Page 1

Cat.No. W365–E1–1

SYSMAC CQM1H Series

CQM1H-SCB41

Serial Communications Board

OPERATION MANUAL

Page 2

SYSMAC

CQM1H Series

CQM1H-SCB41

Serial Communications Board

Operation Manual

Produced September 1999

Page 3

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 4

About this Manual:

This manual describes the installation and operation of the SYSMAC CQM1H-series CQM1H-SCB41 Serial Communications Board and includes the sections described below.

The Serial Communications Board is classified as an Inner Board.

Read this manual and all related manuals listed in the following table carefully and be sure you understand

the information provided before attempting to install and operate a Serial Communications Board.

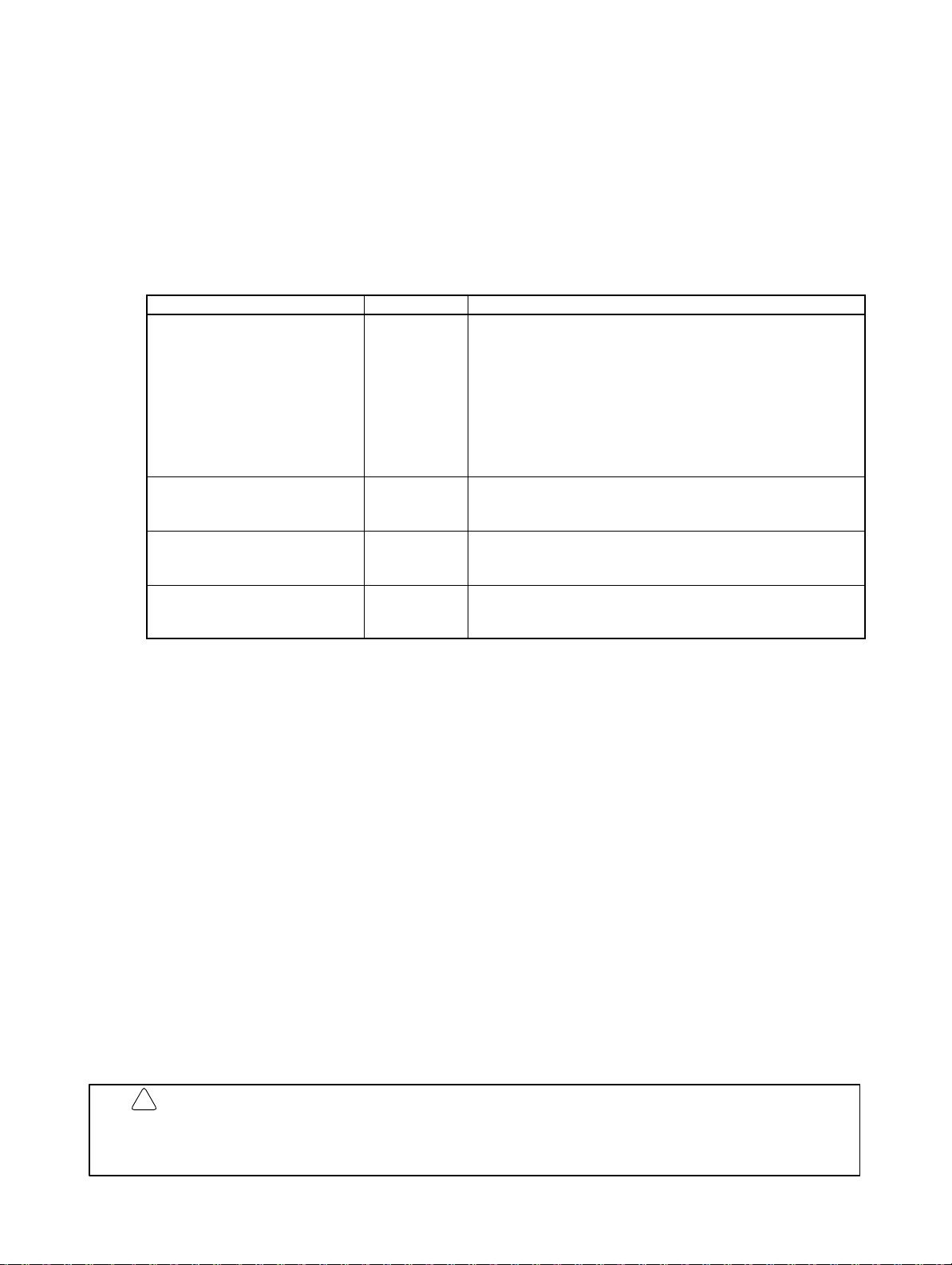

Name Cat. No. Contents

SYSMAC CQM1H-series

CQM1H-SCB41

Serial Communications Board

Operation Manual

SYSMAC CQM1H-series

Programmable Controllers

Operation Manual

SYSMAC CQM1H-series

Programmable Controllers

Programming Manual

SYSMAC WS02-PSTC1-E

CX-Protocol Operation Manual

W365-E1-1 Describes the use of the Serial Communications Board to

perform serial communications with external devices,

including hardware and the usage of standard system

protocols for OMRON products.

Host Link communications commands are described in the

SYSMAC CQM1H-series Programmable Controllers

Programming Manual (W364).

Creating protocol macros is described in the CX-Protocol

Operation Manual (W344).

W363-E1-1 Describes the installation and operation of the

CQM1H-series PCs.

W364-E1-1 Describes the ladder diagram programming instructions

supported by CQM1H-series PCs, Host Link commands,

and other programming information.

W344-E1-1 Describes the use of the CX-Protocol to create protocol

macros as communications sequences to communicate with

external devices.

Section 1 introduces the hardware and software functions of the Serial Communications Board, including

the serial communications modes, system configurations, and specifications.

Section 2 describes the components of the Serial Communications Board, how to connect it in the CPU

Unit, and how to connect it to external devices.

Section 3 describes the settings, control bits, flags, and status information available in the CPU Unit for

use with the Serial Communications Board.

Section 4 describes the procedure and other information required to use Host Link communications.

Section 5 describes the procedure and other information required to use protocol macros.

Section 6 provides information required to use no-protocol communications on a Serial Communications

Board port.

Section 7 provides information required to create 1:1 data links through a Serial Communications Board

port.

Section 8 describes the procedure and other information required to use 1:N-mode and 1:1-mode NT

Links to Programmable Terminals (PTs).

Section 9 describes the troubleshooting and maintenance procedures for the Serial Communications

Boards.

Appendix A to Appendix N provide the specifications of the standard system protocols.

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

vii

Page 5

TABLE OF CONTENTS

PRECAUTIONS xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Conformance to EC Directives xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Overview 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Protocol Overview 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Specifications 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Basic Operating Procedure 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Board Components and Installation 9. . . . . . . . . . . . . . . . .

2-1 Component Names and Functions 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Installation 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Wiring 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Default Settings and Related Bits/Flags 27. . . . . . . . . . . . . .

3-1 Overview 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 PC Setup Settings 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Control Bits, Flags, and Status Information 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Host Link Communications 33. . . . . . . . . . . . . . . . . . . . . . .

4-1 Host Link Communications 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Application Procedure 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Connections 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Host Link Communications 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 Changes from Previous Products 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Protocol Macros 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Overview of the Protocol Macro Functions 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Restrictions in Using the CX-Protocol 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Application Procedure 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Connections 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 Protocol Structure 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6 Control Bits, Flags, and Status Information 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7 Using Protocol Macros 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6

No-protocol Communications 97. . . . . . . . . . . . . . . . . . . . . .

6-1 Overview 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Application Procedure 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Connections 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Using No-protocol Communications 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 6

TABLE OF CONTENTS

SECTION 7

Communications for 1:1 Data Links 107. . . . . . . . . . . . . . . .

7-1 Overview 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 Application Procedure 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3 Connections 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4 Using 1:1 Data Links 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 8

NT Link Communications 113. . . . . . . . . . . . . . . . . . . . . . . . .

8-1 Overview of NT Links 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2 Application Procedure 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3 Connections 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 9

Troubleshooting and Maintenance 119. . . . . . . . . . . . . . . . . .

9-1 Front-panel Indicator Error Displays 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2 Troubleshooting 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-3 Cleaning and Inspection 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-4 Board Replacement 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Introduction 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B CompoWay/F Master Protocol 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C E5jK Digital Controller Read Protocol 153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D E5jK Digital Controller Write Protocol 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E E5ZE Temperature Controller Read Protocol 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F E5ZE Temperature Controller Write Protocol 209. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G E5jJ Temperature Controller Protocol 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H ES100j Digital Controller Protocol 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I K3Tj Intelligent Signal Processor Protocol 283. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

J V500/V520 Bar Code Reader Protocol 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

K 3Z4L Laser Micrometer Protocol 317. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

L Visual Inspection System Protocol 349. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

M V600/V620 ID Controller Protocol 367. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

N Hayes Modem AT Command Protocol 403. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 411. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 419. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ix

Page 7

PRECAUTIONS

This section provides general precautions for using the Serial Communications Boards.

The information contained in this section is important for the safe and reliable application of the Serial Communications Boards and the PC in general. You must read this section and understand the information contained before attempting to set up or operate a PC system containing a Serial Communications Board.

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Conformance to EC Directives xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Applicable Directives xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1-1 Concepts xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1-2 Conformance to EC Directives xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xi

Page 8

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual

close at hand for reference during operation.

3Conformance to EC Directives

WARNING It is extremely important that a Serial Communications Board and all related

!

units be used for the specified purpose and under the specified conditions,

especially in applications that can directly or indirectly affect human life. You

must consult with your OMRON representative before applying a Serial

Communications Board to the above mentioned applications.

3 Safety Precautions

WARNING Never attempt to disassemble any Units while power is being supplied. Doing so

!

may result in electric shock.

WARNING The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

!

PROGRAM mode). Confirm safety thoroughly in advance before changing the

status of any part of memory allocated to I/O Units, Inner Boards, or Dedicated

I/O Units. Any changes to the data allocated to any Unit may result in

unexpected operation of the loads connected to the Unit. Any of the following

operation may result in changes to memory status.

• Transferring I/O memory data to the CPU Unit from a Programming Device.

• Changing present values in memory from a Programming Device.

• Force-setting/-resetting bits from a Programming Device.

• Transferring I/O memory files from a Memory Card or EM file memory to the

CPU Unit.

• Transferring I/O memory from a host computer or from another PC on a network.

xii

WARNING Never touch any of the terminals while power is being supplied. Doing so may

!

result in electric shock.

Caution Execute online edit only after confirming that no adverse effects will be caused

!

by extending the cycle time. Otherwise, input signals may not be read properly.

Page 9

4 Operating Environment Precautions

Caution Do not operate the control system in the following locations:

!

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Caution Take appropriate and sufficient countermeasures when installing systems in the

!

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

5Conformance to EC Directives

Caution The operating environment of the PC System can have a large effect on the lon-

!

gevity and reliability of the system. Improper operating environments can lead to

malfunction, failure, and other unforeseeable problems with the PC System. Be

sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of the system.

5 Application Precautions

Observe the following precautions when using the PC.

WARNING Failure to abide by the following precautions could lead to serious or possibly

!

fatal injury. Always heed these precautions.

• Always ground the system to 100 Ω or less when installing the system to protect against electrical shock.

• Always turn OFF the power supply to the PC before attempting any of the following. Not turning OFF the power supply may result in malfunction or electric

shock.

• Assembling the Units or mounting the Serial Communications Board.

• Setting DIP switches or rotary switches.

• Connecting or wiring the cables.

• Connecting or disconnecting the connectors.

Caution Failure to abide by the following precautions could lead to faulty operation or the

!

PC or the system or could damage the PC or PC Units. Always heed these precautions.

• Do not turn OFF the power supply while transferring protocol macro data.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

xiii

Page 10

• Always discharge static electricity by touching a grounded metal part before

mounting the Serial Communications Board.

• Always discharge static electricity by touching a grounded metal part before

connecting cable connectors to RS-232C or RS-422A/485 port of the Serial

Communications Board.

• Be sure that the connectors, terminal blocks, expansion cables, and other

items with locking devices are properly locked into place. Improper locking

may result in malfunction.

• Confirm that no adverse effect will occur in the system before attempting any of

the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable. An incorrect power supply may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may result in malfunction if foreign matter enters the Unit.

5Conformance to EC Directives

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Confirm polarities before connecting RS-422A/485 cables. Some devices require that SDA/B and RDA/B or signal polarities be reversed.

• Double-check all wiring and switch settings before turning ON the power supply. Incorrect wiring may result in burning.

• Check the user programming (ladder program, protocol macro data, etc.) for

proper execution before actually running it on the Unit. Not checking the program may result in an unexpected operation.

• Resume operation only after transferring to the new CPU Unit the contents of

the DM Area, HR Area, and other data required for resuming operation. Not

doing so may result in an unexpected operation.

• Circuit boards have sharp or pointed edges, such as those on the leads of electrical parts. Do not touch the back of printed boards or mounted sections with

your bare hands.

• Connect or set terminating resistance correctly when using RS-422A/485

cables.

• During transportation and storage, cover the circuit boards with conductive

materials to prevent them from being damaged by static electricity caused by

LSIs or ICs and keep them within the specified storage temperature.

xiv

• Refer to Section 2 Board Components and Installation and correctly wire and

install the Units.

• Do not attempt to take any Units apart, to repair any Units, or to modify any

Units in any way.

• Disconnect the functional ground terminal when performing withstand voltage

tests. Not disconnecting the functional ground terminal may result in burning.

Page 11

6 Conformance to EC Directives

6-1 Applicable Directives

• EMC Directives

• Low Voltage Directive

6-1-1 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or machines. The actual products have been checked for conformity to EMC standards (see the following note). Whether the products conform to the standards in

the system used by the customer, however, must be checked by the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of the

equipment or control panel in which the OMRON devices are installed. The customer must, therefore, perform final checks to confirm that devices and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

6Conformance to EC Directives

EMS (Electromagnetic Susceptibility): EN61131-2

EMI (Electromagnetic Interference): EN50081-2

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC or 75 to

1,500 VDC meet the required safety standards for the PC (EN61131-2).

