OKI OKIPAGE 10i Service manual

OKIPAGE 10i

LED Page Printer

Maintenance Manual

ODA / OEL / INT

Rev.2 98. 1.26

All specifications are subject to change without notice.

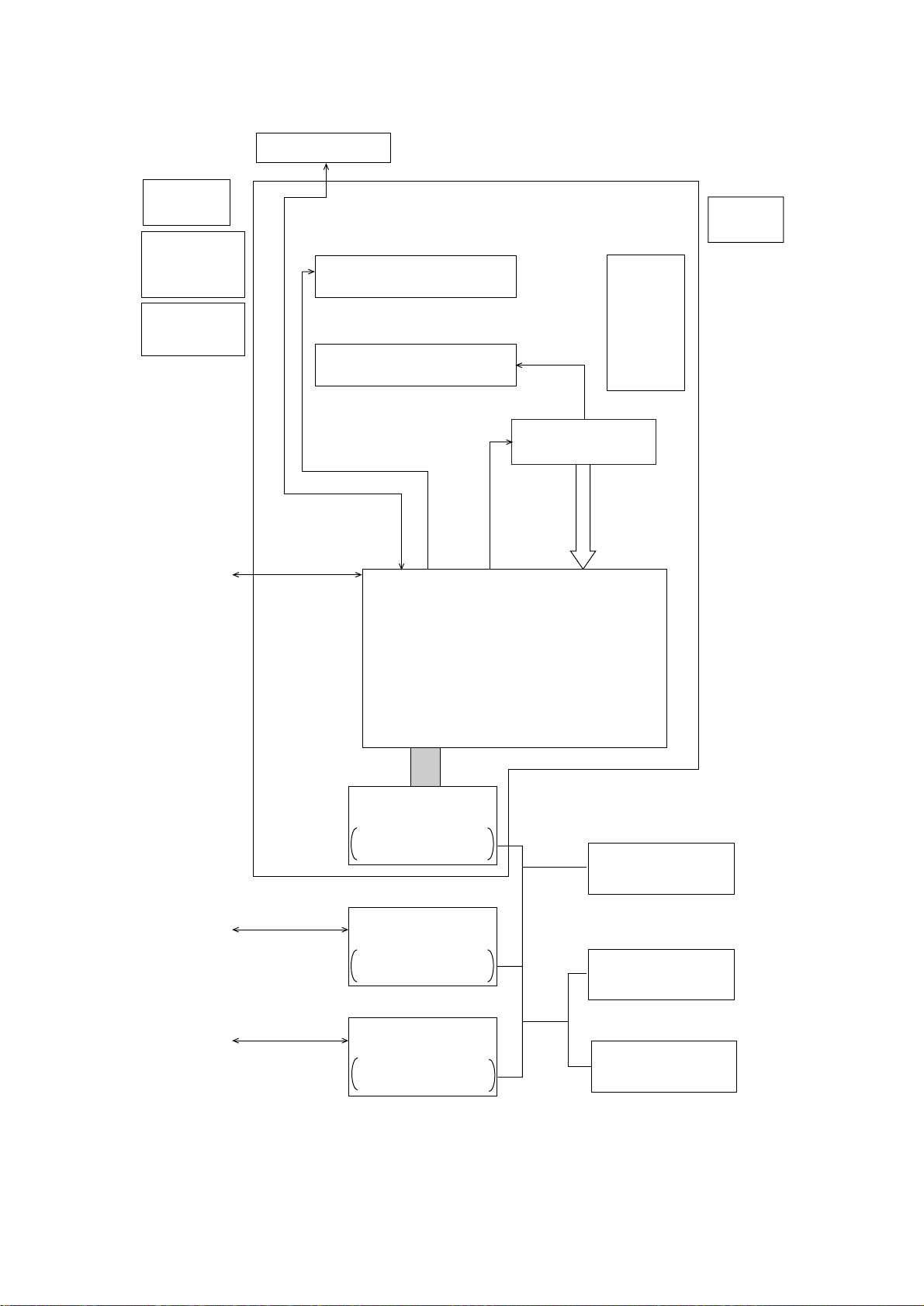

1. CONFIGURATION

1.1 System Configuration

OKIPAGE 10i consists of control and engine blocks in the standard configuration, as shown in

Figure 1-1.

In addition, the options marked with asterisk(*) are available.

1 - 1

Paper

Cassette

*High Capacity

Second Paper

Feeder

Operator Panel

Paper Feeding Mechanism

(First Tray Unit)

Engine Unit

Face Up

Stacker

Face

*Multi Purpose

Feeder

Centronics

Electrophotographic

Processing Unit

Main Control Board

Down

Stacker

Power Supply

and Sensor Board

RS-232C

LAN

(to BASE-T)

Memory*

Expansion Board

1 DRAM SIMM Socket

1 ROM SIMM Socket

or

RS-232C Serial*

Interface Board

1 DRAM SIMM Socket

1 ROM SIMM Socket

or

Network*

Interface Board

1 DRAM SIMM Socket

1 ROM SIMM Socket

Figure 1-1

1 - 2

* : Optional

DRAM SIMM*

PS SIMM*

(Post Script Program)

or

Flash SIMM*

(Flash memory)

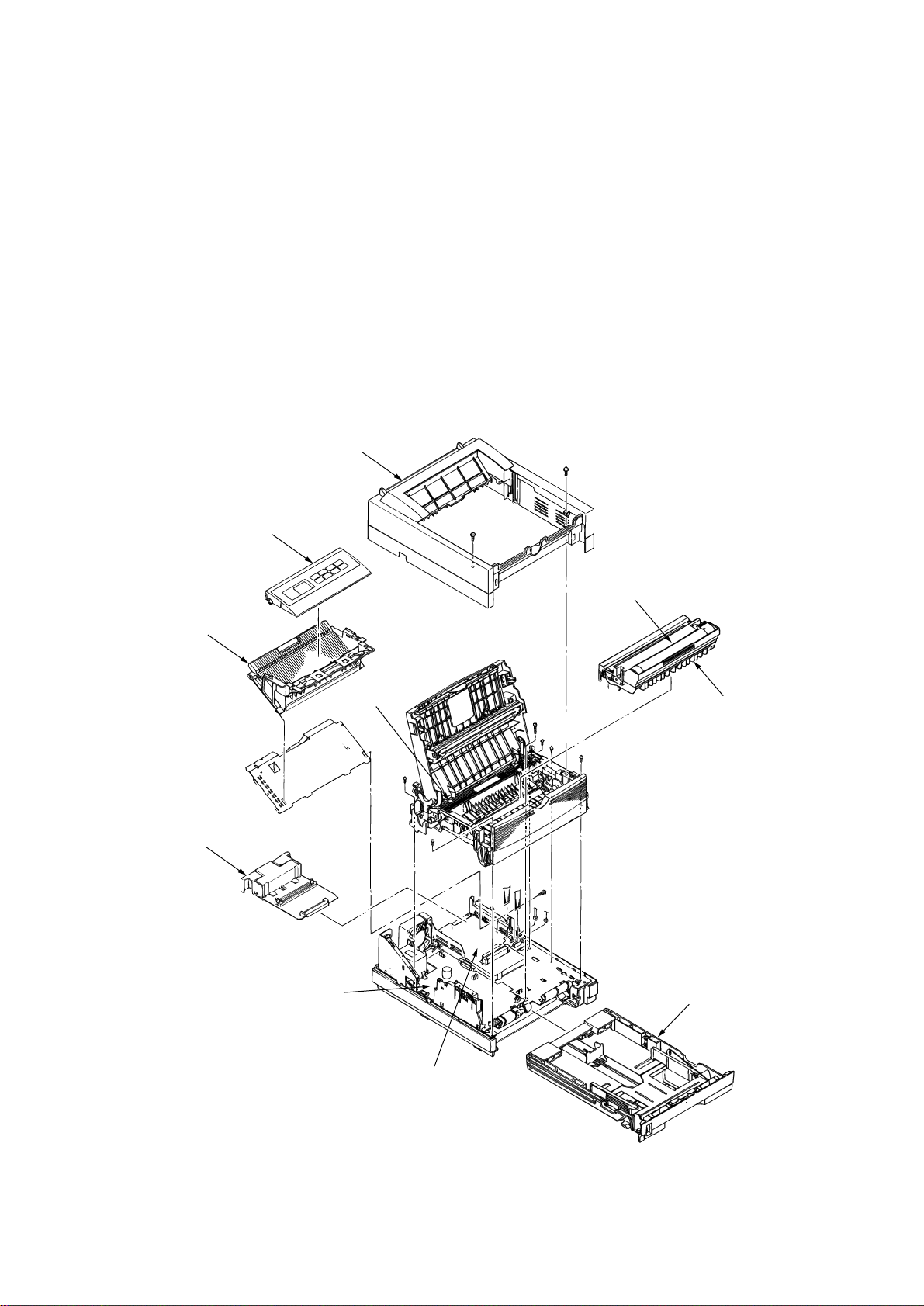

1.2 Printer Configuration

The printer unit consists of the following hardware components:

• Electrophotographic Processor

• Paper Feeder

• Controller

• Operator Panel

• Power Supply Unit

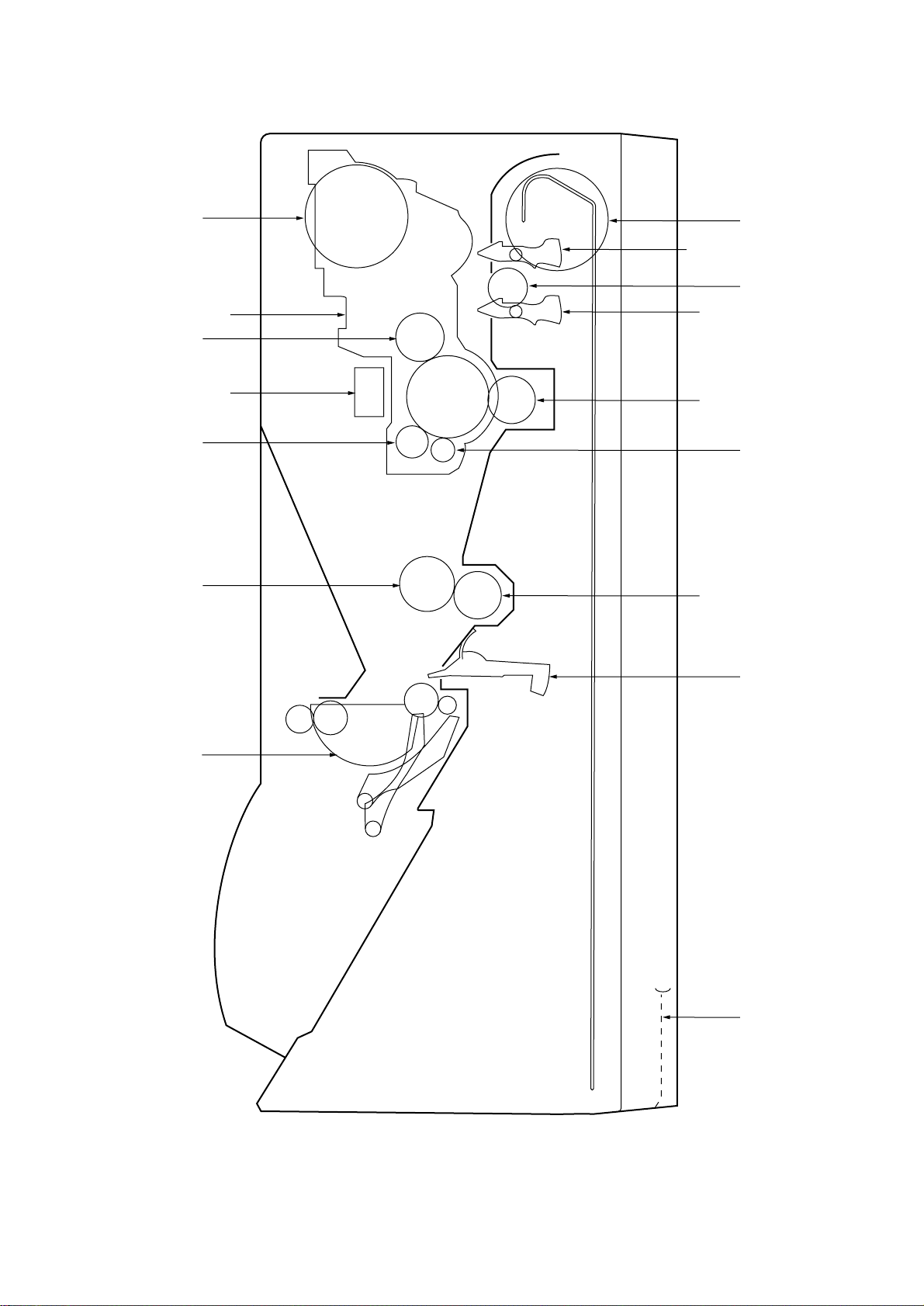

The printer unit configuration is shown in Figure 1-2.

