Page 1

OPERATION MANUAL

Ethernet Units

Construction of Applications

SYSMAC CS and CJ Series

CS1W-ETN21 (100Base-TX)

CJ1W-ETN21 (100Base-TX)

Cat. No. W421-E1-03

Page 2

CS1W-ETN21 (100Base-TX) CJ1W-ETN21 (100Base-TX) Ethernet Units Construction of Applications

Operation Manual

Revised November 2005

Page 3

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2003

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 4

vi

Page 5

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxiv

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

SECTION 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Ethernet Unit Communications Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Functions Listed by Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1-3 Table of Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-4 Common Protocol Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 2

Mail Send Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-1 Mail Send Function Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-2 Mail Send Function Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2-3 Mail Send Function Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-4 Using the Mail Send Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-5 Mail Send Function Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

2-6 I/O Memory Data Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-7 Attached File Transfer Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2-8 Mail Send Function Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

2-9 Example Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

SECTION 3

Receive Mail Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3-1 Mail Receive Function Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-2 Mail Receive Function Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-3 Using the Mail Receive Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-4 Remote Mail Command Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3-5 Mail Receive Function Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3-6 I/O Memory Data Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3-7 Attached File Transfer Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

3-8 Mail Receive Function Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3-9 Example Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

vii

Page 6

TABLE OF CONTENTS

SECTION 4

FTP Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4-2 FTP Server Function Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4-3 Using the FTP Server Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4-4 FTP Server Application Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4-5 Using FTP Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

4-6 Checking FTP Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4-7 Using File Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4-8 FTP File Transfer Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4-9 UNIX Application Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

SECTION 5

Automatic Clock Adjustment Function . . . . . . . . . . . . . . . . 89

5-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5-2 Using the Automatic Clock Adjustment Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

5-3 Automatic Clock Adjustment Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

5-4 Automatic Clock Adjustment Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

SECTION 6

Socket Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6-1 Overview of Socket Communications from Ethernet Units . . . . . . . . . . . . . . . . . . . . . . . . . 99

6-2 Protocol Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6-3 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6-4 Socket Service Function Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

6-5 Using Socket Service Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6-6 Socket Service Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6-7 Using Socket Services by Manipulating Dedicated Control Bits . . . . . . . . . . . . . . . . . . . . . 112

6-8 Using Socket Services with CMND(490) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

6-9 Precautions in Using Socket Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

SECTION 7

Using FINS Communications to Create Host Applications 159

7-1 Overview of FINS Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

7-2 FINS Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

7-3 FINS/UDP Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

7-4 FINS/TCP Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

7-5 Maximum Transmission Delays: Writing/Reading to CPU Unit . . . . . . . . . . . . . . . . . . . . . 192

viii

Page 7

TABLE OF CONTENTS

Appendices

A Ethernet Network Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

B Buffer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

C TCP Status Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

D ASCII Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

E Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

F Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

ix

Page 8

TABLE OF CONTENTS

x

Page 9

About this Manual:

This manual describes the operation of the CS1W-ETN21 and CJ1W-ETN21 Ethernet Units (100BaseTX) for constructing applications and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the Ethernet Unit. Be sure to read the precautions provided in the following section.

Precautions

Section 1 introduces the Ethernet Unit’s communications services, including information on functions

and protocols.

Section 2 describes how to use the Ethernet Unit’s Mail Send Function, including specifications, status details, application examples, and troubleshooting information.

Section 3 describes how to use the Ethernet Unit’s Mail Receive Function, including specifications,

status details, I/O memory data formats, file transfer timing, application examples, and troubleshooting

information.

Section 4 describes the functions provided by the FTP server.

Section 5 provides an overview of the automatic clock adjustment function, including details on speci-

fications, required settings, operations from CX-Programmer, and troubleshooting.

Section 6 describes the functionality provided by the Ethernet Unit via the socket services.

Section 7 provides information on communicating on Ethernet Systems and interconnected networks

using FINS commands. The information provided in the section deals only with FINS communications

in reference to Ethernet Units.

Appendices provide information on Ethernet network parameters, the buffer configuration, TCP status

transitions, ASCII characters, maintenance, and inspections.

The related Operation Manual Construction of Networks (W420) provides the following information.

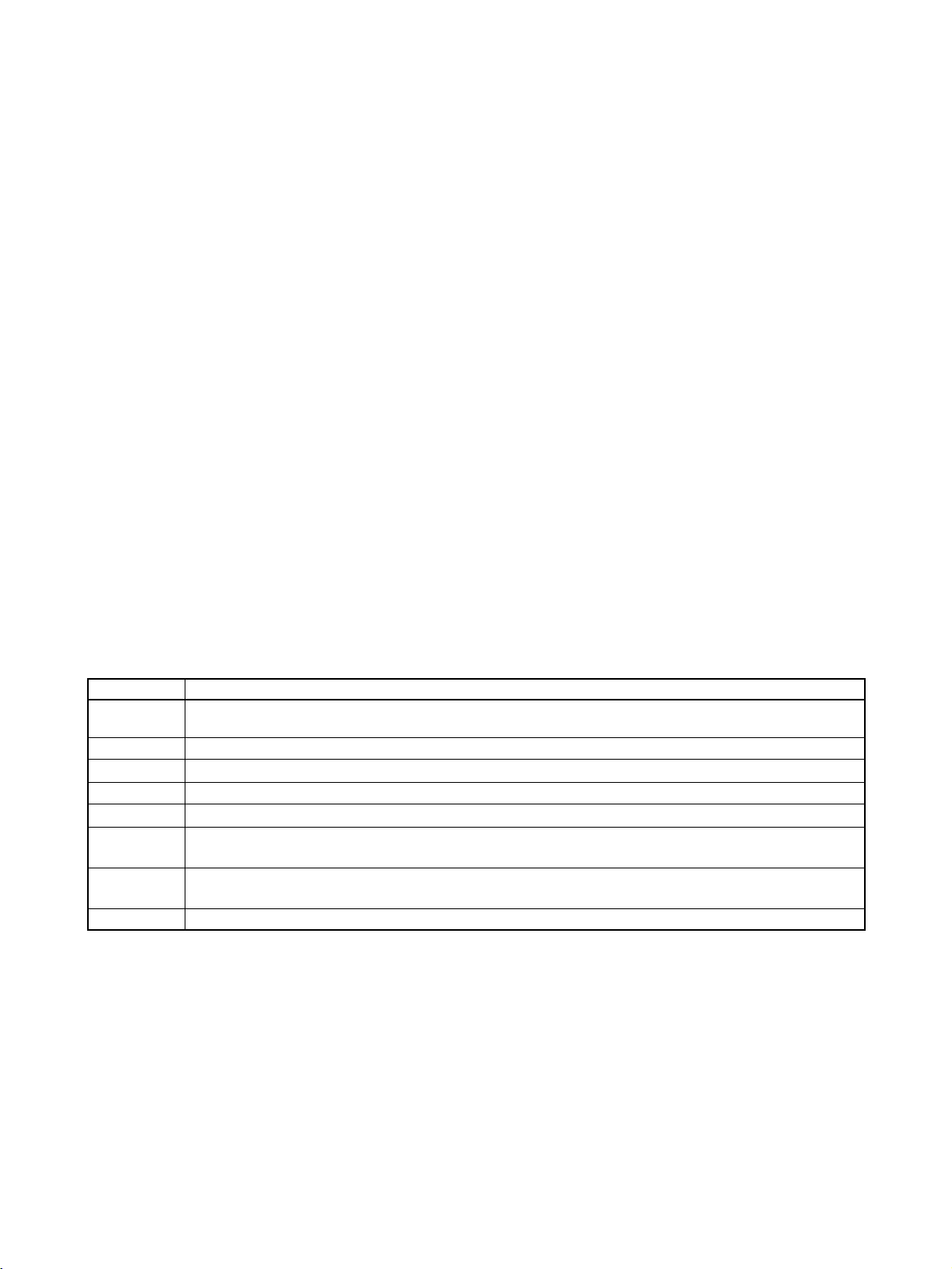

Section Contents

Section 1 Overview of Ethernet Unit features, specifications, and description of the Unit parts and system configura-

tion for constructing Networks.

Section 2 Information on Ethernet Unit’s installation and initial settings required for operation.

Section 3

Section 4 Information on words allocated in the CIO Area and DM Area for Ethernet Units.

Section 5

Section 6

Information

Information on

Information on

commands.

Section 7

Information on

are returned by the Ethernet Unit.

Section 8 Information on troubleshooting.

on setting communications using CX-Programmer.

how to manage and use IP addresses.

