Oliver BM-42 Service Manual

Walker, Michigan, U.S.A. 49534-7564

USER’S OPERATING AND INSTRUCTION MANUAL

BM-42

BOULE MOULDER

0601S20000-CVR

OPERATOR’S MANUAL

SAFETY INSTRUCTIONS

MAINTENANCE & TROUBLE SHOOTING

GEARMOTOR MAINTENANCE INSTRUCTIONS

WARRANTY & PARTS DIAGRAMS & WARRANTY

BM42 BOULE MOULDER

0601S20001 0-1

ATTENTION

ALLOPERATORS

DO NOT INSTALL, OPERATE OR DO MAINTENANCE OF THIS EQUIPMENT WITHOUT READING THE MANUAL.

PROTECT YOURSELF AND OTHERS BY OBSERVING ALL SAFETY INFORMATION AND PROCEDURES.FAILURE TO

COMPLYWITHINSTRUCTIONSCOULDRESULTININJURIESAND

/ORPROPERTYDAMAGES.

SAFETYDEPENDSONYOU!

Trademark(s)ownedbyBloemhofIndustriesLtd.

TollFree1‐800‐253‐3893

OliverPackagingandEquipmentCo

3236WilsonDrNW,Walker,MI49534

0601S20001 0-2

Thank you for purchasing the Bloemhof BM42 Boule Moulder. We invite you to read the

instructions in order to obtain maximum performance, safety, and satisfaction from this

outstanding unit.

The Bloemhof BM42 Boule Moulder is specifically developed to handle the most difficult dough

with up to 15% protein flour as well as traditional artisan breads. The advanced hand moulding

action produces a superior oven jump and a seamless finish.

Our Boule Moulder eliminates the tedious task of hand moulding of medium to large rounds and

with the infinite control settings, all types of dough can be moulded to your complete satisfaction.

Weight range for this machine is from 7 ounce to 4 pounds and up to 1,000 Boules of 36 oz. can

be made in one hour.

The Bloemhof BM42 Boule Moulder features:

Variable speed cone rotation

Variable speed kneading action

Adjustable stroke settings

Heavy duty motor and drive system

Sanitary construction

It should be noted that this machine controls and works the dough pieces through rotation,

kneading, stroke and a time interval. Separate electronic controls and gear motors have been

incorporated for cone rotation and for cone kneading. Cone stroke can also be quickly varied by

adjusting the stroke adjustment knob. This versatility gives you complete control on how much or

how little you work your dough for consistent quality results.

The FDA approved surfaces are clean, durable and will not absorb oils or dough ingredients. A

full scraper system prevents dough buildup and makes cleaning simple.

The Bloemhof BM42 Boule Moulder will be a welcome addition to your shop, since it was

designed to reduce the labor intensive and tedious moulding operations and produce the finest

quality products.

The instructions are in general because of personal preference with regards to dough

consistency, bread types and most important, formulae.

0601S20001 0-3

IMPORTANT

U

NCRATING

This machine was carefully manufactured, tested and crated prior to shipment. When

unpacking this machine, carefully inspect for any shipping damage. Make sure any bolts

or parts that may have loosened during transit are tightened before proceeding.

1. Carefully uncrate the Boule Moulder using claw hammer.

2. This unit weighs 850 pounds and is top heavy, thus care must be taken when removing from

pallet.

3. Discard all shrink wrap & packing materials. Ensure that there are no loose parts, nails,

wood or other foreign material in or underneath cone and tub.

4. Check cone hold down knobs and make sure they are securely fastened.

5. Read operating instructions before attempting to use this machine.

6. DO NOT change the cord end to any other voltage or phase rating.

Serious damage to motors and controls will result which is not covered by warranty!

SAFETY INSTRUCTIONS

WARNING!

DO NOT INSTALL OPERATE OR MAINTAIN THIS EQUIPMENT WITHOUT READING AND UNDERSTANDING THIS

MANUAL

SAFETY DEPENDS ON YOU!

WARNING!

ELECTRICAL SHOCK CAN KILL

Install equipment in accordance with the all national and local electrical codes.

Improper connection of the equipment grounding conductor and line voltage can

result in a risk of electrical shock and / or damage to equipment, (such damages are

not covered by warranty).

Consult with a qualified electrician and / or service person to ensure that the outlet is

properly grounded. Only a qualified electrician can modify the electrical cord and / or

plug-in provided.

Disconnect machine from electrical supply source before performing any and all

maintenance.

0601S20001 0-4

GENERAL SAFETY INSTRUCTIONS

1. R

EAD the Operators Manual carefully. Be thoroughly familiar with the controls and the

proper use of the equipment.

2. O

NLY PERSONS well acquainted with these rules for safe operation should be allowed to

use this machine.

3. Do not wear loose clothing, scarves, or neckties. These items may become caught in

moving parts and result in personal injury.

4. V

ISUALLY inspect machine prior to starting motor. Ensure all safety guards, covers and

devices are in position and in good condition. Keep hands, hair, clothing and tools away

from rollers, V-belts, conveyor belts and all other moving parts when starting, operating or

repairing equipment. Do not disconnect Safety Bar or render it inoperable by tying or

taping it in a fixed position.

5. D

ISCONNECT machine from power supply before performing servicing, maintenance, or

cleaning. In some cases it may be necessary to remove safety guards to perform

required maintenance. Immediately replace guards before placing the machine into

service.

6. T

URN OFF machine control before unplugging. Do not unplug machine and do not attempt

to move the machine by pulling cord.

7. D

O NOT operate machine when children are present and disconnect power supply when

unattended.

8. S

TAY ALERT! Watch what you are doing and use common sense. Do not use the machine

when you are tired, distracted or under the influence of drugs, alcohol or heavy

medication.

0601S20001 0-5

GENERAL INSTRUCTIONS

You should become familiar with the major components of your new Bloemhof Boule Moulder as

we will make reference to them throughout this manual.

WARNING

B

EFORE STARTING, REMOVE DOUGH PIECES, FOREIGN OBJECTS, AND HANDS FROM WORKING AREAS.

DURING OPERATIONS, KEEP FINGERS AND HANDS AWAY FROM THE PINCH POINTS BETWEEN THE TUB AND

CONE

.

I

F MACHINE STOPS DURING OPERATIONS, UN-PLUG UNIT AND WAIT 5 MINUTES

FOR THE ELECTRONIC CONTROLS TO RESET.

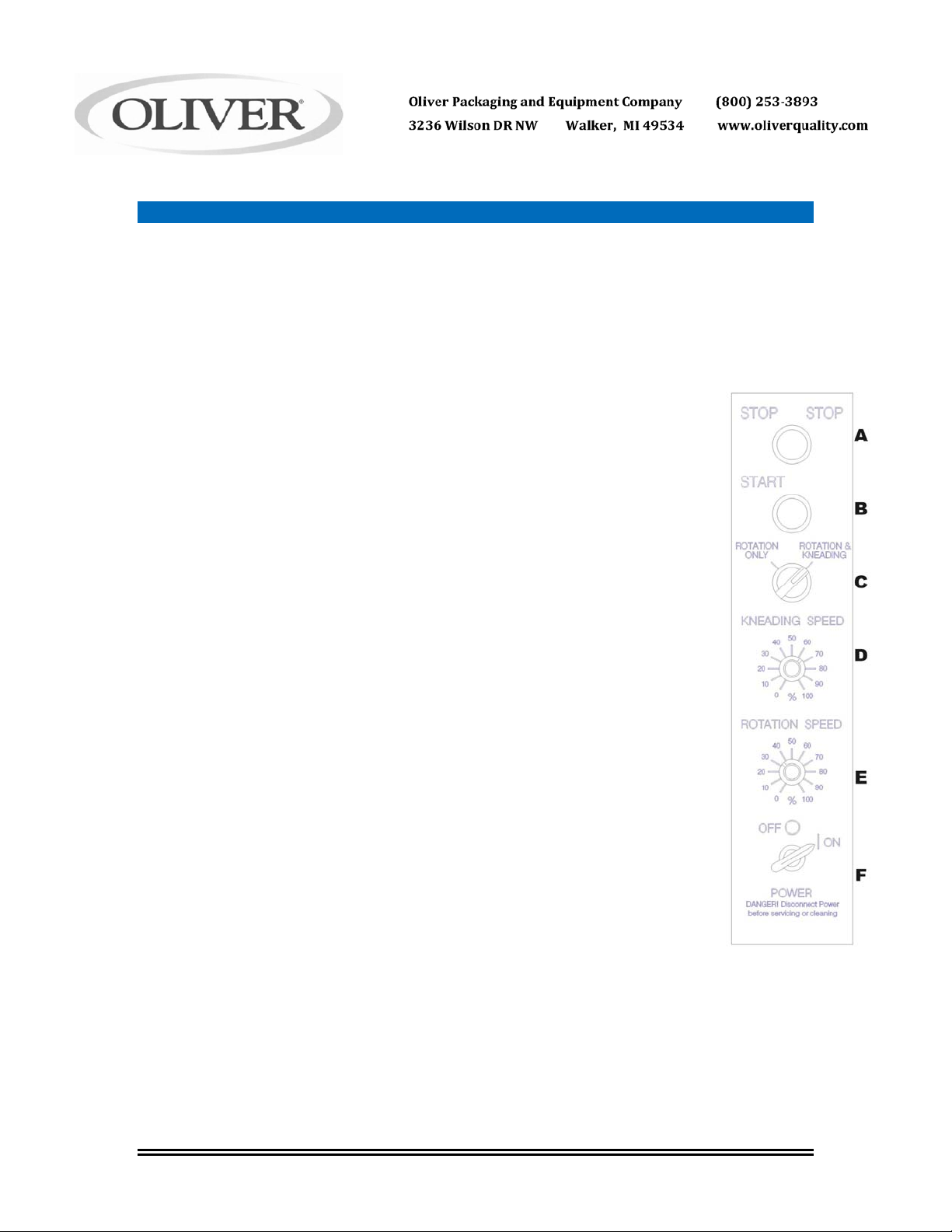

1. C

ONTROL PANEL

The Control Panel controls all the motor functions and is located by the catch

tray.

A. STOP - Stops all motors, twist knob to reset.

B. START - Starts rotations and kneading motors.

C. SELECTOR SWITCH - Turn “counter clockwise” energizes rotation motor

only. Turn “clockwise”, energizes rotation and kneading motors.

D. KNEADING SPEED - Controls the rate the cone kneads or squeezes the

dough piece. Adjustment of this control allows from 35 to 150 hits per minute.

E. ROTATION SPEED - Controls the movement of the dough piece around the

tub and dough ball shape. Adjustment of this control allows from 3 to 12

revolutions per minute.

F. POWER - Disconnects main power from controls. Use this switch to

disconnect machine from supply circuit before performing cleaning,

maintenance or servicing electrical circuits. Shut off Power switch before

unplugging cord from supply.

NOTE

If the selector switch “C” is changed from “rotation only” to “rotation

and kneading” while the cone is rotating, the START selector button “B”

must be pushed to energize the kneading motor.

WARNING

T

URN OFF MAIN POWER SWITCH AND UNPLUG MACHINE FROM POWER SOURCE

BEFORE MAKING ADJUSTMENTS, CLEANING AND/OR MAINTENANCE.

2. C

ONE

The cone moulds the dough pieces against the tub surfaces. Both tub and cone are

covered with a durable FDA approved material.

CONE REMOVAL

a. Turn off Main Power Switch and unplug machine from power source.

0601S20001 0-6

b. Remove six cone hold down knobs. Carefully lift cone from machine. Two people are

required to lift cone.

c. Place cone on a clean smooth surface. Do not drop cone or place on floor as the scraper

edge could get damaged.

d. Clean tub area and cone thoroughly of any old dough and flour. Inspect scraper edge on

cone. Use a plastic scraper and damp cloth to clean cone and scraper edge. DO NOT

IMMERSE CONE IN WATER OR PLACE IN PAN WASHER

.

WARNING!

D

O NOT DROP CONE ONTO TABLE OR FLOOR AS SEVERE SCRAPER DAMAGE COULD RESULT.

ONE INSTALLATION

C

a. Clean any foreign material from top hold down plate.

b. Position cone on top of hold down plate on machine and rotate cone until holes from hold

down plate line up with holes in cone. Two people required to install cone.

c. Install hold down knobs and tighten securely.

WARNING!

MAKE SURE THAT THE CONE KNOBS, WHICH HOLD THE CONE IN POSITION, ARE SECURELY

FASTENED AT ALL TIMES

.

3. CONE SCRAPER

The cone scraper prevents dough from squeezing under the cone and also cleans

the tub bottom. The underside of the scraper must be kept clean to prevent foreign

particles from embedding in the plastic scraper and damaging the tub bottom. Clean

with a plastic scraper only do not use a metal scraper or any another sharp

object.

4. TUB

The tub forms the outer moulding surface. Dough loading is on the right side of the

tub exit. Clean the tub daily with a plastic scraper. Clean with a plastic scraper

only do not use a metal scraper or any another sharp object.

T

UB REMOVAL (SEE PAGE 13 FOR DIAGRAM)

a. Turn off “Main Power Switch” and unplug machine from power source.

b. Remove con e from ma chine.

c. Loosen and remove 8 tub hold down knobs. Remove eye bolts from machine.

d. Carefully remove tub from machi ne. Two people required to remove tub.

UB INSTALLATION

T

a. Clean any foreign material from the top of the machine before positioning tub. Care must

be taken to remove debris from the cone slot.

b. Using two people, carefully position tub on the machine making sure to install the tub the

same way it was removed. The exit end of the tub should be over the catch tray.

c. Line up the slots for the hold down knobs and position hold down eye bolts on each cone

pin.

0601S20001 0-7

d. All 8 knobs should be tightened in sequence. In other words, start at the catch tray end

and work around the cone tightening each knob slightly. Once completed, repeat

procedure starting at the first knob by the catch tray and tighten securely. Do not use a

wrench for this procedure.

5. C

ONE KNOBS

There are six cone knobs that hold the cone in position. Before starting the Boule

Moulder, quickly check to make sure all knobs are securely fastened. A knocking

sound may emanate from the machine if the cone knobs are not secure.

6. STROKE CLAMP KNOB

The stroke clamp knob secures the setting of the stroke adjustment. Before starting Boule

Moulder, make sure that this knob, which is located at the very top of the cone, is securely

fastened. Hand tighten only.

7. STROKE ADJUSTMENT WHEEL

The stroke setting is the range the cone will swing from side to side. This setting will

determine how intense the dough piece is being squeezed in-between the tub and

the cone. This setting will be determined by the formulation, weight range and

tightness required of the product being moulded.

To make this adjustment, loosen the stroke clamp knob on the top of the machine,

and adjust the wheel to a higher or lower number. The higher the number, the larger

the stroke and more intense the squeeze in-between the tub and cone.

8. CATCH PLATE

The catch tray is hinged and can be positioned in the loading position by lifting the

catch tray and positioning the holding bar underneath the catch tray. The catch tray

can be positioned in the storage position by lifting the catch tray and lowering the

holding bar.

9. LOCKING CASTERS

The locking casters are provided to stabilize the Boule Moulder during operations.

Place the unit on a level surface then press the black brake mechanism down on all

four casters. NOTE: Before moving the machine to a new location, make sure

all casters are unlocked.

10. FOOT PADS (When supplied)

When machines are supplied with foot pads, make sure the machine is level

before starting machine. Adjust foot pads as required.

0601S20001 0-8

Loading...

Loading...