Page 1

Page: 1

Service Guide ML380

Chapter 0 About This Manual

ML380

Dot Matrix Printer

Adobe Acrobat printable reference

copy of the OKIDATA Service Training Manual.

09/17/97

Note: This Adobe Acrobat version of the Okidata Service Training Manual was built with the

pictures rendered at 300 dpi, which is ideal for printing, but does not view on most

displays well.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 2

Table of Contents Page

Service Guide ML380

0 About This Manual

Front Cover 1

Manual Copyright 2

1 Product Specifications

1.1 Overview 3

1.2 Physical Specifications 4

1.3 Power Requirements 5

1.4 Environmental Conditions 6

1.5 Agency Approvals 7

1.6 Operational Specifications 8

1.7 Paper Specifications 9

1.8 Memory Specifications 10

1.9 Consumables 11

1.10 Options 12

1.11 Reliability 13

2 Principles of Operation

2.1 Principles of Operation - General Information 14

....2.1.02 Microprocessor and Peripheral Circuits 15

....2.1.03 Initialization 16

....2.1.04 Interface Control 17

....2.1.05 Printhead Drive Circuit 18

....2.1.06 Spacing Drive Circuit 19

....2.1.07 Line Feed Circuit 20

....2.1.08 Alarm Circuits 21

....2.1.09 Paper End Detection Circuit 22

....2.1.10 Power Supply 23

2.2 Mechanical Operation - Printhead Mechanism 24

....2.2.02 Spacing 25

....2.2.03 Ribbon Drive 26

....2.2.04 Paper Feed 27

....2.2.05 Paper-End Detection 28

....2.2.06 Semi-Automatic Sheet Feeder (SASF) 29

....2.2.07 Paper Park 30

3 Maintenance & Disassembly

3.1 Maintenance - General Information 31

....3.1.02 Maintenance Tools 32

....3.1.03 Maintenance Precautions 33

3.2 Disassembly/Assembly Procedures - General Information 34

....3.2.01 Paper Separator 35

....3.2.02 Printhead 36

....3.2.03 Upper Cover Assembly 37

....3.2.04 Space Rack 38

Page 3

Table of Contents Page

....3.2.05 Ribbon Feed Gear Assembly 39

....3.2.06 Mini-Pitch (Space) Belt 40

....3.2.07 Head Connector Assembly 41

....3.2.08 Main Control Board (UMMB) 42

....3.2.09 Operation Panel 43

....3.2.10 Line Feed Motor 44

....3.2.11 Photosensor Assembly (Paper End) 45

....3.2.12 Bail Arms 46

....3.2.13 Carriage Frame 47

....3.2.14 Platen Assembly 48

....3.2.15 Pressure Roller Assembly 49

....3.2.16 Paper Pressure Guide 50

....3.2.17 Tractor Assembly 51

....3.2.18 Microswitch Assembly (SASF) 52

....3.2.19 Microswitch Assembly (Home Position Switch) 53

....3.2.20 Printer Mechanism 54

....3.2.21 Power Supply Unit 55

....3.2.22 Space Motor Assembly 56

....3.2.23 Bottom Paper Guide Lever 57

3.3 Printer Adjustments 58

....3.3.02 Gap Between Platen and Printhead 59

....3.3.03 Space Belt Tension 60

....3.3.04 Key Combinations 61

....3.3.05 Menu Operation / Menu Select Mode - General

Information

........From Print Mode 63

........From Power-OFF 64

........Printing the Menu 65

........Sample Menu 66

........Reset Menu to Factory Defaults 67

........Limited Operation 68

........Menu Settings 69

....3.3.06 Top of Form 70

....3.3.07 Paper Park 71

....3.3.08 Paper Tear Off 72

....3.3.09 Resets 73

3.4 Cleaning 74

3.5 Lubrication 75

3.6 Shipping Instructions 76

4 Failure & Repair Analysis

4.1 Failure & Repair Analysis - Introduction 77

....4.1.02 Printer Serial Number Identification 78

....4.1.03 Firmware Revision Identification 79

4.2 Reporting Problems - General Information 80

62

Page 4

Table of Contents Page

....4.2.02 Problem Lists 81

....4.2.03 Reporting Methods 82

4.3 Troubleshooting Updates General Information 83

4.4 Troubleshooting Tips 84

....4.4.02 Problem Categories 85

....4.4.03 START HERE Flowchart 86

....4.4.04 Tips for Preventing Image Problems 87

....4.4.05 Common Problems 88

4.5 Abnormal Output 89

4.6 Fault Alarms - General Information 90

....4.6.02 Fault Alarm Lamp Display 91

4.7 Repair Analysis Procedures (RAPS) - Using The RAPS 92

....4.7.02 RAP Index 93

........RAP 01: No Power 94

........RAP 02: Space Operation Does Not Operate Normally 95

........RAP 03: Wrong Character or Missing Dots 96

........RAP 04: Line Feed Trouble 97

........RAP 05: Data Receiving Failure 98

4.8 Printer Tests - General Information 99

....4.8.02 Rolling ASCII Test 100

....4.8.03 Font Test 101

....4.8.04 Serial Interface Loopback Test - General Information 102

........Loopback Connector Configuration Diagram 103

........Procedure 104

........Serial Cable Information 105

........Serial Interface Signal Requirements 106

........Commonly Used Serial Cable Configurations 107

....4.8.05 Hexadecimal Dump Mode 108

4.9 Resistance Checks - General Information 109

....4.9.02 Main Control Board (UMMB) Voltage Check Points 110

....4.9.03 Connectors Block Diagram 111

....4.9.04 Connector Location 112

....4.9.05 Resistance Diagrams - Printhead 113

........Space and Line Feed Motors 114

....4.9.06 Head Cable Connection 115

A Board Diagrams

A1 Board Diagrams - General Information 116

A.2 Index To Charts 117

....A.2.01 Main Control Board (UMMB) Original 118

....A.2.02 Main Control Board (UMMB) Current 119

....A.2.03 RS232-C Serial Module (UMRS) 120

B Illustrated Parts Listing

B.1 Overview - General Information 121

....B.1.02 Definition of Terms 122

Page 5

Table of Contents Page

....B.1.03 Parts Ordering Information 123

B.2 Charts 124

....B.2.01 Printer 125

....B.2.02 Covers 126

....B.2.03 Printer Unit 127

....B.2.04 Printer Mechanism (1 of 3) 128

....B.2.05 Printer Mechanism (2 of 3) 129

....B.2.06 Printer Mechanism (3 of 3) 130

....B.2.07 Option Parts 131

....B.2.08 Consumables 132

....B.2.09 Packaging 133

....B2.10 Documentation 134

....B.2.11 Service Training Kit Revision List 135

Page 6

Page: 2

Service Guide ML380

Chapter 0 About This Manual

Manual Copyright

This document may not be reproduced without the written permission of the Okidata Technical Training

Group. Every effort has been made to ensure the accuracy of the information contained in this training

course. Okidata is not responsible for errors beyond its control.

© 1994 by Okidata All rights reserved.

First Edition August, 1989 P/N 59238701

Second Edition September, 1993 P/N 59238702

Third Edition November, 1994 P/N 59238703

Written and produced by the Okidata Technical Training Group

Please address any comments on this publication to:

Technical Training Group

Okidata

532 Fellowship Road

Mount Laurel, NJ 08054-3499

Fax Number: (609) 235-2600, ext. 7034

Okilink Login Name: Technical Training

OKIDATA is a registered trademark of Oki Electric Industry Company, Ltd.; marques deposee de Oki

Electric Industry Company, Ltd.; marca registrada, Oki Electric Industry Company, Ltd.

MICROLINE is a registered trademark of Oki Electric Industry Company, Ltd.; marque depose de Oki

Electric Industry Company, Ltd.

Centronics is a registered trademark of Centronics Inc.

PLUG n PRINT is a registered trademark of Oki America, Inc.; marque deposee de Oki America, Inc.

Epson is a registered trademark of Seiko Epson Corporation.

IBM is a registered trademark of International Business Machine Corporation.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 7

Page: 3

Service Guide ML380

Chapter 1 Product Specifications

1.1 OVERVIEW

1.1.01 General Information

The Microline 380 is an 80 column, impact dot matrix printer using a 24 pin printhead. It emulates the

Epson LQ printer.

A push tractor is standard. An optional pull tractor is available.

Font and Character Pitch selection is available through the operator panel, printer menu, or through

software (using control codes).

A Centronics Parallel interface is standard. An RS232-C serial module is available as an option.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 8

Page: 4

Service Guide ML380

Chapter 1 Product Specifications

1.2 PHYSICAL SPECIFICATIONS

1.2.01 Dimensions

Width: 15.67 inches (398 millimeters)

Depth: 4.72 inches (120 millimeters)

Height: 13.58 inches (345 millimeters)

NOTE: Dimensions DO NOT INCLUDE the platen knob, acoustic cover, and paper separator.

