Page 1

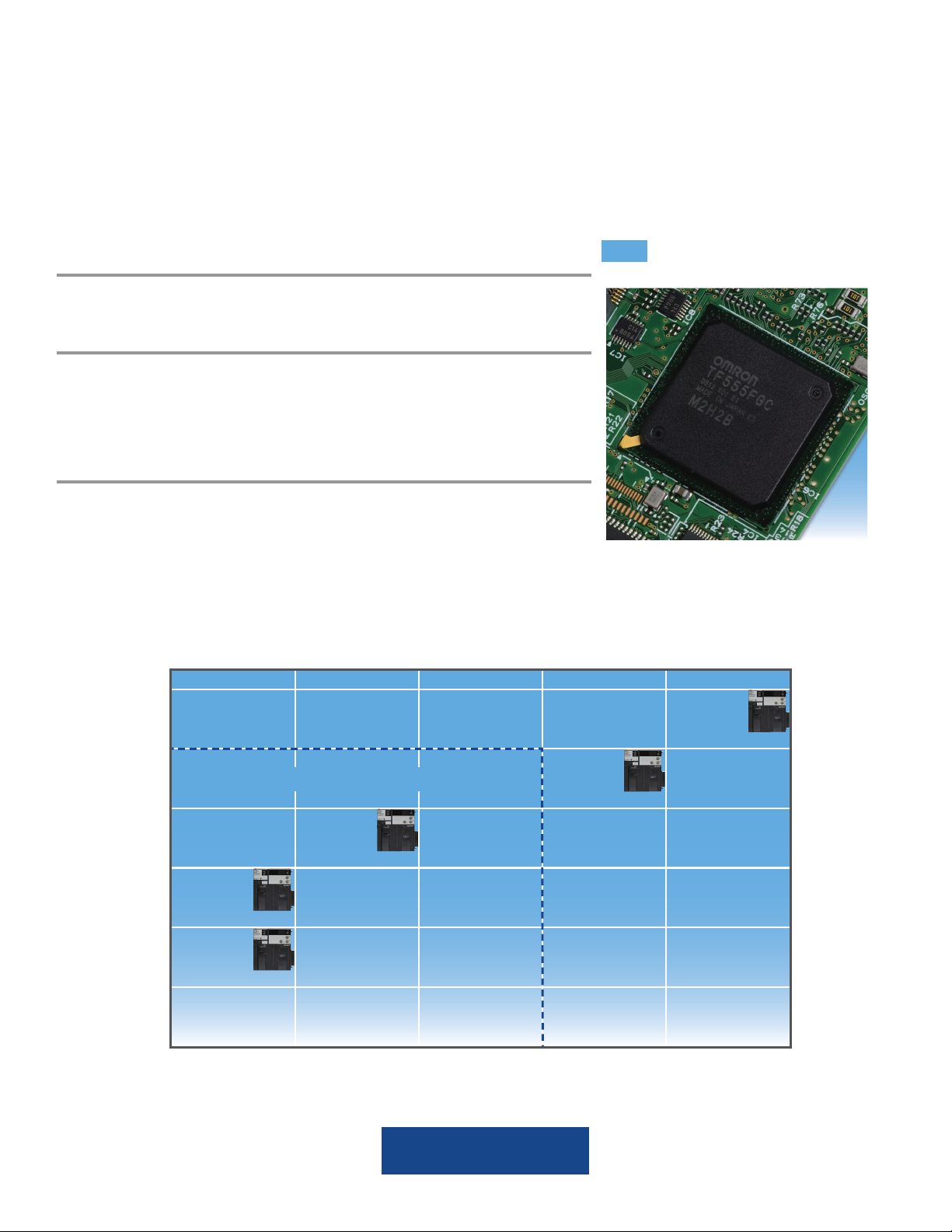

Programmable Automation Controllers

CJ2SERIES

Introducing the Flagship CJ2 CPU Units, with Built-in

Multifunctional EtherNet Port

Built-in EtherNet/IP ports

Tag based programming

Fast processing time

Large memory capacity

Fully compatible with CJ1 modules

Page 2

CJ2 – Omron’s New Small, Fast & Flexible

Modular Flagship PAC, with built-in

EtherNet/IP and Tag Based Programming

The CJ2 Programmable Automation Controller (PAC) delivers PAC features and capabilities as

defined by ARC Advisory Group in Omron’s popular, compact modular CJ PLC platform.

Multi-domain functionality – CJ2 performs logic, motion, HMI and process control on a single platform.

Single multi-discipline development platform - Using a common tag database, PAC and HMI

programming can be developed in parallel, reducing development time. Omron’s CJ2 PAC, NS-Series

HMI’s and middleware all share the same tag database. CX-One Software incorporates 16 different

development tools.

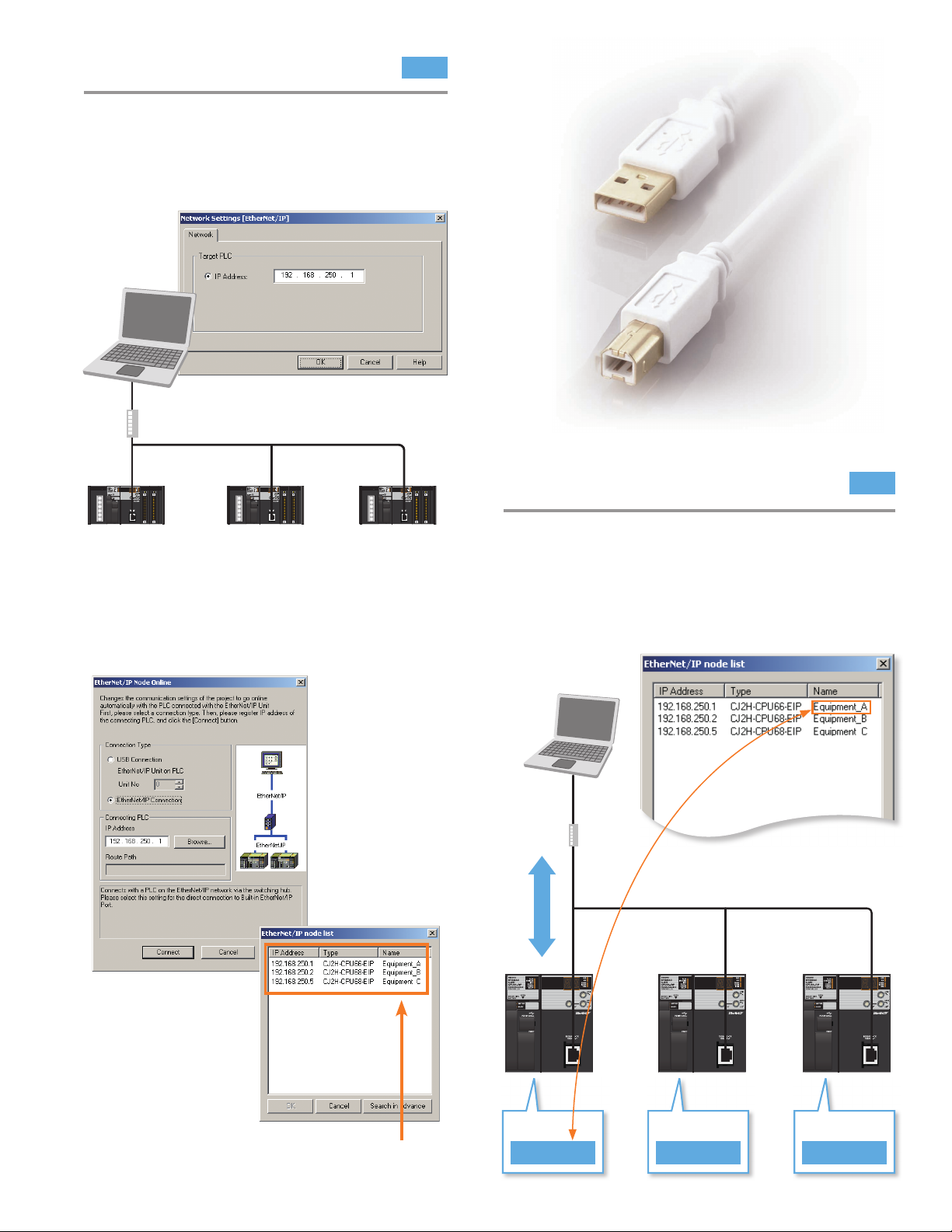

Software tools that allow access across several machines - Omron’s CJ2 PACs supports Single

Point Multiple Access (SPMA) which enables set-up and programming of all local modules and remotely

networked modules.

Open, modular architecture - Omron’s CJ2 supports the capability to handle logic, position & motion

control, RFID, analog and temperature control, HMI, bar code, networking modules, communication

modules, smart sensors, vision and drives, all in a single modular platform.

Standardized Programming & Open Networks - Omron’s CJ2 supports all IEC61131-3 programming

languages: Ladder, Function Block, Structured Text, Sequential Function Chart (SFC) and Instruction List.

Open networks enable seamless communications using these protocols: Ethernet, EtherNet/IP, DeviceNet,

CompoNet, PROFIBUS, PROFINET, FLNet, MECHATROLINK-II and Serial (RS-232C, RS-422, RS-485).

CJ2 CPU’s – Offer built-in EtherNet/IP networking, High-speed, high-capacity data exchange between

PAC’s, PLC’s, HMI’s and I/O devices. EtherNet/IP can be used to perform both information and control

Networking, share up to 184,832 words over 256 nodes. CJ2 PAC’s can easily connect to Rockwell’s

ControlLogix and CompactLogix PLC’s using EtherNet/IP tag data links.

2

Page 3

Key Features and Benefits

Large Memory Capacity –

The CPU program memory capacity has been

increased up to 400K Steps, DM has increased

up to 800K while Function Block Program,

Symbol, Comment Memory has increased to

3.5MB. Large memory allows for larger more

versatile programs, well documented programs

makes it easier and faster to troubleshoot.

Fast –

Processing times are significantly faster. Faster

production, faster development time, faster time

to market and higher throughput means higher

speed applications can be achieved.

One Single Programming

IEC61131-3 Programming –

All 5 programming languages are supported

with the CJ2 PAC. Ladder, Function Block,

Structured Text, Instruction List and Sequential

Function Chart. Hundreds of Pre-built pre-test

Function blocks significantly can reduce design

time. Standard programming languages allow

for fast, flexible and powerful programming.

General-purpose Networks

for Support Software

Interface –

CX-One software applications can be easily

connected using standard USB and EtherNet

Cables via USB and EtherNet/IP ports.

Environment –

CX-One is Omron’s single programming

environment for PAC’s, PLC’s, HMI, Networks,

Process Control, Motion Control and Simulation

Software. Legacy PLC’s are supported and single

click conversion to new hardware makes for easy

migration. The software includes and Update service

that automatically checks for the latest update of

software.

Improved Debugging –

Online editing and data tracing have been

improved, greatly increasing the efficiency of

debugging. The data trace function is built into the

PAC and can monitor & store I/O and data in 1

ms time increments. This allows for easy and faster

debug time, which allows for faster time to market.

Tag Based Programming –

CJ2 CPU Units have a tag name server to

manage tag names and I/O addresses.

This enables access from external devices

using tag names, without needing to know the

I/O addresses.

CJ2 Capabilities –

Offers functions such as motion control, process

control, RFID, Logic and Drives all on the same

controller platform. The modular architecture is

ideal for applications where the user is interested

in saving money by reducing development time &

increasing production.

3

Page 4

Faster and Higher-capacity CPU Units

High-capacity data memory is in demand to meet the need for quality control for equipment and

products and to provide real-time processing and collection of measurement data. Large program

capacity is also in demand due to the need for improving program reusability through modularization

and structured programming.

Great Expanded Program Capacity and Data Memory Capacity

Ample capacity is provided for the data required for control operations.

The High-capacity CJ2H-CPU68-EIP Is Now Available.

» Program capacity: 400 Ksteps (1.6 times larger than before)

» Data memory capacity: 832 Kwords (2 times larger than before)

» Basic Instructions (0.016 µs)

And, All CJ2 Models Have more Capacity than CJ1 Models.

In addition, all models have more capacity than the equivalent CJ1series models to meet needs for structured programming and increasing

amounts of data.

Increased Capacity over CJ1-series CPU Units

Program capacity

400 Ksteps

CJ2-H

250 Ksteps

NEW

CPU68-EIP

CJ1 Product Lineup

150 Ksteps

CPU66-EIP

100 Ksteps

CPU65-EIP

50 Ksteps

CPU64-EIP

30 Ksteps

64 Kwords 160 Kwords 352 Kwords 448 Kwords 512 Kwords 832 Kwords

Program capacity: 400 Ksteps

Data memory capacity: 832 Kwords

4

CPU67-EIP

Data memory capacity

Page 5

High-speed System I/O Throughput

NEW

Improved basic performance enables fl exible

machine control.

