Page 1

Programmable Controller C200HS-series

Replacement Guide From C200HS to CS1

C200HS-CPU0□(-C)

C200HS-CPU2□

C200HS-CPU3□

CS1G-CPU42H

CS1G-CPU43H

P070-E1-0

Page 2

About this document

This document provides the reference information for replacing C200H PLC systems with CS1 series PLC.

This document does not i nc lud e prec aut io ns and reminders ;please rea d an d und e r s tand the important precautions

and reminders described on the manuals of PLCs (both of PLC used in the existing system and PLC you will use to

replace the existing PLC) bef ore attem pting to star t op eratio n.

Company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Page 3

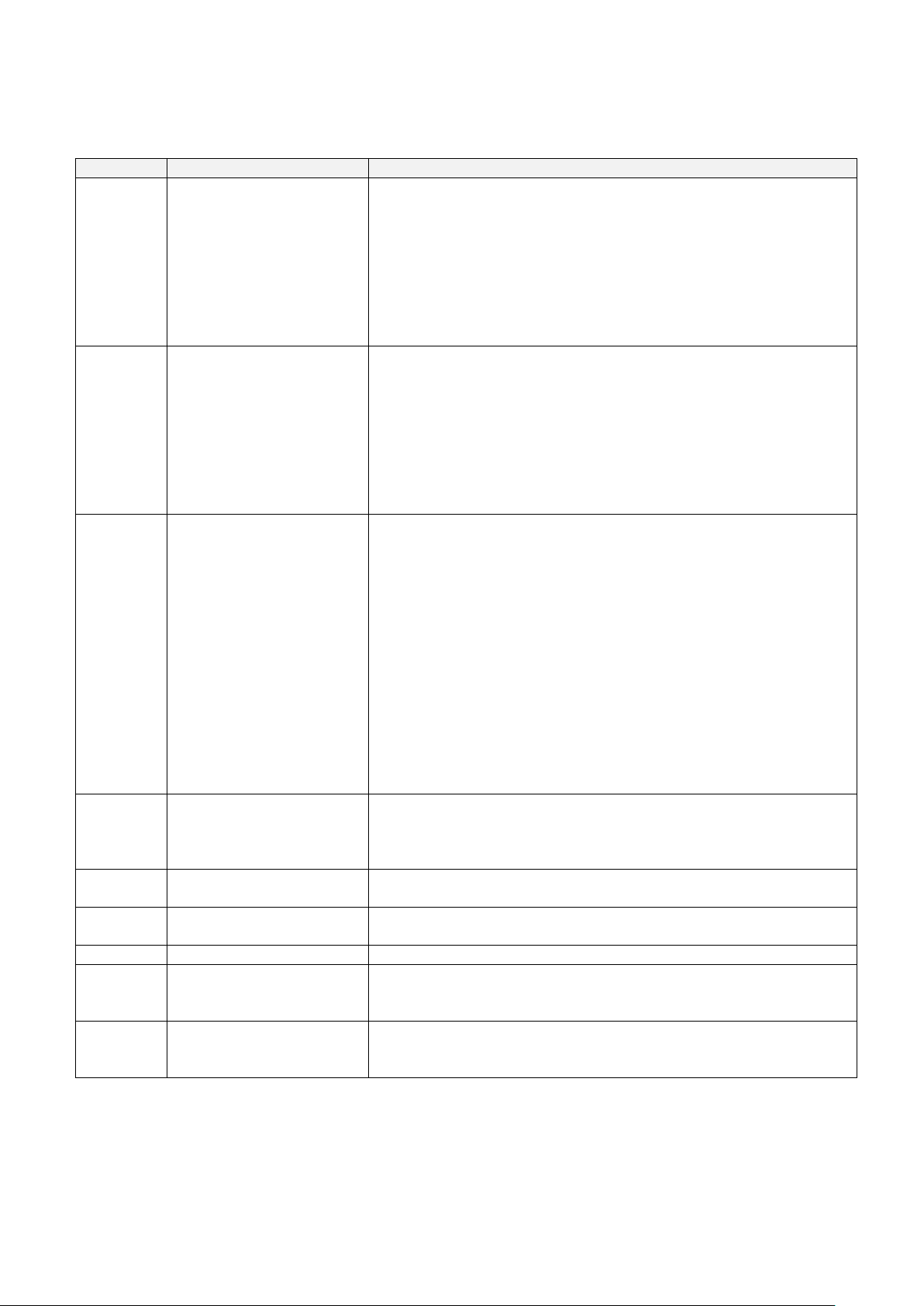

Related Manuals

Man.No.

Model

Manual

NSJ□-□□□□(B)-□□□

NSJ□-□□□□(B)-□□□

NSJ□-□□□□(B)-□□□

CS1W-KS001

CS1G/H-CPU□□-V1

-CPU□□/CPU□□-Z

W303

C200HX/HG/HE

SYSMACα OPERATION MANUAL

C200HE-CPU□□-ZE

3G8F5

CPU Unit s

W394 CS1G/H-CPU□□H

CS1G/H-CPU□□-V1

CS1D-CPU□□H

CS1D-CPU□□S

CJ1H-CPU□□H-R

CJ1G/H-CPU□□H

CJ1G-CPU□□P

CJ1M/G-CPU□□

W474 CS1G/H-CPU□□H

CS1G/H-CPU□□-V1

CS1D-CPU□□H

CS1D-CPU□□S

CJ1H-CPU□□H-R

CJ1G/H-CPU□□H

CJ1G-CPU□□P

CJ1M/G-CPU□□

W342 CS1G/H-CPU□□H

CS1G/H-CPU□□-V1

CS1D-CPU□□H

CS1D-CPU□□S

CS1W-SCU□□-V1

CS1W-SCB□□-V1

CJ1H-CPU□□H-R

CJ1G/H-CPU□□H

CJ1G-CPU□□P

CJ1M/G-CPU□□

CJ1W-SCU□□-V1

CP1H-X□□□□-□

CP1H-XA□□□□-□

CP1H-Y□□□□-□

CS/CJ/NSJ Series PROGRAMMING MANUA L

CS/CJ/NSJ Series INSTRUCTIO NS REFERENCE MANUAL

CS/CJ/CP/NSJ Series Communications Commands REFERENCE MAN UAL

W341 CQM1H-PRO01

CQM1-PRO01

C200H-PRO27

W339 CS1G/H-CPU□□H

W302 C200HX/HG/HE

W322 C200HX-CPU□□-ZE

C200HG-CPU□□-ZE

W227 CV500/CV1000

C200H/C1000H/C2000H/

CS/CJ Series Programming Consoles OPERATION MANUAL

CS Series OPERATION MANUAL

SYSMACα INSTALLATION GUIDE

SYSMACα OPERATION MANUAL

FINS Commands Reference Manual

Page 4

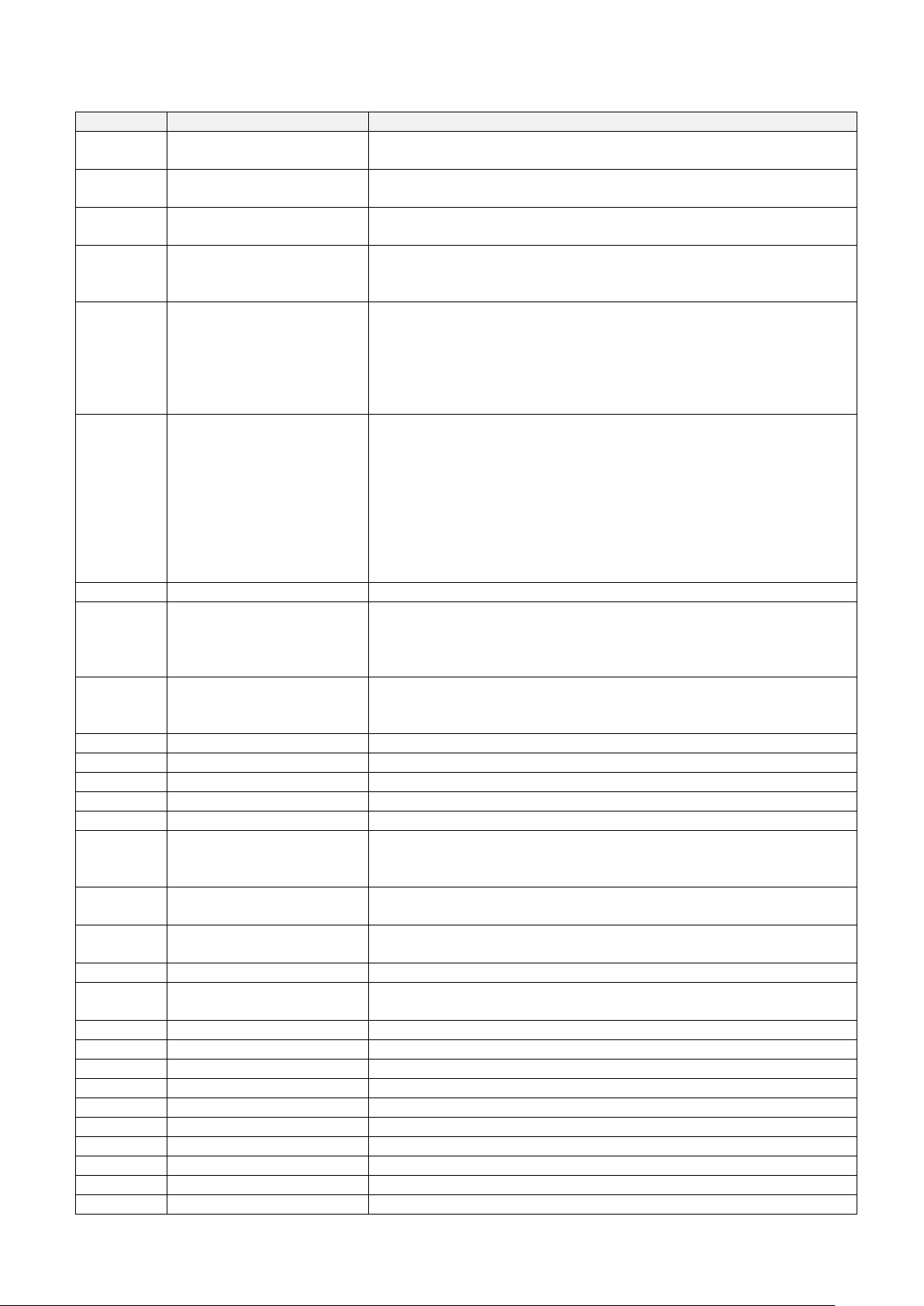

Special I/O Units

Man.No.

