User’s Guide

Shop online at

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

Page 1 of

CN7400

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

Servicing North America:

U.S.A.: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

Customer Service: 1-800-622-2378/1-800-622-BEST

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

®

®

Mexico: En Espan˜ol: (001) 203-359-7803

e-mail: espanol@omega.com

FAX: (001) 203-359-7807

info@omega.com.mx

Servicing Europe:

Czech Republic: Frystatska 184, 733 01 Karvina´, Czech Republic

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Tel: +420 (0)59 6311899

FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

Tel: +49 (0)7056 9398-0

FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

CN7400 Temperature Control

Specifications - Installation and Operating Instructions

OMEGA Engineering

One Omega Drive, Stamford, Connecticut 06907-0047

P.O. Box 4047

Page 1 of 25

Telephone

800/848-4286 or 203/359-1660

Fax

203/359-7700

CONTENTS

MODEL IDENTIFICATION.....................................................................2

GETTING STARTED.............................................................................3

INSTALLATION.....................................................................................4

WIRING................................................................................................5

Wiring for 4 to 20mA Transmitter inputs.....................................6

Wiring for Optional Inputs and Outputs......................................6

FRONT PANEL KEY FUNCTIONS........................................................8

NOTATION CONVENTIONS FOR THE MENUS..................................10

THE HOME DISPLAY..........................................................................11

OPERATION AND PROGRAMMING OF OPTIONS.............................11

PRIMARY MENU................................................................................13

SECONDARY MENU..........................................................................13

SECURE MENU.................................................................................15

DIAGNOSTIC ERROR MESSAGES....................................................20

SPECIFICATIONS...............................................................................22

DIMENSIONS.....................................................................................24

MODEL IDENTIFICATION

CN74

Output A

3 = N.O. Relay

Output B

0 = None

4 = N.C. Relay

Options

PV1 = 0-20 mA

Options:

PV1 Analog Retransmission of Process Variable, 4 to 20 mAdc.

LV 12 - 24 Vdc/Vac 50 - 400 Hz power supply (control operates on

low voltage equipment).

Page 2 of 25

GETTING STARTED

1. Install the control as described on page 4.

2. Wire your control following the instructions on page 5. If you are using a

two-wire transmitter as a input, see the drawing and instructions on page 6.

Option wiring instructions are on page 7. Option descriptions are specific

instructions start on page 16.

3. Most controls do not need many (if any) program changes to work on your

process. For best results when programming changes are necessary, make all

the necessary changes in the Secure Menu (page 26) before making changes

to the Secondary Menu (page 19). If error messages occur, check the

Diagnostic Error Messages on page 35 for help.

Take the example of a Model CN7430 that comes from the factory

programmed for type J thermocouples. Suppose for this example you wish to

change the input to type K and limit the set point range between 0° and

1000°C.

First, enter the Secure menu as instructed on Page 5. Press the INDEX key

until the display shows

shows

CCAA

. Don’t forget to press the ENTER key to retain your setting.

IInnpp

and press the DOWN ARROW until the display

Next, press the INDEX key to display

display shows CC. Press ENTER.

Next, press the INDEX key until

selections). Press the UP ARROW until the display shows 00. Press ENTER.

Finally, press INDEX key to display

display shows

The necessary program changes are now complete. After 30 seconds the

display will switch back to the temperature reading. If you want to return faster,

press the UP ARROW and ENTER keys (at the same time) and then press the

DOWN ARROW and INDEX keys (again at the dame time). This will ‘back out’

of the menu and immediately display the temperature reading.

11000000

. Press ENTER.

UUnniitt

. Press the DOWN ARROW until the

SSPPLL

is displayed (pass the

SSPPHH

. Press the DOWN ARROW until the

Page 3 of 25

ddPPtt

and

IInnPPtt

INSTALLATION

Mount the instrument in a location that will not be subject to excessive

temperature, shock, or vibration. All models are designed for mounting in an

enclosed panel.

