Ohaus RANGER COMPACT COUNTING User Manual

Ranger RC Compact Scales

Instruction Manual

@@@@@

Table of contentsRanger RC

Table of contents

Page

1 Introduction .....................................................................................5

1.1 Safety instructions .............................................................................5

1.2 Description ......................................................................................6

1.3 Putting into operation ......................................................................10

2 Operation ......................................................................................12

2.1 Switching on and off .......................................................................12

2.2 Zeroing / Zero point correction ..........................................................12

2.3 Simple weighing .............................................................................12

2.4 Weighing with tare ..........................................................................13

2.5 Calling up the gross weight and tare value .........................................14

2.6 Displaying weight values with a higher resolution ...............................14

2.7 Displaying the capacity available ......................................................14

2.8 Dynamic weighing ..........................................................................14

2.9 Printing results ...............................................................................15

2.10 Switching scales .............................................................................15

2.11 Cleaning ........................................................................................16

3 Counting .......................................................................................17

3.1 Counting parts into a container .........................................................17

3.2 Counting parts out of a container ......................................................17

3.3 Counting with variable reference quantity ...........................................18

3.4 Counting with minimum accuracy ....................................................18

3.5 Reference optimization ....................................................................18

3.6 Counting with automatic reference determination ................................19

3.7 Counting with two scales .................................................................19

4 Settings in the menu ......................................................................21

4.1 Operating the menu ........................................................................21

4.2 Overview .......................................................................................23

4.3 Scale settings (SCALE) ....................................................................26

4.4 Application settings (APPLICATION) ..................................................28

4.5 Terminal settings (TERMINAL) ..........................................................30

4.6 Configuring interfaces (COMMUNICATION) .........................................31

4.7 Diagnosis and printing out of the menu settings (DIAGNOS) ................34

5 Interface description ......................................................................35

5.1 OHAUS interface commands ............................................................35

5.2 SICS interface commands ................................................................37

5.3 TOLEDO Continuous mode ..............................................................40

6 Event and error messages ..............................................................42

7 Technical data and accessories ......................................................44

7.1 Technical data ................................................................................44

7.

2 Accessories ....................................................................................49

3

Table

of contents

Ranger RC

8 Appendix ...................................................................................... 50

8.1 Information for certified scales in EC countries ................................... 50

2 Safety checks ................................................................................. 50

8.

8.3 Table of Geo Values ........................................................................51

8.4 Sample protocols ...........................................................................54

9 Index ............................................................................................55

4

1 Introduction

1.1 Safety instructions

IntroductionRanger RC

CAUTION

Do

Ou

DANGER!

Electric shock hazard!

DANGER!

Electric shock hazard if the mains cable is damaged!

CAUTION!

On

!

not use Ranger RC in hazardous areas!

r product range includes special devices for hazardous areas.

Always pull out the mains plug before any work on the device.

Check the mains cable for damage regularly and replace it immediately if it is damaged.

On the rear side of the device, maintain a clearance of at least 3 cm in order to

prevent the mains cable bending too much.

no account open the device!

warranty is void if this stipulation is ignored. The device may only be opened by

The

authorized persons.

Call OHAUS Service.

5

troduction

In

Ranger RC

CAUTION!

Handle the compact scale with care.

scale is a precision instrument.

The

When the weighing pan has been removed, never clean the area under the load

plate holder with a solid object!

Do not put excessive loads on the scale.

Avoid banging the weighing pan.

Disposal

Observe the valid environmental regulations when disposing of the scale.

If the device has a rechargeable battery:

The

battery contains heavy metals and therefore must not be disposed of with normal

waste.

Observe the local regulations for disposing of environmentally hazardous materials

.

e Use with foodstuffs

Not

Parts

coming into contact with foodstuffs have smooth surfaces and are easy to clean.

The ma

terials used do not splinter and are free of harmful substances.

With foodstuffs, it is recommended to use the supplied protective cover.

Clean the protective cover regularly and carefully.

Replace damaged or very dirty protective cover immediately.

1.2 Description

This user manual applies to the following types of compact scales:

• Compact scale RC..S with strain gauge weighing cell

• Compact scale RC..M with Monobloc

The compact scales are available in a small and large size in various capacities and

resolution

The

rech

One of the following options can also be ordered:

s.

power supply is carried out via a built-in power supply device, an internal

argeable battery with an external mains adapter or an external battery.