Model

Manual

CJ1W-NC□71(-MA)

CJ1W-MCH71

CJ1W-FLN22(100BASE-TX)

CJ1W-SCU□□-V1

CJ1W-MAD42

CJ1W-PH41U

W902

CS1W-CT021/041

CS Series High-speed Counter Units OPERATION MANUAL

CS1W-HCA12-V1

CS1W-HCA22

W376

CS1W-NC□□□

CS Series Position Control Units OPERATION MANUAL

W359

CS1W-MC□□□-V1

CS Series Motion Control Units OPERATION MANUAL

W124

C200H-TS001/002/101/102

C200H Temperature Sensor Units OPERATION MANUAL

W127

C200H-AD001/-DA001

C200H Analog I/O Units OPERATION GUIDE

W229

C200H-AD002/-DA002

C200H Analog I/O Units OPERATION MANUAL

C200H-MAD01

C200H-TC101/102/103

C200H-TV101/102/103

W241

C200H-PID01/02/03

C200H PID Control Unit OPERATION MANUAL

C200H-CT002

W311

C200H-CT021

C200H High-speed Counter Units OPERATION MANUAL

W224

C200H-CP114

C200H Cam Positioner Units OPERATION MANUAL

W334

C200HW-NC113/213/413

C200HW Position Control Units OPERATION MANUAL

W137

C200H-NC111

C200H Position Control Units OPERATION MANUAL

W128

C200H-NC112

C200H Position Control Units OPERATION MANUAL

W166

C200H-NC211

C200H Position Control Units OPERATION MANUAL

W314

C200H-MC221

C200H Motion Control Units OPERATION MANUAL:INTRODUCTION

W315

C200H-MC221

C200H Motion Control Units OPERATION MANUAL:DETAILS

W165

C200H-ASC02

C200H ASCII Units OPERATION MANUAL

W306

C200H-ASC11/21/31

C200H ASCII Units OPERATION MANUAL

W426 CS1W-NC□71

W435 CS1W-MCH71

W440 CS1W-FLN22

W336

W345 CS1W-AD0□□-V1/-AD161

W368 CS1W-PTS□□

CS1W-SCB□□-V1

CS1W-SCU□□-V1

CS1W-DA0□□

CS1W-MAD44

CJ1W-AD0□□-V1/-AD042

CJ1W-DA0□□/-DA042V

CS1W-PTW□□

CS1W-PDC□□

CS1W-PTR□□

CS1W-PPS□□

CS1W-PMV□□

CJ1W-PTS□□

CJ1W-PDC□□

CS/CJ Series Position Control Un it s OPE RATION MANUAL

CS/CJ series Motion Control Units OPERATION MANUAL

CS/CJ Series FL-net Units OPERATION MANUAL

CS/CJ Series Serial Communications Boards S eri al Communications Units

OPERATION MANUAL

CS/CJ Series Analog I/O Units OPERATION MANUAL

CS/CJ Series Analog I/O Units OPERATION MANUAL

W378

W384 CS1W-HIO01

W325 C200H-AD003

W225 C200H-TC001/002/003

W240 C200H-TV001/002/003

W141 C200H-CT001-V1

CS1W-HIO01-V1

CS1W-HCP22-V1

CS1W-HCA22-V1

CS1W-HCP22

C200H-DA003/-DA004

CS Series Customizable Counter Units OPERATION MANUAL

CS Series Customizable Counter Units PROGRAMMING MANUAL

C200H Analog I/O Units OPERATION MANUAL

C200H Temperature Control Units OPERATION MANUAL

C200H Heat/Cool Temperature Control Units OPERATION MANUAL

C200H High-speed Counter Units OPERATION MANUAL

Page 5

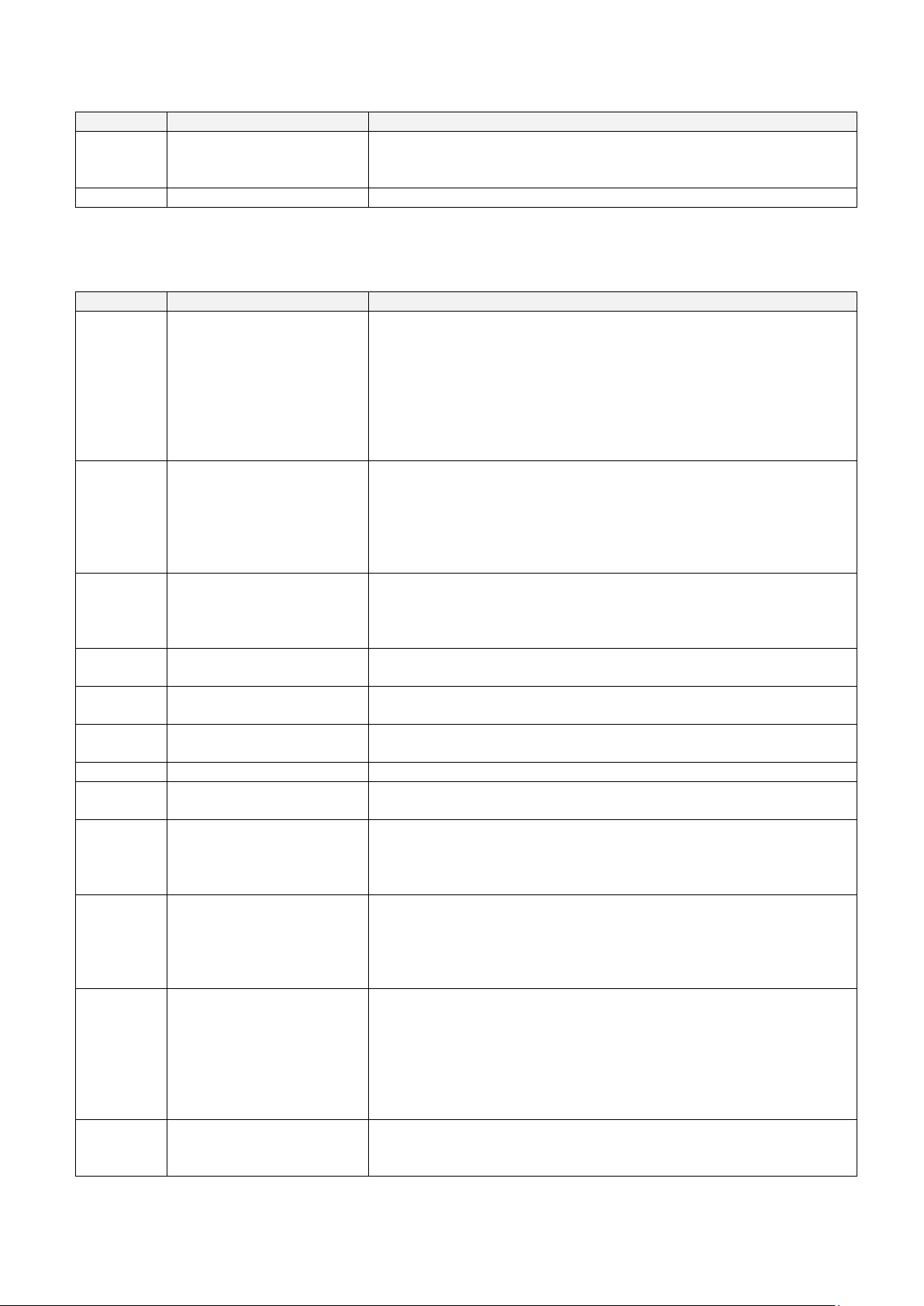

Man.No.

Model

Manual

C200HW-COM06-EV1

W257

CVM1-PRS71

Teaching Box OPERATION MANUAL

Man.No.

Model

Manual

CS1W-RPT0□

CVM1-CLK52(GI Cable)

CJ2M-CPU3□

CJ1W-ETN21 (100Base-TX)

CJ1W-ETN21(100Base-TX)

CJ1W-CRM21

W457

CRT1

CRT1 Series CompoNet Slave Units and Repeater Unit OPERATION MANUAL

CJ1W-DRM21

CVM1

SRT1/SRT2

B500-I/O

3G8F6-CLK21

W304 C200HW-COM01

C200HW-COM02-V1 to

Network Communications Units

W309 CS1W-CLK23

CS1W-CLK21-V1

CJ1W-CLK23

CJ1W-CLK21-V1

C200HW-CLK21

CVM1-CLK21

CQM1H-CLK21

W370 CS1W-CLK13

CS1W-CLK12-V1

CVM1-CLK12(H-PCF Cable)

CS1W-CLK53

CS1W-CLK52-V1

W465 CS1W-EIP21

CJ1W-EIP21

CJ2H-CPU6□-EIP

C200HW Communication Boards OPERATION MANUAL

Controller Link Units OPERATION MANUAL

Optical Ring Controller Link Units OPERATION MANUAL

CS/CJ Series EtherNet/IP Units OPERATION MANUAL

W420 CS1W-ETN21

W421 CS1W-ETN21

W456 CS1W-CRM21

W380 CS1W-DRM21-V1

W267 CS1W/CJ1W/C200HW

DRT1/DRT2

GT1

W266 C200HW-SRM21-V1

CS1W-SRM21

CJ1W-SRM21

CQM1-SRM21-V1

W136 C500-RM001-(P)V1

C120-RM001(-P)

C500-RT001/RT002-(P)V1

C500/C120-LK010(-P)

C200H-RM001-PV1

C200H-RT001/002-P

CS/CJ Series Ethernet Units OPERATION MANUAL Construction of Networks

CS/CJ Series Ethernet Units OPERATION MANUAL Construction of Applications

CS/CJ Series Comp oNet Mast er Unit s O PE RATION MANUAL

CS/CJ Series DeviceNet Units OPERATIO N MA NUAL

DeviceNet OPERATION MANUAL

CompoBus/S OPERATION MANUAL

C series Rack PCs Optical Remote I/O SYSTEM MANUAL

W308 C200HW-ZW3DV2/ZW3PC2

3G8F5-CLK11/21

Controller Link Support Software OPERATION MANUAL

Page 6

Man.No.

Model

Manual

S32-RS1

DRT1

Man.No.

Model

Manual

W463

CX-One FA Integrated Tool Package SETUP MANUAL

W446

CX-Programmer OPERATION MANUAL

W447

CX-Programmer OPERATION MANUAL : Function Blocks/Structured Text

W464

CX-Integrator OPERATION MANUAL

W344

CX-Protocol OPERATION MANUAL

W120 C500-RM201/RT201

C200H-RM201/RT201/202

G71-IC16/OD16

G72C-ID16/OD16

W379 CVM1-DRM21-V1

C200HW-DRM21-V1

W347 C200HW-DRT21

CQM1-DRT21

W135 C200H-LK401

C500-LK009-V1

Support Software

CXONE-AL□□C-V4

CXONE-AL□□D-V4

C series Rack PCs Wired Remote I/O SYSTEM MANUAL

DeviceNet Master Units OPERATION MANUAL

DeviceNet Slaves OPERATION MANUAL

C Series PC Link SYSTEM MANUAL

Page 7

MEMO

Page 8

Terms and Conditions Agreement

Warranties.

(a) Exclusive Warranty. Omron’s exclusive warranty is that the Products will be free from defects in

materials and workmanship for a period of twelve months from the date of sale by Omron (or such other

period expressed in writing by Omron). Omron disclaims all other warranties, express or implied.

(b) Limitations. OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED,

ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based on

infringement by the Products or otherwise of any intellectual property right.

(c) Buyer Remedy. Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the

form originally shipped with Buyer responsible for labor charges for removal or replacement thereof) the

non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be responsible

for warranty, repair, indemnity or any other claims or expenses regarding the Products unless Omron’s

analysis confirms that the P rod ucts were properly handled, st or ed, i nst all ed a nd m ain t ain ed and n ot s ubje c t

to contamination, abuse, misuse or inappropriate modification. Return of any Products by Buyer must be

approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or

unsuitability or the results from the use of Products in combination with any electrical or electronic

components, circuits, sy st em a sse mbl ie s or any ot h er m ater i a ls or su bst anc es or env ir o nm e nts. Any advic e,

recommendations or information given orally or in writing, are not to be construed as an amendment or

addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on which

liability is asserted.

Page 9

Suitability of Use.

Omron Companies shall not be responsible for conformity with any standards, codes or regulations which

apply to the combination of the Product in the Buyer’s application or use of the Product. At Buyer’s request,

Omron will provide applicable third party certification documents identifying ratings and limitations of use

which apply to the Product. This information by itself is not sufficient for a complete determination of the

suitability of the Product in combination with the end product, machine, system, or other application or use.

Buyer shall be solely responsible for determining appropriateness of the particular Product with respect to

Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products.

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or any

consequence thereof.

Performance Data.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for the

user in determining suitabil ity and doe s not con stitute a war ranty. It may represent the result of Omron ’s te st

conditions, and the user must correlate it to actual application requirements. Actual performance is subject

to the Omron’s Warranty and Limitations of Liability.

Change in Specifications.

