Page 1

Page 2

Every effort has been made to ensure that the information in this document is complete,

accurate, and up-to-date. Okidata assumes no responsibility for the results of errors

beyond its control. Okidata also cannot guarantee that changes in software and equipment

made by other manufacturers and referred to in this guide will not affect the applicability

of the information in it. Mention of software products manufactured by other companies

does not necessarily constitute endorsement by Okidata.

© 2007 by Oki Data, Americas. All rights reserved.

Rev 1.1 February, 2007.

Written and produced by the Okidata Training & Publications Department. Please address

any comments by mail to:

Training & Publications Department

Okidata, Division of Oki America, Inc.

2000 Bishops Gate Blvd.

Mount Laurel, NJ 08054-4620

or by email to

pubs@okidata.com

For the latest product information and manuals, we welcome you to visit our web site:

http://www.okidata.com

Year 2000 Compliance

All products currently sold by Okidata are Year 2000 Compliant. Each product contains

information technology that accurately processes date and time data between the years

1999 and 2000. These products, when used in combination with products purchased from

other manufacturers, whose products properly exchange date and time information, will

accurately process the date and time. All future products are committed to meeting the

same Year 2000 compliance.

ENERGY STA R

OKI and OKIDATA are registered trademarks/marques déposées/marcas registradas Oki Electric Industry

Company , Ltd.

Epson is a registered trademark of Epson America, Inc. Ethernet is a trademark of Digital Equipment Corporation.

IBM is a registered trademark of International Business Machines Corp. Microsoft and Windows are

registered trademarks or trademarks of Microsoft Corporation in the U.S. and/or other countries.

®

2

Page 3

Conventions Used in this Users Guide

Notes

Note: Notes are set in regular type and contain general information.

Cautions

Caution! Cautions are set in bold italics and contain information regarding actions

which could potentially cause personal injury or damage to the printer.

Important Information

Important! Important information is set in italics.

3

Page 4

Contents

1: Front Panel.................................................................................................................... 8

Print Mode: Indicator Lights.......................................................................................... 8

Print Mode: Control Panel Buttons ................................................................................ 9

Menu Mode: Control Panel Buttons ............................................................................ 10

Menu Mode: Configuring Your Printer........................................................................ 11

Entering/Exiting the Menu Mode.............................................................................. 11

Changing the Menu Settings ..................................................................................... 11

Saving Configurations............................................................................................... 11

Switching Back and Forth between Configurations.................................................. 12

Resetting the Menu.................................................................................................... 12

Printing a List of Menu Items ................................................................................... 12

Summary of Menu Settings....................................................................................... 13

Explanation of Menu Settings...................................................................................... 17

2: Maintenance................................................................................................................ 22

Replacing the Ribbon................................................................................................... 22

Clearing Paper Jams..................................................................................................... 25

Front Feed Jams ........................................................................................................ 25

Rear Feed Jams.......................................................................................................... 27

Replacing the Power Fuse............................................................................................ 28

Cleaning the Housing................................................................................................... 29

Cleaning the Interior.................................................................................................. 29

Cleaning the Exterior ................................................................................................ 30

3: Troubleshooting .......................................................................................................... 31

General Troubleshooting.............................................................................................. 31

Error Messages............................................................................................................. 34

4

Page 5

4: Service Information.................................................................................................... 38

Getting Service & Support........................................................................................... 38

Your Dealer ............................................................................................................... 38

Okidata Information System Automated Attendant .................................................. 38

Okidata Customer Support Professionals) ................................................................ 39

Okidata Service Locations ........................................................................................ 40

Purchasing Replacement Parts & Accessories .......................................................... 41

Accessories................................................................................................................ 42

OkiLAN Model 6100e Ethernet Network Interface Card ..................................... 42

OKI Adapter Card.................................................................................................. 42

Replacement Parts ..................................................................................................... 42

A: Specifications.............................................................................................................. 44

General Specifications ................................................................................................. 44

Font Specifications....................................................................................................... 45

Reliability.....................................................................................................................46

Paper Specifications..................................................................................................... 46

Front Feed ................................................................................................................. 46

Rear Feed................................................................................................................... 47

Physical Specifications ................................................................................................ 47

Environmental Specifications ...................................................................................... 47

Electrical Specifications............................................................................................... 48

Memory........................................................................................................................ 48

B: Interfacing ..................................................................................................................49

Parallel Interface .......................................................................................................... 49

Parallel Interface Pin Assignments............................................................................ 49

Serial Interface ............................................................................................................. 51

Serial Interface Pin Assignments............................................................................... 51

Commonly Used Serial Cable Configurations .......................................................... 52

Serial Interface Test ................................................................................................... 53

Ethernet 10/100 BaseT Interface.................................................................................. 54

Pin Assignments ........................................................................................................ 54

Print Server Parallel Output Pin Assignments........................................................... 55

5

Page 6

C: Command Summary ................................................................................................. 56

Epson FX Command Summary ................................................................................... 56

IBM Proprinter III Command Summary...................................................................... 69

Okidata Microline Standard Command Summary....................................................... 79

Bar Code Commands ................................................................................................... 91

Select Bar Code Type and Size Command ................................................................ 91

Print Bar Code Data Command................................................................................. 93

Postnet Bar Code Command ..................................................................................... 93

Custom Font Commands: Epson & IBM..................................................................... 94

Epson FX Custom Font Command ........................................................................... 94

IBM Proprinter III Custom Fonts Command ............................................................ 96

Select Menu Item 1 Command..................................................................................... 98

Select Menu Item 2 Command................................................................................... 105

D: Hex Dump Mode.......................................................................................................111

Running a Hexadecimal Dump ...................................................................................111

E: Character Sets.......................................................................................................... 112

Lower ASCII Character Sets...................................................................................... 112

Upper ASCII Character Sets ...................................................................................... 116

Epson International Character Substitutions.............................................................. 120

IBM International Character Substitutions ................................................................ 120

Microline Standard International Character Substitutions ......................................... 121

Code Page Character Sets .......................................................................................... 122

IBM Multilingual Code Page Sets ............................................................................. 126

Multilingual 858 Code Page Character Set................................................................ 128

ISO 8859-15 Code Page Character Set ...................................................................... 128

Epson BRASCII Character Set .................................................................................. 128

Epson Abicomp Character Set ................................................................................... 128

OKI Block Graphics Character Set ............................................................................ 129

Bar Codes................................................................................................................... 130

UPC A ..................................................................................................................... 130

UPC E...................................................................................................................... 130

EAN 8...................................................................................................................... 130

EAN 13.................................................................................................................... 130

Code 39 ................................................................................................................... 130

Code 128 ................................................................................................................. 130

Interleaved 2 of 5..................................................................................................... 130

Postnet ..................................................................................................................... 130

6

Page 7

FCC / IC / CE................................................................................................................ 131

FCC Declaration of Conformity ................................................................................ 131

Federal Communications Commission Radio Frequency Interference Statement..... 132

Industry Canada Radio Interference Statement.......................................................... 132

European Union Council of the European Communities Statement

of Electromagnetic Conformance............................................................................. 132

Warranty ....................................................................................................................... 133

Limited Warranty ....................................................................................................... 133

On-Site Repair......................................................................................................... 133

Index .............................................................................................................................. 135

7

Page 8

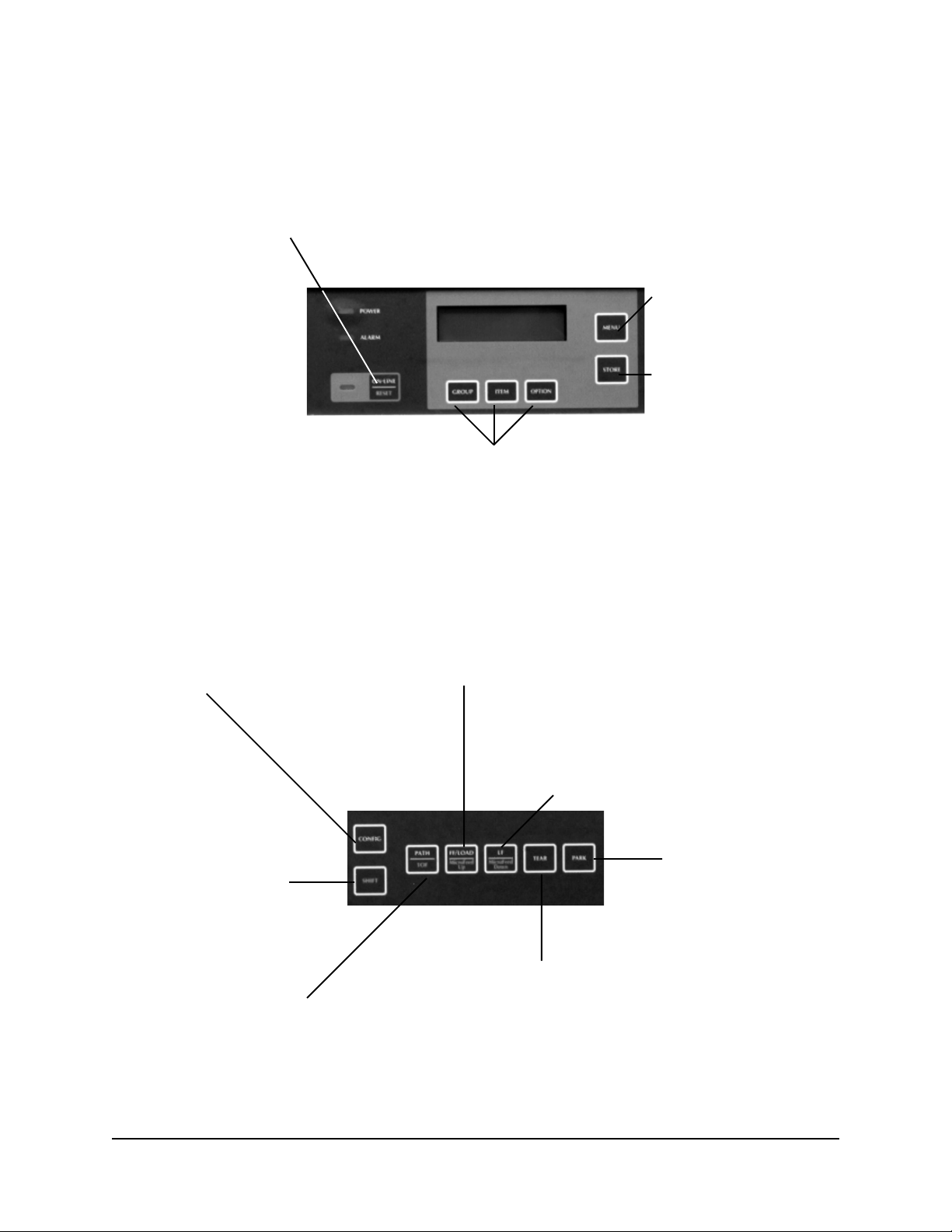

Print Mode: Indicator Lights

Power Light:

On/off: printer on/off.

Alarm Light:

On: printer error such as paper out, paper jam, etc.

Blinking: printer error such as ROM/RAM error, spacing error, etc.

1: Front Panel

Status Light:

On: printer is ready to receive data

Blinking: printer in Print Suppress mode

8

Page 9

Print Mode: Control Panel Buttons

ON-LINE/RESET Button:

Press: switches printer on/off line.

With SHIFT, hold to reset printer.

With SHIFT and printer off-line, press to initialize printer.

GROUP / ITEM / OPTION Buttons:

For use in Menu Mode.

MENU Button:

Press to enter Menu mode.

STORE Button:

No function during printing

CONFIG Button:

With printer off-line and no data

being sent: press to switch between

menu configurations CFG1 and CFG2.

See Section 1 for information on how

to set CFG1 and CFG2.

SHIFT Button:

Press and hold to engage

alternate (lower) button

functions.

PATH/TOF Button:

With printer off-line:

Press to switch paper paths.

Hold to set current paper position as Top of Form.

FF/LOAD/Micro Feed Up Button:

Press to move paper to next Top of Form.

If paper is parked, press to feed paper into print position.

With SHIFT, press for fine line feeds (1/144-inch increments).

LF/Micro Feed Down Button:

Press to execute line feed.

With SHIFT, press for reverse fine line feeds

(1/144-inch increment).

PARK Button:

Press to park continuous

form currently in paper

path.

TEAR Button:

Press to move form up to tear position

9

Page 10

Menu Mode: Control Panel Buttons

MENU Button:

Press to exit Menu mode.

With SHIFT, press to print out a listing of current Menu settings.

STORE Button:

Press to save the new

setting.

GROUP Button:

Press to page through available

groups in the menu.

With SHIFT, press to page

backwards through available

groups.

OPTION Button:

Press to pages through available setting values

for the selected item.

With SHIFT, press to page backwards through

available setting values.

ITEM Button:

Press to page through available items for the selected

group.

With SHIFT, press to page backwards through available

items.

10

Page 11

Menu Mode: Configuring Your Printer

Entering/Exiting the Menu Mode

To enter or exit the menu mode, press MENU.

Changing the Menu Settings

To change menu settings:

1.Press

2.Press

MENU to place the printer in the menu mode.

GROUP until the group in which you wish to make a change appears on the

second line of the display.

3.Press

4.Press

ITEM until the item which you wish to change appears on the display.

OPTION until the value you wish to set for that item appears on the second line

of the display.

5.Press

STORE to save the setting.

An asterisk (*) will appear next to the value on the display.

6.Repeat steps 2 through 5 for each item you wish to change in the menu.

7.Press

MENU to exit the menu mode.

For example, to change to 12 cpi pitch:

1.Press

2.Press

3.Press

MENU.

GROUP until Font appears on the display.

ITEM until Pitch appears on the display.

4.Press

5.Press

OPTION until 12 CPI appears on the display.

STORE.

An asterisk (*) appears next to 12 CPI.

6.Press

MENU.

Saving Configurations

You can establish two user-defined groups of menu settings—CFG1 and CFG2—then

switch back and forth between them.

When you first start up your printer, both CFG1 and CFG2 are set to the same settings as

the factory settings. You will see CFG1 (Configuration 1) at the end of the second line of

the printer display.

If you enter the menu and change settings, the new settings will automatically be stored

under the configuration—CFG1 or CFG2—which appears on the second line of the

display when you make the changes.

11

Page 12

You can change either CFG1 or CFG2 back to the factory settings at any time: see

“Resetting the Menu” below.

Note: The following menu items cannot be set separately for CFG1 and CFG2:

Registration 1 through Registration 7 in the Set-Up group.

Switching Back and Forth between Configurations

To switch from CFG 1 to CFG 2, or vice versa:

1.Press

2.Press

ON-LINE/RESET to place the printer off-line.

CONFIG.

The CFG designation on the second line of the display changes.

3.Press

ON-LINE/RESET to place the printer back on-line.

The new CFG designation appears on the second line of the display.

Resetting the Menu

You can reset the menu to the original factory settings, or engage one of the user-set

values—CFG1 or CFG2—as the default.

To switch to a particular set of values, turn the printer off then:

To engage: Press and hold while turning printer on:

Factory Settings

OPTION + STORE

CFG1 Settings as default GROUP + ITEM

CFG2 Settings as default ITEM + OPTION

Printing a List of Menu Items

To print out a listing of the current menu settings:

1. Press

2. Press

3. Press

ON-LINE/RESET to place the printer off-line.

MENU to enter the menu.

SHIFT and MENU at the same time.

The menu prints.

4. Press

ON-LINE/RESET to exit the menu and place the printer back on-line.