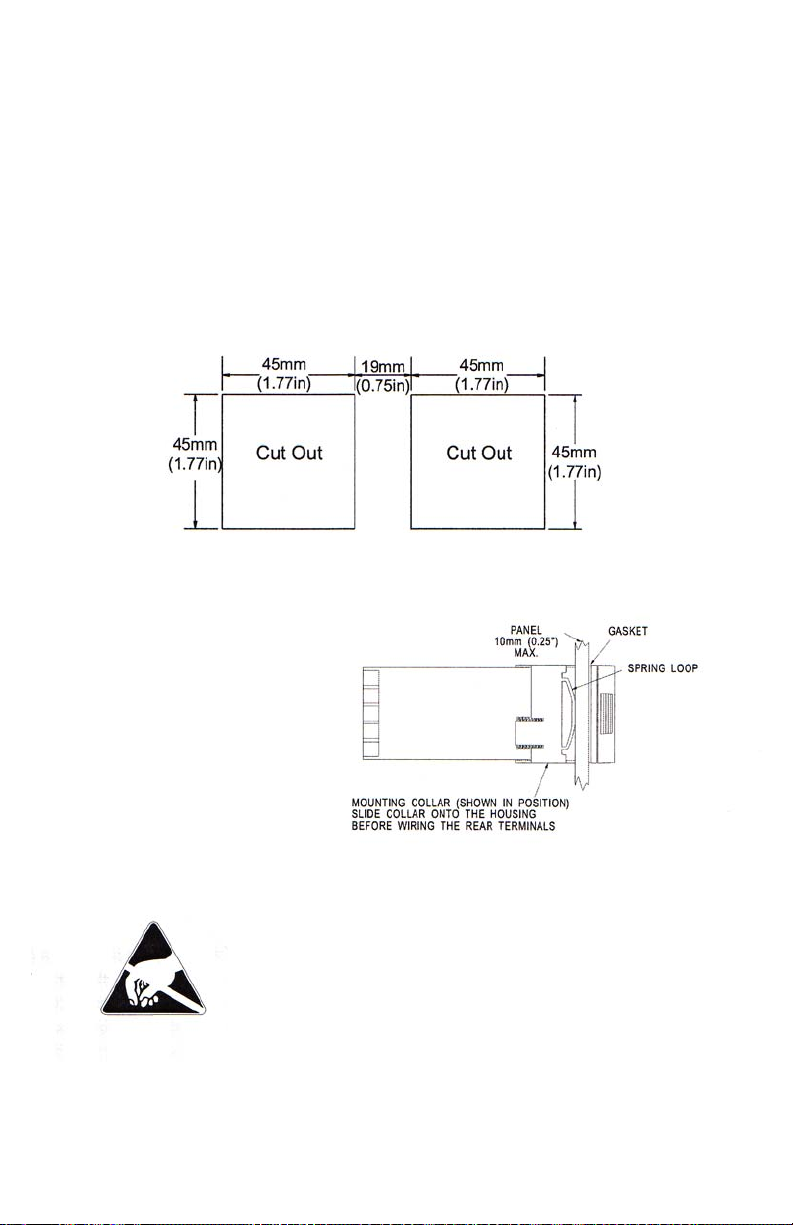

Select the position desired for the instruments on the panel. If more that one

instrument is required, maintain the minimum of spacing requirements as

shown on the drawing below. Closer spacing will structurally weaken the

panel, and invalidate the IP66, UL type 4 rating of the panel.

Prepare the panel by cutting and deburring the required opening.

From the front of the panel, slide the housing through the cut out. The housing

gasket should be against the housing flange before installing.

From the rear of the panel slid the

mounting collar over the housing.

Hold the housing with one hand

and using the other hand, push

the collar evenly against the panel

until the spring loops are slightly

compressed. The ratchets will

hold the mounting collar and

housing in place.