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our pr a cti ce to ch ange par t nu mbers when published r at ing s or features are ch anged , or when

significant construction changes are made. However, some specifications of the Product may be changed

without any notice. When in doubt, special part numbers may be assigned to fix or establish key

specifications for your application. Please consult with your Omron’s representative at any time to confirm

actual specifications of purchased Product.

Errors and Omissions.

Information presented by Omr on Com panies has be en che cked an d is be lieved to be ac curat e; how ever, no

responsibility is assumed for clerical, typographical or proofreading errors or omissions.

Page 10

C200HS Replacement Gu ide

From C200HS to CS1

Table of Contents

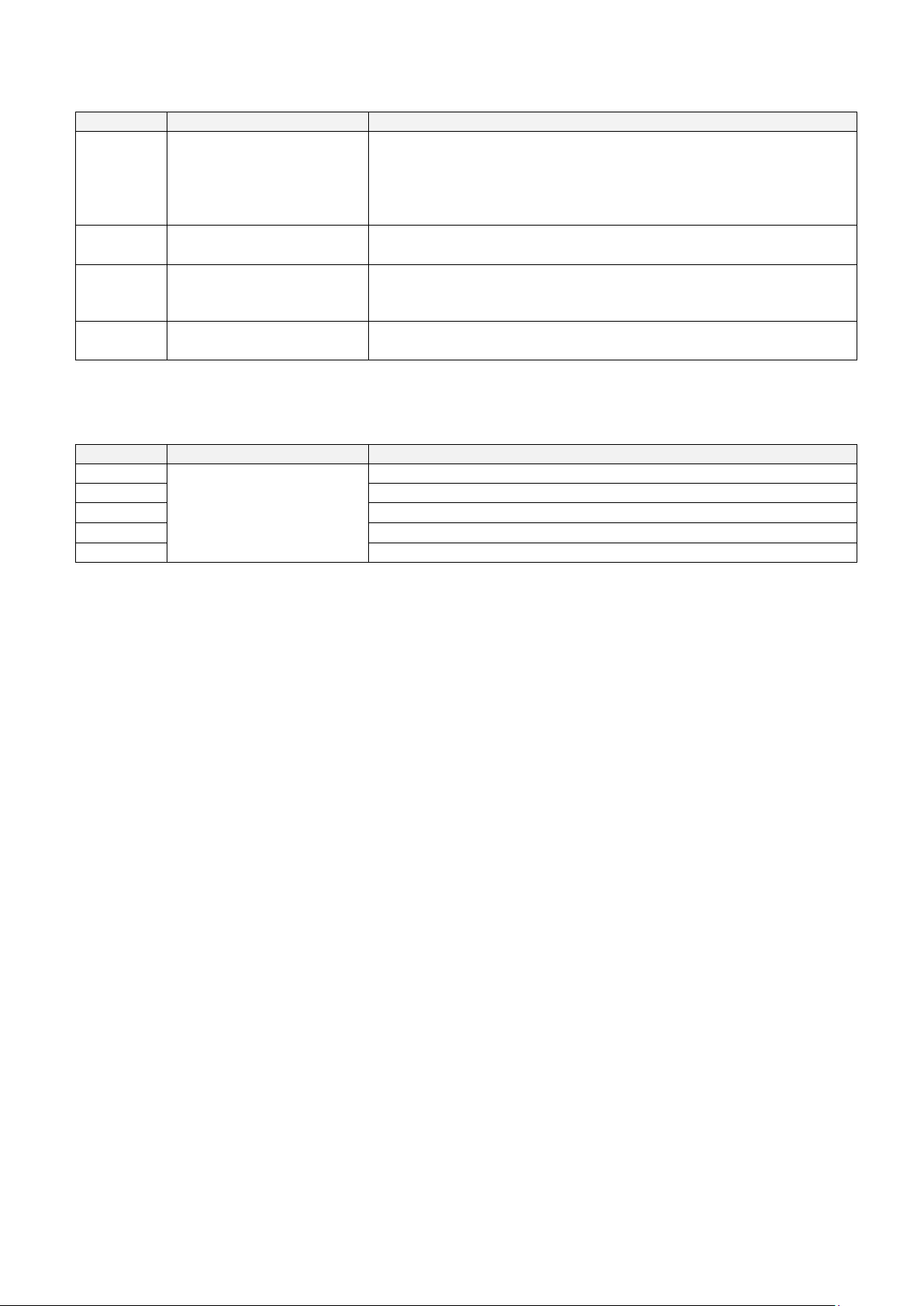

Work flow ......................................................................................................................................................................................................................... 2

1.

2. Selecting the replacement method ...................................................................................................................................................................... 3

3. Selecting the model .................................................................................................................................................................................................... 7

4. Reading data from C200HS .................................................................................................................................................................................. 11

5. Converting the program for CS1 ........................................................................................................................................................................ 13

6. Writing data to CS1 ................................................................................................................................................................................................. 15

7. Appendix ....................................................................................................................................................................................................................... 17

Appendix A. Instructions converted by Change Model on CX-Programmer ......................................................................................... 17

Appendix B. Change of unit area allocation ........................................................................................................................................................ 18

Appendix C. Change in PLC Settings .................................................................................................................................................................... 18

Appendix D. Change of execution timing etc. .................................................................................................................................................... 18

Appendix E. Table of Input/Output Units ............................................................................................................................................................ 19

1

Page 11

This replacement guide describes the procedure to rebuild the system which uses the C200HS-series PLC by

1. Work flow

Selecting the model

Reading PLC data

Description

Reference page

s

Select the units, programming software, and connecting

cables to replace C200HS with CS1.

Some C200HS-seires Units can be used with CS1. However,

some Units can

not be used with CS1. Read the reference

pages (recommended models and remarks) and sel ect the

models.

Load the program, I/O Memory and other settings from the

C200HS using the programming software and connecting

cable.

Converting and modifying data

Convert the data read from C200HS for CS1.

Most of the data can be automatically converted; however, some

instructions and some Unit data cannot be converted.

Refer to the reference pages and modify the data and program

separately.

3. Selecting the model

4. Reading data from C200HS

Preparing Units

Prepare the units, programming software

, and connecting

cables.

5. Converting the program for

CS1

Continue to actual replacement work

Start

Replacing Units

Writing the data to CS1

Description

Reference page

Install the prepared Units instead of C200H-series Units.

*Refer to the

CS1G/H-CPU□□H CS Series Programmable

Controllers OPERATION MANUAL (Cat. No. W339) and

user's manual

s for Special I/O U nit s and CPU Bu s Unit s for

details of installation.

Transfer the converted data to CS1.

To check the wiring, operate input and output bits to see if

they operate correctly.

Checking operation

Turn ON the power and check the operation.

Related Manuals

Wiring

Wiring for the installed Units.

*Refer to the CS1G/H

-CPU□□H CS Serie

s Programmable

Controllers OPERATION MANUAL (Cat. No. W339) and

user's manuals for S pec ial I/O Units and CPU Bus Units for

details of wiring.

6. Writing data to CS1

Replacement completion

1. If production is conducted between uploadin g the progr am a nd executing replacement

work, data handled by the program may change. If so, upload the data right before the

replacement work, modify data (if necessary), and download it to the new PLC.

2. The cycle time of C200HS and CS1 are different, which may affect system operation. If

so, it is necessary to adjust cycle time in the PLC Setup.

introducing the CS1-series PLC instead. The CS1-series PLC has functions which can replace the functions and

operation of the C200HS-series PLC. Follow the below work flow to replace your system. Refer to the reference

pages for details.

1) Preliminary Steps: Take the following steps before starting the replacement work.

2) Actual replacement work: Take the following steps to replace C200HS with CS1.

2

Page 12

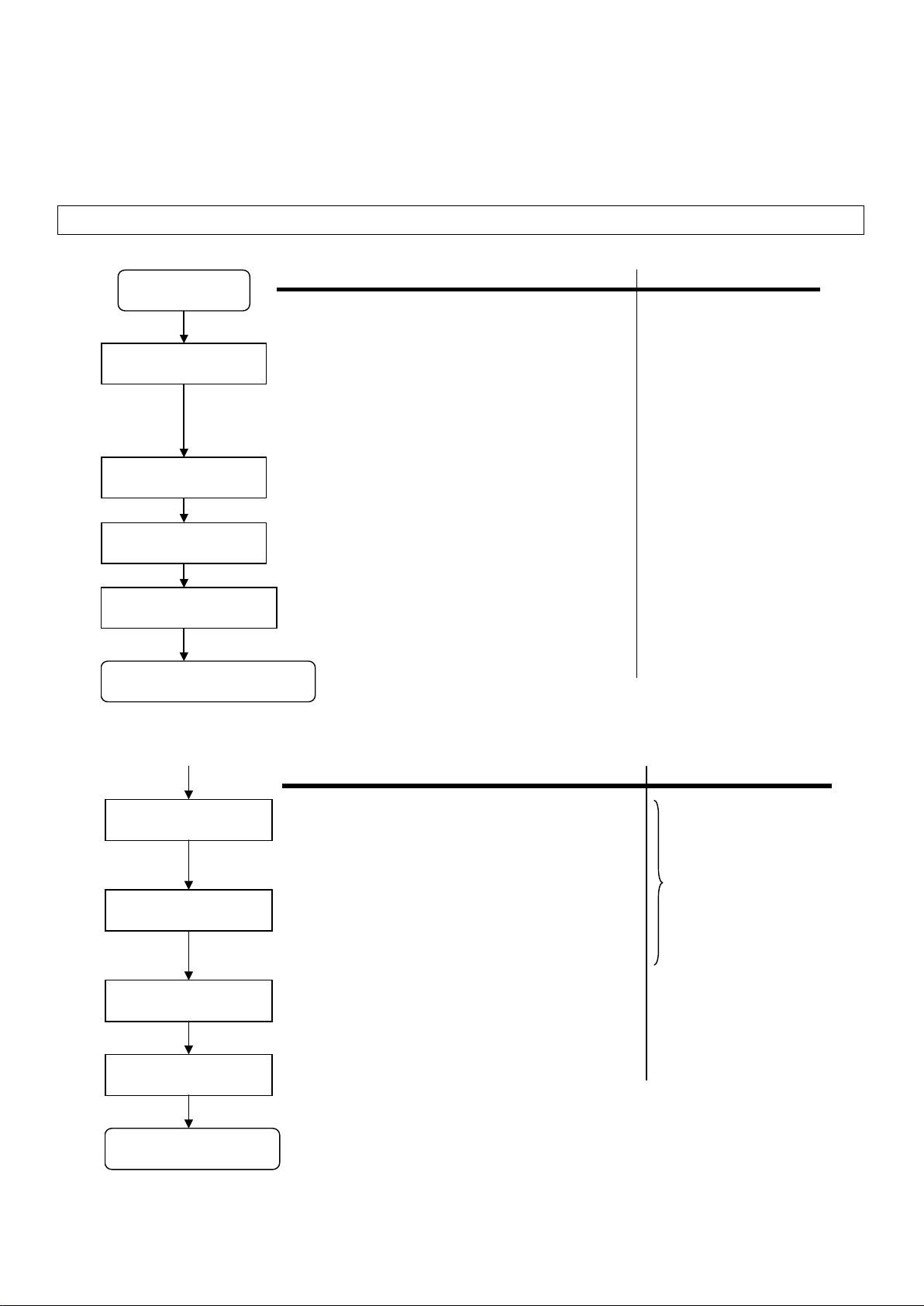

2. Selecting the replacement method

Replacement method

Description

CPU

PS

PS

CS1-series Units

CPU

PS

PS

CS1-series Units

Reusing existing

terminal blocks

Reusing existing

terminal blocks

C200H I/O Terminal Block Conversion Adapters (CS1W-AT2□□)

CPU

PS

CS1-series Units

CS1W-ID231

Conversion Cable

XW2Z-S010

Connecting cable

that was

connected to C200H

-ID215

(reuse)

CS1W-OD231

Conversion

Cable

XW2Z-S011

Connecting cable that was

connected to C200H-OD215

(reuse)

When C200H-series Basic I/O Units are replaced with CS1-series Basic I/O Units, rewiring is required. The C200H

I/O Terminal Block Conversion Adapter that allows the terminal block of the C200H-series Basic I/O Unit to be

reused for the CS1-ser ies Basic I/O Unit is availa ble. T his enables eff icient replacement by eliminating rewiring and

wiring check times.

