Omega Products CN63200 Installation Manual

CN63200 aand CCN63400

1/16 DIN Temperature and

Process Controllers

M4496-0607

GENERAL DESCRIPTION

The Model CN63200 Controller accepts signals from a variety of temperature

sensors (thermocouple or RTD), while the Model CN63400 Controller accepts

either a 0 to 10 VDC or 0/4 to 20 mA DC input signal. Both controllers can

provide an accurate output control signal (time proportional or DC Analog

Output) to maintain a process at a setpoint value. Dual 4-digit displays allow

viewing of the process/temperature and setpoint simultaneously. Front panel

indicators inform the operator of the controller and output status. The

comprehensive programming allows these controllers to meet a wide variety of

application requirements.

MAIN CONTROL

The controller operates in the PID Control Mode for both heating and

cooling, with on-demand auto-tune, that establishes the tuning constants. The

PID tuning constants may be fine-tuned through the front panel and then locked

out from further modification. The controller employs a unique overshoot

suppression feature, that allows the quickest response without excessive

overshoot. Switching to Manual Mode provides the operator direct control of the

output. The controller may also be programmed to operate in On/Off mode with

adjustable hysteresis.

ALARMS

Optional alarm(s) can be configured independently for absolute high or low

acting with balanced or unbalanced hysteresis. They can also be configured for

deviation and band alarm. In these modes, the alarm trigger values track the

setpoint value. Adjustable alarm hysteresis can be used for delaying output

response. The alarms can be programmed for Automatic or Latching operation.

A selectable standby feature suppresses the alarm during power-up until the

temperature stabilizes outside the alarm region.

ANALOG OUTPUT OPTION

The optional DC Analog Output (10 V or 20 mA) can be configured and

scaled for control or re-transmission purposes. The programmable output update

time reduces valve or actuator activity.

CONSTRUCTION

The controller is constructed of a lightweight, high impact, black plastic

textured case and bezel with a clear display window. The front panel meets

NEMA 4X/IP65 specifications when properly installed. In applications that do

not require protection to NEMA 4X, multiple controllers can be stacked

horizontally or vertically. Modern surface-mount technology, extensive testing,

plus high immunity to noise interference makes the controller extremely reliable

in industrial environments.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do not use the controller to directly command motors, valves, or other actuators

not equipped with safeguards. To do so can be potentially harmful to persons or

equipment in the event of a fault to the controller. An independent and redundant

temperature limit indicator with alarm outputs is strongly recommended.

z PID CONTROL WITH REDUCED OVERSHOOT

z CN63200 ACCEPTS TC AND RTD

z CN63400 ACCEPTS 0-10 V AND 0/4-20 mASIGNALS

z ON DEMAND AUTO-TUNING OF PID SETTINGS

z DC ANALOG OUTPUT (OPTIONAL)

