Olympus Sonic 1200S/HR User Manual

Sonic® 1200S/HR Ultrasonic Flaw

Detector

User’s Manual

PN 7720044, PN 7720066 — March 2006

In accordance with European Directive 2002/96/EC on Waste Electrical and Electronic

Equipment, this symbol indicates that the product must not be disposed of as unsorted

municipal waste, but should be collected separately. Refer to your local Olympus NDT

distributor for return and/or collection systems available in your country.

Copyright © 2006 by Olympus NDT. All rights reserved.

No part of this manual may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying, recording, or by any information

storage and retrieval system, without the written permission of Olympus NDT, except

where permitted by law. For information, contact: info@OlympusNDT.com.

Panametrics, Panametrics-NDT, and the Panametrics-NDT logo are trademarks of

Panametrics Inc.

Other product names mentioned in this document may be trademarks of their

respective companies, and are mentioned for identification purposes only.

Printed in the United States of America.

Warranty

The Sonic 1200S/HR has been designed and manufactured as a high quality instrument.

Inspect the unit thoroughly upon receipt for evidence of external or internal damage that may

have occurred during shipment. Notify the carrier making the delivery immediately of any

damage, since the carrier is normally liable for damage in shipment. Preserve packing

materials, waybills, and other shipping documentation in order to establ ish damage claims.

After notifying the carrier, contact Olympus NDT

claims, and provide replacement equipment, if necessary.

Olympus NDT guarantees the Sonic 1200S/HR to be free from defects in materials and

workmanship for a period of one year (twelve months) from date of shipment. This warranty

only covers equipment that has been used in a proper manner as described in this instruction

manual and has not been subjected to excessive abuse, attempted unauthorized repair, or

modification. DURING THIS WARRANTY PERIOD, Olympus NDT LIABILITY IS

STRICTLY LIMITED TO REPAIR OR REPLACEMENT OF A DEFECTIVE UNIT AT ITS

OPTION. Olympus NDT does not warrant the Sonic 1200S/HR to be suitable of intended use,

or fitness for any particular application or purpose. Olympus NDT accepts no liability for

consequential or incidental damages including damage to pro perty and/or personal injury. In

addition to our standard one year warranty, Olympus NDT also offers an optional two year

warranty (call for further details).

TM

so that we may assist in the damage

This warranty does not include transducers, transducer cables, or battery. The customer will

pay shipping expense to the Olympus NDT plant for warranty repair; Olympus NDT will pay

for the return of the repaired equipment. (For instruments not under w arranty, the customer

will pay shipping expenses both ways.)

In this manual, we have attempted to teach the proper operation of the Sonic 1200S/HR

consistent with accepted flaw detection techniques. We believe the procedures and examples

given are accurate. However, the information contained herein is intended solely as a teaching

aid and should not be used in any particular application without independent testing and/or

verification by the operator or the supervisor. Such independent verification of procedures

Warranty iii

become more important as the criticality of the application increases.

For these reasons, we make no warranty, expressed or implied, that the techniques, examples,

or procedures described herein are consistent with industry standards nor that they will m eet

the requirements of any particular application. Olympus NDT expressly discl aims all implied

warranties of merchantability and of fitness for any particular application.

Olympus NDT reserves the right to modify all products without incurring the responsibility for

modifying previously manufactured products. Olympus NDT does not assume any li ability for

the results of particular installations, as these circumstances are not within our control.

THE WARRANTIES SET FORTH HEREIN ARE EXCLUSIVE AND ARE IN LIEU OF

ALL OTHER WARRANTIES WHETHER STATUTORY, EXPRESS, OR IMPLIED

(INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, AND WARRANTIES ARISING FROM COURSE OF DEALING

OR USAGE OR TRADE).

iv Warranty

Table of Contents

Warranty and PowerLink™

1 Preparation for Operation............................................................................. 1

1.1 Unpacking the Sonic 1200S/HR ........................................................................................ 4

1.2 Sonic 1200S/HR Packages................................................................................................. 5

1.3 Sonic 1200S+/HR+ Packages ............................................................................................ 8

1.4 Optional Accessories........................................................................................................ 11

1.5 Initial Inspection Checklist..................................... .......................................................... 11

1.6 Power Requirements ........................................................................................................ 12

1.7 Ni-MH Battery Characteristics......................................................................................... 14

1.8 Li-Ion Battery Characteristics.......................................................................................... 15

1.9 Charging the Ni-MH/Li-Ion Battery................................................................................ 16

1.10 Operating Environment................................... ... ............................................................. 20

2 Technical Data............................................................................................... 21

3 FastBreak Operation.................................................................................... 29

3.1 Getting Started with FastBreak Operation........................................................................29

3.2 Ready................................................................................................................................ 29

3.3 Operating Menu Structure................................................................................................ 30

3.4 Set..................................................................................................................................... 31

4 Control Descriptions..................................................................................... 35

4.1 Instrument Controls........................................................... ............................................... 36

4.2 Power Button.....................................................................................................................37

4.3 Displays............................................................................................................................ 37

4.4 Soft Keys.......................................................................................................... ................ 39

4.5 INC/DEC Arrow Keys......................................................................................................40

4.6 Main Menu Keys.............................................................................................................. 40

Table of Contents

4.7 Enter Key...........................................................................................................................42

4.8 Print Key........................................... ................................................................. ............... 42

4.9 SmartKnob™.................................................................................................................... 42

4.10 RCV and XMIT BNCs .................................................................................................... 42

4.11 Pulser Menu......................................................................................................... ............ 43

4.12 Receiver Menu.............................................................. ....................................................43

4.13 Range Menu..................................................................................................................... 44

4.14 Gate 1 Menu .................................................................................................................... 45

4.15 Gate 2 Menu .................................................................................................................... 46

4.16 Thickness Menu............................................................................................................... 47

4.17 Angle Menu................................ ......................................................................................48

4.18 DAC Menu...................................................................................................................... 49

4.19 Main Menu ............................................ .......................................................................... 50

4.20 SPCL Menu ......................................................... ............................................................ 51

4.21 Program Sub-Menu ......................................................................................................... 54

4.22 Report Form Sub-Menu.................................. ................................................................. 55

4.23 Clock Sub-Menu................................. .............................................................................. 56

4.24 A-scan Sub-Menu............................................................................................................ 57

4.25 A-scan Attribute Sub-Menu ............................................................................................ 58

4.26 Data Sub-Menu................................ ................................................................. ............... 59

4.27 New Block Editor..................................... ....................................................................... 60

4.28 Block Review Sub-Menu .................................................................................................61

4.29 Text Editor................................................ ................................................................. ...... 62

4.30 Instrument Reset.............................................................................................................. 63

5 Applications................................................................................................... 65

5.1 Pulse-Echo Contact Thickness Testing ............................................................................ 65

5.2 Dual Transducer Thickness Testing................................................ ...................................74

5.3 Delay Line Thickness Testing .................................... ...................................................... 87

5.4 Shear Wave (Angle Beam) Testing .................................................................................. 98

5.5 Distance Amplitude Correction (DAC) Testing ............................................................. 112

6 Internal Datalogger..................................................................................... 119

6.1 Introduction .................................................................................................................... 119

6.2 Creating a New Block .....................................................................................................120

6.3 Selecting a Block................................. ........................................................................... 121

6.4 Storing Readings into Memory ...................................................................................... 121

6.5 Selecting Locations and Reviewing Readings ............................................................... 122

6.6 Clearing Readings .......................................................................................................... 122

6.7 Clearing a Block............................................................................................................. 123

6.8 Deleting a Block........................ .................................................................... ................. 124

6.9 Deleting All Blocks.................................................................................................. ...... 124

7 Computer Interface .................................................................................... 127

7.1 Description..................................................................................................................... 127

7.2 RS-232 Communication .................................................................................................128

7.3 Modes of Operation........................................................................................................ 130

7.4 Command Strings........................................................................................................... 130

7.5 Status Reporting............................................................................................................. 131

7.6 RS-232 Command Set................................... ................................................................. 132

7.7 Examples........................................................................................................................ 143

Documentation Comments

Table of Contents

1. Preparation for Operation

What’s in this section?