Ample Instruction Execution Performance

for Machine Control

The CJ2 Series fully responds to customer

requests for improvement and

increased information.

» System Overhead

Common processing 200 µs

Interrupt response: 30 µs

» Basic Instructions

LD instruction execution: 0.016 µs

OUT instruction execution: 0.016 µs

» Floating-point Math

SIN calculation: 0.59 µs

Floating-point decimal addition and

subtraction: 0.24 µs

Faster I/O Refreshing Using the Burst

2.4

2.4

Times

X

800 µs

Transfer Method

I/O refreshing between an EtherNet/IP Unit and

the CPU Unit is now performed at high speed

using the even faster and higher-capacity data

links for EtherNet/IP. This method is standard

for the CJ2 CPU Units. I/O refreshing is now

performed at up to 2.4 times the speed of

previous Communications Units.

I

/O refresh speed

(for 1,000 words)

CJ2

CJ1

330µs

Burst transfer

High-speed, high-capacity

20

Faster Immediate I/O Refreshing

Times

Immediate refreshing of basic I/O is also faster.

Real-time inputs and outputs while instructions

are being executed are up to 20 times faster

than before.

(Example: !LD instruction speed improved from 20 µs to 1 µs)

Air cylinder

Fiber Sensor

E3X-DA

Sensor status is read

just prior to instruction

execution.

CJ2 CPU

Output immediately

after instruction is

executed

Automatic User Memory Recovery

Finer memory production processes have been

accompanied by problems such as bit corruption

caused by cosmic rays. With the CJ2 CPU Units,

corruption in the user program is detected and the

program recovered in real time before program

execution. This reduces equipment down time by

minimizing the number of times that operation is

stopped due to memory errors.

Cosmic rays

User program

data is corrupted

Previously

Operation is stopped due

to memory error.

EtherNet/IP

» I/O Refreshing

16-point Basic I/O Unit: 1.4 µs

8-point Analog Input Unit: 50 µs

Cosmic rays

(Thermal neutrons)

CJ2

User program

data is corrupted

Data is automatically

restored and normal

operation continues.

5

Page 6

Networks Are More Open

EtherNet/IP is an open network that uses the TCP/IP protocol on EtherNet networks, which are widely used

in offi ces and factories throughout the world. The CJ2 CPU Units support EtherNet/IP as a standard feature.

Because EtherNet/IP uses TCP/IP, it provides the many advantages of EtherNet technology.

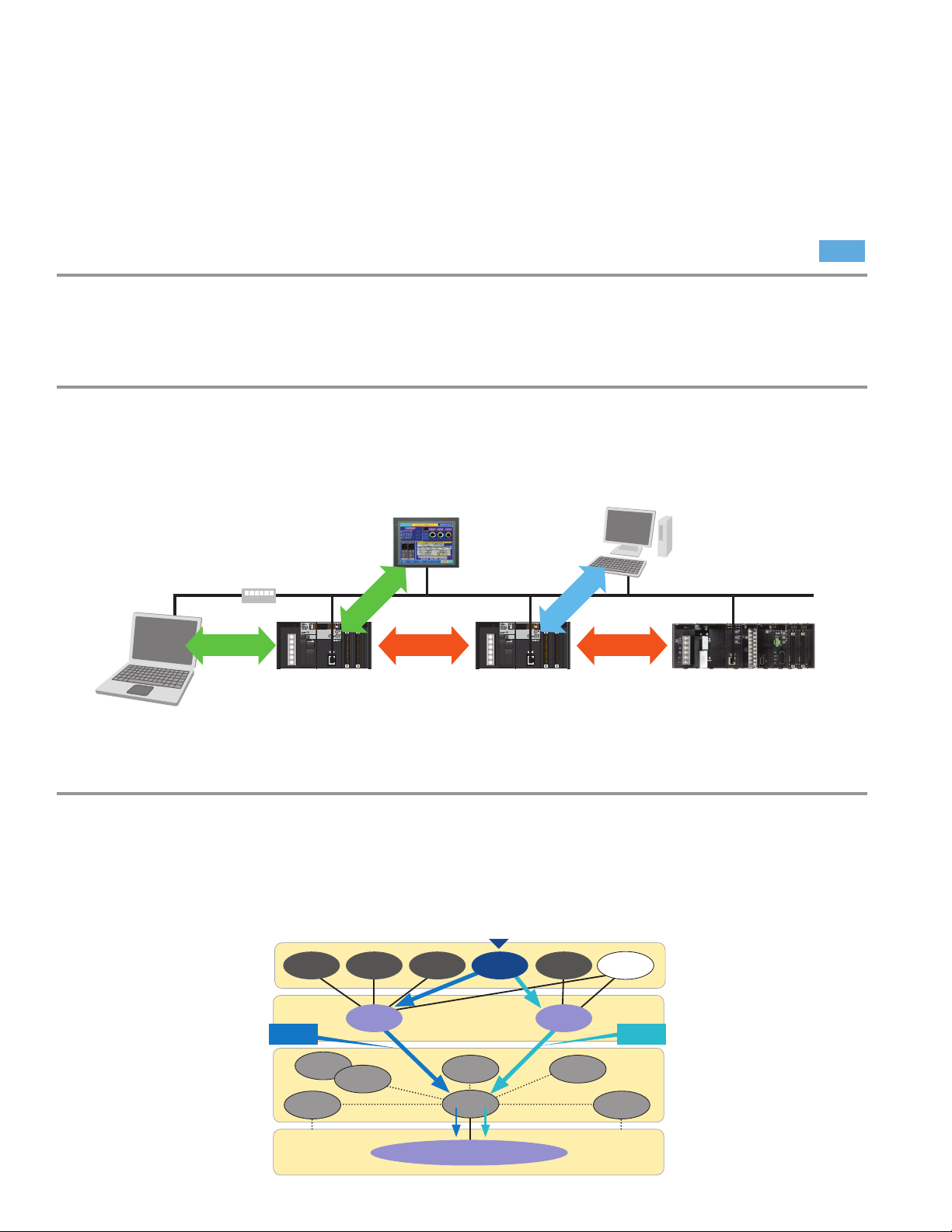

Universal EtherNet and FA Data Links Can Be Used at the Same Time.

NEW

With EtherNet/IP, One Port Is Enough.

FTP Communications, Data Links, and Support Software Can Be Used Simultaneously through

a Single Port.

The CJ2 CPU Units provide as standard equipment a multifunctional EtherNet port that supports EtherNet/

IP. There is no need to add an EtherNet Unit, because universal EtherNet communications, such as data links

between PAC’s, message communications between PAC’s, and FTP transfers, are all enabled simultaneously

through this one port while Support Software is connected.

Programmable Terminal

Host application

EtherNet/IP

HUB

Message

communications

CJ2 CPU

Message

communications

Data links

CJ2 CPU CJ1-EtherNet/IP Unit

FTP

Data links

CX-One

Create a Seamless Data Flow in a Single Network System.

Because it is based on the world-standard CIP open protocol, a seamless data fl ow can be achieved between

control lines and information monitoring lines in a single network system. From here on, EtherNet/IP will be

increasingly used in multi-vendor environments (such as robotics and safety devices).

EtherNet/IP is an industrial network that uses the CIP real-time protocol in the EtherNet

application layer. (Standards: EN 50170 and IEC 61158)

Application

Layer

Transport

Layer

Network

Layer

Data Link

Physical Layer

FTP HTTP SMTP SNMP FINS

Explicit

Messages

OSPF

ARP RARP

TCP UDP

IGRP

IEEE 802.3 EtherNet

CIP

ICMP IGMP

IP

Rea l-ti me Dat a

Links

6

Page 7

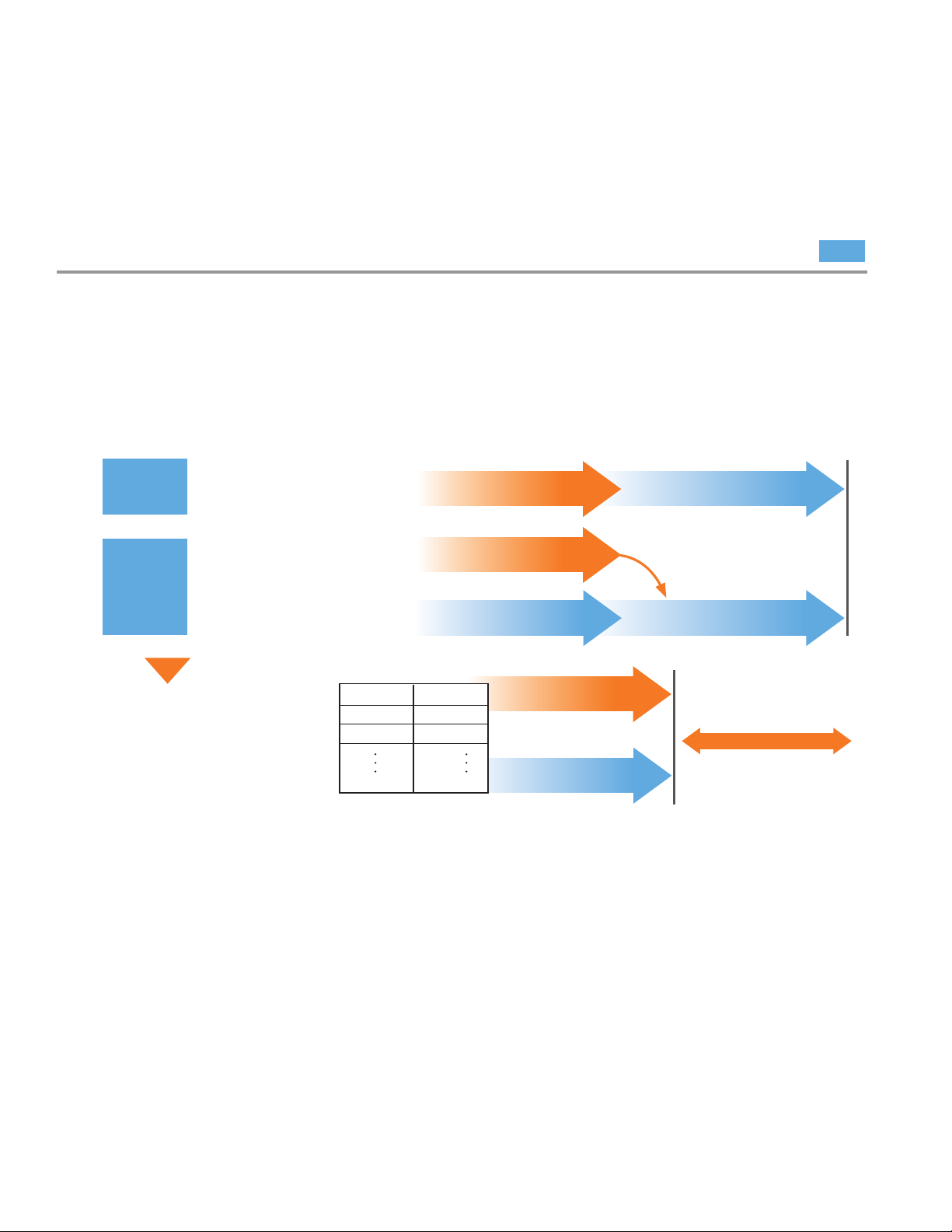

Extremely Fast and High-capacity Data

NEW

Links Compared to Previous FA Networks

Large Data Transfers with High Reliability.

30

High-speed and High-capacity

Times

9

Times

Data Links

From manufacturing recipes and information

on interlocks between processes to production

data, any type of data can be exchanged

at high speed and at the optimal timing.

Communications performance is vastly

improved over OMRON’s Controller Link and

FL-net networks.

Data Link

Capacity (Total)

Data Link

Performance

(See note.)

EtherNet/IP

Controller Link

FL-net(OMRON)

EtherNet/IP

Controller Link

Note: Communications cycle time for 20,000 words

20,000 words

8,704 words

10ms 30X

180,000 words…

300ms

9X

Peripheral Devices (such as Cables, Hubs, and

Wireless Devices) Can Be Used With Universal

EtherNet Technology.

NEW

Automatic Address Allocation Is Expanded

to Up to 240 Kwords, Enabling Allocation of

Large Amounts of Data.

The memory size of the EM Area for automatic

address allocation in CX-Programmer symbol tables

has been expanded to a maximum of 240 Kwords.

When a tag is automatically allocated, data link

design and access from the host are enabled with

no need to be conscious of addresses. Moreover,

bits can be force-set/reset in the areas in which

data is automatically allocated.