z USER PROGRAMMABLE FUNCTION BUTTON

z PC OR FRONT PANEL PROGRAMMING

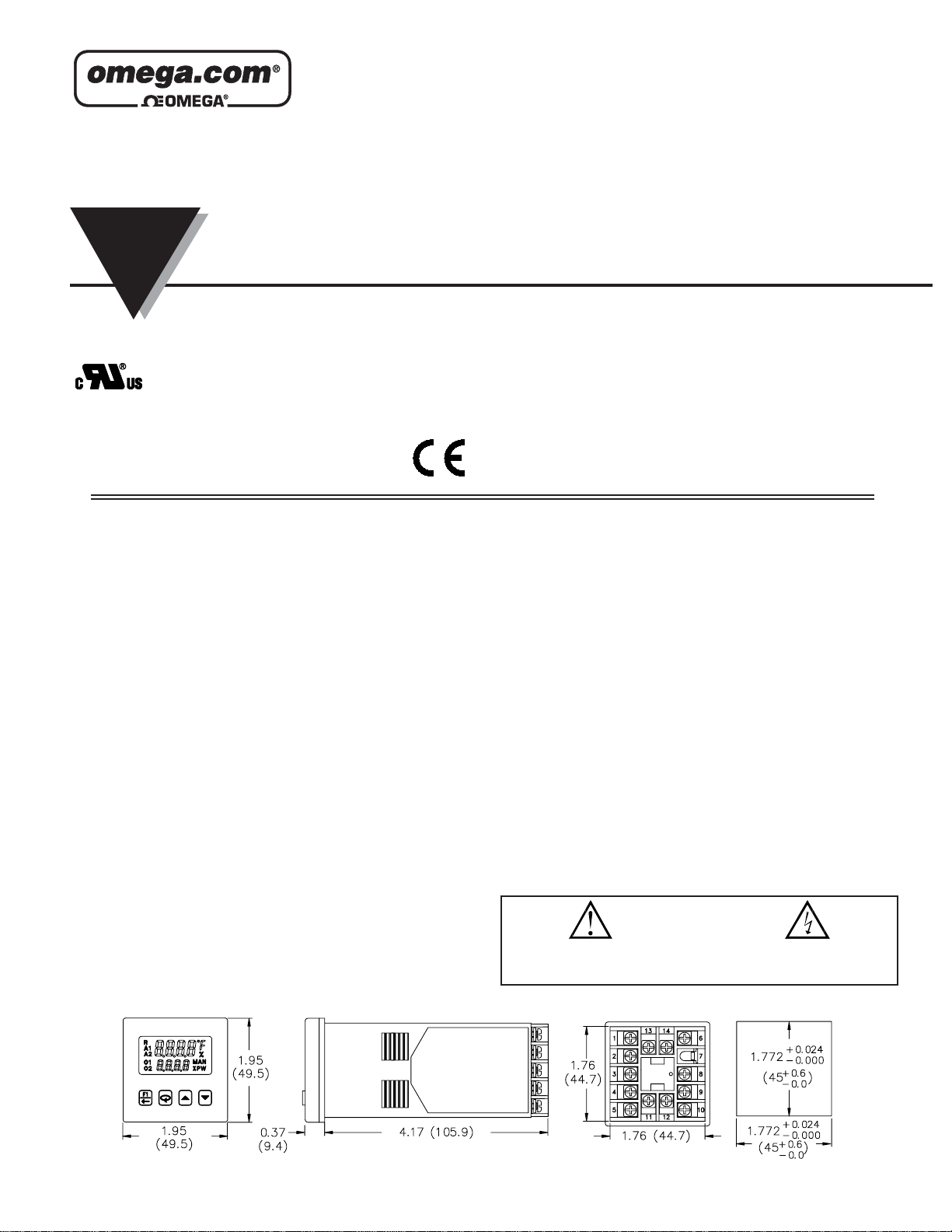

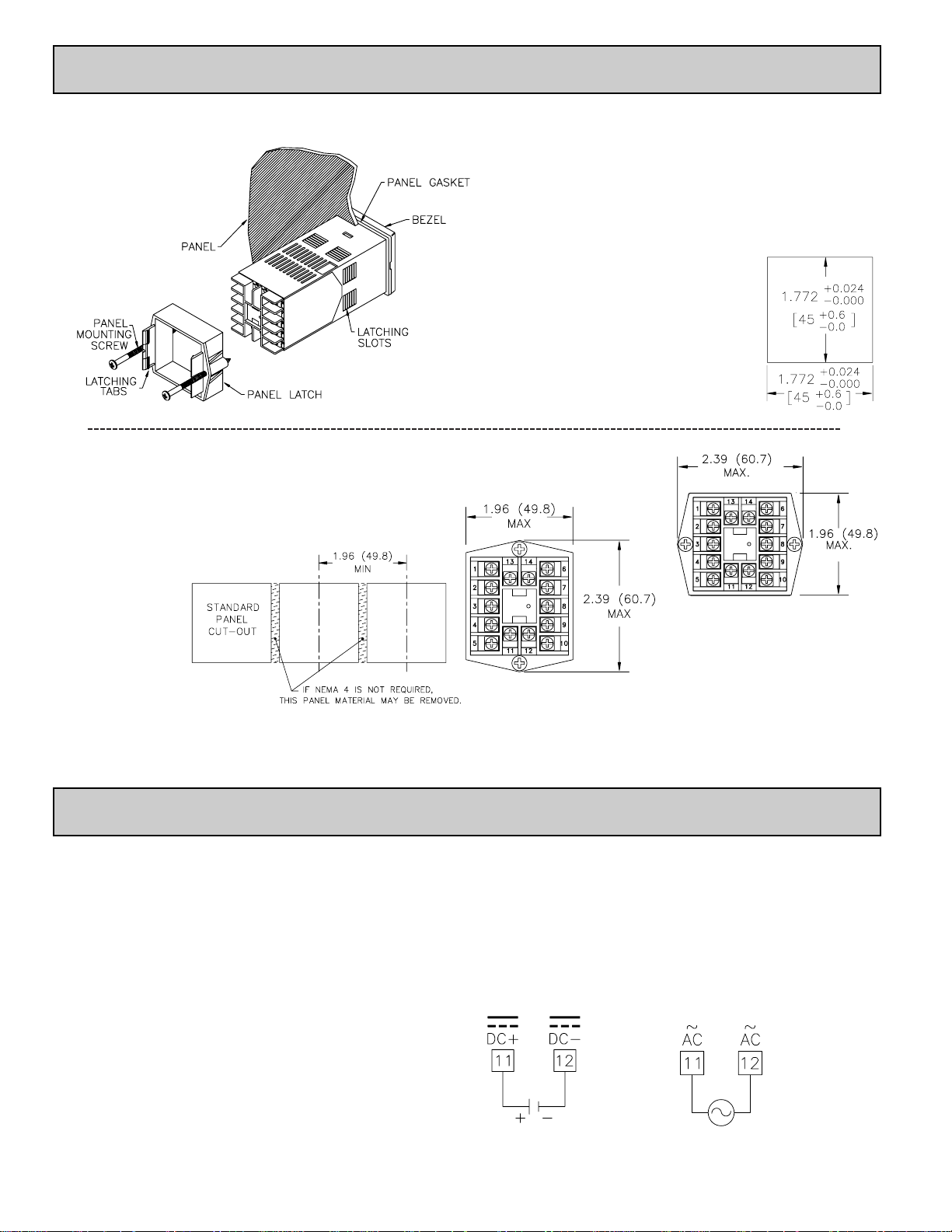

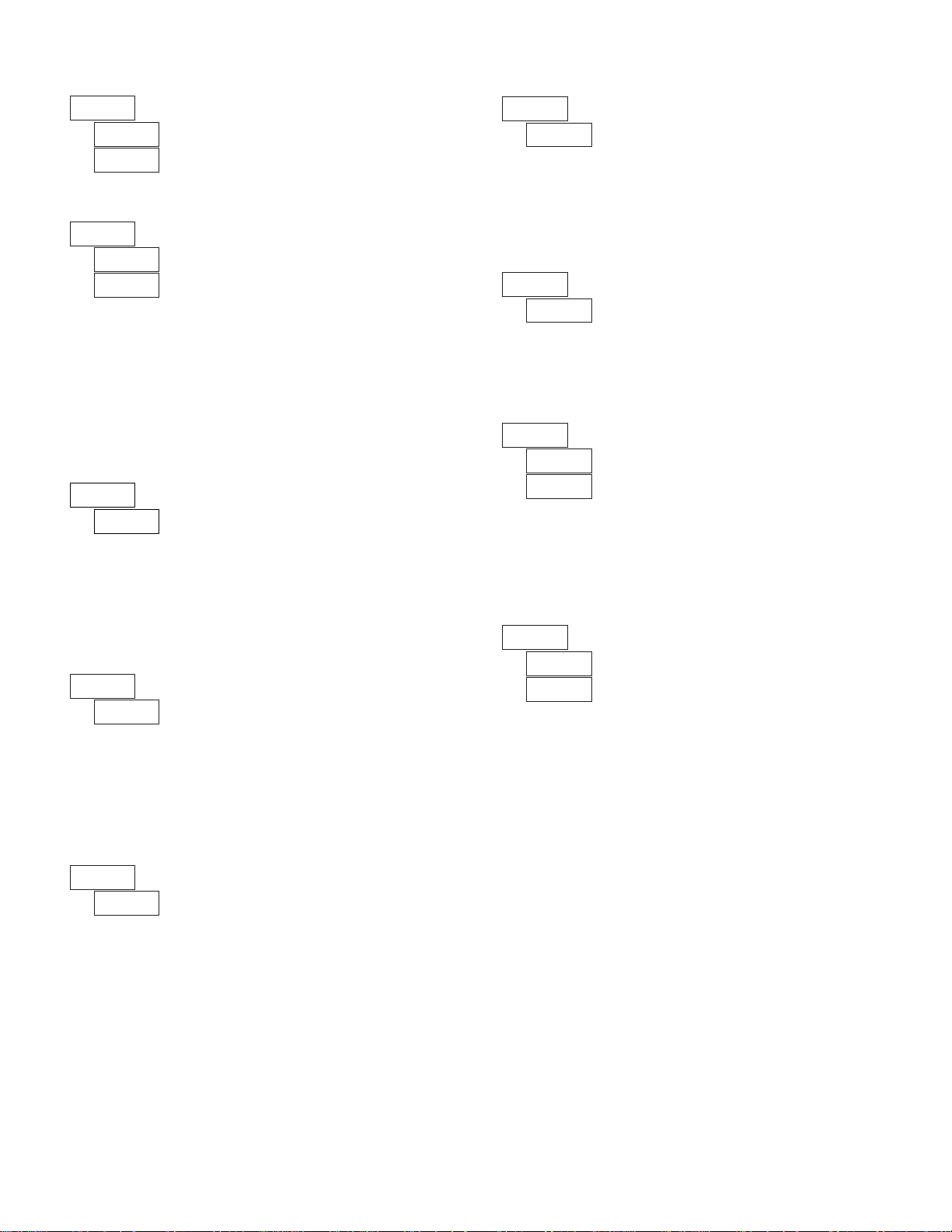

DIMENSIONS In inches (mm)

PANEL CUT-OUT

UL Recognized Component,

File #E123489

CAUTION: Risk of Danger.