Introduction to PowerLink™

• 1.1 Unpacking the Sonic® 1200S/HR

• 1.2 Sonic

• 1.3 Initial Inspection Checklist

• 1.4 Power Requirements

• 1.5 Ni-MH Battery Characteristics

• 1.6 Li-Ion Battery Characteristics

• 1.7 Charging the Ni-MH / Li-Ion Battery

• 1.8 Operating Environment

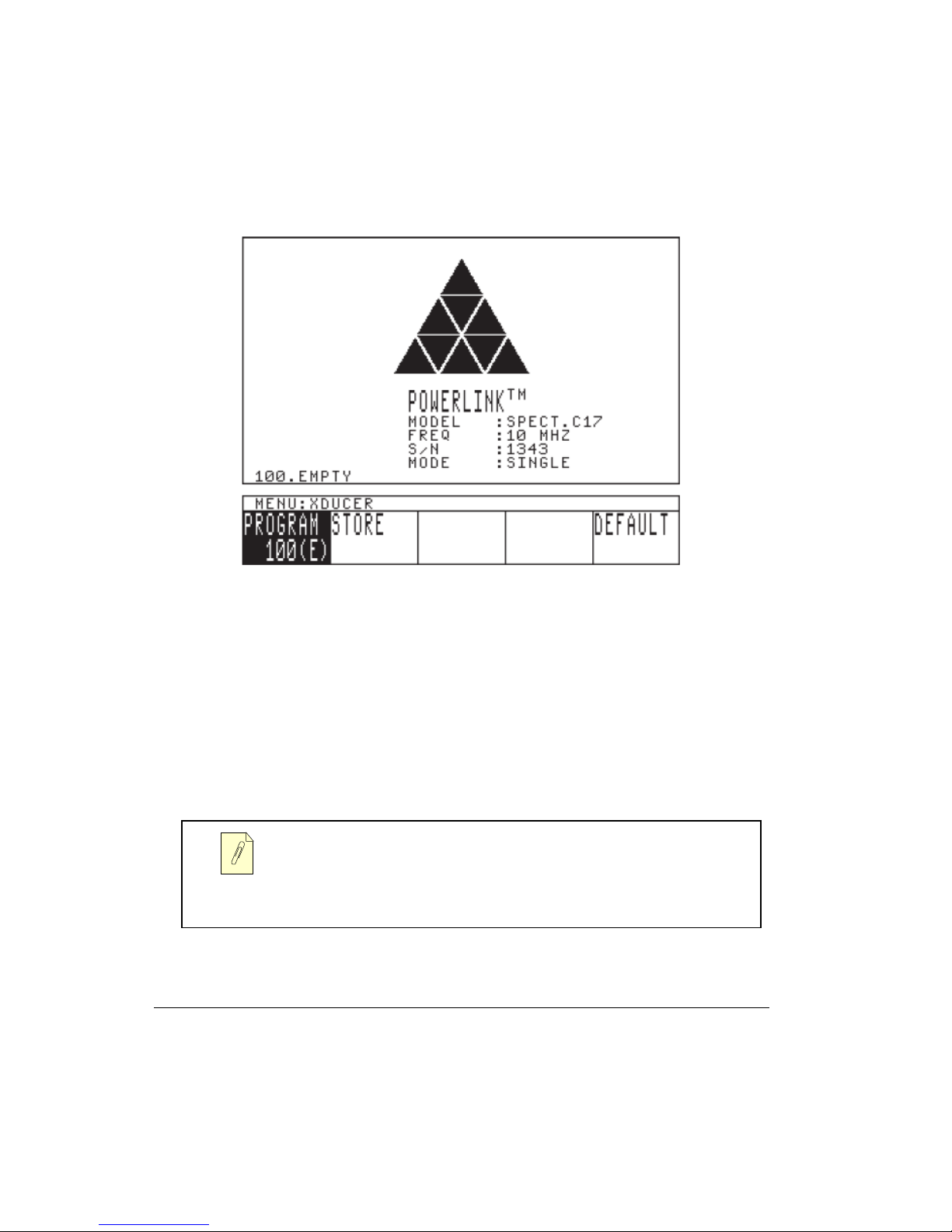

Introduction to PowerLink™

®

1200S/HR Optional Accessories

The PowerLink™ feature enables the Sonic

NDT PowerLink transducer type and provides the capability to modify selected instrument

parameters for program storage and recall. PowerLink has a separate screen with a sign-on

®

1200S/HR instrument to recognize a Olympus

Preparation for Operation 1

message and menu structure (as shown).

Each PowerLink transducer is programmed at the factory to identify itself by model,

frequency, serial number and type. The operator may select the factory default setup for each

transducer type in the event that an instrument setup has not been associated with that

transducer.

The stored program feature is tied into the program store and recall features of the instrument.

This makes stored programs associated with transducers look the same to the operator as other

stored programs.

Before any stored transducer programs can be recalled, a Olympus NDT transducer must be

connected to the instrument and identified. Multiple programs are associated with each

transducer and the operator is allowed to select from the programs stored.

When a transducer linked through PowerLink is removed and replaced with

another transducer, the Sonic

®

1200S/HR instrument MUST be recalibrated, or the

new transducer relinked before testing.

2 Chapter 1

PowerLink™ Connection

®

After connecting a Olympus NDT transducer to your Sonic

1200S/HR instrument, touch and

hold the transducer to the PowerLink contact disc on your EL/LCD display for approximately

4 seconds, or 2 beeps. If contact is not

maintained for the proper amount of time, the screen

will show the PowerLink display with N/A parameters. In this case, try again, until the

PowerLink connection is complete and parameters are displayed.

Menu Description

• ModelTransducer Model

• FrequencyTransducer Nominal Frequency

• S/NSerial Number (stamped on the front of the transducer)

• ModeSingle or Dual

• Program Name and Date Stamp - Program num ber, optional operator-entered description,

and date stamp. The stored program number is shown in the PROGRAM softkey menu

box.

Program

This line displays the program storage location/transducer setup, which is to be stored,

recalled, or erased. Rotating the SmartKnob

™

will cycle through the storage locations

associated with the identified transducer. If no stored locations are associated with the

identified transducer, the number of the next empty storage location will be displayed.

Store/Recall

Instrument settings associated with the identified transducer are stored to or recalled from the

selected program location. If the location is empty, the operator is allowed to store the

instrument setup. Whenever a transducer setup is recalled, the current instrument settings are

overwritten and cannot be recovered unless the setup was previously saved.

Erase

Allows the operator to erase the selected transducer setup. This needs to be done only if the

storage location is to be reused. An ENTER confirmation will be required from the operator

before the program location is cleared. An erased location cannot be recovered.

Name

Allows the operator to enter a name of up to 26 characters to identify the setup. Only program

locations which are not empty may be named.

Preparation for Operation 3

Default

Restores the factory default instrument setup and changes the PULSEWIDTH, FREQUENCY,

and MODE parameters of the receiver in accordance with the identified transducer parameters.

The PowerLink menu may be exited at any time without changing instrument setups by

pressing any menu key on the main keypad. When recalling default setups for an angle b eam

transducer, the operator will be sent to the ANGLE menu on return from the PowerLink menu.

When recalling the default setting from a nonangle beam transducer, the operator will be

returned to the RCVR menu on exit from PowerLink.

1.1 Unpacking the Sonic 1200S/HR

All cartons should be opened and inspected upon receipt. The cartons and contents should be

inspected for any signs of damage that may have occurred during shipment. If damage is noted,

contact the carrier and retain the damaged shipping materials until an inspection can be

performed by a representative of the carrier. With the exception of the UBC (universal battery

charger) and external accessories, all Sonic

shipped. Check the contents of the carton or cartons against the Packing List to ensure that all

accessories ordered have been received.