(1) Replacing all

C200H-series Units

with CS1-series Units

(2) Using C200H I/O

Terminal Block

Conversion Adapters

(3) Using Conversion

Cables for C200H

High-density I/O Units

Replace all C200H-series Units with

CS1-series Units.

Cons: Rewiring of Basic I/ O Uni t s is required.

Reference It takes about 1 hour to rewire all

Basic I/O Units (8 t o 10 Uni t s) mounted to a

Backplane.

Replace all C200H-series Units with

CS1-series Units, and mount the C200H I/O

Terminal Block Convers i on A dapters to

CS1-series Units.

Pros: Rewiring of Basic I/O Units is not

required, which reduces replacement

time.

Cons: The inst al l ation depth is increased.

For details, refer to the C200H I /O Terminal

Block Conversion Adapter Data Sheet.

Replace C200H-ID215 with CS1W-ID231, and

connect CS1W-ID231 using the same

connecting cables used f or C200H-ID215.

In the same way, replace C200H-OD215 with

CS1W-OD231, and connec t CS1W-OD231

using the same cable us ed for C200H-OD215.

Pros: Rewiring of I/O Units is not required,

which reduces replacement ti me.

Note 1. Depending on the type of Basic I/O Unit, there may be some restrictions (e.g. change in I/O

specifications or wiring) or some models cannot be used.

2. When you reuse a terminal block with wiring, confirm that ther e is no problem in the term inal block and

wiring conditions.

• The screws are securely tightened.

• The cables are not damaged.

• There is no rust or corrosion.

• The terminal block is not damaged. (The terminal block is securely inserted and fixed.)

3

Page 13

• Image of replacement using C200H I/O Terminal Block Conversion Adapter

Wired terminal block of

C200H-series Basic I/O

Unit to be replaced

C200H I/O Terminal Block Conversion Adapter

CS1-series Basic I/O Unit

(CS1W-AT2

□□)

4

Page 14

• Replacement of C200H-ID215 and C200H-OD215 using Conversion Cables

C200H-series Unit

CS1-series Unit

Conversion Cable

C200H-ID215

CS1W-ID231

XW2Z-S010

C200H-OD215

CS1W-OD231

XW2Z-S011

Make sure that the connected device operates

correctly.

Make sure that the connected device operates

correctly.

Make sure that the connected device operates

correctly.

2.5 ms max./15 ms max.

(switchable)

2.5 ms max./15 ms max.

(switchable)

8 points/common x

4 circuits (32 inputs)

16 points/common x

2 circuits (32 inputs)

The number of circuits decreased from 4 to 2.

Rewire if separate power supplies are used.

8 points (when pin 2 of the

DIP switch is ON)

* CN1 COM0 and COM1 and

common power supply.

The same connecting c ables that were connected to C200H-ID215 and C200H-OD215 can be used to replace

them with CS1W-ID231 and CS1W-OD231.

XW2Z-S010

CN2 COM2 and COM3 are

internally connected in the

CS1W-ID231 C200H-ID215

Reused cable

CS1-series Unit. When

separate power supplies were

used, rewire to use one

C200H-ID215 CS1W-ID231 Remarks

Rated input voltage 24 VDC 24 VDC

Operating input voltage 20.4 to 26.4 VDC 20.4 to 26.4 VDC

Input impedance 5.6 kΩ 3.6 kΩ

Input current 4.1 mA typical (at 24 VDC) 6 mA typical (at 24 VDC)

ON voltage 14.4 VDC min. 15.4 VDC min.

OFF voltage 5 VDC max. 5 VDC max.

ON response time

OFF response time

No. of circuits

High-speed inputs

8 ms max. (switchable) Can be set to between 0 and 32 ms in the PLC Setup.

8 ms max. (switchable) Can be set to between 0 and 32 ms in the PLC Setup.

Not supported Use CS1W-IDP01 for high-speed inputs.

5

Page 15

XW2Z-S011

16 mA/4.5 VDC to

3.2 A/Unit

Make sure that the connected device operates

correctly.

Make sure that the connected device operates

correctly.

Make sure that the connected device operates

correctly.

8 points/common x

4 circuits (32 outputs)

16 points/common x

2 circuits (32 outputs)

The number of circuits decreased from 4 to 2.

Rewire if separate power supplies are used.

When protection is required, connect a protective

device externally.

5 to 24 VDC±10%,

2.8 mA x no. of ON outputs

* CN1 COM0 and COM1 and

common power supply.

CS1W-OD231 C200H-OD215

Reused cable

CN2 COM2 and COM3 are

internally connected in the

CS1-series Unit. When

separate power supplies were

used, rewire to use one

C200H-OD215 CS1W-OD231 Remarks

Rated voltage 5 to 24 VDC 12 to 24 VDC Use CS1W-MD561 when using 5 VDC.

Max. switching capacity

Leakage current 0.1 mA max. 0.1 mA max.

Residual voltage 0.7 V max. 1.5 V max.

ON response time 0.2 ms max. 0.5 ms max.

OFF response time 0.6 ms max. 1 ms max.

No. of circuits

Fuses 4 (1 fuse/common) None

External power supply

Dynamic outputs 30 mA min. Not supported Dynamic outputs are not supported.

100 mA/26.4 VDC

0.8 A/common,

90 mA min.

0.5 A/point,

2.5 A/common, 5 A/Unit

10.2 to 26.4 VDC

6

Page 16

3. Selecting the model

Outline of the system configuration

C200HS

PC

Expansion Backplane

CS1

PC

Expansion Backplane

SYSMAC Support Soft ware

CX-Programmer

CX-Programmer

Unit name

C200H-series Unit

CS1-series Unit

Description

CPU Unit

C200HS-CPU01

C200HS-CPU33

CS1G-CPU42H

UM 10K steps

CPU Unit-mounting

Host Link Unit

C200HS-CPU21/23/31/33

Built-in Host Link port

Power Supply Unit

(For

C200HS-CPU01/01-C/21/31)

C200HW-PA204

(AC Power Supply Unit)

To use RUN output, prepare an Output Unit

separately.

C200HW-PA204S

With 24 VDC service power supply.

separately.

C200HW-PA204C

(AC Power Supply Unit)

With replacement notification f unction.

C200HW-PA204R

(AC Power Supply Unit)

With RUN output.

C200HW-PA209R

(AC Power Supply Unit)

With RUN output.

(For C200HS-CPU03/23/33)

C200HW-PD024

(DC Power Supply Unit)

To use RUN output, prepare an Output Unit

separately.

C200HW-PD025

(DC Power Supply Unit)

To use RUN output, prepare an Output Unit

separately.

CPU Backplane

C200H-BC031(-□□)

C200H-BC101(-□□)

CS1W-BC033/BC032

CS1W-BC103/BC102

Respectively for 3, 5, 8, and 10 sl ots

The table below lists the C200H-series Units and each corresponding CS1-series Unit. Select the CS1-series Unit

which is compatible with the C200H-series Unit or which has similar specifications to the C200H-series Unit.

Refer to the CS1G/H-CPU□□H CS Series Progr ammable Controllers OPERATION MANUAL (Cat. No. W 339) for

details of the Units.

< CPU Rack >

C200HS-CPU01-C

C200HS-CPU03

C200HS-CPU21

C200HS-CPU23

C200HS-CPU31

C200H-BC051(-□□)

C200H-BC081(-□□)

CS1G-CPU43H

(AC Power Supply Unit)

CS1W-BC053/BC052

CS1W-BC083/BC082

UM 20K steps

Select the model depending on the ladder

program capacity.

To use RUN output, prepare an Output Unit

The mounting hole dimens i ons are the

same.

7

Page 17

< Memory Cassettes >

Unit name

C200H-series Unit

CS1-series Unit

Description

Memory Cassette

EEPROM Memory Cassette

None

The CS1-series CPU Unit has a nonvolati l e

Startup)

EPROM Memory Cassette

None

The CS1-series CPU Unit has a nonvolati l e

Startup)

Unit name

C200H-series Unit

CS1-series Unit

Description

Power Supply Unit

C200H-PS221

C200HW-PA204

(AC Power Supply Unit)

C200HW-PA204C

(AC Power Supply Unit)

With replacement notification f unction.

C200HW-PA204S

(AC Power Supply Unit)

With 24 VDC service power supply.

C200HW-PA204R

(AC Power Supply Unit)

The RUN output does not operate.

C200HW-PA209R

(AC Power Supply Unit)

The RUN output does not operate.

C200H-PS211

C200HW-PD024

(DC Power Supply Unit)

C200HW-PD025

(DC Power Supply Unit)

Backplane

C200H-BC031(-□□)

C200H-BC101(-□□)

CS1W-BI033/BI032

CS1W-BI103/BI102

Respectively for 3, 5, 8, and 10 sl ots

Connecting Cable for

C200H-CN□□1

CS1W-CN□□3

Connects a CS1-series Expansion

CS1-series Expansion Backplane.

CS1W-CN□□1

Connects a C200HW-BI□□1-V2 Expansion

CS-series Expansion Backplane.

< Expansion Rack >

C200HS-ME16K

C200HS-MP16K

C200H-PS221-C

(Complying with EC Directive)

memory for user program i n i t . The Memory

Unit is not required.

It also has the cloc k function. The program

file and the parameters are stored in the

memory card. It i s possible to execute

operation by reading them when the PLC is

turned ON. (Automatic F i l e T rans fer at

memory for user program i n i t . The Memory

Unit is not required.

It also has the cloc k function. The program

file and the parameters are stored in the

memory card. It i s possible to execute

operation by reading them when the PLC is

turned ON. (Automatic F i l e T rans fer at

(Expansion Backplane)

Expansion Backplane

C200H-BC051(-□□ )

C200H-BC081(-□□)

CS1W-BI053/BI052

CS1W-BI083/BI082

The mounting hole dimens i ons are the

same.

Backplane to a CPU Backpl ane or another

I/O Backplane to a CPU Backplane or

8

Page 18

< I/O Units and CPU Bus Units>

Unit name

C200H-series Unit

CS1-series Unit

Description

Basic I/O Unit

C200H-I□□□

C200H-I□□□

C200H-series Basic I/O Units can be used

instead.

Special I/O Unit

C200H-□□□□

C200H-□□□□

C200H-series Special I/O Uni t s can be used

instead.

Communication Unit

[SYSMAC LINK]

[SYSMAC LINK]

C200HW-SLK□□ cannot be used with the

No. W370) for details.

[SYSMAC NET]

[SYSMAC NET]

SYSMAC NET cannot be used with t he

No. W370) for details.

[Host Link]

[Serial Communic ations]

C200H-series Host Link Units cannot be

MANUAL (Cat. No. W336) for details.

C200H-LK101-PV1

None

(+ optical link modul e)

The CS1 Series does not have an

use an external optical link m odul e.

C200H-LK201-V1

CS1W-SCU21-V1

CPU Unit

Use one of the left CS1-series Units/Boards.

C200H-LK202-V1

CS1W-SCU31-V1

CS1W-SCB41-V1

Use one of the left CS1-series Units/Boards.

[PC Link]

[PC Link]

The PC Link Unit can be used with the

No. W370) for details.

