Oliver 1908MX2 Installation Manual

Walker, Michigan, U.S.A. 49534-7564

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 1908MX2

AUTOMATED PACKAGING SYSTEM

1908S20078CV

INDEX

INTRODUCTION AND DESCRIPTION………………………………. PG. 1-1

INSPECTING…………………………………………………………….. PG. 1-2

SAFETY..............................................……………………..………….. PG. 1-3

MACHINE PLACEMENT………………………………………..……… PG. 1-4

MACHINE COMPONENTS…………………………………………….. PG. 1-5

START-UP & OPERATION………..…………………………………… PG. 1-10

TECHNICAL SPECIFICATIONS....................................................... PG. 1-13

CLEANING AND MAINTENANCE....................…..............…........... PG. 1-14

TROUBLE SHOOTING......................................…......................….. PG. 1-18

MAINTENANCE CHECKLIST……....................…..............….......... PG. 2-1

ASSEMBLY DRAWINGS & PARTS LISTS..………………………... PG. 3-1

ELECTRICAL……………………………………………………………. PG. 4-1

WARRANTY...................…............................. GEN 050816

WARRANTY PROCEDURE..........….............. GEN 050817

RETURNED PARTS POLICY......................... GEN 050818

1908S20073

QUICK SPECS

Weight 330 lbs

Overall Dimensions 30” W x 64” L x 50” H

Loading Station 3 tray carriers

Electrical 1 phase, 60 Hz, 115 VAC, 15 amps

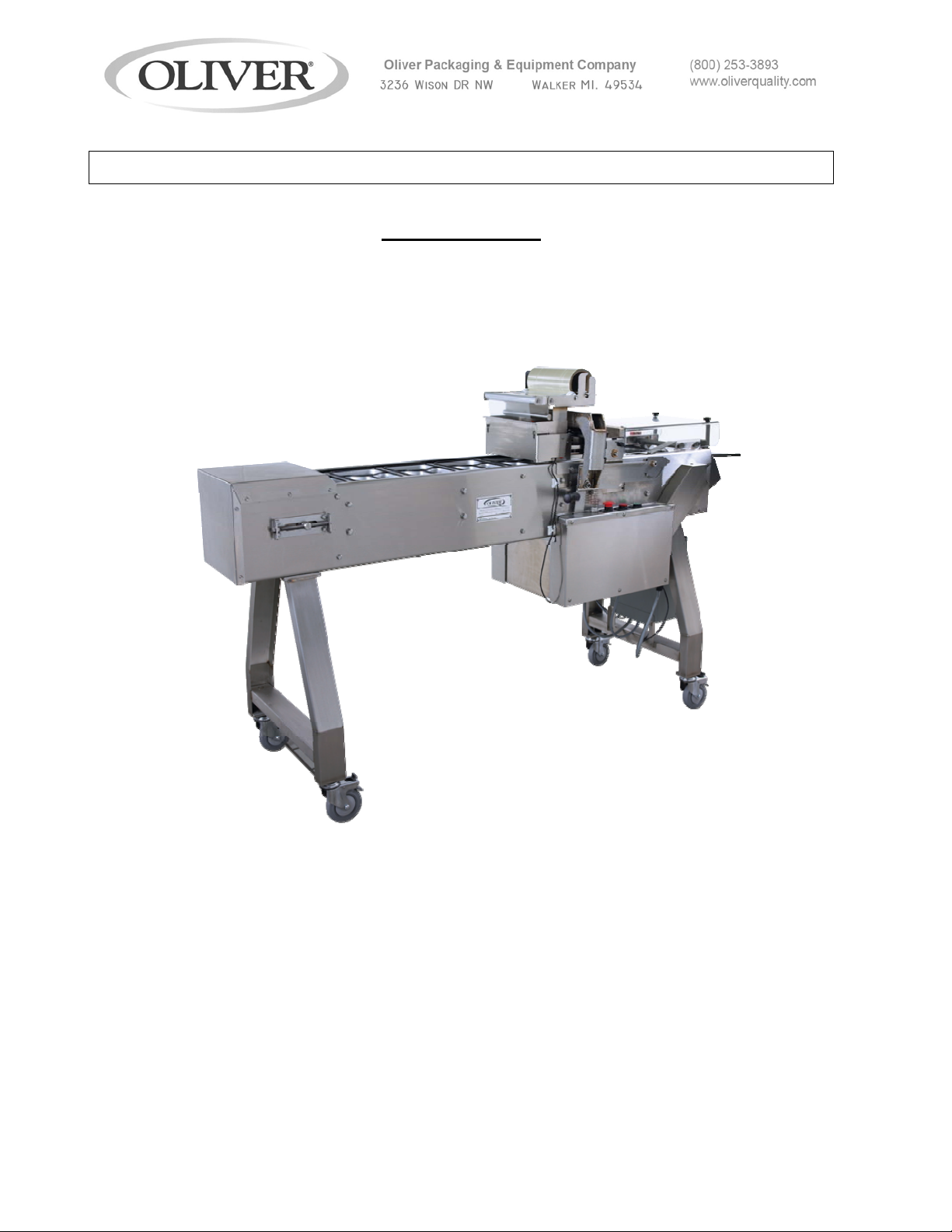

INTRODUCTION AND DESCRIPTION

The OLIVER Model 1908 Lidder has been designed and manufactured to provide a high

quality machine that is a cost effective approach to producing film lidded trays. The

machine can be operated with a 120 V.A.C. outlet. The Model 1908 is an automated

system capable of producing a high volume, but it is easy to operate and requires

minimal space.

The machine consists of a conveyor system that transports the filled trays; a film feed

system, a heated platen and a film cutter unit. These are all packaged together in a

stainless steel framework that also houses all the necessary controls. The conveyor is

intermittent motion and is capable of running speeds of 20 to 27 packages per minute.

1908S20074

1-1

INSPECTING

MODEL 1908

Upon receipt of Machine, inspect the exterior for damage. If damage is noted,

Indicate damage on the Freight Bill and immediately contact the freight Carrier and

notify them of the damage. Have a freight claim filed. This must be done at the

Recipient’s location and not at the Shipper’s Location.

Remove the tie-downs that hold machine to the skid. Lift the machine

off the skid in a safe manner. Remove tape and tie bands that were

used to hold components for shipment.