®

1200S/HR options are installed before the unit is

4 Chapter 1

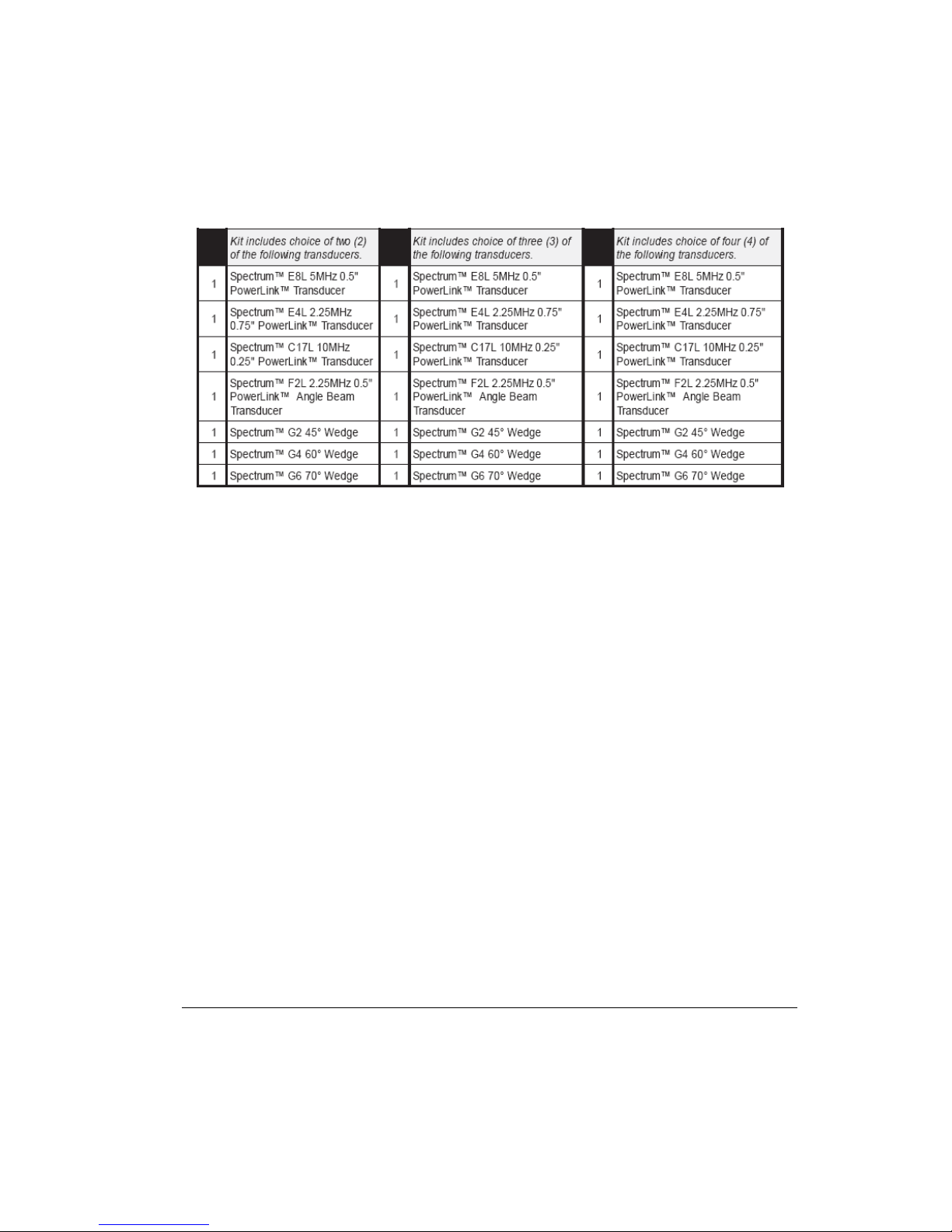

1.2 Sonic® 1200S/HR Packages

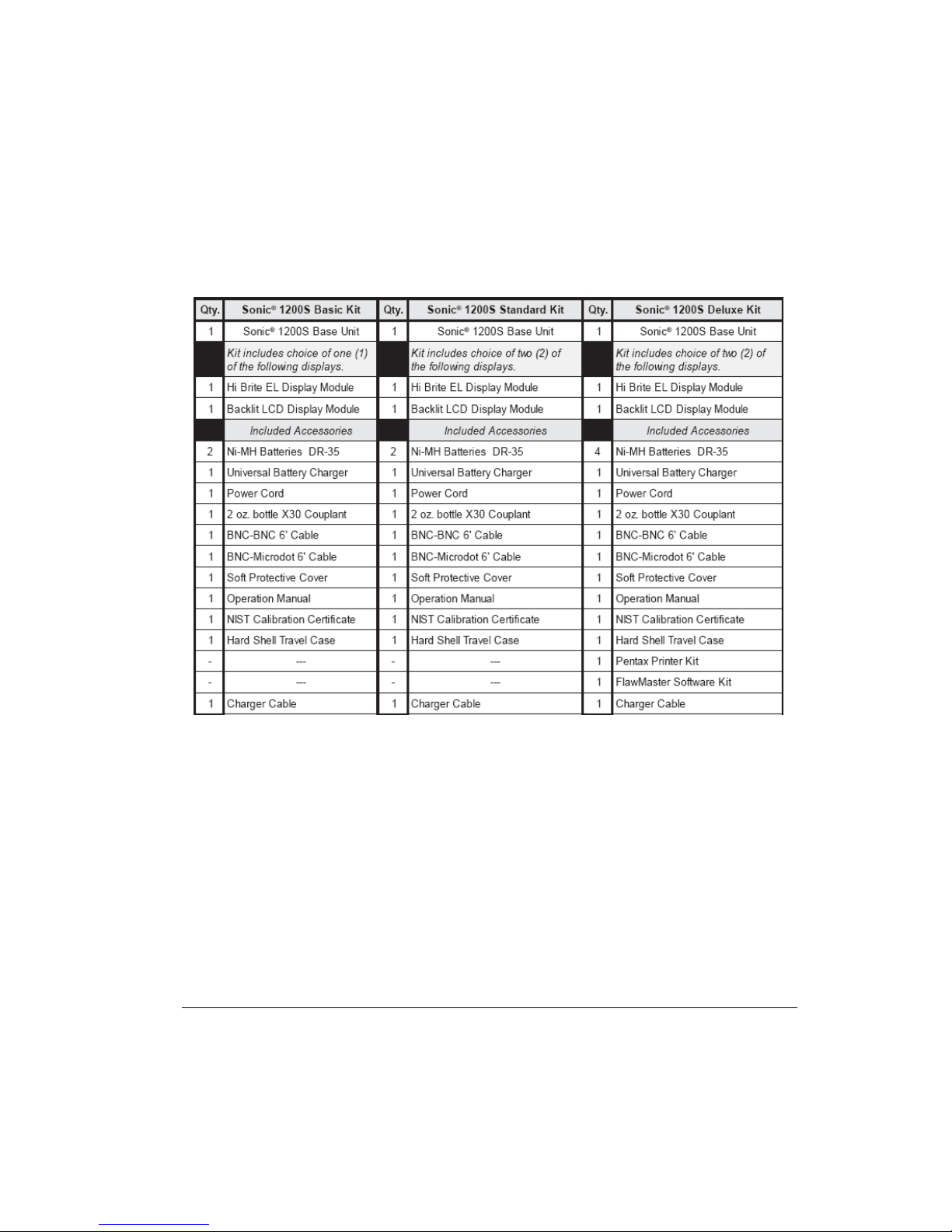

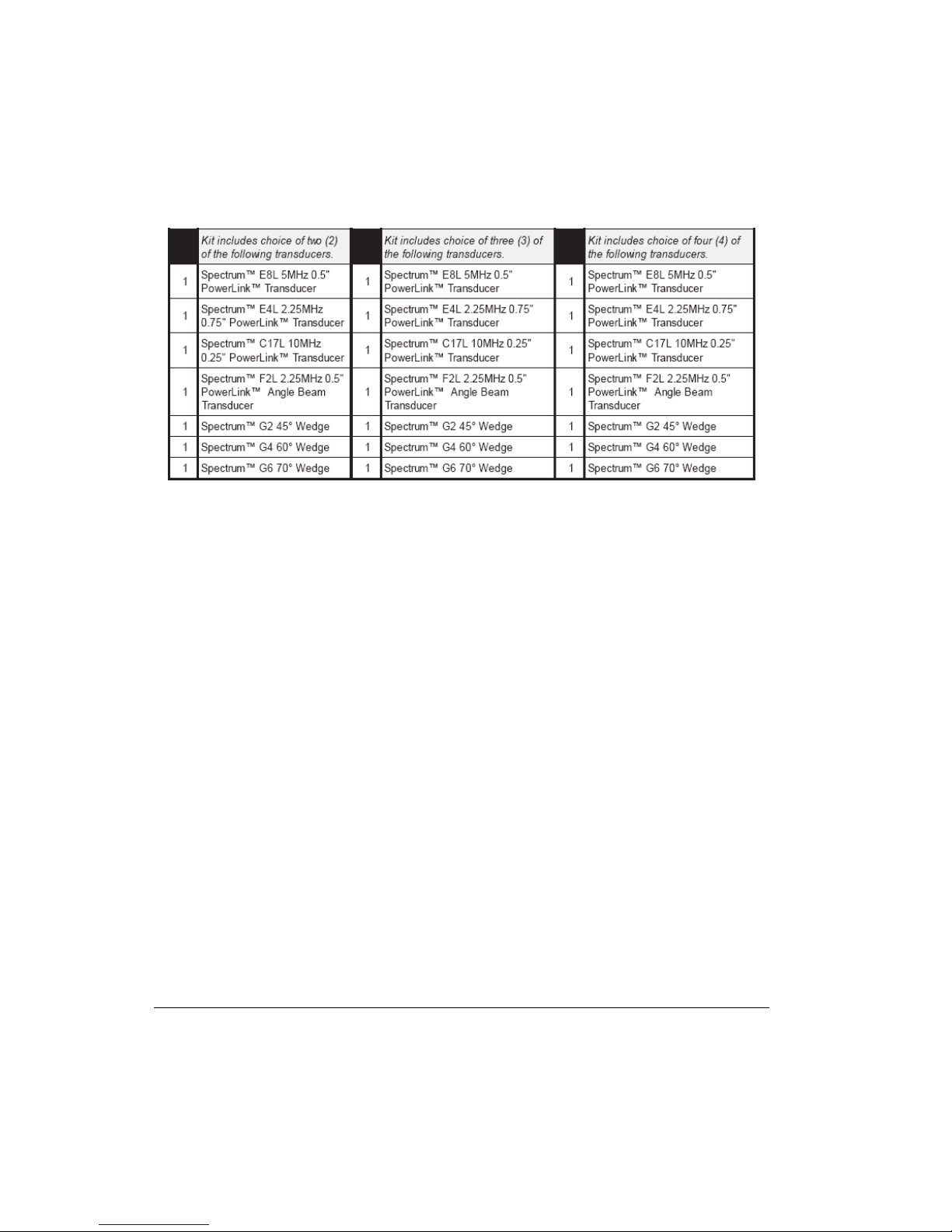

1.2.1 Sonic

®

1200S Packages

Preparation for Operation 5

6 Chapter 1

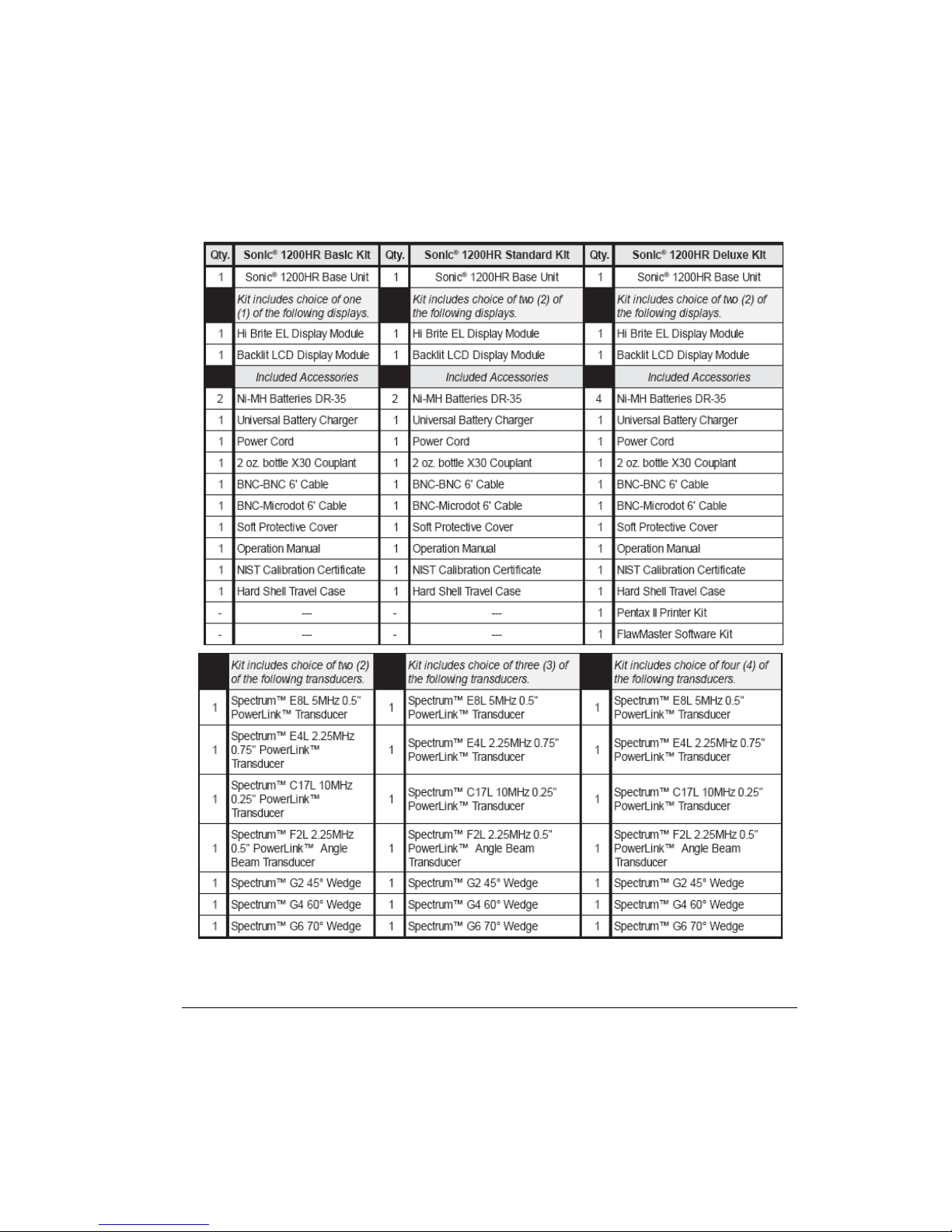

1.2.2 Sonic

®

1200HR Packages

Preparation for Operation 7

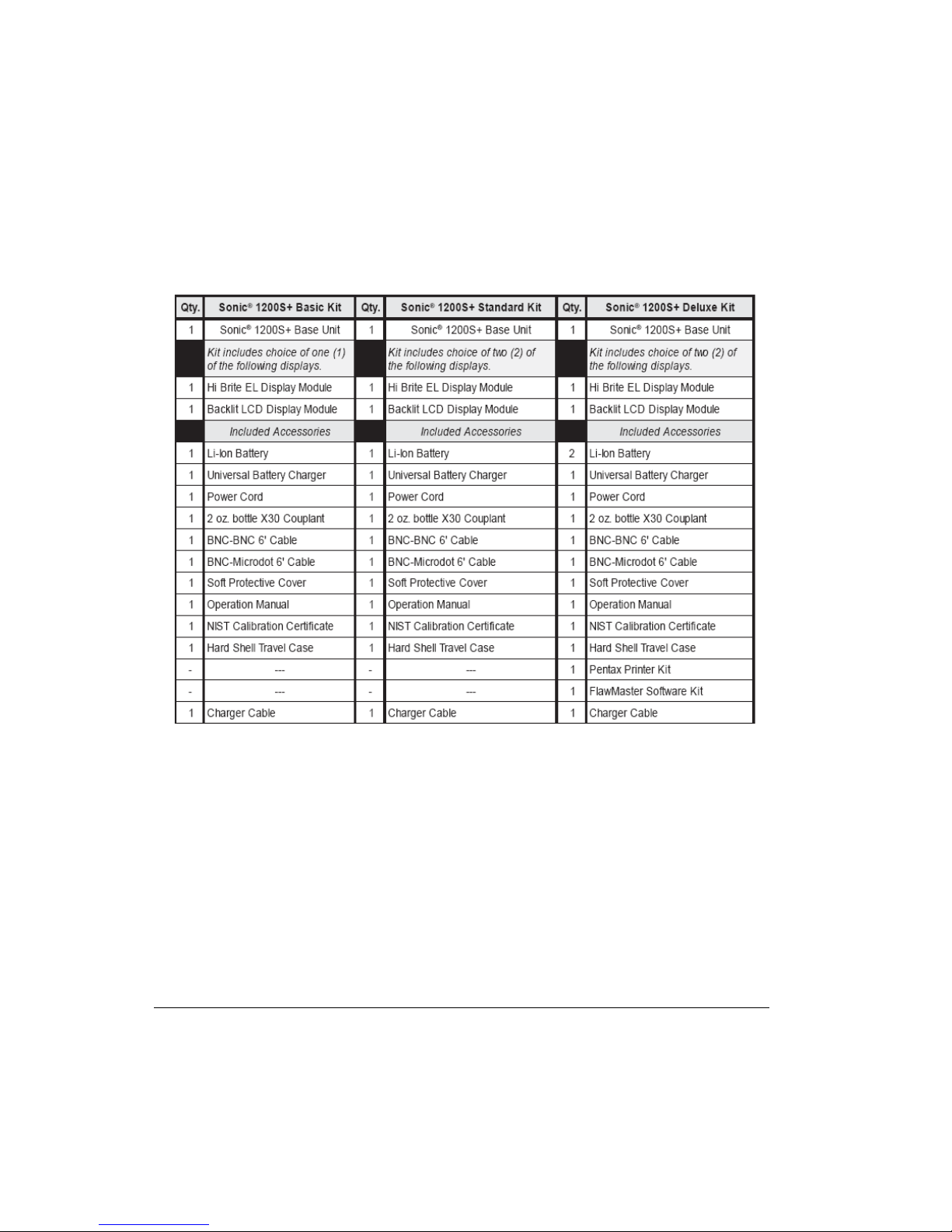

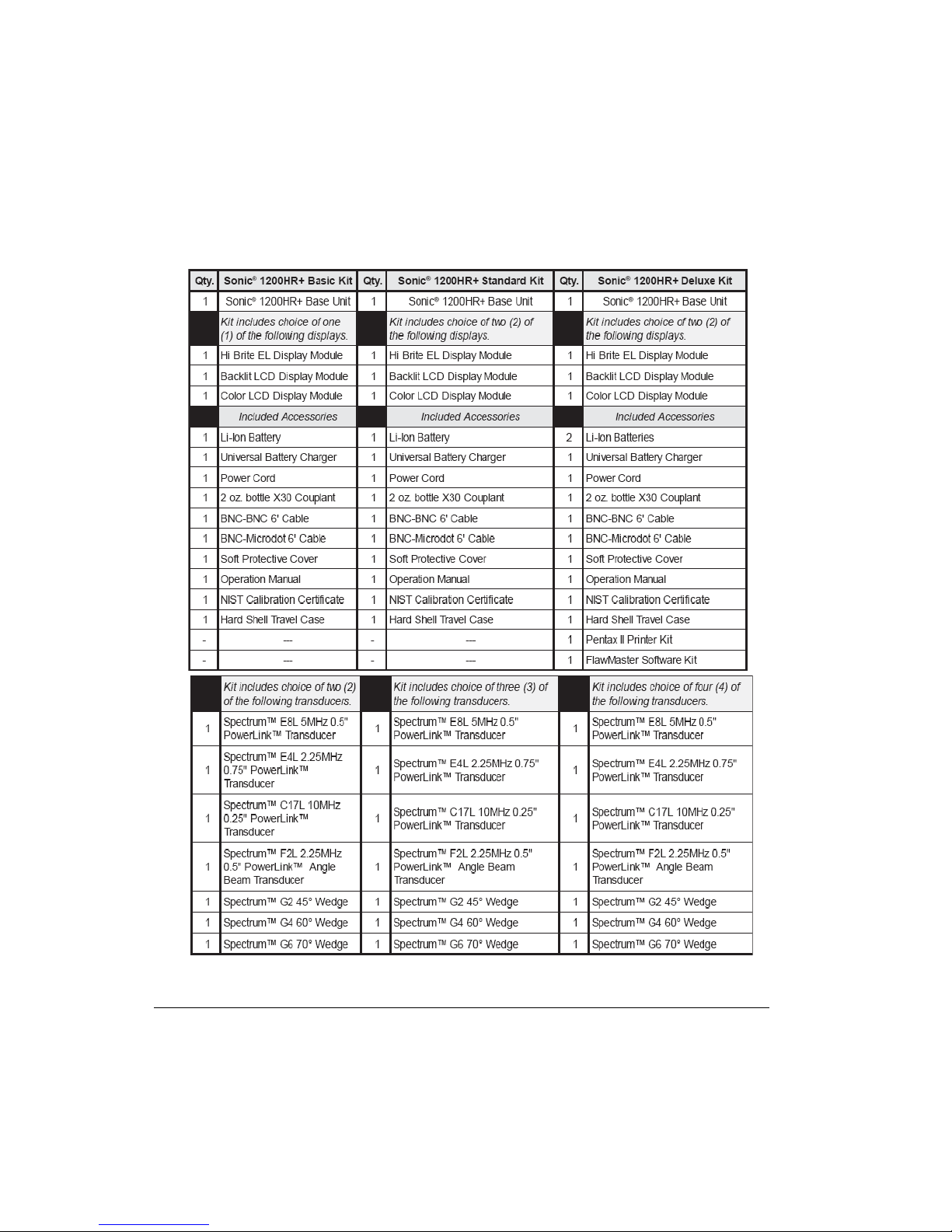

1.3 Sonic® 1200S+/HR+ Packages

