Page 1

MC-860 / CX2633MFP

Service & Troubleshooting Guide

© 2009 OkiData Americas, Inc.

Disclaimer

Every effort has been made to ensure that the information in this document is complete, accurate, and up to date. The

manufacturer assumes no responsibility for the results of errors beyond its control. While all reasonable efforts have been made

to make this document accurate and helpful as possible, we make no warranty of any kind, expressed or implied, as to the

accuracy or completeness of the information contained herein. For the most up-to-date service information available, visit our

website, www.okidata.com

© Okidata Americas, Inc. 2009

Page 2

Chapter 1 Maintenance Procedures – Printer / ADF / Scanner

1.1 Exterior Cleaning

1.2 Cleaning the LED lens array

1.3 Cleaning the Pickup Roller

1.4 Cleaning inside the Printer

1.5 Cleaning the ADF and Scanner

Chapter 2 Service Menus and Adjustments

2.1 How to Enter the Service Menu

2.2 Service Maintenance Menu Overview

2.3 System Maintenance

2.4 Panel Maintenance

2.5 Scanner Maintenance

2.6 Fax Maintenance

2.7 Printer Maintenance

2.7.1 Switch Scan Test

2.7.2 Motor & Clutch Test

2.7.3 Test Print - Monitoring Printer Environmental Conditions

2.7.4 Color Registration Error Correction Test

2.7.5 Density Error Correction Test

2.7.6 Consumable Item Counter Display

2.7.7 Factory/Shipping Mode Switching

2.7.8 Engine Parameter Setting – Fuse Check Method

2.8 Initialization Functions

Chapter 3 Troubleshooting Print Quality

3.1 Print Quality Problems Overview

3.2 Using New Consumable Units for Testing Purposes

3.3 Things to observe when analyzing Test Pages

3.4 Print-Quality Troubleshooting

Chapter 4 Troubleshooting Paper Feeding

4.1 Troubleshooting Paper Feed

4.1.1 Paper Feed Sensor Details

4.1.2 Jam Removal Procedure

Chapter 5 Troubleshooting Error Codes

2

Page 3

Chapter 1 Maintenance Procedures – Printer

1.1 Exterior Cleaning

Clean inside and outside of the printer with a clean dry cleaning cloth and small vacuum cleaner as

required.

Note! Be careful not to touch the image drum terminals, the LED lens array and the LED head

connectors.

1. Turn OFF the power of the MFP.

Select “Setup” then “Shutdown”. Follow the on screen prompts. When shutdown is complete,

turn off the power switch on the printer.

2. Clean the surface of MFP.

Note! Do not use any liquid other than water and neutral detergent.

The MFP requires no lubrication.

Do not lubricate the unit.

Clean the surface of the unit with a clean

cloth wrung out using clean water or

neutral detergent.

Clean surface of the unit with soft clean cloth.

3

Page 4

1.2 Cleaning the LED lens array

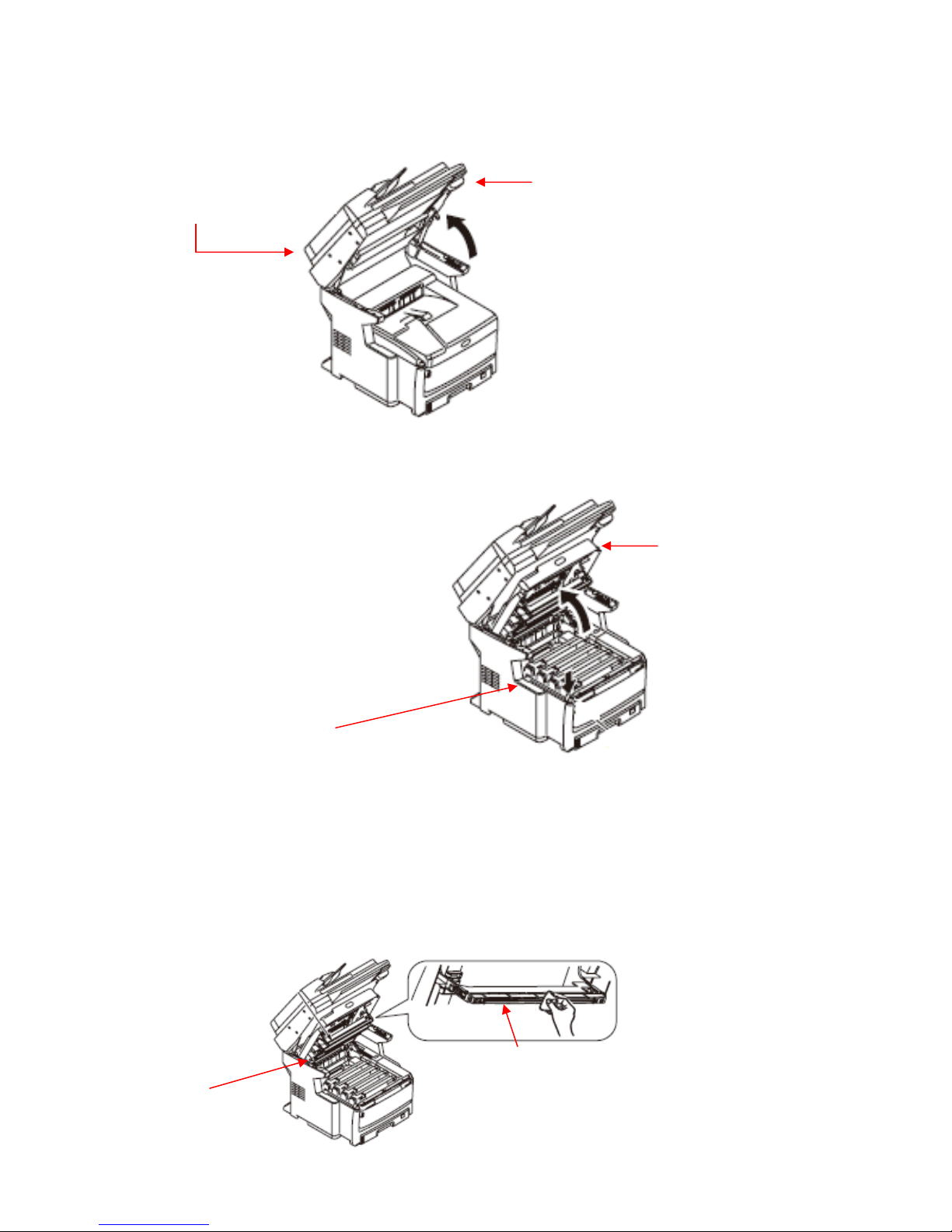

• Pull the document table lock lever to the front to release the lock, and raise the

document table.

Document Table

• Press the top cover button and open the top cover.

Top Cover Button

Document Table Lock Lever

Top Cover

Caution Failure to proceed with caution may result in burn injury. The fuser unit gets

very hot. Do not touch the surface of the fuser unit.

• Wipe the lens surface (at the four positions) of the LED head with soft tissue paper

gently and lightly.

LED Heads

Lens Surface of the LED Head

4

Page 5

T

T

1.3 Cleaning the Pickup Roller

Note! Clean the pickup roller for tray 2 and tray 3 in the same procedure.

For the MP tray, clean the pickup roller in the same procedure for the feed roller only.

(Pad is not used.)

• Pull out the tray.

• Clean the feeder roller (large) and the feeder roller (small) with a clean cloth wrung

out using clean water

• Clean the pad portion of the tray with a clean cloth wrung out using clean water

Feed Roller (Large)

Feed Roller (Small)

Pad

ray 1

Roller

ray 2, Tray 3

5

Page 6

1.4 Cleaning inside the Printer.

Toner can adhere to the metal shaft that is located in between the fuser and the cyan

image drum cartridge depending on the print pattern. Perform cleaning of the inside of

the MFP if toner has adhered to the metal shaft.

• Turn OFF the power of the MFP.

• Pull the document table lock lever to the front to release the lock, and raise

the document table. Then Press the top cover button and open the top cover.

• Remove the four image drum cartridges from the MFP.

• Cover the removed image drum cartridge with a black paper.

Note! Use caution when handling the image drums. Be very careful not to expose the

image drum to direct sun light or intense light. Do not leave it out under normal

illumination even indoors for 5 minutes or longer.

• Remove the fuser unit from the MFP.

Caution Failure to proceed with caution may result in burn injury. The fuser unit gets

very hot. Do not touch the surface of the fuser unit.

• Raise the fuser unit lock lever (shown in blue) in the direction shown by the

arrow.

Drum Cartridges

6

Page 7

(

)

• Hold the handle of the fuser unit and remove it.

Fuser Unit Lock Lever (Blue)

• Remove the Transfer Belt unit from the MFP.

• Thoroughly clean the interior of the printer and re-install the transfer belt,

Transfer Belt

fuser, and drum units. Inspect all units before re-installation.

Fuser Handle

Transfer Belt

Retaining

Screws

Blue

7

Page 8

1.5 Cleaning the ADF and Scanner

Clean the paper path of the ADF once every month or more in order to maintain high

print quality and to transport the documents smoothly.

• Open the document cover OPEN lever and open the document cover.

Document Cover Open Lever

• Clean the document transport roller.

.