Upper cover

Operator panel assy

Toner-cartridge(Type 5)

(consumable)

Stacker assy

Optional board

Power supply/sensor board

Fusing unit

Image drum unit(Type 5)

(consumable)

Legal/universal paper cassette

Main control board

Figure 1-2

1 - 3

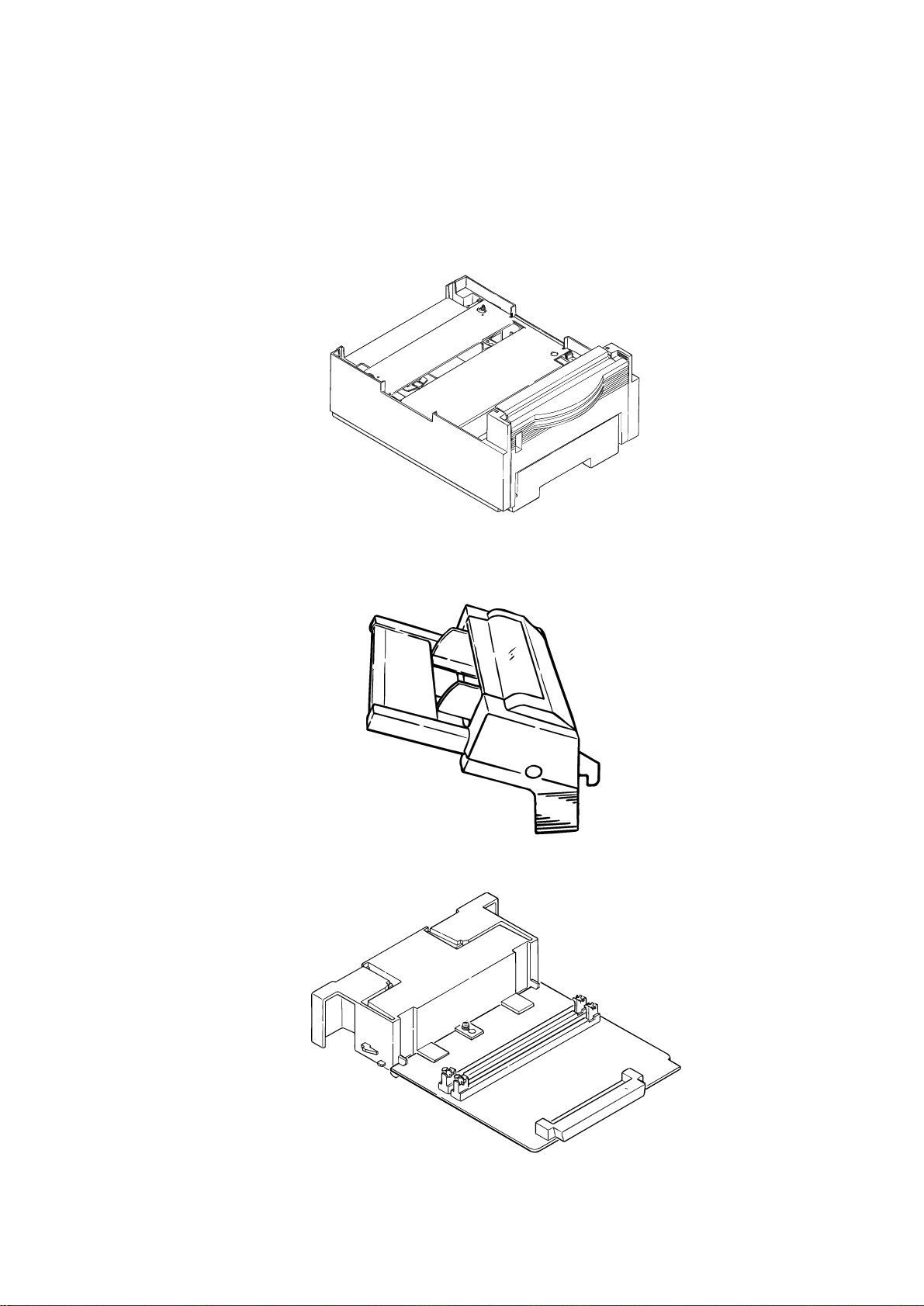

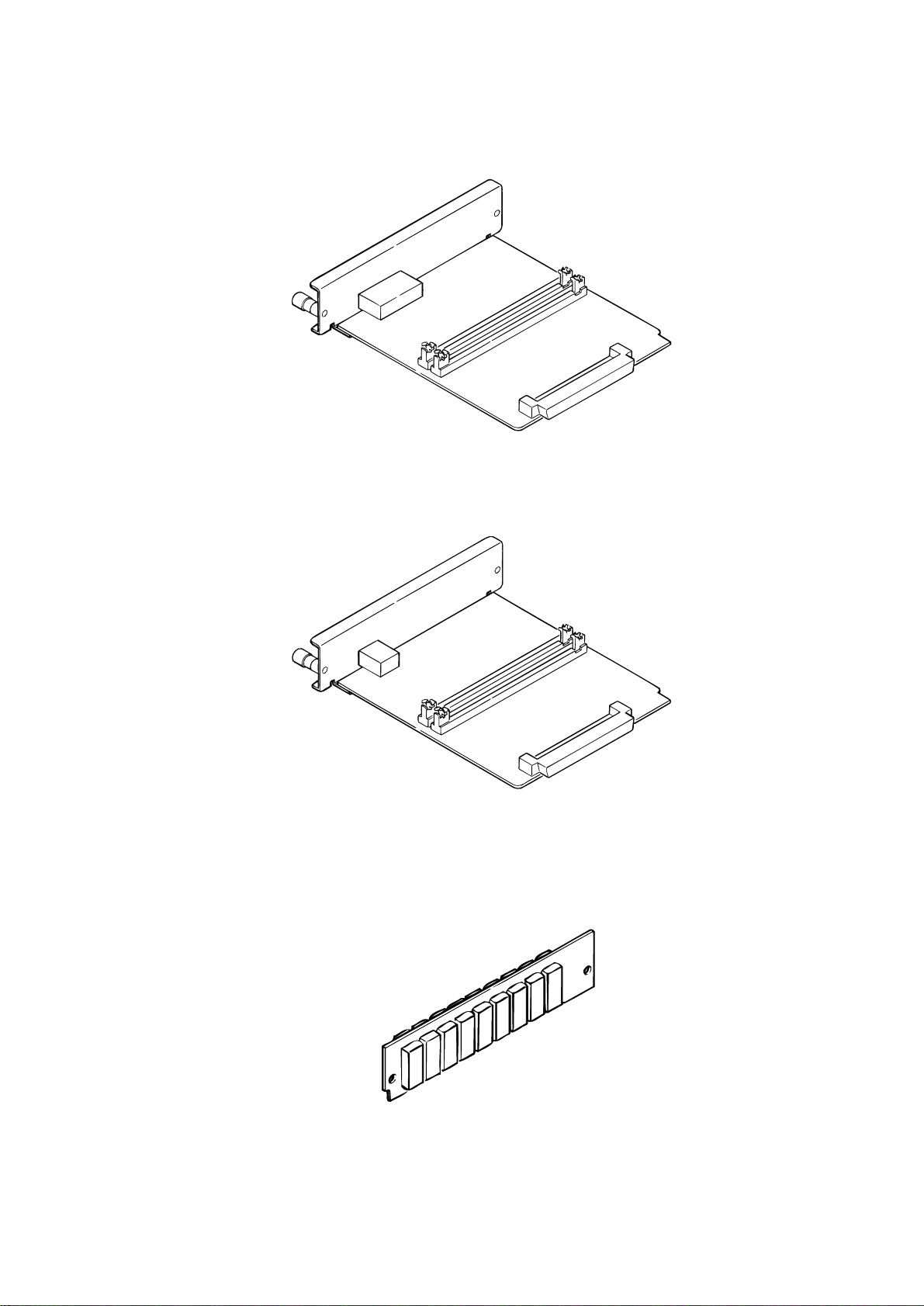

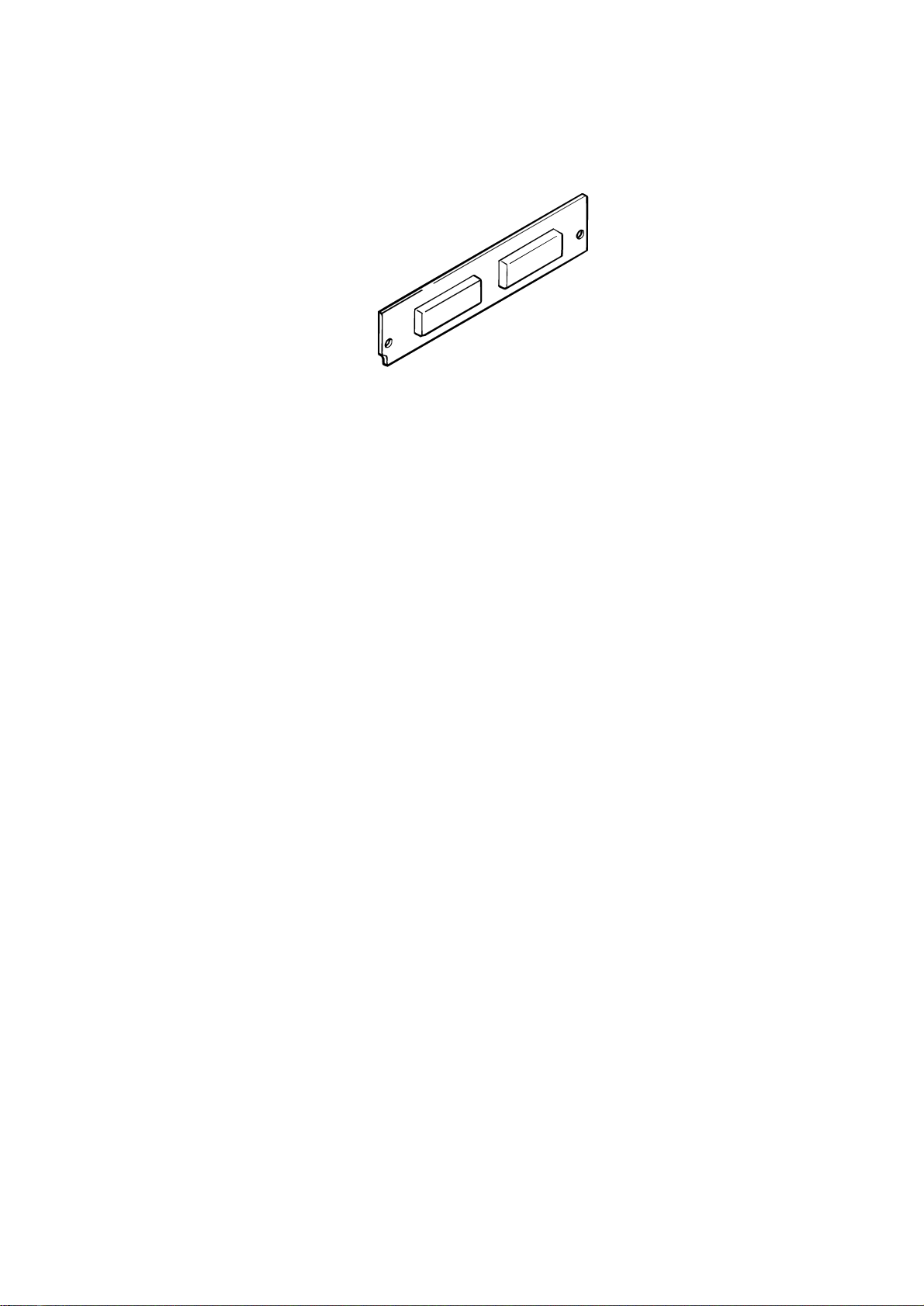

1.3 Optional Configuration

The options shown below are available for use with OKIPAGE 10i. These are available separately

from the printer unit.

