Omega Products CN79000 Installation Manual

User’s Guide

Shop online at

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

Series CN 79000

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

U.S.A.:

ISO 9001 Certified

Canada:

For immediate technical or application assistance:

U.S.A. and Canada:

Servicing North America:

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

Sales Service: 1-800-826-6342/1-800-TC-OMEGA

Customer Service: 1-800-622-2378/1-800-622-BEST

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

®

®

Mexico:

En Espan˜ol: (001) 203-359-7803

e-mail: espanol@omega.com

FAX: (001) 203-359-7807

info@omega.com.mx

Servicing Europe:

Czech Republic:

Germany/Austria:

United Kingdom:

ISO 9002 Certified

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Frystatska 184, 733 01 Karvina´, Czech Republic

Tel: +420 (0)59 6311899

FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0

FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

One Omega Drive, River Bend Technology Centre

Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

INSTRUCTIONS FOR THE CN79000 SERIES

1/32 DIN DUAL ZONE MICROPROCESSOR BASED

TEMPERATURE/PROCESS CONTROL

OMEGA Engineering

One Omega Drive

Stamford, Connecticut 06907-0047

P.O. Box 4047

Telephone: 800/848-4286; 203/359-1660

Fax: 203/359-7700

Contents

INSTALLATION....................................................................................... 3

WIRING...................................................................................................5

Wiring for Optional Inputs and Outputs...................................................6

Wiring for 4 to 20mA Transmitter inputs ................................................. 7

FRONT PANEL KEY FUNCTIONS ......................................................... 8

NOTATION CONVENTIONS FOR THE MENUS.................................. 10

THE HOME DISPLAY ........................................................................... 10

ALARM TYPE AND ACTION ................................................................ 11

OPERATION OF SELF TUNE® FUNCTION......................................... 12

Theory of Operation .............................................................................. 12

Program Setup and Operation...............................................................13

OPERATION AND PROGRAMMING OF OPTIONS ............................. 13

Option C4, Serial Communication. ...................................................... 13