Note! Clean the entire surface of the roller by rotating the roller by hand.

(Some types of rollers can rotate in one direction only.)

• Open the inside cover.

Rollers

• Clean the document retainer roller.

Dial

Inside

top

cover

Inside Cover

Document Cover

Clean surface of the roller with a clean cloth

wrung out using clean water or neutral

detergent.

Clean surface of the roller with a clean cloth

wrung out using clean water or neutral

detergent.

Dial

Clean surface of the roller with a clean cloth

wrung out using clean water or neutral

detergent.

Document

Retainer Roller

8

Page 9

• Open the document table cover.

Clean the surface of the document retaining pad, the platen Glass and the scanning glass

with a clean cloth wrung out using clean water or neutral detergent.

Scanning Glass

Document

Retaining Pad

Platen Glass

9

Page 10

Chapter 2 Service Menus and Adjustments

The service function is to be used for the purposes of MFP maintenance by the experienced

Maintenance / service engineer, and are not open to general users. The respective items of the service

function are contained in the service menu.

2.1 How Enter the Service Menu

Enter the service menu by the following operation.

1. The password entry screen is displayed when the special operation of the hardware keys is operated

while an MFP is running. The MFP enters this condition waiting for password entry.

2. When the password that is entered by maintenance/service engineer matches the specified password,

the service menu is displayed.

Special Operation of the Hardware Keys

The operation procedure to display the password entry screen of the service menu is described as

follows.

1. To display the password entry screen, press the [SETUP] key while an MFP is running.

2. Press the numeric keys in the order of [#] [1] [9] [3] [7].

3. The password entry screen is displayed.

Password Entry Screen

Value Default Display Condition

Enter the password that is required to enter the service menu. (OOOOOO) (Six zeros).

Note! Data entry will appear as

Asterisks.

10

Page 11

Caution! The Password can be changed by the “Change Password” menu of the “System

Maintenance” menu. It is highly recommended that you DO NOT change this password. In the event

that the changed password is lost, the main control board and hard disk drive would need replacement.

This is not a covered expense under any machine warranty and you will incur the cost of the

replacement components.

Operation required to exit the Service Mode Screen

In order to complete operations of the service menu, the [Close] button that is displayed on the service

menu top screen should be pressed.

Note! If any setting change requires reboot of the MFP and the [Close] button is pressed, the MFP will

enter the normal operating condition after the MFP reboots.

11

Page 12

2.2 Service Maintenance Menu – Overview

System Maintenance Screen Panel Maintenance Screen Copy Maintenance Screen

Scan Maintenance Screen Fax Maintenance Screen Printer Maintenance Screen

12

Page 13

Service Maintenance Menu Structure is shown below.

Level 1 Level 2 Level 3 Level 4 Reboot

Process

System

Maintenance

(See Section 2.3)

OKIUSER

Format HDD

Format Flash ROM

Menu Reset

All Reset

Test Print Menu

New Password When Closed

Verify Password When Closed

Side Reg. None FBS

ADF (Front)

ADF (Back)

Echo support None

Modem transmission speed None

Echo support None

Modem transmission speed None

ON period None

Off Period None

Front Edge None

Side Reg. None

Front Edge None

Back Edge None

Side Reg. None

Front Edge None

Back Edge None

Panel

Maintenance

(See Section 2.4)

Copy Maintenance

Scan

Maintenance

(See Section 2.5)

Fax Maintenance

(See Section 2.6)

Change Password

LED Test

LCD Test

OP Key Test

Color Copy

Retrieve Shading Data

Clean RADF Roller

Adjust Scan Position

Country Code

TX

RX

Pulse Make Ratio

MF(Tone) Duration

Calling Timer

Attenuator

MF Attenuator

Relay

Tonal

DTFM

IBM 5577

IBM PPR III XL

EPSON FX

HP-GL/2

Printer

Maintenance

(See Section 2.7)

Line Test

Personality

Peak Control

Engine Diag. Mode

Supplementary Description of “Reboot Process”

When Closed

Reboot when executed Reboot starts automatically when the function is executed.

None Reboot is not executed and the screen moves into the normal operating condition when the [Close] button

Reboot starts automatically when the [Close] button is pressed on the top screen of the service menu.

is pressed on the top screen of the service menu.

When Closed

When Executed

When Executed

None

When Executed

When Closed

None

None

None

When Closed

None

None

When Closed

None

None

None

None

None

None

None

When Closed

When Closed

When Closed

When Closed

When Closed

When Closed

13

Page 14

2.3 System Maintenance

OKIUSER

Sets the MFP for the Destination Country.

Note! Should always be set for ODA (North America). Settings other than ODA may

result in erratic MFP operation. When the screen exits the service menu after this setting

is changed, the MFP reboots automatically.

Format HDD

Initialization of the HDD.

When [Format. HDD] is selected, the following confirmation screen is displayed.

When [Yes] is selected, the screen exits the menu and initialization of the HDD starts.

For details of the HDD initialization, refer to Section 2.8.

Format Flash ROM

Initialization of the Flash ROM.

When [Format Flash ROM] is selected, the following confirmation screen is displayed.

When [Yes] is selected, the screen exits the menu and initialization of the resident

mounted (on-board) Flash device starts.

For details of the Flash ROM initialization, refer to Section 2.8.

14

Page 15

Menu Reset (Administrator Password Reset)

Returns the administrator password to the factory shipment setting (factory default) value.

When [Menu reset] is selected, the following confirmation screen is displayed. When

[Yes] is selected, the administrator password is reset to the factory shipment setting

(factory default) value.

For details of the administrator password reset, refer to Section 2.8.

All Reset

Returns the contents of the EEPROM, FLASH ROM and HDD to the factory shipment

setting (factory default) value. When [All Reset] is selected, the following confirmation

screen is displayed. When [Yes] is selected, the screen exits the menu, and contents of the

EEPROM, FLASH ROM and HDD are reset to the factory shipment setting (factory

default) value.

For details of the reset to the factory shipment setting, refer to Section 2.8.

Test Print Menu

Selects to display or not to display the menu [REPORT] – [PRINT] – [ID Check Pattern]

item, and [Engine Status] item. When [Disable] is selected in this setting, the [ID Check

Pattern] and [Engine Status] items are not displayed all the time. When the screen exits

the service menu after this setting is changed, the MFP reboots automatically.

15

Page 16

Change Password

Note!

Maintenance” menu. It is highly recommended that you DO NOT change this password.

In the event that the changed password is lost, the main control board and hard disk drive

would need replacement. This is not a covered expense under any machine warranty and

you will incur the cost of the replacement components.

The Password can be changed by the “Change Password” menu of the “System

2.4 Panel Maintenance

LED Test

All LED lamps are illuminated to check if any lamp is burned out or not.

Every time when the [SETUP] key is pressed, all LED lamps are turned ON and OFF.

Operating procedure

LED lamp = OFF Red LED lamp = ON

Green LED lamp = ON All LED lamps = ON

When the [Close] button is pressed, the screen returns to the panel maintenance menu.

16

Page 17

LCD Test

Displays the test pattern on the LCD in order to check if there are inactive pixels on the

LCD.

Operating procedure

The following three kinds of test patterns can be displayed. To select the test patterns,

press the [SETUP] key.

Press the [SETUP]

key.

Press the [SETUP]

key.

Press the [SETUP]

key.

17

Page 18

Control Panel Key Test

Checks if the MFP responds normally when the hardware key and the software key on

the control panel is pressed, by observing the LCD screen if the pressed key is displayed

or not on the LCD screen. This test aims at checking all of the keys. Therefore, all keys

should be pressed in the specified order in order to check that all keys have been pressed.

Operating procedure

When this test is selected, the panel key test screen is displayed as shown below. Press all

of the keys in the specified order as shown in the picture below.

When a key is pressed in the specified order, the following messages are displayed.

When a key is pressed in a wrong order, the following messages are displayed.

18

Page 19

2.5 Scanner Maintenance

Shading Data Loading

Shading data of FBS and that of RADF (both-side copy model only) are loaded. This

item should be executed whenever any of the following items is performed.

• When the scanner lamp is replaced *

• When the mirror carriage adjustment is performed *

• When the scanner Main PCB is replaced

Operating procedure

When this item is selected Confirm that the RADF unit is closed.

the following screen is displayed. Then press the [Start] button.

Scanning Roller Cleaning

Operating procedure

When this item is selected, the following screen is displayed.

19

Page 20

Scan Position Adjustment

Side registration adjustment - The separate setting items are prepared for FBS, ADF

(front side) and ADF (back side) independently.

Setting for Flat Bed Scanning (FBS)

Perform adjustment so that the scan start position in the horizontal scanning direction

during FBS Scanning stays within the reference value. Adjustment in increments of 1

item (5/600 dpi = 0.2117 mm) is possible in this setting. When a value is added in the

negative (-) direction, the scan image on a PC moves to the right. When a value is added

in the positive (+) direction, the scan image on a PC moves to the left.

Setting for ADF (front side)

Perform adjustment so that the scan start position in the horizontal scanning direction

during ADF front side scanning stays within the reference value. Adjustment in

increments of 1 item (5/600 dpi = 0.2117 mm) is possible in this setting. When a value is

added in the negative (-) direction, the scan image on a PC moves to the left. When a

value is added in the positive (+) direction, the scan image on a PC moves to the right.