(1) High Capacity Second Paper Feeder

(2) Power Envelope Feeder

(3) 1MB Memory Expausion Board

1 - 4

(4) RS-232C Serial Interface Board

(5) Network Interface Board

(6) DRAM SIMM Memory

DRAM SIMM memory is available with memory of 1MB (min.) to 32MB (max.). The access

time of SIMM memories are 60ns, 70ns, 80ns, and 100ns.

1 - 5

(7) PostScript program SIMM

1 - 6

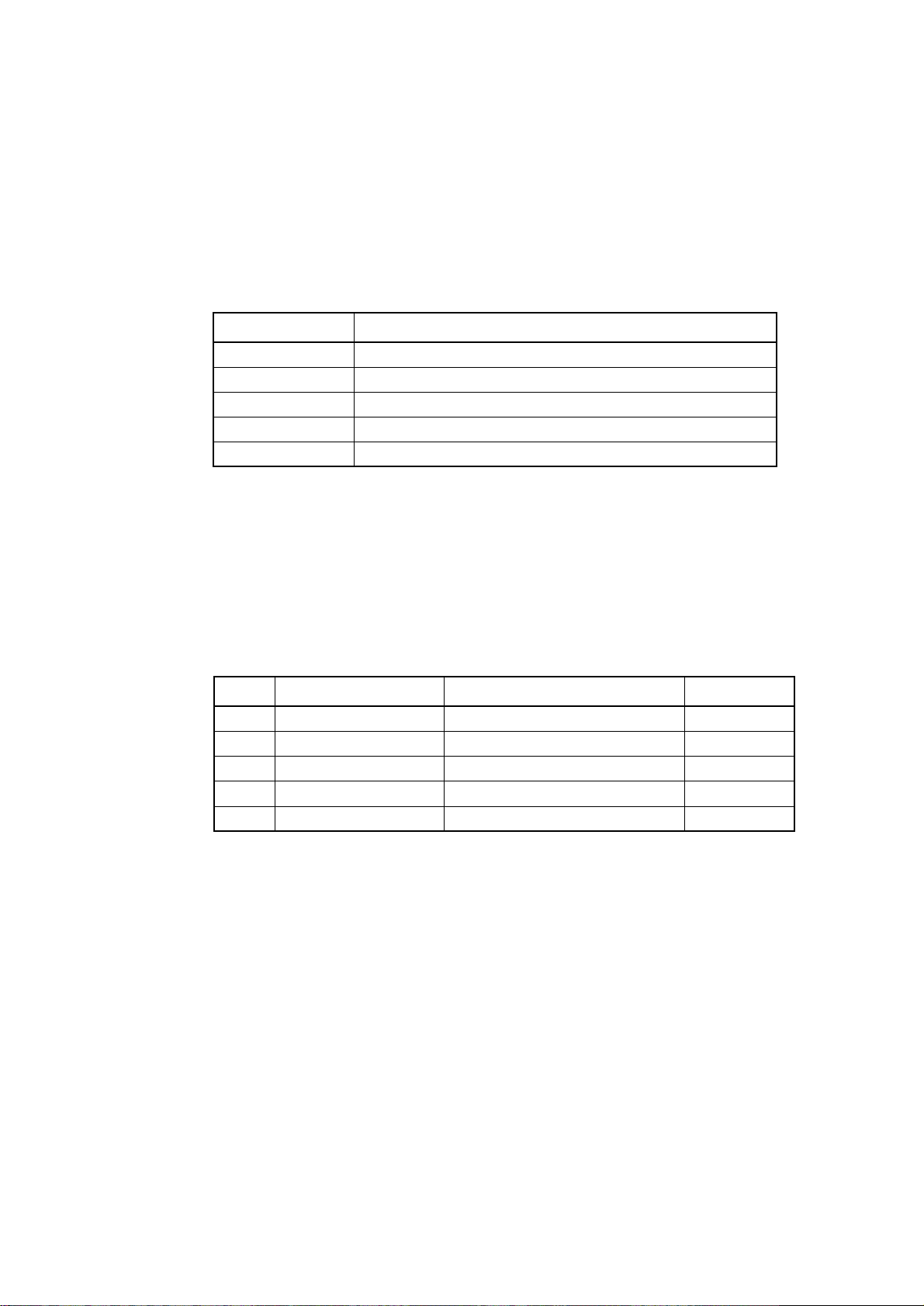

1.4 Specification

(1) Type Desktop

(2) External dimensions Height 7.9” (200 mm)

(excludes protruding Width 13.0” (330 mm)

portion) Depth 14.9” (378 mm)

(3) Weight 10 kg

(4) Developing method Dry electrophotography

Exposing method LED stationary head

(5) Paper used <Type>

• Standard paper

– Xerox 4200 (20 lbs)

• Application paper (manual face-up feed)

– Label

– Envelope

– OHP paper (transparency)

<Size>

• Standard sizes

– Letter

– Legal

– Legal-13

– Executive

– COM-10

– Monarch

– DL

– C5

– COM-9

– A4

– A5

– B5 (JIS)

– A6

• Applicable sizes

– Width: 3.87” to 8.5” (116 to 216 mm)

– Length: 5.83” to 14” (148 to 355.6 mm)

<Thickness>

– Automatic feed: 16 to 28 lbs (60 to 135 g/m2)

– Manual feed: Label, OHP paper (transparency)

Envelope

(6) Printing speed Continuous printing: 10 pages per minute with Letter size

paper. [Except Second Paper Feeder

(8.8PPM), Multi purpose Feeder (8.3ppm)]

Warm-up time:

First page print time: 12 seconds typical for the Letter size

(7) Paper feeding method Automatic feed or manual feed

1 - 7

80 seconds typical at room temperature

[77˚F (25˚C), AC 120/230 V].

paper after warm-up.

(8) Paper delivery method Face down/face up

(9) Resolution 600 x 600 dots/inch

600 x 1200 dots/inch

(10) Power input 120 VAC + 5.5%, -15%

230 VAC ± 10%

(11) Power consumption Peak: Approx. 460W

Typical operation: Approx. 215W

Idle: Approx. 61W

Power save mode: Approx. 18W

(12) Temperature and humidity

In operation Power off mode During Storage Unit

Temperature

Humidity

Maximum wet bulb

temperature

Minimum difference

between wet and dry

bulb temperatures

1. Storage conditions specified above apply to printers in packed condition.

2. Temperature and humidity must be in the range where no condensation occurs.

(13) Noise During operation: 50 dB (A) or less

(14) Consumables Toner cartridge kit 2,000 (5% duty)

50-90

(10-32)

20-80

77

(25)

35.6

(2)

Standby: 38 dB (A) or less

Quiet mode: Back ground level

Image drum cartridge 20,000 (at continuouts printing)

32-110

(0-43)

10-90

80.4

(26.8)

35.6

(2)

14-110

(–10-43)

10-90

14,000 (3 page/job) without Power Save

˚F

(˚C)

%RH

˚F

(˚C)

˚F

(˚C)

1 - 8

1.5 Safety Standards

1.5.1 Certification Label

The safety certification label is affixed to the printer in the position described below.

ODA AC : 120V model ODA AC : 230V model

1.5.2 Warning Label

The warning labels are affixed to the sections which may cause bodily injury.

Follow the instructions on warning labels during maintenance.

1 - 9

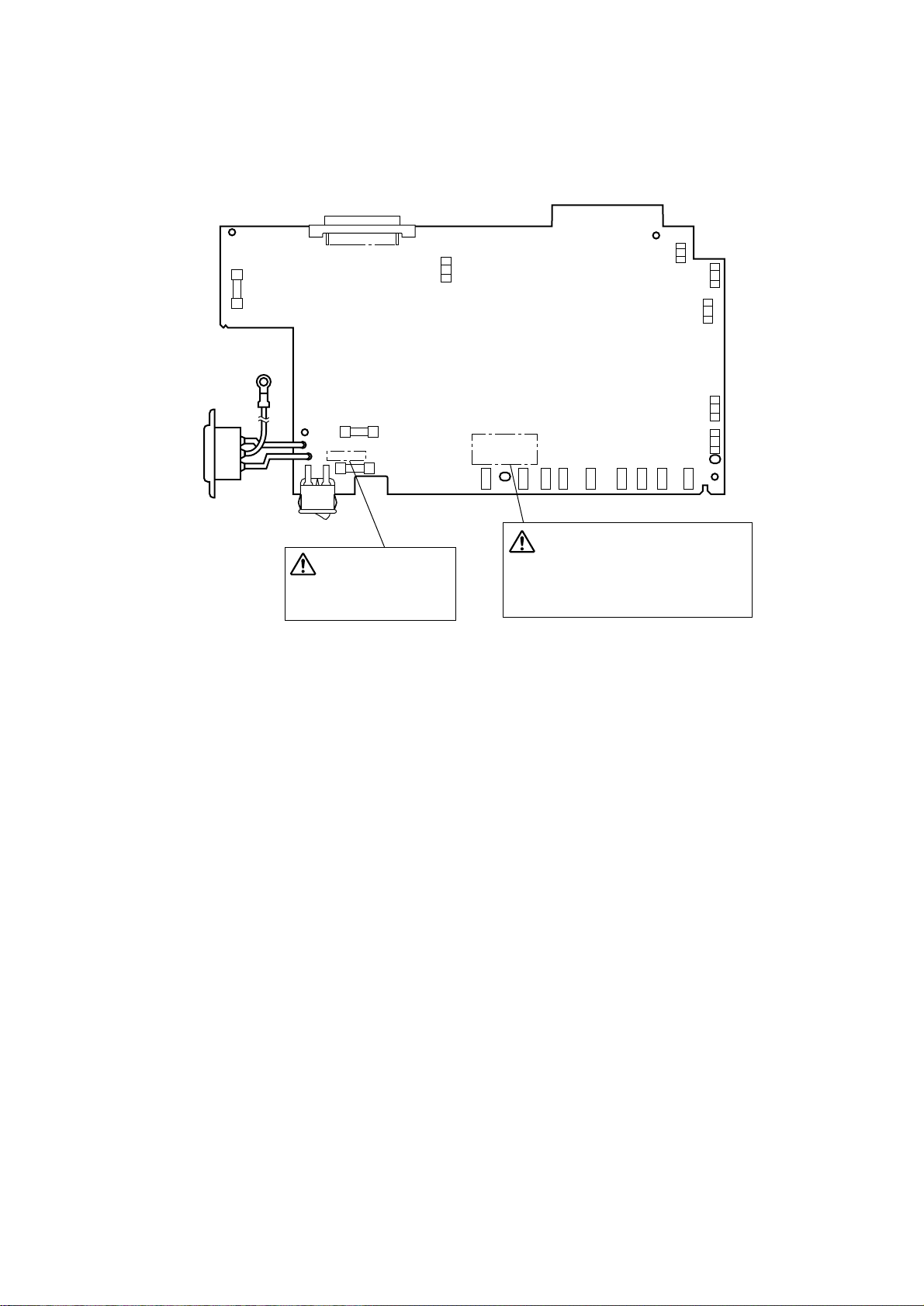

1.5.3 Warning/Caution Marking

The following warning and caution markings are made on the power supply/sensor board.

F3

CAUTION

ATTENTION ATENCÃO

CUIDADO CUIDÃDO

*

WARNING

AVERTISSEMENT

ADVERTENCIA

HEATSINK AND TRANSFORMER

PRESENT RISK OF ELECTRIC SHOCK

TEST BEFORE TOUCHING

ENGLISH

Heatsink and transformer core present risk of electric shock. Test before touching.

FRENCH

Le dissipateur thermique et le noyau du transformateur présentent des risques de choc

électrique. Testez avant de manipuler.

SPANISH

Las disipadores de color el núcel del transformador pueden producir un choque eléctrico.

Compruebe antes de tocar.

PORTUGUESE

O dissipador de calor e o núcleo do fransiormador apresentam risco de choque elétrico. Teste

antes de focar.

ENGLISH

Circuits maybe live after fuses open.

FRENCH

Il se peut que les circuits soient sous tension une fois que les fusibles ont éfé rerirés.

SPANISH

Las circuitos pueden estar activos una vez que se hayan abierio los fusibles.

