Omega Products CN7200 Installation Manual

Bulletin E-90-OCN

Series CN7200, CN7600, CN7800, CN7500

Microprocessor Based Temperature Process Control

Specifications - Installation and Operating Instructions

OMEGA ENGINEERING, INC.

1 - 888 - TC - OMEGA USA & Canada

1 - 203 - 359 - 1660 INTERNATIONAL

TABLE OF CONTENTS

Model Number Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Panel Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Front Panel Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Security Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Control Operation Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Programming and Operation for Ramp and Soak Feature. . . . . . . . . . 11-13

Programming and Operation for PID Function. . . . . . . . . . . . . . . . . . . . . . 14

Description of Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operation Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16

Regulation Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-19

Initial Setting Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-22

Alarm Output Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Communication Register List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

Diagnostic Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Input Sensor Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Page 2

MODEL NUMBER IDENTIFICATION

CN75

OUTPUT 1

2 = Voltage Pulse

3 = Relay

5 = Current

CN72

OUTPUT 1

2 = Voltage Pulse

3 = Relay

5 = Current

6 = Linear Voltage

OUTPUT 2

3 = Relay

OUTPUT 2

3 = Relay

CN78

OUTPUT 1

2 = Voltage Pulse

3 = Relay

5 = Current

CN76

OUTPUT 1

2 = Voltage Pulse

3 = Relay

5 = Current

6 = Linear Voltage

OUTPUT 2

3 = Relay

OUTPUT 2

3 = Relay

GETTING STARTED

1. Install the control as described on page 4.

2. Wire your control following the instructions on pages 6-7. Please read the

Precautions section located at the end of this manual before wiring the control.

3. For best results when programming changes are necessary, make all changes

to the Initial Setting mode (Pages 20-22) before making changes to the

Regulation Mode (Pages 17-19) or Operation Mode (Pages 15-16). If any error

messages occur, check the Diagnostic Error Message Section (Page 26) for

assistance.

Page 3

INSTALLATION

Mount the instrument in a location that will not be subject to excessive temperature,

shock, or vibration. All models are designed for mounting in an enclosed panel.

Select the position desired for the instrument on the panel. Prepare the panel by

cutting and deburring the required opening per the panel cut out dimensions listed

below. Follow the mounting instructions listed on page 5. Lastly, wire the controller

per the appropriate wiring diagram listed on page 6.