1.3.1 Sonic® 1200S+ Packages

8 Chapter 1

Preparation for Operation 9

1.3.2 Sonic® 1200HR+ Packages

10 Chapter 1

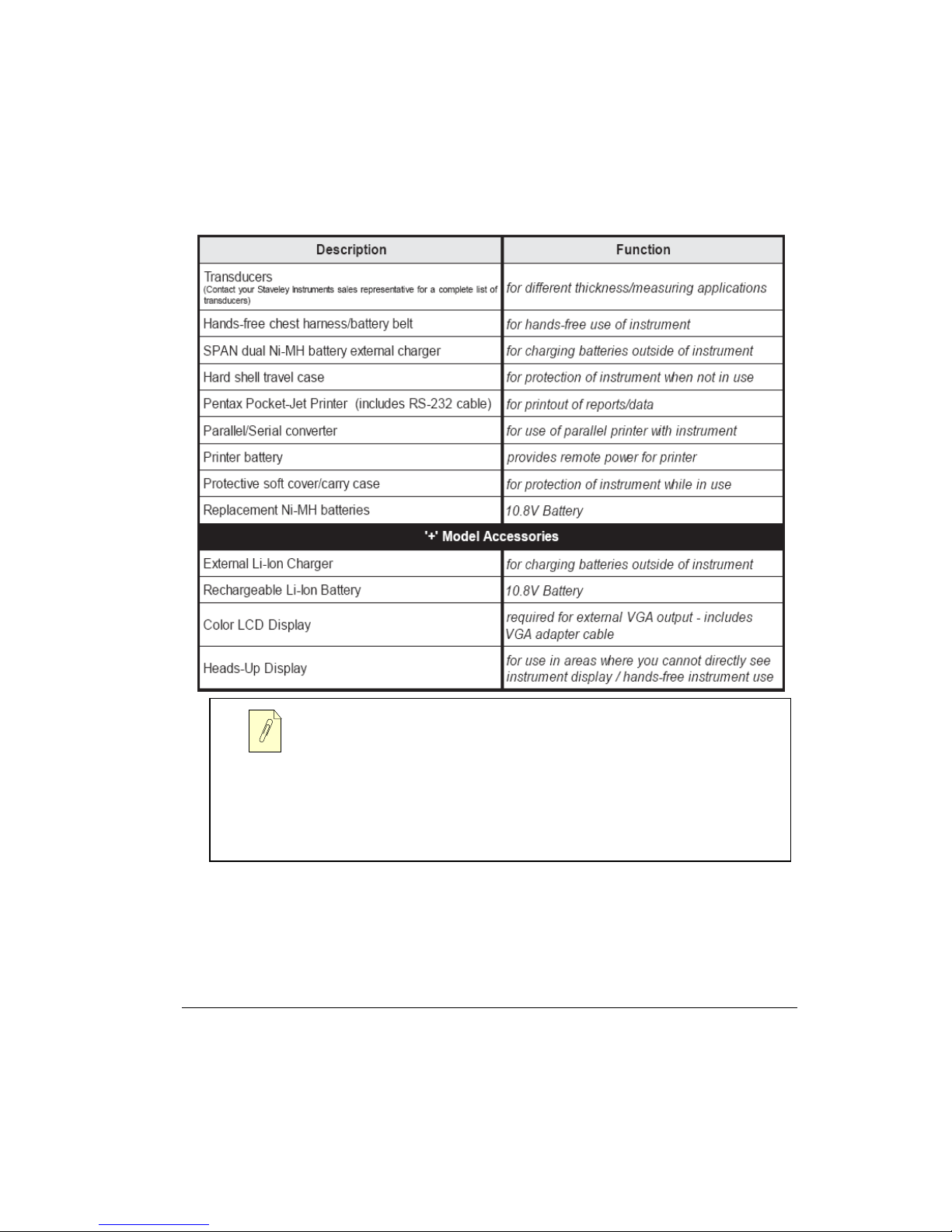

1.4 Optional Accessories

Hands-free Chest Harness/Battery Belt - This accessory is designed to hold the

weight of the Sonic

equipment and it’s accessories. Specifically, the pouch on the chest harness is

designed to hold the DR-35 battery sled, which adds two b atteries to the system to

extend field operation time. THE CHEST HARNESS IS NOT DESIGNED TO

SAFELY SUPPORT THE WEIGHT OF THE USER IN ANY SITUATION!

®

/Nortec®/BondMaster 1200 series of nondestructive test (NDT)

1.5 Initial Inspection Checklist

After the Sonic® 1200S/HR has been unpacked and the contents of the carton have been

checked against the packing list, a visual inspection and a basic operation test should be

Preparation for Operation 11

performed.

• Cosmetic or structural damage?

• Istrument Power “On”

•Power On Self Test

• EL/LCD Sign On Message displays?

