Page 1

INSTRUCTIONS

MECHANICAL LITHOTRIPTOR

BML-3Q-1

BML-4Q-1

USA: CAUTION: Federal law restricts this device to sale by or on the

order of a physician.

0197

Page 2

Page 3

Contents

Symbols

Important Information–Please Read Before Use

Intended Use 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instruction Manual 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Qualifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Compatibility 3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reprocessing and Storage 3. . . . . . . . . . . . . . . . . . . . . . . . . .

Repair and Modification 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Words 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings and Cautions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1 Checking the Package Contents

1.1 Checking the Package Contents 6. . . . . . . . . . . . . . . .

Chapter 2 Instrument

Nomenclature and Specifications

2.1 Nomenclature and Functions 8. . . . . . . . . . . . . . . . . . .

2.2 Specifications 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

Chapter 3 Preparation,

Inspection and Operation

3.1 Preparation 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Inspection 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Operation 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Emergency Treatment

4.1 Emergency Treatment 45. . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Reprocessing

5.1 General Policy 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Required Reprocessing Equipment 59. . . . . . . . . . . . . .

5.3 Cleaning 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Lubrication 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Assembly 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Sterilization 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iMECHANICAL LITHOTRIPTOR

Page 4

Contents

Chapter 6 Storage

6.1 Inspection Before Storage 77. . . . . . . . . . . . . . . . . . . . . .

6.2 Storage 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii MECHANICAL LITHOTRIPTOR

Page 5

Symbols

Symbols

The meaning(s) of the symbol(s) shown on the package,

the back cover of this instruction manual and/or this

instrument are as follows:

Refer to instructions.

Single use only

Use by (expiration date)

STERILE EO

STERILE LOT

LOT

Sterilized using ethylene oxide

Sterilization lot number

Lot number

Manufacturer

Authorised representative in the

European Community

1MECHANICAL LITHOTRIPTOR

Page 6

Important Information–Please Read Before Use

Important Information–Please

Read Before Use

Intended Use

These instruments have been designed to be used with an

Olympus endoscope for crushing calculi inside the bile

duct. Do not use these instruments for any purpose other

than their intended use.

Instruction Manual

This instruction manual contains essential information on

using this instrument safely and effectively. Before use,

thoroughly review this manual and the manuals of all

equipment which will be used during the procedure and

use the instruments as instructed.

Keep this and all related instruction manuals in a safe,

accessible location.

If you have any questions or comments about any

information in this manual, please contact Olympus.

User Qualifications

The operator of this instrument must be a physician or

medical personnel under the supervision of a physician

and must have received sufficient training in clinical

endoscopic technique. This manual, therefore, does not

explain or discuss clinical endoscopic procedures.

2 MECHANICAL LITHOTRIPTOR

Page 7

Important Information–Please Read Before Use

Instrument Compatibility

Refer to the Table in Section 2.2, “Specifications” to

confirm that this instrument is compatible with the ancillary

equipment being used. Using incompatible equipment can

result in patient injury and/or equipment damage.

Reprocessing and Storage

The Basket Wire was shipped in a sterile condition. Store

it following the instructions in Chapter 6, “Storage”.

Improper storage can present an infection control risk,

cause equipment damage or reduce performance.

The Basket Wire is a single-use, disposable item that is not

to be reprocessed. Do not reuse or attempt to sterilize it.

The Coil Sheath, the Tube Sheath and the BML Handle

were not sterilized before shipment. Before using the Coil

Sheath, the Tube Sheath and the BML Handle for the first

time, reprocess them according to the instructions in

Chapter 5, “Reprocessing”.

After using the Coil Sheath, Tube Sheath and BML Handle,

reprocess and store them according to the instructions in

Chapter 5, “Reprocessing” and Chapter 6, “Storage”.

Improper and/or incomplete reprocessing or storage can

present an infection control risk, cause equipment damage

or reduce performance.

Repair and Modification

This instrument and BML Handle do not contain any

user-serviceable parts. Do not disassemble, modify or

attempt to repair them; patient or user injury and/or

equipment damage can result.

3MECHANICAL LITHOTRIPTOR

Page 8

Important Information–Please Read Before Use

Signal Words

The following signal words are used throughout this

manual:

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, may result

in minor or moderate injury. It may also be

used to alert against unsafe practices or

potential equipment damage.

NOTE

Indicates additional helpful information.

Warnings and Cautions

Follow the warning given below when handling this

instrument and the BML Handle. This information is to be

supplemented by the warnings described in each chapter.

S Before use, thoroughly review the

method of use for this instrument and

BML-110A-1 in accordance with the

instruction manuals.

S Do not use this instrument for a

calculus that is assumed impossible to

be crushed by a lithotriptor. The pipe

or the basket wire may break and part

of this instrument may remain in the

body.

S Use this instrument by having the

settings to switch to open surgery and

the hospitalization plan ready in case

the calculus cannot be crushed by

lithotriptor BML-110A-1.

4 MECHANICAL LITHOTRIPTOR

Page 9

Important Information–Please Read Before Use

S A Lithotriptor cannot always crush all

calculi captured in the Basket.

Operation of this instrument is based

on the assumption that open surgery is

to be possible as an emergency

measure. If the calculus is too hard,

there is possibility that the damages

shown in Chapter 4 “Emergency

Treatment” may occur. Use this

instrument by considering that it may

lead to damaging the instrument and

that open surgery may have to take

place.

5MECHANICAL LITHOTRIPTOR

Page 10

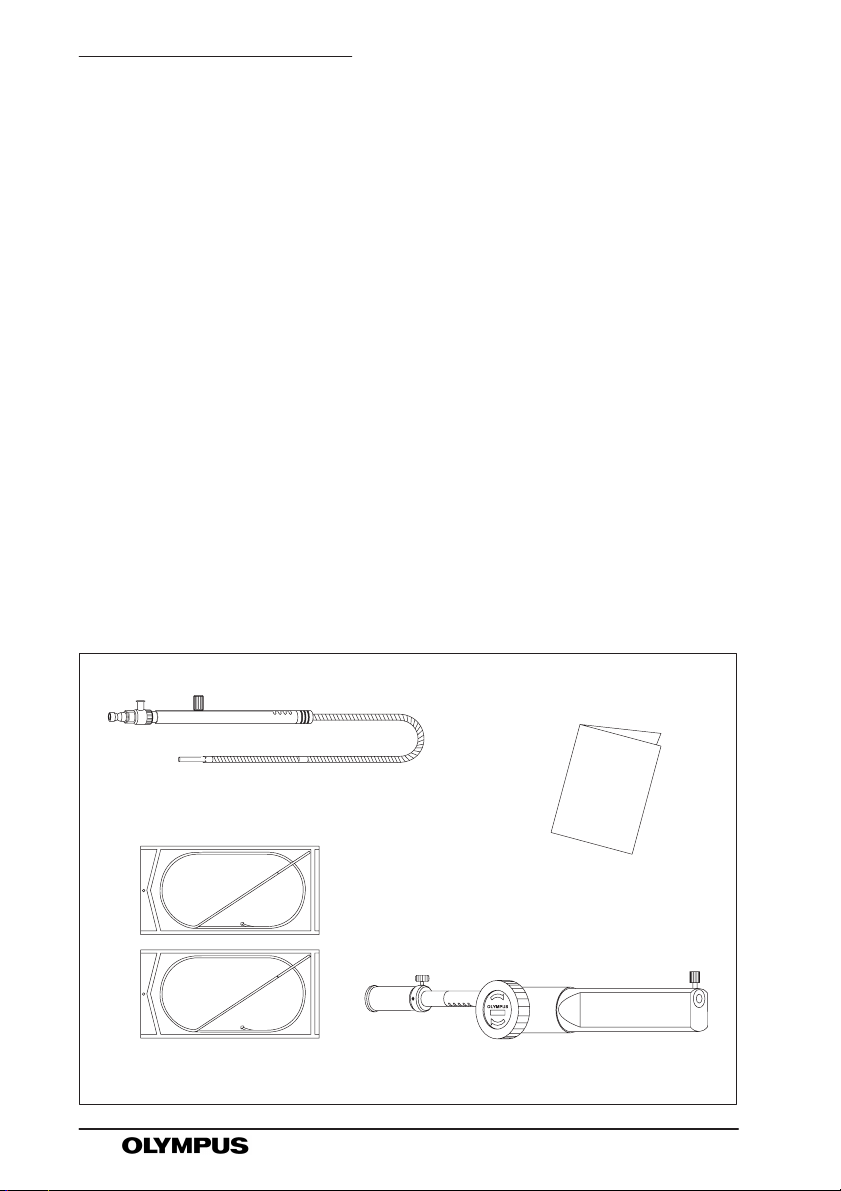

Chapter 1 Checking the Package Contents

Chapter 1 Checking the Package

Contents

1.1 Checking the Package Contents

Match all items in the package with the components shown

below. Inspect each item for damage. If the instrument or

the BML Handle is damaged, a component is missing or

you have any questions, do not use the instrument or the

BML Handle; immediately contact Olympus.

The Coil Sheath, the Tube Sheath and the BML Handle

were not sterilized before shipment. Before using the Coil

Sheath, the Tube Sheath and the BML Handle for the first

time, reprocess them according to the instructions in

Chapter 5, “Reprocessing”.

` A set

Coil Sheath and Tube Sheath

(Reusable)

Basket Wire (Sterile, Single use only)

6 MECHANICAL LITHOTRIPTOR

BML Handle (MAJ-440, Reusable)

Instruction Manual

Page 11

Chapter 1 Checking the Package Contents

` B set

Coil Sheath (Reusable, 1 piece)

Tube Sheath (Reusable, 1 piece)

Basket Wire (Sterile, single use only, 2 pieces)

Instruction Manual

` Coil Sheath

Coil Sheath (Reusable, 1 piece)

` Tube Sheath

Tube Sheath (Reusable, 1 piece)

` Basket Wire

Basket Wire (Sterile, single use only, 1 piece)

` BML Handle

BML Handle (MAJ-440, reusable, 1 piece)

