Grand Rapids, Michigan, U.S.A. 49504-5298

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 1908

AUTOMATED PACKAGING SYSTEM

1908S20000CV

INDEX

QUICK SPECS…...……………………...……………………………… PG. 1-2

INTRODUCTION AND DESCRIPTION………………………………. PG. 1-3

UNCRATING…………………………………………………………….. PG. 1-4

SAFETY..............................................……………………..………….. PG. 1-8

MACHINE PLACEMENT………………………………………..……… PG. 1-9

MACHINE COMPONENTS…………………………………………….. PG. 1-12

START-UP……………………………………………………………….. PG. 1-17

OPERATING PROCEDURE............................................................. PG. 1-20

TECHNICAL SPECIFICATIONS....................................................... PG. 1-24

CLEANING AND MAINTENANCE....................…..............…........... PG. 1-26

TROUBLE SHOOTING......................................…......................….. PG. 1-31

MAINTENANCE CHECKLIST……....................…..............….......... PG. 2-1

ASSEMBLY DRAWINGS & PARTS LISTS..………………………... PG. 3-1

ELECTRICAL……………………………………………………………. PG. 4-1

PNEUMATIC.…………..………………………………………………… PG. 5-1

MACHINE EXCHANGE PROGRAM………… GEN 050815

WARRANTY...................…............................. GEN 050816

WARRANTY PROCEDURE..........….............. GEN 050817

RETURNED PARTS POLICY......................... GEN 050818

11/12/09 1908S20001

1-1

QUICK SPECS

Weight 300 lbs

Overall Dimensions 30” W x 64” L x 50” H

Loading Station 3 tray carriers

Electrical 1 phase, 60 hz, 115 VAC, 15 amps

Air Supply 90 psi ± 10 psi

Air Connector Size ¼”

Air Compressor:

Electrical 1 phase, 60 hz, 115/230 VAC,

1.7 run HP, 13 GAL tank

Dimensions 16.625” W x 30.5” L x 33.75” H

Weight 60 lbs

Length of Air Hose 70 ft

Air Hose I.D. 3/8”

11/12/09 1908S20001

1-2

INTRODUCTION AND DESCRIPTION

The OLIVER Model 1908 Lidder has been designed and manufactured to provide a high

quality machine that is a cost effective approach to producing film lidded trays. The

machine can be operated with a 120 V.A.C. outlet. The Model 1908 is an automated

system capable of producing a high volume, but it is easy to operate and requires

minimal space.

The machine consists of a conveyor system that transports the filled trays, a film feed

system, a heated platen and a film cutter unit. These are all packaged together in a

stainless steel framework that also houses all the necessary controls. The conveyor is

intermittent motion and is capable of running speeds of 5 to 35 packages per minute.

The system also includes an air compressor that is a separate unit that can be located

remotely.

11/12/09 1908S20001

1-3

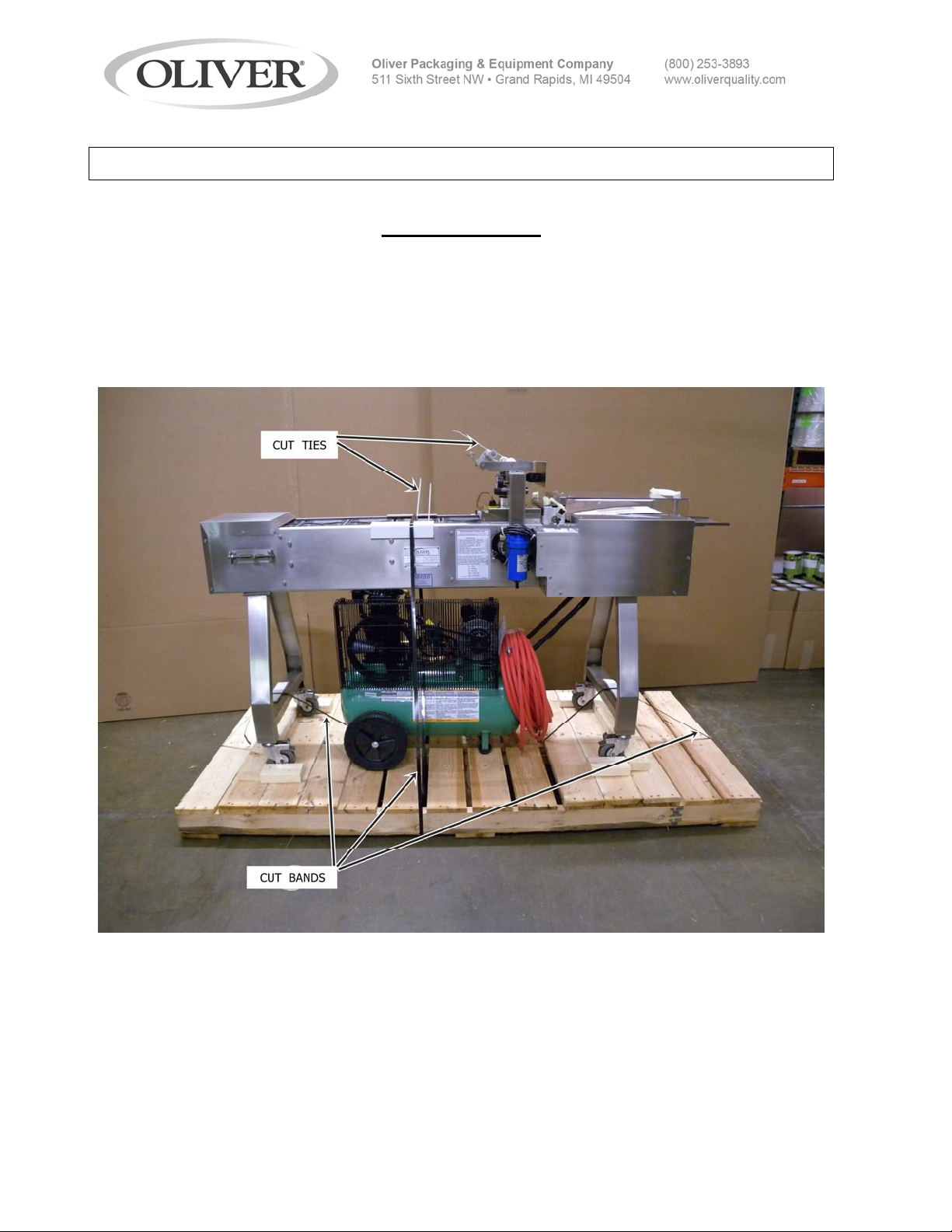

INSPECTING

MODEL 1908

Upon receipt of Machine, inspect the exterior for damage. If damage is noted,

Indicate damage on the Freight Bill and immediately contact the freight Carrier and

notify them of the damage. Have a freight claim filed. This must be done at the

Recipient’s location and not at the Shipper’s Location.

Remove the tie-downs that hold the Trays from moving. Cut bands

that hold the 1908 Machine and the Air Compressor on the skid.

Lift the Air Compressor and then the Machine off the skid in a safe

manner.

