Oliver 1508-NLG Installation Manual

Grand Rapids, Michigan, U.S.A. 49504-5298

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 1508-NLG

SELF-ACTUATING TRAY LIDDER

1508S20000CV2

1508-NLG SELF-ACTUATING LIDDER

INDEX

SAFETY INSTRUCTIONS........................................................................................... 1508S20002

SET UP........................................................................................................................ 1508S20003

OPERATING PROCEDURE......................................................................................... 1508S20004

ADJUSTMENTS........................................................................................................... 1508S20005

TECHNICAL SPECIFICATIONS................................................................................... 1508S20006

CLEANING................................................................................................................... 1508S20007

TROUBLE SHOOTING................................................................................................. 1508S20012-1

PUSHER ADJUSTMENTS............................................................................................ 1508S20012-2

ASSEMBLIES

BASE ASSEMBLY................................................................................................... 1508S20008

HEATER PLATTEN ASSEMBLY ........................................................................... 1508S20009

MANIFOLD ASSEMBLY......................................................................................... 1508S20010

FINAL ASSEMBLY.................................................................................................. 1508S20011

MACHINE EXCHANGE PROGRAM............................................................................. GEN 050819

WARRANTY.................................................................................................................. GEN 040225

WARRANTY PROCEDURE.......................................................................................... GEN 040226

RETURNED PARTS POLICY....................................................................................... GEN 040227

12/23/97 1508S20001

1508-NLG SELF-ACTUATING LIDDER

SAFETY

Various safety devices and methods of guarding have been provided on this machine. It is essential,

however, that machine operators and maintenance personnel observe the following safety

precautions. Improper installation or operation of this equipment may cause injury to personnel or

damage to equipment.

• Before operating the Self-Actuating Lidder read through this manual. Never allow an untrained

person to operate this machine.