C200H-O□□□

C200H-M□□□

Coaxial:

C200H-SLK21-V1

C200HS-SLK22

C200HW-SLK23/24

Optical:

C200H-SLK11

C200HS-SLK12

C200HW-SLK13/14

C200H-SNT31

C200HS-SNT32

C200H-O□□□

C200H-M□□□

or,

CS1W-I□□□

CS1W-O□□□

CS1W-M□□□

or

CS1W-□□□□

Coaxial: CS1W-SLK21

Optical: CS1W-SLK11

or

[Controller Link]

Wired: CS1W-CLK23

Optical: CS1W-CLK13/53

None

[Controller Link]

Wired: CS1W-CLK23

Optical: CS1W-CLK13/53

with CS1-series CPU Units.

Refer to Appendix E. Table of I nput/Output

Units for CS1-series Basic I/O Units

corresponding to C200H-series Basic I/O

Units.

To facilitate m ai nt enance, we recommend

you to use CS-series Basic I/O Units

with CS1-series CPU Units. However, there

are some remarks t o be f ol l owed.

To improve the system performance and to

facilitate mai ntenance, we recommend you

to use the CS-series Speci al I/O Units

CS1-series CPU Unit.

Refer to the SYSMAC CS1W-SLK11/21

SYSMAC LINK Units OPERATION MANUAL

(Cat. No. W367) for det ai l s about SYSMAC

LINK.

We recommend you to use Controller Link

instead.

Refer to the Controller Link Units Operation

Manual (Cat. No. W309) and Optical Ring

Controller Link Units Operation M anual (Cat.

CS1-series CPU Unit.

We recommend you to use Controller Link

instead.

Refer to the Controller Link Units Operation

Manual (Cat. No. W309) and Optical Ring

Controller Link Units Operation M anual (Cat.

C200H-LK401

CS1W-SCU21-V1

CS1W-SCB21-V1

CS1W-SCB41-V1

Host Link port built in the

C200H-LK401

[Controller Link]

Wired: CS1W-CLK23

Optical: CS1W-CLK13/53

used with the CS1-series CPU Uni t.

Refer to the SYSMAC CS/CJ Series Serial

Communications Boards/Units OPERATION

Optical-type Serial Communications

Board/Unit. Use the wired type inst ead or

CS1-series CPU Unit. However, the Link

Area allocation must be changed.

We recommend you to use Controller Link

instead.

Refer to the Controller Link Units Operation

Manual (Cat. No. W309) and Optical Ring

Controller Link Units Operati on M anual (Cat.

9

Page 19

< I/O Units and CPU Bus Units>

Unit name

C200H-series Unit

CS1-series Unit

Description

Communication Unit

[SYSMAC BUS]

[SYSMAC BUS]

SYSMAC BUS can be used with the

No. W266) for details of CompoBus/S.

Unit name

C200H-series Unit

CS1-series Unit

Description

Support Software

SYSMAC C-series Ladder

CX-Programmer

CX-One

higher)

SYSMAC Support Software cannot be used

Peripheral Interface

Unit, Connecting Cable

CQM1-CIF02

CS1W-CN226/626

Programming Console

C200H-PRO27

(+C200HS-CN222 attached)

C200H-PRO27

CS1W-CN□□4 is a Programming Console

Wired: C200H-RM201

Optical: C200H-RM001-PV1

< Support Software and Peripheral Devices >

Support Software

C500-SF610-V6 (5 inches)

C500-SF410-V6 (3.5 inches)

Wired: C200H-RM201

Optical:

C200H-RM001-PV1

[CompoNet]

CS1W-CRM21

[DeviceNet]

CS1W-DRM21-V1

[CompoBus/S]

CS1W-SRM21

CXONE-AL□□C-V□/AL□□DV□

(CX-Programmer Ver3.0 or

CS1-series CPU Unit. However, area

allocation must be changed.

To improve the system performance and to

facilitate mai ntenance, we recommend you

to use left networks inst ead.

Refer to the CS/CJ series CompoNet M as ter

Units OPERATION MANUAL (Cat. No.

W456) and CompoNet Slave Units and

Repeater Unit OPERAT ION MANUAL (Cat.

No. W457) for details of CompoNet.

Refer to the

CS1W-DRM21(-V1),CJ1W-DRM21 CS/CJ

SERIES DeviceNet UNITS OPERATION

MANUAL (Cat. No. W380) for details of

DeviceNet.

Refer to the

C200HW/CS1W/CJ1W/CQM1/SRT1/SRT2

CompoBus/S OPERATION MANUAL (Cat.

with the CS1-series CPU Unit.

Other remarks

(1) The CS1-series CPU Unit is separated from the Power Supply Unit although the C200HS-series CPU Unit

is combined with the Power Supply Unit. The two series use different CPU Backplanes. However, the

mounting hole positions are the same.

(2) The PFP-50N/100N/100N2 DIN Track and C200H-DIN01 Mounting Bracket can be used for the CS1-series

Backplane.

(3) The CS1-series Backplane has an installation structure to be insulated from the control panel. The

C200HW-ATT31/51/81/A1 Insulation Plate for CPU Backplane is not required.

(4) The I/O Unit Mounting Bracket c annot be used with the CS1-series Backplane. CS1-series Units can be

secured with screws. They do not require brackets.

(+C200H-CN222/422)

(+C200HS-CN222/422)

CQM1-PRO01

(+CS1W-CN□□4)

CQM1-PRO01

(+CS1W-CN114)

Connecting Cable.

A cassette interface cannot be used.

10

Page 20

4. Reading data from C200HS

Load the ladder program, PLC settings, and Data Memory from C200HS using the CX-Programmer.

Required items

Support Software

CX-One

CX-Programmer (WS02-CXPC□-V□)

Connecting Cable

CQM1-CIF02

C200HS

PC

CX

-Programmer

Connecting Cable

CQM1-CIF02

Connector for programmin g device

(PC)

(CXONE-AL□□C-V□, CXONE-AL□□D-V□)

or

(1) Connect C200HS and a PC using a connecting cable.

(2) Start up the CX-Programmer. (Select All Prog ram - OMRON - CX-One - CX-Programmer - CX-Programmer

from the Windows Start Menu.)

(3) Select C200HS for the Device Type. (Select New from the File Menu to display the below dialog box.)

11

Page 21

(4) Select Work Online from the PLC Menu to go online.

(5) Transfer the ladder program and I/O table. (Select Transfer - From PLC from the PLC Menu.)

Click the OK Button to start transfer.

(6) Transfer the PLC memory data (Data Memory). (Select Edit - Memory from the PLC Menu.)

Scroll and select all the areas. Click the Transfer from PLC Button to start transfer.

(7) Select Work Online from the PLC Menu to go offline.

(8) Save the program with a new project name. (Select Save As from the File Menu.)

12

Page 22

5. Converting the program for CS1

On the CX-Programmer, convert the program for CS1.

(1) Start the CX-Programmer and open the saved program file for C200HS. (Select Open from the File Menu.)

(2) Change the Device Type from C200HS to CS1. (Select Change Model from the PLC Menu to display the

below dialog box.)

(3) The instructions are autom atically converted. The Output Window shows the conversion r esults. Double-click

an error shown on the Output Window to jump to the corresponding section of the ladder program.

Errors and warnings at conversion will be displayed.

Double-click an error or a warning to jump to the corresponding circuit.

Some instructions cannot be converted. Modify the ladder program referring to Appendix A. Instructions

converted by Change Model on CX-Programmer.

You can check the program by selecting Compile from the Program Menu. T he Output Window shows the

checking results.

13

Page 23

(4) The PLC mem or y data cannot be maintained when the PLC model is changed. Open the PLC Memory Window

for both C200HS and CS1, and copy and paste the necessary memory data.

Select the necessary PLC Memory on the C200HS PLC Memory Window,

and copy and paste it onto the CS1 PLC Memory Window.

(5) The I/O allocation of C200HS is partly different from that of CS1. Ref er to Appendix B. Change of unit area

allocation and modify the ladder program.

(6) The PLC settings of C200HS are partly different from those of CS1. Refer to Appendix C. Change in PLC

settings and change the PLC settings.

(7) Select Compile from the Program Menu to check the program. If an error is detected, correct it.

(8) Save the program with a new project name. (Select Save As from the File Menu.)

14

Page 24

6. Writing data to CS1

Transfer the converted and modified program, PLC settings, and Data Memory to CS1.

Required items

Support Software

CX-One

(CX-Programmer)

Connecting Cable

CS1W-CN226/626

CS1

PC

CX-Programmer

Connecting

Cable

CS1W-CN226/626

Peripheral port on CPU Unit

(PC)

CXONE-AL□□C-V□/ AL□□D-V□

(1) Connect CS1 with a PC.

(2) Start the CX-Programmer and open the converted program file for CS1.

(3) Go online with CS1.

(4) Transfer the ladder program and PLC settings to CS1 (Select Transfer - To PLC from the PLC Menu.)

Select the Program(s) and Settings Check Boxes. Click the OK Button to start transfer.

15

Page 25

(5) Select Edit - Memory from the PLC Menu to display the below dialog box. Select the PLC memory (Data

Memory Area: D and Holding Area: HR) and click the Transfer to PLC Button to start transfer.

(6) Select Work Online from the PLC Menu to go offline.

16

Page 26

7. Appendix

Appendix A. Instructions converted by Change Model on CX-Programmer

Instruction for C200HS

Instruction for CS1

Operand

Number of operands

JMP(04)

JMP(004) or

When #0 is set to the operand, JMP is converted to

If a value other than #0 is set, the operand is the same.

#0: Changed from 1 to 0

JME(05)

JME(005) or

When #0 is set to the operand, JME is converted to

If a value other than #0 is set, the operand is the same.

#0: Changed from 1 to 0

WSFT(16)

Same as C200HS

#0 is added to the first operand.

WSFT St E → WSFT #0 St E

Changed from 2 to 3

FUN17

ASFT(017)

Same as C200HS

Same

XFER(70)

XFERC(565)

Same as C200HS

Same

MOVB(82)

MOVBC(568)

Same as C200HS

Same

DIST(80)

DISTC(566)

Same as C200HS

Same

COLL(81)

COLLC(567)

Same as C200HS

Same

FUN60

CMPL(060)

Same as C200HS

Same

FUN19

MCMP(019)

Same as C200HS

Same

FUN63

LINE(063)

Changed from BCD data to binary data.

Same

FUN64

COLM(064)

Changed from BCD data to binary data.

Same

FUN65

SEC(065)

Same as C200HS

Same

FUN66

HMS(066)

Same as C200HS

Same

INC(38)

++B(594)

Same as C200HS

Same

DEC(39)

--B(596)

Same as C200HS

Same

ADD(30)

+B(404)

Same as C200HS

Same

ADDL(54)

+BL(405)

Same as C200HS

Same

SUB(31)

-B(414)

Same as C200HS

Same

SUBL(55)

-BL(415)

Same as C200HS

Same

MUL(32)

*B(424)

Same as C200HS

Same

MULL(56)

*BL(425)

Same as C200HS

Same

DIV(33)

/B(434)

Same as C200HS

Same

DIVL(57)

/BL(435)

Same as C200HS

Same

ADB(50)

+(400)

Same as C200HS

Same

SBB(51)

-(410)

Same as C200HS

Same

MLB(52)

*(420)

Same as C200HS

Same

DVB(53)

/(430)

Same as C200HS

Same

FUN69

APR(069)

Same as C200HS

Same

FUN89

Not supported

Combine and use the following instructions: MSKS(690), CLI(691), MSKR(692),

DI(693), EI(694)

STEP(08)

Same as C200HS

The CIO, Holding, Work, Auxiliary, Link Areas are all

converted into the Work Area.

Same

SNXT(09)

Same as C200HS

SNXT instruction.

Same as C200HS

Same

FAL(06)

Same as C200HS

#0 is added to the second operand.

FAL N → FAL N #0

Changed from 1 to 2.