7MECHANICAL LITHOTRIPTOR

Page 12

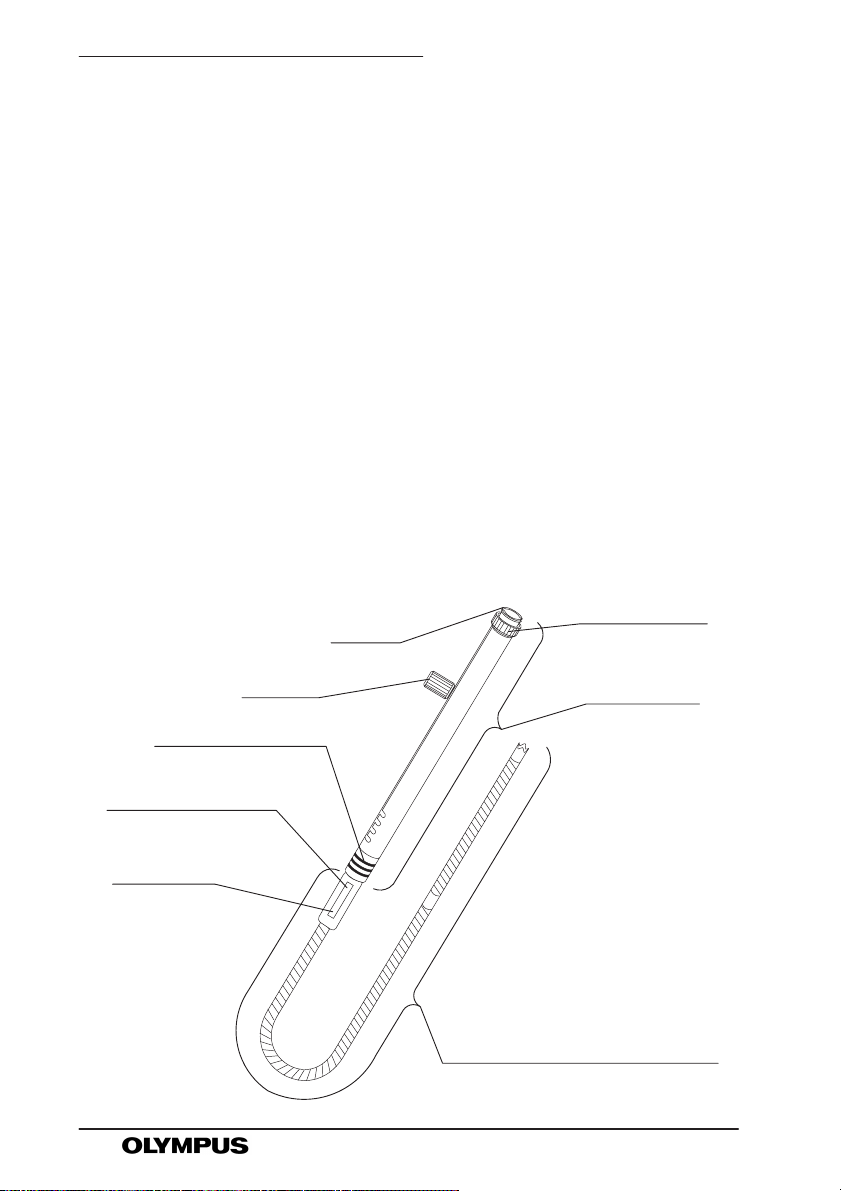

Chapter 2 Instrument Nomenclature and Specifications

Chapter 2 Instrument

Nomenclature and

Specifications

2.1 Nomenclature and Functions

This instrument consists of a Coil Sheath, Tube Sheath

and Basket Wire. The Tube Sheath is inserted into the Coil

Sheath and the Basket Wire is inserted into the Tube

Sheath prior to use.

This instrument must be used in combination with the BML

Handle.

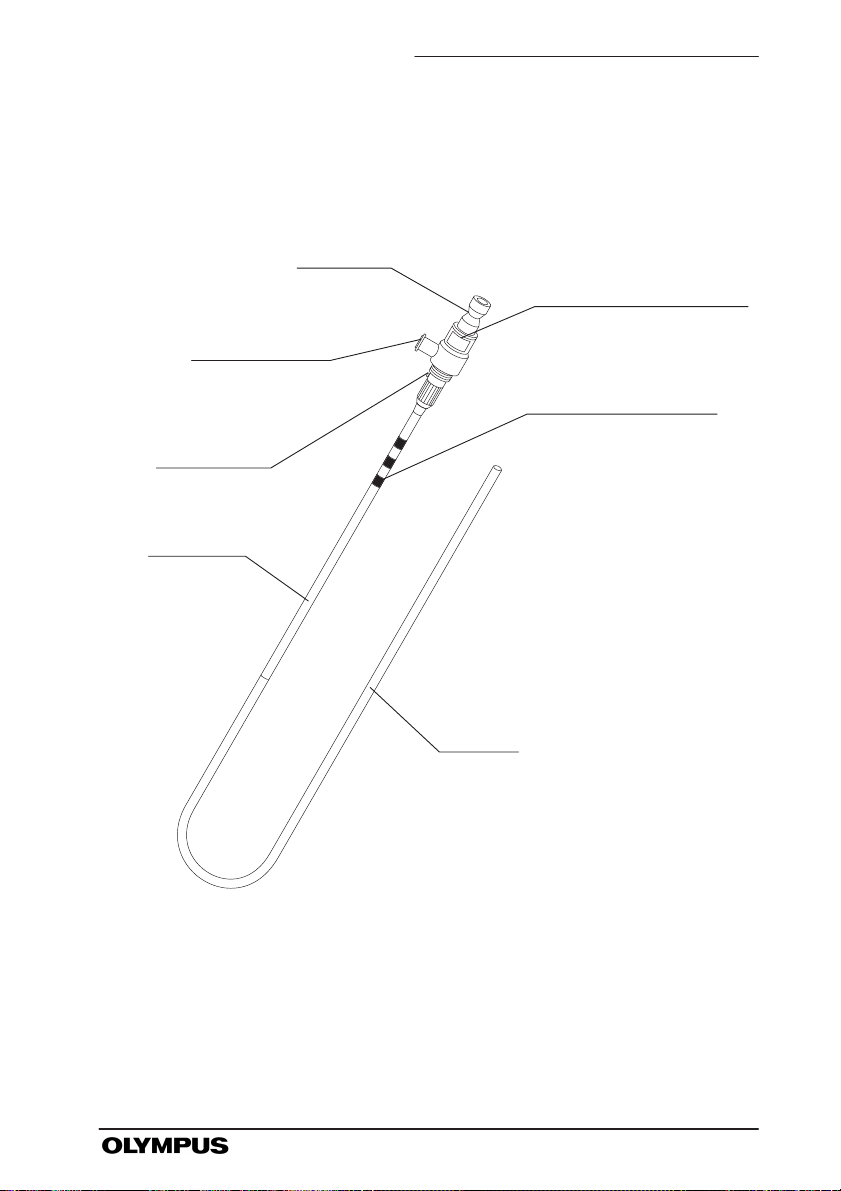

` Coil Sheath (Reusable)

4. Fixing Screw

Notch

3. Knob

2. Identification Mark

1. Model Reference

Label

Lot Number

Insertion Portion/Working Length

8 MECHANICAL LITHOTRIPTOR

Slide Region

Page 13

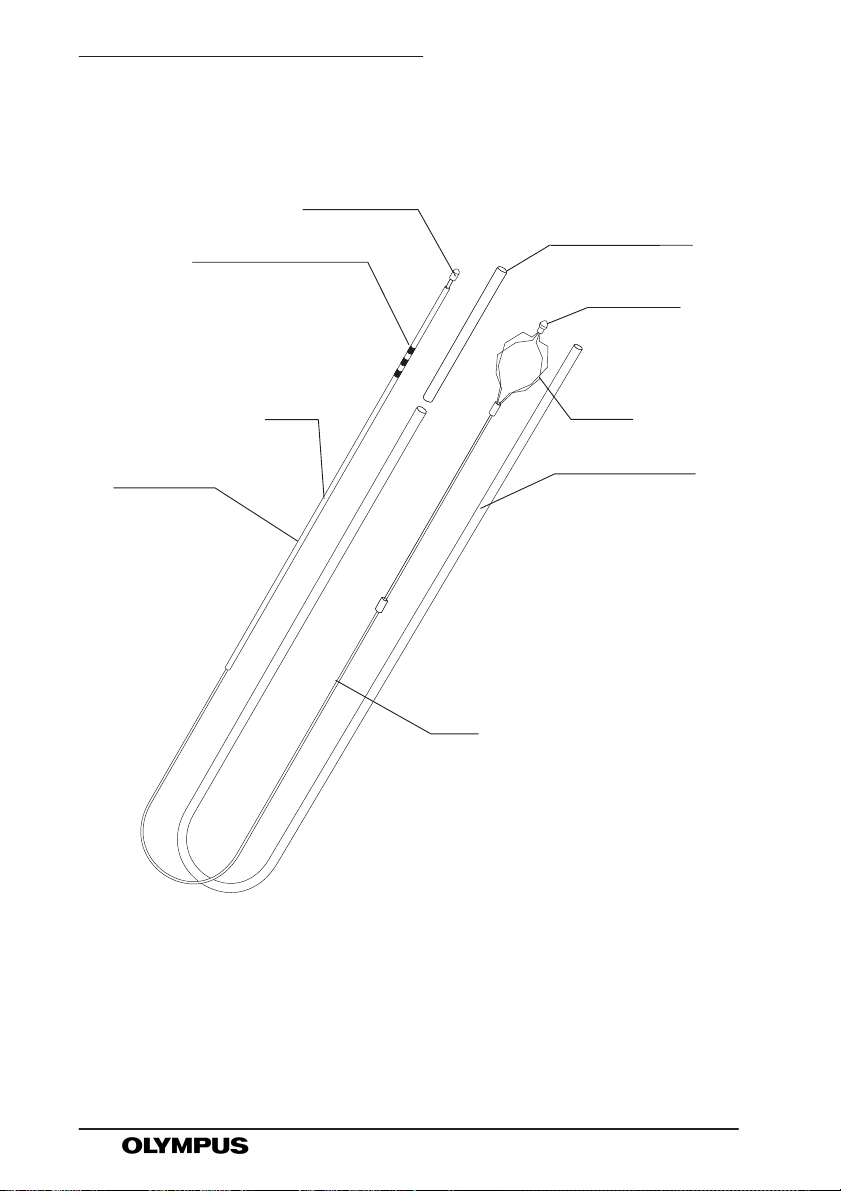

6. Port

5. Guide Pin

Guide Pipe

Chapter 2 Instrument Nomenclature and Specifications

` Tube Sheath (Reusable)

7. Stopper

1. Model Reference Label

2. Identification Mark

8. Tube

9MECHANICAL LITHOTRIPTOR

Page 14

Chapter 2 Instrument Nomenclature and Specifications

` Basket Wire (Sterile, Single use only)

