Page 1

Cat. No. W457-E1-07

CRT1 Series

CompoNet Slave Units

and Repeater Unit

OPERATION MANUAL

Page 2

Page 3

CRT1 Series CompoNet Slave Units and Repeater Unit

Operation Manual

Revised October 2009

Page 4

iv

Page 5

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

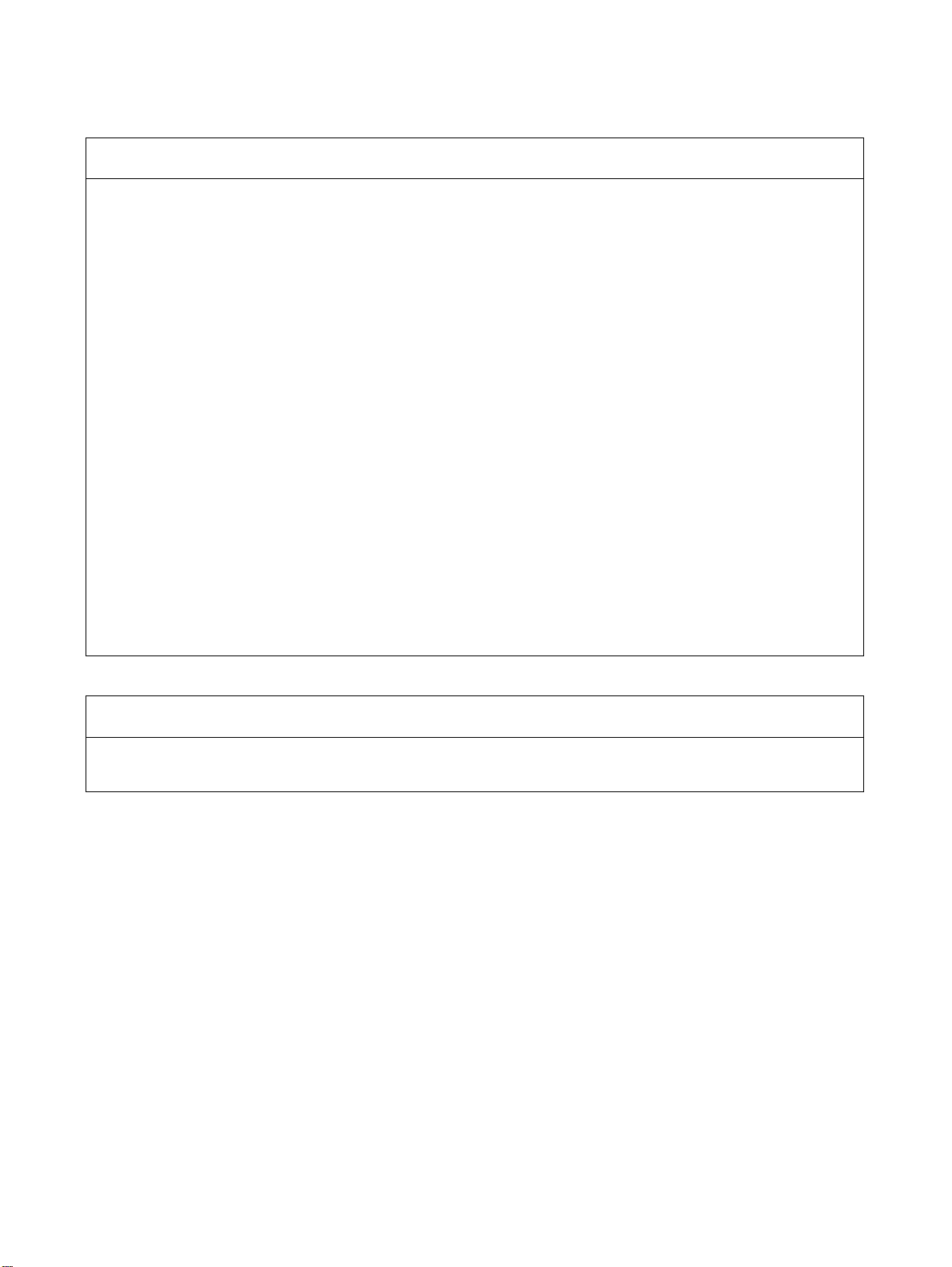

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 6

vi

Page 7

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xx

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

SECTION 1

Features and Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Features of CompoNet Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Slave Unit Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SECTION 2

Wiring Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-1 CompoNet Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

2-2 Wiring Formations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2-3 Communications Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

2-4 Communications Cable Wiring Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

SECTION 3

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3-1 Installing Slave Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3-2 Connecting Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3-3 Preparing Flat Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

3-4 Connecting Cables and Terminating Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3-5 Power Supply Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3-6 Connecting External I/O for Slave Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

SECTION 4

Basic Specifications of Slave Units . . . . . . . . . . . . . . . . . . . . 115

4-1 Basic Specifications of Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

SECTION 5

Digital I/O Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

5-1 Status Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

5-2 Allocating I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

5-3 Units with Screw Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

5-4 Units with Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

5-5 Units with Clamp Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

vii

Page 8

TABLE OF CONTENTS

SECTION 6

Analog I/O Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

6-1 Analog I/O Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

6-2 Summary of the Analog Input Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

6-3 Summary of the Analog Output Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

6-4 Status Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

6-5 Analog Data Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

6-6 Units with Screw Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

6-7 Units with Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

SECTION 7

Temperature Input Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

7-1 Temperature Input Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

7-2 Overview of Temperature Input Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

7-3 Status Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

7-4 Monitoring Temperature Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

7-5 Temperature Input Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 382

SECTION 8

Expansion Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

8-1 Expansion Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392

8-2 Expansion Unit Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

SECTION 9

Bit Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

9-1 Status Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

9-2 Allocating I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 409

9-3 Bit Slave Units with e-CON Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

9-4 Clamp Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .432

9-5 Bit Slave Units with Compact Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

SECTION 10

Repeater Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 471

10-1 Status Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 472

10-2 Repeater Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 474

viii

Page 9

TABLE OF CONTENTS

SECTION 11

Smart Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

11-1 CX-Integrator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 481

11-2 Functions Common to All Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 486

11-3 Functions of Digital I/O Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 495

11-4 Analog I/O Slave Unit (input) Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 507

11-5 Analog I/O Slave Unit (output) Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 530

11-6 Temperature Input Unit Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 540

SECTION 12

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . 579

12-1 Indicator Meanings and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 580

12-2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 581

12-3 Device Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 588

Appendices

A CompoNet Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 591

B Object Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 615

C Current Consumption Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 631

D Precautions with Connecting Two-wire DC Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 637

E I/O Power Supply Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 639

F Node Address Settings for Bit Slave Units with Compact Connectors . . . . . . . . . . . . . . . . 641

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 645

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 649

ix

Page 10

x

Page 11

About this Manual:

This manual describes the installation and operation of the CompoNet Slave Units, and the Repeater

Unit and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate a CompoNet Slave Unit or Repeater Unit. Be sure to read the precautions provided in the following section. Also be sure to read the CompoNet Master Unit Operation Man-

ual (see following table) together with this manual.

Precautions provide general precautions for using the CompoNet Slave Units, Repeater Units, Programmable Controller, and related devices.

Section 1 introduces the CompoNet Slave Units and the various models that are available.

Section 2 describes the configurations of CompoNet Networks.

