Omega Products CN74000 Installation Manual

INSTRUCTIONS FOR THE CN74000

1/32 DIN MICROPROCESSOR BASED

TEMPERATURE / PROCESS CONTROL

CONTENTS

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Wiring for Optional Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Wiring for 4 to 20mA Transmitter inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

FRONT PANEL KEY FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

NOTATION CONVENTIONS FOR THE MENUS . . . . . . . . . . . . . . . . . . . . . . . . . .10

THE HOME DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

PROGRAMMING AND OPERATION FOR RAMP / SOAK FEATURE . . . . . . . . . .11

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Program Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Ramp / Soak Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

AUTO / MANUAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

OPERATION OF SELF TUNE® FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Option C4, Serial Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

CHANGING PROGRAMMING FOR SET POINT 2 AND ALARM . . . . . . . . . . . . .16

FACTORY DEFAULT PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

ALARM TYPE AND ACTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

MENU SELECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

PRIMARY MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

SECONDARY MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

SECURE MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

DIAGNOSTIC ERROR MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34-35

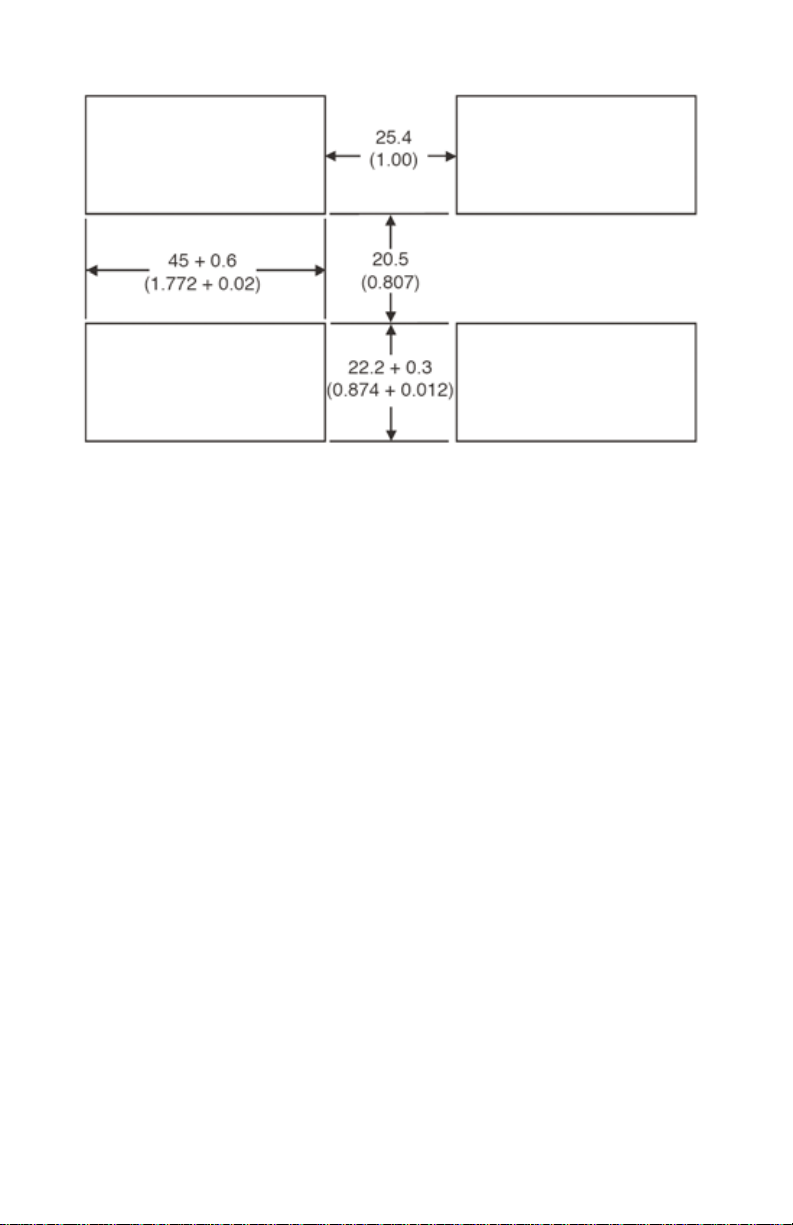

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Front Page

Page 2

GETTING STARTED

Install the control as described on page 4.