FACTORY DEFAULT PROCEDURE .................................................... 14

MENU SELECTIONS ........................................................................... 14

PRIMARY MENU .................................................................................. 14

SECONDARY MENU ............................................................................ 15

SECURE MENU.................................................................................... 25

SPECIFICATIONS ................................................................................ 35

DIAGNOSTIC ERROR MESSAGES ..................................................... 37

DIAGNOSTIC ERROR MESSAGES ..................................................... 38

DIMENSIONS ....................................................................................... 40

Page 2 of 40

CN790

MODEL IDENTIFICATION

Output

2 = Switched

Voltage 5VDC

Output A

2 = Switched Voltage 5 VDC

3 = Relay

3 = Relay

Options

C4 = RS485

LV = Low Voltage

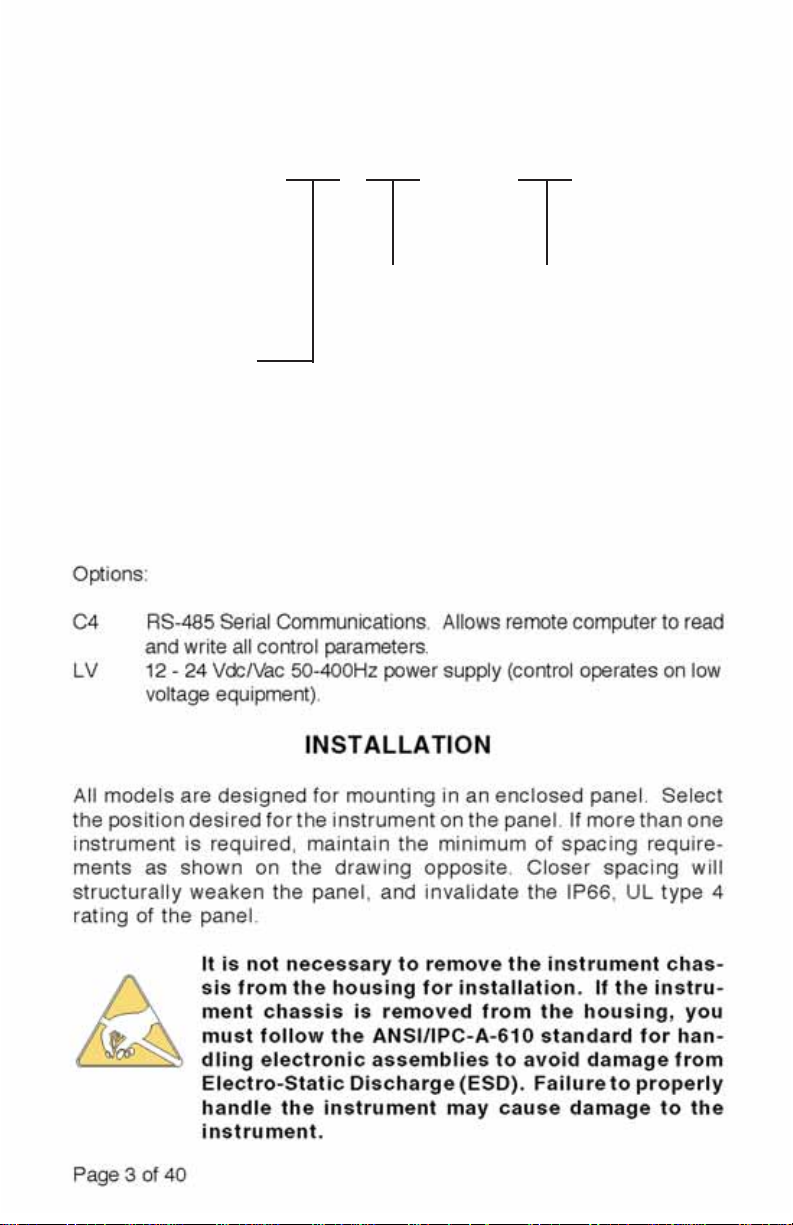

Prepare the panel by cutting and deburring the required opening(s).

25.4

(1.00)

45 + 0.6

(1.772 + 0.02)