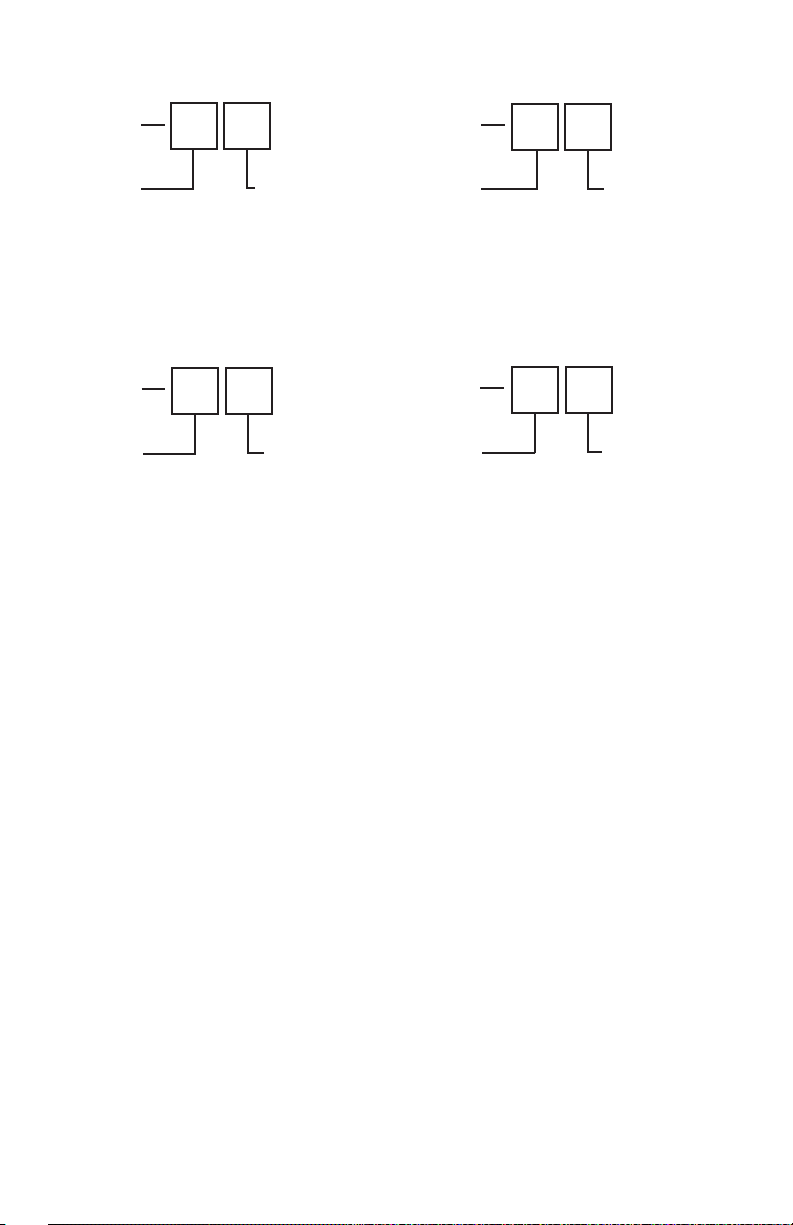

PANEL CUTOUT DIMENSIONS

Page 4

MOUNTING METHOD

Step 1: From the front of the panel, slide the controller housing through

the cut out. The housing gasket should be against the housing

flange before installing.

Step 2: Insert the mounting brackets into the mounting grooves on the

top and bottom of the controller (CN78, CN76, and CN72). For the CN75,

slide the mounting collar over the housing from the rear of the panel.

Step 3: Push the mounting brackets forward until the bracket stops at

the panel wall.

Step 4: Insert and tighten the screws on the bracket to secure the

controller in place. (The screw torque should be 0.8 kgf-cm).

