Page 1

Single use soft brush (MAJ-1888)

MH-553 MH-438MH-443MB-358 MB-142MAJ-1119

MH-856

MH-944 MH-946

MAJ-1339

BW-20T

BW-201T

MH-948 BW-412T

MAJ-1888

INSTRUCTIONS

EVIS EXERA II DUODENOVIDEOSCOPE

OLYMPUS TJF TYPE Q180V

Accessories:

• Water resistant cap (MH-553) • Chain for water-resistant cap (MAJ-1119)

• Biopsy valve (MB-358) • Suction valve (MH-443)

• Air/water valve (MH-438) • Mouthpiece (MB-142)

• Suction cleaning adapter (MH-856) • Channel plug (MH-944)

• Channel cleaning brush (BW-20T) • Injection tube (MH-946)

• Single use channel cleaning brush (BW-201T) • Single use channel-opening cleaning brush (MAJ-1339)

• AW channel cleaning adapter (MH-948) • Single use combination cleaning brush (BW-412T)

• Single use soft brush (MAJ-1888)

Refer to the endoscope’s companion manual, the “OPERATION MANUAL” with your endoscope model

listed on the cover, for operation information.

USA: CAUTION: Federal law restricts this device to sale by or on the order of a physician.

Page 2

Revision History

Note: The Revision History shows the latest changes.

Version Date Description of Changes

RC2409 01 March, 2015 Cover

Section 1.4

Sections 2.10, 3.1, and 4.1

Section 4.2

Sections 4.3 and 5.1

Section 5.2

Section 5.3

Section 5.4

Section 5.5

Section 5.6

Chapter 7

GE8415 09 February,

2015

Single use soft brush (MAJ-1888) information.

Updated WARNING statements for MAJ-1888 and

using an AER.

Updated MAJ-1888 information.

Updated MAJ-1888 and AER information.

Updated MAJ-1888 information.

Updated “Aspirate water” section.

Updated “Detach the endoscope from the light

source” section.

Updated “Equipment needed” chart and CAUTION for

MAJ-1888, Step 5 on page 69, and added “Brush and

flush the forceps elevator recess” section.

Updated “Flush all channels and around the forceps

elevator with disinfectant solution” section.

Updated “Rinse the endoscope and accessories”

section; the “Alcohol flush” section.

Updated WARNING statements for AER.

Page 3

Contents

Contents

Chapter 1 General Policy ......................................................... 1

1.1 Instructions...................................................................................... 1

1.2 Importance of cleaning, disinfection, and sterilization..................... 2

1.3 Signal words ................................................................................... 2

1.4 Precautions ..................................................................................... 3

1.5 Reprocessing before the first use ................................................... 8

1.6 Reprocessing and storage after use ............................................... 9

1.7 Reprocessing before patient procedure.......................................... 9

Chapter 2 Function and Inspection of the Accessories for

Reprocessing........................................................... 10

2.1 Water resistant cap (MH-553)......................................................... 10

2.2 Channel plug (MH-944)................................................................... 12

2.3 Injection tube (MH-946) .................................................................. 14

2.4 Channel cleaning brush (BW-20T).................................................. 16

2.5 Suction cleaning adapter (MH-856) ................................................ 18

2.6 AW channel cleaning adapter (MH-948)......................................... 19

2.7 Single use channel cleaning brush (BW-201T)............................... 20

2.8 Single use channel-opening cleaning brush (MAJ-1339) ............... 22

2.9 Single use combination cleaning brush (BW-412T)........................ 24

2.10 Single use soft brush (MAJ-1888)................................................... 25

2.11 Chain for water-resistant cap (MAJ-1119) ...................................... 27

Chapter 3 Compatible Reprocessing Methods and

Chemical Agents .................................................... 28

3.1 Compatibility summary.................................................................... 28

3.2 Water (for reprocessing) ................................................................. 30

3.3 Detergent solution........................................................................... 31

3.4 Disinfectant solution........................................................................ 31

3.5 Rinse water ..................................................................................... 31

3.6 Alcohol ............................................................................................ 31

3.7 Ethylene oxide gas sterilization....................................................... 32

3.8 Steam sterilization (autoclaving) ..................................................... 33

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

i

Page 4

Contents

Chapter 4 Reprocessing Workflow for the Endoscope

and Accessories ...................................................... 35

4.1 Workflow for manually cleaning and disinfecting the endoscope

and accessories .............................................................................. 36

4.2 Workflow for cleaning and disinfecting the endoscope and

accessories using an AER .............................................................. 38

4.3 Workflow for manually cleaning and sterilizing the endoscope

and accessories .............................................................................. 40

Chapter 5 Reprocessing the Endoscope

(and related reprocessing accessories) ................ 42

5.1 Preparing the equipment for reprocessing ...................................... 44

5.2 Precleaning the endoscope and accessories.................................. 45

5.3 Leakage testing of the endoscope .................................................. 51

5.4 Manually cleaning the endoscope and accessories........................ 56

5.5 Manually disinfecting the endoscope and accessories ................... 80

5.6 Rinsing the endoscope and accessories following disinfection....... 86

5.7 Sterilizing the endoscope and accessories ..................................... 94

Chapter 6 Reprocessing the Accessories .............................. 96

6.1 Manually cleaning the accessories ................................................. 98

6.2 Manually disinfecting the accessories............................................. 101

6.3 Rinsing the accessories following disinfection ................................ 102

6.4 Sterilizing the accessories............................................................... 105

Chapter 7 Reprocessing Endoscopes and Accessories

using an Automated Endoscope Reprocessor..... 106

Chapter 8 Storage and Disposal .............................................. 108

8.1 Storing the disinfected endoscope and accessories ....................... 109

8.2 Storing the sterilized endoscope and accessories .......................... 111

8.3 Disposal .......................................................................................... 111

ii

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 5

Chapter 1 General Policy

1.1 Instructions

• This manual contains the cleaning, disinfection, and sterilization

methods recommended by Olympus for the endoscopes and

accessories listed on the front cover.

• This instruction manual contains essential information on reprocessing

endoscopes and accessories safely and effectively.

• Before reprocessing, thoroughly review this manual and the manuals for

the reprocessing equipment and chemicals that will be used for

reprocessing. Reprocess all the devices as instructed.

• Note that the complete instruction manual set for the endoscope and

accessories consists of this manual and the “OPERATION MANUAL”

with your endoscope model listed on the cover. Both manuals

accompanied the endoscope at shipment.

Chapter 1 General Policy

• Keep this manual and all related manuals in a safe and accessible

location (e.g., in the reprocessing area).

• If you have any questions or comments about any information in this

manual, or if a problem occurs while reprocessing that cannot be solved,

contact Olympus.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

1

Page 6

Chapter 1 General Policy

1.2 Importance of cleaning, disinfection, and

sterilization

The medical literature reports incidents of cross-contamination resulting from

improper cleaning, disinfection, or sterilization. It is strongly recommended that

all individuals engaged in reprocessing closely observe all instructions given in

this manual and the manuals for all ancillary equipment, and have a thorough

understanding of the following items:

• Professional health and safety policies of your hospital

• Instruction manuals for the endoscope, accessories, and all the other

reprocessing equipment

• Structure and handling of endoscope and accessories

• Handling of pertinent chemicals

When selecting appropriate methods and conditions for cleaning and disinfection

and sterilization, follow the policies at your institution, applicable national laws

and standards, and professional society guidelines and recommended practices,

in addition to the instructions given in this manual.

1.3 Signal words

The following signal words are used throughout this manual:

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also

be used to alert against unsafe practices or potential

equipment damage.

Indicates additional helpful information.

2

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 7

1.4 Precautions

Chapter 1 General Policy

• An insufficiently cleaned, disinfected, or sterilized endoscope

and/or accessories may pose an infection control risk to the

patients and/or operators who contact them.

• All disinfection methods (whether performed manually or by

an automated endoscope reprocessor), and all sterilization

methods (whether performed by ethylene oxide gas or

steam) require thorough prior cleaning of the instrument

being reprocessed. If the equipment is not adequately

cleaned prior to disinfection/sterilization, these processes will

be ineffective. Immediately after each patient procedure and

before disinfection/sterilization, thoroughly clean the

endoscope and the accessories used with the endoscope.

• All channels of the endoscope, including the instrument

channel and all accessories used with the endoscope during

the patient procedure, such as all valves, must be cleaned

and high-level disinfected or sterilized after each patient

procedure, even if the channels or accessories were not

used during the patient procedure. Insufficient cleaning and

disinfection or sterilization of these components may pose an

infection control risk to patients and/or operators.

• Disinfectant solutions are hazardous. After disinfection, rinse

all external surfaces and channels of the endoscope and

accessories thoroughly with water to remove residual

disinfectant solution.

• The results of sterilization depend on various factors. These

factors include how the equipment was packaged, and the

placing and loading of the package in the sterilization device.

Verify the sterilization process using biological and/or

chemical indicators. Follow the guidelines for sterilization

issued by national authorities, professional organizations and

infection control professionals, as well as the instruction

manual for the sterilization device.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

3

Page 8

Chapter 1 General Policy

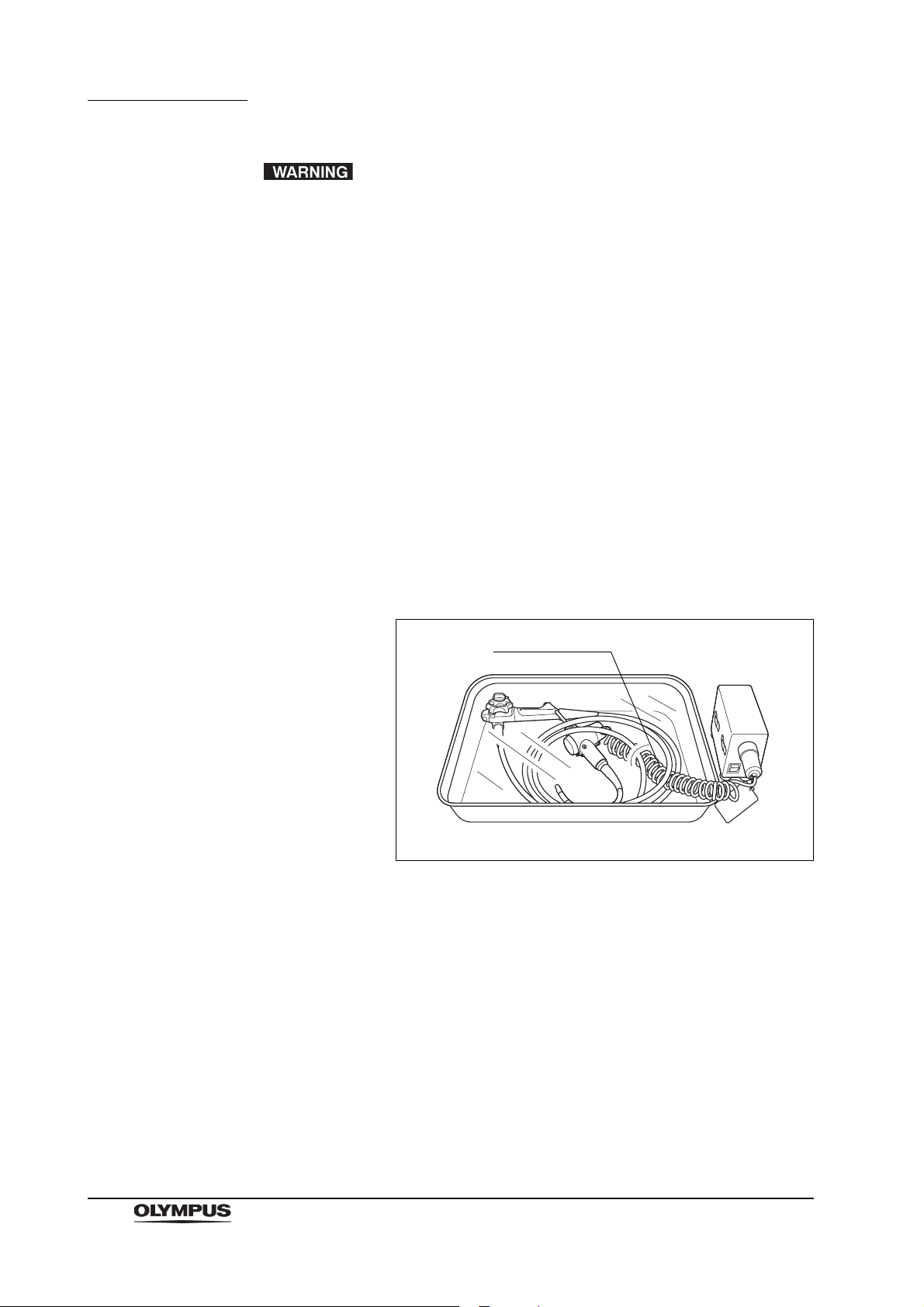

Leakage tester

• Establish an internal system of identifying contaminated

versus reprocessed endoscopes and accessories to prevent

both mix-ups and cross-contamination. Touching a

reprocessed endoscope and/or accessories with

contaminated gloves or placing them on a contaminated

hanger or surface, including letting them touch the floor, will

recontaminate them.

• Prior to each patient procedure, confirm that the endoscope

and accessories have been properly reprocessed and stored.

If there are any doubts or questions, reprocess them again

before the patient procedure, following the instructions given

in this manual.

• Perform a leakage test on the endoscope after each

precleaning procedure. Do not use the endoscope if a leak is

detected. Use of an endoscope with a leak may cause a

sudden loss of the endoscopic image, damage to the

bending mechanism, or other malfunctions. Use of a leaking

endoscope may also pose an infection control risk.

4

Figure 1.1

• Store alcohol in an airtight container. Alcohol stored in an

open container may cause a fire hazard and may result in a

loss of efficacy due to evaporation.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 9

Chapter 1 General Policy

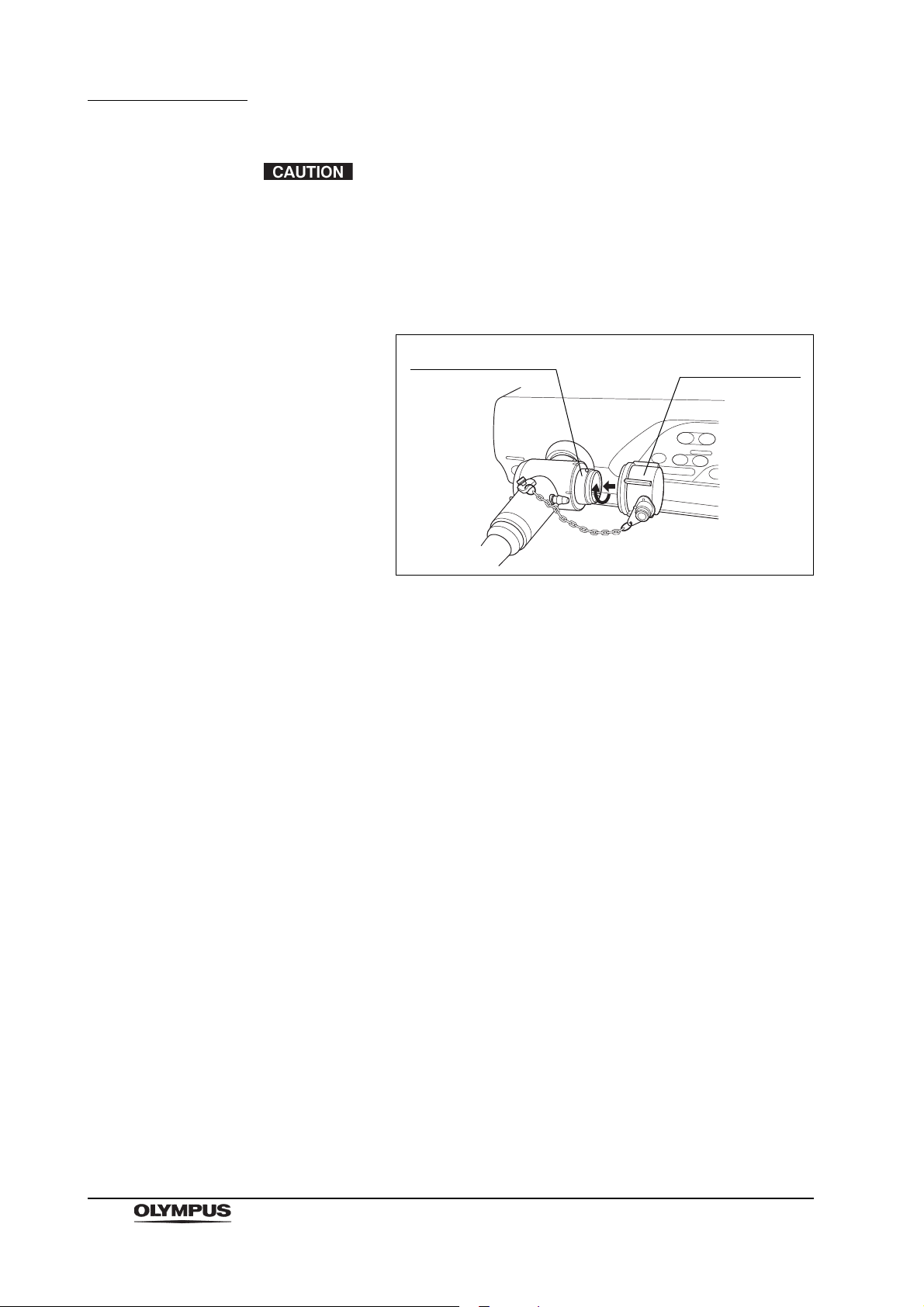

AW channel cleaning

adapter (MH-948)

• Do not use the AW channel cleaning adapter (MH-948) for

patient procedures. It will cause continuous insufflation and

could result in patient injury.