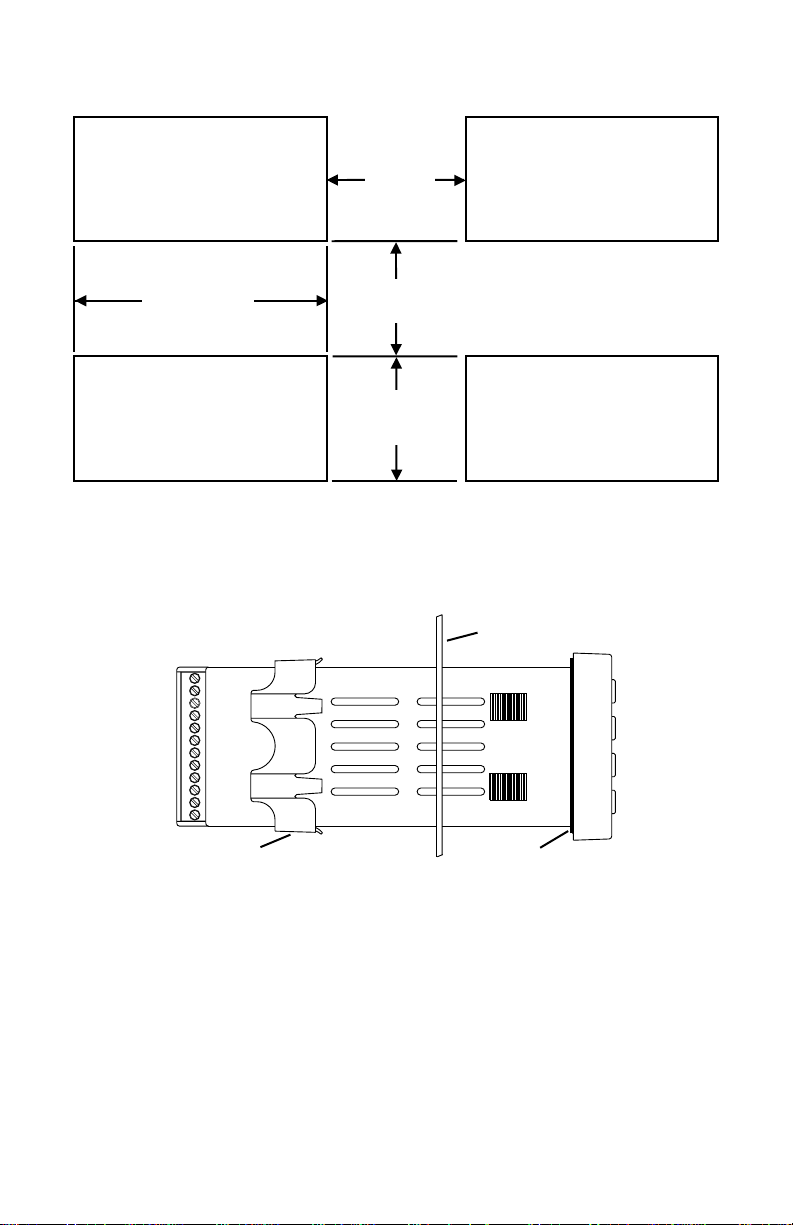

From the front of the panel, slide the housing through the cutout. The

housing gasket should be flat against the housing flange before

installing.

20.5

(0.807)

22.2 + 0.3

(0.874 + 0.012)

Panel

Collar

Gasket

From the rear of the panel slide the mounting collar over the housing.

Hold the housing with one hand and using the other hand, push the

collar evenly against the panel until the spring loops are slightly

compressed. The ratchets will hold the mounting collar and housing

in place. To remove, gently lift the ratchets and slide a piece of

heavy paper or mylar sheet under each ratchet (a business card

works well). Slide the collar off of the housing.