Mounting Bracket Installation

CN78/CN72/CN76 Mounting Method

CN75 Mounting Method

Page 5

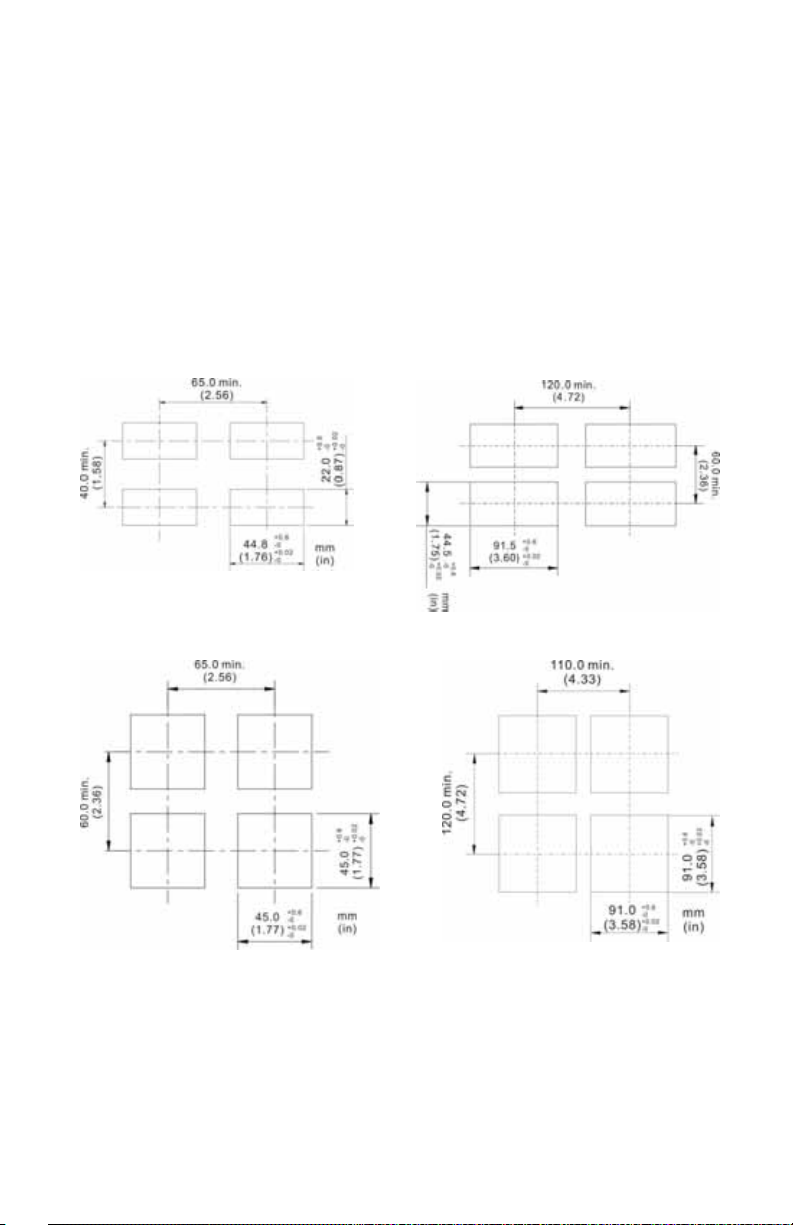

WIRING

Do not run thermocouple or other class 2 wiring in the same conduit as power leads.

Use only the type of thermocouple or RTD probe for which the control has been

programmed. Maintain separation between wiring of sensor, auxiliary in or out, and

other wiring. See the Initial Setting Menu for input selection.

For thermocouple input always use extension leads of the same type designated for

your thermocouple.

For supply connections use No. 16 AWG or larger wires rated for at least 75˚ C. Use

conductors only . All line voltage output cir cuits must have a common disconnect and

be connected to the same pole of the disconnect.

Input wiring for thermocouple, current, and RTD; and output wiring for current 14

VDC is rated CLASS 2.

Control wiring as show below:

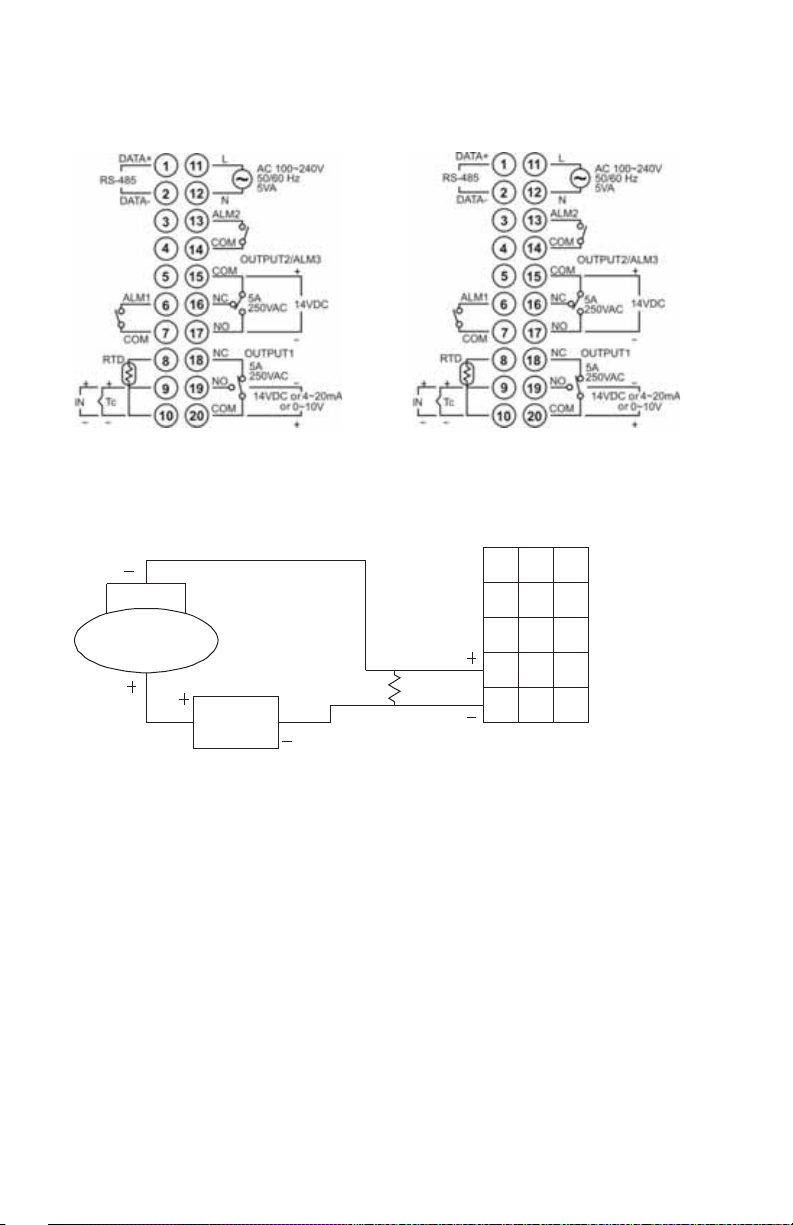

Terminal Identification

CN75

CN78

Page 6

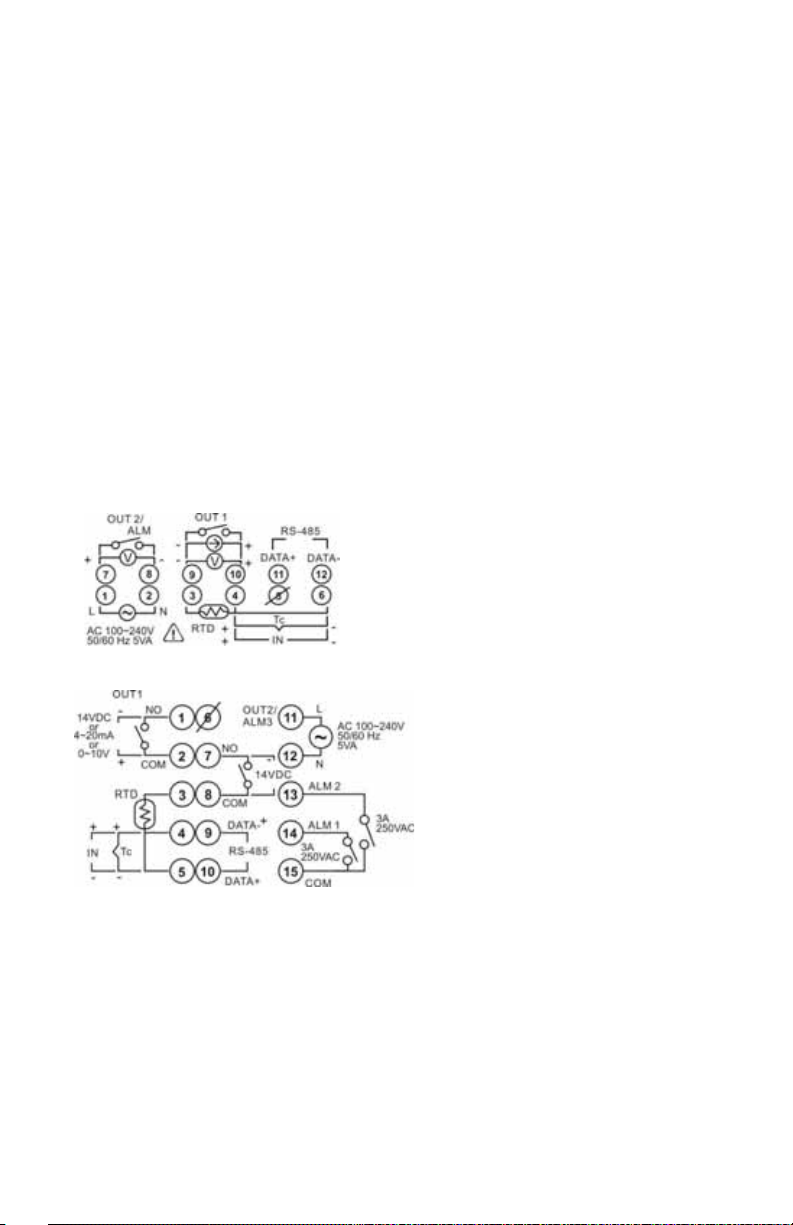

Terminal Identification (Continued)