CCaauuttiioonn:: IItt iiss nnoott nneecceessssaarryy ttoo rreemmoovvee tthhee iinnssttrruummeenntt

cchhaassssiiss ffrroomm tthhee hhoouussiinngg ffoorr iinnssttaalll

cchhaassssiiss iiss rreemmoovveedd ffrroomm tthhee hhoouussiinngg,, yyoouu mmuusstt ffoollllooww

iinndduussttrryy ssttaannddaarrdd pprra

aaggaaiinnsstt EElleeccttrroo--SSttaattiicc DDiisscchhaarrggee ((EESSDD)).. FFaaiilluurree ttoo

eexxeerrcciissee ggoooodd E

iinnssttrruummeenntt..

laattiioonn.. IIff tthhee iinnssttrruummeenntt

accttiiccee ffoorr ccoonnttrrooll aanndd pprrootteeccttiioonn

ESSDD pprraaccttiicceess mmaayy ccaauussee ddaammaaggee ttoo tthhee

Page 4 of 25

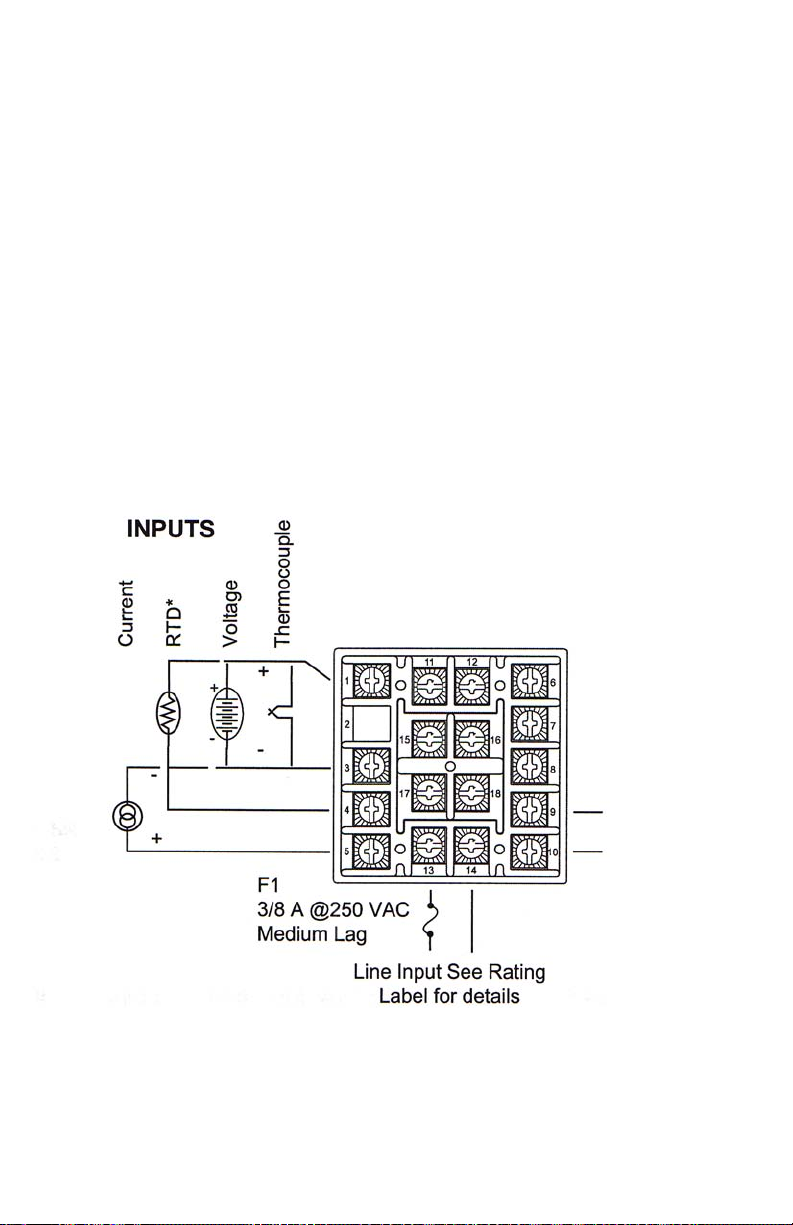

WIRING

Do not run thermocouple or other class 2 wiring in the same conduit as power

leads. Use only the type of thermocouple or RTD probe for which the control

has been programmed. Maintain separation between wiring of sensor, auxiliary

in or out, and other wiring. See the “Secure Menu” for input selection.

For thermocouple input always use extension leads of the same type

designated for your thermocouple.

