Oliver 1708-N Installation Manual

Grand Rapids, Michigan, U.S.A. 49504-5298

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 1708-N

SELF-ACTUATING TRAY LIDDER

1708S20000CV2

1708 SELF-ACTUATING LIDDER

INDEX

SAFETY INSTRUCTIONS........................................................................................... 1708S20008

SET UP........................................................................................................................ 1708S20009

OPERATING PROCEDURE........................................................................................ 1708S20010

ADJUSTMENTS........................................................................................................... 1708S20011

TECHNICAL SPECIFICATIONS.................................................................................. 1708S20012

CLEANING................................................................................................................... 1708S20013

MAINTENANCE & TROUBLE SHOOTING................................................................. 1708S20014

RECOMMENDED SPARE PARTS LIST...................................................................... 1708S20018

ASSEMBLY DRAWINGS & PARTS LIST

Final Assembly........................................................................................................ 1708S20020

Base Assembly....................................................................................................... 1708S20000

Arch Assembly........................................................................................................ 1708S20001

Heater Platen Assembly.......................................................................................... 1708S20002

Pneumatics Assembly............................................................................................. 1708S20003

Tray Carrier Assembly............................................................................................. 1708S20004

Film Roll Dispenser Assembly................................................................................. 1708S20005

MACHINE EXCHANGE PROGRAM............................................................................. GEN 050819

WARRANTY.................................................................................................................. GEN 040225

WARRANTY PROCEDURE.......................................................................................... GEN 040226

RETURNED PARTS POLICY....................................................................................... GEN 040227

4/26/96 1708S20017

1708 SELF-ACTUATING LIDDER

SAFETY

Various safety devices and methods of guarding have been provided on this machine. It is essential,

however, that machine operators and maintenance personnel observe the following safety

precautions. Improper installation or operation of this equipment may cause injury to personnel or

damage to equipment.

• Before operating the Self-Actuating Lidder read through this manual. Never allow an untrained

person to operate this machine.

NOTE

• DO NOT ACTUATE MACHINE WITHOUT A TRAY HOLDER IN PLACE. Personal harm and

damage to the machine may occur if the machine is actuated without a tray carrier in place.

CAUTION

• CAUTION HOT: The heater cover and upper platen are very HOT! Caution must be used to

protect yourself and others.

• Always make sure the unit has been unplugged from power and air before cleaning or servicing.

• In addition to these general safety instructions, follow the specific instructions given through out

this manual.

7/30/96 1708S20008

1708 SELF-ACTUATING LIDDER

SET UP

1. Unpack and carefully remove the Self-Actuating Lidder. Check for completeness of your order

and that none of the items have been damaged during shipment. Save packing material for

future shipping.

2. Place the Self-Actuating Lidder in a suitable location that provides adequate working space. The

location must be sturdy, level, and capable of holding 175 lbs. per machine. For maximum

efficency of the Self-Actuating Lidder use the Workstation Stand option.

3. Use a quick detachable coupler with one way shut-off, connect air pressure to the 1/4” NPT

female fitting located on the filter/regulator. The Self-Actuating Lidder requires a minimum of 1

CFM at 90 PSI. If needed an Air Compressor option is available for the Self-Actuating Lidder.

NOTE

• DO NOT USE AN OILER OR LUBRICATOR WITH THIS MACHINE.

NOTE

• DO NOT CONNECT TO AIR PRESSURE ABOVE 150 PSI.

4. Plug the power cord into a grounded electrical outlet. The Self-Actuating Lidder requires single

phase 90 to 130 VAC, 60 Hertz with 10 ampere (minimum) circuit breaker protection.

5. To install the tray carrier, completely extend the tray carrier supports to their locked position.

Position the tray carrier over the tray carrier supports with the retractable pins facing up and the

knob facing forward. lower the tray carrier into position while locating the four tray carrier holes

on the four tray carrier support pins.