11/12/09 1908S20001

1-4

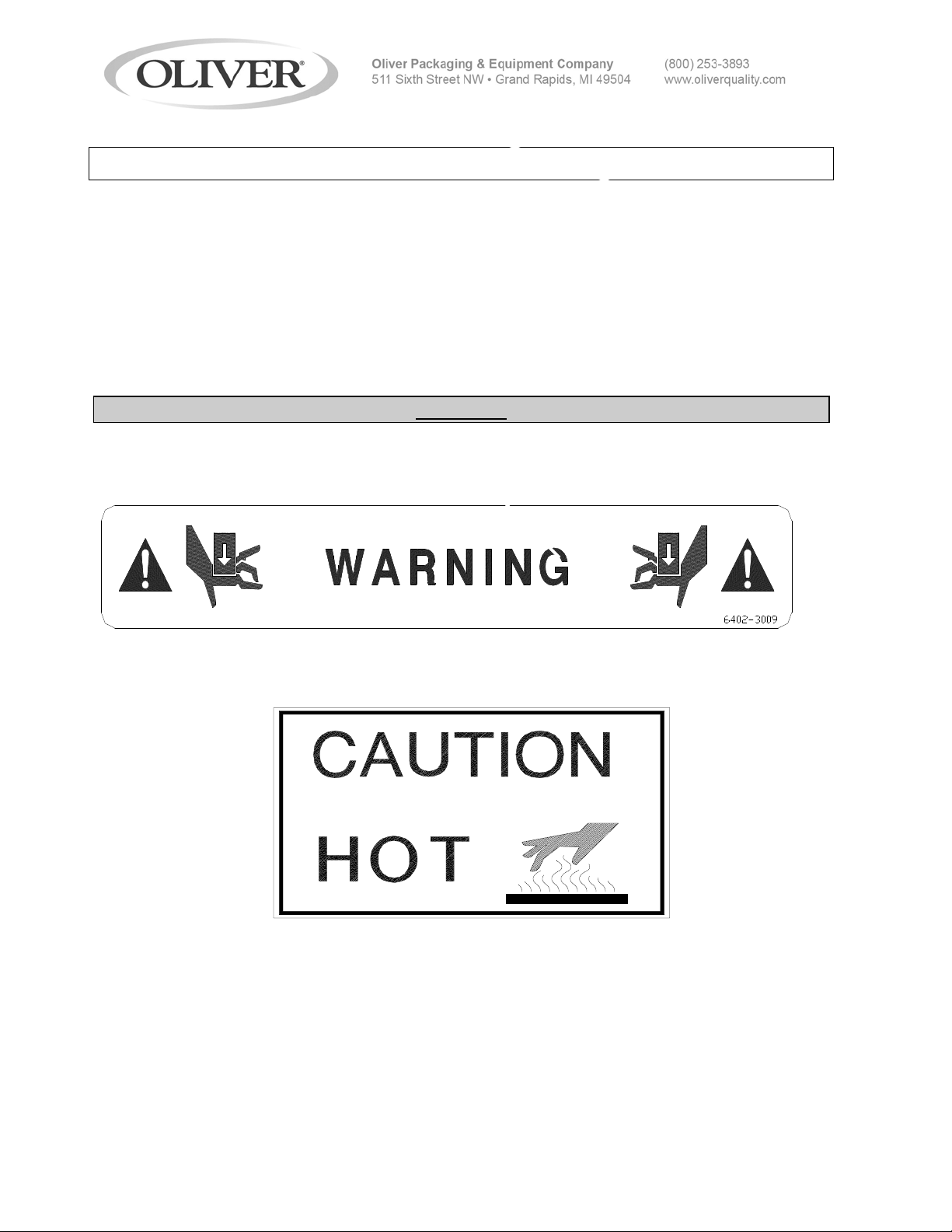

SAFETY

Various safety devices and methods of guarding have been provided on this machine.

Do not operate the machine with guards removed and do not tamper with safety

devices. It is essential that machine operators and maintenance personnel observe the

following safety precautions. Improper installation or operation of this equipment may

cause injury to personnel or damage to equipment.

• Before operating the OLIVER Model 1908 Lidder read through this manual. Never

allow an untrained person to operate this machine

WARNING

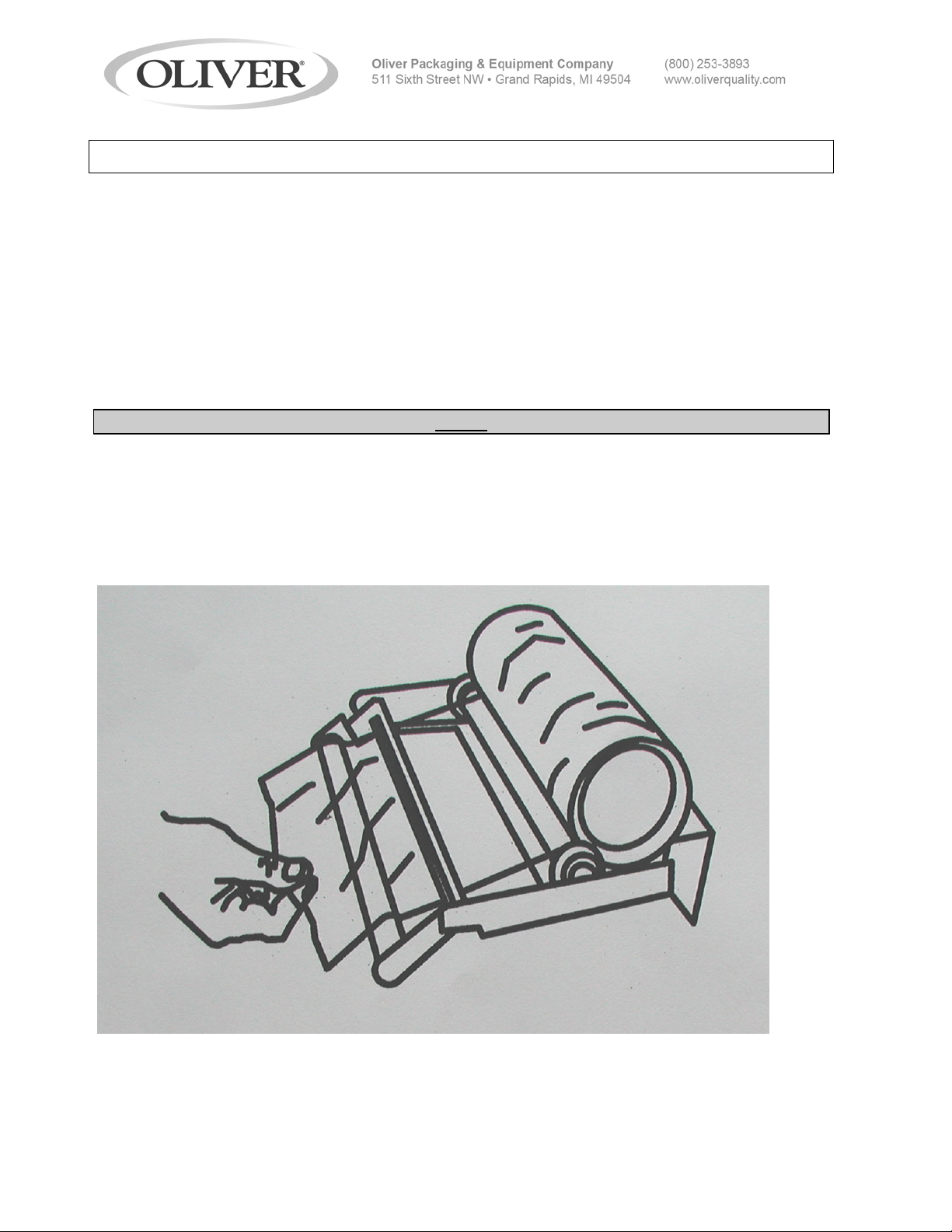

• WARNING PINCH POINT: Keep hands out of machine. Always be sure the

machine has been unplugged from power before cleaning or servicing.

• CAUTION HOT: The heater cover and upper platen are very HOT! Caution must

be used to protect yourself and others.

• In addition to these general safety instructions, follow the specific instructions given

throughout this manual.

11/12/09 1908S20001

1-5

MACHINE PLACEMENT AND UTILITIES

MODEL 1908

Decide on a suitable location for the machine. This location should have ample room to

work around all sides of the machine. Once the machine is in the location where it will

be used, the brakes on the casters should be locked by stepping down on the brake

locking lever. To unlock, lift the lever with your foot. Do not attempt to move machine

with casters in locked position.

LOCKING LEVER

The machine operates on 120 V.A.C., 60 Hz, 15 Amp electrical power. It is

recommended that this power be supplied by an overhead drop to prevent the cord from

becoming a trip hazard.

The machine needs to be connected to compressed air. This is accomplished by

connecting the machine to the air compressor supplied with the machine. This

connection should be made using an overhead drop.

11/12/09 1908S20001

1-6

Air Compressor

Decide on a suitable location for the air compressor. It is best to locate it out of the way

and preferably where the noise will not be a factor. The air compressor operates on

120 V.A.C., 60 Hz, 15 Amp electrical power. The air compressor is supplied with a 70

ft. length of 3/8” ID air hose that needs to be connected between the air compressor and

the Model 1908. This air hose has quick-disconnect fittings at both ends for easy

connection and disconnection. Pull the collar back on the female portion of the quickdisconnect fitting and then push the female portion onto the male portion and release

your hand. Pull on the hose to make sure the connection is secure.