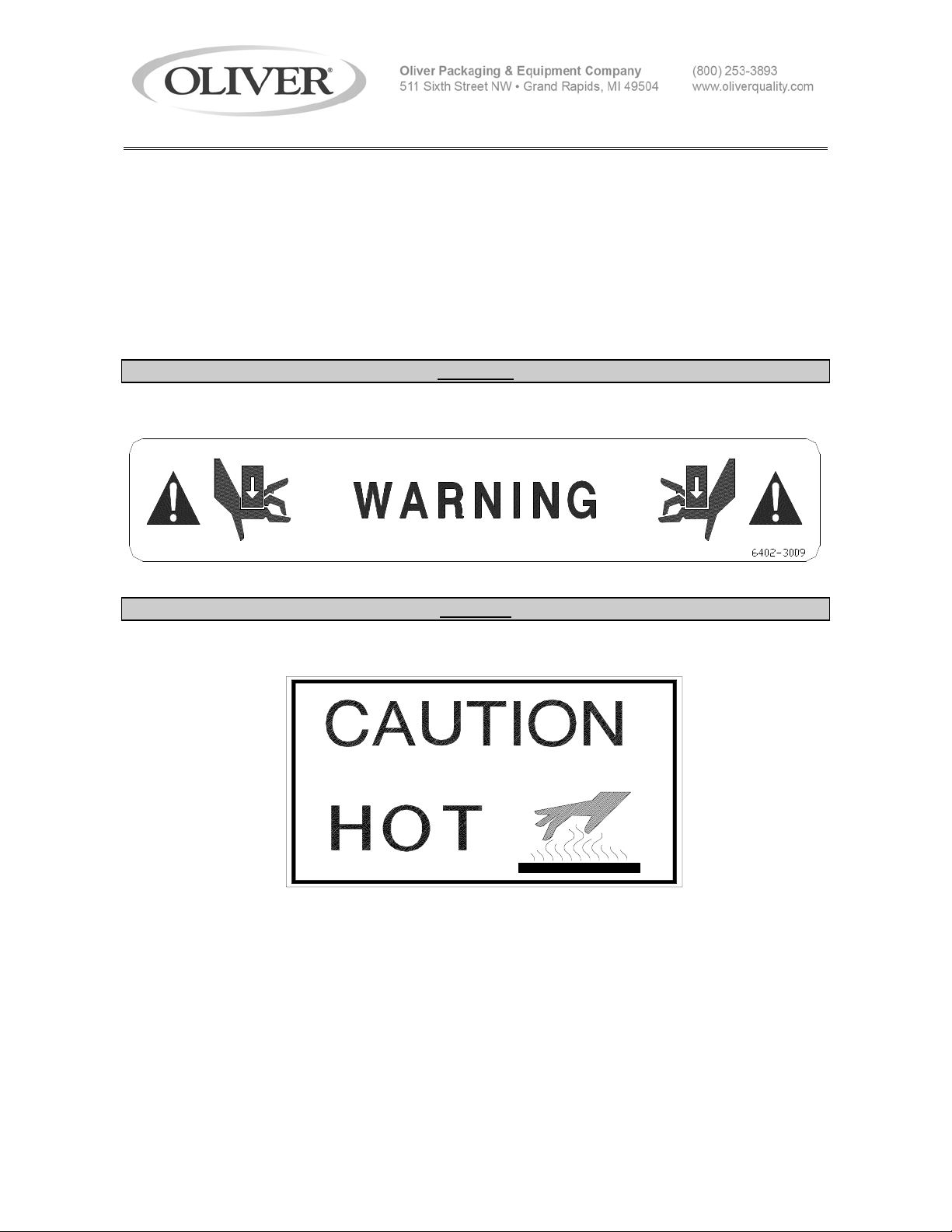

WARNING

• WARNING PINCH POINT: Keep hands out of machine. Always be sure the machine has been

unplugged from power and air before cleaning or servicing.

CAUTION

• CAUTION HOT: The heater cover and upper platen are very HOT! Caution must be used to

protect yourself and others.

• In addition to these general safety instructions, follow the specific instructions given through out

this manual.

12/17/97 1508S20002

1508-NLG SELF-ACTUATING LIDDER

SET UP

1. Unpack and carefully remove the Self-Actuating Lidder. Check for completeness of your order

and that none of the items have been damaged during shipment.

2. Screw the four rubber feet in to place on the bottom of the machine.

3. Place the Self-Actuating Lidder in a suitable location that provides adequate working space. The

location must be sturdy, level, and capable of holding 50 lbs. per machine.