1.2.02 Weight

17.9 pounds (8.1 kilograms)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 9

Page: 5

Service Guide ML380

Chapter 1 Product Specifications

1.3 POWER REQUIREMENTS

1.3.01 Input Power

120 VAC: +5.5 / -15%

220/240 VAC: +5.5 / -15%

Single-phase AC

1.3.02 Power Consumption

Operating: 90 VA

Idle: 30 VA

1.3.03 Power Frequency

120 VAC: 50/60 Hz +/- 2%

220/240 VAC: 50/60 Hz +/- 2%

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 10

Service Guide ML380

Chapter 1 Product Specifications

1.4 ENVIRONMENTAL CONDITIONS

1.4.01 Acoustic Rating

57 dBA

1.4.02 Altitude

10,000 feet (3,050 meters)

1.4.03 Ambient Temperature and Relative Humidity (RH)

While operating: 41 to 95 degrees Fahrenheit (5 to 35 degrees Celsius)

Operating humidity: 20% to 80% RH

While in storage: -40 to 158 degrees Fahrenheit (-40 to 70 degrees Celsius)

Storage humidity: 5% to 95% RH

1.4.04 Impact

Non-operating: 3 G or less

1.4.05 Vibration

Operating: 0.3 G (5 to 150 Hz) or less (except at resonating frequency)

Non-Operating: 1 G (5 to 150 Hz) or less (except at resonating frequency)

Page: 6

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 11

Page: 7

Service Guide ML380

Chapter 1 Product Specifications

1.5 AGENCY APPROVALS

1.5.01 Listings

UL No: UL Standard No. 478 and 114

CSA No: CSA Standard C22.2 No. 154

FCC: FCC Certified per Part 15, Subject J, Class B

VDE: VDE 0806, 0875 Class B, and 0836

BS: BS 5850 / 6204

IEC: 435 / 380

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 12

1.6 OPERATIONAL SPECIFICATIONS

1.6.01 Character Matrix Sizes

Table of Print Speed and Character Matrix

Page: 8

Service Guide ML380

Chapter 1 Product Specifications

Mode

Speed 63 cps (12 cpi) 192 cps (12 cpi) 240 cps (15 cpi)

Matrix (H x V) 30 x 18 9 x 17 7 x 16

1.6.02 Characters Per Line

Maximum Characters Per Line

80 10

96 12

120 15

137 17.1

160 20

1.6.03 Character Pitches

5, 6, 8.5, 10, 12, 15, 17.1, 20 characters per inch

Characters Per Inch = cpi

The character pitches are selected through the following methods.

Operator panel (front panel controls)

Menu Select Mode (Menu Mode)

Control codes in the software

Special Microline 380 drivers

LQ Utility HS Utility

Characters Per Inch

1.6.04 Character Sets

Standard ASCII

EPSON Character Set

IBM Character Set I and II

Foreign Language Sets (14)

Line Graphics

Zero / Slashed Zero

1.6.05 Emulation

Epson LQ

1.6.06 Fonts

Page 13

Letter Quality

Courier

Letter Gothic

Prestige

Orator

Roman

Helvette

Draft

Utility

Special Font Effects

Emphasized / Enhanced

Outline

Shadow

Double Height

Double Width

1.6.07 Front Panel Switches

SELECT / Exit

FEED / Group

TOF / PARK / Item

FONT / Set

PITCH / Print

1.6.08 Graphics Resolution

Graphics Resolution

Maximum: 180 x 360 dpi

Minimum: 60 x 72 dpi

*1.6.09 Interface

Standard

Parallel

Optional

RS232C Serial, 19.2 Kbytes Super-Speed (Ready/Busy, X-ON / X-OFF)

NOTE:

When the serial interface module is installed, the printer's parallel interface connector is NOT accessible.

1.6.10 Line Feed Increments

Fixed

6 lines per inch (lpi) [0.167 inch (4.23 millimeters)]

8 lines per inch (lpi) [0.125 inch (3.175 millimeters)]

Variable

n/60 inch

n/180 inch

1.6.11 Line Feed Time

2.2 inches per second

1.6.12 Menu Mode

Print: Prints the entire menu.

Group: Selects Group Function

Item: Selects Item

Set: Selects Item Value

Exit: Exits Menu Mode, Enters Select

1.6.13 Paper Feed Methods

Page 14

Standard

Friction Feed (Top)

Push Tractor (Rear)

Optional

Pull Tractor (Bottom / Rear)

Single-Bin Cut Sheet Feeder (Top)

CSF 3800

1.6.14 Paper Feed Paths

Top Feed (Standard)

Rear Feed (Standard)

Bottom Feed (by using an Optional feed mechanism)

Special Features

Paper Park

Semi-Automatic Sheet Feeding

Paper Tear Off

1.6.15 Paper Loading

Semi-Automatic Sheet Feeding

Opening the paper bail arm activates the semi-automatic sheet feeder (SASF)

1.6.16 Paper Out Detection

Distance from end of paper

Rear Feed: 2.3 inches (57 millimeters)

Bottom Feed: 1.4 inches (36 millimeters)

Top Feed: 1 inch (25 mm)

1.6.17 Paper Tear Capabilities

Paper Tear-0ff (sharp edge on access cover)

1.6.18 Print Method

Printhead Type

General Information

Impact Dot Matrix

24 pin printhead

.0079 inch (.20 millimeter) diameter pins

Overheat Protection

When printhead temperature is between 90 and 129 degrees Celsius (ALARM 1), the printer stops

bi-directional printing. Uni-directional printing begins.

If the temperature continues to rise (130 degrees Celsius, ALARM 2), printing stops.

Printing will resume when the printhead temperature drops below the ALARM 1 threshold.

NOTE:

Refer to Section Two for more information on printhead operation.

Printhead Gap Information

Two items factor into printhead gap information.

1. Printhead Gap

This is a SERVICE ADJUSTMENT made by a technician.

It is covered in Section 3.3 of this Service Handbook.

The Adjustment measures 0.016, +/- 0.002 inches (0.41, +/- 0.05 mm).

2. Printhead Gap

The printhead gap is modified by moving the printhead gap lever, located on the left side of the housing.

To move the lever, pull it towards the printer housing and push the lever towards the front of the printer.

The settings are 1, 2, 3, 4, and 5.

Use 1 for single sheet.

Adjustment

Adjust

Page 15

Use 2 for multiple sheets or forms (thickness: 2 sheets).

Use 3 for multiple sheets or forms (thickness: 3 sheets).

Use 4 for multiple sheets or forms (thickness: 4 sheets).

Use 5 for envelopes and extra thick paper.

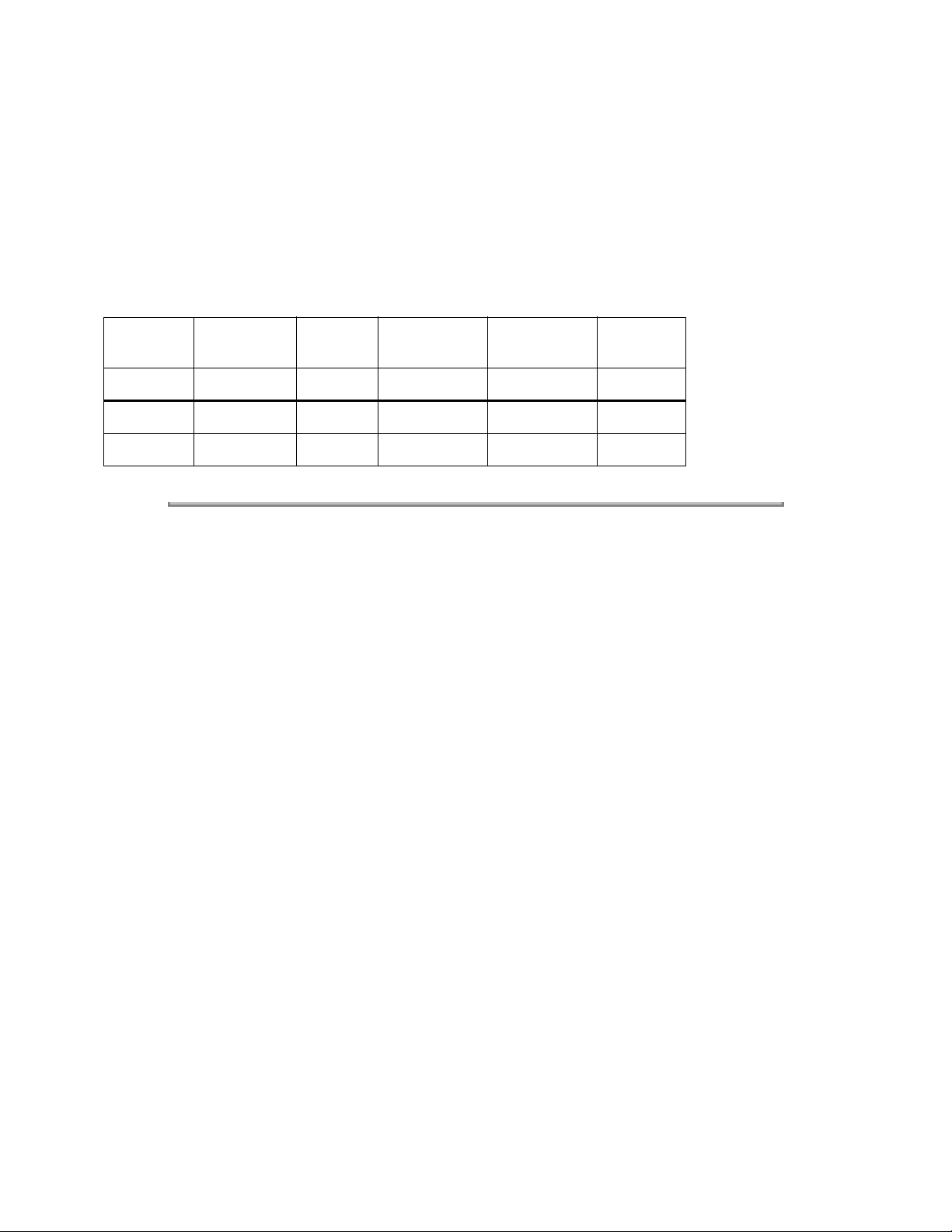

1.6.19 Print Modes

Letter Quality

Utility

1.6.20 Print Speed

Print

Mode

LQ 50 cps 60 cps 75 cps 85 cps 100 cps

Utility 150 cps 180 cps 112.5 cps 128.25 cps 150 cps

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Character

Pitch

10 cpi 12 cpi 15 cpi 17.1 cpi 20 cpi

Page 16

1.7 PAPER SPECIFICATIONS

Page: 9

Service Guide ML380

Chapter 1 Product Specifications

CAUTION:

1.7.01 Types

Card Stock

Length: 3 to 14 inches (76.2 to 356 millimeters)

Number of Copies: Original

Paper Feed Path: Bottom

Printhead Gap Information: Refer to the Printhead Gap Information, Section 1.6

Thickness: .008 inches (0.2 millimeters) Maximum

Weight: 100 lbs. (375 g/m 2 ) Maximum

Width: 5 to 8 inches (127 to 203 millimeters)

Continuous Form

Length: 3 to 14 inches (76.2 to 356 millimeters)

Number of Copies: Original, Original + 2 Interleaf Original + 2 Carbonless

Paper Feed Path: Rear or Bottom

Printhead Gap Information: Refer to the Printhead Gap Information, Section 1.6

Thickness: Single 0.0028 to 0.0039 inches (0.07 to 0.1 millimeters)

Multi 0.01 inch (.25 millimeter) Maximum

Weight:

Single Part 14 - 22 lb. (52.5 to 82.5 to g/m 2 )

Multi-Part, Carbonless 9 - 11 lb. (35 to 40 g/m 2 )

Multi-Part, Interleaf Paper 10 - 12 lb. (38 to 45 g/m 2 ) Carbon 9 lb. (35 g/m 2 )

Width: 3.5 to 10.5 inches (89 to 267 millimeters)

Cut Sheet

Number of Copies: Original, Original + 2 Interleaf Original + 2 Carbonless

Paper Feed Path: Top

Printhead Gap Information: Refer to the Printhead Gap Information, Section 1.6.