Section 3 describes how to install and wire a CompoNet Network.

Section 4 provides the basic specifications of the Slave Units.

Section 5 describes the Digital I/O Slave Units.

Section 6 describes the Analog I/O Slave Units.

Section 7 describes the Temperature Input Units.

Section 8 describes the Expansion Units.

Section 9 describes the Bit Slave Units.

Section 10 describes the Repeater Unit.

Section 11 individually describes the functions provided by CompoNet Slave Unit. The functions are

divided into those supported by all CompoNet Slave Units and those supported only by specific CompoNet Slave Units.

Section 12 provides troubleshooting information that can be used in the event a problem occurs in

CompoNet Slave Unit operation. It also provides information on maintenance that should be performed

to ensure optimum application of the CompoNet Slave Units.

The Appendices provide specialized information, including information on CompoNet explicit messages, object mounting, connectable devices, current consumption, and precautions for connecting

two-wire DC sensors.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xi

Page 12

Related Manuals:

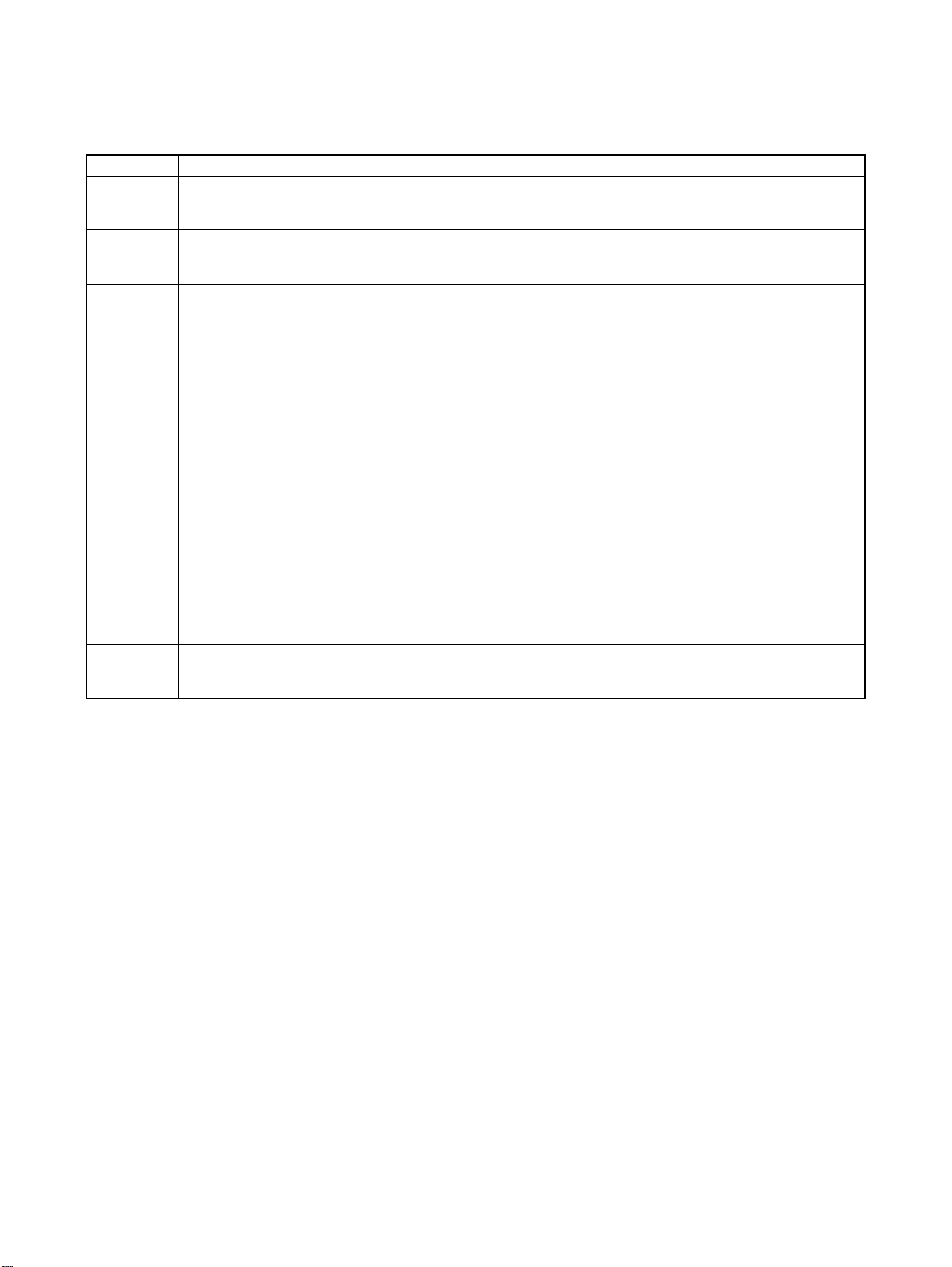

Cat. No. Models Name Description

W457

(this manual)

W456 CS1W-CRM21 and CJ1W-

W342 CS1G/H-CPU@@H

W464 CXONE-AL@@C-EV@/

CRT1 Series CompoNet Slave Units and

CRM21

CS1G/H-CPU@@-EV1

CS1D-CPU@@H

CS1D-CPU@@S

CS1W-SCB@@-V1

CS1W-SCU@@-V1

CJ1G/H-CPU@@H

CJ1G-CPU@@P

CJ1G-CPU@@

CJ1M-CPU@@

CJ1W-SCU@@-V1

CP1H-X@@@@-@

CP1H-XA@@@@-@

CP1H-Y@@@@-@

NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

CXONE-AL@@D-EV@

Repeater Unit Operation

Manual

CS/CJ-series CompoNet

Master Units Operation

Manual

SYSMAC CS/CJ/CP Series

SYSMAC One NSJ Series

Communications Commands Reference Manual

SYSMAC CS/CJ/CP/NSJ

Series CX-Integrator Ver.

2.3 Operation Manual

Provides the specifications of CompoNet

Slave Units and Repeater Unit.

Provides an overview of CompoNet Networks,

communications specifications, wring methods, and CompoNet Master Unit functions.

Describes the communications commands

used with CS-series, CJ-series, and CPseries PLCs and NSJ Controllers.

Describes CX-Integrator operating methods,

e.g., for setting up and monitoring networks.

xii

Page 13

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xiii

Page 14

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xiv

Page 15

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xv

Page 16

xvi

Page 17

PRECAUTIONS

This section provides general precautions for using the CompoNet Slave Units, and the Repeater Unit.

The information contained in this section is important for the safe and reliable application of the CompoNet Slave

Units and Repeater Unit. You must read this section and understand the information contained before attempting

to set up or operate a CompoNet Network using CompoNet Slave Units or Repeater Units.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

6-3 Conformance to EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

xvii

Page 18

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation. Be sure this manual is delivered to the persons actually using the CompoNet Slave Units and Repeater

Units.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart and do not touch the interior of any Unit

while the power is being supplied. Also, do not turn ON the power supply

while the cover is open. Doing any of these may result in electric shock.

!WARNING Do not input voltages or currents exceeding the rated range to the Unit.

