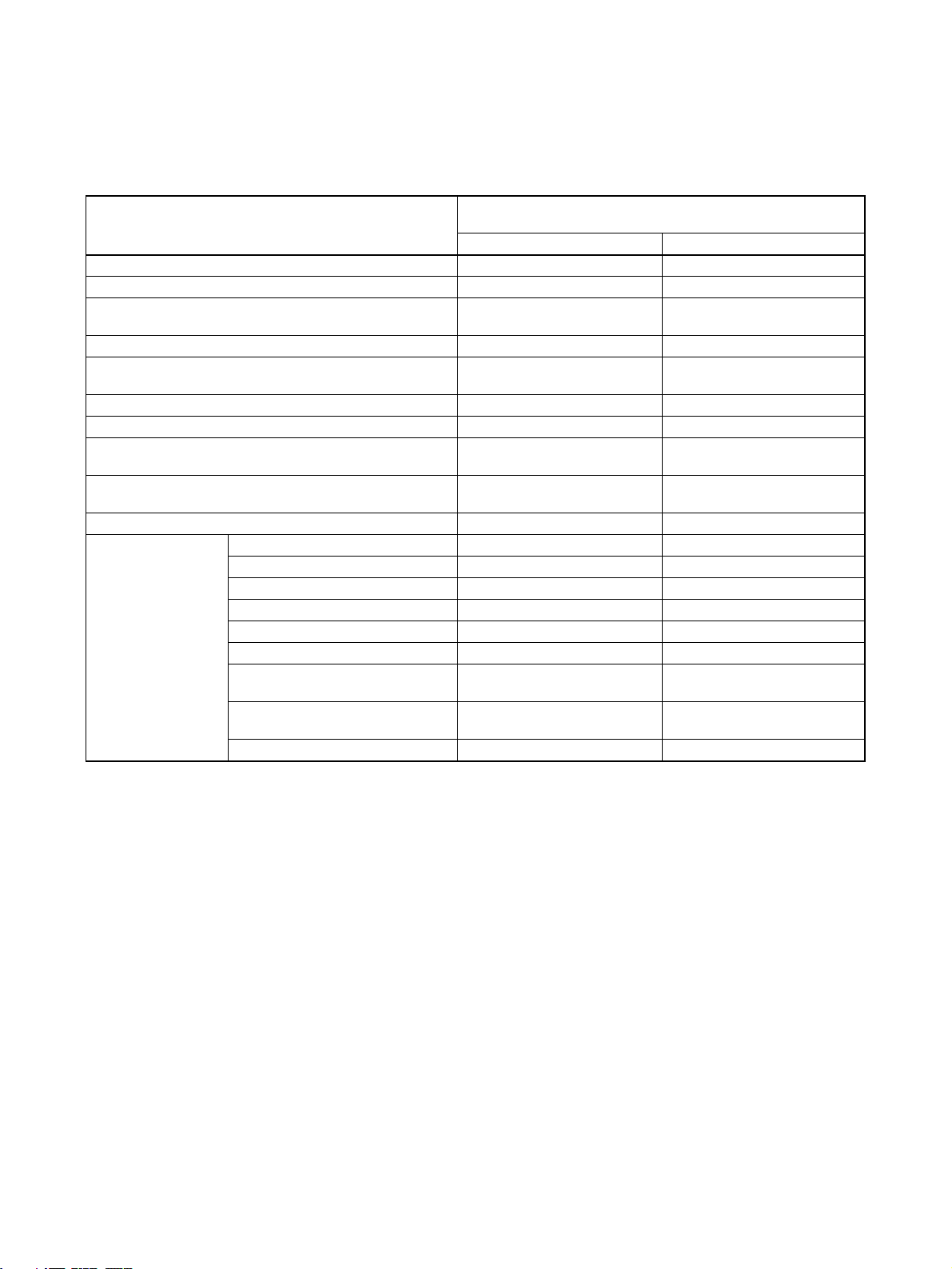

CJ1-H/CJ1M CPU Units

Function CJ1-H CPU Units

Downloading and Uploading Individual Tasks OK --- OK --- OK

Improved Read Protection Using Passwords OK --- OK --- OK

Write Protection from FINS Commands Sent

to CPU Units via Networks

Online Network Connections without I/O

Ta bl e s

Communications through a Maximum of 8

Network Levels

Connecting Online to PLCs via NS-series

PTs

Setting First Slot Words OK for up to

Automatic Transfers at Power ON without a

Parameter File

Automatic Detection of I/O Allocation Method

for Automatic Transfer at Power ON

Operation Start/End Times OK --- OK --- OK

New Applica-

tion Instructions

MILH, MILR, MILC OK --- OK --- OK

=DT, <>DT, <DT, <=DT, >DT,

>=DT

BCMP2 OK --- OK OK OK

GRY OK OK from lot

TPO OK --- OK --- OK

DSW, TKY, HKY, MTR, 7SEG OK --- OK --- OK

EXPLT, EGATR, ESATR,

ECHRD, ECHWR

Reading/Writing CPU Bus

Units with IORD/IOWR

PRV2 --- --- OK, but only

(CJ1@-CPU@@H)

(CJ1H-CPU@@H-R)

(CJ1@-CPU@@H)

(CJ1G-CPU@@P)

Unit version

2.0 or later

OK --- OK --- OK

OK ---

OK --- OK --- OK

OK OK from lot

64 groups

OK --- OK --- OK

--- --- --- --- ---

OK --- OK --- OK

OK --- OK --- OK

OK --- OK --- OK

Other unit

versions

(Supported if

I/O tables are

automatically

generated at

startup.)

number

030201

OK for up to

8 groups

number

030201

CJ1M-CPU12/13/22/23 CJ1M-

Unit version

2.0 or later

OK ---

OK OK from lot

OK for up to

64 groups

OK OK from lot

for CPU Units

with built-in

I/O

CJ1M CPU Units

Other unit

versions

(Supported if

I/O tables are

automatically

generated at

startup.)

number

030201

OK for up to

8 groups

number

030201

--- OK, but only

CPU11/21

Other unit

versions

OK

OK

OK for up to

64 groups

OK

for CPU Units

with built-in

I/O

User programs that contain functions supported only by CPU Units with unit

version 2.0 or later cannot be used on CS/CJ-series Pre-Ver. 2.0 CPU Units.

