Omega Products CN8100 Installation Manual

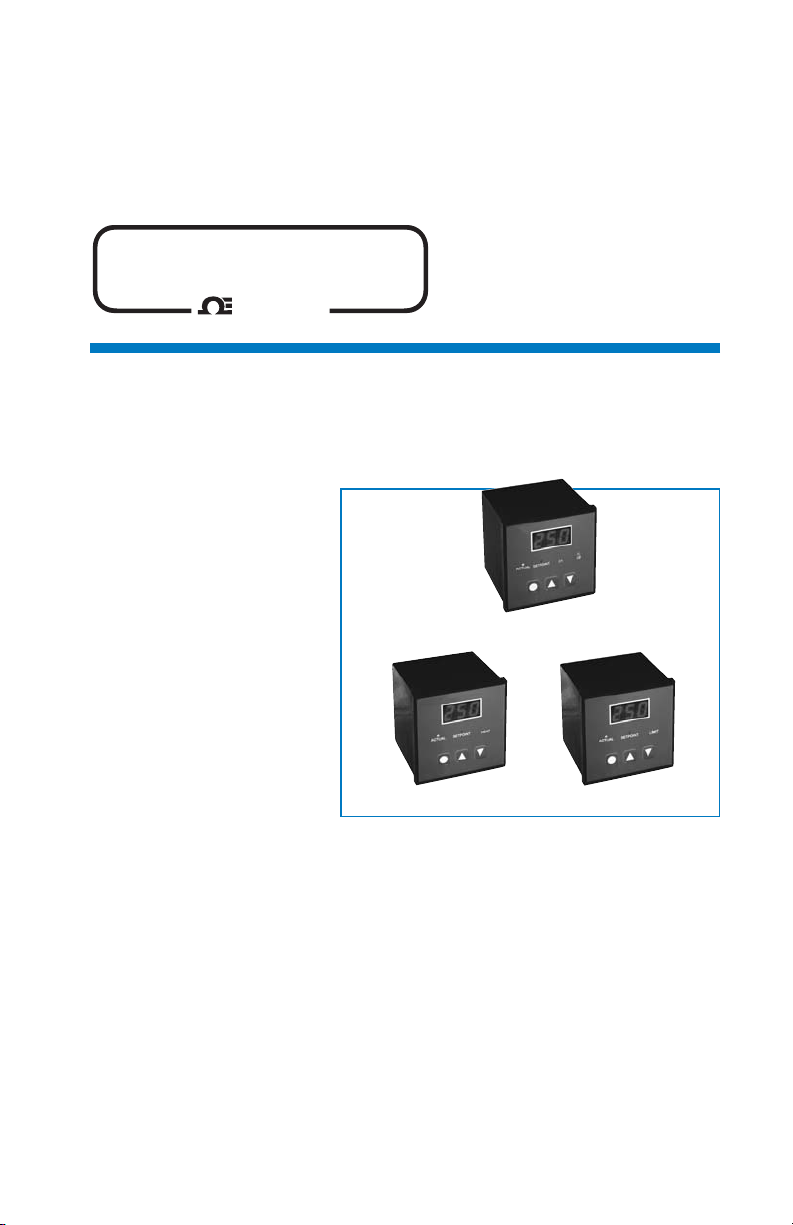

CN8100

CN8110 CN8120

omega.comomega.com

TM

OMEGA

®

SERIES

CN8100

1/4 DIN

TEMPERATURE/

PROCESS

CONTROLLERS

Operating

Instructions

CN8100 Series 1/4 DIN Temperature/Process Controllers

i

Servicing North America:

USA: ISO 9001 Cer

tified Canada:

One Omega Drive, Box 4047 976 Bergar

Stamford, CT 06907-0047 Laval (Quebec) H7L 5A1

Tel: (203) 359-1660 Tel: (514) 856-6928

FAX: (203) 359-7700 FAX: (514) 856-6886

e-mail: info@omega.com e-mail: canada@omega.com

For immediate technical or application assistance:

USA and Canada: Mexico and Latin America:

Sales Service: 1-800-826-6342/1-800-TC-OMEGA

SM

Tel: (95) 800-TC-OMEGA

SM

Customer Service: 1-800-622-2378/1-800-622-BEST

SM

FAX: (95) 203-359-7807

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

SM

En Espan~ol: (203) 359-7803

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA e-mail: espanol@omega.com

Servicing Europe:

Benelux: Germany/Austria:

Postbus 8034, 1180 LA Amstelveen, Daimlerstrasse 26, D-75392

The Netherlands Deckenpfronn, Germany

Tel: (31) 20 6418405 FAX: (31) 20 6434643 Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Benelux: 06 0993344 Toll Free in Germany: 0130 11 21 66

e-mail: nl@omega.com e-mail: germany@omega.com

Czech Republic: United Kingdom: ISO 9002 Cer

tified

ul. Rude armady 1868, 733 01 Karvina-Hranice, •25 Swannington Road, Broughton Astley,

Czech Republic Leicestershire, LE9 6TU, England

Tel: 420 (69) 6311627 FAX: 420 (69) 6311114 Tel: 44 (1455) 285520 FAX: 44 (1455) 283912

e-mail: czech@omega.com •P.O. Box 7, Omega Drive, Irlam,

France: Manchester, M44 5EX, England

9, rue Denis Papin, 78190 Trappes Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Tel: (33) 130-621-400 FAX: (33) 130-699-120 Toll Free in England: 0800-488-488

Toll Free in France: 0800-4-06342 e-mail: uk@omega.com

e-mail: france@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly

pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every

appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts no liability

for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

OOMMEEGGAAnneettSMOOnn--LLiinnee SSeerrvviiccee IInntteerrnneett ee--mmaaiill

hhttttpp::////wwwwww..oommeeggaa..ccoomm iinnffoo@@oommeeggaa..ccoomm

omega.com

OMEGA

®

TM

ii

Table of Contents

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

CN8110 On/Off Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

CN8120 Limit Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

CN8100 PID Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

IEC Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Manual Tuning (Zeigler-Nichols) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Warranty/Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