Setting for ADF (rear side)

Perform adjustment so that the scan start position in the horizontal scanning direction

during ADF rear side scanning stays within the reference value. Adjustment in

increments of 1 item (5/600 dpi = 0.2117 mm) is possible in this setting. When a value is

added in the negative (-) direction, the scan image on a PC moves to the left. When a

value is added in the positive (+) direction, the scan image on a PC moves to the right.

Top End Position Adjustment

Perform adjustment so that the scan start position in the vertical scanning direction during

FBS scanning stays within the reference value. If shade is scanned at the top end of a

document, make adjustment in the positive direction. If deficiency occurs at the top end

of a document, make adjustment in the negative direction. Adjustment in increments of 1

item (0.1408 mm) is possible in this setting. When a value is added in the negative (-)

direction, the scan image on a PC moves down. When a value is added in the positive (+)

direction, the scan image on a PC moves up.

Setting for ADF (front side)

Perform adjustment so that the scan start position in the vertical scanning direction during

ADF front side scanning stays within the reference value. If shade is scanned at the top

end of a document, make adjustment in the positive direction. If deficiency occurs at the

top end of a document, make adjustment in the negative direction. Adjustment in

increments of 1 item (0.0619 mm) is possible in this setting. When a value is added in the

negative (-) direction, the scan image on a PC moves down. When a value is added in the

positive (+) direction, the scan image on a PC moves up.

Setting for ADF (back side)

Perform adjustment so that the scan start position in the vertical scanning direction during

ADF rear side scanning stays within the reference value. If shade is scanned at the top

end of a document, make adjustment in the positive direction. If deficiency occurs at the

top end of a document, make adjustment in the negative direction. Adjustment in

increments of 1 item (0.0619 mm) is possible in this setting. When a value is added in the

negative (-) direction, the scan image on a PC moves down. When a value is added in the

positive (+) direction, the scan image on a PC moves up.

20

Page 21

Back End Position Adjustment

Precaution The rear end position adjustment should be executed after the top end

position adjustment is completed. In addition, scanning is stopped before the rear end is

reached if amount of the specified scanning lines are scanned in the copy mode and scan

mode even though the rear end position adjustment is performed.

Setting for ADF (front side)

Perform adjustment so that the rear end scan position in the vertical scanning direction

during ADF front side scanning stays within the reference value. If shade at the rear end

of document is scanned, perform adjustment in the negative (-) direction. If deficiency

occurs at the rear end of a document, make adjustment in the negative direction.

Adjustment in increments of 1 item (0.0619 mm) is possible in this setting. However,

adjustment should be performed in increments of 16 items (1 mm) as a guide line due to

document running at an angle.

Setting for ADF (back side)

Perform adjustment so that the rear end scan position in the vertical scanning direction

during ADF rear side scanning stays within the reference value. If shade at the rear end of

document is scanned, perform adjustment in the negative (-) direction. If deficiency

occurs at the rear end of a document, make adjustment in the negative direction.

Adjustment in increments of 1 item (0.0619 mm) is possible in this setting. However,

adjustment should be performed in increments of 16 items (1 mm) as a guide line due to

document running at an angle.

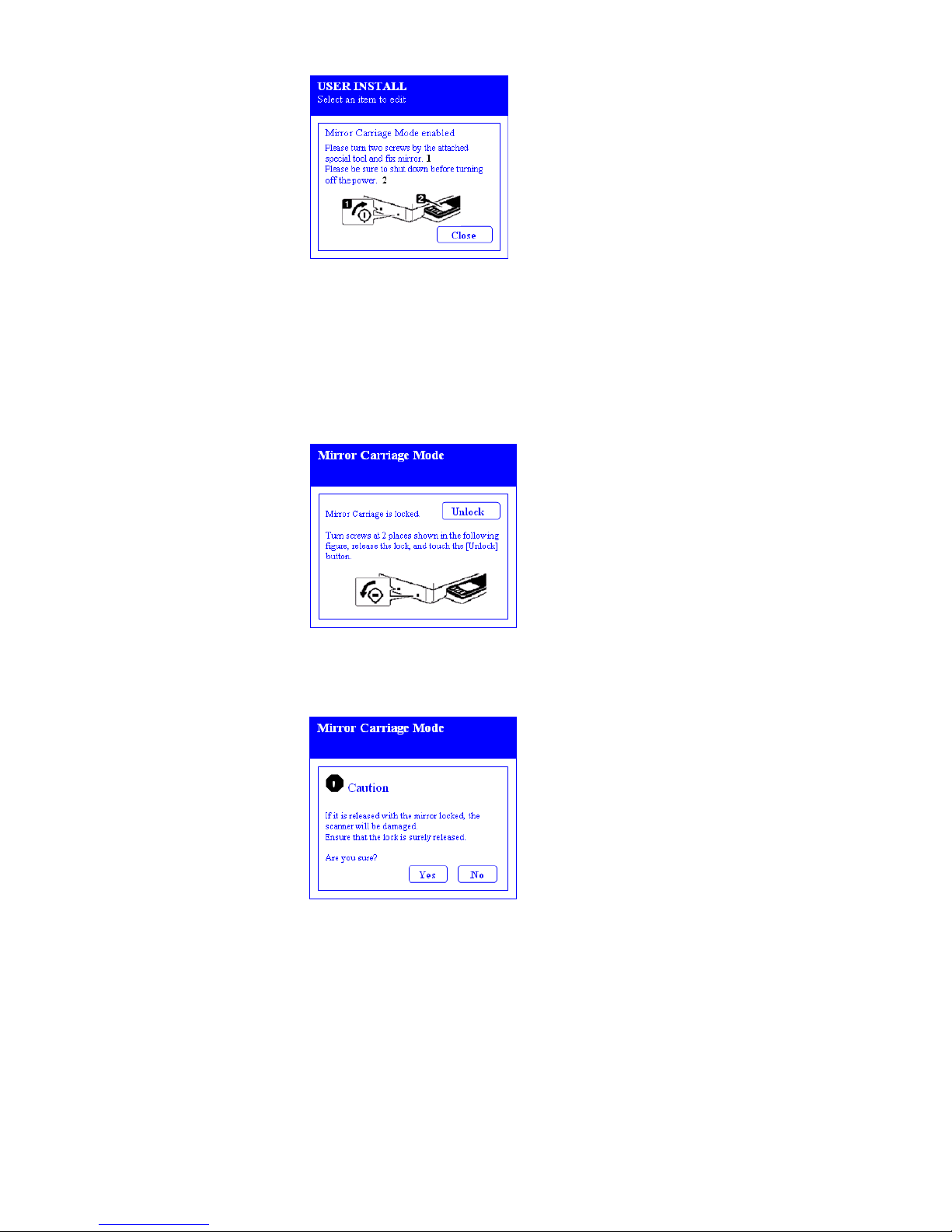

Mirror Carriage Mode

This item sets Operable/Inoperable of the mirror carriage movement.

During transportation and installation of the MFP, this setting should be changed.

How to enter the mirror carriage communication mode

When the menus of [SETUP] – [Admin Setup] – [User Install] – [Mirror carriage mode]

are selected, the following screen is displayed.

Before transportation of the MFP, select [Yes] to start movement of the mirror carriage to

the specified position. When movement of the mirror carriage is complete, the following

screen is displayed.

21

Page 22

Tighten the screws at the locations as specified in the illustration, and press the [Close]

button. When the mirror carriage is locked in the specified position, select the menus

[SETUP] – [Shutdown] to execute the shutdown operation. Then turn OFF the power.

How to release the mirror carriage mode

When the MFP remains in the mirror carriage mode, the following standby screen is

displayed.

Remove the screws at the locations specified in the illustration, and press the [Cancel]

button. The following screen is displayed.

Confirm that the mirror carriage Fixing screws are removed. Then select [Yes] to release

the mirror carriage mode so that the mirror carriage is returned to the normal operating

condition.

22

Page 23

2.6 Fax Maintenance

Country Code

Select the country in which the MFP is going to be installed. (ODA) North America

In this setting, any country code can be selected regardless of the OKIUSER setting.

When the screen exits the service menu after this setting is changed, the MFP reboots

automatically.

Note! If any country code that is not the country of the MFP installation is selected, it

can infringe on regulations and laws of the respective countries. Be careful of this point.

Tone for Echo

TX (During Transmission)

When set to Enable

• DIS ignore once *1: Enable

• EP tone addition during V29 send *2: Enable

• Wait time between DIS – DCS *3: 1000 ms

When set to Disable

• DIS ignore once *1: Disable

• EP tone addition during V29 send *2: Disable

• Wait time between DIS – DCS *3: 0 ms

This setting is effective during all communications of direct dialing and Abbr. dialing.

DIS ignore once *1:

During the overseas communication, the DIS signal can be ignored once in order to restart the echo suppressor function that has been stopped by the CED signal. The MFP

responds against the second DIS signal and sends out the DCS signal. With this setting,

the MFP can send out the DCS signal under a good line condition with less echo. This

setting is used in the case when the communication error such as T.1.1 occurs due to

adverse effect of echo during the overseas communication.