For supply connections use No. 16 AWG or larger wires rated for at least 75°C.

Use copper conductors only. All voltage output circuits must have a common

disconnect and be connected to the same pole of the disconnect.

Input wiring for thermocouple, current, and RTD; limit reset function; and output

wiring for the 15VCD is rated CLASS 2.

Control wiring is as shown.

Alarm Reset

An external

normally open

contact may be

wired across

terminals 9 and

10 for remote

reset.

Multiple units

can not share

common

contacts.

Terminals 9 and

10 share a

common

ground with the

input.

• For 2-wire RTD use terminals 1 & 3 and place a jumper wire between

terminal 3 & 4.

Page 5 of 25

Output A Relay (N.O.) wires to terminals 15 & 16.

Output B Relay (N.C.) wires to terminal 17 & 18.

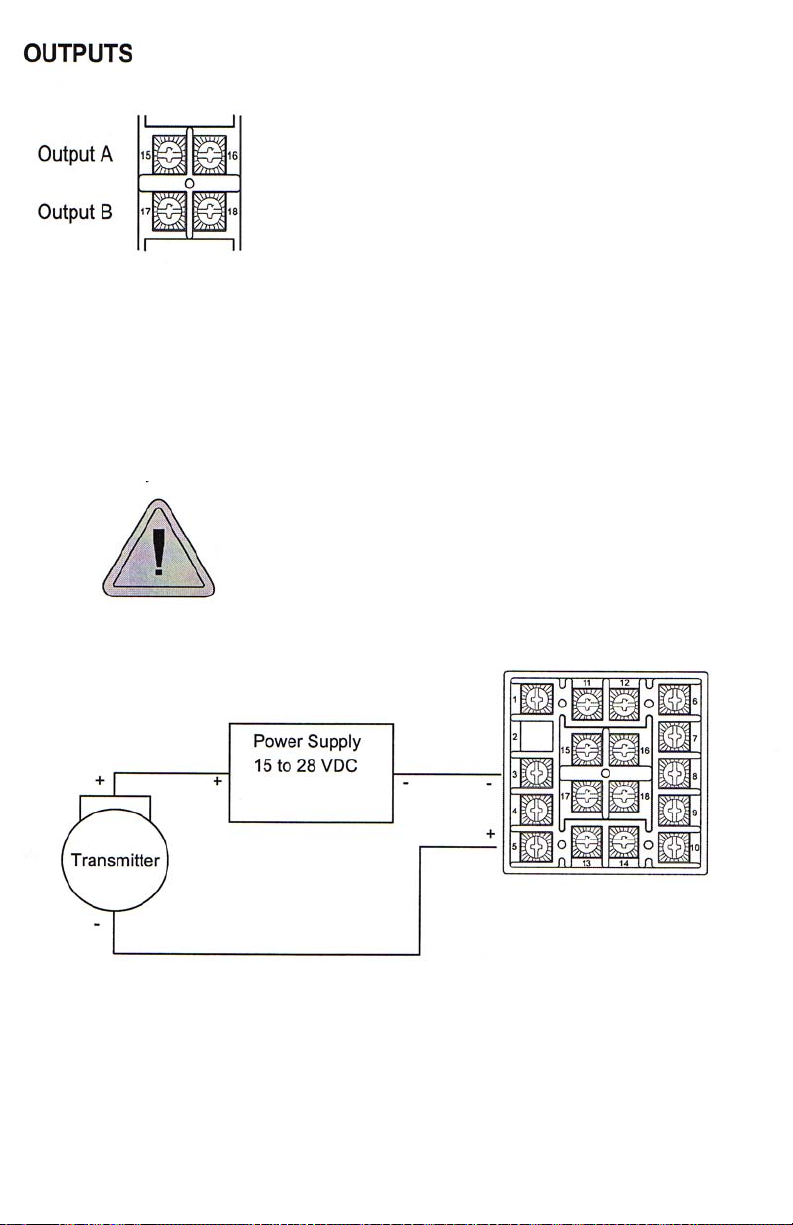

Wiring for 4 to 20mA Transmitter inputs

Wire power and outputs as shown above. Two-wire transmitters wire as shown

below.