communicating on Ethernet Systems and interconnected networks using FINS

the FINS commands that can be sent to an Ethernet Unit and the responses that

xi

Page 10

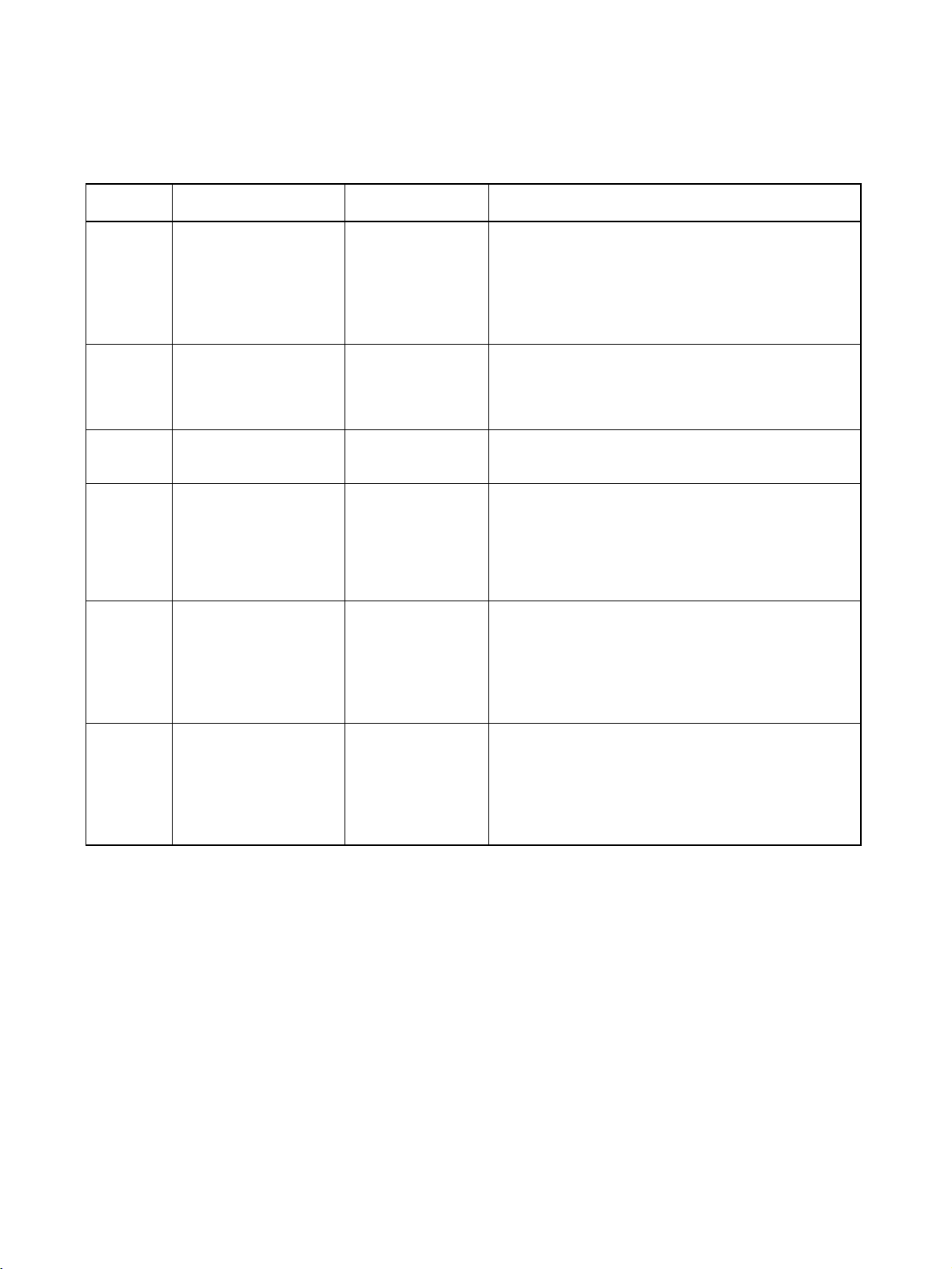

Relevant Manuals

The following table lists CS- and CJ-series manuals that contain information relevant to Ethernet Units.

Manual

number

W420 CS1W-ETN21

CJ1W-ETN21

W421 CS1W-ETN21

CJ1W-ETN21

W343 CS1W-ETN01

CS1W-ETN11

CJ1W-ETN11

W342 CS1G/H-CPU@@H

CS1G/H-CPU-@@V1

CS1W-SCU21

CS1W-SCB21/41

CJ1G/H-CPU@@H

CJ1G-CPU@@

CJ1W-SCU41

W339 CS1G/H-CPU@@H

CS1G/H-CPU-@@V1

W393 CJ1G/H-CPU@@H

CJ1G-CPU@@

Model Name Contents

Ethernet Units Operation Manual

Construction of Networks

Ethernet Units Operation Manual

Construction of

Applications

(this manual)

Ethernet Units Operation Manual

Communications

Commands Reference Manual

Programmable Controllers Operation

Manual

Programmable Controllers Operation

Manual

Provides information on operating and installing

100Base-TX Ethernet Units, including details on basic

settings and FINS communications.

Refer to the Communications Commands Reference

Manual (W342) for details on FINS commands that can

be sent to CS-series and CJ-series CPU Units when

using the FINS communications service.

Provides information on constructing host applications for

100Base-TX Ethernet Units, including functions for sending/receiving mail, socket service, automatic clock adjustment, FTP server functions, and FINS communications.

Describes the installation and operation of the 10Base-5

and 10Base-T Ethernet Units.

Describes the C-series (Host Link) and FINS communications commands used when sending communications

commands to CS-series and CJ-series CPU Units.

Provides an outline of, and describes the design, installation, maintenance, and other basic operations for the CSseries PLCs. Information is also included on features,

system configuration, wiring, I/O memory allocations, and

troubleshooting.

Use together with the Programmable Controllers Pro-

gramming Manual (W394).

Provides an outline of, and describes the design, installation, maintenance, and other basic operations for the CJseries PLCs. Information is also included on features,

system configuration, wiring, I/O memory allocations, and

troubleshooting.

Use together with the Programmable Controllers Pro-

gramming Manual (W394).

xii

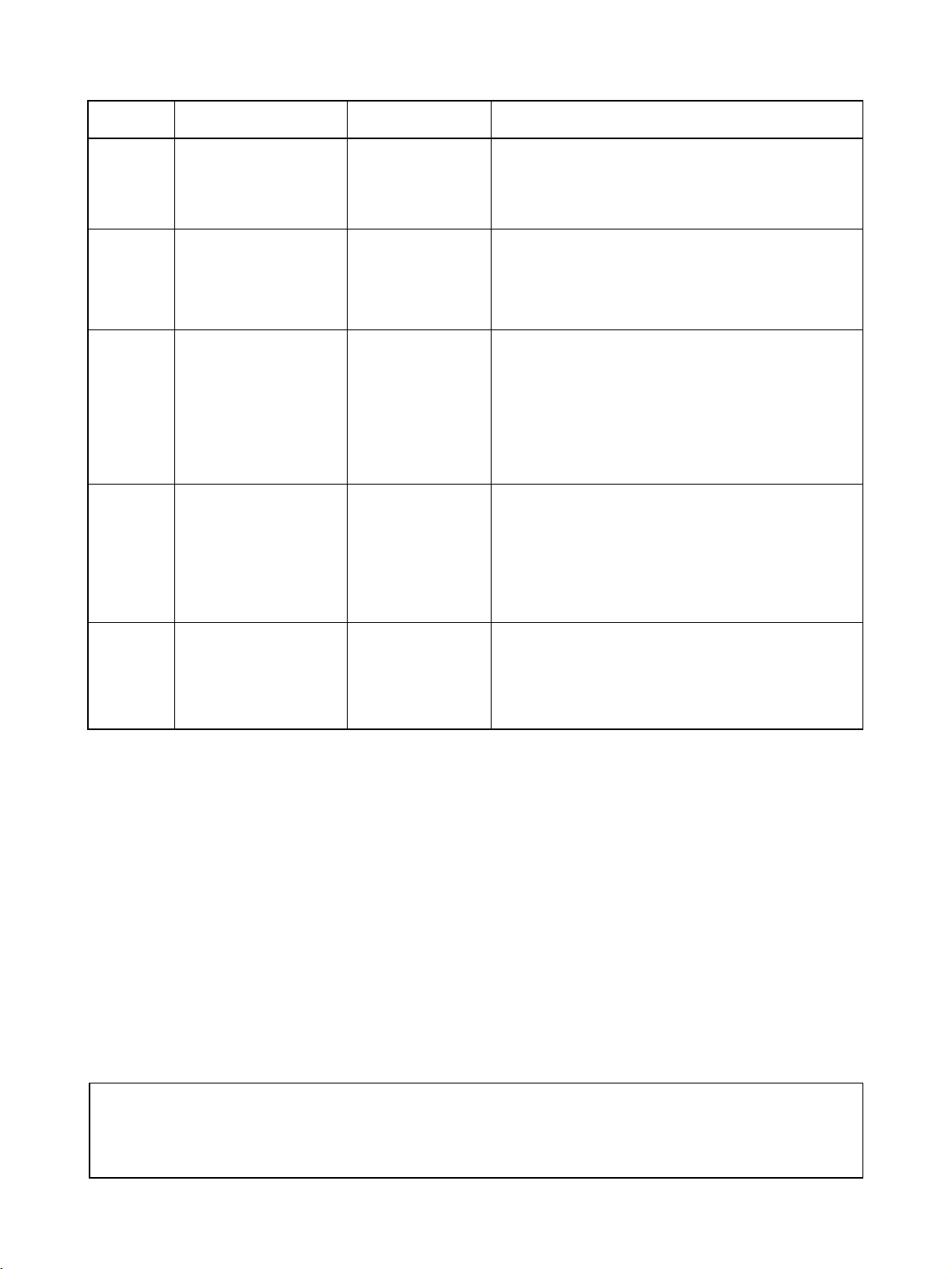

Page 11

Manual

number

W394 CS1G/H-CPU@@H

CS1G/H-CPU-@@V1

CJ1G/H-CPU@@H

CJ1G-CPU@@

W340 CS1G/H-CPU@@H

CS1G/H-CPU-@@V1

CJ1G/H-CPU@@H

CJ1G-CPU@@

W414 WS02-CX-@@JV3 CX-Programmer

W341 CQM1H-PRO01

CQM1-PRO01

C200H-PRO27 +

CS1W-KS001

W336 CS1W-SCB21/41

CS1W-SCU21

CJ1W-SCU41

Model Name Contents

Programmable Controllers Programming Manual

Programmable Controllers Instructions

Reference Manual

@ Operation

Ver.3 .

Manual

Programming Consoles Operation

Manual

Serial Communications Boards and

Serial Communications Units Operation

Manual

Describes programming, tasks, file memory, and other

functions for the CS-series and CJ-series PLCs.

Use together with the Programmable Controllers Opera-

tion Manual (W339 for CS-series PLCs and W393 for CJseries PLCs).

Describes the ladder diagram programming instructions

supported by CS-series and CJ-series PCs. Use together

with the Programmable Controllers Operation Manual

(W339 for CS-series PLCs and W393 for CJ-series

PLCs), and Programmable Controllers Programming

Manual (W394).

Provides information on how to use the CX-Programmer,

a Windows-based programming device, and CX-Net, a

Windows-based network configuration tool.

Use together with the Programmable Controllers Opera-

tion Manual (W339 for CS-series PLCs and W393 for CJseries PLCs), Programmable Controllers Programming

Manual (W394) and the Programmable Controllers

Instructions Reference Manual (W340) to perform pro-

gramming.

Provides information on how to operate the Programming

Console.

Use together with the Programmable Controllers Opera-

tion Manual (W339 for CS-series PLCs and W393 for CJseries PLCs), Programmable Controllers Programming

Manual (W394) and the Programmable Controllers

Instructions Reference Manual (W340) to perform pro-

gramming.

Accessing the PLC connected to the CX-Programmer via

Ethernet or the host computer or other device connected

to the Serial Communications Board or Unit.

Describes the use of Serial Communications Units and

Boards, including details on hardware, software, and

standard system protocols.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xiii

Page 12

xiv

Page 13

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xv

Page 14

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xvi

Page 15

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xvii

Page 16

xviii

Page 17

Unit Versions of CS/CJ-series

Unit Versions A “unit version” has been introduced to manage Units in the CS/CJ Series

according to differences in functionality accompanying Unit upgrades.