EP tone addition during V29 send *2:

During the overseas send, reception of the training signal by the destination machine can

be ensured by adding the EP tone before the sending the training signal to avoid line

delay.

The EP tone of 0.5 seconds is added to the training signal of 9600/7200 bits/s +

TCF/training + image information.

The EP tone of 0.5 seconds at 1700 Hz can be destroyed by the group delay of

communication line so that the head portion of the training signal is damaged. In such a

case, reception of the training signal by the destination machine can be ensured by adding

the EP tone before sending the training signal.

Note! Some types of fax machines cannot receive the training signal 9600/7200 bits/s +

TCF with the EP tone. You should be aware of this type of fax machine.

Wait time between DIS – DCS *3:

Time before the DCS signal send start after the DIS signal reception end.

23

Page 24

RX (During Reception)

When set to Enable

Switching time between CED – DIS *4: 1000 ms

When set to Disable

Switching time between CED – DIS *4: 75 ms

Switching time between CED – DIS *4:

When the CED signal at 2100 Hz is sent out during reception of overseas communication,

the echo suppression stops so that the line condition becomes inferior with much echo.

As the countermeasure against the trouble, an interval is inserted after the echo

suppressor is re-started (echo suppressor re-starts after muting of 0.5 seconds) before

sending out the DIS signal upon \completion of the CED signal send-out by creating a

muted period of time. The international telephone line uses the four-wire system in which

signals are sent to the destination machine via the two-wire system –> four-wire system –

> two-wire system. The international telephone switchboard is equipped with the echo

prevention system (special switch circuit that prevents echo) called echo suppressor.

When it detects the tone signal of 2100 Hz, operation of the echo suppressor is stopped

temporarily.

Modem Transmission Speed

TX (During Transmission)

33.6 Kbps

28.8 Kbps

14.4 Kbps

9.6 Kbps

4.8 Kbps

Sets the initial value of the modem transmission speed during fax send. This setting is

effective during all communications of direct dialing and Abbr. dialing. Communication

at 14.4 kbps (V.17) is performed when the menus [Admin Setup] – [User Install] –

[Super G3] is set to OFF and this setting is set to “33.6 kbps”, “28.8 kbps”. When this

setting is “14.4 kbps (V.17)”, “9.6 kbps (V.29)”, “4.8 kbps (V.27ter)”, communication

with this setting is performed regardless of the “Super G3” setting.

RX (During reception)

33.6 Kbps

28.8 Kbps

14.4 Kbps

9.6 Kbps

4.8 Kbps

Sets the initial value of the modem transmission speed during fax receive.

Communication at 14.4 kbps (V.17) is performed when the menus [Admin Setup] – [User

Install] – [Super G3] is set to OFF and this setting is set to “33.6 kbps”, “28.8 kbps”.

When this setting is “14.4 kbps (V.17)”, “9.6 kbps (V.29)”, “4.8 kbps (V.27ter)”,

communication with this setting is performed regardless of the “Super G3” setting.

Default = 33.6 Kbps

Default = 33.6 Kbps

24

Page 25

Pulse Make Ratio Default 40%

Sets the make ratio of DP (10 pps) during call.

MF (Tome) Duration

ON Period Range 0 - 1 ms to 255 ms Default 80ms

Sets the ON period of MF (Tone) Duration send. When the setting value is “0”, the MFP

runs at the initial value of each country. When the set value is except "0", the set value

operates at 1 to 255m second.

OFF Period Range 0 - 1 ms to 255 ms Default 70ms

Sets the OFF period of MF (Tone) Duration send. When the setting value is “0”, the MFP

runs at the initial value of each country. When the set value is except "0", the set value

operates at 1 to 255m second.

Calling Timer Range 0 - 1 second to 255 seconds Default 55 seconds

Sets the Calling Timer. When the setting value is “0”, the MFP runs at the initial value of

each country. When any value other than “0” is set, the Calling Timer can be selected in

the range of 1 to 255 mm.

Attenuator Range 0 dB to -15 dB

Sets the Attenuator. It can be set in units of 1 dB. When the “Country code” is set to

“Japan”, it can be set in the range of 8 to 15 dB.

MF Attenuator Range 0 dB to -15 dB Default 70dB

Sets the MF Attenuator. It can be set in units of 1 dB.

Line Test

When “Line Test” is selected, the following screen is displayed. Select the desired test

item to be implemented.

Relay Test

Implements the relay ON/OFF test.

Relay test procedure

Press the [Relay] button on the "Line Test” screen.

Select the desired relay that is going to receive the ON/OFF test.

When the [Close] button is pressed, the screen returns to the “Line Test” screen.

When the [Reset] key is pressed, screen returns to the top screen of the service menu.

25

Page 26

Tonal Send Test

Tonal test procedure

Press the [Tonal] button on the "Line Test” screen.

Select a signal to test.

When the [Stop] key is pressed, signal send is interrupted.

When the [Close] button is pressed, the screen returns to the “Line test” screen.

When the [Reset] key is pressed, screen returns to the top screen of the service menu.

DTMF Test

Signals of the frequencies that are used by the push-button telephone can be selected for

the send test.

DTMF test procedure

Press the [DTMF] button on the "Line Test” screen.

Select a frequency to send.

When the [Stop] key is pressed, signal send is interrupted.

When the [Close] button is pressed, the screen returns to the “Line test” screen.

When the [Reset] key is pressed, screen returns to the top screen of the service menu.

2.7 Printer Maintenance

Personality

Default setting of the PDL language that is supported by the respective destination

specification can be changed. The PDL language that has been set to” Disable” by the

PDL setting item will not be displayed as the choices on the following menu: [SETUP][Admin Setup] - [Print Setup] . At the same time, when the print data of the PDL

language that has been set to “Disable” is received, a message “”Invalid data is received”

is displayed and the received data is discarded.

IBM 5577 Settings: Enable /Disable Default: Disable

IBM PPR III XL Settings: Enable /Disable Default: Enable

EPSON FX Settings: Enable /Disable Default: Enable

HP-GL/2 Settings: Enable /Disable Default: Disable

Peak Power Control

Set whether or not to support the low peak power control. When the screen exits the

service menu after this setting is changed, the MFP reboots automatically.

Settings: Low / Normal Default: Normal

26

Page 27

Engine Diagnostic Mode (Self-Diagnostic)

How to enter self-diagnostic mode (Level 1)

1. From the service menu, select [Printer Maintenance] and [Engine Diag. Mode] to enter

the self-diagnostic mode.

2. When the screen enters the self-diagnostic mode (Level 1), the "DIAGNOSTIC

MODE” is displayed.

00.06.06 = PU Firmware Version

S-Mode = Shipping Mode

Press either (2) key or (8) key to move to the respective self-diagnostic items.

(Menu item scrolls when either (2) key or (8) key is pressed.)

Press the (6) key to execute the selected test. Exit the test by pressing the (4) key.

27

Page 28

Level 1 Diagnostic Screens

28

Page 29

Item Self-Diagnostic Menu Adjustment Contents

Switch Scan Test

(See section 2.7.1)

Motor Clutch Test

(See section 2.7.2)

Executing Test Print

(See section 2.7.3)

Color Registration

Correction Test

(See section 2.7.4)

Density Correction Test

(See section 2.7.5)

Consumable Item Counter

Display

(See section 2.7.6)

Consumable Item

Accumulative Counter

Display

(See section 2.7.6)

Factory/Shipping

Mode Switching

(See section 2.7.7)

FUSE Status Check

(See section 2.7.7)

Engine Parameter Setting

(See section 2.7.8)

LED Head Serial Number

Display (Not Used)

SWITCH SCAN

MOTOR&CLTCH TEST

TEST PRINT

REG ADJUST TEST

DENS ADJ TEST

CONSUMABLE

STATUS

PRINTER STATUS

FACTORY MODE

SET

SENSOR SETTING

LED HEAD DATA

Input sensor and switch

Check

Motor and clutch

operational test

PU internal test pattern

print and printer

environmental conditions

Color registration error

correction system, normal

or defective

Density error correction

system, normal or defective

Consumable items,

consumption status display

Consumable items,

accumulative consumption

status display

Factory mode or Shipping

mode switching

Status display of respective

Fuses

Sets valid or invalid of error

detection using various

sensors

Display of LED head serial

Number

29

Page 30

30

Page 31

2.7.1 Switch Scan Test

This self-diagnostic menu is used to check the input sensors and switches of the print

engine.

1. Enter the self-diagnostic mode (Level 1) and press the (2) key or (8) key until

"SWITCH SCAN” is displayed in the top of the screen. Press the (6) key to execute.

(The (2) key increments the test item and (8) key decrements the test item.)