Figure 1.2

• The accessories listed on the front cover of this manual are

consumables, meaning that these accessories cannot be

refurbished or repaired and are intended to be replaced once

they show any signs of wear. Should any irregularity be

observed, use a replacement accessory instead. Using

defective accessories may cause equipment malfunction,

reduce the efficacy of reprocessing, present a risk to patients

and/or operators, or damage the endoscope and/or

accessories.

• Single-use brushes, such as the single use channel cleaning

brush (BW-201T), the single use combination cleaning brush

(BW-412T), the single use channel-opening cleaning brush

(MAJ-1339), and the single use soft brush (MAJ-1888), are

designed for cleaning only one endoscope and its related

accessories. Dispose of the single-use brush immediately

after use. Using a single-use brush to clean multiple

endoscopes and/or accessories may reduce its cleaning

efficacy and may damage the brush leading to brush

breakage or endoscope and/or accessory damage.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

5

Page 10

Chapter 1 General Policy

• Patient debris and reprocessing chemicals are hazardous.

To guard against contact with dangerous chemicals and

potentially infectious material, wear appropriate personal

protective equipment during cleaning, disinfection, and

sterilization. Such protective equipment should include

appropriate eyewear, face mask, cap, moisture-resistant

clothing, shoe covers, and chemical-resistant gloves that fit

properly and are long enough to prevent skin exposure.

• The reprocessing room must be adequately ventilated.

Adequate ventilation protects against the buildup of toxic

chemical fumes.

• Always remove contaminated personal protective equipment

before leaving the reprocessing area to prevent

contamination from spreading.

• Only Olympus-recommended or Olympus-endorsed

automated endoscope reprocessors (AERs) have been

validated by Olympus. When using an AER that is not

recommended by Olympus, the manufacturer of the AER is

responsible for validating compatibility of the AER with each

Olympus endoscope and accessory.

• Before using an AER, confirm that it is capable of

reprocessing the endoscope including all channels, the

forceps elevator recess, and accessories. Be sure to attach

all required connectors. Otherwise, insufficient reprocessing

may pose an infection control risk. If you are uncertain as to

the ability of your AER to reprocess the endoscope including

all channels, the forceps elevator recess, and accessories,

contact the manufacturer of the AER for specific instructions

and information on compatibility and required connectors.

When you use an AER which allows you skip some steps in

precleaning and manual cleaning of endoscopes, confirm

with the AER manufacturer that such skip is applicable to this

endoscope and establish detailed precleaning and manual

cleaning procedures of this endoscope according to both

instructions of this manual and the AER manufacturer.

• Put the forceps elevator in intermediate position of the range

of movement by turning the elevator control lever and set it in

your AER.

6

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 11

Chapter 1 General Policy

• Instructions provided in this manual are not valid for Olympus

devices repaired by a non-Olympus facility. The Olympus

recommended reprocessing procedures have not been

validated for reprocessing devices repaired by a

non-Olympus facility. In the event that your device has been

repaired by a non-Olympus facility, contact that repair facility

for instructions regarding reprocessing.

• Prions, which are the pathogenic agent of the

Creutzfeldt-Jakob disease (CJD), cannot be destroyed or

inactivated by the cleaning, disinfection, and sterilization

methods stated in this instruction manual. When using the

endoscope and accessories on patients with CJD or variant

Creutzfeldt-Jakob disease (vCJD), be sure to use them for

such patients only, or immediately dispose of them after use

in an appropriate manner to prevent the usage of exposed

devices on other patients. For methods to handle CJD, follow

the respective guidelines in your country.

• The endoscope and accessories may be damaged by

published methods for destroying or inactivating prions. For

information on the durability of Olympus equipment against a

particular reprocessing method, contact Olympus. In general,

Olympus cannot guarantee the effectiveness, safety, and

durability of cleaning, disinfection, or sterilization methods

not described in this reprocessing manual. If you chose to

use a reprocessing method not recommended in this manual,

the local institution and/or physicians must assume

responsibility for its safety and efficacy. Make sure to

carefully inspect each piece of endoscopic equipment for

irregularities (damage) prior to each patient procedure. Do

not use the equipment if any irregularity is found.

• Good quality control practices typically require appropriate

documentation. Items such as local SOPs (standard

operating procedures), confirmation of operator training,

routine testing of the disinfectant’s MEC (minimal effective

concentration), confirmation of the disinfectant’s use-life,

etc., should be documented as performed.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

7

Page 12

Chapter 1 General Policy

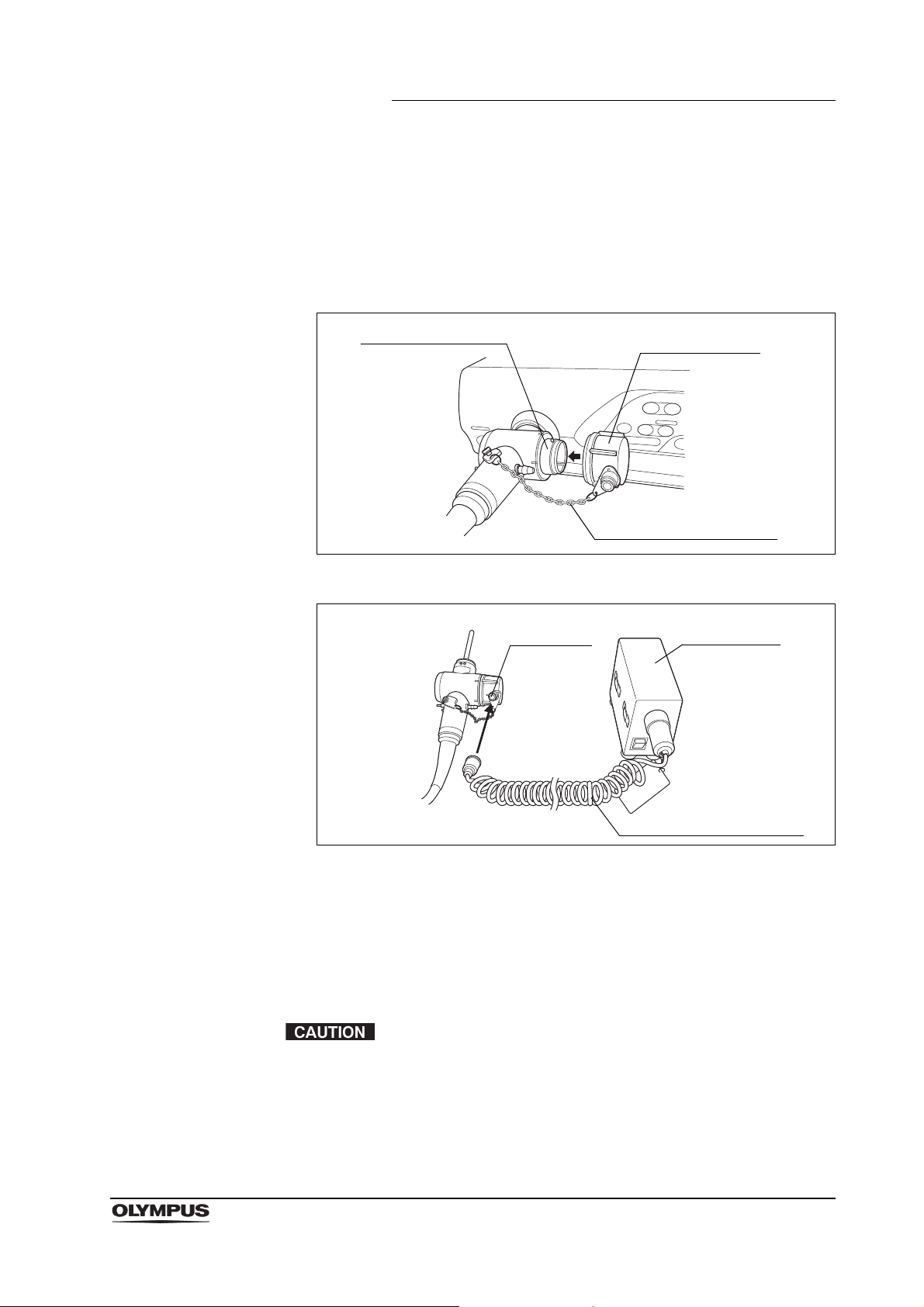

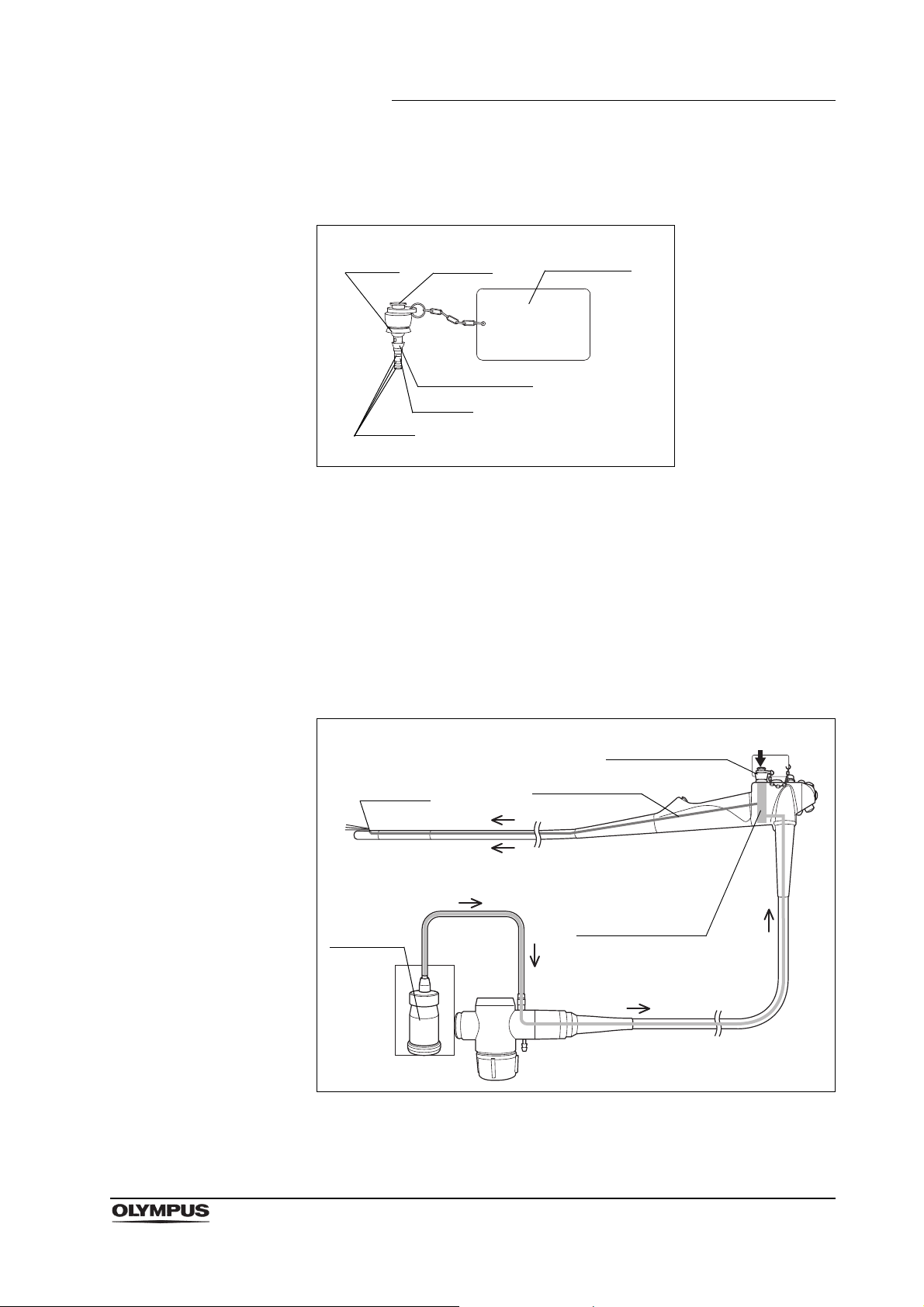

Water resistant

cap (MH-553)

Electrical connector

• When reprocessing the endoscope, confirm that the water

resistant cap (MH-553) is securely attached to the electrical

connector before immersing the endoscope in reprocessing

fluids. If the water resistant cap is not securely attached, the

reprocessing fluids could enter the endoscope and damage

the endoscope.

1.5 Reprocessing before the first use

Figure 1.3

• When aerating or irrigating the endoscope channels, the air

or water pressure must not exceed 0.5 MPa (5 kgf/cm

71 psig). Higher pressures may cause damage to the

endoscope.

• Store spare accessories in their original packaging to prevent

damage.

• To prevent damage, do not apply excessive force to the

endoscope and accessories during reprocessing.

• Vapors from disinfectant solutions and alcohol may damage

electronic devices such as computers.

New endoscopes, repaired endoscopes, accessories, and the carrying case for

endoscopes are not cleaned, disinfected, or sterilized prior to shipping from

Olympus, regardless of whether those instruments are for new purchase, demo

or loaner purposes. Reprocess all such endoscopes and accessories received

from Olympus according to the instructions given in this manual before storage

and before using them in a patient procedure.

2

,

8

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 13

1.6 Reprocessing and storage after use

• Do not reuse rinse water.

• High-level disinfectant solutions are only effective when used

according to the disinfectant manufacturer’s instructions.

Follow the manufacturer’s instructions regarding activation (if

required), concentration, temperature, contact time and use

life required to achieve high-level disinfection.

• If the disinfectant solution is reused, check its efficacy with a

test strip according to the disinfectant manufacturer’s

recommendations prior to use.

• Do not reuse alcohol.

• Alcohol is not a sterilant or high-level disinfectant.

• To maintain sterility of equipment following sterilization, use

sterile packaging and wraps according to national guidelines.

Chapter 1 General Policy

1.7 Reprocessing before patient procedure

• Improper storage practices, such as not thoroughly drying

external and internal surfaces (lumens) including the forceps

elevator recess prior to storage, will lead to an infection

control risk.

• Improper handling, such as touching a reprocessed

endoscope and/or accessories with contaminated gloves,

placing a reprocessed device on a contaminated hanger or

surface, allowing devices to touch the floor, etc., will

recontaminate the device.

Some national or professional guidelines recommend

reprocessing endoscopes prior to their first use of the day.

Confirm that the endoscope and accessories have undergone proper

reprocessing following their last use and that they have been stored properly.