Note: Multi-part cut sheet paper CANNOT be used.

Weight: 14 to 22 lbs. (52.5 to 82.5 g/m 2 )

Width: 7.2 to 10 inches (182 to 254 millimeters)

Length: 3 to 14 inches (76.2 to 356 millimeters)

Thickness: 0.0028 to 0.0039 inches (0.07 to 0.1 millimeters)

Envelopes

Number of Copies: Original

Paper Feed Path: Bottom

Printhead Gap Information: Refer to the Printhead Gap Information, Section 1.6.

Size:

Single Feed

Minimum: 6.5 x 3.6 inches (16.5 x 9.1 centimeters)

Maximum: 9.5 x 4.1 inches (24.1 x 10.4 centimeters)

Continuous

Non-overlap type

Thickness: .016 inches (41 millimeters) Maximum

Weight: 17 to 24 lbs. (64 to 90 g/m 2 ) Maximum

Labels

Length: 3 to 14 inches (76.2 to 356 millimeters)

Use Bottom Feed and/or optional Pull Tractor for card stock and labels.

Page 17

Number of Copies: Original

Paper Feed Path: Bottom

Printhead Gap Information: Refer to the Printhead Gap Information, Section 1.6.

Weight: N/A

Width: Carrier 3.5 to 8.5 inches (88 to 261 millimeters)

Thickness: .01 inches (0.25 mm) Maximum (including backing)

CAUTION:

Use Bottom Feed and/or optional Pull Tractor for card stock and labels.

DO NOT use fabric labels.

DO NOT print on the edge or perforation of the label.

DO NOT use Paper Park with labels.

Transparency

NOTE:

Roller marks may mar the transparency under high temperature / high humidity conditions.

Length: 3 to 14 inches (76.2 to 356 millimeters)

Number of Copies: Original

Paper Feed Path: Top

Printhead Gap Information: Refer to the Printhead Gap Information, Section 1.6.

Weight: 12 to 24 lbs. (45 to 90 g/m 2 )

Width: 8.5 to 11 inches (216 to 280 millimeters)

Thickness: 0.004 inches (0.1 millimeters)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 18

1.8 MEMORY SPECIFICATIONS

1.8.01 EEPROM

256 Kbit EEPROM

Used to store Menu data

Located at Q18 of the main control board

1.8.02 ROM

Program ROM

256 Kbit

Located at Q2 of the main control board

Resident Character Generator ROM

1 Mbit

Masked to the CPU

1.8.03 RAM

32 Kbyte

Located on the main control board

Used as

Receive Buffer

Printer Buffer

Scratch Pad

Page: 10

Service Guide ML380

Chapter 1 Product Specifications

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 19

1.9 CONSUMABLES

1.9.01 Ribbon

Page: 11

Service Guide ML380

Chapter 1 Product Specifications

CAUTION:

Material

Cartridge Fabric

Types

Black Nylon Ribbon

Life (On average, at 10 characters per inch, Utility Mode)

Black Ribbon 2 million characters

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Using a non-Okidata ribbon may damage the printhead and void any warranties.

Page 20

1.10 OPTIONS

1.10.01 Cut Sheet Feeders

CSF-3800

Single Bin with envelope capability

Paper Width: 7.2 to 8.5 inches

182 to 216 millimeters

Paper Length: 10.1 to 11.7 inches

257 to 297 millimeters

Capacity: 50 sheets (20 lb.)

Page: 12

Service Guide ML380

Chapter 1 Product Specifications

1.10.02 Pull Tractor Kit

Bottom Feed

Rear Feed (For Push/Pull Operation)

Paper Types: Continuous Feed and Labels

Page 21

1.10.03 Serial Interface

Super-Speed 19.2K RS-232C

Ready/Busy/X-On/X-Off Protocols

Can be configured through the Menu

When the serial interface module is installed, the printers parallel interface connector is NOT accessible.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 22

Service Guide ML380

Chapter 1 Product Specifications

1.11 RELIABILITY

1.11.01 Mean Time Before Failure (MTBF)

Approximately 4,000 hours: 25% duty cycle / 35% page density

1.11.02 Mean Time To Repair (MTTR)

Approximately 15 minutes to major sub-assembly level

1.11.03 Printer Life

Approximately 12,000 hours of power-on time: 25% duty cycle / 35% page density

1.11.04 Printhead Life

Average 200 million characters in 10 cpi utility mode @ normal 25% duty, 35% page density

1.11.05 Ribbon Life

Approximately 2 million characters in 10 cpi mode

1.11.06 Warranty (Limited)

One year, parts, labor, and printhead

Page: 13

1.11.07 Service

Authorized Okidata Service Centers

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 23

Page: 14

Service Guide ML380

Chapter 2 Principles of Operation

2.1 ELECTRICAL OPERATION

2.1.01 General Information

The control board consists of the microprocessor and its peripheral circuits, the drive circuits, DC power

supply circuit and interface connector. The switches and LED's of the operator panel are mounted on this

board.

The power to the control board is supplied by the power supply unit. The power to the other electrical parts

is distributed via the connectors on the control board.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 24

Page: 15

Service Guide ML380

Chapter 2 Principles of Operation

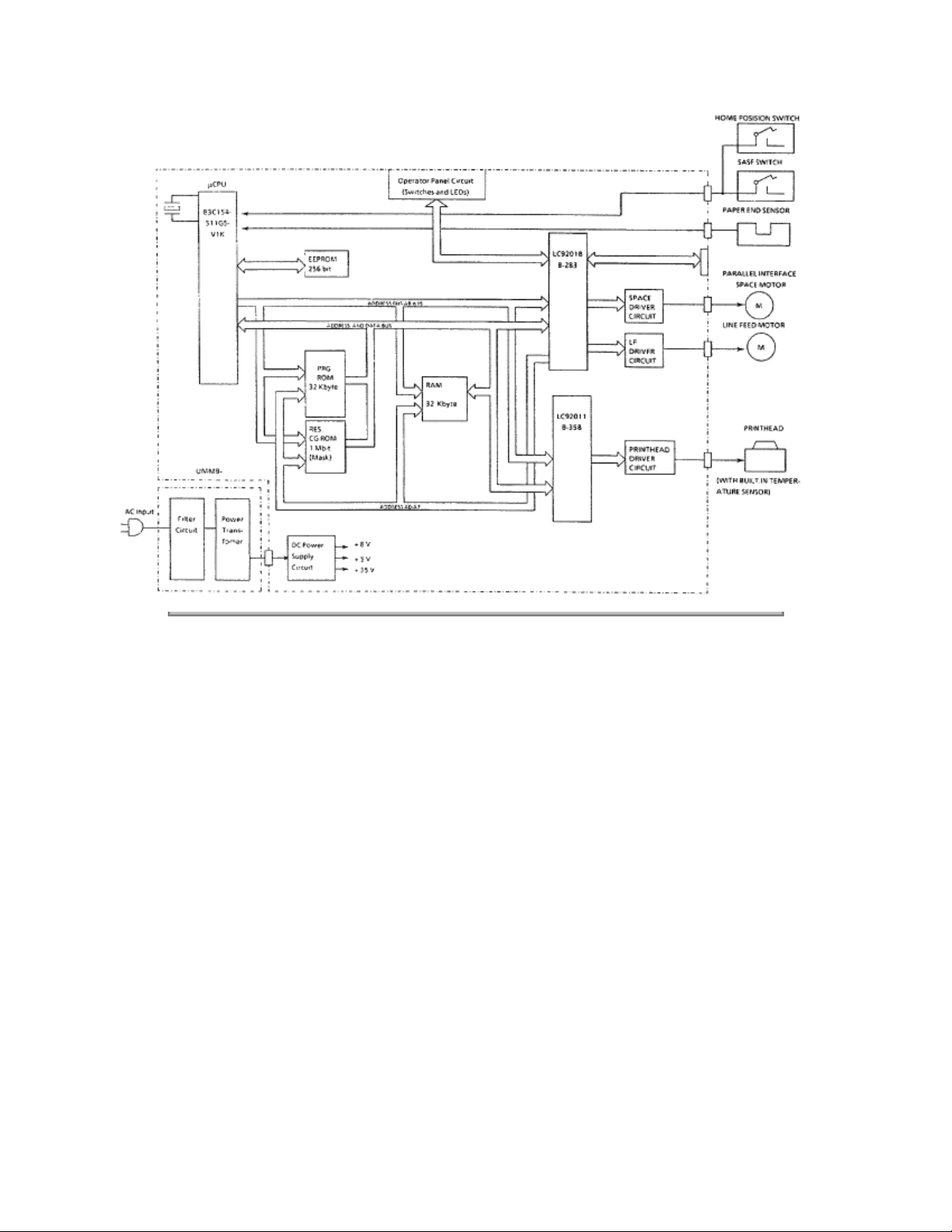

2.1.02 Microprocessor and Peripheral Circuits

Microprocessor (Q5: 83C154GS-551-V1K)

The microprocessor is the nucleus of the control circuit. Its peripheral circuits operate under program

control by this microprocessor. The I/O ports of the microprocessor are connected to the address bus,

data bus, and control lines.