12

Page 13

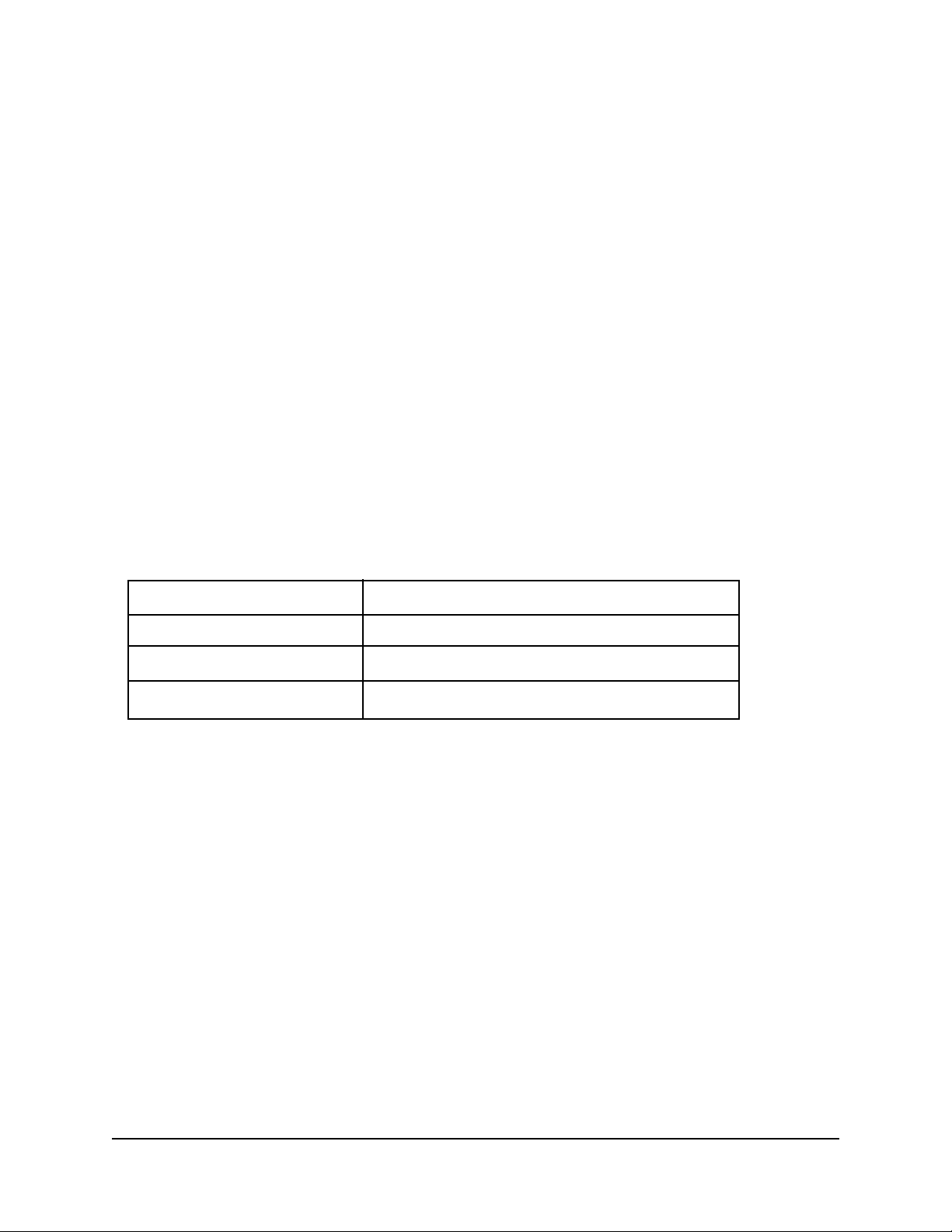

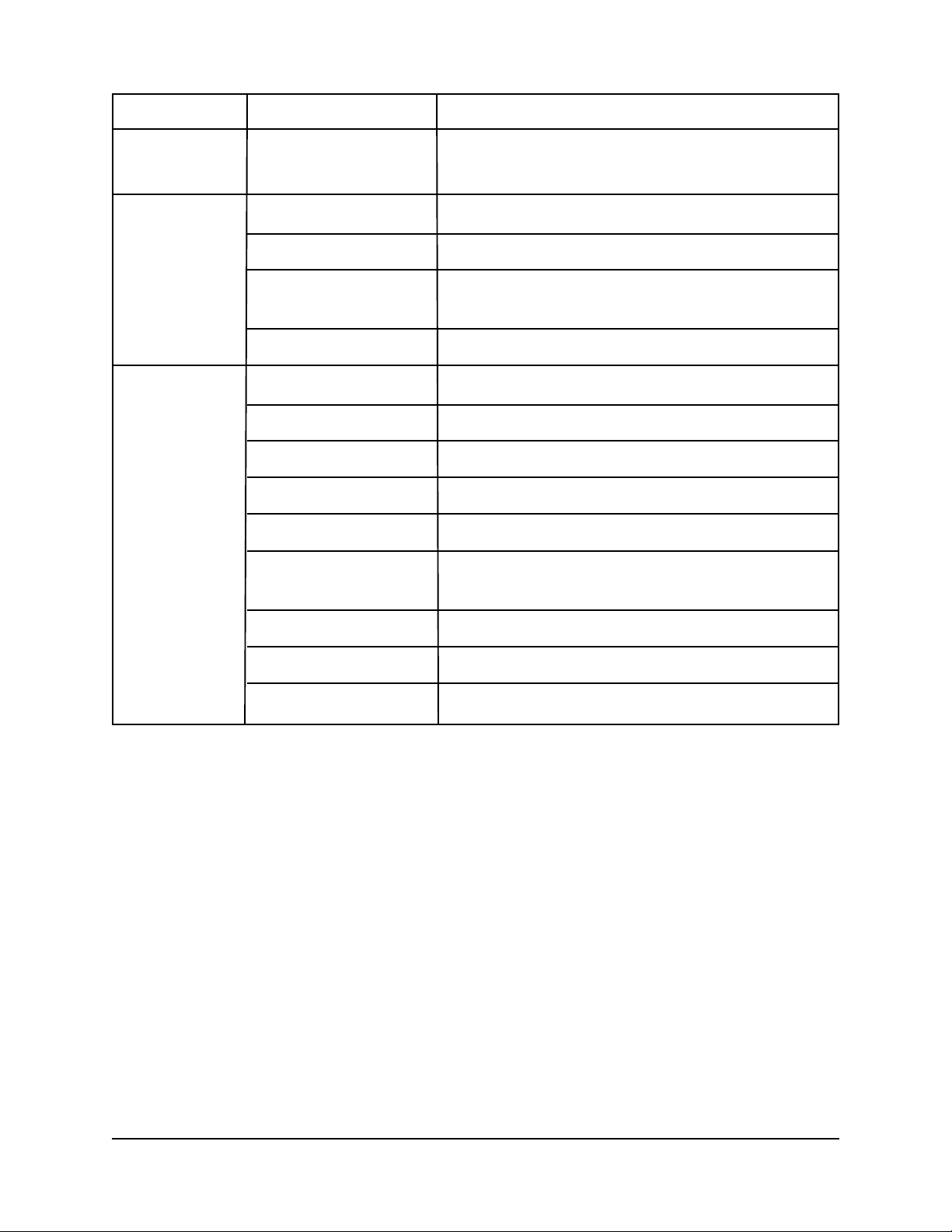

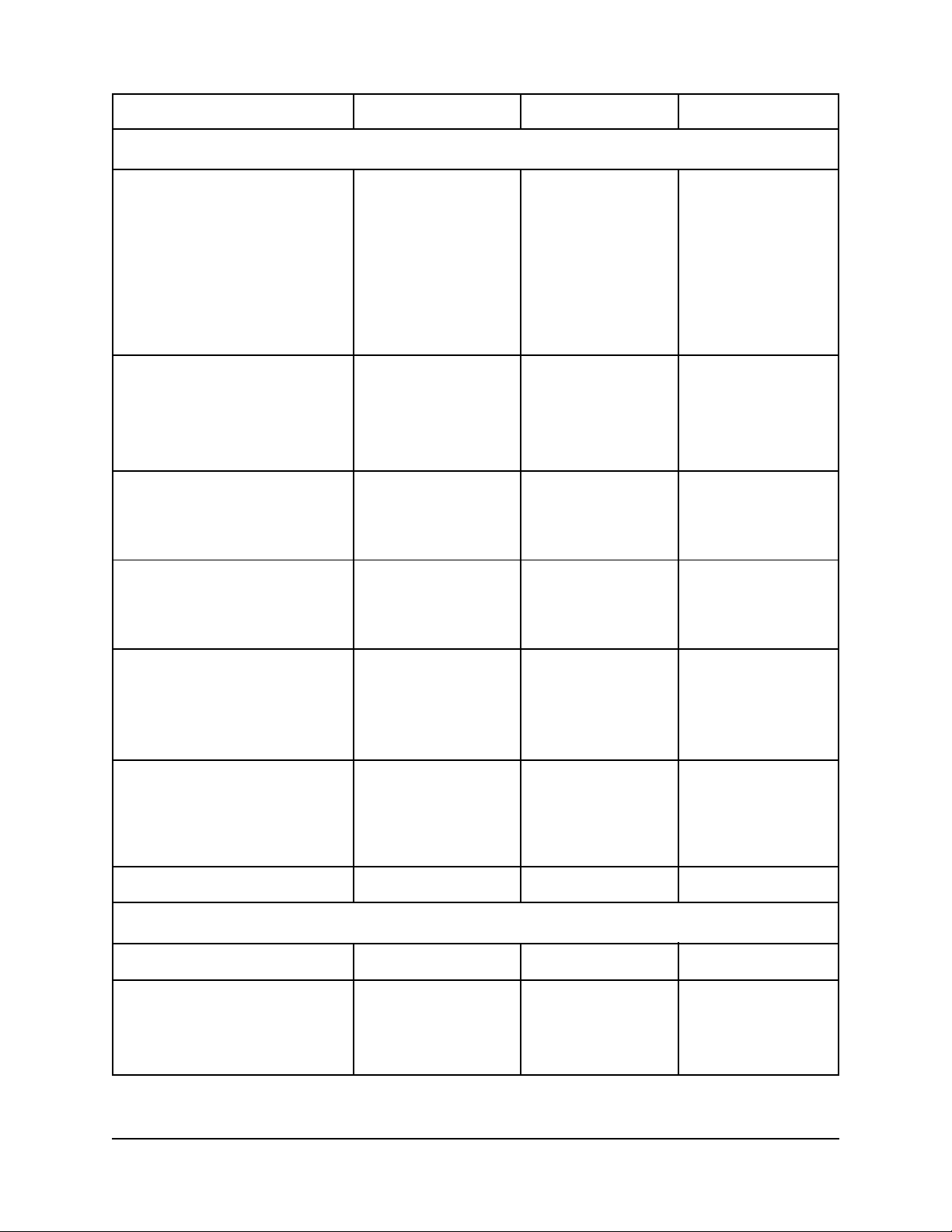

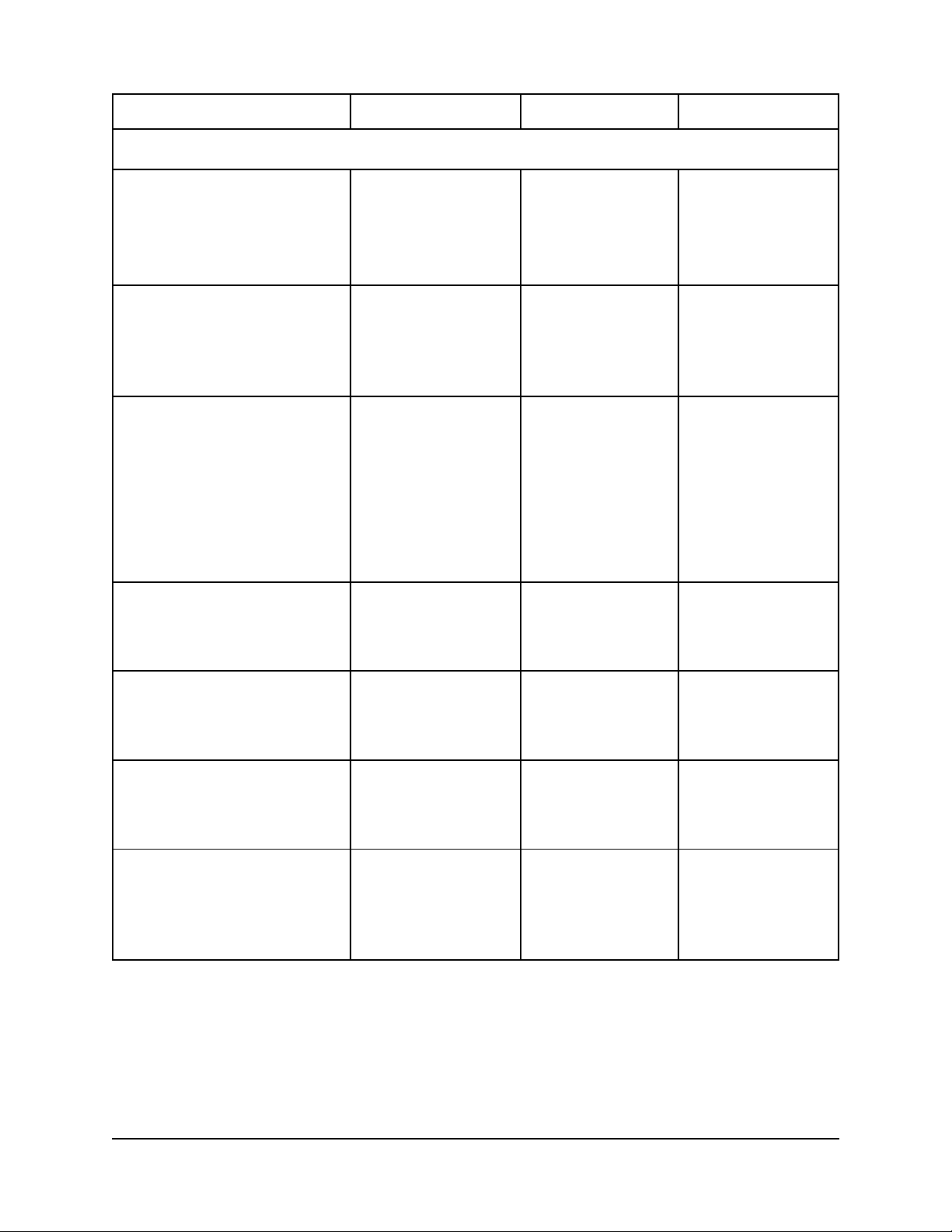

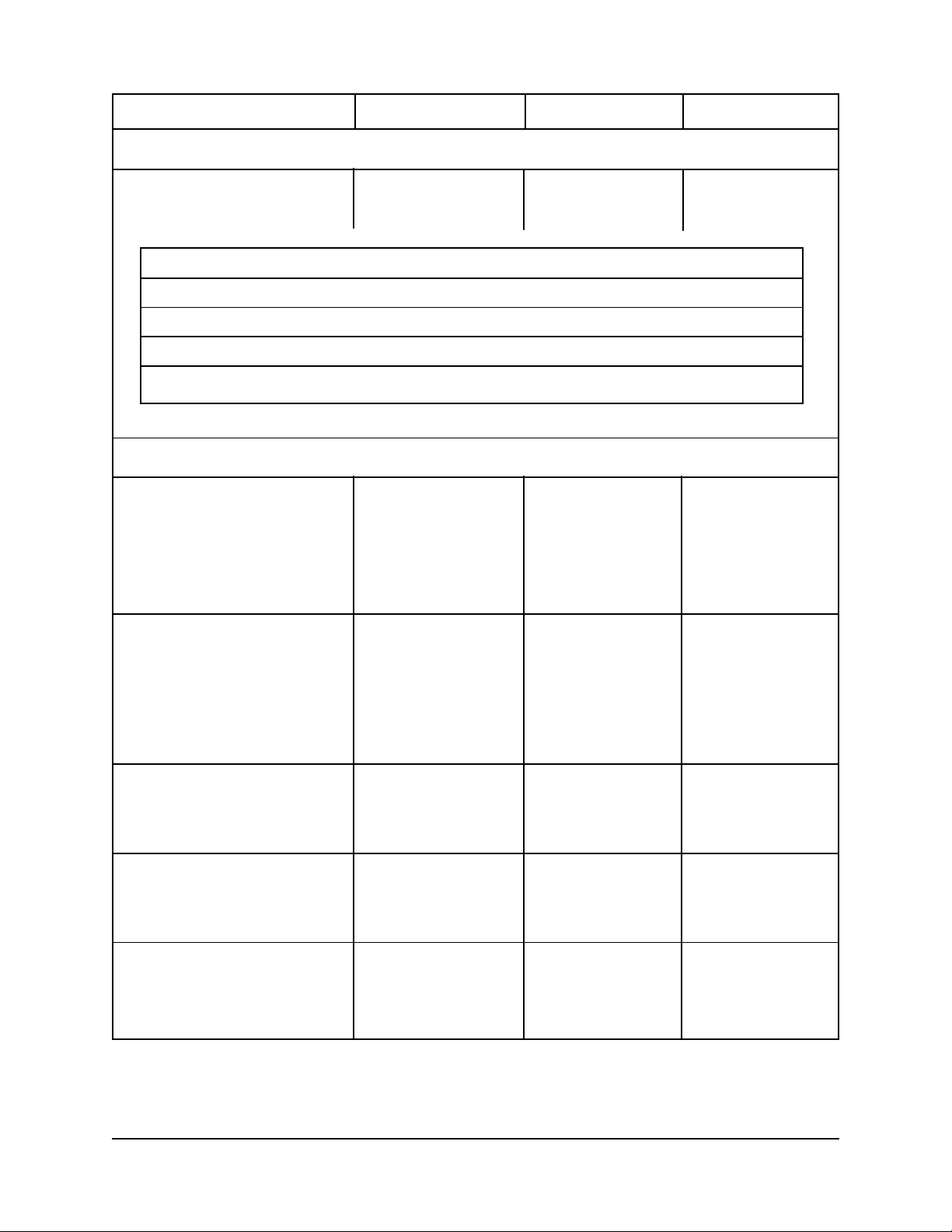

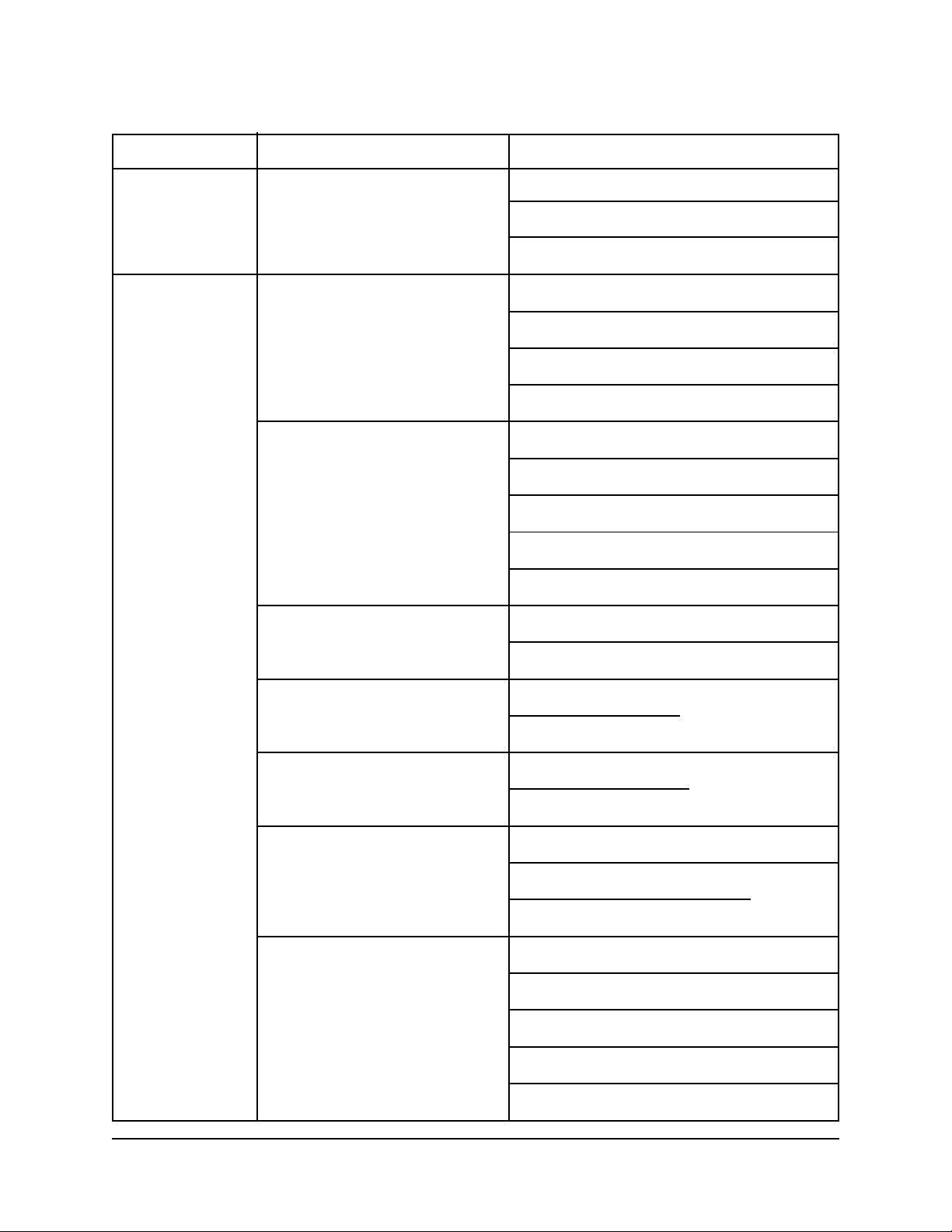

Summary of Menu Settings

Note: Factory settings are indicated by bold italics.

Group Item Settings

Printer Control Emulation Mode IBM-PPR, EPS-FX, OKI-ML

Font Print Mode Utility, NLQ Courier, NLQ Gothic, HSD

Pitch 10 CPI, 12 CPI, 15 CPI, 17.1 CPI, 20 CPI

Prop. Spacing No, Yes

Style Normal, Italics

Size Single, Double

Symbol Sets Character Set Set I (IBM/Epson), Set II (IBM/Epson),

Standard (ML), Line Graphics (ML),

Block Graphics (ML)

Language Set American, French, German, British, Danish I,

Swedish, Italian, Spanish I, Japanese, Norwegian,

Danish II, Spanish II, Latin American,

French Canadian, Dutch, Publisher

Zero Character Slashed, Unslashed

Code Page USA, Canada French, Multilingual, Portugal,

Norway, BRASCII, Abicomp, Multilingual 858,

ISO 8859/15

Rear Feed Line Spacing 6 LPI, 8 LPI

Form T ear-Off Off, 500ms, 1 sec, 2 sec

Skip Over Perf. No, Yes

Page Width 13.6", 8"

Page Length 11", 11-2/3", 12", 14", 17", 3", 3.5", 4", 5", 5.5",

6", 7", 8", 8.5"