CN72 CN76

Wiring for 4 to 20 mA Transmitter Inputs

10

10

6

7

11

12

8

13

9

14

TRANSMITTER

POWER

SUPPLY

1

2

3

4

5

A-277

250 OHM

PRECISION

RESISTOR

Note: CN78 terminal layout used in above example. Use appropriate terminal

layout for selected controller.

Page 7

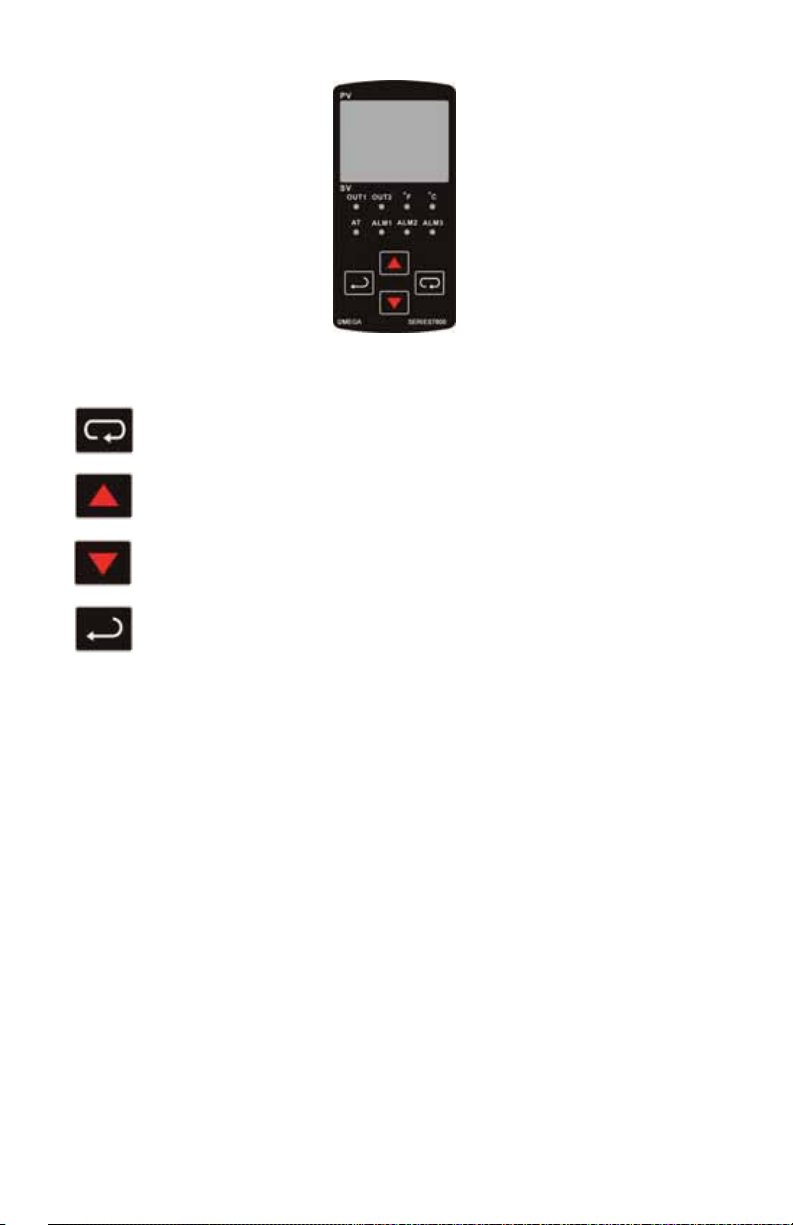

FRONT KEY FUNCTIONS

Key functions are as follows:

INDEX: Pressing the INDEX key advances the display to the next menu

item.