Exceeding the rated range may cause Unit failure or fire.

xviii

Page 19

Operating Environment Precautions 4

!WARNING Provide safety measures in external circuits (i.e., not in the Slave Units),

including the following items, to ensure safety in the system if an abnormality

occurs due to malfunction of the PLC or another external factor affecting the

PLC operation. (“PLC” includes CPU Units, other Units mounted in the PLC,

and Remote I/O Terminals.) Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC outputs may remain ON or OFF due to deposits on or burning of

the output relays, or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-VDC output (service power supply) is overloaded or shortcircuited, the voltage may drop and result in the outputs being turned

OFF. As a countermeasure for such problems, external safety measures

must be provided to ensure safety in the system.

!WARNING The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

PROGRAM mode). Confirm safety thoroughly in advance before changing the

status of any part of memory allocated to I/O Units, Special I/O Units, or CPU

Bus Units. Any changes to the data allocated to any Unit may result in unexpected operation of the loads connected to the Unit. Any of the following operation may result in changes to memory status.

• Transferring I/O memory data to the CPU Unit from a Programming

Device.

• Changing present values in memory from a Programming Device.

• Force-setting/-resetting bits from a Programming Device.

• Transferring I/O memory files from a Memory Card or EM file memory to

the CPU Unit.

• Transferring I/O memory from a host computer or from another PLC on a

network.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals (including acids).

• Locations subject to shock or vibration.

xix

Page 20

Application Precautions 5

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Make sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the

life of the system.

5 Application Precautions

Observe the following precautions when using a CompoNet Network.

• When transporting the Unit, use special packing boxes and protect it from

being exposed to excessive vibration or impact during transportation.

• Do not drop any Unit or subject any Unit to excessive shock or vibration.

Otherwise, Unit failure or malfunction may occur.

• Mount the Units securely using DIN Track, a Mounting Bracket, or screws.

• Make sure that all Slave Unit mounting screws and cable connector

screws are tightened to the torque specified in the relevant manuals.

Incorrect tightening torque may result in malfunction.

• Make sure that the terminal blocks, communications cables, and other

items with locking devices are properly locked into place. Improper locking

may result in malfunction.

• When installing the Units, ground to 100 Ω min.

• Wire all connections correctly according to instructions in the manual.

• Always separate Special Flat Cables (Standard and Sheathed) for different CompoNet systems by at least 5 mm to prevent unstable operation

due to interference. Do not bundle Special Flat Cables.

• Do not extend connection distances or the number of connected nodes

beyond the ranges given in the specifications.

• Do not allow foreign matter to enter the Units when wiring and installing

the Units.

• Use the correct wiring materials to wire the Units.

• Use the correct tools to wire the Units.

• Always use the specified communications cables and connectors.

• Confirm the polarity of all terminals before wiring them.

• Make sure that all terminal block screws are tightened to the torque specified in this manuals. Incorrect tightening torque may result in fire, malfunction, or failure.

• Always use the power supply voltage specified in this manual.

• Do not bend cables past their natural bending radius or pull on cables.

• Observe the following precautions when wiring the communications

cable.

• Separate the communications cables from the power lines or high-tension lines.

• Do not bend the communications cables past their natural bending radius.

• Do not pull on the communications cables.

• Do not place heavy objects on top of the communications cables.

• Always lay communications cable inside ducts.

xx

Page 21

Application Precautions 5

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Confirm voltage specifications when wiring communications, the power

supply, and I/O crossovers. Incorrect wiring may result in malfunction.

• Do not apply voltages or connect loads to the Output Units in excess of

the maximum switching capacity. Excess voltage or loads may result in

burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage. Excess voltages may result in burning.

• After replacing Units, resume operation only after transferring to the new

CPU Unit and/or Special I/O Units the contents of the DM Area, HR Area,

and other data required for resuming operation. Not doing so may result in

an unexpected operation.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in unexpected operation.

• Check all wiring and switch settings to be sure they are correct.

• Always turn OFF the power supply to the PLC and Slave Units before

attempting any of the following. Not turning OFF the power supply may

result in malfunction or electric shock.

• Removing or attaching terminal blocks to Slave Units and Expansion

Units

• Removing or attaching the terminal blocks or connectors

• Replacing components (e.g., relays)

• Setting the DIP Switches and Rotary Switches

• Connecting cables or wiring the system.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC

• Force-setting/force-resetting any bit in memory

• Changing the present value of any word or any set value in memory

from the user program

• Touch a grounded piece of metal to discharge static electricity from your

body before touching any Unit.

• When replacing relays or other parts, be sure to confirm that the ratings of

the new part are correct. Not doing so may result in malfunction or burning.

• Do not attempt to disassemble, repair, or modify any Units. Any attempt to

do so may result in malfunction, fire, or electric shock.

• On IP54 Bit Slaves, tighten the cover screws to the specified torque after

setting the rotary switches or performing wiring. The specified degree of

protection will not be achieved if the screws are not tightened sufficiently.

xxi

Page 22

Conformance to EC Directives 6

• Take appropriate and sufficient countermeasures when installing systems

in the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

The OMRON products described in this manual are designed so that they

individually comply with the related EMC Directives so that they can be more

easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC Directives (see note). Whether the products conform to the standards in the system used by the customer, however,

cannot be checked by OMRON and must be checked by the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61131-2 and EN 61000-6-2

EMI (Electromagnetic Interference): EN 61131-2 and EN 61000-6-4

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75

to 1,500 VDC meet the required safety standards.

Applicable standard: EN 61131-2

6-3 Conformance to EC Directives

The OMRON products described in this manual comply with the related EMC

Directives. To ensure that the machine or device in which the products are

used complies with EC Directives, the products must be installed as follows:

1,2,3... 1. The products must be installed within a control panel.

2. A DC power supply with reinforced insulation or double insulation that can

maintain a stable output even if the input is interrupted for 10 ms must be

used for communications power, internal power, and I/O power. The

OMRON S82J-series Power Supply is recommended. (See note.)

(Radiated emission: 10-m regulations)

xxii

Page 23

Conformance to EC Directives 6

3. Products complying with EC Directives also conform to the Emission Standards (EN 61131-2 and EN 61000-6-4). Radiated emission characteristics

(10-m regulations) may vary depending on the configuration of the control

panel used, other devices connected to the control panel, wiring, and other

conditions. You must therefore confirm that the overall machine or equipment complies with EC Directives.

4. Conformance with the EC Directives was confirmed with a system configuration using I/O wiring lengths of less than 30 m.

Note Conformance with the EMC Directive was confirmed when using

the recommended power supply.

xxiii

Page 24

Conformance to EC Directives 6

xxiv

Page 25

Features and Slave Units

This section introduces the CompoNet Slave Units and the various models that are available.

1-1 Features of CompoNet Slave Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Features of CompoNet Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-3 CompoNet Slave Unit Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2 Slave Unit Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-2-1 Word Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-2-2 Bit Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-2-3 Repeater Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1-2-4 Slave Unit Installation and Connection . . . . . . . . . . . . . . . . . . . . . . 27

SECTION 1

1

Page 26

Features of CompoNet Slave Units Section 1-1

1-1 Features of CompoNet Slave Units

1-1-1 Overview

CompoNet Slave Units do not simply input and output ON/OFF signals, they

can also collect a variety of information that can improve equipment operating

rates.