Read complete instructions prior to

installation and operation of the unit.

CAUTION: Risk of electric shock.

LP0681X

INSTRUCTION

SHEET

Shop online at: omega.com e-mail: info@omega.com

For latest product manuals: omegamanual.info

OMEGAnet®Online Service

omega.com

Internet e-mail

info@omega.com

Servicing North America:

U.S.A.: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico: En Español: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING : These products are not designed for use in, and should not be used for, human applications.

3

INPUT SPECIFICATIONS

1. SENSOR INPUT:

Sample Period: 100 msec (10 Hz rate)

Step Response Time: 300 msec typical, 400 msec max to within 99% of final

value with step input.

Failed Sensor Response:

Main Control Output(s): Programmable preset output

Display: “OPEN”

Alarms: Upscale drive

Analog Output: Upscale drive when assigned to retransmitted input.

Normal Mode Rejection: >40 dB @ 50/60 Hz

Common Mode Rejection: >120 dB, DC to 60 Hz

Overvoltage Protection: 120 VAC @ 15 sec max

2. RTD INPUTS: (CN63200 only)

Type: 2 or 3 wire

Excitation: 150 μA typical

Lead Resistance: 15 Ω max per input lead

Resolution: 1° or 0.1° for all types

3. THERMOCOUPLE INPUTS: (CN63200 only)

Types: T, E, J, K, R, S, B, N, C, and Linear mV

Input Impedance: 20 MΩ for all types

Lead Resistance Effect: 0.25 μV/Ω

Cold Junction Compensation: Less than ±1°C typical (1.5°C max) error

over ambient temperature range.

Resolution: 1° for types R, S, B and 1° or 0.1° for all other types

GENERAL SPECIFICATIONS

1. DISPLAY: 2 Line by 4-digit, LCD negative image transmissive with

backlighting.

Top (Process) Display: 0.3" (7.6 mm) high digits with red backlighting.

Bottom (Parameter) Display: 0.2" (5.1 mm) high digits with green

backlighting.

2. ANNUNCIATORS:

Status Annunciators:

O1 - Main control output is active.

O2 - Cooling output is active (when Alarm 2 is used for cooling).

A1 - Alarm 1 output is active.

A2 - Alarm 2 output is active.

°F, °C - Temperature units.

%PW - Output power percentage is shown in Bottom display.

MAN - Controller is in Manual Mode.

R - Ramping Setpoint indicator.

% - Percent indicator (CN63400 models only).

Display Messages:

OLOL - Measurement exceeds + sensor range

ULUL - Measurement exceeds - sensor range

OPEN - Open sensor is detected (CN63200 only)

SHrt - Shorted sensor is detected (RTD only)

SENS - Measurement exceeds controller limits (CN63400 only)

dddd - Display value exceeds + display range

-ddd - Display value exceeds - display range

3. POWER:

Line Voltage Models:

85 to 250 VAC, 50/60 Hz, 8 VA

Low Voltage Models:

DC Power: 18 to 36 VDC, 4 W

AC Power: 24 VAC, ±10%, 50/60 Hz, 7 VA

4. CONTROLS: Three rubber push buttons for modification and setup of

controller parameters. One additional button (F1) for user programmable

function. One external user input (models with alarms) for parameter lockout

or other user programmable functions.

5. MEMORY: Nonvolatile E

2

PROM retains all programmable parameters.

6. ISOLATION LEVEL:

AC power with respect to all other I/O: 250 V working (2300 V for 1 min.)

Sensor input to analog output: 50 V working (500 V for 1 minute)

Relay contacts to all other I/O: 300 V working (2300 V for 1 minute)

DC power with respect to sensor input and analog output: 50 V working

(500 V for 1 minute)

7. CERTIFICA TIONS AND COMPLIANCES:

SAFETY

UL Recognized Component, File #E123489, UL873, CSA 22.2 No. 24

Recognized to US and Canadian requirements under the Component

Recognition Program of Underwriters Laboratories, Inc.

Type 4X Enclosure rating (Face only), UL50

IEC 61010-1, EN 61010-1: Safety requirements for electrical equipment

for measurement, control, and laboratory use, Part I

IP65 Enclosure rating (Face only), IEC 529

ELECTROMAGNETIC COMPATIBILITY

Notes:

1. Self-recoverable loss of performance during EMI disturbance at 10 V/m:

Measurement input signal may deviate during EMI disturbance.

For operation without loss of performance:

Install one ferrite core one turn to I/O cables at unit.

2. Self-recoverable loss of performance during EMI disturbance at 10 Vrms:

Process and analog output signal may deviate during EMI disturbance.

For operation without loss of performance:

Install one ferrite core one turn to I/O cables and power cable at unit.

Refer to the EMC Installation Guidelines section of this bulletin for

additional information.

8. ENVIRONMENTALCONDITIONS:

Operating Temperature Range: 0 to 50°C

Storage Temperature Range: -40 to 80°C

Operating and Storage Humidity: 85% max relative humidity (non-

condensing) from 0°C to 50°C

Vibration According to IEC 68-2-6: 5 to 150 Hz, in X, Y, Z direction for

1.5 hours, 2 g’s.

Shock According to IEC 68-2-27: Operational 20 g (10 g relay), 11 msec

in 3 directions.

Altitude: Up to 2000 meters

9. CONNECTION: Wire-clamping screw terminals

10. CONSTRUCTION: Black plastic alloy case and collar style panel latch.

Panel latch can be installed for vertical or horizontal instrument stacking.

Black plastic textured bezel with transparent display window. Controller

meets NEMA 4X/IP65 requirements for indoor use when properly installed.

Installation Category II, Pollution Degree 2.