1908S20074

1-2

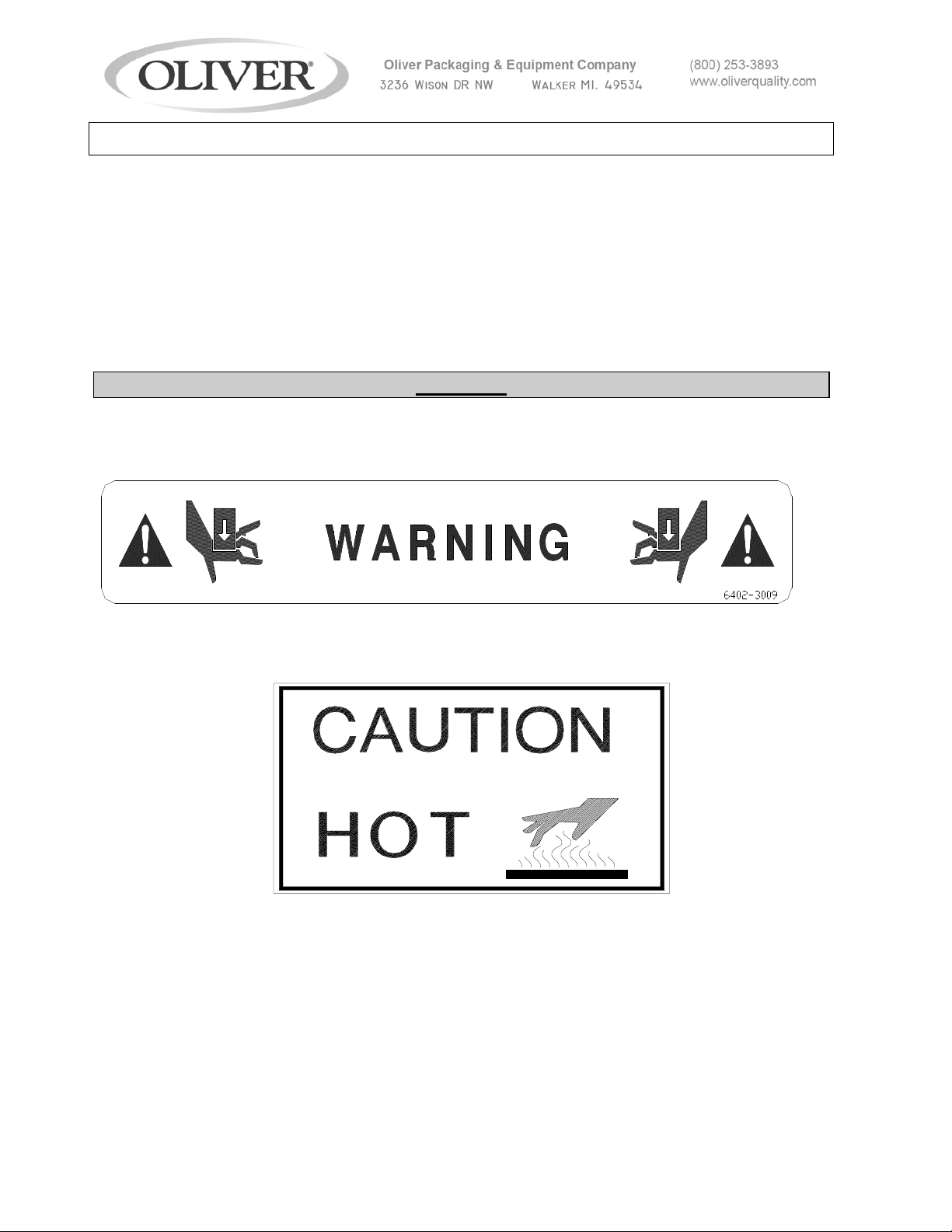

SAFETY

Various safety devices and methods of guarding have been provided on this machine.

Do not operate the machine with guards removed and do not tamper with safety

devices. It is essential that machine operators and maintenance personnel observe the

following safety precautions. Improper installation or operation of this equipment may

cause injury to personnel or damage to equipment.

• Before operating the OLIVER Model 1908 Lidder read through this manual. Never

allow an untrained person to operate this machine

WARNING

• WARNING PINCH POINT: Keep hands out of machine. Always be sure the

machine has been unplugged from power before cleaning or servicing.

• CAUTION HOT: The heater platen and parts around it are very HOT! Caution must

be used to protect yourself and others.

• In addition to these general safety instructions, follow the specific instructions given

throughout this manual.