They can also be used to build maintenance systems separate from control

systems. Coexisting control and maintenance systems can contribute to

reducing equipment startup time, recovery time after problems, and preventative maintenance of equipment.

■ Control System:

For remote I/O communications with the PLC, I/O is allocated for each node

address by default. In addition, Slave Unit status information other than I/O is

allocated in an input area in the Master Unit. The allocation can be set using

the CX-Integrator or explicit messages.

■ Maintenance System:

Slave Units can store several kinds of equipment data. This data can be read

from or written to the Slave Unit’s memory using the CX-Integrator or by sending explicit messages from the Master Unit (PLC) to the Slave Unit.

1-1-2 Features of CompoNet Slave Units

CompoNet Slave Units have the following features.

Main Features

The functions that can be used depend on the type of Slave Unit. For details,

refer to 1-1-3 CompoNet Slave Unit Functions.

Operation Time Monitor The Slave Unit can quickly measure the ON/OFF timing of input and output

contacts without relying on the ladder program. Contact types (IN - OUT, OUT

- IN, IN - IN, OUT - OUT) and trigger patterns (ON → OFF, OFF → ON, ON →

ON, OFF → OFF) can be freely combined for measurement. A time can be

set in the Slave Unit memory to enable notification of the status when the

measured time exceeds the set time.

This data can be set or read by using the CX-Integrator.

Contact Operation

Monitor

Total ON Time Monitor The total ON time of sensors, relays, and other devices are stored in the Slave

The number of times each input contact or output contact is turned ON can be

counted at a sampling frequency of 50 Hz maximum and stored. A value can

also be set in the Slave Unit to enable notification of the status if the number

of contact operations reaches the set value.

This data can be set or read by using the CX-Integrator.

Note The contact operation monitor and the total ON time monitor can-

not both be used for the same contact at the same time.

Unit memory. A value can also be set in the Slave Unit to enable notification of

the status if the total time reaches the set value.

These values can be set or read by using the CX-Integrator.

Note The total ON time monitor and the contact operation monitor can-

not be used at the same time for the same contact.

Automatic Baud Rate

Detection

2

The baud rate is automatically set to the same baud rate as the Master Unit;

therefore, there is no need to set the baud rate of the Slave Units.

Page 27

Features of CompoNet Slave Units Section 1-1

Unit Conduction Time

Monitor

Naming Units The user can set any name for each Unit as a comment. The names are

Naming Connected

Devices

Network Power Voltage

Monitoring

I/O Power Status Monitor The I/O power status monitor function checks if the I/O power is ON or not,

Communications Error

History Monitor

The total ON time of the Slave Unit's internal circuit power supply can be

stored. This value can be read using the CX-Integrator or explicit messages. A

value can also be set in the Slave Unit to enable obtaining notification of the

status if the total time reaches a set monitor value.

This data can be read or written by using the CX-Integrator.

stored in Slave Unit memory.

This data can be read or written by using the CX-Integrator.

Any name can be set for each I/O contact (e.g., sensor or valve) connected to

a Slave Unit. The names are stored in Slave Unit memory.

This data can be read or written by using the CX-Integrator.

The network power supply voltage (present, maximum, and minimum values)

can be stored in the Slave Unit memory. A monitor voltage can also be set in

the Slave Unit to enable notification of the status if the voltage drops to the

preset value.

These values can be set or read by using the CX-Integrator.

and provides notification in a status area.

This data can be checked by using the CX-Integrator.

Enables storing the error condition (communication failure details, the communications power supply voltage at the time of failure, and the Unit conduction time) for the most recent 4 communication failures, within the slave unit.

This data can be read by using the CX-Integrator.

Input Filters The Slave Units read input values multiple times during the set period to elim-

inate the effect of switch chattering and data omissions caused by noise. An

ON delay or OFF delay can also be implemented by using this function.

These settings are made by using the CX-Integrator.

Communications Error

Output Setting

Preventing Malfunctions

Caused by Inrush Current

at Startup

Power Short-circuit

Detection

Load Short-circuit

Detection

The output value when a communications error occurs can be set for each

word of an Output Unit.

These settings are made by using the CX-Integrator.

This function holds inputs from when the power is turned ON until the Unit stabilizes, i.e., inputs are not received while the I/O power is OFF and for 100 ms

after the I/O power is turned ON. This contributes to eliminating input errors

caused by inrush current when the I/O power is turned ON.

These settings are made by using the CX-Integrator.

The I/O power current is monitored. If an excessive current is detected, it is

assumed that a power short-circuit has occurred and the sensor power output

is turned OFF forcibly.

The status can be checked by using the LED indicators on the Slave Unit or

by using the CX-Integrator.

The output load current is monitored. If an excessive current is detected, it is

assumed that an load short-circuit has occurred and the output is turned OFF

forcibly to prevent damage to the Unit's output circuit.

The status can be checked by using the LED indicators on the Slave Unit or

by using the CX-Integrator.

Removable Terminal Block The terminal block can be removed.

3

Page 28

Features of CompoNet Slave Units Section 1-1

Expansion Using

Expansion Units

Scaling Converted data can be scaled to any value by the user. Ladder program cal-

Last Maintenance Date

(Maintenance Function)

Cumulated Count The cumulated count function calculates the integral time for input (or output)

Moving Average An Analog Input Unit or Temperature Input Unit can calculate the moving aver-

One Expansion Unit can be added to a Digital I/O Slave Unit (with 2-tier terminal block and 16 points). This extends the range of possible system configurations by making it possible to expand to a variety of I/O combinations, e.g., 16

inputs and 8 outputs or 24 inputs (16 inputs + 8 inputs).

culations for the Master Unit are not required if the scaling function is used

with the Slave Unit. The offset compensation function can also be used to offset scaled values.

These settings are made by using the CX-Integrator.

The date that maintenance was performed can be written in the Slave Unit by

using the CX-Integrator.

analog values and reads the cumulated value. Monitor values can be set in

Units. If the cumulated counter value exceeds the set monitor value, the

Cumulated Counter Over Flag in general status turns ON.

These values can be set and read by using the CX-Integrator.

age of the last eight inputs and use it as the converted data. Smooth input values can be obtained by averaging the inputs if there are rapid fluctuations in

the input.

Settings for averaging are made by using the CX-Integrator.

Setting the Number of AD

Conversion Points

Rate of Change

Calculations

Comparator Input data captured into the Analog Input Slave Unit/Temperature Input Unit or

Peak/Bottom Hold The peak/bottom hold function holds the maximum (peak) or the minimum

Top/Valley Hold The top/valley hold function holds the top or valley input value to an Analog

The conversion cycle is 4 ms max. when using all 4 analog inputs. The AD

conversion cycle can be made faster if fewer AD conversion points are used.

You can find the rate of change during the set data sampling cycle for the

input value to an Analog Input Unit or Temperature Input Unit.

The rate of change settings are made by using the CX-Integrator.

calculation data is compared to alarm settings (Alarm Trip Point High (HH),

Warning Trip Point High (H), Warning Trip Point Low (L), and Alarm Trip Point

Low (LL)) and the results can be reflected in the "Analog Status Flag" (or

"Temperature Data Status Flag"). The Normal Flag (pass signal) turns ON for

values that are in set range.