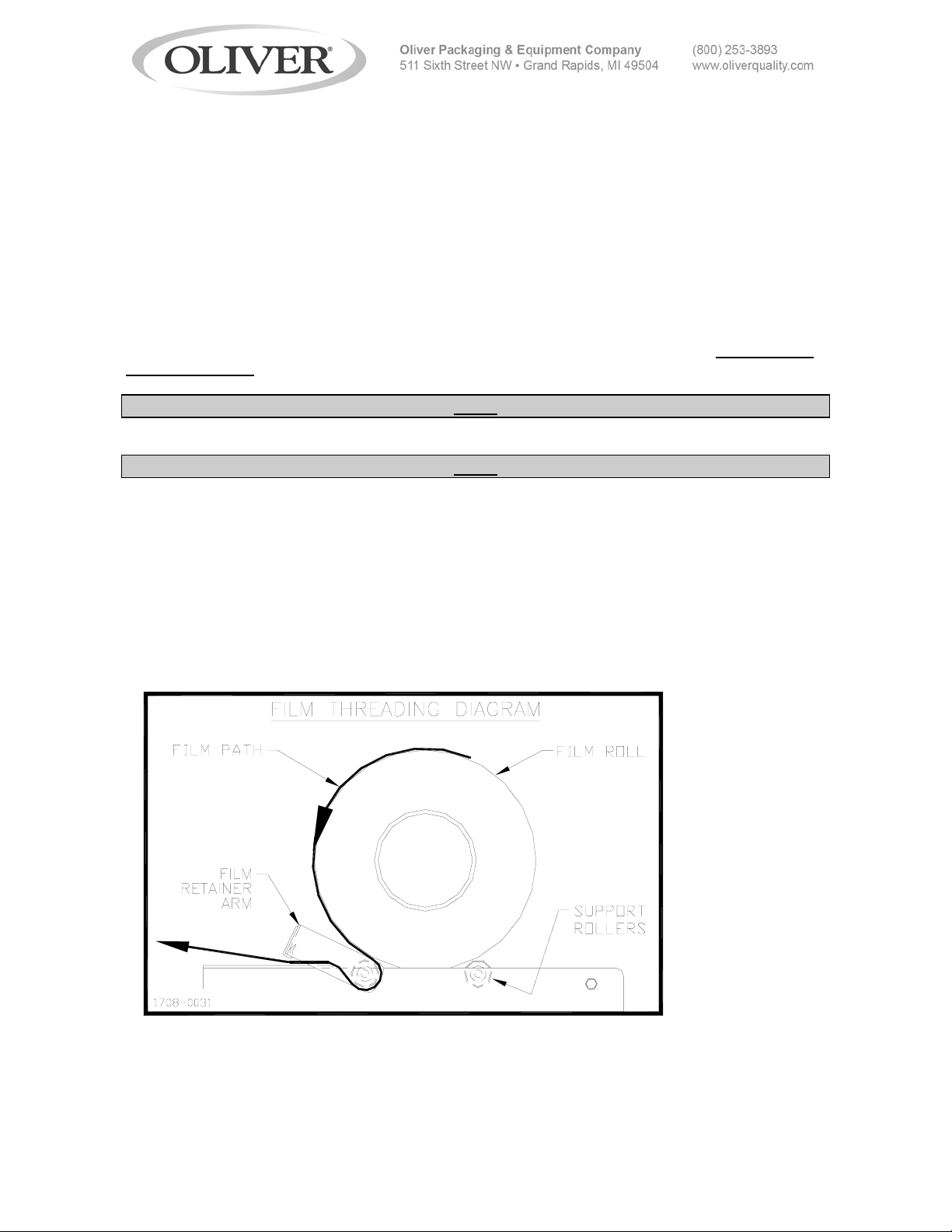

6. Load and thread lid dispenser as shown below.

4/16/96

1708S20009

1708 SELF-ACTUATING LIDDER

OPERATING PROCEDURE

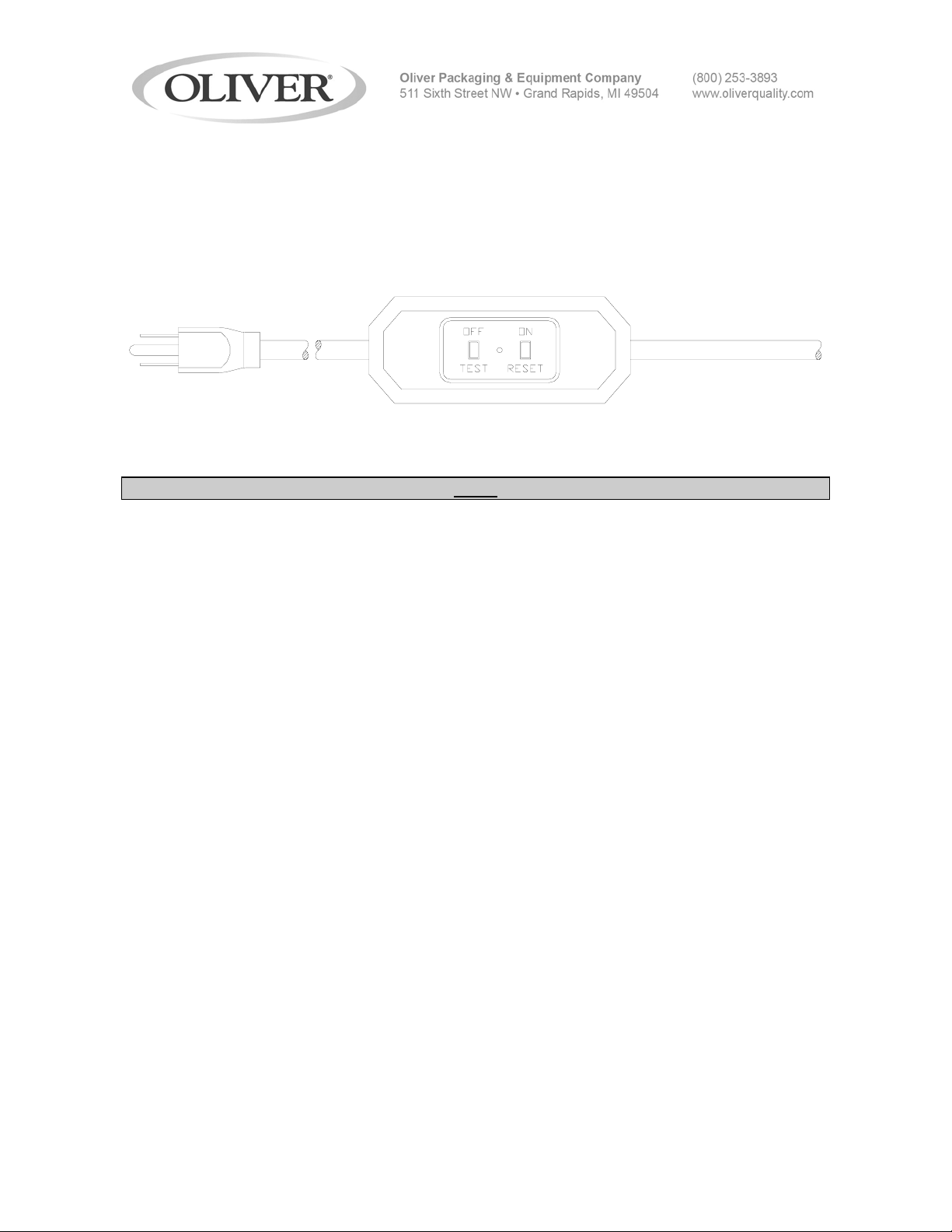

1. Switch the heater power switch on by firmly pressing the “ON/RESET” button located on the

yellow power cord. A small yellow light in the center of the switch will illuminate indicating the

power is on. Wait approximately 40 minutes to allow the heated upper platen time to stabilize at

the working temperature.

2. Place a tray in the tray carrier and position a single lid on the tray. Use the retractable pins on the

tray carrier to center the lids over the tray. Be sure the adhesive side of the lid is against the tray.

NOTE

• The adhesive side of the lid can be determined by pinching a fold and rubbing the lid material

against itself. Test both sides of the lid. The rough or tacky side of the lid will be the adhesive

side.

3. Push the tray carrier into the Self-Actuating Lidder until it stops. This will cycle the heated upper

platen down, applying pressure on the film and tray flanges. As the heated upper platen lifts back

to the open position, the tray carrier will automatically reopen.

4. Remove the lidded tray by rotating the knob on the front of the tray carrier.

4/16/96 1708S20010

1708 SELF-ACTUATING LIDDER

ADJUSTMENTS

Your Self-Actuating Lidder was tested at the factory, using the same trays and film as you will use.

Regulated pressure, temperature, and dwell time where adjusted during this test to provide a good

seal. Our test results indicate the following:

Regulated Pressure

Temperature

Dwell Time

When checking for a good seal look for seal completeness and reasonable seal strength. A poor

seal will occur if the product in the tray contaminates the tray flanges. Moisture will have the same

negative affect. Trays that have irregular flanges or are deformed also seal poorly. Defective trays

should be discarded.

Under different operating conditions, you may find it necessary to adjust one or all of the sealing

parameters. When making adjustments; change only one parameter at a time, make small

incremental adjustments, and record the change made. This is one situation where "MORE IS NOT

BETTER"! In other words, more heat plus more pressure plus longer dwell time does not necessarily

equal better seals.

REGULATED PRESSURE: To adjust the regulated pressure simply pull up the black knob on the

top of the filter/regulator and rotate until the gauge shows the desired pressure (40 PSI min.). Push

the black knob back down to lock. The knob may be removed to assure tamper resistance.