An error message will be displayed if an attempt is made to download programs containing unit version s.0 functions to a Pre-Ver. 2.0 CPU Unit, and

the download will not be possible.

If an object program file (.OBJ) using these functions is transferred to a PreVer. 2.0 CPU Unit, a program error will occur when operation is started or

when the unit version 2.0 function is executed, and CPU Unit operation will

stop.

xv

Page 16

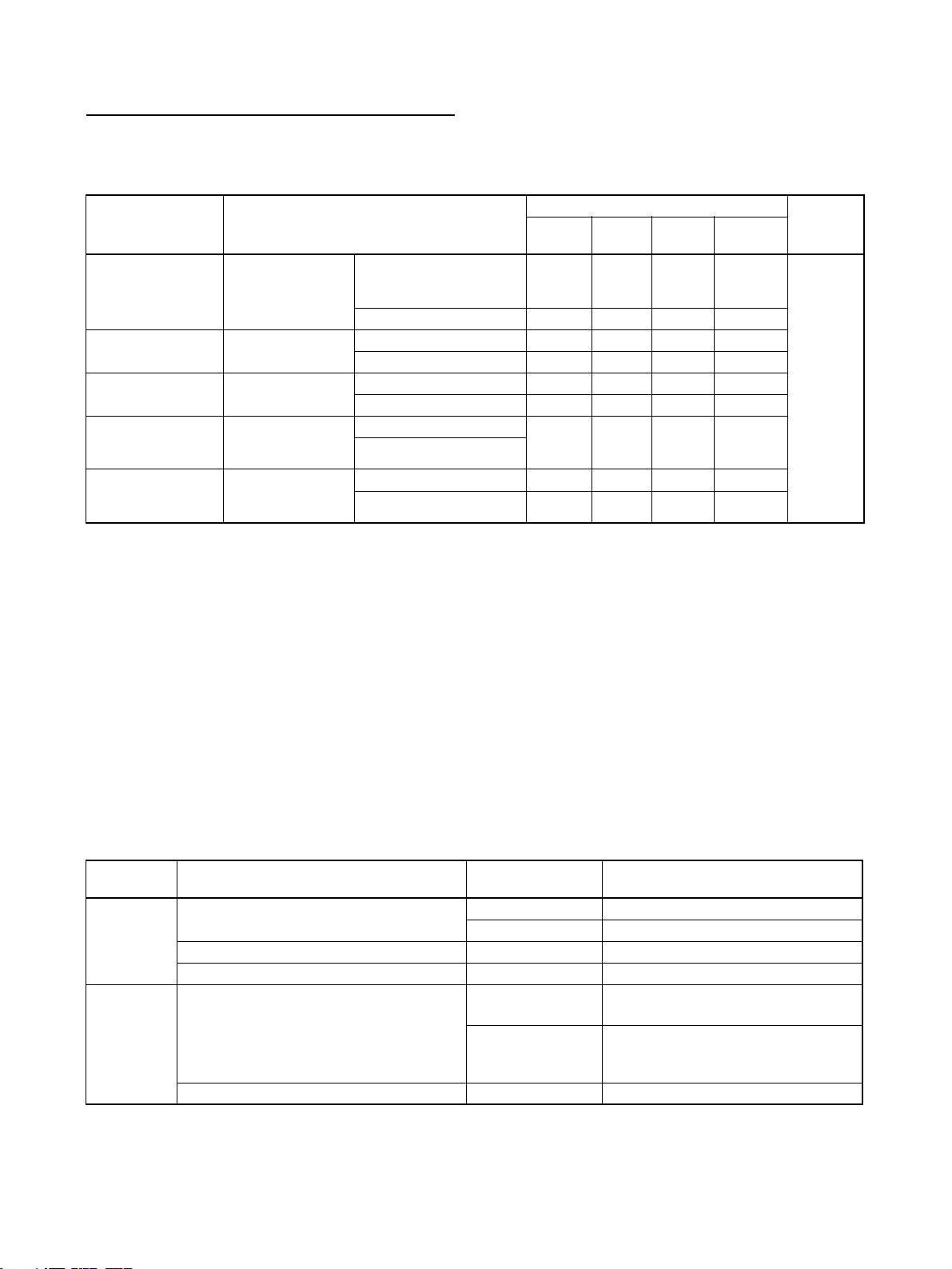

Unit Versions and Programming Devices

The following tables show the relationship between unit versions and CX-Programmer versions.

Unit Versions and Programming Devices

CPU Unit Functions (See note 1.) CX-Programmer Program-

CS/CJ-series unit

Ver. 4.0

CS/CJ-series unit

Ver. 3.0

CS/CJ-series unit

Ver. 2.0

CS1D CPU Units

for Single-CPU Systems, unit Ver. 2.0

CS1D CPU Units

for Duplex-CPU

Systems, unit Ver.1.

Ver. 3.3

or lower

Functions added

for unit version 4.0

Functions added

for unit version 3.0

Functions added

for unit version 2.0

Functions added

for unit version 2.0

Functions added

for unit version 1.1

Using new functions --- --- --- OK (See

Not using new functions OK OK OK OK

Using new functions --- --- OK OK

Not using new functions OK OK OK OK

Using new functions --- OK OK OK

Not using new functions OK OK OK OK

Using new functions --- OK OK OK

Not using new functions

Using function blocks --- OK OK OK

Not using function blocks OK OK OK OK

Note 1. As shown above, there is no need to upgrade to CX-Programmer version

as long as the functions added for unit versions are not used.

Ver. 4.0 Ver. 5.0

Ver. 6. 0

Ver. 7. 0

or higher

notes 2

and 3.)

ming

Console

No

restrictions

2. CX-Programmer version 7.1 or higher is required to use the new functions

added for unit version 4.0 of the CJ1-H-R CPU Units. CX-Programmer version 7.22 or higher is required to use unit version 4.1 of the CJ1-H-R CPU

Units. CX-Programmer version 7.0 or higher is required to use unit version

4.2 of the CJ1-H-R CPU Units. You can check the CX-Programmer version

using the About menu command to display version information.

3. CX-Programmer version 7.0 or higher is required to use the functional improvements made for unit version 4.0 of the CS/CJ-series CPU Units. With

CX-Programmer version 7.2 or higher, you can use even more expanded

functionality.

Device Type Setting The unit version does not affect the setting made for the device type on the

CX-Programmer. Select the device type as shown in the following table

regardless of the unit version of the CPU Unit.