PORTUGUESE

Os circuitos podem estar energizados após os fusiveis se queimarem.

* No fuse is mounted here for 200V series

1 - 10

2. OPERATION DESCRIPTION

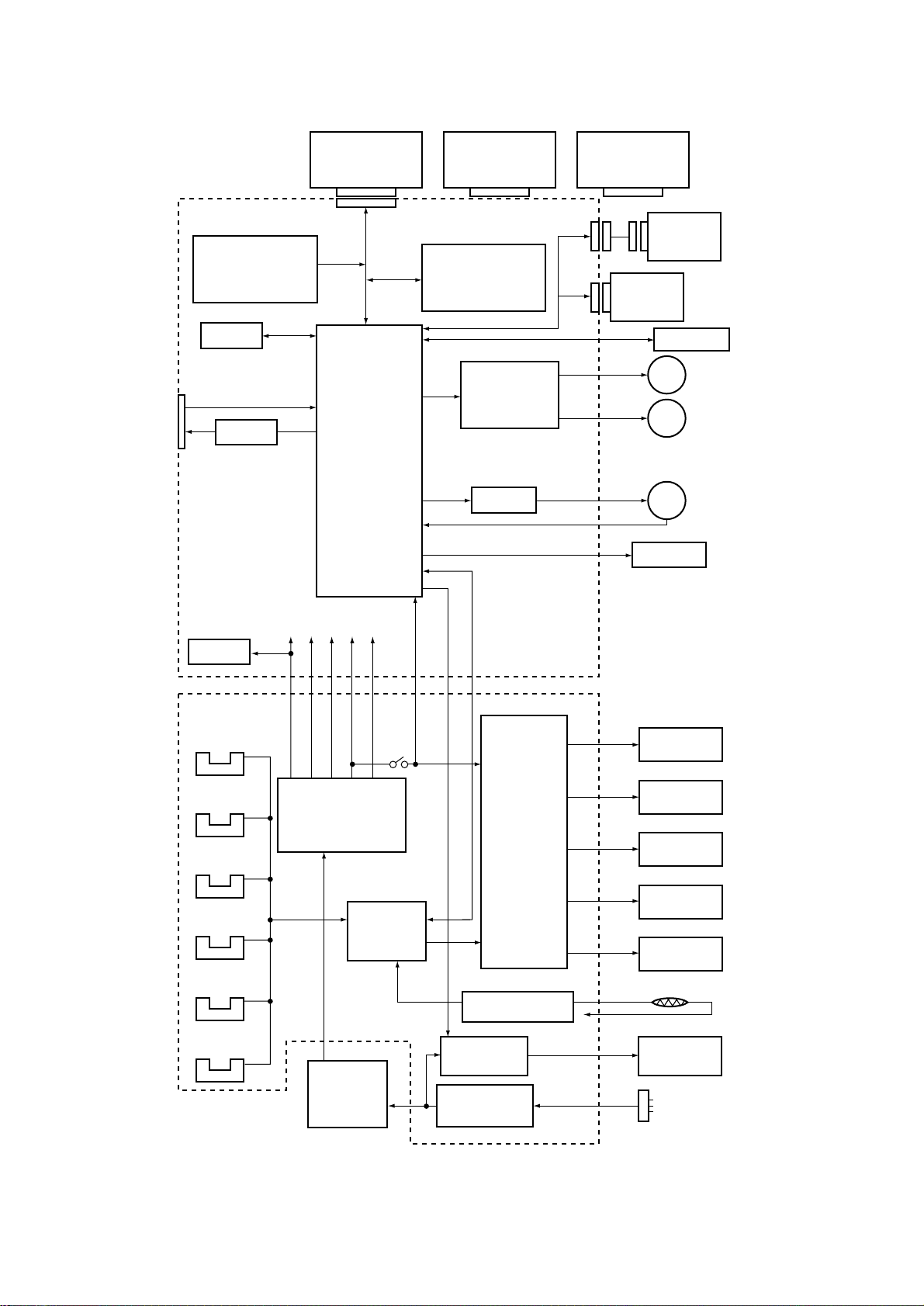

OKIPAGE 10i consists of a main control board, a power supply/sensor board, an operator panel,

an electrophotographic process mechanism, and revision for illumination of LED head.

The main control board receives data via the host I/F, it then decodes, edits and stores the data

in memory. After completing the editing of a single page of data, it references the font memory

and generates bit image data, which is transferred to the LED head in one dot line units.

Through the electrophotographic process mechanism, the data is printed on the paper.

The operator panel is used for operations and status display.

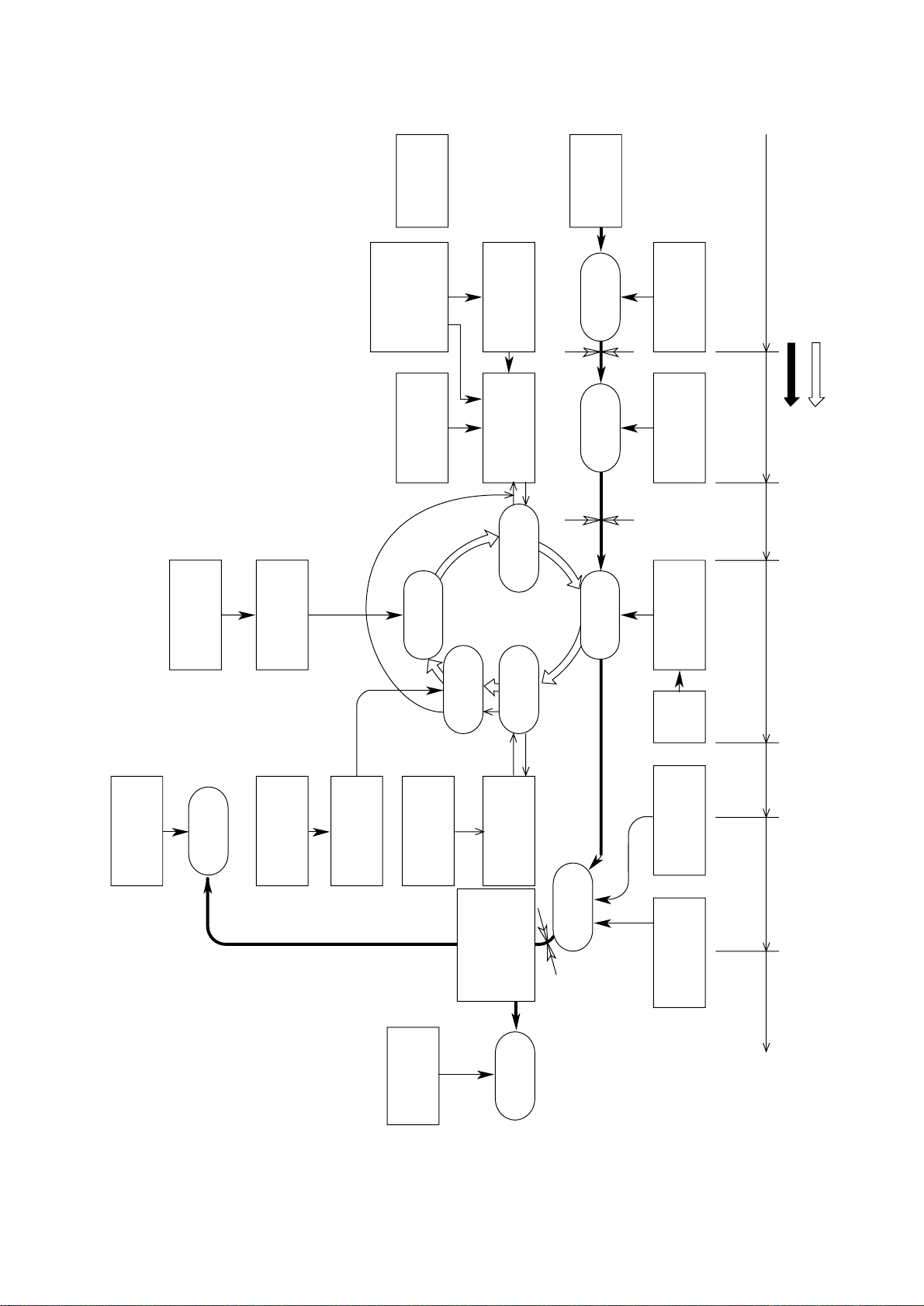

OKIPAGE 10i block diagram is shown in Figure 2-1.

2 - 1

1MB Memory Board

(Option)

RS232C Interface Board

or

(Option)

Network Interface Board

or

(Option)

Main Control Board

Program & Font ROM

6MB Mask ROM

EEPROM

Centronics

parallel I/F

7407

+8V -8V 0V +5V+30V

Reset

circuit

For optional board

DATA

BUS

(32bit)

1 Chip CPU

Resident RAM

512K x 8 DRAM

(2MB)

Drum motor &

Registration motor

HEAT ON

drive circuit

FAN Driver

Multi-Purpose

Feeder (Option)

High Capacity

Second Paper

Feeder (Option)

Operation Panel

Drum Motor

MMRegistration Motor

FAN

FAN ALM

LED Head

Power Supply

Board

Inlet sensor 1

Inlet sensor 2

Paper sensor

Outlet sensor

Paper out sensor

Toner low sensor

Cover

open

switch

Low voltage

generation circuit

LSI

AC

transformer

Charge roller

Transfer roller

High voltage

generation

circuit

Fusing temperature

control circuit

Heater drive

circuit

Filter circuit AC IN

Developping

roller

Toner supply

roller

Cleaning

roller

Thermistor

Heater

Figure 2-1 OKIPAGE 10i Block Diagram

2 - 2

2.1 Main Control Board

The main control board consists of a single chip CPU, two program/font ROMs, four DRAMs, an

EEPROM, a host interface circuit, and a mechanism driving circuit.

(1) Single chip CPU

The single chip CPU is a custom CPU (32-bit internal bus, 32-bit external bus, 28.24-MHz

clock, with input frequency from a 7.06-MHz clock) which incorporates the RISC CPU and

its peripheral devices, and has the following functions:

Built-in device Function

Chip select controller

Bus controller

DRAM controller

DMA controller

Parallel interface controller

Serial interface controller

Video output port

LED STB output port

Timer

Serial I/O port

I/O port

(2) Program and Font ROMs

The Program and Font ROMs store the equipment program and various types of fonts.

EPROM or Mask ROM is used as Program and Font ROMs. The mounting locations of these

Program and Font ROMs vary depending on the type of the ROMs (for the mounting location

see Section 7.4).

Control of ROM, DRAM and I/O device

Transfer of image data from DRAM to video output port

Control of Centronics parallel interface

Control of RS-232C serial interface

Control of LED head

Generation of various control timing

Monitoring of paper running and paper size

Control of operator panel, EEPROM, and options

Input and output of sensor and motor signals

(3) DRAM

The DRAM is a 2MB resident memory on the main control board that stores edited data,

image data, DLL data and macro data.

(4) EEPROM

1,024-bit Electrically Erasable PROM (EEPROM), is loaded with the following kinds of data:

• Menu data

• Various counter data (page counter, drum counter)

• Adjusting parameters (LED head drive time, print start position, paper feed length)

(5) Parallel Interface

Parallel data is received from a host system via parallel interface which conforms to the

IEEE1284 specification.

2 - 3

2.2 Power Supply/Sensor Board

The power supply/sensor board consists of an AC filter circuit, a low voltage power supply circuit,

a high voltage power supply circuit, heater drive circuit, and photosensors.

(1) Low Voltage Power Supply Circuit

This circuit generates the following voltages.

Output voltage Use

+5 V

+30 V

+8 V

–8 V

+3.3V

(2) High Voltage Power Supply Circuit

This circuit generates the following voltages required for electrophotographic process from

+5 V, according to the control sequence from the main control board. When cover open state

is detected, +5 V supply is interrupted automatically to stop the supply of all high-voltage

outputs.