13

Page 14

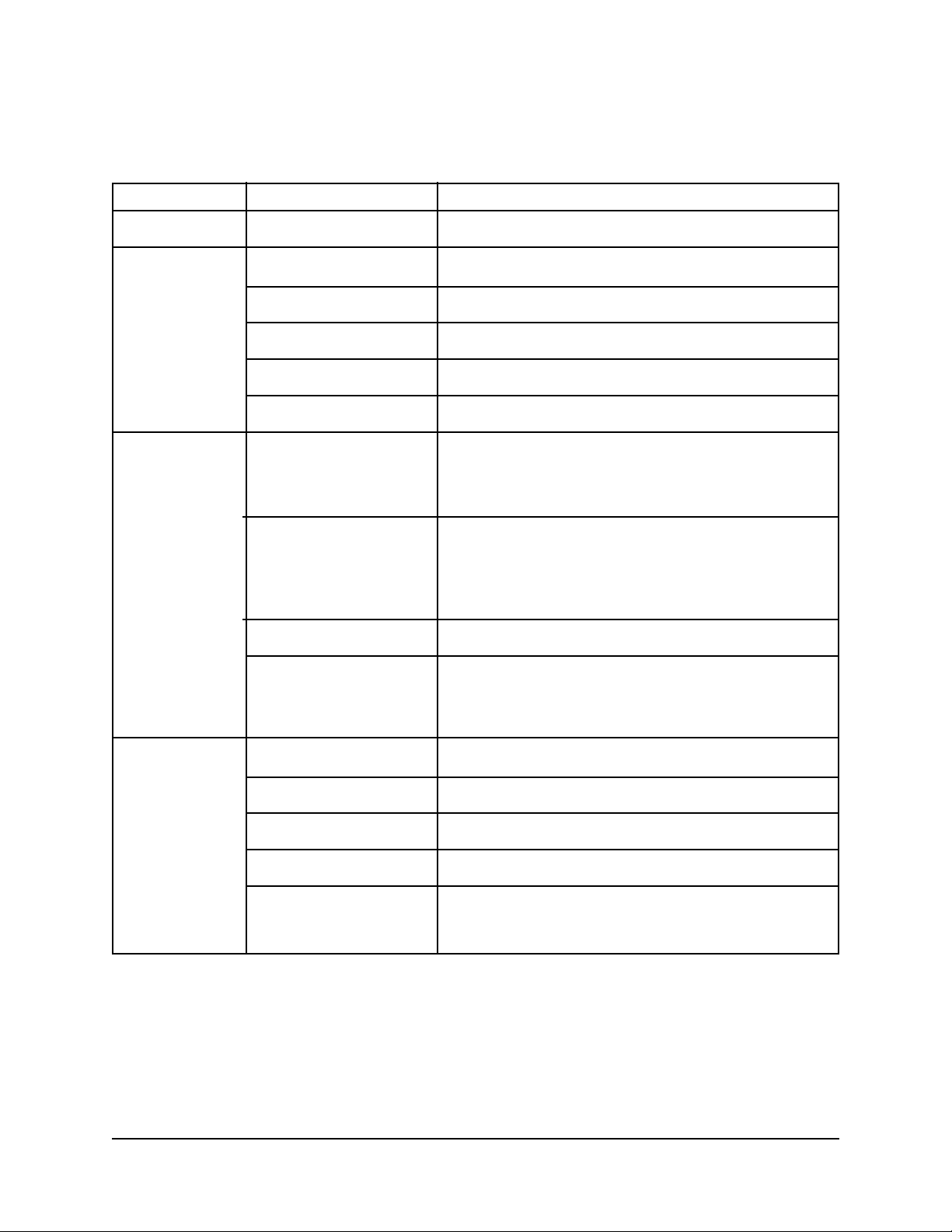

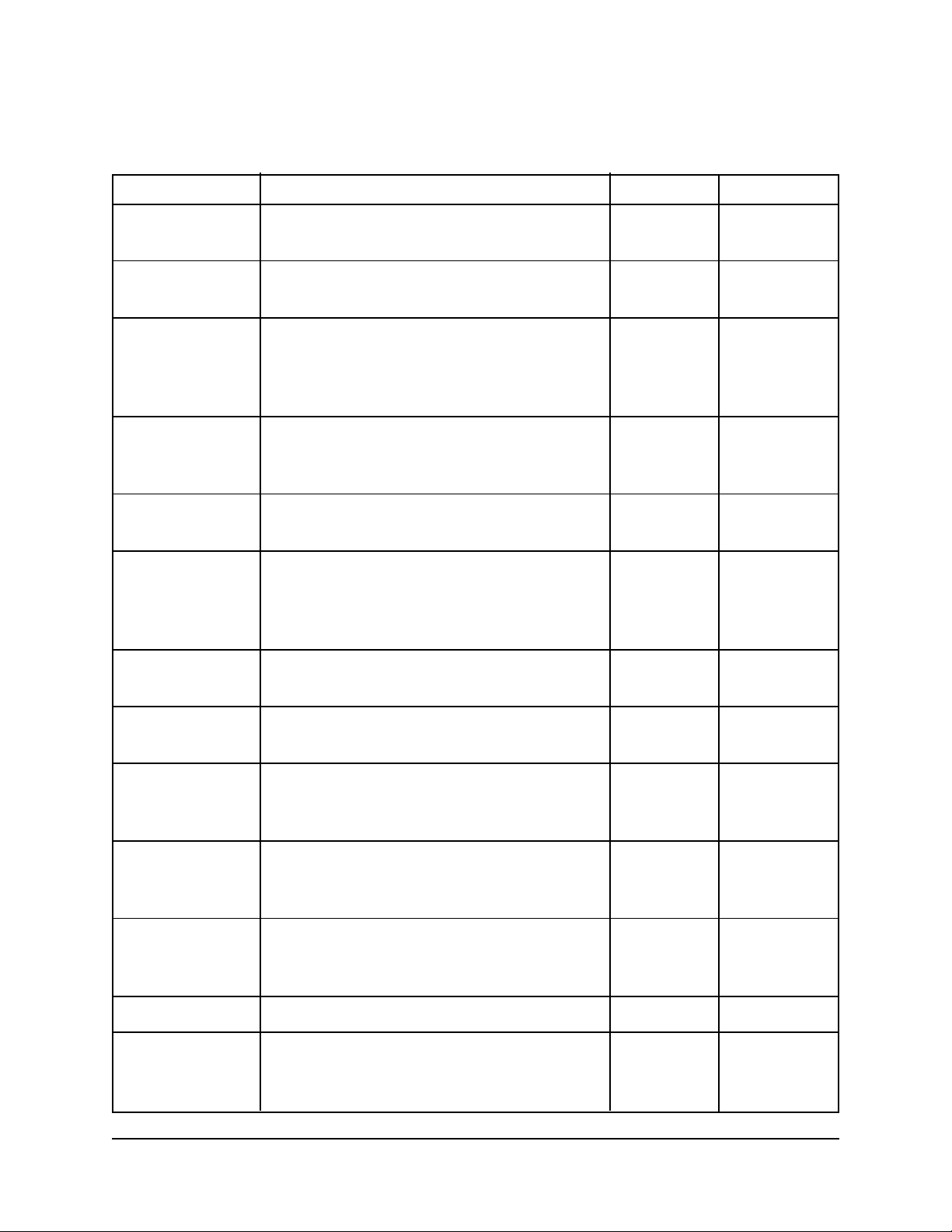

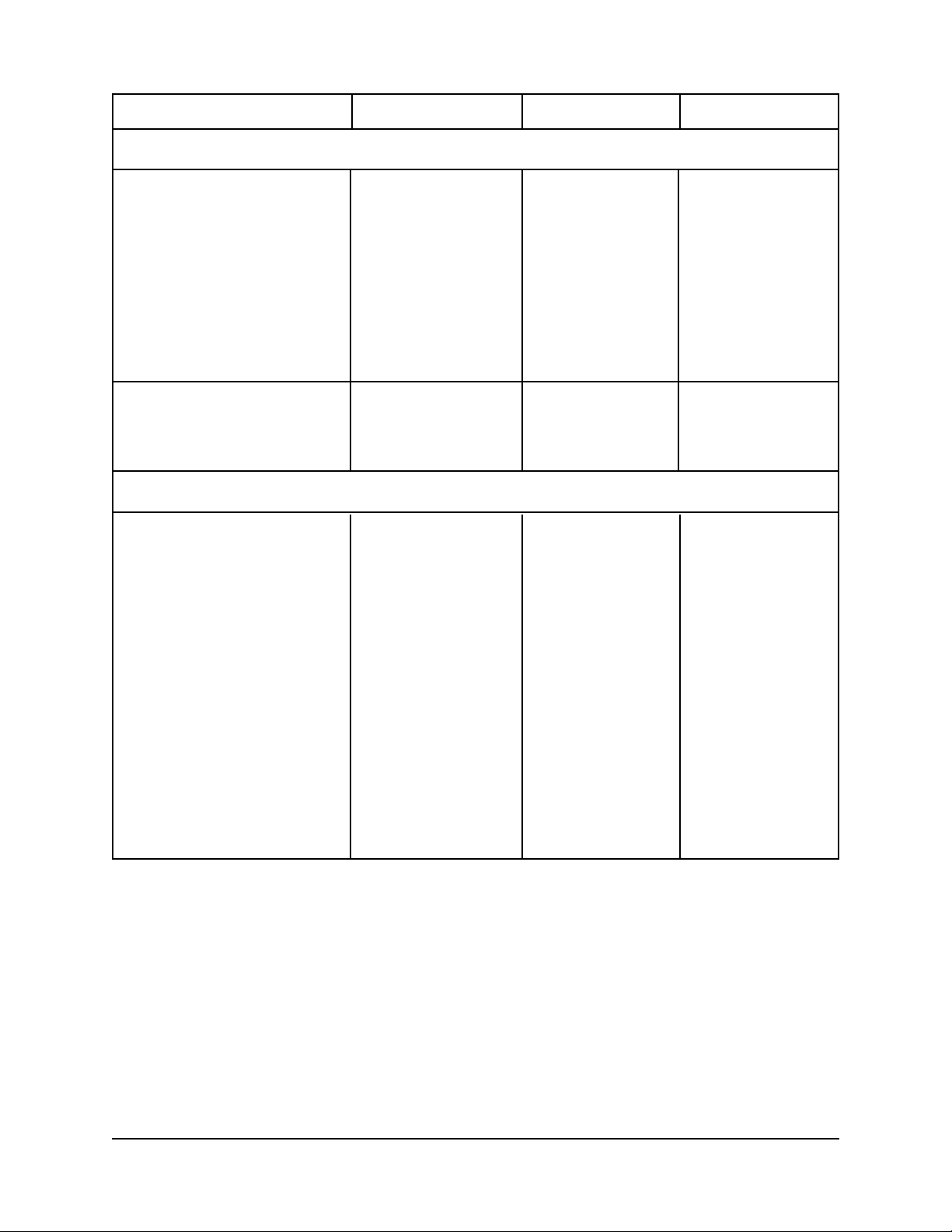

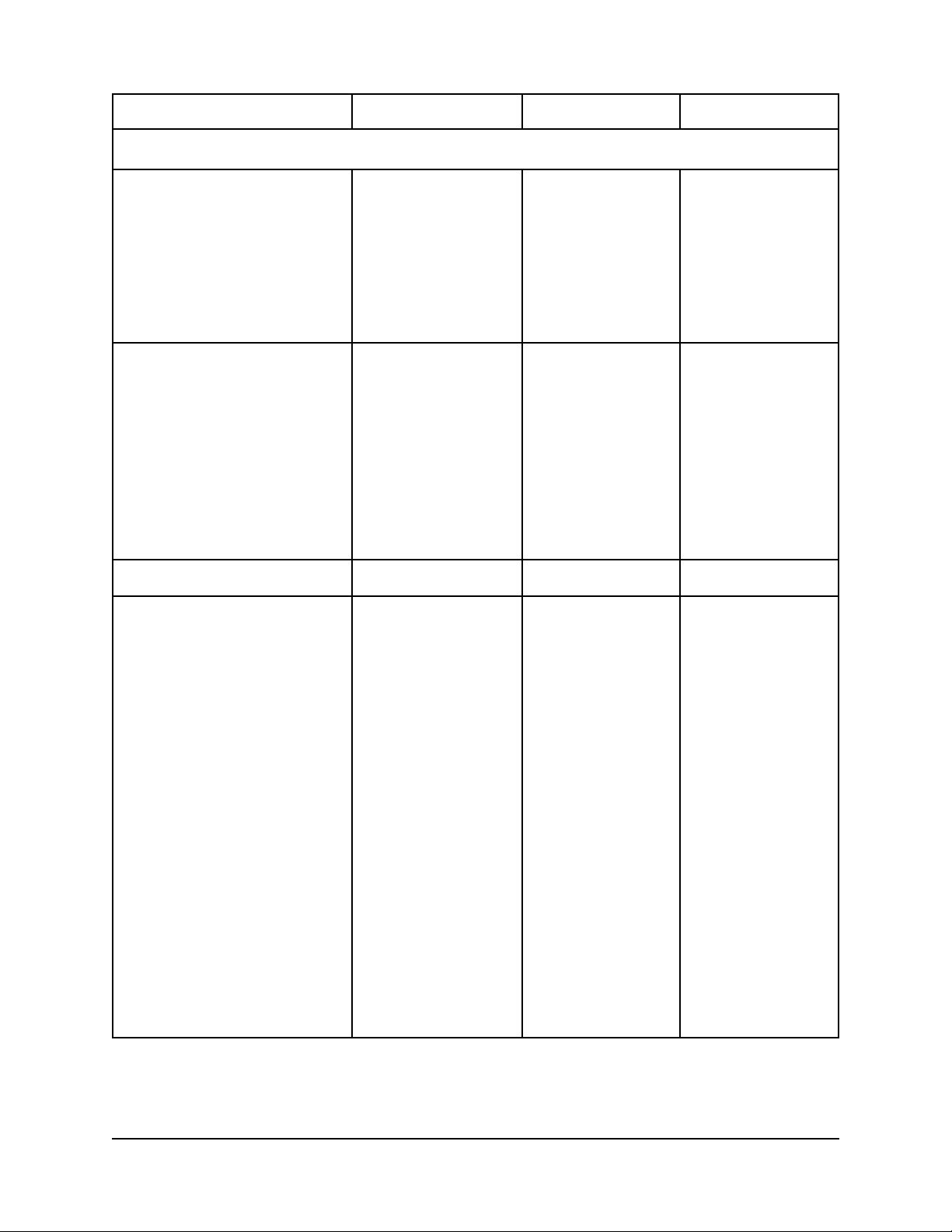

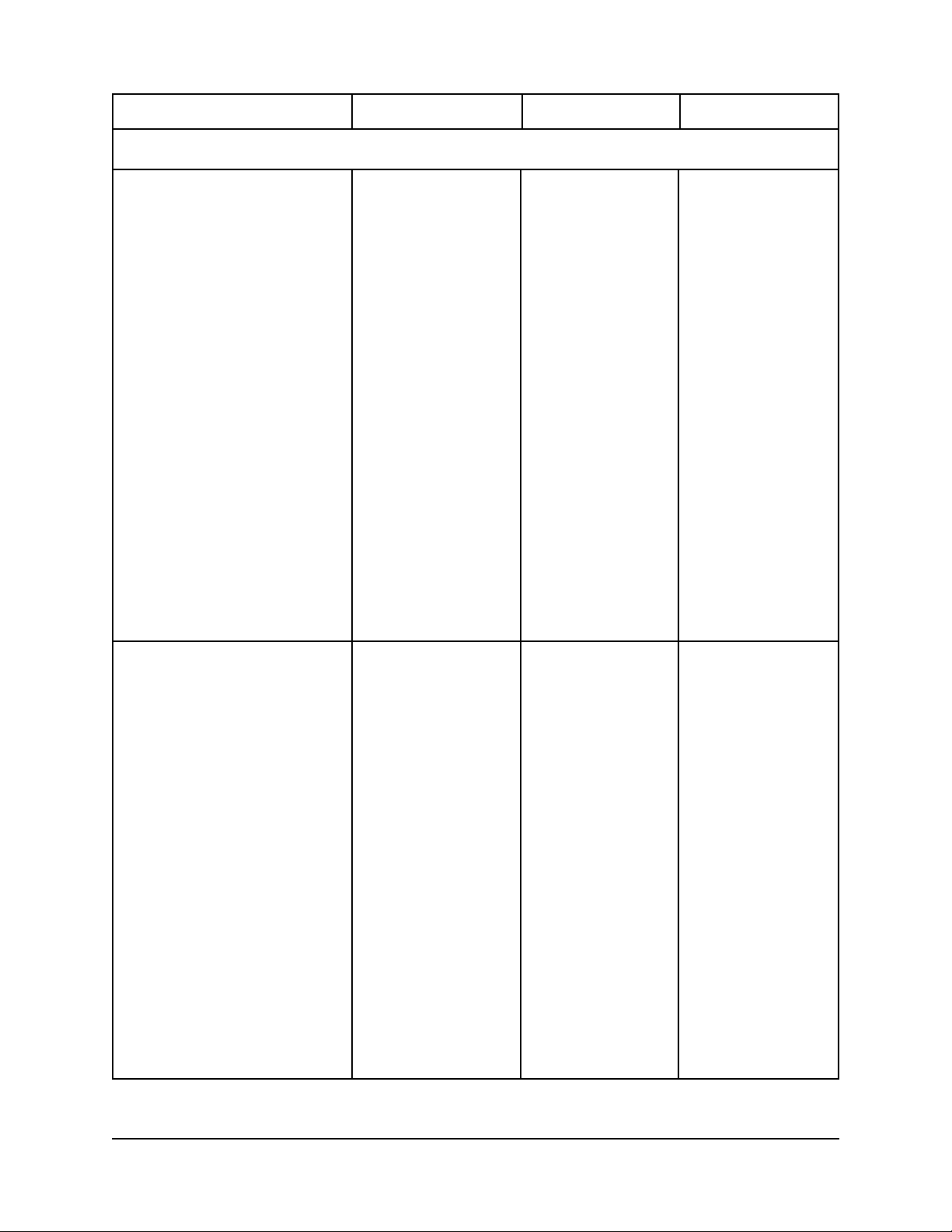

Group Item Settings

Front Feed Line Spacing 6 LPI, 8 LPI

Form Tear-Off Off, 500ms, 1 sec, 2 sec

Skip Over Perf. No, Yes

Page Width 13.6", 8"

Page Length 11", 11-2/3", 12", 14", 17", 3", 3.5", 4", 5", 5.5",

6", 7", 8", 8.5"

Set-Up Graphics Bi-directional, Uni-directional

# Graphic Bits 8, 7

[ML emulation only]

Rcv. Buffer 1 Line, 16K, 28K, 56K (No DLL)

Ppr Out Override No, Yes

Registration 1 0.25 mm Right, 0.20 mm Right, 0.15 mm Right,

0.10 mm Right, 0.05 mm Right, 0, 0.05 mm

Left, 0.10 mm Left, 0.15 mm Left, 0.20 mm

Left, 0.25 mm Left.

Registration 2 0.25 mm Right, 0.20 mm Right, 0.15 mm Right,

0.10 mm Right, 0.05 mm Right, 0, 0.05 mm

Left, 0.10 mm Left, 0.15 mm Left, 0.20 mm

Left, 0.25 mm Left.

Registration 3 0.25 mm Right, 0.20 mm Right, 0.15 mm Right,

0.10 mm Right, 0.05 mm Right, 0, 0.05 mm

Left, 0.10 mm Left, 0.15 mm Left, 0.20 mm

Left, 0.25 mm Left.

Registration 4 0.25 mm Right, 0.20 mm Right, 0.15 mm Right,

0.10 mm Right, 0.05 mm Right, 0, 0.05 mm

Left, 0.10 mm Left, 0.15 mm Left, 0.20 mm

Left, 0.25 mm Left.

Registration 5 0.25 mm Right, 0.20 mm Right, 0.15 mm Right,

0.10 mm Right, 0.05 mm Right, 0, 0.05 mm

Left, 0.10 mm Left, 0.15 mm Left, 0.20 mm

Left, 0.25 mm Left.

Registration 6 0.25 mm Right, 0.20 mm Right, 0.15 mm Right,

0.10 mm Right, 0.05 mm Right, 0, 0.05 mm

Left, 0.10 mm Left, 0.15 mm Left, 0.20 mm

Left, 0.25 mm Left.

