Omron CS1W-MC421, CS1W-MC221 DATASHEET

CS1W-MC421/-MC221

Motion control units

High-precision, motion controller with multitasking G-language programming

• High-speed control of up to 4 axes with one unit and

up to 76 axes with one PLC (19 units x 4 axes)

(assumes that power supply unit capacity is not

exceeded).

• Winding operations easily controlled at high-speed

using traverse positioning control.

• High-speed response to commands from CPU unit

(8 ms for 2 axes, 13 ms for 4 axes).

• Encoder response of 2 Mpps possible with 4x

frequency multiplication for applications with highspeed, high-precision servo motors.

• D interrupt code outputs to CPU unit at end of

positioning or at specified positions (D code output

time: 3.3 ms max.).

• CX-motion Windows-based support software

define user mnemonics to use in place of G codes

to simplify MC program development and analysis.

• Servo trace function from CX-motion to trace error

counter changes or motor speeds.

• Automatic loading function

MC programs and positioning data can be automatically downloaded from computer memory when

required by the MC unit.

Motion controllers

Function

The motion controller provides closed-loop motion control via an alog outputs for up to 4 axes, and supports the G language for

advanced, high-speed, high-precision position control. Multi-tasking allows you to run the axes independently for a wider range of

application.

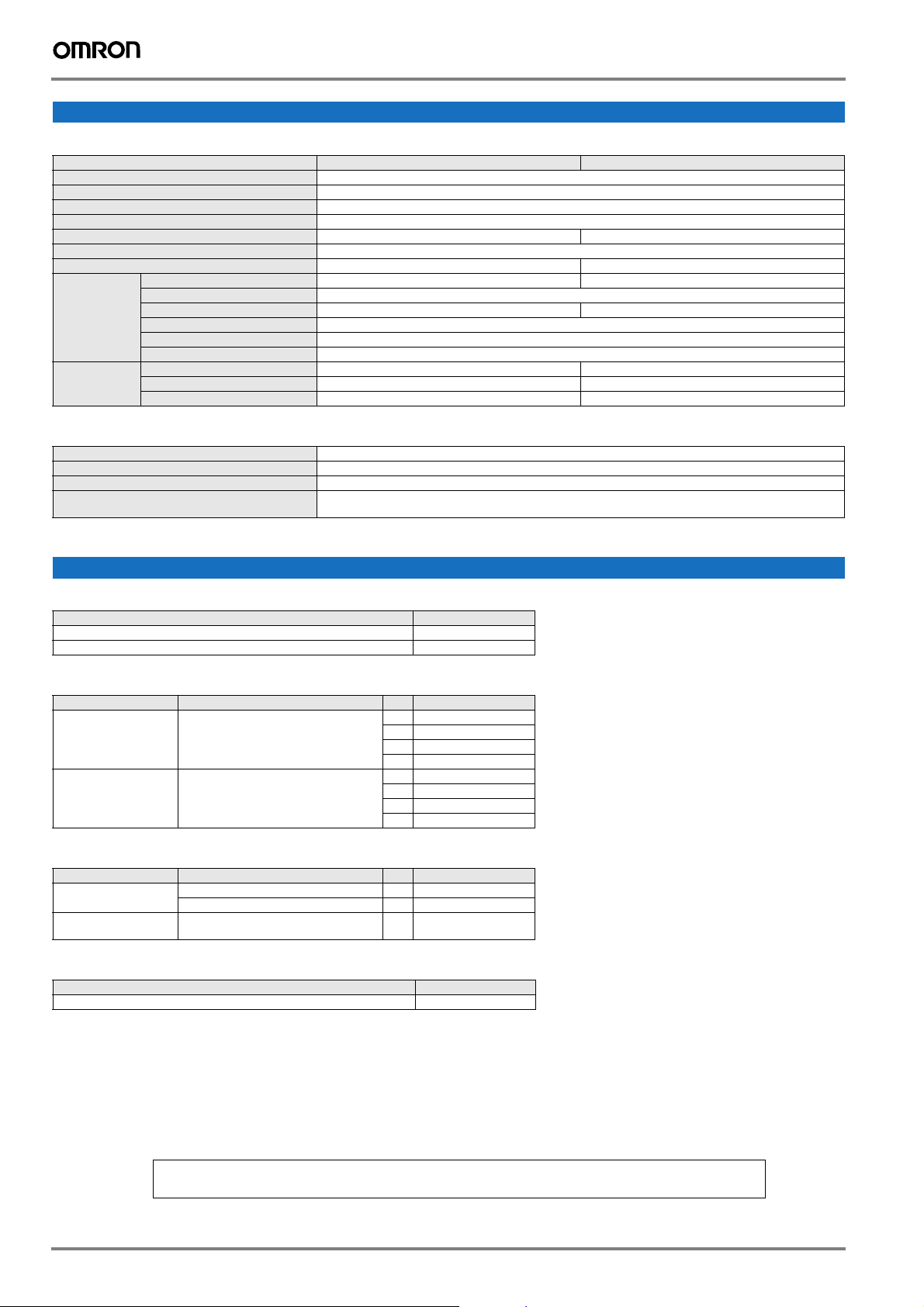

System configuration

Personal computer

Software: CX-One

CS1 series

Motion control unit

CS1W-MC_21

Input

Emergency stop input,

home and limit switches

Accurax G5

Servo drive

Terminal block

I/O signals

(CN1 connector)

Accurax G5

Servo motors

Accurax G5

Servo drive

I/O signals

(CN1 connector)

Accurax G5

Servo motors

45Motion control units

Specifications

General

Model CS1W-MC421-V1 CS1W-MC221-V1

Classification CS1 Special I/O unit

Control method Closed loop with automatic trapezoid or S-curve acceleration/deceleration

Control output signals Analog

Internal programming language G language (program started by command sent from CPU unit’s ladder program.)

Controlled axes 4 axes max. 2 axes max.

