■ ■

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

1 OKI SEMICONDUCTOR

INTRODUCTION

With the continuing demand for smaller and more efficient systems, designers are seeking new ways to reduce power

and increase integration. This paper describes how good use of OKI Semiconductor’s monolithic display drivers can

reduce power consumption and component count in systems that incorporate liquid crystal displays (LCDs). Information in this paper is applicable both to small LCD panels (with a dozen or less segmented digits) and to large LCD

panels (such as used for laptop screens).

LCD elements are capacitive in nature and dissipate virtually no power, whether selected or deselected. When an

LCD element is selected, a voltage is applied across the liquid crystal that varies the element’s reflectivity. Removing

the voltage deselects the LCD element and returns the liquid crystal to its original state.

In general, an alternating-current (AC) source is required to illuminate the individual elements in an LCD panel. A

direct-current (DC) source is not suitable for driving an LCD panel because of electrolytic reactions in the LCD’s

liquid. Placing a potential difference across the liquid in an LCD panel causes ion migration, which gradually erodes

the anode terminal and causes destructive deposition on the cathode terminal. The electrolytic reaction could be

diminished by plating the electrodes with a non-reactive conductive element, such as gold, for example; however,

the high cost of gold and similar non-reactive elements makes this solution impractical for all but the most esoteric

applications.

A far simpler way to eliminate electrolytic corrosion is to use an AC source to drive the LCD panel, eliminating unidirectional ion migration and the associated problems. AC configurations for driving LCDs fall in two main categories, which are:

• Static driver configurations

• Multiplexed driver configurations

The next two sections describe these two configurations. The third section in this application note addresses powerrelated issues. This application note concludes with some complete circuit examples.

USING STATIC DRIVERS

In configurations using static drivers, a separate driver signal (SEG) provides an AC source for each element, and all

elements use a single shared common (COM) terminal.

LCD elements are often segments of an alphanumeric digit. In larger configurations, LCD elements are individual

dots that emulate the appearance of a CRT monitor. Static driver configurations are simple to use and are generally

suitable for LCDs with less than 80 segments.

OKI Semiconductor supplies a range of single-chip solutions for static LCD driver configurations, some of which

also include built-in RC oscillation circuits, in small-outline IC (SOIC) and plastic quad flat pack (PQFP) packages.