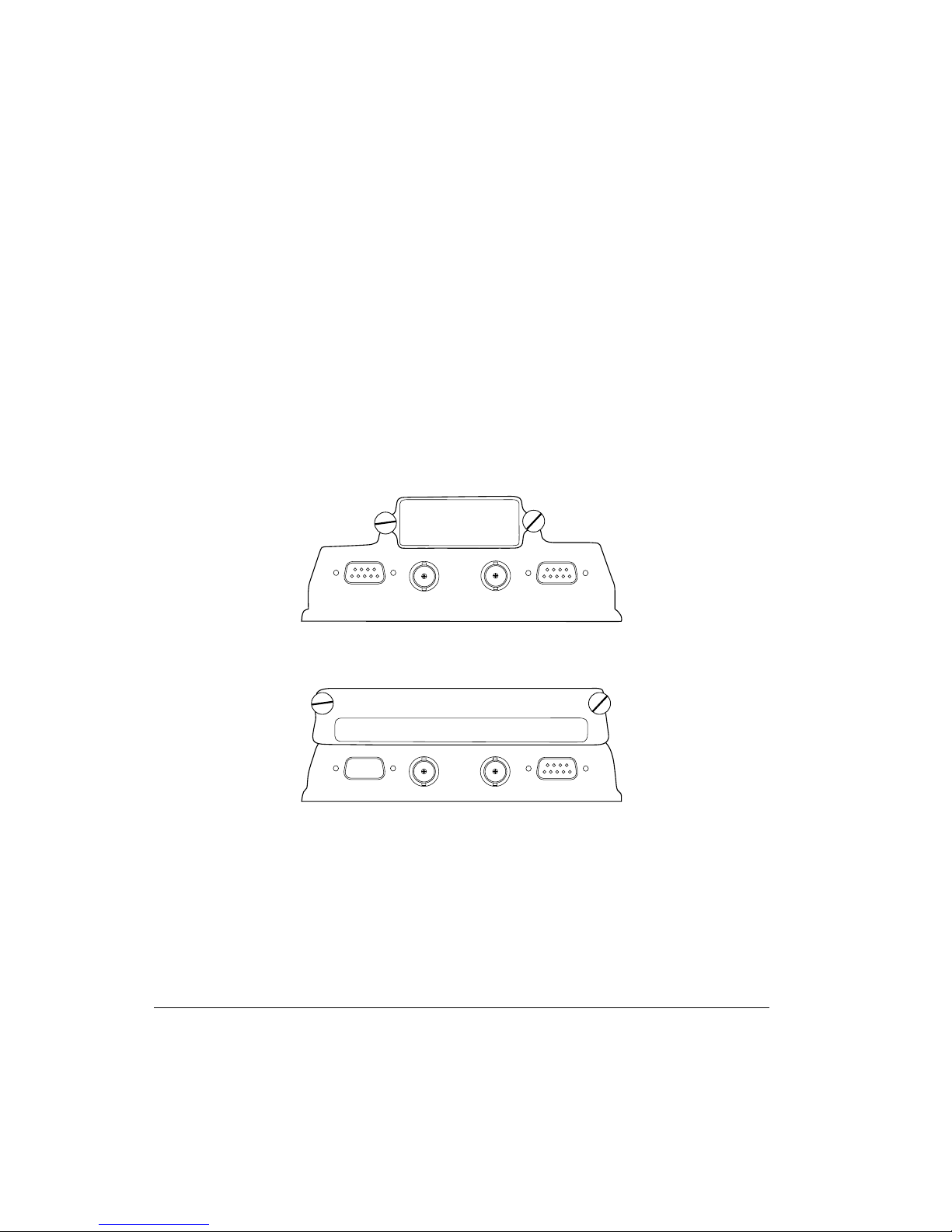

1.6 Power Requirements

As a fully portable inspection instrument, the Sonic® 1200S/HR relies on two nickel-metal

hydride (Ni-MH) batteries (one Lithium Ion (Li-Ion) battery on ë+’ models) as the primary

source of power. The battery compartment is located at the rear of the unit and is conveniently

accessed by loosening the two quick release screws and removing the battery cover.

Li-Ion

RCV XMT

Top of Instrument

Ni-MH

RCV XMT

Figure 1-1: Battery Cover Locations

The batteries provided with the Sonic

®

1200S/HR instrument are small, lightweight, portable,

and capable of delivering long service life between recharges or battery replacement.

A Universal Battery Charger (UBC) unit is pro vided wi th the S onic

®

1200S/HR for recharging

the batteries while in the instrument or external battery pack and allowing the Sonic

1200S/HR to be operated from AC line power. The UBC unit auto senses 90-264 VAC, 47 to

12 Chapter 1

®

63 Hz power.

®

The condition of the batteries used in the Sonic

1200S/HR is monitored by the charger. Fully

discharged Ni-MH batteries will require approximately 8 hours for a complete charging cycle

(4 hours for each battery), while Li-Ion batteries will require approximately 6 hours. The

charger will not charge batteries which are too hot, too cold, or too deeply discharged.

For optimum performance:

• Refer to the manual that came with your instrument or charger for charging instructions.

• When you charge your battery for the first time, your charger may indicate that charging is

complete after just 10 to 15 minutes. This is normal and can happen with all rechargeable

batteries when first charged. Simply remove the battery and then repeat the charging

procedure.

• Upon first use, or after prolonged periods of storage, you may need to charge and

discharge your battery two or three times before obtaining optimum performance.

• It is best to charge the battery at room temperature ranging between 59°F (15°C) and 86°F

(30°C).

• It is normal for the battery to become warm during charging or after use.

• It is not necessary to fully discharge your battery before charging. You can top-off the

charge at any time.

• A charged battery will gradually lose its charge if left in storage. We therefore suggest that

you top-off the charge before use.

• Remove your battery from the equipment, charger or AC adapter when not in use. Store at

room temperature in a dry place.

To avoi d damage to the battery:

• Do not drop the battery or subject it to mechanical shock.

• Use the battery only with equipment that specifies its use.

For safe operation:

• Do not disassemble or attempt to open the battery under any circumstances.

• The battery can explode, leak, or catch on fire if heated or exposed to fire or high

temperatures.

• Do not short circuit the battery by directly connecting the metal terminals (+, -). Be certain

that no metal objects such as coins, paper clips, etc., touch the terminals.

• Only use the charger recommended by the device manufacturer.

Preparation for Operation 13

Note that internal memory batteries should be changed as a preventative maintenance feature

every two (2) years.

It is recommended that you refrain from operating the instrument while recharging

fully discharged batteries. The charge may be incomplete and thus activate the temperature

fault indicator — as a result, battery life and instrument run time may be shortened

significantly. If the indicator is activated, shut off the instrument and disconnect the

instrument from the charger. Allow the batteries to cool, then reconnect the charger to the

instrument to start a new charge cycle.

1.7 Ni-MH Battery Characteristics

• Higher capacity - up to 40% longer run time than ordinary nickel-cadmium bat teries of

equivalent size

• Fast Charge - approximately 4 - 6 hours

• Long cycle life - up to 500 charge/discharge cycles

• Temperature Range (charging) - 32°F to 104°F (0°C to 40°C)

• Temperature Range (operating) - 32°F to 122°F (0°C to 50°C)

• Temperature Range (storage) - -4°F to 122°F (-20°C to 50°C)

• Environmental friendliness - 0% cadmium, no disposal problems

• Size L x W x H - 8.5 x 2.1 x 0.7 in. (215 x 53 x 19 mm)

• Weight - 18.4 oz. (515 g)