14

Page 15

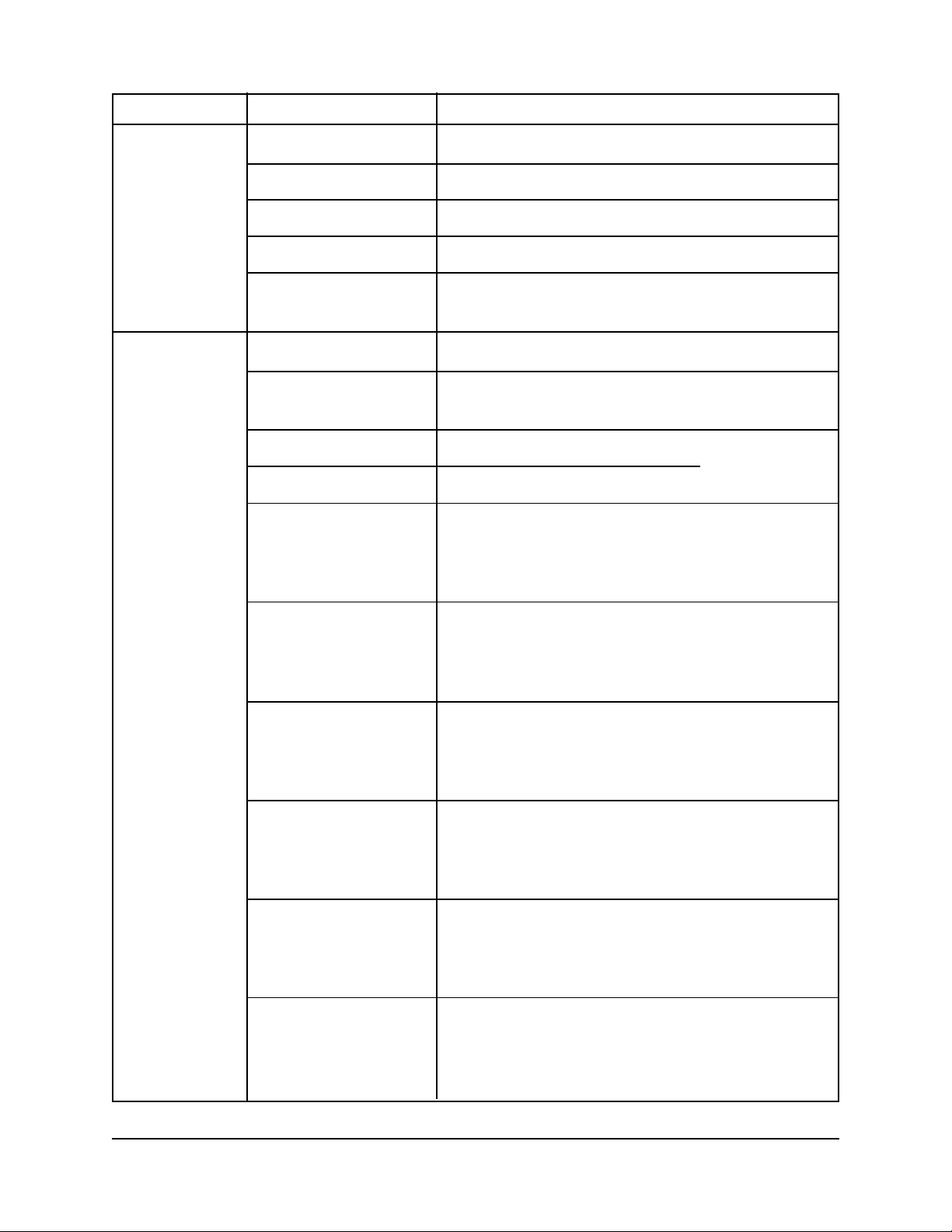

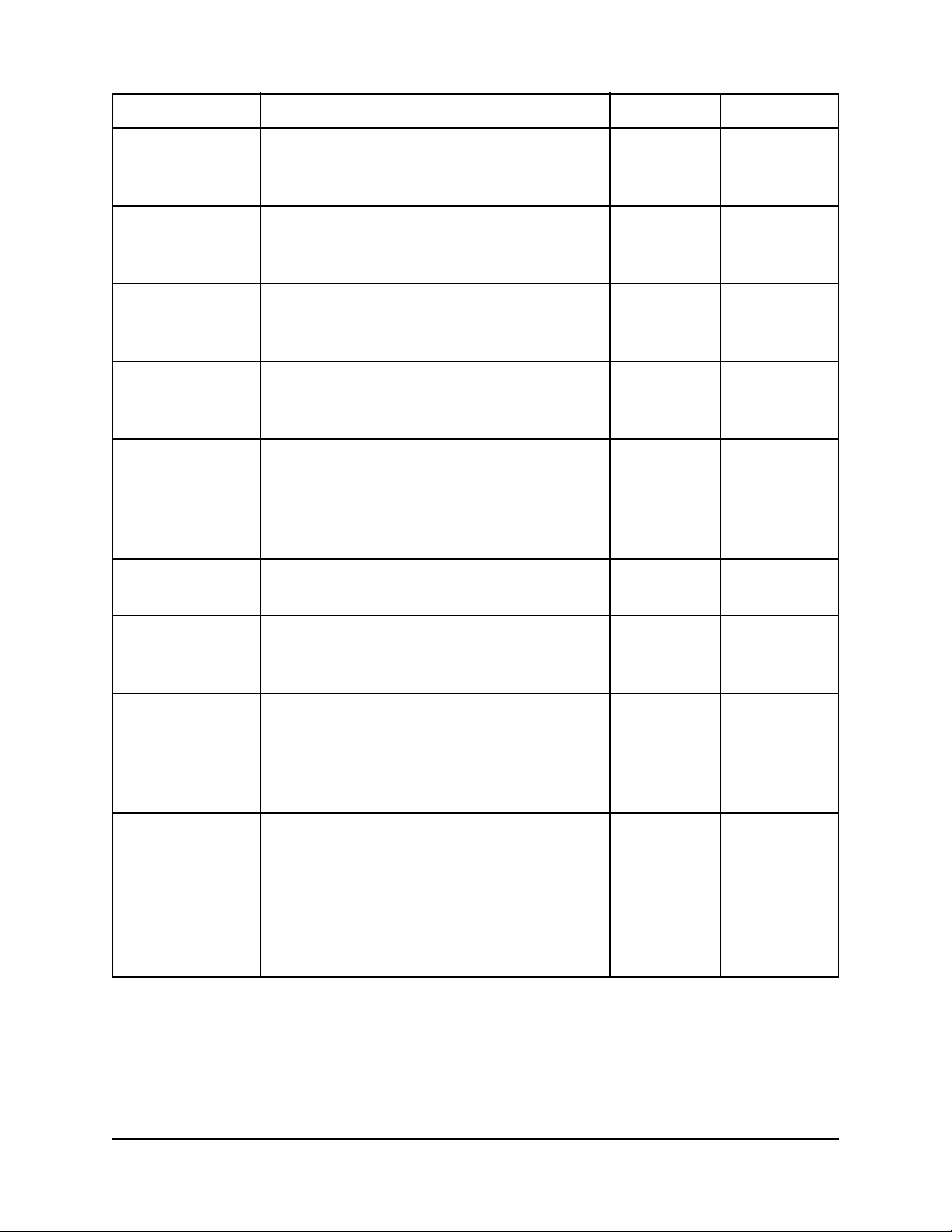

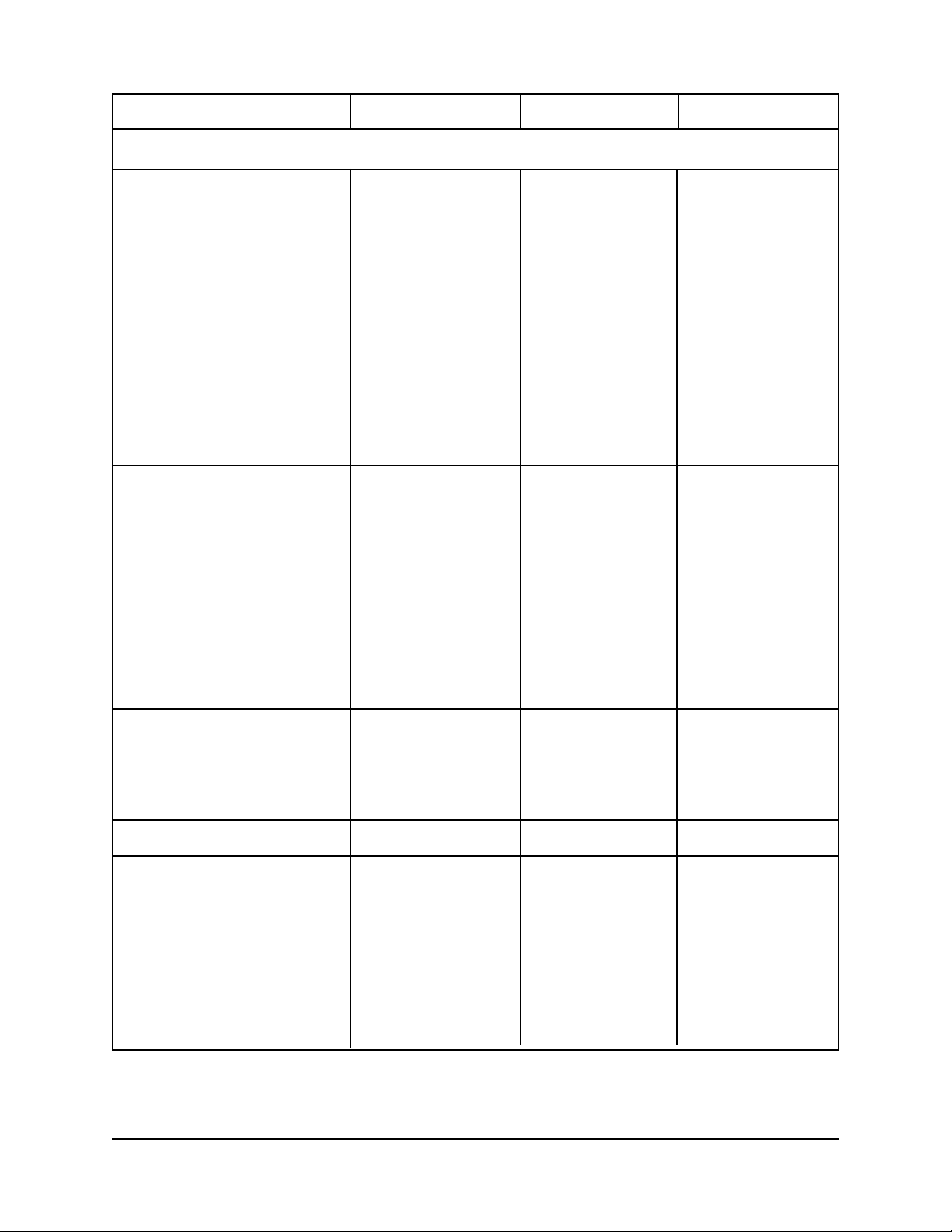

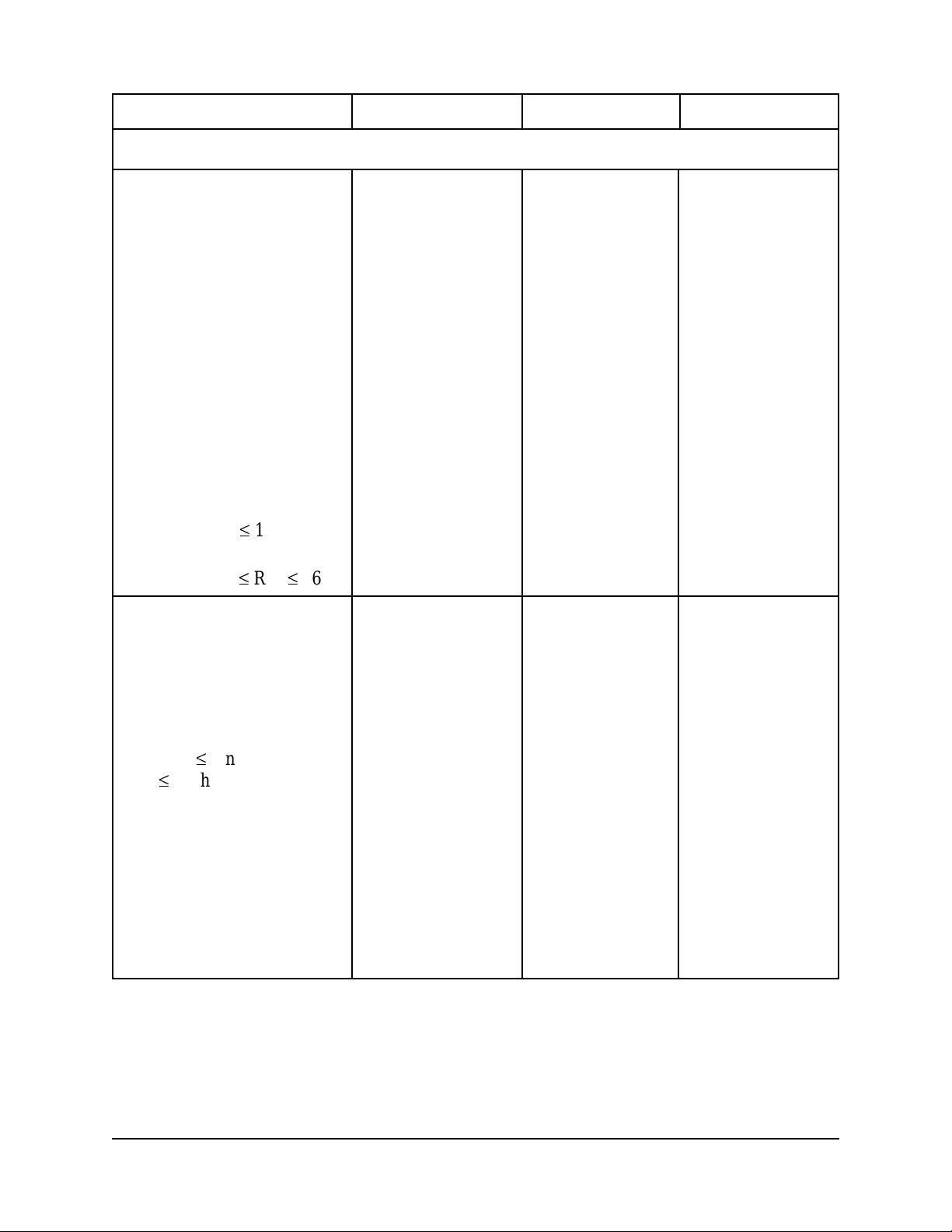

Group Item Settings

Set-Up (cont.) Registration 7 0.25 mm Right, 0.20 mm Right, 0.15 mm Right,

0.10 mm Right, 0.05 mm Right, 0, 0.05 mm

Left, 0.10 mm Left, 0.15 mm Left, 0.20 mm

Left, 0.25 mm Left.

Data W ord Size 8, 7

[ML emulation only]

Op. Panel Function Full Operation, Limit Operation

Reset Inhibit No, Yes

Print Suppress No, Yes

Auto LF No, Yes

Auto CR No, Yes

[ML emulation only]

Print DEL Code No, Yes

[ML emulation only]

SI Pitch (10) 15 CPI, 17.1 CPI

[IBM emulation only]

SI Pitch (12) 12 CPI, 20 CPI

[IBM emulation only]

Time Out Print Valid, Invalid

Auto Select No, Yes

ESC SI Pitch 17.1 CPI, 20 CPI

[IBM emulation only]

Intr Chr Sub St Combined, Code Page Only

[Epson emulation only]

Host Interface Auto Interface, Parallel, Serial,

OKI HSP (print server installed),

Opt. Card (optional card installed)