Page 4 of 40

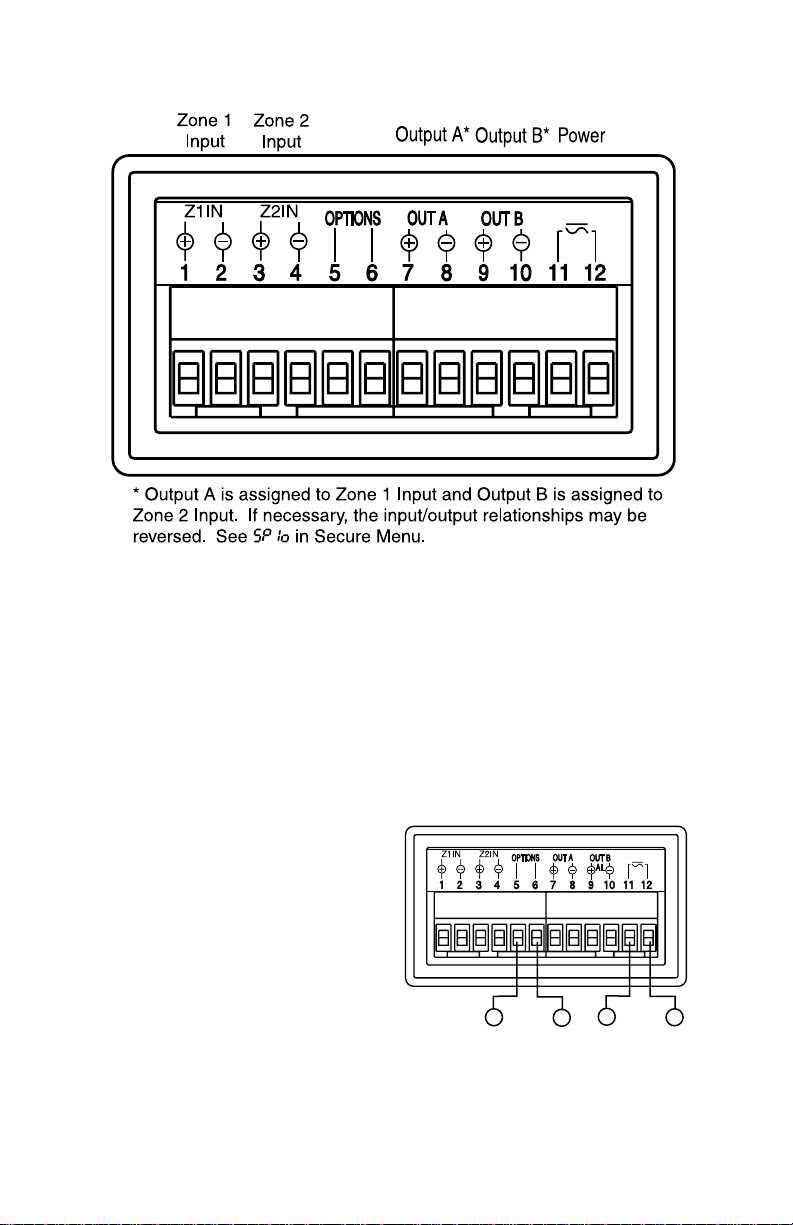

Control wiring is as shown.

The wiring terminals for the CN79000 are compression type. To open

the wiring terminal, turn the screw for that terminal counterclockwise. Slide the wire into the terminal space. While holding the wire

in place, turn the screw clockwise to tighten. Maximum torque is

0.424 N·m(3.75 in. lb.). Do not overtighten. The wire should be held

snugly in place.

Wiring for Optional Inputs and Outputs

Wire power and outputs as shown. Wiring for options is shown below. All wiring

shown below is Class 2. Shielded twisted pair is required for Option C4.

Option 992: Terminal 5 is line A (-).

Terminal 6 is line B (+).

Last control in chain must have 120 ohm ± 1%

resistor across 5 and 6.

Option 9502: Connect 12 to 24 Volt ac or

dc power to terminals 11 and

12. No polarity.

Note: Industry standard designation for

5

RS-485 lines is A and B. Some equipment manufacturers use a non-standard designation of plus and minus. The

association of A to minus and B to plus is based on a sample of devices marked as

plus and minus and is not intended to represent ALL such labelled devices. Final

responsibility for correct identification of leads and terminals rests with the user/

installer and the manufacturer of the other device(s) installed in the system.

Page 6 of 40

11

6

12

Wiring for 4 to 20mA Transmitter inputs

WARNING: The inputs of the instrument are not isolated

from each other. The input sources must be isolated

from each other. Process inputs may not share a

common external ground.

FAILURE TO OBSERVE THIS WARNING MAY CAUSE

DANGEROUS OR LETHAL VOLTAGES TO BE PRESENT

IN THE INSTRUMENT WHICH MAY CAUSE SERIOUS

INJURY OR DEATH.