EtherNet/IP

Tag access

CJ2 CPU Unit

Tags are automatically

allocated to the highcapacity EM Area.

Designing requires tag

names only, with no need to

worry about addresses.

The convenience of a global standard at your

fi ngertips.

» Using Universal EtherNet Reduces Network

Installation and Wiring Costs.

» FA Wireless LAN Makes Mobile Control Easy,

with No Need for Rewiring when

Changing Layout.

Built-in EtherNet/IP port on CPU Units

(multifunctional EtherNet port)

Host application

Easy Monitoring with Excel

CX- Reporter

PAC Access with Visual Basic/C#.NET

CX- Compolet

Switching hub

FA wireless

LAN WE70

Support Software

PLC

CJ1 or CJ2 CPU Unit

Data Links

FINS Messaging

CIP Messaging

FTP

Time Coordination

Programmable

Terminal NS Series

Tag Access

or

7

Page 8

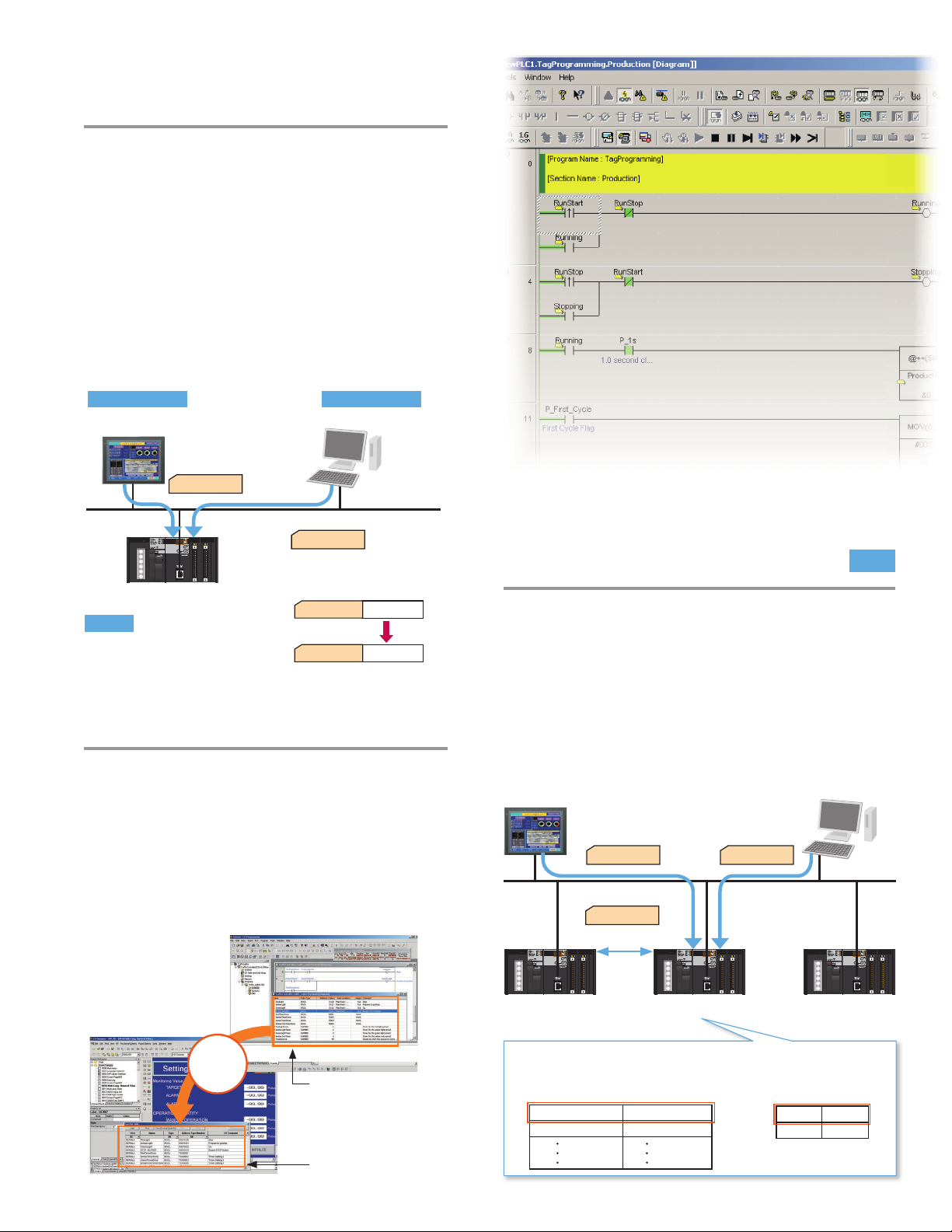

No Need for Memory Map Control.

The CJ2 CPU Units introduce a new feature called tag access, to reduce your TCO (Total Cost of Ownership)

for systems that use Programmable Terminals, multiple PAC’s, and host applications. Tags allow freedom from

memory maps.

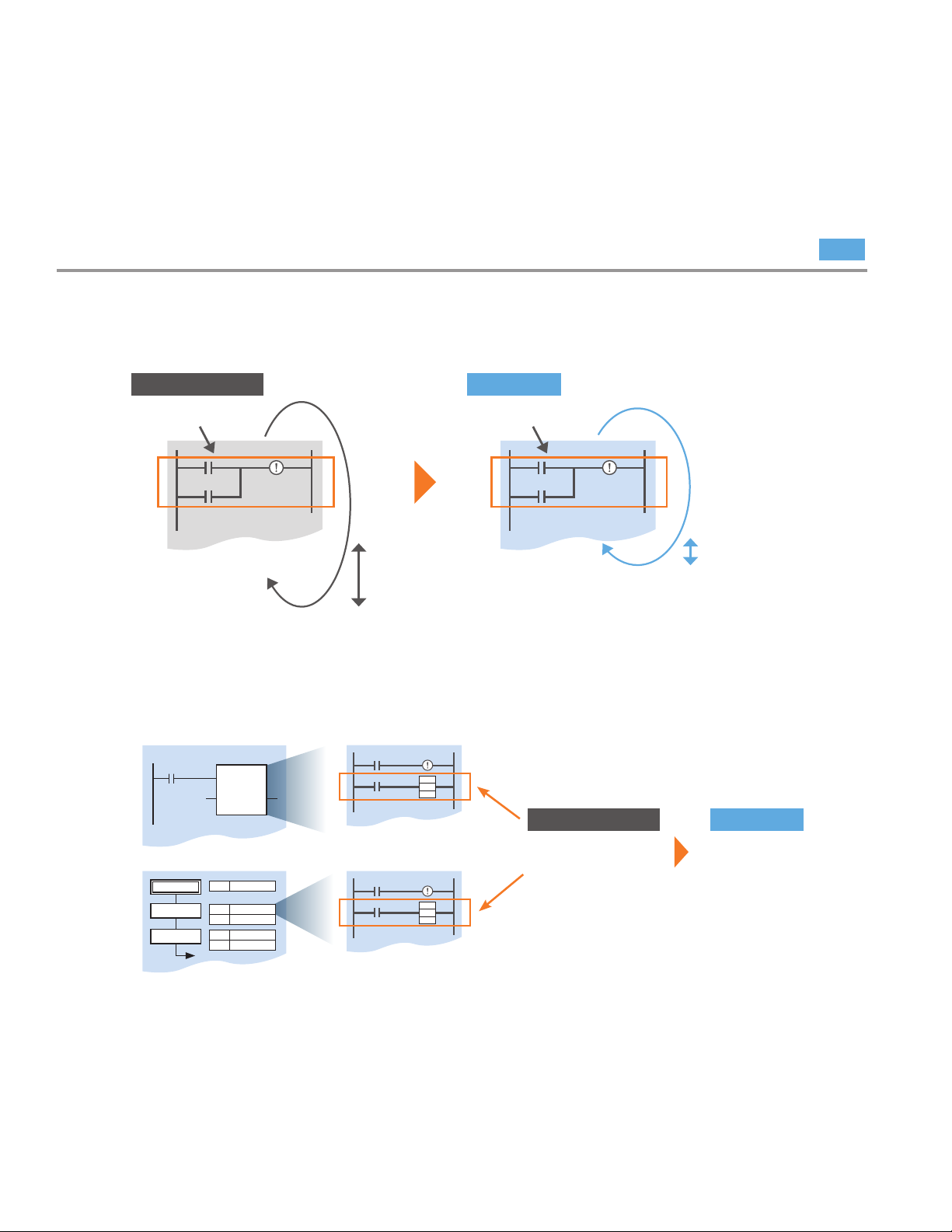

Simultaneous Development Takes the Stress Out of Short Deadlines.

NEW

No Need for Address Allocation Adjustments in Post-processing.

The various Controllers do not depend on addresses, so parallel development at each Controller is enabled

by first simply determining the tag names. There is no need for subsequent address allocation.

Example: Programmable Terminal and CJ2 Development

Previously

Case 1

Case 2

CJ2

By simply setting tag names, PAC and

Programmable Terminal programming

can be performed in parallel.

The PLC program is first

created, and then the ladder

program is referenced to

create the screens.

The screen graphics are

created in advance, and

then addresses are allocated

and checked after the ladder

program is completed.

Tag name

Number_produced

Production_target

Ladder program is created.

Ladder program is created.

Programmable Terminal screens are

created (graphics only).

Address

Undetermined

Undetermined

Ladder program is created.

Addresses are determined while

creating the ladder program.

The screens are created

Programmable Terminal screens

are created.

The addresses are set.

Addresses are allocated and

the allocations are checked.

Design time is shortened

» Simultaneous Development for Programmable

Terminal and CJ2 CPU Unit

Programmable Terminal screens can be designed

using tag names defined in the CJ2 CPU Unit. There

is no need to adjust address allocations in postprocessing.

» Data Links between CJ2 CPU Units

Simply setting tag names allows development to

proceed simultaneously among multiple designers

and multiple vendors. It is then easy to subsequently

change the sizes of data links.

8

The screens are created with no need

to pay attention to addresses.

» Simultaneous Development for Host Application

and CJ2 CPU Unit

Designing can be carried out simply by setting tag

names in the information section and the control

design section. There is no need for physical addresses in the network interface specifications.

Page 9

The Ease of Changing Designs Makes It

Simple to Add or Upgrade Equipment.

There is little effect on address changes.

Previously, when data was exchanged by

address specifi cation and addresses were

changed, the program had to be changed at

other Controllers and various operations, such as

memory checks, had to be performed. Now, tag

names eliminate the dependence on a memory

map and the need for checking items affected

by changes. This allows equipment to be easily

added or upgraded.

Programmable Terminal

NS Series

No change required.

Even after the change, the

number of items produced

is acquired correctly from

H200.

Number_produced

CJ2 CPU

Change

With the CX-Programmer, the address for the tag named “Number

produced” is changed from D100

to H200.

Accessed by tag name

Host application

No change required.

EtherNet/IP

Number_produced

tag name address

Number_produced

Number_produced

D100

H200

Change

Assurance of Quality, Free from Mistakes.

Tags can be shared among the CJ2 CPU Units,

NS-series PTs and Middleware. Tag names can

be shared among controllers that exchange

data using the CX-One or Excel import/export

functions. Because redundant address entry and

address allocation are not needed, checking is

also not required. This makes it easy to construct

high-quality systems.

What is Tag Access?

NEW

A tag is a name given to an address. Tags are

managed in the CJ2 CPU Unit, where they are

defi ned as network symbols. The common userdefi ned tag names are used from Programmable

Terminals and host applications to access memory

in a CJ2 CPU Unit without knowing the actual

memory address.

Programmable Terminal

NS Series

Programmable Terminal screen

Created using tag names.

Number_produced

Number_produced

Data links using tag names

Application

Developed using tag names.

Number_produced

Accessed by tag nameAccessed by tag name

PAC ladder program

Developed using tag names.

Host application

EtherNet/IP

Copy

&

Paste

CX-Programmer symbol table

CX-Programmer symbol tables can

be copied and pasted!

CX-Designer symbol table

CJ2 CPU

Tags are managed in the CJ2 CPU Unit as network symbols.

Symbol Table

Tag name

Number_produced

Production_target

Data link design

Allocated using tag names.

Physical address

D100

D200

CJ2 CPU CJ2 CPU

I/O Memory

Address

D100

D200

Data

&200

&500

9

Page 10

Connecting Support Software is Now

Easier and Safer.

Using General-purpose Networks for Support Software Interface. Connecting to a USB or EtherNet/IP port is

easy, by commercially available cable used around the world.

Easy Connection by USB

Commercially available cable can be connected to a USB port on the front panel of the CPU Unit.

» Simply Connect the Cable, with No Settings Required.