1.

Wire your control following the instructions on page 5. If you are using a two-wire

2.

transmitter as an input, see the drawing and instructions on page 7. Option wiring

instructions are on page 6. Option descriptions are on page 4, and specific

instructions start on page 17.

Most controls do not need many (if any) program changes to work on your

3.

process. For best results when programming changes are necessary, make all

the necessary changes in the Secure Menu (page 26) before making changes to

the Secondary Menu (page 19). If error messages occur, check the Diagnostic

Error Messages on page 34 and 35 for help.

Take the example of a Series CN74000 that comes from the factory programmed for

type J thermocouples. Suppose for this example you wish to change the input to

type K and limit the set point range between 0° and 1000° C.

First, enter the Secure menu as instructed on page 5. Press the INDEX key until the

display shows Inp and press the DOWN ARROW until the display shows CA. Don't

forget to press the ENTER key to retain your setting.

Next, press the INDEX key to display Unit. Press the DOWN ARROW until the display shows C. Press ENTER.

Next, press the INDEX key until SPL is displayed (pass the dPt and InPt selections).

Press the UP ARROW until the display shows 0. Press ENTER.

Finally, press INDEX key to display SPH. Press the DOWN ARROW until the display

shows 1000. Press ENTER.

The necessary program changes are now complete. After 60 seconds the display will

switch back to the temperature reading. If you want to return faster, press the UP

ARROW and ENTER keys (at the same time) and then press the DOWN ARROW and

INDEX keys ( again at the same time). This will 'back out' of the menu and immediately display the temperature reading.

If you want to use Self T une®, Auto/Manual, or the Ramp/Soak Programmer features,

see the special sections on these items. Page numbers for these are in the Contents

section on the previous page.

Page 3

CN74

MODEL IDENTIFICATION

Alarm

0 = No

1 = Yes

Options:

C4 RS-485 Serial Communications. Allows remote computer to read and write

all control parameters.

LV 12-24 VDC/VAC 50-400 Hz power supply (control operates on low voltage

equipment).

Note: Only Option LV may be combined with another option. No other options

may be combined.

Output A

2 = 5 VDC

3 = Relay

Output B

0 = None

3 = Relay

Options

C4 = RS485

LV = Low Voltage

INSTALLATION

Mount the instrument in a location that will not be subject to excessive temperature,

shock, or vibration. All models are designed for mounting in an enclosed panel.

Select the position desired for the instrument on the panel. If more than one instrument is required, maintain the minimum of spacing requirements as shown on the

drawing opposite. Closer spacing will structurally weaken the panel, and invalidate

the IP66, UL type 4 rating of the panel.

Page 4

It is not necessary to remove the control chassis from the

housing for installation. If the control chassis is removed from

the housing, you must follow industry standard practice for

control and protection against Electro-Static Discharge (ESD).

Failure to exercise good ESD practices may cause damage to

the control.

Prepare the panel by cutting and deburring the required opening(s).

From the front of the panel, slide the housing through the cutout. The housing gasket should be flat against the housing flange before installing.

From the rear of the panel slide the mounting collar over the housing. Hold the

housing with one hand and using the other hand, push the collar evenly against

the panel until the spring loops are slightly compressed. The ratchets will hold the

mounting collar and housing in place. To remove,gently lift the ratchets and slide a

piece of heavy paper or mylar sheet under each ratchet (a business card works

well). Slide the collar off of the housing.

WIRING

Do not run thermocouple or other class 2 wiring in the same conduit as power

leads. Use only the type of thermocouple or RTD probe for which the control has

been programmed. Maintain separation between wiring of sensor, auxiliary in or

out, and other wiring. See the "Secure Menu" for input selection.