11. WEIGHT: 6.3 oz (179 g)

-200 to +750°C

-328 to +1382°F

N/AN/AN/A

-5.00 mV to

56.00 mV

mV

ASTM

E988-96

No

standard

No

standard

0 to +2315°C

+32 to +4199°F

C

W5/W6

ITS-90

(+) Orange

(-) Blue

(+) Orange

(-) Red

-200 to +1300°C

-328 to +2372°F

N

ITS-90

No

standard

No

standard

+149 to +1820°C

+300 to +3308°F

B

ITS-90

(+) White

(-) Blue

No

standard

0 to +1768°C

+32 to +3214°F

S

ITS-90

(+) White

(-) Blue

No

standard

0 to +1768°C

+32 to +3214°F

R

ITS-90

(+) Brown

(-) Blue

(+) Yellow

(-) Red

-200 to +1250°C

-328 to +2282°F

K

ITS-90

(+) Yellow

(-) Blue

(+) White

(-) Red

-200 to +760°C

-328 to +1400°F

J

ITS-90

(+) Brown

(-) Blue

(+) Violet

(-) Red

E

ITS-90

(+) White

(-) Blue

(+) Blue

(-) Red

-200 to +400°C

-328 to +752°F

T

BS 1843ANSI

STANDARD

WIRE COLOR

DISPLAYRANGETYPE

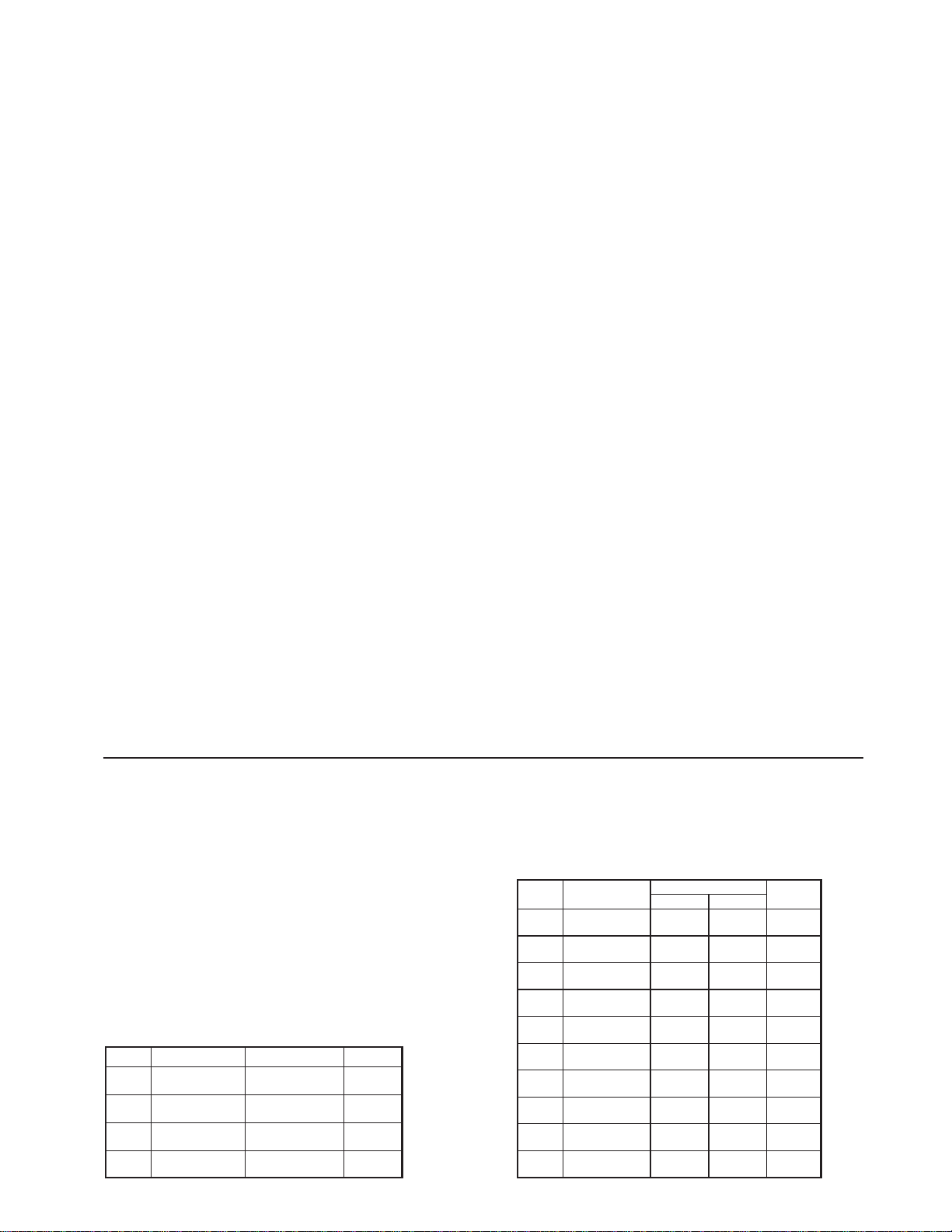

TYPE INPUT TYPE RANGE STANDARD

385

100 Ω platinum,

Alpha = .00385

-200 to +600°C

-328 to +1112°F

IEC 751

392

100 Ω platinum,

Alpha = .003919

-200 to +600°C

-328 to +1112°F

No official

standard

672

120 Ω nickel,

Alpha = .00672

-80 to +215°C

-112 to +419°F

No official

standard

Ohms Linear Resistance

0.0 to 320.0 Ω

N/A

Emissions to EN 50081-2

Enclosure class AEN 55011RF interference

150 KHz - 80 MHz

Level 3; 10 V/rms

2

EN 61000-4-6RF conducted interference

Level 3; 2 kV power

Level 4; 2 kV I/OEN 61000-4-4Fast transients (burst)

80 MHz - 1 GHz

Level 3; 10 V/m

1

EN 61000-4-3Electromagnetic RF fields

Level 2; 4 kV contact

Level 3; 8 kV air

EN 61000-4-2Electrostatic discharge

Immunity to EN 50082-2

Power mains class A

4

EMC INSTALLATION GUIDELINES

Although this controller is designed with a high degree of immunity to

Electromagnetic Interference (EMI), proper installation and wiring methods

must be followed to ensure electromagnetic compatibility (EMC) in each

application. The type of the electrical noise, source or coupling method into the

controller may be different for various installations. The controller becomes

more immune to EMI with fewer I/O connections. Cable length, routing, and

shield termination are very important and can mean the difference between a

successful or troublesome installation. Listed are some EMC guidelines for

successful installation in an industrial environment.

1. The controller should be mounted in a metal enclosure that is properly

connected to protective earth.

2. Use shielded (screened) cables for all Signal and Control inputs. The shield

(screen) pigtail connection should be made as short as possible. The

connection point for the shield depends somewhat upon the application.

Listed below are the recommended methods of connecting the shield, in order

of their effectiveness.

a. Connect the shield only at the panel where the controller is mounted to

earth ground (protective earth).

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is more than 1 MHz.

c. Connect the shield to common of the controller and leave the other end of

the shield unconnected and insulated from earth ground.

3. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors feeding motors, solenoids, SCR controls, and

heaters, etc. The cables should be run through metal conduit that is properly

grounded. This is especially useful in applications where cable runs are long

and portable two-way radios are used in close proximity or if the installation

is near a commercial radio transmitter.

4. Signal or Control cables within an enclosure should be routed as far away as

possible from contactors, control relays, transformers, and other noisy

components.

5. In extremely high EMI environments, the use of external EMI suppression

devices, such as ferrite suppression cores, is effective. Install them on Signal

and Control cables as close to the controller as possible. Loop the cable

through the core several times or use multiple cores on each cable for

additional protection. Install line filters on the power input cable to the

controller to suppress power line interference. Install them near the power

entry point of the enclosure. The following EMI suppression devices (or

equivalent) are recommended:

Ferrite Suppression Cores for Signal and Control cables:

Fair-Rite # 0443167251

TDK # ZCAT3035-1330A

Steward # 28B2029-0A0

Line Filters for input power cables:

Schaffner # FN610-1/07

Schaffner # FN670-1.8/07

Corcom # 1 VR3

Note: Reference manufacturer’s instructions when installing a line filter.

6. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

7. Switching of inductive loads produces high EMI. Use of snubbers across

inductive loads suppresses EMI.

OUTPUT SPECIFICATIONS

1. CONTROLAND ALARM OUTPUTS:

Relay Output:

Type: Form A

Contact Rating: 3 A @ 250 VAC or 30 VDC; 1/10 HP @ 120 VAC

(inductive load)

Life Expectancy: 100,000 cycles at max. load rating

(Decreasing load and/or increasing cycle time, increases life expectancy)

Logic/SSR Output (main control output only):

Rating: 45 mA max @ 4 V min., 7 V nominal

2. MAIN CONTROL:

Control: PID or On/Off

Output: Time proportioning or DC Analog

Cycle Time: Programmable

Auto-Tune: When selected, sets proportional band, integral time, derivative

time, and output dampening time. Also sets input filter and (if applicable)

cooling gain.

Probe Break Action: Programmable

3. ALARMS: (optional) 2 relay alarm outputs.

Modes:

None

Absolute High Acting (Balanced or Unbalanced Hysteresis)

Absolute Low Acting (Balanced or Unbalanced Hysteresis)

Deviation High Acting

Deviation Low Acting

Inside Band Acting

Outside Band Acting

Heat (Alarm 1 on Analog Output models only)

Cool (Alarm 2)

Reset Action: Programmable; automatic or latched

Standby Mode: Programmable; enable or disable

Hysteresis: Programmable

Sensor Fail Response: Upscale

Annunciator: “A1” and “A2” programmable for normal or reverse acting

4. COOLING: Software selectable (overrides Alarm 2).

Control: PID or On/Off

Output: Time proportioning

Cycle Time: Programmable

Proportional Gain Adjust: Programmable

Heat/Cool Deadband Overlap: Programmable

5. ANALOG DC OUTPUT: (optional)

Action: Control or retransmission

Update Rate: 0.1 to 250 sec

* Accuracies are expressed as ± percentages over 0 to 50 °C ambient range

after 20 minute warm-up.

** Outputs are independently jumper selectable for either 10 Vor 20 mA. The

output range may be field calibrated to yield approximately 5% overrange

and a small underrange (negative) signal.

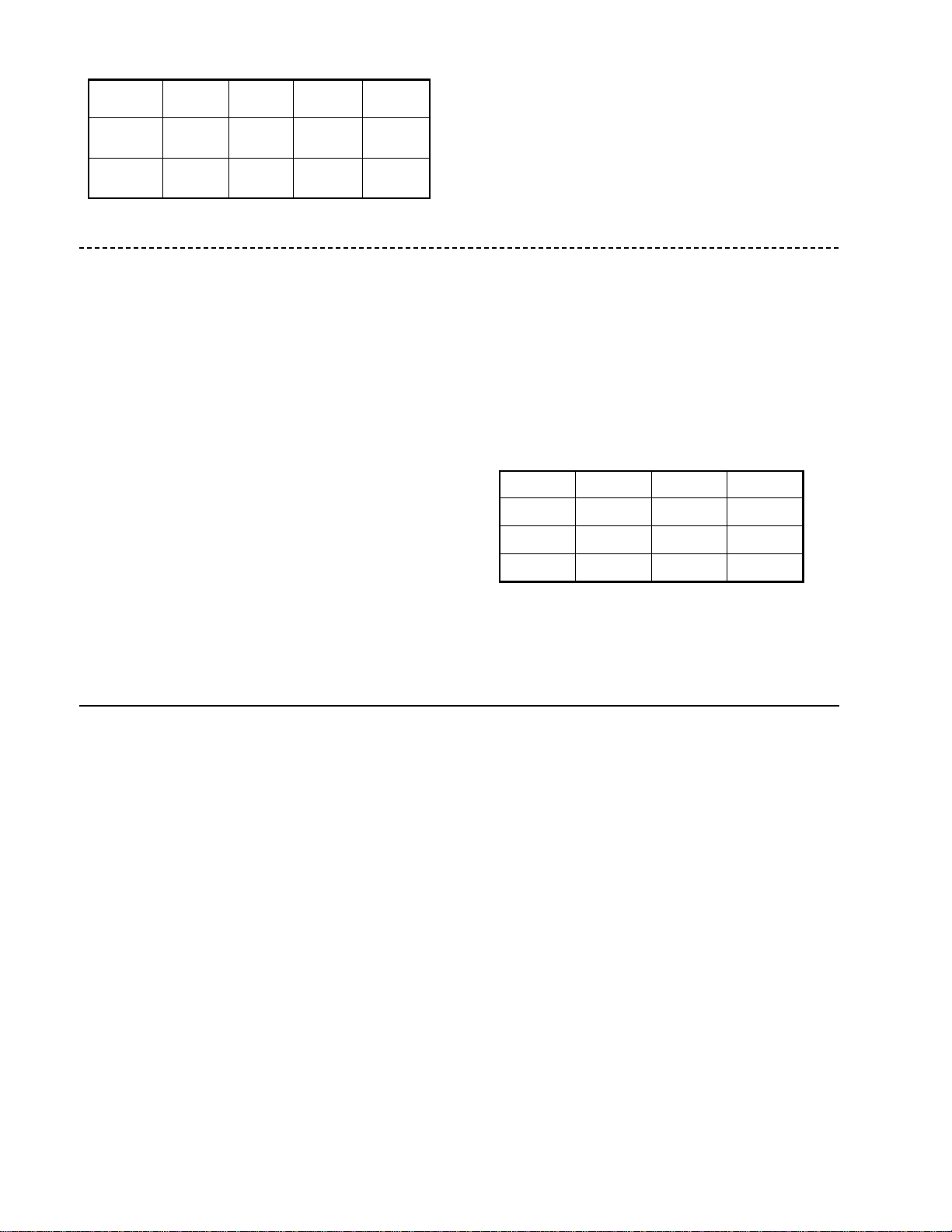

OUTPUT

RANGE **

ACCURACY * COMPLIANCE RESOLUTION

0 to 10 V

0.3% of FS

+ ½ LSD

10 kΩ min

1/8000

0 to 20 mA

0.3% of FS

+ ½ LSD

500 Ω max

1/8000

4 to 20 mA

0.3% of FS

+ ½ LSD

500 Ω max

1/6400

INPUT SPECIFICATIONS (Cont’d)

4. SIGNAL INPUT: (CN63400 only)

* Accuracies are expressed as ± percentages over 0 to 50 °C ambient range

after 20 minute warm-up.

5. TEMPERATURE INDICATION ACCURACY: (CN63200 only)

± (0.3% of span, +1°C) at 23 °C ambient after 20 minute warm up. Includes

NIST conformity, cold junction effect, A/D conversion errors and

linearization conformity.