Output Voltage Use Remarks

CH

DB

SB

TR

CB

-1.3 KV

-265 V/+300 V

-500 V/ 0 V

+500 V to +3.5 KV/-1100 V

+400 V/-1350 V

Logic circuit supply voltage

Motor and fan drive voltage and source voltage for high-voltage supply

RS-232C line voltage

RS-232C line voltage and PS board supply voltage

LED head supply voltage

Voltage applied to charging roller

Voltage applied to developing roller

Voltage applied to toner supply roller

Voltage applied to transfer roller

Voltage applied to clearing roller

Variable

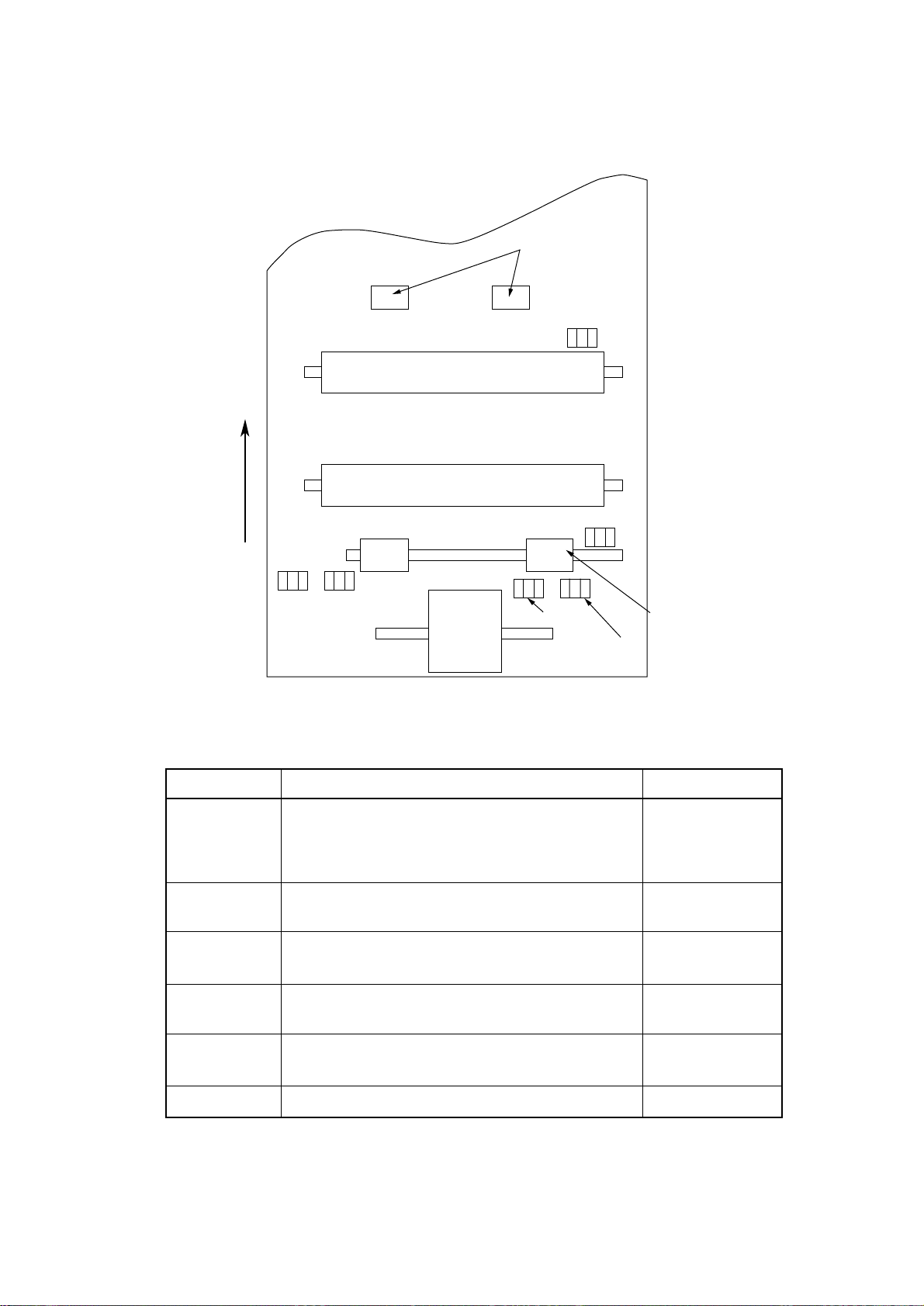

(3) Photosensor

The photosensor mounted on this power supply/sensor board monitors the status of paper

being fed through the printer during printing.

2 - 4

The sensor layout diagram is shown in Figure 2-2.

Heat roller

Transfer roller

Exit roller

Outlet sensor

Paper sensor

Inlet

Toner

sensor 2

sensor

Paper feeding direction

Hopping

roller

Paper end sensor

Inlet sensor 1

Registration roller

Figure 2-2

Sensor Function Sensing state

Inlet sensor 1

Detects the leading part of the paper and gives the monitor timing

for switching from hopping operation to feeding operation.

ON: Paper exists.

OFF: No paper exists.

Monitors paper feeding situation and paper size based on the

paper arrival time and running time.

Intel sensor 2

Detects the paper width.

ON: A4 or larger

OFF: Smaller than A4

Paper sensor

Outlet sensor

Detects the leading portion of the paper.

Monitors the paper feeding situation.

Monitors the paper feeding and size according to the time of

arrival to and leaving past the sensor.

ON: Paper exists.

OFF: No paper exists.

ON: Paper exists.

OFF: No paper exists.

Paper end sensor

Toner low sensor

Detects the end of the paper.

Detects the lack of toner.

2 - 5

ON: Paper exists.

OFF: No paper exists.

- - - - -

2.3 Electrophotographic Process

2.3.1 Electrophotographic Process Mechanism

This mechanism actuates the printing of image data supplied by the main control board on the

paper by electrophotographic process.

The layout of the electrophotographic process mechanism is shown in Figure 2-3.

2 - 6

Paper cassette Outlet sensor plate

Eject roller assy Heat roller Charge roller Developing roller Toner cartridge

LED head Image drum unit

Back-up roller

Cleaning roller

Transfer roller Paper sensor

plate

Inlet

sensor

plate

Registration

roller

Hopping roller

Figure 2-3

2 - 7

(1) Image Drum Unit

The image drum unit consists of a sensitive drum, a charger, and a developer. The unit forms

a toner image on the sensitive drum, using a electrostatic latent image formed by the LED

head.

(2) Registration Motor

The registration motor is a pulse motor of 48 steps/rotation with two-phase excitement by the

signal from the main control board. It drives the hopping and registration rollers via two oneway clutches according to the direction of rotation.

(3) Main (Drum) Motor

The main or drum motor is a pulse motor of 48 steps/rotation with two-phase excitement by

the signal from the main control board and is the main motor of this mechanism.

(4) LED Head

Image data for each dot line from the main control board is received by the shift register and

latch register. The 4992 LED's are driven to radiate the image data on the image drum.

(5) Fuser

The fuser consists of a heater, a heat roller, a thermistor and a thermostat.

The AC voltage from the power supply/sensor board is applied to the heater controlled by

the HEATON signal from the main control board. This AC voltage heats the heater. The main

control board monitors the heat roller temperature via the thermistor, and regulates the

heater roller to keep it at a designated temperature in the menu, depending on the thickness

of the paper (tray 1&2: light=165°C, medium light=170°C, medium=175°C, medium heavy

and heavy=195°C; manual feeding and power envelope feeder: light=175°C, medium

light=180°C, medium=185°C, medium heavy=190°C, heavy=195°C, transparency = 160°C)

by connecting or disconnecting the AC voltage supply to the heater.

When an abnormal rise of the heater roller temperature takes place, the thermostat of the

heater voltage supply circuit becomes active and forcibly cuts the AC voltage supply.

The temperature setting of the fuser can be changed through operator panel setting.

2 - 8

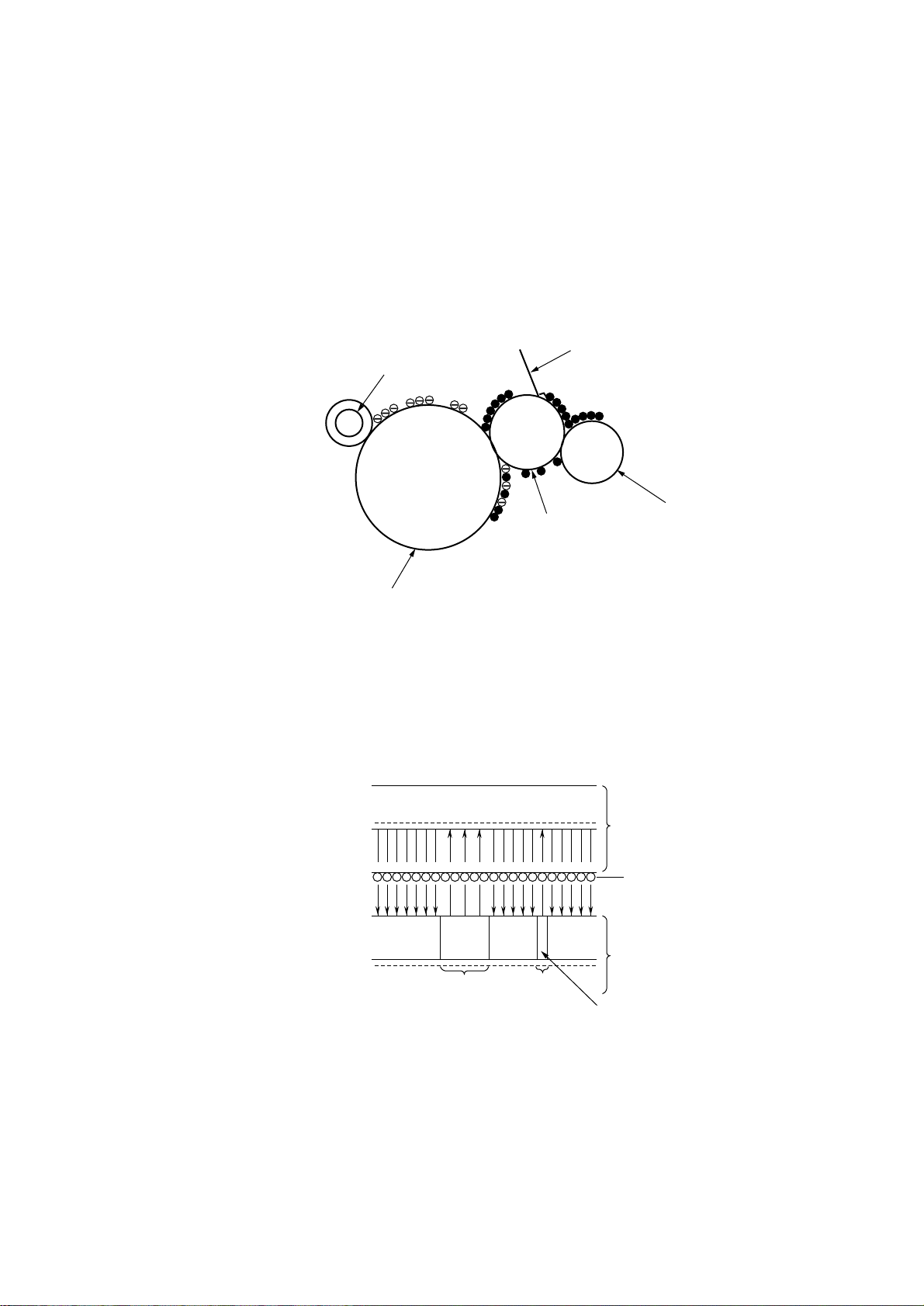

2.3.2 Electrophotographic Process

The electrophotographic processing is outlined below. The electrophotographic printing process

is shown in Figure 2-4.

1 Charging

The surface of the image drum is charged uniformly with a negative charge by applying the

negative voltage to the charge roller.

2 Exposure

Light emitted from the LED head irradiates the negatively charged surface of the image drum.

The surface potential of the irradiated portion of the image drum surface becomes lower,

forming the electrostatic latent image associated with the print image.

3 Developing and toner recovery

When the negatively charged toner is brought into contact with the image drum, it is attracted

to the electrostatic latent image by static electricity, making the image visible.

At the same time, the residual toner on the image drum is attracted to the developing roller

by static electricity.

4 Transfer

When paper is placed over the image drum surface, the positive charge which is opposite

in polarity to that of the toner, is applied to the reverse side of the paper by the transfer roller.

The toner is attracted by the positive charge and is transferred onto the paper. This results

in the transfer of the toner image formed on the image drum onto the paper.

5 Temporary cleaning

Residual toner which remains on the image drum without being transferred is evened out by

the cleaning roller and is temporarily attracted to the cleaning roller by static electricity.