The alarm settings are made by using the CX-Integrator.

(bottom) input value to an Analog Input Unit or Temperature Input Unit. The

maximum (peak) or minimum (bottom) value can be compared with an alarm

set value and used to turn ON an alarm flag as status data. This is called the

comparator function.

The peak/bottom hold settings are made by using the CX-Integrator.

Input Unit or Temperature Input Unit. The Top/Valley Detection Timing Flag

can be used to check when top and valley values were detected. The top and

valley values can be compared with an alarm set value and used as status

data to turn ON alarm flags (comparator function).

The top/valley hold settings are made by using the CX-Integrator.

4

Page 29

Features of CompoNet Slave Units Section 1-1

Disconnected Line

Detection

User Adjustment The user adjustment function can be used to compensate offsets in input (or

Top/Valley Count With Temperature Input Units, the maximum or minimum number of times the

Temperature Range Total

Time Count

With Analog Input Units, the Disconnected Line Detection Flag for each input

can be used in the Master Unit to check whether the analog input lines (for

voltage inputs or current inputs) are disconnected for analog inputs that are

enabled under the setting of the number of AD conversion points.

This function is supported only when the input range is 1 to 5 V or 4 to 20 mA.

With Temperature Input Units, disconnections can be detected for each sensor input. The status can be checked at the Master Unit using the Disconnected Line Detection Flag.

output) values that occur due to the features of or connection method used for

input or output devices to adjust the input (or output). The conversion line is

adjusted at two points: 0% and 100%.

The adjustments can be made by using the CX-Integrator.

top or valley value is reached can be counted for an application that has fixed

cycles of temperature changes. Explicit messages can be used to see if the

number of cycles has exceeded a monitoring set value.

The settings are made by using the CX-Integrator.

With Temperature Input Units, the length of time that the temperature input

value is within a user-set temperature range can be measured in seconds.

Explicit messages can be used to see if the measured time has exceeded a

monitoring set value.

The temperature range total time count settings are made by using the CXIntegrator.

Input Temperature

Variation Detection

Input Error Detection

Disable Function

Other Features

Rotary Switch Setting of

Node Addresses

Bit-level Distribution (Bit

Slaves)

IP54 Dust-tight, Splashproof Units (Bit Slaves)

With Temperature Input Units, the temperature difference between two inputs

for inputs 0 to 3 can be detected and compared with a monitoring set value.

Explicit messages can be used to see if the temperature difference has

exceeded the monitoring set value.

The input temperature variation detection settings are made by using the CXIntegrator.

With Temperature Input Units, if there is an unused input, detection of input

errors (including disconnection) can be disabled.

Input error detection is disabled by using the CX-Integrator.

Node addresses can now be set much more easily using rotary switches.

(except some models)

Slave Units are available with 2 inputs, 2 outputs, 4 inputs, 4 outputs, 1 input/1

output, or 2 inputs/2 outputs. These enable bit-level distribution of Slave Units.

At the same time, unused Slave Unit I/O can be suppressed.

The CRT1B-@D@@SP(-1) Units conform to the IEC IP54 dust-tight, splashproof degree of protection (see note).

Note For protection against human bodies and solid foreign objects,

IP54 requires that dust will not penetrate inside the device to a degree that would affecting operation. For protection against water ingress, water splashing from any direction must have no adverse

effect.

5

Page 30

Features of CompoNet Slave Units Section 1-1

Flat Cable Included

(Bit Slaves, except Bit

Slave Units with Compact

Connectors)

No I/O Power Supply

Wiring Required

(Bit Slaves)

Industry Standard Sensor

e-CON Connectors

(CRT1-V@D08S(-1)/

CRT1-@D@S(-1)/

CRT1-@D16SH(-1)/

CRT1B-@D02S(-1)/

CRT1B-@D0@SP(-1)/

CRT1-VAD04S/

CRT1-VDA02S)

Units with MIL Connectors

(CRT1-V@D@@ML(-1)/

CRT1-VAD04ML/

CRT1-VDA02ML)

Units with Clamp Terminal

Blocks

(CRT1-@D@@SL(-1)/

CRT1B-MD04SLP(-1))

Models of Bit Slave Units are available with a Flat Cable included (standard or

sheathed). Models with a Flat Cable included, however, do not support a baud

rate of 4 Mbps. (Branching is not possible.)

External I/O (sensors or actuators) connected to Bit Slaves using e-CON connectors, clamp terminals, or compact connectors are supplied power from the

CompoNet communications power supply. No separate wiring is required for

I/O power supply.

No special tools are required for connections because industry standard eCON connectors are used. Electrical cables do not need to be stripped and

are simply inserted with pliers. When using e-CON connectors, there is no

need to prepare special tools for wiring, and connectors from different makers

can be used interchangeably.

MIL connectors, widely used in the electronic components and semiconductor

industries, help reduce wiring requirements.

There is no need to tighten the screws because these Units use screw-less

clamp terminal blocks. Connections are made simply by inserting the pin terminals. Wiring can be completed in one step.

6

Page 31

Features of CompoNet Slave Units Section 1-1

1-1-3 CompoNet Slave Unit Functions

Yes: Supported, ---: Not supported

Unit Digital I/O Slave Units

2-tier Terminal block

CRT1-@D08(-1) CRT1-@D16(-1)

Function

Operation Time Monitor Yes

Contact Operation Monitor Yes

Total ON Time Monitor Yes

Automatic Baud Rate Detection Yes

Unit Conduction Time Monitor Yes

Naming Units Yes

Naming Connected Devices Yes

Network Power Voltage Monitor Yes

I/O Power Status Monitor Yes

Communications Error History Monitor Yes

Input Filter Yes --- Yes --- Yes

Communications Error Output --- Yes --- Yes Yes

Preventing Malfunctions Caused by

Inrush Current at I/O Startup

Power Short-circuit Detection --Unconnected Line Detection --Load Short-circuit Detection --Disconnected Line Detection --Removable Terminal Block Structure Yes

Expansion Using Expansion Units --- Yes

Scaling --Last Maintenance Date Yes

Cumulated Count --Moving Average --Setting the Number of AD Conversion

Points

Rate of Change --Comparator --Peak/Bottom Hold --Top/Valley Hold --User Adjustment --Top/Valley Count --Temperature Range Total Time Count --Input Temperature Variation Detection --Input Error Detection Disable Function ---

Input Units Output Units Input Units Output Units I/O Units

Yes --- Yes --- Yes

---

Note The Contact Operation Monitor and the Total ON Time Monitor cannot be

used at the same time for the same contact.