Span Drift (maximum): 130 PPM/°C

6. USER INPUT: (Only controllers with alarms have a user input terminal.)

Internally pulled up to +7 VDC (100 KΩ), V

IN MAX

= 35 V, VIL= 0.6 V max,

VIH= 1.5 V min, I

OFF

= 40 μA max

Response Time: 120 msec max

Functions: Programmable

INPUT RANGE ACCURACY * IMPEDANCE RESOLUTION

10 VDC

(-1 to 11)

1 MΩ

50 V 10 mV

20 mA DC

(-2 to 22)

10 Ω

100 mA 10 µA

MAX

CONTINUOUS

OVERLOAD

0.30 % of

reading

+0.03V

0.30 % of

reading

+0.04mA

5

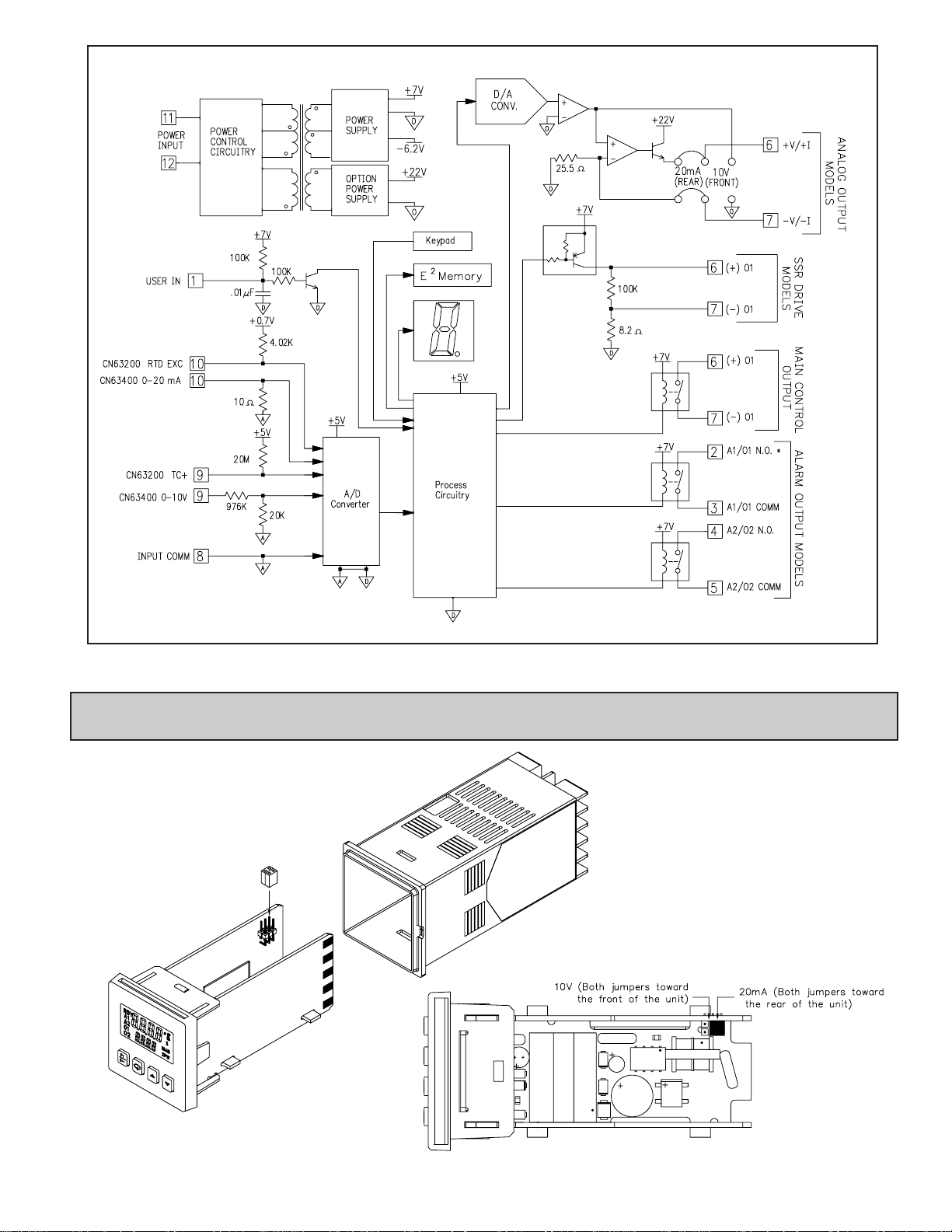

BLOCK DIAGRAM

*A1 becomes main control O1, if selected for heating in the

analog out models.

1.0 S

ETTING THE JUMPERS

(ANALOG O

UTPUT MODELS ONLY)

To insure proper operation, the Analog Output jumpers must be set to the

same range selected in programming Module 2-OP. The default jumper

setting is for 20 mA. The default setting in Module 2-OP is 4-20

mA. To access the jumpers, insert a flat-blade screwdriver

between the front panel and the side case slot. This should

disengage the top and bottom front panel latches

from the case grooves. Pull the front panel assembly

with the controller boards out of the

case. The jumpers are located

inside the controller on the left

board along the back top section.

VIEW FROM TOP OF UNIT

6

3.0 WIRING THE CONTROLLER

WIRING CONNECTIONS

All wiring connections are made to the rear screw terminals. When wiring the

controller, use the numbers on the label and those embossed on the back of the

case, to identify the position number with the proper function.

All conductors should meet voltage and current ratings for each terminal.

Also, cabling should conform to appropriate standards of good installation, local

codes and regulations. It is recommended that power (AC or DC) supplied to the

controller be protected by a fuse or circuit breaker. Strip the wire, leaving

approximately 1/4" (6 mm) bare wire exposed (stranded wires should be tinned

with solder). Insert the wire under the clamping washer and tighten the screw

until the wire is clamped tightly.