For thermocouple input always use extension leads of the same type designated

for your thermocouple.

For supply connections use No. 18 AWG wires rated for at least 75°C. Use copper conductors only. All line voltage output circuits must have a common disconnect and be connected to the same pole of the disconnect.

Input wiring for thermocouple, current, and RTD; and output wiring for current, DC

SSR, and 5 VDC is rated CLASS 2.

Page 5

Control wiring is as shown.

The wiring terminals for the CN74000

are compression type. To open the

wiring terminal, turn the screw for that

terminal counterclockwise. Slide the

wire into the terminal space. While

holding the wire in place, turn the

screw clockwise to tighten. Maximum

torque is 0.424 N•m (3.75 in lb). Do

not overtighten. The wire should be held snugly in place.

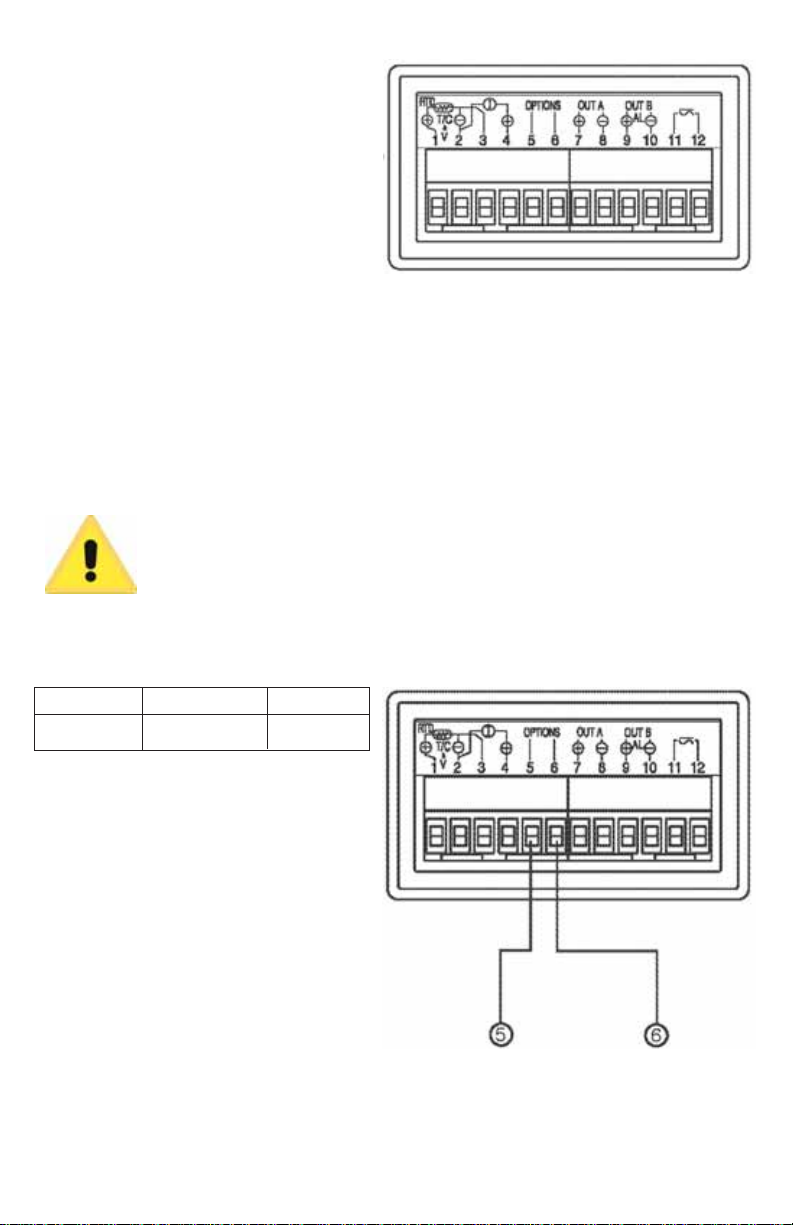

Wiring for Optional Inputs and Outputs

Wire power and outputs as shown on page 5 and 6. Wiring for options is shown

below. All wiring shown below is Class 2. Shielded twisted pair is r equired for Option

C4.