USB port (standard equipment)

Commercially available USB cable

CX-One (e.g., CX-Programmer)

» A CJ2 CPU Unit on an EtherNet/IP Network Can Be Accessed Via USB, with No Need for Routing Tables.

EtherNet/IP

USB

NEW

CX-One (e.g., CX-Programmer)

10

Page 11

Easy Connection by EtherNet/IP

NEW

The built-in EtherNet/IP port enables smooth onsite remote debugging and maintenance.

» EtherNet/IP can be easily connected with

simply an IP address.

HUB

192.168.250.13 192.168.250.14 192.168.250.15

EtherNet/IP

» Even if the IP address is not known, it is easy

to connect by searching the PAC’s on the

EtherNet/IP network and selecting from a list.

Prevention of Erroneous Connection

by PAC Name Verifi cation

A user-set PAC name can be recorded in the CPU

Unit. When connecting online to a PAC, it can

be checked whether the project fi le matches the

name of the PAC that is to be connected, making

it possible to connect with confi dence to a PAC

installed in a location that cannot be seen.

CX-Programmer

HUB

Online connection

Erroneous connection is prevented

by checking whether the PAC name

matches when connecting online.

NEW

The PAC name can be easily found by

selecting from the list that is displayed.

PAC name

Equipment_A

PAC name

Equipment_B

PAC name

Equipment_C

11

Page 12

Easier On-site Debugging

Superior debugging functions reduce the time required for debugging and shorten the total lead time for

system startup and trouble countermeasures.

Stress-free Online Debugging

Effects on machinery operation are reduced.

» The additional cycle time due to Online editing has been reduced to approx. 1 ms

The previous additional cycle time of 8 ms has been shortened to 1 ms.

Previously (CJ1) CJ2

Online editing

CJ1 CPU

Additional time:

Approx.

8 ms

» Unlimited FB and SFC Online Editing

Function blocks and sequential function charts can be edited online with no limitation on program size.

Online editing

CJ2 CPU

Additional time:

Approx.

1 ms

NEW

FB

SFC

FB

FB defi nition

SFC program

Previously (CJ1) CJ2

The size of programs

that could be edited

online was limited to

4 Ksteps.

No limit

12

Page 13

Greatly Improved Debugging Effi ciency

Through Superior Data Tracing

High-speed, High-capacity Data Tracing is

now possible.

High-capacity Data Tracing

Times

More capacity

NEW

8

32 Kwords of data can be traced, and the EM

Area can also be used as trace memory.

Ample Sampling Data type and

Trigger Conditions

NEW

One, two, or four words of data and comparison

conditions can be specifi ed. For example, a

trigger can be set for when double-precision

data is larger than a specifi ed value.

Continuous Data Tracing

NEW

Sampled data in the trace memory of the

CPU Unit can be regularly collected at the

personal computer to enable sampling for

long periods or time. CSV fi les can be saved

at the personal computer.

Data collection

EtherNet/IP

CX-One Data Trace is also Upgraded

Ver.Up

The improved CJ2 trace function is fully utilized.

» A function has been added for superimposing

trace waveforms

» Trace results can be printed or saved as bit maps.

» The measurement times for two selected points can

be checked.

CJ2 CPU Unit

nd

time

2

1st time

Data is collected at the personal

computer at the specifi ed times.

When data that was sampled at high speed in the

PAC’s trace memory is saved at the personal computer,

the trace memory is cleared.

rd

time

3

13

Page 14

D100.05

15

D100

Bit

14 13 12 11 10 9876543210

E0_100.03

D200.00D100.05

W0.00

TIM

100-ms timer (BCD)

100-ms timer (binary)

Timer number

Timer number

Set value

Set value

0001

#10

W0.01

TIMX(550)

0002

#01FF

The BCD TIM and binary TIMX instructions can be used together.

D100 [W100]

Offset n (number of words)

Starting word address

Starting word address: D100

Offset +n

CH 15 0

Array Variable: ABC

Example

Ladder language:

Copy ABC[3] to D200

ST language:

Substitute ABC[0] to ABC[3].

0

1

2

3

4

5

6

7

8

9

WORD data

WORD data

WORD data

WORD data

WORD data

WORD data

WORD data

WORD data

WORD data

WORD data

MOV

ABC[3]

D200

5.00

To access

this data,

specify ABC

[3].

More Flexible Programming

The Greatest Program Diversity in the industry. A programming environment has been created that is highly

readable and can flexibly support changes in specifications, to enable efficient design and program entry

with few mistakes.

Highly Readable Programming

Programs are easy to see and easy to understand.

Bit Addresses can be used in the DM Area and EM Area.

NEW

DM and EM Area bits could not be specified with the previous

SYSMAC PLCs, but they can with the CJ2 CPU Units.

Examples

D100.05: Bit 05 of D100

E0_100.05: Bit 03 of E0_100

BCD and Binary Timer Instructions can be used Together.

NEW

With the CJ1 CPU Units, it was necessary to select in the initial setup of the CPU Unit whether BCD or binary

was to be used as the data format for timer instructions. With the CJ2 CPU Units, BCD or binary can be

selected individually for each instruction by setting the data format of the timer set value.

Address Offsets can be Specified

NEW

An offset can be specified in brackets after a starting

address to offset the starting address. If an address

in I/O memory is specified as the offset, the final

address can be dynamically specified according to

the contents of the specified memory address.

Example

D100[W100]: D100 is the starting address and the contents of W100

is the offset. If W100 is &5, then D105 is specified.

Array Variables make Data Specification Easier to Understand.

By using array variables, any data in a string of

data can be expressed using a subscript, making

programming easy to understand. Array variables

can also be used for data stacks and function block

I/O variables. Because they can be set for network

symbols, the exchange of multiple data items

14

with external devices can be easily programmed.

(Usable languages: Ladder, ST, SFC).

Page 15

data [i]

Symbol that indirectly specifies

the element number

Array variable name

Start of array

Value of element number i

(example when i = 5)

0

1

2

3

4

5

data[0]

data[1]

data[2]

data[3]

data[4]

data[5]

Element number

A Symbol Can be used for an Array

Variable Subscript.

NEW

A physical address or symbol can be specifi ed

for an array subscript, so data can be

dynamically specifi ed.

Example Data[i]: An element number is indirectly specifi ed by the

value of symbol i. If the value of symbol i is &5, data[5] is specifi ed

for element number 5.

Memory Attributes in the Ladder Editor

can be Understood at a Glance.

Tag (network symbols) memory attributes can

be understood at a glance in the Ladder Editor

Window, enabling an easily understandable

program to be created.

Ver.Up

Example

New Instructions are Supported.

:Published :Input :Output

Operation start Operation stop

Operation status

NEW

New instructions such as tracking, sorting, and

fl oating-point decimal maximum/minimum value

search instructions are supported.

The Number of Communications Logic

Ports has Increased to 64.

Programming can be performed with no need to

pay attention to the number of logic ports.

NEW

Up to 128 Cyclic Tasks

4

Times

are Supported.

More than before

NEW

The user program can be divided into up to 128

tasks. Using smaller task programs makes it easier

to structure programs. This also contributes to shorter

cycle times by controlling the tasks that are being

executed or not executed in smaller units.

Languages Conforming to IEC Are Supported.

Ladder diagrams and ST languages can be freely

combined and made into components as function

blocks (FBs), allowing programs to be created in the

optimum language for the particular process.

User program

Task

Task

Task

Task

a:=a+1;

RESULTS=0.0;

IF M = TRUE THEN

RESULTS = SIN(data):

ENDIF;

Ladder diagram

Control of equipment and

external devices

FBs

FB

Modularization

and reusability

ST

Math and character string

processing

Programming Structuring and Reusability.

Highly Independent Programs Can Be

Easily Created.

SFC

Step progression control

The programming language suited to the process can be used.

15

Page 16

CPU Rack

End Cover

CJ1W-TER01

(One End Cover is provided as a standard

accessory with the CPU Unit.)

Power Supply Unit

CJ1W-P@@@ (@)

CPU Unit

CJ2H-CPU@@-EIP

I/O Control Unit

CJ1W-IC101

(Required only when connecting

to an Expansion Rack.)

CJ-series Basic I/O Units

CJ-series Special I/O Units

CJ-series CPU Bus Units

Total: 10 Units max

System Configuration

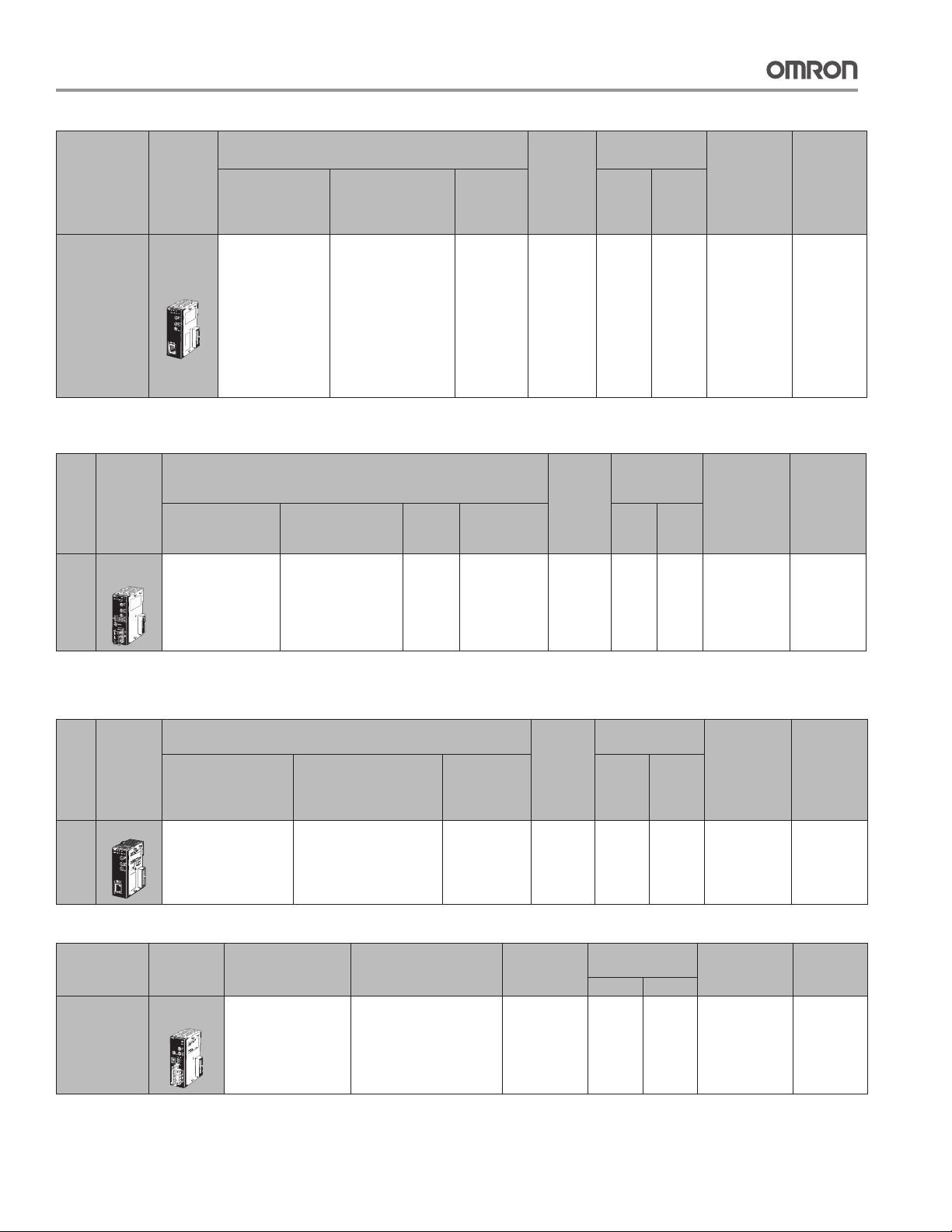

CJ-series CPU Racks ■

A CJ-series CPU Rack consists of a CPU Unit, Power Supply Unit, Configuration Units (Basic I/O Units, Special I/O Units, and CPU

Bus Units), and an End Cover.

Required Units ●

Rack Unit name Required number of Units

Power Supply Unit

CPU Unit

CPU Rack

I/O Control Unit

Number of Configuration Units

End Cover

Types of Units ●

In the SYSMAC CJ Series, Units are classified into the following three types. The number of Racks differs depending on the type.

Type Appearance (example) Description Unit recognition method No. of units

Basic I/O Units

Units with contact inputs and contact outputs. Recognized by the CPU Unit according

1

1

Required only for mounting to an Expansion Rack.

10 max. (Same for all models of CPU Unit.)