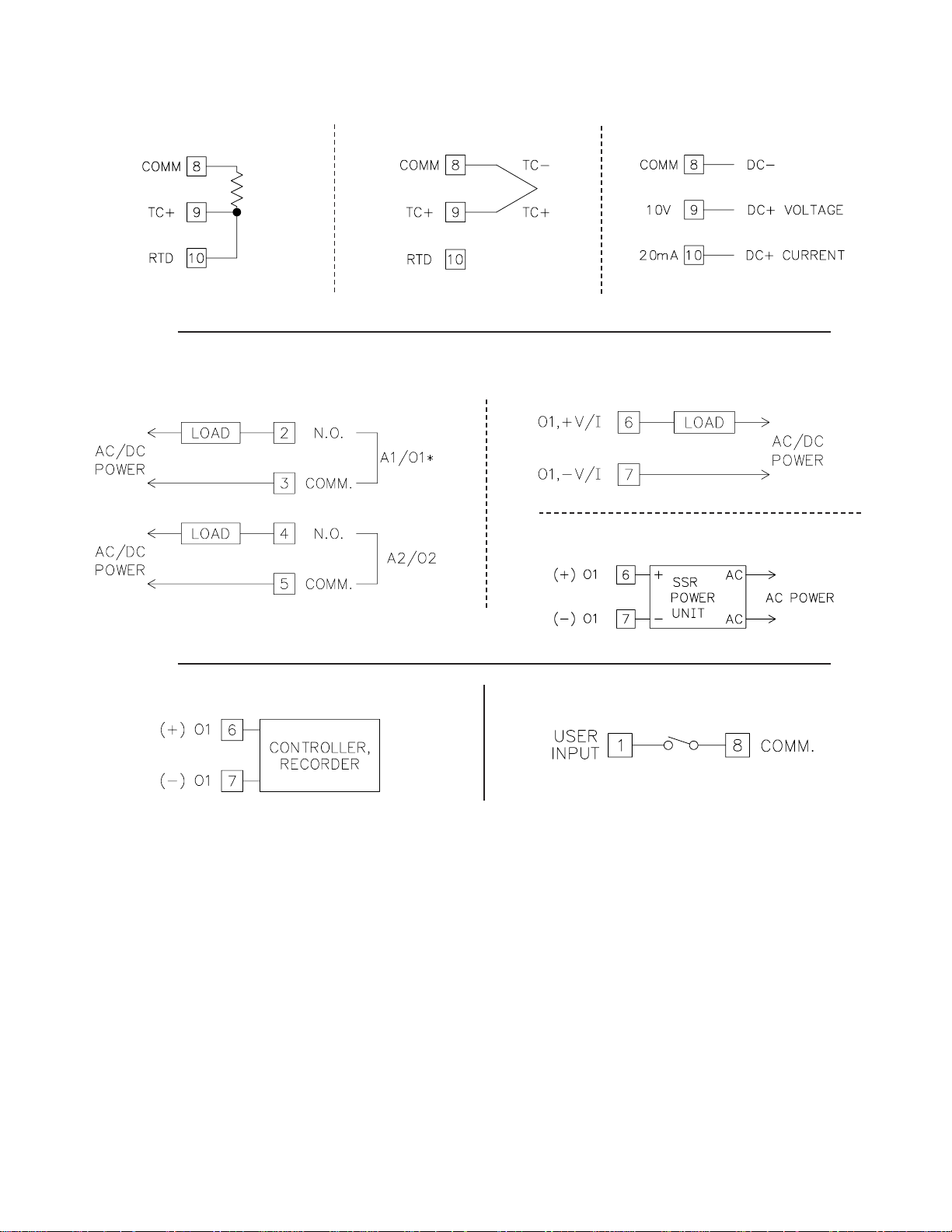

CONTROLLER POWER CONNECTIONS

For best results, the power should be relatively “clean” and within

the specified limits. Drawing power from heavily loaded circuits or

from circuits that also power loads that cycle on and off should be

avoided. It is recommended that power supplied to the controller be

protected by a fuse or circuit breaker.

VDC

VAC

2.0 INSTALLING THE CONTROLLER

The CN63200 and CN63400 controllers meet NEMA 4X/IP65 requirements

for indoor use to provide a watertight seal in steel panels with a minimum

thickness of 0.09", or aluminum panels

with a minimum thickness of 0.12".

The controllers are designed to be

mounted into an enclosed panel.

The bezel assembly must be in

place during installation of

the controller.

Instructions:

1. Prepare the panel cutout to the proper dimensions.

2. Remove the panel latch from the controller. Discard the cardboard sleeve.

3. Carefully remove the center section of the panel gasket and discard. Slide the

panel gasket over the rear of the controller, seating it against the lip at the

front of the case.

4. Insert the controller into the panel cutout. While holding the controller in

place, push the panel latch over the rear of the controller, engaging the tabs

of the panel latch in the farthest forward slot possible.

5. To achieve a proper seal, tighten the panel latch screws evenly until the

controller is snug in the panel, torquing the screws

to approximately 7 in-lb (79 N-cm).

Overtightening can result in distortion of the

controller, and reduce the effectiveness of the seal.

Note: The installation location of the controller is

important. Be sure to keep it away from heat

sources (ovens, furnaces, etc.) and away from

direct contact with caustic vapors, oils, steam, or

any other process by-products in which exposure

may affect proper operation.

Multiple Controller Stacking

The controller is designed to allow for close spacing of multiple controllers

in applications that do not require protection to NEMA 4X. Controllers can be

stacked either horizontally or vertically. For vertical stacking, install the panel

latch with the screws to the sides of the controller. For horizontal stacking, the

panel latch screws should be at the top and bottom of the controller. The

minimum spacing from centerline to centerline of controllers is 1.96" (49.8

mm). This spacing is the same for vertical or

horizontal stacking.

Note: When stacking

controllers, provide

adequate panel

ventilation to ensure

that the maximum

operating temperature

range is not exceeded.

7

INPUT CONNECTIONS

For two wire RTDs, install a copper sense lead of the same gauge and length

as the RTD leads. Attach one end of the wire at the probe and the other end to

input common terminal. Complete lead wire compensation is obtained. This is

the preferred method. If a sense wire is not used, then use a jumper. A

temperature offset error will exist. The error may be compensated by

programming a temperature offset.

CONTROL AND ALARM OUTPUT CONNECTIONS

RTD and Resistance Thermocouple and Millivolt

Voltage and Current

Alarm Models Main Control Relay Models

Main Control Logic/SSR Models

ANALOG DC OUTPUT CONNECTIONS

USER INPUT CONNECTIONS

*A1 becomes main control O1, if selected for

heating in the analog out models.