DWELL TIME: The dwell time adjustment knob is on the top of the control box located on the right

side of the machine. The dwell time can be adjusted from .1 seconds to 30 seconds. Rotate the

knob between the "0" and "F" knob markings until the desired dwell time is found. The greater the

angle (clockwise direction), the greater the dwell time setting.

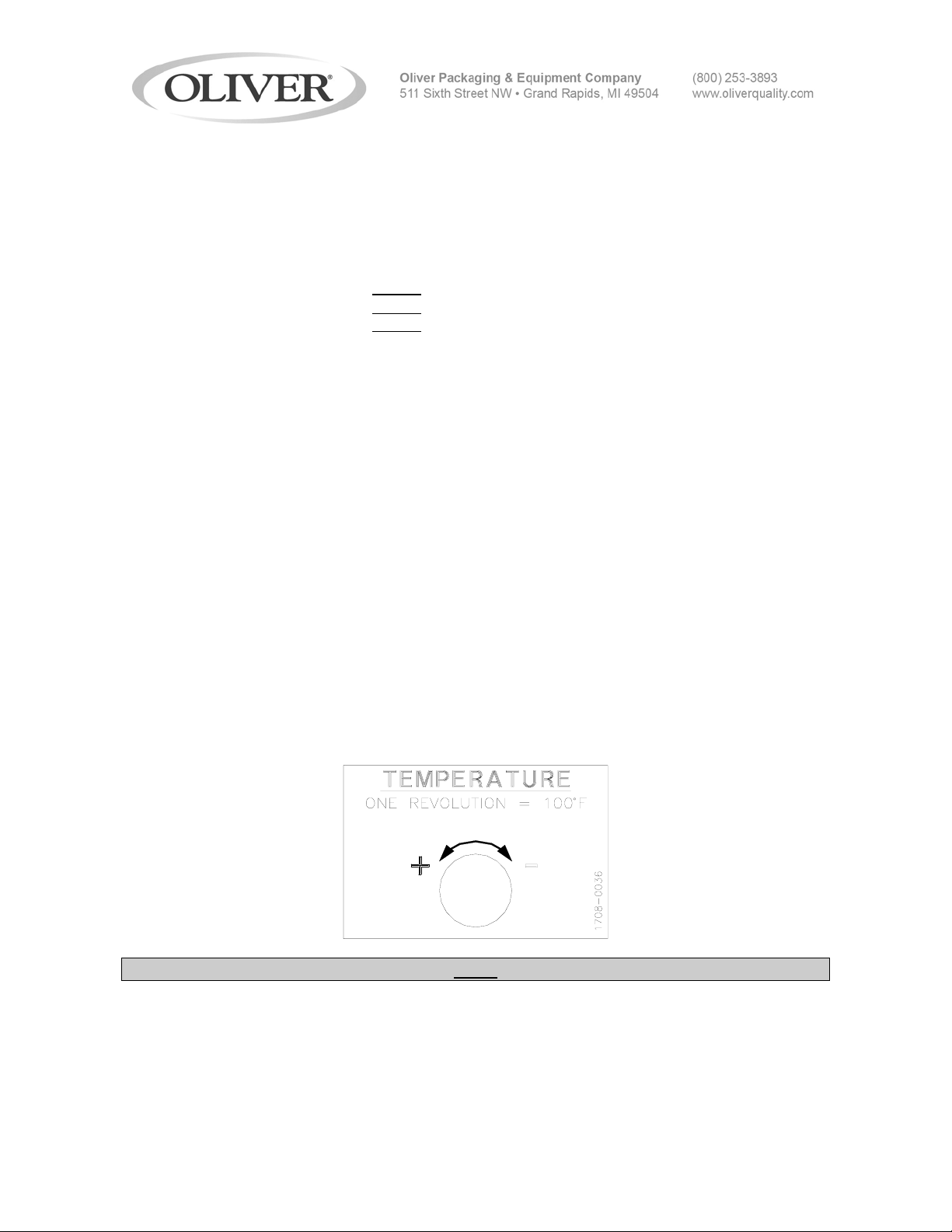

TEMPERATURE: The temperature of the heated upper platen can be adjusted through an access

hole on the back side of the heater cover. Use a slotted blade screwdriver to make the adjustment.

PSI

°F

Seconds

NOTE

• DO NOT remove the adjusting sleeve or turn it in farther than necessary for the desired setting.

This action will permanently damage the thermo-switch.

Once the right combination of the three parameters is found, no further adjustments should be

necessary - so long as you do not change the film or tray material.

4/16/96

1708S20011

Loading...

Loading...