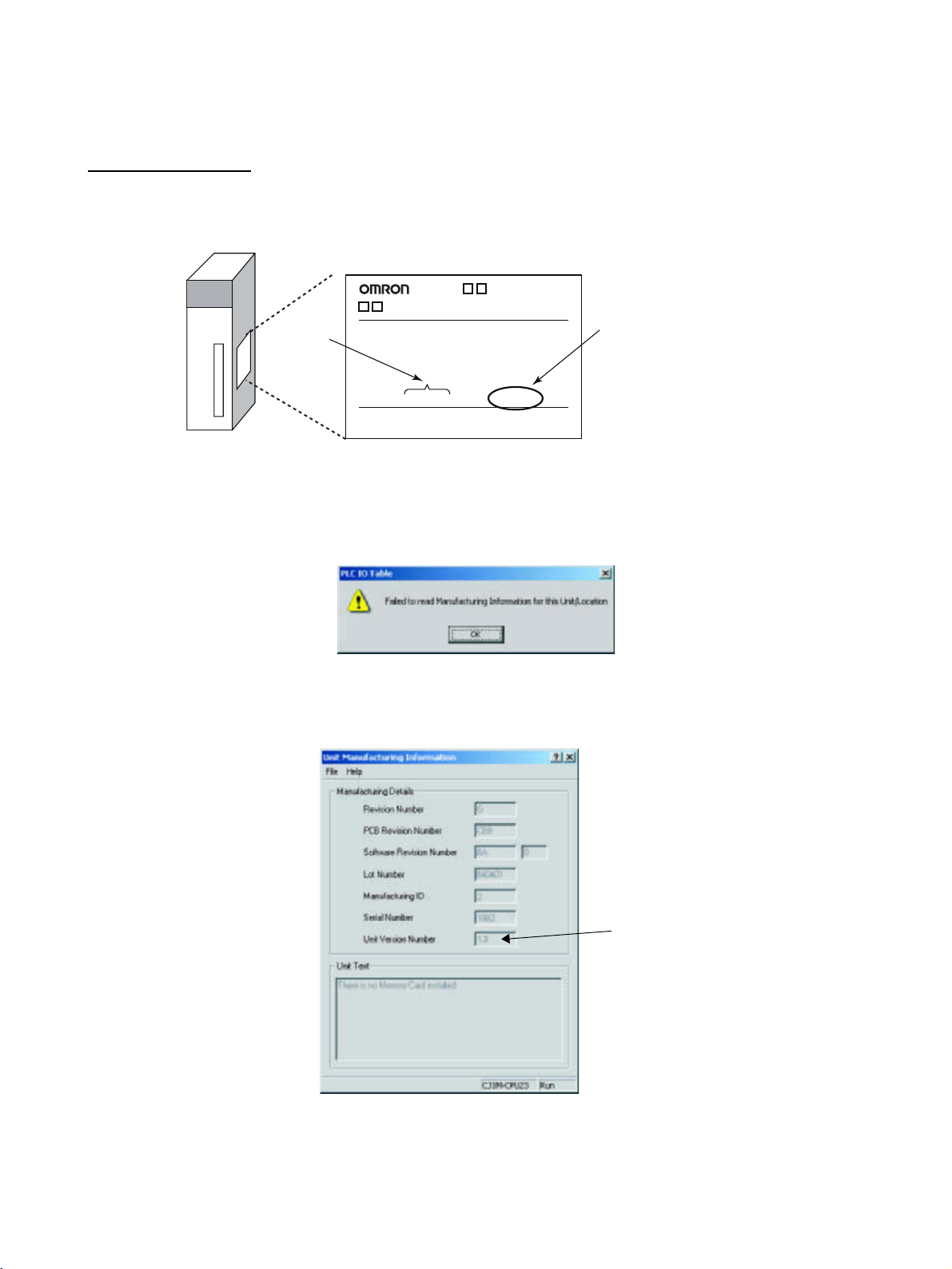

Notation of Unit Versions

on Products

Confirming Unit Versions

with Support Software

The unit version is given to the right of the lot number on the nameplate of the

products for which unit versions are being managed, as shown below.

Product nameplate

CS1W-

UNIT

Lot No.

Lot No. 040401 0000 Ver.1.3

OMRON Corporation MADE IN JAPAN

Unit version

Example for unit version 1.3

CX-Programmer version 4.0 can be used to confirm the unit version using the

Unit Manufacturing Information.

Note The unit versions of Pre-Ver.2.0 Units cannot be confirmed in Unit Manufac-

turing Information. The following dialog box is displayed.

In the IO Table Window, right-click and select Unit Manufacturing informa-

tion - CPU Unit.

The following Unit Manufacturing information Dialog Box will be displayed.

Unit version

Use the above display to confirm the unit version of the Unit connected online.

xix

Page 18

Using Unit Version Label The following unit version label is provided with the Ethernet Unit.

This label can be attached to the front of the Ethernet Unit to differentiate

between Ethernet Units with different unit versions.

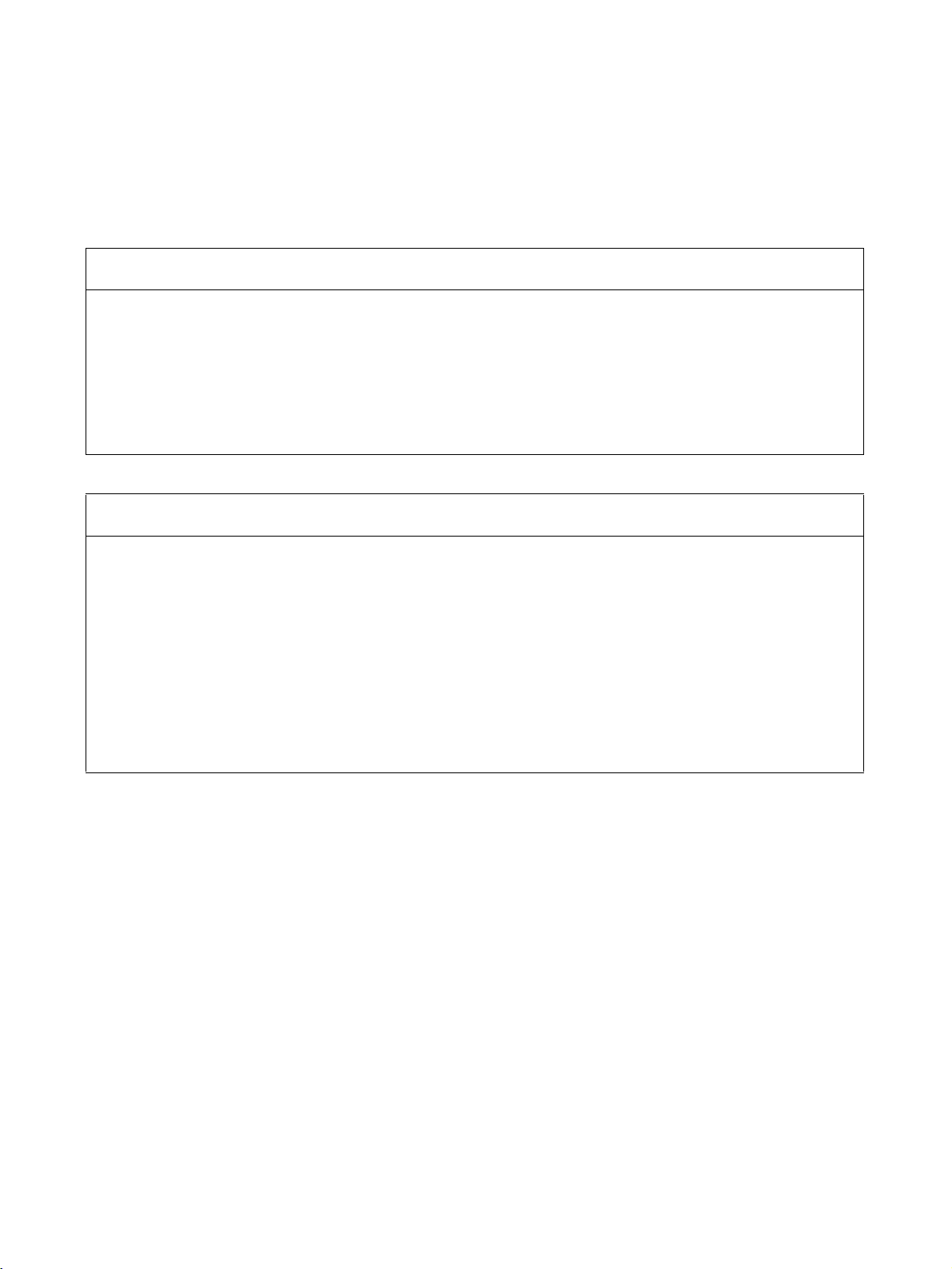

Unit Version Notation In this manual, the unit version of a Ethernet Unit is given as shown in the fol-

lowing table.

Product nameplate Notation used in this manual Special remarks

Ver. 2.0 or later number

shown to right of the lot

number

Blank to the right of lot

number

Ethernet Unit Ver. 1.3 or later Information without reference to specific Unit

Versions applies to all versions of the Unit.

Pre-Ver. 1.3 Ethernet Units

Unit Versions and Lot Numbers

Type Model Date of manufacture

March 2003 or earlier April 2004 or later

Special I/O Unit Ethernet Unit CS1W-ETN21

CJ1W-ETN21

Supported Software CX-Programmer WS02-CXPC1-JV@ Ver. 3.3 or earlier Ver. 4. 0

No version code Unit Ver. 1.3

(Lot No.: 040401)

xx

Page 19

PRECAUTIONS

This section provides general precautions for using the CS1W-ETN21 and CJ1W-ETN21 Ethernet Units (100Base-TX).

The information contained in this section is important for the safe and reliable application of Ethernet Units. You

must read this section and understand the information contained before attempting to set up or operate an Ethernet

Unit.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

xxi

Page 20

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your

OMRON representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

xxii

Page 21

Safety Precautions 3

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC outputs may remain ON or OFF due to deposits on or burning of

the output relays, or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-V DC output (service power supply to the PLC) is overloaded or short-circuited, the voltage may drop and result in the outputs

being turned OFF. As a countermeasure for such problems, external

safety measures must be provided to ensure safety in the system.

!Caution Execute online editing only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

!Caution Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes. Serious accidents may

result from abnormal operation if proper measures are not provided.

!Caution Confirm safety at the destination node before changing or transferring to

another node the contents of a program, the PLC Setup, I/O tables, or I/O

memory. Changing or transferring any of these without confirming safety may

result in injury.

!Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque specified in the operation manual. The loose screws may result in

burning or malfunction.

xxiii

Page 22

Operating Environment Precautions 4

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

5 Application Precautions

Observe the following precautions when using the Ethernet Unit.

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to a ground of 100

connecting to a ground of 100

• Always turn OFF the power supply to the CPU Unit and Slaves before

attempting any of the following. Not turning OFF the power supply may

result in malfunction or electric shock.