Series CPU Unit group CPU Unit model Device type setting on

CS Series CS1-H CPU Units CS1G-CPU@@H CS1G-H

CS1H-CPU@@H CS1H-H

CS1D CPU Units for Duplex-CPU Systems CS1D-CPU@@H CS1D-H (or CS1H-H)

CS1D CPU Units for Single-CPU Systems CS1D-CPU@@S CS1D-S

CJ Series CJ1-H CPU Units CJ1G-CPU@@H

CJ1G-CPU@@P

CJ1H-CPU@@H-R

(See note.)

CJ1H-CPU@@H

CJ1M CPU Units CJ1M-CPU@@ CJ1M

CX-Programmer Ver. 4.0 or higher

CJ1G-H

CJ1H-H

xvi

Note When using a CJ1H-CPU@@H-R CPU Unit, set the CPU Unit model to

CPU67-R, CPU66-R, CPU65-R, or CPU64-R.

Page 17

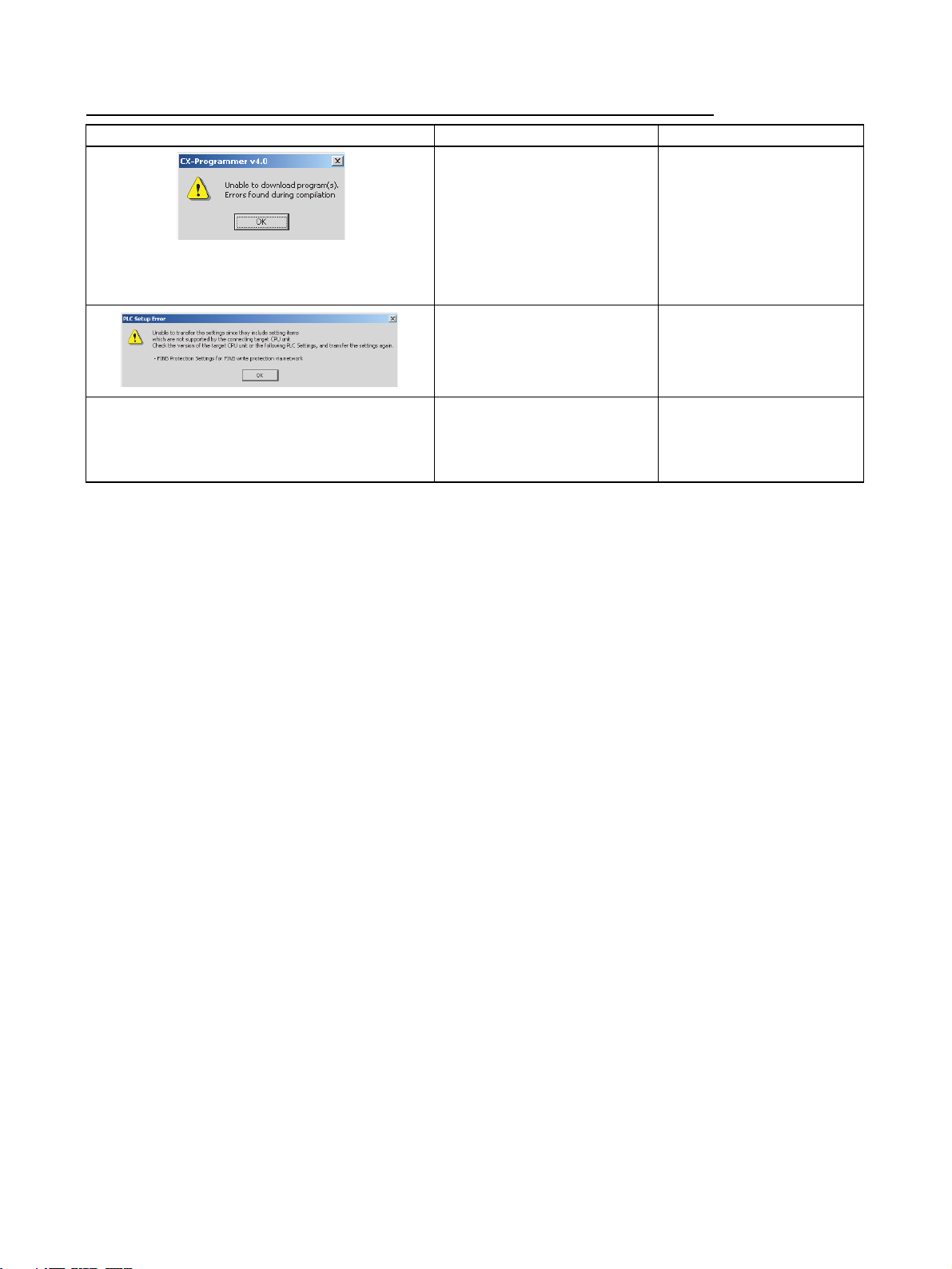

Troubleshooting Problems with Unit Versions on the CX-Programmer

Problem Cause Solution

An attempt was made to download a program containing

instructions supported only by

later unit versions or a CPU Unit

to a previous unit version.

After the above message is displayed, a compiling

error will be displayed on the Compile Tab Page in the

Output Window.

An attempt was to download a

PLC Setup containing settings

supported only by later unit versions or a CPU Unit to a previous

unit version.

Check the program or change

to a CPU Unit with a later unit

version.

Check the settings in the PLC

Setup or change to a CPU Unit

with a later unit version.

“????” is displayed in a program transferred from the

PLC to the CX-Programmer.

An attempt was made to upload a

program containing instructions

supported only by higher versions

of CX-Programmer to a lower

version.