I/F Time Out 15 sec, 30 sec, 45 sec, 1 min, 2 min, 3 min, 4 min,

5 min

Default Path Current Path, Rear Path, Front Path

Auto Path Invalid, Valid

Impact Mode Normal, Quiet, Hi-Impact Copy

15

Page 16

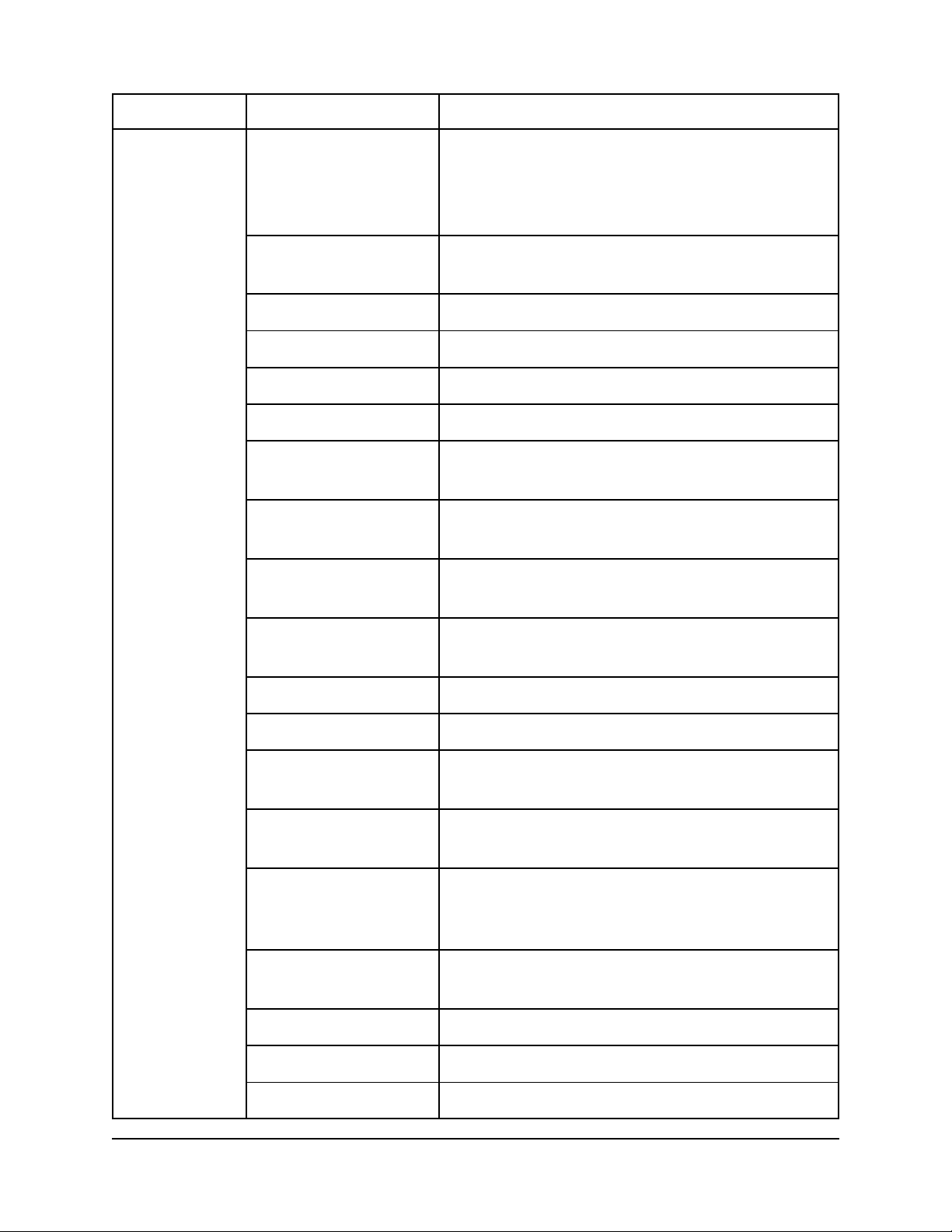

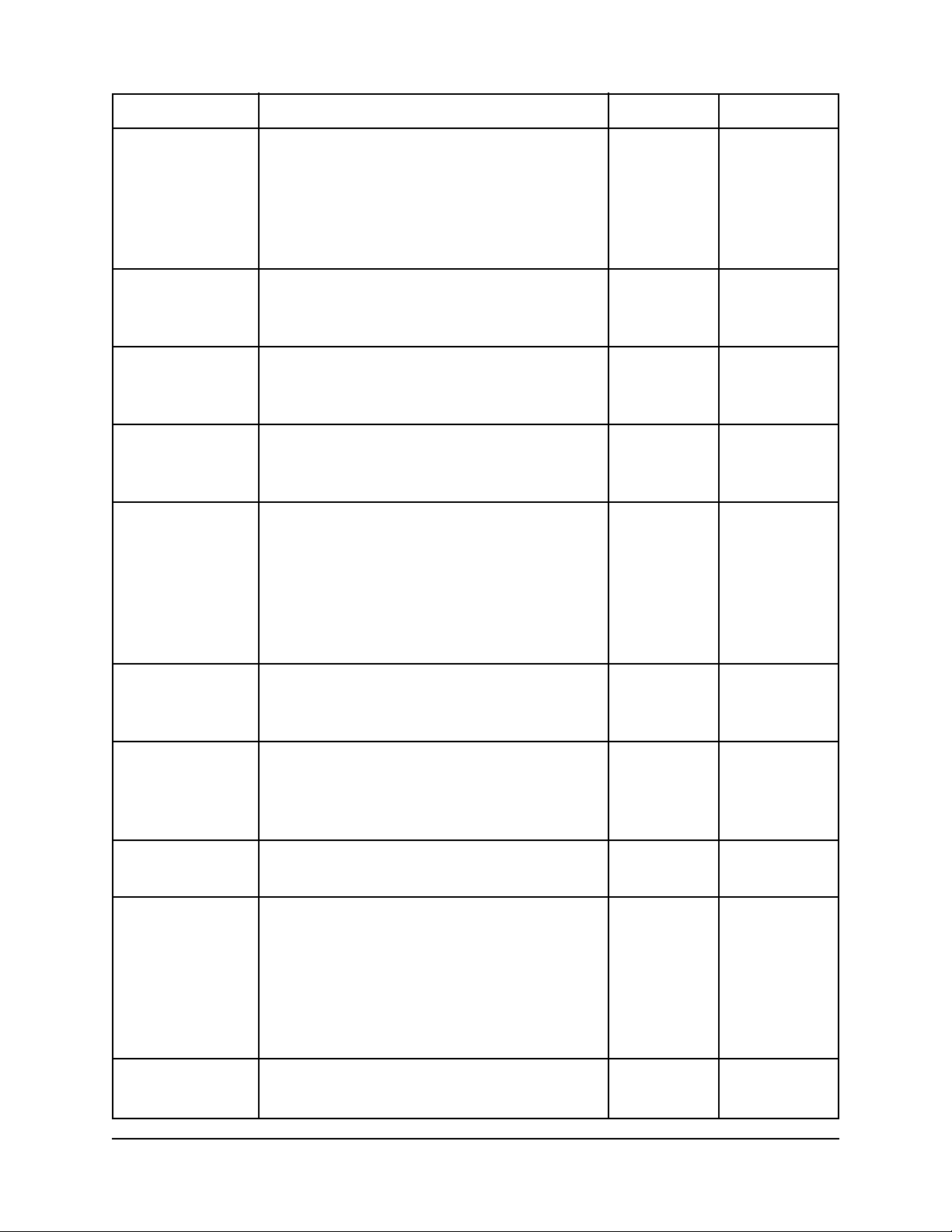

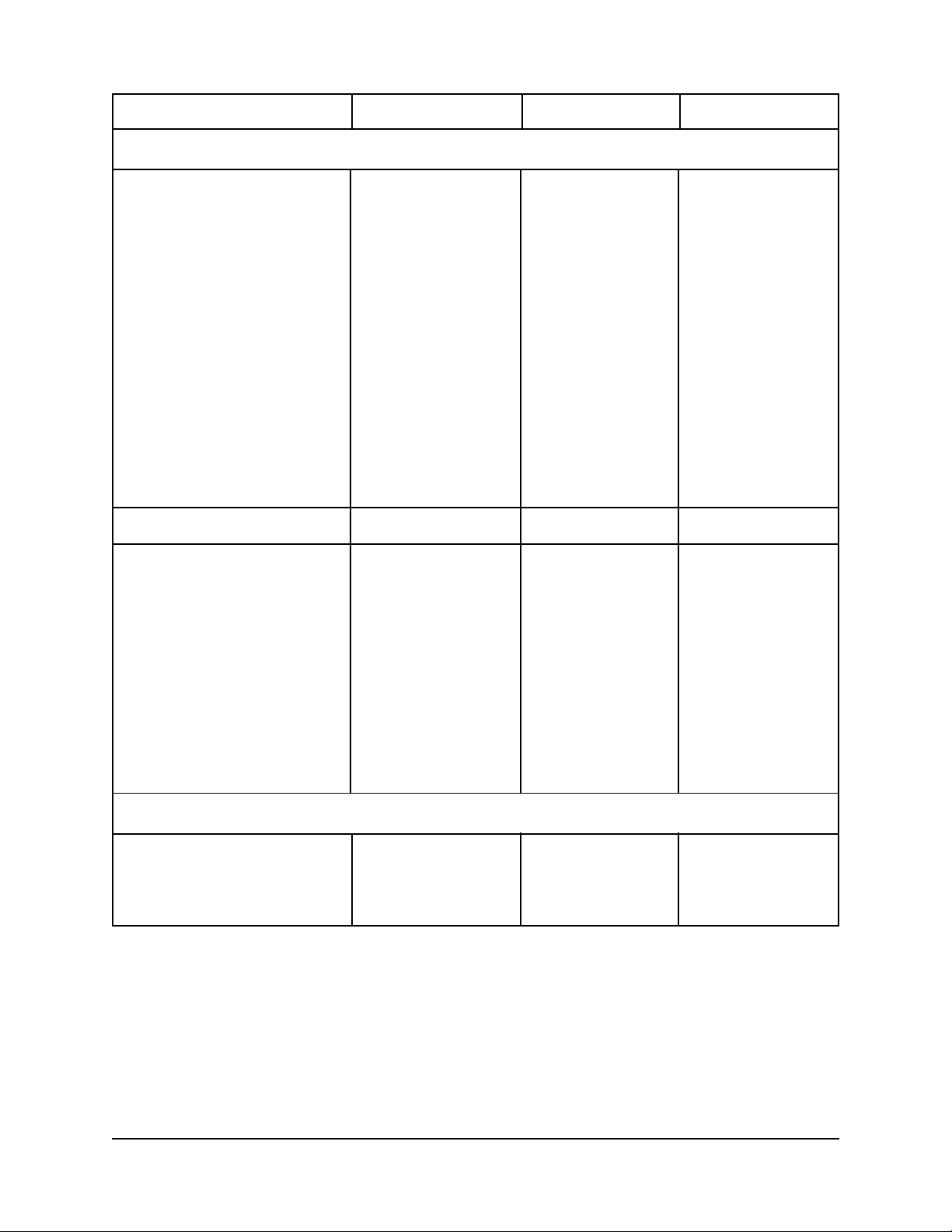

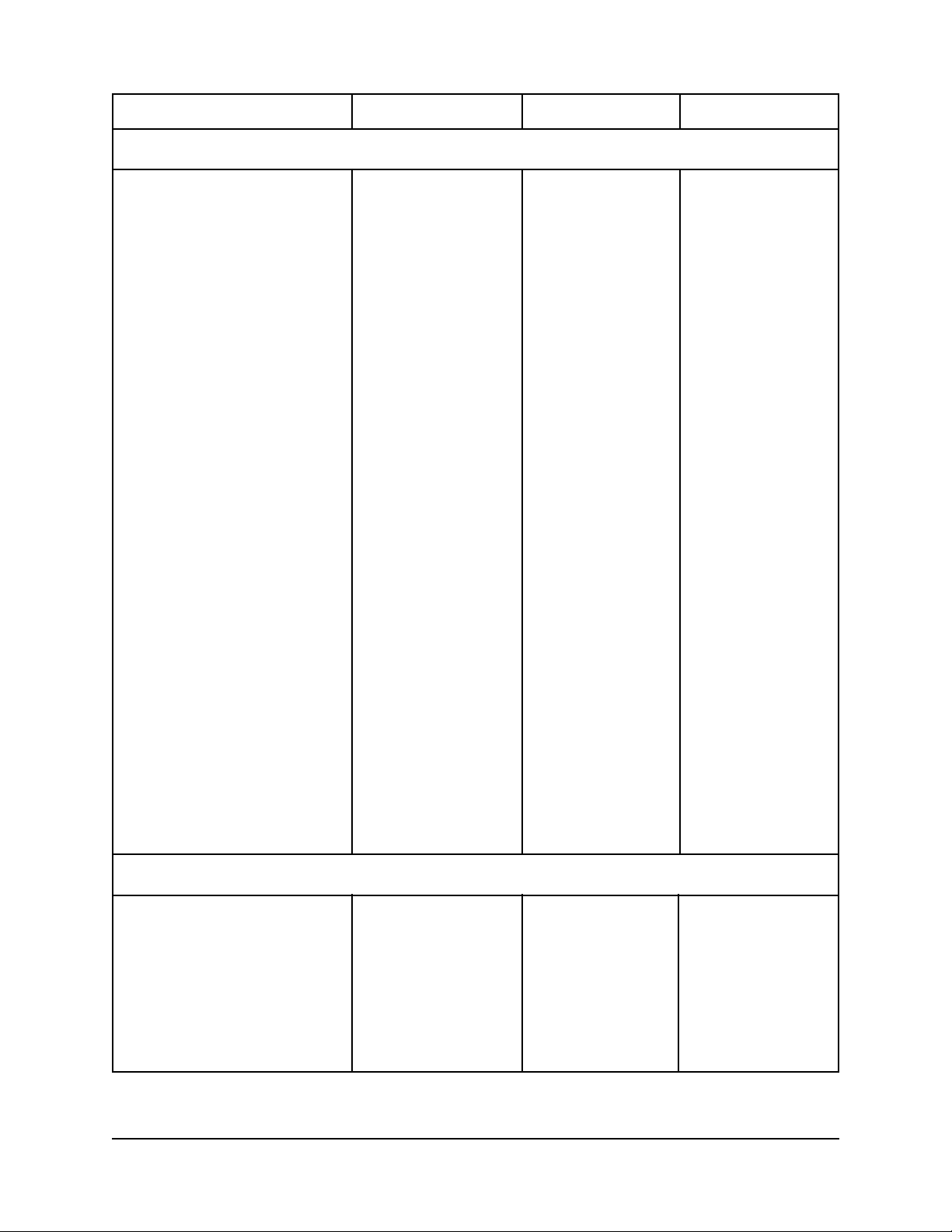

Group Item Settings

Set-Up (cont.) LF Speed Fast, Slow

Width Control Invalid, Mode 1, Mode 2

Parallel I/F I-Prime Invalid, Buffer Print, Buffer Clear

Pin 18 +5V, Open

Auto Feed XT Valid, Invalid

[Epson emulation only]

Bi-Direction Enable, Disable

Serial I/F Parity None, Odd, Even

# Serial Bits 8 Bits, 7 Bits

Protocol Ready/Busy, X-ON/X-OFF

Diagnostic T est No, Y es

Busy Line SSD-, SSD+, DTR, RTS

Baud Rate 9600 BPS, 4800 BPS, 2400 BPS, 1200 BPS,

600 BPS, 300 BPS, 19200 BPS, 38400 BPS

DSR Signal Valid, Invalid

DTR Signal Rdy on Pwr Up, Ready on Select

Busy Time 200 ms, 1 sec

16

Page 17

Explanation of Menu Settings

The items in the table below are arranged in alphabetical order.

Item Description Emulations Group(s)

# Graphic Bits Choose the graphics your system uses: ML only Set-Up

7 or 8 dots in each column printed.

# Serial Bits Change to 7 Bits if your system uses a All Serial I/F

7-bit data format.

Auto CR If you want the printer to automatically add IBM only Set-Up

a carriage return when a Line Feed is

received at the end of a line, change the

setting to Yes.

Auto Feed XT If your system uses pin 14 of the parallel Epson only Parallel I/F

interface to control automatic line feed,

change the setting to Valid.

Auto LF If your printout is consistently double All Set-Up

spaced, select No; if it overprints, select Yes.

Auto Path Invalid = paper path controlled by software; All Set-Up

Valid = paper path controlled by printer;

paper automatically switches to the alternate

path when current paper runs out.

Auto Select If you always use the same Top of Form All Set-Up

position, change the setting to Valid.

Baud Rate Sets the data transmission speed for the All Serial I/F

serial interface.

Bi-Direction Change to disable if you wish to All Parallel I/F

disengage bi-directional communication at

the parallel interface.

Busy Line If the Ready/Busy protocol (factory setting) All Serial I/F

is selected, use this to select which line your

system monitors for a busy signal.

Busy Time Sets the length of the busy signal when the All Serial I/F

Ready/Busy protocol (factory setting) is

engaged.

Character Set Determines the character set the printer uses. All Symbol Sets

Code Page Sets the Code Page set the printer uses: All Symbol Sets

which selections appear depends on the

emulation selected.

17

Page 18

Item Description Emulations Group(s)

Data Word Size If your computer system uses seven bits ML only Set-Up

to make up each unit of data, change this

setting to 7.

Default Path Change to Rear Path or Front Path if you All Set-Up

wish the printer to use that paper path

as its default.

Diagnostic Test Change to Yes if you want to perform a All Serial I/F

diagnostic test of the serial interface

(see Appendix B: Interfacing).

DSR Signal Used with Ready/Busy protocol (factory All Serial I/F

setting) to determine the way your system

handles the DSR (Data Set Ready) signal.

DTR Signal Change to Ready on Select if the DTR All Serial I/F

(Data Terminal Ready) signal is required

when the printer is selected; leave as

Ready on Power Up if the DTR signal is

required when the printer is turned on.

Emulation Mode Sets the printer emulation. Not Printer

applicable Control

ESC SI Pitch Sets the character pitch used when the IBM only Set-Up

ESC SI command is received by the

printer .

Form Tear-Off Select 500 ms, 1 second, or 2 seconds to All Rear Feed,

turn the Form Tear-Off feature on and to Front Feed

set the time interval for the printer to wait

before advancing the paper to the tear-off

position.

Graphics Change to uni-directional printing to All Set-Up

improve alignment between print lines

when printing graphics. This will slow

down the printing. Alternately, you can

leave Bi-directional enabled and optimize

graphics printing by adjusting the print

registration setting in the Set-Up group.

18

Page 19

Item Description Emulations Group(s)

Host Interface If you wish to select a dedicated interface All Set-Up

rather than having the printer automatically

detect the interface being used, select

parallel, serial, OKI HSP (appears only if

the print server is installed), or Opt. Card

(appears only if optional card is installed).

I/F Time Out Sets the length of time the printer will All Set-Up

wait for additional data to be received

at the interface.

Impact Mode Change to Quiet for minimum sound; All Set-Up

change to Hi-Impact Copy for forms

thicker than 7-part carbonless.

Intr Chr Sub St International Character Sub Set: change Epson only Set-Up

to Code page Only if you wish the

printer to ignore the Language Set.

I-Prime Determines what the printer will do All Parallel I/F

when it receives the I-Prime signal from

the software: Buffer Print prints out the

buffer contents before resetting; Buffer

Clear dumps the buffer contents

immediately . Invalid causes the printer

to ignore the I-Prime command.

Language Set Replaces certain standard symbols with All Symbol Sets

special characters used in foreign

languages.

LF Speed Change to Slow if you wish to reduce the All Set-Up

speed with which the printer executes the

line feed command when using thicker

forms.

Line Spacing Change to 8 lines per inch to get more All Rear Feed,

lines per page. Front Feed

Op. Panel Operator Panel Function: Change to All Set-Up

Function Limited Operation to deactivate the

MENU, GROUP, ITEM, OPTION,

STORE and CONFIG buttons. This

prevents these from being changed from

the control panel when several people

are using the printer.

Page Length Sets the length of the continuous forms All Rear Feed,

you are using. Front Feed

19

Page 20

Item Description Emulations Group(s)

Page Width Change to 8" if you are using 9-inch All Rear Feed,

continuous forms. For continuous forms Front Feed

less than 9 inches wide, the page width

must be set using software.

Caution! If the page width is set

narrower than the continuous forms

being used, the printhead will print

directly on the platen: this can

damage the printhead.

Parity Sets the type of parity your system uses. All Serial I/F

Pin 18 Sets the signal on pin 18 of the parallel All Parallel I/F

interface to +5 volts or to open.

Pitch Sets the character width in characters All Font

per inch.

Ppr Out Override Paper Out Override: Senses when less All Set-Up

than 1" (25 mm) of paper remains and

stops printing. Change to Yes to override

the sensor. Caution!! This can cause loss

of data and damage the printhead!

Print DEL Code Change to Yes if you wish to print the DEL ML only Set-Up

code (decimal 27) as a solid box.

Print Mode Sets the typeface used: Utility, NLQ All Font

(Near letter Quality) Courier, NLQ

(Near Letter Quality) Gothic, or

HSD (High Speed Draft).

Print Suppress If you wish to enable the print suppress All Set-Up

command, change the setting to Yes. If

you select Yes, the printer will ignore all

data after it receives the print suppress

command.

Prop. Spacing Change to yes if you wish to engage All Font

proportionally spaced printing.

Protocol Switch to X-ON/X-OFF if that is the All Serial I/F

serial interface protocol you are using.

Rcv . Buffer Sets the size of the receive buffer. All Set-Up

20

Page 21

Item Description Emulations Group(s)

Registration 1 Change the setting as required to obtain the All Set-Up

through best registration for bi-directional printing.

Registration 7 Each time you press OPTION, the next

setting appears on the display and the

printer prints a sample showing the

alignment for that setting. Press STORE to

select the setting with the best alignment

(asterisk appears next to the setting)

before exiting the menu.

Reset Inhibit Change to Yes to prevent your software All Set-Up

from resetting your printer’s settings.

SI Pitch (10) Sets the pitch to be engaged when the IBM only Set-Up

printer control panel is set for 10 cpi and

the SI command is received.

SI Pitch (12) Sets the pitch to be engaged when the IBM only Set-Up

printer control panel is set for 12 cpi and

the SI command is received.

Size Change to Double for double width and All Font

height printing.

Skip Over Perf. Change to Yes if you want the printer to All Rear Feed,

go to the next page when it comes within Front Feed

1" (25 mm) of the bottom of the page.

Keep it set to No if your software has its

own page formatting controls.

Style Change to italics if you want the printed All Font

characters to be slanted.

Time Out Print If your software spends a long time pro- All Set-Up

cessing between portions of data it feeds

to the printer, change the setting to Invalid

to keep your printer from printing the

received data while it is waiting for more.

Width Control Used to limit printhead travel. Select All Set-Up

Mode 1 to wrap print lines which exceed

the width of the paper. Select Mode 2 to

cut off the end of print lines which exceed

the width of the paper.

Zero Character If you do not want the printer to use a slash All Symbol Sets

to distinguish a zero from the capital letter

O, change the setting to Unslashed.

21

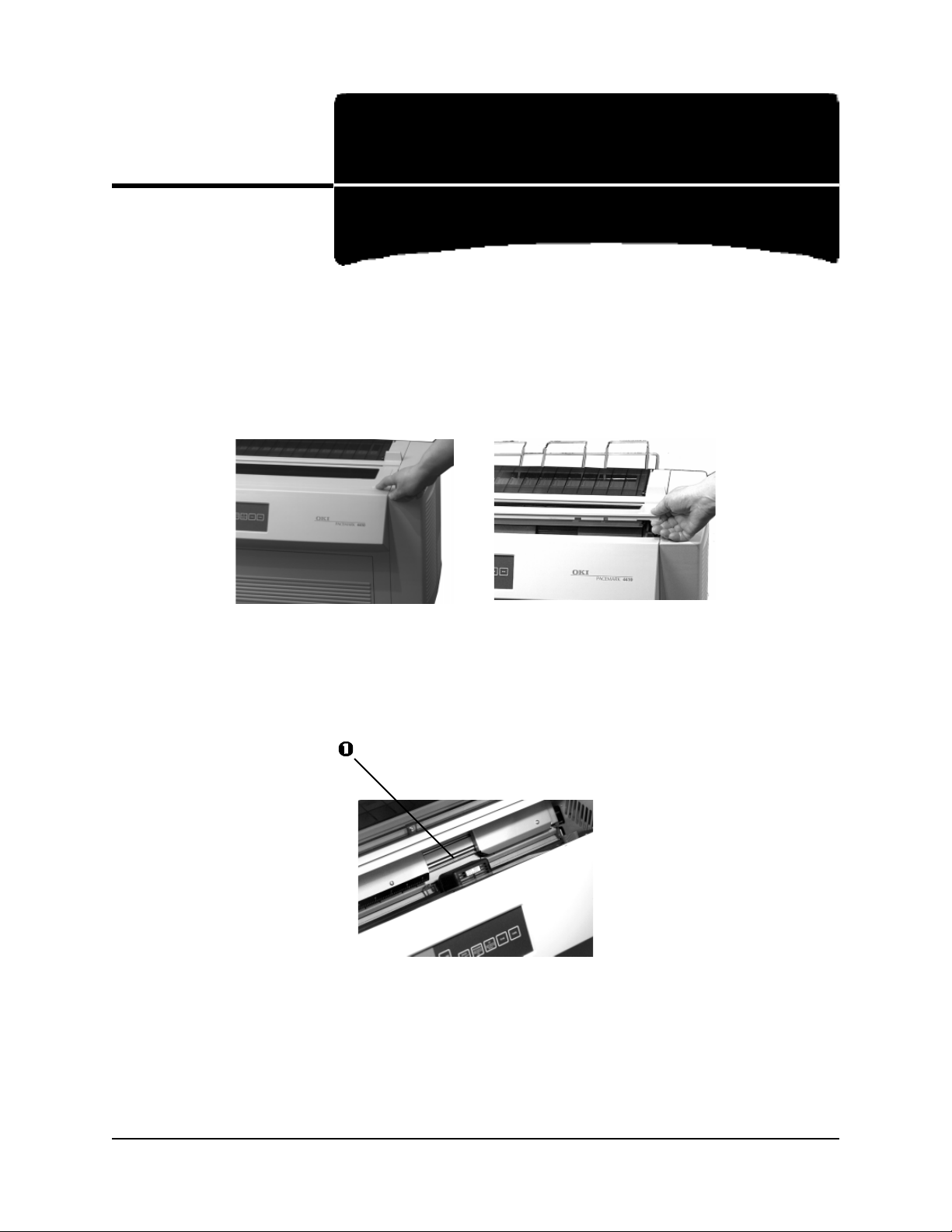

Page 22

2: Maintenance

Replacing the Ribbon

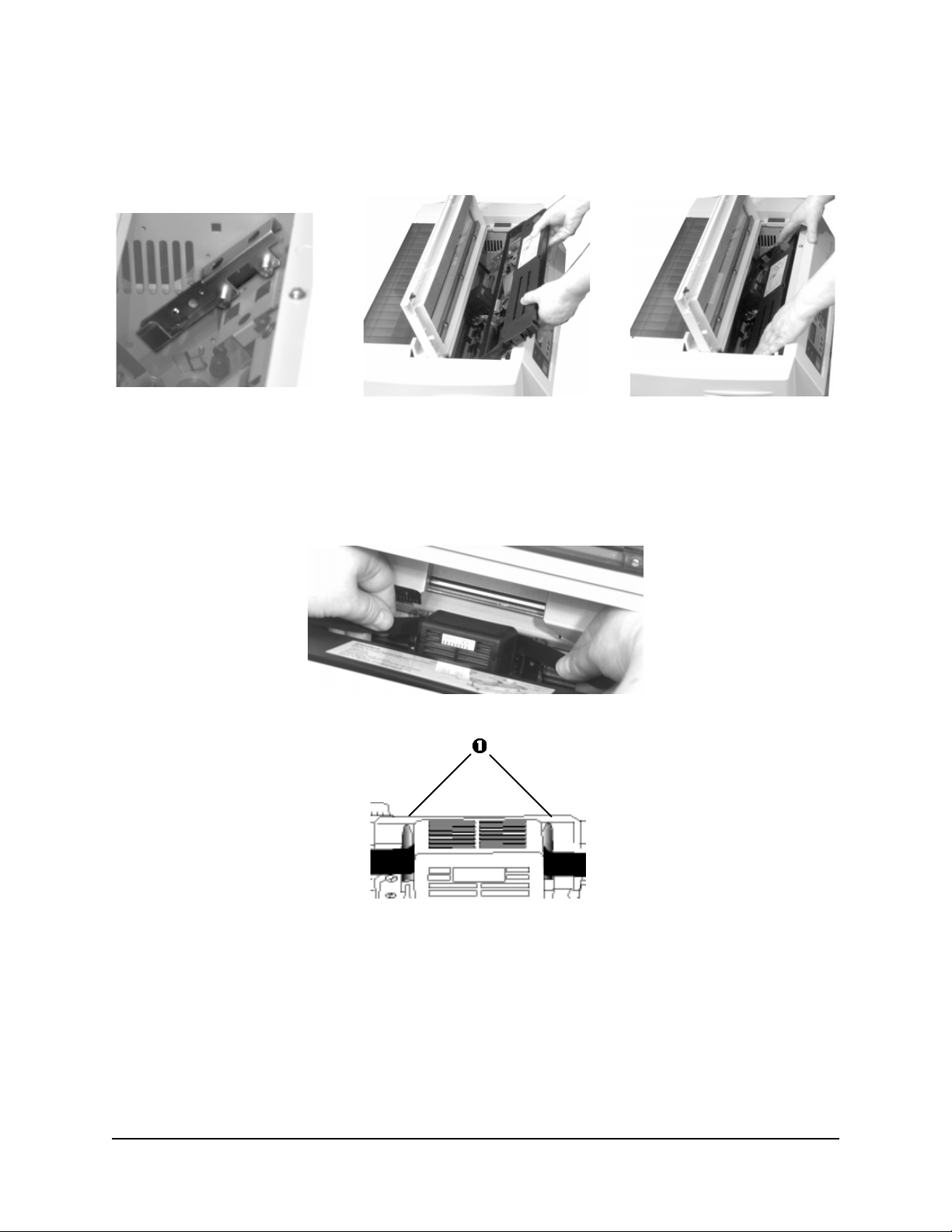

Remove the Old Ribbon

1.Turn the printer off, then press on the area(s) marked PUSH and open the printhead

access cover.

Caution! The printhead may be extremely HOT!

2.Move the printhead to the ribbon loading area (1).

22

Page 23

3.Unthread the ribbon from the printhead, then remove and discard the cartridge.