DO NOT RUN SIGNAL WIRING IN THE SAME CONDUIT OR

CHASE AS THE POWER WIRING. ERRATIC OPERATION OR

DAMAGE TO THE CONTROL CIRCUITRY WILL RESULT.

OPTION

C4

Note 1:

Last control in chain must have

120 ohm ±1% resistor across 5 and 6.

Page 6

Term. 5

Note 1

Terminal 5 is line A (-)

Terminal 6 is line B (+)

Term. 6

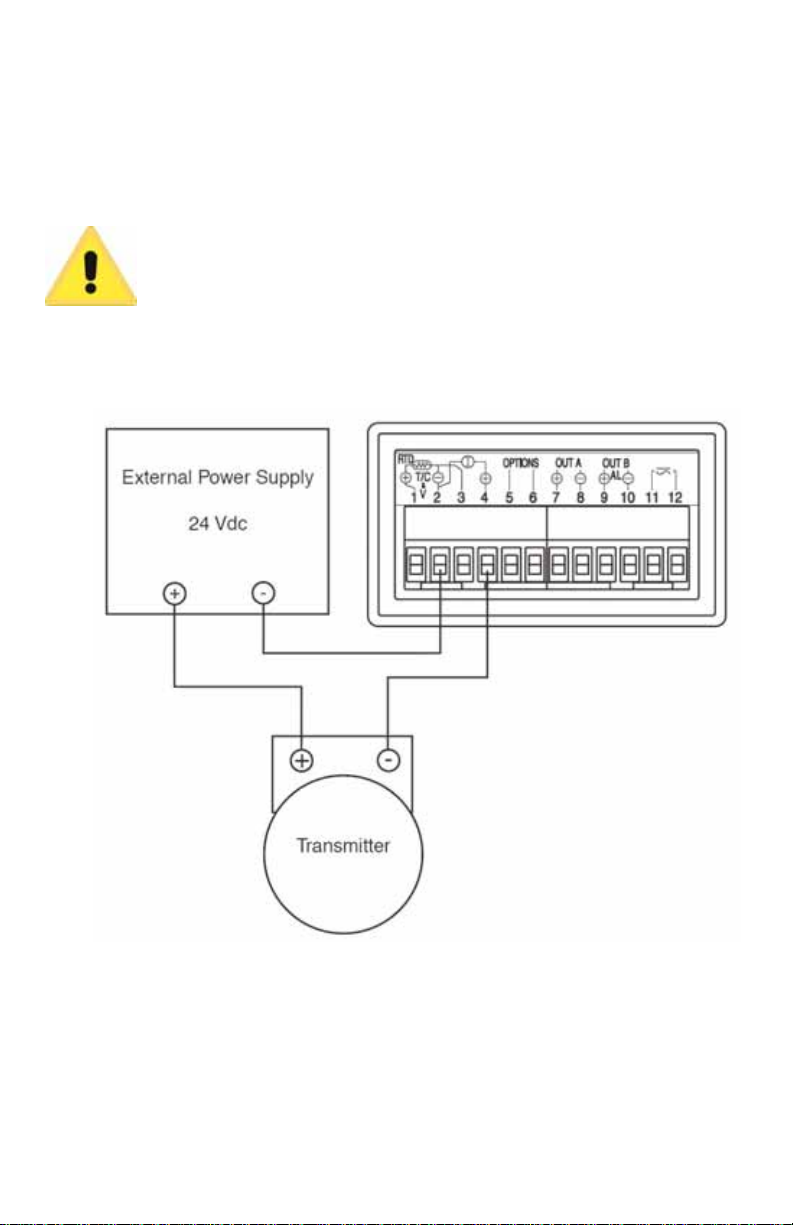

Wiring for 4 to 20mA Transmitter Inputs

Wire power and outputs as shown above. Two-wire transmitters wire as shown

below.