1908S20074

1-3

MACHINE PLACEMENT AND UTILITIES

MODEL 1908

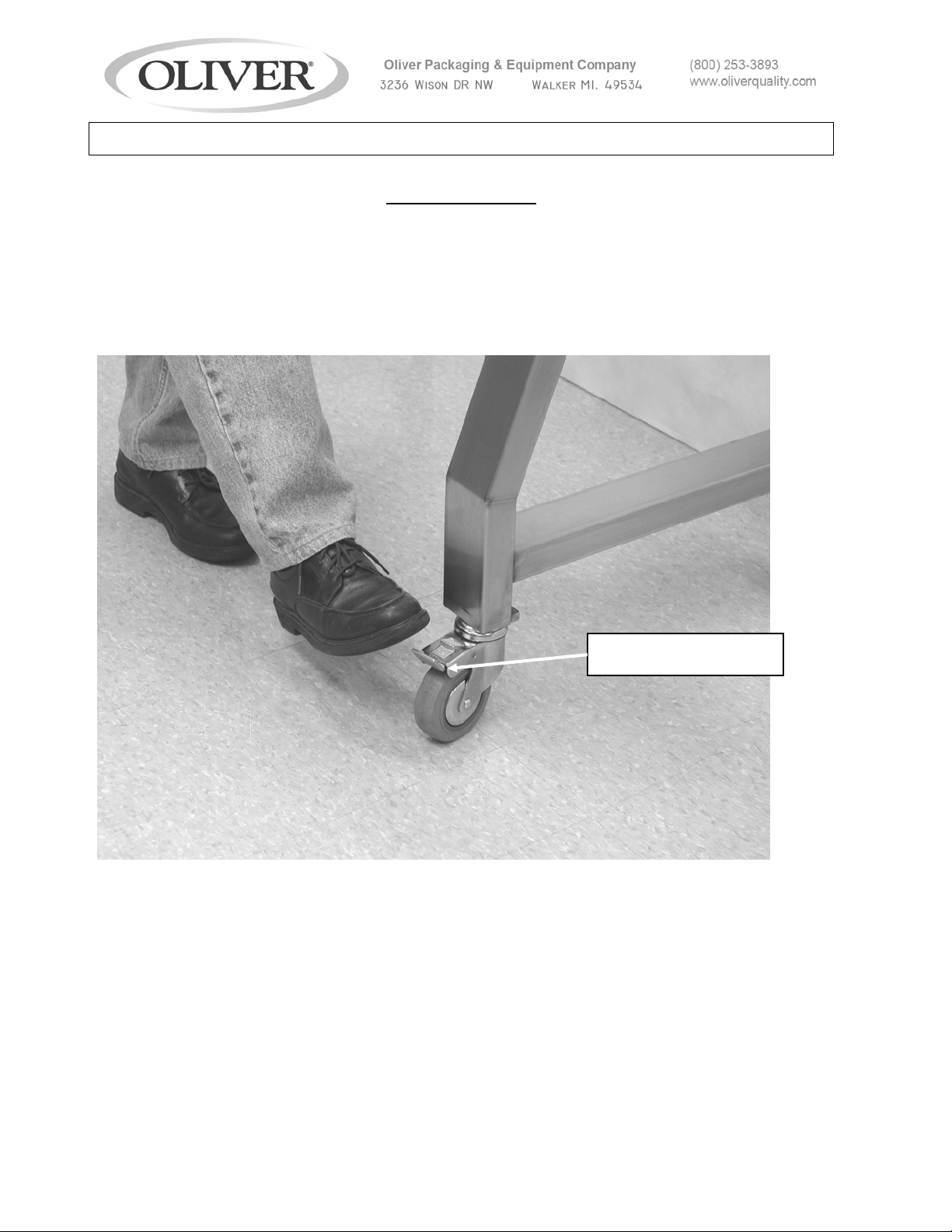

Decide on a suitable location for the machine. This location should have ample room to

work around all sides of the machine. Once the machine is in the location where it will

be used, the brakes on the casters should be locked by stepping down on the brake

locking lever. To unlock, lift the lever with your foot. Do not attempt to move machine

with casters in locked position.

LOCKING LEVER

The machine operates on 120 V.A.C., 60 Hz, 15 Amp electrical power. It is

recommended that this power be supplied by an overhead drop to prevent the cord from

becoming a trip hazard.

1908S20074

1-4

g

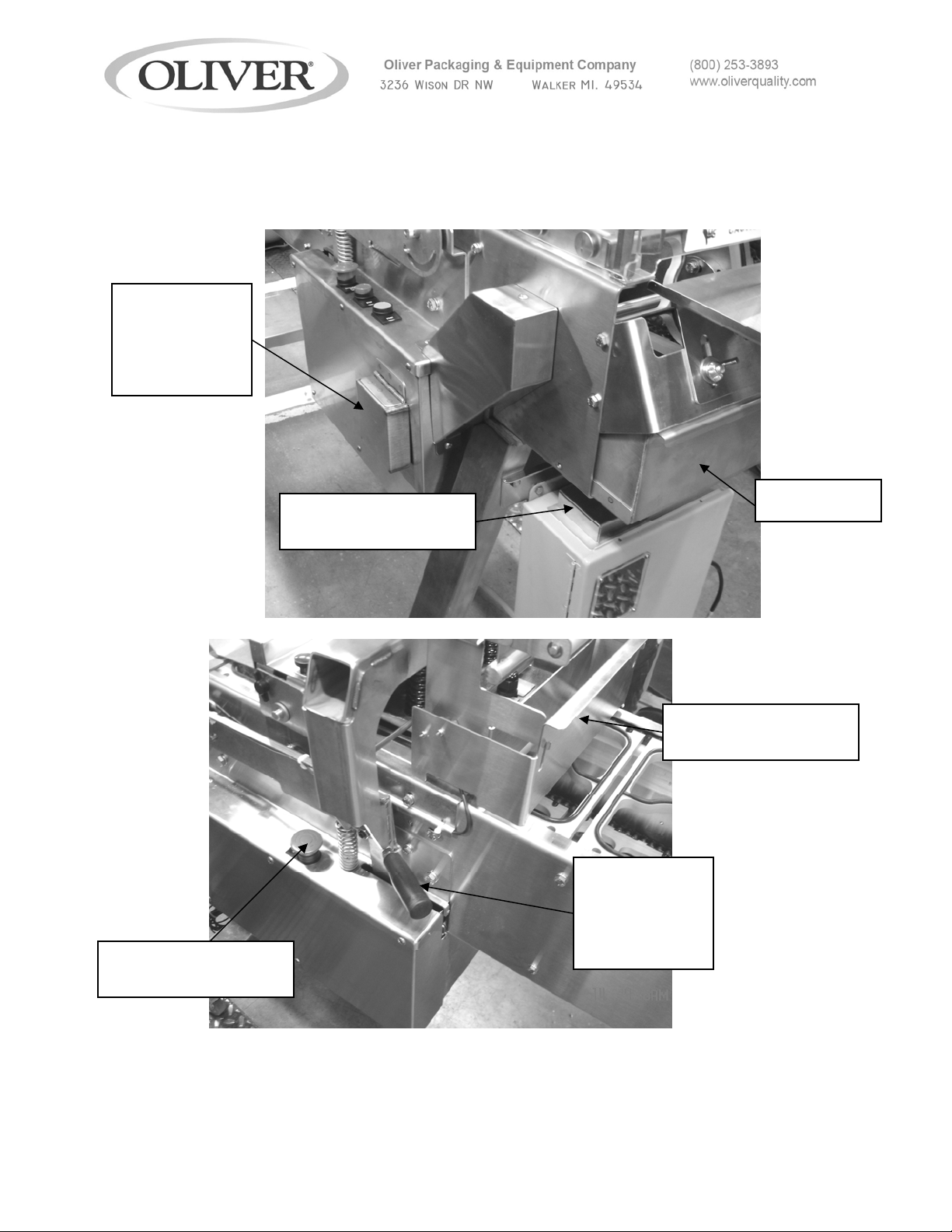

MACHINE COMPONENTS

Before proceeding further, take a moment to familiarize yourself with the

identification of the machine components as shown in the illustrations below.

Film Roll Holder with Film Roll and Roll Weight Installed.