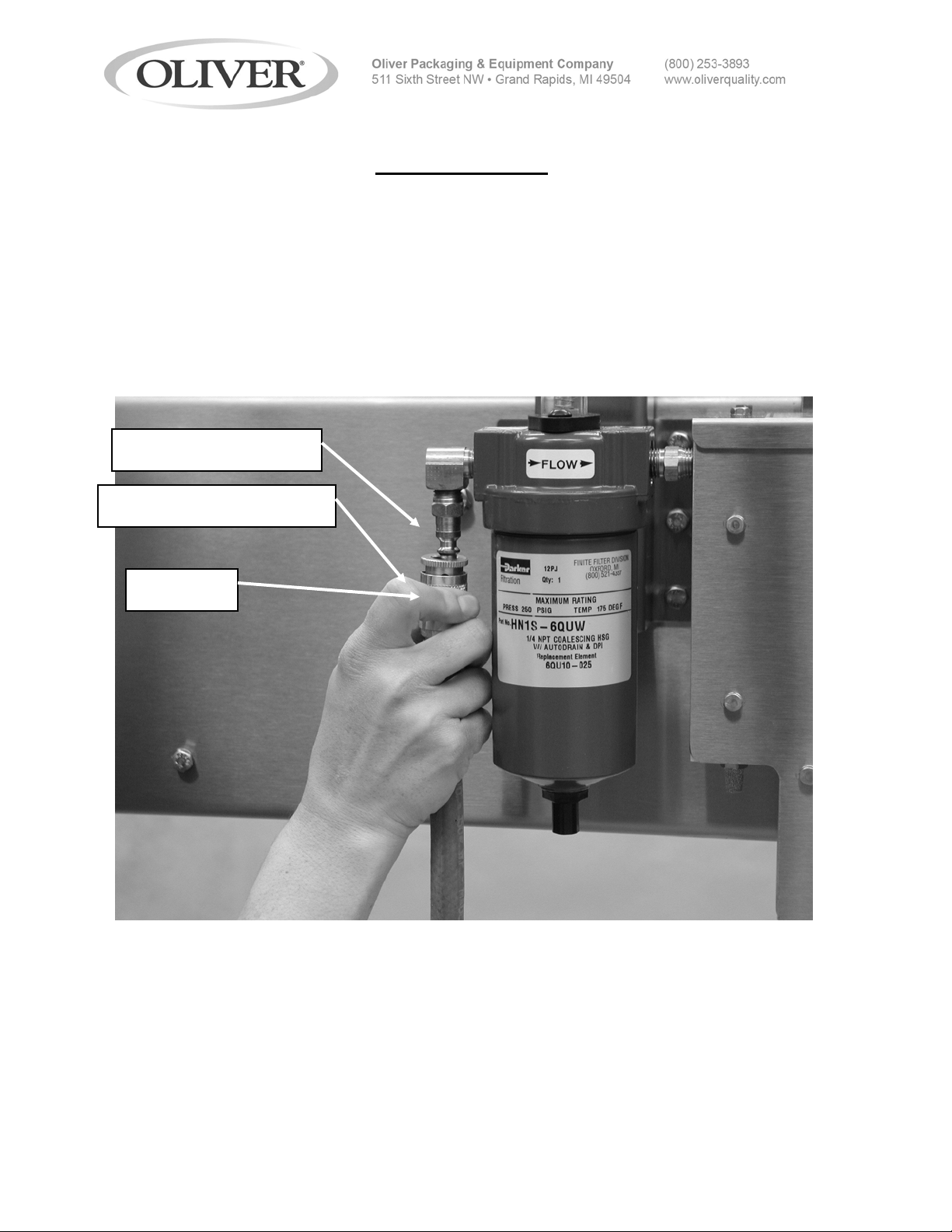

MALE CONNECTOR

FEMALE CONNECTOR

COLLAR

Continued

11/12/09 1908S20001

1-7

Air Compressor Continued

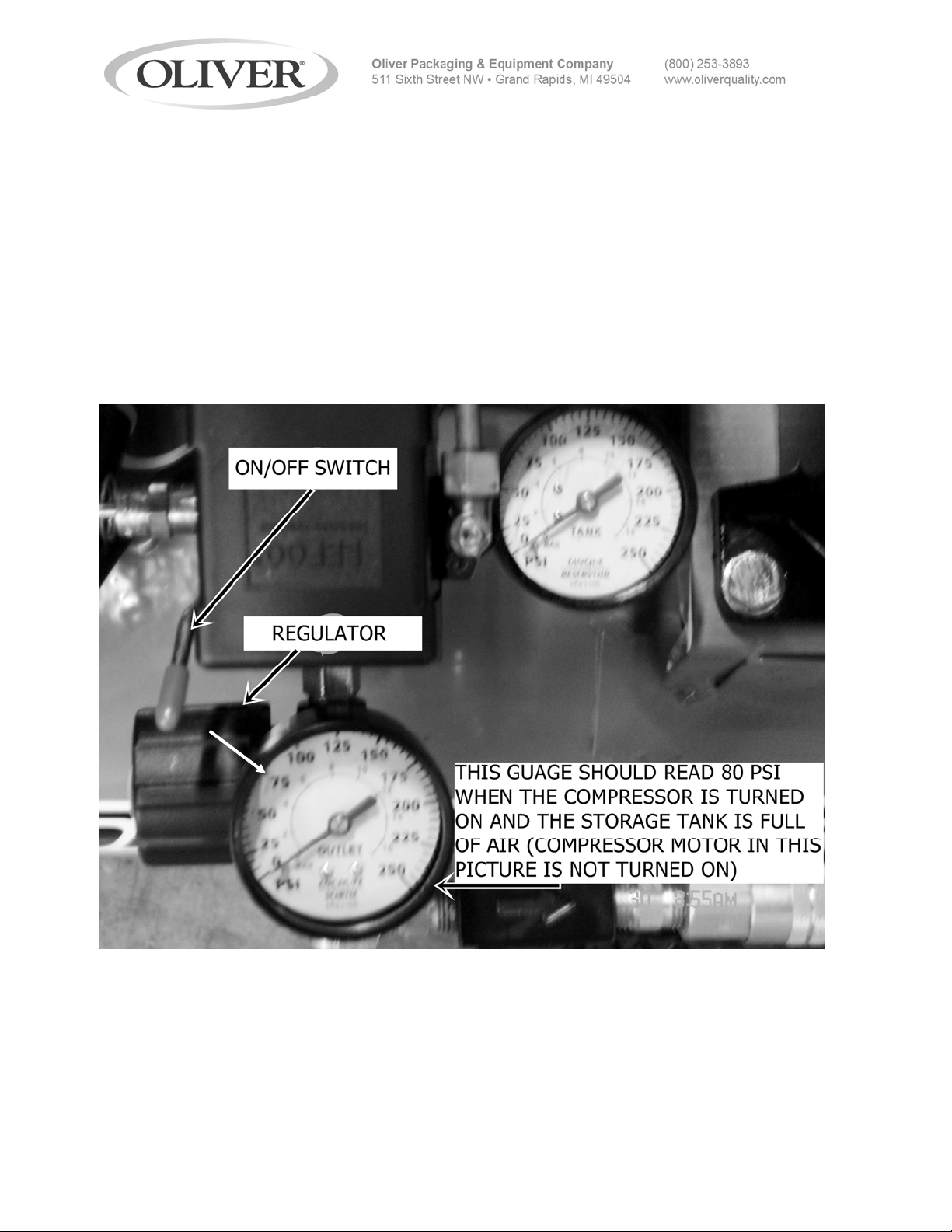

The air compressor has been factory set. If for some reason the settings are not

correct, the following procedure should be followed to set the output pressure from the

compressor.

The gage shown below should be set at 80 PSI. This is accomplished by turning the

knob on the regulator clockwise to increase pressure or counter clockwise to decrease

pressure. It is recommended that the air compressor be left with the switch in the

“AUTO” position. The compressor will only run when there is a demand for air when it is

set in the “AUTO” position. Leaving the switch in this position assures that the

compressor will be ready when it is needed.