6 Fusing

The toner image transferred onto the paper is fused to the paper by heat and pressure.

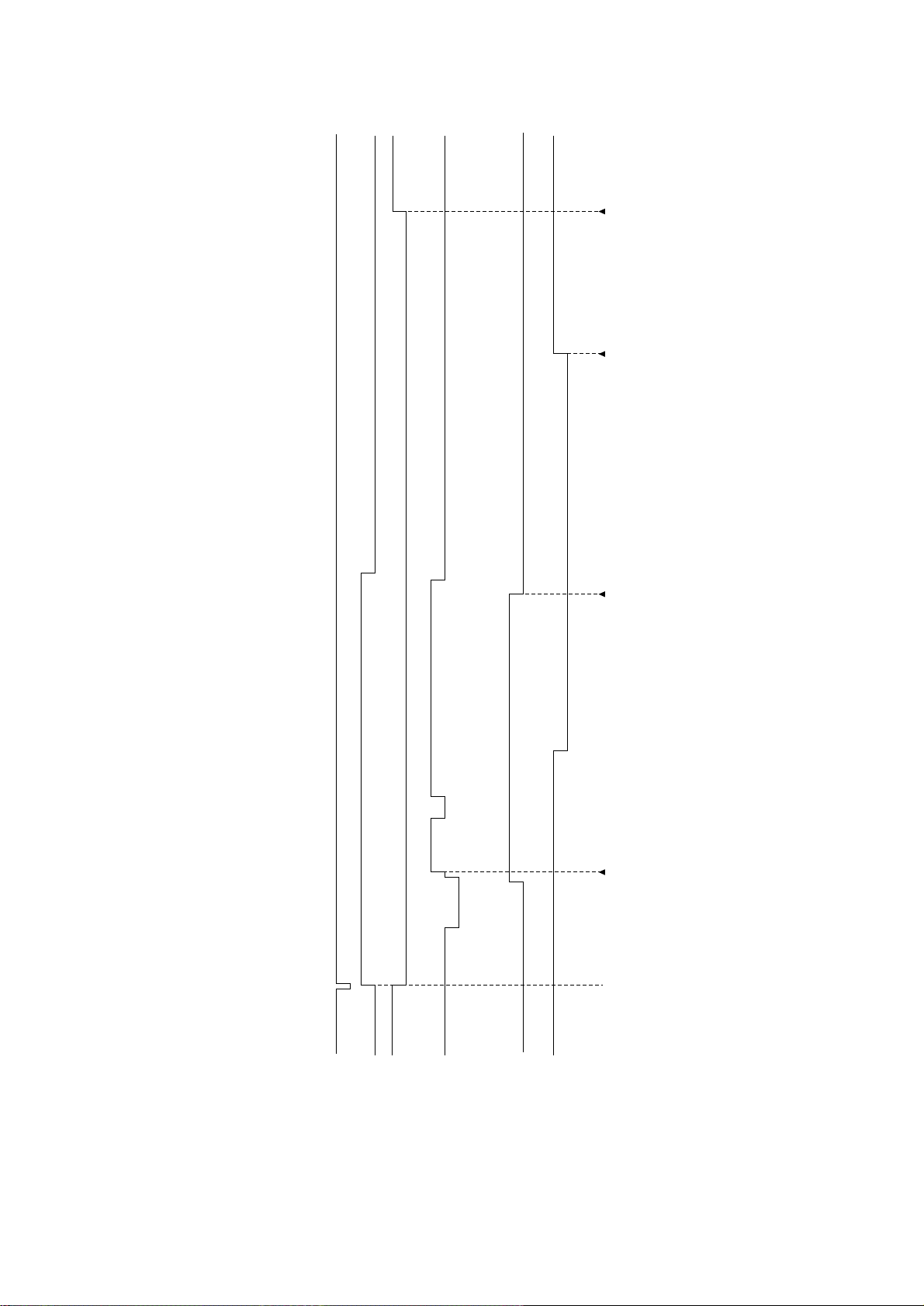

An electrophotographic process timing chart is shown in Figure 2-5.

2 - 9

Paper eject roller

(Face down)

Power supply

Paper eject roller

Paper eject

(Face up)

Cleaning roller

LED head

Image data

Registration roller Hopping roller

Heater roller

Power

supply

Doctor blade

Power supply

(Bias voltage)

Toner supply roller

Toner cartridge

Paper

eject

Fusing

Back-up roller Transfer roller

Charger roller

Charging

Cleaning

Paper hopping

Paper feed

Image

production

developing

Transfer

Cleaning

FusingPaper eject

Path of paper feeding

Direction of rotation of the image drum

Power supply

Outlet sensor

Inlet sensor

Developing

Developing roller

Paper sensor

Exposure

Transfer

Paper path selector

Paper

registration

Paper

supply

Paper tray

Figure 2-4

2 - 10

Feed stopIN Sensor OFFFeed start

OUT Sensor OFF

PRDY-N

PRINT-N

DM-ON-N

Figure 2-5

2 - 11

RM-ON

INSNS

OUTSNS-N

2.3.3 Process Operation Descriptions

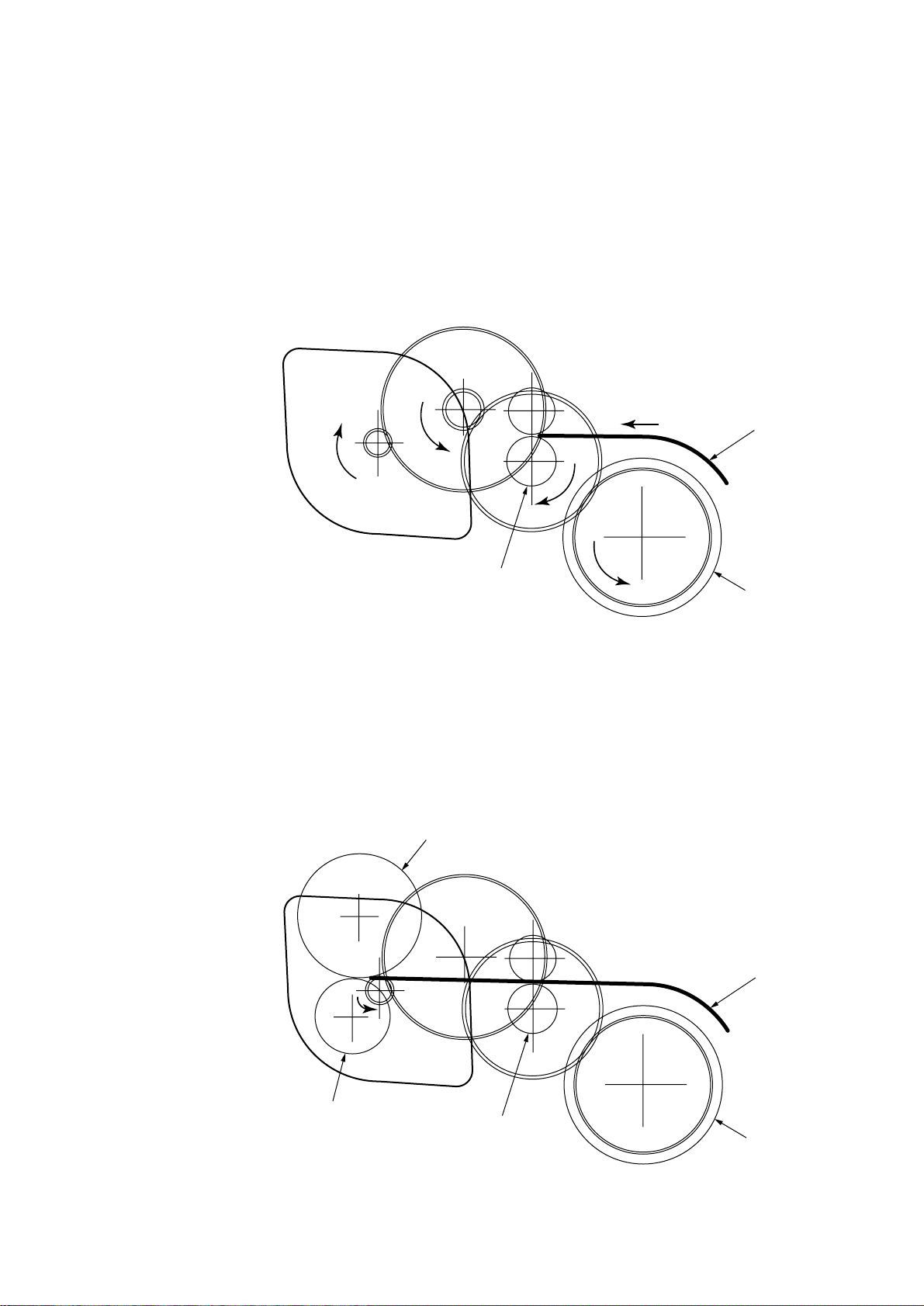

(1) Hopping and Feeding

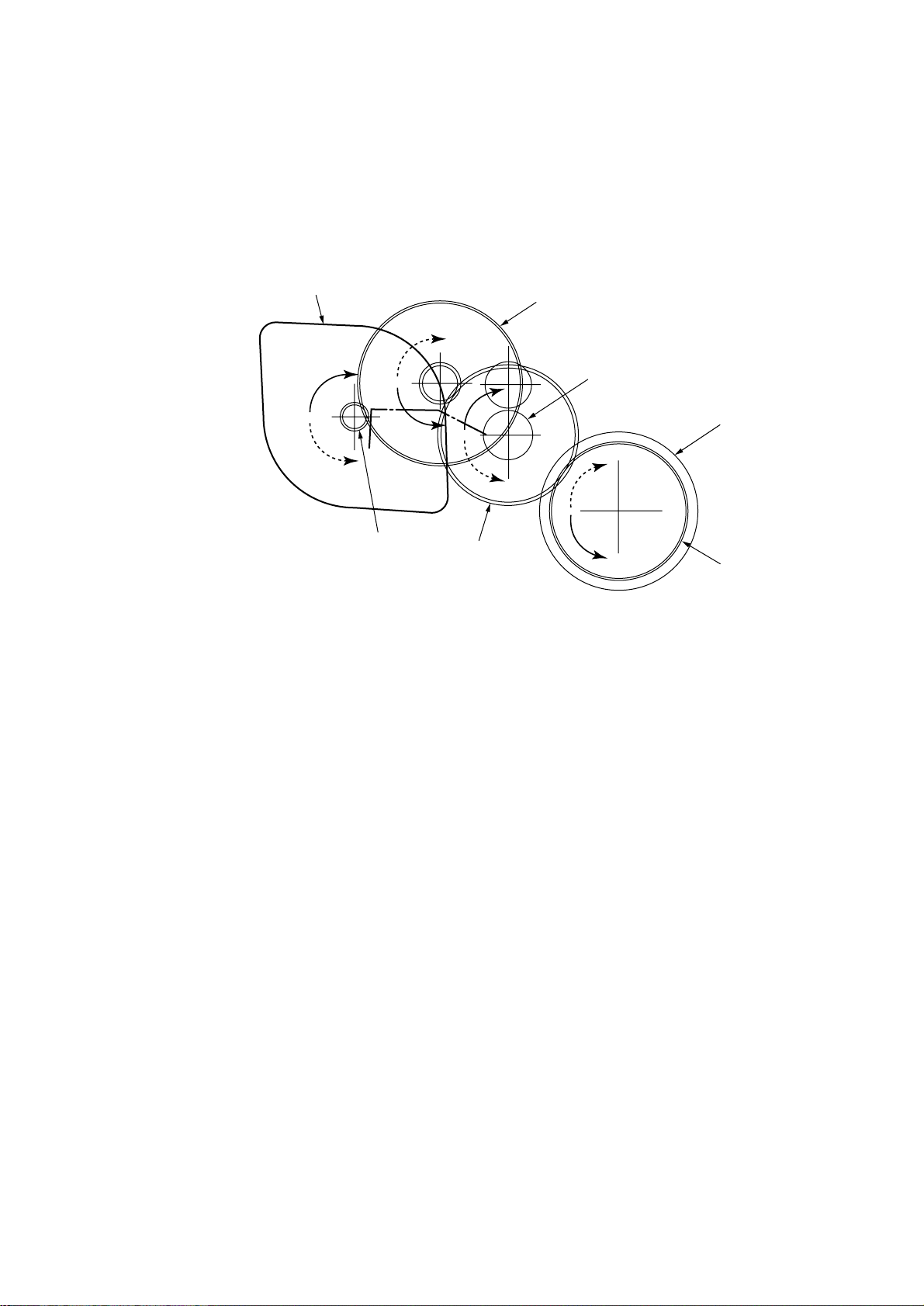

Hopping and feeding motions are actuated by a single registration motor in the mechanism

as shown below:

Registration motor

a

Idle gear

Registration roller

Hopping roller

b

Motor gear

Registration gear

Hopping gear

The registration motor turning in direction "a" drives the hopping roller. The registration motor

turning in direction "b" drives the registration roller. The registration and hopping gears have

one-way bearing, so turning any of these gears in the reverse direction will not transmit the

motion to the corresponding roller.