7

Page 32

Features of CompoNet Slave Units Section 1-1

Yes: Supported, ---: Not supported

Unit Digital I/O Slave Units

2-tier Terminal block

CRT1-ROS08 CRT1-ROS16 CRT1-ROF08 CRT1-ROF16

Function Output Units Output Units

Operation Time Monitor Yes Yes

Contact Operation Monitor Yes Yes

Total ON Time Monitor Yes Yes

Automatic Baud Rate Detection Yes Yes

Unit Conduction Time Monitor Yes Yes

Naming Units Yes Yes

Naming Connected Devices Yes Yes

Network Power Voltage Monitor Yes Yes

I/O Power Status Monitor --- --Communications Error History

Monitor

Input Filter --- --Communications Error Output Yes Yes

Preventing Malfunctions Caused by

Inrush Current at I/O Startup

Power Short-circuit Detection --- --Unconnected Line Detection --- --Load Short-circuit Detection --- --Disconnected Line Detection --- --Removable Terminal Block Structure Yes Yes

Expansion Using Expansion Units --- Yes --- Yes

Scaling --- --Last Maintenance Date Yes Yes

Cumulated Count --- --Moving Average --- --Setting the Number of AD

Conversion Points

Rate of Change --- --Comparator --- --Peak/Bottom Hold --- --Top/Valley Hold --- --User Adjustment --- --Top/Valley Count --Temperature Range Total Time

Count

Input Temperature Variation

Detection

Input Error Detection Disable

Function

Ye s Ye s

--- ---

--- ---

---

---

---

Note The Contact Operation Monitor and the Total ON Time Monitor cannot be

used at the same time for the same contact.

8

Page 33

Features of CompoNet Slave Units Section 1-1

Yes: Supported, ---: Not supported

Unit Digital I/O Slave Units

3-tier Terminal block

CRT1-@D08TA(-1)

(without Short-circuit and

Disconnected Line Detection)

Function Input Units Output Units Input Units Output Units

Operation Time Monitor Yes

Contact Operation Monitor Yes

Total ON Time Monitor Yes

Automatic Baud Rate Detection Yes

Unit Conduction Time Monitor Yes

Naming Units Yes

Naming Connected Devices Yes

Network Power Voltage Monitor Yes

I/O Power Status Monitor Yes

Communications Error History Monitor Yes

Input Filter Yes --- Yes --Communications Error Output --- Yes --- Yes

Preventing Malfunctions Caused by

Inrush Current at I/O Startup

Power Short-circuit Detection --- Yes --Unconnected Line Detection --- Yes --Load Short-circuit Detection --- --- Yes

Disconnected Line Detection --- --- Yes

Removable Terminal Block Structure Yes

Expansion Using Expansion Units --Scaling --Last Maintenance Date Yes

Cumulated Count --Moving Average --Setting the Number of AD Conversion

Points

Rate of Change --Comparator --Peak/Bottom Hold --Top/Valley Hold --User Adjustment --Top/Valley Count --Temperature Range Total Time Count --Input Temperature Variation Detection --Input Error Detection Disable Function ---

Yes --- Yes ---

---

CRT1-@D08TAH(-1)

(with Short-circuit and

Disconnected Line Detection)

Note The Contact Operation Monitor and the Total ON Time Monitor cannot be

used at the same time for the same contact.

9

Page 34

Features of CompoNet Slave Units Section 1-1

Yes: Supported, ---: Not supported

Unit Digital I/O Slave Units

3-tier Terminal block

CRT1-@D16TA(-1)

(without Short-circuit and

Disconnected Line Detection)

Function Input Units Output

Units

Operation Time Monitor Yes

Contact Operation Monitor Yes

Total ON Time Monitor Yes

Automatic Baud Rate Detection Yes

Unit Conduction Time Monitor Yes

Naming Units Yes

Naming Connected Devices Yes

Network Power Voltage Monitor Yes

I/O Power Status Monitor Yes

Communications Error History Monitor Yes

Input Filter Yes --- Yes Yes --- Yes

Communications Error Output --- Yes Yes --- Yes Yes

Preventing Malfunctions Caused by

Inrush Current at I/O Startup

Power Short-circuit Detection --- Yes --- Yes

Unconnected Line Detection --- Yes --- Yes

Load Short-circuit Detection --- --- Yes Yes

Disconnected Line Detection --- --- Yes Yes

Removable Terminal Block Structure Yes

Expansion Using Expansion Units --Scaling --Last Maintenance Date Yes

Cumulated Count --Moving Average --Setting the Number of AD Conversion

Points

Rate of Change --Comparator --Peak/Bottom Hold --Top/Valley Hold --User Adjustment --Top/Valley Count --Temperature Range Total Time Count --Input Temperature Variation Detection --Input Error Detection Disable Function ---

Ye s - - - Ye s Ye s - - - Ye s

I/O Units Input Units Output

(with Short-circuit and Disconnected

---

CRT1-@D16TAH(-1)

Line Detection)

I/O units

Units

10

Note The Contact Operation Monitor and the Total ON Time Monitor cannot be

used at the same time for the same contact.

Page 35

Features of CompoNet Slave Units Section 1-1

Yes: Supported, ---: Not supported

Unit Digital I/O Slave Units

Units with e-CON Connectors

CRT1-V@D08S(-1)

Function Input Units Output Units

Operation Time Monitor Yes

Contact Operation Monitor Yes

Total ON Time Monitor Yes

Automatic Baud Rate Detection Yes

Unit Conduction Time Monitor Yes

Naming Units Yes

Naming Connected Devices Yes

Network Power Voltage Monitor Yes

I/O Power Status Monitor --- Yes

Communications Error History Monitor Yes

Input Filter Yes --Communications Error Output --- Yes

Preventing Malfunctions Caused by Inrush Current at

I/O Startup

Power Short-circuit Detection --Unconnected Line Detection --Load Short-circuit Detection --Disconnected Line Detection --Removable Terminal Block Structure --Expansion Using Expansion Units --Scaling --Last Maintenance Date Yes

Cumulated Count --Moving Average --Setting the Number of AD Conversion Points --Rate of Change --Comparator --Peak/Bottom Hold --Top/Valley Hold --User Adjustment --Top/Valley Count --Temperature Range Total Time Count --Input Temperature Variation Detection --Input Error Detection Disable Function ---

Yes ---

Note The Contact Operation Monitor and the Total ON Time Monitor cannot be

used at the same time for the same contact.

11

Page 36

Features of CompoNet Slave Units Section 1-1

Yes: Supported, ---: Not supported

Unit Digital I/O Slave Units

Units with e-CON Connectors

CRT1-@D16S(-1)

(without Short-circuit and

Disconnected Line Detection)

Function Input Units Output

Units

Operation Time Monitor Yes

Contact Operation Monitor Yes

Total ON Time Monitor Yes

Automatic Baud Rate Detection Yes

Unit Conduction Time Monitor Yes

Naming Units Yes

Naming Connected Devices Yes

Network Power Voltage Monitor Yes

I/O Power Status Monitor --- Yes Yes --- Yes Yes

Communications Error History Monitor Yes

Input Filter Yes --- Yes Yes --- Yes

Communications Error Output --- Yes Yes --- Yes Yes

Preventing Malfunctions Caused by

Inrush Current at I/O Startup

Power Short-circuit Detection --- Yes --- Yes

Unconnected Line Detection --- Yes --- Yes

Load Short-circuit Detection --- --- Yes Yes

Disconnected Line Detection --- --- Yes Yes

Removable Terminal Block Structure --Expansion Using Expansion Units --Scaling --Last Maintenance Date Yes

Cumulated Count --Moving Average --Setting the Number of AD Conversion

Points

Rate of Change --Comparator --Peak/Bottom Hold --Top/Valley Hold --User Adjustment --Top/Valley Count --Temperature Range Total Time Count --Input Temperature Variation Detection --Input Error Detection Disable Function ---

Yes --- Yes Yes --- Yes

I/O Units Input Units Output

(with Short-circuit and Disconnected

---

CRT1-@D16SH(-1)

Line Detection)

I/O units

Units

12

Note The Contact Operation Monitor and the Total ON Time Monitor cannot be

used at the same time for the same contact.