For three or four wire transmitters, follow the wiring instructions provided with your

transmitter.

DO NOT WIRE THE 24 VOLT POWER SUPPLY ACROSS THE

INPUT OF THE CONTROL. DAMAGE TO THE CONTROL INPUT

CIRCUITRY WILL RESULT.

Page 7

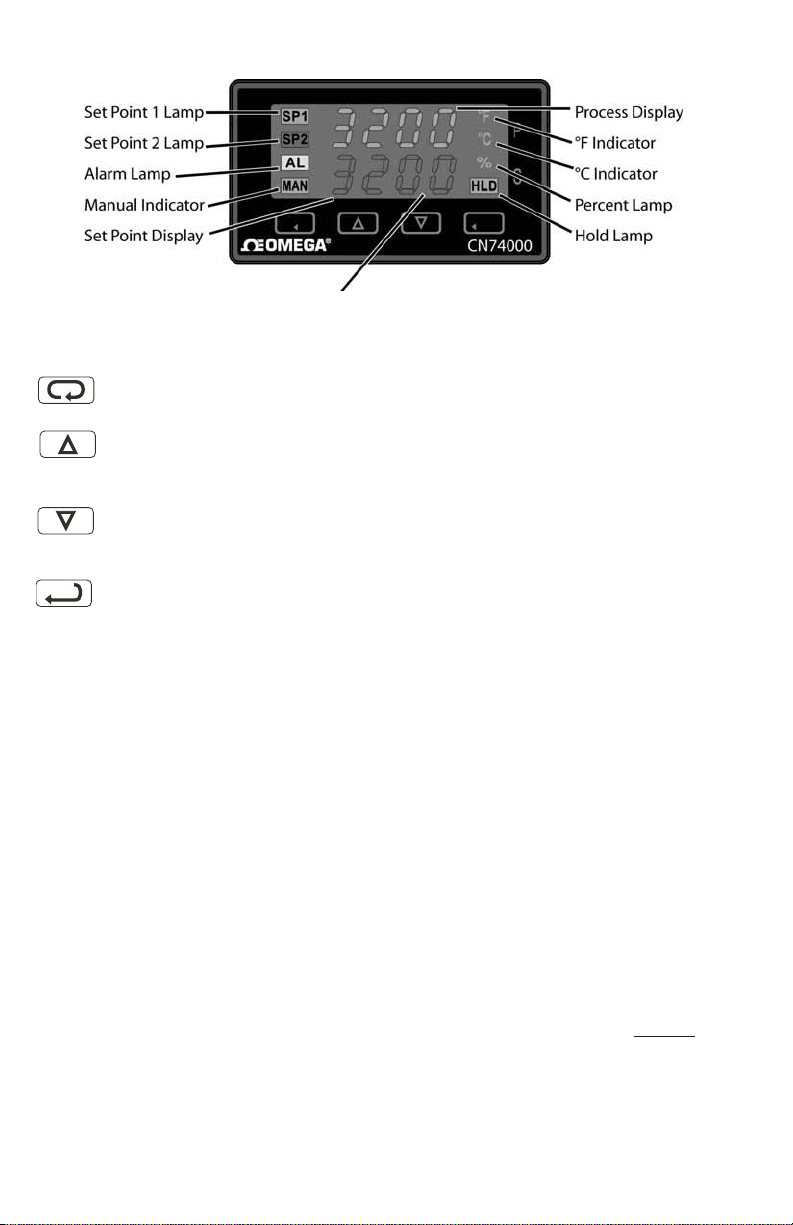

FRONT PANEL KEY FUNCTIONS

The decimal point flashes when Self-Tune is operating.

Keys are illuminated when pressed. Key functions are as follows:

INDEX: Pressing the INDEX key advances the display to the next menu

item. May also be used in conjunction with other keys as noted below.

UP ARROW: Increments a value, changes a menu item, or selects the item

to ON. The maximum value obtainable is 9999 regardless of decimal point

placement.