2 - 12

(a) Hopping

1 For hopping, the registration motor turns in direction "a" (clockwise direction) and

drives the hopping roller to advance the paper until the inlet sensor turns on (in this

case, the registration gear also turns, but the registration roller is prevented from

turning by the one-way bearing).

2 After inlet sensor is turned on by the paper advance, the paper is further advanced

to a predetermined distance until the paper hits the registration roller (the skew of

the paper can thus be corrected).

a

Registration roller

Hopping roller

Paper

(b) Feeding

1 When hopping is completed, the registration motor turning in direction "b" (counter-

clockwise direction) drives the registration roller to advance the paper (in this case,

the hopping gear also turns, but the hopping roller is prevented from turning by the

one-way bearing).

2 The paper is further advanced in synchronization with the print data.

Image drum

b

Transfer roller

Registration roller

Hopping roller

Paper

2 - 13

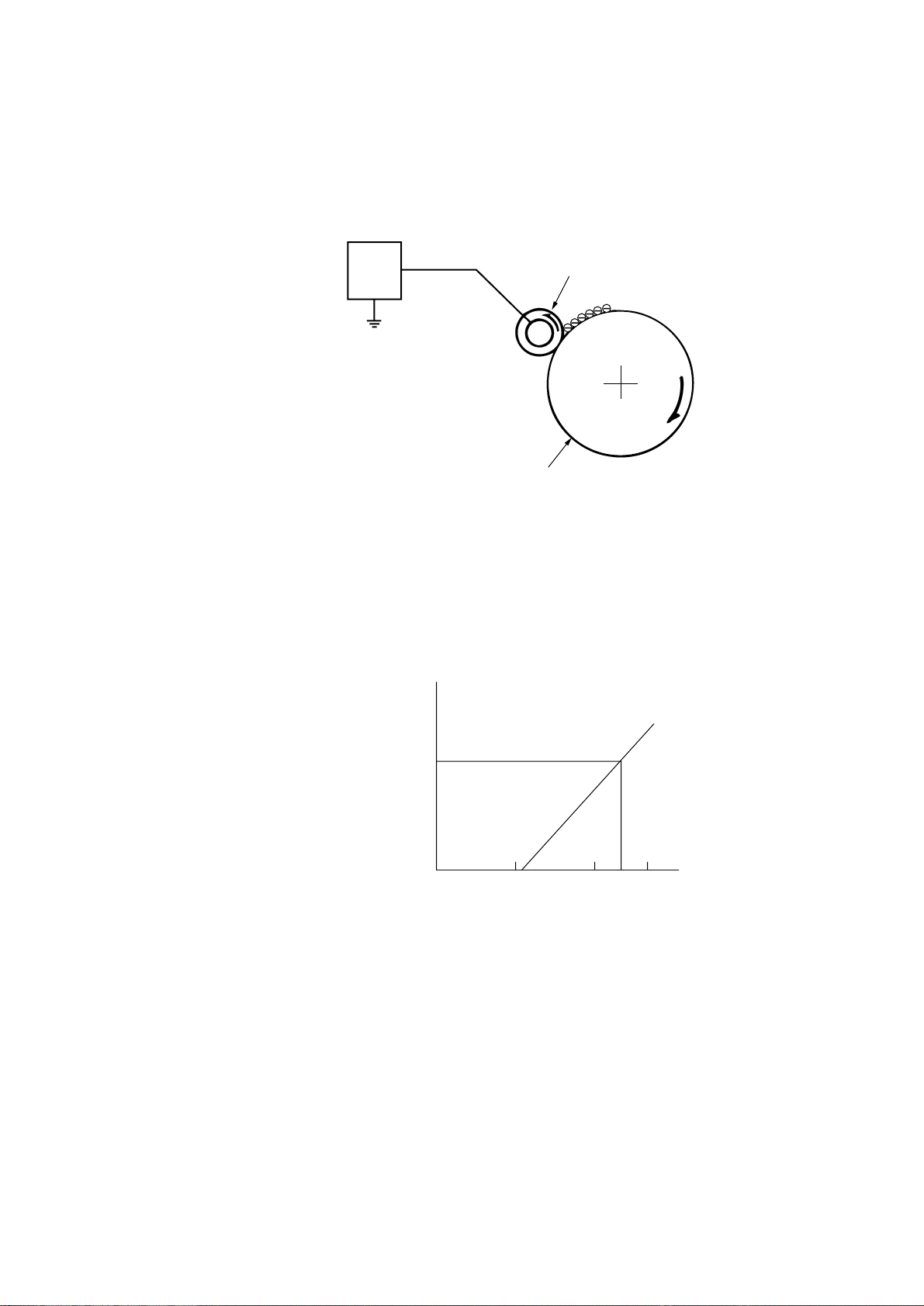

(2) Charging

Charging is actuated by the application of the DC voltage to the charge roller that is in contact

with the image drum surface.

Power

supply

Charge roller

Image drum

The charge roller is composed of two layers, a conductive layer and a surface protective

layer, both having elasticity to secure good contact with the image drum. When the DC

voltage applied by the power supply exceeds the threshold value, charging begins. The

applied voltage is proportional to the charge potential, with offset of approximately –550V.

charge potential

[V]

-750

-1300-550 [V]

applied voltage

2 - 14

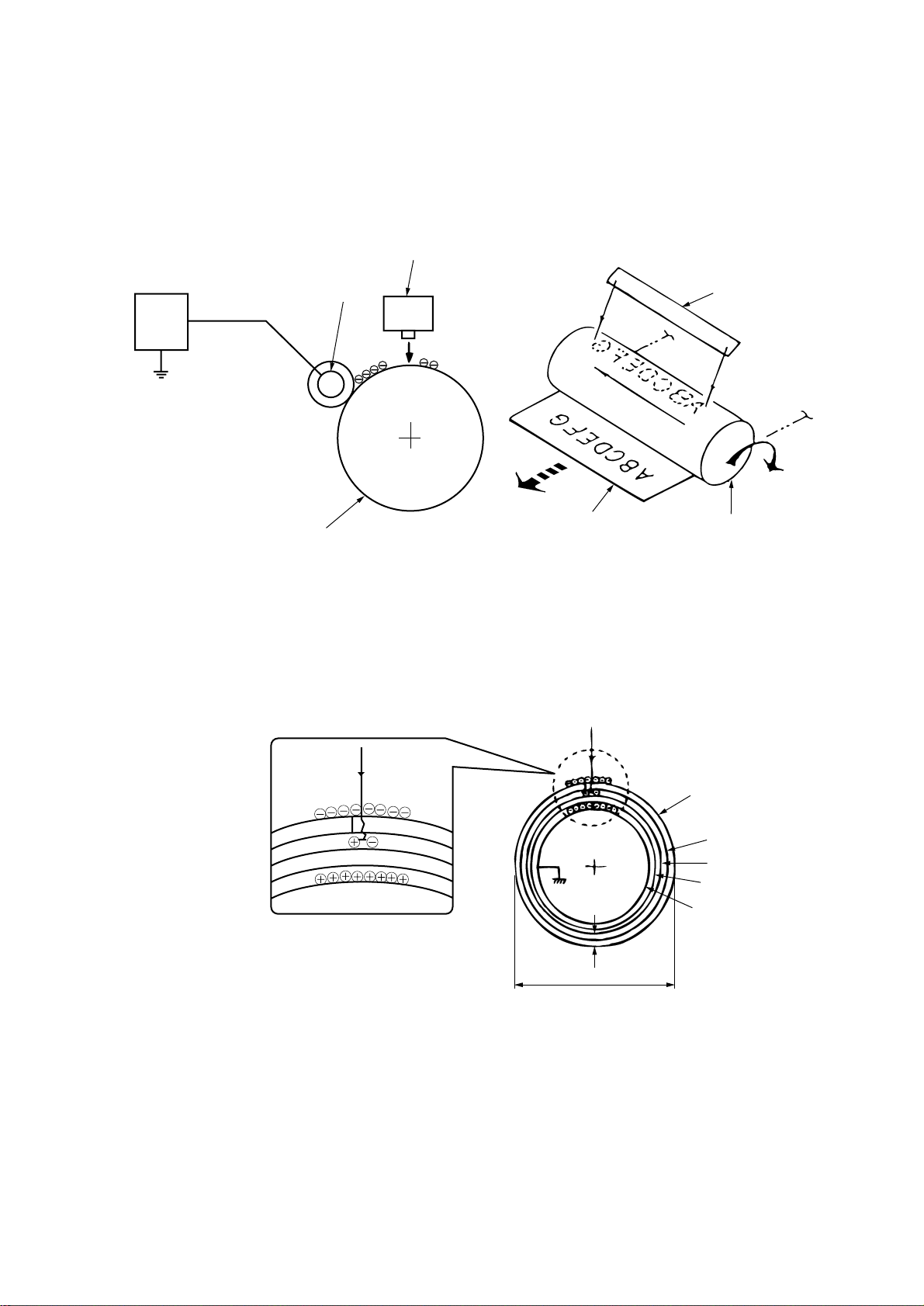

(3) Exposure

Light emitted by the LED head irradiates the image drum surface with a negative charge. The

surface potential of the irradiated portion of the image drum drops, forming an electrostatic

latent image associated with the image signal.

LED head

Power

supply

Charge roller

Paper

Image drum

LED head

Image drum

The image drum is coated with an underlayer (UL), a carrier generation layer (CGL), and

carrier transfer layer (CTL) on aluminum base. The organic photo conductor layer (OPC),

comprising CTL and CGL, is about 20 µm thick.

2 - 15

20

30mm

Image drum

CTL

CGL

UL

Base

µ

m

The image roller surface is charged to about –750 V by the contact charge of the charge roller.

When the light from the LED head irradiates the image drum surface, the light energy

generates positive and negative carriers in the CGL. The positive carriers are moved to the

CTL by an electrical field acting on the image drum. Likewise, the negative carriers flow into

the aluminum layer (ground).

The positive carriers moved to the CTL combine with the negative charges on the image drum

surface accumulated by the contact charge of the charge roller, lowering the potential on the

image drum surface. The resultant drop in the potential of the irradiated portion of the image

drum surface forms an electrostatic latent image on it. The irradiated portion of the image

drum surface is kept to about –100 V.