(The number of Basic I/O Units, Special I/O Units, and CPU Bus Units can be varied. The number does

not include the I/O Control Unit.)

1 (Included with CPU Unit.)

No restrictions.

to the position of the Rack and slot.

16

Special I/O

Units

CPU Bus Units

Special I/O Units provide more advanced functions

than do Basic I/O Units, including I/O other than

contact inputs and contact outputs.

Examples of Special I/O Units are Analog I/O Units

and High-speed Counter Units. They differ from

CPU Bus Units (including Network Communications

Units) in having a smaller area for exchanging data

with the CPU Unit.

CPU Bus Units exchange data with the CPU Unit

via the CPU Bus.

Examples of CPU Bus Units are Network

Communications Units and Serial Communications

Units. They differ from Special I/O Units in having a

larger area for exchanging data with the CPU Unit.

Recognized by the CPU Unit according

to the unit number (0 to 95) set with the

rotary switches on the front panel.

Recognized by the CPU Unit according

to the unit number (0 to F) set with the

rotary switch on the front panel.

A maximum of 96 Units can

be connected. (Multiple unit

numbers are allocated per Unit,

depending on the model and

settings.)

A maximum of 15 Units can be

mounted. (The built-in EtherNet/

IP port on the CPU Unit must

be counted as one of the CPU

Bus Units.)

Page 17

System Configuration

Configuration Units: 10 max.

Power Supply Unit

CJ1W-P@@@(@)

CPU Unit

CJ2H-CPU@@-EIIP

I/O Control Unit

CJ1W-IC101

I/O Interface Unit

CJ1W-II101

Power Supply Unit

CJ1W-P@@@(@)

Power Supply Unit

CJ1W-P@@@(@)

Power Supply Unit

CJ1W-P@@@(@)

CPU Rack

Expansion

Rack

Expansion

Rack

Number of Expansion Racks:

Up to 3 Expansion Racks can be connected.

I/O Connecting Cable

CS1W-CN@@3

Configuration Units: 10 max.

I/O Interface Unit

CJ1W-II101

I/O Interface Unit

CJ1W-II101

I/O Connecting Cable

CS1W-CN@@3

I/O Connecting Cable

CS1W-CN@@3

Expansion

Rack

Total

cable

length

≤ 12 m

Configuration Units: 10 max.

Configuration Units: 10 max.

CJ-series Expansion Racks ■

A CJ-series Expansion Rack consists of a Power Supply Unit, an I/O Interface Unit, Configuration Units (Basic I/O Units, Special I/O

Units, and CPU Bus Units), and an End Cover.

Required Units ●

Rack Unit name Required number of Units

CPU Rack I/O Control Unit

Expansion

Rack

Note: 1. Mounting the I/O Control Unit in any other location may cause faulty operation.

2. Mounting the I/O Interface Unit in any other location may cause faulty operation.

Maximum Number of Configuration Units That Can Be Mounted ●

CPU Unit Model Total Units No. of Units on CPU Rack No. of Expansion Racks

CJ2H CJ2H-CPU68-EIP

Power Supply Unit

I/O Interface Unit

Number of Configuration Units

End Cover

CJ2H-CPU67-EIP

CJ2H-CPU66-EIP

CJ2H-CPU65-EIP

CJ2H-CPU64-EIP

One Unit. Required only when an Expansion Rack is used. Mount the I/O Control Unit immediately to the

right of the CPU Unit. (See note 1.)

One Unit

One Unit. Mount the I/O Interface Unit immediately to the right of the Power Supply Unit. (See note 2.)

Ten Units max. (The number of Basic I/O Units, Special I/O Units, and CPU Bus Units can be varied.

This number does not include the I/O Interface Unit.)

One (Included with the I/O Interface Unit.)

40 10 per Rack 3 Racks x 10 Units

17

Page 18

External Interface

A CJ2H CPU Unit provides three communications ports for external interfaces: a peripheral (USB) port, a serial port and an EtherNet/IP port.

Battery Compartment

LED Indicators

DIP Switch

(inside the battery compartment)

Memory Card Indicators

Indicates the Memory Card status

(access and power supply).

Peripheral (USB) Port

Connected to Programming Devices,

such as the CX-Programmer

Serial Port

Connected to Programming Devices, Host

Computers, general-purpose external devices,

Programmable Terminals, and other devices.

EtherNet/IP Port

Connected to the information management

system such as Host Computer

Simple Backup/Memory Card

Power Supply Switch

Used to back up Memory

Card data or turn OFF the

power when removing the

Memory Card.

Memory Card Connector

Connects the Memory Card

to the CPU Unit.

Memory Card Eject Button

Press the eject button to

remove the Memory Card

from the CPU Unit.

External Interface

18

Page 19

General Specifications

Item

Enclosure Mounted in a panel

Grounding Less than 100 Ω

CPU Rack Dimensions 90 mm × 65 mm × 80 mm (W × H × D)

Weight 280 g or less

Current Consumption 5 VDC, 0.82 A

Use

Environment

Battery Life 5 years at 25°C

Applicable Standards Conforms to cULus and EC Directives.

Ambient Operating Temperature 0 to 55°C

Ambient Operating Humidity 10% to 90%

Atmosphere Must be free from corrosive gases.

Ambient Storage Temperature −20 to 70°C (excluding battery)

Altitude 2,000 m or less

Pollution Degree 2 or less: Conforms to JIS B3502 and IEC 61131-2.

Noise Immunity 2 kV on power supply line (Conforms to IEC 61000-4-4.)

Overvoltage Category Category II: Conforms to JIS B3502 and IEC 61131-2.

EMC Immunity Level Zone B

Vibration Resistance Conforms to JIS C60068-2-6.

Shock Resistance Conforms to JIS C60068-2-27.

Model CJ1W-BAT01

CPU64-EIP CPU65-EIP CPU66-EIP CPU67-EIP CPU68-EIP

5 to 8.4 Hz with 3.5-mm amplitude, 8.4 to 150 Hz

Acceleration of 9.8 m/s

2

, 3 times in X, Y, and Z directions (100 m/s2 for Relay Output Units)

147 m/s

2

for 100 min in X, Y, and Z directions (10 sweeps of 10 min each = 100 min total)

CJ2H-

19

Page 20

Performance Specifications

Item

User Memory 50K steps 100K steps 150K steps 250K steps 400K steps

I/O Bits 2,560 bits

Processing Speed Overhead Processing Time Normal Mode: 200 μs

Execution Time Basic Instructions: 0.016 μs min.;

Interrupt Task Start Time 30 μs

Maximum Number of Connectable Units Total per CPU Rack or Expansion Rack: 10 Units max.;

Maximum Number of Expansion Racks 3 max.

CIO Area I/O Area 2,560 bits (160 words): Words CIO 0000 to CIO 0159

Link Area 3,200 bits (200 words): Words CIO 1000 to CIO 1199

CPU Bus Unit Area 6,400 bits (400 words): Words CIO 1500 to CIO 1899

Special I/O Unit Area 15,360 bits (960 words): Words CIO 2000 to CIO 2959

DeviceNet Area 9,600 bits (600 words): Words CIO 3200 to CIO 3799

Internal I/O Area 3,200 bits (200 words): Words CIO 1300 to CIO 1499

Work Area 8,192 bits (512 words): Words W000 to W511

Holding Area 8,192 bits (512 words): Words H000 to H511

Auxiliary Area Read-only: 31,744 bits (1,984 words)

Temporary Area 16 bits: TR0 to TR15

Timer Area 4,096 timer numbers (T0000 to T4095 (separate from counters))

Counter Area 4,096 counter numbers (C0000 to C4095 (separate from timers))

DM Area 32k words (Bits in the DM Area can be addressed either by bit or by word.)

EM Area 32k words/bank × 25 banks max.: E00_00000 to E18_32767 max.

Force-set/reset Enabled

Banks

Index Registers IR0 to IR15

Cyclic Task Flag Area 128 flags

Memory Card 128 MB, 256 MB, or 512 MB

Operating Modes PROGRAM Mode: Programs are not executed. Preparations can be executed prior to program execution in this

Execution Mode Normal Mode

CPU64-EIP CPU65-EIP CPU66-EIP CPU67-EIP CPU68-EIP

(If tag data links are used with EtherNet/IP, add the following to the above time: 100 μs + Number of

transferred words × 0.33 μs)

Special Instructions: 0.048 μs min.

Total per PAC: 40 Units max.

37,504 bits (2,344 words): Words CIO 3800 to CIO 6143

Cannot be used for external I/O.

Cannot be used for external I/O.

Bits in this area maintain their ON/OFF status when PAC is turned OFF or operating mode is changed.

Words H512 to H1535: These words can be used only for function blocks. They can be used only for

function block instances (i.e., they are allocated only for internal variables in function blocks).

• 7,168 bits (448 words): Words A0 to A447

• 24,576 bits (1,536 words): Words A10000 to A11535

Read/write: 16,384 bits (1,024 words) in words A448 to A1471

DM Area words for Special I/O Units: D20000 to D29599 (100 words × 96 Units)

DM Area words for CPU Bus Units: D30000 to D31599 (100 words × 16 Units)

(Bits in the EM Area can be addressed either by bit or by word.)

32K words × 4

banks

EM3 EM3 EM6 to EM9 EM7 to EME EM11 to EM18

Force-setting/resetting is enabled only for areas specified for automatic address allocation.

These are special registers for storing PAC memory addresses for indirect addressing. (Index

Registers can be set so that they are unique in each task or so that they are shared by all tasks.)

MONITOR Mode: Programs are executed, and some operations, such as online editing, and changes to present

RUN Mode: Programs are executed. This is the normal operating mode.

32K words × 4

banks

mode.

values in I/O memory, are enabled in this mode.

CJ2H-

32K words × 10

banks

32K words × 15

banks

32K words × 25

banks

20

Page 21

Performance Specifications

Item

Programming Languages Ladder Logic (LD),

Function Blocks Maximum number of definitions 2,048

Maximum number of instances 2,048

Tasks Type of Tasks Cyclic tasks

Number of Tasks Cyclic tasks: 128

Symbols

(Variables)

Data Tracing Memory Capacity 8,000 words 16,000 words 32,000 words

File Memory Memory Card (128, 256, or 512 Mbytes) (Use the Memory Cards provided by OMRON.)

Source/Comment

Memory

Type of Symbols • Local symbols: Can be used only within a single task in the PAC.

Data Type of Symbols • BOOL (bit)

Maximum Size of Symbol 32k words

Array Symbols (Array Variables) One-dimensional arrays

Number of Array Elements 32,000 elements max.

Number of Registrable Network

Symbols (Tags)

Length of Network Symbol (Tag)

Name

Encoding of Network Symbols

(Tags)

Number of Samplings Bits = 31, one-word data =16, two-word data = 8, four-word data = 4

Sampling Cycle 1 to 2,550 ms (Unit: 1 ms)

Trigger Conditions ON/OFF of specified bit

Delay Value −32,768 to +32,767 ms

Function block program memory,

comment file, program index file,

symbol tables

CPU64-EIP CPU65-EIP CPU66-EIP CPU67-EIP CPU68-EIP

Sequential Function Charts (SFC),

Structured Text (ST), and

Instruction Lists (IL)

Interrupt tasks (Power OFF interrupt tasks, scheduled interrupt tasks, I/O interrupt tasks, and

external interrupt tasks)

Interrupt tasks: 256

(Interrupt tasks can be defined as cyclic tasks to create extra cyclic tasks. Therefore, the total

number of cyclic tasks is actually 384 max.)

• Global symbols: Can be used in all tasks in the PAC.

• Network symbols (tags): I/O memory in the CPU Unit can be externally accessed using symbols, depending on

parameter settings.

• UINT (one-word unsigned binary)

• UDINT (two-word unsigned binary)

• ULINT (four-word unsigned binary)

• UINT BCD (one-word unsigned BCD)

• INT (one-word signed binary)

• DINT (two-word signed binary)

• LINT (four-word signed binary)

• UDINT BCD (two-word unsigned BCD)

• ULINT BCD (four-word unsigned BCD)

• REAL (two-word oating-point)

• LREAL (four-word oating-point)

• CHANNEL (word)

• NUMBER (constant or number)

• WORD (one-word hexadecimal)

• DWORD (two-word hexadecimal)

• LWORD (four-word hexadecimal)

• TIMER

• COUNTER

20,000 max.

255 bytes max.

UTF-8

(Up to 32k words x 25 banks when EM is specified in CX-Programmer)

Data comparison of specified word

Data size: 1 word, 2 words, 4 words

Comparison Method: Equals (=), Greater Than (>), Greater Than or Equals (≥), Less Than (<), Less Than or Equals

(≤), Not Equal (≠)

EM file memory (Part of the EM Area can be converted for use as file memory.)