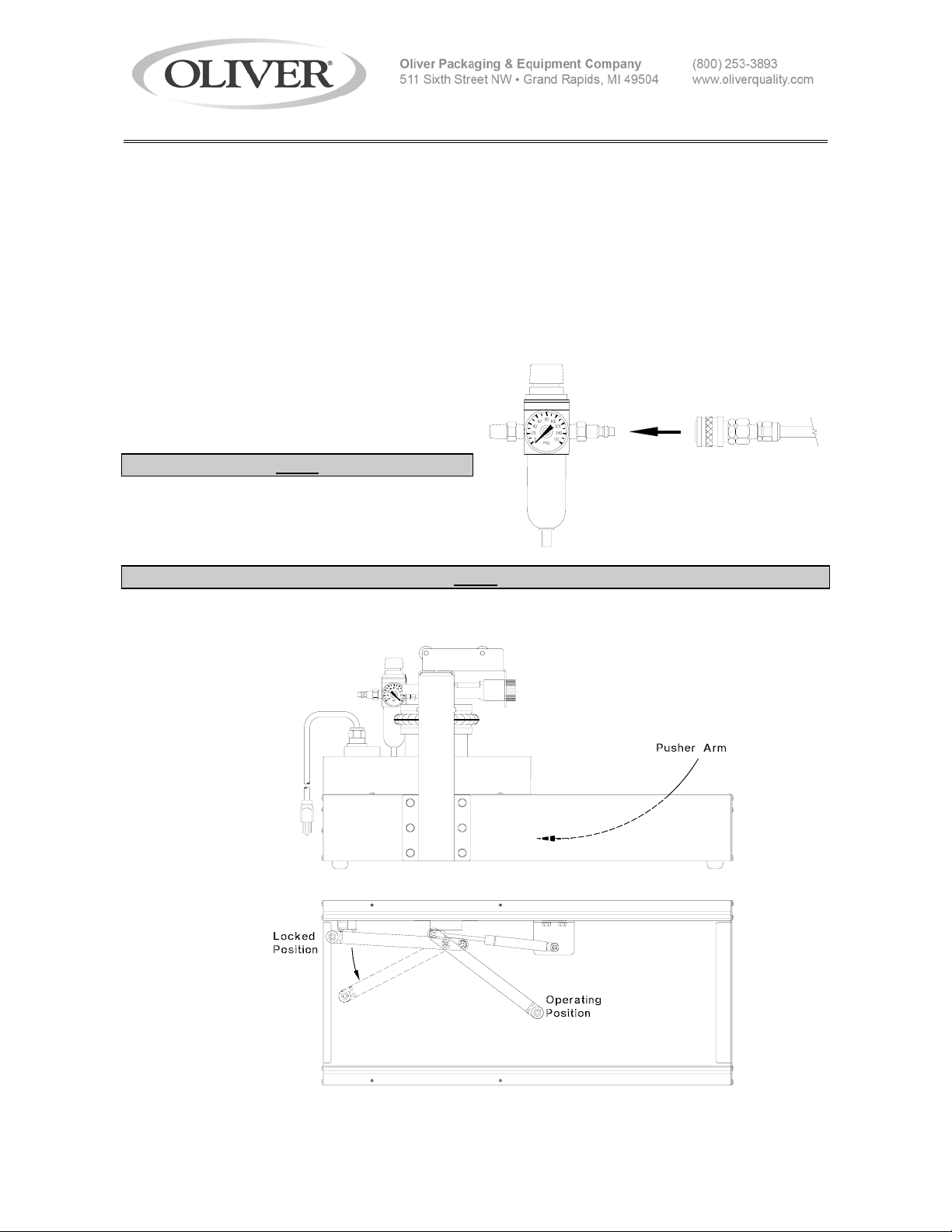

4. Use the quick detachable coupler to

connect air pressure to the filter/regulator. The

Self- Actuating Lidder requires a minimum of

0.1 CFM at 90 PSI.

NOTE

• DO NOT USE AN OILER OR LUBRICATOR

WITH THIS MACHINE.

NOTE

• DO NOT CONNECT TO AIR PRESSURE ABOVE 140 PSI.