• Mounting or dismounting I/O Units, CPU Units, Memory Packs, or

Master Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the Ethernet Unit or the system, or could damage the Ethernet Unit. Always

heed these precautions.

Ω or less when installing the Units. Not

Ω or less may result in electric shock.

xxiv

• Interlock circuits, limit circuits, and similar safety measures in external circuits (i.e., not in the Programmable Controller) must be provided by the

customer.

Page 23

Application Precautions 5

• Always use the power supply voltages specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures

• Make sure that all the Backplane mounting screws, terminal block screws,

and cable connector screws are tightened to the torque specified in the

relevant manuals. Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Observe the following precautions when wiring the communications

cable.

• Separate the communications cables from the power lines or high-tension lines.

• Do not bend the communications cables past their natural bending radius.

• Do not pull on the communications cables.

• Do not place heavy objects on top of the communications cables.

• Always lay communications cable inside ducts.

• Use appropriate communications cables.

• Make sure that the terminal blocks, expansion cable connectors, and

other items with locking devices are locked in place.

• Wire all connections correctly according to instructions in this manual.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors completely.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• After replacing Units, resume operation only after transferring to the new

CPU Unit and/or Special I/O Units the contents of the DM Area, HR Area,

programs, parameters, and other data required for resuming operation.

Not doing so may result in an unexpected operation.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static build-up. Not doing so may result in malfunction or damage.

xxv

Page 24

Conformance to EC Directives 6

• When transporting the Unit, use special packing boxes and protect it from

being exposed to excessive vibration or impacts during transportation.

• CPU Bus Units will be restarted when routing tables are transferred from

a Programming Device to the CPU Unit. Restarting these Units is required

to read and enable the new routing tables. Confirm that the system will

not be adversely affected before allowing the CPU Bus Units to be reset.

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMS (Electromagnetic Susceptibility) and EMI (Electromagnetic

Interference) Standards in the EMC (Electromagnetic Compatibility) standards are as follows:

Ethernet Unit EMS EMI

CS1W-ETN21

CJ1W-ETN21

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 V AC and 75

to 1,500 V DC meet the required safety standards for the PLC (EN61131-2).

EN61000-6-2

EN61000-6-4

(Radiated emission: 10-m

regulations)

xxvi

Page 25

SECTION 1

Introduction

This section introduces the functions and protocols used in Ethernet Unit communications services.

1-1 Ethernet Unit Communications Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Functions Listed by Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-3 Table of Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-4 Common Protocol Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-4-1 SMTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-4-2 POP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4-3 DNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1

Page 26

Ethernet Unit Communications Services Section 1-1

1-1 Ethernet Unit Communications Services

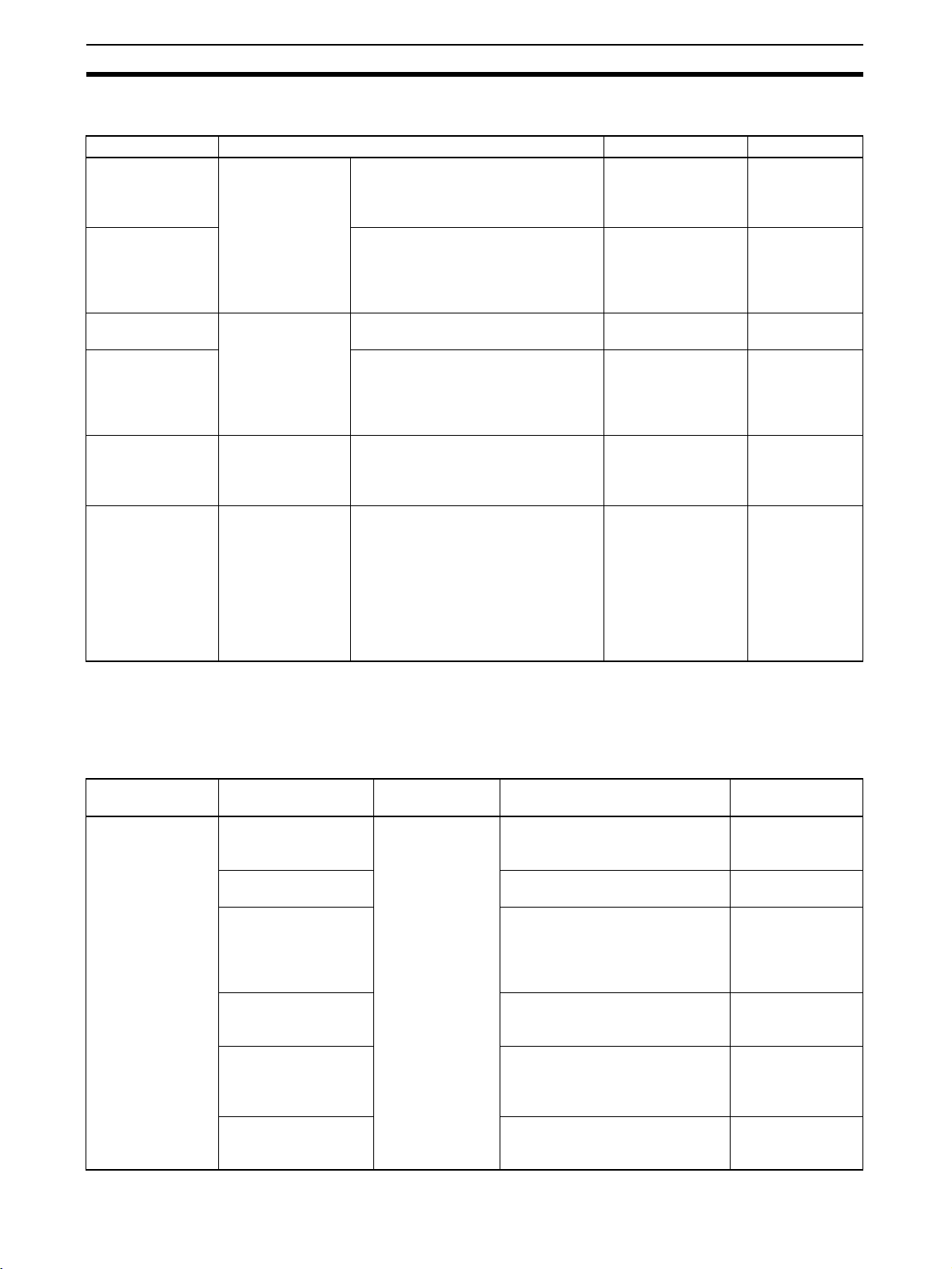

Service Main functions Counterpart device Reference

Mail send function Through intranet or

internet

Mail receive function

FTP server function

Socket service

function

Automatic clock

adjust function

FINS communications

Through intranet or

internet (See note.)

Through intranet Used to automatically adjust the PLC's

Through intranet or

internet (See note.)

Used to e-mail specified I/O memory

data or a file (up to 1 MB) from the

PLC to the computer automatically

when a preset condition is met.

Used to perform operations in the PLC

from the computer, such as reading or

writing I/O memory data, backing up

data, changing the operating mode, or

transferring files (up to 1 MB).

Used to transfer large files between

the computer and PLC.

Used to transfer data between general-purpose applications and the

PLC.

internal clock.

Used to access the PLC from a computer (FINS application) or send message communications from one PLC

to another.

Note The PLC can be accessed with

FINS message communications

even from a DHCP client computer or computer with an

unspecified FINS node address.

Computer

(E-mail software)

Computer

(E-mail software)

Computer

(FTP client software)

Computer

(General applications that do not use

FINS communications)

SNTP Server SECTION 5

Computer

(User-created FINS

communications

application)

SECTION 2 Mail

Send Function

SECTION 3

Receive Mail

Function

SECTION 4

FTP Server

SECTION 6

Socket Services

Automatic Clock

Adjustment

Function

SECTION 7

Using FINS

Communications to Create

Host Applications

Note When transferring data through the internet, a global IP address must be

acquired for the Ethernet Unit.

1-2 Functions Listed by Purpose

Timing and

direction

User-specified timing, sent from computer

User purpose Communications

Reading and writing

data in the CPU Unit's

I/O memory

Changing the CPU

Unit's operating mode

Performing operations

on EM file memory or

a Memory Card

installed in the CPU

Unit

Backing up the user

program or parameter

area in the CPU Unit

Reading or clearing

the error log in the

Ethernet Unit or CPU

Unit

Sending a specific

FINS command to a

specific Unit

service

Mail Receive

Function

Method Restrictions

IOMRead (I/O memory read) and

IOMWrite (I/O memory write) commands

ChangeMode command ---

FileWrite, FileRead, FileDelete,

and FileList commands

UMBackup (User program backup)

and PARAMBackup (Parameter

area backup) commands

ErrorLogRead and ErrorLogClear

commands

FinsSend command ---

The maximum data

size is 6,000

words.

The maximum data

size is 1 MB.