8

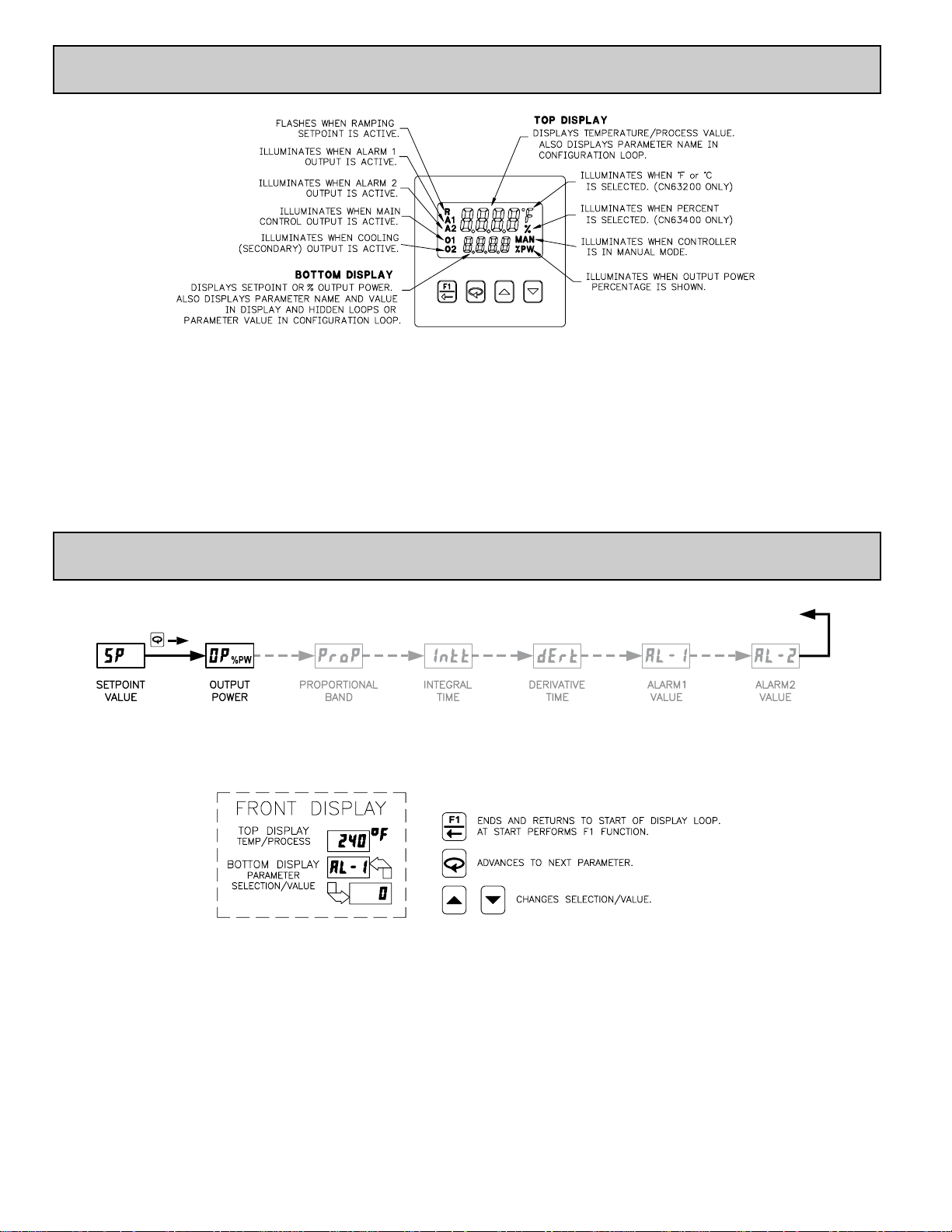

FRONT PANEL KEYS

The F1 key is pressed to exit (or escape) directly to the start of the

Display Loop. While in the Display Loop, the F1 key can be pressed to

activate its programmed function.

The Loop key is pressed to advance to the next parameter, to activate

a changed selection/value, and when held for three seconds, enter the

Hidden Loop.

The Arrow keys are used to scroll through parameter

selections/values and in the Configuration Loop they are used to

scroll to the appropriate Parameter Module.

4.0 REVIEWING THE FRONT KEYS AND DISPLAY

5.0 PROGRAMMING: DISPLAY LOOP

DISPLAY LOOP

Note: Setpoint and Output Power are the only parameters visible in the Display Loop with Factory Settings. The remaining parameters can

be selected for the Display Loop within Module 3.

Parameter availability is model and programming dependent.

DISPLAY LOOP

At power up, all display segments light, and then the programmed input type

and the controller’s software version will flash. Then the Temperature/Process

Value is shown in the top display, and the Setpoint Value is shown in the bottom

display. This is the Display Loop. If the Setpoint is hidden or locked, the Display

Loop will default to Output Power. If Output Power is also hidden or locked out,

the bottom display is blank. During programming, the F1 key can be pressed to

return the controller to this point. (Only in the Display Loop will the F1 key

perform the user function programmed in Input Module .)

When the is pressed the controller advances to the next parameter in the

Display Loop. Except for Setpoint and % Output Power, the bottom display

alternates between the parameter name and its selection/value. The arrow keys

are pressed to change the selection/value for the shown parameter. The new

selection/value is activated when the is pressed. Display Loop parameters

may be locked out or hidden in Lockout Module . Some parameters are

model and programming dependent.

9

SETPOINT VALUE (SP1) *

SETPOINT VALUE (SP2) *

-999 to 9999

0.0

OP

2.0

SP

% OUTPUT POWER *

-100 to 100.0

-999

to 9999

Typically, the controller is operating with the Setpoint value in the bottom

display. There is no annunciator nor parameter indication for Setpoint in the

Display Loop. The parameter name alternates with the setpoint value in the

Hidden Loop. The Setpoint value can be changed, activated and stored by

pressing the arrow keys. This is the only parameter that can be configured as

read only in the Display Loop, but read/write in the Hidden Loop. It is possible

to store a second Setpoint value that can be selected in the Hidden Loop, by the

F1 key or the user input. Both Setpoint values are limited by the Setpoint Low

and High Limits in Input Module .

The % Output Power is shown with the %PW annunciator. The parameter

name alternates with the % Output Power value in the Hidden Loop. While the

controller is in Automatic Mode, this value is read only. When the controller is

placed in Manual Mode, the value can be changed, activated and stored by

pressing the arrow keys. For more details on % Output Power, see Control

Mode Explanations.

ª

«

120

Intt

INTEGRAL TIME

0 to 9999 seconds

Integral action shifts the center point position of the proportional band to

eliminate error in the steady state. The higher the integral time, the slower the

response. The optimal integral time is best determined during PID Tuning. If

time is set to zero, the previous Integral output power value is maintained.

Offset Power can be used to provide Manual Reset.

ª

«

30

dErt

DERIVATIVE TIME

0 to 9999 seconds per repeat

Derivative time helps to stabilize the response, but too high of a derivative

time, coupled with noisy signal processes, may cause the output to fluctuate too

greatly, yielding poor control. Setting the time to zero disables derivative action.

ALARM 1 VALUE

-999 to 9999

On models with alarms, the value for Alarm 1 can be entered here. The value

is either absolute (absolute alarm types) or relative to the Setpoint value

(deviation and band alarm types.) When Alarm 1 is programmed for HEAt or

NonE, this parameter is not available. For more details on alarms, see Alarm

Module "-.

ª

«

0.0

OPOF

OUTPUT POWER OFFSET

When the Integral Time is set to zero and the controller is in the Automatic

Mode, this parameter will appear after % Output Power. It is also shown with

the %PW annunciator illuminated. The power offset is used to shift the

proportional band to compensate for errors in the steady state. If Integral Action

is later invoked, the controller will re-calculate the internal integral value to

provide “bumpless” transfer and Output Power Offset will not be necessary.

ª

«

4.0

ProP

PROPORTIONAL BAND

0.0 to 999.9

(% of full input range)

The proportional band should be set to obtain the best response to a process

disturbance while minimizing overshoot. A proportional band of 0.0% forces

the controller into On/Off Control with its characteristic cycling at Setpoint. For

more information, see Control Mode and PID Tuning Explanations.

* Alternating indication only used in the Hidden Loop.

ALARM 2 VALUE

-999 to 9999

On models with alarms, the value for Alarm 2 can be entered here. The value

is either absolute (absolute alarm types) or relative to the Setpoint value

(deviation and band alarm types.) When Alarm 2 is programmed for CooL or

NonE, this parameter is not available. For more details on alarms, see the Alarm

Module 4-AL.

The values shown for the displays are the factory settings.

CN63200

CN63400

ª

«

0

0.0

AL-1

CN63200

CN63400

ª

«

0

0.0

AL-2

CN63200

CN63400

0

0.0

SP

CN63200

CN63400

-100 to 100.0

Loading...

Loading...