6-1-2 Conformance to EC Directives

The CQM1H-series PCs comply with EC Directives. T o ensure that the machine

or device in which a CQM1H-series PC is used complies with EC directives, the

PC must be installed as follows:

1, 2, 3... 1. The PC must be installed within a control panel.

2. Reinforced insulation or double insulation must be used for the DC power

supplies used for the I/O power supplies.

3. PCs complying with EC Directives also conform to the Common Emission

Standard (EN50081-2). When a PC is built into a machine, however, noise

can be generated by switching devices using relay outputs and cause the

overall machine to fail to meet the Standards. If this occurs, surge killers

must be connected or other measures taken external to the PC.

The following methods represent typical methods for reducing noise, and

may not be sufficient in all cases. Required countermeasures will vary

depending on the devices connected to the control panel, wiring, the configuration of the system, and other conditions.

(Radiated emission: 10-m regulations)

6-1-3 EMI Measures

The CQM1H-series PCs conform to the Common Emission Standards

(EN50081-2) of the EMC Directives. However, the noise generated from Serial

Communications Board communications cables may not satisfy these standards. In such a case, commercially available ferrite cores must be placed on the

communications cable or other appropriate countermeasures must be provided

external to the PC.

xv

Page 12

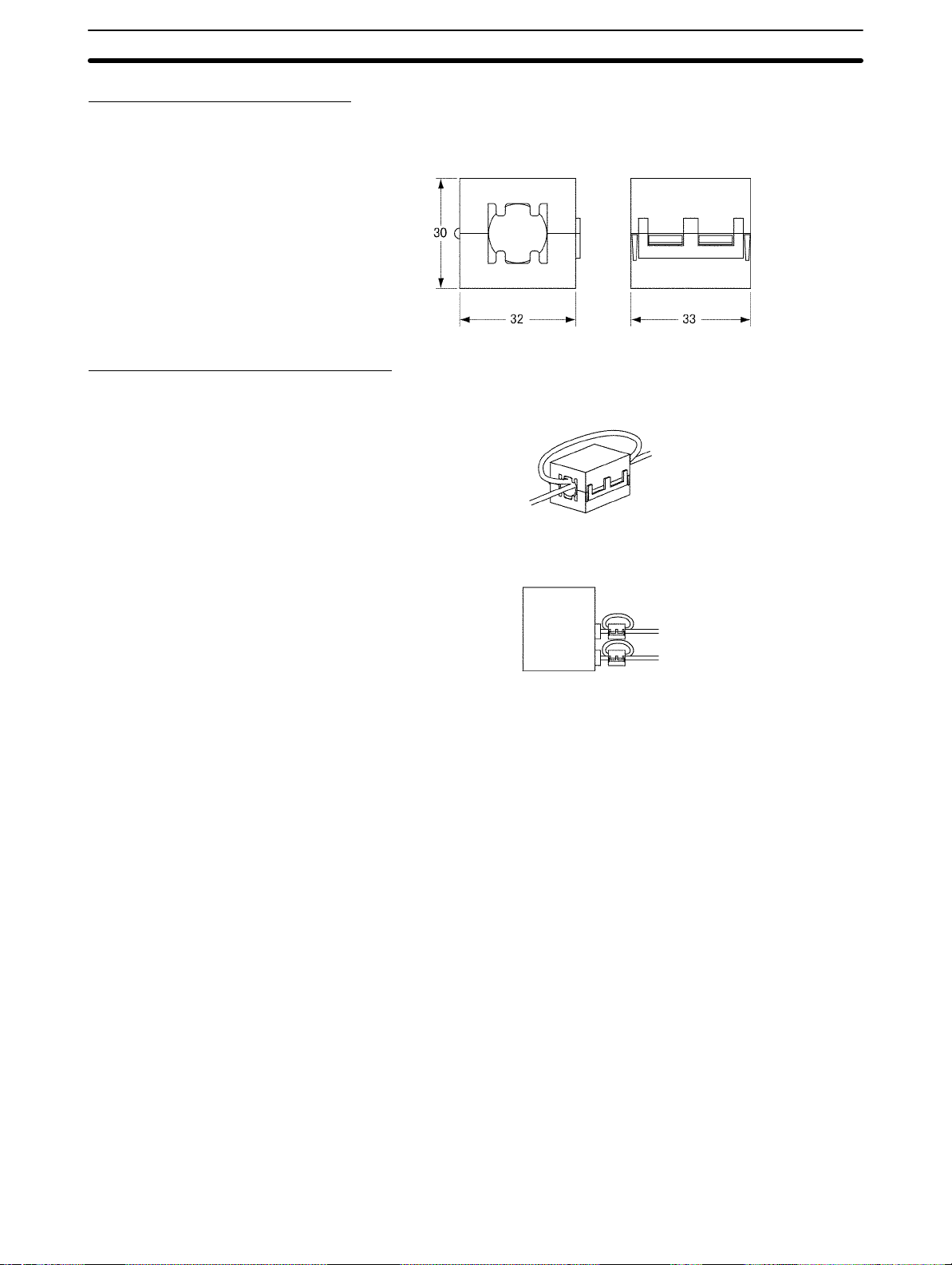

Recommended Ferrite Cores

The following ferrite core (data line noise filter) is recommended:

0443-164151 by Fair-Rite Products Corp.

Low impedance, 25 MHz: 90 Ω, 100 MHz: 160 Ω

Recommended Mounting Method

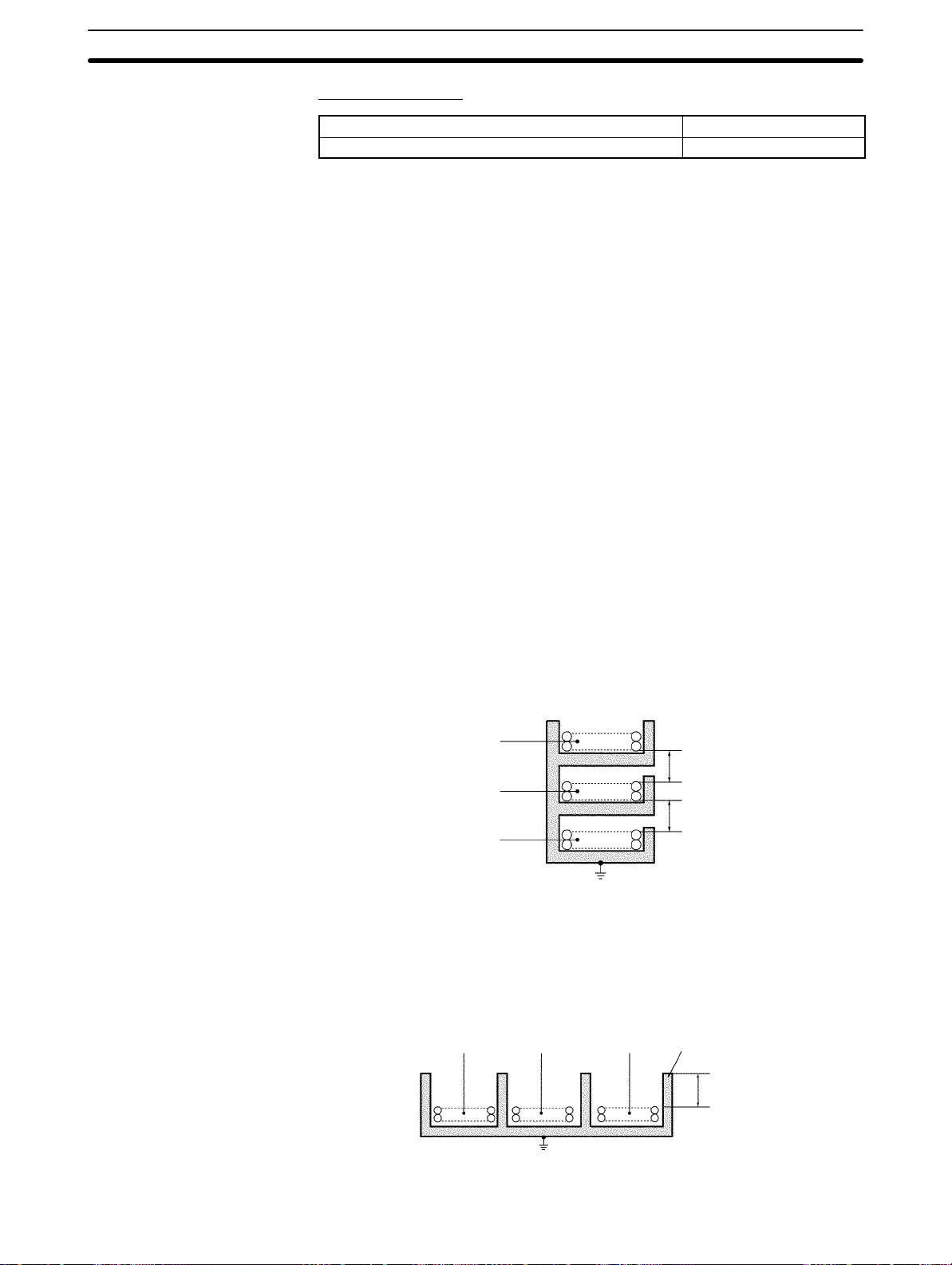

Mount the core on one turn of the communications cable, as shown in the following illustration.

6Conformance to EC Directives

Mount the cores as closely to the end of the communications cable as possible,

as shown in the following illustration.

Serial

Communications

Board

xvi

Page 13

SECTION 1

Introduction

This section introduces the hardware and software functions of the Serial Communications Board, including the serial communications modes, system configurations, and specifications.

1-1 Overview 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-1 Model Number 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-2 Serial Communications Boards 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-3 Features 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-4 System Configuration 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-5 Mounting Location 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Protocol Overview 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1 Host Link Mode 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-2 Protocol Macros 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-3 No-protocol Communications 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-4 PC 1:1 Data Links 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-5 NT Links –– 1:N Mode 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-6 NT Links –– 1:1 Mode 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Specifications 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-1 Serial Communications Board 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-2 General Specifications 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Basic Operating Procedure 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 14

1-1 Overview

1-1-1 Model Number

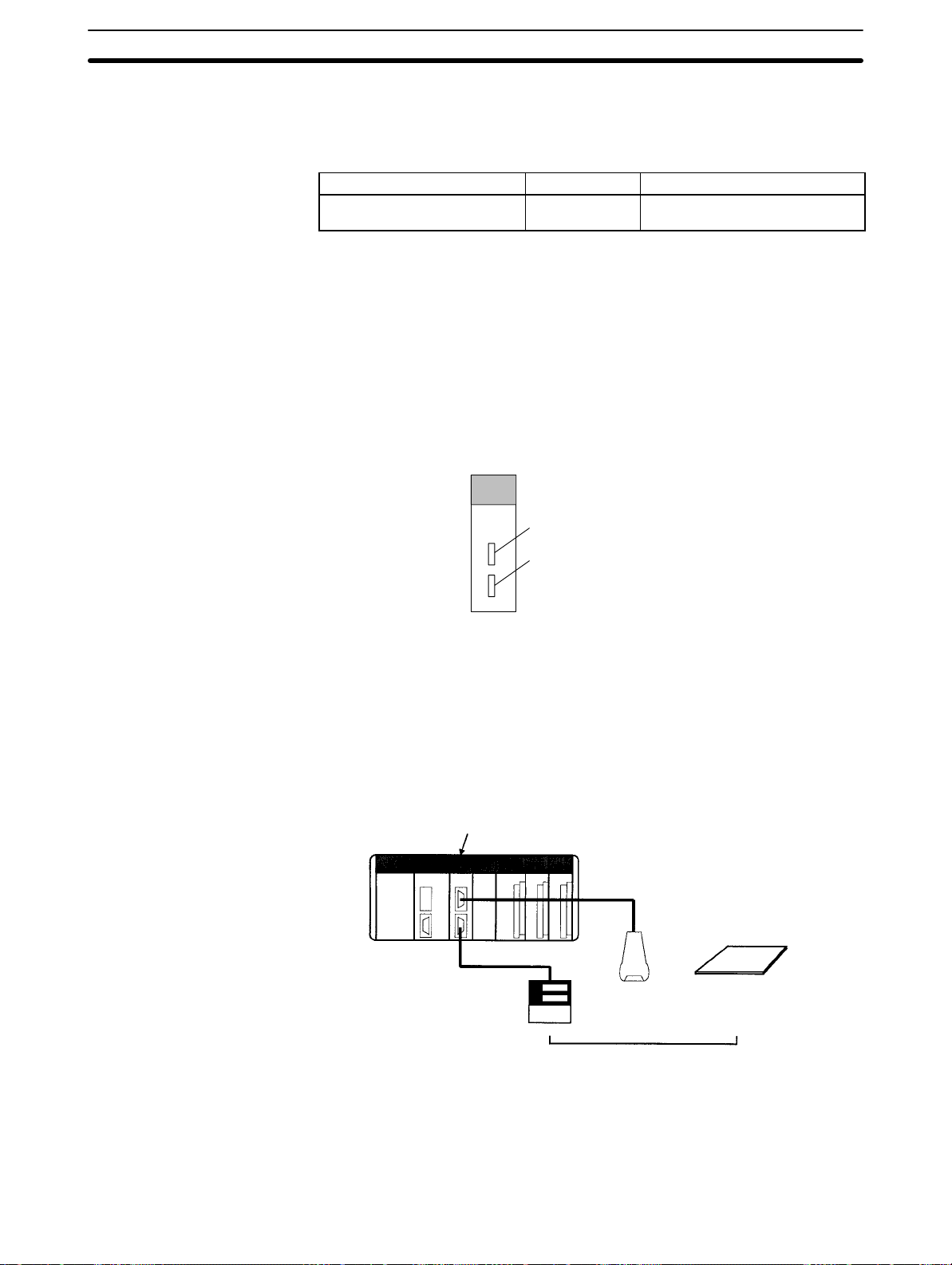

Name Model Specifications

Serial Communications Board CQM1H-SCB41 One RS-232 port

1-1-2 Serial Communications Boards

The Serial Communications Board is an Inner Board for the CQM1H-series PCs.