---

---

2

Page 27

Table of Protocols Section 1-3

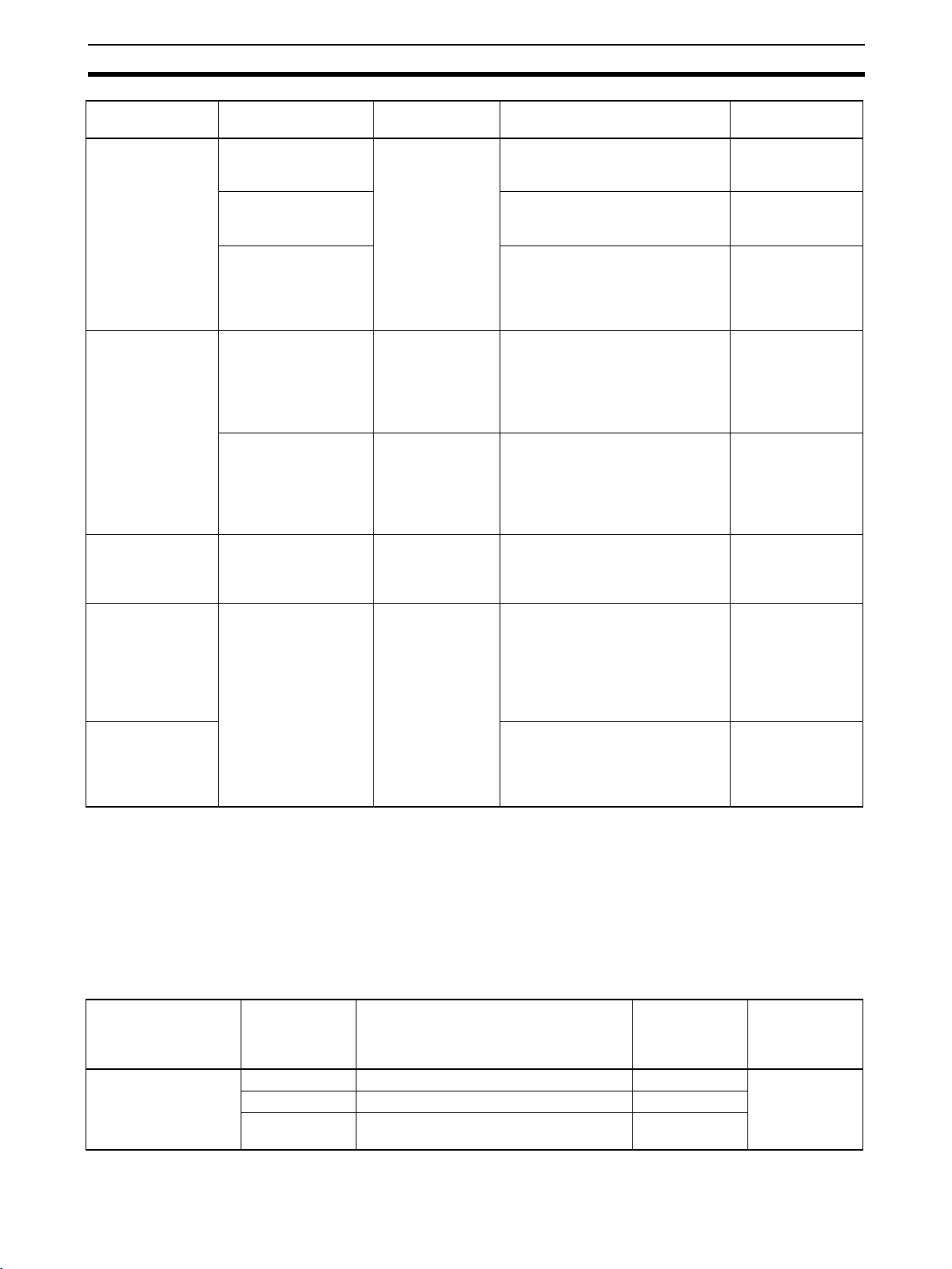

Timing and

direction

Automatic execution when a preset

condition is met,

sent to computer

(See note.)

User-specified timing, sent from computer

Performed at a set

time every day or

from the ladder

program

Temporarily connecting a computer

to perform operations from a FINS

application such as

the CX-Programmer

Performing operations from two or

more FINS applications in the computer

User purpose Communications

Reading data in the

CPU Unit's I/O memory

Reading data from a

Memory Card installed

in the CPU Unit

Receiving a userdefined message as

an e-mail

Performing operations

on EM file memory or

a Memory Card

installed in the CPU

Unit

Reading and writing

data in the CPU Unit's

I/O memory from a

general application

(not using FINS communications)

Automatically correcting the PLC's internal

clock

Performing online

operations on the CPU

Unit

service

Mail Send Function

FTP Server Function

Socket Service

Function

Automatic Clock

Adjust Function

FINS communications

Method Restrictions

Specify a data file as an attached

file and specify the starting read

address and number of words.

Specify any file as an attached file. The maximum data

Store the desired message in

ASCII in the CPU Unit's I/O memory.

Login to the Ethernet Unit from the

FTP client software and send the

FTP command.

Socket service operations can be

executed by executing the CMND

instruction or setting control bits in

the PLC.

Install the SNTP server in the network and schedule the synchronization time in the Ethernet Unit.

One function stores the counterpart FINS nodes' connection information. Another function

automatically assigns node

addresses.

A function supports simultaneous

online connections of multiple

applications in the computer.

The maximum data

size is 6,000

words.

size is 1 MB.

The maximum

message length is

1,024 characters

(alphanumeric

characters only).

The data size is not

restricted. The IP

address for the

Ethernet Unit must

be private and

fixed.

The IP address for

the Ethernet Unit

must be private

and fixed.

---

The IP address for

the Ethernet Unit

must be private

and fixed.

---

Note Any one of the following conditions can be specified to send e-mail automati-

cally:

A periodic timer times out, the Mail Send Switch is turned from OFF to ON, a

specified word contains a particular value, a specified bit turns from OFF to

ON, the CPU Unit's operating mode changes, a fatal error occurs, or an event

is stored in the error log.

1-3 Table of Protocols

Communications

service

Mail Send Function SMTP Required SMTP SECTION 2 Mail

Protocol used Situation when used CX-

Programmer's

Unit setting tag

name

POP When using “POP before SMTP” POP

DNS When specifying the SMTP server and

POP server by host names

DNS

Reference

Send Function

3

Page 28

Common Protocol Settings Section 1-4

Communications

service

Mail Receive Function SMTP Required SMTP SECTION 3

FTP Server Function FTP Optional User set SECTION 4

Socket Service Function

Automatic Clock

Adjust Function

Creating a FINS communications host

application

Protocol used Situation when used CX-

POP Required POP

DNS When specifying the SMTP server and

POP server by host names

TCP/IP Optional User set SECTION 6

UDP/IP Optional User set

SNTP Required Automatic clock

DNS When specifying the SNTP server by a

host name

FINS Optional User set SECTION 7

Programmer's

Unit setting tag

name

DNS

synchronization

DNS

Reference

Receive Mail

Function

FTP Server

Socket Services

SECTION 5

Automatic Clock

Adjustment

Function

Using FINS

Communications to Create

Host Applications

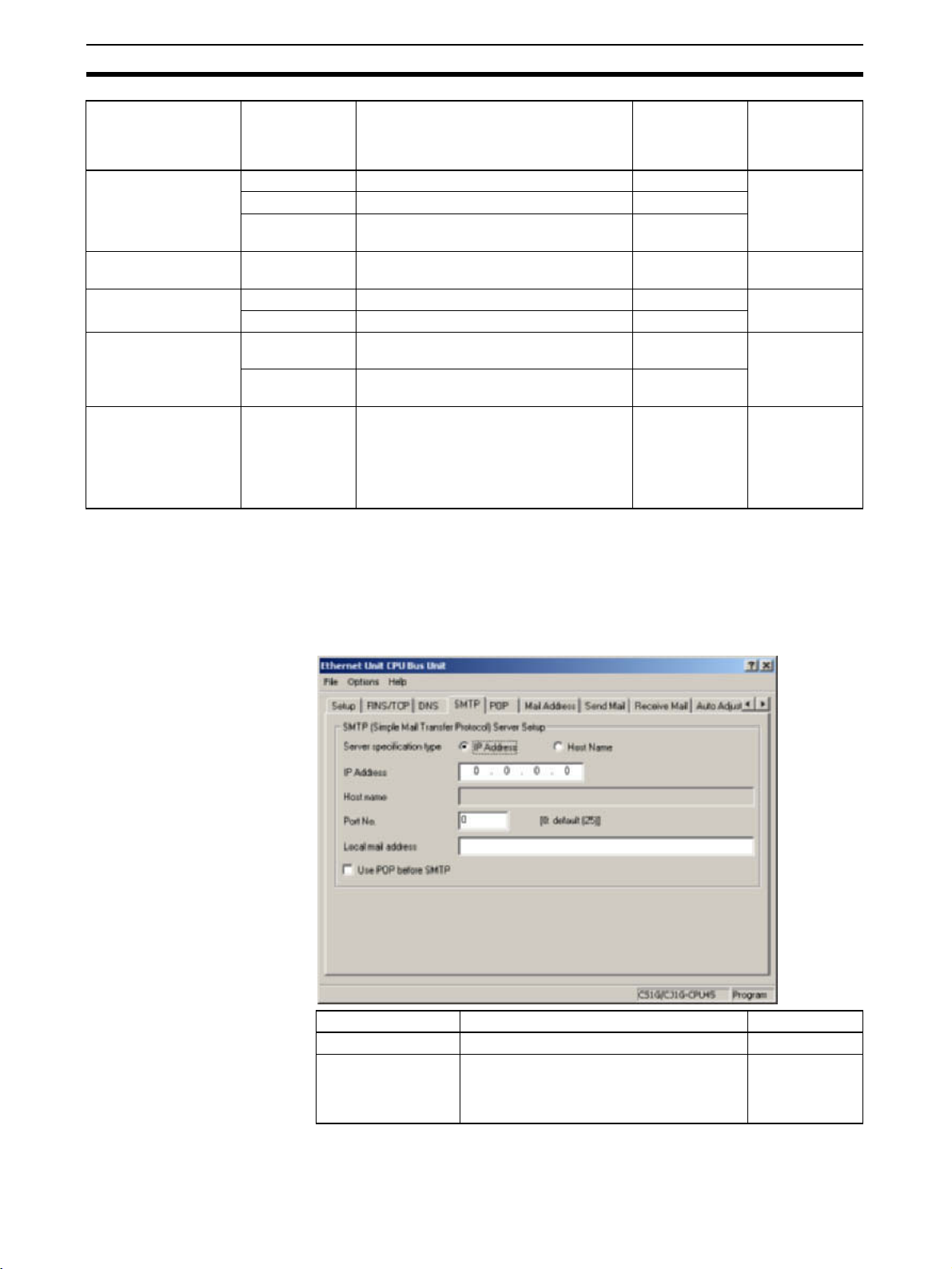

1-4 Common Protocol Settings

1-4-1 SMTP

The SMTP server settings must be made in order to use the Mail Send Function or Mail Receive Function.

Item Contents Default

Local mail address Set the mail address for the Ethernet Unit. None

Server specification

type

Select whether the SMTP server used for

sending mail is to be specified by IP

address or the host's domain name (i.e.,

host name).

IP Address

4

Page 29

Common Protocol Settings Section 1-4

Item Contents Default

IP Address Set the IP address for the SMTP server

Host name Set the host domain name (i.e., the host

Port No. Set the port to be used for connecting to the

Use POP before

SMTP

used for sending mail.

This setting is enabled only when “IP

address” is selected as the method for

specifying the server.

name) for the SMTP server that is to be

used for sending mail.

This setting is enabled only when “host

name” is selected as the method for specifying the server.

SMTP server that is to be used for sending

mail.

This setting does not normally need to be

changed.

Select whether or not to use the mail receiving method (POP before SMTP) in which

the POP server must be accessed (to

receive mail) before the SMTP server is

accessed (to send mail).

Note The “POP before SMTP” is an authentication function required when sending

mail (using the SMTP server). Normally, account name and password authentication is performed with the POP server because there isn't an authentication process in the SMTP server. Most ISPs (Internet Service Providers) use

the “POP before SMTP” authentication method to verify users sending e-mail.