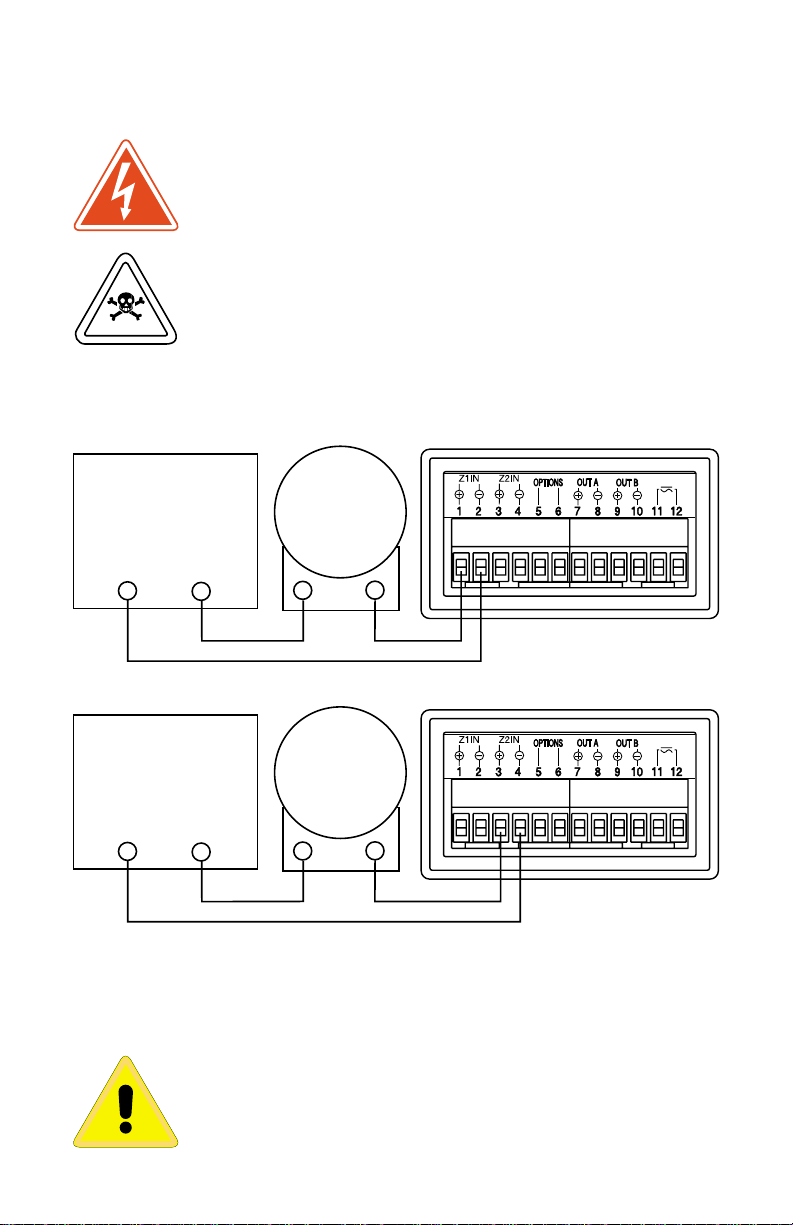

Wire power and outputs as shown above. Two-wire transmitters wire as

shown below.

External Power Supply

24 Vdc

Transmitter

+ -

+ -

Wiring for Z1 Input

External Power Supply

24 Vdc

+ -

Transmitter

+ -

Wiring for Z2 Input

For three or four wire transmitters follow the wiring instructions provided

with your transmitter.

DO NOT WIRE THE 24 VOLT POWER SUPPLY

ACROSS THE INPUT OF THE CONTROL. DAMAGE

TO THE INSTRUMENT INPUT CIRCUITRY WILL RESULT.

Page 7 of 40

temperature value. While in the Secure Menu, if no key is pressed for a

period of 60 seconds, the display will return to the HOME position displaying

the temperature value. Outputs are disabled (turned off) when the Secure

Menu is active.

NOTE: To move to the Primary Menu quickly from any other menu, press

the UP ARROW & ENTER keys followed by pressing the INDEX & DOWN

ARROWkeys.