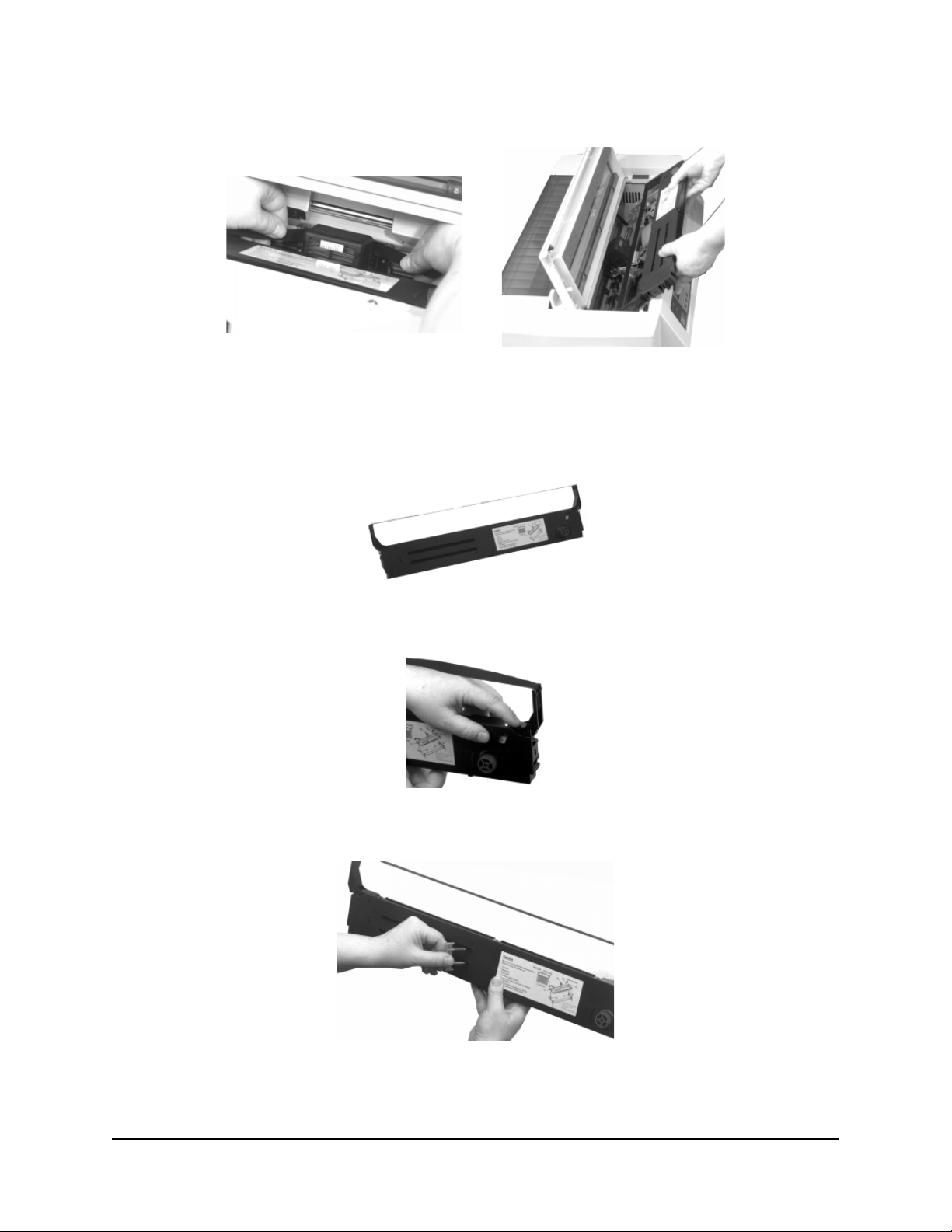

Prepare the New Ribbon

1.Open the new ribbon cartridge and swing out the ribbon arms at either end of the

ribbon cartridge until they snap into place.

2.Push in on the white plastic ribbon restraint at the right end of the cartridge.

3.Pull out the red shipping restraint.

23

Page 24

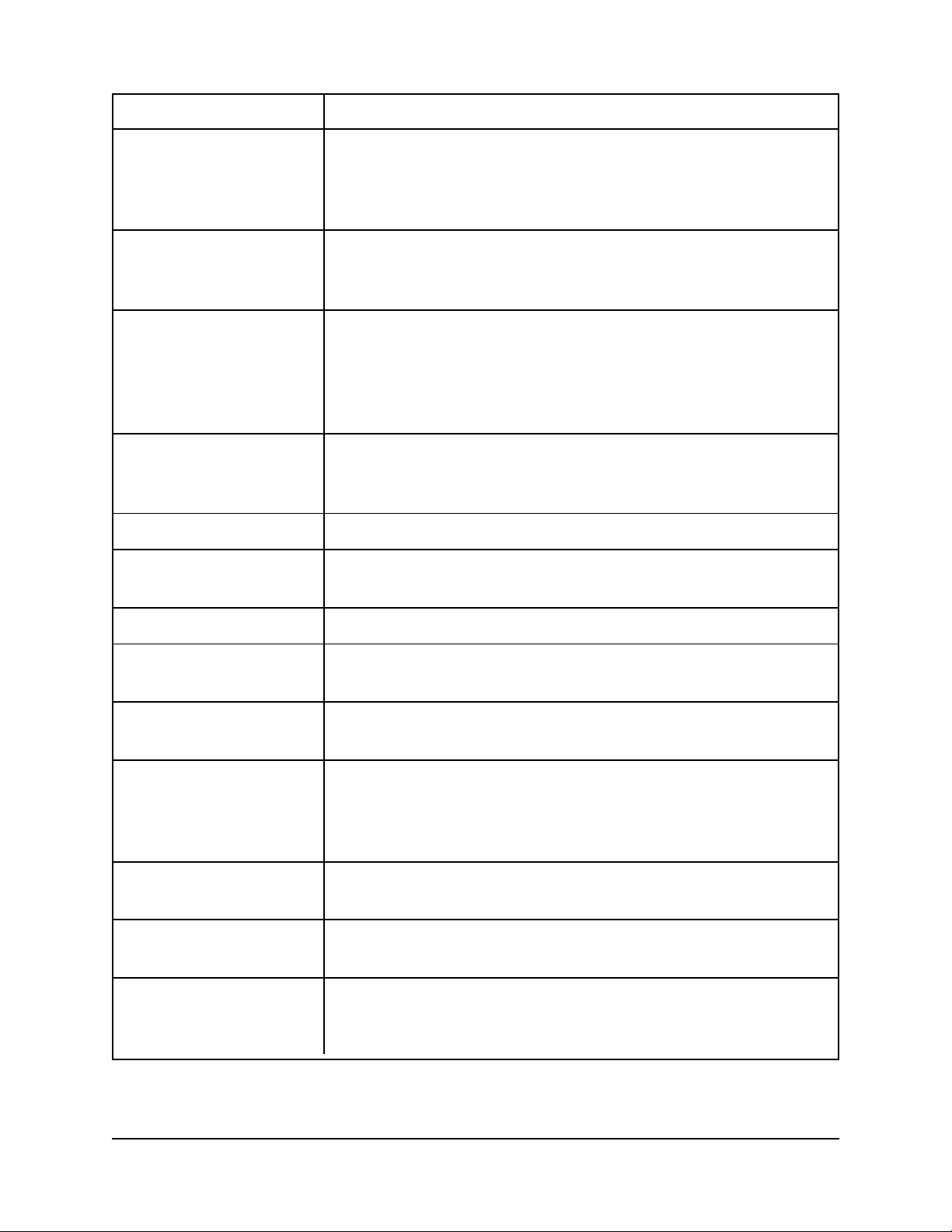

Install the New Ribbon

1.Install the ribbon cartridge in the printer: place the ribbon arms over the metal tabs at

either end, then press down on the cartridge.

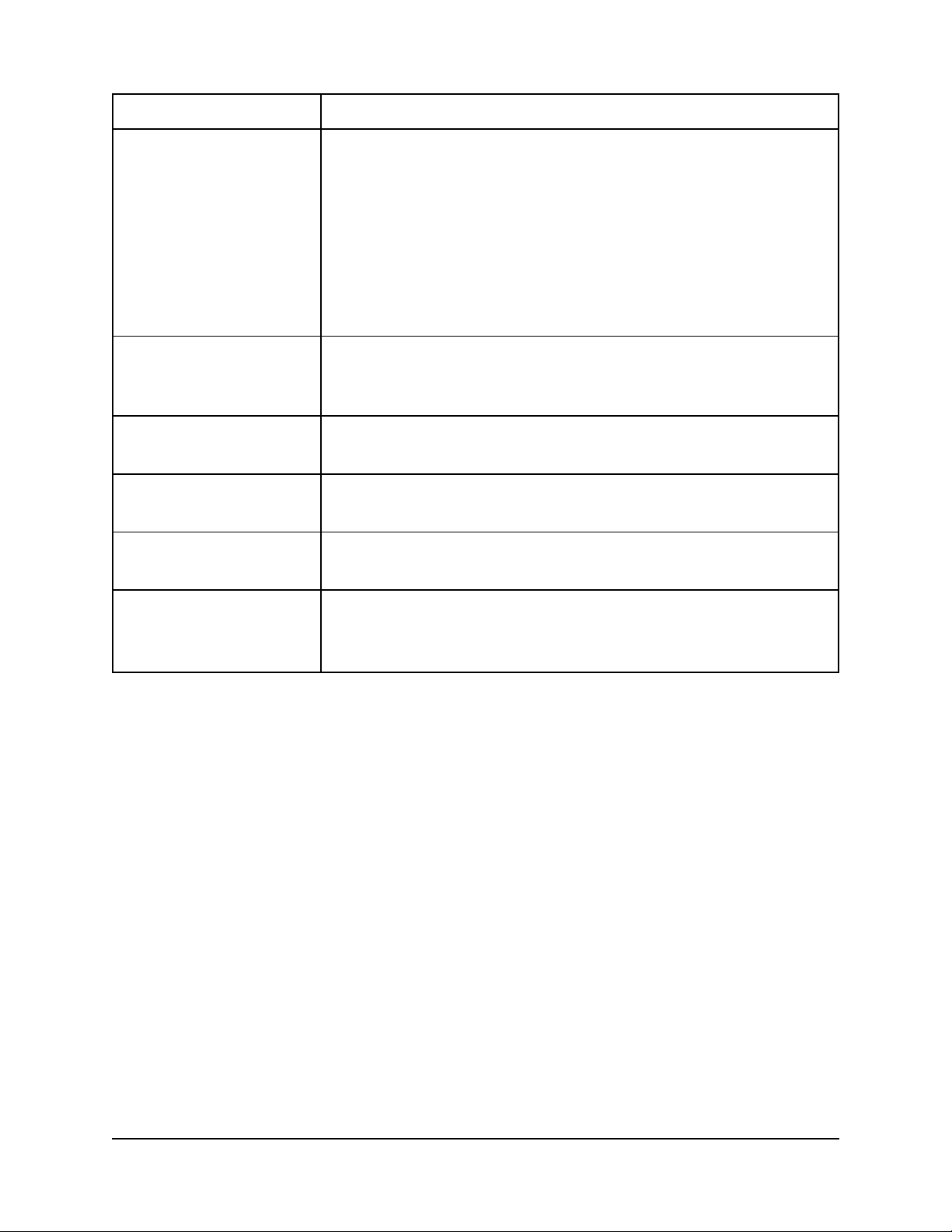

2.Feed the ribbon over the back of the printhead, threading it into the black guides (1) on

either side of the printhead.

Caution! Be careful not to twist the ribbon: this can cause jams.

24

Page 25

3.Turn the blue knob counter clockwise (in the direction of the molded arrows) to take up

any slack in the ribbon, then close the printhead access cover.

Caution! Do NOT turn the knob clockwise: this can cause the ribbon to jam!

Clearing Paper Jams

Front Feed Jams

To clear a front feed paper jam:

1.Press PARK to retract the paper from the paper path.

2.Turn the printer off.

3.Pull the front access door out and lift it up into the open position.

25

Page 26

4.Open the tractor pin covers and remove the jammed paper. Be careful to remove any

ripped pieces.

5.Tear off two or three forms to ensure a clean, unwrinkled form, then reload the

continuous forms on the pins and close the tractor pin covers.

6.Close the front access door and turn the printer on.

7.Press FF/LOAD to load the paper into the print path.

If the paper continues to jam...

If you continue to experience paper jams, there are probably some inaccessible pieces

stuck in the paper path. To correct this:

1.Press the

PARK button to retract the paper from the paper path.

2.Open the front access door.

3.Fold some continuous forms paper over three times to form a thick “sheet,” then load

the sheet on the tractors, and press

FF/LOAD. The sheet will feed into the printer,

pulling any loose pieces through the path and out into the printhead area.

4.Remove the pieces, then press

FF/LOAD and remove the thick paper.

5.Reload your regular continuous forms and close the front access door.

6.Press

FF/LOAD.

26

Page 27

Rear Feed Jams

To clear a rear feed paper jam:

1.Press PARK to retract the paper from the paper path.

2.Turn the printer off.

3.Push on the rear-feed access cover tabs and swing the cover back.

4.Open the tractor covers and remove the jammed paper. Be careful to remove any ripped

pieces.

5.Tear off two or three forms to ensure a clean, unwrinkled form, then reload the

continuous forms on the pins and close the tractor covers.

6.Close the rear-feed access cover and turn the printer on.

7.Press

FF/LOAD to load the paper into the printing path.

27

Page 28

If the paper continues to jam...

If you continue to experience paper jams, there are probably some inaccessible pieces

stuck in the paper path. To correct this:

1.Press the

2.Open the rear-feed access cover.

3.Fold some continuous forms paper over three times to form a thick “sheet,” then load

the sheet on the tractors, and press

pulling any loose pieces through the path and out into the printhead area.

4.Remove the pieces, then press

5.Reload your regular continuous forms and close the rear-feed access cover.

6. Press

PARK button to retract the paper from the paper path.

FF/LOAD. The sheet will feed into the printer,

FF/LOAD and remove the thick paper.

FF/LOAD.

Replacing the Power Fuse

To replace the power fuse:

1.Turn the printer off and unplug it from the outlet.

2.Turn the fuse housing (1) to the left and remove it from the printer.

3.Replace the fuse and reinstall the fuse housing in the printer.

4.Plug the printer back in and turn it on.

28

Page 29

Cleaning the Housing

You should clean the housing every few months (or after about 300 hours of operation).

Caution! Never use solvents or strong detergents on the cabinet: they could damage

the housing.

Cleaning the Interior

1.Press

2.Turn the printer off.

3.Press on the area(s) marked PUSH and open the printhead access cover.

PARK to remove the paper from the print path.

4.Use a clean, dry cloth to dust around inside the printer. Remove any loose bits of paper.

29

Page 30

5.Close the printhead access cover.

6.Pull out the front access cover and lift it into the open position.

7.Vacuum out any paper dust and loose bits of paper, then close the cover.

8.Open the rear-feed access cover and vacuum out any paper dust and loose bits of paper,

then close the cover.

9.Turn the printer back on and press FF/LOAD to load paper back into the print path.

Cleaning the Exterior

Use a damp cloth with a mild detergent to wipe the printer’s external housing clean.

30

Page 31

3: Troubleshooting

General Troubleshooting

Problem:

Nothing happens when I turn on the printer.

Solutions:

1.Check the power cord connection to the outlet.

2.If you are using a power strip, make sure it is turned on and that the fuse has not blown

nor the circuit breaker tripped.

3.Check the fuse (1) at the back of the printer:

Problem:

The printer does not print when the computer sends data.

Solutions:

1.Is the Status light on? If not, press

2.Check that the interface cable is securely connected to both the printer and to the

computer or network.

3.If you have the optional accessory card installed, make sure it is firmly seated in the

printer.

ON-LINE/RESET.

31

Page 32

Problem:

I’m getting strange symbols, incorrect fonts, etc.

Solution:

1.Check to be sure that the printer driver you have selected in your software matches the

printer emulation.

2.If you have embedded any printer commands in your software, check to be sure that

you entered them correctly.

Problem:

The MENU, GROUP, ITEM, OPTION and STORE buttons on the front panel won’t work.

Solution:

The Op. Panel Function in the printer menu can be used to disable these buttons. If the

printer is part of a customized system or if it is used by a number of people, the system

manager may have used this option to make sure the printer is always set properly.

Problem:

The files I send do not print the way I have the menu and front panel set.

Solution:

Before sending a file to the printer, the software may be sending either an “initialization

string” or an I-Prime signal to the printer.

The initialization string contains codes that override the panel and menu settings. To

change the printer to ignore the reset code, press MENU to enter the menu mode, go to

the Set-Up group and change the setting for the Reset Inhibit item to Yes (see Section 1

for more information on changing menu settings).

The I-Prime signal will automatically override any front panel settings you have made. To

eliminate this problem, press MENU to enter the menu mode, go to the Parallel I/F group

and change the setting for I-Prime to Invalid (see Section 1 for more information on

changing menu settings).

32

Page 33

Problem:

I am continuing to have paper exit jams.

Solution:

If you are using front feed, make sure that the front of the printer is flush with the edge of

the table.

If you are using rear feed, make sure that the rear of the printer is flush with the edge of

the table.

If you are switching paper paths on a regular basis, use a table/support for the printer

which is close to the front-to-back depth of the printer so that both the front and rear of

the printer can be placed flush with the edge of the support.

Problem:

The front access door won’t close properly.

Solution:

Make sure that the front-feed tractor covers are properly closed.

33

Page 34

Problem:

I’m trying to print envelopes, but they keep jamming.

Solution:

If you load continuous-form envelopes at the default position, the auto gap thickness is

sensed at the envelope’s flap position which is thinner than the envelope’s main area. This

can cause jamming when the envelopes are being printed.

The auto gap needs to be set at the thicker area of the envelope. To do this:

1.Press

2.Hold

3.Press

4.Press

FF/LOAD to load the envelope forms into the print path.

SHIFT and press FF/LOAD/Micro Feed Up until the bail closes.

PARK to remove the envelopes from the print path.

FF/LOAD.

5.Send one address to start the printhead moving so that the gap is automatically set for

the double thickness area of the envelope.

6.Press

7.Hold

8.Press

PARK to remove the envelopes from the print path.

SHIFT and press PATH/TOF to reset the Top of Form to the factory setting.

FF/LOAD to load the envelopes back into the print path.

Error Messages

Error Message What to Do

AUTO GAP Printhead gap malfunction. Try turning the printer of f, then on

again. If message persists, contact your service provider (see

Section 4).

BAIL Bail motor not functioning properly. Try turning the printer off,

then on again. If message persists, contact your service provider

(see Section 4).

CENTERING Spacing error during centering operation. Try turning the printer

off, then on again. If message persists, contact your service

provider (see Section 4).

CG-ROM Try turning the printer off, then on again. If message persists,

contact your service provider (see Section 4).

COVER OPEN Printhead access cover is open. Close it.

D-RAM Try turning the printer off, then on again. If message persists,

contact your service provider (see Section 4).

34

Page 35

Error Message What to Do

DATA REMAIN Data is being held in the buffer due to the fact that the printhead

cover is open. Close the cover, then press ON-LINE/RESET.

EEPROM Try turning the printer off, then on again. If message persists,

contact your service provider (see Section 4).

EJECT JAM Paper jammed as it was being ejected. Correct the jam and

reload paper.

FEED JAM Paper jammed during a print job as it was feeding through the

printer. Clear the paper jam (see Section 2) and reload paper.

FUSE Internal fuse has blown. Contact your service provider (see

Section 4).

HEAD 1 FAN Printhead Fan 1 is damaged. Contact your service provider (see

Section 4).

HEAD 2 FAN Printhead Fan 2 is damaged. Contact your service provider (see

Section 4).

HEAD THERMAL Printhead has overheated. Turn the printer off and wait for the

printhead to cool down, then try again. If the message persists,

contact your service provider (see Section 4).

HEAD THERMISTOR Printhead thermistor is damaged. Contact your service provider

(see Section 4).

HOMING Try turning the printer off, then on again. If message persists,

contact your service provider (see Section 4).

INVALID IPT Illegal IPT alarm. Try turning the printer off, then on again. If

message persists, contact your service provider (see Section 4).

LCD TIME OUT Try turning the printer off, then on again. If message persists,

contact your service provider (see Section 4).

LF THERMAL The line feed motor has overheated. Turn the printer off and wait

for it to cool down, then try again. If the message persists,

contact your service provider (see Section 4)

LOAD JAM Paper jammed as it was being loaded into the print path. Press

PARK to remove the paper from the print path, then clear the

paper jam (see Section 2) and reload paper.

MAIN LSI Try turning the printer off, then on again. If message persists,

contact your service provider (see Section 4).

OFF-LINE Printer is off line (ALARM light on). Press ON-LINE/RESET

when you are ready to place the printer back on line.

35

Page 36

Error Message What to Do

OKI HSP CONNECT There is a problem with the OKI HSP connection. Check to be

sure that the print server is properly installed and that the

connection is secure. If message persists, contact your service

provider (see Section 4).

OPT CARD ROM There is a problem with the ROM on the optional interface card.

Try turning the printer off, then on again. If message persists,

contact your service provider (see Section 4).

OPT CARD CONNECT There is a problem with the connection to the optional interface

card. Check to make sure that the card is properly installed and

that the connection is firm, then try turning the printer off, then

on again. If message persists, contact your service provider (see

Section 4).

OPTICAL SENSOR Paper width sensor alarm. Try turning the printer off, then on

again. If message persists, contact your service provider (see

Section 4).

PAPER END Paper has run out. Load a new stack of continuous forms.

PAPER JAM Paper edge has ripped and caused a jam. Clear the paper jam

(see Section 2) and reload paper .

PAPER RELEASE The bail is partially open. Press SHIFT + PARK.

PARK JAM Paper jammed as it was being parked. Clear the paper jam (see

Section 2) and reload paper.

PA TH CHANGE Path switching motor is not functioning properly. Contact your

service provider (see Section 4).

PA TH CHANGE JAM Paper jam during change in paper path.

* 1. Check to be sure that paper is loaded in both paths.

* 2. Determine which path is jammed, then clear the jam and

reload paper.

POWER FAN Power supply fan malfunction. Contact your service provider

(see Section 4).

PROGRAM-ROM Try turning the printer off, then on again. If message persists,

contact your service provider (see Section 4).

RIBBON Ribbon motor not functioning properly . Try turning the printer

off, then on again. If message persists, contact your service

provider (see Section 4).

36

Page 37

Error Message What to Do

RIBBON JAM 1. Check to be sure that the ribbon is not twisted: open the

printhead access cover, remove the ribbon from around the

printhead and reload it around the printhead and guides,

making sure that it does not get twisted as you load it.

2. Remove the ribbon from the printer, turn the take-up knob

counter clockwise (in the direction of the molded-on arrows) a

few times, then re-install it (see Section 2).

3. If this does not clear the problem, try installing a new ribbon.

SP THERMAL The spacing motor has overheated. Turn the printer of f and wait

for it to cool down, then try again. If the message persists,

contact your service provider (see Section 4)

SPACE FAN Spacing motor fan malfunction. Contact your service provider

(see Section 4).

SPACING Try turning the printer off, then on again. If message persists,

contact your service provider (see Section 4).

S-RAM Try turning the printer off, then on again. If message persists,

contact your service provider (see Section 4).