One Board can be installed in Inner Board slot 1 of a CQM1H-series CPU Unit.

The Board cannot be installed in slot 2.

The Board provides two serial communications ports for connecting host computers, Programmable Terminals (PTs), general-purpose external devices, and

Programming Devices (excluding Programming Consoles). This makes it possible to easily increase the number of serial communications ports for a CQM1Hseries PC.

1-1SectionBasic Operating Procedure

One RS-422A/485 port

1-1-3 Features

Port 1: RS-232C

Port 2: RS-422A/485

The Serial Communications Board is an option that can be mounted in the CPU

Unit to increase the number of serial ports without using an I/O slot. It supports

protocol macros (which are not supported by the ports built into the CPU Units),

allowing easy connection to general-purpose devices that have a serial port.

Inside controlled machine

Serial Communications Board

RS-232C

RS-422A/485

Temperature controller

or other device

Bar code reader

or other device

OR

Dedicated controller

or other device

External device with RS-232C or

RS-422A/485 port

Both RS-232C and RS-422A/485 ports are provided. The RS-422A/485 port enables 1:N connections to general-purpose external devices without going

through Converting Link Adapters. The 1:N connections can be used with protocol macros or 1:N-mode NT Links.

2

Page 15

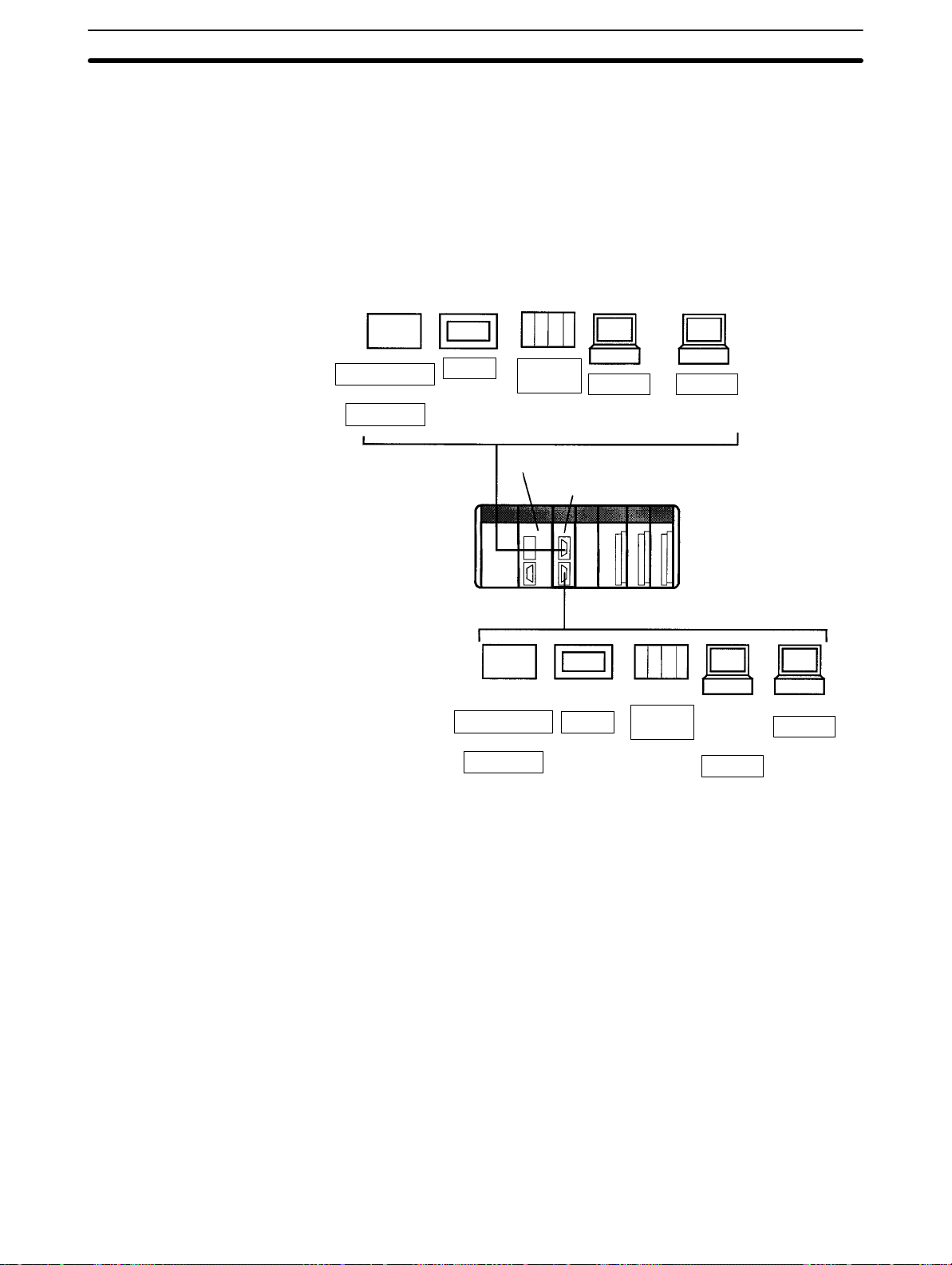

1-1-4 System Configuration

The following serial communications modes are supported by the Serial Communications Board: Host Link (SYSMAC W AY), protocol macro, no-protocol, 1:1

Data Links, 1:N-mode NT Link, and 1:1-mode NT Link modes. The devices

shown in the following diagram can be connected.

Note The 1:1-mode NT Link and 1:N-mode NT Link communications modes use dif-

ferent protocols that are not compatible with each other.

General-purpose

external device

Programmable

Terminal (PT)

C-series PC

Programming

Device

(excluding

Programming

Console)

1-1SectionProtocol Overview

Host computer

Protocol macros

NT Link

1:1

Data Link

Host Link Host Link

No-protocol

RS-232C

CQM1H-series CPU Unit

Serial Communications Board

RS-422A/485

General-purpose

external device

Protocol macros

No-protocol

Programmable

Terminal (PT)

NT Link

C-series PC

1:1

Data Link

Programming

Device

(excluding

Programming

Console)

Host Link

Host computer

Host Link

Note An NT-AL001-E Converting Link Adapter can be used to convert between

RS-232C and RS-422A/485. This Link Adapter requires a 5-V power supply.

Power is provided by the RS-232C port on the Serial Communications Board

when the Link Adapter is connected to it, but must be provided separately when

connecting the Link Adapter to other devices.

3

Page 16

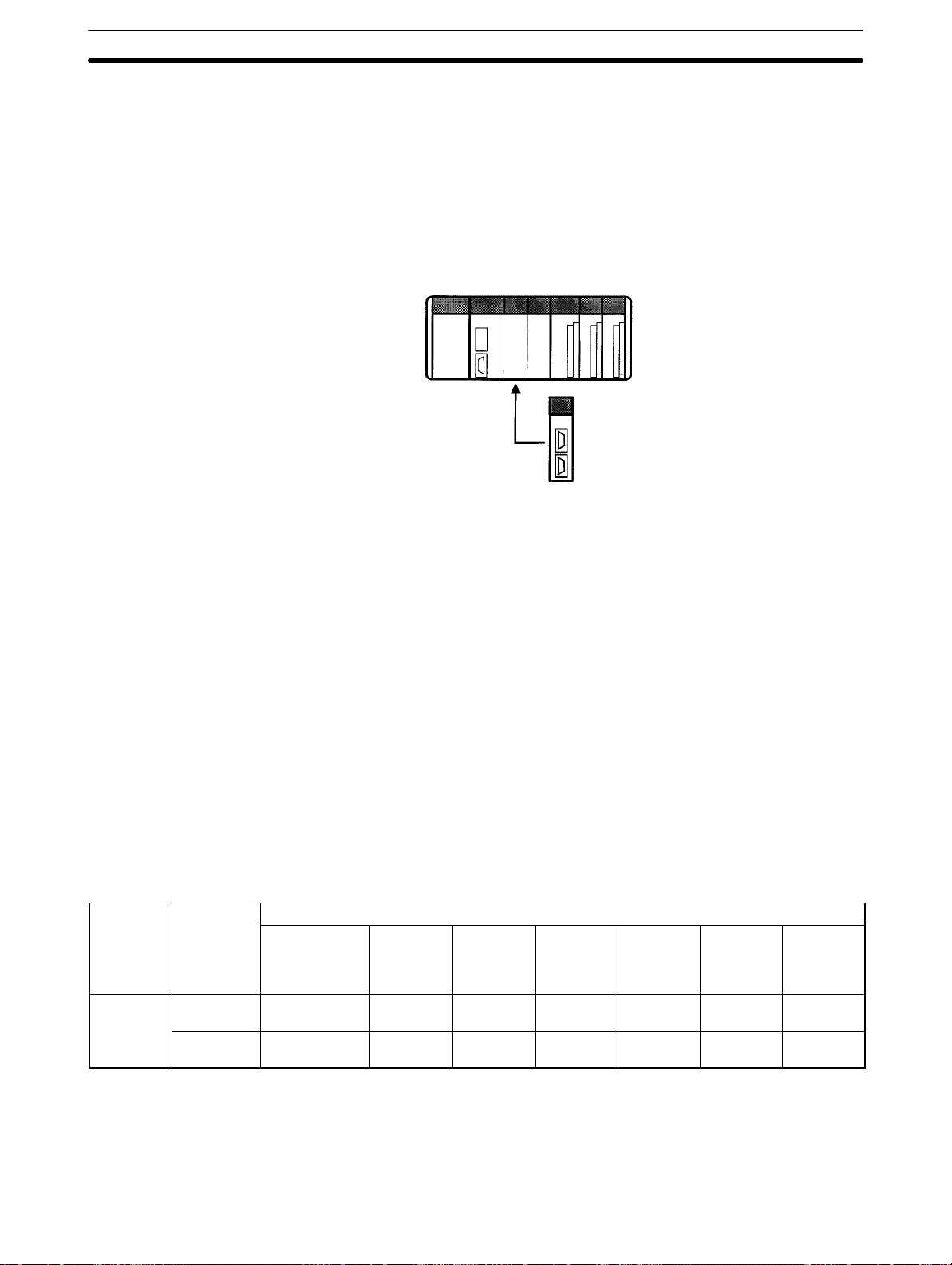

1-1-5 Mounting Location

The Serial Communications Board can be installed in Inner Board slot 1 of a

CQM1H-series CPU Unit. The Board cannot be installed in slot 2.

Slot 2: Not mountable

Slot 1: Mount here

Serial Communications Board

1-2SectionBasic Operating Procedure

1-2 Protocol Overview

The following six serial communications modes can be used as required for

each serial communications port on the Serial Communications Board.

• Host Link:

For connections to host computers, personal computer peripheral devices, or

Programmable Terminals

• Protocol Macros:

For communications with general-purpose external devices using protocols

• No-protocol:

For connections to general-purpose devices for no-protocol communications

using TXD(––) and RXD(––) instructions

• 1:1 Data Links:

For 1:1 data links with a C-series PC, including another CQM1H

• 1:N-mode NT Link:

For communications with one or more Programmable Terminals (PTs)

• 1:1-mode NT Link:

For communications with one PT

Communications Ports and Serial Communications Modes

Board Port

Serial

Communications

Boards

RS-232C

(port 1)

RS-422A/

485 (port 2)

Peripheral

bus or

Programming

Console bus

No OK OK OK OK OK (See

No OK (See

Host Link

(SYSMAC

WAY)

note 1)

Note 1. A 4-wire connection must be used when using Host Link, no-protocol, or 1:1

Data Link communications with an RS-422A/485 connector.

2. The PT Programming Control functions are not supported.

Connection examples for the serial communications modes are shown in the following sections.