FALS(07)

Same as C200HS

#0 is added to the second operand.

FALS N → FALS N #0

Changed from 1 to 2.

MSG(46)

MSG(046)

#0 is added to the first operand.

words) to 32 characters (16 words).

Changed from 1 to 2.

FUN47

Not supported

Use MSG(046) instead.

―

FUN67

BCNTC(621)

Same as C200HS

Same

WDT(94)

WDT(094)

Control data configuration is changed.

Same

FUN61

IORF(097)

In CS1, Unit No. of C200H Group-2 High-density I/O Units is disabled. Specify

the allocation by using IORF in the same way as Basic I/O Units.

FUN18

Enter the settings in the PLC Setup.

FUN48

Not supported

―

―

FUN49

Enter the settings f in the PLC Setup.

FUN90

SEND(090)

Control data configuration is changed.

Same

FUN98

RECV(098)

Control data configuration is changed.

Same

(1) The data type of operand is changed from BCD to binary for some instructions.

(2) The number of operands is changed for some instructions.

(3) Interrupt control instructions must be changed. (Use MSKS, MSKR, CLI, DI, and EI)

Refer to the list below for details. The table lists the instructions which differ between before and after conversion. The other

instructions remain unchanged after conversion.

JMP0(515)

JME0(516)

JMP0 and the operand is deleted.

JME0 and the operand is deleted.

<> #0: Same

<> #0: Same

Use a differentiated

execution

condition for the

MSG FM → MSG #0 M

The number of characters (words) to be registered from

the first message word is changed from 16 characters (8

17

Page 27

Appendix B. Change of unit area allocation

Item

C200HS

CS1

Description

I/O allocation

"Free location and fixed word allocation"

"Free location and free word allocation"

used in the program.

For CS1, it is necessary t o

I/O allocation

IR 100 to IR 199

CIO 2000 to CIO 2199

used in the program.

Refer to the

allocation.

I/O allocation

IR 030 to IR 049

The allocation is decided i n t he same

used in the program.

Special Relay Area

SR 236 to SR 255

(1) Auxiliary Area and bits

"P_1ms".

In CS1, operation flags and

PLC Link Words

SR 247 to SR 250

(in SR Area)

CIO 0247 to CIO 0250

A442

Link Relay Area

LR 00 to LR 63

CIO 1000 to CIO 1199

used in the program

SYSMAC BUS Area

IR 050 to IR 099

CIO 3000 to CIO 3049

used in the program

Optical I/O Unit and

I/O Terminal Area

IR 200 to IR 231

CIO 3100 to CIO 3131

Error Log Area

DM 6000 to DM 6030

A100 to A199

Change the program if the

program.

Temporary Relay Area

(TR)

TR 00 to TR 07

TR 00 to TR 15

Holding Relay Area

(HR)

HR 00 to HR 99

H 000 to H 511

Work Area (WR)

IR 030 to IR 235

CIO 1200 to CIO 1499

W000 to W511

Item

C200HS

CS1

Description

PLC Setup

Always uses the DM Area (DM 6600 to

Uses dedicated area for PLC Setup

users).

Refer to related manuals for

Item

C200HS

CS1

Description

Interrupt execution

Write interrupt programs in subroutines.

Write interrupt programs in interrupt

In CS1, interrupt tasks are

or I/O is being refreshed.

Cycle time

-

The cycle time is shortened with CS1.

conversion.

To keep the same cycl e t i me

Read Protection

function

FUN49

Use password protection functi on of the

CX-Programmer.

This section describes the differences in unit area allocation in C200HS and CS1. Refer to related manuals for details.

Basic I/O

Special I/O

Group-2

High-density I/O

(SR)

Auxiliary Relay Area

(AR)

(LR)

(10 words allocated for each Unit No.)

DM 1000 to DM 1999

(100 words allocated for each Unit No.)

(2 or 4 words allocated for each I/O

word)

SR 256 to SR 299

AR 00 to AR 27

Change the word and bit addresses

(10 words allocated for each Unit No.)

D20000 to D21999

(100 words allocated for each Unit No.)

Change the word and bit addresses

way as Basic I /O Units depending on

the installed position (rac k and slot).

Change the word and bit addresses

Change the word and bit addresses

used in the program.

(2) Condition flags and clock pul s es

Change the arithmetic fl ags in the

program to the condition f l ags . Clock

pulses are specified usi ng gl obal

symbols, such as "P_0.1ms" and

Change the word and bit addresses

Change the word and bit addresses

register the I/O table.

CS1G/H-CPU□□H CS Series

Programmable Controllers

OPERATION MANUAL (Cat.

No. W339) for details on I/O

condition flags are speci f i ed

by labels.

IR 300 to IR 511

CIO 3800 to CIO 6143

Error Log Area is read in the

Appendix C. Change in PLC Settings

Functions which can be configured in the PLC Setup differ between C200HS and CS1.

Although the DM Area (DM 6600 to DM 6655) is allocated for the PLC Setup in C200HS, CS1 does not use the DM Area for the

PLC Setup; the settings are changed from the CX-Programmer or a Programming Console.

DM 6655).

(there is no address for sett i ng by

details.

Appendix D. Change of execution timing etc.

method and execution

timing

tasks.

If the system operation is affected by

cycle time, check the operation after

executed even when an

instruction is being executed

as C200HS, set Minimum

Cycle Time in the PLC Set up.

18

Page 28

Appendix E. Table of Input/Output Units

C200H-series Unit

Corresponding CS-series Unit

Description

Difference

C200H-ID211

CS1W-ID211

DC Input Unit with terminal

1) Terminal block

(5 VDC: 10 mA → 100 mA)

12 to 24 VDC, 10 mA, Terminal

24 VDC, 7 mA, Termi nal bl ock,

C200H-ID212

CS1W-ID211

DC Input Unit with terminal

1) Terminal block

(5 VDC: 10 mA → 100 mA)

24 VDC, 7 mA, Termi nal bl ock,

24 VDC, 7 mA, Termi nal bl ock,

C200H-ID215

CS1W-ID231

DC Input Unit with connector

1) Connector

(5 VDC: 130 mA → 150 mA)

24 VDC, 4.1 mA, Connect or,

24 VDC, 6 mA, Connector,

C200H-ID216

CS1W-ID231

DC Input Unit with connector

1) No. of circuits (32 point s/common x 1 circuit

(5 VDC: 100 mA → 150 mA)

24 VDC, 4.1 mA, Connect or,

24 VDC, 6 mA, Connector,

C200H-ID218

CS1W-ID231

DC Input Unit with connector

1) No. of circuits (32 point s/common x 1 circuit

(5 VDC: 100 mA → 150 mA)

24 VDC, 6 mA, Connector,

24 VDC, 6 mA, Connector,

C200H-ID111

CS1W-ID261

DC Input Unit with connector

1) No. of circuits (32 point s/common x 2 circuit s

(5 VDC: 120 mA → 150 mA)

12 VDC, 4.1 mA, Connect or,

24 VDC, 6 mA, Connector,

C200H-ID217

CS1W-ID261

DC Input Unit with connector

1) No. of circuits (32 point s/common x 2 circuit s

(5 VDC: 120 mA → 150 mA)

24 VDC, 4.1 mA, Connect or,

24 VDC, 6 mA, Connector,

C200H-ID219

CS1W-ID261

DC Input Unit with connector

1) No. of circuits (32 point s/common x 2 circuit s

(5 VDC: 120 mA → 150 mA)

24 VDC, 6 mA, Connector,

24 VDC, 6 mA, Connector,

■ Input Unit

(1) If a different type of terminal block or connector is used, change the wiring.

(2) If the input specifications differ, make sure that the system operates correctly.

(3) If the number of circuits increases, rewire the terminals to each common terminal.

(4) If internal current consumption is different, make sure the power supply capacity is large enough.

(5) C200H-series Units can be used with CS1-series CPU Units.

(6) Refer to the related manuals for details. Although CS-series Units have basic functions of C200H-series Units ,

some specifications may differ..

< DC Input Units >

block, 8 inputs

16 inputs

32 inputs (Special I/O)

32 inputs (Group-2)

16 inputs

16 inputs

32 inputs

32 inputs

block for 8 inputs.

Replace this unit with a DC

Input Unit with 16 inputs.

block for 16 inputs.

for 32 inputs.

for 32 inputs.

2) Input points (8 points → 16 points)

3) Input circuit spec ifications

Input voltage range

(12 to 24 VDC → 24VDC)

Input impedance (2 kΩ → 3.3 kΩ)

ON voltage (10.2 VDC → 14.4 VDC)

OFF voltage (3 VDC → 5 VDC)

4) Internal current consum ption

2) No. of circuits (16 point s/common x 1 circuit

→ 8 points/common x 2 circuits)

3) Input circuit spec i f i cation

Input impedance (3 kΩ → 3.3 kΩ)

4) Internal current consum ption

Use the XW2Z-S010 Conversion Cable to

reuse the connecting cable.

2) No. of circuits (8 point s/common x 4 circuit s

→ 16 points/common x 2 circuits)

3) Input circuit spec i f i cations

Input impedance (5.6 kΩ → 3.9 kΩ)

ON voltage(14.4 VDC → 15.4 VDC)

4) Internal current consumption

→ 16 points/common x 2 circuits)

2) Input circuit spec i f i cations

Input impedance (5.6 kΩ → 3.9 kΩ)

ON voltage (14.4 VDC → 15.4 VDC)

3) Internal current consum ption

32 inputs (Group-2)

64 inputs (Group-2)

64 inputs (Group-2)

64 inputs (Group-2)

32 inputs

64 inputs

64 inputs

64 inputs

for 32 inputs.

for 64 inputs.

for 64 inputs.

for 64 inputs.

→ 16 points/common x 2 circuits)

2) Internal current consum ption

→ 16 points/common x 4 circuits)

2) Input circuit spec i f i cations

Input voltage (12 VDC → 24 VDC)

Input impedance (2.7 kΩ → 3.9 kΩ)

ON voltage (8 VDC → 15.4 VDC)

OFF voltage (3 VDC → 5 VDC)

3) Internal current consum ption

→ 16 points/common x 4 circuits)

2) Input circuit spec i f i cations

Input impedance (5.6 kΩ → 3.9 kΩ)

ON voltage (14.4 VDC → 15.4 VDC)

3) Internal current consum ption

→ 16 points/common x 4 circuits)

2) Internal current consum ption

19

Page 29

< TTL Input Unit >

C200H-series Unit

Corresponding CS-series Unit

Description

Difference

C200H-ID501

TTL Input Unit with connector f or 32 inputs. The CS Series does not have t he

CS1W-MD561 TTL I/O Unit instead.

5 VDC, 3.5 mA, Connector,

C200H-series Unit

Corresponding CS-series Unit

Description

Difference

C200H-IA121

CS1W-IA111

100 VAC Input Unit with

1) Terminal block

(5 VDC: 10 mA → 110 mA)

100 to 120 VAC/10 mA,

100 to 120 VAC/10 mA,

C200H-IA221

CS1W-IA211

200 VAC Input Unit with

1) Terminal block

(5 VDC: 10 mA → 110 mA)

200 to 240 VAC, 10 mA,

200 to 240 VAC, 10 mA,

C200H-IA122/IA122V

CS1W-IA111

100 VAC Input Unit with

1) Terminal block

(5 VDC: 10 mA → 110 mA)

100 to 120 VAC/10 mA,

100 to 120 VAC/10 mA,

C200H-IA222/IA222V

CS1W-IA211

200 VAC Input Unit with

1) Terminal block

(5 VDC: 10 mA → 110 mA)

200 to 240 VAC, 10 mA,

Directive

200 to 240 VAC, 10 mA,

C200H-series Unit

Corresponding CS-series Unit

Description

Difference

C200H-IM211

CS1W-ID211

AC/DC Input Unit with

1) Terminal block

(5 VDC: 10 mA → 100 mA)

12 to 24 VAC/VDC,

24 VDC, 7 mA, Termi nal bl ock,

C200H-IM212

CS1W-ID211

AC/DC Input Unit with

wiring for DC inputs.