Check the storage period of reprocessed endoscopes, and check for surface

contamination (e.g., dust). Check the sterilization expiration date(s) of all items

so marked and for tears or breaches in sterile packaging. If there are any doubts

or questions concerning whether a device is contaminated, reprocess it again

following the instructions given in this manual.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

9

Page 14

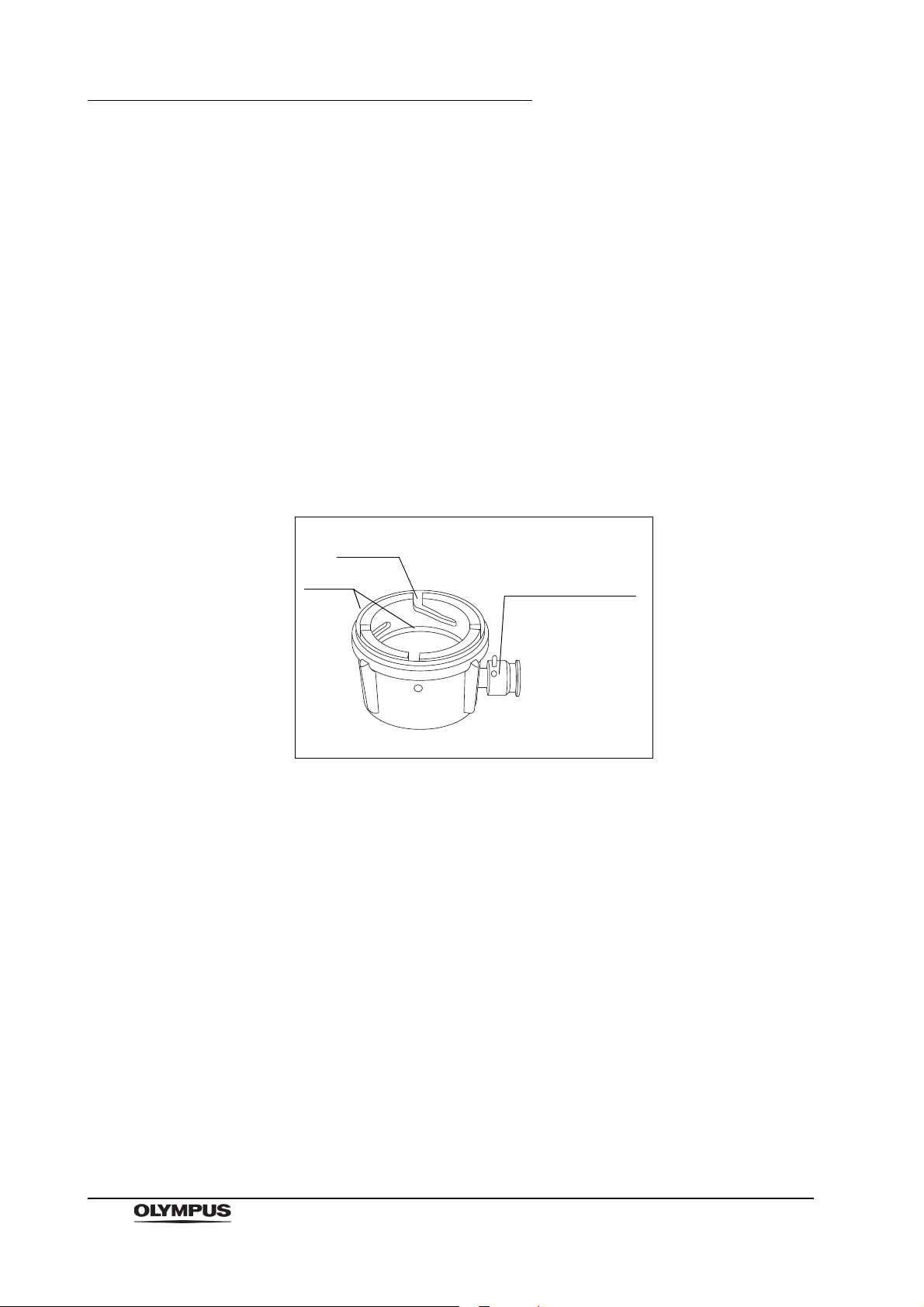

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Groove

Venting connector

Seals

Chapter 2 Function and Inspection of

the Accessories for

Reprocessing

Certain accessories are required for reprocessing the endoscope. This chapter

describes the function of these accessories. It also describes how to inspect

these accessories before using them to reprocess the endoscope.

2.1 Water resistant cap (MH-553)

10

Figure 2.1

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 15

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Water resistant

cap (MH-553)

Chain for water-resistant

cap (MAJ-1119)

Electrical connector

Maintenance

unit (MU-1)

Venting

connector

Leakage tester (MB-155)

Function

The water resistant cap is attached to the electrical connector on the endoscope

to protect the connector and the endoscope from water penetration during

reprocessing. During leakage testing, the leakage tester (MB-155) is attached to

the venting connector of the water resistant cap.

Figure 2.2

Figure 2.3

The water resistant cap must be attached to the electrical connector of the

endoscope whenever the endoscope is immersed in reprocessing fluids. It is

detached from the connector whenever the endoscope is used for patient

procedures, being sterilized by ethylene oxide gas, or stored in an endoscope

storage cabinet.

Always use a dry water resistant cap. Any water remaining

inside the cap may cause damage to the endoscope.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

11

Page 16

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Biopsy valve cap

Plug frame

Suction plug

Air/water plug

Use the chain for water-resistant cap (MAJ-1119) to connect

the water resistant cap to the endoscope. The water resistant

cap can remain connected to the endoscope by the chain at

all times (including during patient procedures, reprocessing,

and storage of the endoscope).

Inspection

1. Confirm that the inside of the cap is dry and free from debris. Wipe with a

dry, lint-free cloth if the inside of the cap is wet or if debris is detected.

2. Confirm that the seals inside the cap are free from scratches, cuts, and

debris.

3. Check to ensure that the venting connector on the cap is not loose.

2.2 Channel plug (MH-944)

Figure 2.4

12

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 17

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Instrument

channel port

Channel plug

Function

The channel plug is used to plug the openings of the instrument channel port

and the suction and air/water cylinders of the endoscope whenever the injection

tube (MH-946) is used to flush the suction and air/water channels of the

endoscope with reprocessing fluids.

Figure 2.5

When attached to the endoscope, the channel plug is

designed to allow a small amount of fluid to exit from the

openings of the endoscope. This enables reprocessing fluids

to contact the endoscope openings.

Inspection

Confirm that the suction plug, air/water plug, and the biopsy valve cap of the

channel plug are free from cracks, scratches, and debris.

The channel plug does not need to be cleaned, disinfected,

or sterilized prior to its first use.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

13

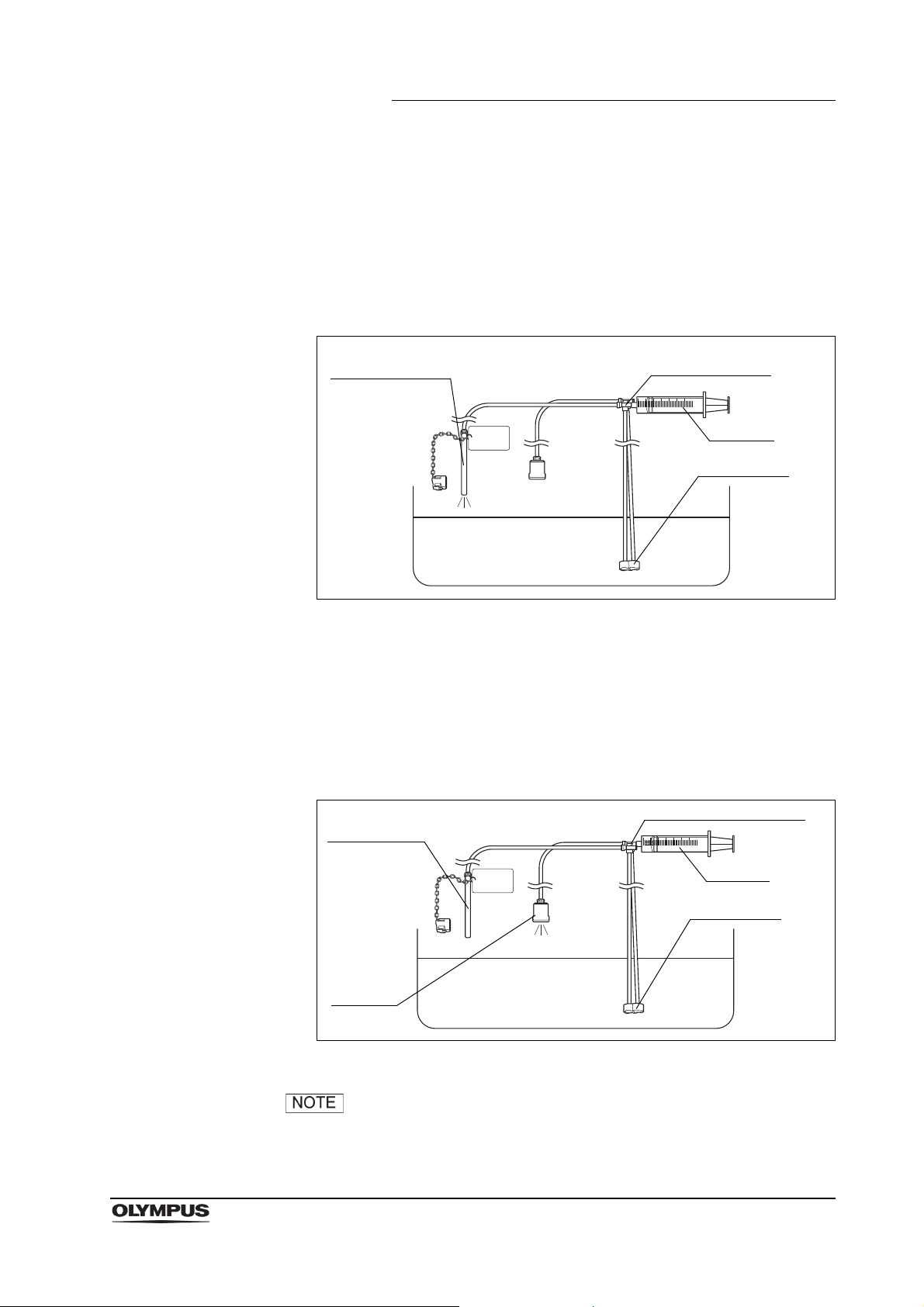

Page 18

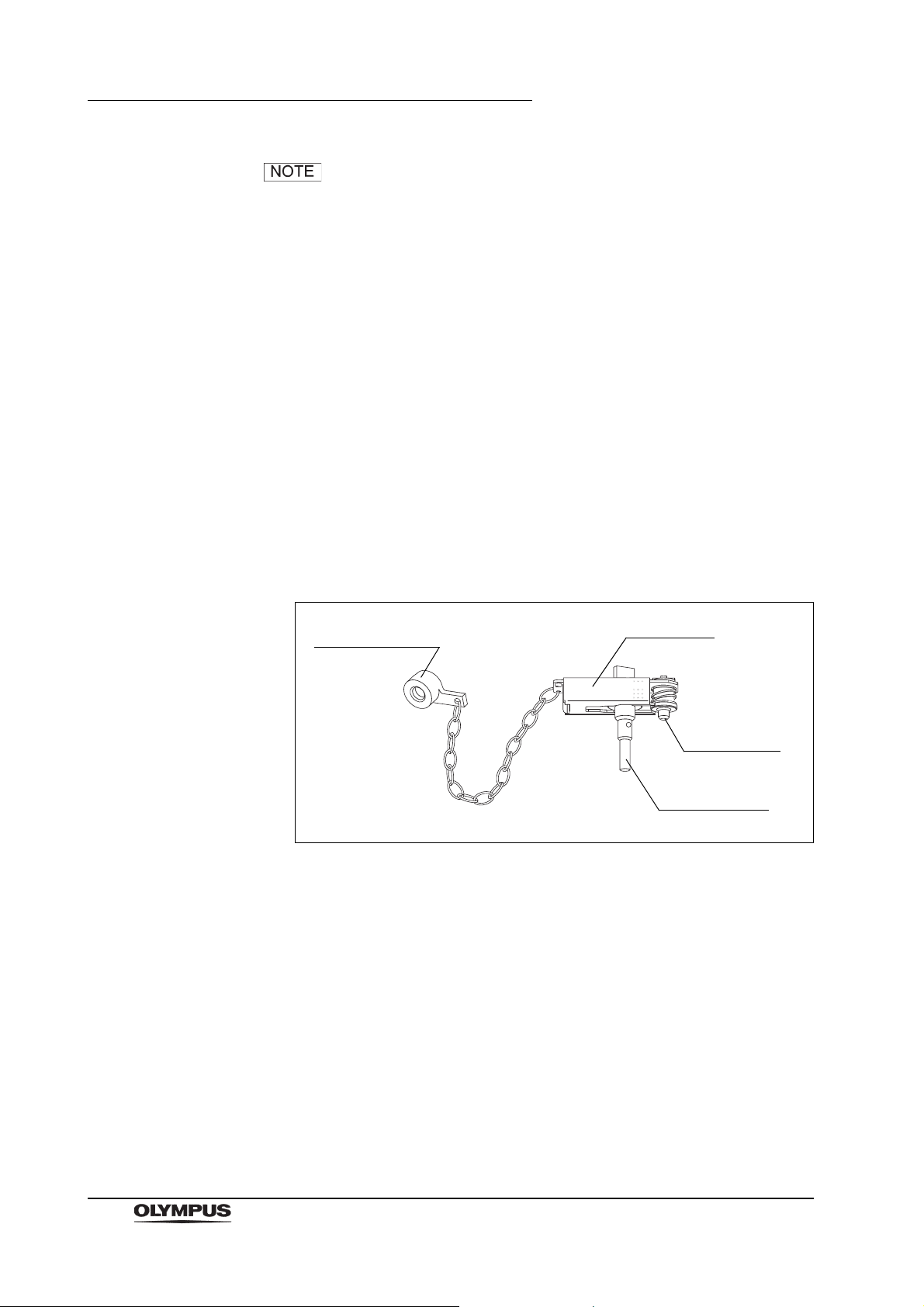

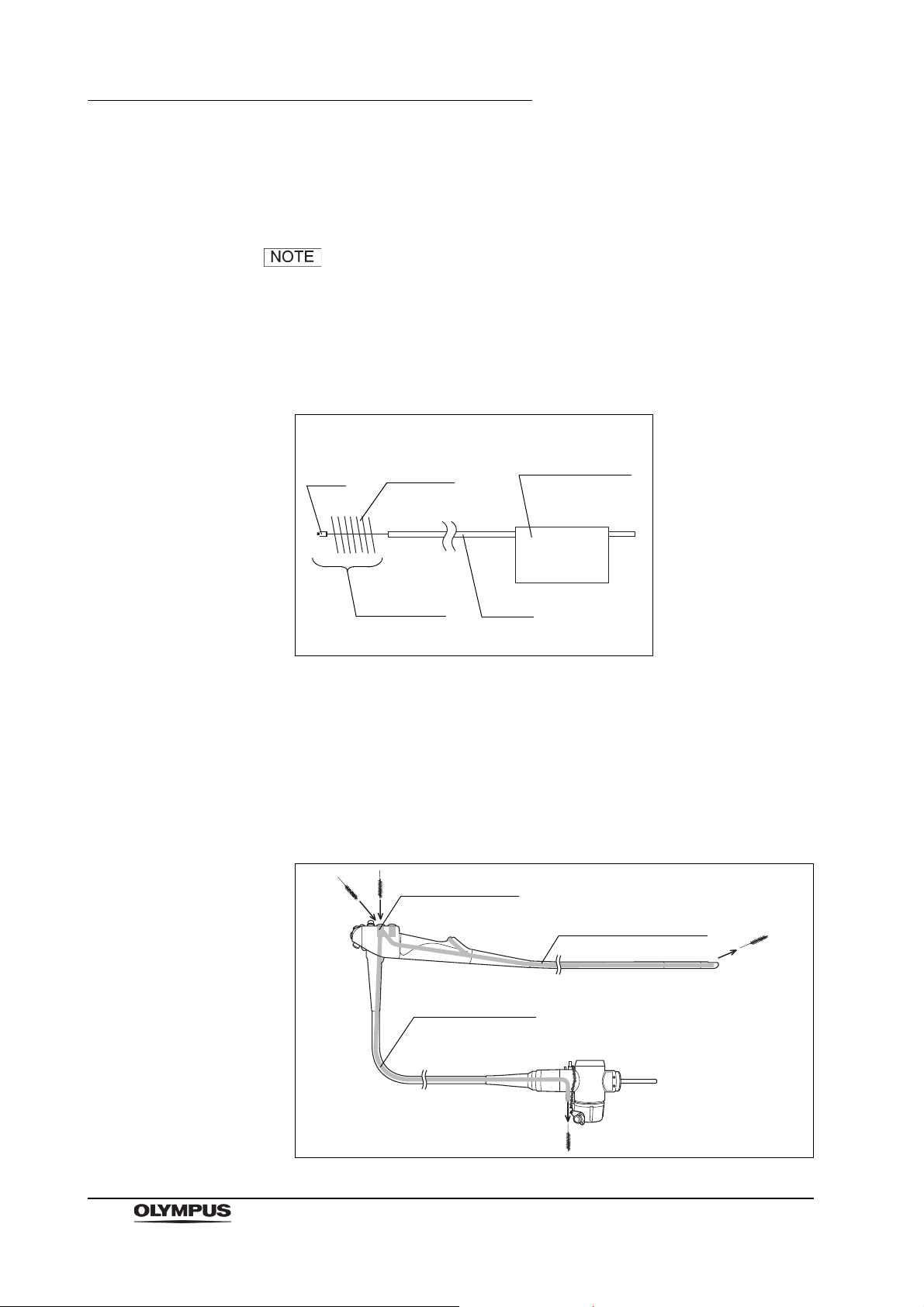

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Suction channel tube

Information

card

Connector plug

Suction

channel port

Air pipe port

Air/water

channel port

Suction port

Air/water channel tube

(including the filter mesh)

Filter tube

Filter mesh

Syringe

Air/water channel tube

Suction channel tube

Air pipe port

Suction port

Basin

Reprocessing

fluids

Connector plug

2.3 Injection tube (MH-946)

Figure 2.6

Function

The injection tube is used to inject reprocessing fluids into the instrument

channel, suction channel, and air/water channels of the endoscope. It is also

used to flush air through these channels to expel fluids.