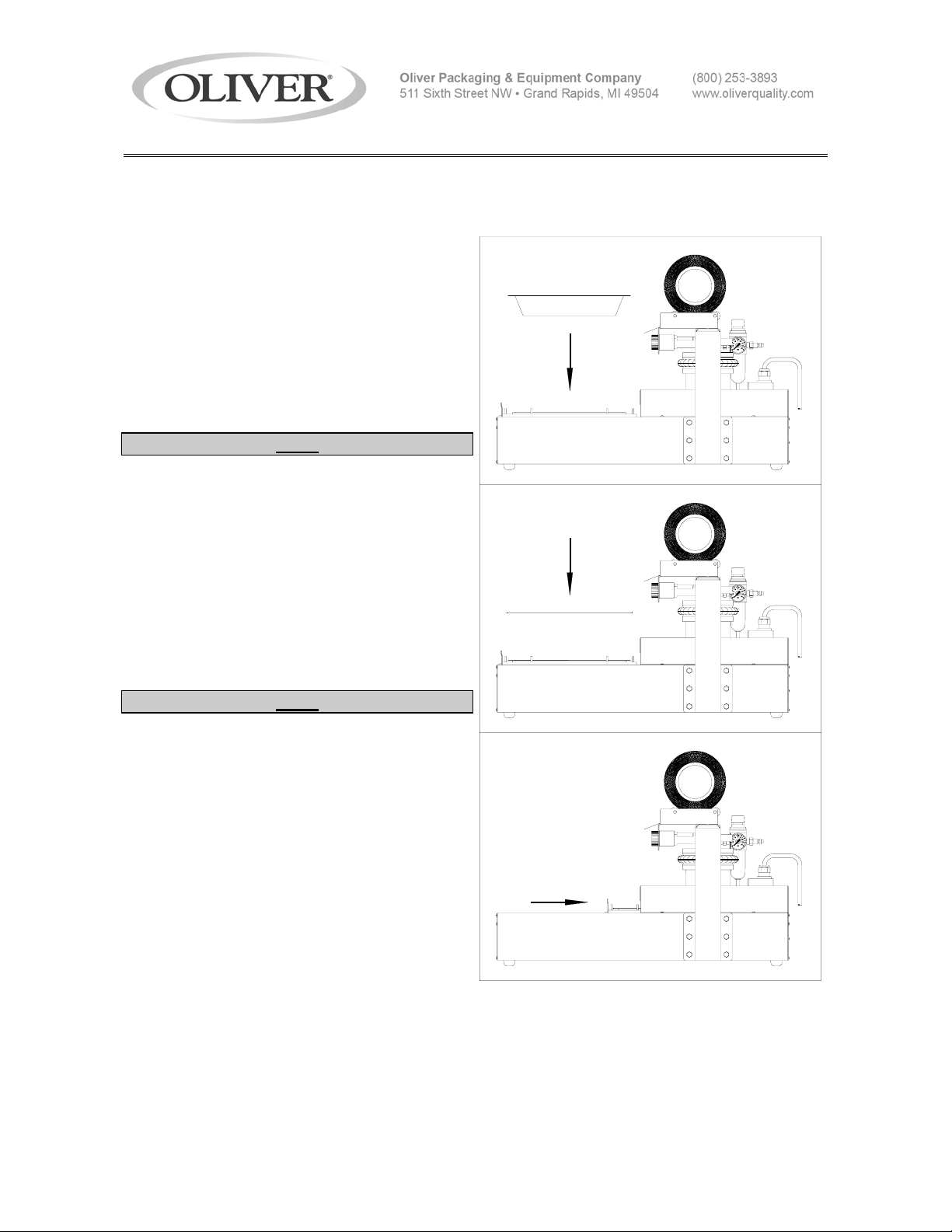

5. Pull the ejector bar to its operating position as shown.

11/9/09 1508S20003-1

1508-NLG SELF-ACTUATING LIDDER

6. SET UP (continued)

6. Plug the power cord into a grounded electrical outlet. The Self-Actuating Lidder requires single

phase 110 VAC, 60 Hertz with 10 ampere (minimum) circuit breaker protection.