1) Terminal block

24 VAC/VDC, Terminal bl ock,

24 VDC, 7 mA, Termi nal block,

32 inputs (Special I/O)

< AC Input Units >

Terminal block, 8 i nputs

Terminal block, 8 inputs

Terminal block, 16 inputs,

IA122V: Complying with EC

Directive

No replacement model

100 to 120 VDC/1.5 mA,

Terminal block, 16 inputs

Terminal block, 16 inputs

100 to 120 VDC/1.5 mA,

Terminal block, 16 inputs

same type of Unit.

Use C200H-ID501 with CS1 or use the CS1W-ID231 24-VDC Input Unit or

terminal block for 8 i nput s.

Replace this unit with a 100

VAC Input Unit with 16 inputs.

terminal block for 8 i nput s.

Replace this unit with a 200

VAC Input Unit with 16 inputs.

terminal block for 16 i nputs.

2) Input points (8 points → 16 points)

3) Input circuit spec i f i cations

Input impedance

(9.7 kΩ/50 Hz → 10 kΩ/50 Hz)

ON voltage (60 VAC → 65 VAC)

4) Internal current consum ption

2) Input points (8 points → 16 poi nts)

3) Internal current consum ption

2) No. of circuits (16 point s/common x 1 circuit

→ 8 points/common x 2 circuits)

3) Input circuit spec i f i cations

Input impedance

(9.7 kΩ/50 Hz→ 10 kΩ/50 Hz)

ON voltage (60 VAC → 65 VAC)

4) Internal current consumption

Terminal block, 16 inputs,

IA222V: Complying with EC

< AC/DC Input Units >

Terminal block, 8 inputs

16 inputs

Terminal block, 16 inputs

16 inputs

16 inputs

terminal block for 16 i nputs.

terminal block for 8 i nput s.

Replace this unit with a DC

Input Unit with 16 inputs.

*The CS Series does not

have an AC/DC Input Unit. If

this Unit is used with AC

inputs, use this C200H-series

Unit with CS1 or change the

wiring for DC inputs.

terminal block for 16 i nputs.

Replace this unit with a DC

Input Unit with 16 inputs.

*The CS Series does not

have an AC/DC Input Unit. If

this Unit is used with AC

inputs, use this C200H-series

Unit with CS1 or change the

2) No. of circuits (16 point s/common x 1 circuit

→ 8 points/common x 2 circuits)

3) Internal current consum ption

2) Input points (8 points → 16 points)

3) Input circuit spec i f i cations

Input voltage range

(12 to 24 VAC/VDC → 24 VDC)

Input impedance (2 kΩ → 3.3 kΩ)

ON voltage (10.2 VDC → 14.4 VDC)

OFF voltage (3 VDC → 5 VDC)

4) Internal current consum ption

2) No. of circuits (16 point s/common x 1 circuit

→ 8 points/common x 2 circuits)

3) Input circuit spec i f i cations

Input voltage range (24 VAC/VDC → 24 VDC)

Input impedance (3 kΩ→ 3.3 kΩ)

4) Internal power consumption

(5 VDC: 10 mA → 100 mA)

20

Page 30

■ Output Unit

C200H-series Unit

Corresponding CS-series Unit

Description

Difference

C200H-OC223

CS1W-OC201

Relay Output Unit with

1) Terminal block

26 VDC: 46 mA → 48 mA)

250 VAC/24 VDC, 2 A,

250 VAC/120 VDC, 2 A,

C200H-OC224

CS1W-OC201

Relay Output Unit with

1) Terminal block

26 VDC: 75 mA → 48 mA)

250 VAC/24 VDC, 2 A,

250 VAC/120 VDC, 2 A,

C200H-OC224V, OC224N

CS1W-OC201

Relay Output Unit with

1) Terminal block

26 VDC: 90 mA → 48 mA)

250 VAC/24 VDC, 2 A,

250 VAC/120 VDC, 2 A,

C200H-OC221

CS1W-OC211

Relay Output Unit with

1) Terminal block

26 VDC: 75 mA → 96 mA)

250 VAC/24 VDC, 2 A,

250 VAC/120 VDC, 2 A,

C200H-OC222

CS1W-OC211

Relay Output Unit with

1) Terminal block

26 VDC: 75 mA → 96 mA)

250 VAC/24 VDC, 2 A,

250 VAC/120 VDC, 2 A,

C200H-OC222V, OC222N

CS1W-OC211

Relay Output Unit with

1) Terminal block

26 VDC: 90 mA → 96 mA)

250 VAC/24 VDC, 2 A,

250 VAC/120 VDC, 2 A,

(1) If a different type of terminal block or connector is used, change the wiring.

(2) If the number of circuits increases, rewire the terminals to each common terminal.

(3) If the output specifications differ, make sure that the system operates correctly.

(4) The relay lifetime may vary depending on usage when the different relay is used. Refer to About Contact

Output Units under Appendix A Specifications of Basic I/O Units and High-density I/O Units in the

CS1G/H-CPU□□H CS Series Programmable Controllers OPERATION MANUAL (Cat. No. W339) for details.

(5) If internal current consumption is different, make sure the power supply capacity is large enough.

(6) If the voltage and current consumption of the external power supply differ, make sure the power supply

capacity is large enough.

(7) C200H-series Units can be used with CS1-series CPU Units.

(8) Refer to the related manuals f or details. Although CS-s eries Units has basic func tions of C200H -ser ies Units,

some specifications may differ.

< Relay Output Units >

Terminal block, 5 out put s

(independent contacts)

Terminal block, 8 out put s

(independent contacts)

Terminal block, 8 out put s

(independent contacts)

Terminal block, 8 out put s

Terminal block, 12 out puts

Terminal block, 8 out put s

(independent contacts)

Terminal block, 8 out put s

(independent contacts)

Terminal block, 8 out put s

(independent contacts)

Terminal block, 16 out puts

Terminal block, 16 out put s

terminal block for 5 outputs

(independent contacts).

Replace this unit with a Relay

Output Unit with 8 outputs

(independent contacts).

terminal block for 8 outputs

(independent contacts).

terminal block for 8 outputs

(independent contacts).

terminal block for 8 outputs.

Replace this unit with a Relay

Output Unit with 16 outputs.

terminal block for 12 outputs.

Replace this unit with a Relay

Output Unit with 16 outputs.

2) Output points

(independent contacts 5 points → 8 points)

3) Output circuit spec i f i cations

ON/OFF response time (10 ms → 15 ms)

Used relay

4) Internal current consum ption

(5 VDC: 10 mA → 100 mA,

2) Output circuit spec i f i cations

ON/OFF response time (10 ms → 15 ms)

Used relay

3) Internal current consum ption

(5 VDC: 10 mA → 100 mA,

2) Output circuit spec i f i cation

Used relay

3) Internal current consum ption

(5 VDC: 10 mA →100 mA,

2) Output points (8 points → 16 poi nt s)

3) Output circuit spec i f i cations

ON/OFF response time (10 ms → 15 ms)

Used relay

4) Internal current consum ption

(5 VDC: 10 mA → 100 mA,

2) Output points (12 points → 16 poi nt s)

3) No. of circuits (12 point s/common x 1 circuit

→ 8 points/common x 2 circuits)

4) Output circuit spec i f i cations

ON/OFF response time (10 ms → 15 ms)

Used relay

5) Internal current consum ption

(5 VDC: 10 mA → 100 mA,

Terminal block, 12 out put s

Terminal block, 16 out put s

terminal block for 12 outputs.

Replace this unit with a Relay

Output Unit with 16 outputs.

2) Output points (12 points → 16 points)

3) No. of circuits (12 point s/common x 1 circuit

→ 8 points/common x 2 circuits)

4) Output circuit spec i f i cation

Used relay

5) Internal current consum ption

(5 VDC: 10 mA → 100 mA,

21

Page 31

< Relay Output Units >

C200H-series Unit

Corresponding CS-series Unit

Description

Difference

C200H-OC225

CS1W-OC211

Relay Output Unit with

1) Terminal block

26 VDC: 75 mA → 96 mA)

250 VAC/24 VDC, 2 A,

250 VAC/120 VDC, 2 A,

C200H-OC226, OC226N

CS1W-OC211

Relay Output Unit with

1) Terminal block

26 VDC: 90 mA → 96 mA)

250 VAC/24 VDC, 2 A,

250 VAC/120 VDC, 2 A,

C200H-series Unit

Corresponding CS-series Unit

Description

Difference

C200H-OD411

CS1W-OD211

Transistor Output Unit with

1) Terminal block

(5 VDC: 140 mA → 170 mA)

12 to 48 VDC, 1 A, Sinking,

12 to 24 VDC, 0.5 A, Sinki ng,

C200H-OD213

CS1W-OD211

Transistor Output Unit with

1) Terminal block

(5 VDC: 140 mA → 170 mA)

24 VDC, 2.1 A, Sinking,

12 to 24 VDC, 0.5 A, Sinki ng,

C200H-OD214

CS1W-OD212

Transistor Output Unit with

1) Terminal block

0.5 A/point, 5 A/Unit )

(5 VDC: 140 mA → 170 mA)

24 VDC, 0.8 A, Sourcing,

12 to 24 VDC, 0.5 A, Sourcing,

C200H-OD216

CS1W-OD212

Transistor Output Unit with

1) Terminal block

24 VDC)

(Not required → 24 VDC/40 mA)

5 to 24 VDC, 0.3 A, Sourci ng,

12 to 24 VDC, 0.5 A, Sourcing,

C200H-OD211

CS1W-OD211

Transistor Output Unit with

1) Terminal block

(5 VDC: 160 mA → 170 mA)

24 VDC, 0.3 A, Sinking,

12 to 24 VDC, 0.5 A, Sinki ng,

Terminal block, 16 out put s

Terminal block, 16 out put s

< Transistor Output Units >

Terminal block, 8 out put s

Terminal block, 16 out put s

Terminal block, 16 out put s

Terminal block, 16 out put s

terminal block for 16 outputs.

terminal block for 16 outputs.

terminal block for 8 outputs.

Replace this unit with a

Transistor Output Unit with 16

outputs.

2) No. of circuits (16 points/common x 1 circ ui t

→ 8 points/common x 2 circuits)

3) Output circuit spec i f i cations

ON/OFF response time (10 ms →15 ms)

Used relay

4) Internal current consum ption

(5 VDC: 10 mA → 100 mA,

2) No. of circuits (16 point s/common x 1 circuit

→ 8 points/common x 2 circuits)

3) Output circuit spec i f i cation

Used relay

4) Internal current consum ption

(5 VDC: 10 mA → 100 mA,

2) Output points (8 points→ 16 poi nt s)

3) Output circuit spec i f i cations

Output capacity

(1 A/point, 3 A/Unit → 0.5 A/point, 8 A/Unit)

Voltage range (12 to 48 VDC → 12 to 24VDC)

Residual voltage (1.4 V → 1.5 V)

ON response time (0.2 ms → 0.5 ms)

OFF response time (0.3 ms → 1.0 ms)

4) Internal current consum ption

Terminal block, 8 out put s

Terminal block, Load s hort

circuit protection, 8 outputs

Terminal block, 8 out put s

Terminal block, 12 out put s

22

terminal block for 8 outputs.

Terminal block, 16 out puts

Terminal block, Load s hort

circuit protection, 16 outputs

Terminal block, Load s hort

circuit protection, 16 outputs

Terminal block, 16 out put s

Replace this unit with a

Transistor Output Unit with 16

outputs.

terminal block for 8 outputs.