• Additional interface RS232 or RS485

• Ethernet interface

• USB interface

• Digital I/O

• Analog second scale interface

6

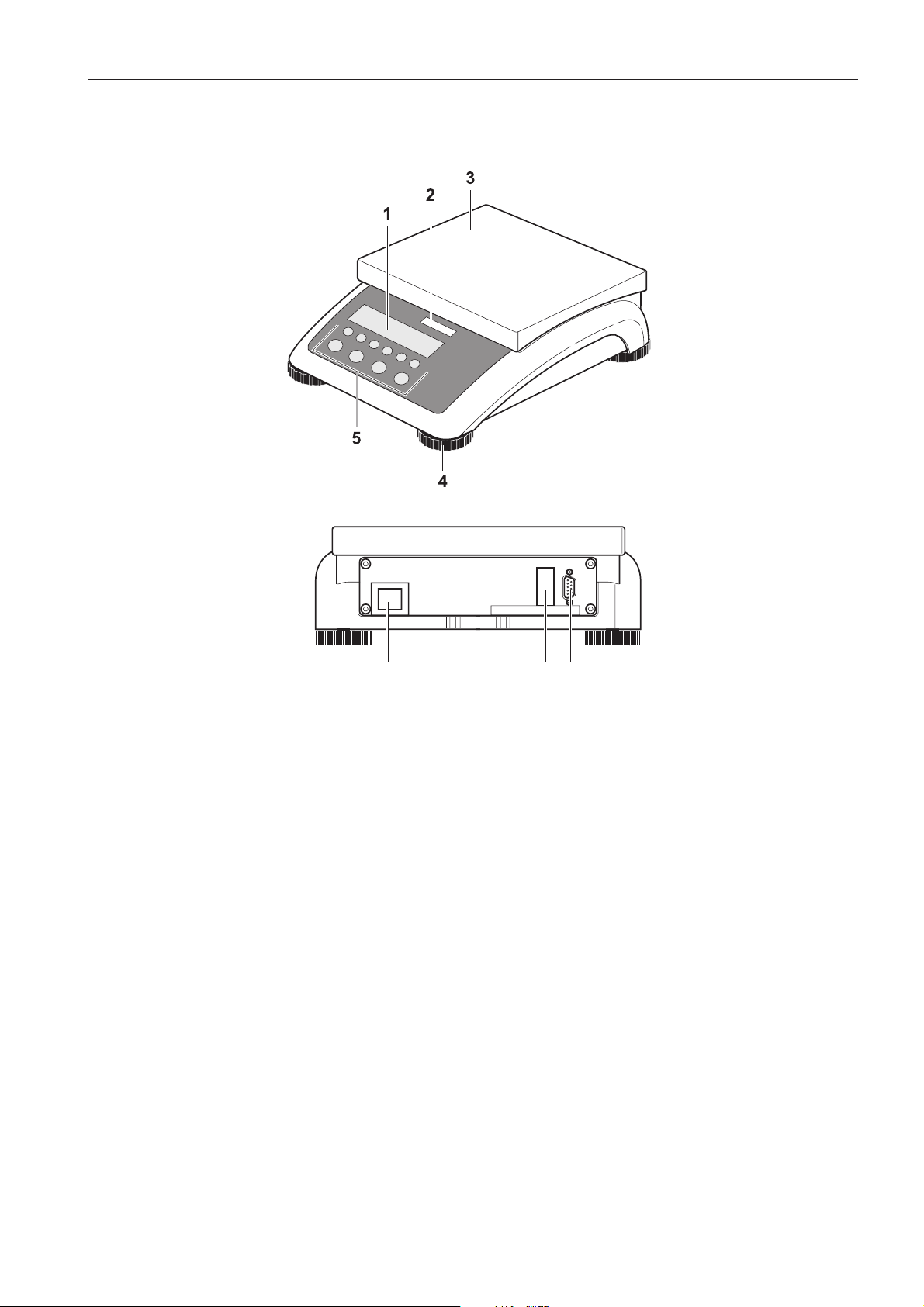

1.2.1 Overview

1 Display

2 Scale specifications

3 Load plate

4 Adjustable foot

5 Keys

IntroductionRanger RC

1 Power supply

connection

2 Optional interface

3 RS232 interface

321

7

troduction

In

Ranger RC

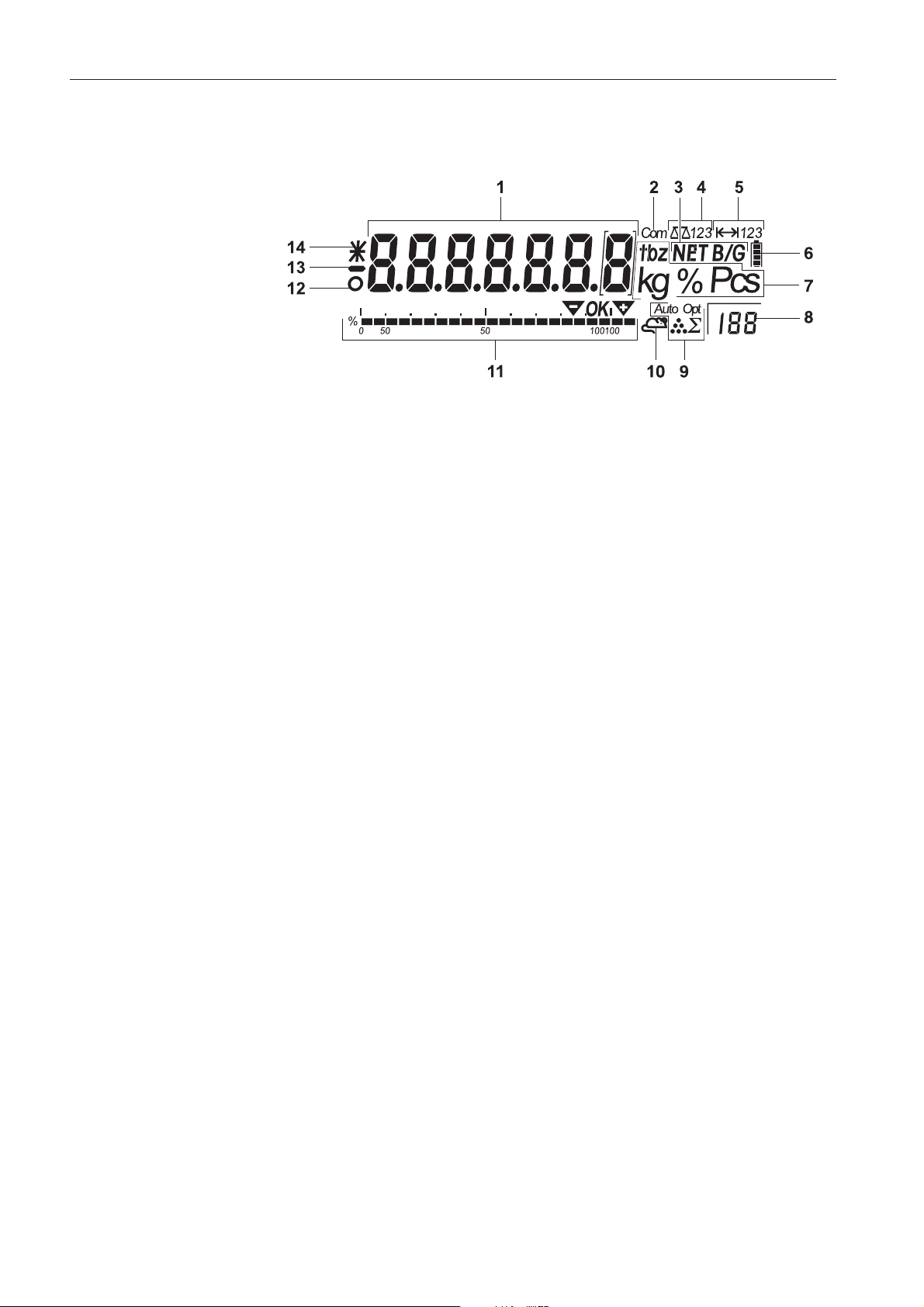

1.2.2 Display

1 7-segment display, 7 digits, with decimal point

2 Active interface