CN8100 Series 1/4 DIN Temperature/Process Controllers

1

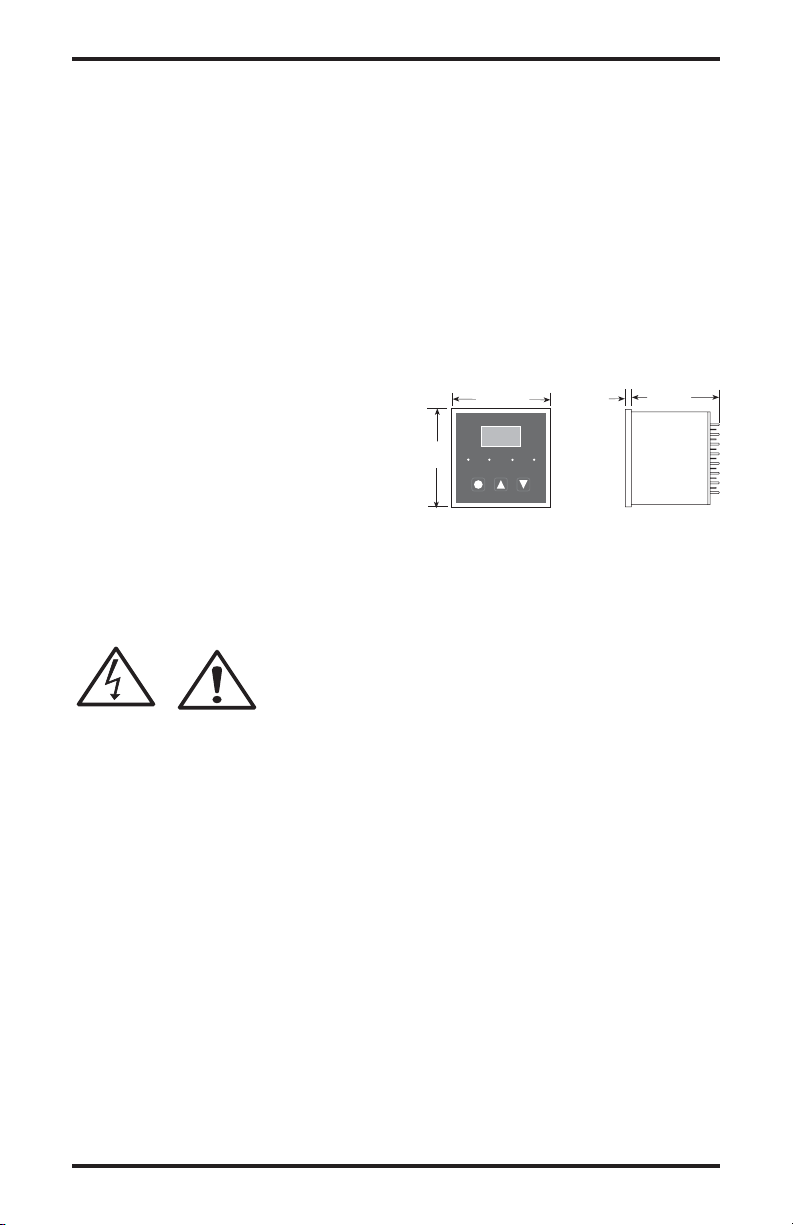

0.25"

(6.35 mm)

3.5"

(88.9 mm)

3.780"

(96 mm)

3.780"

(96 mm)

°F

ACTUAL SETPOINT 02

01

Features

Type J Input (CN8110, CN8120)

Type J or K Input (CN8100)

±0.3% FS Accuracy

Large, Easy-to-Read LED Display,

Selectable for Either Setpoint or Process

Temperature

Adjustable Output Hysteresis to Prevent

Rapid Cycling Around Setpoint

Temperature (CN8110)

Adjustable Deviation Alarm Flashes

Display When Measured Temperature

Exceeds or Falls Below Setpoint

Temperature

NEMA 4X Front Bezel, Splash-Proof and

Resistant to Dust

Discrete Status Indicators Illuminate When

Temperature Display, Setpoint Display or

Heat/Cool Output is Active

Approvals: UR, cUR, CE

Safety Warnings

In addition to presenting a potential

fire hazard, high voltage and high

temperature can damage equipment and

cause severe injury or death. When

installing or using this instrument, follow

all instructions carefully and use approved

safety controls. Electrical connections and

wiring should be performed only by

suitably trained personnel.

Do not locate this instrument where it is

subject to excessive shock, vibration, dirt,

moisture, oil, or other liquids. The safe

operating temperature range for this unit

is 32°F to 140°F (0°C to 60°C).

Installation

Pre-Installation Instructions

1. Inspect shipping carton for obvious

signs of mishandling.

2. After removing the controller from the

shipping carton, inspect it carefully for

damage. Never attempt to install

and use a damaged unit.

3. Verify that the ordering code number

indicated on the side of the controller

matches what was ordered.

Figure 1. Case Dimensions

Prior to mounting the CN8100 in your

panel, make sure that the cutout opening

is of the right size, 3.622" x 3.622"

(92 mm x 92 mm), and deburred to

enable a smooth fit.

A minimum of 5.0" (127.0 mm) of depth

behind the panel is required.