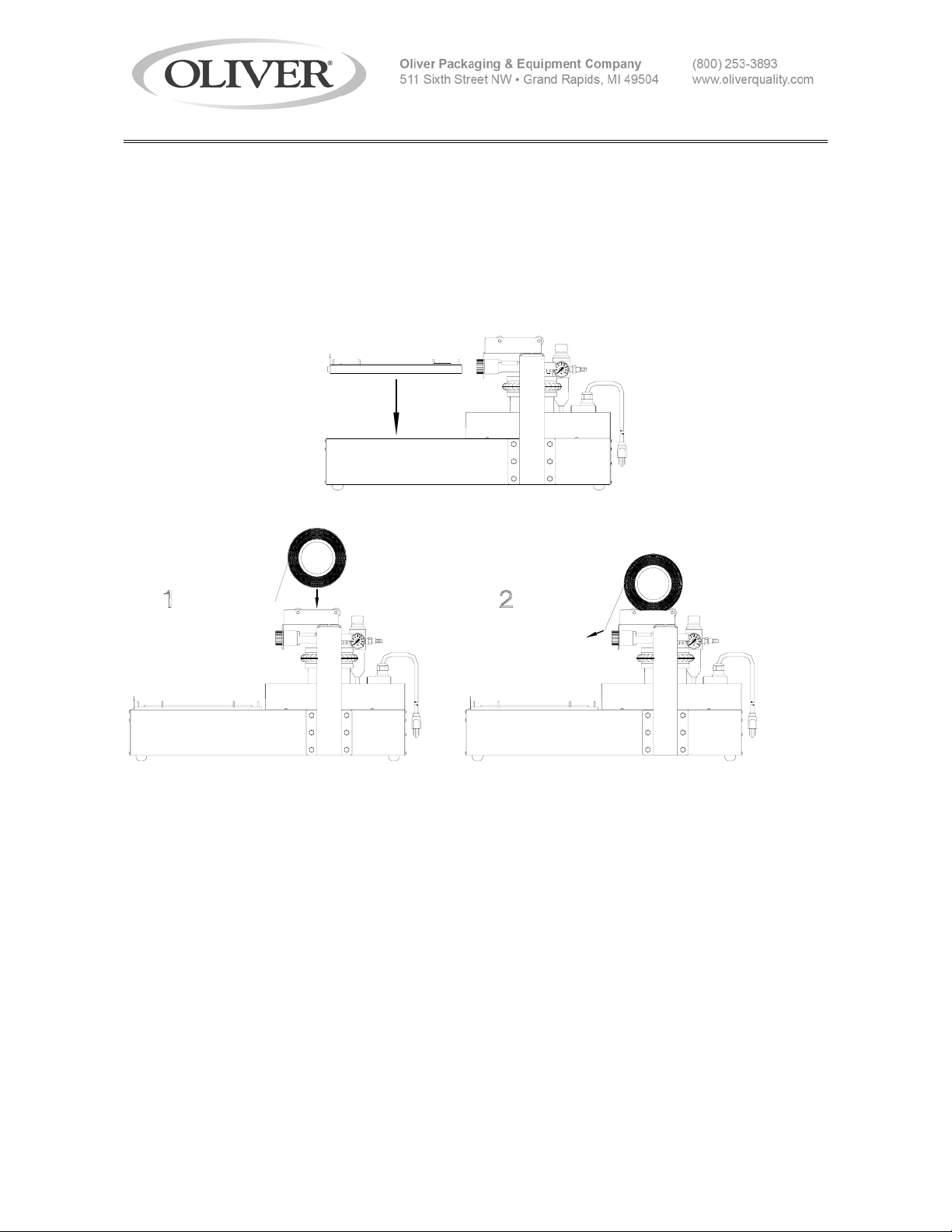

7. Install the tray carrier:

8. Load lid dispenser:

11/9/09 1508S20003-2

1508-NLG SELF-ACTUATING LIDDER

OPERATING PROCEDURE

1. To turn the machine on plug in the power

cord. Wait 40 minutes to allow the heated upper

platen to reach temperature.

2. Place a tray in the tray carrier.

3. Position a single lid on the tray. Use the

retractable pins on the tray carrier to center

the lids over the tray. Be sure the adhesive

side of the lid is down.

NOTE

• The adhesive side of the lid can be

determined by pinching a fold and rubbing the

lid material against itself. Test both sides of the

lid. The rough or tacky side of the lid will be the

adhesive side.

4. Push the tray carrier into the Self-Actuating

Lidder until it stops. This will cycle the heated

upper platen down, applying pressure on the

film and tray flanges. As the heated upper

platen lifts back to the open position, the tray

carrier will automatically reopen.

NOTE

• Actuating machine with no tray or lid a in

place may cause the tray carrier to stick closed.

5. To remove the lidded tray push up on the

bottom of the tray with your hand and lift from

tray carrier.

12/17/97 1508S20004

Loading...

Loading...