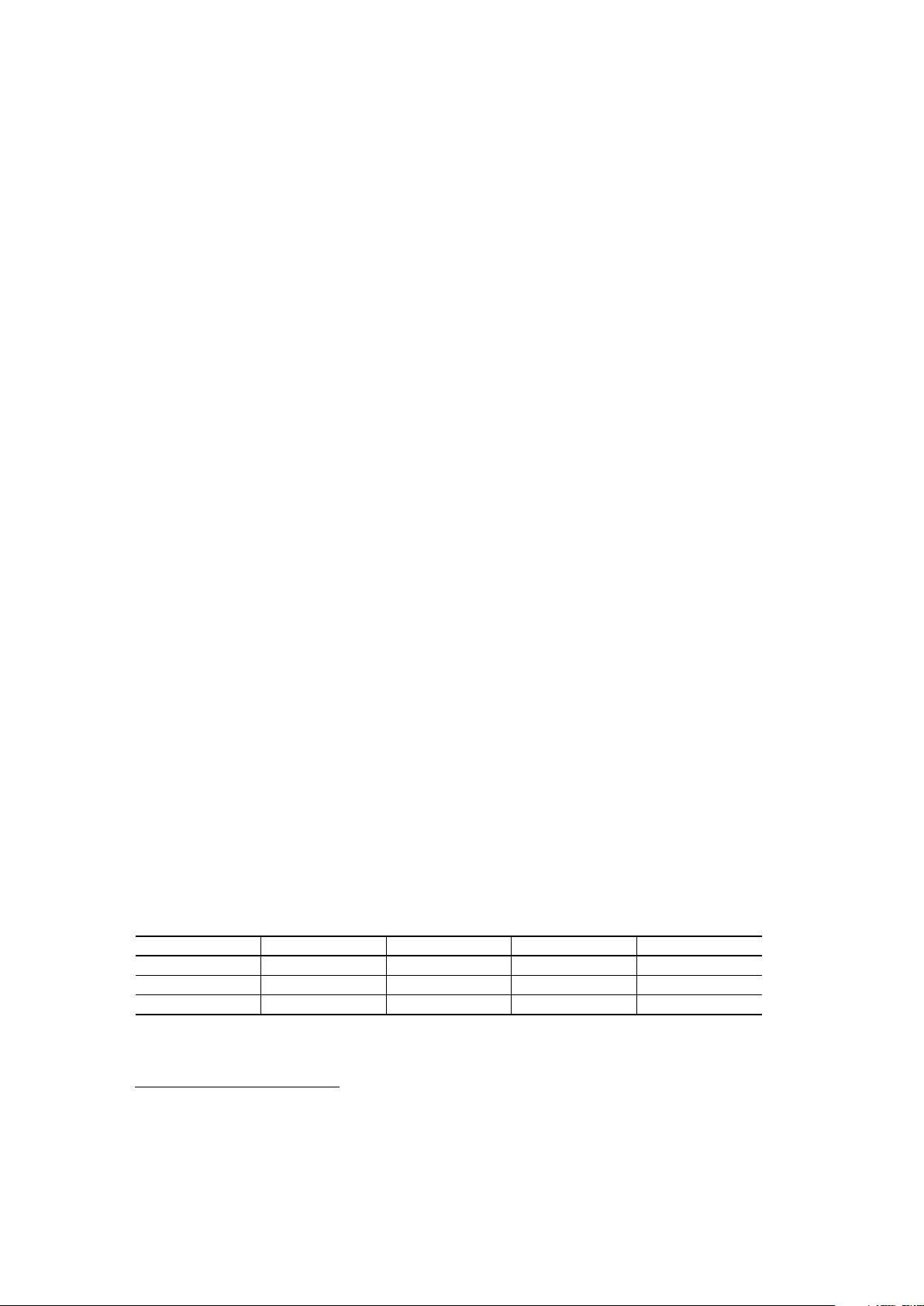

The table below lists the main characteristics of single-chip static LCD drivers from OKI Semiconductor.