Maximum position value –39,999,999 to 39,999,999 (for minimum setting unit of 1)

Synchronous axis control 4 axes max. 2 axes max.

Positioning Linear interpolation 4 axes max. 2 axes max.

Task

programming

capacity

CX-Motion: Windows-based support software

Model WS02-MCTC1-EV@

Supported MC units CS1W-MC221/421, C200H-MC221, and CV500-MC221/421

Applicable computer DOS, OS: Windows 95/98 or Windows NT Version 4.0

Functions Functions required for MC unit control: creating/editing/saving/pr inting system parameters, positioning data,

Arc interpolation 2 axes max. in a plane

Helical interpolation 2-axis arc interpolation in a plane + feed axis ---

Traverse 2-axis traverse feeding

Infinite feed Infinite feeding of one or more axes

Interrupt feed Interrupt feeding for specified axes (positioning can be specified for when there is no interrupt.)

Number of tasks 4 tasks max. 2 tasks max.

Number of programs 25 programs when using 4 tasks 50 programs when using 2 tasks

Program capacity 500 blocks per task when using 4 tasks 1,000 blocks per task when using 2 tasks

and MC programs; monitoring MC unit operation

Ordering information

Motion control unit

Name Model

2 axes motion control unit. CS1W-MC221-V1

4 axes motion control unit. CS1W-MC421-V1

Accurax G5 servo drive cables

Description Connect to Model

Axis control cable

(1 axis)

Axes control cable

(2 axis)

I/O terminal block and cables

Description Connect to motion control unit Model

Terminal block CS1W-MC221 - XW2B-20J6-6

Cable form PLC unit to

terminal block.

Computer software

Specifications Model

CX-One CX-One

Motion control units

CS1W-MC221 (1 cable needed)

CS1W-MC421 (2 cables needed)

Motion control units

CS1W-MC221 (1 cable needed)

CS1W-MC421 (2 cables needed)

CS1W-MC421 - XW2B-40J6-7

CS1W-MC221

CS1W-MC421

1 m R88A-CPG001M1

2 m R88A-CPG002M1

3 m R88A-CPG003M1

5 m R88A-CPG005M1

1 m R88A-CPG001M2

2 m R88A-CPG002M2

3 m R88A-CPG003M2

5 m R88A-CPG005M2

1 m XW2Z-100J-F1

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. I06E-EN-03A

In the interest of product improvement, specifications are subject to change without notice.

46 Motion controllers

Loading...

Loading...