Film Roll

Guide

Film Roll

Weight

Emergency Stop, Stop, and Start Buttons

Heat Platen

Lift Sprin

Heat shield

1908S20074

1-5

Drive and Platen Release Locations and Speed Control Location

Conveyor

release knob

(Under

Cover)

Rear Emergency

Stop Button

Speed Control knob

Bottom Pan

(Under Cover)

In-feed guard (with

safety switch)

Heater Platen

release lever

(Pull to

release)

1908S20074

1-6

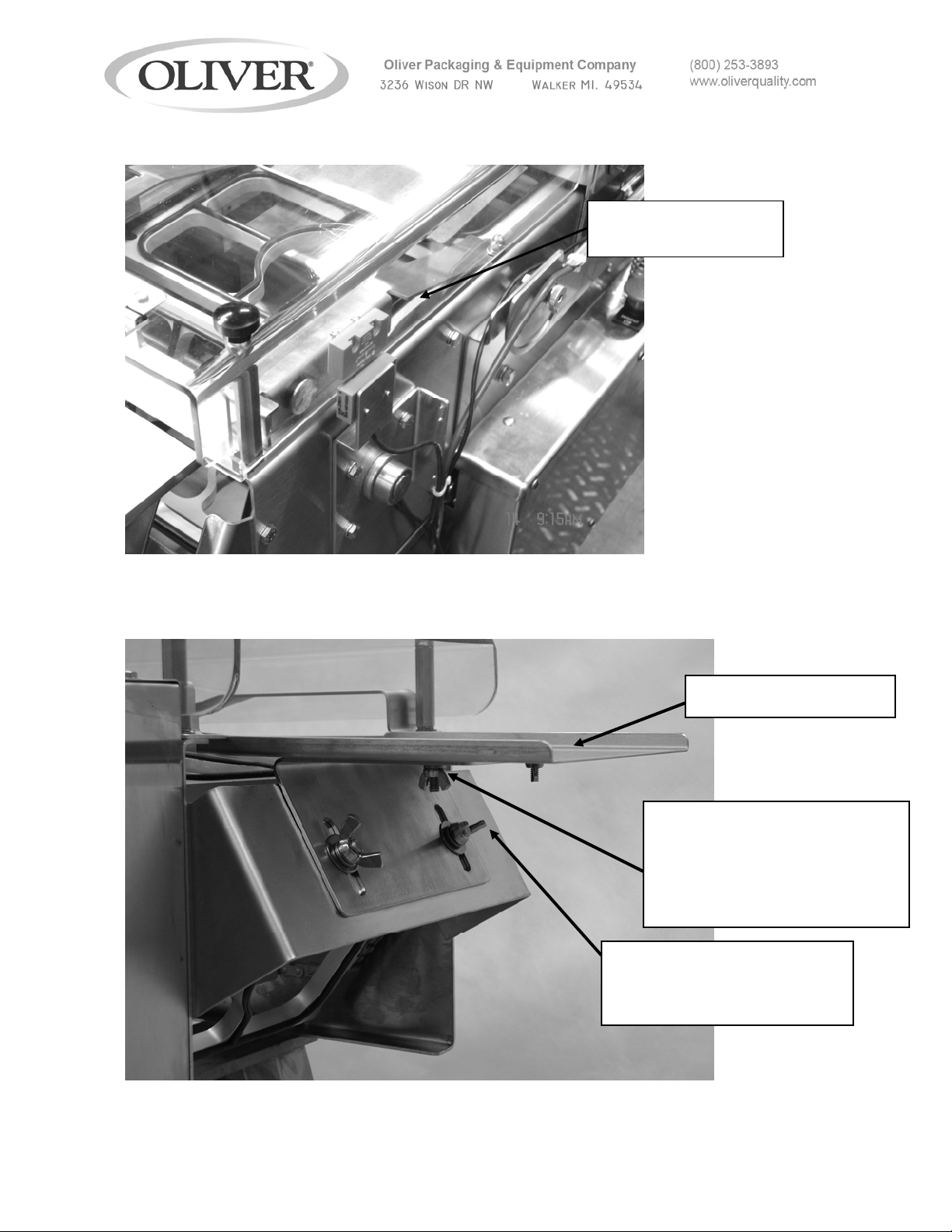

Out feed or discharge area

Discharge Cover

(with safety switch)