11/12/09 1908S20001

1-8

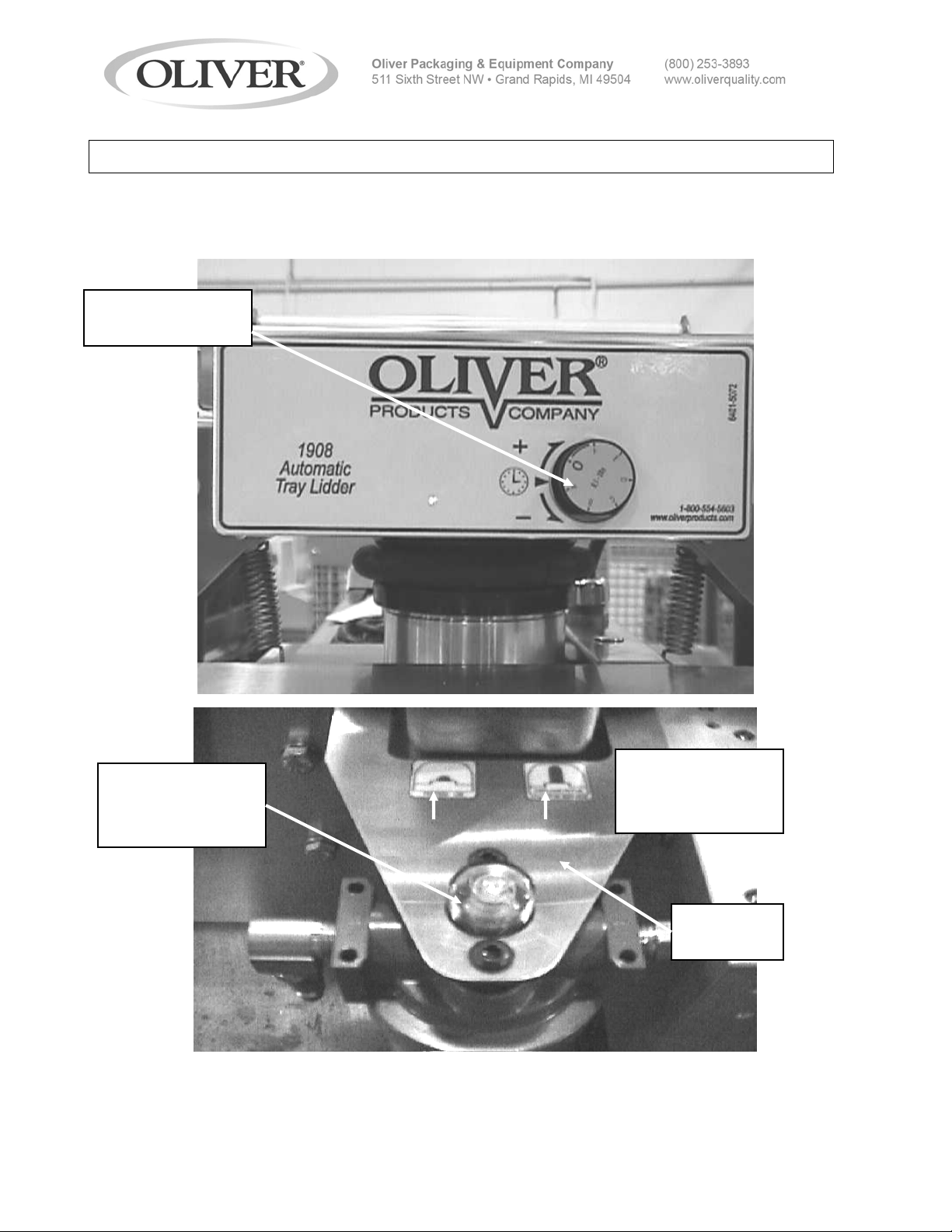

MACHINE COMPONENTS

Before proceeding further, take a moment to familiarize yourself with the

identification of the machine components as shown in the illustrations below.