31

Page 32

Switch Scan Test

Display Detail

on Printer LCD

Paper R

oute: PU

Toner Sensor

CVO UP_LU_FU

REG L/R_OHP_WG

HT THERMISTER

HUM_TEMP_DEN

BELT_T

ID UP/DOWN

RFID COLOR*1

F-RL FI BL DT-DC

T1 PE_PNE_CVO

T1 CASETTE SIZE*2 Size setting

T2 PE_PNE_CVO_CA Tray 2 paper

T2 HOP_LF_FED

T2 CASETTE SIZE*2 Size setting

T3 PE_PNE_CVO_CA Tray 3 paper

T3 HOP_LF_FED

T3 CASETTE SIZE*2 Size setting

DUP IN_RA_FNT

DUP SK_CVO

Location 1 Location 2 Location 3 Location 4

Sensor

Tested

Entrance

Sensor 1

Toner K Sensor H - Off

Cover Upper H - Closed

Color

registration

error sensor L

Fuser

thermistor,

Upper sensor

Humidity

sensor

Belt thermistor AD value:

RFID

antenna K

Fuser release

sensor

Tray 1 paper

end sensor

switch 1

end sensor

switch 1

end sensor

switch 1

Duplex input

sensor

Duplex bottom

sensor

Display

Condition

H - Absent

L – Present

L - On

Sensor

Tested

Entrance

Sensor 2

Toner Y

Sensor

Display

Condition

H - Absent

L – Present

H - Off

L - On

Sensor

Tested

Write

Sensor

Toner M

Sensor

Display

Condition

H - Absent

L – Present

H - Off

L - On

Sensor

Tested

Unload

(Exit) Sensor

Toner C

Sensor

Display

Condition

H - Absent

L – Present

H - Off

L – On

L – Open

AD value:

***H

AD value:

***H

AD value:

***H

Color

registration

error sensor R

Fuser

thermistor,

Lower

Temperature

sensor

AD value:

***H

AD value:

***H

AD value:

***H

Fuser

thermistor,

AD value:

***H

Heater frame

thermistor

AD value:

***H

Upper sensor,

side

Density

sensor (K)

AD value:

***H

Density sensor

(YMC)

AD value:

***H

***H

UID:

***H

H: ON

L: OFF

H: absent

L: present

Port level

H, L

H: absent

L: present

Port level

H, L

H: absent

L: present

Port level

H, L

H: absent

L: present

H: absent

L: present

RFID

antenna Y

Fuse entrance

sensor

UID:

***H

H: ON

L: OFF

RFID

antenna M

UID:

***H

Size setting

switch 2

Port level

H, L

Size setting

switch 3

Port level

H, L

Size setting

switch 2

Port level

H, L

Tray 2

entrance sensor

Size setting

switch 3

H: absent

L: present

Port level

H, L

Size setting

switch 2

Duplex rear

sensor

Duplex cover

sensor

Port level

H, L

H: absent

L: present

H: Close

L: Open

Tray 3

entrance sensor

Size setting

switch 3

Duplex front

sensor

H: absent

L: present

Port level

H, L

H: absent

L: present

Up Down

sensor

RFID

antenna C

Size setting

switch 4

H: Up

L: Down

UID:

***H

Port level

H, L

Size setting

switch 4

Port level

H, L

Size setting

switch 4

Port level

H, L

32

Page 33

2.7.2 Motor & Clutch Test

This self-diagnostic menu is used to test the motors and clutches of the print engine.

1. Enter the self-diagnostic mode (Level 1) and press the (2) key or (8) key until

[MOTOR & CLUTCH TEST] is displayed in the top of the screen.

Press the (6) key to execute.

The (2) key increments the test item and (8) key decrements the test item.

2. Press the (2) key or the (8) key until the item that corresponds to the unit which is

going to be tested is displayed in the bottom of the screen.

3. When the (6) key is pressed, the test is started. The unit name starts blinking and the

corresponding unit runs for 10 seconds.

Note! After running for 10 seconds, screen returns to the item 2 state. When the

corresponding switch is pressed, the test program restarts.

• The clutch solenoid repeats ON and OFF during the normal print job. (For the model in

which the independent drive is not possible due to mechanism structure, the motor will

run at the same time.) *”ID UP/DOWN” continues running until the (#) key is pressed.

• When the desired motor is selected and the [ENTER] key is pressed for an extended

time (2 seconds), it keeps running.

4. When the (#) key is pressed, the corresponding unit stops running.

(The corresponding unit is kept displayed on the screen.)

5. Repeat items 2 to 4 as required.

6. When the (4) key is pressed, the screen exits the test.

(Screen returns to the item 1 condition.)

33

Page 34

Unit Name Display

ID MOTOR

BELT MOTOR

FUSER MOTOR

FUSER MTR REV

FUSER_RLS

REGIST MOTOR

T1 HOPPING MOTOR

FRONT MOTOR

REGIST SHUTTER

EXIT SOLENOID

DUPLEX MOTOR

DUPLEX CLUTCH

T2 HOPPING MOTOR

T2 FEED CLUTCH

T3 HOPPING MOTOR

T3 FEED CLUTCH

ID UP/DOWN

LV FAN TEST

FUSER FAN TEST

FUSER2 FAN TEST

DUPLEX FAN TEST

PS FAN TEST

Drive Restriction Conditions

Drives when all of the IDs (K/Y/M/C) are

removed.

Drives when all of the IDs (K/Y/M/C) are

removed.

If option installed

If option installed

If option installed

TOP/FRONT covers, closed condition

34

Page 35

2.7.3 Test Print

This self-diagnostic menu is used to print the test pattern contained in the PU. Other test

patterns are contained in the controller.

1. Enter the self-diagnostic mode (Level 1) and press the (2) key or (8) key until

[TEST PRINT] is displayed in the top of the screen.

Press the (6) key to execute.

The (2) key increments the test item and (8) key decrements the test item.

2. The setting items that are applicable to the test print only are displayed in the lower

column of display window. Press the (2) key or the (8) key until the corresponding item

is displayed. (When the setting value for each item is not required [Default setting],

advance to item 2.)

3. Keep pressing the (2) key or the (8) key, and press the (6) key at the item that is set in

item 2. The setup item is displayed in the upper column, and the setting value is displayed

in the lower column of the display window.

(The setting value that is displayed last is applied.)

Pressing the (4) key determines the setting value, and the screen returns to item 2.)

Repeat item 3 as required.

Display Setup Value Function

PRINT EXECUTE

TEST PATTERN

TEST CASSETTE

PAGE

COLOR

DUPLEX

MONO SPEED

0

TRAY1

TRAY2

MPT Tray

0000 Setting the number of test prints.

ON

OFF

2 PAGES STACK

OFF

1PAGES STACK

LOW

HIGH

Pressing the (4) key starts

printing/Pressing the (#) key ends

printing (in page unit).

0 = White paper print

1 to 7 Refer to next page. (Pattern print)

8 to 15 = White paper print

Select the paper feed source.

If TRAY2 is not installed, TRAY2 is not

displayed.

Selecting color or monochrome print.

ON is specified, ON/OFF setting for

each color appears.

Duplex print is executed with two sheets

stack.

Duplex print OFF select

Duplex print is executed with single

sheet stack.

Selecting monochrome print speed.

LOW: 30ppm

HIGH: 34ppm(A4),33ppm(Letter)

35

Page 36

Print Patterns

Pattern 1 Pattern 2 Pattern 3

Pattern 4 Pattern 5 Pattern 6

Pattern 7

Note! If the solid print data (Pattern 7) that is contained in

the local print function is used for test print with 100%

setting of each color, it causes offset. To prevent offset,

select the print setting of each color so that the number of

colors to be printed at the same time should be limited to 2

colors or less.

36

Page 37

Monitoring Printer Environmental Conditions

The following printer environmental conditions can be monitored during generation of

test prints.

The following messages are displayed during test print.

P *** = Number of test prints (unit: sheet)

W*** = Print wait time (unit: sheet)

Pressing the (2) key switches the display. When the (#) key is pressed, the screen exits

the test. (Screen returns to the item 1 condition.)

T =*** = Environment temperature measurement value [unit: °C]

U =*** = Upper heater temperature measurement value. [unit: °C] [###] = target temperature [unit: °C]

H =***% = Environment humidity measurement value [unit: %]

L = *** = Lower thermistor measurement value. [unit: °C] [###] = Lower thermistor AD value [unit: HEX]

Pressing the (2) key switches the display. When the (#) key is pressed, the screen exits

the test. (Screen returns to the item 1 condition.)

KTR, YTR, MTR and CTR are the transfer voltage setting values for each color. (measured in KV)

Pressing the (2) key switches the display. When the (#) key is pressed, the screen exits

the test. (Screen returns to the item 1 condition.)

KR, YR, MR, CR are transfer roller resistance values for each color. [measured in μA]

Pressing the (2) key switches the display. When the (#) key is pressed, the screen exits

the test. (Screen returns to the item 1 condition.)

ETMP: Hopping motor standard speed correction parameter (Environment temperature) [unit: DEC]

37

Page 38

UTMP: Fuser motor standard speed correction parameter (Fuser target temperature) [unit: DEC]

REG: Hopping motor standard speed timer value (I/O setting value) [unit: HEX]

EXT: Fuser motor standard speed timer value (I/O setting value) [unit: HEX]

Pressing the (2) key switches the display. When the (#) key is pressed, the screen exits

the test. (Screen returns to the item 1 condition.)

KID, YID, MID and CID are the standard speed timer values for each ID motor (I/O setting value) [unit: HEX]

Pressing the (2) key switches the display. When the (#) key is pressed, the screen exits

the test. (Screen returns to the item 1 condition.)