Serial communications mode

Protocol

macro

OK OK (See

No-

protocol

note 1)

1:1 Data

Link

OK (See

note 1)

1:N-mode

NT Link

note 2)

OK (See

note 2)

1:1-mode

NT Link

OK (See

note 2)

OK (See

note 2)

4

Page 17

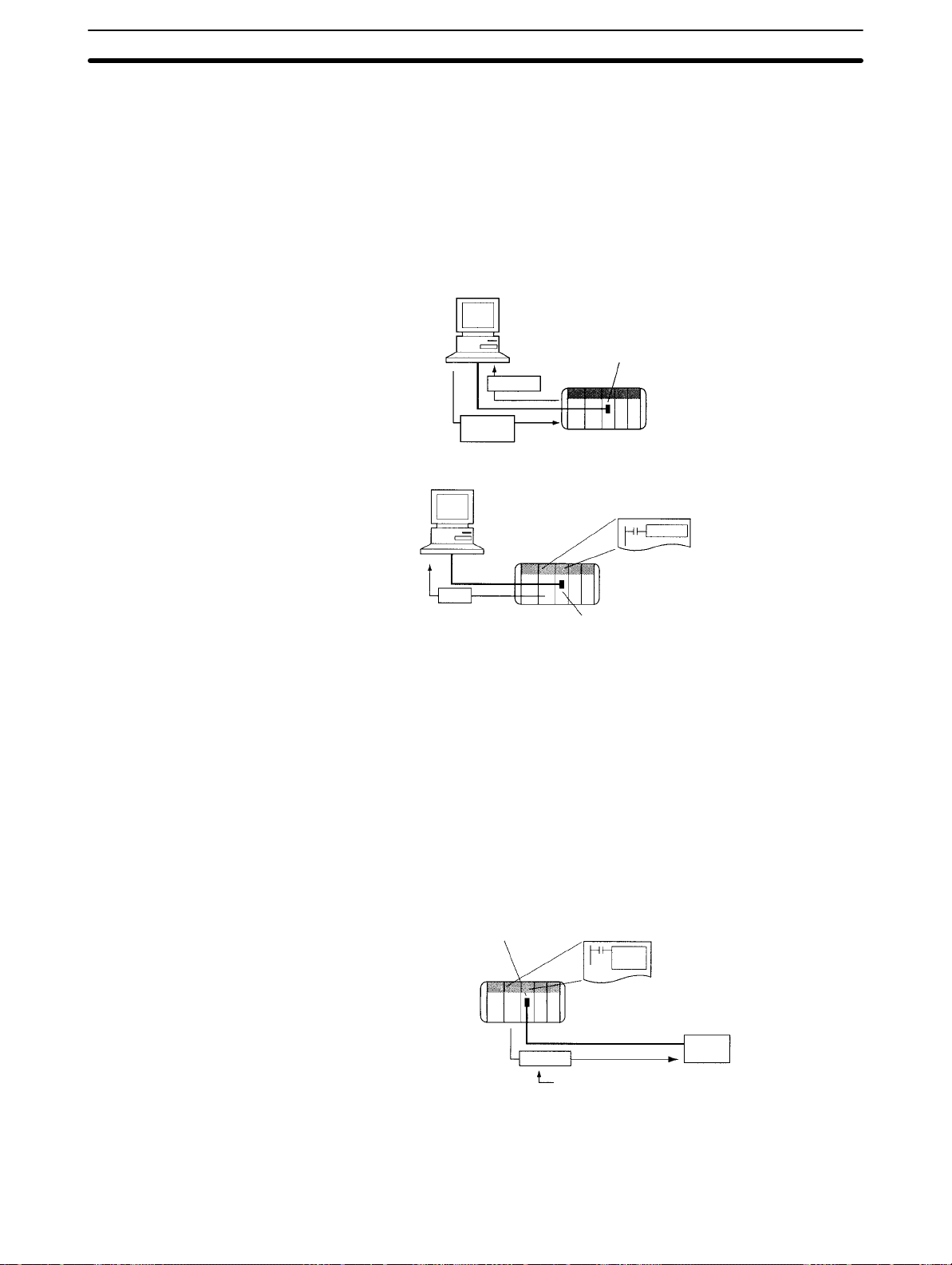

1-2-1 Host Link Mode

In Host Link Mode, C-mode Host Link commands can be sent from a computer,

PT, or other host to read or write I/O memory in the PC or to control the PC’s oper-

ating modes.

The TXD(––) instruction can be used to send ASCII data to the host. This is

called slave-initiated communications or unsolicited communications.

Note 1. Programming Devices can also be connected in Host Link mode.

2. A 4-wire connection must be used when using an RS-422A/485 port.

Sending C-mode Host Link Commands

Slave-initiated Communications

Host computer

Response

Host Link

command

Host computer

1-2SectionProtocol Overview

Serial Communications Board

TXD(––)

1-2-2 Protocol Macros

Data transfer procedures (called protocols) with general-purpose external devices can be created as macros using the CX-Protocol to match the communications specifications of the external device (but, half-duplex communications and

start-stop synchronization must be used).

These protocols are stored in the Serial Communications Boards from the CXProtocol, and enable data to be exchanged with general-purpose external devices simply by executing the PMCR(––) instruction in the CPU Unit.

Standard system protocols for exchanging data with OMRON devices (such as

Temperature Controllers, Intelligent Signal Processors, Bar Code Readers, and

Modems) are provided as a standard feature in the Serial Communications

Boards and the CX-Protocol. The CX-Protocol can also be used to change the

standard system protocols according to user requirements.

Data

CQM1H

Serial Communications Board

CQM1H

Message

PC initiates communication.

Serial Communications Board

PMCR

(––)

External device

RS-232C

Protocol made specifically for the

required communications specifications

with RS-232C port

Note There are some restrictions in using the CX-Protocol to manipulate protocols or

perform other operations for the CQM1H-series Serial Communications Board.

These restrictions are described below.

5

Page 18

• Pin 8 on the DIP switch on the front of the CQM1H-series CPU Unit must be

turned ON t o use the CX-Protocol. While pin 8 is ON, you will not be able to use

any of the CPU Unit or Board ports for the CX-Programmer, SYSMAC-CPT , o r

SYSMAC Support Software.

• The model of PC must be set to the C200HG and the model of CPU Unit must

be set to the CPU43.

• Refer to 5-2 Restrictions in Using the CX-Protocol for further details.

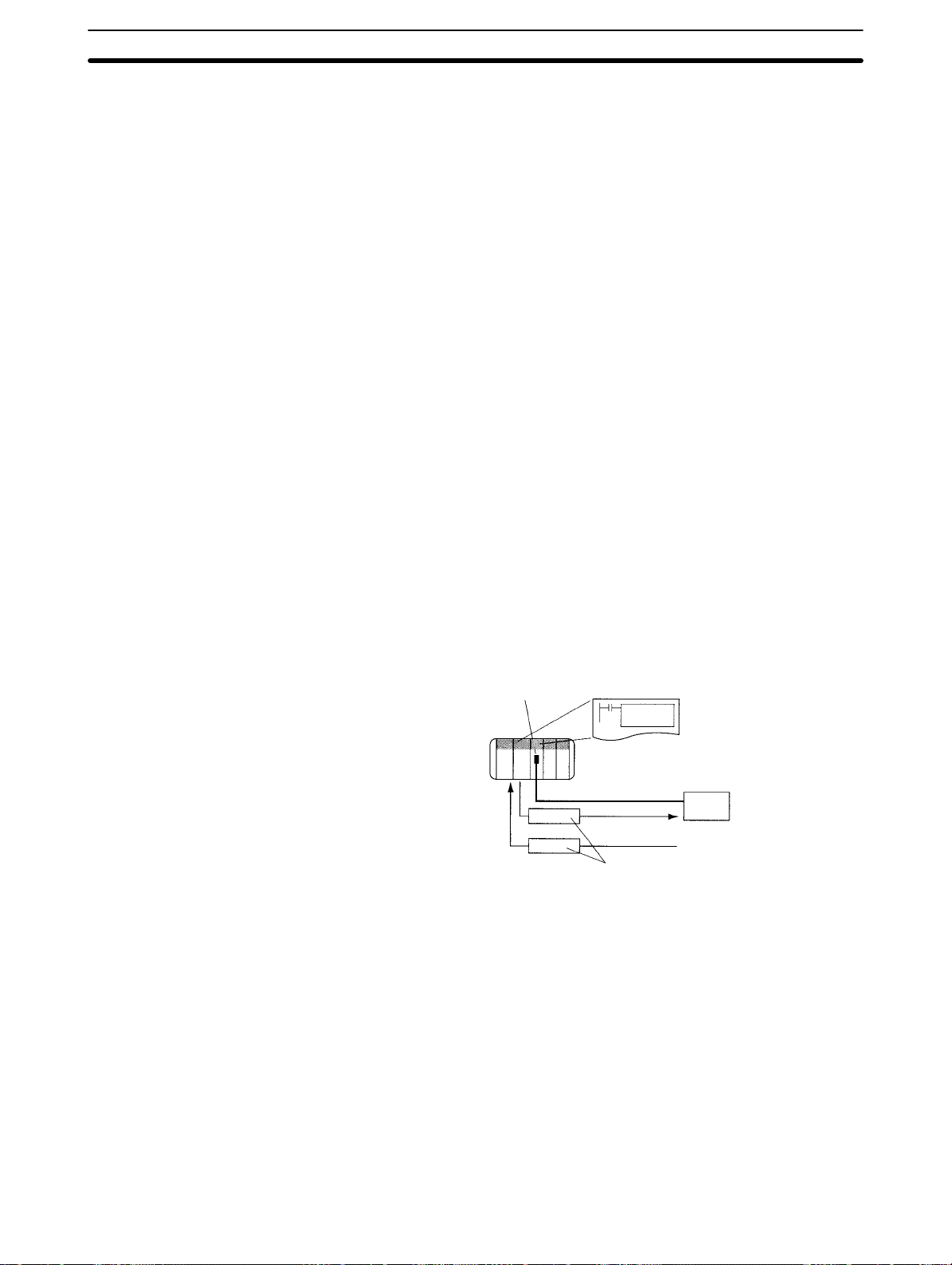

1-2-3 No-protocol Communications

The TXD(––) and RXD(––) instructions can be used in the ladder program to

send and receive data without conversion through the RS-232C port to and from

an external device.

A start code can be sent before the data and an end code can be sent after it.

Alternately, the amount of data being sent can be specified. A communications

frame, however , cannot be created according to the specifications of the partner

device, providing less flexibility than protocol macros. Retry processing, data

form conversions, controlling processing based on a response, and other communications procedures cannot be performed.

1-2SectionBasic Operating Procedure

No-protocol communications are suitable for communications with bar code

readers and other devices that only send data or printers and other devices that

only receive data.

Note A 4-wire connection must be used when using an RS-422A/485 port.

1-2-4 PC 1:1 Data Links

Serial Communications Board

CQM1H

RS-232C

OR

TXD(––) or

RXD(––)

Data only

External device

with RS-232C port

Two PCs can be connected via RS-232C cable to create a data link between

them of u p t o 6 4 words in the LR area. The link words written by one PC are automatically transferred to the other PC for reading.

One of the following three ranges of words can be set to be linked:

LR 00 to LR 63, LR 00 to LR 31, or LR 00 to LR 15

A 1:1 Data Link communications system can be created between the CQM1H

and another CQM1H, or between the CQM1H and the CQM1, C200HX/HG/HE,

C200HS, CPM1, CPM1A, CPM2A, CPM2C, or SRM1(-V2).

6

Page 19

Note A 4-wire connection must be used when using an RS-422A/485 port.

Serial Communications Board

1-2SectionProtocol Overview

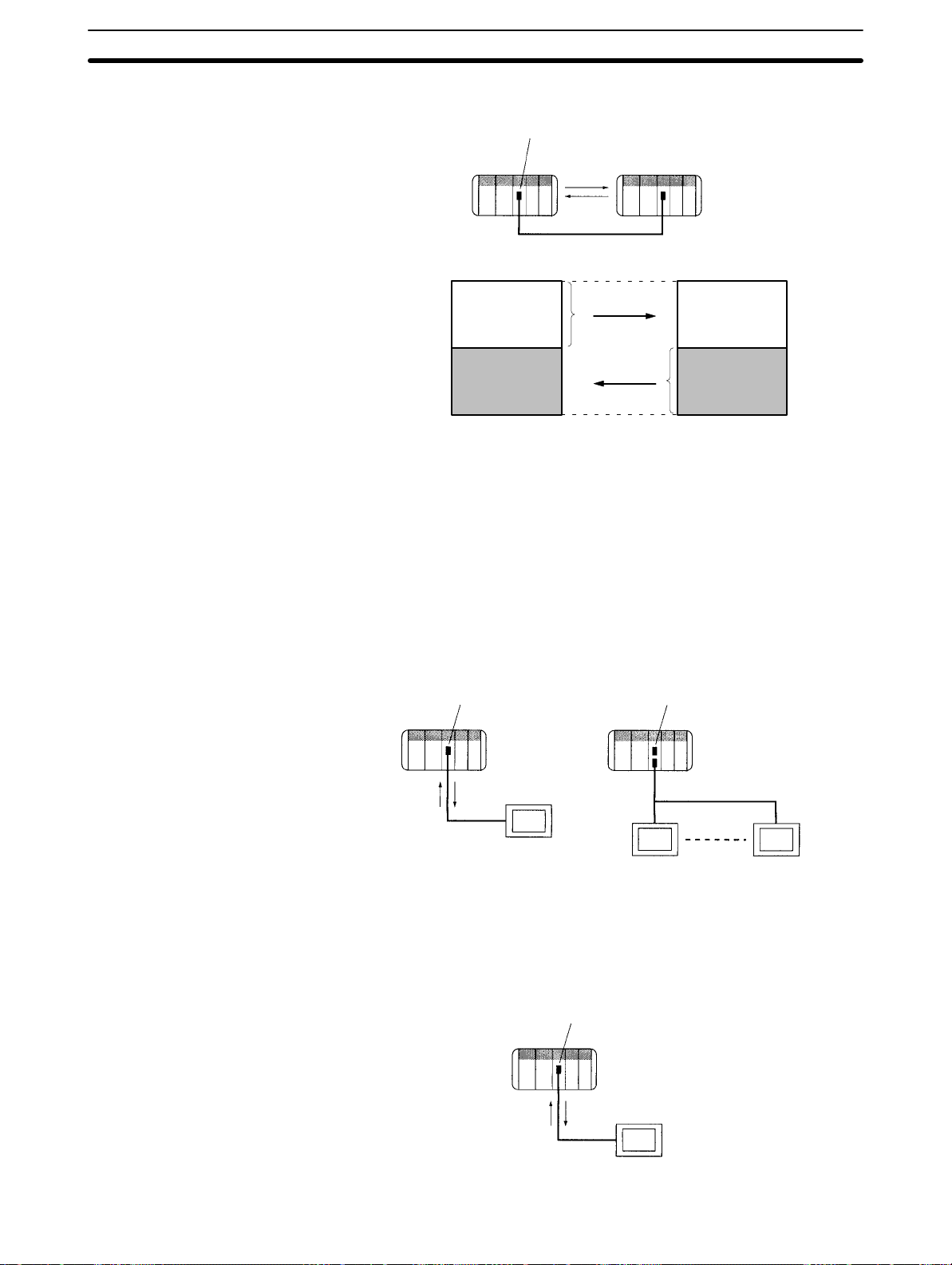

1-2-5 NT Links –– 1:N Mode

A PC can be connected to one or more Programmable Terminals (PTs) using an

RS-232C or RS-422A/485 port. The I/O memory of the PC is allocated to the

Status Control Areas and the Status Notification Areas used by the PTs, as well

as to display objects, such as touch switches, lamps, and memory tables. This

enables the status of the I/O memory in the PC to be controlled and monitored by

operations from the PTs, without the use of a ladder diagram programming in the

PC. Up to eight PTs can be connected to a PC.