New instructions cannot be

uploaded to lower versions of

CX-Programmer. Use a higher

version of CX-Programmer.

xvii

Page 18

xviii

Page 19

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxviii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxii

SECTION 1

CPU Unit Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Initial Setup (CS1 CPU Units Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Using the Internal Clock (CS1 CPU Units Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Internal Structure of the CPU Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-4 Operating Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-5 Programs and Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-6 Description of Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SECTION 2

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-1 Basic Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-2 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2-3 Checking Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

SECTION 3

Instruction Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3-1 Sequence Input Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

3-2 Sequence Output Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3-3 Sequence Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3-4 Timer and Counter Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3-5 Comparison Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

3-6 Data Movement Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

3-7 Data Shift Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

3-8 Increment/Decrement Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3-9 Symbol Math Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

3-10 Conversion Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3-11 Logic Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

3-12 Special Math Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

3-13 Floating-point Math Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

3-14 Double-precision Floating-point Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

3-15 Table Data Processing Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

3-16 Data Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

3-17 Subroutine Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

3-18 Interrupt Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

3-19 High-speed Counter and Pulse Output Instructions (CJ1M-CPU21/22/23 Only) . . . . . . . . 134

3-20 Step Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

3-21 Basic I/O Unit Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

3-22 Serial Communications Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

3-23 Network Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

3-24 File Memory Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

3-25 Display Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

3-26 Clock Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

xix

Page 20

TABLE OF CONTENTS

3-27 Debugging Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

3-28 Failure Diagnosis Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

3-29 Other Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

3-30 Block Programming Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

3-31 Text String Processing Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

3-32 Task Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

3-33 Model Conversion Instructions (CPU Unit Ver. 3.0 or Later Only) . . . . . . . . . . . . . . . . . . . 159

3-34 Special Function Block Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

SECTION 4

Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

4-1 Task Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

4-2 Using Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

4-3 Interrupt Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

4-4 Programming Device Operations for Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

SECTION 5

File Memory Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

5-1 File Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

5-2 Manipulating Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

5-3 Using File Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

SECTION 6

Advanced Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

6-1 Cycle Time/High-speed Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

6-2 Index Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

6-3 Serial Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .291

6-4 Changing the Timer/Counter PV Refresh Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

6-5 Using a Scheduled Interrupt as a High-precision Timer (CJ1-H-R and CJ1M Only) . . . . . 319

6-6 Startup Settings and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

6-7 Diagnostic Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

6-8 CPU Processing Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .341

6-9 Peripheral Servicing Priority Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

6-10 Battery-free Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

6-11 Other Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

SECTION 7

Program Transfer, Trial Operation, and Debugging . . . . . 357

7-1 Program Transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

7-2 Trial Operation and Debugging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

Appendices

A PLC Comparison Charts: CJ-series, CS-series, C200HG/HE/HX,CQM1H, CVM1,

and CV-series PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .367

B Changes from Previous Host Link Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

xx

Page 21

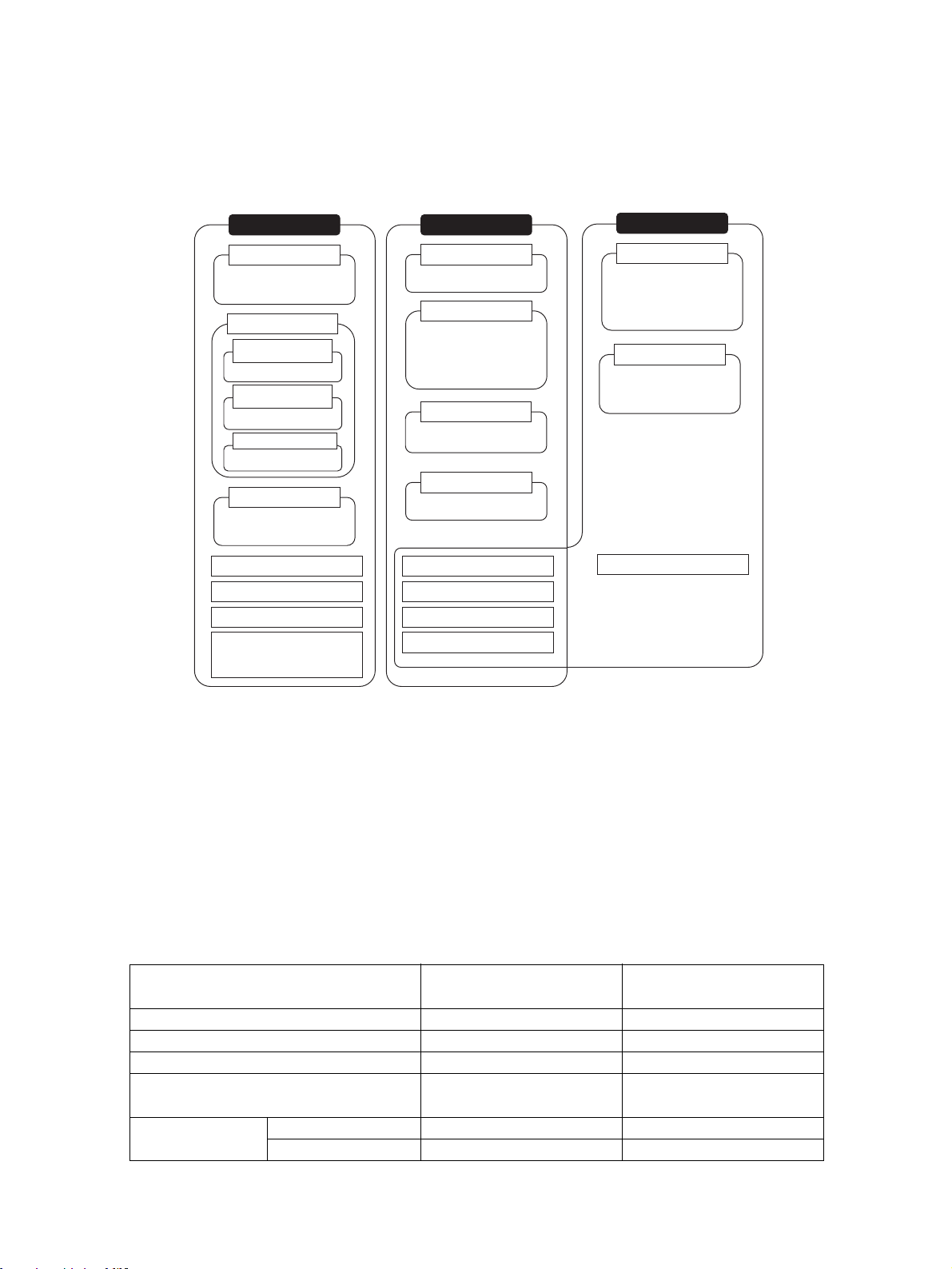

About this Manual:

This manual describes the programming of the CPU Units for CS/CJ-series Programmable Controllers

(PLCs) and includes the sections described on the following page. The CS Series, CJ Series and NSJ

Series are subdivided as shown in the following figure.