Program ROM (Q2)

The program ROM (256 Kbit) contains the control program for the printer. The microprocessor operates

by execution of this program.

RAM (Q4)

The RAM stores received data (to be printed). (32 Kbytes)

CGROM (Q3)

1 MBit ROM which stores the resident character fonts.

EEPROM (Q18)

This 256-bit serial Electrically Erasable and Programmable ROM stores the Menu Mode data.

LSI (Q7: LC92018B-283)

This LSI switches the phase of the space motor, and generates the timing of print dots for each print

density. The LSI performs the following functions.

Space Pulse Motor Control

To obtain the carriage speed instructed by the microprocessor, the LSI generates the pulse switch timing

and overdrive time.

Dot Timing generation

Parallel Interface Control

LF Motor Control

LED Drive

General Purpose Input Port

Used to read Operator Board Switches.

LSI (Q6: LC92011B-284)

This LSI drives the 24 pin printhead and controls memory. The following describes the function of the LSI.

Printhead Drive Control

Head Pin Counting Function

Counts the number of printwires to be driven then, changes the duration of the HD ON signal accordingly.

Memory Control

Extends the addressable memory by switching banks in/out.

LED Drive Output Port

Microline 380 Block Diagram

Page 25

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 26

Page: 16

Service Guide ML380

Chapter 2 Principles of Operation

2.1.03 Initialization

The printer is initialized whenever it is powered ON or when the I-PRIME signal is received at the parallel

interface. Initialization is started when the RST-P signal is sent from the reset circuit (Q8:Pin 1) to Q5, Q6

and Q7.

When RST-P is generated, ROM program execution starts with the mode setting of Q5, Q6 and Q7. Next,

ROM and RAM are checked for errors, RAM is initialized and the carriage is homed. The program finally

establishes the Interface signals (output level of ACK, BUSY, etc.), switches the SELECT indicator ON,

and informs the host computer that the printer is ready to receive data.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 27

Page: 17

Service Guide ML380

Chapter 2 Principles of Operation

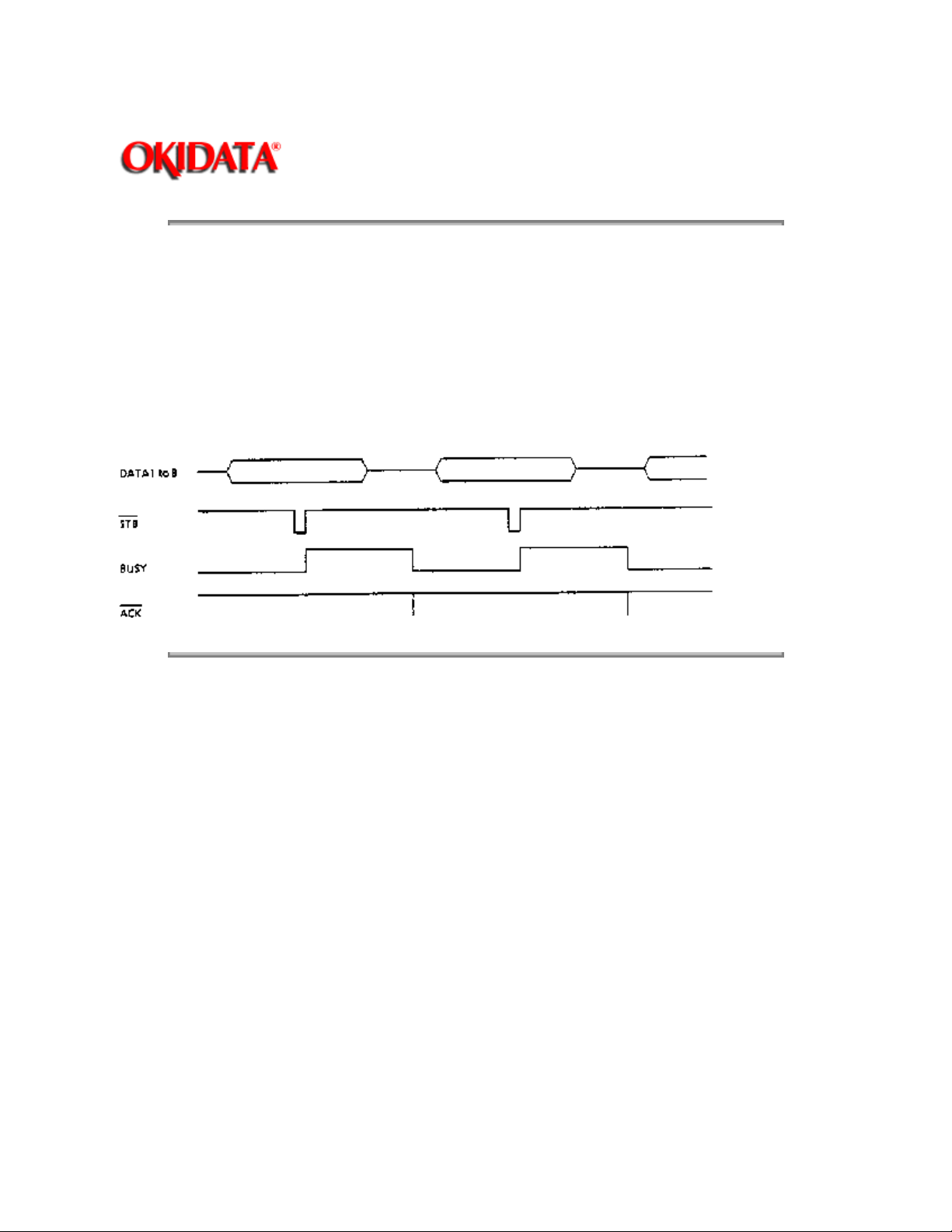

2.1.04 Interface Control

Parallel Interface

The data from the interface is received through connector (CN-1) and the Interface LSI (Q7) latches this

data in sync with the STB signal.

The BUSY signal is switched ON as the data is processed. When processing is completed, the BUSY

signal is switched OFF and an ACK signal is sent to the host to request more data.

The BUSY signal is also switched ON when the printer is not able to receive data (buffer is full, printer is

deselected or an error condition exists).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 28

Page: 18

Service Guide ML380

Chapter 2 Principles of Operation

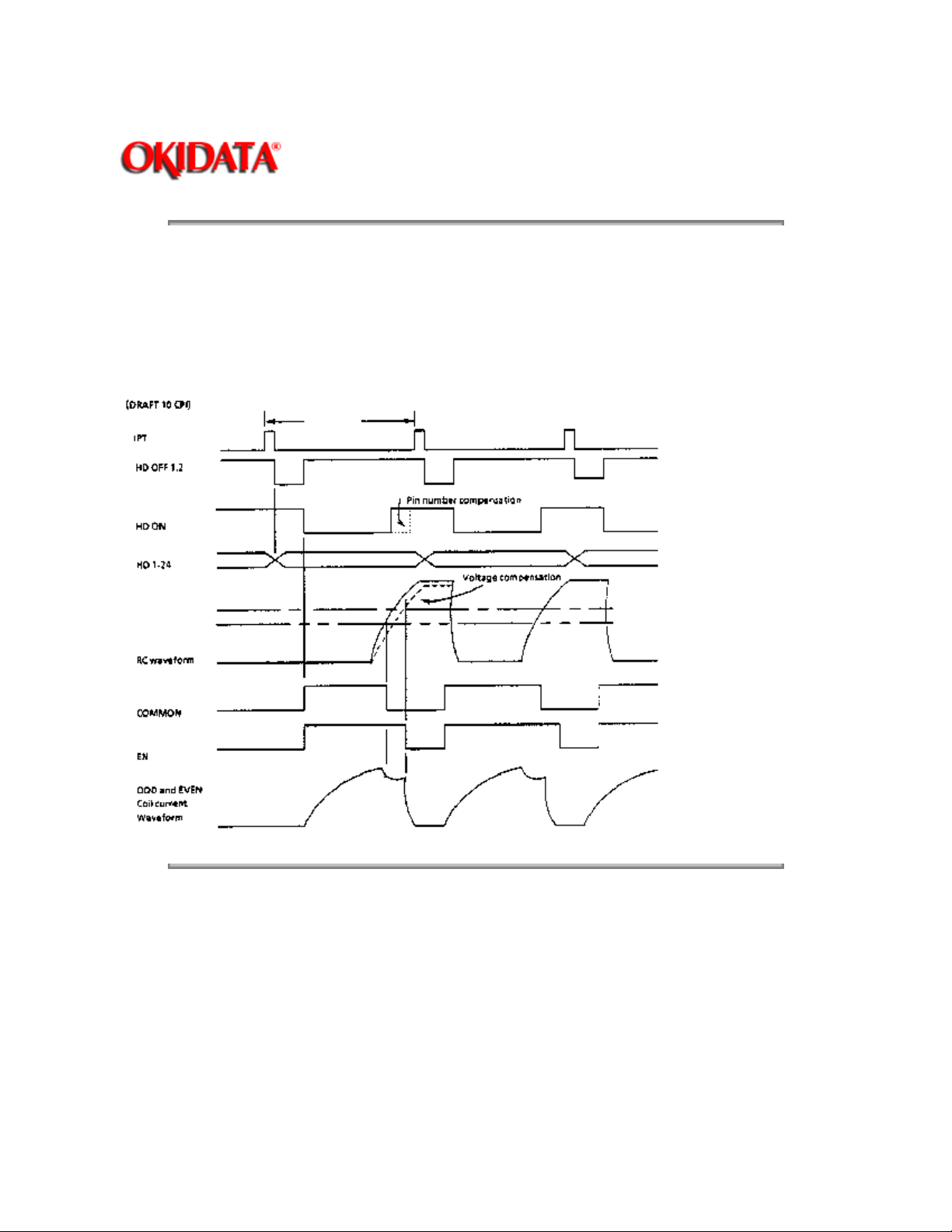

2.1.05 Printhead Drive Circuit

This circuit is used to drive the 24 print wires. The signals HD1 through HD24 control the individual print

wires. The HD ON signal (even/odd trigger) enables the drive circuit when printing is desired. The head

drive duration is determined by an RC integrating circuit which modifies the HD ON pulsewidth. The

pulsewidth of the HD ON signal varies with the number of pins being driven. The drive time increases as

more pins are driven, and decreases as fewer pins are driven. The RC circuit compensates for the

fluctuation of drive voltage (+35 vdc).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 29

Page: 19

Service Guide ML380

Chapter 2 Principles of Operation

2.1.06 Spacing Drive Circuit

The space motor is driven by a two-phase pulse motor.