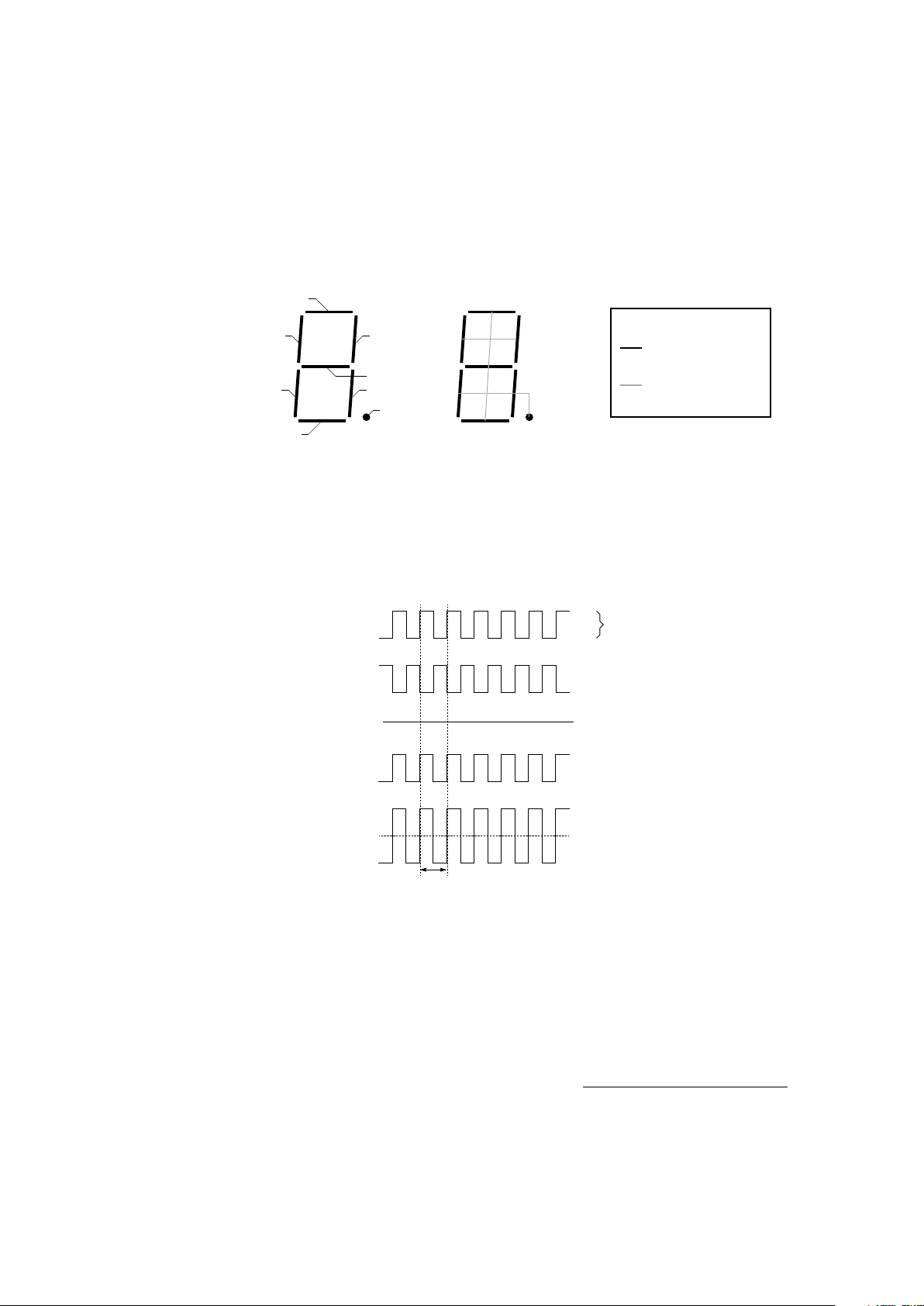

Figure 1 below shows static driver connections to a single-digit, seven-segment alphanumeric display. Separate driv-

ers, SEG1 - SEG8, power each segment. All segments share a common ground connection, COM.

LCD Drivers for Static Configurations

Part Number Segments On-Chip Oscillator Drive Voltage (V

LCD

) Package

MSM5219B 48

√

4.0 - 7.0 60-lead PQFP

MSM5221 56 X 3.0 - 7.0 80-lead PQFP

MSM5265 80

√

3.0 - 6.0 100-lead PQFP

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ■

2OKI SEMICONDUCTOR

Figure 2 below shows the AC waveforms for driving the illustrated display. When an element is deselected, the com-

bined COM and SEG signals negate each other, as shown for the (COM – SEG1) signal illustrated below. When an

element is selected, the combined COM and SEG signals constructively reinforce each other, as shown for the (COM

– SEG2) signal below.

In static drive configurations, the AC frequency used to drive each segment is identical. This AC frequency is called

the frame frequency . In static drive configurations, a single element is selected or deselected in any one individual

frame, as shown in Figure 2 above.

Static driver configurations generally use a frame frequency in the 20-200 Hz range. Lower frame frequencies can

cause visible flicker. Higher frame frequencies do not provide sufficient time for charging the capacitive LCD elements.

SEG7

SEG6

SEG1

SEG2

SEG3

SEG5

SEG4

SEG8

Figure 1. Segment Connections for Static-Drive Configurations

COM

Segment connections over

the liquid crystal.