9. Wire Joint

Lot Number

2. Identification Mark

Pipe

Protective Tube

Basket Tip

Basket

Protective Tube

Wire

10 MECHANICAL LITHOTRIPTOR

Page 15

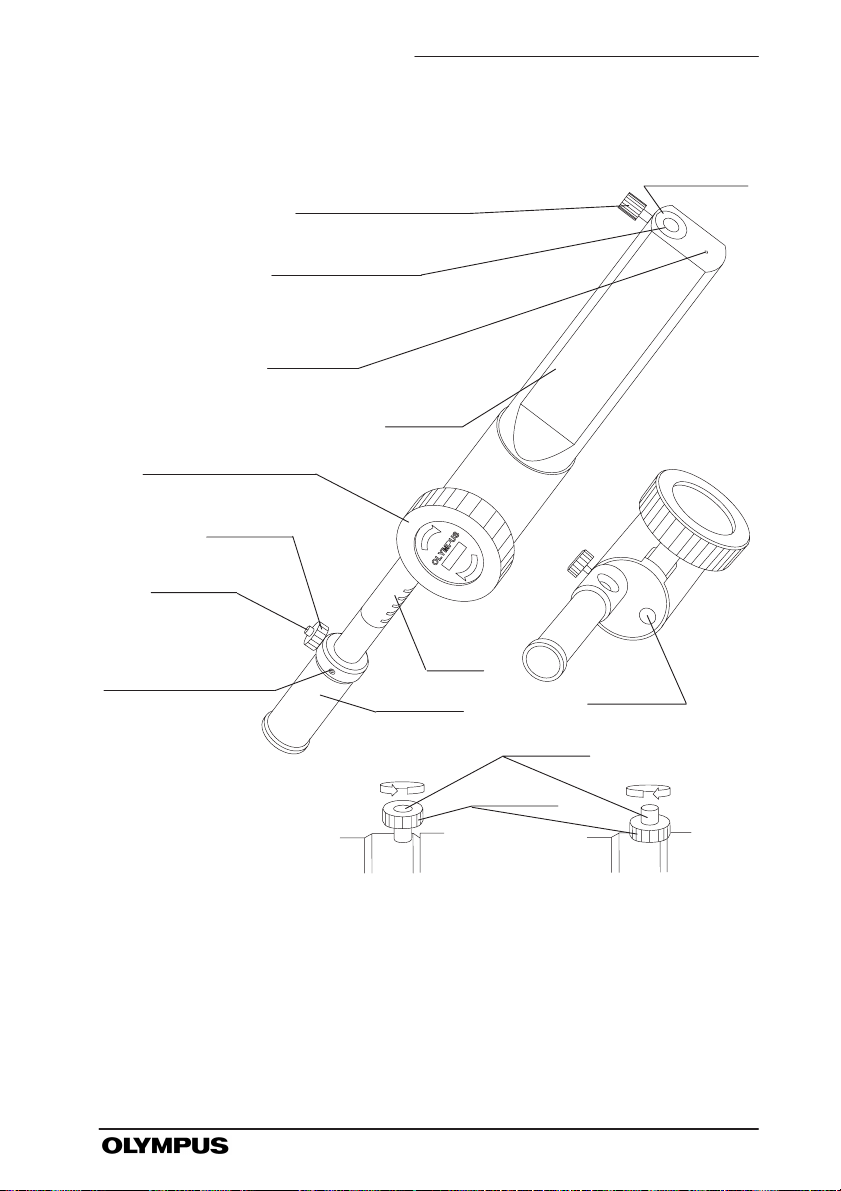

` BML Handle (MAJ-440, Reusable)

15. Insertion Hole

14. Outlet

13. Rotatable Knob

12. Screw

11. Button

Chapter 2 Instrument Nomenclature and Specifications

Lot Number

16. Clamping Screw

Grip

10. Checking Window

Rack

17. Holder

Button Unlocked

14. Outlet

11. Button

12. Screw

Button Locked

11MECHANICAL LITHOTRIPTOR

Page 16

Chapter 2 Instrument Nomenclature and Specifications

1. Model Reference Label

Indicates the product number.

A green reference label indicates that the instrument

is autoclavable.

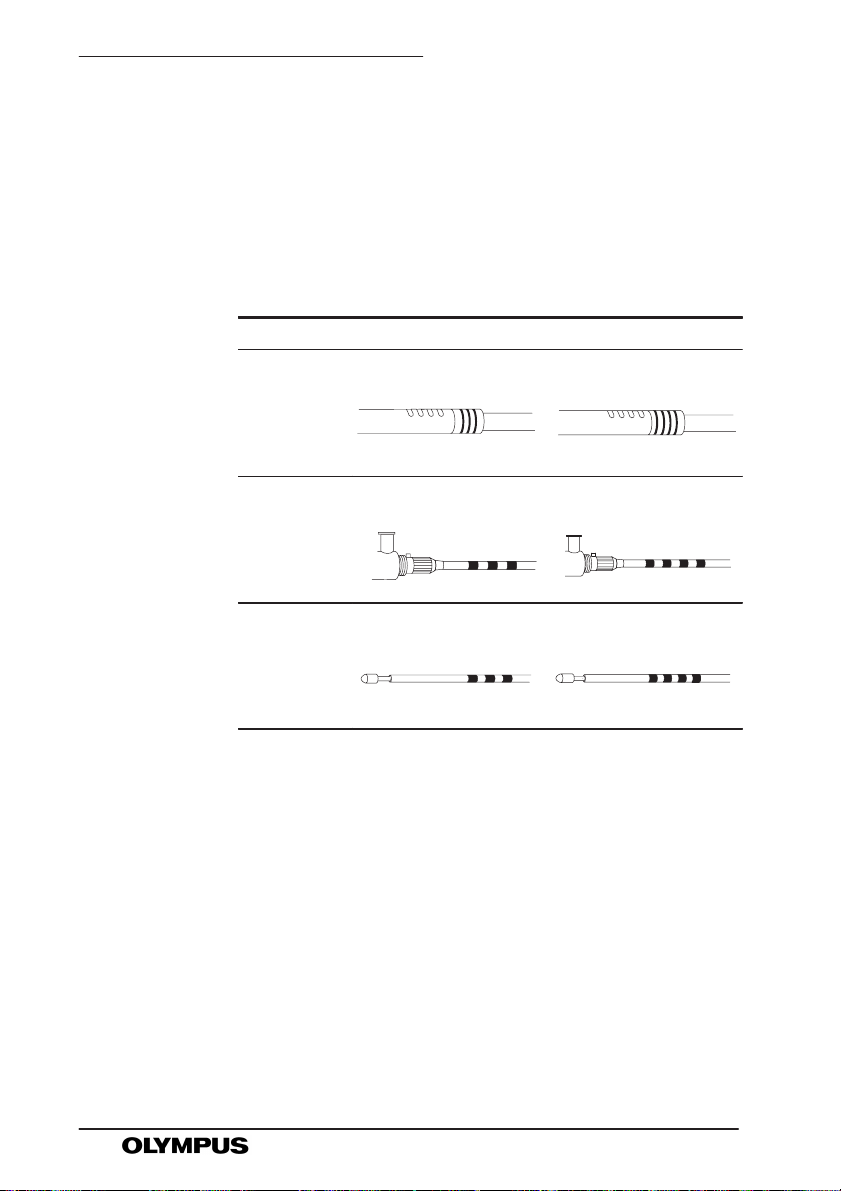

2. Identification Mark

The Coil Sheath, Tube Sheath and Basket Wire are

marked as follows for each model.

Model BML-3Q-1 BML-4Q-1

Side Region

3 black stripes

Coil Sheath

Side Region

4 black stripes

Guide Pipe

3 black stripes

Tube Sheath

Pipe

3 black stripes

Basket Wire

Guide Pipe

4 black stripes

Pipe

4 black stripes

3. Knob

Used to slide the Coil Sheath. Locks the position of

the Slider Region when tightened.

4. Fixing Screw

Secures the Tube Sheath when tightened.

5. Guide Pin

Aligned with the Notch at the proximal end of the Coil

Sheath to properly align the Coil Sheath with the Tube

Sheath.

6. Port

Attach a syringe here to inject contrast medium

(BML-3Q-1 only) or flush reprocessing chemicals,

water and air through the Tube Sheath when

reprocessing (BML-3Q-1 and BML-4Q-1).

12 MECHANICAL LITHOTRIPTOR

Page 17

Chapter 2 Instrument Nomenclature and Specifications

7. Stopper

Attached to the BML Handle.

8. Tube

On the BML-3Q-1, works as the channel through

which contrast medium is injected during use. It also

works as the channel through which reprocessing

chemicals, water or air are flushed to the distal end

when reprocessing.

9. Wire Joint

Attached to the Holder of the BML Handle. If the Wire

Joint has groove on it, the handling, operating and

maintenance procedures described in this manual are

applicable.

10. Checking Window

Allows user to view the Wire Joint when attaching it to

the Holder of the BML Handle.

11. Button

Secures and releases the Wire Joint of the Basket

Wire.

12. Screw

Turn the Screw to lock and unlock the Button.

13. Rotatable Knob

When turned, the Basket is gradually retracted in

order to crush the calculi.

14. Outlet

Discharge the remaining lubricant from here when

reprocessing.

15. Insertion Hole

The Basket Wire’s Pipe and the Tube Sheath’s

Stopper are inserted here.

16. Clamping Screw

Tightened to secure the Stopper of the Tube Sheath.

17. Holder

Moved back and forth to open and close the Basket

when the BML Handle is connected to the instrument.

13MECHANICAL LITHOTRIPTOR

Page 18

Chapter 2 Instrument Nomenclature and Specifications

2.2 Specifications

The compatible Olympus endoscopes are listed in the

Table on the following page. New endoscopes released

after the introduction of this instrument and BML Handle

may also be compatible for use in combination with this

instrument and BML Handle. For further details, contact

Olympus.

Use this instrument and BML Handle only

in combination with products

recommended by Olympus. If combined

with products not recommended by

Olympus, patient or operator injury,

malfunction and/or equipment damage

may result.

Operating Environment

Ambient Temperature 10 to 40°C (50 to 104°F)

Relative Humidity 30 to 85%

Air Pressure 700 to 1060 hPa

(0.71 to 1.08 kgf/cm

(10.1 to 15.4 psia)

Specifications

The recommended Coil Sheath, Tube Sheath and Basket

Wire combinations for each instrument are as follows:

Do not use the Coil Sheath, Tube Sheath

or Basket Wire in combinations other than

those listed below. An incorrect

combination could cause patient injury

and/or equipment damage.

14 MECHANICAL LITHOTRIPTOR

2

)

Page 19

Chapter 2 Instrument Nomenclature and Specifications

Product Name BML-3Q-1 BML-4Q-1

Coil Sheath MAJ-242 MAJ-245

Tube Sheath MAJ-243 MAJ-246

Basket Wire MAJ-244 MAJ-247

Model BML-3Q-1 BML-4Q-1

Shape of the

Grasping Basket

Maximum Insertion

Portion Diameter (mm)

Working Length (mm) 1950

Opening Length (mm) 30

Model

and

Compatible

Olympus

Endoscopes

(All of the parameters

should be met.)

Compatible

Olympus Handle

Compatible

Olympus

Lithotriptor for

Emergency Use

Length

Channel

Inner

Diameter

(mm)

(Color

Code)

ø 3.7 ø 2.9

Working

Length less

than 1400

mm;

TJF

ø 4.2

(Orange);

ø 5.5

(Pink)

BML Handle: MAJ-440

BML-110A-1

Working

Length less

than 1400

mm;

JF, TJF

ø 3.2

(Yellow);

ø 4.2

(Orange);

ø 5.5

(Pink)

15MECHANICAL LITHOTRIPTOR

Page 20

Chapter 2 Instrument Nomenclature and Specifications

Medical Device

Directive

This device complies with the

requirements of Directive

93/42/EEC concerning medical

0197

devices.

Classification: Class I

16 MECHANICAL LITHOTRIPTOR

Page 21

Chapter 3 Preparation, Inspection and Operation

Chapter 3 Preparation,

Inspection and

Operation

The Basket Wire was shipped in a sterile condition.

The Coil Sheath, the Tube Sheath and the BML Handle

were not sterilized before shipment.

S Do not use the Basket Wire after the

expiration date displayed on the sterile

package. Doing so may pose an

infection control risk and/or cause

tissue irritation.