3 Symbol for displaying gross and net values

4 Active scale

5 Weighing range display

6 Battery charge level; only present on scales with a battery

7 Weight units

8 Selected reference quantity

9 Symbols for optimizing the average piece weight

10 Symbol for dynamic weighing

11 Graphic display of the weighing range

12 Stability monitor (goes out when a stable weight value is reached)

13 Sign

14 Identification for changed or calculated weight values, e.g. higher resolution,

minimum weight not reached

8

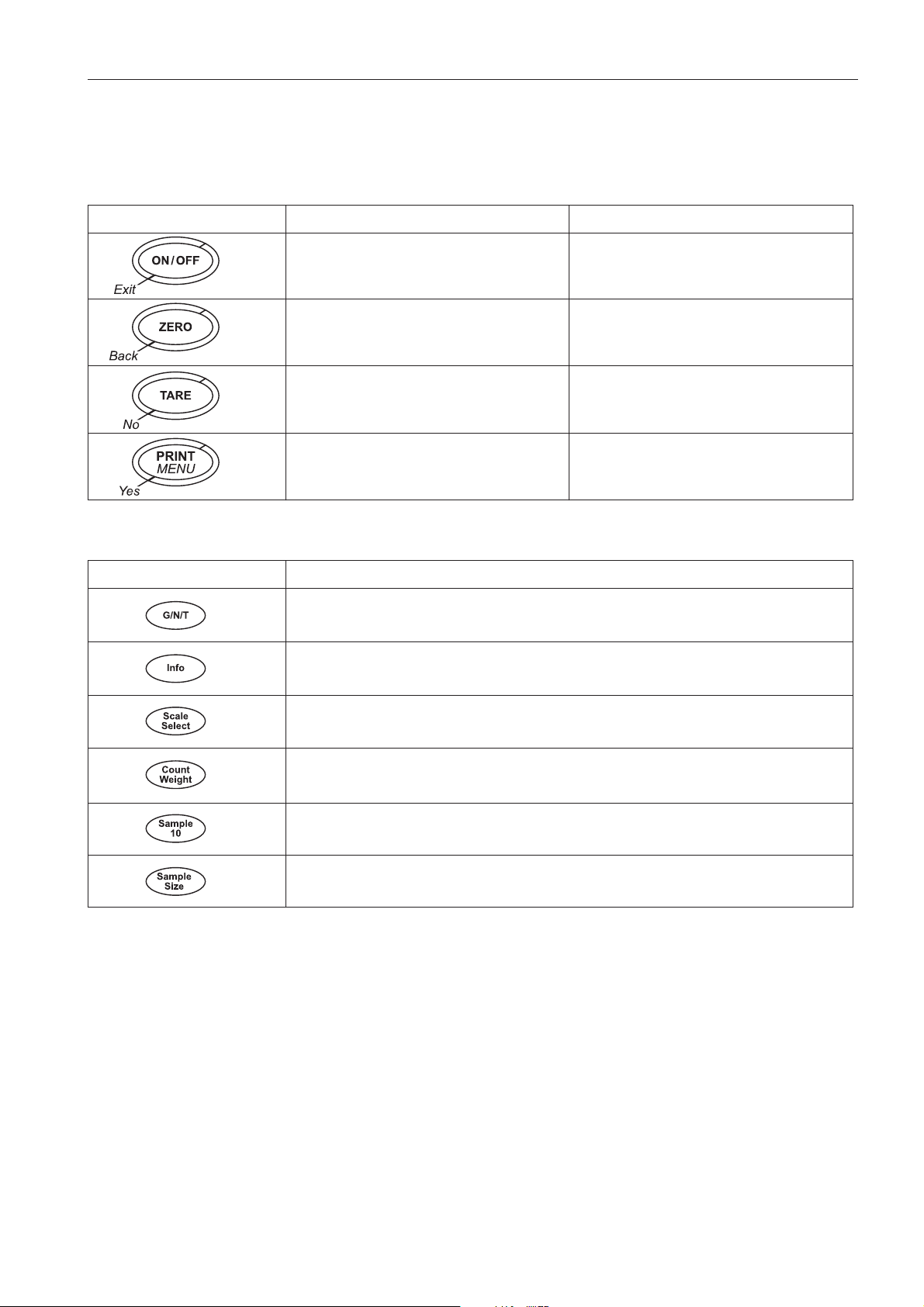

1.2.3 Keypad

Main

functions

Ke

y Function in operating mode Function in the menu

Switching device on / off, abort To the last menu item –End-

Setting scale to zero Scrolling back

Taring scale Scrolling forward

IntroductionRanger RC

Transfer

key press: Calling up menu

Long

Additional functions

Key Function

Switching between gross and net weight; displaying tare specification

Calling up additional information, e.g. gross weight, average piece weight, higher

resolut

ion ...