Capacity: 3.5 Mbytes

CJ2H-

21

Page 22

Performance Specifications

Item

Logical Ports for

Communications

Cip

Communications

Specification

Peripheral (USB) Port USB 2.0-compliant B-type connector

Baud Rate 12 Mbps max.

Transmission Distance 5 m max.

Serial Port Interface: Conforms to EIA RS-232C.

Communications Method Half-duplex

Synchronization Method Start-stop

Baud Rate 0.3, 0.6, 1.2, 2.4, 4.8, 9.6, 19.2, 38.4, 57.6, or 115.2 (kbps)

Transmission Distance 15 m max.

EtherNet/IP Port —

Media Access Method CSMA/CD

Modulation Baseband

Transmission Paths Star

Baud Rate 100 Mbps (100Base-TX)

Transmission Media Shielded twisted-pair (STP) cable; Categories: 5, 5e

Transmission Distance 100 m (between hub and node)

Number of Cascade Connections No restrictions if switching hub is used.

Transmission Specifications

CIP Communications: Tag Data Links —

Communications

Communication Specifications

CIP Communications: Explicit Messages —

FINS Communications —

EtherNet/IP Conformance Test Conforms to A5.

EtherNet/IP Interface 10Base-T/100Base-TX

Note 1. “Packets per second” is the number of communications packets that can be processed per second.

2. Large Forward Open (CIP optional specification) must be supported in order for 505 to 1,444 bytes to be used as the data size. Application is supported between CS/CJ-series PLCs.

When connecting to devices from other manufacturers, make sure that the devices support the Large Forward Open specification.

3. If the maximum number is exceeded, refreshing will require more than one CPU Unit cycle.

4. When changing parameters, however, the EtherNet/IP port where the change is made will be restarted. In addition, a timeout will temporarily occur at the other node that was

communicating with that port, and it will then recover automatically.

5. The EtherNet/IP port supports an IGMP client, so unnecessary multicast packets are filtered by using a switching hub that supports IGMP snooping.

Logical Ports 8 ports (Used for SEND, RECV, CMND, PMCR, TXDU, and RXDU instructions.)

Extended Logical Ports 64 ports (Used for SEND2, RECV2, CMND2, and PMCR2 instructions.)

Class 3

(Number of Connections)

UCMM

(Non-connection Type)

Number of Connections 256

Packet Interval (Refresh period) 0.5 to 10,000 ms (Unit: 0.5 ms)

Permissible Communications Band 6,000 pps (See note 1.)

Number of Tag Sets 256

Type of Tags CIO, DM, EM, HR, and WR

Number of Tags per Connection 8 (Seven tags if PAC status is included in the segment.)

Maximum Link Data Size per Node 184,832 words

Maximum Data Size per Connection 252 or 722 words (See note 2.)

Number of Registrable Tag Set 256 (1 connection = 1 segment)

Maximum Tag Set Size 722 words (One word is used when PAC status is included in the segment.)

Maximum Number of Tags Refreshable in

a Single Cycle of CPU Unit (See note 3.)

Data Size Refreshable in a Single Cycle

of CPU Unit (See note 3.)

Change of Tag Data Link Parameter

Settings during Operation

Multi-cast Packet Filter (See note 5.) OK

Class 3 (Number of Connections) Number of connections: 128

UCMM (Non-connection Type) Maximum number of clients that can communicate at the same time: 32

CIP Routing OK (CIP routing is enabled for the following remote Units: CJ1W-EIP21 and CJ2H-CPU6

FINS/UDP OK

FINS/TCP 16 connections max.

CPU64-EIP CPU65-EIP CPU66-EIP CPU67-EIP CPU68-EIP

Number of connections: 64

Maximum number of clients that can communicate at the same time: 32

Maximum number of servers that can communicate at the same time: 40

Can be set for each connection. (Data will be refreshed at the set interval, regardless of the number of nodes.)

(Data is synchronized within each connection.)

Output/send (CPU Unit to EtherNet/IP): 256

Input/receive (EtherNet/IP to CPU Unit): 256

Output/send (CPU to EtherNet/IP): 6,432 words

Input/receive (EtherNet/IP to CPU): 6,432 words

OK (See note 4.)

Maximum number of servers that can communicate at the same time: 32

Auto Negotiation/Fixed Setting

CJ2H-

-EIP.)

22

Page 23

Performance Specifications

International Standards

• The standards indicated in the “Standards” column are

those current for UL, CSA, cULus, cUL, NK, and Lloyd

standards and EC Directives as of the end of May 2008.

The standards are abbreviated as follows: U: UL, U1: UL

Class I Division 2 Products for Hazardous Locations, C:

CSA, UC: cULus, UC1: cULus Class I Division 2 Products

for Hazardous Locations, CU: cUL, N: NK, L: Lloyd, and CE:

EC Directives.

• Ask your OMRON representative for the conditions under

which the standards were met.

● EC Directives

The EC Directives applicable to PAC’s, PLC’s include the

EMC Directives and the Low Voltage Directive. OMRON

complies with these directives as described below.

● EMC Directives Applicable Standards

EMI: EN61000-6-4, EN61131-2

EMS: EN61000-6-2, EN61131-2

PAC’s, PLC’s are electrical devices that are incorporated

in machines and manufacturing installations. OMRON

PAC’s, PLC’s conform to the related EMC standards so

that the devices and machines into which they are built

can more easily conform to EMC standards. The actual

PAC’s, PLC’s have been checked for conformity to EMC

standards. Whether these standards are satisfied for

the actual system, however, must be checked by the

customer.

EMC-related performance will vary depending on the

configuration, wiring, and other conditions of the equipment

or control panel in which the PAC, PLC is installed. The

customer must, therefore, perform final checks to confirm

that the overall machine or device conforms to

EMC standards.

● Low Voltage Directive

Applicable Standard:EN61131-2

VDC must satisfy the appropriate safety requirements.

With PAC’s, PLC’s, this applies to Power Supply Units and

I/O Units that operate in these voltage ranges.

These Units have been designed to conform to

EN61131-2, which is the applicable standard for PAC’s

and PLC’s.

23

Page 24

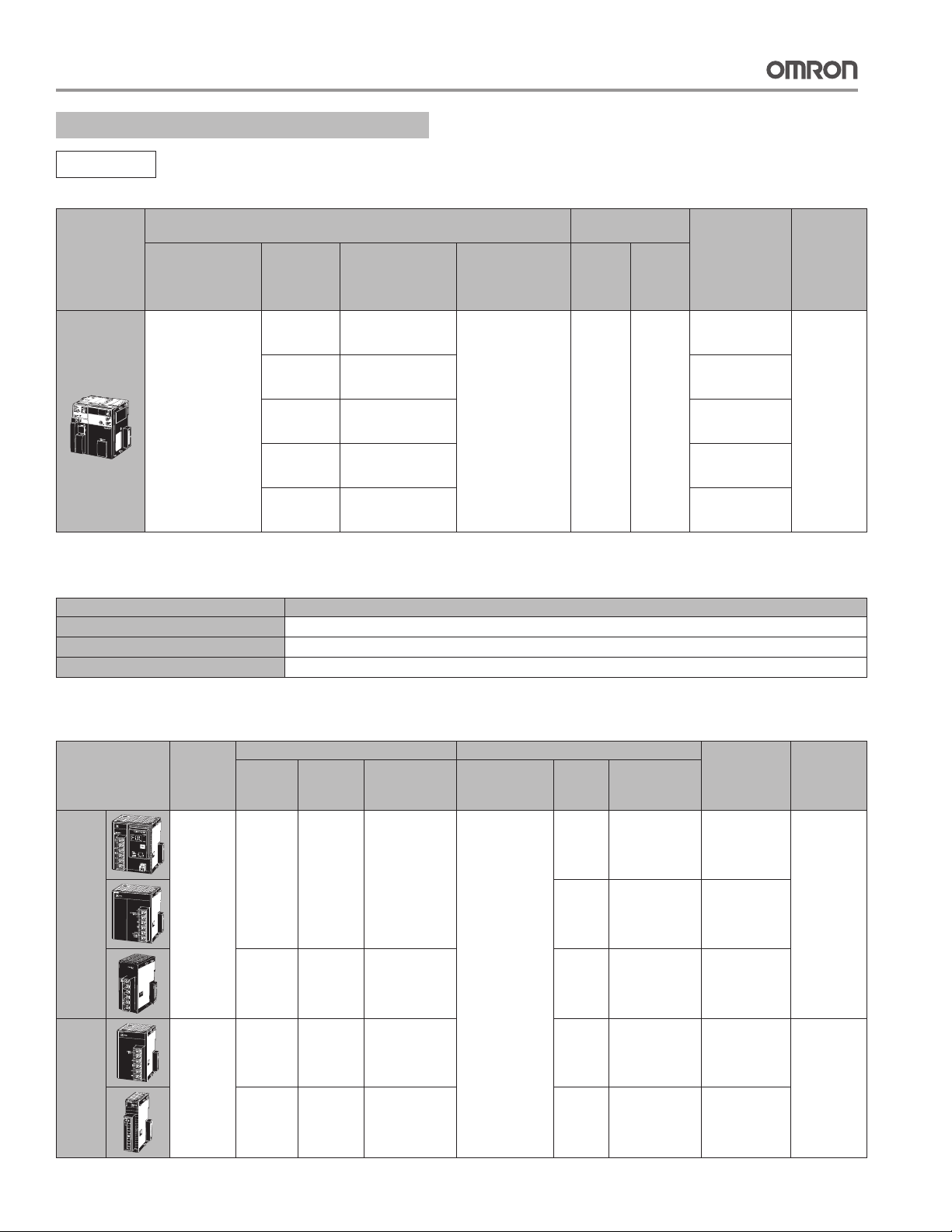

Ordering Information

Basic Configuration Units

CPU Units

CJ2 CPU Units ■

Specifications

Product

name

CJ2 CPU Units

Note: Add 0.15 A per Adapter when using NT-AL001 RS-232C/RS-222A Adapters.

Add 0.04 A per Adapter when using CJ1W-CIF11 RS-422A Adapters.

The following accessories are included with the CPU Unit.

Battery

End Cover

End Plate

I/O capacity/

Mountable Units

(Expansion

Program

capacity

Data memory

capacity

Racks)

832K words

(DM: 32K words, EM:

32K words × 25 banks)

512K words

(DM: 32K words, EM:

32K words × 15 banks)

352K words

(DM: 32K words, EM:

32K words × 10 banks)

160K words

(DM: 32K words, EM:

32K words × 4 bank)

160K words

(DM: 32K words, EM:

32K words × 4 bank)

2,560 points/

40 Units

(3 Expansion

Racks max.)

400K steps

250K steps

150K steps

100K steps

50K steps

Item Specifications

CJ1W-BAT01

CJ1W-TER01(The End Cover must be connected to the right end of the CPU Rack.)

PFP-M(2 stoppers)

Function block

program,

comment, symbol

memory

3.5MB

Current

consumption (A)

5 V 24 V

0.82

(See

note.)

—

Model Standards

CJ2H-CPU68H-EIP

CJ2H-CPU67H-EIP

CJ2H-CPU66H-EIP

CJ2H-CPU65H-EIP

CJ2H-CPU64H-EIP

UC1, N, L,

CE

Power Supply Units ■

One Power Supply Unit is required for each Rack.

Output capacity Options

24-VDC

output

capacity

Product name

AC

Power

Supply

Unit

DC

Power

Supply

Unit

Power

supply

voltage

100 to 240

VAC

24 VDC

5-VDC

output

capacity

5 A 0.8 A 25 W

2.8 A 0.4 A 14 W No No CJ1W-PA202

5A 0.8 A 25 W No No CJ1W-PD025

2 A 0.4 A 19.6 W No No CJ1W-PD022

Total power

consumption

24-VDC

service power

supply

No

RUN

output

Maintenance

forecast

monitor

No Yes CJ1W-PA205C

Yes No CJ1W-PA205R

Model Standards

UC1, N, L,

CE

UC1, CE

24

Page 25

Ordering Information

Expansion Racks

Select the I/O Control Unit, I/O Interface Unit, Expansion Connecting Cable, and CJ-series Power Supply Unit.

CJ-series I/O Control Unit (Mounted on CPU Rack when Connecting Expansion Racks) ■

Current

Product name Specifications

CJ-series I/O

Control Unit

Note: Mounting the I/O Control Unit in any other location may cause faulty operation.

Mount one I/O Control Unit on the CJ-series CPU Rack when connecting one

or more CJ-series Expansion Racks.

Connecting Cable: CS1W-CN

Connected Unit: CJ1W-II101 I/O Interface Unit

Mount to the right of the CPU Unit.