KEY:

Common base connections

under the liquid crystal.

Figure 2. Functional Waveforms for Static Drive Configurations

COM

SEG1

SEG2

COM – SEG2

V

DD

V

L

V

DD

V

L

V

DD

V

L

V

LCD

-V

LCD

0V

COM – SEG1

(Selected)

(Deselected)

0V

V

LCD

1 Frame

(Deselected)

(Selected)

■ ■

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

3 OKI SEMICONDUCTOR

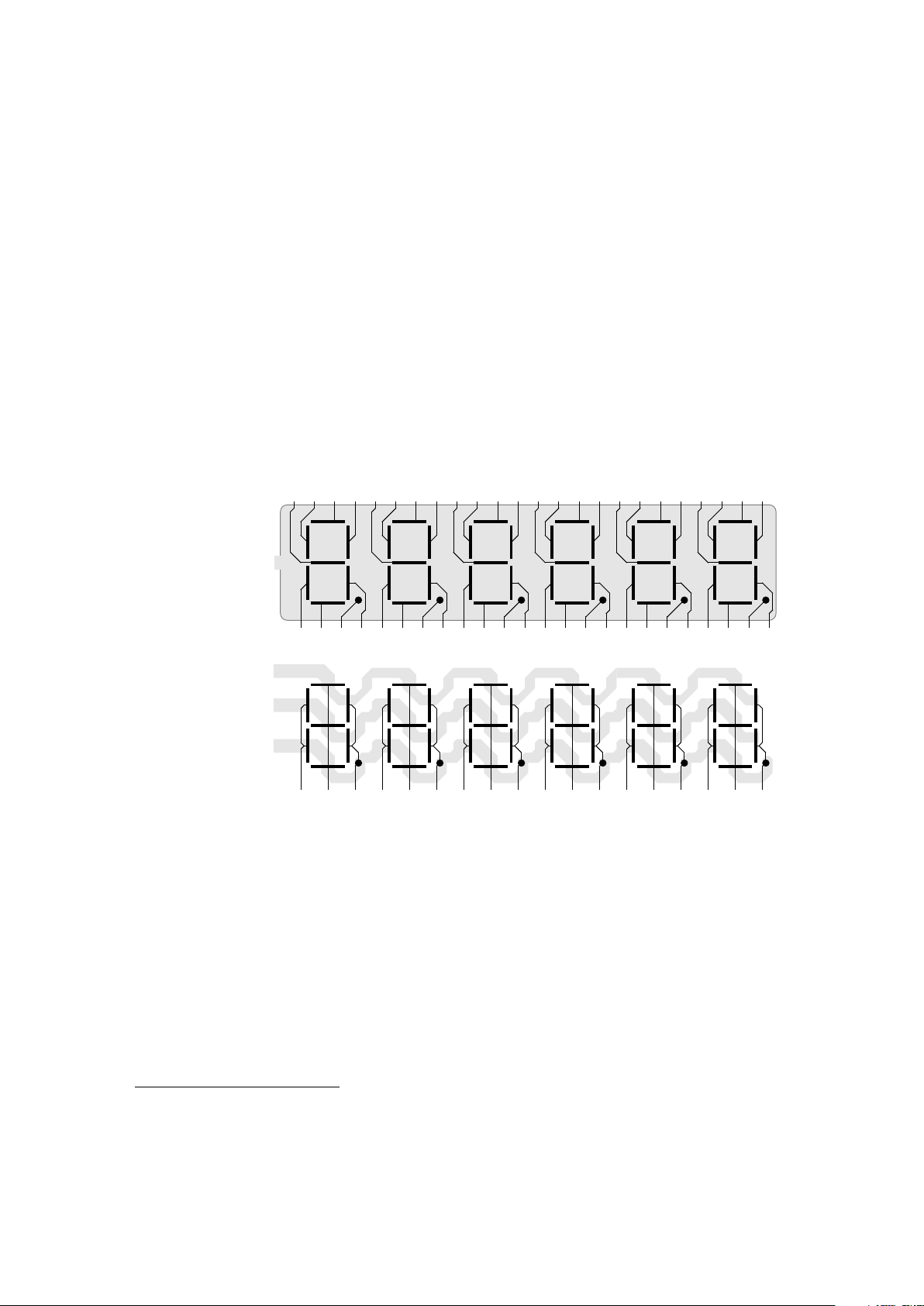

USING MULTIPLEXED DRIVERS

For configurations requiring more than about 80 drivers, it is more efficient to multiplex the COM and SEG signals

than to use a static driver configuration. In multiplexed configurations, each SEG driver signal powers more than one

segment, and the circuit uses more than one COM signal. The SEG and COM signals actually form a grid, with each

segment driven by a unique SEG/COM node. The multiplexed drive method reduces the number of driver circuits

and the number of connections between the circuit and the display cell. This reduces cost when driving many display

elements.

Figure 1 below illustrates this reduction in driver count by comparing static and multiplexed drive configurations for

a six-digit display. The static driver configuration requires 49 connections to the LCD, whereas the multiplexed configuration requires only 21 connections. Increasing the degree of multiplexing can further reduce the number of connections; however, increased multiplexing also reduces the circuit’s tolerance to voltage variation.

A range of multiplexed configurations are possible, distinguished by:-

• Bias , indicating the number of voltage levels used to power the LCD display.

• Duty Cycle , indicating the number of segments driven by each individual output driver.

• Frame Frequency Type, indicating whether the COM signal alternates over one frame (Type A) or two frames

(Type B).

For example, in a 1/2 bias, 1/2 duty-cycle configuration, each individual output driver uses two voltage levels to drive

two segments. Similarly, in a 1/3 bias, 1/3 duty-cycle configuration, each driver uses three voltage levels to drive

three segments ( Figure 1 above is a 1/3 bias, 1/3 duty cycle configuration).