0.0.0.0

None

0

(No. 25 is used.)

Disabled

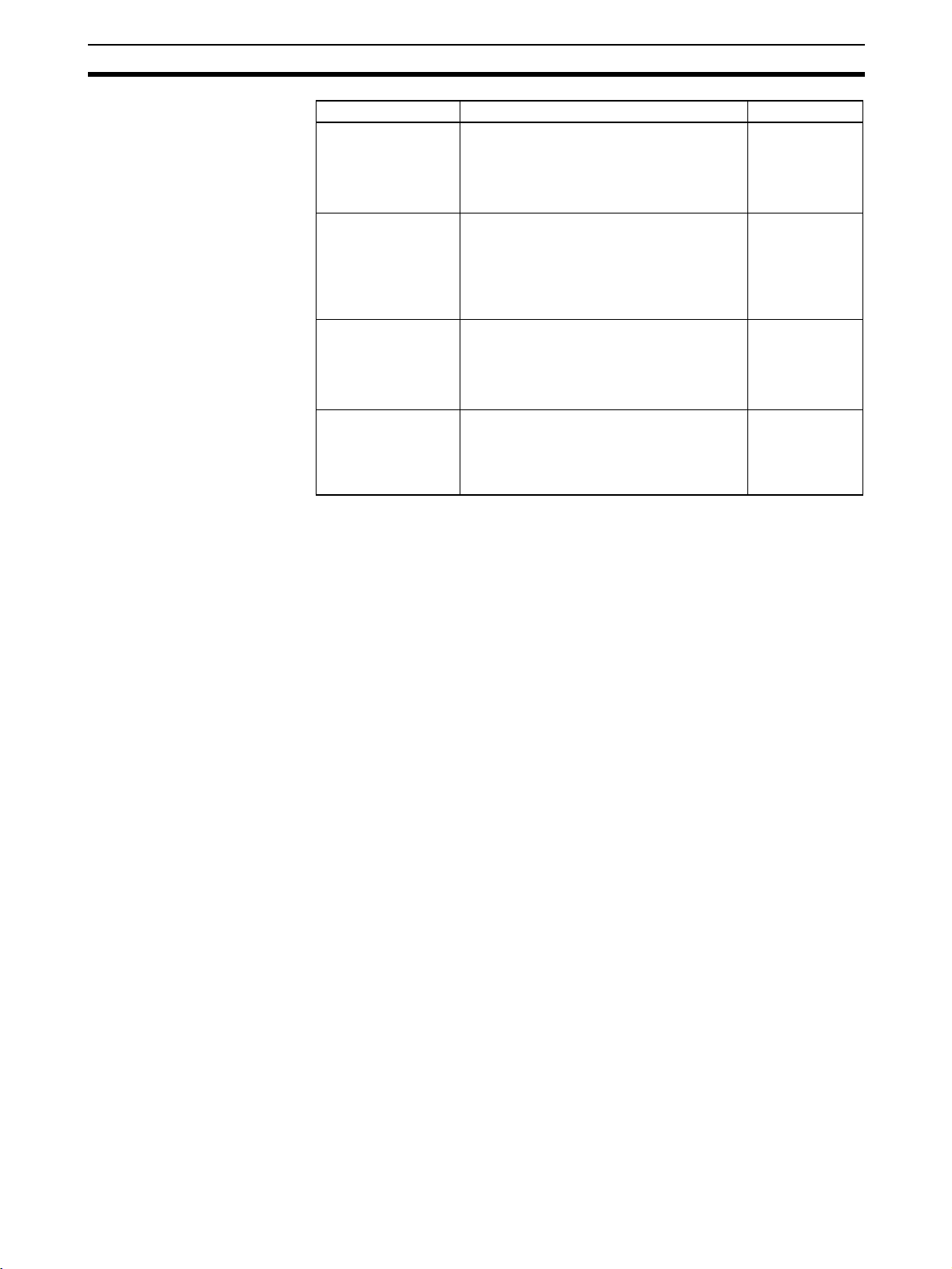

1-4-2 POP

Always enter the POP server settings when using the Mail Receive Function.

Also, set the POP server settings when using “POP before SMTP” in the Mail

Send Function.

5

Page 30

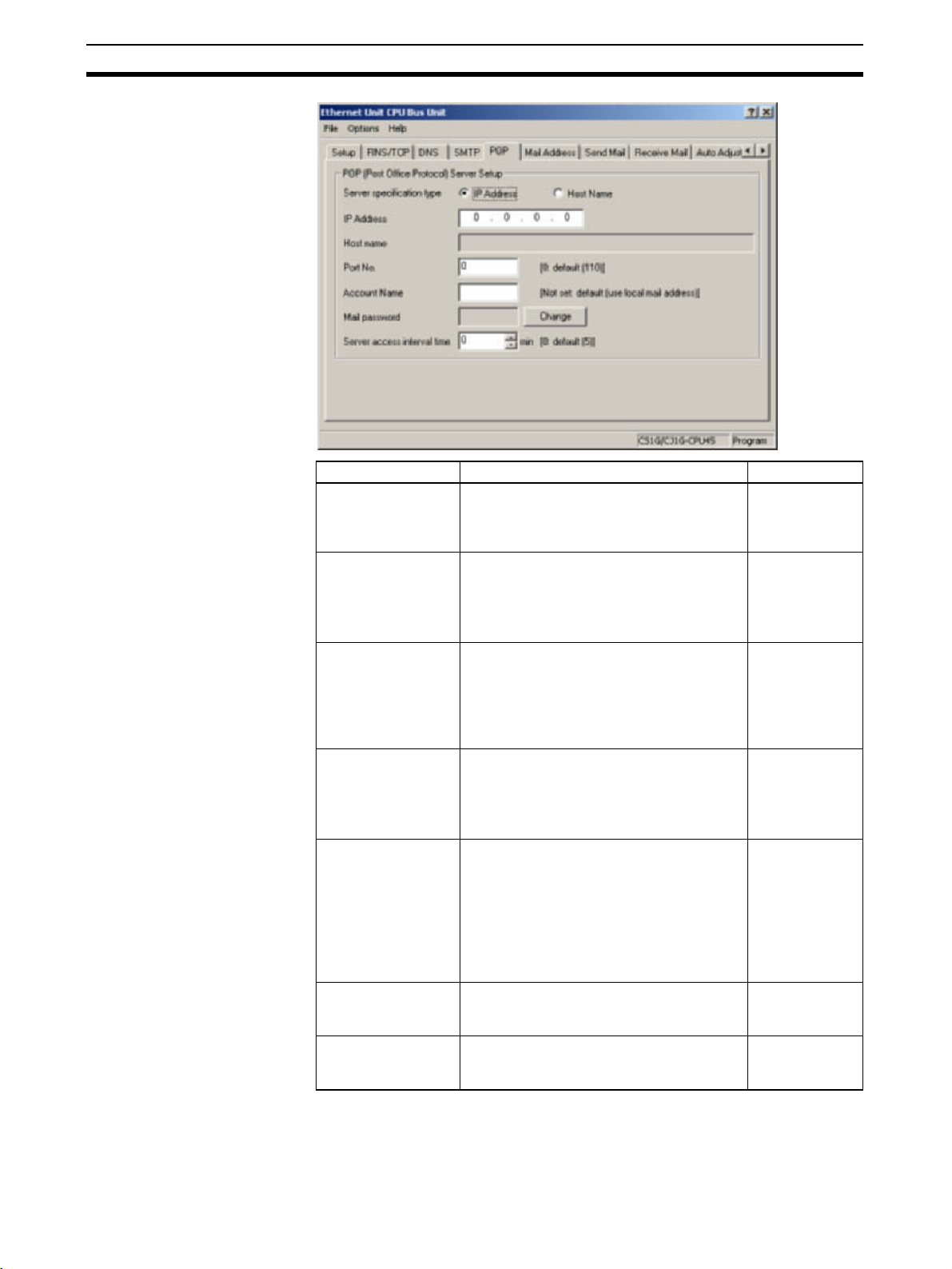

Common Protocol Settings Section 1-4

Item Contents Default

Server specification

type

IP Address Set the IP address for the POP3 server

Host name Set the host domain name (i.e., the host

Port No. Set the port to be used for connecting to the

Account Name Sets the account name (up to 9 characters)

Mail password Sets the password (up to 8 characters) of

Server access interval time

Select whether the POP3 server used for

receiving mail is to be specified by IP

address or the host's domain name (i.e.,

host name).

used for receiving mail.

This setting is enabled only when “IP

address” is selected as the method for

specifying the server.

name) for the POP3 server that is to be

used for receiving mail.

This setting is enabled only when “host

name” is selected as the method for specifying the server.

POP3 server that is to be used for receiving

mail.

This setting does not normally need to be

changed.

of the account used to send and receive email.

Only alphanumeric characters can be used.

If no account name is set, the portion of the

local e-mail address to the left of the @ will

be used. In this case, the number of characters in the account name is not restricted.

the account used to send and receive email.

Set the interval for sending and receiving

mail. Mail will be automatically sent and

received at the interval set here.

IP Address

0.0.0.0

None

0

(Number 110 is

used.)

None

None

0

(5 minutes)

1-4-3 DNS

6

The DNS server's settings must be entered when the POP3 server, SMTP

server, and SNTP server are specified with host names.

Page 31

Common Protocol Settings Section 1-4

The DNS server manages the IP addresses and host names of the nodes that

communicate in the network. The Ethernet Unit automatically acquires each

server's IP address from the DNS server and uses those acquired IP

addresses.

Item Contents Default

IP Address Set the IP address for the DNS server. None

Port No. Set the port to be used for connecting to the

DNS server. Normally, the default setting is

used.

Retry Timer Set the time to elapse before retrying when

a connection to the DNS server fails. Normally, the default setting is used.

Units: Seconds

Number of retries: Fixed at 3

0

(Number 53 is

used.)

0

(Sets 10 seconds.)

7

Page 32

Common Protocol Settings Section 1-4

8

Page 33

SECTION 2

Mail Send Function

This section provides an overview and describes how to use the Ethernet Unit’s Mail Send Function, including application

examples and troubleshooting information.