CS Series

CS1-H CPU Units

CS1H-CPU@@H

CS1G-CPU@@H

CS1D CPU Units

CS1D CPU Units for

Duplex Systems

CS1D-CPU@@H

CS1D CPU Units for

Simplex Systems

CS1D-CPU@@S

CS1D Process-control CPU Units

CS1D-CPU@@P

CS1 CPU Units

CS1H-CPU@@(-V1)

CS1G-CPU@@(-V1)

CS-series Basic I/O Units

CS-series Special I/O Units

CS-series CPU Bus Units

CS-series Power Supply Units

Note: A special Power Supply Unit must

be used for CS1D CPU Units.

CJ Series

CJ2 CPU Units

CJ2H-CPU@@-@@@

CJ1-H CPU Units

CJ1H-CPU@@H-R

CJ1H-CPU@@H

CJ1G-CPU@@H

CJ1G -CPU@@P

(Loop-control CPU Units)

CJ1M CPU Units

CJ1M-CPU@@

CJ1 CPU Units

CJ1G-CPU@@

CJ-series Basic I/O Units

CJ-series Special I/O Units

CJ-series CPU Bus Units

CJ-series Power Supply Units

NSJ Series

NSJ Controllers

NSJ5-TQ@@(B)-G5D

NSJ5-SQ@@(B)-G5D

NSJ8-TV@@(B)-G5D

NSJ10-TV@@(B)-G5D

NSJ12-TS@@(B)-G5D

NSJ Controllers

NSJ5-TQ@@(B)-M3D

NSJ5-SQ@@(B)-M3D

NSJ8-TV@@(B)-M3D

NSJ-series Expansion Units

Please read this manual and all related manuals listed in the table on the next page and be sure you

understand information provided before attempting to install or use CS/CJ-series CPU Units in a PLC

System.

NSJ-series Controller Notation

For information in this manual on the Controller Section of NSJ-series Controllers, refer to the

information of the equivalent CJ-series PLC. The following models are equivalent.

NSJ-series Controllers Equivalent CJ-series CPU Unit

NSJ@-TQ@@(B)-G5D CJ1G-CPU45H with unit version 3.0

NSJ@-TQ@@(B)-M3D CJ1G-CPU45H with unit version 3.0 (See note.)

Note: The following points differ between the NSJ@-TQ@@(B)-M3D and the CJ1G-CPU45H.

Item CJ-series CPU Unit

CJ1G-CPU45H

I/O capacity 1280 points 640 points

Program capacity 60 Ksteps 20 Ksteps

No. of Expansion Racks 3 Racks max. 1 Rack max.

EM Area 32 Kwords × 3 banks

E0_00000 - E2_32767

Function blocks Max. No. of definitions 1024 128

Max. No. of instances 2048 256

Controller Section in

NSJ@-@@@@(B)-M3D

None

xxi

Page 22

Capacity in built-in

file memory

Item CJ-series CPU Unit

CJ1G-CPU45H

FB program memory 1024 KB 256 KB

Variable tables 128 KB 64 KB

Controller Section in

NSJ@-@@@@(B)-M3D

This manual contains the following sections.

Precautions provides general precautions for using the CS/CJ-series Programmable Controllers

(PLCs) and related devices.

Section 1 describes the basic structure and operation of the CPU Unit.

Section 2 describes basic information required to write, check, and input programs.

Section 3 outlines the instructions that can be used to write user programs.

Section 4 the operation of tasks.

Section 5 describes the functions used to manipulate file memory.

Section 6 provides details on the following advanced functions: cycle time/high-speed processing

functions, index register functions, serial communications functions, startup and maintenance functions, diagnostic and debugging functions, Programming Device functions, and the Basic I/O Unit input

response time settings.

Section 7 describes the processes used to transfer the program to the CPU Unit and the functions that

can be used to test and debug the program.

The Appendices provide a comparison of CS/CJ-series, restrictions in using C200H Special I/O Units,

and changes made to Host Link Systems.

xxii

Page 23

About this Manual, Continued

Name Cat. No. Contents

SYSMAC CS/CJ/NSJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H, CS1DCPU@@H, CS1D-CPU@@S, CJ1H-CPU@@H-R, CJ1GCPU@@, CJ1G/H-CPU@@H, CJ1G-CPU@@P, C J 1 M CPU@@, NSJ@-@@@@(B)-G5D, NSJ@-@@@@(B)-M3D

Programmable Controllers Programming Manual

SYSMAC CS Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H

Programmable Controllers Operation Manual

SYSMAC CJ Series

CJ1H-CPU@@H-R, CJ1G/H-CPU@@H, CJ1G-CPU@@P,

CJ1G-CPU@@, CJ1M-CPU@@

Programmable Controllers Operation Manual

SYSMAC CJ Series

CJ1M-CPU21/22/23

Built-in I/O Functions Operation Manual

SYSMAC CS Series

CS1D-CPU@@H CPU Units

CS1D-CPU@@S CPU Units

CS1D-DPL1 Duplex Unit

CS1D-PA207R Power Supply Unit

Duplex System Operation Manual

SYSMAC CS/CJ/NSJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H, CS1DCPU@@H, CS1D-CPU@@S, CJ1H-CPU@@H-R, CJ1GCPU@@, CJ1G/H-CPU@@H, CJ1G-CPU@@P, C J 1 M CPU@@, NSJ@-@@@@(B)-G5D, NSJ@-@@@@(B)-M3D

Programmable Controllers Instructions Reference Manual

SYSMAC CS/CJ Series

CQM1H-PRO01-E, C200H-PRO27-E, CQM1-PRO01-E

Programming Consoles Operation Manual

SYSMAC CS/CJ/NSJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H, CS1DCPU@@H, CS1D-CPU@@S, CJ1M-CPU@@, CJ1GCPU@@, CJ1G-CPU@@P, CJ1G/H-CPU@@H, CS1WSCB@@-V1, CS1W-SCU@@-V1, CJ1W-SCU@@-V1,

CP1H-X@@@@-@, CP1H-XA@@@@-@, CP1H-Y@@@@-@,

NSJ@-@@@@(B)-G5D, NSJ@-@@@@(B)-M3D

Communications Commands Reference Manual

NSJ Series

NSJ5-TQ@@(B)-G5D, NSJ5-SQ@@(B)-G5D, NSJ8-

TV@@(B)-G5D, NSJ10-TV@@(B)-G5D, NSJ12-TS@@(B)-

G5D

Operation Manual

W394

(This

manual)

W339 Provides an outlines of and describes the design,

W393 Provides an outlines of and describes the design,

W395 Describes the functions of the built-in I/O for

W405 Provides an outline of and describes the design,

W340 Describes the ladder diagram programming

W341 Provides information on how to program and

W342 Describes the C-series (Host Link) and FINS

W452 Provides the following information about the NSJ-

This manual describes programming and other

methods to use the functions of the CS/CJ/NSJseries PLCs.

installation, maintenance, and other basic operations for the CS-series PLCs.

installation, maintenance, and other basic operations for the CJ-series PLCs.