Switching the scale

Switching between weight value and number of pieces

Determining

Determining

key

Activating menu item

Accepting selected setting

average piece weight from 10 pieces

average piece weight from any number of pieces

9

troduction

In

1.3 Putting into operation

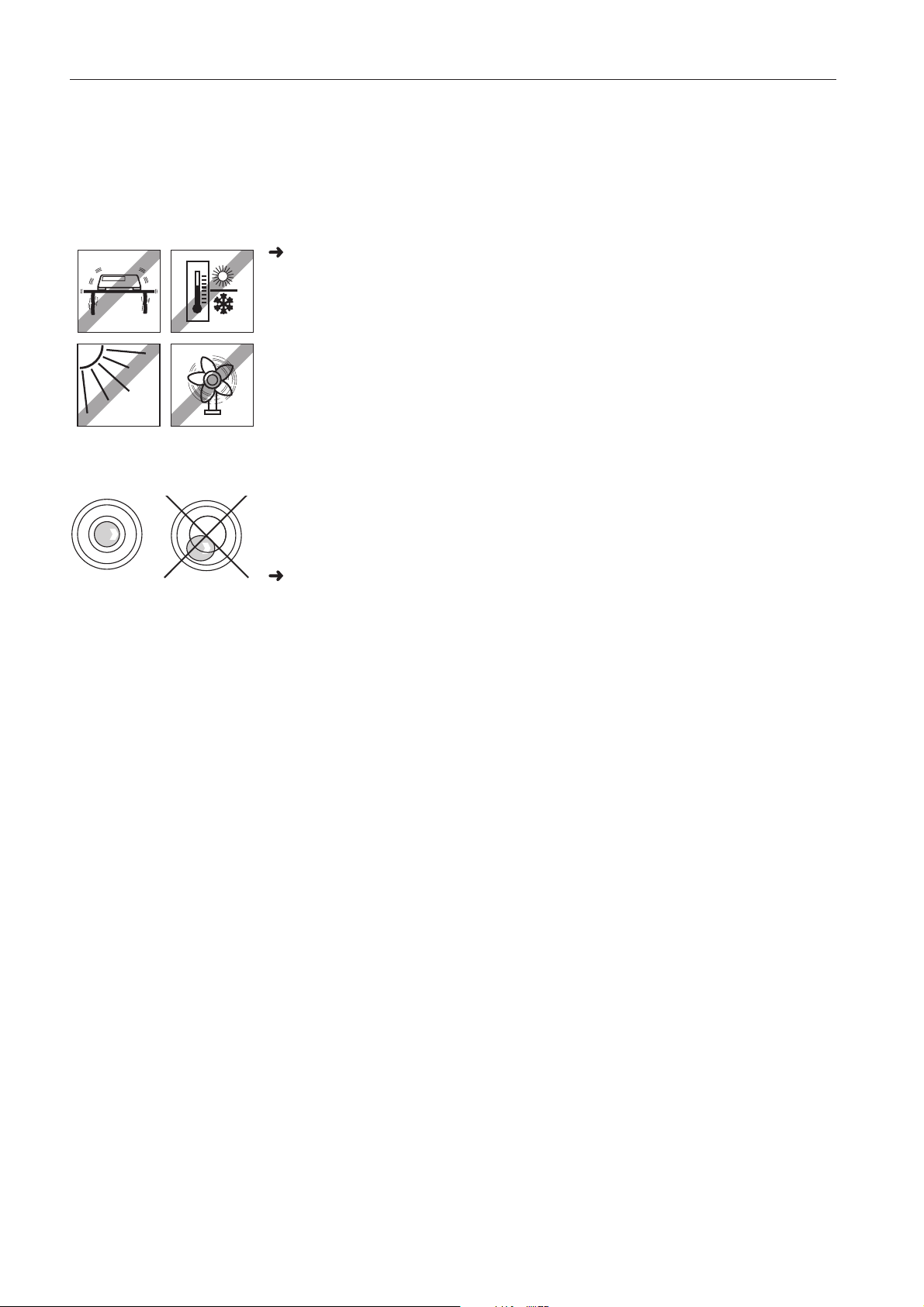

1.3.1 Selecting or changing the location

The correct location is crucial to the accuracy of the weighing results!

Select a stable, vibration-free and if possible a horizontal location.

ound must be able to safely bear the weight of the fully loaded scale.

The gr

Observe the following environmental conditions:

• No direct sunlight

• No strong drafts

• No excessive temperature fluctuations

Aligning the scale

Onl

y scales that have been aligned precisely horizontally provide accurate weighing

re

sults. The certified scales have a spirit level to simplify alignment.

Ranger RC

Major geographical

location

changes

Turn the adjustable feet of the scale until the spirit level’s air bubble is inside the

circle.

inner

The manufacturer adjusts each scale to the local gravity conditions (GEO value). In

the event of major geographical location changes, this setting must be adjusted by a

rvice technician. Certified scales must also be recertified observing the national cer-

se

cation regulations. These steps are not necessary for scales with an internal cali-

tifi

br

ation weight.