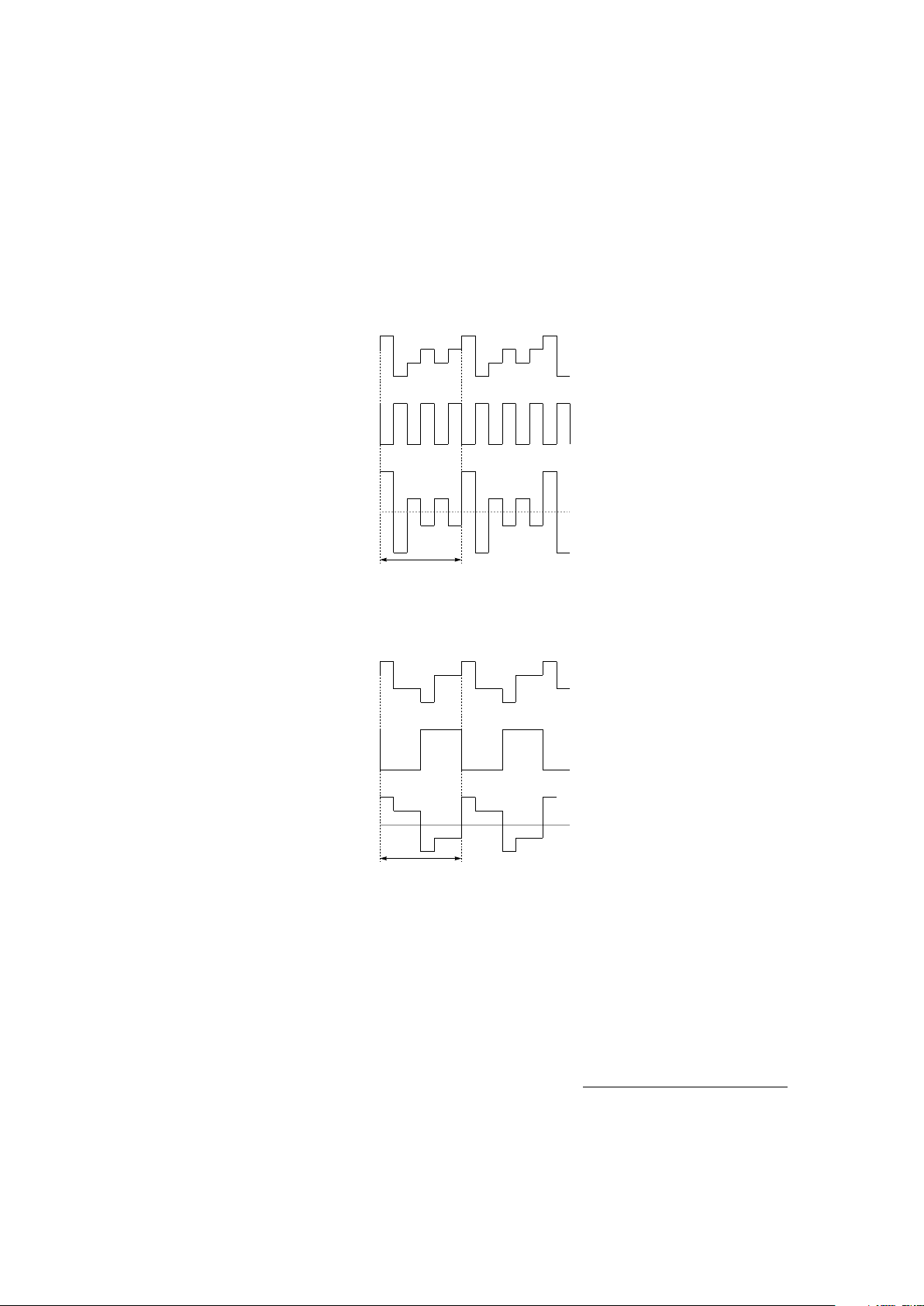

Frame frequency determines the degree of flickering and vividness. For a high degree of multiplexing, the type-B

configuration can make the display more vivid, but can also introduce flickering at lower clock frequencies. Figure 4

1

A

ComA

ComB

ComC

Common

Static

Multiplex

1/3 bias,

1/3 duty cycle

2

A

3

A

4A5

A

7A6

A

8

A

1B2

B

3

B

4B5

B

7B6

B

8

B

1C2

C

3

C

4C5

C

7C6

C

8

C

1D2

D

3

D

4D5

D

7D6

D

8

D

1E2

E

3

E

4E5

E

7E6

E

8

E

1F2

F

3

F

4F5

F

7F6

F

8

F

S

3

S1S

2

S

6

S4S

5

S

9

S7S

8

S10S11S12S13S14S15S16S17S

18

Figure 3. Static versus Multiplexed Configurations

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ■

4OKI SEMICONDUCTOR

and Figure 5 below illustrate the difference between type-A and type-B configurations for the LCD driver network

shown in Figure 1 above.

Type B configurations are more common, as the maximum required frequency is lower. Figure 6 through Figure 10

illustrate various multiplexed configuration, all of which use a Type B configuration to reduce frame frequency.

Figure 6 on the next page illustrates how a 1/2 bias, 1/2 duty cycle, Type B configuration can drive 62 outputs. This

particular example is suitable for systems using the MSM6660. Full V

LCD

voltage is applied across the selected seg-

ment for display and less than full V

LCD

voltage is applied across the deselected segment.

COM

SEG

COM – SEG

1 Frame

Figure 4. A-Type Waveforms for a 1/3 Duty Cycle, 1/3 Bias Configuration

SEG

COM – SEG

1 Frame

Figure 5. B-Type Waveforms for a 1/3 Duty Cycle, 1/3 Bias Configuration

COM

Loading...

Loading...