BELT: Belt motor standard speed timer value (I/O setting value) [unit: HEX]

FRM: [***] = Frame thermistor read-out AD value [unit: HEX] ( xxx ) = Frame temperature [unit: °C]

Pressing the (2) key switches the display. When the (#) key is pressed, the screen exits

the test. (Screen returns to the item 1 condition.)

DB: Develop voltage setup table ID number [unit: HEX]

Pressing the (2) key switches the display. When the (#) key is pressed, the screen exits

the test. (Screen returns to the item 1 condition.)

TR1: Transfer voltage parameter VTR1 table ID number [unit: HEX]

TR2: Transfer voltage parameter VTR2 table ID number [unit: HEX]

Pressing the (2) key switches the display. When the (#) key is pressed, the screen exits

the test. (Screen returns to the item 1 condition.)

The message is displayed but does not function.

Pressing the (2) key switches the display. When the (#) key is pressed, the screen exits

the test. (Screen returns to the item 1 condition.)

38

Page 39

2.7.4 Color Registration Error Correction Test

This self-diagnostic menu is used for adjustment and to investigate cause of the color

registration error of the MFP.

1. Enter the self-diagnostic mode (Level 1) and press the (2) key or (8) key until

[TEST PRINT] is displayed in the top of the screen.

2. When the (6) key is pressed, the following message is displayed.

Press the (2) key or (8) key until the desired item is displayed.

3. When the (6) key is pressed, test of the item that is being displayed on the panel is

implemented.

<< When REG ADJ EXECUTE is executed >>

• The color registration correction test is implemented. (The [ON LINE] lamp

blinks.)

• When the test is complete, the test result (OK or error name) is displayed in the

upper column of the display window and **** RESULT is displayed in the

lower column of the display window.

When the (2) key is pressed, test results are incremented and displayed in order.

When the (8) key is pressed, test results are decremented and displayed in order.

When the (4) key is pressed, screen returns to the item 2 status.

• When the (#) key is pressed while the test in progress, the test is interrupted (the

[ON LINE] lamp lights) and screen returns to the item 2 status.

<< REG ADJ RESULT is executed >>

The key operations are the same as those above.

<< When BLT REFLECT TEST is executed >>

• The color registration error correction belt reflection test is implemented. (The

[ON LINE] lamp blinks.)

• When the test is complete, the test result (OK or error name) is displayed in the

upper column of the display window and **** RESULT is displayed in the lower

column of the display window.

The key operations are the same as those above.

39

Page 40

<< When BLT REFLECT RSLT is executed >>

The key operations when BLT REFLECT RSLT is executed The key operations are the

same as those above.

When the (4) key is pressed, the screen exits the test. (Screen returns to the item 1 condition.)

Color registration correction test items

Display Details

REG ADJ EXECUTE

REG ADJ RESULT

BLT REFLECT TEST

Execution of color registration error

correction

Referring to the result of color registration

error correction

Execution of color registration error

correction belt reflectance Good/Bad

Judgment

BLT REFLECT RSLT

Referring to the result of color registration

error correction belt reflectance

Good/Bad judgment

2.7.5 Density Error Correction Test

This self-diagnostic menu is used to test the density error correction function of the MFP.

1. Enter the self-diagnostic mode (Level 1) and press the (2) key or (8) key until

[TEST PRINT] is displayed in the top of the screen.

2. When the (6) key is pressed, the following message is displayed.

Press the (2) key or (8) key until the desired item is displayed.

3. When the (6) key is pressed, test of the item that is being displayed on the panel

is implemented.

40

Page 41

<< When DENS ADJ EXECUTE is executed >>

• The Density error correction test is executed. (The [ON LINE] lamp blinks.)

• When the test is complete, the test result (OK or error name) is displayed in the

upper column of the display window and **** RESULT is displayed in the lower

column of the display window.

When the (2) key is pressed, test results are incremented and displayed in order.

When the (8) key is pressed, test results are decremented and displayed in order.

When the (4) key is pressed, screen returns to the item 2 status.

• When the (#) key is pressed while the test in progress, the test is interrupted (the

[ON LINE] lamp lights) and screen returns to the item 2 status.

•

<< When DENS ADJ RESULT is executed >>

The key operations are the same as those above.

<< When DENS ADJ PAR-SET is executed >>

The message is displayed but does not function.

<< AUTO CALIBRATION is executed >>

• Automatic setting of the density sensor sensitivity correction value is executed.

(The [ON LINE] lamp blinks.)

• When the test is complete, the test result (OK or error name) is displayed in the

upper column of the display window and **** RESULT is displayed in the lower

column of the display window.

When the (4) key is pressed, screen returns to the item 2 status.

When the (#) key is pressed while the test in progress, the test is interrupted (the [ON

LINE] lamp lights) and screen returns to the item2 status.

When the (4) key is pressed, the screen exits the test. (Screen returns to the item 1 condition.)

Display Details

DENS ADJ EXECUTE

DENS ADJ PAR-SET

DENS ADJ RESULT

AUTO CALIBRATION

Execution of density correction

The message is displayed but does not

function.

Referring to the result of density correction

Automatic setting of density sensor

sensitivity correction value

41

Page 42

2.7.6 Consumable Item Counter Display

This self-diagnostic menu is used to display the consumption status of the consumable items.

1. Enter the self-diagnostic mode and press the (2) key or (8) key until

[CONSUMABLE STATUS] is displayed on the screen.

Press the (6) key to execute.

The (2) key increments the test item and (8) key decrements the test item.

2. When the (2) key or (8) key is pressed, consumption status of the consumable items

are displayed in order. Pressing the (*) key or the (#) key is invalid.

When the (4) key is pressed, the screen exits the test. (Screen returns to the item 1

condition.)

Display Unit of Measure Details

K-ID UNIT Images

Y-ID UNIT Images

M-ID UNIT Images

C-ID UNIT Images

FUSER UNIT Prints Number of sheets up to the

TR BELT UNIT Images Number of sheets up to the

K-TONER (FULL) Percentage

Y-TONER (FULL) Percentage

M-TONER (FULL) Percentage

C-TONER (FULL) Percentage

M-WASTE TNR CNT Times

C-WASTE TNR CNT Times

K-STC MODE CNT Times

Y-STC MODE CNT Times

M-STC MODE CNT Times

C-STC MODE CNT Times

K OVER RIDE CNT Times

K OVER RIDE CNT Times

K OVER RIDE CNT Times

K OVER RIDE CNT Times

Number of rotations up to the

present time since the new ID

UNIT for each color has been

installed is displayed after

the data is converted to the

equivalent value of A4, 3Page/

Job.

present time since the new

FUSER unit has been installed.

present time since the new Belt

UNIT has been installed.

Amount of consumption of the

respective color toners are

displayed.

Amount of waste toner is

displayed.

* When it reaches 32 times, the

Waste toner FULL is issued.

Number of printed character dot

counts for the respective toners

are displayed. (Accumulative

value since the MFP has started

running.)

Accumulative number of times

of the toner cartridges for

respective colors are displayed.

42

Page 43

Printed Sheets Counter Display

This self-diagnostic menu is used to display the number of printed sheets status of the MFP.

1. Enter the self-diagnostic mode and press the (2) key or (8) key until

[PRINTER STATUS] is displayed on the screen.

Press the (6) key to execute.

The (2) key increments the test item and (8) key decrements the test item.

2. When the (2) key or (8) key is pressed, number status of the printed sheets are

displayed in order. Pressing the (*) key or the (#) key is invalid.

When the (4) key is pressed, the screen exits the test. (Screen returns to the item 1

condition.)

Display Unit of Measure Details

K – IMPRESSIONS

Y – IMPRESSIONS

M – IMPRESSIONS

C – IMPRESSIONS

TOTAL SHEET CNT

2.7.7 Factory/Shipping Mode Switching

This self-diagnostic menu is used to switch the PU PCB from the Factor mode to the

Shipping mode.

1. Enter the self-diagnostic mode (Level 1) and press the (2) key or (8) key until the

following message is displayed.

Images

Images

Images

Images

Prints

Number of printed sheets for each

color are displayed.

Total number of printed sheets

are displayed.

2. When the (6) key is pressed, the following message is displayed.

Press the (2) key or (8) key until the desired item (refer to the table below) is displayed.

3. While desired item to set is being displayed, press the (6) key to enable operator to

select the setting value.

4. While desired item to set is being displayed, press the (6) key for an extended time (3

seconds) to register the display value in EEPROM. Screen returns to the item 2

condition.

When the (4) key is pressed, the screen exits the test. (Screen returns to the item 1

condition.)

43

Page 44

Upper Display Lower Display Function

FACTORY MODE

FUSE INTACT

Note! Indicates whether fuse is

INTACT or BLOWN.

FACTORY MODE

SHIPPING MODE

BELT UNIT ******

FUSE UNIT ******

K-ID UNIT ******

Y-ID UNIT ******

M-ID UNIT ******

C-ID UNIT ******

Sets up the Factory work mode.

This is a production mode.

Note! The unit should always be set

for Shipping mode or erratic

operation may result.

Sets up the Shipping mode for

normal operation.

Checks the FUSE status of the

transfer belt unit.

Checks the FUSE status of the

fuser.