CN8100 Series 1/4 DIN Temperature/Process Controllers

2

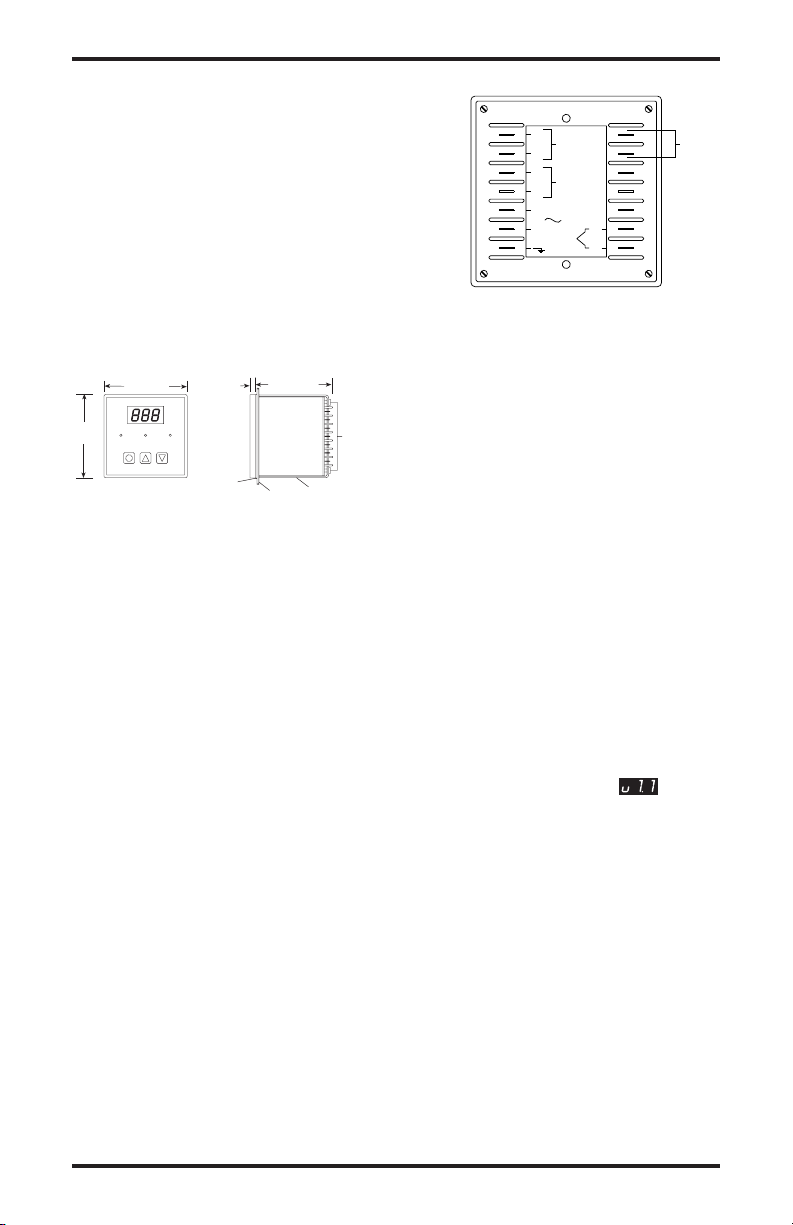

Mounting

Before installing the CN8100, ensure

gasket seats evenly around edges of unit

and that there are no breaks or tears in

the gasket.

Insert the CN8100 through the front

panel cutout, slide mounting “U” bracket

around unit and secure it with the

screws provided.

Gasket should be evenly compressed

around all sides to provide liquid-tight

mounting.

Figure 2. Mounting Diagram

RESET

Figure 3. Wiring Connections

Wiring

IMPORTANT: All electrical wiring

connections should be made only by

trained personnel using Class 1 wiring,

and in strict accordance with the National

Electrical Code and local regulations.

Both of the incoming power lines should

be fused with 2AG, 0.5 A maximum

rated fuses.

The CN8100 controller has built-in

circuitry to reduce the effects of electrical

noise (RFI) from various sources;

however, power and signal wires should

always be kept separate. We recommend

separating wires into one bundle for

power (from line power and output)

and one bundle for signal (from

thermocouple).

The CN8100 power supply accepts 100

through 250 Vac and 120 through 250

Vdc line power without any switch

settings or polarity considerations.

Operation

Omega CN8100 Digital

Temperature Controllers

Just a few easy steps are required before

your CN8100 can be placed into service.

After completing the mounting and wiring

procedures as previously instructed, set

each controller parameter using the

simple front-panel keys as instructed.

Power On

When power is first applied to the

CN8100, all segments of the LED display,

as well as the discrete indicators, will

be momentarily illuminated while the

instrument goes through a series of

diagnostic checks to verify proper

operation of the unit. A software version

will then be displayed, e.g., . The

last two digits of this code indicate the

software revision supplied with your

controller. Please provide this revision

number when contacting us regarding

your unit. This display is followed by a

mnemonic code representing the

model type.

3.780"

(96 mm)

0.25"

(6.35 mm)

3.5"

(88.9 mm)

COM.

OUTPUT #2

N.O.

COM.

OUTPUT #1

N.O.

L2

(-)

L1

T/C

(+)

3.780"

ACTUAL SETPOINT HEAT

(96 mm)

GASKET

PANEL

BRACKET

MOUNTING

SCREWS

Loading...

Loading...