10

1.3.2 Connecting the power supply

CAUTION!

Before connecting the scale to the mains, check whether the voltage value printed on

rating plate corresponds with the local mains voltage.

the

Never connect the device if the voltage value printed on the rating plate is different

local mains voltage.

to the

Plug the mains plug into the socket.

After connection, the device performs a self-test. When the zero display appears,

the

device is ready to weigh.

Calibrate the device in order to obtain the greatest possible precision, see

Sectio

n 4.3.2.

e Partially certified scales (scales with first-level certification) must be certified by an

Not

authorised body or by the OHAUS Service.

Call OHAUS Service.

IntroductionRanger RC

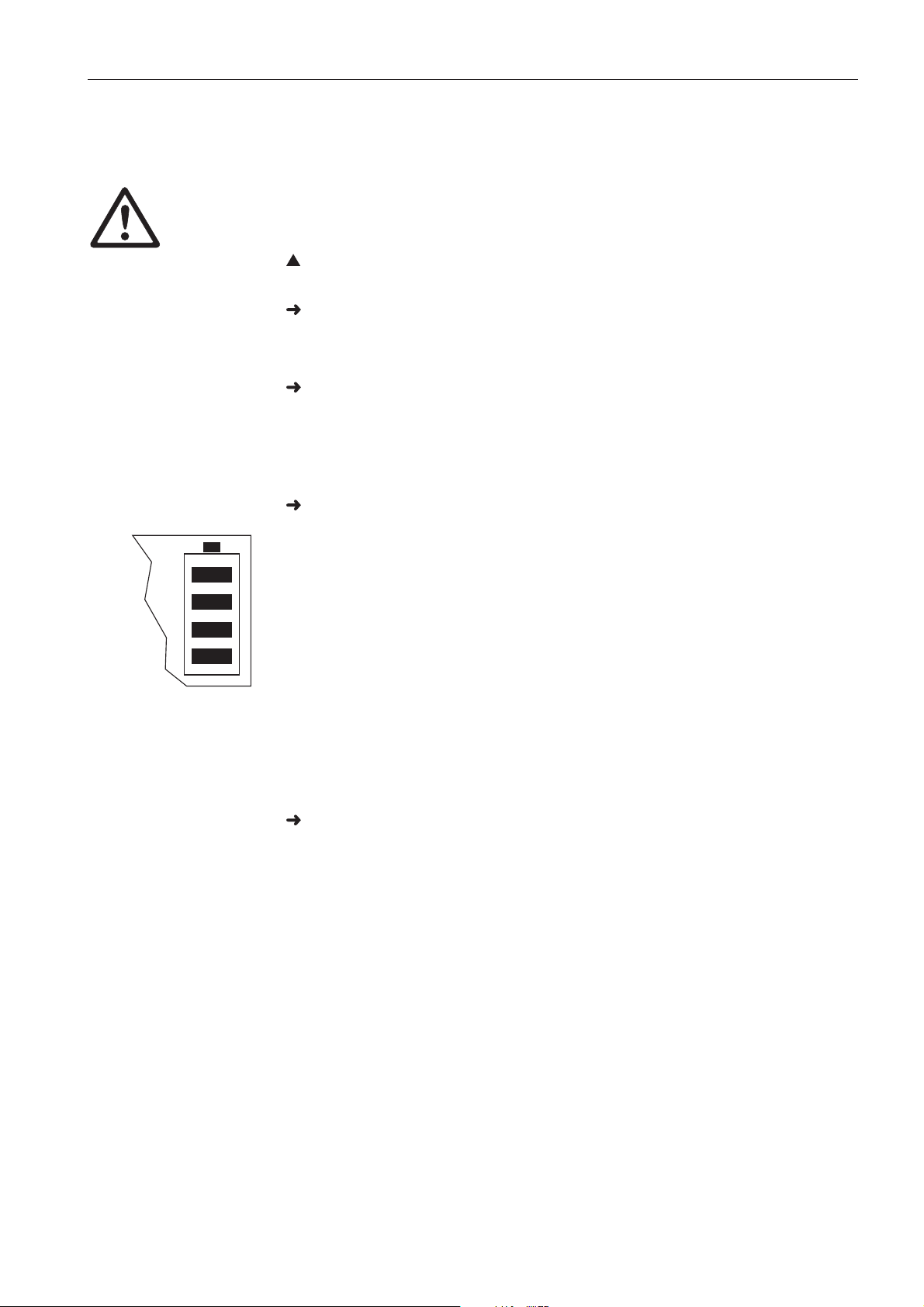

Scales with a built-in battery can work independently from the mains for approximately 30 hours in normal operation. A prerequisite for this is that the background

lighting is switched off and that no peripheral devices are connected.