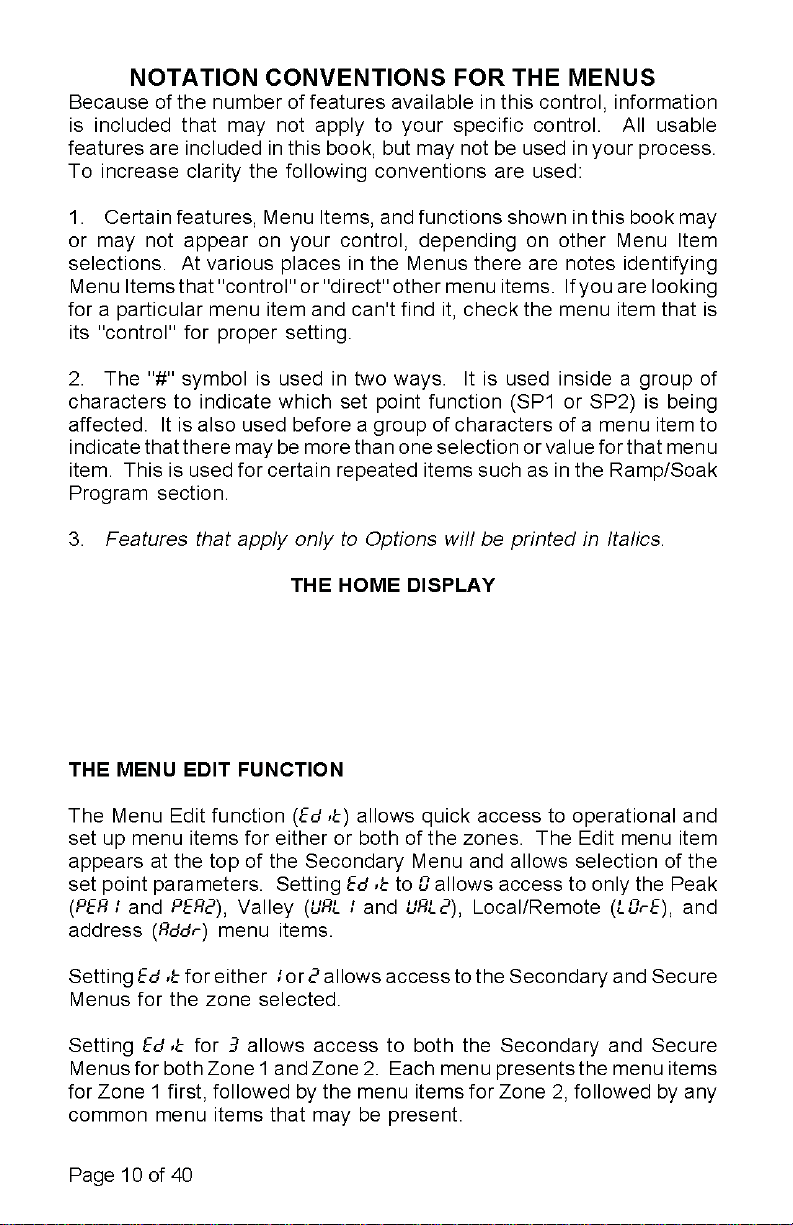

SECURITY LEVEL SELECTION

Four levels of security are provided. The display shows the current security

level. To change security levels change the password value using the

UPARROW and DOWN ARROW keys and pressing the ENTER

key. Refer to the password table (following) for the correct value to enter

for the security level desired. The

may be viewed or changed at any time regardless of the present security

level.

SEC1SEC1

SEC1 or

SEC1SEC1

SEC2SEC2

SEC2 menu items security level

SEC2SEC2

To set the access level to, for example,

UP ARROW key until the upper display shows the password,

Press the ENTER key. The display will blink, and return with the level

value,

The password values shown in the table cannot be altered, so retain a copy

of these pages for future reference. This is the only reference made to

password values in this instruction book.

22

2, in the upper display.

22

Security Level

Menu Status

Primary Locked

Secondary Locked

Secure Locked

Primar y Unlocked

Secondary Locked

Secure Locked

Primar y Unlocked

Secondary Unlocked

Secure Locked

Primar y Unlocked

Secondary Unlocked

Secure Unlocked

PASSWORD TABLE

Displayed Value

22

2, at the

22

When Viewed

1

2

3

4

SEC1SEC1

SEC1 menu item press the

SEC1SEC1

11011101

1101.