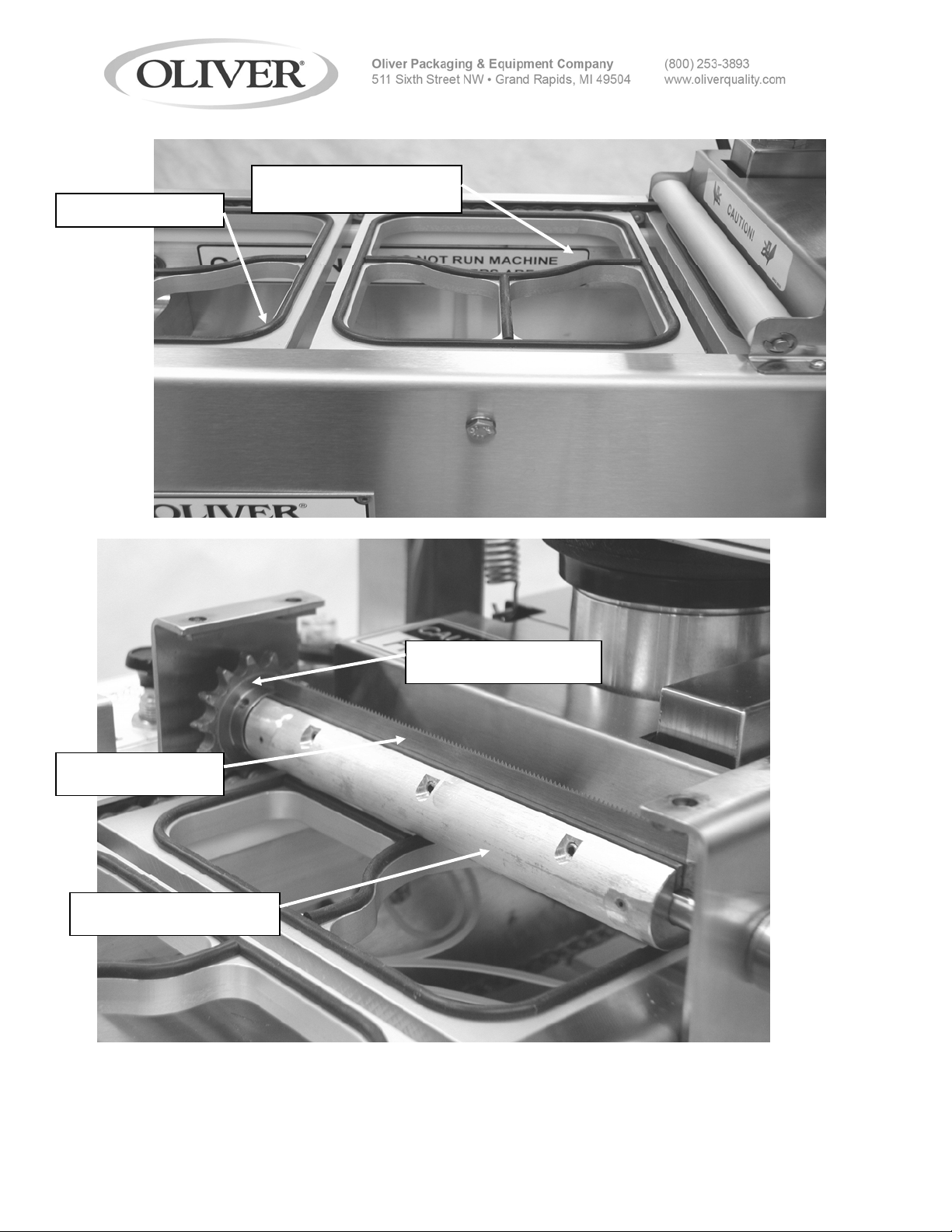

HEAT SEAL

DWELL TIMER

FILTER

REPLACEMENT

INDICATOR

FILTER

OK / REPLACE

LABELS

FILTER

BRACKET

11/12/09 1908S20001

1-9

SPEED ADJUSTMENT-TURN

CLOCKWISE TO SLOW DOWN

TURN COUNTER CLOCKWISE

TO SPEED UP

ON/OFF KNOB

PULL UP TO START

PUSH DOWN TO STOP

LOCKING NUT

11/12/09 1908S20001

1-10

TRAY CARRIER

RUBBER GASKET

CUTTER BLADE

CUTTER ASSEMBLY

DRIVE SPROCKET

11/12/09 1908S20001

1-11

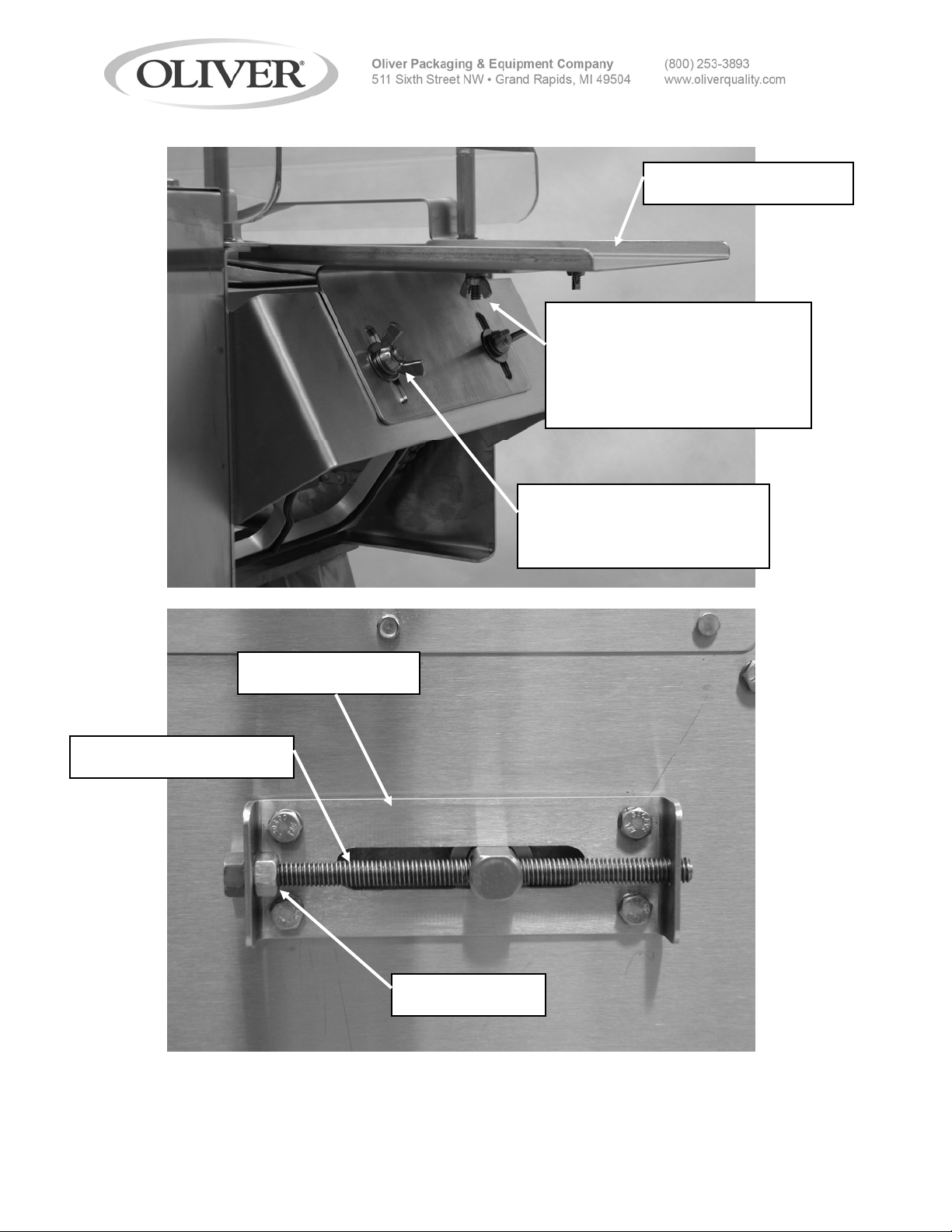

DISCHARGE TABLE

THESE WING NUTS

ALLOW FOR MOVING THE

DISCHARGE TABLE IN

AND OUT TO CLEAR THE

TRAY CARRIERS

WING NUTS

LOOSEN TO ADJUST

TABLE UP OR DOWN

TAKE-UP DEVICE

ADJUSTMENT SCREW

LOCKING NUT

11/12/09 1908S20001

1-12

START-UP

To turn the machine on, plug in the power cord. Wait 30 minutes to allow the heated

platen to reach operating temperature. At this time, turn on the air compressor so it can

fill the storage tank with compressed air.

The machine has been shipped from the factory with the speed set at approximately 7

to 10 trays per minute. This speed has been chosen as a good place to start.

Depending on your production rates, you may need to speed up or slow down the tray

sealer. This adjustment is explained in the “Machine Operation” section of the manual.

First, run the machine without trays and film to make sure everything is cycling properly.

NOTE

• Never run the machine with trays and no film. Doing so can possibly cause a jam

because the trays can stick to the heated platen and be pulled out of the tray

carriers.

Load the film on the film stand as shown on the film-threading diagram located on the

side of the machine and also shown in the diagram below.

11/12/09 1908S20001

1-13

NOTE

1. The adhesive side of the film can be determined by pinching a fold and rubbing the

lid material against itself. Test both sides of the lid. The rough or tacky side of the

lid will be the adhesive side. The film supplied by Oliver Products Company is

wound with the adhesive side toward the inside of the roll. If the film is loaded in

accordance with the “FILM FEED” diagram it will be positioned properly for applying

the adhesive side of the film to the flange of the tray. If the film is loaded improperly,

it can cause the adhesive side to come in contact with the heated platen and the film

to stick to the heated platen. If this happens, the platen will need to be cleaned.

2. To thread the film through the machine, pull enough film off the roll so that you can

insert it into the slot between the tray carrier that is partially under the film stand and

the carrier that is upstream from that. After the film is hanging down underneath the

tray carrier, reach through the tray carrier and pull the film down so that it touches

the tray carriers underneath that are returning to come back up on top. Then insert

a tray into the tray carrier next to the film and cycle the machine one time by pulling

up on the “Black Palm Button” until the conveyor moves one index, then push the

palm button down to stop the machine. This should seal the film to that tray and you

can now fill the rest of the conveyor with filled trays and begin running.

Note: Film dancer bar must move freely up and down.

FILM DANCER BAR,

PULL FILM DOWN SO THAT

IT TOUCHES THE TRAY

CARRIER UNDERNEATH

11/12/09 1908S20001

1-14

ON/OFF KNOB

PULL UP TO START

PUSH DOWN TO STOP

11/12/09 1908S20001

1-15

OPERATING PROCEDURE

An abbreviated version of these operating procedures is attached to the Model 1908 for

use as a daily reference.

If you miss putting a tray in the machine it will not cause any problems, but the film will

be sealed to the top of the empty tray carrier. Let the machine continue to run until that

tray carrier goes around the bottom of the conveyor and comes back up on top, then

remove the piece of film.

Once you have settled into a fairly consistent production rate, adjust the machine speed

to match your production rate as close as possible and lock the speed adjustment knob

with the locknut.

To operate the Model 1908, plug in the power cord. Wait 30 minutes to allow the

heated platen to reach operating temperature. Turn on the air compressor.

1. Load a toll of film onto the film support stand as shown on the “FILM FEED”

diagram located on the side of the machine. It is important that the roll of film is

centered on the conveyor. There are white plastic film guides on either side of

the film roll. These guides can be adjusted from side-to-side by pushing them

with your hand. If the film is not centered, move both guides toward the side that

the film needs to go to. It may take a little bit of running time before you can tell if

the film is in the correct position.

2. To get the film threaded through the machine, pull enough film off the roll so that

you can insert it in the slot between the tray carrier that is partially under the film

stand and the carrier that is upstream from that. After the film is hanging down

underneath the tray carrier, reach through the tray carrier and pull the film down

so that it touches the tray carriers underneath that are returning to come back up

on top. Then insert a tray in the tray carrier next to the film and cycle the

machine one time by pulling up on the “Black Palm Button” until the conveyor

moves one index, then push the palm button down to stop the machine. This

should seal the film to that tray and you can now fill the rest of the conveyor with

the filled trays and begin running.

3. Place filled trays in tray carriers. Take care to avoid spilling food product on the

flange of the tray. Contamination of the flange can result in poor heat seals.

11/12/09 1908S20001

1-16

NOTE

• Never run the machine with trays and no film. Doing so can possibly cause a jam

because the trays can stick to the heated platen and be pulled out of the tray

carriers.

4. Pull the black palm button up to start the machine running. After a few trays

come out of the machine, stop and check to see that the seals are acceptable.

Poor seals may be caused if the dwell time of heated platen is set too short. The

machine was shipped from the factory with the dwell time set properly. However,

it could have come out of adjustment during shipment. The 0.1-3 second dwell

time adjustment knob should be set with indicator arrow between the letter “B &

C” as shown in the illustration below. Do not turn the knob so that the indicator

arrow goes past the letter “F” and before the letter “A”. The closer the indicator

arrow is to the “A”, the shorter the dwell time.

NOTE

• Dwell timer with (0.1-30s) should be set between A &B. The indicator arrow should

not be turned past these letters.

INDICATOR ARROW

11/12/09 1908S20001

1-17

NOTE

• The machine can be stopped at any time by pushing the black palm button down.

When started again, the machine will pick up sealing where it left off.

5. Once you are running at a constant rate, set the speed of the machine to match

your production rate. This is done by turning the “Speed Adjustment” knob

clockwise to slow the machine down or counterclockwise to speed the machine

up. A locking nut is provided on the speed adjustment knob that can be used to

lock the speed adjustment after you have found the desired setting.

6. Make certain that the sealed trays are discharging off the end of the machine

smoothly. If they are not, raise or lower your accumulating table or conveyor to

allow for a smooth discharge of the trays. The discharge table on the Model

1908 has a height adjustment. The discharge table should be set at the proper

height so that the bottoms of the trays are just slightly above it as they leave the

tray carriers.

Discharge table

7. At the end of the day, unplug the Model 1908 from the wall outlet. This is the

only way to turn off the machine.

11/12/09 1908S20001

1-18

NOTE

• IT IS NOT RECOMMENDED TO LEAVE THE MACHINE PLUGGED IN WHEN IT

IS GOING TO BE OUT OF OPERATION FOR AN EXTENDED PERIOD OF TIME.

TECHNICAL SPECIFICATIONS

Model 1908

Tray Capacities: 6-3/8” (162mm) by 8.5” (216mm) maximum top-outside-dimensions of

the tray.

Temperature Range: Factory preset to approx. 300 degrees F.

Weight: 300 LBS.

Electrical: 120 VAC, 15 Amps, Single Phase, and 60 Hz

Air Requirements: 6 CFM @ 80 PSI

11/12/09 1908S20001

1-19

Machine Dimensions

64”

45”

34”

17”

11/12/09 1908S20001

1-20

Air Compressor

Weight: 60 LBS.

Electrical: 115 VAC, 15 Amps, Single Phase, and 60 Hz

Length of Air Hose: 70 Ft.