LR 00

to

LR 31

LR 32

to

LR 63

CQM1H

Master PC Slave PC

Master area

(sent)

Slave area

(received)

CQM1H or other C-series PC

RS-232C

LR 00

to

LR 31

LR 32

to

LR 63

Master area

(received)

Slave area

(sent)

Note The user does not need to be aware of NT Link commands. The user only has to

allocate the PC memory to the PTs.

1-2-6 NT Links –– 1:1 Mode

The functionality of the 1:1 mode is the same as that of the 1:N mode, but only a

1:1 connection is possible. The 1:1 and 1:N modes are not compatible as protocols.

Serial Communications Board

CQM1H

1:1

PT

Serial Communications Board

CQM1H

Serial Communications Board

CQM1H

1:N

RS-422A/485

PT

1:1

PT

PT

7

Page 20

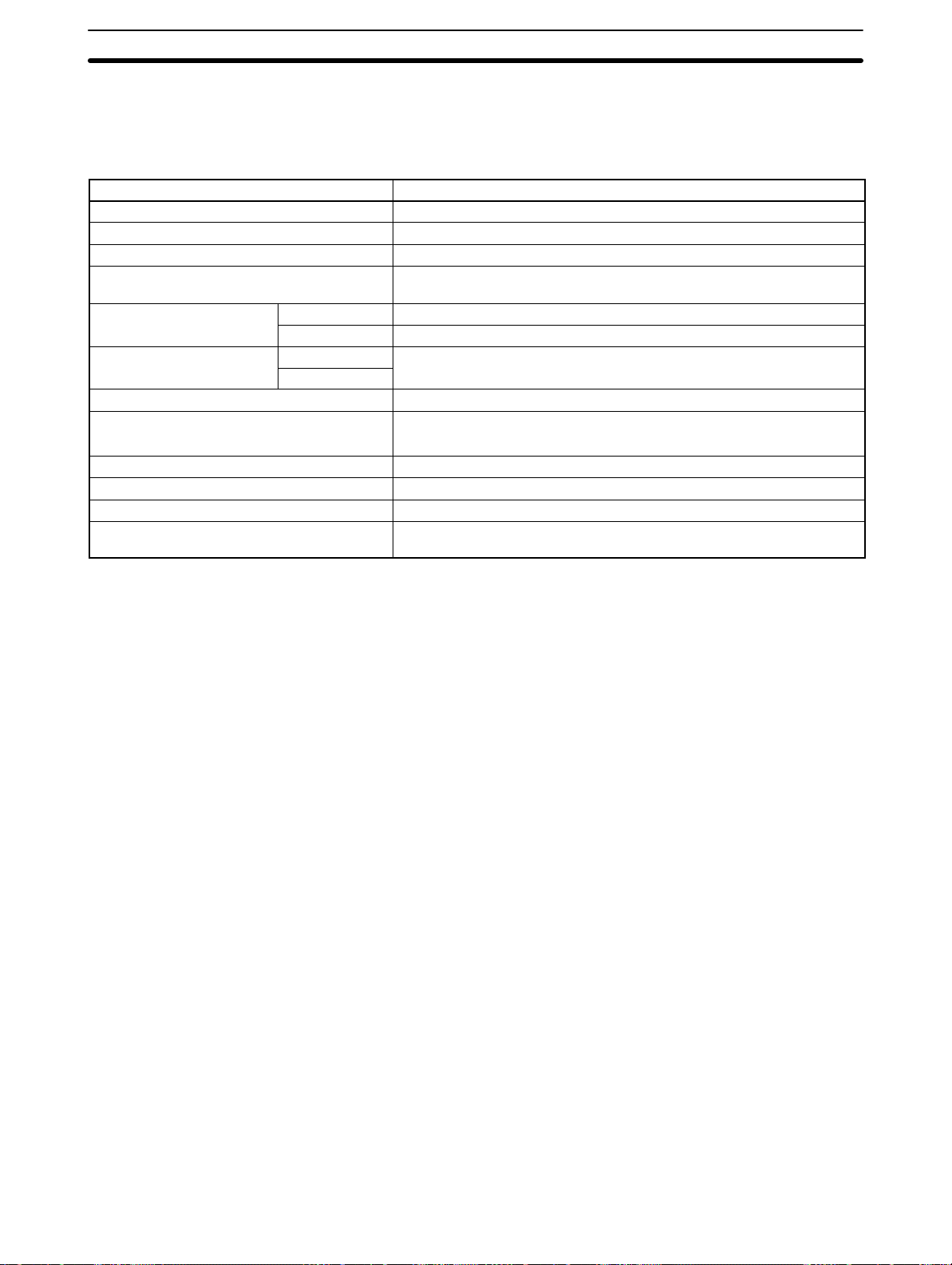

1-3 Specifications

1-3-1 Serial Communications Board

Device name Serial Communications Board

Model number CQM1H-SCB41

Classification CQM1H-series Inner Board

Supporting CPU Units CQM1H-CPU51/61

Number of mountable Boards/PC and

mounting location

Serial communications

ports

Protocols

Software interface with CPU Unit IR 200 to IR 207 (words for Inner Board slot 1)

PC Setup settings DM 6550 to DM 6559 (in read-only DM area in CPU Unit)

Current consumption (see note) 200 mA max. at 5 V DC

Dimensions 25 × 110 × 107 (mm) (W × H × D)

Weight 90 g max.

Standard accessories Socket: XM2SA-0901 (OMRON) (two included)

Port 1 RS-232C

Port 2 RS-422A/485

Port 1

Port 2

One Board per PC maximum, must be in Inner Board slot 1

Host Link, protocol macro, no-protocol, 1:1 Data Link, 1:N-mode NT Link

or 1:1-mode NT Link can be selected for each port.

Set from Programming Device

Hood: XM2SA-0911-E (OMRON) (two included, ESD compatible)

1-4SectionBasic Operating Procedure

Note The current consumption is for one Serial Communications Board. Power is sup-

plied from the CQM1H

When an NT-AL001-E Link Adapter is connected to the Serial Communications

Board, power is supplied to the Link Adapter from the Board. A current consumption of 150 mA must be added for each Link Adapter that is connected. In the

above specifications, “x” indicates that 150 mA must be added for each port to

which an NT-AL001-E Link Adapter is connected to provide the required 5-V

power supply.

1-3-2 General Specifications

Conform to SYSMAC CQM1H-series CPU Unit specifications.

1-4 Basic Operating Procedure

An overview of the basic operating procedure is provided here. Details are provided in sections 4 to 8 of this manual according to the serial communications

mode.

1, 2, 3... 1. Turn OFF the power supply to the PC.

2. Mount the Board.

3. Connect the Board and the external device(s).

4. Turn ON the power supply to the PC.

5. Set the PC Setup settings from a Programming Device (e.g., Programming

Console or CX-Protocol).

6. Execute communications.

Use the control bits, flags, and words allocated in the IR area in the ladder

program to control communications.

8

Page 21

SECTION 2

Board Components and Installation

This section describes the components of the Serial Communications Board, how to connect it in the CPU Unit, and how to

connect it to external devices.

2-1 Component Names and Functions 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 Indicators 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 RS-232C Port 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-3 RS-422A/485 Port 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-4 Switches 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Installation 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 Mounting the Board 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 External Dimensions 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-3 Mounting Height and Connector Cover Dimensions 15. . . . . . . . . . . . . . . . . . . . . .

2-2-4 Precautions in Handling the Board 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Wiring 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-1 Connectors 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-2 Wiring Precautions 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-3 Reducing Electrical Noise for External Wiring 18. . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-4 Port Applicability and Restrictions for 2-Wire/4-Wire Connections 19. . . . . . . . . . .

2-3-5 Recommended RS-232C Wiring Examples 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-6 Recommended RS-422A/485 Wiring Examples 21. . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-7 Wiring Connectors 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-8 Soldering 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-9 Assembling Connector Hood 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-10 Connecting to the Board 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

Page 22

2-1 Component Names and Functions

The components of the Serial Communications Board are described in this section.

Serial Communications Board

(Inner Board slot 1)

Port 1:

RS-232C

Terminating resistance

switch

2-1SectionInstallation

Applicable Connectors

Socket: XM2SA-0901 (OMRON)

Hood: XM2SA-0911-E (OMRON)

(Two of each are included with the Board)

2-wire or 4-wire switch

2-1-1 Indicators

Board Indicators

RDY

COMM1

COMM2

Port 2:

RS-422A/485

There are three LED indicators on the Board, as described below.

RDY: Lit when the Board is operational (green)

COMM1: Lit when data is being sent or received on the RS-232C port (Yellow)

COMM2: Lit when data is being sent or received on the RS-442A/485 port (Yellow)

Indicator Color Status Meaning

RDY Green

COMM1 Yellow

COMM2 Yellow

Lit Operating normally, and protocol macro

preparations have been completed.

Flashing There is an error in the PC Setup settings for the

Board or in the protocol macros contained in the

Board.

Not lit A hardware error has occurred in the Board.

Flashing Port 1 is being used for sending or receiving.

Not lit Port 1 is not being used for sending or receiving.

Flashing Port 2 is being used for sending or receiving.

Not lit Port 2 is not being used for sending or receiving.

10

Page 23

2-1SectionWiring

CPU Unit Indicators

A Serial Communications Board is mounted as an Inner Board in the CPU Unit

and thus affects the CPU Unit ERR/ALM indicator.

Indicator Color Status Meaning

ERR/ALM Red

Lit Fatal error If a fatal error occurs, the CPU

Unit will stop operation in

either RUN or MONITOR

mode.

Flashing Non-fatal

error

Not lit Normal

operation

If a non-fatal error occurs, the

CPU Unit will continue

operation in either RUN or

MONITOR mode.

The CPU Unit is operating

normally. This indicator will

also not be lit when a

watchdog timer error occurs.

If an error in the Inner Board is the cause of the error indicated on the ERR/ALM

indicator, the Inner Board Error Flag (SR 25415) will turn ON and information on

the error will be stored in AR 0400 to AR 0407. Refer to Section 9 Troubleshoot-

ing and Maintenance for details.

2-1-2 RS-232C Port

Protocol Host Link No-protocol Protocol macros 1:1 Data Links 1:N NT Links 1:1 NT Links

Communications method

Synchronization

Baud rate 1,200/2,400/4,800/9,600/ 19,200 bps 19,200 bps 38,400 bps 19,200 bps

Connections 1:1

Transmission

distance

Interface Complies with EIA RS-232C

Half-duplex

Start-stop synchronization (asynchronous)

(1:N possible using Converting Link Adapters)

15 m max. (See note)

Note The maximum cable length for RS-232C is 15 m. The RS-232C standard, how-

ever, does not cover baud rates above 19.2 Kbps. Refer to the manual for the

device being connected to confirm support.

1:1 1:1

(1:N possible using Link Adapters)

1:1

Connector Pin Layout

Pin No. Abbreviation Signal name I/O

1 (See note 1) FG Shield --2 SD Send data Output

3 RD Receive data Input

4 RTS (RS) Request to send Output

5 CTS (CS) Clear to send Input

6 (See note 2) 5V Power supply --7 DSR (DR) Data set ready Input

8 DTR (ER) Data terminal ready

(See note 4)

9 SG Signal ground --Shell (See note 1) FG Shield ---

Output

Note 1. Pin No. 1 and the shell are connected to the ground terminal (GR) of the

Power Supply Unit inside the Serial Communications Board. Therefore, the

cable shield can be grounded by grounding GR of the Power Supply Unit.

2. Pin 6 (5 V) is required when the NT-AL001-E Link Adapter is connected. For

details on connection methods, refer to 2-3 Wiring.

11

Page 24

Caution Do not connect the 5-V power supply of pin 6 to any external device other than an

!

NT-AL001-E Link Adapter. Otherwise, the external device and the Serial Communications Board may be damaged.

The following cables are provided for connection to NT-AL001-E Link Adapters.

We recommend that these cables be used.

NT-AL001-E connecting cables: XW2Z-070T-1 (0.7 m)

XW2Z-200T-1 (2 m)

2-1SectionInstallation

Applicable Connectors

Socket: XM2A-0901 (OMRON) or equivalent

Hood: XM2S-0911-E (OMRON, conforms to ESD) or equivalent

One Socket and one Hood are provided for each port.

Recommended Cables

UL2464 AWG28 5P IFS-RVV-SB (UL-approved, Fujikura Ltd.)

AWG28 5P IFVV-SB (not UL-approved, Fujikura Ltd.)

UL2464-SB (MA) 5P 28AWG (7/0.127) (UL-approved, Hitachi Cable, Ltd.)

CO-MA-VV -SB 5P 28AWG (7/0.127) (not UL-approved, Hitachi Cable, Ltd.)

Cable length: 15 m max.

2-1-3 RS-422A/485 Port

Protocol Host Link No-protocol Protocol macros 1:1 Data Links 1:N NT Links 1:1 NT Links

Communications method

4-wire, 1:1 OK OK OK OK OK OK

4-wire, 1:N OK OK OK No OK No

2-wire, 1:1 No No OK No OK No

2-wire, 1:N No No OK No OK No

Synchroniza-

tion

Baud rate 1,200/2,400/4,800/9,600/ 19,200 bps 19,200 bps 38,400 bps 19,200 bps

Connections 1:N (N: 32 Units max.) 1:1 1:N (N: 8 Units

Transmission

distance

Interface Complies with EIA RS-485

Half-duplex

Start-stop synchronous (asynchronous)

1:1

max.)