11011101

Password Value

To Enter

1110

1101

1011

111

Page 9 of 40

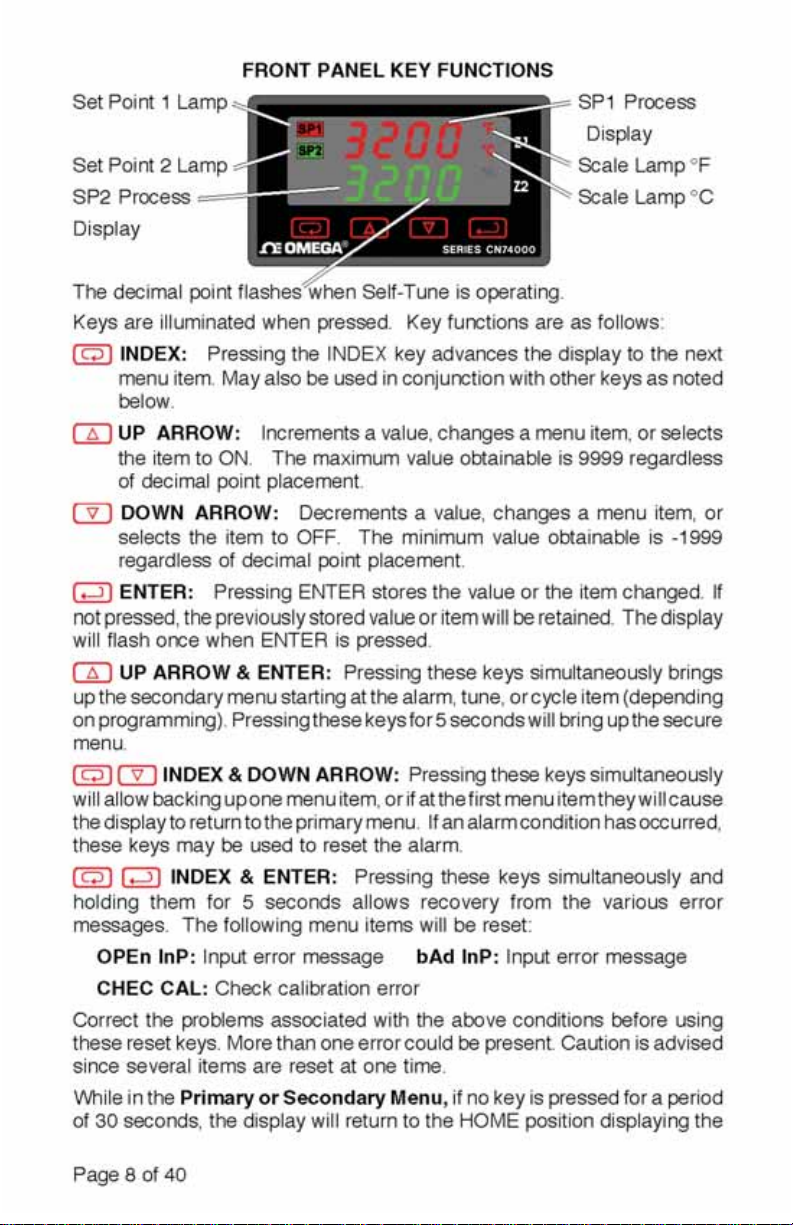

The home display is the normal display while the control is operating.

If no errors or functions are active, the HOME display will indicate the

Process Variable for Set Point 1 on the top display and the Process

variable for Set Point 2 on the bottom.

Menu items that are dedicated to either Zone 1 or Zone 2 will have either

a 1 or 2 in them for identification.

If Edit is set to any value other than 0, the setting will be retained for

a period of five minutes to allow handy, repeated access to that zone's

menues. After five minutes of keypad inactivity, the Edit setting will

revert to 0, giving an added layer of security to prevent inadvertant

changes to the instrument.

PROGRAMMING SET POINTS FOR ALARM FUNCTIONS

Caution: In any critical application where failure could

cause expensive product loss or endanger personal

safety, a redundant limit controller is required.

The C N 74000 Series allows Zone 1 and / or Zone 2 to operate as limit or alarm

type outputs. This function is available on both outputs. To enable a zone

output to act as an alarm or limit,

be set for

OnOfOnOf

OnOf.

OnOfOnOf

Out1Out1

Out1 (for Zone 1) or

Out1Out1

Out2Out2

Out2 (for Zone2) should

Out2Out2

Out1Out1

When

Out1 and / or

Out1Out1

will appear in the Secure Menu for the selected zone(s).

When Set Point Power Interrupt (

SS

Reset (

after a power failure and on subsequent power restoration if no alarm

condition is present.

If Set Point Inhibit (

upon power up until the process value passes through the alarm set point

once. Alarm inhibit can be restored as if a power up took place by pressing

both the INDEX and ENTER keys for 5 seconds.

Page 11 of 40

rErE

S#

rE) is programmed for

SS

rErE

Out2Out2

Out2 are set to

Out2Out2

SS

iHiH

S#

iH) is selected

SS

iHiH

Warning: If inhibit is on and a power failure occurs

during a high alarm, on restoration of power inhibit will

suppress the alarm. Do not use the Set Point Inhibit

feature if a hazard may be created by this action. Be sure

to test all combinations of high and low set point inhibit

actions before placing control into operation.