DOWN ARROW: Decrements a value, changes a menu item, or selects the

item to OFF. The minimum value obtainable is -1999 regardless of decimal

point placement.

ENTER: Pressing ENTER stores the value or the item changed. If not

pressed, the previously stored value or item will be retained. The display will

flash once when ENTER is pressed.

UP ARROW & ENTER: Pressing these keys simultaneously brings up the secondary menu starting at the alarm, tune, or cycle item (depending on programming).

Pressing these keys for 5 seconds will bring up the secure menu.

INDEX & DOWN ARROW: Pressing these keys simultaneously will allow backing

up one menu item, or if at the first menu item they will cause the display to return to

the primary menu. If an alarm condition has occurred, these keys may be used to

reset the alarm. To reset an alarm press and hold both keys for three seconds.

INDEX & ENTER: Pressing these keys simultaneously and holding them for 5 seconds allows recovery from the various error messages. The following menu items will

be reset:

ALiH: Alarm inhibit OPEn InP: Input error message

bAd InP: Input error message CHEC CAL: Check calibration error

Correct the problems associated with the above conditions before using

these reset keys. More than one error could be present. Caution is advised since

several items are reset at one time.

Page 8

While in the Primary or Secondary Menu, if no key is pressed for a period of 30

seconds, the display will return to the HOME position displaying the temperature

value. While in the Secure Menu, if no key is pressed for a period of 60 seconds,

the display will return to the HOME position displaying the temperature value.

Outputs are disabled (turned off) when the Secure Menu is active.

NOTE: To move to the Primary Menu quickly from any other menu, press the UP

ARROW & ENTER keys followed by pressing the INDEX & DOWN ARROW keys.