3 Expansion Connecting Cable

CJ-series I/O Interface Unit (Mounted on Expansion Rack) ■

Product name Specifications

CJ-series I/O

Interface Unit

One I/O Interface Unit is required on each Expansion Rack.

Connecting Cable: CS1W-CN

Mount to the right of the CPU Unit.

3 Expansion Connecting Cable

consumption (A)

5 V 24 V

0.02 — CJ1W-IC101

Current

consumption (A)

5 V 24 V

0.13 — CJ1W-II101

Model Standards

Model Standards

UC1, N, L,

CE

UC1, N, L,

CE

Note: Mounting the I/O Interface Unit in any other location may cause faulty operation.

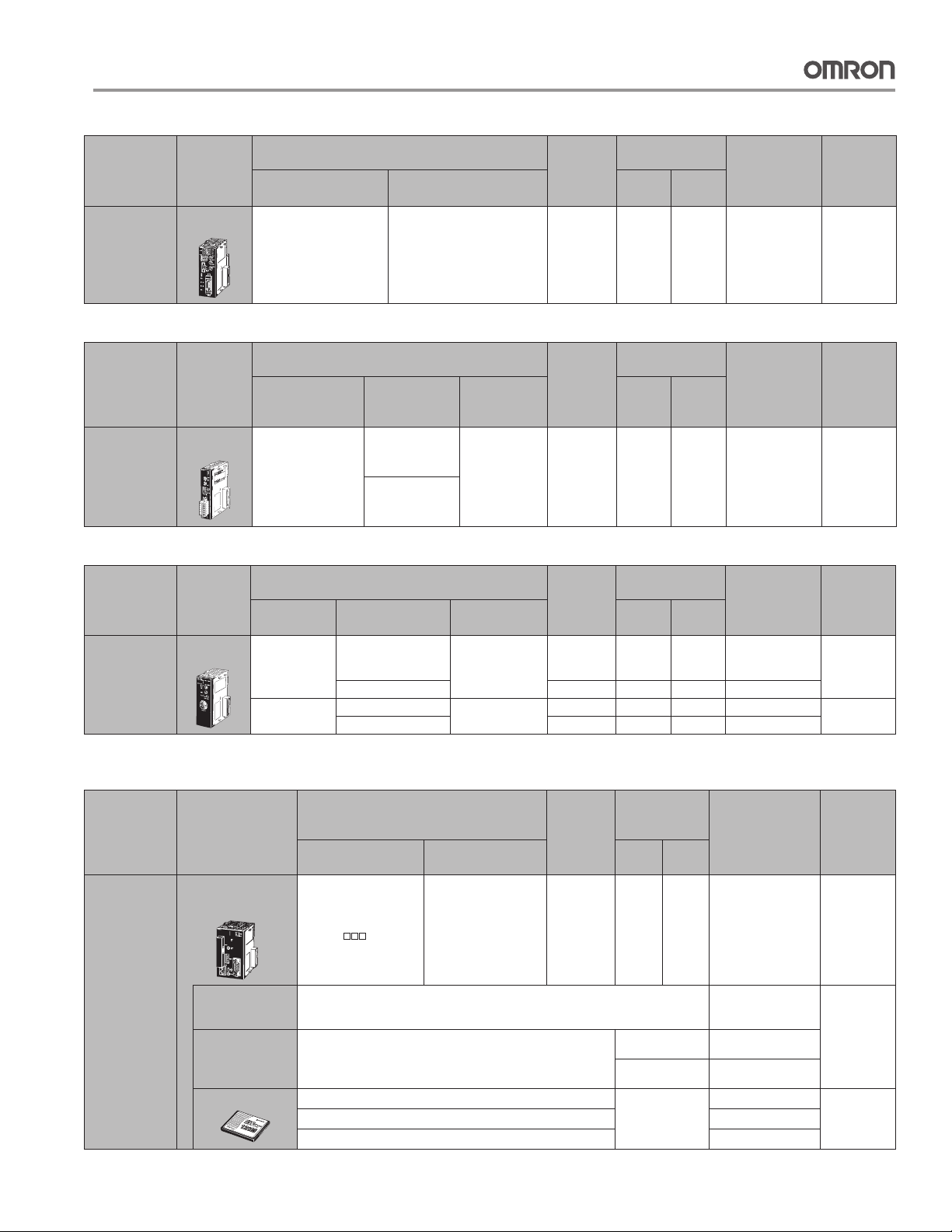

I/O Connecting Cables ■

Product name Specifications Model Standards

Cable length: 0.3 m CS1W-CN313

I/O Connecting

Cable

• Connects an I/O Control Unit on CJ-series CPU Rack to an I/O Interface Unit on a

CJ-series Expansion Rack.

or

• Connects an I/O Interface Unit on CJ-series Expansion Rack to an I/O Interface Unit on

another CJ-series Expansion Rack.

Cable length: 0.7 m CS1W-CN713

Cable length: 2 m CS1W-CN223

Cable length: 3 m CS1W-CN323

Cable length: 5 m CS1W-CN523

Cable length: 10 m CS1W-CN133

Cable length: 12 m CS1W-CN133-B2

N, L, CE

25

Page 26

Ordering Information

Programming Devices

Support Software ■

Product name Specifications Model Standards

The CX-One is a comprehensive software package that integrates Support Software

FA Integrated Tool

Package CX-One

Ver. 3.

Note: If the complete CX-One package is installed, approximately 2.5 GB of Hard disk space will be required.

for OMRON PAC’s , PLC’s and components.

CX-One runs on the following OS.

Windows 2000 (Service Pack 3 or higher), XP, or Vista

CX-One Version 3.

For details, refer to the CX-One catalog (Cat. No. R134).

includes CX-Programmer Ver.8. and CXSimulator Ver. 1. .

Number of

licenses

1 license

3 licenses CXONE-AL03C-V3

10 licenses CXONE-AL10C-V3

30 licenses CXONE-AL30C-V3

50 licenses CXONE-AL50C-V3

Media

CXONE-AL01C-V3

CD

—

Programming Device Connecting Cable

Peripheral (USB) Port ■

Use commercially available USB cable.

Specifications: USB 1.1 or 2.0 cable (A connector - B connector), 5.0 m max.

EtherNet/IP Port ■

Support Software can also be connected via the built-in EtherNet/IP port. Use commercially available 100Base-TX twisted-pair cable

with the same specifications as for an EtherNet/IP Unit.

Specifications: Twisted-pair cable with RJ45 modular connectors at both ends. Connect between EtherNet/IP Unit or built-in EtherNet/

IP port and switching hub. Use STP (shielded twisted-pair) cable of category 5 or 5e.

Optional Products and Maintenance Products

Product name Specifications Model Standards

Memory Cards

Flash memory, 128 MB HMC-EF183

N, L, CE Flash memory, 256 MB HMC-EF283

Flash memory, 512 MB HMC-EF583

Memory Card Adapter (for computer PCMCIA slot) HMC-AP001 CE

Product name Specifications Model Standards

Battery Set

End Cover

Battery for CJ2H-CPU -EIP and CJ1M-CPU

CPU Unit maintenance

Mounted to the right-hand side of CJ-series CPU

Racks or Expansion Racks.

Note 1. The battery is included as a standard

accessory with the CPU Unit.

2. The battery service life is 5 years at 25°C.

(The service life depends on the ambient

operating temperature and the power

conditions.)

3. Use batteries within two years of

manufacture.

One End Cover is provided as a standard accessory

with each CPU Unit and I/O Interface Unit.

CJ1W-BAT01 CE

CJ1W-TER01 UC1, N, L, CE

26

Page 27

Ordering Information

Basic I/O Units

Input Units ■

Product

Unit

name

classification

I/O

points

Input voltage

and current

Specifications

Commons

Additional

functions

External

connection

No. of

words

allocated

Current

consumption

(A)

5 V 24 V

Model Standards

DC Input

Units

CJ

Basic

I/O

Units

AC Input

Units

Note: Connectors are not provided with these connector models. Either purchase one of the following 40-pin Connectors,

or use an OMRON XW2

8 inputs

16 inputs 24 VDC, 7 mA

32 inputs 24 VDC, 4.1 mA

32 inputs 24 VDC, 4.1 mA

64 inputs 24 VDC, 4.1 mA

64 inputs 24 VDC, 4.1 mA

16 inputs

8 inputs

12 to 24 VDC,

10 mA

100 to 120 VAC,

7 mA (100 V,

50 Hz)

200 to 24 VAC,

10 mA (200 V,

50 Hz)

Connector-Terminal Block Conversion Unit or a G7 I/O Relay Terminal.

Independent

contacts

16 points,

1 common

16 points,

1 common

16 points,

1 common

16 points,

1 common

16 points,

1 common

16 points,

1 common

8 points,

1 common

Removable

terminal block

Removable

terminal block

Fujitsu

connector

MIL connector 2 words 0.09 —

—

Fujitsu

connector

MIL connector 4 words 0.09 —

Removable

terminal block

Removable

terminal block

1 word 0.09 — CJ1W-ID201

1 word 0.08 — CJ1W-ID211

2 words 0.09 —

4 words 0.09 —

1 word 0.09 — CJ1W-IA111

1 word 0.08 — CJ1W-IA201

CJ1W-ID231

(See note.)

CJ1W-ID232

(See note.)

CJ1W-ID261

(See note.)

CJ1W-ID262

(See note.)

UC1, N, L, CE

27

Page 28

Ordering Information

Output Units ■

Product

Unit

name

classification

Relay

Contact

Output

Units

I/O

points

8

outputs

250 VAC/

24 VDC, 2 A

Maximum

switching

capacity

Specifications

Commons

Independent

contacts

Additional

functions

External

connection

Removable

terminal block

No. of

consumption

words

allocated

1 word 0.09

5 V 24 V

Current

(A)

0.048

max.

Model Standards

CJ1W-OC201

CJ

Basic

I/O

Units

Transistor

Output

Units

Triac

Output

Unit

16

outputs

8

outputs

8

outputs

8

outputs

8

outputs

16

outputs

16

outputs

32

outputs

32

outputs

32

outputs

64

outputs

64

outputs

64

outputs

8

outputs

250 VAC/

24 VDC, 2 A

12 to 24 VDC,

2 A, sinking

24 VDC, 2 A,

sourcing

12 to 24 VDC,

0.5 A, sinking

24 VDC, 0.5 A,

sourcing

12 to 24 VDC,

0.5 A, sinking

24 VDC, 0.5 A,

12 to 24 VDC,

0.5 A, sinking

12 to 24 VDC,

0.5 A, sourcing

12 to 24 VDC,

0.5 A, sinking

12 to 24 VDC,

0.3 A, sinking

12 to 24 VDC,

0.3 A, sourcing

12 to 24 VDC,

0.3 A, sinking

250 VAC, 0.6 A

16 points,

1 common

4 points,

1 common

4 points,

1 common

8 points,

1 common

8 points,

1 common

16 points,

1 common

16 points,

1 common

16 points,

1 common

16 points,

1 common

16 points,

1 common

16 points,

1 common

16 points,

1 common

16 points,

1 common

8 points,

1 common

—

Short-circuit

protection,

disconnection

detection

—

Short-circuit

protection

—

Short-circuit

protection

—

Short-circuit

protection

— MIL connector 2 words 0.14 —

—

— MIL connector 4 words 0.17 —

— MIL connector 4 words 0.17 —

—

Removable

terminal block

Removable

terminal block

Removable

terminal block

Removable

terminal block

Removable

terminal block

Removable

terminal block

Removable

terminal block

Fujitsu

connector

MIL connector 2 words 0.15 —

Fujitsu

connector

Removable

terminal block

1 word 0.11

1 word 0.09 — CJ1W-OD201

1 word 0.11 — CJ1W-OD202

1 word 0.10 — CJ1W-OD203

1 word 0.10 — CJ1W-OD204

1 word 0.10 — CJ1W-OD211

1 word 0.10 — CJ1W-OD212

2 words 0.14 —

4 words 0.17 —

1 word 0.22 — CJ1W-OA201

0.096

max.

CJ1W-OC211

UC1, N, L, CE

CJ1W-OD231

(See note.)

CJ1W-OD232

(See note.)

CJ1W-OD233

(See note.)

CJ1W-OD261

(See note.)

CJ1W-OD262

(See note.)

CJ1W-OD263

(See note.)

Note: Connectors are not provided with these connector models. Either purchase one of the following 40-pin Connectors,

or use an OMRON XW2

Connector-Terminal Block Conversion Unit or a G7 I/O Relay Terminal.