Checks the FUSE status of the

K-ID unit.

Checks the FUSE status of the

Y-ID unit.

Checks the FUSE status of the

M-ID unit.

Checks the FUSE status of the

C-ID unit.

2.7.8 Engine Parameter Setting

This self-diagnostic menu is used to set Enable or Disable of error detections using

various sensors.

This menu enables service engineer to Disable or Enable the error detection temporarily.

When use of this menu is completed, be sure to return the setting values to the default.

1. Enter the self-diagnostic mode (Level 1) and press the (2) key or (8) key until the

following message is displayed.

2. When the (6) key is pressed, the following message is displayed.

Press the (2) key or (8) key until the desired item (refer to the table below) is displayed.

3. When the (6) key is pressed, the setting values that are shown in the lower column of

the display window become selectable.

Pressing the (2) key increments the setting value. Pressing the (8) key decrements the

setting value.

4. While the desired item to set is being displayed, press the (6) key for an extended time

(3 seconds) to register the displayed value in EEPROM. Screen returns to the item 2

condition.

Press the (4) key (excluding the condition of item 4) to exit the menu. (Screen returns to

the item 1 condition.)

44

Page 45

Display Setting Operation Function

ENABLE To detect TONER SENSOR

DISABLE Not to detect

ENABLE To check BELT UNIT

CHECK__ENABLE

DISABLE Not to check

ENABLE To check ID UNIT CHECK

DISABLE Not to check

ENABLE To detect UP/DOWN SENSOR

DISABLE Not to detect

ENABLE To stop REG ADJUST ERROR

DISABLE Not to stop

Stop To prolong life DRUM OVER LIFE

Continuance

LED Head Serial Number Display

Not used for servicing the MFP at this time.

Fuse Check Method

Not to prolong

life

Sets Enable/Disable of

the toner sensor

operation

Sets Enable/Disable of

the belt installation

check job.

Sets Enable/Disable of

the ID installation check

job.

Sets Enable/Disable of

the ID UP/DOWN

sensor operation

Sets Enable/Disable of

the error stop caused by

the color registration

error detected value.

To prolong or not to

prolong the drum life

when it reaches the

lifetime.

45

Page 46

2.8 Initialization Functions

Items that can be initialized by the Administrator

The following table shows the setup items that can be initialized by administrator.

The gray colored items indicate that the data is stored in the CU side.

The white items indicate that the data is stored in the scanner unit side.

The items with the characters “CL” indicate that the registered data will be deleted

when this function is executed.

The items with the characters “FR” indicate that the data will be returned to the default

setting when this function is executed.

46

Page 47

Initialization Functions Admin Page 2

47

Page 48

Initialization Functions Admin Page 3

*1 The group counter – Reset is confidential and menu is not open in FCS.

*4 When HDD Disable is set, only administrator can log on.

(Because the access control mode setup values is stored in Flash, but the user information

is not stored in HDD.)

48

Page 49

Items that can be initialized by the Service Engineer

The initialization operations that can be performed by service engineer are shown below.

The following table shows the setup items that can be initialized by the service engineer.

Descriptions regarding description in the table are added.

The gray colored items indicate that the data is stored in the CU side.

The white items indicate that the data is stored in the scanner unit side.

The items with the characters “CL” indicate that the registered data will be deleted when

this function is executed.

The items with the characters “FR” indicate that the data will be returned to the default

setting when this function is executed.

49

Page 50

Initialization Functions Service Engineer Page 2

50

Page 51

Initialization Functions Service Engineer Page 3

51

Page 52

Initialization Functions Service Engineer Page 4

*2 Only the setups that change their initial values depending on destination or counter

code are initialized.

*3. [Filename (standard)] and [E-mail edit fixed phrase] under the menus [Scanner

function] - [E-mail setting] are initialized.

*4 When HDD Disable is set, only administrator can log on.

(Because the access control mode setup values is stored in Flash, but the user information

is not stored in HDD.)

*5 When destination is changed from Japan (such as "JP1","JPOEM") to overseas (such

as “ODA”), the portions in which Japanese language has been input are cleared. When

the profile name is Japanese language, the parameters excluding character string are

initialized at the same time.

52

Page 53

Chapter 3 Troubleshooting Print Quality

3.1 Print Quality Problems Overview

Print-quality defects can be attributed to printer components, consumables, media,

internal software, external software applications, and environmental conditions. To

successfully troubleshoot print-quality problems, eliminate as many variables as possible.

The first step is to generate prints using printable pages embedded in the printer on paper

from the Supported Media List. Use paper from a fresh, unopened ream that is acclimated

to room temperature and humidity. If the print-quality defect is still present when printing

on approved media, then investigate software applications and environmental conditions.

The printers use separate Imaging Units to develop a latent image for each color where

the colors are combined on the Transfer Unit to form the final image. In most cases,

print-quality defects are the result of one particular component in the print engine, See

the Repeating Defects chart. When a single component of the Imaging Unit is causing a

print quality defect, replace the Imaging Unit.

When analyzing a print-quality defect, first determine if the defect occurs in all colors or

only one color and if it is repeating or random. Continuous defects in the process

direction, such as voids and lines, are the most difficult to diagnose. Inspect the visible

surfaces of all rollers for obvious defects. If no defects are observed, replace the Imaging

Units, Transfer Unit, and Fuser one at a time until the defect is eliminated.

Defects Associated with Specific Printer Components

Some print-quality problems can be associated with specific assemblies, the most

common problems and the associated assemblies are listed below. Also, refer to the

printer’s Troubleshooting Print-Quality Problems pages or a specific print-quality

troubleshooting procedure for more information.

Imaging Unit

• Streaks in Process Direction (in the direction of feed, parallel with paper travel)

• Banding in Scan Direction (across the page, perpendicular to paper travel)

• Uneven Density

• Voids

• Repeating Defects

• Mis-registration

Transfer Unit

• Toner on the back side of the printed page (simplex mode)

• Light Prints

• Repeating Defects

• Mis-registration - only when there is obvious damage to the belt.

Fuser

• Hot or Cold Offsetting

• Repeating Defects

• Dark Streaks in Process Direction

LED Head

• Streaks in the Process Direction

• Uneven Density in the Scan Direction

Test Prints

A variety of test prints are available to aid in determining the quality of output from the

printer and to assist in troubleshooting. See sections 2.7.3 and 2.7.5 for details.

53

Page 54

3.2 Using New Consumable Units for Testing Purposes

The MC-860 / CX2633 will allow you to utilize new consumable units for print quality

diagnosis and troubleshooting purposes.

Note! When using new units (Drum, Transfer Belt, Fuser) to assist in troubleshooting,

you should temporarily set the printer to “Factory Mode” (See Section 2.7.8). Setting

to factory mode will allow you to use brand new units for testing purposes without

cutting the fuse.

Caution! Be sure to reset the printer to “Shipping Mode” when testing is complete.

Leaving the printer in Factory Mode may cause erratic operation of the MFP.

3.3 Things to observe when analyzing Test Pages

• Streaks in Process Direction (in the direction of feed, parallel with paper travel)

• Banding in Scan Direction (across the page, perpendicular to paper travel)

• Uneven Density

• Voids

• Repeating Defects

• Mis-registration

Note: Consult the “Repeating Defect Spacing Chart” below.

Repeating Defects Spacing

Component Defect Spacing Defect Location

Imaging Drum 94.3 mm Imaging Unit

Developer Roller 39.7 mm Imaging Unit

Charge Roller 37.7 mm Imaging Unit

Supply Roller 58.4 mm Imaging Unit

Fuser Belt 125.5 mm Fuser

Heat Roller 87.7 mm Fuser

Transfer Roller 50.3 mm Transfer Unit

54

Page 55

3.4 Print-Quality Troubleshooting

Light Prints in All Colors

The overall image density is too light in all colors. If the image is light in only one color,

see "Light Print in Only One Color".

Initial Actions to Perform

■ Perform Initial Actions from Maintenance Procedures in Chapter 1.

■ Verify the media used is supported by this printer.

■ Verify the media settings are correct at the Control Panel.

■ Print the ID Check Pattern (Reports – Print – ID Check Pattern) and

Demo page (Reports – Information – Demo Page) to see if it is an application problem.

■ Perform isolation Test Prints (Section 2.7.3).

■ Run the Density Error Correction Test in Section 2.7.5.

Areas of the Printer that Apply

■ Imaging Unit

■ LED Head

■ Transfer Unit

■ HVPS

■ PU Board

1. Verify all packaging material has been removed form the toner cartridges

2. Remove the Imaging Units and the Transfer Unit and check for toner contamination on the

high voltage contacts. Are the contacts contaminated?

3. Are the LED Heads dirty? Clean the heads with a clean, lint-free cloth. Did this correct the

problem?

4. Are the wiring harnesses on the LED Heads undamaged, properly routed and seated?

5. Inspect the high-voltage wiring harness. Reseat the wiring Harness. Did this correct the

problem?

Troubleshooting Steps

Yes – Go to Step 2

No - Remove packing material

Yes – Clean the contacts

No - Go to Step 3

Yes – Complete

No - Go to Step 4

Yes – Repair / Replace Harnesses

No - Go to Step 5

Yes – Complete

No - Replace in the following order:

Transfer Unit / Imaging Unit Sensor

Board / HVPS / PU Board

Resolution

55

Page 56

Light Prints in Only One Color

Only one color; yellow, magenta, cyan, or black, is too light on the printed image.