Page 37

Features of CompoNet Slave Units Section 1-1

Yes: Supported, ---: Not supported

Unit Digital I/O Slave Units

Units with e-CON Connectors

CRT1-@D32S(-1)

(without Short-circuit and

Disconnected Line Detection)

Function Input Units Output

Units

Operation Time Monitor Yes

Contact Operation Monitor Yes

Total ON Time Monitor Yes

Automatic Baud Rate Detection Yes

Unit Conduction Time Monitor Yes

Naming Units Yes

Naming Connected Devices Yes

Network Power Voltage Monitor Yes

I/O Power Status Monitor --- Yes Yes --- Yes Yes

Communications Error History Monitor Yes

Input Filter Yes --- Yes Yes --- Yes

Communications Error Output --- Yes Yes --- Yes Yes

Preventing Malfunctions Caused by

Inrush Current at I/O Startup

Power Short-circuit Detection --- Yes --- Yes

Unconnected Line Detection --- Yes --- Yes

Load Short-circuit Detection --- --- Yes Yes

Disconnected Line Detection --- --- Yes Yes

Removable Terminal Block Structure --Expansion Using Expansion Units --Scaling --Last Maintenance Date Yes

Cumulated Count --Moving Average --Setting the Number of AD Conversion

Points

Rate of Change --Comparator --Peak/Bottom Hold --Top/Valley Hold --User Adjustment --Top/Valley Count --Temperature Range Total Time Count --Input Temperature Variation Detection --Input Error Detection Disable Function ---

Yes --- Yes Yes --- Yes

I/O Units Input Units Output

(with Short-circuit and Disconnected

---

CRT1-@D32SH(-1)

Line Detection)

I/O units

Units

Note The Contact Operation Monitor and the Total ON Time Monitor cannot be

used at the same time for the same contact.

13

Page 38

Features of CompoNet Slave Units Section 1-1

Yes: Supported, ---: Not supported

Unit Digital I/O Slave Units

Units with MIL Connectors

CRT1-V@D16ML(-1) CRT1-V@D32ML(-1)

Function

Operation Time Monitor Yes

Contact Operation Monitor Yes

Total ON Time Monitor Yes

Automatic Baud Rate Detection Yes

Unit Conduction Time Monitor Yes

Naming Units Yes

Naming Connected Devices Yes

Network Power Voltage Monitor Yes

I/O Power Status Monitor Yes

Communications Error History Monitor Yes

I n p ut F i lt e r Ye s - - - Ye s - -- Ye s

Communications Error Output --- Yes --- Yes Yes

Preventing Malfunctions Caused by

Inrush Current at I/O Startup

Power Short-circuit Detection --Unconnected Line Detection --Load Short-circuit Detection --Disconnected Line Detection --Removable Terminal Block Structure --Expansion Using Expansion Units --Scaling --Last Maintenance Date Yes

Cumulated Count --Moving Average --Setting the Number of AD Conversion

Points

Rate of Change --Comparator --Peak/Bottom Hold --Top/Valley Hold --User Adjustment --Top/Valley Count --Temperature Range Total Time Count --Input Temperature Variation Detection --Input Error Detection Disable Function ---

Input Units Output Units Input Units Output Units I/O Units

Ye s - - - Ye s - - - Ye s

---

14

Note The Contact Operation Monitor and the Total ON Time Monitor cannot be

used at the same time for the same contact.

Page 39

Features of CompoNet Slave Units Section 1-1

Yes: Supported, ---: Not supported

Unit Digital I/O Slave Units

Units with Screw-less Clamp Terminals

CRT1-@D08SL(-1) CRT1-@D16SL(-1)

Function

Operation Time Monitor Yes

Contact Operation Monitor Yes

Total ON Time Monitor Yes

Automatic Baud Rate Detection Yes

Unit Conduction Time Monitor Yes

Naming Units Yes

Naming Connected Devices Yes

Network Power Voltage Monitor Yes

I/O Power Status Monitor Yes

Communications Error History Monitor Yes

I n p ut F i lt e r Ye s - - - Ye s - - - Ye s

Communications Error Output --- Yes --- Yes Yes

Preventing Malfunctions Caused by

Inrush Current at I/O Startup

Power Short-circuit Detection --Unconnected Line Detection --Load Short-circuit Detection --Disconnected Line Detection --Removable Terminal Block Structure Yes

Expansion Using Expansion Units --Scaling --Last Maintenance Date Yes

Cumulated Count --Moving Average --Setting the Number of AD Conversion

Points

Rate of Change --Comparator --Peak/Bottom Hold --Top/Valley Hold --User Adjustment --Top/Valley Count --Temperature Range Total Time Count --Input Temperature Variation Detection --Input Error Detection Disable Function ---

Input Units Output Units Input Units Output Units I/O Units

Ye s - - - Ye s - - - Ye s

---

Note The Contact Operation Monitor and the Total ON Time Monitor cannot be

used at the same time for the same contact.

15

Page 40

Features of CompoNet Slave Units Section 1-1

Yes: Supported, ---: Not supported

Unit Analog l I/O Slave Units

Units with 2-tier

Terminal block

CRT1-AD04

CRT1-DA02

Function Input

Units

Operation Time Monitor --Contact Operation Monitor --Total ON Time Monitor --Automatic Baud Rate Detection Yes

Unit Conduction Time Monitor Yes

Naming Units Yes

Naming Connected Devices Yes

Network Power Voltage Monitor Yes

I/O Power Status Monitor --Communications Error History Monitor Yes

Input Filter --Communications Error Output --- Yes --- Yes --- Yes

Preventing Malfunctions Caused by Inrush

Current at I/O Startup

Power Short-circuit Detection --Unconnected Line Detection --Load Short-circuit Detection --Disconnected Line Detection Yes --- Yes --- Yes --Removable Terminal Block Structure Yes

Expansion Using Expansion Units --Scaling Ye s

Last Maintenance Date Yes

Cumulated Count Yes

Moving Average Yes --- Yes --- Yes --Setting the Number of AD Conversion Points Yes --- Yes --- Yes --Rate of Change Yes --- Yes --- Yes --Comparator Yes --- Yes --- Yes --Peak/Bottom Hold Yes --- Yes --- Yes --Top/Valley Hold Yes --- Yes --- Yes --User Adjustment Yes

Top/Valley Count --Temperature Range Total Time Count --Input Temperature Variation Detection --Input Error Detection Disable Function ---

Output

Units

Units with e-CON

Connectors

CRT1-VAD04S

CRT1-VDA02S

Input

Units

Output

Units

---

Units with MIL

Connectors

CRT1-VAD04ML

CRT1-VDA02ML

Input

Units

Output

Units

16

Note The Contact Operation Monitor and the Total ON Time Monitor cannot be

used at the same time for the same contact.