CJ1M CPU Units.

installation, maintenance, and other basic operations for a Duplex System based on CS1D CPU

Units.

instructions supported by CS/CJ-series PLCs.

operate CS/CJ-series PLCs using a Programming

Console.

communications commands used with CS/CJseries PLCs.

series NSJ Controllers:

Overview and features

Designing the system configuration

Installation and wiring

I/O memory allocations

Troubleshooting and maintenance

Use this manual in combination with the following

manuals: SYSMAC CS Series Operation Manual

(W339), SYSMAC CJ Series Operation Manual

(W393), SYSMAC CS/CJ Series Programming

Manual (W394), and NS-V1/-V2 Series Setup

Manual (V083)

xxiii

Page 24

Name Cat. No. Contents

SYSMAC WS02-CX@@-V@

CX-Programmer Operation Manual

SYSMAC WS02-CX@@-V@

CX-Programmer Operation Manual: Function Blocks

(CS1G-CPU

CJ1H-CPU@@H, CJ1M-CPU@@, CP1H-X@@@@-@,

CP1H-XA@@@@-@, and CP1H-Y@@@@-@ CPU Units)

SYSMAC CS/CJ Series

Programming Consoles Operation Manual

CQM1H-PRO01-E, CQM1-PRO01-E, C200H-PRO27-E

SYSMAC CS/CJ Series

CS1W-SCB

CJ1W-SCU

Serial Communications Boards/Units Operation Manual

SYSMAC WS02-PSTC1-E

CX-Protocol Operation Manual

CXONE-AL@@C-V3/AL@@D-V3

CX-Integrator Operation Manual

CXONE-AL@@C-V3/AL@@D-V3

CX-One Setup Manual

@@H, CS1H-CPU@@H, CJ1G-CPU@@H,

@@-V1, CS1W-SCU@@-V1,

@@-V1

W446 Provides information on how to use the CX-Pro-

grammer for all functionality except for function

blocks.

W447 Describes specifications and operation methods

related to function blocks. This information is

required only when using function blocks.

W341 Provides information on how to program and

operate CS/CJ-series PLCs using a Programming

Console.

When programming, use this manual together

with the Programmable Controllers Operation

Manual (W339 for CS-series PLCs and W393 for

CJ-series PLCs), CS/CJ-series Programmable

Controllers Programming Manual (W394,) and

the CS/CJ-series Programmable Controllers

Instructions Reference Manual (W340).

W336 Describes the use of Serial Communications Unit

and Boards to perform serial communications

with external devices, including the use of standard system protocols for OMRON products.

Refer to the CS/CJ Series Communications Commands Reference Manual (W342) for details on

sending commands in host link mode from a

Serial Communications Board or Unit’s port.

Refer to the WS02-PSTC1-E CX-Protocol Operation Manual (W344) for details on creating protocol macros.

W344 Describes the use of the CX-Protocol to create

protocol macros as communications sequences

to communicate with external devices.

W464 Describes operating procedures for the CX-Inte-

grator Network Configuration Tool for CS-, CJ-,

CP-, and NSJ-series Controllers.

W463 Installation and overview of CX-One FA Inte-

grated Tool Package.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xxiv

Page 25

PRECAUTIONS

This section provides general precautions for using the CS/CJ-series Programmable Controllers (PLCs) and related devices.

The information contained in this section is important for the safe and reliable application of Programmable

Controllers. You must read this section and understand the information contained before attempting to set up or

operate a PLC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxii

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxii

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxii

6-3 Conformance to EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxiii

6-4 Relay Output Noise Reduction Methods . . . . . . . . . . . . . . . . . . . . . xxxiii

xxv

Page 26

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

PROGRAM mode). Confirm safety thoroughly in advance before changing the

status of any part of memory allocated to I/O Units, Special I/O Units, or CPU

Bus Units. Any changes to the data allocated to any Unit may result in unexpected operation of the loads connected to the Unit. Any of the following operation may result in changes to memory status.

• Transferring I/O memory data to the CPU Unit from a Programming

Device.

• Changing present values in memory from a Programming Device.

• Force-setting/-resetting bits from a Programming Device.

• Transferring I/O memory files from a Memory Card or EM file memory to

the CPU Unit.

• Transferring I/O memory from a host computer or from another PLC on a

network.

xxvi

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

Page 27

Safety Precautions 3

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-V DC output (service power supply to the PLC) is overloaded or short-circuited, the voltage may drop and result in the outputs

being turned OFF. As a countermeasure for such problems, external

safety measures must be provided to ensure safety in the system.

!Caution Confirm safety before transferring data files stored in the file memory (Mem-

ory Card or EM file memory) to the I/O area (CIO) of the CPU Unit using a

peripheral tool. Otherwise, the devices connected to the output unit may malfunction regardless of the operation mode of the CPU Unit.

!Caution Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes. Abnormal operation may

result in serious accidents.

!Caution The CS1-H, CJ1-H, CJ1M, and CS1D CPU Units automatically back up the

user program and parameter data to flash memory when these are written to

the CPU Unit. I/O memory (including the DM, EM, and HR Areas), however, is

not written to flash memory. The DM, EM, and HR Areas can be held during

power interruptions with a battery. If there is a battery error, the contents of

these areas may not be accurate after a power interruption. If the contents of

the DM, EM, and HR Areas are used to control external outputs, prevent inappropriate outputs from being made whenever the Battery Error Flag (A40204)

is ON.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

!Caution Confirm safety at the destination node before transferring a program to

another node or changing contents of the I/O memory area. Doing either of

these without confirming safety may result in injury.

xxvii

Page 28

Operating Environment Precautions 4

!Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque specified in the operation manual. The loose screws may result in

burning or malfunction.

!Caution Do not touch the Power Supply Unit when power is being supplied or immedi-

ately after the power supply is turned OFF. The Power Supply Unit will be hot

and you may be burned.