Figure 2.7

Inspection

14

1. Confirm that all components of the injection tube are free from cracks,

scratches, flaws, and debris (see Figure 2.6).

2. Confirm that the filter mesh is in the suction port of the injection tube.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 19

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Suction port

Suction channel

port

Suction channel

tube

Syringe

Suction port

Air/water channel port

Air pipe

port

Suction

channel tube

Syringe

3. Attach a clean 30 ml syringe to the suction channel port of the injection tube.

With the suction port of the injection tube immersed in the water referred to

in Section 3.2, withdraw the syringe plunger and confirm that the water is

drawn into the syringe. Depress the plunger and confirm that the water is

emitted from the suction channel tube of the injection tube. Confirm that the

water is not emitted from the suction port when removing the suction port

from the water.

Figure 2.8

4. Move the syringe to the air/water channel port of the injection tube. With the

suction port of the injection tube immersed in the water, withdraw the

syringe plunger and confirm that the water is drawn into the syringe.

Depress the plunger and confirm that the water is emitted from the air pipe

port of the injection tube. Confirm that the water is not emitted from the

suction port when removing the suction port from the water.

Figure 2.9

The injection tube does not need to be cleaned, disinfected,

or sterilized prior to its first use.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

15

Page 20

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Metal tip

Shaft

Brush head

Bristles

Suction cylinder

Instrument channel

Suction channel

2.4 Channel cleaning brush (BW-20T)

Figure 2.10

Function

The channel cleaning brush is used to brush the inside of the instrument channel

and suction channel of the endoscope, and the interior and openings of the

suction valve (MH-443), the air/water valve (MH-438) and the biopsy valve

(MB-358).

Figure 2.11

16

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

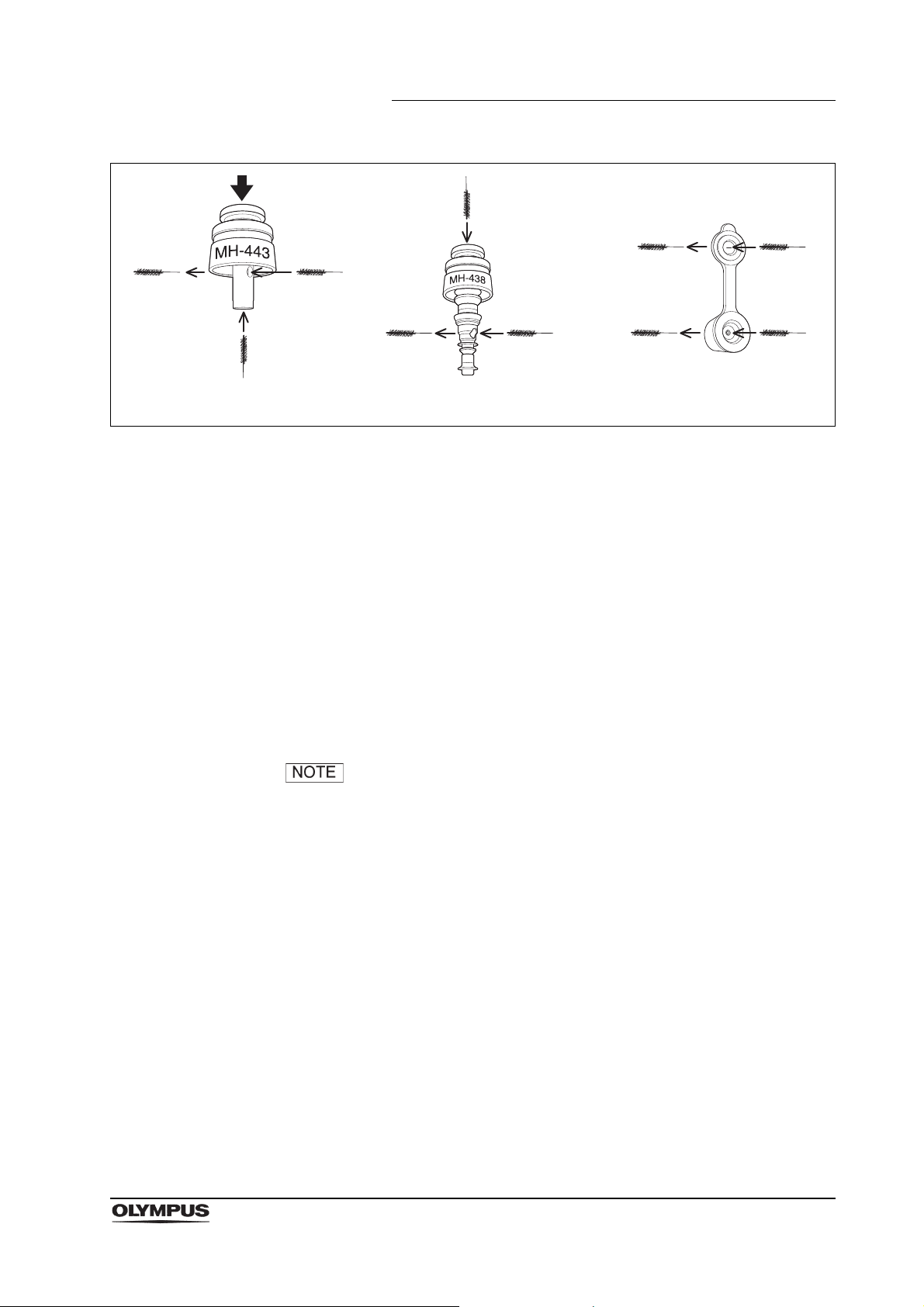

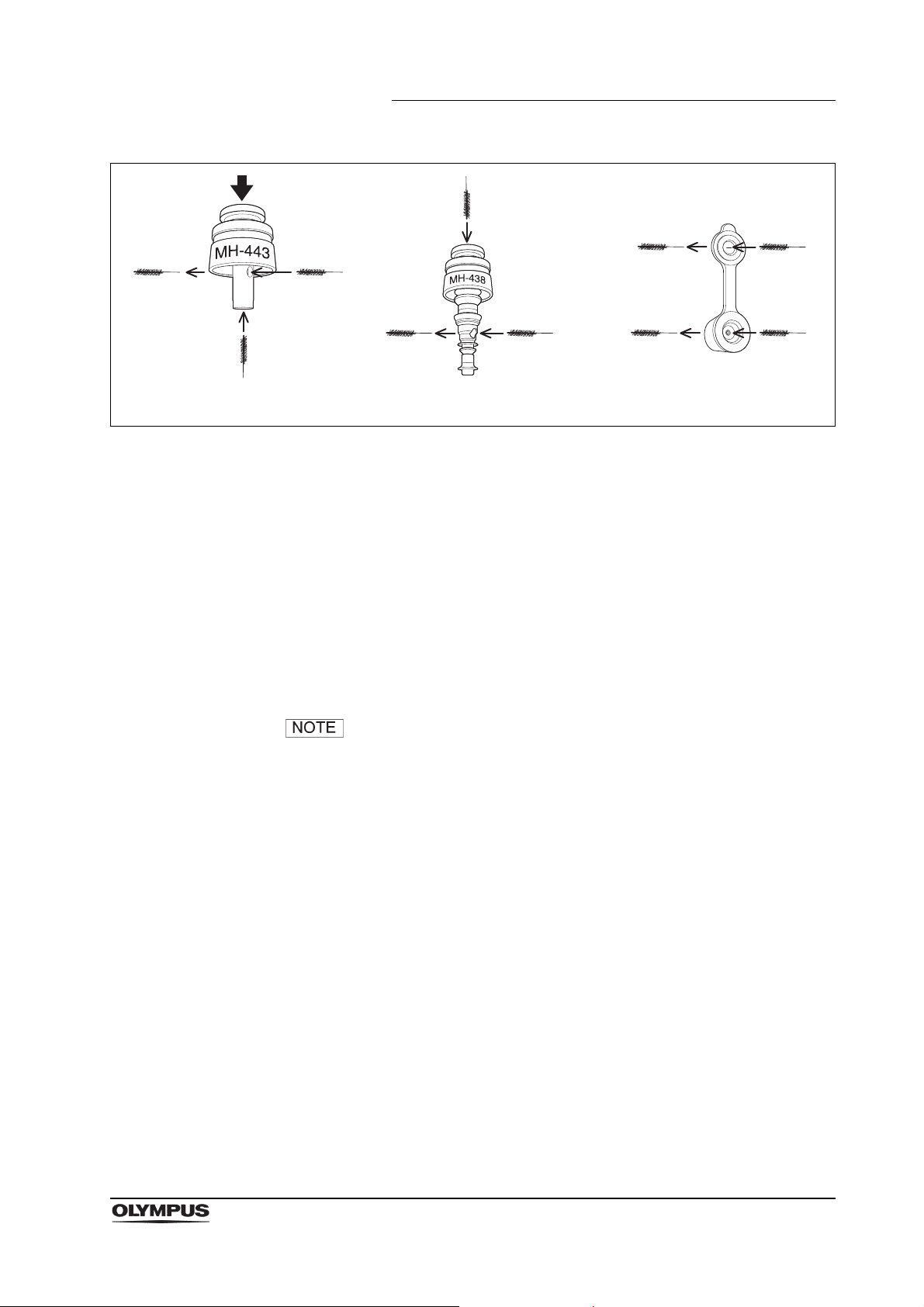

Page 21

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Depress

Suction valve

(MH-443)

Air/water valve

(MH-438)

Biopsy valve (MB-358)

Figure 2.12

Inspection

1. Confirm that the brush head and the metal tip of the distal end are securely

attached. Check the brush head for loose or missing bristles.

2. Check the bristles for damage. If the bristles are crushed, gently straighten

them with your gloved fingertips.

3. Check for bends, scratches, and other damage to the shaft.

4. Visually check for debris on the shaft and/or the bristles of the brush head. If

there is debris on the brush, immerse the brush in the water referred to in

Section 3.2 and clean the brush until no debris is observed on the brush.

The channel cleaning brush does not need to be cleaned,

disinfected, or sterilized prior to its first use.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

17

Page 22

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Weighted end

Connecting end

Suction cleaning

adapter

Connecting end

Weighted end

Suction pump

Instrument

channel port

Suction cylinder

2.5 Suction cleaning adapter (MH-856)

Figure 2.13

Function

The suction cleaning adapter is used to aspirate reprocessing fluids through the

instrument channel port of the endoscope.

Figure 2.14

18

Inspection

Check for debris, cracks, scratches, and other damage.

The suction cleaning adapter does not need to be cleaned,

disinfected, or sterilized prior to its first use.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 23

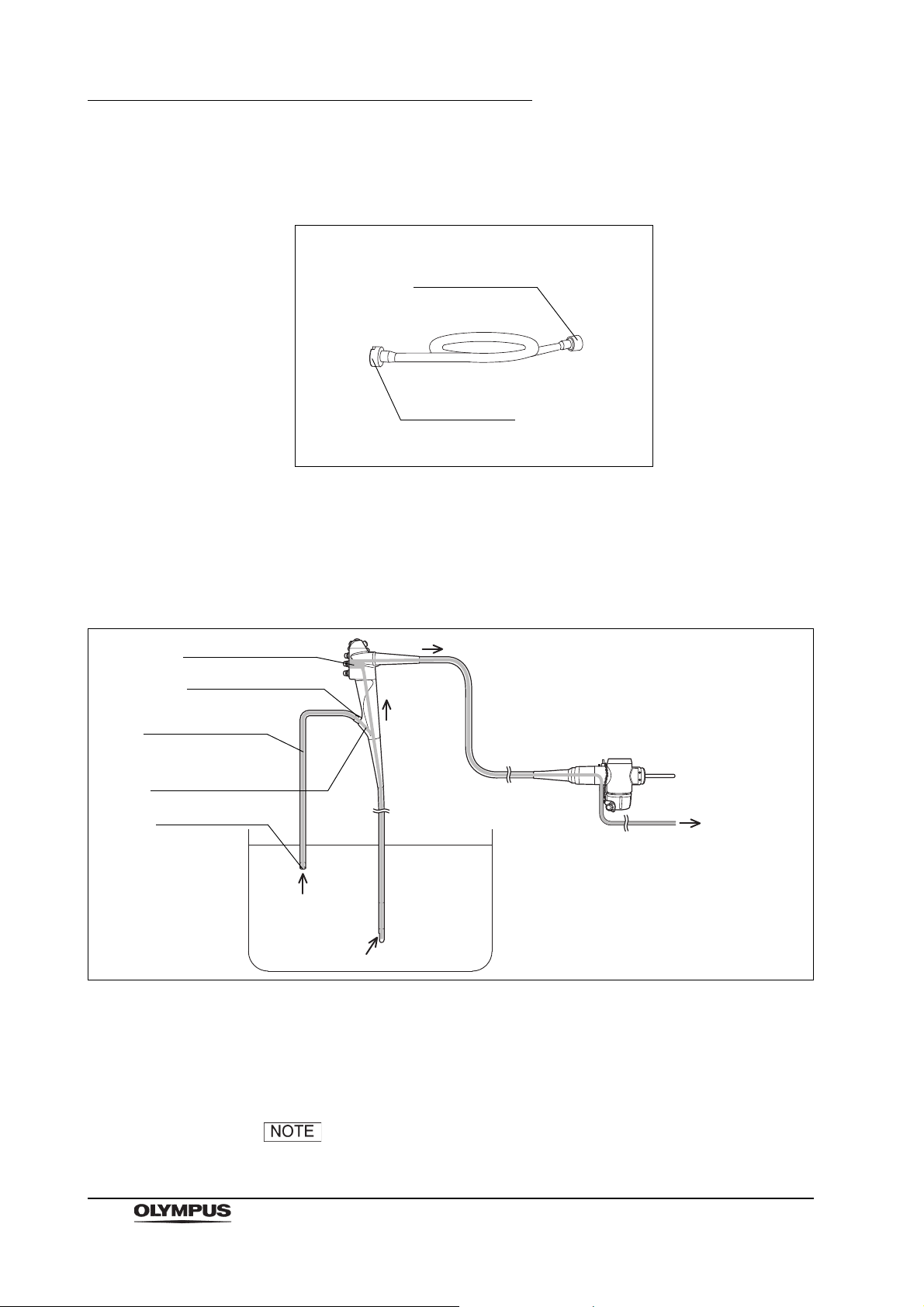

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Information

card

Slider

One-way valve

Piston

Seals

Button

AW channel

cleaning adapter

Air/water

nozzle

Depress

Air channel

Air/water cylinder

Water

container

2.6 AW channel cleaning adapter (MH-948)

Figure 2.15

Function

During precleaning of the endoscope, the AW channel cleaning adapter is

attached to the air/water cylinder of the endoscope. When the button of the

adapter is depressed, the water in the water container is fed through the air/

water nozzle of the endoscope to clean the nozzle and air/water channels of the

endoscope. Air is continuously fed through the air/water channels when the

button is not depressed.