Air Hose I.D.: 3/8”

Air Connector Size: ¼” NPT

Oil: Use a full synthetic motor oil like Mobil-1 10w -30 DO

NOT USE REGULAR AUTOMOTIVE OIL SUCH AS 10W-30

Air Compressor Dimensions

11/12/09 1908S20001

1-21

CLEANING AND MAINTENANCE

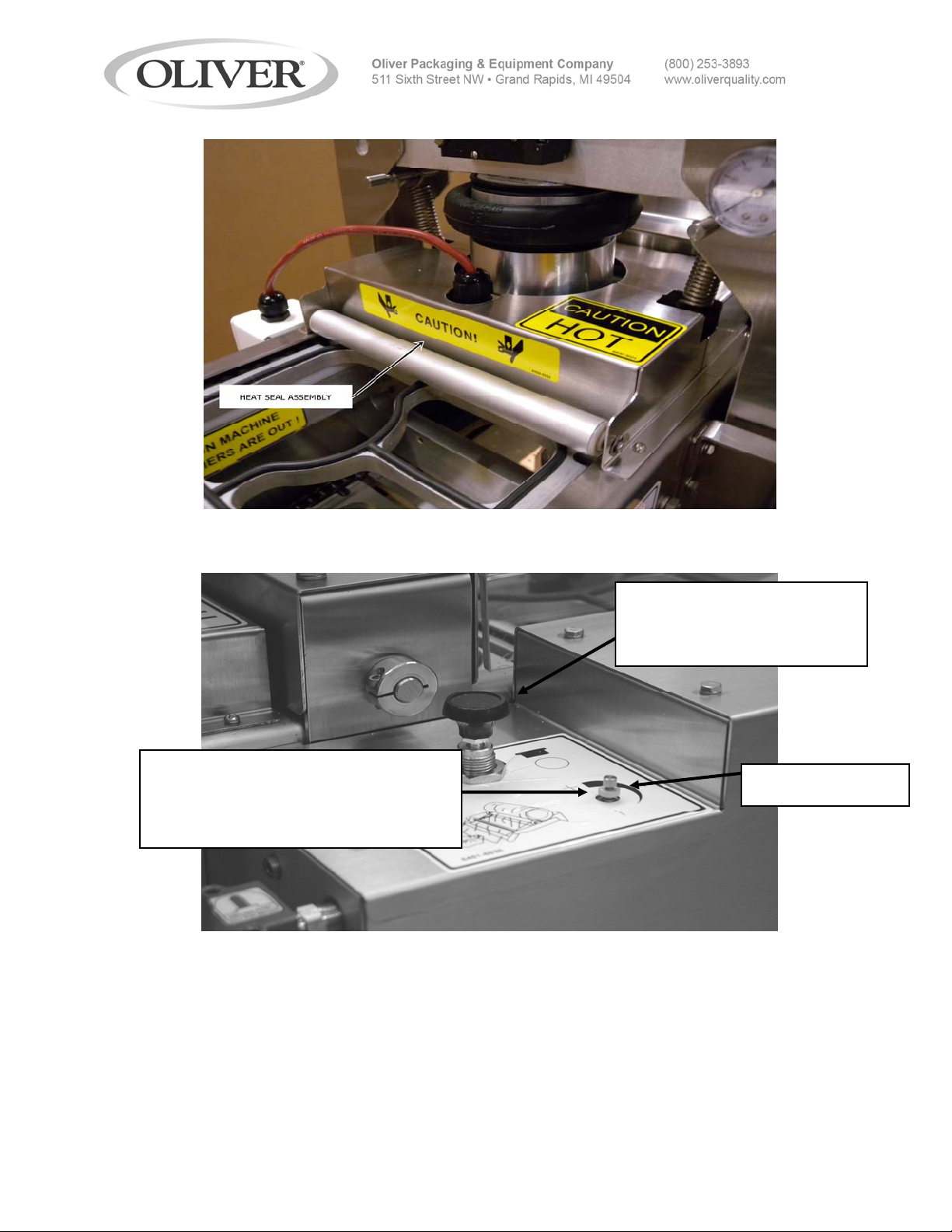

Disconnect the power from the Model 1908 and allow the unit to cool before cleaning.

The tray carriers should be removed and cleaned daily. It is better to remove them for

cleaning rather than trying to clean them in the machine. The tray carriers can be

placed in your dishwasher for cleaning if you desire. Care should be taken so that the

rubber gaskets do not become damaged.

CAUTION

• Do NOT run the machine with the tray carriers removed. Doing so could cause

damage to the heat seal assembly.

The diagram on the next page shows how to remove the tray carriers. It is a simple

process that just requires lifting up on the tray carrier and shifting it over to one side

while pulling the carrier next to it to the other side to disengage the pins on the opposite

side and then completely removing the carrier as shown. The carriers should be

removed in the middle of the in-feed area on the top of the conveyor. As the carriers

are removed, the conveyor must be pulled forward to keep getting to the remaining

carriers. To move the conveyor forward, grasp a tray carrier toward the infeed-end of

the machine and pull the conveyor forward. This must be done with the air connected.

NOTE

• When replacing the tray carriers, it is extremely import to make sure that all four pins

on the conveyor chains are fully engaged in the holes of the tray carrier. If the tray

carriers are put in on an angle because the pins are not engaged on one side, it

could cause damage to the cutter assembly.

11/12/09 1908S20001

1-22

REMOVING TRAY CARRIERS

NOTE

• These cleaning recommendations are not meant to replace or supersede plantstandard manufacturing procedures or regulatory requirements.

• If the machine has been operating, allow the unit to cool before cleaning.

CAUTION

• CAUTION HOT: The heater cover and upper platen are very HOT! Care must be

taken to protect yourself and others.

11/12/09 1908S20001

1-23

WARNING

• Make sure the unit has been unplugged from power.

Clean the OLIVER Model 1908 Lidder with a with mild cleaner or sanitizing solution and

a damp cloth. It is important that the surface of the heated platen be kept clean and

smooth. If food product comes in contact with the surface of the platen it tends to burn

on and become hard. This results in an irregular surface on the face of the platen that

can result in poor seals. If this happens, it will be necessary to remove this burnt on

food material. When cleaning the surface of the platen care must take to avoid

scratching or gouging the surface. DO NOT SCRAPE THE SURFACE OF THE

PLATEN WITH SHARP OBJECTS AND AVOID THE USE OF METAL TOOLS.

Instead use a plastic or soft-metal scouring pad such as Scotch Brite® or Chore Boy®

brands provide a safe and effective means of cleaning the heated platen. Wipe all

surfaces with a sanitizing agent after cleaning.

WARNING

• If the platen will be cleaned while it is still hot make sure hand protection is used to

prevent skin contact with the platen.

• The heat seal platen needs to be cleaned to remove food deposits. This must be

done while the tray carriers are removed from the machine.

WARNING

• Disconnect and Lock out air supply / Electrical cords before performing

maintenance. The cutter assembly is very sharp!

Clean the cutter assembly with a mild cleaner or sanitizing solution and a damp cloth

11/12/09 1908S20001

1-24

NOTE

• The use of plastic or soft-metal scouring pads such as Scotch Brite® or Chore Boy®

brands provide a safe and effective means of cleaning the cutter assembly. Wipe all

surfaces with a sanitizing agent after cleaning.

Once a month the conveyor chains should be lubricated with vegetable oil such as

cooking spray. If you use hose-down cleaning, this should be done twice a month.

SPRAY CHAINS WHILE

MACHINE IS CYCLING

Once a month the conveyor chains should be checked for proper tension. The tension

can be checked by lifting the lower tray carriers at the middle of the machine. If you can

easily lift them up more than 3 inches, the chains are too loose and should be tightened

by adjusting the tensioners at the infeed-end of the machine. Loosen the locking nuts

and turn the adjusting screws clockwise to tighten the chains then retighten the locking

nut. It is important to adjust both sides equally. The easiest way to do this is to count

the turns that you tighten one side and then do the same on the other side. The best

method is to adjust each side in ¼ turn increments and then recheck the chain tension.

11/12/09 1908S20001

1-25

ADJUSTING

SCREW

LOCKING NUT

11/12/09 1908S20001

1-26

TROUBLESHOOTING

There are no user serviceable parts on your OLIVER Model 1908 Lidder except for the

cutter blade. Should you experience problems with your machine call the Oliver

Products Company 24 Hour Emergency Service number @ 1 800-253-3893.

Please have the serial number of your machine available to give to the Customer

Service representative.

Before calling for assistance please check the list below to see if the problem you are

experiencing is listed. If it is, try the corrective action items listed for that problem

before calling for assistance.