WDT Watch dog time-out alarm. T ry turning the printer of f, then on

again. If message persists, contact your service provider (see

Section 4).

37

Page 38

4: Service Information

Getting Service & Support

Note: For the latest information on getting service and support, consult our multilingual

web site (English, French, Spanish, Portuguese): http://www.okidata.com

Your Dealer

Consult the store where you purchased your printer, or in the U.S. and Canada, call 1800-OKIDATA (1-800-654-3282) for the location of the nearest Authorized Okidata

Service Dealer. Have your ZIP code ready.

• Proof of purchase is required for warranty work. Be sure to retain your purchase

documents.

Okidata Information System Automated Attendant

1-800-OKI-DATA (1-800-654-3282)

U.S and Canada only.

For automated customer support information, call 1-800-OKI-DATA (1-800-654-3282).

The Okidata Information System Automated Attendant is available 24 hours a day, seven

days a week, and can provide immediate assistance with:

• Sales and service referrals

• Parts and supplies referrals

• Product information

• Access to Faxable Facts retrieval system

1-800-OKI-DATA (1-800-654-3282) also provides access to our Okidata Customer

Support Professionals.

38

Page 39

Okidata Customer Support Professionals

1-800-OKI-DATA (1-800-654-3282)

U.S and Canada only.

Our Customer Support staff is available 24 hours a day, 7 days a week. Please be sure that

you are calling from a telephone close to your printer so you can describe your problem

accurately.

Our Customer Support Professionals are trained on all current OKI products. They can

answer your questions regarding:

• Locations of Sales & Service Dealers

• Installation of your OKI printer

• Usage/normal maintenance of your printer

• Availability/installation of printer drivers

• Error message interpretation/solutions

• Parts and Supplies identification

• Consumer relations

Note: Customer Support Professionals are not trained to provide assistance with the use

of commercial software packages. Please consult your software users manual for

times and availability of the manufacturers support.

39

Page 40

Okidata Service Locations

If repair to your printer becomes necessary, the repair can be handled by one of Okidata’s

many repair facilities.

In the U.S. and Canada

Before shipping your printer, call 1-800-OKI-DATA (1-800-654-3282) for a return

authorization number. Select the “service” option to find an appropriate service depot.

After receiving your return authorization number, you will be given directions for

shipping your product to one of our repair facilities.

• Allow 10 days for round trip shipping repair via a depot.

• Carry-in repairs must be called in first to schedule service.

In Latin America

Before shipping your printer, call one of the service centers listed below. For a complete

listing of all available service centers in Latin America, consult the Spanish and

Portuguese sections of our multilingual web site at http://www.okidata.com.

Service Location Listings

United States Canada

Oki Data Americas, Inc. Oki Data Americas, Inc.

Phone 1-800-654-3282 Phone 1-800-654-3282

Fax 1-609-222-5247 Fax 1-905-238-4427

Brazil Mexico

Oki Data do Brasil, Ltda. Oki Data de mexico, S.A. de C.V.

Phone (5511) 5589-1518 Phone 525-661-6860

Fax (5511) 5584-0267 Fax 525-661-5861

40

Page 41

Purchasing Replacement Parts & Accessories

Before you order, know your printer model number (Pacemark 4410) and have the correct

part number and description of the item

Ways to Purchase

• Consult the dealer where you purchased your printer

• Consult an Okidata Authorized Sales or Service Dealer.

In the U.S. and Canada, call 1-800-OKIDATA (1-800-654-3282) for the nearest

Authorized Sales and Service location. Have your ZIP code ready for our Customer

Support Representatives.

• In the U.S., order toll-free by phone at 1-800-OKIDATA (1-800-654-3282), using

VISA

®

, MasterCard®, or American Express®.

• In Canada, call 905-602-6400 to order parts: VISA and American Express are accepted.

• Check office supply catalogs or your local stationery store. Most carry Okidata brand

ribbons. Be sure to ask for genuine Okidata ribbons!

41

Page 42

Accessories

Note: For the latest available accessories for the Pacemark 4410 printer, check our web

site —

OkiLAN® Model 6100e Ethernet® Network Interface Card, P/N 70034201

http://www.okidata.com.

For Pacemark 4410 non-network version only. Installs in the network/option slot to

convert the printer for use in network environments.

OKI Adapter Card

For Pacemark 4410 non-network version only. This card installs in the network/option

slot to allow use with third-party options such as Twinax/Coax boards. For more

information, check our web site — http://www.okidata.com — or call

1-800-OKI-DATA (1-800-654-3282).

Replacement Parts

Fuse, 120 volt ...............................Order # 56305901

Paper Guide

..................................................Order # 40658201

Power Cords

120 volt .....................................Order # 56631801

220 volt .....................................Order # 56631901

Printhead Access Cover

..................................................Order # 40520201

Ribbon Cartridge

..................................................Order # 40629302

42

Page 43

Tear Bar Cover

..................................................Order # 40519801

43

Page 44

A: Specifications

General Specifications

Print Method: Serial impact dot matrix

Printhead: Two rows of nine pins in a single-head diamond configuration

Graphics Resolution (Maximum)

Microline Standard Mode: 288 dpi horizontal x 144 dpi vertical

Epson/IBM Modes: 240 dpi horizontal x 216 dpi vertical

Print Speed

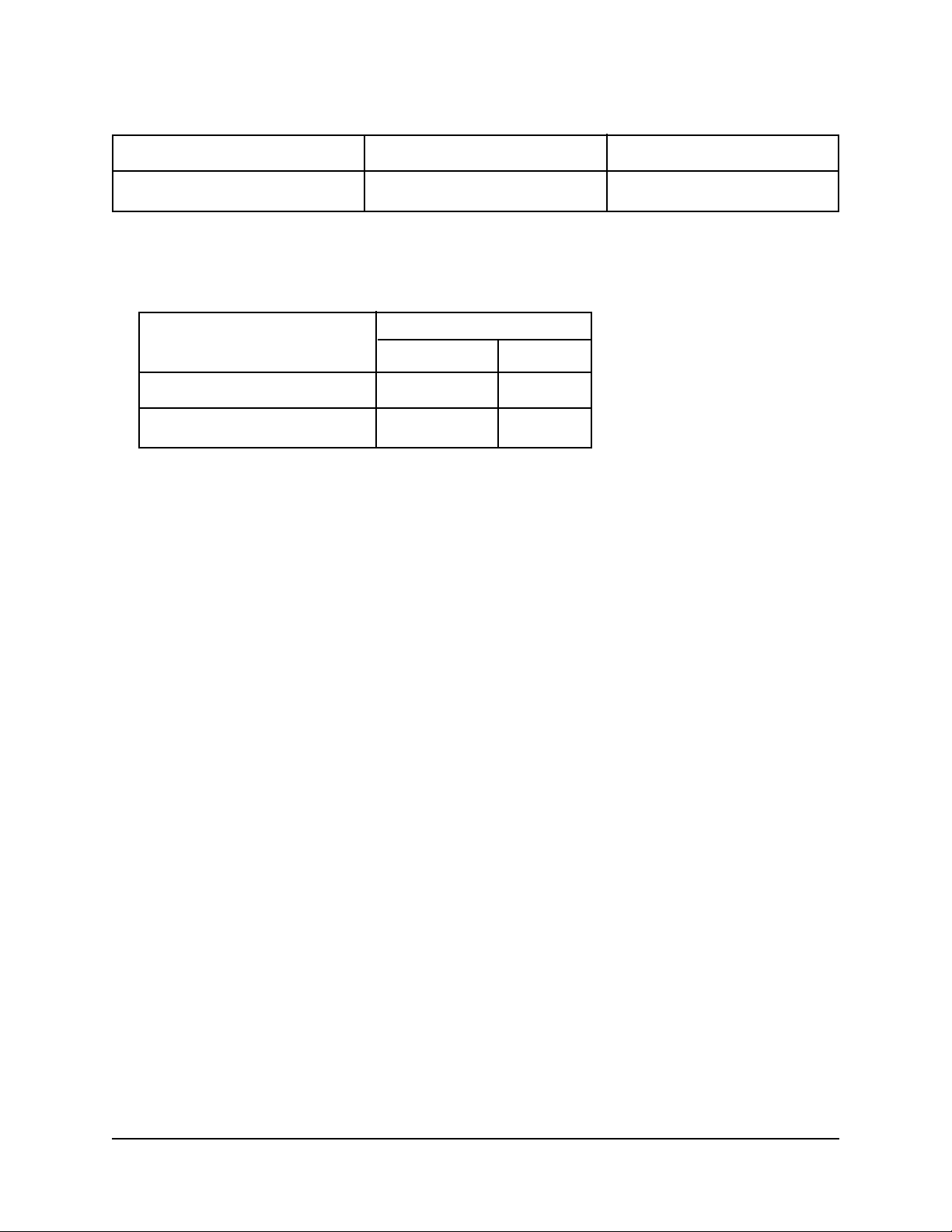

Mode Characters per Inch Speed , Characters per Second

HSD (High Speed Draft) 10 cpi 1066 cps

12 cpi 1066 cps

15 cpi 1066 cps

17.1 cpi 1066 cps

20 cpi 1066 cps

Utility 10 cpi 800 cps

12 cpi 800 cps

15 cpi 800 cps

17.1 cpi 800 cps

20 cpi 800 cps

NLQ (Near Letter Quality) 10 cpi 200 cps

12 cpi 200 cps

15 cpi 200 cps

17.1 cpi 200 cps

20 cpi 200 cps

44

Page 45

Characters per Line

Setting, Characters per Inch Characters per Line

10 cpi 136 cpl

12 cpi 163 cpl

15 cpi 204 cpl

17.1 cpi 233 cpl

20 cpi 272 cpl

Emulations: Epson FX, IBM Proprinter III, Okidata Microline Standard

Interface

Model 4410

Standard: Centronics parallel IEEE-1284, Nibble Mode

RS-232C 25-pin Serial, 38.4 KBps maximum baud rate

Optional: OkiLAN 6100e EtherNet

®

Network Print Server

Model 4410 Network Ready

Standard: Centronics parallel IEEE-1284, Nibble Mode

RS-232C 25-pin Serial, 38.4 KBps maximum baud rate

OkiLAN 6100e EtherNet

®

Network Print Server

Font Specifications

Mode/Type Available Fonts

NLQ (Near Letter Quality) Courier, Gothic

Utility Gothic

HSD (High Speed Draft) Gothic

Scalable Fonts (22 to 216 point) Courier, Gothic

Bar Code Fonts Code 39, UPC A, UPC E, EAN 8, EAN 13,

Interleaved 2 of 5, Code 128, PostNet

45

Page 46

Reliability

Parameter Reliability

Mean Time Between Failures (MTBF) 15,000 hours at 25% duty cycle and

35% page density

Mean Time to Repair (MTTR) 15 minutes, major subassembly level

Printhead Life 400 million characters average in 10 cpi utility

mode at 25% density and 35% page density

Ribbon Life (on average, 10 cpi utility) 15 million characters

Paper Specifications

Front Feed

Maximum thickness: 0.031 inches (0.79 mm)

Type Weight Thickness Width

Single Part 12 to 24 lb. 0.031 inch 3* to 16½ inches

(45 to 90 g/m2) (0.79 mm) (76 to 419 mm)

Carbonless (1 + 9 max.)** 9 to 11 lb. 0.031 inch 3* to 16½ inches

(34 to 40 g/m2) (0.79 mm) (76 to 419 mm)

Interleaf (1 + 6 max) 9 to 14 lb. paper 0.031 inch 3* to 16½ inches

(34 to 52 g/m2) (0.79 mm) (76 to 419 mm)

9 lb. carbon (34 g/m2)

Labels N.A. 0.011 inch 3¼ to 15 inches

(0.28 mm) (83 to 381 mm)

Envelopes 24 lb. (90 g/m2) max. 0.014 inch 3 to 10 inches

(0.36 mm) (76 to 254 mm)

Card Stock 100 lb. (375 g/m2) max. 0.008 inch 3 to 8 inches

(0.20 mm) (76 to 203 mm)

* For paper widths less than 5 inches (127 mm), remove the support between the tractors.

** When using forms thicker than 7-part carbonless or its equivalent, you must enter the Menu

mode, then go to the Impact Mode item in the Set-Up group and select High-Impact Copy

as the setting.

46

Page 47

Rear Feed

Maximum thickness: 0.014 inches (0.36 mm)

Type Weight Thickness Width

Single Part 12 to 24 lb. 0.014 inches 3* to 16½inches

(45 to 90 g/m2) (0.36 mm) (76 to 419 mm)

Carbonless (1 + 5 max.) 9 to 11 lb. 0.014 inches 3* to 16½ inches

(34 to 40 g/m2) (0.36 mm) (76 to 419 mm)

Interleaf (1 + 3 max) 9 to 14 lb. paper 0.014 inches 3* to 16½ inches

(34 to 52 g/m2) (0.36 mm) (76 to 419 mm)

9 lb. carbon (34 g/m2)

* For paper widths less than 5 inches (127 mm), remove the support between the tractors.

Physical Specifications

Dimensions

Width: 30¼ inches (768 mm)

Depth: 15-5/32 inches (385 mm)

Height: 14-7/8 inches (378 mm)

Weight: 92.6 lbs (42 kg)

Environmental Specifications

Temperature

Operating: 41 to 95°F (5 to 35°C)

Storage: 14 to 109°F (-10 to +43°C)

Relative Humidity

Operating: 20 to 80%RH (Maximum wet bulb temperature 30°C)

Storage: 5 to 95%RH (Maximum wet bulb temperature 40°C)

47

Page 48

Electrical Specifications

Voltage: 90 to 264 Volts, AC, universal

Frequency: 50 or 60 Hz, ±2%

Power Consumption

Idling: Less than 15 watts

Local Test: About 295 watts

Memory

ROM: two x 512 KB EPROM

RAM:

Resident: 512KB

Receive Buffer Size: 28KB maximum (56KB maximum, no DLL)

DLL: 27.75KB maximum (NLQ = 2 x 12KB; UTL = 3.25K)

48

Page 49

B: Interfacing

Parallel Interface

The parallel interface is standard IEEE 1284 bi-directional with a 36-pin, Amphenol

57-40360-12-D56 receptacle. It requires a Centronics-equivalent parallel cable with the

following:

• Amphenol 57-30360 or AMP 552274-1 plug (or equivalent) with 36 pins

• AMP 552073--1 (or equivalent) cover

• UL and CSA approved shielded cable, maximum 6 feet, with twisted pair conductors.

Parallel Interface Pin Assignments

Pin No. Signal Return Pin Direction

1 Data Strobe 19 To printer

2 Data Bit 1 20 To printer

3 Data Bit 2 21 To printer

4 Data Bit 3 22 To printer

5 Data Bit 4 23 To printer

6 Data Bit 5 24 To printer

7 Data Bit 6 25 To printer

8 Data Bit 7 26 To printer

9 Data Bit 8 27 To printer

10 Acknowledge 28 From printer

11 Busy 29 From printer

12 Paper End 30 From printer

13 Select No return From printer

14 Auto Feed To printer

49

Page 50

15 Unused - 16 0V No Return 17 Chassis Ground No Return 18 +5V - From printer

19 to 30 0V - 31 I-Prime - To printer

32 Fault - From printer

33 0V - 34 Unused - 35 - - 36 Select-I - To printer

50

Page 51

Serial Interface

The serial interface is EIA Standard RS-232C serial input, start-stop synchronization.

• Baud Rate: 300, 600, 1200, 2400, 4800, 9600 (default), 19,200, or 38,400 bps

• Data Word Length: 7 (default) or 8 bits

• Parity: None (default), odd, even

• Stop Bit Length: 1 bit or more

• Message Buffer Length: 8,192 bytes

• Communication Protocol: Ready/Busy (default) or X-ON/X-OFF

Serial Interface Pin Assignments

Pin No. Signal Symbol Direction

1 Protective Ground PG 2 Transmitted Data TD From printer

3 Received Data RD To printer

4 Request to Send RTS From printer

5 Unused - 6 Data Set Ready DSR To printer

7 Signal Ground SG 8 to 10 Unused - 11 Supervisory Send Data SSD From printer

12 to 19 Unused - 20 Data T erminal Ready DTR From printer

21 to 25 Unused - -

51

Page 52

Commonly Used Serial Cable Configurations

IBM 25-Pin Cable Configuration

Computer Printer

PG1 ______________ 1 PG

TD2 ______________ 3 RD

RD 3 ______________ 2 TD

CTS 5 ______________ 11 SSD

DSR 6 ______________ 20 DTR

6 DSR

SG 7 ______________ 7 SG

4 RTS

5 CTS

IBM 9-Pin Cable Configuration

Computer Printer

RD 2 ______________ 2 TD

TD 3 ______________ 3 RD

SG 5 ______________ 7 SG

DSR 6 ______________ 20 DTR

6 DSR

CTS 8 ______________ 11 SSD

4 RTS

5 CTS

52

Page 53

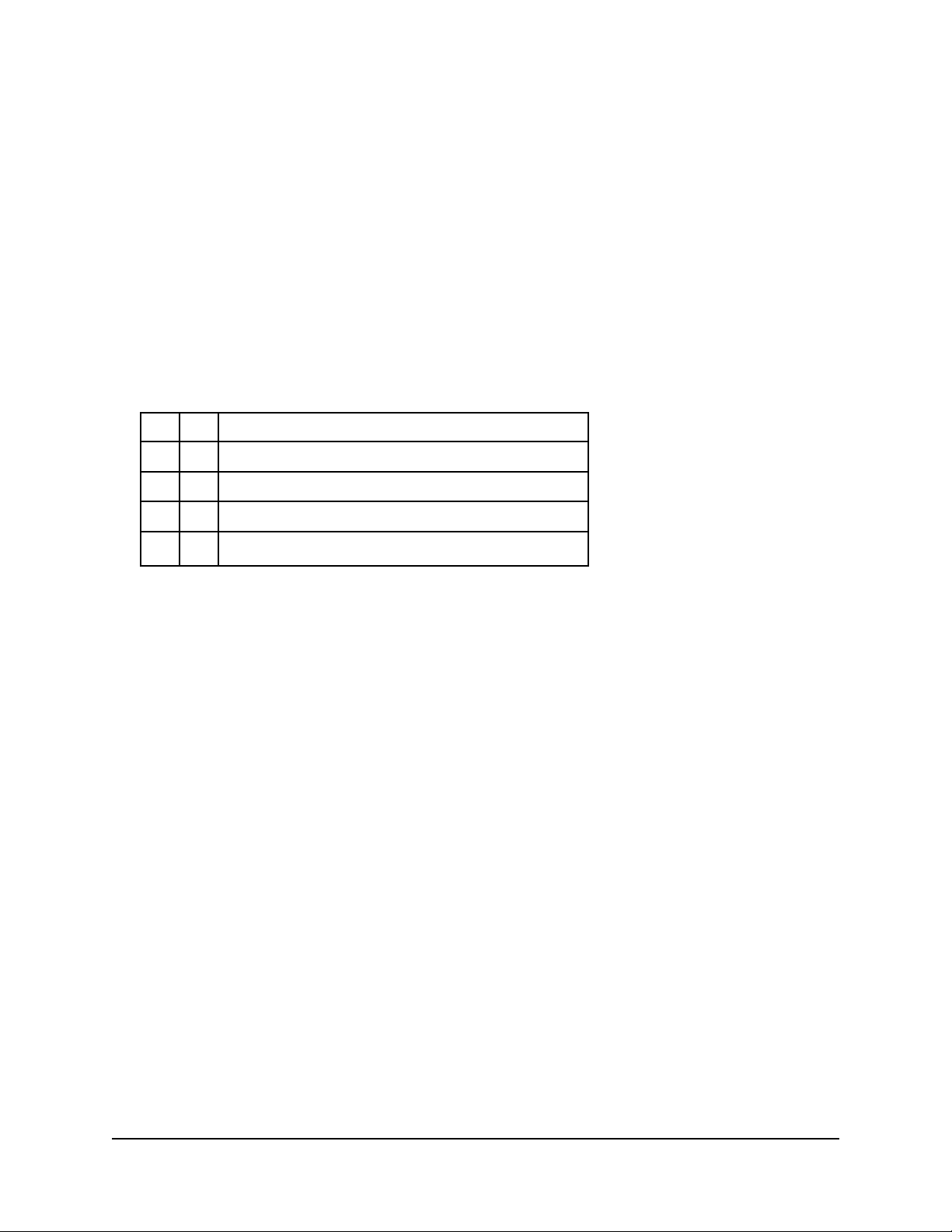

Serial Interface Test

To perform a local diagnostic test of the serial interface:

Note: To stop the test at any time, turn the printer off.