Figure 2.16

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

19

Page 24

Chapter 2 Function and Inspection of the Accessories for Reprocessing

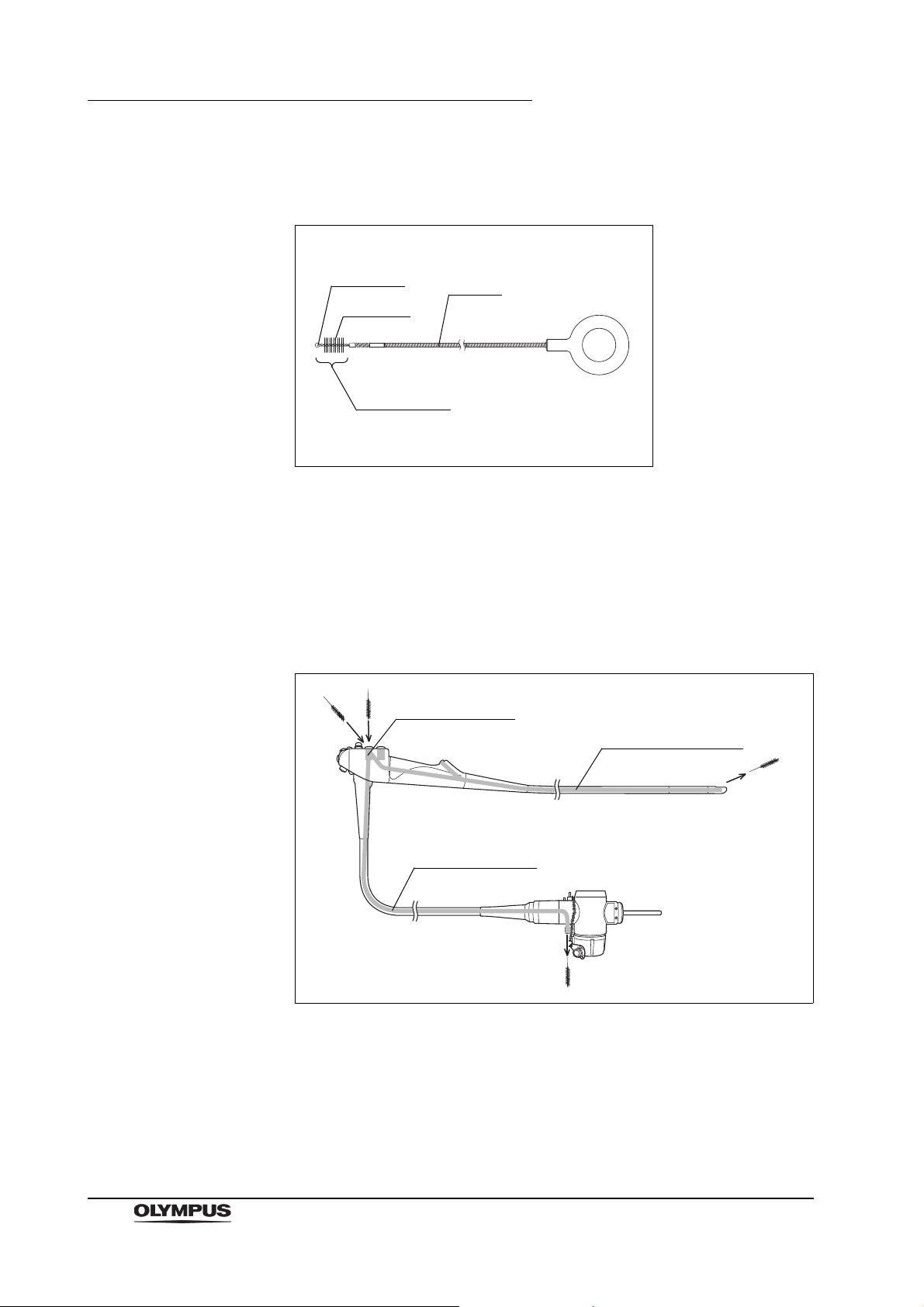

Tip

Shaft

Brush head

Caution sticker

Bristles

Suction channel

Instrument channel

Suction cylinder

Inspection

Check for debris, cracks, scratches, and other damage.

The AW channel cleaning adapter does not need to be

cleaned, disinfected, or sterilized prior to its first use.

2.7 Single use channel cleaning brush (BW-201T)

Figure 2.17

Function

The single use channel cleaning brush is used to brush the inside of the

instrument channel and suction channel of the endoscope and the interior and/or

openings of the suction valve (MH-443), the air/water valve (MH-438), and the

biopsy valve (MB-358).

20

Figure 2.18

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 25

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Depress

Suction valve

(MH-443)

Air/water valve

(MH-438)

Biopsy valve (MB-358)

Figure 2.19

Inspection

1. Remove the brush from its packaging just prior to use.

2. Confirm that the tip and brush head at the distal end are securely attached.

Check the brush head for loose or missing bristles.

3. Check the bristles for any damage. If the bristles are crushed, gently

straighten them with your fingertips.

4. Check for bends, scratches, and other damage to the shaft.

The single use channel cleaning brush does not need to be

cleaned, disinfected, or sterilized prior to use.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

21

Page 26

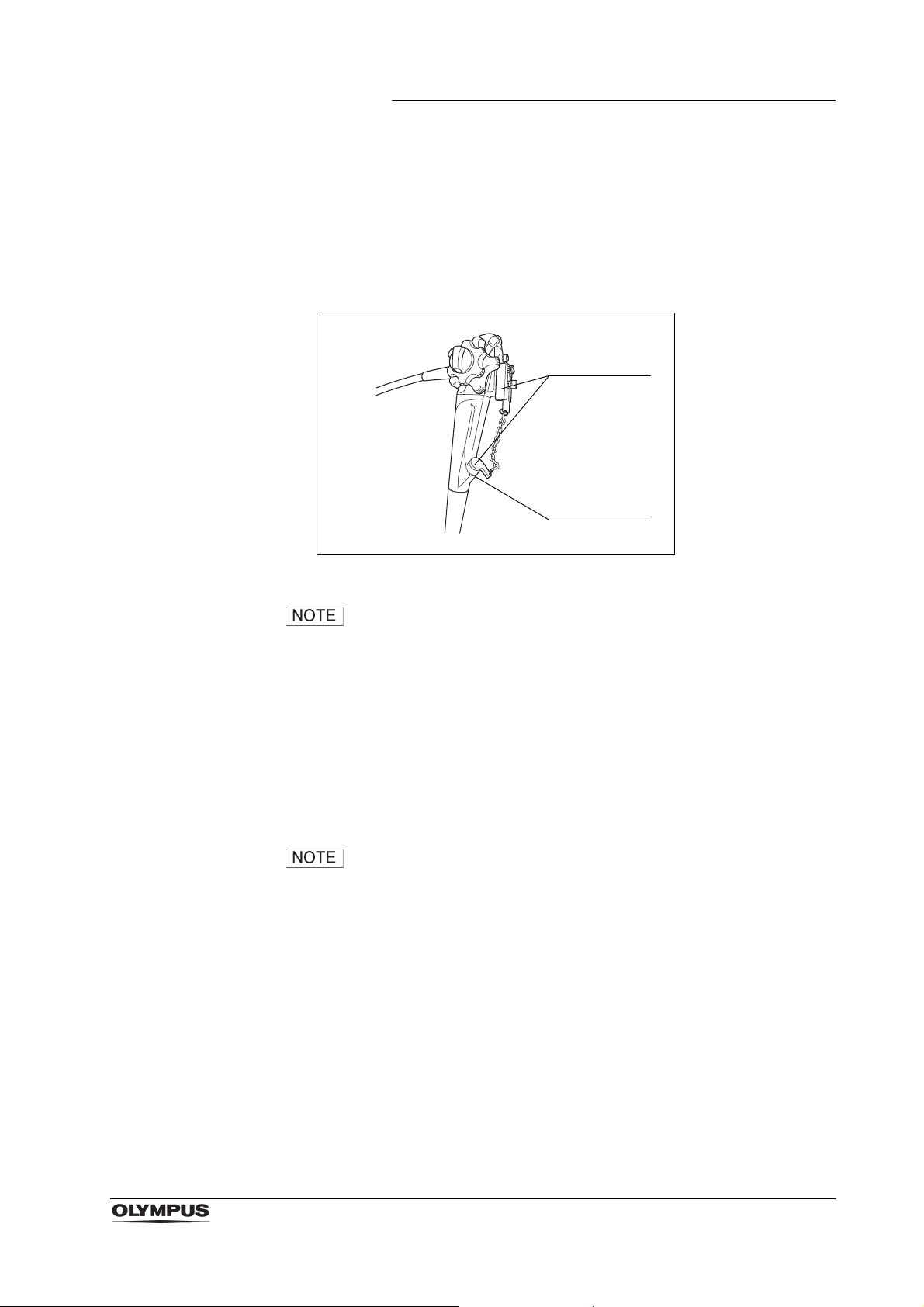

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Brush head

Handle

Instrument

channel port

Suction

cylinder

2.8 Single use channel-opening cleaning brush

(MAJ-1339)

Figure 2.20

Function

The single use channel-opening cleaning brush is used to brush the suction

cylinder, the instrument channel port, the distal end, the forceps elevator, and the

forceps elevator recess.

Figure 2.21

22

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 27

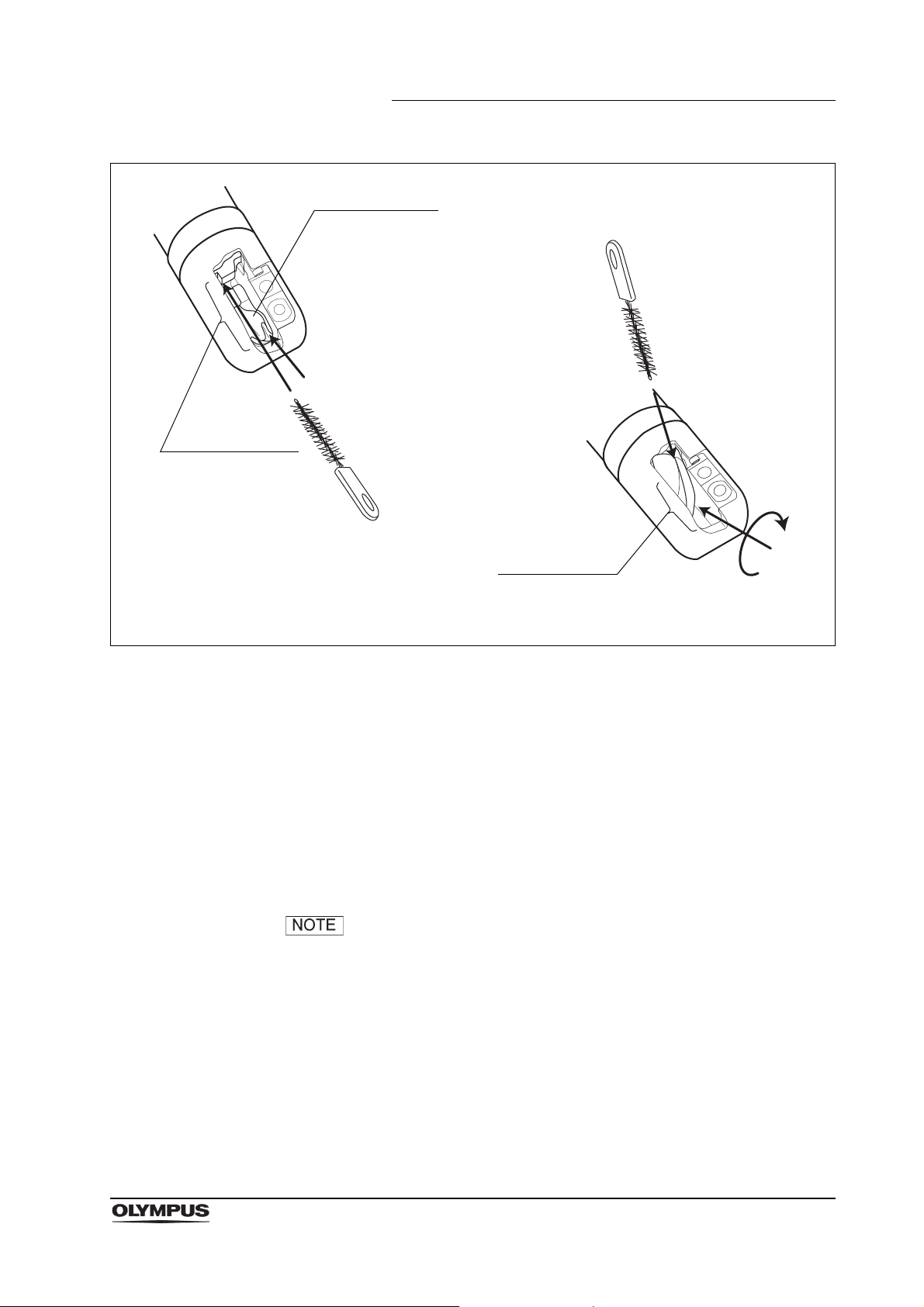

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Forceps elevator

recess

Forceps elevator

Forceps elevator

recess

(a) Brushing when forceps elevator is lowered. (b) Brushing when forceps elevator is raised.

Figure 2.22

Inspection

1. Remove the brush from its packaging just prior to use.

2. Check the brush head for loose or missing bristles.

3. Check the bristles for any damage. If the bristles are crushed, gently

straighten them with your fingertips.

4. Check for bends, scratches, and other damage to the shaft.

The single use channel-opening cleaning brush does not

need to be cleaned, disinfected, or sterilized prior to use.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

23

Page 28

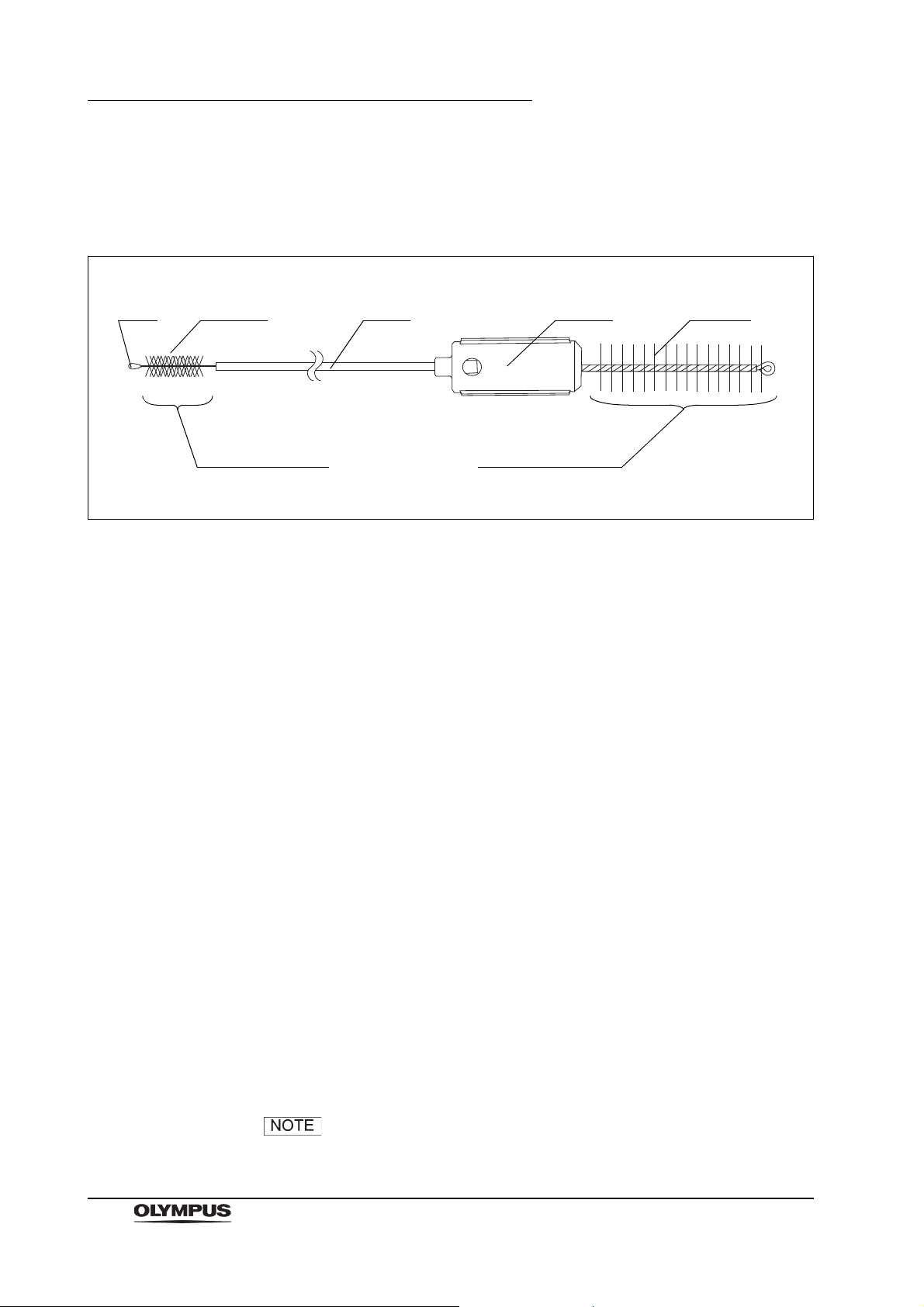

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Tip

Shaft

Channel cleaning

brush part

Handle

Channel-opening

cleaning brush part

Bristles Bristles

2.9 Single use combination cleaning brush

(BW-412T)

Figure 2.23

Function

The channel cleaning brush part of the single use combination cleaning brush is

used to brush the inside of the instrument channel and suction channel of the

endoscope, and the interior and/or openings of the suction valve (MH-443), the

air/water valve (MH-438), and the biopsy valve (MB-358). The channel-opening

cleaning brush part of the single use combination cleaning brush is used to

brush the suction cylinder, the instrument channel port, the distal end, the

forceps elevator, and the forceps elevator recess of the endoscope.