500 m max.

(The total combined cable length is 500 m max. T-branch lines must be a maximum of 10 m long.)

Connector Pin Layout

12

Pin No. Abbreviation Signal name I/O

1 (See note 1) SDA Send data – Output

2 (See note 1) SDB Send data + Output

3 NC Not used --4 NC Not used --5 NC Not used --6 (See note 1) RDA Receive data – Input

7 NC Not used --8 (See note 1) RDB Receive data + Input

9 NC Not used --Shell (See note 2) FG Shield ---

Note 1. When 2-wire connections are used, use pins 1 and 2, or pins 6 and 8.

2. The shell is connected to the ground terminal (GR) of the Power Supply Unit

inside of the Serial Communications Board. Therefore, the cable shield can

be grounded by grounding the GR of the Power Supply Unit.

Page 25

2-1SectionWiring

Internal Circuits

Receiver

Driver

Caution Confirm polarities before connecting RS-422A/485 cables. Some devices re-

!

Applicable Connectors

The internal circuits for port 2 are shown below.

Pin 8: RDB (+)

Terminating resistance: 200 Ω

Terminating resistance switch

Pin 6: RDA (–)

2-wire/4-wire switch

Pin 2: SDB (+)

Pin 1: SDA (–)

quire that SDA/B and RDA/B or signal polarities be reversed.

Socket: XM2A-0901 (OMRON) or equivalent

Hood: XM2S-0911-E (OMRON, conforms to ESD) or equivalent

One Socket and one Hood are provided for each port.

Recommended Cables

2-1-4 Switches

Terminating Resistance

Switch

2-Wire or 4-Wire Switch

CO-HC-ESV-3P 7/0.2 (Hirakawa Hewtech Corp.)

Cable length: 500 m max.

(The total combined cable length is 500 m max. T -branch lines must be a maximum of 10 m long.)

The TERM and WIRE switches are on the front panel of the Serial Communications Board. Refer to page 10 for a diagram of the Board.

When an RS-422/485 port is used, turn ON the switch if the Serial Communications Board is on the end of the transmission line. Refer to information on specific

serial communications modes for the ON/OFF settings.

Label Name Settings Factory setting

TERM Terminating

resistance switch

OFF:Terminating

resistance

OFF

ON: Terminating

resistance ON

OFF:Terminating

resistance

OFF

When an RS-422/485 port is used, set the switch to 2 when 2-wire connections

are used, and set the switch to 4 when 4-wire connections are used.

Label Name Settings Factory setting

WIRE 2-wire or 4-wire

switch

2: 2-wire

4: 4-wire

2: 2-wire

Note Host Link, no-protocol, and 1:1 Data Link modes cannot use 2-wire

RS-422A/485 communications. Always use 4-wire connections when using

RS-422A/485 communications for these serial communications modes. Refer

to 2-3 Wiring for connections.

13

Page 26

2-2 Installation

2-2-1 Mounting the Board

This section describes how to mount a Serial Communications Board in Inner

Board slot 1 of a CPU Unit. Slot 1 is the slot on the left. Only one Serial Communications Board can be installed in each CPU Unit.

Note 1. The Serial Communications Board cannot be mounted in Inner Board slot 2.

2. Always turn OFF the power before installing or removing the Serial Communications Board. Installing or removing the Serial Communications Board

with the power ON can cause the CPU Unit to malfunction, damage internal

components, or cause communications errors.

3. Before handling the Serial Communications Board, touch a grounded metallic object in order to discharge any static build-up from your body.

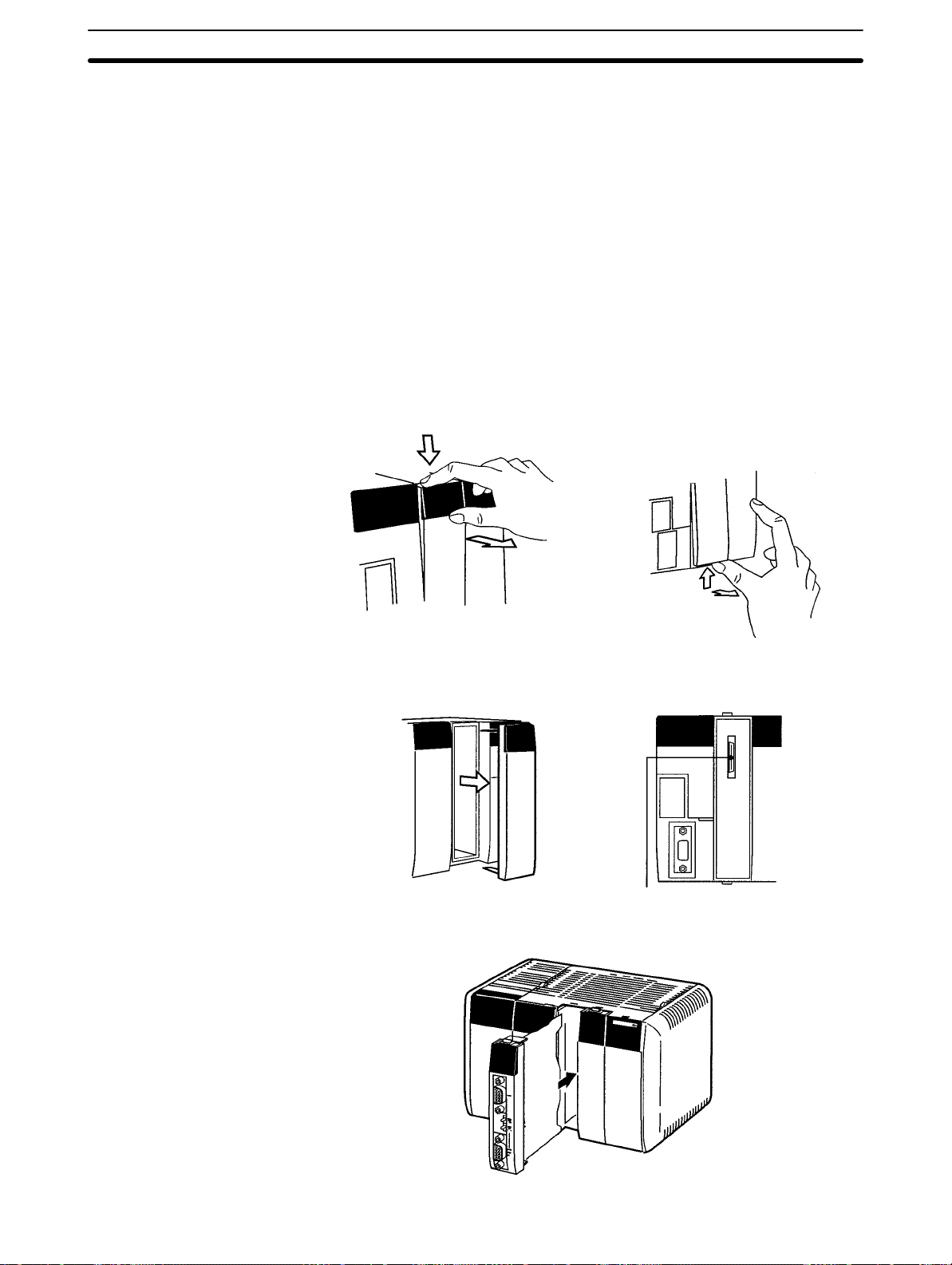

1, 2, 3... 1. Press the catches at the top and bottom of the Inner Board slot 1 compart-

ment cover.

2-2SectionInstallation

Press the top catch. Press the bottom catch.

2. Remove the compartment cover.

Inner Board Connector

3. Insert the Serial Communications Board.

14

Page 27

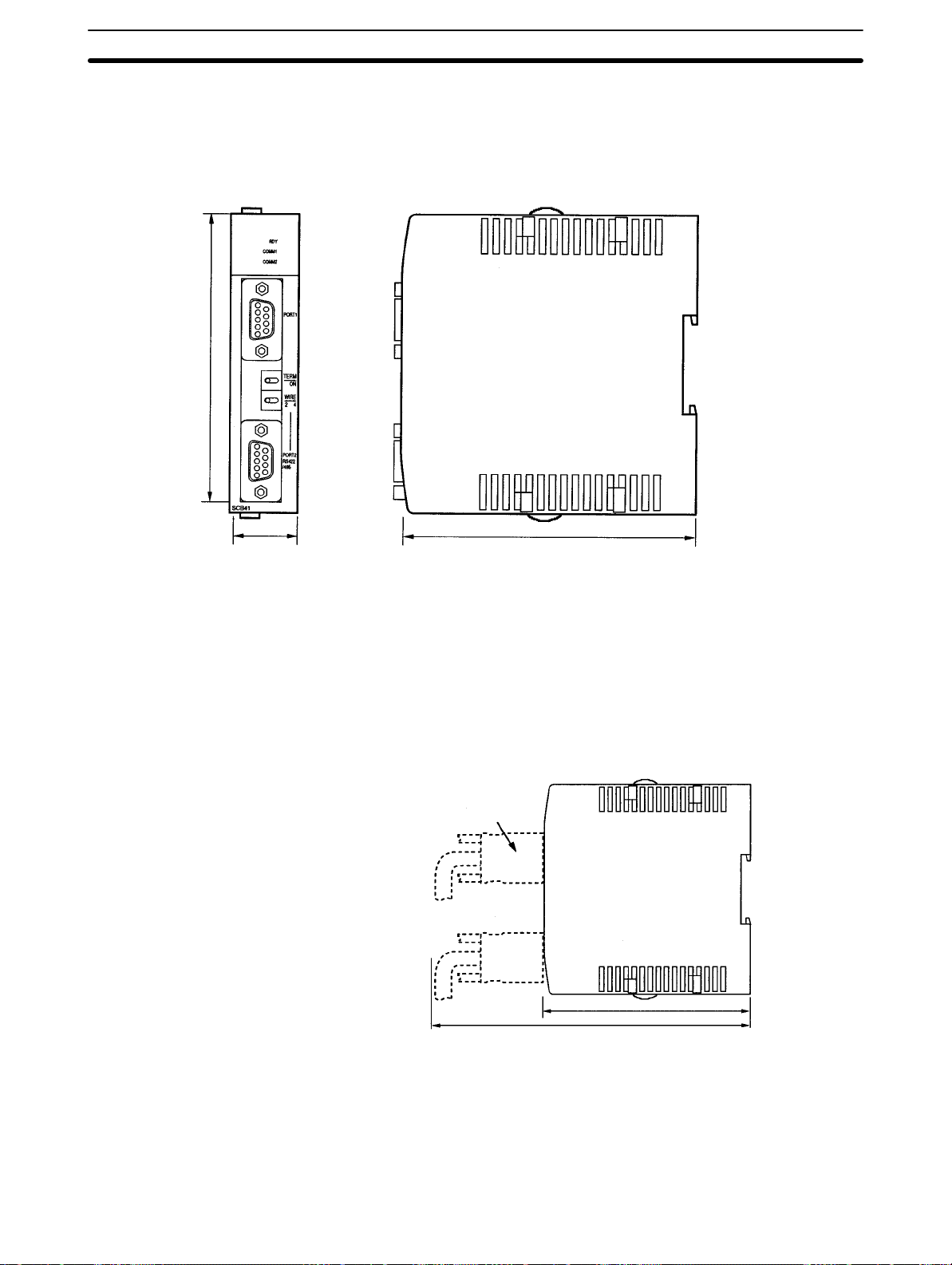

2-2-2 External Dimensions

CS1W-SCB41

110

2-2SectionWiring

Unit: mm

Mounted in the CPU Unit

10725

2-2-3 Mounting Height and Connector Cover Dimensions

When mounting the Serial Communications Board, make sure to provide space

for the mounting height and connector cover dimensions shown below.

Serial Communication Unit

mounted in the CPU Unit

Connecting Cable connector

123

223

Note The mounting heights shown above are applicable when the attached connec-

tors, connector covers, and recommended cables are used. The mounting

height may differ when other connectors, connector covers, and cables are

used. Determine the mounting height, taking into account the connectors, connector covers, and the minimum bending radius of the cables.

15

Page 28

2-2-4 Precautions in Handling the Board

• Turn OFF the power supply to the CPU Unit before mounting or removing the

Board.

• Turn OFF the power supply to the CPU Unit before before connecting or disconnecting Board connectors or wiring.

• Separate the port connector lines from the high-tension or power lines to reduce external noise.