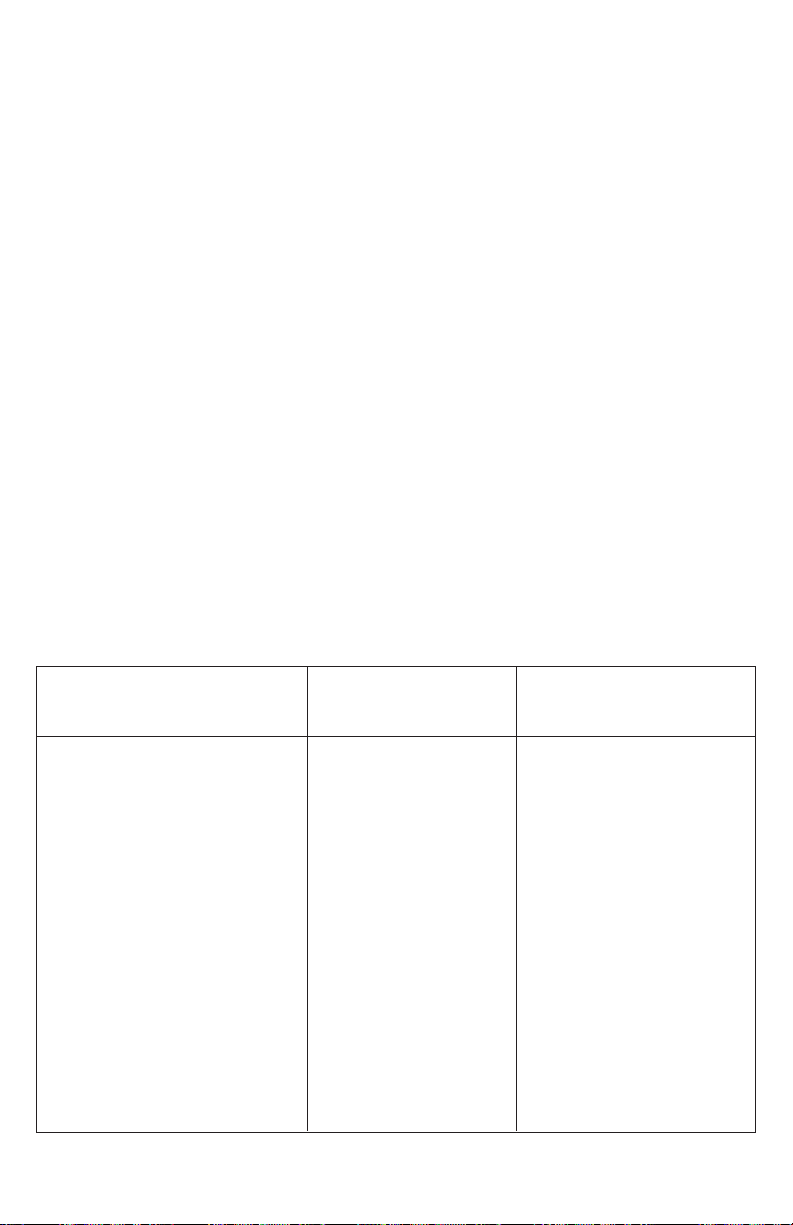

SECURITY LEVEL SELECTION

Four levels of security are provided. The display shows the current security level. To

change security levels change the password value using the UP & DOWN ARROW

keys and pressing the ENTER key. Refer to the password table (following) for the

correct value to enter for the security level desired. The SECr menu item security

level may be viewed or changed at any time regardless of the present security level.

To set the access level to, for example, 2, at the SECr menu item press the UP

ARROW key until the upper display show the password, 1101. Press the ENTER

key. The display will blink, and return with the level value, 2, in the upper display.

The password values shown in the table cannot be altered, so retain a copy of these

pages for future reference. This is the only r eference made to passwor d values in this

instruction book.

Security Level

Menu

Primary

Secondary

Secure

Primary

Secondary

Secure

Primary

Secondary

Secure

Primary

Secondary

Secure

Status

Locked

Locked

Locked

Unlocked

Locked

Locked

Unlocked

Unlocked

Locked

Unlocked

Unlocked

Unlocked

PASSWORD TABLE

Displayed Value

When Viewed

1

2

3

4

Password Value

to Enter

1110

1101

1011

111

Page 9

NOTATION CONVENTIONS FOR THE MENUS

Because of the number of features available in this control, information is included

that may not apply to your specific control. All usable features are included in this

book, but may not be used in your process. To increase clarity the following conventions are used:

1. Certain features, Menu Items, and functions shown in this book may or may not

appear on your control, depending on other Menu Item selections. At various places

in the Menus there are notes identifying Menu Items that "control" or "direct" other

menu items. If you are looking for a particular menu item and can't find it, check the

menu item that is its "control" for proper setting.

2. The "#" symbol is used in two ways. It is used inside a group of characters to

indicate which set point function (SP1 or SP2) is being affected. It is also used before

a group of characters of a menu item to indicate that there may be more than one

selection or value for that menu item. This is used for certain repeated items such as

in the Ramp/Soak Program section.

3. Features that apply only to Options will be printed in Italics.

THE HOME DISPLAY

The home display is the normal display while the control is operating. If no errors or

functions are active, the HOME display will indicate the Process Variable (the temperature, pressure, flow, RH, etc., that is being measured) on the top display and the

Set Variable (Set Point 1) on the bottom.

Items that can change the HOME display are the Auto/Manual function, the Prog

function, the PctO function, and any error message. Description of these special displays follow.

If Auto/Manual is enabled, the Manual indicator lights, and the home display is

changed. The upper display continues to show the Process Variable (PV), but the

lower display changes to show the percentage of output in tenths of a percent to

99.9% (0.0 to 99.9), or 100 if 100%. The display digit to the right of the number

shows a flashing letter oto indicate that the value displayed is no longer the SV, but

percent output. The SP2 output is indicated by the use of an overline on the letter

o

. Access to the SP2 value is done by the INDEX key. See Auto/Manual Operation

on Page 13 for further information.

If Prog is turned On, the HOME display changes the SV display from SP1to the

Present Set Variable as calculated by the Ramp/Soak Programmer function. See

Programming and Operation for Ramp/Soak Feature for more information.

Page 10

Loading...

Loading...