DISCHARGE TABLE

THESE WING NUTS

ALLOW FOR MOVING THE

DISCHARGE TABLE IN

AND OUT TO CLEAR THE

TRAY CARRIERS

WING NUTS

LOOSEN TO ADJUST

TABLE UP OR DOWN

1908S20074

1-7

Tray Carriers

Film Cut-Off

RUBBER GASKET

TRAY CARRIER

DRIVE SPROCKET

CUTTER BLADE

CUTTER ASSEMBLY

1908S20074

1-8

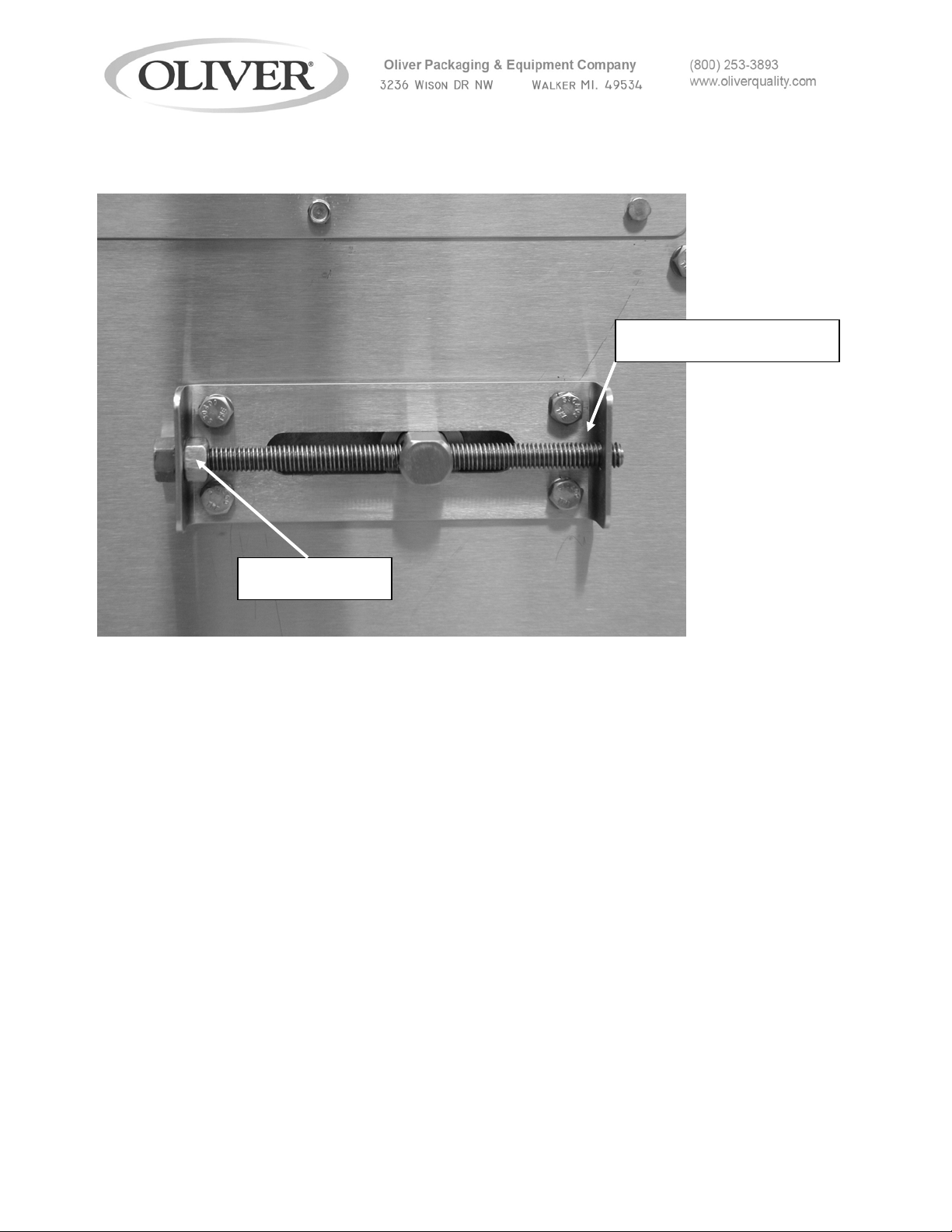

Conveyor Chain Tension Adjustment Mechanism

ADJUSTMENT SCREW

LOCKING NUT

1908S20074

1-9

START-UP & OPERATION

To turn the machine on, plug in the power cord and wait 15 minutes to allow the heated

platen to reach operating temperature before attempting to seal trays.

Run the machine without trays and film to make sure everything is cycling properly.

1. VERIFY THE CONVEYOR IS READY TO OPERATE: Remove any extra items

that may have been placed on the conveyor and verify people are clear of the

trays and tray carriers. The guards (in-feed gate and clear exit cover) must be in

place and the emergency stop buttons must be in the up position (twist and allow

the button to pop up to reset).

2. VERIFY THE SEALING PLATEN IS CONNECTED TO THE PULL-DOWN

ARMS: Lift the black handles and hook the roller on the platen arch. This may be

left undone if it is desired to run the conveyor without operating the sealer.

3. PUSH THE GREEN “RUN” BUTTON.

4. PUSH THE RED “STOP” BUTTON TO STOP THE MACHINE WITH THE

SEALING PLATEN UP (NOT PRESSING ON A TRAY OR TRAY CARRIER).

NOTE: USE THE EMERGENCY-STOP BUTTONS OR THE SAFETY GATE

SWITCHES TO STOP THE MACHINE IN EMERGENCY SITUATIONS ONLY.

These switches act immediately and do not wait for the sealing cycle to finish.

This will leave the heater in contact with the tray resulting in over-heated

packaging materials. Stopping the machine improperly will result in a

shortened machine life.

5. TO CHANGE THE CONVEYOR SPEED: Adjust (turn) the black knob on the top

of the electrical box (lift the small stainless steel cover to access).

IMPORTANT NOTES

• Never run the machine with trays without film. Doing so can possibly cause a

jam because the trays can stick to the heated platen and be pulled out of the tray

carriers.

• Adjusting the speed of the conveyor will also change the dwell time of the sealer.

Excessively slow speeds will result in excessively sealed trays.

• If the conveyor becomes jammed, stop the conveyer and turn the power

off. The conveyor drive release knob may be pulled to allow manual movement

of the conveyor to aid removing jammed materials.

1908S20074

1-10

6. Load the film on the film stand as shown on the film-threading diagram located

on the machine and also shown in the diagram below.

NOTES

• The adhesive side of the film can be determined by pinching a fold and rubbing

the lid material against itself. Test both sides of the lid. The rough or tacky side

of the lid will be the adhesive side. The film supplied by Oliver is wound with the

adhesive side toward the inside of the roll. If the film is loaded in accordance

with the “FILM FEED” diagram it will be positioned properly for applying the

adhesive side of the film to the flange of the tray. If the film is loaded improperly,

it can cause the adhesive side to come in contact with the heated platen and the

film to stick to the heated platen. If this happens, the platen will need to be

cleaned.

• To thread the film through the machine, pull enough film off the roll so that you

can insert it into the slot between the tray carrier that is partially under the film

stand and the carrier that is upstream from that. After the film is hanging down

underneath the tray carrier, reach through the tray carrier and pull the film down

so that it touches the tray carriers underneath that are returning to come back up

on top. Then insert a tray into the tray carrier next to the film and cycle the

machine one time. This should seal the film to that tray and you can now fill the

rest of the conveyor with filled trays and begin running.

• The film dancer bar must move freely up and down.

• If you miss putting a tray in the machine it will not cause a problem, but the film

will be sealed to the top of the empty tray carrier. Let the machine continue to

run until that tray carrier goes around the bottom of the conveyor and comes

back up on top, then remove the piece of film.

1908S20074

1-11

• It is important that the roll of film is centered on the conveyor. There are white

plastic film guides on either side of the film roll. These guides can be adjusted

from side-to-side by pushing them with your hand. If the film is not centered,

move both guides toward the side that the film needs to go to. It may take a little

bit of running time before you can tell if the film is in the correct position.

7. Place filled trays in tray carriers. Take care to avoid spilling food product on the

flange of the tray. Contamination of the flange can result in poor heat seals.

8. After a few trays come out of the machine, stop and inspect the acceptability of

the seals. If the seals are not acceptable or the trays do not come out of the

machine smoothly, refer to the trouble shooting guide.

9. The machine can be stopped at any time by pushing the stop button down.

When started again, the machine will pick up sealing where it left off.

NOTE

• IT IS NOT RECOMMENDED TO LEAVE THE MACHINE PLUGGED IN IF IT IS

GOING TO BE OUT OF OPERATION FOR AN EXTENDED PERIOD OF TIME.

1908S20074

1-12

TECHNICAL SPECIFICATIONS

Model 1908

Tray Capacities: 6-3/8” (162mm) by 8.5” (216mm) maximum top-outside-dimensions of

the tray.

Temperature Range: Factory preset to approx. 300 degrees F.