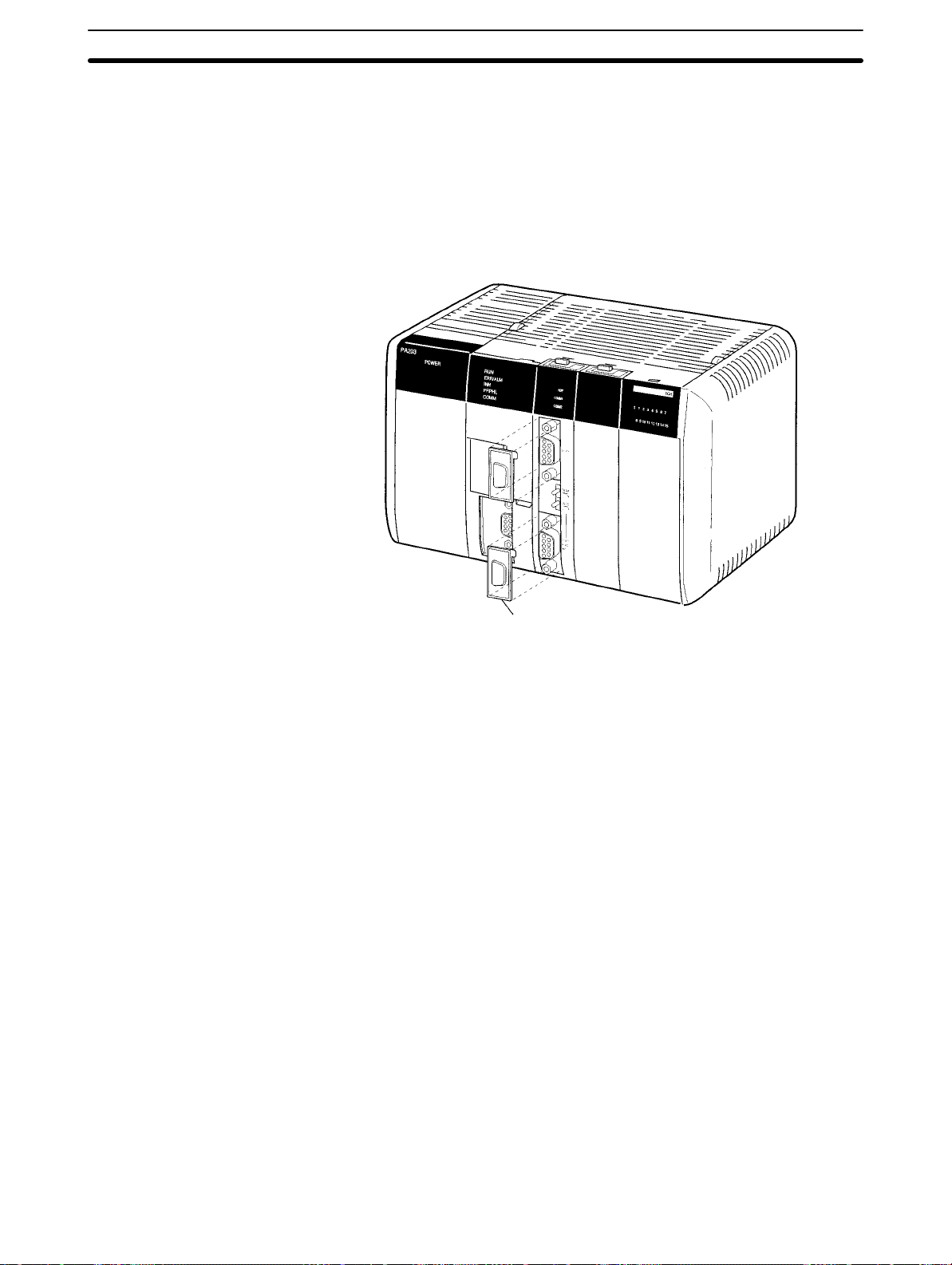

• Leave the port cover attached when not using a communications port.

2-2SectionInstallation

Port cover

16

Page 29

2-3 Wiring

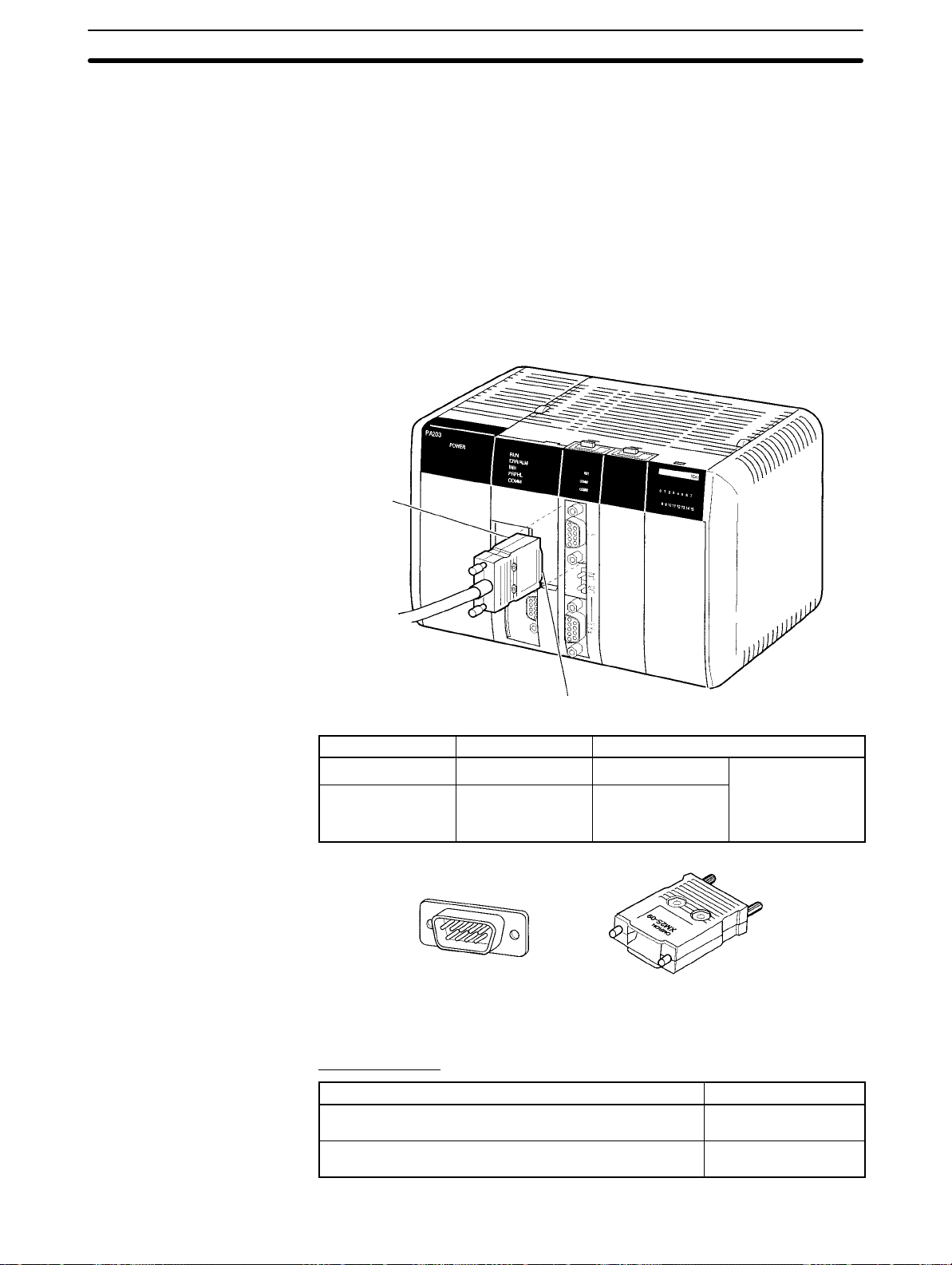

2-3-1 Connectors

2-3SectionWiring

Prepare connecting cables for port 1 (RS-232C) and port 2 (RS422A/485) using

the Sockets and Hoods provided with the Board and the recommended cables.

Connection methods vary with the serial communications mode that is being

used. Refer to the following sections for connection examples.

Host Link: Section 4 Host Link Communications

Protocol macros: Section 5 Protocol Macros

No-protocol: Section 6 Non-protocol Communications

1:1 Data Links: Section 7 Communications for 1:1 Data Links

NT Links: Section 8 NT Link Communications

Hood

Standard Connectors

(for Both RS-232C and

RS-422A/485)

Recommended Cables

Socket

Name Model Specifications

Socket XM2A-0901 9-pin male

Hood XM2S-0911-E For 9-pin, metric

screws, conforms

to ESD

Socket:

XM2A-0901

Hood:

XM2S-0911-E

RS-232C Cables

Model Manufacturer

UL2464 AWG28×5P IFS-RVV-SB (UL-approved)

AWG28×5P IFVV-SB (not UL-approved)

UL2464-SB (MA) 5P×AWG28 (7/0.127) (UL-approved)

CO-MA-VV-SB 5P×AWG28 (7/0.127) (not UL-approved)

Used together

(provided with

Serial

Communications

Board).

Fujikura Ltd.

Hitachi Cable, Ltd.

17

Page 30

RS-422A/485 Cable

CO-HC-ESV-3P×7/0.2 Hirakawa Hewtech Corp.

Refer to pages 11 and 12 for the connector pin layouts. Refer to 2-3-5 Recom-

mended RS-232C Wiring Examples and 2-3-6 Recommended RS-422A/485

Wiring Examples for wiring examples, and to 2-3-7 Wiring Connectors for wiring

methods.

Standard cables are available for connection to personal computers and PTs.

Refer to Section 4 Host Link Communications for personal computer cables and

to your PT user’s manual for PT cables.

2-3-2 Wiring Precautions

• Before connecting or disconnecting the communications cables, always make

sure that the PC is turned OFF.

• Tighten the communications connector screws firmly with your fingers.

• Serial Communications Boards can be connected to various devices. For

compatibility, refer to the operation manuals for the devices to which they are to

be connected.

2-3SectionInstallation

Model Manufacturer

2-3-3 Reducing Electrical Noise for External Wiring

Observe the following precautions for external wiring.

• When multi-conductor signal cable is being used, avoid using I/O wires and

other control wires in the same cable.

• If wiring racks are running in parallel, allow at least 300 mm between the racks.

Low-current cables

Communications

cables

Control cables

PC power supply

and general control

circuit wiring

Power lines

• If the I/O wiring and power cables must be placed in the same duct, they must

be shielded from each other using grounded steel sheet metal.

PC power supply

Communications

cables

and general control

circuit wiring

Power cables

Ground to 100 Ω or less.

Power lines

300 mm min.

300 mm min.

Steel sheet metal

18

200 mm min.

Ground to 100 Ω or less.

Page 31

2-3SectionWiring

2-3-4 Port Applicability and Restrictions for 2-Wire/4-Wire Connections

The following table shows the port connections that can be used for each serial

communications mode.

Serial communications

mode

Host Link OK OK (See

Protocol macros OK OK OK OK OK

No-protocol OK OK OK No No

1:1 Data Links OK No OK No No No

1:N-mode NT Links OK OK OK OK OK

1:1-mode NT Links OK No OK No No No

RS-232C port RS-422A/485 port

1:1 1:N

OK OK No No

note 2)

4-wire 2-wire

1:1 1:N 1:1 1:N

Note 1. The 1:N connection method can be used by converting between RS-232C

and RS-422A/485 through NT-AL001-E Converting Link Adapters.

2. Use 4-wire connections between the Converting Link Adapters.

3. The 2-wire RS-422A/485 connections cannot be used for Host Link communications. Use 4-wire connections.

The transmission circuits for 2-wire and 4-wire connections are different, as

shown in the following diagram.

Example of 4-Wire Connections

Example of 2-Wire Connections

2/4-wire switch

(DPDT)

Board

NT-AL001-E Link Adapter

Settings

2/4-wire switch

Other Unit

Other Unit

(DPDT)

Board

Not connected

Other UnitOther Unit

Note 1. Use the same transmission circuit (2-wire or 4-wire) for all nodes.

2. Do not use 4-wire connections when the 2/4-wire switch on the Board is set

to 2-wire.

The NT-AL001-E Link Adapter has a DIP switch for setting RS-422A/485 communications conditions. When connecting the Board, refer to the DIP switch settings shown in the following table.

19

Page 32

Pin Function Factory

1 Not used. Always set this pin to ON. ON

2 Built-in terminating resistance setting

ON: Connects terminating resistance.

OFF: Disconnects terminating resistance.

3

4

5

2/4-wire setting

2-wire: Set both pins to ON.

4-wire: Set both pins to OFF.

Transmission mode (See note)

Constant transmission: Set both pins to OFF.

Transmission performed when CTS signal in RS-232C

6

Transmission performed when CTS signal in RS-232C

interface is at high level: Set pin 5 to OFF and pin 6 to ON.

Transmission performed when CTS signal in RS-232C

interface is at low level: Set pin 5 to ON and pin 6 to OFF.

Note When connecting to a CQM1H-series CPU Unit, turn OFF pin 5 and turn ON pin 6.

2-3-5 Recommended RS-232C Wiring Examples

It is recommended that RS-232C cables be connected as described below, especially when the Serial Communications Board is used in an environment

where it is likely to be subject to electrical noise.

2-3SectionInstallation

setting

ON

OFF

OFF

ON

OFF

Serial

Communications

Board

Pin Signal

SD

RD

RTS

CTS

SG

FG

Hood

FG

1, 2, 3... 1. Always use shielded twisted-pair cables as communications cables.

Model Manufacturer

UL2464 AWG28x5P IFS-RVV-SB (UL-approved)

Fujikura Ltd.

AWG28x5P IFVV-SB (not UL-approved)

UL2464-SB (MA) 5Px28AWG (7/0.127) (UL-approved)

CO-MA-VV-SB 5Px28AWG (7/0.127) (not UL-approved)

Hitachi Cable,

Ltd.

2. Combine signal wires and SG (signal ground) wires in a twisted-pair cable.

At the same time, bundle the SG wires to the connectors on the Serial Communications Board and the remote device.

3. Connect the shield of the communications cable to the Hood (FG) terminal

of the RS-232C connector on the Serial Communications Board. At the

same time, ground the ground (GR) terminal of the Power Supply Unit to

100 Ω or less.

4. A connection example is shown below.

Example: Twisted-pair Cable Connecting SD-SG, RD-SG, RTS-SG, and

CTS-SG Terminals

Actual Wiring Example

SG signal wires

Remote device

Signal

RD

SD

CTS

RTS

SG

FG

Shield

Twist the braided shield to make

it thinner and connect to Pin No.

1 (FG). Cover this section with

heat-shrink tube to avoid contact

with other sections.

Bundle the SG wires.