S When using the instrument and the

BML Handle, always wear appropriate

personal protective equipment,

Otherwise, blood, mucous and other

potentially infectious material from the

patient could pose an infection control

risk. Appropriate personal protective

equipment may include: Eye wear, a

face mask, moisture-resistant clothing

and chemical-resistant gloves, that fit

properly and are long enough so that

your skin is not exposed.

17MECHANICAL LITHOTRIPTOR

Page 22

Chapter 3 Preparation, Inspection and Operation

S Before each case, prepare and inspect

the instrument and the BML Handle as

instructed below. Inspect other

equipment to be used with the

instrument and the BML Handle as

instructed in their respective

instruction manuals.

Should the slightest irregularity be

suspected, do not use the instrument

or the BML Handle; contact Olympus.

Damage or irregularity may

compromise patient or user safety,

since it may pose an infection control

risk, cause tissue irritation, punctures,

hemorrhages or mucous membrane

damage. It may also result in more

severe equipment damage.

S The coil Sheath, the Tube Sheath and

the BML Handle were not sterilized

before shipment. Before using the Coil

Sheath, the Tube Sheath and the BML

Handle for the first time, reprocess and

assemble them according to the

instructions in Chapter 5,

“Reprocessing”.

Do not use an instrument or the BML

Handle that has not been cleaned and

sterilized. This could pose an infection

control risk and/or can cause tissue

irritation.

S Do not coil the Insertion Portion with a

diameter of less than 15 cm. This

could damage the Insertion Portion.

S Never use excessive force to operate

the instrument and the BML Handle.

This could damage the instrument

and/or the BML Handle.

18 MECHANICAL LITHOTRIPTOR

Page 23

3.1 Preparation

Equipment and Personal Protective Equipment

Prepare all equipment and personal protective equipment

which will be used with the instrument and BML Handle in

accordance with their respective instruction manuals.

Appropriate personal protective equipment may include:

Eye wear, a face mask, moisture-resistant clothing and

chemical-resistant gloves.

Spare Instrument and BML Handle

Always have a spare instrument and BML Handle

available.

Sterilized Syringe and Contrast Medium for

Inspection

Chapter 3 Preparation, Inspection and Operation

Prepare a sterile syringe and contrast medium for

inspection.

Reprocessing Equipment

Prepare reprocessing equipment as described in Section

5.2, “Required Reprocessing Equipment” for immediate

reprocessing after use.

19MECHANICAL LITHOTRIPTOR

Page 24

Chapter 3 Preparation, Inspection and Operation

Equipment to be Used in Emergency

Always have pliers ready to cut the Coil Sheath, Tube

Sheath and/or Basket Wire in case lithotripsy cannot be

performed. Also have the Olympus Lithotriptor

BML-110A-1 ready.

3.2 Inspection

Wear the personal protective equipment as specified in the

Table on page 59.

Before each case, always inspect the instrument and the

BML Handle according to the following procedures.

If an abnormality in the instrument or the BML Handle is

detected, use a spare instrument or BML Handle,

inspecting it thoroughly before use.

Inspection of the Sterile Package

Inspect the sterile package for tears, inadequate sealing

or water damage. If the sterile package shows any

irregularities, the sterile condition of the instrument or the

BML Handle may have been compromised. Use a spare

instead.

Appearance Inspection

If any of following steps reveals irregularities, do not use

the instrument or the BML Handle; use a spare instead.

Before use, carefully inspect the entire

coil sheath as instructed in this chapter;

confirm that it is not crushed, bent,

deformed or otherwise damaged. A

damaged coil sheath may not be able to

properly crush a calculus and/or it could

cause the instrument to break.

20 MECHANICAL LITHOTRIPTOR

Page 25

Chapter 3 Preparation, Inspection and Operation

` Inspecting the Instrument

Be sure to inspect the Coil Sheath before

assembly. Never attempt to use the

instrument if you suspect that the Coil

Sheath has an irregularity or is damaged.

If an instrument in this condition is used,

it may malfunction or cause patient injury,

such as punctures, hemorrhages or

mucous membrane damage. Equipment

damage and performance deterioration

may also result.

When pulling the Basket Wire out of the

Protective Tube, take care not to bend the

Pipe of the Basket Wire. This could

damage the Basket Wire.

1. Straighten the Protective Tube containing the Basket

Wire. Then, hold the Basket Tip and withdraw the

Basket Wire all the way. Dispose of the Protective

Tube. (See Figure 3.1)

Protective Tube

Figure 3.1

Basket Tip

Basket

21MECHANICAL LITHOTRIPTOR

Page 26

Chapter 3 Preparation, Inspection and Operation

NOTE

Do not withdraw the Basket Wire forcibly

if the Wire Joint catches on the Protective

Tube. Use your fingers to gently extricate

the part of the Basket Wire that is caught

and then withdraw it.

2. Confirm that the Coil Sheath, Tube Sheath and

Basket Wire are free from disconnection or

looseness.

3. Gently run your fingertips over the entire length of the

Coil Sheath and Tube Sheath to check for any

crushed areas, excessive bends, etc..

4. Confirm that there is no unraveled, disconnected or

broken wires, sharp protrusions, sharp edges or any

other apparent abnormalities of the Basket Wire.

` Inspecting the BML Handle

Make sure that there are no cracks on the BML Handle.

Assembling and Inspection

S Do not use excessive force when

assembling the instrument. This could

damage the instrument.

S Be sure to keep the Coil Sheath and

Tube Sheath straight when

assembling the instrument. If the Coil

Sheath or Tube Sheath is not straight,

the instrument could be damaged.

S Move the Basket Wire’s Pipe back and

forth slowly. Fast or abrupt movement

could damage the Pipe.

1. Straighten the Tube Sheath.

2. Insert the Basket Wire into the proximal end of the

Tube Sheath as shown in Figure 3.2.

22 MECHANICAL LITHOTRIPTOR

Page 27

Chapter 3 Preparation, Inspection and Operation

Tube Sheath Wire Joint

Figure 3.2

NOTE

The Basket Wire’s Pipe bends easily. Use

extra care when handling it.

3. Extend the Wire Joint from the Stopper on the

proximal end of the Tube Sheath as shown in Figure

3.3.

Wire Joint

Stopper

Tube Sheath

Figure 3.3

23MECHANICAL LITHOTRIPTOR

Page 28

Chapter 3 Preparation, Inspection and Operation

NOTE

Force is sometimes required to extend the

Wire Joint from the Stopper on the

proximal end of the Tube Sheath. If this

is the case, do not try to insert the Wire

Joint forcibly. Keep the insertion portions

of the Coil Sheath and Tube Sheath as

straight as possible.

4. Withdraw the Pipe from the Stopper until the Basket

is completely closed.

5. While operating the Pipe to open and close the

Basket, confirm that the Basket Wire is free from

disconnection or looseness.

6. Open the Basket. Make sure that there are no

unraveled, disconnected or broken Wires, sharp

protrusions, sharp edges or any other apparent

abnormalities.

7. Make sure that there are no excessive bends, sharp

edges or other apparent deformations in the Pipe of

the Basket Wire.

8. Confirm that the distal end of the Basket Wire appears

exactly as shown in the Table in Section 2.2

“Specifications” and is not damaged.

Making and Inspecting the Connections

S Make sure the screw is tightened. If

not securely tightened, the pipe may

disattach, the basket may not to be

moved, and/or the calculus may not be

crushed.

24 MECHANICAL LITHOTRIPTOR

Page 29

Chapter 3 Preparation, Inspection and Operation

S Make sure to have the stopper and the

BML handle connected. If the

instrument separates from the BML

handle during operation, the pipe may

break or become uncontrollable. Also,

this instrument with calculus engaged

may not be removed from the body.

S Do not hold the BML Handle by the

Holder if the Tube Sheath’s Stopper is

not connected. The weight of the

instrument could bend the Basket

Wire.

S Make sure that the Tube Sheath’s

Stopper is securely attached to the

BML Handle. If the BML Handle’s

Holder is extended when the Handle is

not attached firmly, the instrument

may become detached and the Basket

Wire could be damaged.

S When connecting the BML Handle

with the Wire Joint, fully unlock the

Button on the Handle’s Holder by

turning the Screw. If the Button is

pressed before the Screw is

completely unlocked, the Basket Wire

may come off from the BML Handle,

and it may lead to malfunctioning of the

handle or breakage of the Wire Joint.

NOTE

The Screw on the BML Handle may be

locked so that the Button cannot be

pressed by mistake, which would cause

the Basket Wire to be disconnected.

If any of following steps reveals irregularities, do not use

the instrument or the BML Handle; use a spare instead.

1. Turn the Screw on the BML Handle counterclockwise

to unlock the Button. (See Figure 3.4)

25MECHANICAL LITHOTRIPTOR

Page 30

Chapter 3 Preparation, Inspection and Operation

Button

Screw

Figure 3.4

2. Loosen the Clamping Screw of the BML Handle by

turning it counterclockwise until it stops.

3. Push the Holder of the BML Handle as far as it can go.

4. Insert the Basket Wire’s Pipe into the BML Handle’s

Insertion Hole as far as it can go. (See Figure 3.5)

1. Unlock the Button

2. Press the Button

Clamping

Screw

Grip

Figure 3.5

Wire Joint

Pipe

Insertion Hole

26 MECHANICAL LITHOTRIPTOR

Page 31

Chapter 3 Preparation, Inspection and Operation

5. After completing Step 4., press the Button on the BML

Handle’s Holder (See Figure 3.4). While pressing the

Button, insert the Basket Wire’s Pipe further into the

Insertion Hole until it stops. (See Figure 3.5)

6. Release the Button when the Pipe can be inserted no

further.

7. Confirm that Wire Joint of Basket is visible Wire

through the Slit (See Figure 3.6). Then, push and pull

the Basket Wire’s Pipe to make sure that the Wire

Joint is securely attached to the Holder.

Holder

Figure 3.6

Checking Window

Wire Joint

8. Insert the Tube Sheath’s Stopper as far as possible

into the BML Handle’s Insertion Hole.

(See Figure 3.7)

27MECHANICAL LITHOTRIPTOR

Page 32

Chapter 3 Preparation, Inspection and Operation

Clamping

Screw

Insertion Hole

Figure 3.7

Pipe

Stopper

Tube Sheath

9. Tighten the BML Handle’s Clamping Screw by turning

it clockwise until it stops. (See Figure 3.7)

10. Turn the Screw on the BML Handle clockwise to lock

the Button. (See Figure 3.8)

Button

Screw

Figure 3.8

11. Push and pull the Slide Region of the Coil Sheath to

make sure the Tube Sheath’s Stopper is securely

attached to the BML Handle.

28 MECHANICAL LITHOTRIPTOR

Page 33

Inspection of Operation

After assembly, check that no abnormality

is detected in the action of the handle. If

there is any abnormality, the calculus may

not be crushed and/or the instrument with

stone engaged may not be removed from

the body.

If the instrument does not operate smoothly and as

intended, do not use the instrument or the BML Handle;

use a spare instead.

1. Holding the instrument and the BML Handle as shown

in Figure 3.9, form a loop in the Insertion Portion

approximately 20 cm in diameter.

Chapter 3 Preparation, Inspection and Operation

Close

Slide

Approximately

20 cm.

Figure 3.9

Open

2. Operate the Holder and confirm that the Basket opens

and closes smoothly.

3. Move the Coil Sheath’s Knob back and forth to make

sure that it slides smoothly.

29MECHANICAL LITHOTRIPTOR

Page 34

Chapter 3 Preparation, Inspection and Operation

4. Move the Coil Sheath’s Knob until it sits in the groove

nearest to the Identification Mark. Make sure that the

Tube Sheath does not extend from the distal end of

the Coil Sheath.

Inspecting Irrigation

Perform the following inspection only when using the

BML-3Q-1. Irrigation inspection is not necessary when

using the BML-4Q-1.

NOTE

Do not use the instrument if the contrast medium cannot

be injected or if it leaks from any area other than the distal

end. In this case, use a spare instead.

The BML-4Q-1 is not designed for

injection of a contrast medium.

Use a contrast medium intended for

patient use when inspecting irrigation.

Other fluids may remain inside the

channel and pose an infection control risk

and/or cause tissue irritation.

1. Open the Basket and inject a contrast medium into the

instrument’s Port using a sterile syringe. Confirm that

the contrast medium only comes out of the distal end

of the instrument. (See Figure 3.10)

30 MECHANICAL LITHOTRIPTOR

Page 35

Syringe

Chapter 3 Preparation, Inspection and Operation

Figure 3.10

2. Make sure that the contrast medium does not leak

from any area other than the distal end of the

instrument.

3. Connect a sterile syringe to the instrument’s Port.

Inject air into the Insertion Portion to discharge the

contrast medium.

3.3 Operation

The operator of the instrument and the BML Handle must

be a physician or medical personnel under the supervision

of a physician and must have received sufficient training

in clinical endoscopic technique.

This manual, therefore, does not explain or discuss clinical

endoscopic procedures. It only describes basic operation

and precautions related to the operation of this instrument

and BML Handle.

Grip

Port

Coil Sheath

Tube Sheath

31MECHANICAL LITHOTRIPTOR

Page 36

Chapter 3 Preparation, Inspection and Operation

S Operation of this instrument is based

on the assumption that open surgery is

possible as an emergency measure.

In the course of crushing a hard

calculus, the pipe and/or the basket

wire could break and fall off of the

instrument inside the patient. If the

pipe or basket wire is damaged during

use, immediately stop using the

instrument and follow the appropriate

instruction(s) given in Chapter 4,

“Emergency Treatment”.

S Do not insert the instrument into the

endoscope unless you have a clear

endoscopic field of view. If you cannot

see the distal end of the Insertion

Portion in the endoscopic field of view

or in X-ray images, do not use it. This

could cause patient injury, such as

punctures, hemorrhages or mucous

membrane damage. It may also

damage the endoscope and/or

instrument.

S Do not angulate the Bending Section

of the Endoscope or operate the

Forceps Elevator abruptly while the

distal end of the Insertion Portion is

extended from the Distal End of the

endoscope. This could cause patient

injury, such as punctures,

hemorrhages or mucous membrane

damage.

S Do not force the distal end of the

Insertion Portion against body cavity

tissue. This could cause patient injury,

such as punctures, hemorrhages or

mucous membrane damage.

32 MECHANICAL LITHOTRIPTOR

Page 37

Chapter 3 Preparation, Inspection and Operation

Inserting Into the Endoscope

S Do not insert the instrument into the

endoscope, if the Basket is not

completely retracted into the Insertion

Portion. The distal end of the Insertion

Portion may extend from the Distal

End of the endoscope tip abruptly.

This could cause patient injury, such

as punctures, hemorrhages or

mucous membrane damage. It may

also damage the endoscope and/or

instrument.

S When inserting the instrument into the

endoscope, raise the Forceps

Elevator to its maximum height. If the

Forceps Elevator is down, you will not

be able to see the distal end of the

Insertion Portion in the endoscopic

field of view. This could cause patient

injury, such as punctures,

hemorrhages or mucous membrane

damage.

S When inserting the instrument into the

endoscope, hold the Holder firmly.

Otherwise, the Basket may extend

from the Distal End of the endoscope

abruptly. This could cause patient

injury, such as punctures,

hemorrhages or mucous membrane

damage. It may also damage the

endoscope and/or instrument.

33MECHANICAL LITHOTRIPTOR

Page 38

Chapter 3 Preparation, Inspection and Operation

S Do not force the instrument, if

resistance to insertion is encountered.

Reduce the angulation or lower the

Forceps Elevator of the endoscope

until the instrument passes smoothly.

This could cause patient injury, such

as punctures, hemorrhages or

mucous membrane damage. It may

also damage the endoscope and/or

instrument.

S Do not advance or extend the

instrument abruptly. This could cause

patient injury, such as punctures,

hemorrhages or mucous membrane

damage. It could also damage the

endoscope and/or instrument.

S When inserting the instrument into the

endoscope, hold it close to the Biopsy

Valve and keep it as straight as

possible relative to the Biopsy Valve.

Otherwise, the Insertion Portion could

be damaged.

S Insert the instrument slowly. Abrupt

insertion may damage the endoscope

and/or instrument.

1. Raise the Forceps Elevator to its maximum height.

2. Loosen the Coil Sheath’s Knob by turning it clockwise

and slide the Knob toward the proximal end until it

stops as shown in Figure 3.11. Tighten the Knob to

secure it in position.

34 MECHANICAL LITHOTRIPTOR

Page 39

Chapter 3 Preparation, Inspection and Operation

Knob

Coil Sheath

Tube Sheath

Figure 3.11

3. Retract the Basket into the Tube Sheath.

4. With the Basket retracted, carefully insert the

instrument into the Biopsy Valve of the endoscope.

(See Figure 3.12)

Keep as straight as possible.

Coil Sheath

Hold the Insertion

Portion close to the

Biopsy Valve

Figure 3.12

Biopsy Valve.

5. When the distal end of the Insertion Portion contacts

the Forceps Elevator, lower the Forceps Elevator.

35MECHANICAL LITHOTRIPTOR

Page 40

Chapter 3 Preparation, Inspection and Operation

6. Advance the instrument another 20 mm and raise the

Forceps Elevator. You will see the distal end of the

instrument in the endoscopic field of view.

Inserting Into the Bile Duct

Insert the distal end of the instrument into the bile duct via

the opening in the duodenal papilla.

Do not forcibly insert the Insertion Portion

into the Bile Duct. This could cause

patient injury, such as punctures,

hemorrhages or mucous membrane

damage.

NOTE

Grasping

If resistance is too strong and insertion of

the instrument is difficult, lower the

Forceps Elevator and move the distal end

of the instrument slightly forward. Then

raise the Forceps Elevator.

S Do not withdraw this instrument with

stone engaged from the bile duct

abruptly and/or with excessive force.

This could cause punctures,

hemorrhages, mucous membrane

damage or edema.

S Do not push the Holder abruptly, as it

may cause the Basket to open

abruptly. This could cause patient

injury, such as punctures,

hemorrhages or mucous membrane

damage. It could also damage the

endoscope and/or instrument.

36 MECHANICAL LITHOTRIPTOR

Page 41

Chapter 3 Preparation, Inspection and Operation

S When the lithotriptor’s basket does not

smoothly open or close, do not apply

force but move the forceps elevator or

the scope’s angle back, or move the

position of the basket until the basket

opens or closes with ease. If the

action is forced, the tube may stretch

and cannot be stored inside the coil

sheath. Also, the calculus may not be

crushed, and/or the instrument with

calculus engaged may not be removed

from the body.

S Do not grasp calculi forcibly as this

could deform the distal end of the Tube

Sheath. This could damage the

instrument.

S Do not open and close the Basket too

quickly. Doing so could damage the

instrument.

1. To grasp the target calculi, angulate the endoscope

and/or advance the instrument required distance.

2. Push the Holder to open the Basket.

3. Surround the target calculus, with the open Basket.

4. Pull the Holder to grasp the target calculis.

37MECHANICAL LITHOTRIPTOR

Page 42

Chapter 3 Preparation, Inspection and Operation

Crushing the Calculi

S This instrument will deform and/or

deteriorate by performing lithotripsy.

When lithotripsy is repeated, it will

deform and/or deteriorate

furthermore. By such deformation

and/or deterioration, calculus may not

be crushed and/or the instrument with

calculus engaged may not be removed

from the body. If lithotripsy is required

to be repeated in a single case, make

sure to check each time that no

abnormality is found in action and/or

appearance (e.g. basket wire cut or

worn, tube sheath bent, notable coil

sheath bent or gap etc.). Stop use

when any abnormality is detected.

S If resistance is too great and it is

difficult to slide the Coil Sheath, adjust

the angulation of the endoscope until

the Coil Sheath slides smoothly.

Forcible sliding may cause the distal

end of the Coil Sheath to extend

abruptly. This could cause patient

injury, such as punctures,

hemorrhages or mucous membrane

damage. It may also damage the

endoscope and/or instrument.

S During lithotripsy, keep the portion;

from the coil sheath to the BML

handle, straight in line with the scope’s

biopsy valve, as much as possible. If

not straight, the coil sheath may bend,

calculus may not be crushed, and/or

the instrument with calculus engaged

may not be removed from the body.

38 MECHANICAL LITHOTRIPTOR

Page 43

Chapter 3 Preparation, Inspection and Operation

S Do not rotate the BML handle knob

abruptly. This instrument may break,

and/or calculus may not be crushed.

Also, the instrument with calculus

engaged may not be removed from the

body.

S Lower the endoscope’s forceps

elevator when performing lithotripsy.

If lithotripsy is performed when the

elevator is not lowered, the scope or

the instrument may break and/or the

calculus may not be crushed. Also,

the instrument with calculus engaged

may not be removed from the body.

S Do not forcibly push or pull the

instrument or the BML Handle during

lithotripsy. This could cause patient

injury, such as punctures,

hemorrhages or mucous membrane

damage. It may also damage the

endoscope and/or instrument.

S During lithotripsy, make sure to have

the knob of the coil sheath properly set

in the groove of the slider part. If the

coil sheath moves, the stone may not

be crushed and/or the instrument with

calculus engaged may not be removed

from the body.

S Do not push the BML handle’s holder

forcibly when the basket does not

open after crushing the calculus. As it

may cause the basket to open

abruptly. This could cause patient

injury, such as punctures,

hemorrhages or mucous membrane

damage. It could also damage the

endoscope and/or instrument.

39MECHANICAL LITHOTRIPTOR

Page 44

Chapter 3 Preparation, Inspection and Operation

1. Lower the Forceps Elevator.

2. Loosen the Knob on the Coil Sheath.

3. While gently inserting the Coil Sheath, slowly move

the Knob as shown in Figure 3.13.

S When making the coil sheath slide,

confirm under X-ray image that the

tube sheath is completely covered by

coil sheath. If not completely covered,

the calculus may not be crushed

and/or the instrument with calculus

engaged may not be removed from the

body.

While rotating the Knob, it will generate

resistance in the opposite direction. Do

not loosen your grip because the Knob

could create friction that could hurt your

hand.

Figure 3.13

40 MECHANICAL LITHOTRIPTOR

Page 45

Chapter 3 Preparation, Inspection and Operation

NOTE

The operati on sh own i n Fig ure 3.13

requires coordination between the

operator and assistant. Practice this

operation before actually performing it on

a patient.

4. While observing the X-ray image, move the distal end

of the Coil Sheath in front of the calculus. Cover the

Tube Sheath completely with the Coil Sheath. Then,

set the Knob in the groove nearest possible to the

Identification Marks, and tighten the Knob.

(See Figure 3.14)

Slide Region

Figure 3.14

5. Make sure that the Knob is firmly attached to the Slide

Region.

6. Without releasing the calculus, turn the Rotatable

Knob on the BML Handle in the direction of arrow.

This will cause the Basket to squeeze the calculus,

crushing it.

41MECHANICAL LITHOTRIPTOR

Page 46

Chapter 3 Preparation, Inspection and Operation

NOTE

S The Basket Wire, Coil Sheath and/or

Tube Sheath may become deformed

when strong force is used to crush a

calculus. In this case, replace the

deformed Basket Wire, Coil Sheath or

Tube Sheath

S To prevent damaging the instrument,

the Rotatable Knob on the BML

Handle can be turned even when the

Holder is fully extended. At this point,

the Basket cannot be pulled in any

further. If this condition occurs, stop

turning the Rotatable Knob.

with a spare.

Withdrawing the Instrument From the Endoscope

S Do not withdraw the instrument

abruptly from the bile duct. It could

cause mucous membrane damage or

edema.

S Do not withdraw the instrument from

the endoscope quickly. This could

scatter blood, mucous or other patient

debris and pose an infection control

risk.

S Do not withdraw the instrument from

the endoscope if the Basket is not

completely retracted into the Tube

Sheath. This could damage the

endoscope and/or instrument.

S Do not withdraw the instrument from

the endoscope if the Forceps Elevator

is up. This could damage the

endoscope and/or instrument.

1. Pull the Holder to retract the Basket into the Tube

Sheath.

42 MECHANICAL LITHOTRIPTOR

Page 47

2. Withdraw the instrument from the endoscope.

Detaching

1. Loosen the Clamping Screw on the BML Handle by

2. Turn the Screw on the BML Handle counterclockwise

3. Firmly press the Button on the BML Handle and

4. Straighten the Insertion Portions of the Coil Sheath

Chapter 3 Preparation, Inspection and Operation

Do not pull the Basket Wire from the Tube

Sheath quickly. Do not pull the Tube

Sheath from the Coil Sheath quickly. This

could scatter blood, mucous or other

patient debris and pose an infection

control risk.

turning it counterclockwise and remove the Coil

Sheath and Tube Sheath.

to unlock the Button.

remove the Basket Wire.

and the Tube Sheath. While holding the Basket Tip,

withdraw the Basket Wire from the Tube Sheath.

5. Loosen the Fixing Screw on the Coil Sheath and

withdraw the Tube Sheath from the Coil Sheath

Disposal of Used Basket Wire

S After use, dispose of the Basket Wire

in an appropriate manner. If it is not

properly disposed of, it could pose an

infection control risk.

S Do not reuse the Basket Wire.

Reusing the Basket Wire could pose

an infection control risk, cause tissue

irritation or malfunction.

After using the Basket Wire, dispose of it in an appropriate

manner.

.

43MECHANICAL LITHOTRIPTOR

Page 48

Chapter 3 Preparation, Inspection and Operation

44 MECHANICAL LITHOTRIPTOR

Page 49

Chapter 4 Emergency Treatment

Chapter 4 Emergency Treatment

4.1 Emergency Treatment

If lithotripsy can no longer be performed, follow the

procedures described in this Chapter. If there is little

resistance from the BML Handle’s Rotatable Knob, the

instrument may be damaged and lithotripsy may not be

possible.

If the calculus is too hard and the

Lithotriptor is damaged as described on

pages 46 – 51, it may be necessary to use

the BML-110A-1. In this case, also refer

to the instruction manual for the

BML-110A-1.

1. Loosen the Clamping Screw on the BML Handle by

turning it counterclockwise, and remove the Coil

Sheath and Tube Sheath.

2. Turn the Screw on the BML Handle counterclockwise

to unlock the Button.

3. Firmly press the Button on the BML Handle, and

remove the Basket Wire.

4. Perform the appropriate treatment given on the charts

on Pages 46 through 51.

45MECHANICAL LITHOTRIPTOR

Page 50

Chapter 4 Emergency Treatment

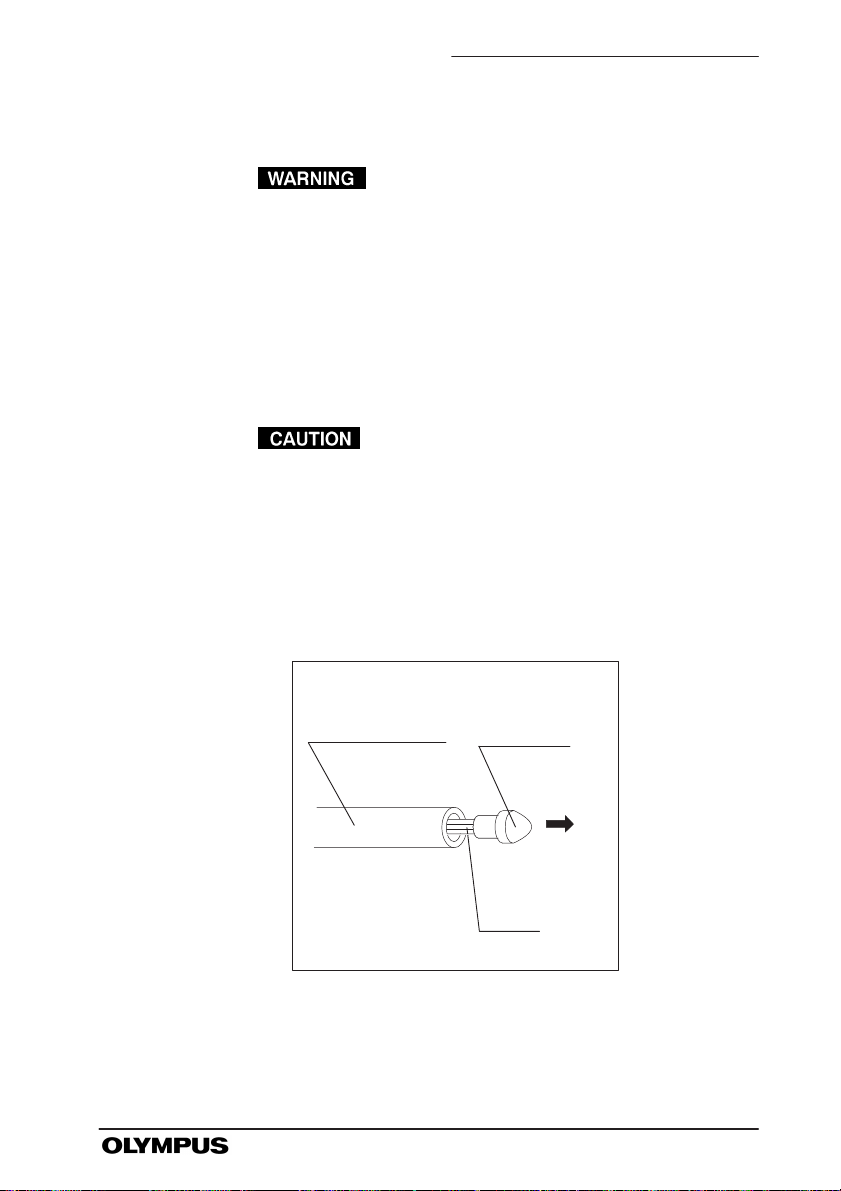

` When the Pipe is Fractured.

When the Pipe is fractured.

Move the Basket back and forth

to release the calculus.

When the Pipe can

be moved.

fractured here.

Cut the Coil Sheath, Tube

fractured here.

When the Pipe cannot

be moved.

Sheath and Basket Wire

using pliers or wire cutters.

Cut

46 MECHANICAL LITHOTRIPTOR

Page 51

Remove the instrument

from the endoscope.

Chapter 4 Emergency Treatment

When the calculus

can be released.

When the calculus

cannot be released.

Cut the Coil Sheath, Tube

Sheath and Basket Wire

using pliers or wire cutters.

Cut.

Withdraw the endoscope.

A certain amount of force is

sometimes required to withdraw

the endoscope.

Dispose of the Basket

Wire and carefully inspect

the Coil Sheath and Tube

Sheath.

Withdraw the Coil Sheath,

Tube Sheath and

endoscope together.

When the Coil Sheath and

Tube Sheath can be moved.

Withdraw the Coil

Sheath and Tube

Sheath.

When the Coil Sheath and Tube

Sheath cannot be moved.

Carry out open

surgery or other

possible treatment.

Use the

Olympus’s

lithotriptor

BML-110A-1 or

carry out open

surgery or

other possible

treatment.

Use the

Olympus’s

lithotriptor

BML-110A-1 or

carry out open

surgery or

other possible

treatment.

47MECHANICAL LITHOTRIPTOR

Page 52

Chapter 4 Emergency Treatment

` When the Pipe is not Fractured.

All four wires on the Basket have

broken and the Basket Tip has

become separated.

When the Pipe is not fractured.

Some of the wires on the Basket

have been broken.

The calculus is not inside the

Basket and the instrument is not

broken.

48 MECHANICAL LITHOTRIPTOR

Page 53

Chapter 4 Emergency Treatment

After retracting the Basket Wire

into the Tube Sheath, withdraw

the instrument.

WARNING

Retract the Basket Wire into the Tube Sheath, then retract Tube Sheath into the

endoscope. Then withdraw the endoscope and instrument together.

If the broken wires of the Basket Wire cannot be retracted into

the Tube Sheath, do not withdraw the instrument and endoscope

with excessive force. This could cause patient injury, such as

punctures, hemorrhages or mucous membrane damage.

WARNING

Carry out open surgery or other

possible treatment.

Do not withdraw the

instrument or its fall-offs

of the instrument from

the bile duct with

excessive force. This

could cause punctures,

hemorrhages, mucous

membrane damage or

edema.

Withdraw the instrument.

Dispose of the Basket

Wire and carefully

inspect the Coil Sheath

and Tube Sheath.

49MECHANICAL LITHOTRIPTOR

Page 54

Chapter 4 Emergency Treatment

` When the Pipe Does not Extend From the

When the Pipe does not extend

from the proximal end of the Tube

Sheath.

Proximal End of the Tube Sheath.

Withdraw the Coil Sheath, Tube

Sheath and endoscope together.

When the Coil Sheath

can be moved forward

or back with respect to

the endoscope.

When the Coil Sheath

cannot be moved forward

or back with respect to

the endoscope.

50 MECHANICAL LITHOTRIPTOR

Cut the Coil Sheath, Tube

Sheath and Basket Wire

using pliers or wire cutters.

Cut

Page 55

Use the

Olympus’s

lithotriptor

BML-110A-1 or

carry out open

surgery or

other possible

treatment.

Chapter 4 Emergency Treatment

Withdraw the endoscope.

A certain amount of force is

sometimes required to withdraw

the endoscope.

When the Coil Sheath and

Tube Sheath can be moved.

Withdraw the Coil

Sheath and Tube

Sheath.

When the Coil Sheath and Tube

Sheath cannot be moved.

Carry out open

surgery or other

possible treatment.

Use the

Olympus’s

lithotriptor

BML-110A-1 or

carry out open

surgery or

other possible

treatment.

51MECHANICAL LITHOTRIPTOR

Page 56

Chapter 4 Emergency Treatment

` When to use the BML-110A-1

S Before use, thoroughly review the

method of use for lithotriptor

BML-110A-1 in accordance with the

instruction manuals.

S Do not use this lithotriptor BML-110A-1

for a calculus that is assumed

impossible to be crushed by this

lithotriptor. The basket wire etc. may

break and part of this lithotriptor may

remain in the body.

S Use this instrument by having the

settings to switch to open surgery and

the hospitalization plan ready in case

the calculus cannot be crushed by

lithotriptor BML-110A-1.

S Operation of Mechanical Lithotriptor

BML-110A-1 is based on the

assumption that open surgery is

possible as an emergency measure.

If the calculus is too hard and the

Basket Wire or Mechanical Lithotriptor

is damaged, lithotripsy cannot be

continued. Use the BML-110A-1 with

the understanding that its could

become damaged Basket Wire and

that open surgery may have to take

place.

52 MECHANICAL LITHOTRIPTOR

Page 57

Chapter 4 Emergency Treatment

If the calculus is too hard, it is possible that the damages

shown below (See Figures 4.1, 4.2 and 4.3) and other

damages may occur. In addition, before using

BML-110A-1, thoroughly review the manual of

BML-110A-1 and use the instruments as instructed.

The Operation Wire is Cut

Figure 4.1

53MECHANICAL LITHOTRIPTOR

Page 58

Chapter 4 Emergency Treatment

All of the Basket Wires are Cut

Figure 4.2

Some of the Basket Wires are Cut

Figure 4.3

54 MECHANICAL LITHOTRIPTOR

Page 59

Chapter 5 Reprocessing

S The Coil Sheath, the Tube Sheath and

the BML Handle were not sterilized

before shipment. Before using the Coil

Sheath, the Tube Sheath and the BML

Handle for the first time, reprocess

them according to the instructions in

this Chapter.

Do not use the BML Handle that has

not been cleaned and sterilized. This

poses an infection control risk and/or

can cause tissue irritation.

S The Basket Wire is single-use,

disposable item that is not to be

reprocessed. Do not reuse or attempt

to sterilize it

an infection control risk and/or cause

tissue irritation.

after use. This could pose

Chapter 5 Reprocessing

5.1 General Policy

S The medical literature reports incidents of patient

cross contamination resulting from improper

cleaning or sterilization. It is strongly

recommended that reprocessing personnel have

a thorough understanding of and follow all national

and local hospital guidelines and policies.

A specific individual or individuals in the

endoscopy unit should be responsible for

reprocessing endoscopic equipment. It is highly

desirable that a trained backup be available should

the primary reprocessing individual(s) be absent.

S All individuals responsible for reprocessing should

thoroughly understand:

55MECHANICAL LITHOTRIPTOR

Page 60

Chapter 5 Reprocessing

S your institution’s reprocessing

procedures

S occupational health and safety

regulations

S all national and local hospital

guidelines and policies

S the instructions in this manual

S the mechanical aspects of endoscopic

equipment

S pertinent germicide labeling

S Failure to properly clean and sterilize

the Coil Sheath, the Tube Sheath and

the BML Handle after each

examination can compromise patient

safety. During use, the instrument

normally comes in contact with intact

mucous membranes. To minimize the

risk of transmitting diseases from one

patient to another, after each

examination the instrument and the

BML Handle must undergo thorough

cleaning followed by sterilization.

S If the Coil Sheath, the Tube Sheath or

the BML Handle is not cleaned

meticulously, effective sterilization

cannot be obtained. Clean the Coil

Sheath, the Tube Sheath and the BML

Handle thoroughly before sterilization

to remove microorganisms or organic

material which can limit the

effectiveness of the sterilization

process.

56 MECHANICAL LITHOTRIPTOR

Page 61

Chapter 5 Reprocessing

S Patient debris and reprocessing

chemicals are hazardous. Wear

personal protective equipment to

guard against dangerous chemicals

and infectious material. During

cleaning and sterilization, always wear

appropriate personal protective

equipment, such as eye wear, a face

mask, moisture-resistant clothing and

chemical-resistant gloves that fit

properly and are long enough so that

your skin is not exposed. Always

remove contaminated protective

clothing before leaving the

reprocessing area.

S The reprocessing procedures

described in this manual should be

completed the same day the Coil

Sheath, the Tube Sheath and the BML

Handle have been used. If

reprocessing is delayed, residual

organic debris will solidify and it may

be difficult to effectively reprocess the

Coil Sheath, the Tube Sheath and/or

the BML Handle.

S With the cleaning and sterilization

methods stated in this instruction

manual, prions, which are considered

to be the pathogenic substance of the

Creutzfeldt-Jakob disease (CJD)

cannot be destroyed or inactivated.

When using this instrument on a

patient with CJD or variant

Creutzfeldt-Jakob disease (vCJD), be

sure to use this product for such

patient only and/or immediately

dispose of this product after use in an

appropriate manner. For methods to

handle CJD, please follow the

respective guidelines in your country.

57MECHANICAL LITHOTRIPTOR

Page 62

Chapter 5 Reprocessing

S This instrument is not durable, or does

not have sufficient durability against

the respective methods stated in the

guidelines of each country for

destroying or inactivating prions. For

information on the durability against

each method, please contact

Olympus. If cleaning and sterilization

methods not stated in this instruction

manual are performed, Olympus

cannot guarantee the effectiveness,

safety and durability of this instrument.

Make sure to confirm that there is no

abnormality before use, and use under

responsibility of a physician. Do not

use if any abnormality is found.

NOTE

Olympus Endo-Therapy Accessories are

compatible with 2.0% to 3.2%

glutaraldehyde solutions. However,

routine biological monitoring is not

feasible with glutaraldehyde and,

therefore, it should not be used to sterilize

reusable medical devices that are

compatible with other methods of

sterilization that can be biologically

monitored, such as steam sterilization.

58 MECHANICAL LITHOTRIPTOR

Page 63

Chapter 5 Reprocessing

5.2 Required Reprocessing Equipment

Wear the personal protective equipment as specified in the

Table on page 59.

1. Prepare the following equipment. The required

amount of detergent solution, lubricant and other

equipment depends on the number of Coil Sheaths,

Tube Sheaths and BML Handles to be reprocessed.

2. Fill an immersion basin with detergent solution and fill

a second immersion basin with lubricant at the

temperatures and concentration recommended by

the manufacturer. Also fill the ultrasonic cleaner with

a detergent solution appropriate for ultrasonic

cleaning.

Equipment Needed for Reprocessing

To perform proper reprocessing, the equipment in the

following table is required. For details on preparation and

directions for use of the following equipment, refer to the

respective instruction manuals or contact the equipment

manufacturer.

Contact Olympus for the names of specific brands of

detergent solutions and lubricants.

Equipment Needed

Protective

Equipment

Immersion Basin

for Detergent

Solution

Appropriate personal protective equipment

may include: eye wear, face mask,

moisture-resistant clothing and

chemical-resistant gloves.

Use a basin with a depth and diameter large

enough to allow complete immersion of the

instrument when the Insertion Portion is coiled

with a diameter of not less than 15 cm.

59MECHANICAL LITHOTRIPTOR

Page 64

Chapter 5 Reprocessing

Detergent Solution

for Immersion

3

10 cm

(10 ml)

Use a neutral pH, low-foaming, medical-grade

detergent solution.

syringe

Ultrasonic Cleaner Use a medical-grade ultrasonic cleaner with a

frequency range of 38 to 47 kHz, and with a

depth and a diameter large enough to allow

complete immersion of the instrument when

the Insertion Portion is coiled with a diameter

of not less than 15 cm.

Compatible ultrasonic cleaner includes

OLYMPUS ULTRASONIC CLEANER KS-2.

Detergent Solution

for Ultrasonic

Use a neutral pH, low-foaming, medical-grade

detergent solution with no abrasive.

Cleaning

Immersion Basin

for Lubricant

Use a basin with a depth and diameter large

enough to allow complete immersion of the

instrument when the Insertion Portion is coiled

with a diameter of not less than 15 cm.

Lubricant Use a medical-grade, water soluble or

low-viscosity emulsion type lubricant. A high

viscosity lubricant will be difficult to inject into

the Port.

Lint-free Cloths

Packages for

Steam Sterilization

Use packages compatible with steam

sterilization (autoclaving). The packages

should be large enough to accommodate the

instrument when the Insertion Portion is coiled

with a diameter of not less than 15 cm.

The packages should be large enough to

contain the BML Handle.

Sealing Device for

Sterile Packages

Sealing the packages may require a device

such as a heat sealer. Prepare an appropriate

sealing device according to the packages to

be used.

Autoclave Use an autoclave that will operate at the

conditions specified in Section 5.6,

“Sterilization”

60 MECHANICAL LITHOTRIPTOR

Page 65

5.3 Cleaning

Immersion

Chapter 5 Reprocessing

When cleaning, avoid exposure to the

fluids discharged from the Insertion

Portion and reprocessing chemicals.

They may pose an infection control risk or

cause skin irritation.

S When reprocessing, do not coil the

Insertion Portion with a diameter of

less than 15 cm. This could damage

the Insertion Portion.

S Never use excessive force to open or

close the Coil Sheath, the Tube

Sheath or the BML Handle. This could

damaged the Coil Sheath, the Tube

Sheath and/or BML Handle.

S Do not withdraw the Tube Sheath from

the Coil Sheath quickly. This could

scatter blood, mucous or other patient

debris and pose an infection control

risk.

S Immerse the Coil Sheath, the Tube

Sheath and the BML Handle in

detergent solution immediately after

use. If the Coil Sheath, the Tube

Sheath or the BML Handle is not

cleaned immediately, it may be difficult

to effectively reprocess, and this could

result in reduced performance.

61MECHANICAL LITHOTRIPTOR

Page 66

Chapter 5 Reprocessing

1. Immerse the Insertion Portion of the Tube Sheath in

the detergent solution.

2. Connect a 10 cm

solution to the Port.

3

(10 ml) syringe filled with detergent

3. Cover the Stopper’s opening with your finger and

3

(10 ml) of detergent solution into the

Inject 10 cm

Insertion Portion. (See Figure 5.1)

If it is not possible to inject the detergent solution or

if it leaks from any areas other than the distal end of

the Insertion Portion, do not use the Tube Sheath.