Page 41

Features of CompoNet Slave Units Section 1-1

Yes: Supported, ---: Not supported

Unit Temperature Input Units

CRT1-TS04T

CRT1-TS04P

Function Input Units

Operation Time Monitor --Contact Operation Monitor --Total ON Time Monitor --Automatic Baud Rate Detection Yes

Unit Conduction Time Monitor Yes

Naming Units Yes

Naming Connected Devices Yes

Network Power Voltage Monitor Yes

I/O Power Status Monitor --Communications Error History Monitor Yes

Input Filter --Communications Error Output --Preventing Malfunctions Caused by Inrush

Current at I/O Startup

Power Short-circuit Detection --Unconnected Line Detection --Load Short-circuit Detection --Disconnected Line Detection Yes

Removable Terminal Block Structure Yes

Expansion Using Expansion Units --Scaling Yes

Last Maintenance Date Yes

Cumulated Count Yes

Moving Average Yes

Setting the Number of AD Conversion Points --Rate of Change Yes

Comparator Yes

Peak/Bottom Hold Yes

Top/Valley Hold Yes

User Adjustment Yes

Top/Valley Count Yes

Temperature Range Total Time Count Yes

Input Temperature Variation Detection Yes

Input Error Detection Disable Function Yes

---

Note The Contact Operation Monitor and the Total ON Time Monitor cannot be

used at the same time for the same contact.

17

Page 42

Features of CompoNet Slave Units Section 1-1

Yes: Supported, ---: Not supported

Unit Bit Slave Units Bit Slaves with Compact Connectors Repea

CRT1B-

@D02S(-1)

Function Input

Operation Time Monitor Yes --- --- ---

Contact Operation Monitor Yes --- --- ---

Total ON Time Monitor Yes --- --- ---

Automatic Baud Rate

Detection

Unit Conduction Time Monitor Yes --- --- Yes

Naming Units Yes --- --- Yes

Naming Connected Devices Yes --- --- ---

Network Power Voltage

Monitor

I/O Power Status Monitor --- --- --- ---

Communications Error History

Monitor

Input Filter Yes --- Yes --- Yes Yes --- Yes Yes --- Yes ---

Communications Error Output --- Yes --- Yes Yes --- Yes Yes --- Yes Yes ---

Preventing Malfunctions

Caused by Inrush Current at

I/O Startup

Power Short-circuit Detection Yes --- Yes --- Yes --- --- ---

Unconnected Line Detection --- --- --- ---

Load Short-circuit Detection --- Yes --- Yes Yes --- --- ---

Disconnected Line Detection --- --- --- ---

Removable Terminal Block

Structure

Expansion Using Expansion

Units

Scaling --- --- --- ---

Last Maintenance Date Yes --- --- Yes

Cumulated Count --- --- --- ---

Moving Average --- --- --- ---

Setting the Number of AD

Conversion Points

Rate of Change --- --- --- ---

Comparator --- --- --- ---

Peak/Bottom Hold --- --- --- ---

Top/Valley Hold --- --- --- ---

User Adjustment --- --- --- ---

Top/Valley Count --- --- --- ---

Temperature Range Total

Time Count

Input Temperature Variation

Detection

Input Error Detection Disable

Function

Output

Units

Units

Yes --- Yes --- Yes --- --- ---

CRT1B-@D0@SP(-1)

CRT1B-MD04SLP(-1)

Input

Output

Units

Ye s Ye s Ye s Ye s

Yes --- --- Yes

Yes --- --- Yes

Units

--- --- --- ---

--- --- --- ---

--- --- --- ---

--- --- --- ---

--- --- --- ---

--- --- --- ---

units

CRT1B-@D02JS(-1) CRT1B-@D04JS(-1) CRS1-

I/O

Input

Units

Output

Units

I/O

units

Input

Units

Output

Units

units

I/O

ter

Unit

RPT01

18

Note The Contact Operation Monitor and the Total ON Time Monitor cannot be

used at the same time for the same contact.

Page 43

Slave Unit Models Section 1-2

1-2 Slave Unit Models

CompoNet Slave Units can be classified into the following groups.

Word Slave Units Word Slave Units are Slave Units that are allocated units of 16 bits (i.e.,

1 word) in I/O memory of the CPU Unit.

Digital I/O Slave Units: Slave Units with digital I/O

Analog I/O Slave Units: Slave Units with analog I/O

Temperature Input Units: Slave Units with temperature inputs

Expansion Units: Units that can be used to expand the number of I/O

points for Digital I/O Slave Units (with 2-tier terminal blocks and 16 points).

Bit Slave Units Bit Slave Units are Slave Units that are allocated units of 2 bits in I/O memory

of the CPU Unit.

Bit Slave Units : Bit Slave Units are Slave Units with 2 points or 4

points of digital I/O. They come with a Standard or

Sheathed Flat Cable included.

Bit Slaves with Compact Connectors:

Bit Slave Units with Compact Connectors are Slave

Units with 2 points or 4 points of digital I/O. They

have built-in compact connectors for the I/O interface that support connections with communications

cables using internal hook communications connectors.

Repeater Units Units that can be used to expand the network by extending trunk lines or

branching.

19

Page 44

Slave Unit Models Section 1-2

1-2-1 Word Slave Units

Digital I/O Slave Units

Terminal Block with

Screws

Type Appearance I/O capacity Model Features

Digital I/O Slave Units

with 2-tier Terminal

Block

1

1

1

0

1

89

567

01234

T

U

R

O

D

A

E

D

O

N

1

X

D

R

O

W

0

]

1

3

X

S

6

-

N

0

[

MS

MRON

O

8 inputs (NPN) CRT1-ID08 • Terminal blocks can be attached/

8 inputs (PNP) CRT1-ID08-1

8 outputs (NPN) CRT1-OD08

removed from the Unit.

• Expansion Units cannot be

added.

8 outputs (PNP) CRT1-OD08-1

5

1

4

1

3

1

2

16 inputs (NPN) CRT1-ID16 • Terminal blocks can be attached/

16 inputs (PNP) CRT1-ID16-1

removed from the Unit.

• Expansion Units can be added.

16 outputs (NPN) CRT1-OD16

16 outputs (PNP) CRT1-OD16-1

8 inputs/8 outputs

(NPN)

8 inputs/8 outputs

(PNP)

CRT1-MD16 • Terminal blocks can be attached/

removed from the Unit.

CRT1-MD16-1

• Expansion Units cannot be

added.

8 outputs (relay

outputs)

8 outputs

(SSR outputs)

16 outputs

(relay outputs)

16 outputs

(SSR outputs)

CRT1-ROS08

CRT1-ROF08

CRT1-ROS16 • Terminal blocks can be attached/

removed from the Unit.

CRT1-ROF16

• Expansion Units can be added.

20

Page 45

Slave Unit Models Section 1-2

Type Appearance I/O capacity Model Features

Digital I/O Slave

Units with 3-tier

Terminal Block

Without

Short-circuit and

Disconnected

Line

Detection

With

Short-circuit and

Disconnected

Line

Detection

Without

Short-circuit and

Disconnected

Line

Detection

With

Short-circuit and

Disconnected

Line

Detection

8 inputs (NPN) CRT1-ID08TA • Terminal blocks can be