Aluminum foil

20

XM2S-0911-E

Page 33

2-3SectionWiring

Note The Hood (FG) is internally connected to the ground terminal (GR) on the Power

Supply Unit. Therefore, FG is grounded by grounding the ground terminal (GR)

on the Power Supply Unit. Although there is conductivity between the Hood (FG)

and pin 1 (FG), connect the Hood (FG) to the shield because the Hood (FG) has

smaller contact resistance with the shield than pin 1 (FG), and thus provides better noise resistance.

Power Supply Unit

Hood and GR are

internally connected.

Ground to 100 Ω or less Grounding the GR terminal

grounds the Hood (FG).

Serial Communications Board

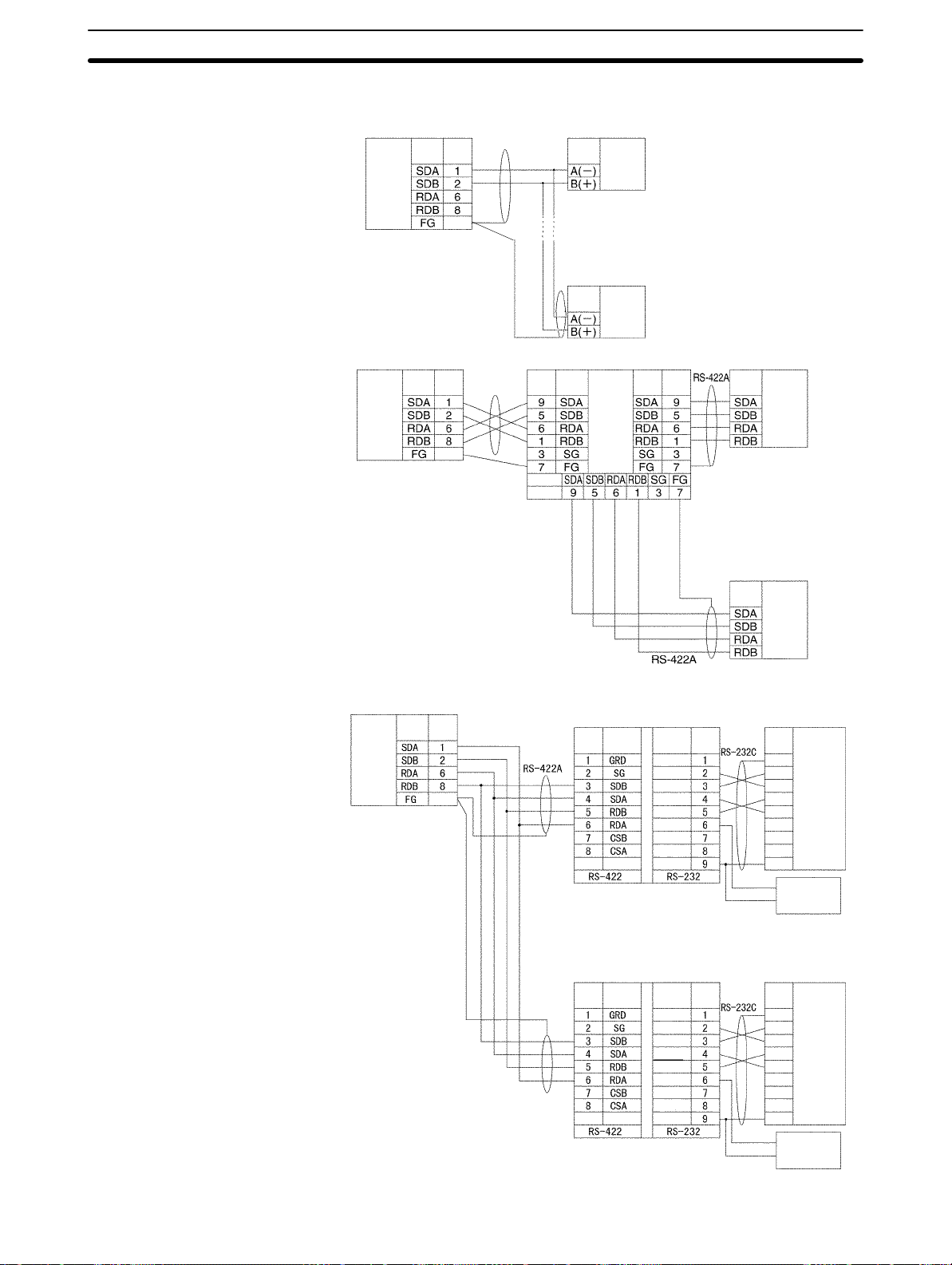

2-3-6 Recommended RS-422A/485 Wiring Examples

Recommended RS-422A/485 Cable

We recommend the following wiring methods to ensure quality transmissions for

RS-422A/485 communications.

1, 2, 3... 1. Always use shielded twisted-pair cables for the communications cables.

2-Wire Connections

Model Manufacturer

CO-HC-ESV-3Px7/0.2 Hirakawa Hewtech Corp.

2. Connect the shield of the communications cable to the Hood (FG) of the

RS-422A/485 connector on the Serial Communications Board. At the same

time, ground the ground (GR) terminal of the Power Supply Unit to 100 Ω or

less.

Note Always ground the shield only at the Board end. Grounding both ends of the

shield may damage the device due to the potential difference between the

ground terminals.

Connection examples are shown below.

Serial Communications

Board

Pin

Signal

Hood

Shield

Remote device

Signal

21

Page 34

4-Wire Connections

Using a 3G2A9-AL001 Link Adapter

Serial Communications

Board

Signal

Pin

Hood

Serial Communications

Board

Pin

Signal

Hood

Pin

Signal

Pin

3G2A9-AL001

Signal

RS-422

interface

Shield

Signal Pin

2-3SectionInstallation

Remote device

Signal

Remote device

Signal

Remote device

Signal

Using an NT-AL001-E RS-232C/RS-422 Link Adapter

Serial Communications

Board

Pin

Hood

Signal

SD

RD

RTS

CTS

5V

DSR

DTR

SG

FG

Pin

Signal

RD

SD

CTS

RTS

5V

DSR

DTR

SG

Shield

(See note.)

Note The following cables are available for this connection.

Length Model

70 cm XW2Z-070T-1

2 m XW2Z-200T-1

NT-AL001-E

Signal

Pin

Remote device

Signal

Remote device

Signal

22

It is recommended that one of these cables be used to connect the RS-232C port

on the Serial Communications Board to the NT-AL001-E Converting Link Adapter.

Page 35

2-3SectionWiring

Note The Hood (FG) is internally connected to the ground terminal (GR) on the Power

Supply Unit. Therefore, FG is grounded by grounding the ground terminal (GR)

on the Power Supply Unit.

3. Be sure to turn ON the terminating resistance at the last Unit at the end of the

2-3-7 Wiring Connectors

Use the following steps to wire connectors.

Cable Preparation

See the following diagrams for the length of the cable portion to be cut in each

step.

Power Supply Unit

Serial Communications Board

Hood and GR are

internally connected.

Ground to 100 Ω or less Grounding the GR terminal

grounds the Hood (FG).

RS-422A/485 cable.

Shield Connected to Hood (FG)

1, 2, 3... 1. Cut the cable to the required length.

2. Remove the specified length of the sheath from the cable using a knife. Be

careful not to scratch the braided shield.

25 mm (RS-422A)

40 mm (RS-232C)

3. Trim off the braided shield using scissors so that the remaining shield length

is 10 mm.

10 mm

4. Remove the insulation from each conductor using a stripper so that the exposed conductor length is 5 mm.

5 mm

23

Page 36

5. Fold back the braided shield.

6. Wrap aluminum foil tape around the folded shield.

Shield Not Connected to Hood (FG)

1, 2, 3... 1. Cut the cable to the required length.

2. Remove the specified length of the sheath from the cable using a knife. Be

2-3SectionInstallation

Aluminum foil tape

careful not to scratch the braided shield.

25 mm (RS-422A)

40 mm (RS-232C)

3. Trim off all the braided shield using scissors.

4. Remove the insulation from each conductor using a stripper so that the exposed conductor length is 5 mm.

5 mm

5. Wrap adhesive tape around the conductor from which the braided shield

was removed.

Adhesive tape

24

Page 37

2-3-8 Soldering

1, 2, 3... 1. Thread a heat-shrinking tube through each conductor.

2-3SectionWiring

2. Temporarily solder each conductor to the corresponding connector terminals.

3. Completely solder each conductor.

Soldering iron

Heat-shrinking tube

Inside diameter:

1.5 mm, l = 10

4. Return the heat-shrinking tube to the soldered portion, then heat the tube to

shrink it in place.

2-3-9 Assembling Connector Hood

Assemble the connector Hood as shown below.

Heat-shrinking tube

Grounding plate

End connected to FG

Adhesive tape

End not connected to FG

Aluminum foil tape

25

Page 38

2-3-10Connecting to the Board

Tighten the screws firmly

with your fingers.

2-3SectionInstallation

26

Page 39

SECTION 3

Default Settings and Related Bits/Flags

This section describes the settings, control bits, flags, and status information available in the CPU Unit for use with the Serial

Communications Board.

3-1 Overview 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 PC Setup Settings 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Control Bits, Flags, and Status Information 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27

Page 40

3-1 Overview

3-2SectionPC Setup Settings

The following settings, control bits, flags, and information are available in the

CPU Unit memory for use with the Serial Communications Board.

Contents Addresses

PC Setup settings for the Serial

Communications Board

Control bits, flags, and status information

for the Inner Board slot 1

Error flags and information for Inner

Boards

Port 1: DM 6555 to DM 6559

Port 2: DM 6550 to DM 6554

IR 200 to IR 207

SR 25415: Inner Board Error Flag

AR 04: Inner Board Error Code

CX-Protocol (for protocol

macro mode operation)

CPU Unit

Backup

battery

PC Setup settings

(DM 6550 to DM 6559)

Inner Board Slot 1

Area

(IR 200 to IR 207)

Inner Board Error Flag

and Error Code

(SR 25415 and AR 04)

3-2 PC Setup Settings

Settings for the Serial Communications Board can be made from a Programming Device in the following words of the PC Setup.

Port 1: DM 6555 to DM 6559

Port 2: DM 6550 to DM 6554

The settings stored in these words are read constantly; the PC does not need to

be restarted or reset when changes are made to the settings. They will be updated automatically as soon as they are changed.

The settings in these words depend on the serial communications mode that is

being used. Refer to the following sections for details.

Host Link: Section 4 Host Link Communications

Protocol macros: Section 5 Protocol Macros

No-protocol: Section 6 Non-protocol Communications

1:1 Data Links: Section 7 Communications for 1:1 Data Links

NT Links: Section 8 NT Link Communications

An overview of the PC Setup settings for the Serial Communications Board is

given next. The default setting for each word is all zeros (0000).

Read

constantly

Refreshed

Serial Communications Board

Flash memory

Protocol macro

data (for protocol

macro mode

operation)

Protocol

macro data

28

Page 41

Word(s) Bit(s) Function Applicable

mode

DM 6550

(port 2)

DM 6555

(port 1)

DM 6551

(port 2)

DM 6556

DM 6556

(port 1)

DM 6552

(port 2)

DM 6557

(port 1)

DM 6553

(port 2)

DM 6558

(port 1)

(port 1)

DM 6554

(port 2)

DM 6559

(port 1)

00 to 03 Port settings

0: Standard (1 start bit, 7-bit data, even parity, 2 stop bits, 9,600 bps)

1: Settings in DM 6551 (DM 6556 for port 1)

04 to 07 CTS control settings

0: Disable; 1: Set

08 to 11 Link words for 1:1 Data Link (when bits 12 to 15 are set to 3)

0: LR 00 to LR 63; 1: LR 00 to LR 31; 2: LR 00 to LR 15

or

Maximum Programmable Terminal unit number (when bits 12 to 15 are set to 5)

1 to 7 (BCD)

12 to 15 Serial communications mode

0: Host Link; 1: No-protocol; 2: 1:1 Data Link slave; 3: 1:1 Data Link master;

4: NT Link in 1:1 mode; 5: NT Link in 1:N mode; 6: Protocol macro

00 to 07 Baud rate

00: 1.2K, 01: 2.4K, 02: 4.8K, 03: 9.6K, 04: 19.2K

08 to 15 Frame format

Start Length Stop Parity

00: 1 bit 7 bits 1 bit Even

01: 1 bit 7 bits 1 bit Odd

02: 1 bit 7 bits 1 bit None

03: 1 bit 7 bits 2 bit Even

04: 1 bit 7 bits 2 bit Odd

05: 1 bit 7 bits 2 bit None

06: 1 bit 8 bits 1 bit Even

07: 1 bit 8 bits 1 bit Odd

08: 1 bit 8 bits 1 bit None

09: 1 bit 8 bits 2 bit Even

10: 1 bit 8 bits 2 bit Odd

11: 1 bit 8 bits 2 bit None

00 to 15 Transmission delay

0000 to 9999 (BCD): Set in units of 10 ms, e.g., a setting of 0001 equals 10 ms

00 to 07 Host Link unit number

00 to 31 (BCD)

08 to 11 Start code enable

0: Disable; 1: Set

12 to 15 End code enable

0: Disable (number of bytes received)

1: Set (specified end code)

2: CR, LF

00 to 07 Start code (No-protocol)

00 to FF (hexadecimal)

08 to 15 When bits 12 to 15 of DM 6553 or DM 6558 are set to 0 Hex:

Number of bytes received

00: Default setting (256 bytes)

01 to FF: 1 to 255 bytes

When bits 12 to 15 of DM 6553 or DM 6558 are set to 1 Hex:

End code (No-protocol)

00 to FF (hexadecimal)

Host Link, noprotocol, protocol macros

Host Link, noprotocol, 1:1

Data Links

1:1 Data Link

master (link

words)

or

NT Link (max.

unit number)

All modes

Host Link, noprotocol, protocol macros

Host Link, noprotocol, protocol macros

Host Link, noprotocol

Host Link

No-protocol

No-protocol

No-protocol

No-protocol