28

Page 29

Ordering Information

I/O Units ■

Unit

classification

CJ

Basic

I/O

Units

Product

name

points

DC Input/

Transistor

Output

Units

TTL I/O

Units

I/O

16

inputs

16

inputs

16

inputs

16

inputs

16

inputs

16

inputs

32

inputs

32

inputs

32

inputs

32

inputs

32

inputs

32

inputs

Input voltage,

Input current

Maximum

switching

24 VDC, 7 mA

250 VAC/24

VDC, 0.5 A,

sinking

24 VDC, 7 mA

24 VDC, 0.5 A,

sourcing

24 VDC, 7 mA

12 to 24 VDC,

0.5 A, sinking

24 VDC, 4.1 mA

12 to 24 VDC,

0.3 A, sinking

24 VDC, 4.1 mA

12 to 24 VDC,

0.3 A, sinking

5 VDC, 35 mA

5 VDC, 35 mA

capacity

Specifications

Commons

16 point,

1 common

16 point,

1 common

16 point,

1 common

16 point,

1 common

16 point,

1 common

16 point,

1 common

16 point,

1 common

16 point,

1 common

16 point,

1 common

16 point,

1 common

16 point,

1 common

16 point,

1 common

Additional

functions

—

—

—

Short-circuit

protection

—

—

—

—

—

—

—

—

External

connection

Fujitsu

connector

MIL

connector

MIL

connector

Fujitsu

connector

MIL

connector

MIL

connector

Current

consumption

No. of

(A)

words

allocated

2 words 0.13 —

2 words 0.13 —

2 words 0.13 —

4 words 0.14 —

4 words 0.14 —

4 words 0.19 —

5 V 24 V

Model Standards

CJ1W-MD231

(See note 2.)

CJ1W-MD232

(See note 2.)

CJ1W-MD233

(See note 2.)

CJ1W-MD261

(See note 1.)

CJ1W-MD263

(See note 1.)

CJ1W-MD563

(See note 1.)

UC1, N, CE

UC1, N, L, CE

UC1, N, CE

Note 1. Connectors are not provided with these connector models. Either purchase one of the following 40-pin Connectors,

or use an OMRON XW2

2. Connectors are not provided with these connector models. Either purchase one of the following 20-pin or 24-pin Connectors,

or use an OMRON XW2

Connector-Terminal Block Conversion Unit or a G7 I/O Relay Terminal.

Connector-Terminal Block Conversion Unit or a G7 I/O Relay Terminal.

29

Page 30

Ordering Information

Interrupt Input Units ■

Specifications

Product

Unit

name

classification

Interrupt

Input

CJ

Unit

Basic

I/O

Units

Note 1. Can be used only on CPU Racks, and not on Expansion Racks.

2. The locations where the Units can be mounted depend on the CPU Rack and the CPU Unit model.

CJ1G, CJ1H: From the slot next to the CPU Unit until the fifth slot.

CJ1M: From the slot next to the CPU Unit until the third slot.

points

outputs

I/O

16

Input

voltage

current

24 VDC,

7 mA

Commons

16 point,

1 common

High-speed Input Units ■

Product

Unit

classification

CJ

Basic

I/O

Units

name

Highspeed

Input

Unit

I/O

points

16

outputs

Input voltage,

Input current

24 VDC, 7 mA

Input

pulse

width

conditions

ON time:

0.05 ms

max.

OFF time:

0.5 ms max.

Specifications

Commons

16 point,

1 common

Max. Units

mountable

per Unit

2

Input pulse

width

conditions

ON time:

0.05 ms max.

OFF time: 0.5

ms max.

External

connection

Removable

terminal

block

External

connection

Removable

terminal block

Current

consumption

No. of

words

allocated

1 word 0.08 — CJ1W-INT01 UC1, N, L, CE

(A)

Model Standards

5 V 24 V

Current

No. of

words

allocated

1 word 0.08 — CJ1W-IDP01 UC1, N, L, CE

consumption

(A)

5 V 24 V

Model Standards

Note: There are no restrictions on the mounting position or number of Units.

B7A Interface Units ■

Specifications

Product

Unit

classification

CJ

Basic

I/O

Units

name

B7A

Interface

Units

I/O points

64 inputs

32 inputs/outputs 0.07 — CJ1W-B7A22

External connection 5 V 24 V

Removable terminal block 4 words

No. of words

allocated

Current

consumption (A)

Model Standards

0.07 — CJ1W-B7A14

UC1, CE 64 outputs 0.07 — CJ1W-B7A04

30

Page 31

Ordering Information

Special I/O Units and CPU Bus Units

Process I/O Units ■

Isolated-type Units with Universal Inputs ●

Current

Product

Unit

name

Input

points

Signal

range

selection

Signal range

Conversion

speed

(resolution)

classification

Universal inputs:

Pt100 (3-wire),

JPt100 (3-wire),

Pt1000 (3-wire),

Pt100 (4-wire), K,

J, T, E, L, U, N, R,

Set

4

separately

inputs

for each

4

inputs

input

Set

separately

for each

input

Process

Input

Units

(Isolated-

type

CJ

Special

I/O

Units

Note: L and −100°C or less for K and T are ±2°C±1 digit max., and 200°C or less for R and S is ±3°C±1 digit max. No accuracy is specified for 400°C or less for B.

Units

with

Universal

Inputs)

S, B, WRe5-26, PL

II, 4 to 20 mA, 0 to

20 mA, 1 to 5 V,

0 to 1.25 V, 0 to 5

V, 0 to 10 V, ±100

mV selectable

range −1.25 to

1.25 V, −5 to 5 V,

−10 to 10 V, ±10 V

selectable range,

potentiometer

Universal inputs:

Pt100, JPt100,

Pt1000, K, J, T,

L. R, S, B, 4 to

20 mA,

0 to 20 mA, 1 to

5 V, 0 to 5 V, 0 to

10 V

Resolution

(conversion

speed):

1/256,000

(conversion

cycle: 60 ms/

4 inputs)

1/64,000

(conversion

cycle: 10 ms/

4 inputs)

1/16,000

(conversion

cycle: 5 ms/

4 inputs)

Conversion

speed:

250 ms/

4 inputs

Accuracy

(at ambient

temperature of

25°C)

Standard

accuracy: ±0.05%

of F.S.

Accuracy:

Platinum

resistance

thermometer

input: (±0.3% of

PV or ±0.8°C,

whichever is

larger) ±1 digit

max.

Thermocouple

input: ±0.3% of

PV or ±1.5°C,

whichever is

larger) ±1 digit

max. (See note.)

Voltage or current

input: ±0.3% of

F.S. ±1 digit max.

External

connection

Removable

terminal

block

No. of

numbers

allocated

Isolated-type Thermocouple Input Units ●

Unit

classification

Product

name

Input

points

Signal

range

selection

Signal range

Conversion

speed

(resolution)

Accuracy

(at ambient

temperature

of 25°C)

External

connection

No. of

unit

numbers

allocated

consumption

unit

(A)

5 V 24 V

0.30 — CJ1W-PH41U UCI, CE

1

.032 — CJ1W-AD04U UCI, CE

Current

consumption

(A)

5 V 24 V

Model Standards

Model Standards

Process

Input

Units

(Isolated-

type

CJ

Special

I/O

Units

Note 1. The accuracy depends on the sensors used and the measurement temperatures. For details, refer to the user’s manual.

2. This is for an external power supply, and not for internal current consumption.

3. L and −100°C or less for K and T are ±2°C±1 digit max., and 200°C or less for R and S is ±3°C±1 digit max. No accuracy is specified for 400°C or less for B.

Thermo-

couple

Input

Units)

2

inputs

4

inputs

Set

separately

for each

input

Thermocouple:

B, E, J, K, L, N, R,

S, T, U, WRe5-26,

PLII

DC voltage:

±100 mV

Thermocouple:

R, S, K, J, T, L, B

Conversion

speed:

10 ms/

2 inputs,

Resolution:

1/64,000

Conversion

speed:

250 ms/

4 inputs

Standard

accuracy:

±0.05% of F.S.

(See note 1.)

Accuracy:

(±0.3% of PV or

±1°C,

whichever

is larger) ±1

digit max.

(See note 3.)

Removable

terminal

block

0.06

0.18

1

0.25 — CJ1W-PTS51

(See

note

2.)

CJ1W-PTS15

UC1, CE

31

Page 32

Ordering Information

Isolated-type Resistance Thermometer Input Units ●

Unit

name

Product

Input

points

Signal

range

selection

Signal range

classification

2

Process

Analog

Input Units

(Isolated-type

CJ

Special

I/O

Units

Note: This is for an external power supply, and not for internal current consumption.

Resistance

Thermometer

Input Units)

inputs

4

inputs

Set

separately

for each

input

Common

inputs

Resistance

thermometer:

Pt100, JPt100,

Pt50, Ni508.4

Resistance

thermometer:

Pt100, JPt100

Isolated-type DC Input Units ●

Unit

classification

Product

name

Input

points

Signal range selection

Conversion

speed

(resolution)

Conversion

speed:

10 ms/

2 inputs,

Resolution:

1/64,000

Conversion

speed:

250 ms/

4 inputs

Conversion

speed

(resolution)

Accuracy

(at ambient

temperature

of 25°C)

Accuracy:

±0.05% of F.S.

or ±0.1°C,

whichever is

larger.

Accuracy:

±0.3°C of PV

or ±0.8°C,

whichever is

larger, ±1 digit

max.

Accuracy

(at ambient

temperature

of 25°C)

External

connection

Removable

terminal

block

External

connection

No. of

unit

numbers

allocated

1

No. of

unit

numbers

allocated

Current

consumption

(A)

Model Standards

5 V 24 V

0.18

0.25 — CJ1W-PTS52

0.07

(See

note.)

CJ1W-PTS16

Current

consumption

(A)

Model Standards

5 V 24 V

UC1, CE

Isolatedtype DC

CJ

Special

I/O

Units

Note: This is for an external power supply, and not for internal current consumption.

Input

Units

DC voltage:

0 to 1.25 V, −1.25 to 1.25 V,

0 to 5 V, 1 to 5 V, −5 to 5 V,

2

0 to 10 V, −10 to 10 V, ±10 V

inputs

selectable range

DC current:

0 to 20 mA, 4 to 20 mA

Conversion

speed:

10 ms/

2 inputs

Resolution:

1/64,000

Standard

accuracy:

±0.05% of F.S.

Removable

terminal

block

1 0.18

Analog I/O Units ■

Analog Input Units ●

Product

Unit

name

Input

points

Signal

range

selection

Signal

range

Resolution

Conversion

speed

classification

Analog

Input

CJ

Special

I/O

Units

Note 1. The resolution and conversion speed cannot be set independently. If the resolution is set to 1/4,000, then the conversion speed will be 1 ms/point.

2. At 23 ±2°C

Units

8

inputs

4

inputs

Set

separately

for each

input

1 to 5 V,

0 to 5 V,

0 to 10 V,

−10 to 10

V, 4 to 20

mA

1/8000,

(Settable to

1/4000)

(See note 1.)

250 μs/point

max.

(Settable to

1 ms/point)

(See note 1.)

Accuracy

(at ambient

temperature

of 25°C)

Voltage:

±0.2% of F.S.

Current:

±0.4% of F.S.

(See note 2.)

External

connection

Removable

terminal

block

No. of

numbers

allocated

consumption

unit

5 V 24 V

0.42 —

1

0.42 —

0.09

(See

note.)

Current

(A)

CJ1W-PDC15 UC1, CE

Model Standards

CJ1WAD081V1

UC1, N, L,

CE

CJ1WAD041V1

32

Page 33

Ordering Information

Analog Output Units ●

8

8

4

2

No. of

points

Signal

range

selection

Set

separately

for each

input

Signal

range

selection

Signal

range

1 to

5 V,

0 5 to

5 V,

0 to 10

V,

−10 to

10 V

4 to 20

mA

1 to

5 V,

0 to

5 V,

0 to 10

V,

−10 to

10 V,

4 to 20

mA

Signal

range

Resolution

1/4,000

(Settable

to

1/8,000)

1/4000

Resolution

(See note.)

Conversion

1 ms/ point

max.

(Settable to

250

μs/point)

1 ms/ point

max.

Conversion

Product

Unit

name

Output

points

classification

outputs

Analog

Putput

CJ

Special

I/O

Units

Note: This is for an external power supply, and not for internal current consumption

Units

outputs

outputs

outputs

Analog I/O Units ●

Product

Unit

name

classification

speed

speed

(See note.)

Accuracy (at

ambient

temperature of

25°C)

±0.3% of

F.S.

Voltage

output:

±0.3% of

F.S.

Current

output:

±0.5% of

F.S.

Accuracy

(at ambient

temperature

of 25°C)

External

connection

Removable

terminal

block

External

connection

External

power

supply

24

VDC

+10%