• Nominal Voltage - 10.8V

• Rated capacity - 3.8 Ah nominal

• Hours of Operation - 10+ hours with EL display or Monochrome LCD display

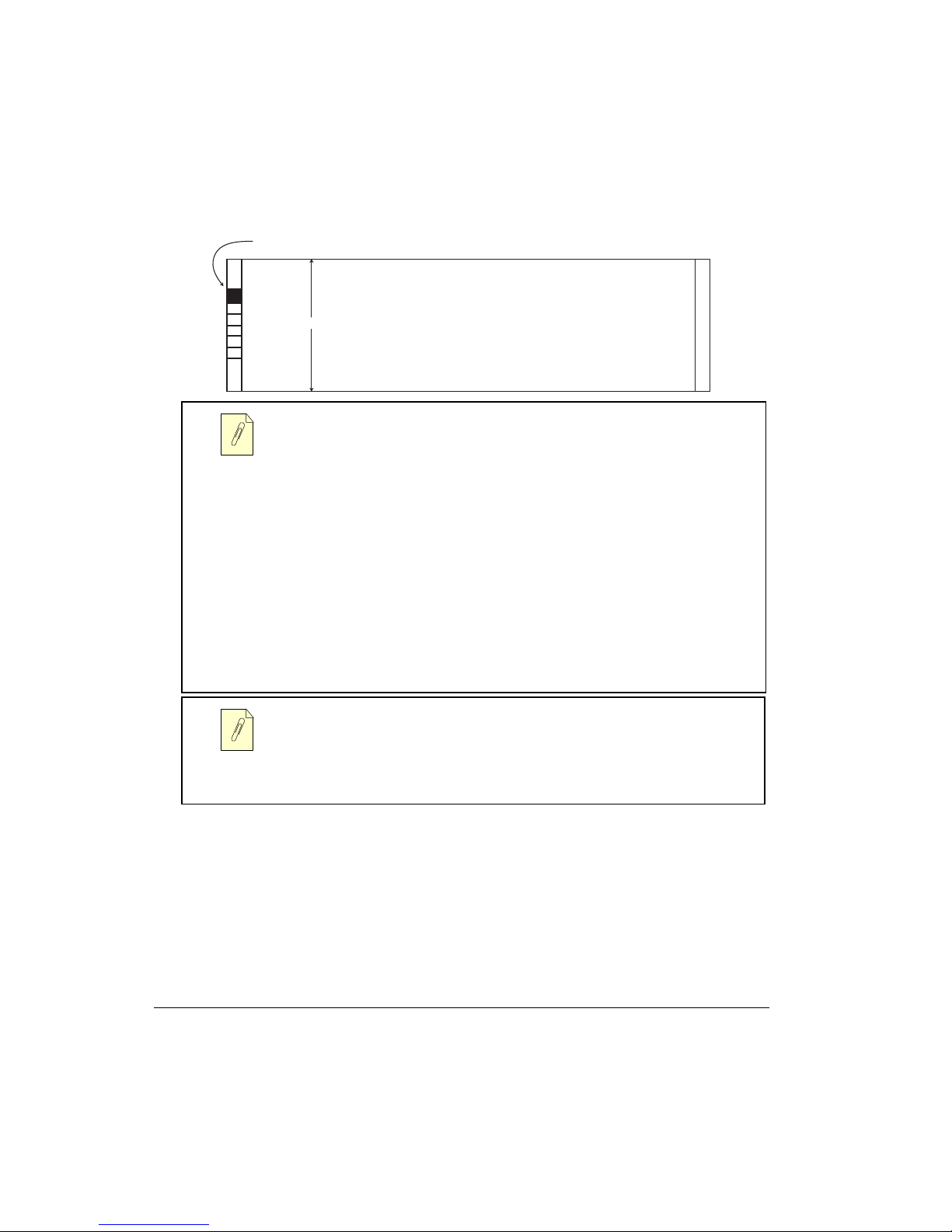

Narrow Keyway

+

2" Wide

-

14 Chapter 1

Ni-MH Battery

1.8 Li-Ion Battery Pack Characteristics

• Higher capacity - up to 60% longer run time than ordinary Ni-MH batteries of equivalent

size

• Fast Charge - approximately 4 - 6 hours

• Long cycle life - up to 300 charge/discharge cycles

• Temperature Range (charging) - 32°F to 104°F (0°C to 40°C)

• Temperature Range (operating) - -4°F to 140°F (-20°C to 60°C)

• Temperature Range (storage) - -4°F to 122°F (-20°C to 50°C)

• Environmental friendliness - 0% cadmium, no disposal problems

• Size L x W x H - 8.5 x 2.3 x 0.9 in. (215 x 59 x 23 mm)

• Weight - 17.6 oz. (493 g)

• Nominal Voltage - 10.8V

• Rated capacity - 6.6 Ah nominal

Preparation for Operation 15

• Hours of Operation - 8+ hours with EL display, Monochrome LCD, or Color LCD display

Wide Keyway

+

-

2¼" Wide

Li-Ion Battery

Fully charge battery before first use. Instrument run time is affected by

variables such as: quality of charge, age of battery, and display type. The battery

charge indicator on the display is an estimation of expected run time. Instruments are

equipped with a circuit that shuts off power prior to full discharge. Battery life is

affected by: number of charge/discharge cycles, storage conditions, temperature, and

use. Batteries stored for extended periods of time (mon ths/years) without use may no

longer recharge. Under normal use Nickel-Metal Hydride (NiMH) batteries last

approximately 500 charge/discharge cycles, while a Lithium-Ion battery will last

approximately 300 cycles. Expect to change the batteries after 1 year of heavy use or 3

years of light use under normal conditions. Batteries must be disposed of in

accordance to local law or returned to Olympus NDT Instruments. Olympus NDT

Instruments does not warranty batteries, due to op erating conditions beyo nd Olympus

NDT’s control affecting battery life.

Dual Ni-MH battery run time for the Sonic

is at least 10 hours. Dual Ni-MH battery run time for the Sonic

®

1200S/HR with the LCD module

®

1200S/HR with the

electroluminescent (EL) display module at 100% intensity, is at least ten (10) hours.

1.9 Charging the Ni-MH/Li-Ion Battery Pack

Proper charging of the Ni-MH/Li-Ion battery packs is critical for overall life and performance.

The Universal Battery Charger (UBC) will charge either the Li-Ion battery used in the single

battery instruments or both Ni-MH batteries in the dual battery instruments. Th e selection of

charging system is made by the detachable cable to instrument connection. The two instrument

categories have very different, non-interchangeable connectors to prevent an incorrect

16 Chapter 1

connection. Note that the UBC to instrument cables are detachable and replaceable as catalog

items.

The charger also functions as a battery eliminator to operate the instrument from the AC power

source. Batteries do not have to be installed to operate the instrument from AC. When operated

from the UBC without a battery installed in the instrument, disregard any battery charge status

indications from the UBC charge indicator. The instrument can be operated while a Li-Ion

battery is being charged, but is not recommended while charging Ni-MH batteries.

1.9.1 UBC Specifications

Power Requirements: 100-240 volts, 47 to 63 Hz.

The UBC contains an internal fuse.

Nickel Metal Hydride battery charging system: Sequentially charges two DR-35 style (Ni-

MH) batteries. Charges at approximately 1 ampere rate. A pair of 3.8 AH batteries take about 8

hours to fully charge.

Lithium Ion battery charging system: Charges one Li-Ion battery . Char ges at approximately 1.5

ampere rate. A 6.6 AH battery charges in approximately 6 to 8 hours.

Temp erature range: Batteries should be charged between 40° to 100° F (4° to 38° C) for best

results. If the batteries become too hot, the battery charger will terminate the charging process.

If the batteries are being charged while using the instrument, the heat from normal operation of

the instrument may cause the battery charger to terminate the charging process before the

batteries are fully charged.

To start a charge cycle, the charger can be reset by disconnecting and reconnecting either the

instrument or AC power to the UBC.

1.9.2 Charger Status Indicators

The charger status is indicated by a red/green LED lamp.

The light may blink red or green for a few seconds when first connected to either AC power or

an instrument. It will then light steady red as the charging process starts. This is normal as the

circuits initialize. If a problem is detected during charging, the light will blink red. Reset the

charger by disconnecting the AC power for a few seconds and re-connect. If the problem

persists, service is required.

Preparation for Operation 17

1.9.3 Charger Operation Instructions

1. Connect the UBC to a source of AC power.

2. Connect either the single battery Li-Ion or dual Ni-MH cable to the instrument and

charger.

3. Ni-MH batteries: The red charging indicator will light, indicating that the batteries are

charging. The charger will charge one battery and automatically switch to the second

battery when the first is charged. The indicator will turn green when both batteries are

charged. If only charging one battery, the green charge complete indicator will not light.

The red charging lamp will go out when the battery is charged. Ni-MH batteries generate

heat while in use, especially during charging. This heat, added to that generated by the

instrument, can cause the charger to terminate the charge cycle before the batteries are

fully charged. It is not recommended that NiMH batteries be charged while operating the

instrument. This is not due to power supply capacity, but heat build up within the

instrument.

4. Ni-MH batteries receive a continuous trickle charge whenever they are connected to the

UBC. If the instrument is being used on AC power for long periods of time, the batteries

should be removed from the instrument. They should be re-installed and recharged and

then removed at regular intervals to keep them fresh. 30 to 60 day intervals are

recommended.

5. Lithium-Ion batteries: The red charging indicator will light, indicating that the batteries

are charging. The indicator will turn green when the battery is charged.

6. The charger circuits can be reset if a problem occurs by disconnecting either the AC power

for at least 15 seconds or the UBC to instrument cable (either end) and then re-connecting.

Li-Ion batteries are sensitive to over charge. For this reason, the full charge detection

system is very sensitive and may shut off the charging process before the charge is

complete. If this happens, reset the charger. During use, the UBC case will become warm.

7. The charger is designed to shut off after a Li-Ion battery is fully charged (the instrument

power is always available). It does not provide a maintenance charge, because Li-Ion

batteries can be damaged by trickle charging. To recharge a Li-Ion battery, reset the

charger by either disconnecting the AC supply or instrument for a few seconds to reset the

charger circuit. Li-Ion batteries have a long shelf life and should only require recharging

after many months of storage if not used.

1.9.4 Battery Safety

Old batteries that will no longer deliver satisfactory service shoul d be disposed of in a legal

and environmentally friendly manner. In the USA, call 1-800-8BATTERY for the nearest

battery recycle center. If there is no convenient battery recycle center, the batteries may be

returned to Olympus NDT Instruments for proper disposal.

18 Chapter 1

No battery should be disposed of by fire or abused by puncturing its case or disassembled. All

batteries contain potentially hazardous chemicals, however neither Ni-MH or Li-Ion batteries

contain lead, cadmium or mercury.

Lithium-Ion batteries contain an internal safety circuit. Both Nickel-Metal Hydride and

Lithium-Ion batteries contain internal fuses. If this fuse blows or the safety circuit shuts off the

battery, the battery is no longer fit for service. The internal safety circuits are not serviceable.