The phase signals (Phase 1, Phase 2, Phase 3 and Phase 4) and the basic pulse signals are output from

the LSI (Q7). The pulse signals are modified by the drive voltage compensation circuit and sent back to

the LSI (Q7).

The space overdrive signals (Phase 1DVOV, Phase 2 DVOV, Phase 3DVOV and Phase 4DVOV) switch

Q16 and Q17 ON, setting up the proper phase relationship of analog space motor drive signals (SP Phase

1 through SP Phase 4). These signals are then sent to the space motor.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 30

Page: 20

Service Guide ML380

Chapter 2 Principles of Operation

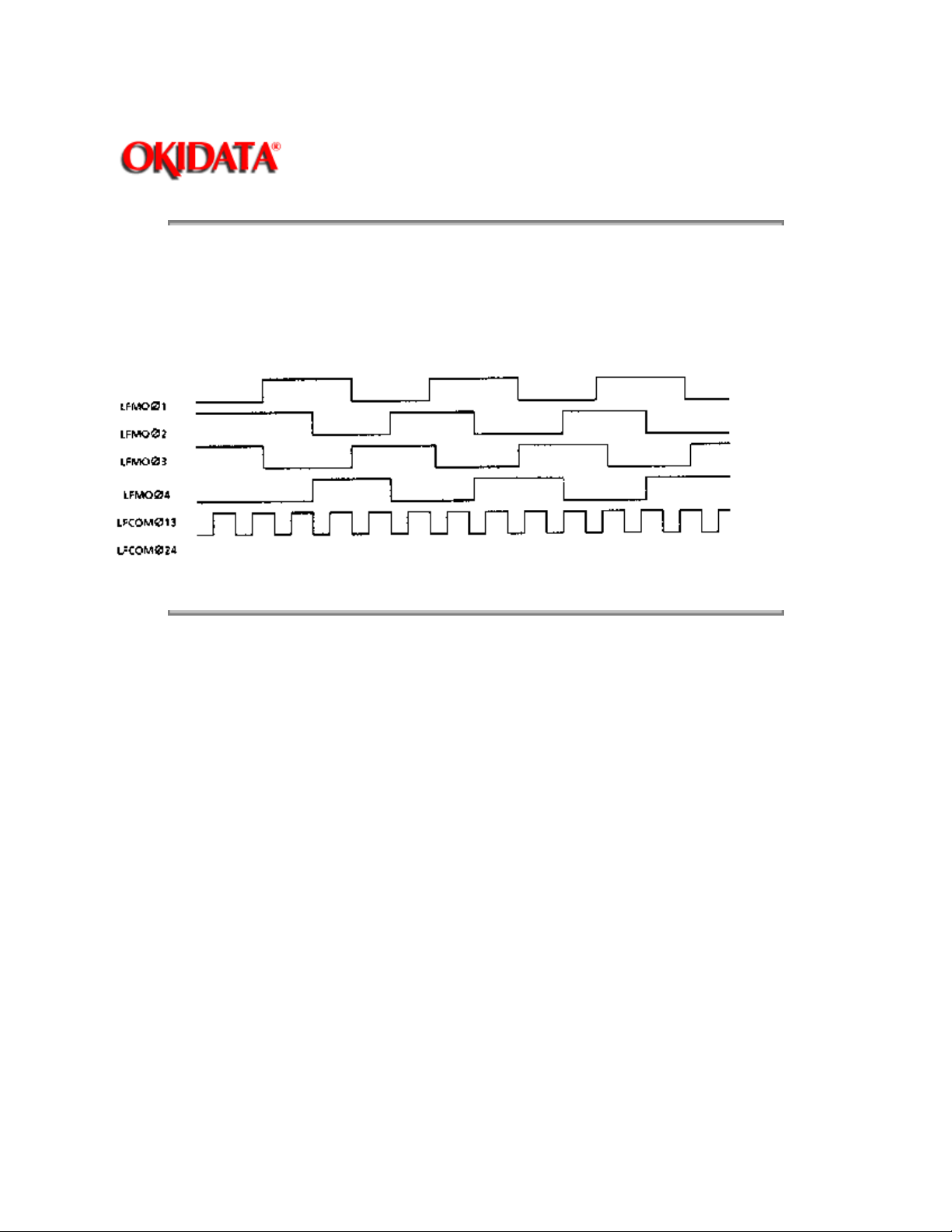

2.1.07 Line Feed Circuit

The line feed motor shaft is held stationary by + 8 vdc (the holding current is approximately 30 ma)

whenever in a stopped position.

During line feed operation, the line feed motor is driven in accordance with the LF OVD signal. The signals

LFMO Phase 1 through LFMO Phase 4 establish the proper phase relationship for driving the motor.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 31

Page: 21

Service Guide ML380

Chapter 2 Principles of Operation

2.1.08 Alarm Circuits

Fault Alarm Circuit (in Power Supply Unit)

This protective circuit causes the AC fuse to open when a fault occurs in the printhead drive circuit or line

feed drive circuit, thus preventing component failure.

To accomplish this, the circuit monitors the overdrive signal of each drive circuit. If the duration of any

drive circuit exceeds a predetermined time, the appropriate signal (HEAD ALM, LF ALM1 or LF ALM2) will

be sent to the fault alarm circuit. The fault alarm circuit generates the ALM signal (high), which switches

on an SCR.

This causes the secondary coil (40 volts) of the main transformer to short-circuit, causing an overcurrent

to flow through the primary coil and open the AC fuse.

Printhead Overheat Alarm Circuit

In order to protect the printhead coils, this circuit monitors the printhead temperature by using a thermistor

contained in the printhead. The CPU senses this circuit every time a line is printed.

Whenever printing, the printhead temperature increases. If the head temperature reaches approximately

90 degrees - 129 degrees Celsius, a head overheat ALARM 1 is generated. When ALARM 1 is detected,

bi-directional printing stops. Uni-directional printing begins.

If the printhead temperature continues to increase (130 degrees Celsius), ALARM 2 is generated. Printing

stops until the head temperature decreases. When the head temperature drops below the ALARM 1

threshold, printing resumes.

Low DC Voltage Detection Circuit

The + 35 vdc drive voltage is monitored for a low voltage condition during each print operation. If the + 35

vdc drops, the negative terminal input voltage of the comparator (Q8) decreases, the comparator reverses

state, and the DC LOW-P signal is switched ON.

When the signal DC LOW-P is active, printing is accomplished by using twelve of the twenty-four

printwires in a dual-pass print.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 32

Page: 22

Service Guide ML380

Chapter 2 Principles of Operation

2.1.09 Paper End Detection Circuit

PAPER END is detected by a photosensor. When the printer detects an out-of-paper condition, the PEN

signal goes low, printing is stopped, and the ALARM LAMP is switched ON.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 33

Page: 23

Service Guide ML380

Chapter 2 Principles of Operation

2.1.10 Power Supply

The power supply consists of the power transformer, the filter board and the DC power supply circuit on

the control board.

The AC input voltage is transformed into 8.6 VAC and 46 VAC by the power transformer. These AC

voltages are converted to + 8 vdc, + 5 vdc and + 35 vdc levels by the DC power supply circuit on the

control board. The + 5 vdc is a regulated voltage.

Filter Board

The filter board consists of the power switch, AC fuse and AC noise filter.

Power Transformer

If the internal temperature of the power transformer rises abnormally, the built-in temperature fuse will

open to prevent any damage to other electrical components.

NOTE:

If the temperature fuse in the transformer opens, the transformer must be replaced.

Power Supply Circuit

Converts the AC Voltage input to + 8 vdc, + 5 vdc and + 35 vdc and supplies it to the control board. This

circuit also regulates the + 5 vdc.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 34

Page: 24

Service Guide ML380

Chapter 2 Principles of Operation

2.2 MECHANICAL OPERATION

2.2.01 Printhead Mechanism

The Microline 380 uses a highly efficient stored energy type printhead. Power is not consumed until the

printwires are activated, thereby extending the printhead life to approximately 200 million characters.

The printhead uses 24 printwires (two columns of 12 wires each). Each wire is welded to an armature.

Behind this armature is a spacer ring.

Each of the 24 printwire armatures have a permanent magnet behind them. The magnets attract the

armatures, drawing the printwires into the wire guide, thus keeping the wires inside the printhead. A coil is

wrapped around each of the permanent magnets.

When a dot is to be printed, current is passed through the appropriate coil. This creates a magnetic field

which counters the magnetic field of the permanent magnet. The armature can then spring forward and

the print wire (which is attached to the armature) strikes the ribbon and imprints a dot on the paper.

When current is removed from the coil, the magnetic field of the permanent magnet attracts the armature,

causing the printwire to retract into the wire guide once again.

The printhead contains a built-in thermistor used to monitor the printhead temperature.

The printhead is composed of the following parts.

Wire Guide

Print Wires

Armature Assembly

Yoke

Spring

Spacer

Magnet Assembly

Thermistor

Printed Circuit Board

Page 35

Page 36

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 37

Page: 25

Service Guide ML380

Chapter 2 Principles of Operation

2.2.02 Spacing

Spacing is performed when the main shaft (installed in parallel with the platen), and carriage (mounted on

the space rack) are driven by the pulse motor.

Spacing involves the parts listed below.

Pulse Motor

Drive Pulley

Idle Pulley

Carriage Shaft

Carriage Frame

Space Rack

Spacing Operation

The carriage containing the printhead moves parallel to the platen along the main carriage shaft and

space rack. Power from the space motor is transferred via the mini-pitch belt, which is attached to the

bottom of the carriage frame. When the pulse motor rotates clockwise (as viewed from above), the driving

force is transmitted to the mini pitch belt through the drive pulley, and the carriage moves from left to right.