2-1 Mail Send Function Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-1-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-1-2 Comparison with the Earlier Mail Send Function . . . . . . . . . . . . . . 11

2-1-3 Mail Send Function's Compatibility with Earlier Models . . . . . . . . 11

2-2 Mail Send Function Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-2-1 Contents of E-mail Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2-2 Contents of E-mail Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-2-3 Attached File Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-2-4 Summary of E-mail Body Information and Attached Files . . . . . . . 16

2-3 Mail Send Function Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-3-1 Function Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-3-2 Details of the Available Mail Triggers . . . . . . . . . . . . . . . . . . . . . . . 18

2-4 Using the Mail Send Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-4-1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-4-2 Settings Required for the Mail Send Function . . . . . . . . . . . . . . . . . 19

2-4-3 Mail Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-4-4 Send Mail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-5 Mail Send Function Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-5-1 Send Mail Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-5-2 Mail Send Switch, Accessing Memory/Sending Mail Flag . . . . . . . 25

2-6 I/O Memory Data Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-7 Attached File Transfer Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2-8 Mail Send Function Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-8-1 Identifying and Correcting Mail Send Function Errors . . . . . . . . . . 28

2-8-2 Troubleshooting Mail Send Errors with LED Indicators . . . . . . . . . 29

2-8-3 Error Log Error Codes for the Mail Send Function . . . . . . . . . . . . . 29

2-9 Example Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-9-1 Step 1. Create the I/O Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-9-2 Step 2. Make the Unit Setup Settings from the CX-Programmer. . . 30

2-9-3 Step 3. Transfer the CPU Bus Unit Setup Settings. . . . . . . . . . . . . . 32

2-9-4 Step 4. Automatic Transmission when Send Condition is Satisfied. 32

9

Page 34

Mail Send Function Overview Section 2-1

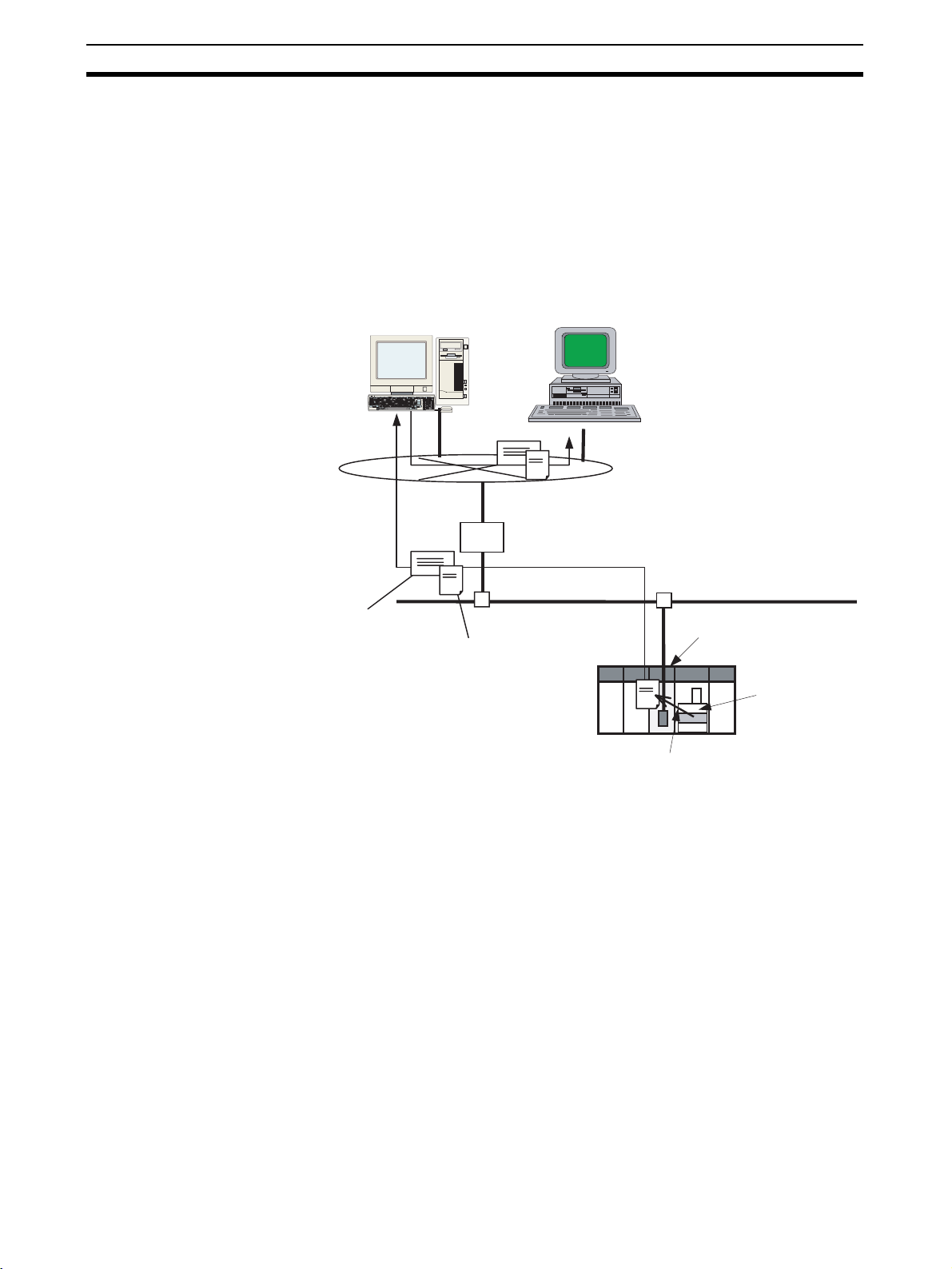

2-1 Mail Send Function Overview

2-1-1 Introduction

The Mail Send Function sends an e-mail from the Ethernet Unit to a specified

e-mail address when a predetermined condition occurs in the PLC.

Data in the CPU Unit's I/O memory areas (or any file in the Memory Card) can

be sent as an attached file.

In addition, user-set ASCII information as well as the Ethernet Unit's error log

and status information can be sent as text in the body of the e-mail.

Internet or

intranet

E-mail

Body: User

information,

error log, or

Unit status

SMTP server

User

E-mail

E-mail reception

Router

Sent automatically when

preset condition is met.

Ethernet

Ethernet Unit

Attached file:

Specified I/O memory

file in CPU Unit

I/O memory

The Ethernet Unit converts the

specified I/O memory data to a file.

Advantages A specific range of I/O memory data in the CPU Unit can be sent automati-

cally as an attached file (through the internet or intranet) when a particular

condition occurs. Some conditions that can be used are a bit turning ON to

indicate an error, a specified word containing a given value, or a periodic time

being reached.

E-mails can be sent when various conditions in the existing ladder program

are met. It is not necessary to modify the existing ladder program.

The Mail Send Function can be used to create various applications such as

error monitoring of remote equipment, periodic monitoring of equipment, and

quality control applications.

Description When a specified sending condition is met, the following e-mail body data and

attached files can be sent automatically as an e-mail to the e-mail address

specified in the CPU Bus Unit System Setup.

■ Body Data

Any desired combination of user-set information (any ASCII character string),

error log information, and status information can be sent.

10

Page 35

Mail Send Function Details Section 2-2

■ Attached Files

An I/O memory data file created automatically by the Ethernet Unit (a specified range of the CPU Unit's I/O memory data converted to a .IOM, .TXT, or

.CSV file) or any file in file memory (in the CPU Unit's Memory Card) can be

sent as an attached file.

■ Send Timing

An e-mail can be sent automatically when a dedicated control bit goes from

OFF to ON, a specified word's value meets a preset condition, a specified bit's

status changes, an entry is recorded in the Ethernet Unit's error log, the CPU

Unit's status changes (a non-fatal error occurs, a fatal error occurs, or the

operating mode changes), or at periodic intervals.

■ Send Mail Conditions

Up to 8 send mail conditions can be preset to send an e-mail automatically

when the specified conditions are met. Conditions include the send destination, trigger type, I/O memory addresses to be converted to a data file or the

name of the file to be read from file memory, and periodic sending interval.

2-1-2 Comparison with the Earlier Mail Send Function

Item Earlier version Current version

Model CS1W-ETN01/11

Attached file Not supported. Supported.

Send mail conditions

and CJ1W-ETN11

Any of the following:

A dedicated control

bit (the Mail Send

Switch) goes OFF to

ON, the status of the

Ethernet Unit

changes (an entry is

recorded in the error

log), periodic timer

CS1W/CJ1W-ETN21

A range of I/O memory data can be converted to a data file and attached, a file in a

Memory Card mounted in the CPU Unit can

be attached, or a file in the CPU Unit's EM

file memory can be attached.

Any of the following:

• A dedicated control bit (Mail Send Switch)

goes OFF-to-ON.

• A specified word's value changes (=, <>,

<, <=, >=, or > condition).

• A specific bit changes (OFF-to-ON or ONto-OFF).

• Ethernet Unit changes (entry in error log).

• CPU Unit changes (non-fatal error occurs,

fatal error occurs, or operating mode

changes).

• Periodic timer

2-1-3 Mail Send Function's Compatibility with Earlier Models

When a CS1W-ETN21 or CJ1W-ETN21 is used to replace a CS1W-ETN01/

11 or CJ1W-ETN11 Ethernet Unit in an application, the Unit's functions are

downwardly compatible if the following status bits are used.

ETN01/11 ETN21

User mail send status Status of send condition setting 5

Periodic mail send status Status of send condition setting 6

Error mail send status Status of send condition setting 7

2-2 Mail Send Function Details

The Mail Send Function can send information in the body of the e-mail as well

as in an attached file.

11

Page 36

Mail Send Function Details Section 2-2

2-2-1 Contents of E-mail Body

Date and time

Ethernet Unit's e-mail address

Date: Fri, 1 Jan 2004 13:00:00 +0900

From: alpha@omron.co.jp

Message-Id: <XXXXXXXXXXX@omron.co.jp>

To: beta@omron.co.jp

Subject: OMRON Ethernet Unit Mail Service (posted at regular intervals)

Content-Type: text/plain; charset=US-ASCII

Content-Transfer-Encoding: 7bit

Header

Trigger Setting Number = 1

This is OMRON ethernet unit mail posting service.

This mail have been posted at regular intervals.

======================================================================

Ethernet Unit Identification

======================================================================

Model : CS1W-ETN21

Version : VX.XX

IP address : XXX.XXX.XXX.XXX

Subnet mask : XXX.XXX.XXX.XXX

IP conversion : Table used

======================================================================

User Message

======================================================================

TEST MAIL.