UP ARROW: Increments a value or changes a menu item. If pressed

during the Operation Mode, the set point value will be increased.

DOWN ARROW: Decrements a value or changes a menu item. If pressed

during the Operation Mode, the set point value will be decreased.

ENTER: Stores the value or item change. If not pressed, the previously

stored value or item will be retained. When pressed during the Operation

Mode, the controller switches to the Regulation Mode. If held for more

than 3 seconds during the Operation Mode, the controller switches to

the Initial Setting Mode. If pressed during the Regulation Mode or

Initial Setting Mode, the controller will return to the Operation Mode.

SECURITY FEATURES

This series of controllers have two built in security lock settings to prevent

unauthorized personnel from changing parameter settings. These parameters are set

in the Operation Mode.

The LoC1 setting affects all parameters in the controller. If LoC1 setting is enabled,

the operator will have to unlock the controller to make any changes to the controller’s

parameters.

The LoC2 setting affects all parameters except the set point. If LoC2 setting is

enabled, the only parameter that the operator will be able to change is the set point.

In order to change any other parameters, the operator will have to unlock the control

before making a change.

In order to unlock the control, the operator must depress the ENTER and INDEX key

simultaneously.

Page 8

CONTROL OPERATION DESCRIPTION

The HOME display is the normal display while the control is operating. If no errors or

functions are active, the HOME display will indicate the Process Variable (the

temperature, pressure, flow, %RH, etc.) that is being measured on the top display

and the Set Variable on the bottom display.

Items that can change the HOME display are the Ramp and Soak function and any

error messages. Descriptions of these special displays follow.

If the Ramp and Soak feature is active, then bottom display will show the current

execution pattern and current execution step. The UP and DOWN arrows can be

pressed to change the bottom display to show the Set Point (SP) of the current

execution step or the Time Remaining (r-ti) of the current execution step. After

changing the bottom display to either the Time Remaining or the Set Point, the

ENTER key must be pressed to display the values.

Error Messages are shown on page 26.

Page 9

Heating, Cooling or Dual Loop Control

Temperature Control can be achieved by either heating or cooling. In the B series

controllers, heating and cooling can be operated simultaneously using Dual Loop

Output Control to maintain a temperature set point. When Dual Loop Output Control

is used, control outputs must be connecting to the heating and cooling devices.

Please refer to the following for the operation of each setting.

Control Modes are selected by changing the S-HC parameter in the Initial Setting

Mode.

Select HEAt, for heating or reverse acting control for output 1. If selected, output 2

will become alarm 3.

Select CooL, for cooling or direct acting control for output 1. If selected, output 2 will

become alarm 3.

Select H1C2 or C1H2 for Dual Loop Output Control for output 1 and 2. If H1C2 is

selected, output 1 would be fore heating or reverse acting control and output 2

would be for cooling or direct acting control. If C1H2 is selected, output 1 would be

for cooling or direct acting control and output 2 would be for heating or reverse

acting control.

Setting the control mode to PID when the controller is set for Dual Loop Output

Control Activates the Proportional Band Coefficient (CoEF) parameter and the Dead

Band (dead) parameter.

The Proportional Band Coefficient (CoEF) sets the Proportional band value for Output

2 based on the Proportional band of output 1. The Proportional Band of Output 2

would be equal to the Proportional Band (Pn) of Output 1 multiplied by the

Proportional Band Coefficient (CoEF). The Integral Time (in) and the Derivative Time

(dn) will be the same for both Outputs.

The Dead Band (dEAd) parameter sets an area in which the heating and cooling

outputs are operating at 0% on. The Dead Band is centered on the Set Point in Dual

Loop Output Control mode. Please see the Dead Band illustrated on page 19.

Page 10

Loading...

Loading...