The device automatically switches to battery operation as soon as the mains supply

is

interrupted. When the mains supply is restored, the device automatically switches

back to mains operation.

The

battery symbol indicates the present charging level of the battery. 1 segment cor-

res

ponds to approx. 25 % capacity. When the symbol flashes the battery must be

rged (min. 4 hours). The charging period is extended if work is continued during

cha

rging. The battery is protected against overcharging.

cha

e The battery’s charging capacity can be reduced under continuous mains operation.

Not

To maintain the charging capacity, after a maximum of 4 weeks discharge the bat-

completely before recharging it.

tery

11

Operation

2 Operation

2.1 Switching on and off

Switching on Press ON/OFF.

Ranger RC

The scale conducts a display test. When the weight display appears, the scale is

dy to weigh.

rea

Switching

off Press ON/OFF.

Before

the display goes out, -OFF- appears briefly.

2.2 Zeroing / Zero point correction

Zeroing corrects the influence of slight changes on the load plate.

Manual 1. Unload scale.

2. Press ZERO.

The zero display appears.

Automatic In the case of scales that cannot be certified, the automatic zero point correction can

be deactivated in the menu or the amount can be changed.

As standard, the zero point of the scale is automatically corrected when the scale is

unloaded.

2.3 Simple weighing

1. Place weighing sample on scale.

2. Wait until the stability monitor goes out.

12

3. Read weighing result.

2.4 Weighing with tare

2.4.1 Taring

Place the empty container on the scale and press TARE.

The zero display and the symbol NET appear.

The tare weight remains saved until it is cleared.

2.4.2 Clearing the tare

Unload scale and press TARE.

The symbol NET goes out, the zero display appears.

If A.CL-tr is activated in the menu, the tare weight is automatically cleared as soon

as the scale is unloaded.

.3 Automatic taring

2.4

Pr

erequisite

OperationRanger RC

A-tArE is activated in the menu, the symbol T flashes in the display.

.4 Chain tare

2.4

Pr

The

With

aced between individual layers in a container.

pl

1. Place the first container or packaging material on the scale and press TARE.

2. Weigh the weighing sample and read/print out the result.

3. Place the second container or packaging material on the scale and press TARE

Place the container or packaging material on the scale.

The packaging weight is automatically saved as the tare weight, the zero display

and the symbol NET appear.

erequisite

tare function CHAIn.tr is activated in the menu.

this function it is possible to tare several times if, for example, cardboard is

The packaging weight is automatically saved as the tare weight, the zero display

and the symbol NET appear.

again.

The total weight on the scale is saved as the new tare weight. The zero display

appears.

4. Weigh the weighing sample in the second container and read/print the result.

5. Repeat the last two steps for other containers.

13

Operation

2.5 Calling up the gross weight and tare value

1. Press G/N/T.

The gross weight is displayed for 2 seconds.

2. Press G/N/T again while the gross weight is displayed.

tare value is displayed. After a few seconds, the scale changes back to the net

The

wei

ght display.

2.6 Displaying weight values with a higher resolution

Press Info.

The current weight value is displayed for 2 seconds in a higher resolution. The

scale then changes back to the normal resolution.

2.7 Displaying the capacity available

The scale has a graphic display of the scale capacity available. The bar indicates how

ny per cent of the scale capacity is already occupied and what capacity is still

ma

available. In the example, approx. 65 % of the scale capacity is occupied.

Ranger RC

2.8 Dynamic weighing

With the dynamic weighing function, it is possible to weigh restless weighing samples

such

pl

With

ations

manual start Prerequisite

With

AVErAGE -> MAnuAL is selected in the menu.

The

1. Place the weighing sample on the scale and wait until it has stabilized.

2. Press PRINT to start dynamic weighing.

3. Unload the scale to be able to start a new dynamic weighing operation.

as live animals. If this function is activated, the symbol appears in the dis-

ay.

dynamic weighing, the scale calculates the mean value from 56 weighing oper-

within 4 seconds.

weighing sample must be heavier than 5 scale divisions.

During dynamic weighing, horizontal segments appear in the display, and the

dynamic result

is then displayed with the symbol *.

14

With automatic start Prerequisite

AVErAGE -> AUtO is selected in the menu.

weighing sample must be heavier than 5 scale divisions.