======================================================================

Error Log Information

======================================================================

MM/DD/YY HH:MM:SS Error Detail Description

-------- -------- ---- ---- -----------------------------------03/05/29 12:00:00 0006 0000 CPU unit error

03/05/29 12:30:00 0121 0101 Destination IP address not registered

======================================================================

Status Information

======================================================================

*Error Status

IP router table error : OFF

IP address setting error : OFF

IP address table error : OFF

Routing table error : OFF

Address mismatch : OFF

EEP-ROM error : OFF

Body

POP server error : OFF

SMTP server error : OFF

SNTP server error : OFF

DNS server error : OFF

----------------------------------------------------*UDP Socket Connection Status

UDP Socket No.1 connection status : Opened

UDP Socket No.2 connection status : Closed

UDP Socket No.3 connection status : Closed

UDP Socket No.4 connection status : Closed

UDP Socket No.5 connection status : Closed

UDP Socket No.6 connection status : Closed

UDP Socket No.7 connection status : Closed

UDP Socket No.8 connection status : Closed

----------------------------------------------------*TCP Socket Connection Status

TCP Socket No.1 connection status : Established

TCP Socket No.2 connection status : Closed

TCP Socket No.3 connection status : Closed

TCP Socket No.4 connection status : Closed

TCP Socket No.5 connection status : Closed

TCP Socket No.6 connection status : Closed

TCP Socket No.7 connection status : Closed

TCP Socket No.8 connection status : Closed

----------------------------------------------------*Number Information

Total number of receive packets : 123,456

Total number of receive errors : 0

Total number of send packets : 234,567

Total number of send errors : 0

Total number of send collisions : 0

Destination e-mail address

Title (depends on trigger condition)

Content-Type (fixed)

Trigger number (required)

Trigger information (required)

Ethernet Unit model (required)

Unit version (required)

Ethernet Unit IP address (required)

User-set information (optional)

Error log information (optional)

Status information (optional)

12

Attached file

Page 37

Mail Send Function Details Section 2-2

2-2-2 Contents of E-mail Body

Ethernet Unit's Status

Information Header

The following header information is included.

• Subject: OMRON Ethernet Unit Mail Service

(Indicates trigger condition. See

note.)

• Content-Type: text/plain;charset=US-ASCII

• Content-Transfer-Encoding:7bit

Note The following trigger conditions are available.

Trigger condition Text entered as subject

Software switch posted by user request

Change in specified

word's contents

Change in specified

bit

Change in ETN Unit posted at error occurrence

Change in CPU Unit posted at changing CPU mode

Periodic timer posted at regular intervals

posted at changing channel value(= flag)

posted at changing channel value(<> flag)

posted at changing channel value(< flag)

posted at changing channel value(<= flag)

posted at changing channel value(>= flag)

posted at changing channel value(> flag)

posted at rising edge of bit

posted at falling edge of bit

posted at CPU error occurrence(FAL)

posted at CPU error occurrence(FALS)

Trigger Information The trigger information is always included in the e-mail.

• Trigger number: 1 to 8

• Shared message: “This is OMRON ethernet unit mail posting

service.”

• Trigger-specific messages: The following messages are displayed.

Tri gge r

condition

Software switch This mail have been posted by user request

Change in

specified word's

contents (See

note.)

Change in

specified bit's

status

Change in ETN

Unit

This mail have been posted at changing channel value(=

flag)

This mail have been posted at changing channel value(<>

flag)

This mail have been posted at changing channel value(<

flag)

This mail have been posted at changing channel value(<=

flag)

This mail have been posted at changing channel value(>=

flag)

This mail have been posted at changing channel value(>

flag)

This mail have been posted at rising edge of bit

This mail have been posted at falling edge of bit

This mail have been posted at error occurrence

Trigger-specific message in e-mail header

13

Page 38

Mail Send Function Details Section 2-2

Tri gge r

condition

Change in CPU

Unit

Periodic timer This mail have been posted at regular intervals

This mail have been posted at changing CPU mode (PRG>MON)

This mail have been posted at changing CPU mode (PRG>RUN)

This mail have been posted at changing CPU mode (MON>PRG)

This mail have been posted at changing CPU mode (MON>RUN)

This mail have been posted at changing CPU mode (RUN>PRG)

This mail have been posted at changing CPU mode (RUN>MON)

This mail have been posted at changing CPU mode

(PowerON->PRG)

This mail have been posted at changing CPU mode

(PowerON->MON)

This mail have been posted at changing CPU mode

(PowerON->RUN)

This mail have been posted at CPU error occurrence(FAL)

This mail have been posted at CPU error occurrence(FALS)

Trigger-specific message in e-mail header

Note Another sentence will be attached indicating how the specified

word's value has changed: “Channel data has changed from XX to

XX.”

Ethernet Unit Information The Ethernet Unit information is always included in the e-mail.

• Model

• Version

• IP address (decimal notation)

• Subnet mask (decimal notation)

• IP address conversion method

Optional Information The optional information that can be included in the e-mail body is listed

below.

Different information can be selected with each mail trigger, and more than

one type of information can be selected. (The selections are specified in the

CPU Bus Unit System Setup.) If no optional information is selected, the e-mail

will not be sent even when the trigger condition is met.

■ User-set Information

User-set information is ASCII text set by the user in the CPU Unit's memory.

Up to 1,024 bytes of data can be sent from the user-set mail data address set

in the CPU Bus Unit Area.

Note (a) The user-set message sent in each e-mail can be changed just

by changing the contents of the relevant words in the CPU Bus

Unit Area. To change the user-set message easily, prepare several messages in advance and copy the desired message to the

CPU Bus Unit Area when it is required.

The data set by the user is sent just as it is, and the code is not

converted.

(b) If there is a null code character (00 Hex) in the data, only the data

up to that point will be sent.

(c) The user-set data is sent as-is and the codes are not converted.

14

Page 39

Mail Send Function Details Section 2-2

■ Error Log Information

The error log information includes all of the data stored in the Ethernet Unit's

error log. The error log can contain up to 64 records. For details on the error

log, refer to 8-3 Error Log in the Operation Manual Construction of Networks

(W420).

■ Status Information

The following Ethernet Unit data is sent.

1. Open/closed status of UDP sockets 1 to 8

2. TCP status of TCP sockets 1 to 8

3. Unit error information

4. Counter information

Total number of receive packets, total number of receive errors, total number of send packets, total number of send errors, total number of send collisions

2-2-3 Attached File Details

Files that can be attached to e-mails are broadly divided into the following 2

groups.

• I/O memory data (IOM, TXT, and CSV formats)

• File data

Only one file can be attached to each e-mail.

I/O Memory Data (6,000

Words Max.)

Sends e-mail.

Ethernet

When it is time to send the e-mail, the Ethernet Unit reads the specified

amount of data starting at the specified I/O memory address in the CPU Unit,

creates a file with that data, and sends the file with the e-mail as an attachment.

Files can be created with filename extension “.IOM”, “.TXT”, or “.CSV”. These

are CS/CJ Series file memory function files.

Extension Content

.IOM This is a binary file containing the specified number of words starting at

.TXT This is a tab-delimited text file containing the specified number of words

.CSV This is a comma-delimited text file containing the specified number of

One area (Example: DM)

Start word: D00100

End word: D00119

the specified address. The words must be in the same data area.

starting at the specified address. The words must be in the same data

area.

words starting at the specified address. The words must be in the same

data area.

Data when send condition

is established.

Example

I/O memory

Data size:

E.g., 20

E-mail

D00100 1 2 3 4

D00101 5 6 7 8

D00102 9 A B C

to to

Automatically created by Ethernet Unit

Example: CSV file

Specified amount of comma-separated data

starting from the specified starting word

1234,5678,9ABC

Data file:

Example: DATA0.CSV

Sent as an attached file.

15

Page 40

Mail Send Function Details Section 2-2

• Since the Ethernet Unit creates the data file automatically, the Accessing

Memory/Sending Mail Flag (bit 01 of n+17 in the allocated CPU Bus Unit

Area) will be ON while the CPU Unit's I/O memory is being accessed.

• To maintain the integrity of the data, write-protect the region of I/O memory being converted to a data file by preventing the region from being written from the ladder program while this flag is ON.

File Data (1 MB Max.) Any file stored in the Memory Card installed in the CPU Unit (root directory

MEMCARD) can be sent with the e-mail as an attached file.

Sends e-mail.

Ethernet

Any file in the

Memory Card

Send any Windows file or a CS/CJ

format file such as a user program file

(.OBJ) or parameter file (.STD).

Memory Card

E-mail

Sent as an attached file.

• Generally, CS/CJ file memory files are attached, such as program files

(.OBJ), parameter files (.STD), and data files stored in the Memory Card

(.IOM, .TXT, or .CSV).

2-2-4 Summary of E-mail Body Information and Attached Files

Data sent Body/Attached file

E-mail body Attached file

User-set information ASCII text

(Set in the CPU Unit's I/O

memory by the user.)

Ethernet Unit's error

log

Ethernet Unit's status information

I/O memory data (up

to 6,000 words)

File data (Up to

1MB)

ASCII text

(Generated automatically by

the Ethernet Unit.)

ASCII text

(Generated automatically by

the Ethernet Unit.)

--- The Ethernet Unit automati-

--- Specify any file in the Memory

---

---

---

cally creates the data file

(.IOM, .CSV, or .TXT) when

the mail send condition (trigger setting) is established.

Card installed in the CPU

Unit.

16

Page 41

Mail Send Function Specifications Section 2-3

2-3 Mail Send Function Specifications

2-3-1 Function Specifications

Item Specifications

Destination e-mail address Up to 2 addresses can be registered in the Unit Setup (CPU Bus Unit System Setup) and

Subject Fixed text (Depends on the trigger condition.)

Body User-set information (up to 1,024 bytes), the Ethernet Unit's error log, and the Ethernet

Attached

file

Mail triggers The mail triggers can be selected in the Unit Setup (CPU Bus Unit System Setup).

Number of mail triggers Up to 8 triggers can be set and operated simultaneously.

Contents of send mail condi-

tion settings 1 to 8

Sending method

(encoding)

Encryption None

Compression None

Protocols used SMTP (port number 25: can be changed with the CX-Programmer Unit Setup)

Mail send status Transmission status information such as mail being sent, normal completion, and error

Data format Any one of the following files can be selected in the Unit Setup (CPU Bus Unit System

Data size • I/O memory data: Up to 6,000 words (The max. size is the same for all file types.)

Format MIME (version 1.0) format

Number of

attachments

the addresses can be up to 50 characters long.

Unit's status information can be included individually or in any combination.

Setup).

• I/O memory data

When the mail send condition is established, the data starting at the specified address in

the CPU Unit's I/O memory is automatically converted to a data file (.IOM, .TXT, or

.CSV) and sent as an attachment.

• File data

A Windows file with any filename extension

• File data: Up to 1 MB

Only 1 allowed

1. OFF to ON transition of a dedicated control bit (the Mail Send Switch)

2. Change in the value of a specified word (=, <>, <, <=, >=, or >)

3. Change in the status of a specified bit (OFF-to-ON or ON-to-OFF transition)

4. Change in the Ethernet Unit (event entered into the error log)