Inspection

1. Remove the brush from its packaging just prior to use.

2. Confirm that the channel cleaning brush part and tip at the distal end are

securely attached.

3. Check the channel cleaning brush and the channel-opening cleaning brush

parts for loose or missing bristles.

4. Check the bristles of the channel cleaning brush and the channel-opening

cleaning brush parts for any damage. If the bristles are crushed, gently

straighten them with your fingertips.

5. Check for bends, scratches, and other damage to the shaft.

24

The single use combination cleaning brush does not need to

be cleaned, disinfected, or sterilized prior to use.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

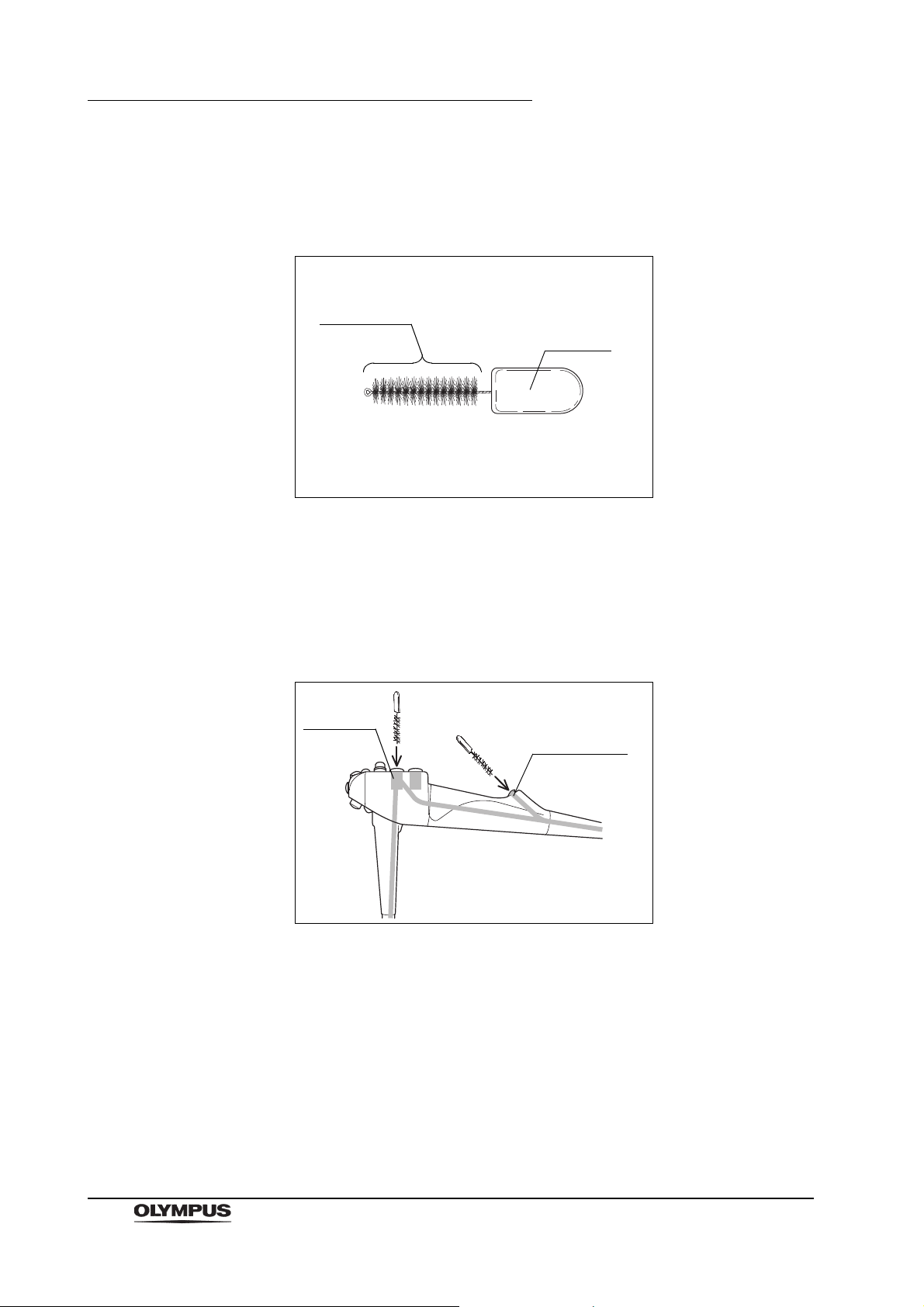

Page 29

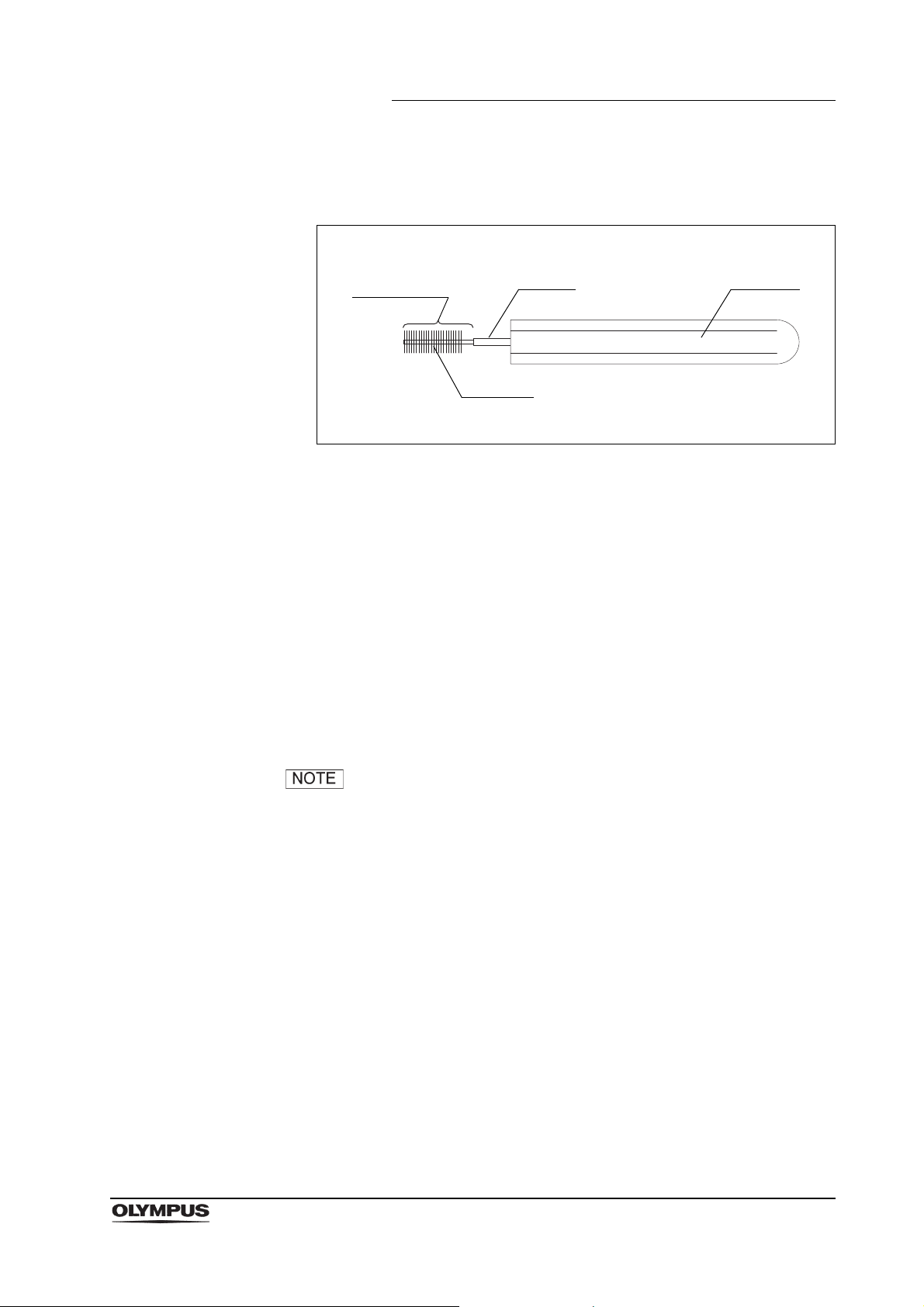

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Bristles

Shaft

Brush head

Handle

2.10 Single use soft brush (MAJ-1888)

Figure 2.24

Function

The single use soft brush is used to brush around the forceps elevator.

Inspection

1. Check the brush head for loose, missing bristles, and other damage. If the

bristles are crushed and/or bent, gently straighten them with your fingers.

2. Check for bends, scratches, and other damage to the shaft.

3. Check for debris on the shaft and or in the bristles of the brush head.

The single use soft brush does not need to be cleaned,

disinfected, or sterilized prior to use.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

25

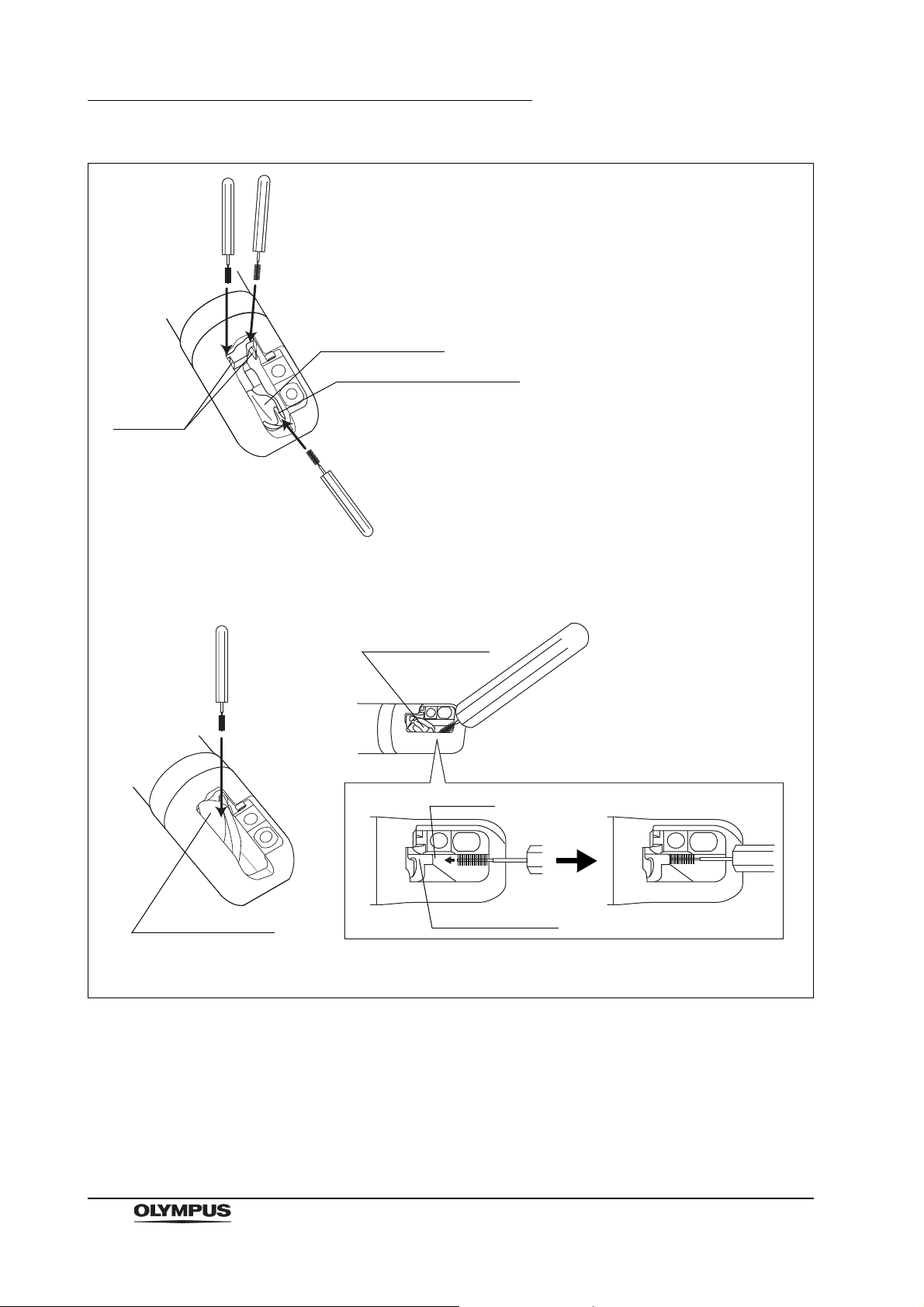

Page 30

Chapter 2 Function and Inspection of the Accessories for Reprocessing

Groove

Forceps elevator

Guidewire-locking groove

Forceps elevator

Forceps elevator

Forceps elevator

Groove

(a) Brushing when forceps elevator is lowered.

(b) Brushing when forceps elevator is raised.

Figure 2.25

26

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 31

Chapter 2 Function and Inspection of the Accessories for Reprocessing

2.11 Chain for water-resistant cap (MAJ-1119)

Figure 2.26

Function

The chain for water-resistant cap is used to keep the water resistant cap

(MH-553) with the endoscope at all times.

Inspection

It is not necessary to inspect the chain before reprocessing.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

27

Page 32

Chapter 3 Compatible Reprocessing Methods and Chemical Agents

Chapter 3 Compatible Reprocessing

Methods and Chemical

Agents

3.1 Compatibility summary

The endoscope and accessories are compatible with several methods of

reprocessing. However, not all reprocessing methods are compatible with all

endoscopes and all accessories. Reprocessing with incompatible methods can

cause equipment damage even if the number of reprocessing cycles is small.

For appropriate reprocessing methods, see Table 3.1.

Follow the policies at your local institution when choosing which methods listed

in Table 3.1 to employ.

• Methods listed as “compatible” in Table 3.1 are compatible

for routine use only when used according to manufacturer’s

instructions. Repeated use and reprocessing of endoscopes

and accessories leads to gradual wear and tear. But

reprocessing methods that employ higher temperatures and

more caustic/corrosive materials may lead to faster

deterioration. In general, sterilization processes are harsher

on equipment than disinfection processes. Before each

patient procedure, inspect the endoscope and accessories

for damage, according to the instructions described in this

manual and its companion “OPERATION MANUAL”.

• Instructions provided in this manual regarding material

compatibility are not valid for Olympus devices repaired by a

non-Olympus facility. Olympus repairs devices to

manufacturer’s specifications using original equipment

manufacturer’s (OEM) materials. The use of non-OEM

materials to repair an Olympus device may affect the material

compatibility of the device with certain reprocessing

chemicals or methods. In the event that your device has

been repaired by a non-Olympus facility, contact that repair

facility for instructions regarding material compatibility.