The carriage is designed to move 0.8 inch when the pulse motor performs one rotation.

Head Gap Adjusting

The head gap adjusting mechanism adjusts the gap between the platen and printhead. This is

accomplished by moving the adjusting lever on the left side of the printer mechanism. When the lever is

moved, the carriage shaft rotates. Since the carriage shaft is attached to the printer mechanism with

eccentric collars, as the carriage shaft rotates, the distance between the platen and carriage shaft

changes.

Page 38

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 39

Page: 26

Service Guide ML380

Chapter 2 Principles of Operation

2.2.03 Ribbon Drive

The ribbon drive mechanism moves the ribbon in synchronization with the space motor operation.

The ribbon drive mechanism consists of the following items.

Ribbon Drive Gear assembly

Space Rack

Ribbon Cartridge

Ribbon Cartridge

An endless ribbon with a single direction feed is used. Ink is supplied from an ink tank, which is built into

the ribbon cartridge.

Ribbon Feed Operation

The rotation of the space pulse motor is transmitted to the drive gear in the ribbon cartridge through the

space rack and ribbon feed gear assembly, thereby feeding the ink ribbon.

The feed direction of the ribbon is maintained by switching the rotational direction of the gears in the

ribbon drive assembly. This ensures uni-directional ribbon movement when bi-directional printing is used.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 40

Page: 27

Service Guide ML380

Chapter 2 Principles of Operation

2.2.04 Paper Feed

Paper feeding is performed by turning the platen and the pin tractor. The tractor is driven by the line feed

pulse motor.

The paper feed mechanism consists of the following items.

Pulse motor with gears

Idler Gear

Change Spring

Change Gear

Platen

Tractor Feed Unit

Pressure Roller Assembly

Friction Feed

When the release lever is set to the FRICTION FEED position, the change gear is disengaged from the

tractor gear. At the same time, the release lever applies pressure to push the pressure rollers against the

platen, allowing paper to be fed.

Tractor Feed

When the release lever is set to the TRACTOR FEED position, the release lever allows the reset spring to

push the change gear toward the tractor gear. At the same time, the release lever pushes the pressure

rollers away from the platen, allowing paper to be fed by the tractors.

NOTE:

Drive power from the line feed motor is transferred from the platen to the idler gear and then to the change

gear.

Page 41

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 42

Page: 28

Service Guide ML380

Chapter 2 Principles of Operation

2.2.05 Paper-End Detection

Continuous Sheet Paper-End

When continuous sheet paper is installed, the paper moves the continuous sheet paper-end lever to A1

and the sensor is switched ON. When out of continuous sheet paper, the paper-end lever moves to

position B1 and the sensor is switched OFF indicating a paper-end condition.

Bottom Feed Paper-End

When paper is installed, it moves the bottom paper-end lever to position A2 and the sensor is switched

ON. When a paper out condition exists, the bottom paper-end lever moves to position B2 and the sensor

is switched OFF, indicating a paper-end condition.

Cut-Sheet Paper-End

When cut-sheet paper is installed, the paper moves the cut-sheet paper-end lever to position A3 and the

sensor is ON. At the end of printing, the cut-sheet paper-end lever moves to position B3 and the sensor is

switched OFF, indicating a paper-end condition.

Page 43

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 44

Page: 29

Service Guide ML380

Chapter 2 Principles of Operation

2.2.06 Semi-Automatic Sheet Feeder (SASF)

The Semi-Automatic Sheet Feeder (SASF) is used to automatically set the print start position when using

cut-sheet or continuous sheet paper.

The procedure is as follows.

Cut-Sheet SASF

1. Push the paper release lever to the cut-sheet side (rear of printer).

2. Insert the paper from behind the platen.

3. Open the paper bail arm (pull toward the front of the printer). This activates the SASF switch.

4. Line feed operation will feed the paper 2.76 inches.

If the paper does not move, the SASF motion becomes invalid and is treated like an ordinary paper-end.

5. Once the paper bail arm is closed, a reverse line feed of about 0.18 inches is performed. This moves

the paper to the print start position.

Continuous Sheet (Rear Feed) SASF

1. Push the paper release lever to the continuous sheet side (front of the printer).

2. Insert the paper into the push tractor.

3. Open the paper bail arm (pull toward the front of the printer). This activates the SASF switch.

4. Line feed operation will feed the paper 3.6 inches.

If the paper does not move within 2.4 inches of motion, the SASF motion becomes invalid and this is

treated like an ordinary paper-end.

5. Once the paper bail arm is closed, a reverse line feed of about 0.18 inches is performed. This moves

the paper to the print start position.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 45

Page: 30

Service Guide ML380

Chapter 2 Principles of Operation

2.2.07 Paper Park

Paper park operates as follows.

1. Press PAPER PARK.

2. Reverse line feed retracts the paper until a PAPER-END condition exists

or

14 inches of paper have been fed.

3. When the PAPER-END condition exists, the printer retracts 0.49 inches of paper. The paper is still

installed on the push tractor, but cut sheet paper may now be fed.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 46

Page: 31

Service Guide ML380

Chapter 3 Maintenance & Disassembly

3.1 OVERVIEW

3.1.01 General Information

This section lists the parts replacement, adjustment, cleaning, lubrication, and shipping procedures.

Disassembly should not be performed unless absolutely necessary.

malfunctioning printer until you have followed the failure analysis procedures in Section Four of this

Service Handbook.

NEVER

perform disassembly on a

Follow the procedures listed in

either consumable or parts are replaced. Failure to perform these procedures could result in unnecessary

service calls.

Proper performance of maintenance and cleaning will help to achieve the best possible print quality from

the printer.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Adjustments and Service Settings

. Adjustments may be required when

Page 47

Chapter 3 Maintenance & Disassembly

3.1.02 Maintenance Tools

The following tools are required to service the printer.

#2 Phillips Screwdriver (with magnetic tip)

Straight-slot Screwdriver

Needle Nose Pliers (4 Inch)

Awl or large, opened paper clip

Wire Cutters

Digital Multimeter

Feeler Gauge (capable of measuring .014 inches)

Shop Vacuum

Clean, soft, and lint-free Cloth

All-Purpose Cleaner

Contact Kleen (Okidata P/N 51802301)

Platen Cleaner

Machine Grease

Machine Oil

Page: 32

Service Guide ML380

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 48

Page: 33

Service Guide ML380

Chapter 3 Maintenance & Disassembly

3.1.03 Maintenance Precautions

1. Do not disassemble the unit if it is operating normally.

2. Before starting disassembly and assembly, always turn the AC power switch OFF and pull out the AC

plug.

3. Detach the interface cable, if installed.

4. Do not remove parts unnecessarily. Try to keep disassembly to a minimum.

5. Use the recommended maintenance tools.

6. When disassembling, follow the listed sequence. Failure to follow the correct sequence may result in

damaged parts.

7. Since screws, collars and other small parts are easily lost, they should be temporarily attached to the

original positions.

8. When handling circuit boards use extreme care. Integrated circuits (microprocessors, ROM, and RAM)

can be destroyed by static electricity.

9. Do not place printed circuit boards directly on conductive surfaces.

10. Follow the recommended procedures when replacing assemblies and units.

11. Perform the printhead gap adjustment procedure when any of the following occur.

3.3 of this Service Handbook.

Print Quality is darker on one side of the document.

Parts are replaced.

Printhead (3.2.02)

Space Rack (3.2.04)

Carriage Frame (3.2.13)

12. Perform the space belt tension adjustment procedure when the following parts are installed.

Refer to Section 3.3 of this Service Handbook.

Space Belt (3.2.06)

Space Motor Assembly (3.2.22)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Refer to Section

Page 49

Page: 34

Service Guide ML380

Chapter 3 Maintenance & Disassembly

3.2 DISASSEMBLY/ASSEMBLY PROCEDURES

General Information

This section contains the printer disassembly procedures. Only the removal procedures are explained

here. Reverse the procedure for the installation.

At the bottom of each procedure is a listing of the parts covered in that procedure. The Okidata part

number, item description, comment (RSPL, Option, Consumable) and cross-reference to Appendix B is

provided for each part. Items included in the Recommended Spare Parts List are indicated by the acronym

RSPL. N/A will appear where a part number is not available.

Part Item Comment Appendix B Number Description Reference

This Service Handbook lists the disassembly procedures for major components of the unit. Okidata DOES

NOT recommend disassembling a unit which is operating normally. If you decide to perform disassembly

only

during this training, Okidata recommends that you perform

items. All other procedures are provided to assist you in identifying parts. It is not likely that you will

perform these procedures while servicing the unit.

the disassembly procedures for RSPL

Be sure to read all notes, cautions, and warnings, as they contain important information regarding

disassembly / assembly.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 50

Service Guide ML380

Chapter 3 Maintenance & Disassembly

3.2.01 Paper Separator

1. Raise the access cover (1).

2. Move the bail lever (2) toward the front of the printer.

3. Push the paper separator (3) at location A and release it from the platen shaft (4).

4. Lift the paper separator to detach the guide pins (5) from the printer mechanism (6).

P/N N/A AC Cable B.2.03

P/N 53511401 Separator: Paper RSPL B.2.03

Page: 35

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Page 51

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 52

Page: 36

Service Guide ML380

Chapter 3 Maintenance & Disassembly

3.2.02 Printhead

1. Move the bail lever (1) to back of the printer.

2. Remove the ribbon cartridge (2).

3. Grasp the tab of the head clamp (3), lift up and swing it 90° in the direction of Arrow A to unlock the

printhead (4).

4. Lift the printhead from the carriage frame (5).

NOTE:

Perform the printhead gap adjustment procedure after installing this part.

Refer to Section 3.3 of this Service Handbook.

P/N 52104001 Ribbon: Cartridge Consumable B.2.08

P/N 50079301 Printhead RSPL B.2.03

Page 53

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 54

Service Guide ML380

Chapter 3 Maintenance & Disassembly

3.2.03 Upper Cover Assembly

1. Perform this procedure: 3.2.01.

2. Remove the platen knob (1).

3. Raise the sheet separator (2), and pull it out diagonally in the direction of Arrow A.

4. Do the following to avoid interference when removing the upper cover assembly.

Close the covers of the tractor assemblies (3).