OnOFOnOF

OnOF, then the alarm function menu items

OnOFOnOF

SS

PiPi

S#

Pi) is programmed

SS

PiPi

HoldHold

Hold, the alarm will automatically reset

HoldHold

ONON

ON, an alarm condition is suspended

ONON

ONON

ON and Set Point

ONON

Set Point 2 Tracking

Some applications will call for Set Point 2 to follow or 'track' the setting for

Set Point 1. This can be done by changing the S2t setting in the Secure Menu

(edit set for 2 or 3). For a tracking SP2, set S2t to dE.

The Factory Default setting for S2t is ABS, making SP2 completely

independent of SP1.

When setting

dEdE

=

dE), set the difference in value from the Set Point 1 (

dEdE

example if Set Point 2 is required to be 5 degrees below the

SP2SP2

SP2 to

-5. If Set Point 2 is required 20 degrees above the

SP2SP2

2020

to

20. If

2020

relationship as originally set.

When setting SP2 value when Set Point 2 is programmed as absolute (S2t

= AbS), simply set the value at which the alarm is to occur.

Self Tune® allows automatic selection of the necessary parameters to

achieve best control operation from your CN74000 Series control. If you are

using the control output as a simple on-off function (e.g.

none of the following will apply.

Theory of Operation

The Self Tune function calculates the

PID1 tunEPID1 tunE

the

PID1 tunE selection,

PID1 tunEPID1 tunE

selection, the

as shown in the Secondary Menu . These values are determined by measuring

the response of the process connected to the control. When Self Tune is

started, the control temporarily acts as an on-off control. While in this mode

the control measures the overshoot and undershoot of the process, and the

period of the process (the time from peak value to the next peak value). These

measurements are collected over a period that lasts three periods of overshoot

and undershoot. The data collected over this time is then compared and

calculated into final PID and Fuzzy Logic values. The effect of Fuzzy Logic

on the process is still controlled by the

Fi 1Fi 1

If

Fi 1 or Fi 2 is

Fi 1Fi 1

have no effect.

SP2SP2

SP2 value when Set Point 2 is programmed as deviation (

SP2SP2

-5-5

-5-5

SP1SP1

SP1 is changed, the

SP1SP1

OPERATION OF SELF TUNE® FUNCTION

Pb2Pb2

Pb2,

Pb2Pb2

Fbd1Fbd1

Fbd1 and

Fbd1Fbd1

Frt1Frt1

Frt1 parameters, and the

Frt1Frt1

00

Fbd1Fbd1

0, the

Fbd1,

00

Fbd1Fbd1

SP2SP2

SP2 setting will continue to hold the same

SP2SP2

Pb1Pb1

rES2rES2

rES2, and

rES2rES2

Frt1Frt1

Fbd2Fbd2

Frt1,

Fbd2, and

Frt1Frt1

Fbd2Fbd2

rES1rES1

Pb1,

rES1, and

Pb1Pb1

rES1rES1

rtE2rtE2

rtE2 parameters under the

rtE2rtE2

Fi 1Fi 1

Fi 1 and Fi 2 (fuzzy intensity) settings.

Fi 1Fi 1

rtE1rtE1

rtE1 parameters under

rtE1rtE1

Fbd2Fbd2

Fbd2 and

Fbd2Fbd2

Frt2Frt2

Frt2 will be calculated, but will

Frt2Frt2

SP1SP1

SP1) desired. For

SP1SP1

SP1SP1

SP1, then set

SP1SP1

SP1SP1

SP1, then set

SP1SP1

Out1Out1

Out1 set for

Out1Out1

Frt2Frt2

Frt2 parameters,

Frt2Frt2

S2tS2t

S2t

S2tS2t

SP2SP2

SP2

SP2SP2

OnOFOnOF

OnOF),

OnOFOnOF

PID2 tunEPID2 tunE

PID2 tunE

PID2 tunEPID2 tunE

The calculations for Zone 1 and Zone 2 are completely independent. Each zone

has separate Self Tune and Fuzzy Logic parameters.

Page 12 of 40

Loading...

Loading...