!Caution Be careful when connecting personal computers or other peripheral devices

to a PLC to which is mounted a non-insulated Unit (CS1W-CLK12/52(-V1) or

CS1W-ETN01) connected to an external power supply. A short-circuit will be

created if the 24 V side of the external power supply is grounded and the 0 V

side of the peripheral device is grounded. When connecting a peripheral

device to this type of PLC, either ground the 0 V side of the external power

supply or do not ground the external power supply at all.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

5 Application Precautions

Observe the following precautions when using the PLC System.

• You must use the CX-Programmer (programming software that runs on

Windows) if you need to program more than one task. A Programming

Console can be used to program only one cyclic task plus interrupt tasks.

xxviii

Page 29

Application Precautions 5

A Programming Console can, however, be used to edit multitask programs originally created with the CX-Programmer.

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to a ground of 100

connecting to a ground of 100

• A ground of 100 Ω or less must be installed when shorting the GR and LG

terminals on the Power Supply Unit.

• Always turn OFF the power supply to the PLC before attempting any of

the following. Not turning OFF the power supply may result in malfunction

or electric shock.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units, Inner Boards, or any other Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the PLC or the system, or could damage the PLC or PLC Units. Always heed

these precautions.

• The user program and parameter area data in the CS1-H, CS1D, CJ1-H,

and CJ1M CPU Units are backed up in the built-in flash memory. The

BKUP indicator will light on the front of the CPU Unit when the backup

operation is in progress. Do not turn OFF the power supply to the CPU

Unit when the BKUP indicator is lit. The data will not be backed up if

power is turned OFF.

• When using a CS-series CS1 CPU Unit for the first time, install the

CS1W-BAT1 Battery provided with the Unit and clear all memory areas

from a Programming Device before starting to program. When using the

internal clock, turn ON power after installing the battery and set the clock

from a Programming Device or using the DATE(735) instruction. The clock

will not start until the time has been set.

• When the CPU Unit is shipped from the factory, the PLC Setup is set so

that the CPU Unit will start in the operating mode set on the Programming

Console mode switch. When a Programming Console is not connected, a

CS-series CS1 CPU Unit will start in PROGRAM mode, but a CS1-H,

CS1D, CJ1, CJ1-H, or CJ1M CPU Unit will start in RUN mode and operation will begin immediately. Do not advertently or inadvertently allow operation to start without confirming that it is safe.

• When creating an AUTOEXEC.IOM file from a Programming Device (a

Programming Console or the CX-Programmer) to automatically transfer

data at startup, set the first write address to D20000 and be sure that the

size of data written does not exceed the size of the DM Area. When the

data file is read from the Memory Card at startup, data will be written in

the CPU Unit starting at D20000 even if another address was set when

the AUTOEXEC.IOM file was created. Also, if the DM Area is exceeded

(which is possible when the CX-Programmer is used), the remaining data

will be written to the EM Area.

Ω or less when installing the Units. Not

Ω or less may result in electric shock.

xxix

Page 30

Application Precautions 5

• Always turn ON power to the PLC before turning ON power to the control

system. If the PLC power supply is turned ON after the control power supply, temporary errors may result in control system signals because the

output terminals on DC Output Units and other Units will momentarily turn

ON when power is turned ON to the PLC.

• Fail-safe measures must be taken by the customer to ensure safety in the

event that outputs from Output Units remain ON as a result of internal circuit failures, which can occur in relays, transistors, and other elements.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Interlock circuits, limit circuits, and similar safety measures in external circuits (i.e., not in the Programmable Controller) must be provided by the

customer.

• Do not turn OFF the power supply to the PLC when data is being transferred. In particular, do not turn OFF the power supply when reading or

writing a Memory Card. Also, do not remove the Memory Card when the

BUSY indicator is lit. To remove a Memory Card, first press the memory

card power supply switch and then wait for the BUSY indicator to go out

before removing the Memory Card.

• If the I/O Hold Bit is turned ON, the outputs from the PLC will not be

turned OFF and will maintain their previous status when the PLC is

switched from RUN or MONITOR mode to PROGRAM mode. Make sure

that the external loads will not produce dangerous conditions when this

occurs. (When operation stops for a fatal error, including those produced

with the FALS(007) instruction, all outputs from Output Unit will be turned

OFF and only the internal output status will be maintained.)

• The contents of the DM, EM, and HR Areas in the CPU Unit are backed

up by a Battery. If the Battery voltage drops, this data may be lost. Provide

countermeasures in the program using the Battery Error Flag (A40204) to

re-initialize data or take other actions if the Battery voltage drops.

• When supplying power at 200 to 240 V AC with a CS-series PLC, always

remove the metal jumper from the voltage selector terminals on the Power

Supply Unit (except for Power Supply Units with wide-range specifications). The product will be destroyed if 200 to 240 V AC is supplied while

the metal jumper is attached.

• Always use the power supply voltages specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage. Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of

the maximum switching capacity. Excess voltage or loads may result in

burning.

xxx

Page 31

Application Precautions 5

• Separate the line ground terminal (LG) from the functional ground terminal (GR) on the Power Supply Unit before performing withstand voltage

tests or insulation resistance tests. Not doing so may result in burning.

• Install the Units properly as specified in the operation manuals. Improper

installation of the Units may result in malfunction.

• With CS-series PLCs, be sure that all the Unit and Backplane mounting

screws are tightened to the torque specified in the relevant manuals.

Incorrect tightening torque may result in malfunction.

• Be sure that all terminal screws, and cable connector screws are tightened to the torque specified in the relevant manuals. Incorrect tightening

torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Wire all connections correctly.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors completely.

• Be sure that the terminal blocks, Memory Units, expansion cables, and

other items with locking devices are properly locked into place. Improper

locking may result in malfunction.

• Check switch settings, the contents of the DM Area, and other preparations before starting operation. Starting operation without the proper settings or data may result in an unexpected operation.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC (including the setting of the

startup operating mode).

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so

may break the cables.

• Do not use commercially available RS-232C personal computer cables.

Always use the special cables listed in this manual or make cables

according to manual specifications. Using commercially available cables

may damage the external devices or CPU Unit.

• Never connect pin 6 (5-V power supply) on the RS-232C port on the CPU

Unit to any device other than an NT-AL001 or CJ1W-CIF11 Adapter. The

external device or the CPU Unit may be damaged.

xxxi

Page 32

Conformance to EC Directives 6

• When replacing parts, be sure to confirm that the rating of a new part is

correct. Not doing so may result in malfunction or burning.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static build-up. Not doing so may result in malfunction or damage.