SYMPTOM

Machine does not cycle Make sure that the compressor is plugged in and

Make sure that the airline is connected to the

Check the air regulator to see that it is set

CORRECTIVE ACTION

there is power at the outlet

compressor and the Model 1908

Make sure the air compressor is turned on

between 70 and 80 PSIG - If not, adjust it to this

setting - Turning the knob counterclockwise

lowers the pressure and clockwise raises the

pressure

Check to see that dwell setting knob is not past

“O” or “A”

Check to see if that conveyor chain tension is not

overly tight

Check to make certain that a tray carrier is not

installed improperly where the pins on the

conveyor chains are not engaged in the holes of

the tray carrier

Check to see that film has not wound around the

cutter mechanism to the point that it is bound up

on the tray carriers

11/12/09 1908S20001

1-27

SYMPTOM CORRECTIVE ACTION

Poor seal quality Verify that the platen is heated by placing your

hand near the platen and try to detect if there is

heat radiating out from it-DO NOT TOUCH THE

PLATEN

Check to see if the platen is dirty

Check rubber gasket on tray carriers for damaged

or missing pieces

Check to see that the film is centered on the tray

Check to see that the heat seal dwell is set

properly

Make sure that the tray flanges are not

contaminated with product

_____________________________________________________________

Platen does not heat up Verify that the power cord is plugged into outlet

Verify that there is power at the outlet

_________________________________________________________________

Film does not cut

Check to see if there is film wrapped around the

cutter blade-You must remove the cutter guard to

do this and if there is film wrapped around it the

film must be cut away and pulled off- THE

CUTTER BLADE IS SHARP, DO NOT TOUCHREMOVE AIR AND ELECTRICAL POWER PRIOR

TO REMOVING GUARD

Check to see if cutter blade is missing

Check to see if cutter blade is dull

Check to see if the cutter blade is dirty

Film is not centered on tray Adjust the plastic guides on the film holder so

that the film is centered over the trays

11/12/09 1908S20001

1-28

MAINTENANCE CHECK LIST

WARNING: Disconnect and lock out Air supply / Electrical

cords before performing Maintenance

1908 Machine:

Clean Tray carriers/Chain (pg 24&25)

1

Insp Rubber Gaskets in tray carriers (pg 24)

2

Line pressure is at 80 psi (pg10)

3

Check/Clean hot platten (pg 26)

4

D

D

D

D

Oil chain (pg 27)

5

Blue filter- check for replacement (pg 11)

6

7

Insp/Clean cutter blade (pg 13 & 26)

Film dancer bar is moving freely (pg 16)

8

Compressor:

9

Check Oil level (pg 4 comp. manual)

Drain water out of tank (pg 2 comp. manual)

10

Check safety valve (pg 6 comp. manual)

11

Insp/Replace air filter (pg 2 comp. manual)

12

Change oil (pg 4 comp. manual)

13

D = Daily

W= Weekly

M= Monthly

3M= 3 Months

M

D

W

D

D

D

W

6M

3M

6M= 6 Months

Note: Refer to Manuals for instructions

Rev. 8/16/05

1908S20002

2-1

MECHANICAL REPLACEMENT PARTS LIST

EXPLODED VIEW (FRAME)

For Service Parts Call Oliver Products @ 800-253-3893

3/31/09 1908S2003 3-1

MECHANICAL REPLACEMENT PARTS LIST

EXPLODED VIEW (FRAME)

ITEM NO PART DESCRIPTION PART NUMBER QUANITY

1 FRAME FRONT 1908-0001 1

2 FRAME REAR 1908-0002 1

3 BEARING-FLG NYLNR THOM.4L2FF 5257-0205 7

4 SPACER FRAME 1908-0003 4

5 SCREW HEX HD 3/8 -16 5843-1052 16

6 WASHER 3/8 STST SPRING LOCK 5851-9359 16

7 TAKE UP - FRAME 1908-0054 2

8 SCREW - HEX HD 1/4 - 20 5843-1001 8

9 WASHER - LOCK 1/4 “ 5851-9357 8

10 SCREW – TAKE UP 6.250 LONG 1908-0005 2

NUT – HEX FULL 3/8 – 16 5832-0522 2

12 SUPPORT CHAIN UPPER AND LOWER 1908-0007 4

15 MAIN – CHAIN (266 PITCHES) HYDRO 5603-4928 2

16 GUARD INFEED 1908-0021 1

17 SCREW HEX HD 10-24 5843-1231 10

18 WASHER - #10 STST SPRING LOCK 5851-9355 10

19 STRIP CARRIER SUPPORT 1908-0024 2

26 SCREW - HEX HD 3/8 - 16 5843-1052 8

27 WASHER – FLAT 3/8” 5851-9306 8

28 STRIP – WEAR 48.5 LONG 1908-0052 2

For Service Parts Call Oliver Products @ 800-253-3893

3/27/09

1908S20003 3-2

MECHANICAL REPLACEMENT PARTS LIST

EXPLODED VIEW (LEGS & CASTERS)

(PER LEG)

ITEM NO PART DESCRIPTION PART NUMBER QUANITY

101 LEG SENIOR MEAL UNIT 1908-0027 1

102 NUT – HX FULL 1/4 -20 5832-0520 4

103 SCREW – HEX HD 1/4 -20 5843-1005 4

104 WASHER – LOCK 1/4 “ STST SPRING 5851-9357 4

105 CASTER – STEM, 4” WHEEL 5902-2409 2

For Service Parts Call Oliver Products @ 800-253-3893

3/27/09

1908S20003 3-3

MECHANICAL REPLACEMENT PARTS LIST

EXPLODED VIEW (ARCH & HEATER PLATEN)

222

306

209

232

233

302

301

219

207

309

221

211

223

304

210

218

212

209

305

307

308

311

213

217

216

241

209

220

240

224

215

214

327

3/27/09 1908S20003 3-4

MECHANICAL REPLACEMENT PARTS LIST

EXPLODED VIEW (ARCH & HEATER PLATEN)

ITEM NO PART DESCRIPTION PART NUMBER QUANITY

207 MANIFOLD-MAIN 5130-0023 1

209 WASHER-SPRING LOCK 5851-9357 20

210 FITTING-ELBOW 90 SWIVEL 5115-1775 4

211 PLUG-PIPE CSNK 1/4 5115-1428 1

212 PLUG-PIPE BR CSNK 1/8 5115-1427 2

213 MUFFLER-EXHAUST 5130-7005 2

214 ARCH 1908-0122 2

215 HEX HD 1/4 -20 5843-1001 12

216 4-WAY VALVE 5148-5531 1

217 SCREW – ROUND HD 4-40 5843-5196 1

218 O-RING 6909-3102 1

219 TIMER PNUEMATIC 1-3 SEC. 5148-6511 1

220 SPRING AIR ACTUATOR 5143-2002 1

221 O-RING 6909-3113 1

222 SCREW HEX HD 3/8-16 5843-1061 2

223 WASHER - 3/8 SPRING LOCK 5851-9359 2

224 PUSHER – SPACER HEATER PLATEN 1508-0018-3 1

232 PIN SPRING SUPPORT 1908-0123 2

233 SPRING TENSION 7024-4104 2

For Service Parts Call Oliver Products @ 800-253-3893

3/27/09

1908S20003 3-5

MECHANICAL REPLACEMENT PARTS LIST

EXPLODED VIEW (ARCH & HEATER PLATEN)

ITEM NO PART DESCRIPTION PART NUMBER QUANITY

240 GAUGE - PRESS 0-160 P.S.I. 5118-0533 1

241 BUSHING – REDUCING ¼ TO 1/8 5115-1250 1

301 FILM DISPENSER 1908-0042 1

302 SCREW HEX HD 1/4 -20 5843-1002 8

304 SPACER FILM DISPENSER 1508-0016-1 1

305 ROD FILM DISPENSER 1908-0043 3

306 TUBE 4639-1414-1115 2

307 BEARING ROLL END 5252-3002 4

308 RING RETAINER (G) 5840-1273 6

309 ROLLER FILM GUIDE 1908-0041 2

311 BRACKET FILM TAKEUP ROLLER 1908-0163 1

327 SEE NEXT LAYOUT ------------- 1

For Service Parts Call Oliver Products @ 800-253-3893

3/27/09 1908S20003 3-6

MECHANICAL REPLACEMENT PARTS LIST

EXPLODED VIEW (CUTTER & DISCHARGE)

For Service Parts Call Oliver Products @ 800-253-3893

3/27/09

1908S20003 3-7

MECHANICAL REPLACEMENT PARTS LIST

EXPLODED VIEW (CUTTER & DISCHARGE)