28

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 33

.

Endoscope

Chapter 3 Compatible Reprocessing Methods and Chemical Agents

For sterilization Steam sterilization (autoclaving)

Ethylene oxide gas sterilization

(gas mixture 20% ethylene oxide gas/80% CO

for countries other than the USA)

Ethylene oxide gas sterilization

(100% ethylene oxide gas)

For disinfection

ACECIDE disinfectant solution

2 – 3.5% glutaraldehyde

For alcohol flush 70% ethyl or 70% isopropyl

alcohol

For cleaning Detergent solution

Ultrasonic

cleaning

1

,

2

3

Water resistant cap

(MH-553)

Chain for water-resistant

cap (MAJ-1119)

Channel cleaning brush

(BW-20T)

Air/water valve (MH-438)

Suction valve (MH-443)

Biopsy valve (MB-358)

Channel plug (MH-944)

Injection tube (MH-946)

AW channel cleaning

adapter (MH-948)

Suction cleaning adapter

(MH-856)

Mouthpiece (MB-142)

Single use channel

cleaning brush (BW-201T)

Single use channel-opening

cleaning brush (MAJ-1339)

Single use combination

cleaning brush (BW-412T)

Single use soft brush

(MAJ-1888)

2

compatible not compatible

Table 3.1

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

29

Page 34

Chapter 3 Compatible Reprocessing Methods and Chemical Agents

Green

marking

AUTOCLAVABLE

Air/water valve (MH-438)

1 The endoscope is only compatible with ultrasonic cleaning as performed

in an Olympus-recommended endoscope reprocessor such as OER-AW,

OER-Pro (OER-AW and OER-Pro are not available in some areas). When

using an AER that is recommended by Olympus other than listed above,

contact Olympus.

2 The water resistant caps (MH-553) and the chain for water-resistant cap

(MAJ-1119) can only be ultrasonically cleaned if attached to an endoscope

that is being cleaned in an automated endoscope reprocessor with an

ultrasonic cleaning phase.

3 ACECIDE are not available in some areas.

Accessories that are marked by the words “AUTOCLAVE” or

“AUTOCLAVABLE”, or with green markings (such as a green

component or label) are compatible with steam sterilization

(autoclaving).

3.2 Water (for reprocessing)

30

Figure 3.1

Water is used for leakage testing and manual cleaning of the endoscope and

accessories. For these purposes, use either fresh, potable tap water or water

that has been processed (e.g., filtered, deionized or purified) to improve its

chemical and/or microbiological quality. Consult with your hospital’s infection

control committee.

When rinsing the endoscope and accessories following high-level disinfection,

use the water referred to in Section 3.5.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 35

Chapter 3 Compatible Reprocessing Methods and Chemical Agents

3.3 Detergent solution

• Excessive foaming prevents detergent from properly

contacting the surfaces and channel walls of the endoscope

and accessories, and may impair effective cleaning.

• Do not reuse detergent solutions.

Use a medical-grade, low-foaming, neutral pH detergent. Follow the instructions

provided by the detergent manufacturer regarding concentration, temperature,

contact time, and expiration date. Contact Olympus for the names of specific

brands of detergent solution that have been tested for compatibility with

endoscopes and accessories.

3.4 Disinfectant solution

Use a high-level disinfectant cleared by your national regulatory agency for use

in reprocessing flexible endoscopes. Follow the disinfectant manufacturer’s

instructions regarding activation (if required), concentration, temperature,

contact time, and expiration date.

For further information regarding the compatibility of glutaraldehyde-based or

non glutaraldehyde-based disinfectant solutions, contact Olympus.

3.5 Rinse water

Use sterile water for rinsing the endoscope and accessories following high-level

disinfection.

If sterile water is not available, use either fresh, potable tap water or water that

has been processed (e.g., filtered, deionized or purified) to improve its chemical

and/or microbiological quality, and flush the endoscope and accessories with the

alcohol referred to in Section 3.6 after rinsing. Consult with your hospital’s

infection control committee regarding local policies on water quality.

3.6 Alcohol

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Use medical-grade 70% ethyl or 70% isopropyl alcohol.

31

Page 36

Chapter 3 Compatible Reprocessing Methods and Chemical Agents

3.7 Ethylene oxide gas sterilization

The endoscope and accessories listed as compatible with ethylene oxide gas

sterilization in Table 3.1 can be sterilized by ethylene oxide gas and aerated

within the parameters given in Table 3.2 and 3.3. When performing ethylene

oxide gas sterilization, follow all national, professional, and institutional

reprocessing protocols as well as the instructions provided by the manufacturer

of your sterilization equipment.

Exceeding the recommended parameters may cause

equipment damage (see Table 3.2 and 3.3).

Parameters for 100% ethylene oxide gas sterilization

cycles

Process phase Parameter Value

Sterilization Temperature

Vac uum

(Absolute pressure)

Relative humidity 50 – 80%

Ethylene oxide gas

concentration

Exposure time 60 minutes

Aeration Minimum aeration

parameters

55

C (130F)

0.05 – 0.07 MPa

(7.25 – 10.15 psia)

0.735 – 0.740 mg/cm

(735 – 740 mg/L)

12 hours in an aeration chamber

at 50 – 57C(122 – 135F) or

7 days at room temperature

3

32

Table 3.2

Parameters for 20% ethylene oxide gas/80% CO2 gas

sterilization cycles, for countries other than the USA

Process phase Parameter Value

Sterilization Temperature

Relative pressure 0.1 – 0.17 MPa

Relative humidity 55%

Ethylene oxide gas

concentration

Exposure time 105 minutes

Aeration Minimum aeration

parameters

Table 3.3

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

57

C (135F)

0.6 – 0.7 mg/cm

(600 – 700 mg/L)

12 hours in an aeration chamber

at 50 – 57C (122 – 135F) or

7 days at room temperature

3

Page 37

Chapter 3 Compatible Reprocessing Methods and Chemical Agents

3.8 Steam sterilization (autoclaving)

The accessories listed as compatible with steam sterilization in Table 3.1 can be

sterilized by steam within the parameters given in Table 3.4. When steam

sterilizing, follow all national, professional, and institutional reprocessing

protocols as well as the instructions provided by the manufacturer of your

sterilization equipment.

• Do not steam sterilize the endoscope. Steam sterilization will

cause severe damage.

• Exceeding the recommended parameters may damage the

accessories (see Table 3.4).

Process Parameters

Prevacuum Temperature 132 – 134C

Exposure time 5 minutes

(270 – 274F)

Table 3.4

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

33

Page 38

Chapter 3 Compatible Reprocessing Methods and Chemical Agents

34

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 39

Chapter 4 Reprocessing Workflow for the Endoscope and Accessories

Chapter 4 Reprocessing Workflow for

the Endoscope and

Accessories

This chapter describes the workflow for reprocessing the endoscope and

accessories.

Deviation from the recommended workflow may pose an

infection control risk.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

35

Page 40

Chapter 4 Reprocessing Workflow for the Endoscope and Accessories

Endoscope

Patient procedure

Section 5.2, “Precleaning

the endoscope and

accessories”

Section 5.3, “Leakage testing

of the endoscope”

Section 5.4, “Manually

cleaning the endoscope and

accessories”

Section 8.1, “Storing the disinfected endoscope and accessories”

Section 5.5, “Manually

disinfecting the endoscope

and accessories”

Section 5.6, “Rinsing the

endoscope and accessories

following disinfection”

Mouthpiece

(MB-142)

Air/water

valve

(MH-438)

Biopsy

valve

(MB-358)

Suction

valve

(MH-443)

Water

resistant cap

(MH-553)

Patient

procedure

Section 5.2

Section 6.1, “Manually cleaning the accessories”

Section 6.2, “Manually disinfecting the accessories”

Section 6.3, “Rinsing the accessories following disinfection”

Chain for

water-resistant

cap

(MAJ-1119)

1

AW channel

cleaning

adapter

(MH-948)

Section 5.2

4.1 Workflow for manually cleaning and disinfecting

the endoscope and accessories

The water resistant cap (MH-553) should remain connected to the endoscope at all times using the chain for water-resistant

1

cap (MAJ-1119).

36

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 41

Chapter 4 Reprocessing Workflow for the Endoscope and Accessories

Injection

tube

(MH-946)

Suction

cleaning

adapter

(MH-856)

Single use

channelopening

cleaning

brush

(MAJ-1339)

Channel

cleaning

brush

(BW-20T)

Section 5.4

Section 6.1

Section 6.2

Section 6.3

Section 8.1

Section 5.5

Section 5.6

Single use

channel

cleaning

brush

(BW-201T)

Channel

plug

(MH-944)

Single use

combination

cleaning

brush

(BW-412T)

Single use

soft brush

(MAJ-1888)

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

37

Page 42

Chapter 4 Reprocessing Workflow for the Endoscope and Accessories

Air/water

valve

(MH-438)

Endoscope

Patient procedure

Section 5.2, “Precleaning

the endoscope and

accessories”

2

Section 5.3, “Leakage

testing of the endoscope”

3

Section 5.4, “Manually cleaning the

endoscope and accessories”

4

Section 8.1, “Storing the disinfected endoscope and accessories”

Chapter 7, “Reprocessing Endoscopes and Accessories using an Automated Endoscope Reprocessor”

5

Section 5.5, “Manually disinfecting

the endoscope and accessories”

Mouthpiece

(MB-142)

7

Biopsy

valve

(MB-358)

Suction

valve

(MH-443)

Patient

procedure

Section 5.2

2

Section 6.1, “Manually cleaning the accessories”

Section 6.2, “Manually disinfecting the accessories”

Section 6.3, “Rinsing the accessories following disinfection”

Chain for

water-resistant

cap (MAJ-1119)

1

Some endoscopes can be cleaned and disinfected with an AER while others cannot. The endoscopes that can be

cleaned and disinfected vary, depending upon which model AER is used. Check the AER’s instruction manual to

confirm which endoscopes can be cleaned and disinfected in the AER.

AW channel

cleaning

adapter

(MH-948)

7

Section

5.2

2

Section 5.6, “Rinsing the

endoscope and accessories

following disinfection”

Water resistant

cap (MH-553)

When you use an AER which allows you skip some steps in precleaning and manual cleaning of

endoscopes, confirm with the AER manufacturer that such skip is applicable to this endoscope and

establish detailed precleaning and manual cleaning procedures of this endoscope according to both

instructions of this manual and the AER manufacturer.

4.2 Workflow for cleaning and disinfecting the

endoscope and accessories using an AER

The water resistant cap (MH-553) should remain connected to the endoscope at all times using the chain for water-resistant

1

cap (MAJ-1119).

When using Olympus AER OER-Pro or OER-AW for reprocessing this endoscope, you are able to simplify the standard

2

manual precleaning procedure. When simplifying the procedure, follow the instruction manual “Modified precleaning and

cleaning of TJF-Q180V when using OER-Pro/OER-AW”.

Check the instruction manual for your AER to determine how to leakage test the endoscope using the AER. When leakage

3

testing an endoscope within an AER basin it may be difficult to fully angulate the bending section. Perform leakage testing in

the AER and/or manually, depending upon the policy of your institution.

38

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 43

Chapter 4 Reprocessing Workflow for the Endoscope and Accessories

Section 5.4

4

Section 6.1

Section 6.2

Section 6.3

Section 8.1

Chapter 7

5

Section 5.5 & 5.6

or

Section 6.2 & 6.3

6

Some accessories can be cleaned and disinfected with an AER while others cannot. The accessories that can be

cleaned and disinfected vary, depending upon which model AER is used. Check the AER’s instruction manual to

confirm which accessories can be cleaned and disinfected in the AER.

Manually disinfect all endoscopes and accessories that cannot be reprocessed in the AER.

Injection

tube

(MH-946)

7

Suction

cleaning

adapter

(MH-856)

7

Single use

channelopening

cleaning

brush

(MAJ-1339)

Channel

cleaning

brush

(BW-20T)

7

Single use

channel

cleaning

brush

(BW-201T)

Channel

plug

(MH-944)

7

Single use

combination

cleaning

brush

(BW-412T)

Single use

soft brush

(MAJ-1888)

4

5

6

7 The accessory(s) are not compatible with the OER-Pro.

When using Olympus AER OER-Pro or OER-AW for reprocessing this endoscope, you are able to simplify the standard

manual cleaning procedure. When simplifying the procedure, follow the instruction manual “Modified precleaning and

cleaning of TJF-Q180V when using OER-Pro/OER-AW”.

If the endoscope and/or the accessories are compatible with the AER, clean and disinfect them in the AER, following the

AER’s instruction manual. If the endoscope and/or the accessories are not compatible with the AER, manually clean,

disinfect and rinse them following the instructions of this manual, as shown in the dotted boxes.

If the endoscope and the accessory(s) are not compatible with the AER, manually disinfect and rinse them, according to

Sections 5.5 and 5.6. If the endoscope is compatible and the accessory(s) are not compatible, manually disinfect and rinse

the accessory(s) according to Section 6.2 and 6.3.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

39

Page 44

Chapter 4 Reprocessing Workflow for the Endoscope and Accessories

Patient procedure

Section 5.2, “Precleaning

the endoscope and

accessories”

Section 5.3, “Leakage

testing of the endoscope”

Section 5.4, “Manually

cleaning the endoscope and

accessories”

Section 8.2, “Storing the sterilized endoscope and accessories”

Section 5.7, “Sterilizing the

endoscope and

accessories”

Patient

procedure

Section 5.2

Section 6.1, “Manually cleaning the accessories”

Section 6.4, “Sterilizing the accessories”

If required by the local policy of your institution, disinfect and rinse the endoscope and accessories

manually, or clean and disinfect them with an AER between manual cleaning and sterilization.

Section 5.2

Endoscope Mouthpiece

(MB-142)

Air/water

valve

(MH-438)

Biopsy

valve

(MB-358)

Suction

valve

(MH-443)

Water

resistant cap

(MH-553)

Chain for

water-resistant

cap

(MAJ-1119)

1

AW channel

cleaning

adapter

(MH-948)

4.3 Workflow for manually cleaning and sterilizing

the endoscope and accessories

The water resistant cap (MH-553) should remain connected to the endoscope at all times using the chain for water-resistant

1

cap (MAJ-1119).

40

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 45

Chapter 4 Reprocessing Workflow for the Endoscope and Accessories

Section 5.4

Section 8.2

Section 5.7

Injection

tube

(MH-946)

Suction

cleaning

adapter

(MH-856)

Single use

channelopening

cleaning

brush

(MAJ-1339)

Channel

cleaning

brush

(BW-20T)

Single use

channel

cleaning

brush

(BW-201T)

Channel

plug

(MH-944)

Single use

combination

cleaning

brush

(BW-412T)

Single use

soft brush

(MAJ-1888)

Section 6.1

Section 6.4

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

41

Page 46

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories)

Forceps elevator

Guidewire-locking

groove

Groove

Forceps elevator recess

Chapter 5 Reprocessing the

Endoscope (and related

reprocessing accessories)

Certain accessories are required to manually reprocess the endoscope. Some of

these accessories are cleaned and disinfected along with the endoscope. The

steps for reprocessing the endoscope and these accessories are explained in

this chapter. Chapter 6, “Reprocessing the Accessories” describes the steps for

reprocessing accessories that are not reprocessed together with the endoscope.

The reprocessing workflow of all accessories is outlined in Chapter 4,

“Reprocessing Workflow for the Endoscope and Accessories”.

Figure 5.1

The TJF-Q180V endoscope has a forceps elevator. The

surface and surrounding area of the forceps elevator, such as

the groove, guidewire locking groove, and forceps elevator

recess, have a complex shape. Reprocess these parts

carefully following the procedure described in Chapter 5.

Insufficient reprocessing may pose an infection control risk to

patient and/or operators.

42

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 47

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories)

Bending section

Insertion section

Insertion tube

Distal end

• The insertion section of the endoscope is composed of the

insertion tube, the bending section, and the distal end. The

bending section is covered by a thin, easily damaged elastic

covering. Do not allow reprocessing equipment to forcefully

contact the bending section. Do not allow any sharp edges,

such as the distal ends of EndoTherapy accessories

(needles, forceps, snares, etc. used in the instrument

channel of the endoscope) to contact the bending section.

Such improper handling may damage the covering and

cause the endoscope to leak.