(V)

–750

Image drum

surface potential

–100

0

Charged part

Light

from

LED

Part

irradiated

by

LED

Charged

part

2 - 16

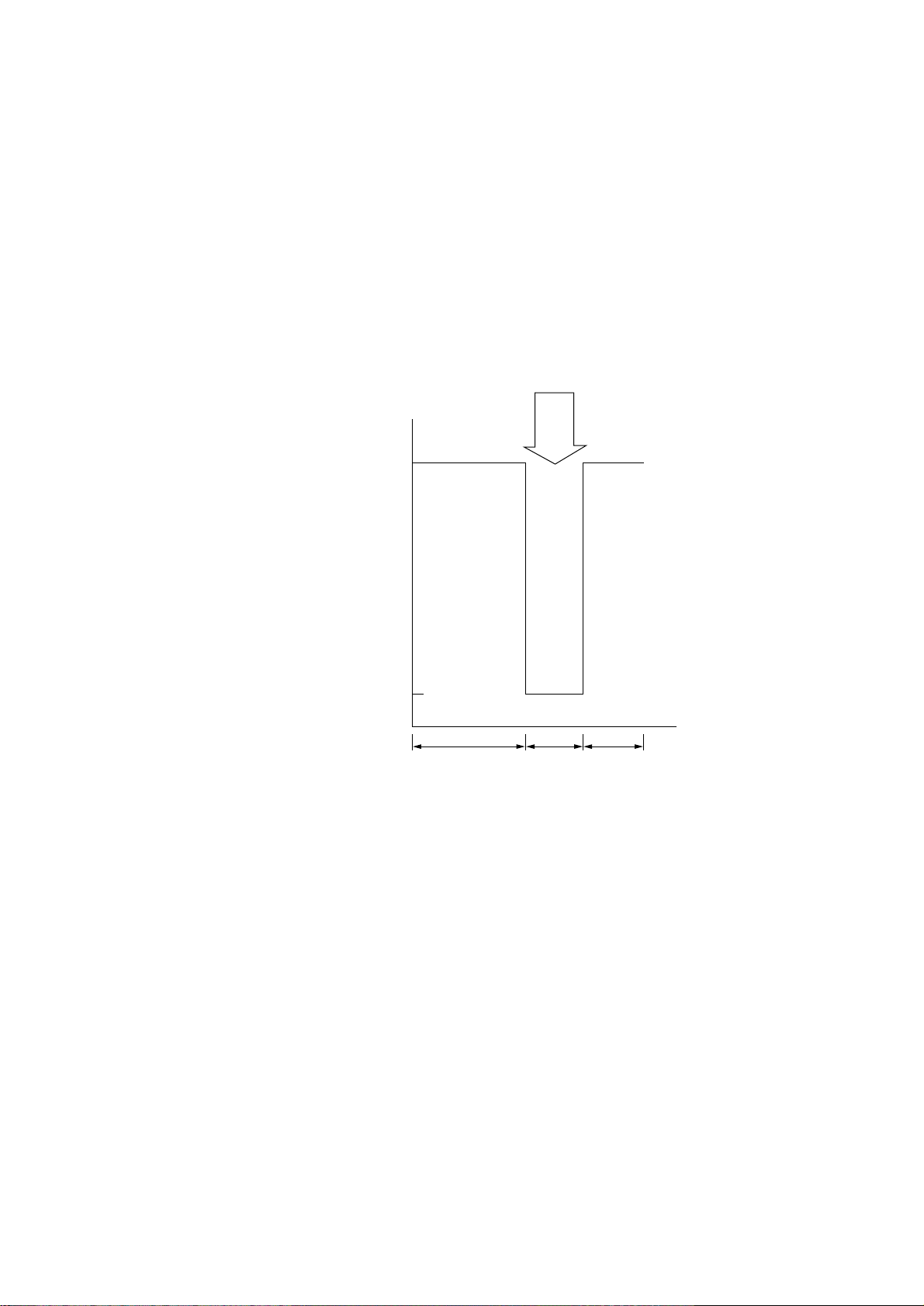

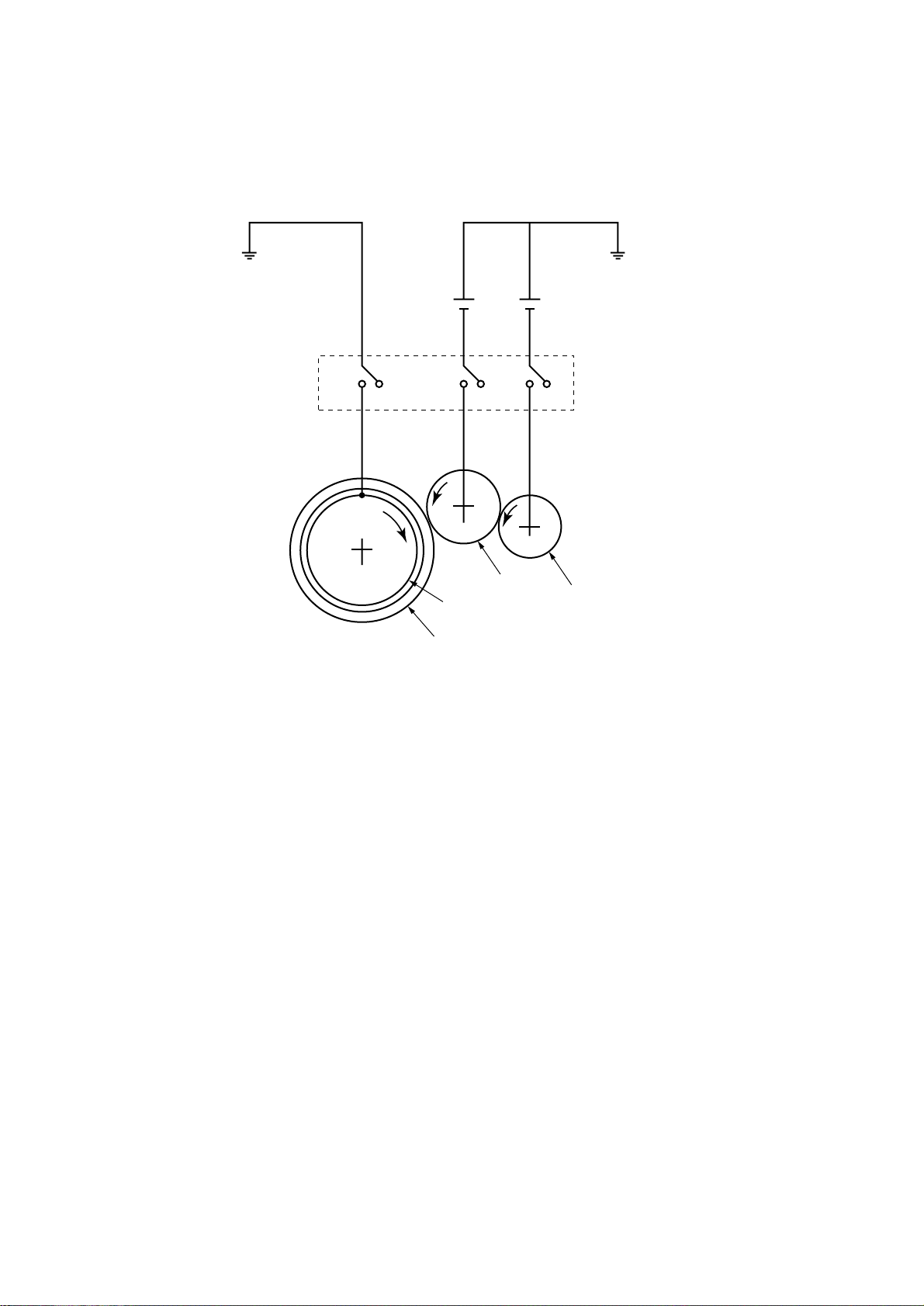

(4) Developing

Toner is attracted to the electrostatic latent image on the image drum surface, converting it

into a visible toner image. Developing takes place through the contact between the image

drum and the developing roller.

1 As the toner supply roller rotates while rubbing on the developing roller, a friction charge

is generated between the developing roller and the toner, allowing the toner to be

attracted to the developing roller (the developing roller surface is charged positive and

the toner, negative).

Doctor blade

Charge roller

Developing roller

Image drum

Toner supply roller

2 The toner attracted to the developing roller is scraped off by the doctor blade, forming a

thin coat of toner on the developing roller surface.

3 Toner is attracted to the exposed portion (low-potential part) of the image drum at the

contact of the image drum and the developing roller, making the electrostatic latent

image visible.

-300V

Developing roller

+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+

+++++++++++++++++++++++

-750V -100V -750V -750V

–

Toner

Image drum

Exposed

part

An illustration of activities at the contact point of the image drum surface and

the developing roller (arrow marks denote the direction of the electrical field).

Exposed

part

-100V

2 - 17

Note:

The bias voltage required during the developing process is supplied to the toner supply roller and

the developing roller, as shown below. –500 VDC is supplied to the toner supply roller, –265 VDC

to the developing roller.

Connected and bias supplied

when the cover is closed.

Developing roller

Base

Image drum

Toner supply roller

2 - 18

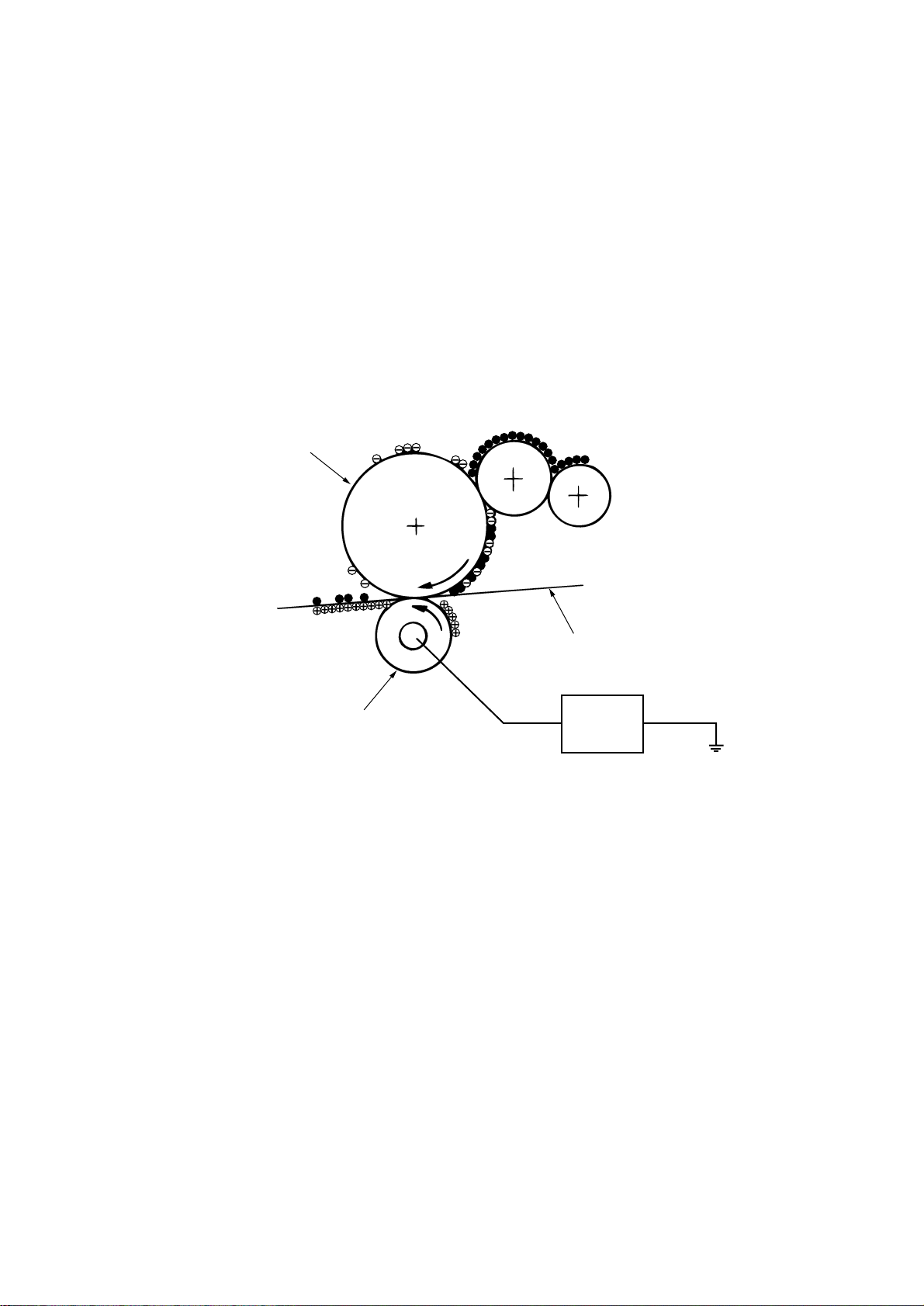

(5) Transfer

Image drum

Transfer roller

Paper

Power

supply

The transfer roller is composed of conductive sponge material, and is designed to get the

image drum surface and the paper in a close contact.

Paper is placed over the image drum surface, and the positive charge, opposite in polarity

to that of the toner, is applied to the paper from the reverse side.

The application of a high positive voltage from the power supply to the transfer roller causes

the positive charge inducement on the transfer roller surface, transferring the charge to the

paper as it contacts the transfer roller. The toner with negative charge is attracted to the

image drum surface, and it is transferred to the upper side of the paper due to the positive

charge on the reverse side of the paper.

2 - 19

Loading...

Loading...