4. Disconnect the syringe from the Port.

Stopper

Figure 5.1

62 MECHANICAL LITHOTRIPTOR

Page 67

Chapter 5 Reprocessing

5. Fully immerse the BML Handle in the detergent

solution. Make sure that the Rotatable Knob is facing

up. (See Figure 5.2)

6. Immerse the entire the Coil Sheath, the Tube Sheath

and the BML Handle in the detergent solution for the

time specified in manufacturer’s instructions. If no

time is specified, immerse for between 5 minutes and

3 hours.

Rotatable Knob

BML Handle

Figure 5.2

7. Remove the Coil Sheath, the Tube Sheath and the

BML Handle from the detergent solution.

63MECHANICAL LITHOTRIPTOR

Page 68

Chapter 5 Reprocessing

8. Put the Holder of the BML Handle downwards, and

discharge the remaining detergent solution from the

Outlet. Then, push and pull the Holder two or three

times. (See Figure 5.3)

BML Handle

Outlet

Figure 5.3

Holder

64 MECHANICAL LITHOTRIPTOR

Page 69

Ultrasonic Cleaning

Immerse the distal end of the Tube Sheath in the

1.

ultrasonic cleaner containing detergent solution.

2. Connect a 10 cm

solution to the Port.

Chapter 5 Reprocessing

3

(10 ml) syringe filled with detergent

3. Cover the Stopper’s opening with your finger and

3

(10 ml) of detergent solution into the

Inject 10 cm

Insertion Portion. If it is not possible to inject the

detergent solution or if it leaks from any area other

than the distal end of the Tube Sheath, do not use the

Tube Sheath.

NOTE

Even if the same type of detergent

solution is used for both immersion and

ultrasonic cleaning, make sure to inject

detergent solution at this time. Replacing

the detergent solution inside the Insertion

Portion will increase the effectiveness of

cleaning.

4. Disconnect the syringe from the Port.

5. Immerse the entire Coil Sheath, Tube Sheath and

BML Handle in the detergent solution. Make sure the

Rotatable knob is forcing up. (See Figure 5.2)

6. Clean ultrasonically for 30 minutes. For details on

operation of the ultrasonic cleaner, refer to the

instruction manual of the ultrasonic cleaner.

7. Remove the Coil Sheath, the Tube Sheath and the

BML Handle from the detergent solution.

8. Put the Holder of the BML Handle downwards, and

discharge the remaining detergent solution from the

Outlet. Then, push and pull the Holder two or three

times. (See Figure 5.3)

65MECHANICAL LITHOTRIPTOR

Page 70

Chapter 5 Reprocessing

Rinsing

S After ultrasonic cleaning, rinse the Coil

Sheath, the Tube Sheath and the BML

Handle thoroughly to remove residual

detergent. Residual detergent

solution could cause tissue irritation in

the next patient.

S Do not forcefully squeeze, wipe or

scrub the Coil Sheath, the Tube

Sheath and the BML Handle. This

could cause damage to the Coil

Sheath, the Tube Sheath and/or the

BML Handle result in reduced

performance.

1. Connect a 10 cm

water to the Port.

3

(10 ml) syringe filled with clean tap

2. Cover the Stopper’s opening with your finger and

Inject 10 cm

If it is not possible to inject water or if it leaks from any

area other than the distal end of the Tube Sheath, do

not use the Tube Sheath.

3

(10 ml) of water into the Tube Sheath.

3. Disconnect the syringe from the Port.

4. Repeat Steps 1. through 3. to inject a total of 20 cm

(20 ml) of water into the Tube Sheath.

5. Rinse the Coil Sheath, the Tube Sheath and the BML

Handle under clean running tap water.

6. Push and pull the Holder two or three times under

clean running tap water.

7. Confirm that no debris is left on the surfaces of the Coil

Sheath, the Tube Sheath.

8. Push and pull the Holder and confirm that no debris

remains on the other surface of the BML Handle.

9. Connect a 10 cm

Port.

3

(10 ml) syringe filled with air to the

3

66 MECHANICAL LITHOTRIPTOR

Page 71

Chapter 5 Reprocessing

10. Cover the Stopper’s opening with your finger and

Inject 10 cm

11. Disconnect the syringe from the Port.

12. Repeat Steps 9. through 11. until no liquid comes out

of the distal end of the Tube Sheath.

13. Wipe the exterior of the Coil Sheath, the Tube Sheath

and the BML Handle with a clean, dry lint-free cloth.

5.4 Lubrication

1. Immerse the entire Coil Sheath and the BML Handle

in the lubricant for 2 to 3 seconds.

2. Connect a 10 cm

to the Port.

3

(10 ml) of air into the Tube Sheath.

When lubricating, avoid exposure to the

fluids discharged from the Insertion

Portion and lubricant. It may pose an

infection control risk and/or cause skin

irritation.

Do not coil the Insertion Portion with a

diameter of less than 15 cm. This could

damage the Insertion Portion.

3

(10 ml) syringe filled with lubricant

3. Cover the Stopper’s opening with your finger and

inject the lubricant until it comes out of the distal end.

If it is not possible to inject the lubricant or it leaks from

any area other than the distal end of the Tube Sheath,

do not use the Tube Sheath.

4. Disconnect the syringe from the Port.

5. Connect a 10 cm

Port.

3

(10 ml) syringe filled with air to the

6. Cover the Stopper’s opening with your finger and

inject 10 cm

3

(10 ml) of air into the Tube Sheath once.

67MECHANICAL LITHOTRIPTOR

Page 72

Chapter 5 Reprocessing

7. Disconnect the syringe from the Port.

8. Repeat steps 5. through 7. until no lubricant comes

out of the distal end of the Tube Sheath.

9. Loosen the Knob on the Slide Region of the Coil

Sheath. Then move the Knob back and forth to slide

the Slide Region a few times.

10. Remove the BML Handle from the lubricant. Put the

Holder of the BML Handle downwards, and discharge

the remaining lubricant from the Outlet. Then, push

and pull the Holder two or three times.

(See Figure 5.3)

11. Wipe the exterior of the Coil Sheath, the Tube Sheath

and the BML Handle with a clean, dry lint-free cloth

and allow them to air dry.

68 MECHANICAL LITHOTRIPTOR

Page 73

5.5 Assembly

Inspection Before Assembly

Chapter 5 Reprocessing

Be sure to inspect the Coil Sheath and the

Tube Sheath before assembly. Never

attempt to use the instrument if you

suspect that the Coil Sheath and the Tube

Sheath has an irregularity or is damaged.

If an instrument in this condition is used,

it may malfunction or cause patient injury,

such as punctures, hemorrhages or

mucous membrane damage. Equipment

damage and performance deterioration

may also result.

To avoid damaging the Coil Sheath, the

Tube Sheath or the BML Handle, do not

use excessive force when handling them.

Inspect the instrument and the BML Handle according to

the following procedure. If an abnormality is detected, do

not use the instrument or the BML Handle. Use a spare

instead.

1. Confirm that the Coil Sheath and Tube Sheath are

free from disconnection or looseness.

2. Gently run your fingertips over the entire length of the

Coil Sheath and Tube Sheath to check for any

crushed areas, excessive bends, etc..

3. Gently run your fingertips over the entire length of the

Tube Sheath to check for broken areas, etc..

69MECHANICAL LITHOTRIPTOR

Page 74

Chapter 5 Reprocessing

Assembly

S Do not use excessive force when

assembling the Coil Sheath and the

Tube Sheath. This could damage the

Coil Sheath and the Tube Sheath.

S Be sure to keep the Coil Sheath and

Tube Sheath straight when

assembling the Coil Sheath and the

Tube Sheath. If the Coil Sheath or

Tube Sheath is not straight, the Coil

Sheath and the Tube Sheath could be

damaged.

1. Loosen the Knob on the Coil Sheath and slide it as far

as possible toward the proximal end. Then tighten the

Knob to fix the position of the Slide Region.

(See Figure 5.4)

Knob

Coil Sheath

Figure 5.4

2. Straighten the Coil Sheath.

70 MECHANICAL LITHOTRIPTOR

Page 75

Chapter 5 Reprocessing

3. Insert the Tube Sheath into the proximal end of the

Coil Sheath as shown in Figure 5.5.

Coil Sheath

Tube Sheath

Figure 5.5

NOTE

S The Tube Sheath may get caught

inside the Coil Sheath when it is

inserted. If this happens, do not try to

insert the Tube Sheath forcibly.

Instead, pull or turn the Tube Sheath

gently to make it easier to insert.

S The connection of the Guide Pipe and

the Tube of the Tube Sheath is very

fragile. Use extra care when handling

it.

71MECHANICAL LITHOTRIPTOR

Page 76

Chapter 5 Reprocessing

4. Align the guide pin of the Tube Sheath with the Notch

at the proximal end of the Coil Sheath as shown in

Figure 5.6. Tighten the Fixing Screw to secure them.

Guide Pipe

Guide Pin

Notch

Coil Sheath

Tube Sheath

Figure 5.6

Fixing Screw

5. Make sure that the Tube Sheath is extended from the

distal end of the Coil Sheath.

72 MECHANICAL LITHOTRIPTOR

Page 77

5.6 Sterilization

Sealing the Package

1. Before sterilization, the Coil Sheath, the Tube Sheath

and the BML Handle must be thoroughly cleaned and

dried. Residual moisture inhibits sterilization.

2. Coil the Coil Sheath, the Tube Sheath and place it in

the package.

Chapter 5 Reprocessing

S Do not coil the Coil Sheath, the Tube

Sheath with a diameter of less than 15

cm. This could damage the

instrument.

S Seal the Coil Sheath, the Tube Sheath

and the BML Handle in separate

packages. Otherwise, they could be

damaged.

3. Place the BML Handle in a separate package.

4. Seal the packages. For details on sealing, refer to the

instruction manual of the packages and the sealing

device.

Steam Sterilization (Autoclaving)

S Use biological indicators as

recommended by your hospital’s

policy and follow the manufacturer’s

instructions, all national and local

hospital guidelines and policies.

S Always leave space between the

packages in the autoclave. If the

packages are placed too close

together, effective sterilization will not

be possible.

73MECHANICAL LITHOTRIPTOR

Page 78

Chapter 5 Reprocessing

S Allow the sterile packages to dry within

the autoclave using the autoclave’s

drying cycle (if applicable) or by

opening the door of the autoclave and

allowing the packages to air dry.

Handling a wet package can

compromise its sterility.

S The results of sterilization depend on

various factors such as how the

sterilized instrument was packed or

the positioning, method of placing and

loading of the instrument in the

sterilization device. Please verify the

sterilization effects by using biological

or chemical indicators. Also follow the

guidelines for sterilization issued by

medical administrative authorities,

public organizations or the infection

management sections at each

medical facility, as well as the

instruction manual of the sterilization

device.

1. Place the sealed packages containing the Coil

Sheath, the Tube Sheath and the BML Handle in the

autoclave and sterilize in accordance with the

conditions listed below. For details on operation of the

autoclave, refer to the instruction manual for the

autoclave or other manufacturer instructions.

2. After steam sterilization, let the Coil Sheath, the Tube

Sheath and the BML Handle gradually cool down to

room temperature. Sudden changes in temperature

may damage the Coil Sheath, the Tube Sheath and/or

the BML Handle.

74 MECHANICAL LITHOTRIPTOR