Weight: 330 LBS.

Electrical: 120 VAC, 15 Amps, Single Phase, and 60 Hz

Air Requirements: 6 CFM @ 80 PSI

Machine Dimensions: 17” (43.2 cm) Wide x 64” (162.5 cm) Long x 45” (114.3 cm) High

1908S20074

1-13

CLEANING AND MAINTENANCE

WARNING

Disconnect the power from the Model 1908 and allow the unit to cool before

performing cleaning and/or maintenance procedures.

These cleaning recommendations are not meant to replace or supersede plant-standard

manufacturing procedures or regulatory requirements. Do not immerse, hose down,

pressure wash, or otherwise soak electrical switches, electrical control box,

mechanical drive box, and electrical connections. Avoid getting these areas wet.

If your cleaning procedure involves liquid amounts greater than the use of a

damp cloth, protect these areas by shielding with plastic bags.

1. Heater Platen Cleaning:

CAUTION

• CAUTION HOT: The platen and surfaces around it may be very HOT! Care must

be taken to protect yourself and others. If the platen will be cleaned while it is still hot

make sure hand protection is used to prevent skin contact with the platen.

If food product comes in contact with the surface of the platen it tends to burn on and

become hard. This results in an irregular surface on the face of the platen that can

result in poor seals. If this happens, it will be necessary to remove this burnt on food

material.

1.1. Remove the In-feed guard.

1.2. Tip the film roll holder forward until it is resting on the side rails of the machine.

1.3. Remove the discharge cover and heat shield by removing the 4 black plastic

screw knobs on top of the covers and lift the covers off.

1.4. Release and tip the heater platen up by pulling the large black handles and

rotating the heater platen upwards until it is against the stops. The bottom of the

heater plate will be easily accessible.

1.5. Clean any food residue off the heater platen. When cleaning the surface of the

platen care must take to avoid scratching or gouging the surface. DO NOT

SCRAPE THE SURFACE OF THE PLATEN WITH SHARP OBJECTS AND

AVOID THE USE OF METAL TOOLS. Instead use a plastic or soft-metal

scouring pad such as Scotch Brite® or Chore Boy® brands provide a safe and

effective means of cleaning the heated platen. Wipe all surfaces with a

sanitizing agent after cleaning.

1908S20074

1-14

2. Tray Carrier Cleaning:

The tray carriers should be removed and cleaned daily. It is better to remove them

for cleaning rather than trying to clean them in the machine. The tray carriers can be

placed in your dishwasher for cleaning if you desire. Care should be taken so that

the rubber gaskets do not become damaged.

2.1. Disconnect the conveyor from the drive unit by lifting the cover on the side of the

machine and pulling the knob out. The knob will stay out if it is twisted ¼ turn

while pulling. This allows the conveyor to be moved manually.

The carriers should be removed in the middle of the in-feed area on the top of the

conveyor.

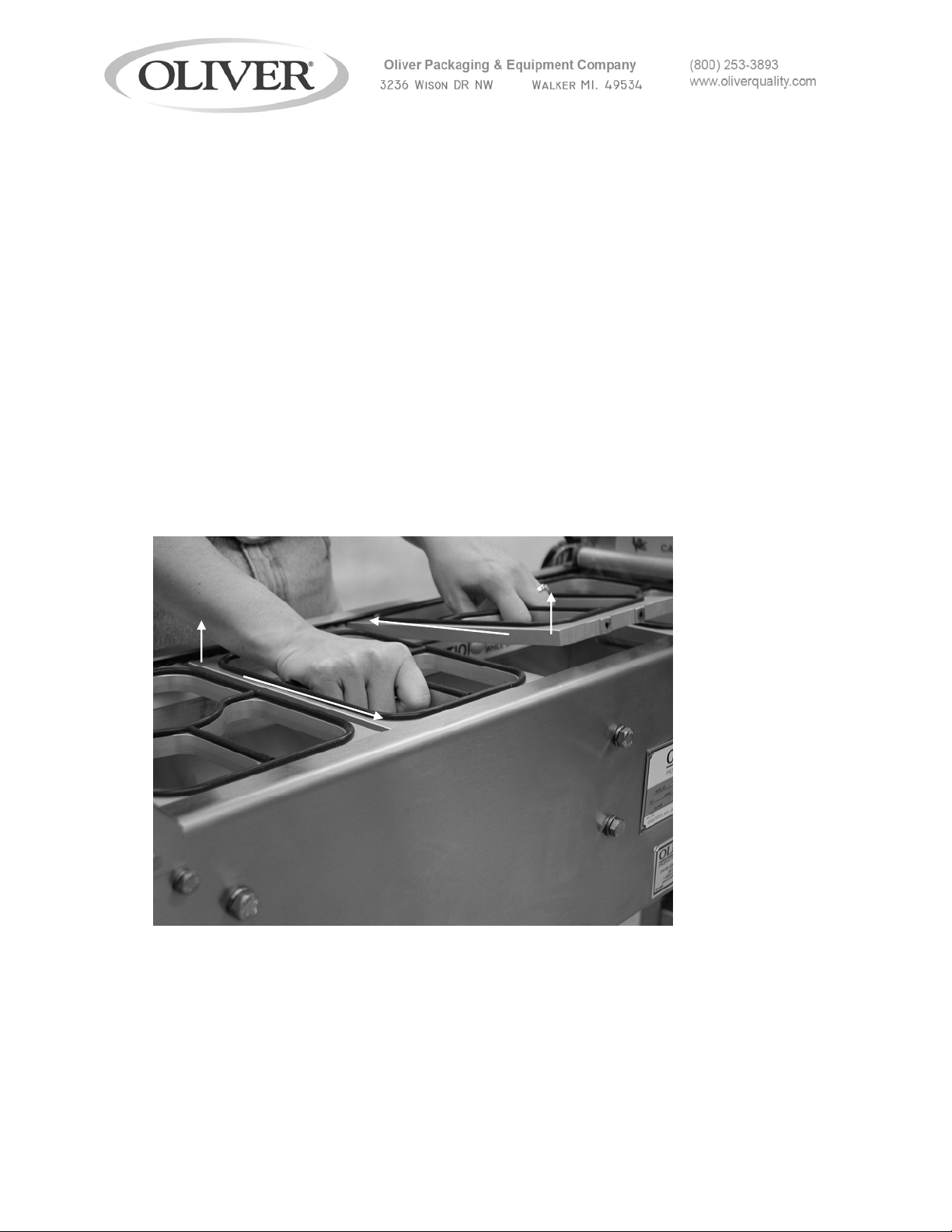

2.2. Lift up on two tray carriers next to each other and push one to one side while

pulling the other it to the other side. This spreads the chains so the pins can be

disengaged. Completely remove the two carriers as shown.