ITEM NO PART DESCRIPTION PART NUMBER QUANITY

23 (SEE OTHER ASSEMBLY –ARCH) -------------- 1

24 (SEE OTHER ASSEMBLY –FRAME) -------------- 1

25 SPROCKET SET SCREW 1/4 -20 5843-2031 1

26 SAME AS (4) 5843-1002 4

27 SAME AS (5) 5851-9357 4

28 SAME AS (6) 5851-9304 4

29 SCREW SOCSET CUPPT 1/4 -20 5843-2034 2

30 PIN SPRING 1/8” 5835-6572 2

31 SCREW SOCSET CUPPT 1/4 -20 5842-6131 3

401 HOLDER BLADE 7” 1908-0030 1

402 SHAFT BLADE HOLDER 1908-0029 2

405 SPROCKET TYPE B HUB 40B14 1/2B 4617-4014-1631 1

407 BLADE CUTTER – STST 1808-0071 1

408 STRIP BACKER 1908-0031 1

414 BEARING SINT BRZ FLNG FB812-4 5254-3110 2

415 COVER CUTTER 1908-0032-001 1

416 BRACKET SIDE CUTTER – RH 1908-0065-0001 1

417 BRACKET SIDE CUTTER – LH 1908-0065-0002 1

418 RETAINER FRONT BUSHING W/TAB 1908-0066-1001 1

For Service Parts Call Oliver Products @ 800-253-3893

3/27/09 1908S20003 3-8

MECHANICAL REPLACEMENT PARTS LIST

EXPLODED VIEW (CUTTER & DISCHARGE)

ITEM NO PART DESCRIPTION PART NUMBER QUANITY

419 RETAINER REAR BUSHING W/TAB 1908-0066-1002 1

422 KNOB -4-PRONG 5/16-18 5911-7118 2

501 MOUNTING BRACKET DISCHARGE 1908-0085 1

513 SPACER COVER 1908-0058-001 2

521 HOLD DOWN—CUP ASSY 1908-0113 1

522 BASE LIFT TRAY GUIDE (L) 1908-0090 1

523 BRACKET SPACER 1908-0074 1

524 BASE LIFT TRAY GUIDE 1908-0089 1

525 RETAINER- LIFT RAMP INSIDE 1908-0084 2

529 KNOB KNRLD - 1/4 – 20 5911-7024 2

653 COVER BOTTOM DRIVE 1908-0047 1

703 SUPPORT SHELF 69042 1

704 ADJUSTABLE GUIDE SHELF 69043 1

708 LIFT SENIOR MEALS TRAY 1908-0088 1

For Service Parts Call Oliver Products @ 800-253-3893

3/27/09 1908S20003 3-9

MECHANICAL REPLACEMENT PARTS LIST

EXPLODED VIEW (PLATEN)

864

850

856

854

855

859

851

852

852

851

228

237

862

868

858

234

857

226

336

335

867

236

235

333

866

225

865

863

227

228

327

329

341

For Service Parts Call Oliver Products @ 800-253-3893

3/27/09

1908S20003 3-10

MECHANICAL REPLACEMENT PARTS LIST

EXPLODED VIEW (PLATEN)

ITEM NO PART DESCRIPTION PART NUMBER QUANITY

209 WASHER - 1/4” STST SPRING LOCK 5851-9357 4

225 COVER – FRONT PLATEN 1908-0269 1

226 COVER – REAR PLATEN 1908-0270 1

227 SCREW RND HD 6-32 5843-5210 4

228 WASHER #6 SPRING LOCK 5851-9353 5

234 TUBE 4639-1414-1115 1

236 ROD FILM DISPENSER 1908-0040 1

237 RING RETAINER G 5840-1273 2

307 BEARING ROLL END 5252-3002 2

327 ENCLOSURE ELECT. W/L 1308-0060-2 1

329 BRACE GROUND 1308-0062 1

333 ENTRY 1 POLE W/ LIGHT RED 5746-7910 1

335 FUSE DRAWER W / SHORTING BAR 5746-7950 1

336 SCREW – FLAT HD 4-40 5843-5022 2

341 SCREW – STST PN HD SLOTTED M3.5 8843-2261 2

850 INSULATOR – PUSHER SILICONE 6516-0070 1

851 SCREW RND HD 6-32 STST 5843-5211 1

852 WASHER - #6 FLAT STST 5851-9300 1

854 SPRING BRACKET PLATE 1908-0265 1

855 SPACER - PLATEN 1908-0266 6

For Service Parts Call Oliver Products @ 800-253-3893

3/27/09 1908S20003 3-11

MECHANICAL REPLACEMENT PARTS LIST

EXPLODED VIEW (PLATEN)

ITEM NO PART DESCRIPTION PART NUMBER QUANITY

856 SCREW HEX HD 1/4 - 20 STST 5843-1004 4

858 WASHER - 1/4” FLAT STST 5851-9304 4

859 BRACKET STRAIN RELEIF 1908-0267 4

862 BUSHING STRAIN RELIEF 5765-1110 2

863 NUT HEX HD LOCK (MET) 5766-7786 2

864 PLATE – HEATER 115V 1908-0264 1

865 ELECTRICAL ENCLOSURE BRACKET 1908-0268 1

866 SCREW HEX HD 10-24 STST 5843-1231 2

867 WASHER #10 STST SPRING LOCK 5851-9355 2

868 NUT – HEX MACHINE # 10-24 STST 5832-0578 2

For Service Parts Call Oliver Products @ 800-253-3893

3/27/09 1908S20003 3-12

ELECTRICAL

11/10/09 1908S20050

4-1

PNEUMATIC DIAGRAM

11/10/09 1908S20051

5-1

WARRANTY

PARTS

Oliver Products Company (Oliver) warrants that if any part of the equipment (other than a

part not manufactured by Oliver) proves to be defective (as defined below) within one year

after shipment, and if Buyer returns the defective part to Oliver within one year, Freight

Prepaid to Oliver’s plant in Grand Rapids, MI, then Oliver, shall, at Oliver’s option, either

repair or replace the defective part, at Oliver’s expense.

LABOR

Oliver further warrants that equipment properly installed in accordance with our special

instructions, which proves to be defective in material or workmanship under normal use

within one (1) year from installation or one (1) year and three (3) months from actual

shipment date, whichever date comes first, will be repaired by Oliver or an Oliver Authorized

Service Dealer, in accordance with Oliver’s published Service Schedule.

For purposes of this warranty, a defective part or defective equipment is a part or equipment

which is found by Oliver to have been defective in materials workmanship, if the defect

materially impairs the value of the equipment to Buyer. Oliver has no obligation as to parts

or components not manufactured by Oliver, but Oliver assigns to Buyer any warranties

made to Oliver by the manufacturer thereof.

This warranty does not apply to:

1. Damage caused by shipping or accident.

2. Damage resulting from improper installation or alteration.

3. Equipment misused, abused, altered, not maintained on a regular basis, operated

carelessly, or used in abnormal conditions.

4. Equipment used in conjunction with products of other manufacturers unless such use is

approved by Oliver Products in writing.

5. Periodic maintenance of equipment, including but not limited to lubrication, replacement

of wear items, and other adjustments required due to installation, set up, or normal wear.

6. Losses or damage resulting from malfunction.

The foregoing warranty is in lieu of all other warranties expressed or implied AND OLIVER

MAKES NO WARRANTY OF MERCHANTABILITY OR FITNESS FOR PURPOSE

REGARDING THE EQUIPMENT COVERED BY THIS WARRANTY. Oliver neither

assumes nor authorizes any person to assume for it any other obligations or liability in

connection with said equipment. OLIVER SHALL NOT BE LIABLE FOR LOSS OF TIME,

INCONVENIENCE, COMMERCIAL LOSS, INCIDENTAL OR CONSEQUENTIAL

DAMAGES.

GEN 050816

WARRANTY PROCEDURE

1. If a problem should occur, either the dealer or the end user must contact the Customer

Service Department and explain the problem.

2. The Customer Service Manager will determine if the warranty will apply to this particular

problem.

3. If the Customer Service Manager approves, a Work Authorization Number will be

generated, and the appropriate service agency will perform the service.

4. The service dealer will then complete an invoice and send it to the Customer Service

Department at Oliver Products Company.

5. The Customer Service Manager of Oliver Products Company will review the invoice and

returned parts, if applicable, and approve for payment.

GEN 050817

RETURNED PARTS POLICY

This policy applies to all parts returned to the factory whether for warranted credit,

replacement, repair or re-stocking.

Oliver Products Company requires that the customer obtain a Return Material Authorization

(RMA) number before returning any part. This number should appear on the shipping label

and inside the shipping carton as well. All parts are to be returned prepaid. Following this

procedure will insure prompt handling of all returned parts.

To obtain an RMA number contact the Repair Parts Deptartment toll free at (800) 253-3893.

Parts returned for re-stocking are subject to a RE-STOCKING CHARGE.

Thank you for your cooperation,

Repair Parts Manager

Oliver Products Company

GEN 050818

Loading...

Loading...