The

1. Place the weighing sample on the scale.

The scale starts the dynamic weighing automatically.

During dynamic weighing, horizontal segments appear in the display, and the

dynamic result

2. Unload the scale to be able to perform a new dynamic weighing operation.

2.9 Printing results

If a printer or computer is connected to the scale, the weighing results can be printed

or sent to a computer.

out

Press PRINT.

The display contents are printed out and transferred to the computer. See

Sect

ion 8.4 for sample protocols.

OperationRanger RC

is then displayed with the symbol *.

2.10 Switching scales

If a second scale or a weighing platform is connected, e. g. via the optional analog

cond scale interface, the currently active scale is shown in the display.

se

The

second scale can be operated in exactly the same way as the first scale.

Press Scale Select.

The d

isplay changes from one scale to the other.

15

Operation

2.11 Cleaning

CAUTION!

Electric shock hazard!

Before cleaning with a damp cloth, pull out the mains plug to disconnect the unit

from

the power supply.

CAUTION!

When the weighing pan has been removed, never clean the area under the load plate

holder with a solid objec

This could damage the weighing cell.

Other cleaning information:

• Use damp cloths.

• Do not use any acids, alkalis or strong solvents.

Ranger RC

t!

• Do not clean using a high-pressure cleaning unit or under running water.

• If very dirty, remove the weighing pan, protective cover (if present) and adjustable

and clean these items separately.

feet

• Follow all the relevant instructions regarding cleaning intervals and permissible

cleaning

agents.

16

3 Counting

The Ranger RC compact scales have additional functions for piece counting.

The

relevant settings in the menu are described in Section 4.4.1.

3.1 Counting parts into a container

1. Place the empty container on the scale and press TARE.

The container is tared and the zero display appears.

2. Place 10 reference parts on the scale and press Sample 10.

-or-

Place the number of pieces displayed above the key Sample Size on the scale

and

press Sample Size.

The scale determines the average piece weight and then shows the number of

ces.

pie

CountingRanger RC

3. Add more parts to the container until the required number of pieces is reached.

e

Not

• The average piece weight remains saved in the factory setting until a new average

pie

ce weight is determined.

• With Count Weight it is possible to switch between the number of pieces and the

ght.

wei

• When the number of pieces is displayed, it is possible to display the average

weight with Info, i. e. the weight of a single reference part, for 2 seconds.

piece

• If A.CL-APW ON is set in the menu, the average piece weight is automatically

cleared

mine

• If ACCurCY ON is set in the menu, the accuracy achieved is briefly shown after

the

after each counting operation. The average piece weight must be deter-

d again for the next counting operation.

number of pieces is determined.

3.2 Counting parts out of a container

1. Place the full container on the scale and press TARE.

The

container is tared and the zero display appears.

2. Remove 10 reference parts and press Sample 10.

-or-

Remove the number of pieces displayed above the key Sample Size and press

Sample Size

The

scale determines the average piece weight and then shows the number of

pie

ces removed, together with a minus sign.

3. Remove more parts from the container until the required number of pieces is

reache

.

d.

17

Counting

3.3 Counting with variable reference quantity

If VAr-SPL ON is set in the menu, it is possible to select from 5 preset reference

quantities

The rest of the counting process is as described earlier.

via Sample Size.

Press Sample Size as often as necessary until th e display above the key has

changed to the desired reference quantity.

3.4 Counting with minimum accuracy

The item Min.rEFW in the menu allows to preset a minimum accuracy of 97.5 %,

99.

0 % or 99.5 %. On the basis of this, the scale calculates the minimum reference

necessary to reach the defined accuracy.

weight

1. Place the reference parts on the scale and press Sample 10 or Sample Size.

2. If the average piece weight is not sufficient to ensure the desired accuracy,

Ad

d x PCS appears.

3. Add the displayed number of pieces.

Ranger RC

The scale then automatically determines the average piece weight with the larger

reference

The rest of the counting process is as described earlier.

quantity.

3.5 Reference optimization

The greater the reference quantity, the more accurately the scale determines the

number

3.5

.1 Automatic reference optimization

rEF.OPt -> AUtO must be set in the menu for this. The symbol Auto Opt appears

in the display.

1. Place the reference parts on the scale and press Sample 10 or Sample Size.

2. Place additional reference parts, max. the same number as for the first reference

The

of pieces.

de

termination, on the scale.

The

scale automatically optimises the average piece weight with the larger number

of reference parts

rest of the counting process is as described earlier.

.

18

Not

e The reference optimization can be performed several times.

Loading...

Loading...