Slide the assemblies to the center of the printer unit.

5. Remove the two screws (4). The screws are at the back of printer, on the bottom.

6. Lift the rear part of the upper cover (5), pull it forward, and remove it.

7. Raise the access cover (6) 90° and remove it from the upper cover.

Page: 37

P/N 50071101 Separator: Sheet (Assembly) RSPL B.2.02

P/N 50071201 Separator: Sheet B.2.02

P/N 53510201 Support: Sheet B.2.02

P/N 51901101 Knob: Platen RSPL B.2.03

P/N 53510401 Guide: Sheet (L) B.2.02

P/N 53510301 Guide: Sheet (R) B.2.02

P/N 53510101 Cover: Access RSPL B.2.02

P/N 53510001 Cover: Middle RSPL B.2.02

Page 55

Page 56

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 57

Page: 38

Service Guide ML380

Chapter 3 Maintenance & Disassembly

3.2.04 Space Rack

1. Perform this procedure: 3.2.02.

2. Remove the two screws (1) on the carriage plate (2). Do not remove the ribbon feed gear assembly.

3. Slide the carriage frame (3) in the direction of Arrow A, leaving the carriage plate in place.

4. Set the carriage plate under the space rack (4).

5. Release the claw (5).

6. Remove the B side of the space rack from the guide pin (6), and lift the space rack.

7. Remove the C side of the space rack from guide pin (7), and remove the space rack.

NOTE:

Perform the printhead gap adjustment procedure after installing this part.

Refer to Section 3.3 of this Service Handbook.

P/N 53510801 Rack: Space RSPL B.2.04

Page 58

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 59

Page: 39

Service Guide ML380

Chapter 3 Maintenance & Disassembly

3.2.05 Ribbon Feed Gear Assembly

1. Perform this procedure: 3.2.02.

2. Release the four claws (1).

3. Insert a screwdriver into the grooves (2) and pry the claws away from the carriage plate (3).

4. Lift the ribbon feed gear assembly (4) in the direction of arrow A. Slide it in the direction of Arrow B, and

remove it.

P/N 50071501 Gear: Ribbon Feed (Assembly) RSPL B.2.06

Page 60

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 61

3.2.06 Mini-Pitch (Space) Belt

Page: 40

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.02

2. Use pliers to remove the belt tension spring (1).

3. Loosen the screw (2).

4. Remove the belt (3) from the idle pulley (4).

5. Remove the head connector assembly (5) from the carriage plate (6).

6. Remove the carriage plate.

7. Detach the belt from the space motor assembly gear (7).

8. Remove the belt clamp (8) mounted to bottom of the carriage plate.

9. Use a screwdriver to push the claw of the belt clamp in the direction of arrow A. Then, remove the belt

clamp and belt by lowering the claw in the direction of arrow B.

and 3.2.05.

NOTE:

Perform the space belt tension adjustment procedure after installing this part.

Refer to Section 3.3 of this Service Handbook.

P/N 50904801 Spring: Coil RSPL B.2.04

P/N 51304001 Belt: Mini-Pitch (Space Belt) RSPL B.2.06

P/N N/A Screw: Self Tapping B.2.04

P/N 51004001 Slider RSPL B.2.06

P/N 51219201 Pulley: Idle RSPL B.2.04

P/N 53330401 Plate: Carriage RSPL B.2.06

P/N 50704701 Clamp: Belt RSPL B.2.06

P/N 53330301 Bracket: Idle Pulley RSPL B.2.04

Page 62

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 63

3.2.07 Head Connector Assembly

Page: 41

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. Remove the two head cables (1) from the connectors (2) on the control board. When cable clamp (3) is

lifted, the head cables can be removed.

3. Pull the head cables under the cable guides (4), and remove the head cables.

P/N 56725301 Connector: Head (Assembly) RSPL B.2.06 Head Cable

, 3.2.02 , 3.2.03 , 3.2.05 , and 3.2.06 .

Page 64

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 65

3.2.08 Main Control Board (UMMB)

Page: 42

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. Remove the five connectors (1) connected to the control board (2).

3. Remove the five screws (3).

4. Release the two claws (4), and move the control board in the direction of arrow A to remove.

P/N 55047801 PCB: UMMB (Main Control) RSPL B.2.03

P/N 55938501 IC: EEPROM BR93CS46-Z-NW RSPL B.2.03

P/N 56304201 Fuse: 125V 1.6A RSPL B.2.03

P/N 56304301 Fuse: 125V 2.5A RSPL B.2.03

and 3.2.03 .

w/o ROM

Page 66

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 67

3.2.09 Operation Panel

Page: 43

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. Use a screwdriver to release the six claws (1) on the operation panel (2) and remove the operation

panel from the control board (3).

P/N 53524301 Sheet: Operation Panel RSPL B.2.03

and 3.2.03 .

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 68

3.2.10 Line Feed Motor

Page: 44

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. Use a screwdriver to open the lock levers (1) in the directions of arrows A and B, and push the bracket

(2) of the line feed motor (3) in the direction of arrow C.

3. Pull the line feed motor out of the guide holes (4), in the direction of arrow D.

NOTE:

After installation, check that the platen gear (5) engages firmly and rotates smoothly.

P/N 56507801 Motor: Line Feed RSPL B.2.04

and 3.2.02 .

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 69

3.2.11 Photosensor Assembly (Paper End)

Page: 45

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. Pull the paper end sensor (1) from the sensor guide (2).

P/N 56106901 Photosensor: (Assembly) RSPL B.2.04 Paper End

, 3.2.02 and 3.2.10 .

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 70

3.2.12 Bail Arms

Page: 46

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. Use pliers to remove the left bail arm spring (1).

3. Push claw (2) downward, pull it out of guide hole (3) of main frame and remove the left bail arm (4).

4. Remove the left bail arm from the bail bar (5).

5. Use pliers to remove the right bail arm spring.

6. Push claw downward, pull it out of guide hole of main frame and remove the right bail arm.

7. Remove the right bail arm from the bail bar.

P/N 50911801 Spring: Bail Arm (L) RSPL B.2.04

P/N 53511001 Bail Arm (L) RSPL B.2.04

P/N 50911701 Spring: Bail Arm (R) RSPL B.2.04

P/N 53511101 Bail Arm (R) RSPL B.2.04

P/N 51110501 Shaft: Indicator (Assembly) RSPL B.2.04 Bail Bar

, 3.2.02 , 3.2.10 , and 3.2.11 .

Page 71

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 72

3.2.13 Carriage Frame

Page: 47

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. Open the supporting point A, and remove the head clamp (1).

3. Insert a screwdriver into the groove of carriage frame (2), and remove ribbon protector (3).

4. Turn the white left adjust bushing (4) to the lower end, and remove it.

5. Turn the black right adjust bushing (5) to the lower end, and remove it.

6. Turn the blue adjusting lever (6) to the lower end.

7. Slide the carriage shaft (7) to the right.

8. Remove the shaft and the adjusting lever.

9. Pull the carriage shaft in the direction of arrow B, and remove it from the carriage frame (8). Be

careful not to lose the eccentric collar (9). When installing the eccentric collar, place notched section (10)

toward the carriage shaft.

, 3.2.02 , and 3.2.03 .

NOTE:

Perform the printhead gap adjustment procedure after installing this part.

Refer to Section 3.3 of this Service Handbook.

P/N 50702901 Clamp: Head RSPL B.2.06

P/N 53056201 Protector: Ribbon RSPL B.2.06

P/N 53330201 Frame: Carriage RSPL B.2.06

P/N 51606501 Bushing: Adjust (L) RSPL B.2.04

P/N 51606601 Bushing: Adjust (R) RSPL B.2.04

P/N 53510701 Lever: Adjust RSPL B.2.04

P/N 51110401 Shaft: Carriage RSPL B.2.04

P/N 50704601 Collar: Eccentric RSPL B.2.04

P/N N/A Code: Earth B.2.04

Page 73

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 74

3.2.14 Platen Assembly

Page: 48

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. Pull lock levers (1) in the direction of arrow A, and raising them at an angle of 90°. This releases the

platen assembly (2) from the main frame (3).

3. Lift the A side of the platen assembly until the B side clears the release lever (4).

NOTES:

After installation, check that the platen gear engages firmly with the line feed motor gear and that the

platen rotates smoothly.

Set the release lever to OPEN (front) and check that the groove (5) of the paper chute firmly engages with

the groove (6) of the main frame. Then, lock the platen assembly.

P/N 50061305 Platen: (Assembly) RSPL B.2.04

and 3.2.03 .

Page 75

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 76

3.2.15 Pressure Roller Assembly

Page: 49

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. Remove the paper chute (1). Be careful not to damage the grounding strap.

3. Open the claw (2), and remove the paper release lever (3).

4. Remove the change gear (4) and the spring (5).

5. Remove the idle gear (6).

6. Remove the boss (7) from the guide hole (8) of the main frame (9), and remove the release link (10).

7. Pull part A of the pressure roller assembly shaft (11) out of the main frame, in the direction of arrow B.

8. Pull the C part of the pressure roller assembly shaft out of the main frame in the direction of arrow D.

9. Remove the shaft.

, 3.2.03 and 3.2.14 .

NOTES:

Installation

Position the tab (12) of the paper chute firmly with the groove (13) of the main frame.

Engage the cut-sheet paper end lever (14), attached to bottom of paper chute, to the bottom paper end

lever (15) under the main frame, and install the paper chute.

The Kit: Idler/Change Gear (ML300) includes the change and idler gears. Order this kit when replacing

these parts.