The picture below shows how to remove the tray carriers.

2.3. As the carriers are removed, the conveyor must be pulled forward to keep

getting to the remaining carriers. To move the conveyor forward, grasp a tray

carrier toward the infeed-end of the machine and pull the conveyor forward.

This must be done with the conveyor disconnected from the drive (step 2.1).

2.4. Wipe all surfaces with a sanitizing agent after cleaning.

2.5. Replace the tray carriers after cleaning the remainder of the machine.

1908S20074

1-15

Note: Look for a white painted chain link to center on the side of the first tray

carrier re-installed to get the tray carrier/ chain timing correct.

Note: When replacing the tray carriers, it is extremely import to make sure that

all four pins on the conveyor chains are fully engaged in the holes of the tray

carrier. If the tray carriers are put in on an angle because the pins are not

engaged on one side, it could cause damage to the cutter assembly.

2.6. Re-engage the conveyor drive by twisting the release knob until it snaps in.

Move the conveyor manually until the pin locks in and prevents further

movement.

3. Clean the remainder of the machine:

3.1. Remove the two bottom pans by sliding them toward the discharge end of the

machine. Note: the pans may need to be jostled up and down slightly to get

them over bolt heads and other obstacles.

3.2. Clean the cutter assembly with a mild cleaner or sanitizing solution and a damp

cloth.

NOTE

The use of plastic or soft-metal scouring pads such as Scotch Brite® or Chore

Boy® brands provide a safe and effective means of cleaning the cutter assembly.

Wipe all surfaces with a sanitizing agent after cleaning.

3.3. Clean the pans and remaining surfaces of the machine with a mild cleaner or

and a damp cloth. Wipe all surfaces with a sanitizing agent after cleaning.

1908S20074

1-16

4. Conveyor Chain Maintenance

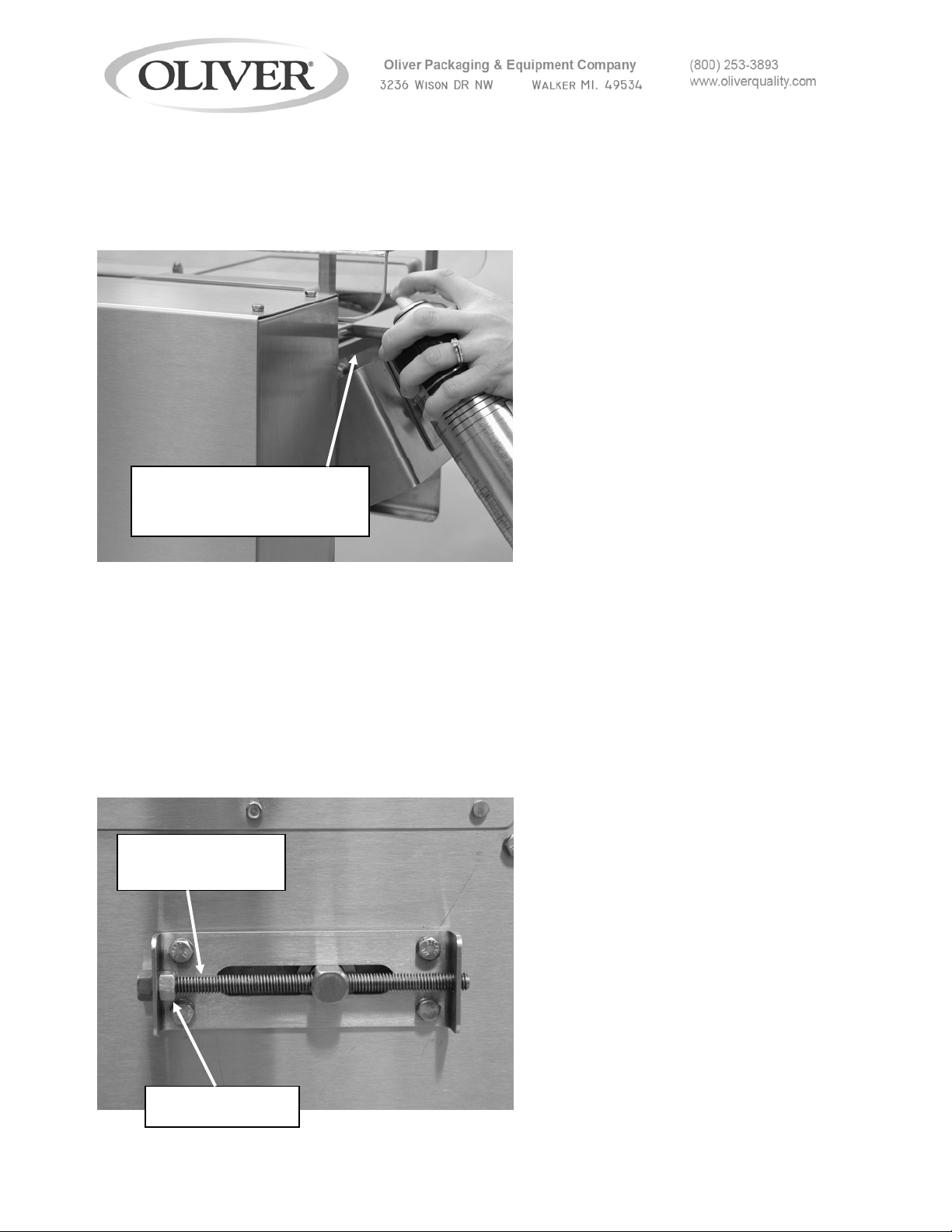

4.1. Once a month the conveyor chains should be lubricated with vegetable oil such

as cooking spray. If you use hose-down cleaning, this should be done twice a

month.

SPRAY CHAINS WHILE

MACHINE IS CYCLING

4.2. Once a month the conveyor chains should be checked for proper tension. The

tension can be checked by lifting the lower tray carriers at the middle of the

machine. If you can easily lift them up more than 3 inches, the chains are too

loose and should be tightened by adjusting the tensioners at the infeed-end of

the machine. Loosen the locking nuts and turn the adjusting screws clockwise

to tighten the chains then retighten the locking nut. It is important to adjust both

sides equally. The easiest way to do this is to count the turns that you tighten

one side and then do the same on the other side. The best method is to adjust

each side in ¼ turn increments and then recheck the chain tension.