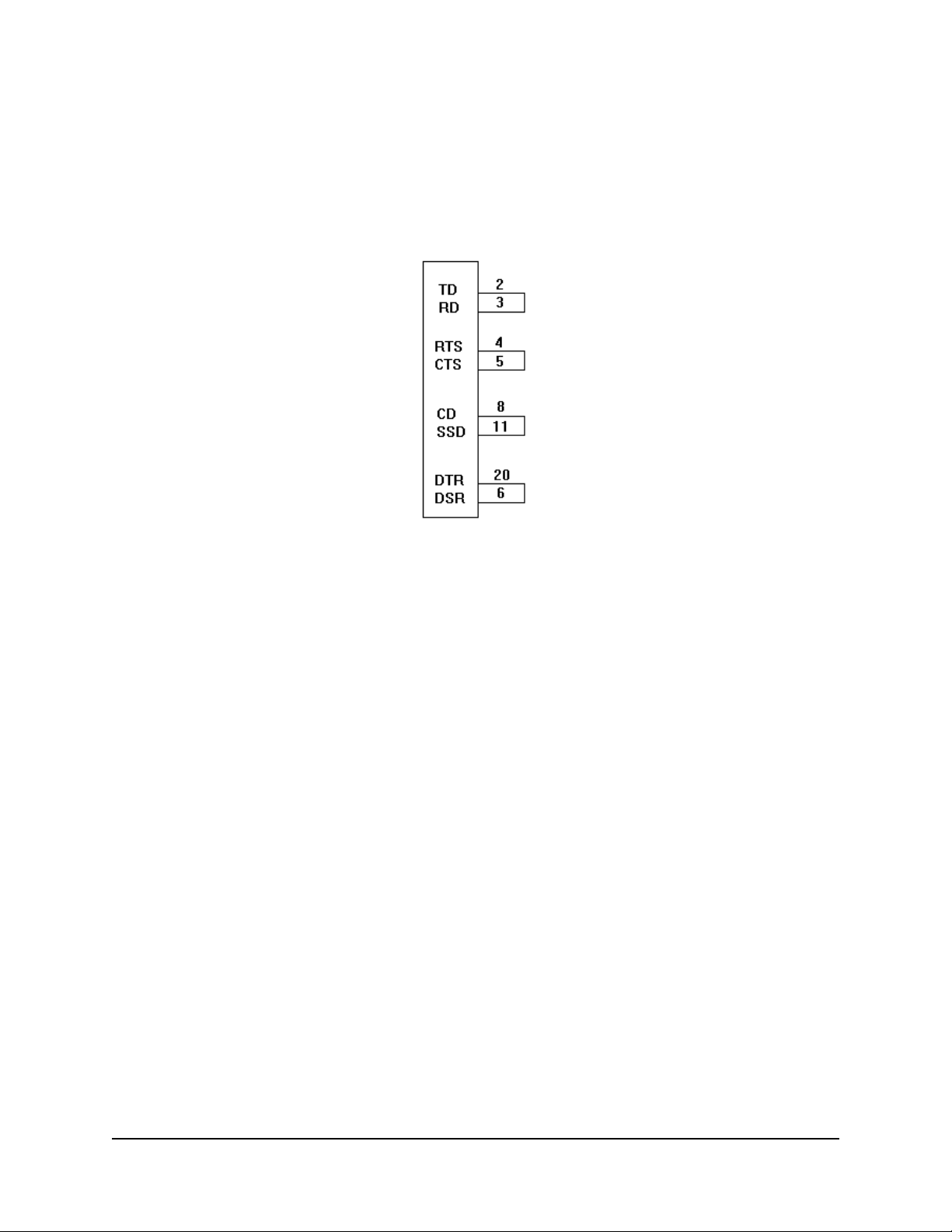

You need a test connector to jumper the following pins:

1.Enter the printer menu and change the Diagnostic Test item in the Serial I/F group to

Yes.

2.Turn the printer off.

3.Plug the test connector into the serial interface receptacle.

4.Turn the printer on:

• The printer prints the message “LOOP TEST”

• The printer checks the memory function of the message buffer, then prints “RAM

GOOD” if the memory check is okay, or “RAM BAD” if the memory check fails.

• The signal logic is checked. If the signal logic is okay, “I/F GOOD” prints. If it is

faulty, “I/F BAD” prints.

• Hexadecimal characters from 20 to 7E are transmitted through the TD (Transmit

Data) line, and received through the RD (Receive Data) line, then written to the

message buffer. The above stored data is then printed.

• This process repeats until the printer is turned off.

5.Turn the printer off, then press and hold

MENU while turning the printer back on.

This ends the test and places you in the Menu mode.

6.Go to the Serial I/F group and change Diagnostic Test back to No.

7.Press

STORE to save the setting, then press MENU to exit the Menu mode.

53

Page 54

Ethernet® 10/100 BaseT Interface

The print server has an Ethernet 10/100 BaseT interface with an RJ45 receptacle and a

parallel interface for interconnection with the printer.

The interface is supplied with a short cable for connection of the parallel interface.

Note: The Ethernet port requires a 10/100 BaseT cable with two twisted-wire pairs.

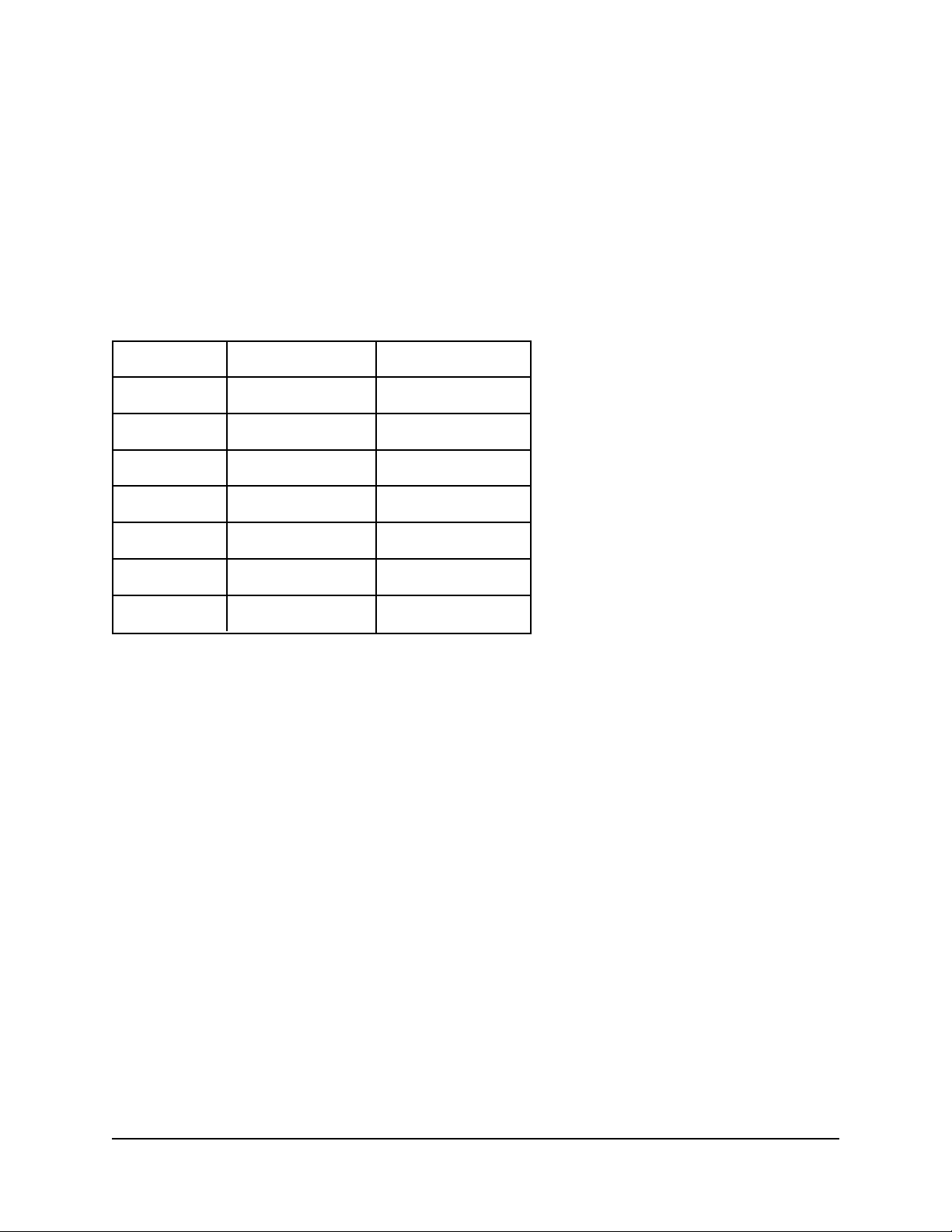

Ethernet 10/100 BaseT Interface

Pin Assignments

Pin No. Signal Description

1 TD+ Transmit Data +

2 TD- Transmit Data 3 RD+ Receive Data +

4 Not Used 5 Not used 6 RD- Receive Data

7, 8 Not Used -

54

Page 55

Print Server Parallel Output Pin Assignments

Pin No. Signal Source Description

1 nSTROBE Print Server Indicates when the data on the data

lines is valid.

2-9 DATA 1-8 Print Server Eight lines used for data transfer.

10 nACK Printer Data acknowledge signal.

11 BUSY Printer Indicates the printer is not ready to

receive data.

12 PAPER ERROR Printer Indicates a paper error.

13 SELECT Printer Indicates the printer is online.

14 nAUTOFEED Print Server Used for IEEE-1284 compliance.

15 nFAULT Printer Indicates a printer error condition.

16 nINIT Print Server Instructs the printer to initialize.

17 nSELECT IN Print Server Used for IEEE-1284 compliance.

18-25 GND - Ground

55

Page 56

C: Command Summary

Epson FX Command Summary

Epson Command ASCII Hexadecimal Decimal

Printer Operation/Data Control

Configuration Group

Select CFG1 ESC DLE J P1 1B 10 4A P1 01 27 16 74 P1 1

P1 = 0: command valid SOH

P1 = 1: command invalid

Select CFG2 ESC DLE J P1 1B 10 4A P1 02 27 16 74 P1 2

P1 = 0: command valid STX

P1 = 1: command invalid

Delete DEL 7F 128

Emulation Mode, Select

Epson FX ESC { @ 1B 7B 40 27 123 64

IBM Proprinter ESC { NUL 1B 7B 00 27 123 0

OKI Microline Standard ESC { ! 1B 7B 21 27 123 33

MSB Control

Cancel MSB control ESC # 1B 23 27 35

Set MSB equal to 0 ESC = 1B 3D 27 61

Set MSB equal to 1 ESC > 1B 3E 27 62

Paper-Out Sensor

Disable ESC 8 1B 38 27 56

Enable ESC 9 1B 39 27 57

56

Page 57

Epson Command ASCII Hexadecimal Decimal

Printer Operation/Data Control (continued)

Paper Path, Change to

Rear Path

P1 represents the number ESC DLE I P1 0 1B 10 49 P1 30 27 16 73 P1 48

of bytes of data

Front Path

P1 represents the number ESC DLE I P1 1 1B 10 49 P1 31 27 16 73 P1 49

of bytes of data

Print Direction

Unidirectional ESC U 1 1B 55 31 27 85 49

Bidirectional ESC U 0 1B 55 30 27 85 48

Unidirectional for one line ESC < 1B 3C 27 60

Print Speed, Half

On ESC s 1 1B 73 31 27 115 49

Off ESC s 0 1B 73 30 27 115 48

Print Suppress

On DC3 13 19

Off DC1 11 17

Reset

Clear Print Buffer ESC @ 1B 40 27 64

Clear Buffer and CAN 18 24

Initialize Printer

Select Menu Item

See the end of this ESC DLE D Pno P

Appendix for details Pb1 Pa2 Pb2...Pan P

1B 10 44 Pno P

a1

Pb1 Pa2 Pb2...Pan P

bn

27 16 68 Pno P

a1

bn

Pb1 Pa2 Pb2...Pan P

on this command.

Software I-Prime ESC } 1B 7D 27 125

Vertical Control

Form Feed, Execute FF 0C 12

Form Length

Set in inches, n = 0 or 128 ESC C NUL n 1B 43 00 n 27 67 0 n

Set in lines, n = 1 to 127 ESC C n 1B 43 n 27 67 n

a1

bn

57

Page 58

Epson Command ASCII Hexadecimal Decimal

Vertical Control (continued)

Line Feed

n/144 inch, n = 0 to 255 ESC % 5 n 1B 25 35 n 27 37 53 n

n/216 inch, n = 0 to 255 ESC J n 1B 4A n 27 74 n

Forward LF with CR LF 0A 10

Reverse LF, n = 0 to 255 ESC j n 1B 6A n 27 106 n

Line Spacing

n/72-inch increments ESC A n 1B 41 n 27 65 n

n = 0 to 85, 128 to 213

n/144-inch increments ESC % 9 n 1B 25 39 n 27 37 57 n

n = 1 to 255

n/216-inch increments, ESC 3 n 1B 33 n 27 51 n

n = 0 to 255

1/6-inch ESC 2 1B 32 27 50

1/8-inch ESC 0 1B 30 27 48

7/72-inch ESC 1 1B 31 27 49

Margins, Bottom

(Auto Skip)

Cancel ESC O 1B 4F 27 79

Define, n = 0 to 127 lines ESC N n 1B 4E n 27 78 n

Vertical Tabs

Execute VT 0B 11

Define tab stops ESC B n1 n2...n

k

1B 42 n1 n2...n

k

27 66 n1 n2...n

n = 1 to 255 NUL 00 0

k = 1 to 16

Define tab stops in ESC b n m

1

1B 62 n m

1

27 98 n m

channels m2...mk NUL m2...mk 00 m2...mk 0

m = 0 to 255

n = 0 to 7

Select channel ESC / n 1B 2F n 27 47 n

n = 0 to 7, 128 to 135

k

1

58

Page 59

Epson Command ASCII Hexadecimal Decimal

Horizontal Control

Backspace BS 08 8

Carriage Return CR 0D 13

Horizontal Tabs

Execute HT 09 9

Set, up to 32 tabs ESC D x1 x2 x3...x

1B 44 x1 x2 x3...x

k

27 68 x1 x2 x3...x

k

x = 1 to 255 NUL 00 0

k = 1 to 32

Margins, Set by character

columns

Set left margin ESC l n 1B 6C n 27 108 n

Pitch Range for n

10 cpi 1 to 134

12 cpi 1 to 162

15 cpi 1 to 202

17.1 cpi 1 to 231

20 cpi 1 to 255

Set right margin ESC Q n 1B 51 n 27 81 n

Pitch Range for n

10 cpi 2 to 136

12 cpi 3 to 164

15 cpi 3 to 204

17.1 cpi 4 to 234

20 cpi 4 to 255

k

59

Page 60

Epson Command ASCII Hexadecimal Decimal

Horizontal Control (continued)

Print Position

Define position by dot ESC \ n1 n

2

1B 5C n1 n

2

columns, indexed from

present position.

Dot position =

n1 + (n2 x 256)

n1 = 0 to 255

n2 = 0 to 255

Execute print position ESC $ n1 n

2

1B 24 n1 n

2

from current left margin

Dot position =

[n1 + (n2 x 256)]/60

n1 = 0 to 255

n2 = 0 to 255

Set print position ESC DLE @ n A1 A21B 10 40 n A1 A

n = 0 to 255: # of bytes P1 P2 P3 P

4

P1 P2 P3 P

4

to follow

A1 = 0 to 255: even,

print position absolute

from left edge; odd,

print position relative

to current position

27 92 n1 n

27 36 n1 n

27 16 64 n A1 A

2

P1 P2 P3 P

2

2

2

4

A2 = 0 to 255: even,

toward right margin

(forward); odd, toward

left margin (reverse)

P1P2P3P4 = 0000 to

9999 ASCII

Print Style/Print Size Control

Character Pitch

Select 10 cpi ESC P 1B 50 27 80

Select 12 cpi ESC M 1B 4D 27 77

Condensed (17, 20 cpi)

Select ESC SI or SI 1B 0F or 0F 27 15 or 15

Cancel DC2 12 18

Select 15 CPI ESC g 1B 67 27 103

60

Page 61

Epson Command ASCII Hexadecimal Decimal

Print Style / Print Size Control (continued)

Composite Command, Select

Print Features and Pitch ESC ! n 1B 21 n 27 33 n

n = 0 to 255

Bit 1 0

b7: Underline Set Reset

b6: Italics Set Reset

b5: Dbl. Width Set Reset

b4: Enhanced Set Reset

b3: Emphasized Set Reset

b2: Compressed Set Reset

b1: Proportional Set Reset

b0: Set cpi 12 cpi 10 cpi

Double Height Printing

On ESC w 1 1B 77 31 27 119 49

Off ESC w 0 1B 77 30 27 119 48

Double Width (Expanded)

Printing

On ESC W 1 1B 57 31 27 87 49

Off ESC W 0 1B 57 30 27 87 48

One line only

On ESC SO, SO 1B 0E, 0E 27 14, 14

Off DC4 14 20

Print Quality

HSD ESC ( 0 1B 28 30 27 40 48

NLQ ESC x 1 1B 78 31 27 120 49

Utility ESC x 0 1B 78 30 27 120 48

Proportional Width

On ESC p 1 1B 70 31 27 112 49

Off ESC p 0 1B 70 30 27 112 48

61

Page 62

Epson Command ASCII Hexadecimal Decimal

Print Style / Print Size Control (continued)

Select font by pitch/point ESC X Pn Lp H

p

1B 10 46 Pn Lp Hp27 16 70 Pn Lp H

(for Option ROM)

Pn = 0: fixed spacing

Pn = 1: proportional

spacing

Lp, Hp = 00H to FFH

Np = Lp + (Hp x 256)

Np > 43

Point Size = Np/2

Typestyles

Courier ESC k 0 1B 6B 30 27 107 48

Gothic ESC k 1 1B 6B 31 27 107 49

OCR-B ESC k 5 1B 6B 35 27 107 53

Character Control

Emphasized Mode

Reset ESC F 1B 46 27 70

Set ESC E 1B 45 27 69

p

Enhanced (Double Strike)

Reset ESC H 1B 48 27 72

Set ESC G 1B 47 27 71

Inter-Character Clearance, ESC SP n 1B 20 n 27 32 n

Set by dot columns

n = 0 to 255

Justification

Left ESC a 0 1B 61 30 27 97 48

Center ESC a 1 1B 61 31 27 97 49

Right ESC a 2 1B 61 32 27 97 50

Full ESC a 3 1B 61 33 27 97 51

62

Page 63

Epson Command ASCII Hexadecimal Decimal

Character Control (continued)

Superscript/Subscript

Cancel ESC T 1B 54 27 84

Subscript ESC S 1 1B 53 31 27 83 49

Superscript ESC S 0 1B 53 30 27 83 48

Underline

On ESC - 1 1B 2D 31 27 45 49

Off ESC - 0 1B 2D 30 27 45 48

Character Set

Assign character table ESC ( t H

Ln, Hn = 0 to 255 Pn1 Pn2 P

n

n3

1B 28 74 H

Pn1 Pn2 P

n3

n

27 40 116 H

Pn1 Pn2 P

Pn1, Pn2, Pn3 = 0 to 255

Control Codes, Printable

Reset ESC 7 1B 37 27 55

Set ESC 6 1B 36 27 54

Control Codes/Printable

Characters — on/off

Interprets codes as ESC | 1 1B 49 31 27 73 49

printable characters

Interprets codes as ESC | 0 1B 49 30 27 73 48

control codes

n

n3

63

Page 64

Epson Command ASCII Hexadecimal Decimal

Character Set (continued)

International Language

Chararacter Sets

American ESC R NUL 1B 52 00 27 82 0

French ESC R SOH 1B 52 01 27 82 1

German ESC R STX 1B 52 02 27 82 2

British ESC R ETX 1B 52 03 27 82 3

Danish I ESC R EOT 1B 52 04 27 82 4

Swedish ESC R ENQ 1B 52 05 27 82 5

Italian ESC R ACK 1B 52 06 27 82 6

Spanish I ESC R BEL 1B 52 07 27 82 7

Japanese ESC R BS 1B 52 08 27 82 8

Norwegian ESC R HT 1B 52 09 27 82 9

Danish II ESC R LF 1B 52 0A 27 82 10

Spanish II ESC R VT 1B 52 0B 27 82 11

Latin American ESC R FF 1B 52 0C 27 82 12

French Canadian ESC R CR 1B 52 0D 27 82 13

Dutch ESC R SO 1B 52 0E 27 82 14

Publisher ESC R @ 1B 52 40 27 82 64

Code Page

Multilingual 850 ESC R SUB 1B 52 1A 27 82 26

Norway 865 ESC R ESC 1B 52 1B 27 82 27

Portugal 860 ESC R FS 1B 52 1C 27 82 28

Canada French ESC R + 1B 52 2B 27 82 43

BRASCII ESC R P 1B 52 50 27 82 80

Abicomp ESC R Q 1B 52 51 27 82 81

ISO 8859/15 ESC R R 1B 52 52 27 82 82

IBM Multilingual 858 ECS R S 1B 52 53 27 82 83

Italic Character Set

Cancel ESC 5 1B 35 27 53

Select ESC 4 1B 34 27 52

Slant (Italics)/Graphics

Character Table

Slant (italic) ESC t 0 1B 74 30 27 116 48

Epson Graphics ESC t 1 1B 74 31 27 116 49

64

Page 65

Epson Command ASCII Hexadecimal Decimal

DLL Character Set

Copy Pre-defined ROM

data to RAM

NLQ Courier ESC : NUL NUL 1B 3A 00 00 00 27 58 0 0 0

NUL

NLQ Gothic ESC : NUL SOH 1B 3A 00 01 00 27 58 0 1 0

NUL

NLQ OCR-B ESC : NUL ENQ 1B 3A 00 05 00 27 58 0 5 0

NUL

Select DLL Font

DLL character set ESC % 1 1B 25 31 27 37 49

Pre-defined character set ESC % 0 1B 25 30 27 37 48

Graphics Control

Bit Image Graphics

Double Horizontal ESC L n1 n

2

1B 4C n1 n

2

27 89 n1 n

2

Density , normal speed <graphics data> <graphics data> <graphics data>

n1, n2 = 0 to 255,

specifies # of columns

Double Horizontal ESC Y n1 n

2

1B 59 n1 n

2

27 89 n1 n

2