Replace this unit with a

Transistor Output Unit with 16

outputs.

terminal block for 8 outputs.

Replace this unit with a

Transistor Output Unit with 16

outputs.

terminal block for 12 outputs.

Replace this unit with a

Transistor Output Unit with 16

outputs.

2) Output points (8 points → 16 poi nt s)

3) Output circuit spec i f i cations

Output capacity

(2.1 A/point, 5.2 A/Uni t → 0.5 A/point, 8 A/Unit )

Residual voltage (1.4 V → 1.5 V)

ON response time (0.2 ms → 0.5 ms)

OFF response time (0.3 ms → 1.0 ms)

4) Internal current consum ption

2) Output points (8 points → 16 poi nt s)

3) Output circuit spec i f i cations

Output capacity

(0. 8A/point, 2.4 A/Uni t →

ON response time (1 ms → 0.5 ms)

4) Internal current consum ption

2) Output points (8 points → 16 poi nt s)

3) Output circuit spec i f i cation

Output voltage range (5 to 24 VDC →

4) Internal current consum ption (5 VDC: 10 mA

→ 170 mA, 26 VDC: 75 mA → 0 mA)

5) External power supply

2) Output points (12 points → 16 poi nt s)

3) No. of circuits (12 point s/common x 1 circuit

→ 8 points/common x 2 circuits)

4) Output circuit spec i f i cations

Residual voltage (1.4 V → 1.5 V)

ON response time (0.2 ms → 0.5 ms)

OFF response time (0.3 ms → 1.0 ms)

5) Internal current consum ption

Page 32

< Transistor Output Units >

C200H-series Unit

Corresponding CS-series Unit

Description

Difference

C200H-OD217

CS1W-OD212

Transistor Output Unit with

1) Terminal block

(Not required → 24 VDC: 40 mA)

5 to 24 VDC, 0.3 A, Sourcing,

12 to 24 VDC, 0.5 A, Sourcing,

C200H-OD212

CS1W-OD211

Transistor Output Unit with

1) Terminal block

OFF response time (0.3 ms → 1.0 ms)

24 VDC, 0.3 A, Sinking,

12 to 24 VDC, 0.5 A, Sinki ng,

C200H-OD21A

CS1W-OD212

Transistor Output Unit with

1) Terminal block

6) Alarm output (Supported → Not s upported)

24 VDC, 1.0 A, Sourcing,

12 to 24 VDC, 0.5 A, Sourcing,

C200H-OD218

CS1W-OD231

Transistor Output Unit with

1) No. of circuits (32 point s/common x 1 circuit

→ 12 to 24 VDC: 50 mA)

4.5 to 26.3 VDC, 0.1A, Si nking,

12 to 24 VDC, 0.5A, Sinki ng,

C200H-OD215

CS1W-OD231

Transistor Output Unit with

1) Connector

(5 to 24 VDC: 90 mA → 12 to 24 VDC: 50 mA)

4.5 to 26.3 VDC, 0.1 A, Si nking,

12 to 24 VDC, 0.5A, Sinki ng,

C200H-OD21B

CS1W-OD232

Transistor Output Unit with

1) No. of circuits (32 point s/common x 1 circuit

(5 VDC: 180 mA → 270 mA)

24 VDC, 0.5 A, Sourcing,

12 to 24 VDC, 0.5 A, Sourcing,

Terminal block, 12 out put s

Terminal block, 16 out put s

Terminal block, Load s hort

circuit protection, 16 outputs

Terminal block, Load s hort

circuit protection, 16 outputs

Terminal block, 16 out put s

Terminal block, Load s hort

circuit protection, 16 outputs

terminal block for 12 outputs.

Replace this unit with a

Transistor Output Unit with 16

outputs.

terminal block for 16 outputs.

terminal block for 16 outputs.

2) Output points (12 points → 16 points)

3) No. of circuits (12 point s/common x 1 circuit

→ 8 points/common x 2 circuits)

4) Output circuit spec i f i cation

Output voltage range (5 to 24 VDC → 24 VDC)

5) Internal current consum ption

(5 VDC: 10 mA → 170 mA,

26 VDC: 75 mA → 0 mA)

6) External power supply

2) No. of circuits (16 point s/common x 1 circuit

→ 8 points/common x 2 circuits)

3) Output circuit spec i f i cations

Residual voltage (1.4 V → 1.5 V)

ON response time (0.2 ms → 0.5 ms)

2) No. of circuits (16 point s/common x 1 circuit

→ 8 points/common x 2 circuits)

3) Output circuit spec i f i cations

Output capacity

(1 A/point, 4 A/Unit → 0.5 A/point, 5 A/Unit)

Residual voltage (0.8 V → 1.5 V)

ON response time (0.1 ms → 0.5 ms)

OFF response time (0.3 ms → 1.0 ms)

4) Internal current consum ption

(5 VDC: 160 mA → 170 mA)

5) External power supply

(24 VDC: 35 mA → 40 mA)

Connector, 32 outputs

(Group-2)

Connector, 32 outputs

(Special I/O)

Connector, Load short circuit

protection, 32 outputs (Group-2)

Connector, 32 outputs

Connector, 32 outputs

Connector, Load short circuit

protection, 32 outputs

connector for 32 outputs.

connector for 32 outputs.

*The CS1-series Unit does

not support dynamic output s.

Use this C200H-series Unit

with CS1 or change the wiring

for static outputs .

connector for 32 outputs.

→ 16 points/common x 2 circuits)

2) Output circuit spec i fications

Output voltage range

(5 to 24 VDC → 12 to 24 VDC)

Residual voltage (0.8 V → 1.5 V)

ON response time (0.1 ms → 0.5 ms)

OFF response time (0.4 ms → 1.0 ms)

3) Internal current consum ption

(5 VDC: 180 mA → 270 mA)

4) External power supply (5 to 24 VDC: 110 mA

Use the XW2Z-S011 Conversion Cable to

reuse the connecting cable.

2) Output method

(Dynamic or static mode → Static mode only)

Based on specificat i ons in static output mode

3) No. of circuits (8 point s/common x 4 circuit s

→ 16 points/common x 2 circuits)

4) Output circuit spec i f i cations

Output voltage range

(5 to 24 VDC → 12 to 24 VDC)

Residual voltage (0.7 V → 1.5 V)

ON response time (0.2 ms → 0.5 ms)

OFF response time (0.6 ms → 1.0 ms)

5) Internal current consum ption

(5 VDC: 220 mA → 270 mA)

6) External power supply

→ 16 points/common x 2 circuits)

2) Output circuit spec i f i cations

Output capacity (0.5 A/ poi nt , 5 A/Unit

→ 0.5 A/point, 2.5 A/ common, 5 A/Unit )

Residual voltage (0.8 V → 1.5 V)

ON response time (0.1 ms → 0.5 ms)

OFF response time (0.3 ms → 1.0 ms)

3) Internal current consum ption

23

Page 33

< Transistor Output Units >

C200H-series Unit

Corresponding CS-series Unit

Description

Difference

C200H-OD219

CS1W-OD261

Transistor Output Unit with

1) No. of circuits (32 point s/common x 2 circuit s

(5 VDC: 270 mA → 390 mA)

4.5 to 26.3 VDC, 0.1 A, Si nking,

12 to 24 VDC, 0.3 A, Sinking,

C200H-series Unit

Corresponding CS-series Unit

Description

Difference

C200H-OD501

TTL Output Unit with connector f or 32 out puts. The CS Series does not have t he

CS1W-MD561 TTL I/O Unit instead.

5 VDC, 35 mA, Connector,

C200H-series Unit

Corresponding CS-series Unit

Description

Difference

C200H-OA223

CS1W-OA201

Triac Output Unit with

1) Terminal block

(5 VDC: 180 mA → 230 mA)

250 VAC, 1.2 A, Termi nal bl ock,

250 VAC, 1.2 A, Termi nal bl ock,

C200H-OA221

CS1W-OA201

Triac Output Unit with

1) Terminal block

(5 VDC: 140 mA → 230 mA)

250 VAC, 1.2 A, Termi nal bl ock,

250 VAC, 1.2 A, Termi nal bl ock,

C200H-OA224

CS1W-OA211

Triac Output Unit with

1) Terminal block

(5 VDC: 270 mA → 406 mA)

250 VAC, 0.5 A, Termi nal bl ock,

250 VAC, 0.5 A, Termi nal bl ock,

C200H-OA222V

CS1W-OA211

Triac Output Unit with

1) Terminal block

(5 VDC: 200 mA → 406 mA)

250 VAC, 0.3 A, Termi nal bl ock,

250 VAC, 0.5 A, Termi nal bl ock,

Connector, 64 outputs

(Group-2)

< TTL Output Unit >

32 outputs (Special I/O )

< Triac Output Units >

8 outputs

Connector, 64 outputs

No replacement model

8 outputs

connector for 64 outputs..

same type of Unit.

Use C200H-OD501 with CS1 or use the CS1W-OD231 Transistor Output Unit or

terminal block for 8 outputs.

→ 16 points/common x 4 circuits)

2) Output circuit spec i f i cations

Output voltage range

(5 to 24 VDC → 12 to 24 VDC)

Residual voltage (0.8 V → 1.5 V)

ON response time (0.1 ms → 0.5 ms)

OFF response time (0.4 ms → 1.0 ms)

3) Internal current consum ption

2) Output circuit spec i f i cation

Max. inrush current (15 A: Pulse width 100 m s ,

30 A: Pulse width 10 ms → 10 A : Pulse width

100 ms, 20 A: Puls e width 10 ms)

3) Internal current consum ption

8 outputs

12 outputs

12 outputs (CE marked)

24

8 outputs

16 outputs

16 outputs

terminal block for 8 outputs.

terminal block for 12 outputs.

Replace this unit with a Triac

Output Unit with 16 outputs.

terminal block for 12 outputs.

Replace this unit with a Triac

Output Unit with 16 outputs.

2) Output circuit spec ifications

Max. inrush current (No regulation → 10 A:

Pulse width 100 ms, 20 A: P ul se width 10 ms)

Residual voltage (1.2 VAC →

50 to 1200 mA: 1.5 VAC, 10 to 50 mA: 5 VAC)

OFF response time (1/2 of load frequency or

less → 1/2 of load frequency + 1 ms or less)

3) Internal current consum ption

2) Output points (12 points → 16 poi nt s)

3) No. of circuits (12 point s/common x 1 circuit

→ 8 points/common x 2 circuits)

4) Output circuit spec i f i cations

Max. switching capacity

(250 VAC 0.5 A/point, 2 A/ Uni t

→ 0.5 A/point, 2 A/c ommon, 4 A/Unit)

Max. inrush current

(10A: Pulse width 100 ms, 20A : Pulse width

10 ms → 15A: Pulse width 10 ms)

Min. switching capacity

(10 VAC: 100 mA, 24 VA C: 50 mA, 100 VAC:

10 mA →75 VAC: 50 mA )

Residual voltage (50 to 500 mA: 1.5 VAC,

10 to 50 mA: 5 VAC → 1.6 V AC

5) Internal current consum ption

2) Output points (12 points → 16 poi nt s)

3) No. of circuits (12 point s/common x 1 circuit

→ 8 points/common x 2 circuits)

4) Output circuit spec i f i cations

Max. inrush current

(No regulation → 15 A: Pulse width 10 ms)

Min. switching capacity (10 VA C: 10 mA

(resistive load)/40 mA (inductive load)

→ 75 VAC: 50 mA)

Residual voltage (1.2 VAC → 1.6 VAC)

ON response time

(1/2 of load frequency or less → 1 ms or less)

OFF response time (1/2 of l oad frequency or

less → 1/2 of load frequency + 1 ms or les s )

5) Internal current consum ption

Page 34

■ I/O Unit

C200H-series Unit

Corresponding CS-series Unit

Description

Difference

C200H-MD115