Olympus NDT Instruments purchases batteries from reputable vendors. Although Olympus

NDT Instruments tests and qualifies the batteries for use in Olympu s NDT prod ucts, Olym pus

NDT can not guarantee that batteries obtained from other sources will be satisfactory or that

Olympus NDT supplied batteries will work in non Olympus NDT products. The Universal

Battery Charger is designed to work with Olympus NDT equipment only.

1.9.5 Battery Characteristics

Most batteries will not deliver their full charge on first use or after extended storage. Use them

until the instrument shuts off after full discharge (automatic low battery shut off) and recharge.

This will recondition the battery. This is especially prudent with Ni-MH batteries.

The battery is considered by the manufacturer to be beyond its service life when it delivers less

than 80% of its rated capacity. A Ni-MH battery should have a life expectancy of 500

charge/discharge cycles and Li-ion batteries, 300 cycles. These specifications are obtained

under laboratory conditions and real world usage will be different.

Battery life will be prolonged if they are not subjected to harsh temperatures, either hot or cold,

and stored in a charged condition. Ni-MH batteries should be recharged periodically. They

should not be left in the instrument when not being used over extended time.

Batteries have reduced capacity at low temperatures. Exact percentages are not specified but

operation below freezing is not recommended.

Preparation for Operation 19

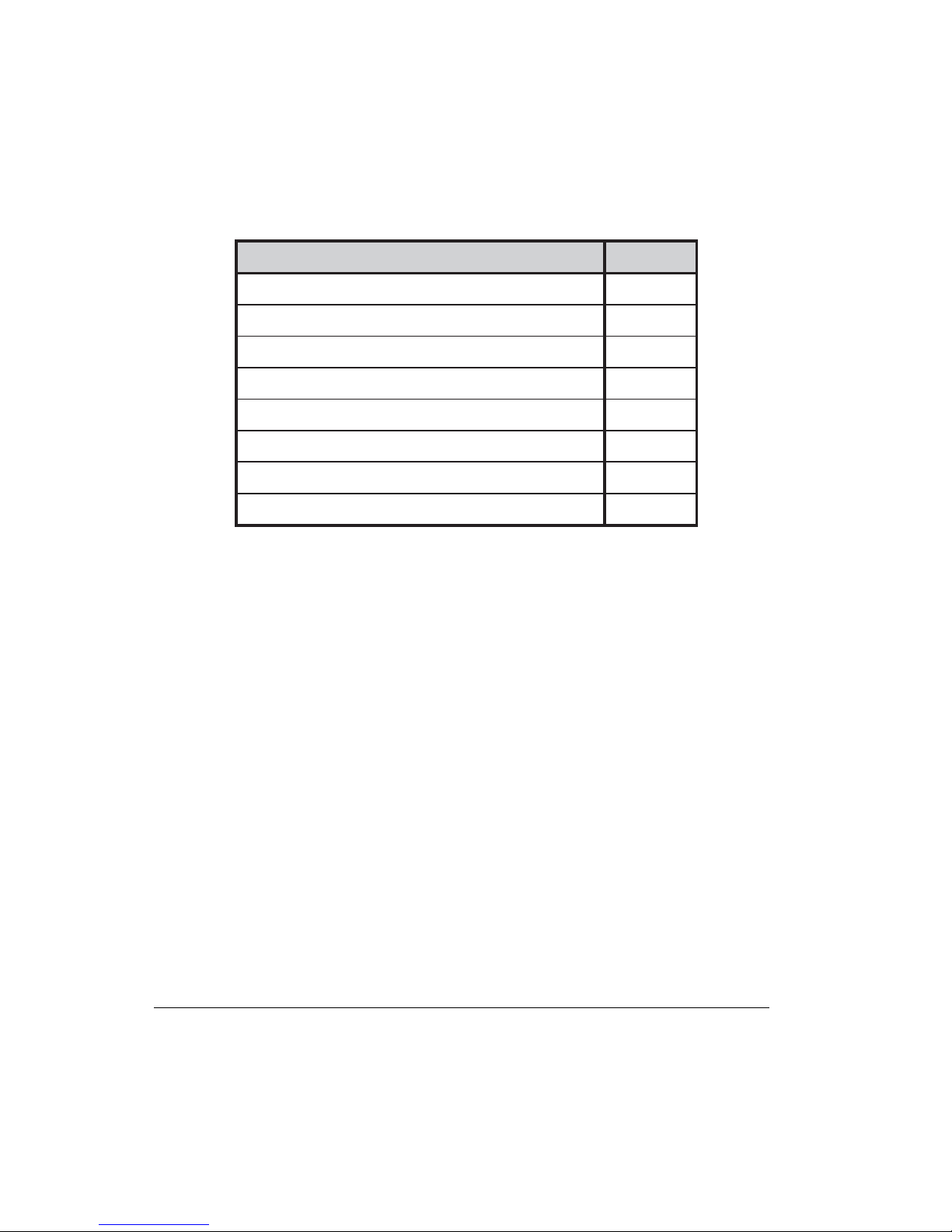

1.9.6 UBC Spare Parts

noitpircseDtraP rebmuNtraP

)CBU(regrahCyrettaBlasrevinU 3512259

NID 9222219

wopCA 9595020

taBedirdyHlateMlekciN53RD 7449110

yret

yrettaBnoImuihtiL 1549110

)023CEIotgnorpeerhtSU(elbacre

)023CEIotpma31KU(elbacrewopCA 9512220

)023CEIotrotcudnoc3nailartsuA(elbacrewopCA 5422220

)yrettabnoI-iL(stnemurtsniyrettabelgnisrofelbacrotcennoc

)yrettabHM-iN(stnemurtsniyrettablaudrofelbacrehcsiFnip7 0322219

1.10 Operating Environment

The Sonic® 1200S/HR is designed as a portable instrument and, as such, requires no special

site preparation before operation. When operating, the in strument should be firmly support ed

to prevent damage due to a fall. The unit should be protected as much as possible from water or

chemical splashes, rapid temperature changes, and should be operated away from large

electrical equipment that may interfere with the operation of internal circuitry.

20 Chapter 1

2. Technical Data

Pulser:

Type: Square wave.

Pulse Width: 30 to 1000 ns (HR: 15 to 500 ns

Accuracy: ±10% or 10 ns, whichever is greater.

Pulse Voltage: Selectable 300 or 150 volts.

Accuracy: +10/-15%.

Rise Time: < 15 ns.

Fall Time: < 60 ns damping 200 ohms. < 20 ns damping 50 ohms.

Damping: Selectable 25, 50 or 200 ohms.

Modes: Selectable single, dual, or through transmission.

Receiver:

Frequency Band: 0.3 to 20 MHz, +/-3 dB nominal.

Gain: 0 to100 dB in wideband, highpass, 10 MHz, and 15 MHz (HR). 0 to 110 dB in 1, 2.25,

and 5 MHz frequency settings.

Accuracy: ±0.5 dB for any 10 dB increment, cumulative errror < ±2.0 dB.

Control: Continuous adjustment in selectable 0.2, 1.0, 2.0, 6.0 or 12dB steps.

T echnical Data 21

+dB switch: Selectable 6, 12, 18, or 24 increment.

Accuracy: ±0.5 dB.

Tuning Range: Selectable 1, 2.25, 5, 10, 15(HR) MHz, wideband (0.3-15 MHz), and highpass

(3-20MHz).

Q: 0.9 less than or equal to Q less than or equal to 1.2

Linear Reject: 0 to 80% full screen.

Accuracy: ±0.5%.

Vertical Linearity: ± 2% full screen for 10% to 90% of full screen display.

Dynamic Range:> 34 dB (largest signal = 100% full screen height, smallest signal <= 2% full

screen height).

Sensitivity: Better than 200 µV.

Noise: <15 µV RMS

Display Modes: RF, R F+, RF-, fullwave, halfwave+, halfwave-, filter 1, 2, 3.

Thickness/RF: Thickness measure on live and frozen RF display modes.

DAC: Segmented with 25 operator selected points, segments generated automatically.

Range: 40dB, total of gain and DAC limited to 110dB maximum.

Accuracy: DAC range ±2dB, echo adjustment ±0.5dB.

Slew Rate: 6dB per µs.

Depth: Sum of timebase delay and range up to 400µs.

DAC Display: Selection of multiple curves showing compensation; single curve at signal level

(0 dB); three curves at +6 dB, 0, and -6 dB; four curves at +6 dB, 0, -6 dB, and -14 dB, JIS

curves at +6 dB, 0, -6 dB, and -12 dB, DAC compensated echoes only; single curves with

DAC compensated echoes.

Gates:

Gate Functions: Gate 1 time of flight, amplitude detect ion and flaw alarm. Gate 2 amplitude

detection and flaw alarm, time of flight for echo-to-echo mode.

22 Chapter 2

Loading...

Loading...