Figure 5.2

• Handle the insertion section carefully. Tightly gripping or

sharply bending the insertion tube or the bending section can

stretch or severely damage the insertion tube and/or the

covering of the bending section.

• To prevent damage to the endoscope, do not immerse the

endoscope with objects other than the equipment used for

reprocessing the endoscope.

• To prevent damage, do not coil the insertion tube or the

universal cord of the endoscope with a diameter of less than

12 cm.

Use sterile equipment, such as sterile syringes and cloths, for all reprocessing

steps occurring after immersion of the endoscope and accessories in

disinfectant solution.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

43

Page 48

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories)

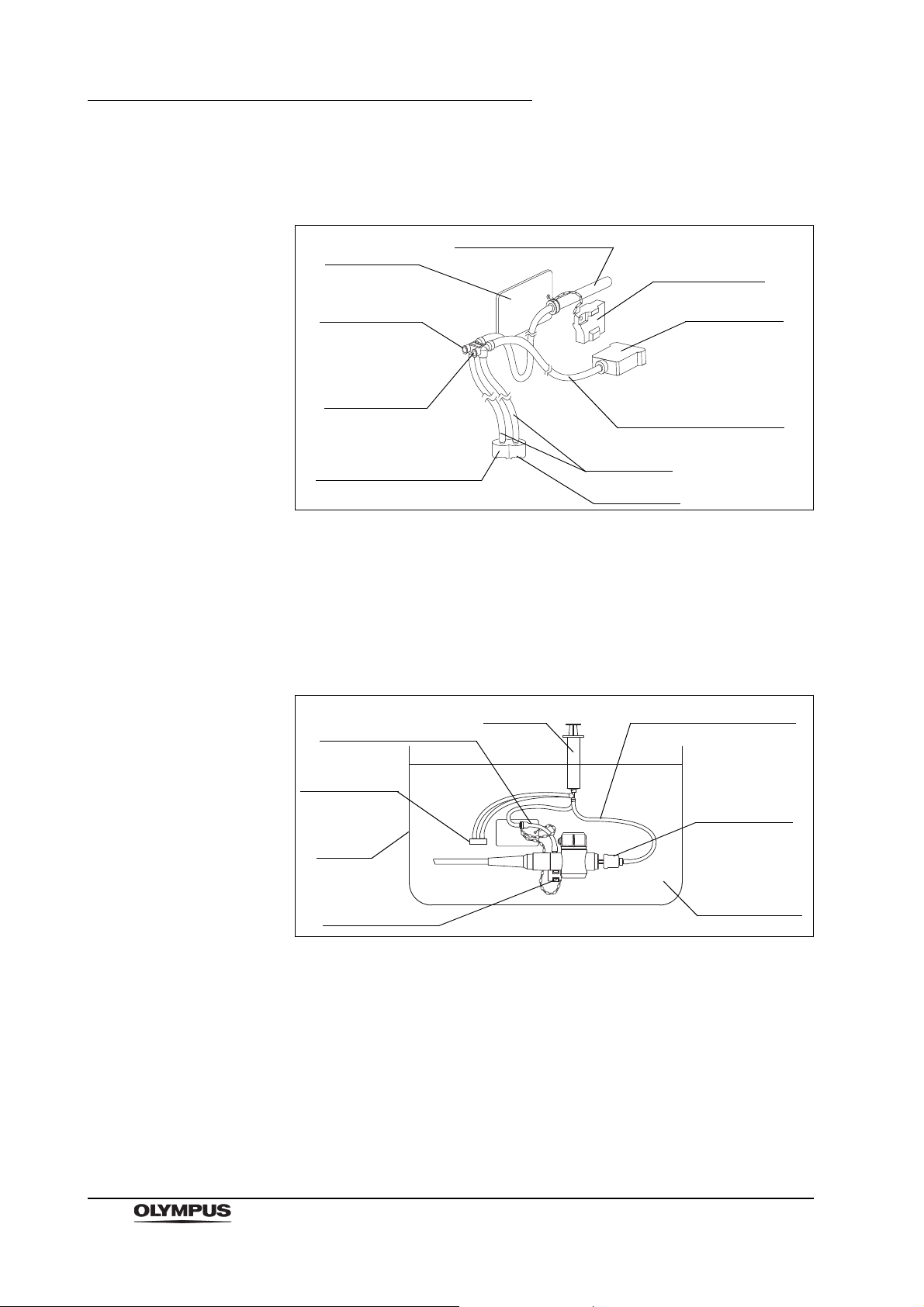

Leakage tester (MB-155)

(Sold separately. Refer to

its instruction manual.)

Water resistant cap

(MH-553)

Channel cleaning

brush (BW-20T)

AW channel

cleaning adapter

(MH-948)

Suction cleaning

adapter (MH-856)

Channel plug

(MH-944)

Injection tube

(MH-946)

Maintenance unit (MU-1)

(Sold separately. Refer

to its instruction

manual.)

Suction pump

(KV-4, KV-5, SSU-2) and Tube

(Sold separately. Refer to its

instruction manual.)

Single use channel

cleaning brush

(BW-201T)

1

Single use channel-opening

cleaning brush

(MAJ-1339)

1

Single use combination

cleaning brush

(BW-412T)

1

Single use soft brush

(MAJ-1888)

5.1 Preparing the equipment for reprocessing

Equipment needed

The following equipment is necessary to perform the reprocessing steps

described in this chapter.

• Personal protective equipment • Water for cleaning (Refer to Section 3.2)

• Detergent solution (Refer to Section 3.3) • Disinfectant solution (Refer to Section 3.4)

• Rinse water (Refer to Section 3.5) • 70% ethyl or 70% isopropyl alcohol (Refer to Section

• Clean, soft brush(s)

• Sterile lint-free cloths

• Sterile cotton swabs • Clean 30 ml (30 cc) syringe(s)

• Sterile 30 ml (30 cc) syringe(s) • Clean, 500 ml containers

• Clean, large basins with tight-fitting lids

(size: 40 (W) × 40 (H) × 25 (D) cm or more)

• Sterile, large basins

(size: 40 (W) × 40 (H) × 25 (D) cm or more)

44

2

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

3.6)

• Clean lint-free cloths

• Clean sponge(s)

• Clean, large basins

(size: 40 (W) × 40 (H) × 25 (D) cm or more)

• Sterile, small basins with tight-fitting lids

(size: 25 (W) × 10 (H) × 25 (D) cm or more)

2

Page 49

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories)

AW channel

cleaning adapter

(MH-948)

Suction pump (KV-4, KV-5, SSU-2)

and Tube (Sold separately. Refer

to its instruction manual.)

Water resistant cap

(MH-553)

1 These products may not be available in some areas.

2 All cloths used in reprocessing are recommended to be lint-free. Lint or cloth fibers shed into

reprocessing fluids may be injected into the endoscope channels. There is the potential for lint or

cloth fibers to lodge in channels or become trapped in the air/water nozzle. If gauze is used to

reprocess the endoscope, ensure that fibers do not get caught on or remain trapped by

protruding components like the air/water nozzle.

5.2 Precleaning the endoscope and accessories

If the endoscope and accessories used in the patient

procedure are not immediately cleaned after each patient

procedure, residual organic debris will begin to dry and

solidify, hindering effective removal and reprocessing

efficacy. Preclean the endoscope and the accessories at the

bedside in the patient procedure room immediately after

each patient procedure.

Equipment needed

Prepare the following equipment.

• Water for cleaning (Refer to Section 3.2) • Detergent solution (Refer to Section 3.3)

• Clean lint-free cloths • Clean sponge(s)

• Clean 30 ml (30 cc) syringe(s) • Clean, 1,000 ml containers

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

45

Page 50

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories)

Cap

Suction valve

(MH-443)

Preparation

Immediately following the patient procedure, with the endoscope still connected

to the equipment used in the patient procedure (i.e., the light source, video

system center, suction pump), perform the following precleaning steps at the

patient bed side.

1. Turn the video system center and light source OFF.

2. Prepare a clean 1,000 ml container of the water referred to in Section 3.2.

Wipe the insertion section

Dip a clean, lint-free cloth or sponge in the water and wipe the entire insertion

section of the endoscope. Wipe from the boot at the control section toward the

distal end.

Aspirate water

1. Turn the suction pump ON.

2. Close the cap on the biopsy valve.

Monitor the suction bottle on the suction pump carefully to

ensure that it does not overflow.

46

Figure 5.3

3. Lower the forceps elevator by turning the elevator control lever and immerse

the distal end of the insertion section in the water. Depress the suction valve

(MH-443) on the endoscope and aspirate the water through the endoscope

for 30 seconds.

4. While continuing the immersion and the aspiration, raise and lower the

forceps elevator three times by turning the elevator control lever.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 51

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories)

AW channel

cleaning adapter

Air/water valve

5. Remove the distal end from the water. Depress the suction valve and

aspirate air for 10 seconds.

6. Turn the suction pump OFF.

Flush the air/water channel with water and air

• To prevent clogging of the air/water nozzle of the endoscope,

flush water into the air/water channel of the endoscope, using

the AW channel cleaning adapter (MH-948) after each

patient procedure.

• Do not apply lubricants to the AW channel cleaning adapter.

Lubricants may cause malfunction of the AW channel

cleaning adapter.

1. Turn the light source ON.

2. Switch “OFF” the airflow regulator on the light source.

3. Detach the air/water valve (MH-438) from the endoscope and place it in the

detergent solution. Attach the AW channel cleaning adapter (MH-948) to the

air/water cylinder of the endoscope.

Figure 5.4

• The air/water valve (MH-438) is to be reprocessed, according

to Chapter 6, “Reprocessing the Accessories”.

• Water may drip from the air/water cylinder when the air/water

valve is detached. The water dripping from the air/water

cylinder is clean (i.e., sterile water in the water container). If

water is dripping from the air/water cylinder, hold the control

section higher than the water container.

4. Immerse the distal end of the insertion section in the water.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

47

Page 52

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories)

5. Switch the airflow regulator on the light source to maximum output (“HIGH”

or “3”).

6. Depress the button of the AW channel cleaning adapter to flush the air

channel with water from the water container for 30 seconds.

7. Release the button to flush air for 10 seconds.

8. Turn the light source OFF.

Detach accessories from the endoscope

1.

Detach the videoscope cable (MAJ-1430, MAJ-843, or MH-976) from the

electrical connector of the endoscope.

2. Detach the suction tube from the suction connector on the endoscope

connector.

3. Detach the metal tip of the water container (MAJ-901 or MH-884) from the

air/water supply connector on the endoscope connector. Put the metal tip of

the water container tube into the receptacle on the lid of the water container,

as described in the instruction manual for the water container.

Attach the water resistant cap (MH-553)

If the exterior surface of the electrical connector of the

endoscope is scratched, the connection with the water

resistant cap (MH-553) may no longer be waterproof and the

cap’s seal may be damaged. If the electrical connector is

damaged, send the endoscope to Olympus for repair.

The water resistant cap can be attached in two different

positions. Attach the water resistant cap to the endoscope as

shown in Figure 5.5 to allow the endoscope and cap to lay

properly in the reprocessing basin.

48

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 53

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories)

2.

Rotate

Rotate

4.

4.

Attachment

completed

(b) When using KC-10/TD-20(a) When using an Olympus automated endoscope

reprocessor or an Olympus reprocessing

equipment other than KC-10/TD-20.

2.

Mark 2 (yellow)

Water resistant

cap

Mark 2 (yellow)

Attachment

completed

Figure 5.5

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

49

Page 54

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories)

Pin

Groove

1. Confirm that the exterior surface of the electrical connector is free from

scratches.

2. When using an Olympus automated endoscope reprocessor, or Olympus

reprocessing equipment other than the KC-10/TD-20, align the OER/ETD/

EW characters or the EW characters on the water resistant cap with mark 2

on the electrical connector housing. When using the KC-10/TD-20, align the

KC/TD characters on the cap with mark 2 on the housing.

3. Align the pins on the electrical connector with the grooves on the cap.

Figure 5.6

4. Attach the cap to the electrical connector by pushing in and rotating the cap

clockwise until it stops (approximately 45 degrees).

50

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 55

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories)

Leakage tester (MB-155)

Maintenance unit (MU-1)

(Sold separately. Refer to

its instruction manual.)

Leakage tester connector

Connector cap

5.3 Leakage testing of the endoscope

Equipment needed

Prepare the following equipment.

• Water for cleaning (Refer to Section 3.2) • Detergent solution (Refer to Section 3.3)

• Clean, large basins

(size: 40 (W) × 40 (H) × 25 (D) cm or more)

Detach the endoscope from the light source

1. Detach the endoscope from the light source.

2. Transport the endoscope to the reprocessing area. Use a covered container

if required by local policy.

3. Detach the AW channel cleaning adapter (MH-948), the suction valve

(MH-443), and the biopsy valve (MB-358) from the endoscope and place

them in the detergent solution.

Do not touch the light guide of the endoscope connector

immediately after detaching it from the light source because it

is extremely hot. Injury may result.

The AW channel cleaning adapter, the suction valve, and the

biopsy valve are to be reprocessed according to Chapter 6,

“Reprocessing the Accessories”.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

4. When using the single use biopsy valve (MAJ-1555), detach the single use

biopsy valve from the endoscope and discard it.

51

Page 56

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories)

Figure 5.7

• Remove the single use biopsy valve from the instrument

channel port after breaking off its lever. Otherwise, it may

spray patient debris or fluids, and it may pose an infection

control risk.

• Do not reuse the single use biopsy valve. Reusing the single

use biopsy valve could pose an infection control risk and

cause malfunction. After use, dispose of it in an appropriate

manner.

52

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 57

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories)

Perform the leakage test

• If you identify a leak during leakage testing, remove the

endoscope from the water with both the water resistant cap

(MH-553) and the leakage tester (MB-155) still attached.

Contact Olympus regarding instructions for reprocessing a

leaking endoscope in preparation for returning the

endoscope to Olympus for repair.

• Do not attach/detach the water resistant cap or the leakage

tester while immersed. Attaching/detaching under water

could allow the water to enter the endoscope, resulting in

endoscope damage.

• When attaching the connector cap of the leakage tester to

the venting connector of the water resistant cap, make sure

that both the connector cap and the venting connector are

thoroughly dry. Water on the surface of either component

may enter the endoscope and could cause endoscope

damage.

• When attaching the connector cap of the leakage tester to

the venting connector of the water resistant cap, push on and

rotate the connector cap clockwise fully until it stops. If it is

not fully and properly attached, the interior of the endoscope

will not be properly pressurized and accurate leakage testing

will be impossible.

• Detach the leakage tester from the maintenance unit (MU-1)

or the light source before detaching the leakage tester from

the water resistant cap. If the leakage tester is detached from

the water resistant cap before detaching the leakage tester

from the maintenance unit or the light source, the air

pressure inside the endoscope will not vent properly. This

may damage the endoscope.

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

53

Page 58

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories)

Pin

Connector cap

1. Fill a clean, large basin with the water referred to in Section 3.2.

2. Attach the leakage tester connector of the leakage tester (MB-155) to the

output socket of the maintenance unit (MU-1) or the light source. Turn the

maintenance unit or the light source ON. Set the light source’s airflow

regulator switch to its maximum level.

3. Depress the pin located inside the connector cap of the leakage tester and

listen to confirm that air is emitted from the connector cap.

Figure 5.8

4. Confirm that both the connector cap of the leakage tester and the venting

connector of the water resistant cap are dry. If not, dry with a clean, lint free

cloth. Attach the connector cap to the venting connector by pushing on and

rotating clockwise until it stops.

5. With the leakage tester attached, immerse the endoscope in the water and

observe for approximately 30 seconds while deflecting the bending section

of the endoscope by turning the endoscope’s UP/DOWN and RIGHT/LEFT

angulation control knobs, and while raising and lowering the forceps

elevator by moving the endoscope’s elevator control lever. Confirm that

there is no location on the endoscope from which a continuous series of air

bubbles emerge.

54

EVIS EXERA II TJF TYPE Q180V REPROCESSING MANUAL

Page 59

Chapter 5 Reprocessing the Endoscope (and related reprocessing accessories)

Air bubbles

Channel opening

Bending section

• A continuous series of air bubbles emerging from any

location on the endoscope indicates a leak at that location. If

there is a leak in the instrument channel or suction channel of

the endoscope, a continuous series of air bubbles will