Initial Actions to Perform

■ Perform Initial Actions from Maintenance Procedures in Chapter 1.

■ Print the ID Check Pattern (Reports – Print – ID Check Pattern) and

Demo page (Reports – Information – Demo Page)

■ Perform isolation Test Prints (Section 2.7.3).

■ Check that the Toner Cartridge pull strip is completely removed from the affected color.

■ Run the Density Error Correction Test in Section 2.7.5.

Areas of the Printer that Apply

■ Imaging Unit

■ LED Head

■ Transfer Unit

■ HVPS

■ PU Board

1. Verify all packaging material has been removed form the toner cartridges

2. Print the 100% Solid Fill test print. Can the problem be isolated to one primary color?

3. Remove the Toner Cartridge and check for toner starvation in the Imaging Unit. Is there

evidence of toner starvation

4. Remove the Imaging Units and the Transfer Unit and check for toner contamination on the

high voltage contacts. Are the contacts contaminated?

5. Are the LED Heads dirty? Clean the heads with a clean, lint-free cloth. Did this correct the

problem?

6. Swap the LED Head of the problem color with any other LED Head.

Print a Solid Fill Test Pattern. Has the problem moved with the LED Head?

7. Are the wiring harnesses on the LED Heads undamaged, properly routed and seated?

Troubleshooting Steps

Resolution

Yes – Go to Step 2

No - Remove packing material

Yes – Go to Step 3

Yes – Replace the Toner Cartridge

No - Go to Step 4

Yes – Clean the contacts

No - Go to Step 5

Yes – Complete

No - Go to Step 6

Yes – Replace the LED Head

No - Go to Step 7

Yes – Reseat the wiring Harnesses

No - Replace in the following order:

Transfer Unit / LVPS / PU Board

56

Page 57

Blank Prints

Initial Actions to Perform

■ Perform Initial Actions from Maintenance Procedures in Chapter 1.

■ Perform isolation Test Prints (Section 2.7.3) to isolate the problem between the CU

Board and the PU Board.

Areas of the Printer that Apply

■ Imaging Unit

■ LED Head

■ PU Board

1. Print a 100% Solid Fill Test Print. Is the entire test print blank?

2. Remove the Toner Cartridge and check for toner starvation inside the Imaging Unit. Is

there evidence of toner starvation?

3. Are the LED Heads dirty? Clean the heads with a clean, lint-free cloth.

Did this correct the problem?

4. Are the wiring harnesses on the LED Heads undamaged, properly routed and seated?

5. Inspect the high-voltage wiring harness. Reseat the wiring Harness. Did this correct the

problem?

Troubleshooting Steps

Resolution

Yes – Go to Step 2

No - Have the customer check there

application and printer settings.

Yes – Replace the Toner Cartridge.

No - Go to Step 3

Yes – Complete

No - Go to Step 4

Yes – Repair / Replace Harnesses

No - Go to Step 5

Yes – Complete

No - Replace in the following order:

Transfer Unit / LVPS / Imaging Unit

Sensor Board / HVPS / PU Board

57

Page 58

Mottled or Splotchy Prints

The print image has a mottled appearance.

Note! This defect is known to occur at low humidity, and when printing on heavy weight

media.

Initial Actions to Perform

■ Perform Initial Actions from Maintenance Procedures in Chapter 1.

■ Verify the media used is supported by this printer.

■ Verify the media settings are correct at the Control Panel.

■ Print the ID Check Pattern (Reports – Print – ID Check Pattern) and

Demo page (Reports – Information – Demo Page) to see if it is an application problem.

■ Perform isolation Test Prints (Section 2.7.3).

■ Run the Density Error Correction Test in Section 2.7.5.

Areas of the Printer that Apply

■ Imaging Unit

■ LED Head

■ HVPS

■ PU Board

Troubleshooting Steps

1. Ensure the media is approved and the Control Panel and driver settings match the loaded

media. Try different media to verify consistent, reproducible problem.

2. Print the configuration page to verify the operating environment.

NOTE: Low humidity, less than 20% relative humidity can cause mottling on prints.

3. Check for toner contamination on the high voltage contacts. Remove the Imaging Units

and Transfer Unit. Is there contamination?

4. Check / Replace the Transfer Unit. Is the problem resolved?

Resolution

Yes – Go to Step 2

No - Have the customer load

approved media or correct the

settings.

Yes – Go to Step 3

No - Advise customer regarding the

printer’s environmental

specifications.

Yes – Clean the contacts

No - Go to Step 4

Yes – Complete

No - Replace in the following order:

LVPS / HVPS / PU Board

58

Page 59

Unexpected Colors

The colors produced by the printer are dramatically different from the color expected.

Initial Actions to Perform

■ Perform Initial Actions from Maintenance Procedures in Chapter 1.

■ Verify the media used is supported by this printer.

■ Verify the media settings are correct at the Control Panel.

■ Print the ID Check Pattern (Reports – Print – ID Check Pattern) and

Demo page (Reports – Information – Demo Page) to see if it is an application problem.

■ Perform isolation Test Prints (Section 2.7.3).

■ Run the Density Error Correction Test in Section 2.7.5.

Areas of the Printer that Apply

■ Imaging Unit

■ HVPS

■ PU Board

1. Print the ID Check Pattern / Demo Page and evaluate the colors. Are the colors on the test

pages representative of what the customer expects?

2. Print a configuration page to check the Imaging Unit life remaining. If the Imaging Unit is

reaching it’s maximum image count, this can reduce print-quality.

3. Print the 100% Solid Fill Test pattern and check for any missing colors. Is the problem

with a single color?

4. Is there debris or contamination on the LED Head?

5. Swap the LED Head of the problem color with any other LED Head. Print a Solid Fill Test

Pattern. Has the problem moved with the LED Head?

6. Swap the Imaging Unit of the problem color with any other Imaging Unit.

NOTE: Remove the keys before swapping. Print a Solid Fill Test Pattern to check for defects.

Has the problem color moved with the Imaging Unit?

7. Check for toner contamination on the high voltage contacts. Remove the Imaging Units

and the Transfer Unit and Is there contamination on the contacts?

8. Are the wiring harnesses on the LED heads undamaged, properly routed and seated?

9. Inspect the high-voltage wiring harness.

Troubleshooting Steps

Resolution

Yes – Complete, the problem is with

the Customer application.

No - Go to Step 2.

Yes – replace the Imaging Unit.

No - Go to Step 3.

Yes –Go to Step 4.

No - Go to Step 6

Yes – Clean with a dry, lint free cloth.

No - Go to Step 5

Yes – Replace the defective LED Head

No – Go to Step 6

Yes – Replace the Imaging Unit

No - Go to Step 7.

Yes – Clean the contacts.

No - Go to Step 8.

Yes – Go to Step 9.

No - reseat the wiring harness.

Yes – reseat the wiring harness.

No - Replace in the following order:

Transfer Unit / LVPS / Imaging Unit

Sensor Board / HVPS / PU Board

59

Page 60

Repeating Bands, Lines, Marks, or Spots

This is usually caused by a damaged roller. In some instances, the spots may be dark

instead of white and are repeated.

Initial Actions to Perform

■ Perform Initial Actions from Maintenance Procedures in Chapter 1.

■ Verify the media used is supported by this printer.

■ Verify the media settings are correct at the Control Panel.

■ Print the ID Check Pattern (Reports – Print – ID Check Pattern) and

Demo page (Reports – Information – Demo Page) to see if it is an application problem.

■ Perform isolation Test Prints form Section 2.7.3.

■ Run the Density Error Correction Test in Section 2.7.5.

Areas of the Printer that Apply

■ Imaging Unit

■ Fuser

■ Transfer Unit

Repeating Defects Spacing

Component Defect Spacing Defect Location

Imaging Drum 94.3 mm Imaging Unit

Developer Roller 39.7 mm Imaging Unit

Charge Roller 37.7 mm Imaging Unit

Supply Roller 58.4 mm Imaging Unit

Fuser Belt 125.5 mm Fuser

Heat Roller 87.7 mm Fuser

Transfer Roller 50.3 mm Transfer Unit

Troubleshooting Steps

60

Page 61

Mis-Registration, Color Layers Not Correctly Registered

The image appears blurred and the primary colors are not aligning correctly onto the final image.

Initial Actions to Perform

■ Perform Initial Actions from Maintenance Procedures in Chapter 1.

■ Verify the media used is supported by this printer.

■ Verify the media settings are correct at the Control Panel.

■ Print the ID Check Pattern (Reports – Print – ID Check Pattern) and

Demo page (Reports – Information – Demo Page) to see if it is an application problem.

■ Perform isolation Test Prints (Section 2.7.3).

■ Run the

Areas of the Printer that Apply

■ Imaging Unit

■ LED Heads

■ Color Registration Sensors

■ Transfer Unit

■ HVPS

■ CU Board

■ PU Board

1. Cycle power to the printer. Did this correct the problem?

2. Process Direction: Remove the Imaging Units and Transfer Unit. Inspect the Color