ADJUSTING

SCREW

LOCKING NUT

1908S20074

1-17

TROUBLESHOOTING

There are no user serviceable parts on your OLIVER Model 1908 Lidder except for the

cutter blade. Should you experience problems with your machine call the Oliver

Products Company 24 Hour Emergency Service number @ 1 800-253-3893.

Please have the serial number of your machine available to give to the Customer

Service representative.

Before calling for assistance please check the list below to see if the problem you are

experiencing is listed. If it is, try the corrective action items listed for that problem

before calling for assistance.

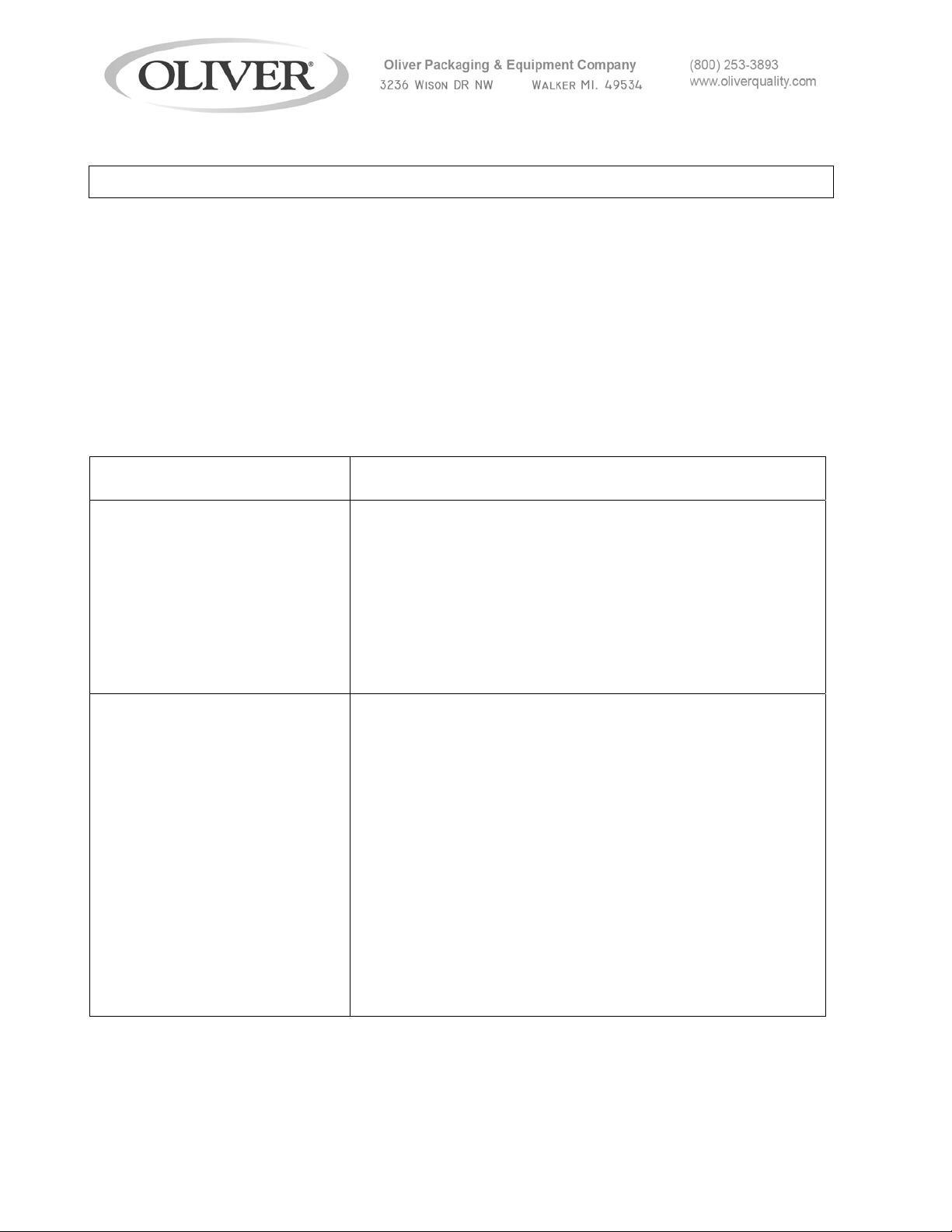

OPERATION ISSUES:

Symptom:

Machine does not power-up

(does not run and/or the

heater platen does not get

hot)

Machine receives power, but

the conveyor does not move

when the start button is

pushed.

Corrective Action:

1. Verify the machine is plugged in to a working

outlet.

2. If the platen does not heat, unplug the power

and remove and inspect the fuse (located in the

electrical panel, see section 4). Replace if

necessary (see parts list).

3. Verify the two e-stop buttons are not engaged

(pushed down). Twist the button to release it to

the ready to run position.

4. Verify the in-feed guard is installed in the correct

position (stainless steel gate hung in front of the

heater platen).

5. Verify the discharge cover is installed correctly

(plastic cover).

6. Verify the speed control knob is turned to 75% to

100% of the speed range.

1908S20074

1-18

Conveyor does not move

when the start button is

pushed and steps 1-4

(above) have been taken.

A mechanical jam is

preventing the conveyor from

moving as indicated by a red

light in the electrical box

window.

7. Turn the speed up to 100%. Look in the window

of the electrical box under the conveyor outfeed. A green or red light should be visible.

--A green light indicates the motor is receiving power

and should be able to run. If only a green light is

visible, go to step 12.

--A red light indicates a mechanical jam— turn off the

main power immediately. Go to step 8.

--No light indicates power is not available to the motor

because a guard, e-stop switch, or main power switch

is tripped. Go to step 13.

8. Mechanically disconnect the indexer drive from

the conveyor by pulling the disconnect knob and

turning it 90 degrees (1/4 turn) so it stays out.

9. Mechanically disconnect the platen by pulling

the large black plastic handles. Allow the platen

springs to hold the platen up off the conveyor,

but do not remove guards and lift it as you

would for cleaning.

10. Manually pull the conveyor. If it pulls freely, the

problem is in the transmission box (Call for

service). If the conveyor does not move, look for

a jammed tray, an incorrectly installed and/or

wedged tray carrier, excessive food build-up,

excess film wrapped around a conveyor part or

the cutter, or excessive chain tension.

11. If no correctable cause is found for the jam, call

for service.

1908S20074

1-19

Loading...

Loading...