For three of four wire transmitters follow the wiring instructions provided with

your transmitter.

CAUTION: DO NOT WIRE THE 24 VOLT POWER

SUPPLY ACROSS THE INPUT OF THE CONTROL.

DAMAGE TO THE CONTROL INPUT CIRCUITRY WILL

RESULT

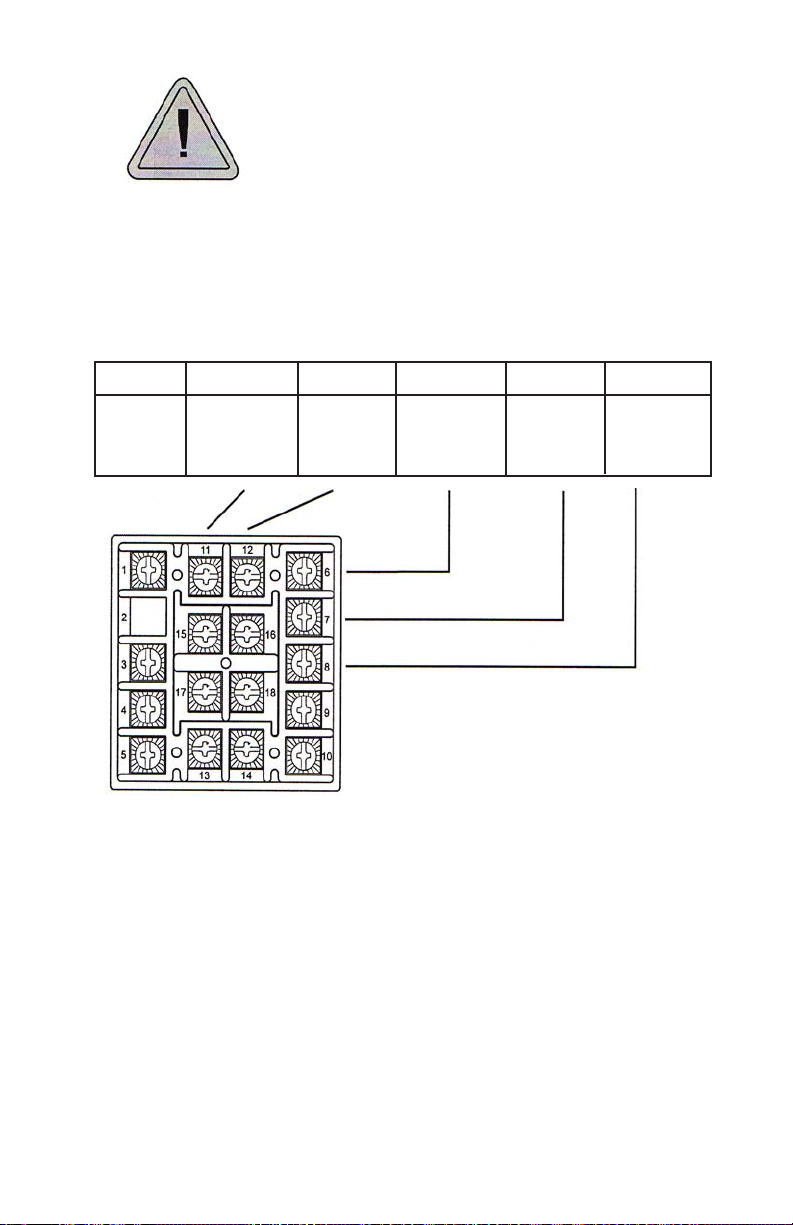

Wiring for Optional Inputs and Outputs

Wire power outputs as shown on page 5 and 6. Wiring for options is shown

opposite. All wiring shown below is Class 2.

Page 6 of 25

CAUTION: DO NOT RUN SIGNAL WIRING IN THE

SAME CONDUIT OR CHASE AS THE POWER

WIRING. ERRATIC OPERATION OR DAMAGE TO

THE CONTROL CIRCUITRY WILL RESULT.

OPTION

PV1

11

+

12

-

6

NA

7

NA

8

NA

Page 7 of 25

Loading...

Loading...