P/N 50071701 Chute: Paper (Assembly) RSPL B.2.05

P/N 53511201 Lever: Release RSPL B.2.05

P/N 51219101 Gear: Change RSPL B.2.05

P/N 50915101 Spring: Change Gear RSPL B.2.05

P/N 58227501 Kit: Idler/Change Gear (ML300) RSPL B.2.05

P/N 51216001 Gear: Idler B.2.05

P/N 53511301 Link: Release RSPL B.2.05

P/N 50071601 Roller: Pressure (Assembly) RSPL B.2.05

Page 77

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 78

3.2.16 Paper Pressure Guide

Page: 50

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. Working from the underside of the printer mechanism and using a screwdriver, detach the connection

hole section (1) from the projection (2) of the main frame (3). Begin at point A and end at point B.

3. Remove the paper pressure guide (4).

NOTE:

On installation, be sure to install the projections and guide plates (5) simultaneously.

P/N 50911501 Guide: Paper Pressure RSPL B.2.05

, 3.2.02 , 3.2.03 and 3.2.05 .

Page 79

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 80

Page: 51

Service Guide ML380

Chapter 3 Maintenance & Disassembly

3.2.17 Tractor Assembly

NOTE:

Horizontal movement of the left tractor is restricted by a stopper on the lower cover.

1. Perform these procedures: 3.2.01 and 3.2.03 .

2. Remove the tractor drive shaft locking clamp.

3. Open the claw (1), and remove the drive gear (2) from the groove (3) of the drive shaft (4).

4. Release the right groove (5) of the drive shaft from the guide (6) of the main frame.

5. Shift the groove in the direction of Arrows A and B. This releases the left part of the drive shaft from the

guide hole (7) of the main frame.

6. Push the left part of lock shaft (8), and move the groove (9) in the direction of Arrow C to release the

groove from the hole (10) in the main frame.

7. Shift the lock shaft (8) to the right, and move the shaft in the direction of Arrow D to remove the shaft

from the larger guide hole (11).

8. Push the left part of the tractor assembly in the direction of Arrow E, and remove the tractor assembly

(12) while pulling the drive shaft in the direction Arrow F. This moves the shaft out of the guide holes (13

and 14) of the printer frame.

9. Remove the center guide (15), the left pin tractor assembly (16), and the right pin tractor assembly (17)

from the two shafts (4) and (8).

NOTES:

Marks A (18) and B (19) of the left (20) and right pin tractors (21) must be aligned when installed.

Install the left pin tractor assembly to the left of the stopper on the lower cover. This limits movement and

correctly positions the paper against the paper end sensor.

P/N 50071901 Tractor: Pin [L] (Assembly) RSPL B.2.06

P/N 51216101 Gear: Tractor RSPL B.2.05

P/N 51003901 Guide: Center RSPL B.2.06

P/N 50071801 Tractor: Pin [R] (Assembly) RSPL B.2.06

P/N 51109503 Shaft: Drive RSPL B.2.06

P/N 51110601 Shaft: Lock RSPL B.2.06

Page 81

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 82

3.2.18 Microswitch Assembly (SASF)

Page: 52

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. The microswitch assembly (1) is fastened to the frame on two pins. The first pin (2) is part of the switch.

The second pin (3) is part of the printer mechanism. The first pin must be released before the switch will

pivot on the second pin.

3. To release the first pin, use an opened paper clip to push the pin out of the hole. Access the hole from

the inside of the printer frame. Then, pivot the switch on the second pin, in the direction of arrow A, until

the switch clears the bracket (4).

4. Remove the microswitch assembly.

P/N 56211301 Microswitch: (Assembly) SASF RSPL B.2.05

and 3.2.03 .

Page 83

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 84

Service Guide ML380

Chapter 3 Maintenance & Disassembly

3.2.19 Microswitch Assembly (Home Position Switch)

Page: 53

1. Perform these procedures: 3.2.01

2. Open the switch clamp (1) and release the home position switch (2) from the pin (3).

3. Pull the switch through the opening (4) in the printer frame.

4. Release the cables from the guides on the frame.

5. Remove the microswitch assembly.

P/N 56211301 Microswitch: (Assembly) RSPL B.2.05 Home Position

and 3.2.03 .

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 85

3.2.20 Printer Mechanism

Page: 54

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. Open the claws (1) of the lower cover assembly (2) and lift the printer mechanism (3) to remove it.

P/N 54148708 Screw: No. 3 x 8 MM Self Tapping RSPL B.2.02

P/N 53330101 Plate: Shield RSPL B.2.02

P/N 50071301 Cover: Lower (Assembly) RSPL B.2.03

P/N 53510601 Cover: Lower RSPL B.2.02

P/N 53452701 Foot: Rubber RSPL B.2.02

P/N 50071401 Chassis: Mechanism (Assembly) RSPL B.2.05

and 3.2.03 .

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Page 86

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 87

3.2.21 Power Supply Unit

Page: 55

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. Open the claws (1) and remove the AC power cord shock restraint (2).

3. Remove the two screws (3).

4. Remove the grounding cord (4) to the AC power cord (5).

5. Remove the grounding cord (6) to the transformer (7).

6. Remove the four screws (8).

7. Remove the transformer, the AC switch (9), and the AC power cord from the lower cover assembly

(10).

8. The power supply unit is made of the grounding cords, the transformer, the AC switch, and the

connector (11).

, 3.2.03 , and 3.2.20 .

NOTE:

Installation

Firmly insert the AC switch into the A and B guides of the lower cover. The side with the red line goes is

the front.

Be careful not to cover the grounding mark (12) when installing the grounding cords.

P/N 56408201 Power Supply Unit 120V RSPL B.2.03

P/N 56408301 Power Supply Unit 220/240V RSPL B.2.03

P/N 56304101 Fuse: 125V 3.15A RSPL B.2.03

P/N 56304501 Fuse: 250V 1.25A RSPL B.2.03

Page 88

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 89

3.2.22 Space Motor Assembly

Page: 56

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. Raise the printer mechanism (1), and remove the space motor cord (2) from the guides (3).

3. Open the two claws (4) and pull the space motor assembly (5) in the direction of arrow A.

4. Remove the brackets (6) from the guide holes (7) of the main frame and remove the space motor

assembly.

NOTE:

Installation

On installation, align the brackets with guide holes and push the space motor assembly down until it snaps

into position under the two claws.

Perform the space belt tension adjustment procedure after installing this part.

Refer to Section 3.3 of this Service Handbook.

P/N 56507901 Motor: Space (Assembly) RSPL B.2.05

, 3.2.03 , and 3.2.20 .

Page 90

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 91

3.2.23 Bottom Paper Guide Lever

Page: 57

Service Guide ML380

Chapter 3 Maintenance & Disassembly

1. Perform these procedures: 3.2.01

2. Push the pin (1) of the bottom paper guide lever (2), and remove the pin from the guide hole (3) of the

main frame.

3. Remove the pin (4) from the guide hole (5) of the main frame, and remove the bottom paper guide

lever.

NOTE:

When the paper chute (6) is installed, the cut-sheet paper end lever (7) must engage firmly with the

bottom paper guide lever.

P/N 53510901 Lever: Bottom Paper Guide RSPL B.2.05

, 3.2.03 and 3.2.20 .

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Page 92

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 93

Page: 58

Service Guide ML380

Chapter 3 Maintenance & Disassembly

3.3 PRINTER ADJUSTMENTS

3.3.01 General Information

This section contains the procedures for performing adjustments on the printer. These procedures may be

required when replacing either consumables or parts. The disassembly/assembly procedures list the

required adjustments and refer you to this section. Failure to perform these procedures may result in

unnecessary service calls.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 94

Service Guide ML380

Chapter 3 Maintenance & Disassembly

3.3.02 Gap Between Platen and Printhead

General Information

The printhead gap adjustment should be performed when the following occur.

1. Print quality is darker on one side of the document.

2. Parts are replaced.

Printhead (3.2.02)

Space Rack (3.2.04)

Carriage Frame (3.2.13)

The printhead gap should measure .016 inch, + / - .002 inch (0.41 + / - 0.05 millimeters)

Procedure

Page: 59

1. Move the release lever (1) to the open position (front).

2. Set the printhead gap adjusting lever (2) to range 1

3. Move the carriage to the left side of the platen and rotate the left adjusting collar (3) to obtain the correct

gap between the platen and the printhead.

4. Move the carriage to the right side of the platen and rotate the right adjusting collar to obtain the correct

gap between the platen and the printhead.

5. Check the gap setting at the left, center, and right of the platen.

When the gap is correct at all positions, do the following check.

1. Set the adjusting lever to range 5

2. Check the gap setting at the left, center, and right of the platen. It should measure .027 inch, + / - 0.002

inch.

Page 95

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 96

Service Guide ML380

Chapter 3 Maintenance & Disassembly

3.3.03 Space Belt Tension

General Information

The space belt tension adjustment should be performed when the following parts are replaced.

Space Belt (3.2.06)

Space Motor Assembly (3.2.22)

Procedure

1. Slightly loosen the screw of the idle pulley.

DO NOT remove the screw.

2. Manually slide the carriage assembly back and forth across the entire length of the platen.

Page: 60

3. Tighten the screw.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 97

3.3.04 Key Combinations

Page: 61

Service Guide ML380

Chapter 3 Maintenance & Disassembly

Key Combinations

FONT + PITCH (While ON-LINE) Enter Menu Mode (While ON-LINE)

FONT (Hold during Power-ON) Enter Menu Mode (From Power-OFF

SEL + FEED (Hold during

Power-ON)

TOF + PARK (Hold during

Power-ON)

FEED (Hold during Power-ON) Activate Font Test

SEL + TOF/PARK (Hold during

Power-ON)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Description

Access Menu if Menu set to LIMITED

OPERATION)

Reset Menu to Factory Defaults.

Activate Rolling ASCII Test

Activate Hexadecimal Dump Test

Page 98

Page: 62

Service Guide ML380

Chapter 3 Maintenance & Disassembly

3.3.05 Menu Operation / Menu Select Mode

NOTE:

Using the front panel or commands sent from the computer will override the features set in the menu.

However, when the printer is powered OFF, features set by these methods will be canceled. Features set

in the menu will stay in effect, even when the printer is powered OFF.

General Information

Menu Select Mode allows customization of printer settings and features. Selections made are stored in the

printers permanent memory. However, they can be changed through software commands, control panel

settings, or by resetting the menu.