• When transporting or storing circuit boards, cover them in antistatic material to protect them from static electricity and maintain the proper storage

temperature.

• Do not touch circuit boards or the components mounted to them with your

bare hands. There are sharp leads and other parts on the boards that

may cause injury if handled improperly.

• Do not short the battery terminals or charge, disassemble, heat, or incinerate the battery. Do not subject the battery to strong shocks. Doing any

of these may result in leakage, rupture, heat generation, or ignition of the

battery. Dispose of any battery that has been dropped on the floor or otherwise subjected to excessive shock. Batteries that have been subjected

to shock may leak if they are used.

• UL standards required that batteries be replaced only by experienced

technicians. Do not allow unqualified persons to replace batteries.

• Dispose of the product and batteries according to local ordinances as they apply. Have qualified specialists properly

dispose of used batteries as industrial waste.

• With a CJ-series PLC, the sliders on the tops and bottoms

of the Power Supply Unit, CPU Unit, I/O Units, Special I/O Units, and CPU

Bus Units must be completely locked (until they click into place). The Unit

may not operate properly if the sliders are not locked in place.

• With a CJ-series PLC, always connect the End Plate to the Unit on the

right end of the PLC. The PLC will not operate properly without the End

Plate

• Unexpected operation may result if inappropriate data link tables or

parameters are set. Even if appropriate data link tables and parameters

have been set, confirm that the controlled system will not be adversely

affected before starting or stopping data links.

• CPU Bus Units will be restarted when routing tables are transferred from

a Programming Device to the CPU Unit. Restarting these Units is required

to read and enable the new routing tables. Confirm that the system will

not be adversely affected before allowing the CPU Bus Units to be reset.

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

6-2 Concepts

xxxii

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

Page 33

Conformance to EC Directives 6

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility):

CS Series: EN61131-2 and EN61000-6-2

CJ Series: EN61000-6-2

EMI (Electromagnetic Interference):

EN61000-6-4

(Radiated emission: 10-m regulations)

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 V AC and 75

to 1,500 V DC meet the required safety standards for the PLC (EN61131-2).

6-3 Conformance to EC Directives

The CS/CJ-series PLCs comply with EC Directives. To ensure that the

machine or device in which the CS/CJ-series PLC is used complies with EC

Directives, the PLC must be installed as follows:

1,2,3... 1. The CS/CJ-series PLC must be installed within a control panel.

2. You must use reinforced insulation or double insulation for the DC power

supplies connected to DC Power Supply Units and I/O Units.

3. CS/CJ-series PLCs complying with EC Directives also conform to the

Common Emission Standard (EN61000-6-4). Radiated emission characteristics (10-m regulations) may vary depending on the configuration of the

control panel used, other devices connected to the control panel, wiring,

and other conditions. You must therefore confirm that the overall machine

or equipment complies with EC Directives.

6-4 Relay Output Noise Reduction Methods

The CS/CJ-series PLCs conforms to the Common Emission Standards

(EN61000-6-4) of the EMC Directives. However, noise generated by relay output switching may not satisfy these Standards. In such a case, a noise filter

must be connected to the load side or other appropriate countermeasures

must be provided external to the PLC.

Countermeasures taken to satisfy the standards vary depending on the

devices on the load side, wiring, configuration of machines, etc. Following are

examples of countermeasures for reducing the generated noise.

Countermeasures

(Refer to EN61000-6-4 for more details.)

Countermeasures are not required if the frequency of load switching for the

whole system with the PLC included is less than 5 times per minute.

Countermeasures are required if the frequency of load switching for the whole

system with the PLC included is more than 5 times per minute.

xxxiii

Page 34

Conformance to EC Directives 6

Countermeasure Examples

When switching an inductive load, connect an surge protector, diodes, etc., in

parallel with the load or contact as shown below.

Circuit Current Characteristic Required element

AC DC

CR method

C

Power

supply

R

Diode method

Power

supply

Varistor method

Power

supply

Yes Yes If the load is a relay or solenoid, there is

a time lag between the moment the circuit is opened and the moment the load

is reset.

If the supply voltage is 24 or 48 V, insert

Inductive

load

the surge protector in parallel with the

load. If the supply voltage is 100 to

200 V, insert the surge protector

between the contacts.

No Yes The diode connected in parallel with

the load changes energy accumulated

by the coil into a current, which then

flows into the coil so that the current will

be converted into Joule heat by the

Inductive

load

resistance of the inductive load.

This time lag, between the moment the

circuit is opened and the moment the

load is reset, caused by this method is

longer than that caused by the CR

method.

Yes Yes The varistor method prevents the impo-

sition of high voltage between the contacts by using the constant voltage

characteristic of the varistor. There is

time lag between the moment the cir-

Inductive

load

cuit is opened and the moment the load

is reset.

If the supply voltage is 24 or 48 V, insert

the varistor in parallel with the load. If

the supply voltage is 100 to 200 V,

insert the varistor between the contacts.

The capacitance of the capacitor must

be 1 to 0.5 µF per contact current of

1 A and resistance of the resistor must

be 0.5 to 1 Ω per contact voltage of 1 V.

These values, however, vary with the

load and the characteristics of the

relay. Decide these values from experiments, and take into consideration that

the capacitance suppresses spark discharge when the contacts are separated and the resistance limits the

current that flows into the load when

the circuit is closed again.

The dielectric strength of the capacitor

must be 200 to 300 V. If the circuit is an

AC circuit, use a capacitor with no

polarity.

The reversed dielectric strength value

of the diode must be at least 10 times

as large as the circuit voltage value.

The forward current of the diode must

be the same as or larger than the load

current.

The reversed dielectric strength value

of the diode may be two to three times

larger than the supply voltage if the

surge protector is applied to electronic

circuits with low circuit voltages.

---

xxxiv

When switching a load with a high inrush current such as an incandescent

lamp, suppress the inrush current as shown below.

Countermeasure 1 Countermeasure 2

OUT

R

COM

Providing a dark current of

approx. one-third of the rated

value through an

incandescent lamp

OUT

COM

Providing a limiting resistor

R

Page 35

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xxxv

Page 36

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xxxvi

Page 37

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS