Oliver 2005 Parts List

Grand Rapids, Michigan, U.S.A. 49504-5298

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 2005

VARIABLE SLICE THICKNESS

BREAD SLICER

2005S20000-CV

INDEX

Section Description

Document No. Page No.

SAFETY INSTRUCTIONS ------------------------------- 2005S20001 --------------------- 1-1

DESCRIPTION/SPECIFICATIONS ------------------- - 2005S20002------------- --------- 2-1

Description -------------------------------------------------------------------------------------- 2-1

Physical Specifications----------------------------------------------------------------------- 2-1

OPERATING INSTRUCTIONS ------------------------- 2005S20003 --------------------- 3-1

Automatic Diagnostic Check --------------------------------------------------------------- 3-1

Standard Operation --------------------------------------------------------------------------- 3-1

Stopping ------------------------------------------------------------------------------------------ 3-2

MAINTENANCE -------------------------------------------- 2005S20004 --------------------- 4-1

Cleaning ----------------------------------------------------------------------------------------- 4-1

Lubrication -------------------------------------------------------------------------------------- 4-1

Changing a Blade ----------------------------------------------------------------------------- 4-1

TROUBLESHOOTING ------------------------------------ 2005S20005 --------------------- 5-1

Automatic Diagnostic Check --------------------------------------------------------------- 5-1

Error Display ------------------------------------------------------------------------------------ 5-1

Slice Thicknesses Are Not Equal ---------------------------------------------------------- 5-1

Slices Are Being Pulled Up Or Pushed Down Between the Tables --------------- 5-2

The Blade is Crushing the Bread ---------------------------------------------------------- 5-2

Slicing Starts Before the Bread is Beneath the Blade -------------------------------- 5-2

The Knife Vibrates Excessively ------------------------------------------------------------ 5-2

The Machine Makes a Loud Thumping Sound ----------------------------------------- 5-2

Nothing Happens When the Machine is Turned On ---------------------------------- 5-3

Manual Diagnostic Mode -------------------------------------------------------------------- 5-3

RECOMMENDED SPARE PARTS -------------------- 2005S20006 --------------------- 6-1

REPLACEMENT PARTS SECTION

MAIN FRAME ----------------------------------------------- 2005S20007 --------------------- 7-1

Drawing ------------------------------------------------------------------------------------- 7-1

Parts List ----------------------------------------------------------------------------------- 7-2

BLADE & CLUTCH DRIVE ------------------------------ 2005S20008 --------------------- 8-1

Drawing ------------------------------------------------------------------------------------- 8-1

Parts List ----------------------------------------------------------------------------------- 8-2

CUTOFF ARM --------------------------------------------- 2005S20009 --------------------- 9-1

Drawing ------------------------------------------------------------------------------------- 9-1

Parts List ----------------------------------------------------------------------------------- 9-2

Continued

2005S20000 0-1

INDEX (Continued)

REPLACEMENT PARTS SECTION (Continued)

Section Description

Document No. Page No.

PUSHER WITH STEPPER ----------------------------- 2005S20010 -------------------- 10-1

Drawing ------------------------------------------------------------------------------------ 10-1

Parts List ---------------------------------------------------------------------------------- 10-2

TABLES & COVERS -------------------------------------- 2005S20011 -------------------- 11-1

Drawing ------------------------------------------------------------------------------------ 11-1

Parts List ---------------------------------------------------------------------------------- 11-2

CLUTCH ----------------------------------------------------- 2005S20012 -------------------- 12-1

Drawing ------------------------------------------------------------------------------------ 12-1

Parts List ---------------------------------------------------------------------------------- 12-2

ELECTRICAL SUB-PANEL ----------------------------- 2005S20013 -------------------- 13-1

Drawing ------------------------------------------------------------------------------------ 13-1

Parts List ---------------------------------------------------------------------------------- 13-2

ELECTRICS 1-60-115 VAC ----------------------------- 2005S20014 -------------------- 14-1

Drawing ------------------------------------------------------------------------------------ 14-1

Parts List ---------------------------------------------------------------------------------- 14-2

WIRING DIAGRAMS ------------------------------------- 2005S20015 -------------------- 15-1

1-60-115 VAC --------------------------------------------------------------------------- 15-1

WARRANTY ------------------------------------------------ GEN 040225

WARRANTY PROCEDURE ---------------------------- GEN 040226

RETURNED PARTS POLICY -------------------------- GEN 040227

REV. 3/2/04

2005S20000 0-2

SAFETY INSTRUCTIONS

Various safety devices and methods of guarding have been provided on this machine. It

is essential, however, that machine operators and maintenance personnel observe the

following safety precautions. Improper installation or operation of this equipment may

cause injury to personnel or damage to equipment.

1. Read this manual before attempting to operate your machine. Never allow an

untrained person to operate or service this machine.

2. Connect the machine to a properly grounded electrical supply that matches the

requirements shown on the electrical specification plate and follow specifications of

local electrical codes.

3. Disconnect and lock-out the machine from the power supply before cleaning or

servicing.

4. Check and secure all guards before starting the machine.

5. Observe all caution and warning labels affixed to the machine.

6. Use only proper replacement parts.

7. Do not wear loose fitting clothing or unrestrained long hair. Shirt tails should be

tucked in.

8. Wear proper personal safety equipment.

9. Keep Hands away from the moving parts of this machine while it is in operation.

10. In addition to these general safety instructions, also follow the more specific safety

instructions given for the different areas of the machine in the operating instructions.

WARNING

DO NOT USE FOR OTHER THAN ORIGIN ALLY INTENDED PURPOSE

2005S20001 1-1

DESCRIPTION/SPECIFICATION

Description

The Oliver Model 2005 is a variable slice thickness bread slicer, which utilizes a new and

innovative way to slice bread. The bread is moved past a circular blade, which is

mounted, to a moving arm, cutting each slice individually to whatever thickness is

selected. The slicer is designed for on-demand slicing allowing your customers to

choose a slice thickness, which satisfies their needs. The 2005 slicer also has a multilingual digital display prompting the user with normal operating information.

The slicer employs a disc brake on the blade drive motor, which mechanically engages

to stop the blade whenever the blade is exposed due to a door being opened, or after

the slicing cycle is finished.

NOTE

THIS MACHINE IS NOT INTENDED TO BE USED TO SLICE WARM,

STICKY, NUT AND/OR FRUIT BREADS.

Physical Specifications

Product Capacities:

The slicer will process loaves up to 9 inches by 4-1/4 inches by 15 inches long.

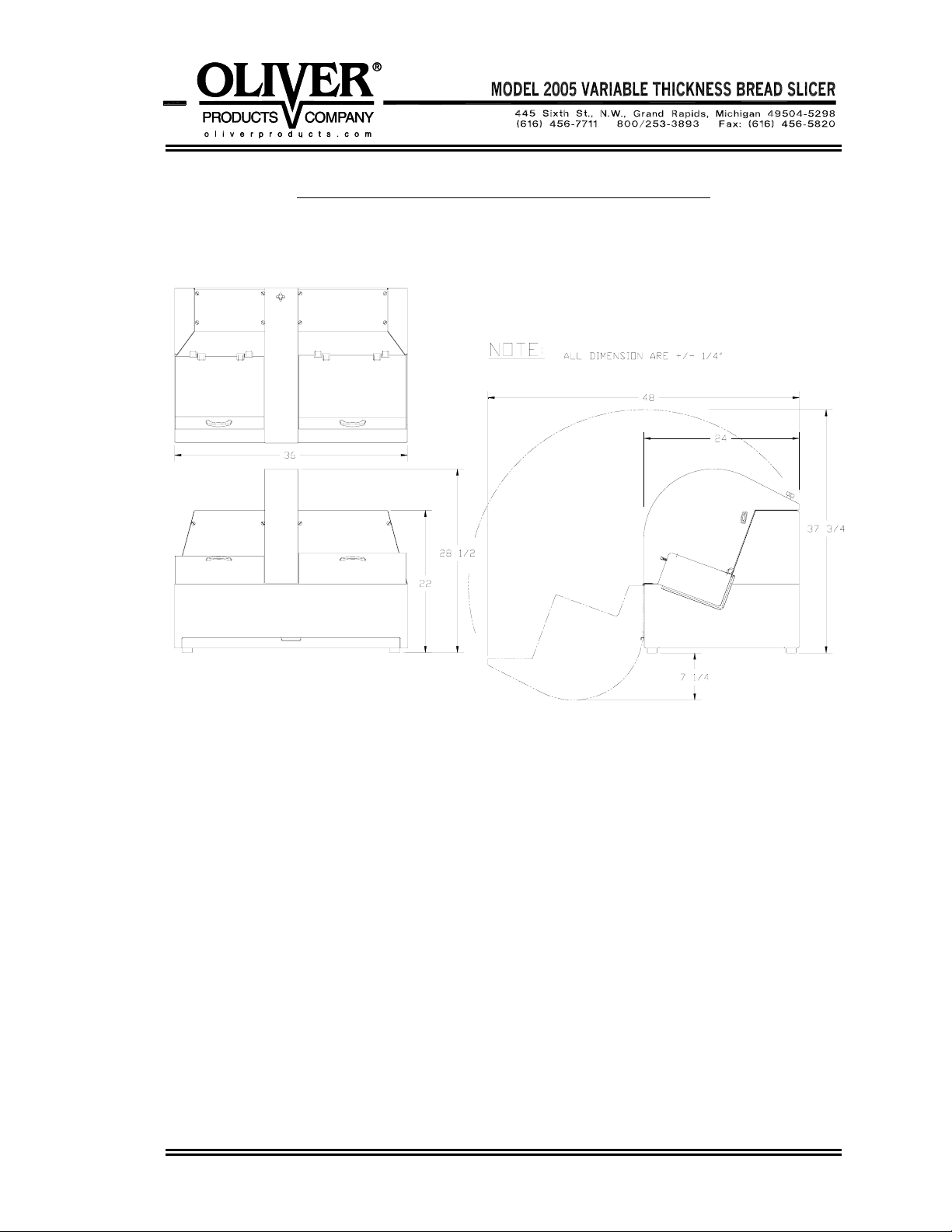

Overall Machine size:

• Width = 36 inches

• Height = 28-1/2 inches, Requiring a minimum of 38” in overhead clearance to

open the blade guard.

• Depth = 24 inches, 48” inches with Blade Guard all the way open.

Net Weight:

Approximately 360 pounds.

Shipping Weight:

Approximately 375 pounds.

Slice Thickness:

3/8, 7/16, 1/2, 5/8, 3/4, 7/8, 1, and 1-1/2 inches.

Electrics:

3/4 Horse Power, 1 phase, 50/60 hertz, 115 Volts AC, 9 Amps,

(20 Amp Dedicated Circuit).

3/4 Horse Power, 1 phase, 50/60 hertz, 230 Volts AC, 4.5 Amps,

(10 Amp Dedicated Circuit).

Rev 11-05

2005S20002 2-1

OVERALL MACHINE DIMENSIONS

2005S20002 2-2

OPERATING INSTRUCTIONS

Automatic Diagnostic Check:

Close both doors. Turn the machine on. The display will read “Vari-slicer” and then give

you the software version. Next, the machine will automatically perform a diagnostic

check on the “end” and “home” proximity sensors (PS). You should observe the pusher

going to its “end”, (right), sensor after which it will return to the “home” (left) sensor.

After it has returned you may begin standard operation.

Standard Operation:

• Upon a successful completion of the diagnostic check, the machine is ready for

slicing.

• Hold open the left door with left hand.

• Place a loaf of bread on the infeed, (left hand), table.

• Slide the loaf onto the pins of the pusher so that pins penetrate the loaf, until it is

firmly against the front of the pusher block.

• Close door(s).

NOTE

THE MACHINE WILL NOT OPERATE IF EITHER DOOR IS OPEN.

• Select the appropriate slice thickness setting. Upon selection slicing will begin

immediately.

• Wait for bread to be sliced. When the machine stops, the bread will be in the right

hand compartment.

• Open the right hand door and remove the loaf.

• Close the door, allowing the pusher to return to the home positon.

• Once the pusher has returned and stopped you may repeat the above procedure to

slice additional loaves.

2005S20003 3-1

Stopping:

If a slice gets jammed, press STOP, to stop slicing, turn the power off, disconnect and

lockout the slicer before trying to clear the machine.

CAUTION

DO NOT OPEN THE DOORS WHILE THE SLICER IS OPERATING.

DOING SO WILL CAUSE SLICING TO STOP.

2005S20003 3-2

MAINTENANCE

WARNING

DISCONNECT AND LOCK OUT THE MACHINE FROM THE POWER

SUPPLY BEFORE CLEANING OR SERVICING. REMEMBER TO USE

CARE WHENEVER YOU ARE WORKING NEAR THE BLADE.

Cleaning:

Use a mild detergent solution applied with a cloth or spray cleaner on all exterior and

interior surfaces as necessary. Remove and empty contents of the crumb tray daily.

Periodically remove the blade and clean the blade compartment.

The blade must be cleaned each day, you Do Not

need to remove the blade to clean it.

Use a mild detergent solution or spray cleaner. For harder deposits use a non scratch

cleaning pad similar to Scotch-brite (tm).

Lubrication:

all motors and bearings are pre-lubricated and sealed, lubrication in not required. Do

Not attempt to oil or grease the motor.

Changing a blade:

WARNING

DISCONNECT AND LOCK OUT THE MACHINE FROM THE POWER

SUPPLY BEFORE CLEANING OR SERVICING. REMEMBER TO USE

CARE WHENEVER YOU ARE WORKING NEAR THE BLADE.

• Tilt the blade guard forward after removing the knob, (located at the top of the

guard), which secures it in place. Gently rest it all the way open.

• Remove the blade mounting screw using a 1/2 inch wrench.

• Remove the lock-washer, special washer, 2 inch diameter collar, and the circular

knife.

• The blade can be replaced by reversing the above procedure.

• When reinstalling the blade, make sure the beveled side faces the outfeed (FLAT

SIDE TOWARD INFEED). Make sure the blade is centered and supported on the

arbor.

2005S20004 4-1

TROUBLE SHOOTING GUIDE

WARNING

DISCONNECT AND LOCK OUT THE MACHINE FROM THE POWER

SUPPLY BEFORE CLEANING OR SERVICING.

WARNING

REMEMBER TO USE CARE WHENEVER YOU ARE WORKING NEAR THE BLADE.

WARNING

TROUBLESHOOTING OF ELECTRICAL EQUIPMENT MUST BE

PERFORMED BY QUALIFIED PERSONNEL ONLY.

Software on the 2005 is continually performing diagnostic checks on itself. The first

diagnostic check occurs when the machine is initially turned on.

Automatic Diagnostic Check:

Close both doors. Turn the machine on. The display will read “Vari-slicer” and then give

you the software version. Next, the machine will automatically perform a diagnostic

check on the “end” and “home” proximity sensors (PS). You should observe the pusher

going to its “end”, (right), sensor after which it will return to the “home”, (left), sensor.

After it has returned you may begin standard operation.

Error Display

Other checks are made each time a loaf of bread is sliced. The digital display will

prompt the operator of what to do next as well as inform the operator of problems and

their possible solutions.

Solving Other Problems

Slice Thicknesses Are Not Equal.

• The bread is not being pressed completely onto the pins of the pusher block,

therefore allowing the loaf to shift on the pins between cuts.

• Bread is getting caught in the gap between the infeed and outfeed tables preventing

free movement of the product. Re-adjust the outfeed table for minimum gap, while

still allowing free movement of the slicer blade. Do NOT adjust the infeed table.

• The slicer blade is loose. Check the blade mounting screw and tighten if necessary.

2005S20005 5-1

Solving Other Problems (Cont’d.)

Slices Are Being Pulled Up Or Pushed Down Through The Gap Between The Tables.

• A build-up on the blade from slicing warm bread or sticky fruit breads can cause this

type of product damage or malfunction.

• The gap between the tables is too large. Re-adjust the outfeed table so that the gap

between the infeed and outfeed tables is minimized while still allowing a comfortable

clearance for the spinning knife.

• The arms of the hold-down could be bent to far away from the blade so that they

cannot maintain control over the slices or crusts and they are pulled between the

blade and hold-down.

The Blade Is Crushing The Bread.

• The bread may be too warm for slicing.

• A build-up on the blade from slicing warm bread or sticky fruit breads can cause this

type of product damage or malfunction.

• The slicer drive motor may not be running, (the slicer knife will not be rotating).

The motor is protected by a circuit breaker, located on the back of the machine, which

may need to be reset.

• The Knife has become extremely dull and needs to be replaced.

Slicing Begins Too Soon, The Knife Takes Several Strokes Before The Product Is

Beneath The Knife.

• The reflector inside of the Knife Cover is dirty.

• The “Product Detect” scanner is dirty or has failed.

The Knife Vibrates Excessively.

• Loose or mis-aligned knife or clutch drive belt’(s). Align or re-tighten as necessary.

The Machine Makes A Loud Thumping Sound Before Making The First Slice.

• Check for a loose blade drive V-belt, or clutch drive belt.

2005S20005 5-2

Loading...

Loading...