Oliver 860L Installation Manual

Walker, Michigan, U.S.A. 49534-7564

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 860L

DOUGH MOULDER

0860S20000-CVR

860L DOUGH MOULDER

Jun 2016

860L Bread & Roll Moulder

OPERATOR’S MANUAL

SAFETY INSTRUCTIONS, MAINTENANCE & TROUBLE SHOOTING,

PARTS LIST, DIAGRAMS & WARRANTY

SAFETY

DEPENDS O N Y O U !

D

O NOT INSTALL, OPERATE OR DO

MAINTENANCE OF THIS EQUIPMENT WITHOUT

READING THE MANUAL. PROTECT YOURSELF

AND OTHERS BY OBSERVING ALL SAFETY

INFORMATION AND PROCEDURES. FAILURE TO

COMPLY WITH INSTRUCTIONS COULD RESULT IN

INJURIES AND/OR PROPERTY DAMAGES

.

RECEIVING, UNCRATING & UNPACKING

This machine was carefully manufactured, tested and crated prior to shipment. When receiving, carefully

inspect this machine for any shipping damage and report this to the carrier. When unpacking, ensure

that all packing materials are removed prior to use. Make sure any bolts or parts that may have loosened

during transit are tightened before proceeding.

2

860L DOUGH MOULDER

Trademark(s) owned by Bloemhof Industries Ltd.

M

ANUFACTURER OF QUALITY BAKERY EQUIPMENT SINCE

Toll Free 1-800-253-3893

1960

Oliver 3236 Wilson Dr NW, Walker MI. 49534 Tel 616-356-2950

SAFETY INSTRUCTIONS

ELECTRICAL SAFETY

WARNING! ELECTRICAL SHOCK CAN KILL

• INSTALL EQUIPMENT IN ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE AND ALL LOCAL

ELECTRICAL CODES.

• IMPROPER CONNECTION OF THE EQUIPMENT GROUNDING CONDUCTOR AND LINE VOLTAGE CAN

RESULT IN A RISK OF ELECTRIC SHOCK AND/OR DAMAGE TO EQUIPMENT. RESULTING DAMAGE IS

NOT COVERED BY THE WARRANTY.

• CHECK WITH A QUALIFIED ELECTRICIAN TO ENSURE THAT THE OUTLET IS PROPERLY GROUNDED.

DO NOT MODIFY THE CORD OR PLUG PROVIDED.

• DISCONNECT MACHINE FROM SUPPLY CIRCUIT BEFORE PERFORMING CLEANING, MAINTENANCE

OR SERVICING ELECTRICAL CIRCUITS.

• WARNING! ELECTRONICALLY ENERGIZED CIRCUIT For machines ordered with the electronic speed

control, the Master Power Switch must be turned on to power up the machine at the beginning of the day and

turned off when the days production is completed. Use the Stop/Start stations on either side of the machine for

production runs.

If the machine turns off unexpectedly for any reason wait 5 minutes before restarting the machine.

GENERAL SAFETY INSTRUCTIONS

WARNING! TO AVOID SERIOUS PERSONAL INJURY, INJURY TO

OTHERS AND DAMAGE TO THE EQUIPMENT OR PROPERTY:

1. Read the Operators Manual carefully. Be thoroughly familiar with the controls and the proper use of

the equipment. Do not discard these instructions. Maintain these in a safe place for continuous

reference and training.

2. Only persons well acquainted with these rules for safe operation should be allowed to use this

machine.

3. Do not wear loose clothing, scarves, or neckties. These items may become caught in moving parts

and result in personal injury.

4. Visually inspect machine prior to starting motor. Ensure all safety guards, covers and devices are in

position and in good working condition. Keep hands, hair, clothing and tools away from rollers, Vbelts, conveyor belts and all other moving parts when starting, operating or repairing equipment.

3

860L DOUGH MOULDER

5.

Do not reach into the hopper at any time with power connected to the machine. Pushing down on

the red safety bar, will disconnect power to the motor and shut the machine off. To turn the machine

off after a production run, use the on/off switch and not the inter-lock switch connected to the in-feed

hopper. Do not disconnect interlock switch from the safety bar or render it inoperable by tying,

wedging, locking or taping it in a fixed position. The safety system is there for your protection!

6. Disconnect machine from supply circuit before performing cleaning, maintenance or servicing

electrical circuits or removing stalled dough pieces. In some cases it may be necessary to remove

safety guards to perform required maintenance. Immediately replace guards before placing the

machine into service.

7. Turn off machine before unplugging. Do not unplug machine and do not attempt to move the

machine by pulling on the electrical cord.

8. Do not operate machine when children are near and disconnect power supply when unattended.

9. STAY ALERT! Watch what you are doing and use common sense. Do not use the machine when

you are tired, distracted or under the influence or drugs, alcohol or medication.

WELCOME TO BLOEMHOF

You have just purchased the best BREAD & ROLL MOULDER money can buy.

We invite you to read the instructions in order to obtain maximum performance, safety and satisfaction from this

outstanding unit. Do not discard these instructions. Maintain these in a safe place for continuous reference and

training.

The 860L will be a welcome addition to your shop since it was designed to reduce the labour intensive and tedious

moulding operations and produce the finest quality products.

The 860L features:

• Gentle spring loaded roller system

• Double pressure plate controls front and back

• Quick adjustable in-feed guides

• Fully adjustable side guides

• Oversized non-stick dough rollers with rust free scrapers

• Heavy duty motor and drive system

• Sanitary construction

The instructions are in general because of the nationwide distribution of the 860L, personal preference with regards

to dough consistency, bread types and most important, customer formulas

4

860L DOUGH MOULDER

BE SURE TO PREPARE YOUR PRESSURE PLATE WELL BEFORE THE FIRST USE!

The fabric surfaces of the pressure plates and return plate should be conditioned or seasoned before the first use.

Remove the pressure plate(s) and return plate from the moulder and rub flour into the fabric evenly. Turn over the

plate(s) and tap out excess flour. This will condition the fabric to reduce dough sticking. Once done, reinstall the

plate(s) as per instruction and start moulding. See pressure plate removal instructions on following pages.

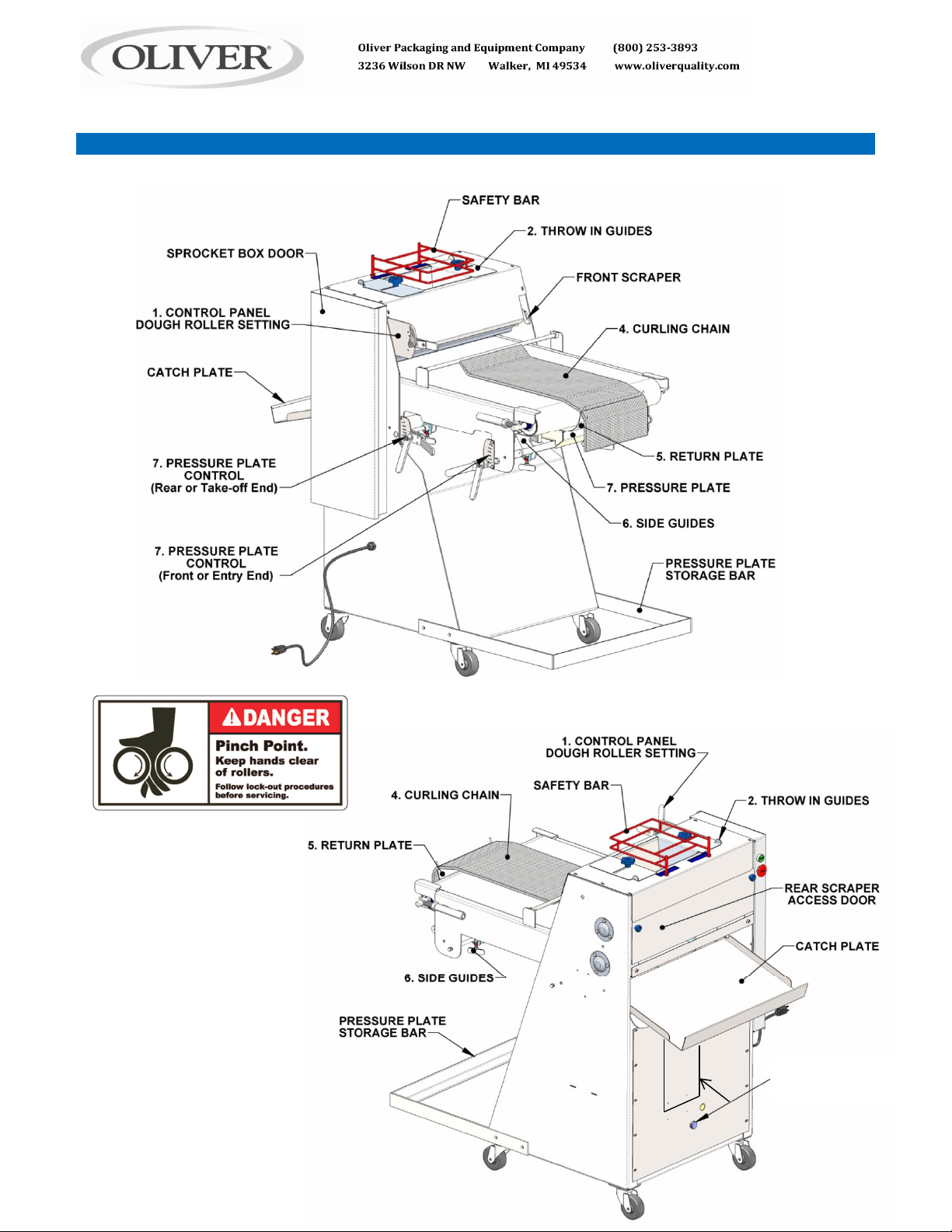

MACHINE DESCRIPTIONS

The instructions are in general because of personal preference with regards to dough consistency, bread types and

most important, customer formulas.

Before starting your new moulder, read through the instructions and we’ll discuss the features on this unit and the

function of the various controls.

DANGER!

KEEP HANDS CLEAR

FROM DOUGH ROLLERS.

S

TOP MACHINE BEFORE

REMOVING DOUGH PIECES

5

860 & 860L MOULDER OPERATING POINTS

860L DOUGH MOULDER

VFD AND GEARBOX

6

Loading...

Loading...